Page 1

Not for

Reproduction

GE Home Generator Systems

Generator System

Model 040350 and Model 040374

Operator’s Manual

Page 2

Not for

Reproduction

Thank you for purchasing this quality-built GE home generator. We’re pleased that you’ve placed your confidence in

the GE brand. When operated and maintained according to the instructions in this manual, your home generator will

provide many years of dependable service.

This manual contains safety information to make you aware of the hazards and risks associated with home standby

generators and how to avoid them. Because we do not necessarily know all the applications this equipment could

be used for, it is important that you read and understand these instructions thoroughly before attempting to start or

operate this equipment.

Save these instructions for future reference.

This home standby generator requires professional installation before use. Refer to the separate installation manual

for full information. Your installer should follow the instructions completely.

Where to Find Us

You never have to look far to find GE support and service for your generator. For quick service when you need it, keep

your original receipt with this manual. You may contact Customer Service at (888) 575-8226 between 8:00 AM and 5:00

PM CT., or click on SERVICE & SUPPORT at http://www.gegenerators.com, which provides a list of authorized dealers.

Generator and engine model and serial numbers should be recorded in the installation manual.

2

Page 3

Not for

Reproduction

Table of Contents

Safety Rules................................................4

Important Safety Instructions ...............................................4

Installation ................................................7

For the Home Owner .......................................................7

For the Installing Dealer/Contractor .........................................7

Owner Orientation ..........................................................8

Generator Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Delivery Inspection ........................................................10

Controls ..................................................11

Access Panels .............................................................13

System Control Panel ......................................................15

Operation.................................................19

Important Owner’s Considerations .........................................19

Automatic Operation.......................................................20

Setting Exercise Timer .....................................................20

Wireless Monitor...........................................................21

Maintenance ..............................................24

Servicing the System.......................................................24

Service Code Detection System ............................................24

Maintenance Schedule.....................................................26

Generator Maintenance....................................................26

Battery ....................................................................27

Engine Maintenance .......................................................28

Adjust Valve Lash..........................................................28

Engine Oil .................................................................29

Service Air Cleaner.........................................................30

Fuel System Inspection and Maintenance...................................31

Service Spark Plugs ........................................................32

Clean Air Cooling System and Oil Cooler Fins................................32

When Calling for Assistance................................................32

Storage ...................................................................32

Troubleshooting ..........................................34

Wireless Monitor Troubleshooting...........................35

Warranty .................................................36

Specifications .............................................39

Generator Specifications ...................................................39

Engine Specifications ......................................................39

3

Page 4

Not for

Reproduction

Safety Rules

Important Safety Instructions

SAVE THESE INSTRUCTIONS - This manual contains

important instructions that should be followed during

installation and maintenance of the generator and batteries.

Safety Symbols and Meanings

Explosion

Toxic Fumes

Lift Hazard

Fire

Rotating Parts

Read Manual

Electrical Shock

Hot Surface

Chemical BurnExplosive PressureAuto Start

The manufacturer cannot possibly anticipate every possible

circumstance that might involve a hazard. The warnings

in this manual, and the tags and decals affixed to the unit

are, therefore, not all-inclusive. If you use a procedure, work

method or operating technique that the manufacturer does

not specifically recommend, you must satisfy yourself that it

is safe for you and others. You must also make sure that the

procedure, work method or operating technique that you

choose does not render the generator system unsafe.

WARNING Running engine gives off carbon monoxide, an

odorless, colorless, poison gas.

Breathing carbon monoxide could result in death, serious

injury, headache, fatigue, dizziness, vomiting, confusion,

seizures, nausea or fainting.

• Operate this product ONLY outdoors in an area that will not

accumulate deadly exhaust gas.

• Keep exhaust gas away from any windows, doors, ventilation

intakes, soffit vents, crawl spaces, open garage doors or other

openings that can allow exhaust gas to enter inside or be drawn

into a potentially occupied building or structure.

• Carbon monoxide detector(s) MUST be installed and maintained

indoors according to the manufacturer’s instructions/

recommendations. Smoke alarms cannot detect carbon

monoxide gas.

The safety alert symbol indicates a potential personal

injury hazard. A signal word (DANGER, WARNING, or

CAUTION) is used with the alert symbol to designate a degree

or level of hazard seriousness. A safety symbol may be used

to represent the type of hazard. The signal word NOTICE is

used to address practices not related to personal injury.

DANGER indicates a hazard which, if not avoided, will

result in death or serious injury.

WARNING indicates a hazard which, if not avoided, could

result in death or serious injury.

CAUTION indicates a hazard which, if not avoided, could

result in minor or moderate injury.

NOTICE addresses practices not related to personal injury.

4

WARNING The engine exhaust from this product contains

chemicals known to the State of California to cause cancer, birth

defects, or other reproductive harm.

WARNING Certain components in this product and related

accessories contain chemicals known to the State of California

to cause cancer, birth defects, or other reproductive harm. Wash

hands after handling.

Page 5

Not for

Reproduction

WARNING Storage batteries give off explosive hydrogen gas

during recharging.

Slightest spark will ignite hydrogen and

cause explosion, resulting in death or

serious injury.

Battery electrolyte fluid contains acid and is extremely caustic.

Contact with battery contents could cause severe chemical burns.

A battery presents a risk of electrical shock and high short circuit

current.

• DO NOT dispose of battery in a fire. Recycle battery.

• DO NOT allow any open flame, spark, heat, or lit cigarette during

and for several minutes after charging a battery.

• DO NOT open or mutilate the battery.

• Wear protective goggles, rubber apron, rubber boots and

rubber gloves.

• Remove watches, rings, or other metal objects.

• Use tools having insulated handles.

WARNING Propane and Natural Gas are extremely flammable

and explosive, which could cause burns, fire or

explosion resulting in death or serious injury.

• Install the fuel supply system according to NFPA 37 and other

applicable fuel-gas codes.

• Before placing the generator into service, the fuel system lines

must be properly purged and leak tested.

• After the generator is installed, you should inspect the fuel

system periodically.

• NO leakage is permitted.

• DO NOT operate engine if smell of fuel is present or other

explosive conditions exist.

• DO NOT smoke around the generator. Wipe up any oil spills

immediately. Ensure that no combustible materials are left in the

generator compartment. Keep the area near the generator clean

and free of debris.

WARNING Generator produces hazardous voltage.

Failure to properly ground generator could result

in electrocution.

Failure to isolate generator from utility power could result

in death or serious injury to electric utility workers due to

backfeed of electrical energy.

• When using generator for backup power, notify utility company.

• DO NOT touch bare wires or bare receptacles.

• DO NOT use generator with electrical cords which are worn,

frayed, bare or otherwise damaged.

• DO NOT handle generator or electrical cords while standing in

water, while barefoot, or while hands or feet are wet.

• If you must work around a unit while it is operating, stand on an

insulated dry surface to reduce the risk of a shock hazard.

• DO NOT allow unqualified persons or children to operate or

service generator.

• In case of an accident caused by electrical shock, immediately

shut down the source of electrical power and contact the local

authorities. Avoid direct contact with the victim.

• Despite the safe design of the residential generator, operating

this equipment imprudently, neglecting its maintenance or being

careless could cause possible injury or death.

• Remain alert at all times while working on this equipment.

Never work on the equipment when you are physically or

mentally fatigued.

• Before performing any maintenance on the generator, disconnect

the battery cable indicated by a NEGATIVE, NEG or (-) first. When

finished, reconnect that cable last.

• After your system is installed, the generator may crank and start

without warning any time there is a power failure. To prevent

possible injury, always set the generator’s system switch to OFF,

remove the service disconnect from the disconnect box AND

remove the 15 Amp fuse BEFORE working on the equipment.

WARNING Unintentional sparking could cause fire or electric

shock resulting in death or serious injury.

WHEN ADJUSTING OR MAKING REPAIRS TO YOUR GENERATOR

• Disconnect the spark plug wire from the spark plug and place the

wire where it cannot contact spark plug.

WHEN TESTING FOR ENGINE SPARK

• Use approved spark plug tester.

• DO NOT check for spark with spark plug removed.

5

Page 6

Not for

Reproduction

WARNING Exhaust heat/gases could ignite combustibles or

structures resulting in death or serious injury.

Contact with muffler area could cause burns

resulting in serious injury.

• DO NOT touch hot parts and AVOID hot exhaust gases.

• Allow equipment to cool before touching.

• Exhaust outlet side of weatherproof enclosure must have at least

5 ft (1.5 m) minimum clearance from any structure, shrubs, trees or

any kind of vegetation.

• Standby generator weatherproof enclosure must be at least 5 ft

from windows, doors, any wall opening, shrubs or vegetation over

12 inches (30.48 cm) in height.

• Standby generator weatherproof enclosure must have a minimum

of 5 ft (1.5 m) overhead clearance from any structure, overhang or

trees.

• DO NOT place weatherproof enclosure under a deck or other type

of structure that may confine airflow.

• USE ONLY flexible steel fuel line provided. Connect provided fuel

line to generator, DO NOT use with or substitute any other flexible

fuel line.

• Smoke detector(s) MUST be installed and maintained indoors

according to the manufacturer’s instructions/ recommendations.

Carbon monoxide alarms cannot detect smoke.

• Keep at least minimum distances shown in Generator Placement

to insure for proper generator cooling and maintenance

clearances.

• It is a violation of California Public Resource Code, Section 4442,

to use or operate the engine on any forest-covered, brushcovered, or grass-covered land unless the exhaust system is

equipped with a spark arrester, as defined in Section 4442,

maintained in effective working order. Other states or federal

jurisdictions may have similar laws.

Contact the original equipment manufacturer, retailer, or dealer to

obtain a spark arrester designed for the exhaust system installed

on this engine.

• Replacement parts must be the same and installed in the same

position as the original parts.

WARNING Starter and other rotating parts could entangle

hands, hair, clothing, or accessories resulting in

serious injury.

CAUTION Installing the 15 Amp fuse could cause the engine

to start at any time without warning resulting in minor or

moderate injury.

• Observe that the 15 Amp fuse has been removed from the control

panel for shipping.

• DO NOT install this fuse until all plumbing and wiring has been

completed and inspected.

CAUTION Excessively high operating speeds could result in

minor injury.

Excessively low speeds impose a heavy load on generator.

• DO NOT tamper with governed speed. Generator supplies correct

rated frequency and voltage when running at governed speed.

• DO NOT modify generator in any way.

NOTICE Improper treatment of generator could damage it and

shorten its life.

• Use generator only for intended uses.

• If you have questions about intended use, contact your

authorized dealer.

• Operate generator only on level surfaces.

• Adequate, unobstructed flow of cooling and ventilating air is

critical for correct generator operation.

• The access panels/door must be installed whenever the unit

is running.

• DO NOT expose generator to excessive moisture, dust, dirt, or

corrosive vapors.

• Remain alert at all times while working on this equipment.

Never work on the equipment when you are physically or

mentally fatigued.

• DO NOT start engine with air cleaner or air cleaner cover removed.

• DO NOT insert any objects through cooling slots.

• DO NOT use the generator or any of its parts as a step. Stepping

on the unit could cause stress and break parts. This may result in

dangerous operating conditions from leaking exhaust gases, fuel

leakage, oil leakage, etc.

• If connected devices overheat, turn them off and disconnect them

from generator.

• Shut off generator if:

-electrical output is lost;

-equipment sparks, smokes, or emits flames;

-unit vibrates excessively.

-unit makes unusual noises.

• NEVER operate generator without protective housings, covers, or

guards in place.

• DO NOT wear loose clothing, jewelry or anything that could be

caught in the starter or other rotating parts.

• Tie up long hair and remove jewelry.

• Before servicing, remove 15 Amp fuse from control panel and

disconnect Negative (NEG or -) battery cable.

6

Page 7

Not for

Reproduction

Installation

We sincerely appreciate your patronage. For this reason, we

have made every effort to provide for a safe, streamlined

and cost-effective installation. Because each installation is

unique, it is impossible to know of and advise the trade of all

conceivable procedures and methods by which installation

might be achieved. Neither could we know of possible

hazards and/or the results of each method or procedure. For

these reasons,

Only current licensed electrical and plumbing

professionals should attempt home generator system

installations. Installations must strictly comply with all

applicable codes, industry standards and regulations.

Your home generator is supplied with this “Operator’s

Manual” and a separate “Installation Manual”. These are

important documents and should be retained by the owner

after the installation has been completed.

This product is only for use as an optional generator system

which provides an alternate source of electric power and

to serve loads such as heating, refrigeration systems, and

communication systems that, when stopped during any

power outage, could cause discomfort or inconvenience.

NOTICE This product does NOT qualify for either an

emergency standby or legally required standby system as

defined by NFPA 70 (NEC).

• Emergency generator systems are intended to

automatically supply illumination, power, or both,

to designated areas and equipment in the event of

failure of the normal supply. Emergency systems may

also provide power for such functions as ventilation

where essential to maintain life, where current

interruption of the normal supply would produce

serious life safety or health hazards.

• Legally Required standby generator systems are

intended to automatically supply power to selected

loads in the event of failure of the normal source

which could create hazards or hamper rescue or firefighting operations.

Every effort has been made to ensure that information in this

manual is accurate and current. However, we reserve the

right to change, alter, or otherwise improve the product and

this document at any time without prior notice.

Only current licensed electrical and plumbing professionals

should attempt home generator system installations.

Installations must strictly comply with all applicable codes,

industry standards, laws and regulations.

For the Home Owner

To help you make informed choices and communicate

effectively with your installation contractor(s),

Read and understand Owner Orientation in this manual

before contracting or starting your generator installation.

To arrange for proper installation, contact the store at

which you purchased your generator, your dealer, a licensed

electrician or your utility power provider.

For the Installing Dealer/Contractor

For most applications, the installation manual contains

all the information required to properly install and start

the generator. This operator’s manual describes routine

operation and owner maintenance procedures.

The generator warranty is VOID unless the system is

installed by licensed electrical and plumbing professionals.

Every effort has been made to ensure that information in this

manual is accurate and current. However, we reserve the

right to change, alter, or otherwise improve the product and

this document at any time without prior notice.

The Emission Control System for this generator is warranted

to standards set by the U.S. Environmental Protection Agency

and by the California Air Resources Board (CARB).

If you need more information in this matter, please call

888 575‑8226 between 8:00 AM and 5:00 PM CT.

7

Page 8

Not for

Reproduction

Owner Orientation

This section provides generator owners with the information

necessary to achieve the most satisfactory and cost effective

installation possible.

Federal and local codes, appearance, noise levels, fuel types,

and distances are the factors that must be considered when

negotiating with an installation professional.

Remember that as the distance from the existing electrical

service and gaseous fuel supply increases, and the

number of 90 degree bends in the fuel supply increases;

compensations in piping and wiring materials must be made.

This is necessary to comply with local codes and overcome

electrical voltage drops and gaseous fuel pressure drops.

The factors mentioned above will have a direct affect on

the overall price of your generator installation.

In some areas you may need to acquire electrical permits for

installing the home generator, building permits for installing

gas lines, and permits for noise allowances. Your installer

should check your local codes AND obtain the permits before

installing the system.

Power Decrease at High Altitude or

High Temperature

Air density is less at high altitudes, resulting in less available

engine power. Specifically, engine power will decrease 3.5%

for each 1,000 feet (300 meters) above sea level and 1%

for each 10° F (5.6°C) above 77°F (25°C). Make sure you and

your installer consider these factors when determining total

generator load.

8

Page 9

Not for

Reproduction

Generator Location

The actual physical location of your home generator has a

direct affect on:

1. The amount of plumbing required to fuel

your generator.

2. The amount of wiring required to control and connect

your generator.

Specific location guidelines are discussed in the installation

manual. Acquaint yourself with that information and confer

with your installer. Be sure to ask how your site might

affect installation costs and compliance with local codes

and standards.

• Install generator outdoors in an area that will not

accumulate deadly exhaust gas.

• DO NOT install generator where exhaust gas could

accumulate and enter inside or be drawn into a

potentially occupied building or structure.

• By law it is required in many states to have a Carbon

Monoxide (CO) detector in operating condition in

your home. Carbon monoxide detector(s)

be installed and maintained indoors according to

the manufacturer’s instructions/ recommendations.

A CO monitor is an electronic device that detects

hazardous levels of CO. When there is a buildup of

CO, the monitor will alert the occupants by flashing

visual indicator light and alarm. Smoke alarms cannot

detect CO gas.

A

MUST

WARNING Running engine gives off carbon monoxide, an

odorless, colorless, poison gas.

Breathing carbon monoxide could result in death, serious

injury, headache, fatigue, dizziness, vomiting, confusion,

seizures, nausea or fainting.

• Operate this product ONLY outdoors in an area that will not

accumulate deadly exhaust gas.

• Keep exhaust gas away from any windows, doors, ventilation

intakes, soffit vents, crawl spaces, open garage doors or other

openings that can allow exhaust gas to enter inside or be drawn

into a potentially occupied building or structure.

• Carbon monoxide detector(s) MUST be installed and maintained

indoors according to the manufacturer’s instructions/

recommendations. Smoke alarms cannot detect carbon

monoxide gas.

• Ensure exhaust gas is kept away from any windows,

doors, ventilation intakes, soffit vents, crawl spaces,

open garage doors or other openings that can

allow exhaust gas to enter inside or be drawn into

a potentially occupied building or structure. Your

neighbor(s) home may be exposed to the engine

exhaust from your standby generator and must be

considered when installing your standby generator.

• Wind and air currents should be taken into

consideration when positioning generator.

See the installation manual for full details on safe generator

location.

A

WARNING Exhaust heat/gases could ignite combustibles or

structures resulting in death or serious injury.

• Exhaust outlet side of weatherproof enclosure must have at least

5 ft (1.5 m) minimum clearance from any structure, shrubs, trees or

any kind of vegetation.

• Standby generator weatherproof enclosure must be at least

5 ft (1.5 m) from windows, doors, any wall opening, shrubs or

vegetation over 12 inches (30.5 cm) in height.

• Standby generator weatherproof enclosure must have a minimum

of 5 ft (1.5 m) overhead clearance from any structure, overhang or

trees.

• DO NOT place weatherproof enclosure under a deck or other type

of structure that may confine airflow.

• USE ONLY flexible steel fuel line provided. Connect provided fuel

line to generator, DO NOT use with or substitute any other flexible

fuel line.

• Smoke detector(s) MUST be installed and maintained indoors

according to the manufacturer’s instructions/ recommendations.

Carbon monoxide alarms cannot detect smoke.

• DO NOT place weatherproof enclosure in manner other than shown

in illustrations.

9

Page 10

Not for

Reproduction

Delivery Inspection

Carefully inspect the home generator for any damage that

may have occurred during shipment.

If loss or damage is noted at time of delivery, have the

person(s) making delivery note all damage on the freight bill

and affix his signature under the consignor’s memo of loss or

damage. If loss or damage is noted after delivery, separate

the damaged materials and contact the carrier and your

installer for claim procedures. Parts damaged in shipping are

not warranted.

The home generator system is supplied with:

• Oil (5W30 Synthetic)

• Flexible steel fuel line

• Installation and start-up manual

• Operator’s manual

• Spare access roof keys

• Spare 15 Amp ATO-type fuse

• Remote wireless monitor

• Antenna

Not included:

• Carbon monoxide detector(s)

• Smoke detector(s)

• Starting battery

• Connecting wire and conduit

• Fuel supply valves/plumbing

• Crane, lifting straps, chains or cables

• Two 60” lengths of 3/4” nominal minimum scheduled

40 steel pipe (NOT conduit)

• Torque screwdriver, 5 to 50 inch-pound range

• Voltage/frequency meter

• Two (2) AA batteries for remote wireless monitor

10

Page 11

Not for

Reproduction

Controls

8kW Generator

Read this operator’s manual and Important Safety Instructions before operating your generator.

Compare the illustration with your generator to familiarize yourself with the locations of various

controls and adjustments. Save this manual for future reference.

E

D

F

C

B

A

Generator is shown with roof and access covers removed

for clarity.

A

- Lifting Holes — Provided at each corner for

lifting generator.

- Exhaust Port — High-performance muffler lowers engine

B

noise to comply with most residential codes.

- Alternator — An electrical machine that generates an

C

alternating current.

- Spark Plug — A device in the cylinder head of the engine

D

that ignites the fuel mixture by means of an electric spark.

G

H

J

E

- Air Cleaner — Uses a dry type filter element and foam

precleaner to protect engine by filtering dust and debris out

of intake air.

- Control Panel — Used for various test, operation and

F

maintenance functions. See System Control Panel.

G

- Circuit Breaker — Protects the system from shorts and

other over-current conditions.

- Battery — (installer supplied) — 12 Volt DC, sealed battery

H

provides power to start the engine.

- Fuel Inlet Port — Attach appropriate fuel supply to

J

generator here.

11

Page 12

Not for

Reproduction

10 kW Generator

E

D

C

B

F

G

H

J

A

Generator is shown with roof and access covers removed

for clarity.

A

- Lifting Holes — Provided at each corner for

lifting generator.

- Exhaust Port — High-performance muffler lowers engine

B

noise to comply with most residential codes.

- Alternator — An electrical machine that generates an

C

alternating current.

- Muffler — A device to reduce engine noise.

D

- Air Cleaner — Uses a dry type filter element and foam

E

precleaner to protect engine by filtering dust and debris out

of intake air.

12

F

- Control Panel — Used for various test, operation and

maintenance functions. See System Control Panel.

G

- Circuit Breaker — Protects the system from shorts and

other over-current conditions.

- Battery — (installer supplied) — 12 Volt DC, sealed battery

H

provides power to start the engine.

- Fuel Inlet Port — Attach appropriate fuel supply to

J

generator here.

Page 13

Not for

Reproduction

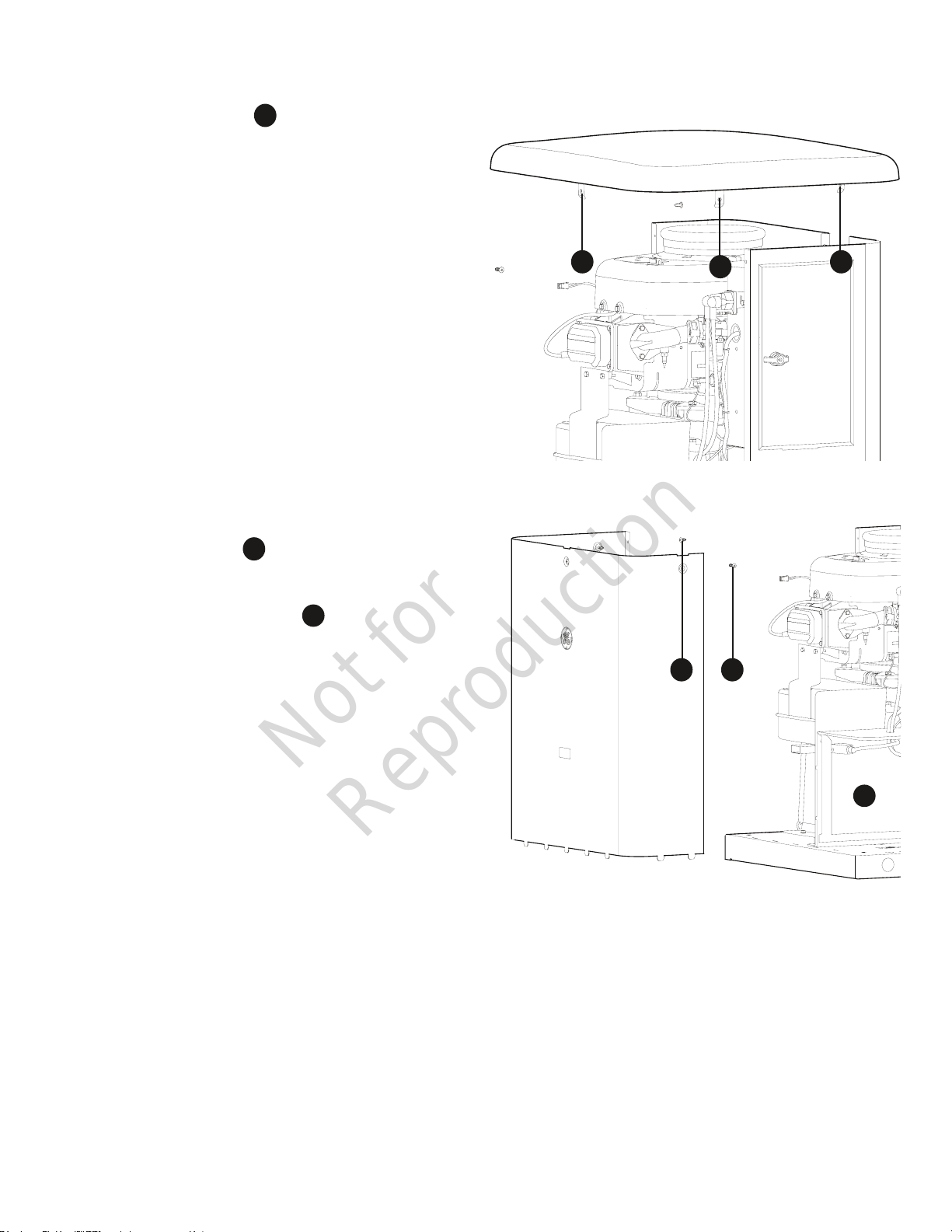

Access Panels

The generator is equipped with an enclosure that has several

access panels, as shown.

Front Panel that is used to access:

A

• Battery Compartment

• Engine Oil Drain Hose

• Engine Oil Filter

• Engine Valve Cover

• Spark Plugs

Each generator is shipped with a set of identical keys.

A

13

Page 14

Not for

Reproduction

To remove roof:

1. Remove the five screws that secure the roof to

the unit.

2. Carefully lift and remove roof from unit.

A

To remove front panel:

1. Remove the two screws that secure the panel to the

unit.

2. Lift and flex panel outward and off base. Use caution

not to damage the battery box (C.

To secure front panel:

1. Place panel in unit.

2. Secure the panel with two screws.

B

C

A

A

B B

A

14

C

B

Page 15

Not for

Reproduction

System Control Panel

The generator control board, located inside the generator,

under the roof, is shown below. Brief descriptions of the

controls used during installation are:

A

- Menu/Programming Navigation Buttons — See

Menu section for details

B

- Mini USB Port — Authorized Dealer Service Use Only.

C

- Generator Operation Control Buttons —

• “AUTO” Normal operating position. Press and hold

button to put unit into Automatic mode. In Automatic

mode, if a utility power outage is sensed, the system

will start the generator. When utility power is restored,

auto lets the engine stabilize internal temperatures,

shuts o the generator, and waits for the next utility

outage.

• “OFF” Turns o running generator, prevents unit from

starting, and resets any detected service codes.

OFF must be pressed and held for more than 5 seconds in

order to reset service code memory.

•“MANUAL” Used to manually start the generator.

D

– 15 Amp Fuse — Protects the home generator DC

control circuits. If the fuse has ‘blown’ (melted open)

or was removed, the engine cannot crank or start.

Replace the fuse using only an identical ATO 15A fuse.

One spare fuse is supplied with the unit.

E

- Cover — This protective cover must be removed to

access the fuse and the USB port.

F

- Digital Display — Displays generator mode, menu

options, service codes, and service engine indicators

More information may be found in Controls in the

operator’s manual.

F

menu

A

B

auto

C

ok

esc

E

D

off manual

15

Page 16

Not for

Reproduction

Menu

ok

ok

ok

ok

ok

ok

ok

ok

ok

The following chart shows the icons for the buttons that control the system control panel.

ok

MENU

ESCAPE (EXIT)

RIGHT ARROW

LEFT ARROW

MANUAL MODE

OFF

AUTOMATIC MODE

ENTER THE MENU (VIEW SETTINGS)

PRESS TO CONFIRM SELECTION WHEN PROGRAMMING.

RETURN TO LAST MENU ITEM

TOGGLE THROUGH MENU OPTIONS

SETTING SYSTEM PARAMETERS

TOGGLE THROUGH MENU OPTIONS

SETTING SYSTEM PARAMETERS

USED TO MANUALLY START THE GENERATOR. PRESS AND HOLD BUTTON TO START

THE GENERATOR.

TURNS OFF RUNNING GENERATOR, PREVENTS UNIT FROM STARTING, AND RESETS

ANY DETECTED SERVICE CODES.

NORMAL OPERATING POSITION. PRESS AND HOLD BUTTON TO PUT UNIT INTO

AUTOMATIC MODE. IF A UTILITY POWER OUTAGE IS SENSED, THE

SYSTEM WILL START THE GENERATOR. WHEN UTILITY POWER IS RESTORED, AUTO

LETS THE ENGINE STABILIZE INTERNAL TEMPERATURES, SHUTS OFF THE GENERATOR, AND WAITS FOR THE NEXT UTILITY POWER OUTAGE.

The following chart describes key sequences for accessing different programming modes;

ok

16

GENERAL

SET-UP

WIRELESS

LINK MODE

PRESS AND HOLD [ARROW LEFT AND ARROW RIGHT] FOR

THREE SECONDS TO ENTER THE PROGRAM MODE.

PRESS AND HOLD [MENU AND ESC] FOR THREE SECONDS TO

ENTER THE WIRELESS LINKING MODE. (ONLY APPLICABLE ON

CERTAIN MODELS).

Page 17

Not for

Reproduction

General Set Up Screen

ok

ok

For general set up, press and hold the left arrow and right arrow for 3 seconds. Follow the prompts as outlined below.

NOTE: Date and Time were set at the factory and stored in the control panel memory. The Exercise Cycle was also set at

the factory. The default exercise cycle occurs on Tuesdays, at 2:00 P.M. Central Standard Time. To update or change these

settings, follow the steps below.

SET DATE

or

SET TIME

or

YEAR

FLASHING

or or or

HOURS

FLASHING

or or or

or

MONTH

FLASHING

MINUTES

FLASHING

DAY##

FLASHING

AM/PM

FLASHING

If set to OFF, display will read:

EXERCISE CYCLE OFF

or

SET EXERCISE

CYCLE

EVENT LOG

DAY OF WEEK

FLASHING

or or or or

HOURS

FLASHING

MINUTES

FLASHING

Display will scroll last service code event, date, time,

and ambient temperature of when the event occurred.

IF DURING PROGRAMMING NO BUTTONS ARE PRESSED FOR 30 SECONDS,

THE CONTROL PANEL WILL AUTOMATICALLY EXIT THE PROGRAM MODE.

AM/PM

FLASHING

or

17

Page 18

Not for

Reproduction

Control Panel Prompts

Automatic Mode

In Automatic Mode, the display screen will display via

scrolling text:

• GENERATOR READY - if the unit is in standby and utility

power is present.

• GENERATOR ON - if the unit is running and utility

power is not on.

• SERVICE CODE - if a system service code has been

detected.

General System Parameters

To view general system parameters, press the MENU button.

The following will scroll across the digital display and then

move to the next item:

• Run time (total hours the unit has run since installation)

• Date

• Time

• Exercise Cycle date and start time

The user can press the LEFT ARROW or RIGHT ARROW at any

time to move to the next item.

The user can press ESCAPE to go back to GENERATOR READY.

If no user inputs are made for 10 seconds after all the items

have been displayed, the control board will reset to

GENERATOR READY.

AUTOMATIC MODE

GENERATOR READY OR SERVICE CODE DESCRIPTION

(When Generator NOT Running - Auto Mode)

GENERATOR ON

(When Generator Running - Auto Mode)

ok

(MENU)

RUN TIME

or

DATE

or

18

TIME

or

EXERCISE CYCLE

Page 19

Not for

Reproduction

Operation

Important Owner’s Considerations

Engine Oil

The engine is shipped from the factory pre-run and filled

with synthetic oil (API SJ/CF 5W-30). This allows for system

operation in a wide range of temperature and climate

conditions. Before starting the engine, check oil level as

described in Maintenance.

NOTICE Any attempt to crank or start the engine before it has

been properly serviced with the recommended oil will result in

equipment failure.

• Damage to equipment resulting from failure to follow this

instruction will void engine and generator warranty.

Battery

WARNING Battery posts, terminals and related accessories

contain lead and lead compounds, chemicals known to the State

of California to cause cancer and reproductive harm. Wash hands

after handling.

The installer must supply a rechargeable 12 volt DC starting

battery. See Battery in Final Installation Considerations in the

installation manual.

With the battery installed, all wiring to transfer switch and

home generator completed, utility power supplied to the

automatic transfer switch, and the unit in AUTO mode, the

battery receives a trickle charge while the engine is not

running. The trickle charge cannot be used to recharge a

battery that is completely discharged.

NOTICE A battery booster should never be used to quick

charge a low battery.

15 Amp Fuse

The generator’s 15 Amp fuse is critical to correct system

operation. The 15 Amp fuse was removed at the factory.

Your installer will ensure the fuse is properly installed upon

completion of the installation.

19

Page 20

Not for

Reproduction

Automatic Operation

The generator’s control board constantly monitors utility

voltage. Should utility voltage drop below a preset level, the

control board will signal the engine to crank and start.

When utility voltage is restored above a preset voltage level,

the engine is signaled to shut down.

The actual system operation is not adjustable and is

sequenced by sensors and timers on the control board,

as follows:

Utility Voltage Dropout Sensor

• This sensor monitors utility source voltage.

• If utility source voltage drops below about 70 percent

of the nominal supply voltage, the sensor energizes

a 3 second timer. The timer is used to ‘sense’

brown-outs.

• Once the timer has expired, the engine will crank

and start.

Utility Voltage Pickup Sensor

This sensor monitors utility voltage. When utility voltage is

restored above 80 percent of the nominal source voltage,

a time delay starts timing and the engine will go to engine

cool-down.

Engine Cool-down Timer

When utility power is sensed and the load transfers back to

the utility source, the engine will go into a cool down period

as described below:

• If the generator has run for MORE than 5 minutes,

once the utility transfer occurs, the engine will

continue to run for about 1 minute before shutting

down.

• If the generator has run for LESS than 5 minutes, once

the utility transfer occurs, the engine will continue to

run until 5 minutes has elapsed before shutting down.

Setting Exercise Timer

The generator is equipped with an exercise timer. During the

exercise period, the unit runs for approximately 20 minutes

and then shuts down. Electrical load transfer DOES NOT

occur during the exercise cycle (unless an utility power

outage occurs).

The generator will only enter the exercise cycle if the unit

is in the AUTO mode and this exact procedure is followed.

To set the exercise timer:

NOTICE The generator is set with a deservice code exercise

cycle setting of Tuesday at 2:00 P.M, Central Time. To change

the cycle setting, proceed to the following steps:

1. Choose the day and time you want your generator to

exercise.

2. Press and hold the left arrow and right arrow

simultaneously for three seconds to enter the General

Set-Up program mode. See General Set-Up flow chart

in Menu Section.

3. Verify and/or set the time and date on the unit.

4. Go to the SET EXERCISE prompt and hit the “OK”

button.

NOTICE Items will flash until they are selected.

SELECT DAY: Use the left or right arrow to toggle

through the days of the week, Once the day is

selected, hit the “OK” button.

SELECT HOUR: Use the left or right arrow to toggle

through between 1 and 12. Choose the hour of day

you want the generator to exercise then hit the “OK”

button.

SELECT MINUTE: Use the left of right arrow to toggle

between :00 and :59. Choose the minute of the day

you want the generator to exercise then hit the “OK”

button.

SELECT AM/PM: Use the left of right arrow to toggle

between AM and PM. Once chosen, hit the “OK”

button.

NOTICE During the weekly exercise cycle, the generator will

run for 20 minutes, but it will not supply power to the home.

During the exercise cycle, the in-home monitor will continue

blinking the GENERATOR READY green LED.

If you want to change the day and time the unit exercises,

simply perform the procedure again.

To turn off the generator exercise cycle, go to the OFF

selection within the day of the week menu and press OK. The

display will then scroll: EXERCISE CYCLE OFF.

20

Page 21

Not for

Reproduction

Wireless Monitor

DEALER NAME

DEALER

PHONE

generator power

service needed

generator ready

system update

1 low battery voltage

2 low uid level

3 under/over voltage

4 engine does not start

part #: 316196 fcc id: MCQ-XBS2C IC id: 1846A-XBS2C

5 low frequency

6 engine overspeed

7 high temperature

8 transfer switch

# of flashes service needed

The generator is supplied with a battery-powered, wireless

monitor.

The monitor communicates wirelessly with the generator

control panel. The monitor may be placed in a suitable

location in the home. The system has a line-of-sight range of

about 200 feet, but this distance will decrease if the signal

has to pass through walls or other objects.

The wireless monitor communicates with the generator,

every 10 minutes and will display the status via a green or

red LED light on the front of the monitor.

Compare the illustration below with your monitor to

familiarize yourself with these important components.

• Generator Ready (A) - Green LED

• Generator Power (B) - Green LED

• Service Needed (C) - Red LED

• System Update (D) - Press for current system update

with generator.

• Service code descriptions (E) - Name and number

of flashes are listed on the backside of the wireless

monitor.

• Battery Access Cover (F) - Record the dealer name

and phone number on the label provided. Once

removed, two non-rechargeable AA batteries are

installed in the compartment (). .

A

B

C

D

E

F

G

A

B

C

D

E

G

F

21

Page 22

Not for

Reproduction

Wireless Monitor Operation

1 low battery voltage

2 low uid level

3 under/over voltage

5 low frequency

6 engine overspeed

7 high temperature

# of flashes service needed

1 low battery voltage

2 low uid level

3 under/over voltage

4 engine does not start

part #: 316196 fcc id: MCQ-XBS2C IC id: 1846A-XBS2C

5 low frequency

6 engine overspeed

7 high temperature

8 transfer switch

# of flashes service needed

1. Remove battery access cover (A) on back of monitor

A

and install 2 AA batteries. (Observe correct battery

polarity which is embossed in the bottom of the

battery compartment). Replace battery access cover.

vice needed

4 engine does not start

part #: 316196 fcc id: MCQ-XBS2C IC id: 1846A-XBS2C

e

8 transfer switch

4. “LINKING MODE” will scroll across the generator

control panel.

5. Locate and hold the SYSTEM UPDATE button (C) on

C

the wireless monitor for 5 seconds. All 3 LEDs will flash

until the monitor links to the generator. Once it links,

the monitor will display the current state. The monitor

will try to link for 1 minute. (This step can only be

completed when the generator is in Linking Mode).

DEALER NAME

DEALER

PHONE

A

NOTICE The wireless monitor was linked to the generator at

the factory. Communication will begin upon the installation

of the batteries and the generator being placed in AUTO

mode. You may need to press System Update one time.

2. The wireless monitor does not have an on/off

switch. When batteries are installed correctly,

the GENERATOR READY green LED light will flash

once every 10 seconds indicating the status of the

generator.

NOTICE If communication does not begin upon placing the

generator in AUTO, installing batteries, and pressing System

Update, the monitor may need to be re-linked. To link, follow

Steps 3 through 6.

3. Locate the MENU AND ESCAPE buttons on the control

panel (B) . Press and hold for 3 seconds to enter the

B

linking mode.

generator ready

generator power

service needed

C

system update

6. Once the link has been confirmed, press the OK

button on the generator control panel to exit or the

control board will turn off linking after 5 minutes. The

generator will now communicate with the wireless

monitor.

NOTICE It may take up to 1 minute for the monitor to begin

displaying the generator status correctly.

menu

ok

esc

off manual

B

B

auto

22

Page 23

Not for

Reproduction

Standard Operation:

Wireless Monitor Status LED’s

• The wireless monitor receives data from the generator

every 10 minutes and displays the generator status

through 3 LED’s.

• Pressing the SYSTEM UPDATE button will provide

current generator status by flashing the status LED’s.

When pressed, all 3 LEDs will flash until the generator

status is received.

NOTICE Generator control panel must be in AUTO mode or

no communication with monitor will occur.

• In order to conserve power and to extend battery life,

the LED’s are not lit continuously; instead they are

briefly flashed as indicated below.

NOTICE During the weekly exercise cycle, the generator will

run for 20 minutes, but it will not supply power to the home.

During the exercise cycle, the monitor will continue blinking

the GENERATOR READY green LED.

• GENERATOR READY - When active, the green LED will

flash once every 7 seconds. The green LED indicates

that the generator is in AUTO mode and that it is

ready to run in the event of a loss of utility power.

• GENERATOR POWER - When active, the green LED will

flash every 7 seconds. The green LED indicates that

the generator is supplying power.

• SERVICE NEEDED - When active, the red LED will flash

in a sequence that corresponds to the service code.

For example, when Low Frequency scrolls across the

control board, the red LED will flash 5 times with a 3

second pause between series of blinks until it is reset

or the condition is corrected. When the red LED is lit,

contact your nearest authorized service dealer.

NOTICE None of the conditions on the display unit can be

cleared at the wireless monitor. All alerts must be cleared at

the generator control panel.

NOTICE Service conditions will only be displayed on the

basic monitor when the control board is placed in AUTO

mode.

Other:

LED Lighting Codes

• Batteries Inserted - GENERATOR READY LED will light

for 5 seconds.

• Wireless Communication Lost - SERVICE NEEDED LED

will flash 20 fast pulses, then pause for 5 seconds,

and repeat the sequence until the communication

has been restored.

• Linking Error or Not Linked - SERVICE NEEDED LED will

light for 4 seconds, pause for 4 seconds, and repeat

the sequence until a successful link is completed.

23

Page 24

Not for

Reproduction

Maintenance

Servicing the System

Before performing any generator maintenance, always

perform the following steps:

1. Set generator’s circuit breaker to its OFF position.

2. Press and hold the control board OFF button.

3. Remove 15 Amp fuse from control board.

Service Code Detection System

The generator may have to run for long periods of time

with no operator present. For that reason, the system is

equipped with sensors that automatically shut down the

generator in the event of potentially damaging conditions,

such as low oil pressure, high temperature, over speed, and

other conditions.

The generator’s control board shows service code

descriptions scrolling across the digital display. The service

code descriptions are listed below:

• Low Battery Voltage

• Low Oil Pressure

• Under Voltage

• Over Voltage

• Engine Does Not Start

• Low Frequency

• Engine Overspeed

• High Oil Temperature

• Transfer Switch Service code

• No Wireless Communication

• Battery Charge Circuit

4. Utility voltage is present at generator control board.

Disconnect power before servicing control board by

removing the fuses from the transfer switch.

5. After all servicing has been completed, replace fuses

in transfer switch, replace 15 Amp fuse in control

board, set circuit breaker ON and press and hold

control board AUTO button.

Reset Service code Detection System

The operator must reset the service code detection system

each time it activates. To do so, press the control board OFF

button for 5 seconds. Once the display turns off, leave it off

for at least 30 seconds. Remedy the service code condition,

then return the home generator to service by pressing and

holding the control board AUTO button and installing the 15

Amp fuse (if removed).

Low Battery Voltage

This service code is indicated by Low Battery Voltage scrolling

across the digital display and a single flash on the wireless

monitor. This condition occurs if the battery voltage drops

below the preset value. Causes for this problem may be a

service code battery or battery charge circuit. See Battery

Charge Circuit,

Remove the 15 Amp fuse and disconnect the battery from

the generator. Test the battery voltage. If voltage meets

specifications, take the battery to a local battery store for

analysis. Or contact your local service center for assistance.

Reinstall the battery (replace if necessary - see Battery in

Final Installation Considerations in the installation manual).

Then reset the service code detection system, as described

earlier.

24

Page 25

Not for

Reproduction

Low Oil Pressure

This service code is indicated by Low Oil Pressure scrolling

across the digital display and two flashes on the wireless

monitor. The unit is equipped with an oil pressure switch

that uses normally closed contacts held open by engine oil

pressure during operation. Should oil pressure drop below

the 8 psi range, switch contacts close and the engine will

shut down.

To remedy the low oil pressure condition, add the

recommended oil to the FULL mark on the dipstick.

If the low oil pressure condition still exists, the engine will

start, then shut down again. The service code will appear. In

this case, contact an authorized dealer.

Under Voltage

This service code is indicated by Under Voltage scrolling

across the digital display and three flashes on the wireless

monitor. This condition is caused by a restriction in the

fuel flow, the electronic governing system not functioning

properly, a broken or disconnected signal lead, a failed

alternator winding, the control board circuit breaker is open,

or the generator is overloaded.

To remedy the problem, contact your installer or an

authorized dealer.

Over Voltage

This service code is indicated by Over Voltage scrolling across

the digital display and three flashes on the wireless monitor.

This feature protects devices connected to the transfer

switch by shutting the generator down if the generator

output voltage happens to increase above the preset limit.

This condition is most likely caused by a failed voltage

regulator, alternator excitation circuit or a load imbalance. To

remedy the problem, contact your installer or an

authorized dealer.

Engine Does Not Start

This service code is indicated by Engine Does Not Start

scrolling across the digital display and four flashes on the

wireless monitor. This feature prevents the generator from

damaging itself if it continually attempts to start in spite

of another problem, such as no fuel supply. Each time the

system is directed to start, the unit will crank for 10 seconds,

pause for 10 seconds, and repeat. If the system does not

begin producing electricity after approximately 2 minutes,

the unit will stop cranking.

The most likely cause of this problem is no fuel supply or

incorrect fuel selector setting. See Fuel Selection Switch in

the installation manual. Check the internal and external fuel

shut off valves to ensure they are fully open. Other causes

could be failed spark plug(s), a loose electronic governor

connection, a failed engine ignition, or the engine air filter

is clogged. You may need to contact your installer for

assistance if you can’t remedy these problems.

Low Frequency

This service code is indicated by Low Frequency scrolling

across the digital display and five flashes on the wireless

monitor. This feature protects devices connected to the

transfer switch by shutting the generator down if the engine

runs slower than 55 Hz for three seconds. This condition is

caused by a failed engine component, electronic governor

system, or by excessive loads on the generator. To resolve

the problem, contact your installer or an authorized dealer.

Engine Overspeed

This service code is indicated by Engine Overspeed scrolling

across the digital display and six flashes on the wireless

monitor. This condition can be caused by a problem within

the electronic governor system.

To resolve the problem, contact your installer or an

authorized dealer.

High Oil Temperature

This service code is indicated by High Oil Temperature

scrolling across the digital display and seven flashes on the

wireless monitor. The contacts of the temperature switch

are normally open. If the engine temperature exceeds a

predetermined temperature, the service code is detected and

the engine shuts down.

Common causes for this condition include running the

unit with an access doors removed, obstructed air inlet

or exhaust port, or debris in the engine compartment or

running unit with roof open.

To resolve the problem, let the engine cool down and remove

any accumulated debris and obstructions. Ensure that the

access doors are installed and the roof is closed whenever

the unit is running. If problem persists, contact your installer

or an authorized dealer.

Transfer Switch Service code

This service code is indicated by Transfer Switch Service

code scrolling across the digital display (if transfer switch is

equipped with service code detection) and eight flashes on

the wireless monitor.

The most likely cause of this service code is a blown fuse in

the transfer switch. To remedy the problem, contact your

installer or an authorized dealer.

No Wireless Communication

This service code is indicated by No Monitor Communication

scrolling across the digital display. The SERVICE NEEDED red

LED on the wireless monitor will flash 20 fast pulses, pause

5 seconds, and repeat if there is a loss in communication

between the wireless monitor and the generator.

To resolve the problem, move the wireless monitor closer to

generator. Re-link if necessary.

Battery Charge Circuit

This service code is indicated by Battery Charge Circuit

scrolling across the digital display. The most likely cause is

an electrical problem with the control panel. To remedy the

problem, contact your installer or an authorized dealer.

25

Page 26

Not for

Reproduction

Maintenance Schedule

Follow the hourly or calendar intervals of operation,

whichever occurs first.

First 5 Hours

Change Engine Oil

Every 8 Hours or Daily

Clean Debris

Check Engine Oil Level

Every 100 Hours or Annually

Change Air Filter

Change Engine Oil and Filter

Replace Spark Plugs

Check Valve Clearance

Check Circuit Breaker Torques

Annually

Clean Oil Cooler Fins

Regular maintenance will improve the performance and

extend the life of the generator. See any authorized dealer

for service.

Emissions Control

Maintenance, replacement, or repair of the emissions

control devices and systems may be performed by any

non-road engine repair establishment or individual.

However, to obtain ”no charge” emissions control service, the

work must be performed by a factory authorized dealer. See

the Emissions Warranty.

Generator Maintenance

The generator’s warranty does not cover items that have

been subjected to operator abuse or negligence. To receive

full value from the warranty, the operator must maintain the

generator as instructed in this manual.

Some adjustments will need to be made periodically to

properly maintain your generator.

All service and adjustments should be made at least once

each season. Follow the requirements in the Maintenance

Schedule chart.

Generator maintenance consists of keeping the unit

clean. Operate the unit in an environment where it will

not be exposed to excessive dust, dirt, moisture or any

corrosive vapors. Cooling air louvers on the enclosure

must not become clogged with snow, leaves, or any other

foreign material. To prevent generator damage caused by

overheating, keep the enclosure cooling inlets and outlets

clean and unobstructed at all times.

Check the cleanliness of the unit frequently and clean when

dust, dirt, oil, moisture or other foreign substances are visible

on its exterior/interior surface. Inspect the air inlet and outlet

openings inside and outside the enclosure to ensure air flow

is not blocked.

DO NOT use direct spray from a garden hose to clean

generator. Water can enter the engine and generator and

cause problems.

26

NOTICE Improper treatment of generator could damage it and

shorten its life.

• DO NOT expose generator to excessive moisture, dust, dirt, or

corrosive vapors.

• DO NOT insert any objects through cooling slots.

Clean the generator as follows:

1. Press and hold the control board OFF button.

2. Remove 15 Amp fuse from control board.

3. Clean generator as desired.

• Use a damp cloth to wipe exterior surfaces clean.

• Use a soft, bristle brush to loosen caked on dirt, etc.

• Use a vacuum cleaner to pick up loose dirt and debris.

• Use low pressure air (not to exceed 25 psi) to blow

away dirt. Inspect cooling air slots and openings on

the generator. These openings must be kept clean

and unobstructed.

4. Reinstall 15 Amp fuse in control board.

5. Press and hold the control board AUTO button.

Page 27

Not for

Reproduction

Battery

Servicing of batteries is to be performed or supervised

by personnel knowledgeable of batteries and the

required precautions. Keep unauthorized personnel away

from batteries.

Servicing the Battery

If it is necessary to service the battery, proceed as follows:

1. Press and hold the control board OFF button.

2. Remove 15 Amp fuse from control panel.

3. Service or replace battery as required. See Battery

in Final Installation Considerations in the installation

manual for specific battery needed.

4. Connect red battery cable to battery positive terminal

(indicated by POSITIVE, POS, or (+)).

Charging the Battery

If it is necessary to charge the battery, proceed as follows:

1. Press and hold the control board OFF button.

2. Remove 15 Amp fuse from control board.

3. Disconnect negative battery cable from negative

battery terminal (indicated by NEGATIVE, NEG, or (-)).

NOTICE Failure to disconnect negative battery cable could result in

equipment failure.

• DO NOT attempt to jump start the generator.

• Damage to equipment resulting from failure to follow this

instruction will void engine and generator warranty.

WARNING Battery posts, terminals and related accessories

contain lead and lead compounds, chemicals known to the State

of California to cause cancer and reproductive harm. Wash hands

after handling.

6. Connect black negative battery cable to negative

battery terminal (indicated by NEGATIVE, NEG, or (-).

7. Ensure hardware on both positive and negative

battery terminals is secure.

8. Reinstall 15 Amp fuse in control panel.

9. Press and hold the control board AUTO button.

DON’T POLLUTE. CONSERVE RESOURCES, RETURN

USED BATTERY TO RECYCLING COLLECTION CENTER.

4. Charge battery with battery charger at 2 Amps until

battery holds 12 Volts. DO NOT exceed 13.7 volts

when charging.

NOTICE DO NOT use a battery booster to quick charge a low

battery.

5. Connect negative battery cable to negative battery

terminal (indicated by NEGATIVE, NEG, or (-)).

6. Ensure hardware on both positive and negative

battery terminals is secure.

7. Reinstall 15 Amp fuse in control board.

8. Press and hold the control board AUTO button.

WARNING Storage batteries give off explosive hydrogen gas

during recharging.

Slightest spark will ignite hydrogen and

cause explosion, resulting in death or

serious injury.

Battery electrolyte fluid contains acid and is extremely caustic.

Contact with battery contents could cause severe chemical burns.

A battery presents a risk of electrical shock and high short

circuit current.

• DO NOT dispose of battery in a fire. Recycle battery.

• DO NOT allow any open flame, spark, heat, or lit cigarette during

and for several minutes after charging a battery.

• DO NOT open or mutilate the battery.

• Wear protective goggles, rubber apron, rubber boots and

rubber gloves.

• Remove watches, rings, or other metal objects.

• Use tools having insulated handles.

CAUTION With the system switch set to AUTO, the engine could

crank and start at any time without warning, resulting in

minor or moderate injury.

• To prevent possible injury that could be caused by such sudden

starts, always set the system switch to OFF if performing

maintenance on the system.

• Remove the 15 Amp fuse before working on or around the

generator or transfer switch.

27

Page 28

Not for

Reproduction

Engine Maintenance

WARNING Unintentional sparking could cause fire or electric

shock resulting in death or serious injury.

WHEN ADJUSTING OR MAKING REPAIRS TO YOUR GENERATOR

• Disconnect the spark plug wire from the spark plug and place the

wire where it cannot contact spark plug.

WHEN TESTING FOR ENGINE SPARK

• Use approved spark plug tester.

• DO NOT check for spark with spark plug removed.

Adjust Valve Lash

The valve lash must be checked every 100 hours of

operation. Measure valve clearance with the engine cold.

To adjust the valve lash, proceed as follows:

1. Remove spark plug(s) to ease manual rotation of

engine crankshaft.

2. Turn crankshaft counterclockwise until the piston is at

Top Dead Center on the compression stroke.

3. Insert a narrow screwdriver or rod into spark

plug hole as a gauge, then slowly turn crankshaft

counterclockwise until the piston has moved down

the bore by 1/4”.

4. For the Model 31 Engine:

• Use a feeler gauge (A) , measure the valve

clearance.

• Adjust the rocker nut to obtain the correct

clearance as follows: 0.005 (0.013 mm) intake

and 0.007 (0.018 mm) exhaust.

• Hold rocker nut and tighten the rocker ball set

screw (B) to 45 in/lb (5 Nm).

5. For the Model 35 Engine:

• Use a feeler gauge (A) to measure the valve

clearance.

• Adjust the clearance by loosening the lock nut

(B) then turn the adjusting screw (C) to obtain

B C

the following measurement: 0.005 in. (0.013 mm)

intake and exhaust.

• Once the clearance is properly set, hold the

adjusting screw while torquing the lock nut to 70

in/lbs. (8 Nm).

6. Repeat for the other valve, if applicable.

B

A

A

When all engine servicing is complete, replace 15 Amp fuse

in control board and reset exercise timer.

A

B

Model 31 Engine

B

C

28

Model 35 Engine

Page 29

Not for

Reproduction

Engine Oil

The engine is filled with synthetic oil (API SJ/CF 5W-30).

This allows for system operation in the widest range of

temperature and climate conditions.

We recommend the use of Briggs & Stratton Warranty

Certified oils for best performance. Other high-quality

detergent oils are acceptable if classified for service SJ or

higher. DO NOT use special additives.

Outdoor temperatures determine the proper oil viscosity for

the engine. Use the chart to select the best viscosity for the

outdoor temperature range expected.

NOTICE Synthetic oil meeting ILSAC GF-2, API

certification mark and API service symbol with “SJ/

CF ENERGY CONSERVING” or higher, is an acceptable

oil at all temperatures. Use of synthetic oil does not

alter required oil change intervals.

Changing Engine Oil and Oil Filter

Open roof and remove front panel to access the oil filter and

to add engine oil.

* Below 40°F (4°C) the use of SAE 30 will result in hard

starting.

** Above 80°F (27°C) the use of 10W30 may cause increased

oil consumption. Check oil level more frequently.

Checking/Adding Engine Oil

1. Open roof to access dipstick and oil fill area.

2. Clean the oil fill area of any debris.

3. Remove the dipstick and wipe with a clean cloth.

4. Fully insert dipstick into oil fill.

5. Remove dipstick and check oil level. Verify oil is at Full

mark on dipstick.

6. If needed, slowly pour recommended oil into oil fill

opening. DO NOT overfill. After adding oil, wait one

minute and recheck oil level.

NOTICE Overfilling with oil could cause the engine to not start, or

hard starting.

• DO NOT overfill.

• If over the FULL mark on dipstick, drain oil to reduce oil level to

FULL mark on dipstick.

7. Replace oil dipstick.

8. Close roof and secure.

29

Page 30

Not for

Reproduction

Changing Engine Oil and Oil Filter

CAUTION Avoid prolonged or repeated skin contact with used

motor oil.

• Used motor oil has been shown to cause skin cancer in certain

laboratory animals.

• Thoroughly wash exposed areas with soap and water.

KEEP OUT OF REACH OF CHILDREN. DON’T POLLUTE.

CONSERVE RESOURCES. RETURN USED OIL TO

COLLECTION CENTERS.

NOTICE Any attempt to crank or start the engine before it has

been properly serviced with the recommended oil will result in

equipment failure.

• DO NOT attempt to crank or start the engine before it has been

properly serviced with the recommended oil. This may result in

an engine failure.

• Damage to equipment resulting from failure to follow this

instruction will void engine and generator warranty.

Change the oil while the engine is still warm from running, as

follows:

1. Press and hold the control board OFF button.

2. Remove 15 Amp fuse from control board.

3. Place oil drain hose into an approved container.

4. Remove brass fitting from end of drain hose and drain

oil into an approved container.

5. When oil has drained, replace brass fitting on hose.

6. Place oil absorbing towels under oil filter.

7. Remove oil filter and dispose of properly.

8. Before installing a new oil filter, lightly lubricate the oil

filter gasket with fresh, clean oil.

9. Install the oil filter by hand until the gasket contacts

the oil filter adapter, then tighten the oil filter 1/2 to

3/4 turn.

10. Add oil.

11. Remove container from under oil filter and clean up

any spilled oil.

12. Start and run engine. As engine warms up, check for

oil leaks.

13. Stop engine, wait for oil to settle, check oil level and

add if necessary.

Service Air Cleaner

Your engine will not run properly and may be damaged if you

run it with a dirty air cleaner. Clean or replace more often if

operating under dusty or dirty conditions.

To service the air cleaner, follow these steps:

1. Remove the knobs and the cover.

2. Remove air filter.

3. To loosen debris, gently tap air cleaner on a hard

surface. If air cleaner is excessively dirty, replace with

a new air cleaner.

4. Install the air filter.

5. Install the cover and secure with knobs.

NOTICE

same position as the original parts.

Replacement parts must be the same and installed in the

30

Page 31

Not for

Reproduction

Fuel System Inspection and Maintenance

Natural Gas / Propane Fuel System

The fuel system installed on this industrial engine has been

designed to various standards to ensure performance and

reliability. To ensure compliance to these standards, follow the

recommended maintenance schedule contained in this section.

Pressure Regulator Maintenance and Inspection

If the regulator fails to operate or develops a leak, it should be

repaired or replaced with the OEM recommended replacement

parts.

Venturi / Throttle Control Device Maintenance and

Inspection

NOTICE The venturi and throttle body components have been

specifically designed and calibrated to meet the fuel system

requirements of the engine.

NOTICE A dirty air cleaner may significantly alter the venturi

performance.

When inspecting the venturi and throttle body, check for the

following items:

• Leaks at all fittings.

• Ensure the venturi and throttle body are securely

mounted.

NOTICE The fuel system components have been specifically

designed and calibrated to meet the fuel system

requirements of the engine. If a fuel system component

fails to operate or develops a leak, it should be repaired or

replaced with the OEM recommended replacement parts.

When inspecting the regulator, check for the following items:

• Check for any fuel leaks at the inlet and outlet fittings.

• Check for any fuel leaks in the regulator body.

• Check to ensure the regulator is securely mounted

and the mounting bolts are tight.

• Check the regulator for external damage.

• Inspect air cleaner element according to the

recommended maintenance schedule found in this

section.

• Check fuel lines for cracking, splitting, or chaffing,

Replace if any of these conditions exist.

• Check for leaks at the throttle body and intake

manifold.

Exhaust System Maintenance and Inspection

When inspecting the exhaust system, check for the following

items:

• Inspect exhaust manifold at the cylinder head for leaks

and that all retaining bolts and shields (if used) are in

place.

• Inspect manifold to exhaust pipe fasteners to ensure

they are tight and that there are not exhaust leaks.

Repair as necessary.

Engine Exterior

Periodically inspect the engine exterior for contamination

and potential damage from dirt, leaves, rodents, spider webs,

insects, etc. and remove.

• Inspect exhaust pipe connection for leaks. Repair as

necessary.

31

Page 32

Not for

Reproduction

Service Spark Plugs

Changing the spark plugs will help your engine to start easier

and run better.

1. Clean area around spark plugs.

2. Remove and inspect spark plugs.

3. Check electrode gap with wire feeler gauge and reset

spark plug gap to recommended gap if necessary

(see Specifications).

4. Replace spark plugs if electrodes are pitted, burned

or porcelain is cracked. Use the recommended

replacement spark plugs. See Specifications.

5. Install spark plugs and tighten to 180 in/lbs (20 Nm).

Clean Air Cooling System and Oil Cooler Fins

Over time debris may accumulate in cylinder cooling fins

and cannot be observed without partial engine disassembly.

Unobstructed air flow is critical for correct generator

operation. For this reason, we recommend you have an

authorized service dealer clean the cooling system per

recommended intervals (see Maintenance Schedule in the

Maintenance section). Equally important is to keep top of

engine free from debris. Make sure the oil cooler fins are free

of dirt and debris. Also see Cleaning.

When Calling for Assistance

You must have the following information at hand if it is

necessary to contact a local service center regarding

service or repair of this unit:

1. Obtain the unit Model Number and Serial Number

from the unit ID label. See Controls for location of

the label or refer to the information recorded on the

inside front cover of the installation manual.

2. Obtain the engine identification numbers from the

engine label. See Controls for location of the label or

refer to the information recorded on the inside front

cover of the installation manual.

Storage

The home generator system is designed for long term service

as a backup generator. There is no need to take any storage

precautions. However, if it becomes necessary to take the

system out of service for an extended period, call Technical

Services at 888 575-8226, between 8:00 AM and 5:00 PM CT

for specific recommendations.

32

Page 33

Not for

Reproduction

PAGE INTENTIONALLY LEFT BLANK

33

Page 34

Not for

Reproduction

Troubleshooting

Problem Cause Correction

Eng ine is running, but no AC output is available.

Eng ine runs well at no-load but “bogs down” when

loads are connected.

Eng ine will not start; or starts and runs rough.

Engine shuts down during operation.

1. Circuit breaker open or defective.

2. Service code in generator control board.

3. Poor wiring connections or defective transfer

switch.

1. Generator is overloaded.

2. Short circuit in a connected load.

3. Shorted generator circuit.

4. Fuel pressure or mixture is incorrect.

5. Kinked fuel line between regulator and engine.

1. 15 Amp fuse missing or blown.

2. Thermal fuse(s) blown.