GBT A2-035, A2-050, A2-097, A2-120, A2-140 Installation & Operating Instructions Manual

...

INSTALLATION & OPERATING

WARNING:

gas supplier.

INSTRUCTIONS

For All A2000 Series Water

Heaters & Water Boilers

If these instructions are not followed exactly, a fire or explosion may result causing

property damage, personal injury or death.

FOR YOUR SAFETY: Do not store or use gasoline or other flammable vapors and liquids or

other combustible materials in the vicinity of this or any other appliance. To do so may result in

an explosion or fire.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency or the

Note: Place a copy of these instructions adjacent to the boiler/heater; notify the owner to keep for future reference.

If Shipping Damage is noted, receiver must make damage claim on Bill of Lading (see page 6).

918 West Walnut St. Danville, Kentucky 40422

Visit Us On The Web: www.gbt-inc.com

For Customer Service Please Call: 859-236-3181

W3260001 Rev. D Effective May, 2011

SAFETY

Safety messages and instructions located in this manual and on the heater/boiler provide warnings to

you and others of potential hazards. Before installing, operating or servicing this heater/boiler, it is

important to read and understand these safety instructions and messages.

The safety alert symbol alerts you to potential hazards. The message that follows this

symbol must be obeyed to avoid possible injury or death.

DANGER indicates the presence of immediate hazards which, if not avoided, could result in

severe personal injury, death, or substantial property damage.

WARNING indicates a potentially hazardous situation which, if not avoided, could result in

severe personal injury, death or substantial property damage.

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury, or property damage.

Qualified Installer: Must have the ability of a licensed tradesman in the fields of gas supply, plumbing and

venting, including a thorough understanding of the National Fuel Gas Code as it relates to gas fired water

heaters and boilers. The installer must thoroughly review and understand this manual.

Service Agency: Must have the ability of a licensed tradesman in the fields of gas supply, plumbing and

venting, including a thorough understanding of the National Fuel Gas Code as it relates to gas fired water

heaters and boilers. The servicer must thoroughly review and understand this manual and perform service and

repairs strictly in accordance with the manufacturer’s service instructions.

Gas Supplier: A natural gas or propane Utility or service company that supplies gas for water heater and boiler

appliances, typically having responsibility for the inspection and code approval of the gas piping up and

including the meter or Propane storage tank. Many gas suppliers meet the requirements of a Qualified Installer

or Service Agency.

Verify that the gas hooked up to the appliance is the same type specified on the Name Plate

label, located on the heater/boiler.

Should overheating occur, or the gas valve fails to shut, do not turn off the electrical supply to

the heater/boiler. Shut off the gas supply at a location away from the heater/boiler.

Do not use this heater if any part has been under water. Have the heater/boiler inspected by

a qualified service technician. Replace any electrical or gas control system which has been

under water.

This unit requires an inlet water temperature of at least 120

condensation. Condensation may cause pre-mature heat exchanger failure. Prolonged

operation of this heater/boiler with return temperatures below 120 oF will void the warranty.

Maintain the area surrounding the heater/boiler clean and free of combustible materials,

gasoline, and other flammable liquids or vapors. The heater/boiler should never be covered.

This heater/boiler requires a constant supply of fresh air for proper combustion. Failure to

provide an adequate flow of fresh air may result in series injury or death.

o

F (49 oC) to avoid flue gas

Page 1

INTRODUCTION …………………………………………………………………………… 4

General

Dimensions & Specifications

Model Identification

Ratings & Certifications

INSTALLATION ……………………………………………………………………………. 6

Product Receipt

High Elevation

Location & Placement

Combustion Air Requirements

Electrical Requirements

Gas Requirements

Water Connections

Venting System

START-UP & OPERATION ……………………………………………………………... 15

Pre-Start Checklist

Filling The System With Water

Purging Air From Gas Lines

Preparation

Start-Up

Shut-Down Procedure

Operation

MAINTENANCE & INSPECTION …………………………………………………….. 22

Heat Exchanger

Burner & Pilot Flame

Gas Manifold Pressure

Vent System

Burner & Flue Passageway

Pressure Relief Valve

High Temperature Switch

Flow Switch

Heat Exchanger Protections

Condensation

Removal of Existing Appliance

TROUBLESHOOTING …………………………………………………………………. 25

DIAGRAMS ………………………………………………………………………………. 29

Typical Hydronic Heating Loop Piping Diagram

Low Temperature Heating Loop Piping Diagram

Single Heater Domestic System Piping Diagram

Dual Heater Domestic System Piping Diagram

By-Pass Loop Plumbing For Low Temperature Systems

Wiring Diagrams

PARTS LIST ………………………………………………………………………….…. 37

WARRANTY INFORMATION …………………………………………………………. 41

TABLE OF CONTENTS

Page 2

Thank you for purchasing an A2000 Series water heater/boiler from Green Boiler Technologies. Your model

was proudly built in the United States with high quality components and craftsmanship. With the proper

installation and maintenance, your A2000 heater/boiler will provide years of outstanding performance.

The A2000 series water heaters and water boilers utilize efficient copper fin-tube heat exchangers and are

certified as Category I Appliances. Category I equipment utilizes natural draft to remove flue gases without need

of a fan or draft inducer, and has flue gas temperatures more than 140° F above the dew point.

The unique design of the appliance provides excellent heat transfer and a small footprint. The heat exchanger

resists build-up of lime scale and allows de-liming without disassembly of the unit.

INTRODUCTION

DIMENSIONS & SPECIFICATIONS

Model A B C D E F G H K

A2-035

A2-050

A2-070

A2-097

A2-120

A2-140

Dimensions in Inches; Dimensions For Units With Standard Gas Train

Model BTU

A2-035

A2-050

A2-070

A2-097

A2-120

A2-140

7 17 ½ 34 ½ 38 58 9 24 10 29

8 16 ½ 33 42 69 10 28 18 ½ 33

10 ¼ 13 ¼ 33 38 ¾ 66 12 32 25 36 ¼

6 ¾ 17 ¾ 38 41 ¼ 77 ¼ 16 35 20 43

7 17 ½ 44 ½ 48 ½ 84 ½ 16 35 22 43

7 17 ½ 44 ½ 48 ½ 100 ½ 18 35 22 43

GPH @

Input **

350,000 336 1

500,000 480 1

700,000 672 1 ¼

970,000 932 1 ¼

1,200,000 1152 1 ½

1,400,000 1345 1 ½

Dimensions In Inches; GPH = Gallons Per Hour; * Approximate

100o Rise

** Propane Model Input Is 10% Less

Gas

Connection

Water

Connection

1 ½

1 ½

1 ½

1 ½

1 ½

1 ½

Vent

Diameter

9 460

10 600

12 650

16 700

16 804

18 944

Shipping

Weight *

Page 3

MODEL IDENTIFICATION

The model number can be found on the Name Plate label, located on the heater/boiler.

A2 - (H,X,B,T,C) - (###) - (NG,LP,NH,LH)

A2 = A2000 Series Water Heater or Boiler

H = Water Heater

X = Water Heater with 2-Stage burner controls

B = Boiler

T = Boiler with 2-Stage burner controls

C = Boiler with ASME CSD-1 controls

### = Nominal Rated Input

NG = Natural Gas

LP = Propane

NH = Natural Gas, High Altitude

LH = Propane, High Altitude

RATINGS AND CERTIFICATIONS

The A2000 models are certified to the following standards:

• ANSI Z21.13 – CSA 4.9 Gas-Fired Hot Water Boilers, Latest Edition

• ANSI Z21.10.3 – CSA 4.3 Gas Water Heaters, Latest Edition

All A2000 models are ASME National Board Approved and are constructed in accordance with Section IV of the

ASME Heater Pressure Vessel Code (160 psi working pressure) and bears the ASME “H” stamp.

Do not alter or replace the heat exchanger without the approval of Green Boiler

Technologies. To do so will void the warranty and the ASME certification.

Ensure the fuel that the appliance will burn is the same as that specified on the boiler rating

plate. Conversions must be completed by a Qualified Service Agency or Gas Provider. Call

your Green Boiler Technologies Representative or Customer Service for instructions and the

proper conversion kit.

Page 4

INSTALLATION

This manual must be thoroughly reviewed and understood before installing your A2000

heater/boiler. Installation and Service must be completed by a Qualified Installer, Service

Agency or Qualified Gas Supplier. If you have any questions which are not covered in the

manual, please contact Green Boiler Technologies or your local representative.

PRODUCT RECEIPT

On receipt of your heater/boiler, visually check for external damage to the appliance or shipping crate. If the

crate is damaged, make a note to that effect on the Bill of Lading before signing for the shipment. After

removing the appliance from the shipping crate, report any damage to the carrier immediately. If any items were

shipped loose, make sure they were received. All carrier claims are your responsibility.

All claims for damage or shortages must be filed with the carrier. Before product is returned, permission and an

Authorized Return Goods Number (RMA) must be acquired from the manufacturer. Product returned to the

factory without an authorized RMA will not be accepted. All returned product is subject to a restocking charge.

HIGH ELEVATION

For units installed at elevations above 2,000 feet over sea level, consult the factory for the proper burner

orifices.

Units installed at elevations above 2,000 feet must be de-rated to account for the

lower percentage of oxygen present in the air. Personal injury due to the inhalation

of Carbon Monoxide may result if the unit input is not properly de-rated.

INSTALLATION CODE REQUIREMENTS

1. The installation of the unit must conform to the requirements of the authority having jurisdiction or, in the

absence of such requirements, to the National Fuel Gas Code, ANSI, Z223.1 / NFPA 54, Latest Edition

and the National Electric Code (NEC) ANSI/NFPA 70.

2. Where required by authority having jurisdiction, the installation of water boilers must conform to

American Society of Mechanical Engineers Safety Code for Controls and Safety Devices for

Automatically Fired Boilers, No. CSD-1.

3. For Canada only, the installation must conform to CAN/CGA B149 and CSA C22.1 Part 1.

It is important to wear eye protection and gloves while installing, servicing or

repairing the unit. A dust respirator is recommended while servicing or repairing the

burner assembly or combustion chamber area. Use caution when working on roofs

and/or scaffolding. Proper and safe scaffolding and/or ladders must be used and all ladders should be

secured when in use. Check overhead for antennas, power lines and other obstacles before erecting

ladders or scaffolding and while working on any roof structure.

Page 5

LOCATION & PLACEMENT

When installing the boiler or heater, consideration must be given to proper location. In addition to the following

requirements, the installation must adhere to all local or state code requirements.

1. The unit should be leveled.

2. Minimum clearance for hot water pipes and venting from combustible material is 6 inches.

3. The boiler/heater must not be installed on carpeting or other combustible flooring.

4. The unit is for alcove installation on non-combustible floors only. The minimum clearance for

combustible material:

Minimum Clearance A-035 A-050 A-070 A-097 A-120 A-140

Back & Side Walls

Top of Jacket to Ceiling

5. The heater/boiler must be installed so that it can be serviced without removing the heater/boiler or any

surrounding structure. The minimum space required in front of the boiler to allow removal of the burner

is:

Minimum Clearance A-035 A-050 A-070 A-097 A-120 A-140

Burner Removal

6. A hot water boiler installed above radiation level must be provided with a low water cutoff device either

as a part of the boiler or at the time of boiler installation.

7. The boiler/heater shall be protected from freezing. Heat exchangers damaged by freezing shall not be

considered for warranty.

8. The unit must be located where condensation or leakage from the heat exchanger or connections can

be drained and will not result in damage to the adjacent area or to lower floors of the structure. If this

cannot be avoidable, use of an adequately drained catch pan is recommended. The pan must not

restrict combustion air flow to the burner.

9. The boiler/heater must be installed such that the gas ignition system and other electrical components

are protected from water (dripping, spraying, rain, etc.) during operation and service.

Maintain the area surrounding the heater/boiler clean and free of combustible

materials, gasoline, and other flammable liquids or vapors. The heater/boiler should

never be covered.

24 24 24 24 24 24

51 51 56 56 56 56

Dimensions in Inches

23 28 32 35 35 35

Dimensions in Inches

COMBUSTION AIR REQUIREMENTS

The boiler/heater room must be provided with TWO openings to assure adequate combustion air and proper

ventilation. One opening should be 6 to 12 inches above the floor and the other 6 to 12 inches below the ceiling,

preferably on opposite walls. The size of each opening will vary based on whether the air is taken from inside or

outside the building, and with the input rating of the boiler/heater.

The make-up air must be sized for the total BTU per hour demand of ALL gas fired or

air using appliances served by these openings.

Page 6

When air is taken directly from the outdoors or through a vertical duct, each opening must have a minimum of 1

square inch (6.5 cm2) per 4,000 Btu/hour. If a horizontal duct is used, each opening must have a minimum of 1

square inch per 2,000 Btu/hour is required.

When air is taken from another interior space, each opening should have a minimum free area of 1 square inch

for each 1,000 Btu/hour of gas input, but not less than 100 square inches. The area of the room the boiler is

located in, plus the area it is communicating with for combustion air, must meet the large room criteria described

in the National Fuel Gas Code.

Example 1: One 500,000 btu/hr input boiler with air taken from the outdoors through two horizontal ducts. The

open area of each duct must be at least 250 square inches (161 cm2). [500,000 / 2,000] = 250]

Example 2: One 350,000 and one 1,400,000 btu/hr input boilers, with air taken from the outdoors through two

vertical ducts. The open area of each duct must be at least 437.5 square inches (2823 cm2). [(1,400,000 +

350,000) / 4,000 = 437.5]

Provision for combustion and ventilation air must be in accordance with Section 5.3 of the National Fuel Gas

Code, ANSI Z223.1 (latest edition) or applicable provisions of the local building code.

Under no circumstances should the boiler room ever be under a negative pressure.

Particular care must be taken when steam boilers, exhaust fans, compressors, air

handling units or other equipment may rob air from the unit.

The combustion air supply must be free of chemical fumes, which may be destructively corrosive when

burned. Examples of chemicals that must be avoided are fluorocarbons and other

halogenated compounds, commonly present as refrigerants or solvents, such as

Freon, trichloroethylene, and chlorine. These chemicals, when burned, form acids that

will attack the boiler tubes, flue collectors, and boiler stack, resulting in premature boiler failure.

Canadian Installations: All combustion air must be drawn from outside the building. The mechanical

equipment room must communicate directly with the outdoors. Refer to CGA B149 Installation Code for

additional information.

ELECTRICAL REQUIREMENTS

Installations must follow the National Electrical Code (NEC) ANSI/NFPA No. 70, latest edition (CSA C22.1 CEC

Part 1 for Canada) and any other local codes or regulations having jurisdiction. The unit must be electrically

grounded in accordance with NEC. Install a separate disconnect means for the heater/boiler.

The electrical conductors shall be type MTW 105 oC wire, with black for hot, white for neutral, and green for

ground. All electrical wiring must be protected from mechanical damage. The conduit and junction box shall be

UL approved with the wall thickness of the steel junction box at least 0.031 inches (0.79 mm).

The A2000 water boiler/heater operates on 115V, 15 amp, 60Hz power. A transformer is provided to reduce the

voltage to 24 volts for the ignition control module and gas valve operation. Consult the wiring diagram located

on the heater/boiler or the Wiring Diagrams section of this manual for the specific connection points and control

devices applicable for your model.

ELECTRICAL SHOCK HAZARD: Ensure electrical power to the heater/boiler is disconnected before

connecting power, auxiliary controls and components or servicing.

Do not attach any electrical components to the interior or exterior of this boiler/heater

unless given authority to do so by a representative of Green Boiler Technologies.

All models are furnished with a pre-wired, manual reset, water high limit temperature switch.

This temperature switch must not be used as an operating aquastat. A separate operating

temperature controller is required for proper operation of this appliance (see wiring diagrams for suggested

location in the electrical circuit). Failure to install a separate operating temperature controller will result in short

cycling. Typically, water heaters are installed along with a storage tank and the temperature controller is

Page 7

Max Length

3/411-1/4

1-1/2

2

2-1/2

3

4

10

273

514

1060

1580

3050

4860

8580

17500

20

188

353

726

1090

2090

3340

5900

12000

30

151

284

583

873

1680

2680

4740

9660

40

129

243

499

747

1440

2290

4050

8270

50

114

215

442

662

1280

2030

3590

7330

60

104

195

400

600

1160

1840

3260

6640

7095179

368

552

1060

1690

3000

6110

8089167

343

514

989

1580

2790

5680

9083157

322

482

928

1480

2610

5330

10079148

304

455

877

1400

2470

5040

12570131

269

403

777

1240

2190

4460

15063119

244

366

704

1120

1980

4050

17558109

224

336

648

1030

1820

3720

20054102

209

313

602

960

1700

3460

Gas Pipe Sizing Chart: Cubic Feet of Gas Per Hour

Size Schedule 40 Metallic Pi pe (i nches)

Typical Na tural Gas = 102 5 Btu per cuft ; Typical Propa ne = 2,500 btu/cuft

mounted in the lower half of the storage tank. Boiler temperature controls are typically mounted in the primary

loop. If the temperature control sensor is mounted directly on the heater/boiler water piping, the sensor must be

installed on the inlet water piping to prevent short cycling of the appliance.

A water flow switch must be installed by the installer and wired to prevent the unit from firing if for any reason

there is an inadequate flow of water through the boiler/heater (see wiring diagrams for suggested location in the

electrical circuit). NOTE: CSD-1 model boilers only, are equipped with a factory installed operating

aquastat.

Optional, circulation pumps can be supplied for single or three phase and 115 to 460 volts as required. The

pump power must be wired independently and should be adequate for the amp rating of the pump motor. Refer

to the Operating Instructions and Wiring Diagrams sections of this manual for more information regarding

pumps.

GAS REQUIREMENTS

Ensure the fuel the appliance will burn is the same as that specified on the boiler

rating plate. Conversions must be completed by a Qualified Service Agency or Gas

Provider. Call your Green Boiler Technologies Representative or Customer Service

for instructions and the proper conversion kit.

The gas supply meter, regulator, and piping must have sufficient capacity to supply all gas fired appliances they

feed without undue pressure loss. If the gas meter, regulator or piping is too small, request the gas company

install equipment with adequate capacity.

The allowable pressure loss in gas piping between the gas meter or service regulator and each appliance is

generally between 0.3 to 0.5 inches of water column. Refer to the National Fuel Gas Code, ANSI Z223.1, Latest

Edition, for sizing guidelines.

(Equival ent feet)

Ta bl e Value s For Natura l Gas, Sp ecifi c Gra vity 0.60

Example: For 20 equivalent feet of 1-1/2 inch piping, the maximum cuft/hr gas flow with a 0.3 inch w.c.

pressure loss is 726. For natural gas at 1025 Btu/cuft, the maximum firing rate is 744,000 Btu/hr

[726 x1025]. For propane at 2500 Btu/cuft, the maximum firing rate is 1,815,000 Btu/hr [726 x

2500].

Maximum and minimum gas pressure delivered to the boiler/heater is shown below. If the gas supply line

pressure is greater than the maximum listed, a pressure regulator must be installed at least 10 pipe diameters

upstream of the boiler/heater.

Page 8

Maximum Pressure Minimum Pressure

Natural Gas

Propane

Units: Inches of Water

The A2000 series water boiler/heater is not intended to operate at a gas supply

pressure other than shown on the rating plate. Exposure to a higher gas supply

pressure may cause damage to the gas valves, which can result in fire or explosion.

The gas supply piping must have a 3 inch (7.6 cm) minimum sediment trap

(sometimes referred to as a dirt trap or drip leg) and a manual shut off valve

ahead of the boiler/heater. The sediment trap should be located as close to the

heater as possible, be readily accessible and not subject to freezing conditions. A

union of the ground joint or flanged joint type must be installed in the gas supply

piping adjacent to the boiler/heater for ease of service.

all supply pipe and fittings prior to insulation. Do not use Teflon tape. Use

only a joint compound suitable for natural gas and propane. Apply the joint

compound sparingly, only on the male threads and do not apply to the first

two threads.

To prevent damage, do not apply excessive torque when attaching the gas supply line

to the boiler/heater gas valve.

The gas supply piping must be adequately supported by using hangers or other suitable types of support. Do

not use the boiler/heater gas train to support the gas supply piping.

The boiler/heater and its gas connections must be leak tested prior to placing the unit in operation. Use soap

and water solutions or other material acceptable for the purpose of locating gas leaks. Do not use matches,

candles, flame, or other sources of ignition for this purpose.

During pressure testing, disconnect the heater/boiler from the gas supply if the test pressure is equal to or

greater than ½ psig (3.5 kPa). The gas supply line must be capped when not connected to the boiler during this

process. Relieve the gas pressure in the gas supply line prior to re-connecting to the boiler/heater. Failure to

follow this process may damage the gas valves and voids the warranty on the gas valves.

Do not subject the boiler/heater gas train components to pressures equal to or greater

than ½ psig. Damage to the gas valves may result.

Local codes may require the vents on the supply regulators and safety vent valves be piped to the outside.

When required, this piping is part of the gas supply piping and not part of the boiler/heater. It is important to

insure these vents are protected against blockage, with special care given to prevent blockage from rain,

condensation, ice, or snow.

When multiple appliances are fed gas from the same supply line, individual point of use regulators are

recommended to minimize variations in supply pressure.

9 5

15 13

It is important to guard against gas valve fouling from

contaminants in the gas piping. Fouling may cause

improper operation, fire or explosion. Clean the inside of

Page 9

Recommended Temperature Rise: 20 - 45

F

WATER CONNECTIONS

The type of system in which the boiler/heater is to be used will determine the type of water connections to be

made. Consult the piping schematics provided in the DIAGRAMS section before beginning the installation. Be

sure to install the unit in accordance with the installation instructions to insure proper operation and safety.

The heater/boiler should be located so that any water leaks will not cause damage to the adjacent area or

structures. If this cannot be avoided, use of a properly sized, drained catch pan is recommended. The catch

pan must not impair combustion air flow to the burner. Union connections and shut off valves must be provided

at the unit to facilitate future service which may be required.

The ASME pressure relief valve supplied on the unit must be piped to a drain or to a safe location to prevent

accidental burns should the valve discharge hot water. DO NOT install a valve between the relief valve and the

heater. DO NOT install reducing coupling, restriction, or valve in the relief valve discharge line. DO NOT pipe

to an area where freezing could occur. Local code requirements concerning size, type and placement of other

safety valves must be followed. The relief valve should be checked at least once yearly by manually operating

the release lever to insure proper operation.

A discharge line must be connected to the pressure relief valve and piped to a safe

location. Do Not Install a valve or other restriction between the relief valve and

heater, or the relief valve and the end of the discharge line. Water discharging from

the relief valve will be very hot and may cause series injury.

If the heater/boiler is connected to a water storage tank, a temperature and pressure relief valve must be

installed on the tank. The temperature/pressure relief valve serves as a safety device to prevent excessive

pressure and temperature. Excessive pressure may be caused by the expansion of water when it is heated in a

closed system. A closed system is one that has a check valve, back-flow-preventer, or a pressure-reducing

valve in the cold water supply line. In this type of system it is normal for the relief valve to relieve small

quantities of water from the closed system when the boiler is firing and no water is being used. An expansion

tank or other suitable means must be provided to control thermal expansion.

Insulating or dielectric unions or bushings should be used in connections between dissimilar metal fittings (such

as between copper and galvanized). These fittings are required to minimize electrolytic corrosion, which can

result from direct connection of dissimilar metals in a water system.

A flow switch must be installed and wired to prevent the unit from firing if there is an inadequate flow of water

through the boiler/heater. A flow switch on this unit meets CSD-1 safety requirements as a low water cut-off

device. Note: A factory-wired flow switch is provided on all CSD-1 models. The flow switch should be set

so that the heater/boiler will not fire when the flow rate is less than that which will provide greater than a 80o F

(44 oC) temperature rise through the heater/boiler.

Flow Switch

Temp Rise

deg F deg C A2-035 A2-050 A2-070 A2-097 A2-120 A2-140

80 44 7.0 10.0 14 19 24 28

70 39 8.0 11 16 22 28 32

60 33 9.4 13 19 26 32 37

50 28 11 16 22 31 39 45

40 22 14 20 28 39 48 56

30 17 19 27 37 52

20 11 28 40 56

When used for both potable water heating and space heating, all piping and components connected to the

system for space heating must also be suitable for use with potable water. Do not introduce toxic chemicals,

such as those used for boiler treatment, into the system. Any components previously used with non-potable

water must not be connected to the potable water system.

Flow Rate (gpm) Vs. Water Temperature Rise

A2000 Model

Page 10

o

When the system requires water for space heating at temperatures higher than 140o F (60o C), use a mixing

valve or similar means to reduce the potable water supply temperature to avoid scald injuries. The operating

thermostat should be set at the lowest possible temperature that provides useful service for the application. For

potable water uses, 120 – 125 oF (49 – 51 oC) is recommended (use a tank mounted Operating Aquastat).

This heater/boiler requires forced water circulation when the burner is operating. Pump selection and sizing

depends upon the type of system in which the heater/boiler will be used. Pressure loss through the A2000 heat

exchanger is provided below. The maximum flow rate through the A2000 heat exchanger is 56 gpm due to

velocity induced tube erosion.

The A2000 models are designed to operate with a return water temperature of 120o F (49 oC) or greater.

Condensation of the flue gasses may result if the inlet water temperature is under 120° F. This appliance and

the venting connected to it are not designed to withstand repeated condensation. Low operating temperatures

and frequent cold start-ups must be prevented. Frequent operation below 120°F return water temperature will

damage the heat exchanger and void the warranty. If low operating temperatures cannot be avoided, a

feedback loop (by-pass) must be installed as shown in the DIAGRAMS section.

Water temperature thermometers should be obtained and field installed as shown in the DIAGRAMS section.

Water Chemistry: Water that is very soft, very hard, having a high total dissolved solids (TDS), or an acidic or

alkaline pH will shorten the life of the heat exchanger. The water should be between 5 and 15 grains per gallon

hardness. Water with a hardness exceeding 15 grains or a TDS exceeding 2500 ppm should be softened or

treated to prevent scaling of the heat exchanger, which reduces efficiency and ultimately may cause premature

failure of the heat exchanger due to overheating. Water softer than 5 grains may be corrosive, causing

premature heat exchanger failure, and must be treated with a suitable buffer. The ideal pH for water used in a

storage tank or copper heating system is 7.2 to 7.8. Corrosion of the heat exchanger may result when the pH is

lower than 6 or higher than 8.

Scaling of the heat exchanger is aggravated with low water flow rates and high water temperatures. To

minimize scaling, use the highest water flow rate and lowest water temperature set-point suitable for the

application.

Leak Testing: The A2000 heater/boiler does not require hydrostatic pressure testing, as the heat exchanger

was factory tested for 160 psig operating pressure. However, the water piping connections to the heater, and

the balance of the water system should be leak tested prior to putting the system into operation. Leaks must be

immediately repaired to prevent damage to the heater or property.

Head Loss (ft hd) Vs. Water Flow Rate Through Heat Exchanger (Approximate)

Flow

(gpm) A2-035 A2-050 A2-070 A2-097 A2-120 A2-140

10 1.5 2.0 2.5 4.5 4.5 4.5

20 4 6 8 12 12 12

30 9 13 15 21 21 21

40 17 22.5 26 35 35 35

50 36 46 52 52 52

56 57 64 64 64

psi = (ft hd) x 0.434

Do not operate your A2000 heater/boiler with inlet water temperatures lower than

120oF (49oC). Consistent operation below these temperatures will cause heat

exchanger corrosion and void the warranty. A By-Pass piping arrangement is

required when inlet water temperatures are consistently below 120 oF.

FAILURE TO PROPERLY OBSERVE THE ABOVE WATER CHEMISTRY

RECOMMENDATIONS WILL VOID THE WARRANTY AND MAY RESULT IN A VERY

SHORT LIFE OF YOUR BOILER/HEATER.

A2000 Model

Page 11

Draft Ho

od

When a boiler is used in connection with refrigeration systems, it must be installed so

the chilled medium is piped in parallel with the heating boiler with appropriate valves

to prevent the chilled medium from entering the boiler. When a boiler is connected to

heating coils located in air handling units where they may be exposed to refrigerated air circulation, it

must be equipped with flow control valves or other automatic means to prevent gravity circulation of the

boiler water during the cycle.

IMPORTANT: Before attempting to start the unit, be sure the system is full and the water is free to flow through

the unit. All air must be relieved from the unit and piping and the pump must be working before the unit is fired.

VENTING SYSTEM

Proper installation of the flue venting is critical for the safe and efficient operation of

your heater/boiler. Failure to conform with any of these requirements may violate

local, state or federal codes as well as create conditions that may cause catastrophic

property damage or personal injury.

The venting system must comply with the National Fuel Gas Code, ANSI, Z223.1 / NFPA 54, Latest Edition, or

for Canada, CAN/CGA B149.1, and all local codes. Venting must be provided to completely remove all gases

and products of combustion to the outside, without condensation in the stack or spillage at the draft hood.

The A2000 heater/boilers are negative vent, non-condensing Category I appliances and can utilize un-insulated

single wall “B” vent connectors. Vent material must be listed by a nationally recognized test agency. Insulated

metal vent pipe must be used for outdoor vent sections in cold climates to reduce condensation. Observe

clearances in accordance with applicable codes from all combustible materials. Use insulated venting or vent

pipe spacers where the vent passes through combustible roofs, floors, and walls.

Natural draft vent systems utilize natural buoyancy of the hot flue products to create the pressure difference that

allows the flue products to exhaust from the flue. The negative pressure draft should be -0.1 to -0.8 inches of

water column when measured 12 inches (30 cm) above the draft hood to ensure proper operation.

Do not reduce the vent diameter and avoid sharp turns in the vent piping. Use the same size stack and draft

diverter as the discharge from the unit. The vent sizes for A-2000 models are:

Model: A2-035 A2-050 A2-070 A2-097 A2-120 A2-140

Vent Diameter

The draft hood that was supplied with you’re A-2000 model must be installed

directly on top of the unit. The draft hood slips over the flue outlet flange.

General Venting Requirements:

• The maximum and minimum vent length for Category I systems is

determined by the National Fuel Gas Code, or for Canada, B149.

• Avoid long horizontal runs of vent pipe, reductions, restrictions, and 90o

elbows. The length of the horizontal run should be as short as possible,

but must not exceed 75% of chimney height.

• All horizontal runs must slope upward toward the termination at least ¼ inch per foot (2 cm per meter)

and be adequately supported.

• A2000 models are designed to operate with a negative pressure in the exhaust venting. This appliance

is NOT approved for side-wall venting. Consult your GBT representative or Customer Service if sidewall venting is required.

• When any horizontal vent extends for more than 6 feet (1.8 meter), vent supports must be installed with

9” 10” 12” 16” 16” 18”

Page 12

subsequent supports after every additional 6 feet. The support must be secured using at least #10

fasteners to a solid material (solid masonry or wood framing or blocking). Do not fasten to drywall

sheathing using hollow wall anchors. As an alternative, a threaded rod and trapeze support in

accordance with SMACNA HVAC Construction Standards – Metal and Flexible, latest edition, shall be

installed every 6 feet of continuous horizontal vent and after any offset elbows.

• Install an approved cap for the stack outlet. The bottom of the cap must be one stack diameter above

the top of the stack and so designed to prevent snow or any debris from blocking the vent. The top of

the stack must be carried to a minimum of two feet above the highest point of the roof or any other

obstructions within 8 feet (2.4 meter) of the termination. The vent must not terminate near an air supply

inlet to any building.

• The venting system must be planned so as to avoid possible contact with concealed plumbing or

electrical wiring inside the walls.

• Venting in a multi-family structure must be enclosed when passing through occupied or unoccupied

spaces above the connected boiler. The enclosure is to be of materials no less fire resistant than

surrounding floors and walls. It is recommended that the system be enclosed whenever passing through

occupied spaces. Be sure to check your local building codes for additional requirements.

• Minimum clearance of 4 feet (1.2 meter) (6 feet or 1.8 meter in Canada) horizontally must be maintained

between the unit and vent stack from electric meters, gas meters, regulators and relief equipment (no

part of the unit or venting may be directly above or below electric meters, gas meters, or regulators).

• A vertical support must be installed at least twice in any continuous vertical run, or every 10 feet. Install

a Vent Roof Jack Assembly or Fire stop Plate at every penetration of a floor or ceiling.

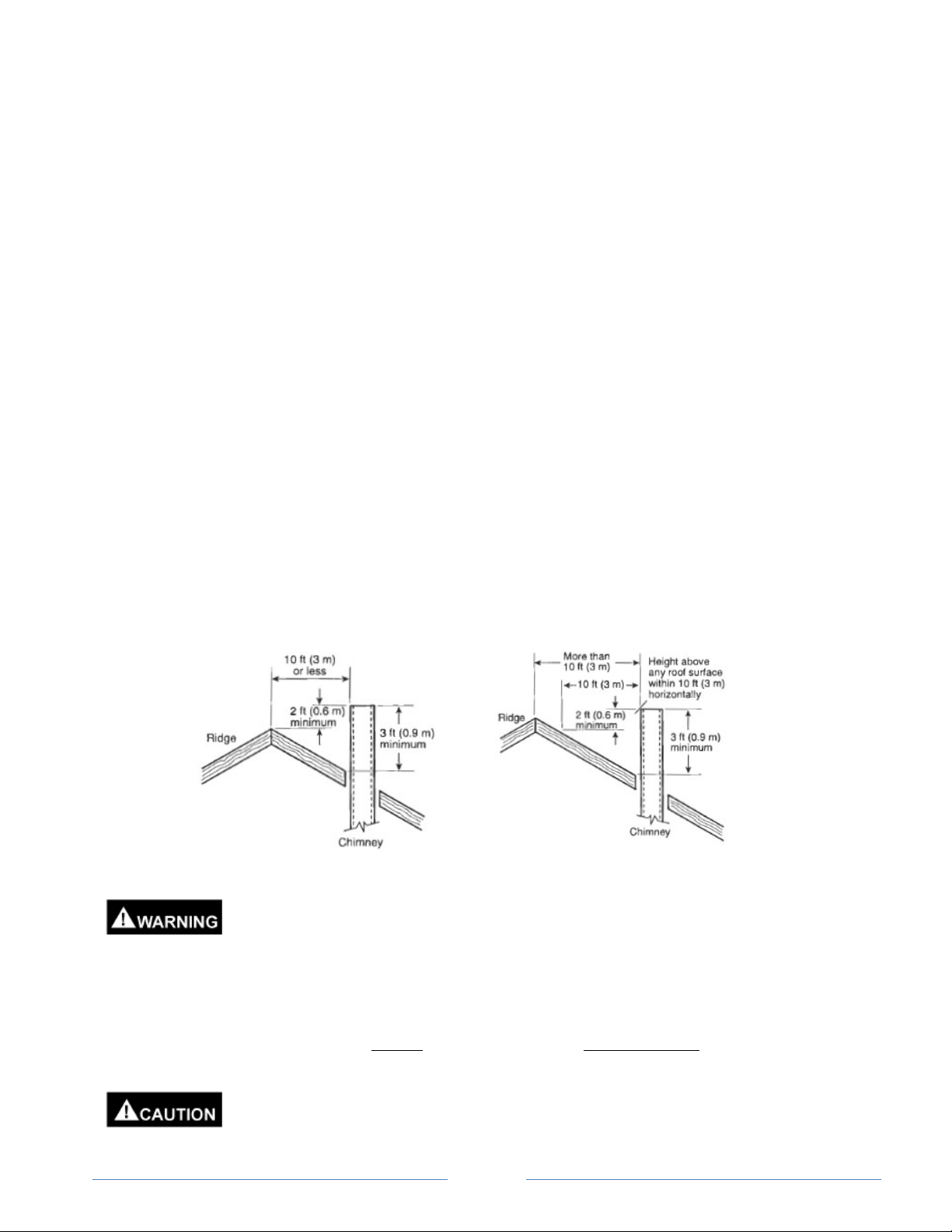

• Roof Line: The vent system must terminate at least 3 feet (0.9 meter) and no more than 6 feet (1.8

meter) above the roof line, and no closer than 8 feet (2.4 meter) from any wall or vertical structure.

Vents extending above the roof more than 5 feet (1.5 meter) should be secured using guy wires or

braces to withstand wind or snow loads.

These units are engineered for natural draft and may not be connected into any

portion of a mechanical or other draft system operating under positive pressure.

Verify that the venting is under negative pressure when all boiler room doors are

closed, the heater/boiler is firing, and all other air using appliances in the room are operating. If the

venting is under positive pressure during operation a draft inducer must be installed, vent material

suitable for positive pressure must be installed and all joints must be sealed.

Common Vent System: Manifolds that connect more than one heater/boiler to a common chimney must be

sized to handle the combined load. At no time should the area of the common vent be less than the area of the

largest heater/boiler exhaust outlet.

Common vent systems may be too large if an existing unit is removed. When an

existing appliance is removed, the vent system design must be carefully evaluated

for proper sizing (Refer to MAINTENANCE Section of this manual).

Page 13

START-UP & OPERATION

Follow these instructions exactly. A fire or explosion may result, potentially causing

personal injury, loss of life and property damage.

Do not use this appliance if any part has been flooded or heavily sprayed with water.

Immediately call a qualified service technician to inspect the controls and replace any

part that has been damaged by water.

PRE-START CHECKLIST

Before starting the boiler, review the following:

• Is the unit properly sized for the application?

• Is the gas supply properly sized and installed?

• Is the vent system properly installed?

• Is the combustion and ventilation air adequate?

• Is the water system properly installed and filled with water?

• Is the proper operation understood and all instructions followed?

This appliance is equipped with an ignition device, which automatically lights the

burner. DO NOT TRY TO LIGHT THE BURNER BY HAND.

FILL THE SYSTEM WITH WATER.

Fill the system with water and purge all air. Trapped air can prevent proper water circulation. Check the water

piping system for leaks and if found, repair immediately.

PURGE AIR FROM GAS LINES

For a new installation, or if the gas lines feeding the heater/boiler were opened to the atmosphere during

installation or service, air in the gas lines must be purged before operating the unit.

Before purging gas lines, ensure electrical power is turned off to the heater/boiler AND ALL OTHER

APPLIANCES IN THE VICINITY OR ROOM. TURN OFF GAS TO ALL APPLIANCES IN THE VICINITY OR

ROOM.

Provide ventilation from the area around the heater/boiler to the outdoors, preferably using

a fan or blower.

Loosen the pipe union or fitting upstream and adjacent to the heater/boiler. Slowly, partially open the manual

gas valve installed upstream of the loosened union or connection. Allow the trapped air to exit the gas piping

until the smell of gas is noticed. Close the manual gas valve and reconnect the pipe union or fitting. Wait at

least 15 minutes before turning electrical power back and/or gas back on to the other appliances, and only after

you are sure purged gases have dissipated.

PREPARATION

1. Ensure the manual gas valve upstream of the heater/boiler is CLOSED.

2. For A2-035 and A2-050 models, ensure the main regulating gas valve is closed.

Before turning on the power to this appliance smell all around the appliance for gas. Be sure to smell

next to the floor because some gas is heavier than air and will collect near the floor.

Page 14

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

A2-(H,B) 035/050 Main Regulating Gas Valve

Manual Gas Shut-Off Valve, All Other

Models

3. Turn on electrical power to the heater/boiler. Using a multi-meter, check voltage between the HOT and

COMMON (should be about 120 Volts).

4. Check voltage between the HOT and Ground (should be about 120 Volts).

5. Check voltage between the COMMON and Ground (should be less than 1 Volt).

If the COMMON – Ground is more than 1 Volt, STOP! Contact a licensed electrician to

correct the ground fault.

6. Turn OFF electrical power to the heater/boiler.

7. Attach 24 inch manometers to the gas line so that the gas pressure can be measured upstream of the

first heater/boiler automatic gas valve, downstream of the last automatic gas valve, and between

automatic gas valves. NOTE: Depending upon the model, your heater/boiler may be equipped

with one or two automatic gas valves.

8. Install water temperature measurement thermometers in the water inlet and outlet piping.

9. Slowly turn on the manual gas shut off valve upstream of the heater/boiler.

10. Read the gas supply pressure using the manometer. Verify that the supply gas supply pressure is

between the minimum and maximum per the table below. If the pressure is not within these limits,

check to see if a service gas regulator is installed and adjust accordingly.

Maximum Pressure Minimum Pressure

Natural Gas

Propane

Units: Inches of Water

Do not operate heater/boiler if the gas supply pressure is not within the limits shown

in the table above.

11. Turn OFF the manual gas shut off valve upstream of the heater/boiler.

12. Turn ON electrical power to the heater/boiler ON.

13. Turn the operating thermostat to a setting high enough to turn on the water pump. Verify water is

flowing though the heater/boiler by verifying the flow switch has closed.

9 5

15 13

Page 15

14. Turn the operating thermostat to its lowest setting so that water pump stops.

START-UP

1. Slowly turn on the manual gas valve upstream of the heater/boiler. For A2-035 and 050 models only,

turn on the manual valve located on top of the Robertshaw automatic gas valve.

2. Turn the operating thermostat to a setting high enough to turn on the water pump.

3. The ignition control module will turn on the spark ignition system and pilot operating valve to light the

pilot burner. If the pilot does not light the first time, it will retry, up to three times. This is normal during

the initial start-up due to air in the pilot line. If, after trying three times, the pilot burner does not light,

remove power to the ignition module to reset, by either turning the operating thermostat down to its

lowest setting or turning off electrical power to the heater/boiler.

NOTE: CSD-1 models only utilize an ignition module that waits 5 minutes before attempting to

re-light the pilot.

4. After the pilot burner is lit and pilot flame is proven, the Ignition Module will open the automatic main gas

valve(s) and the main burner will light.

If the pilot or main burner fails to light after repeated attempts, shut off the

manual gas valve upstream of the heater/boiler, remove electrical power from

the heater/boiler, and call your qualified service technician or gas supplier.

5. Check for gas leaks in the gas train assembly using soap and water or an appropriate leak check fluid.

DO NOT use an open flame to check for gas leaks.

6. Using the manometers with the heater/boiler operating, check to make sure the gas supply pressure is

within the limits shown above.

7. Check the manifold gas pressure downstream of the automatic gas valves using the outlet pressure tap

provided on the gas valve (A2-035 and 050 models only) or the pressure tap provided in the gas piping.

• For Natural Gas models, the manifold pressure should be set to 4.0” water column.

• For Propane Gas models, the manifold pressure should be set to 10.5” water column.

• For 2-Stage models, see the Operating Section for setting the gas manifold pressure.

a. For A2-035 and A2-050 models, adjust the manifold pressure using the adjustment screw

located on top of the Robertshaw gas valve (remove the dust cover cap to expose the

adjustment screw).

b. For A2-070, 970, 120 and 140 models, adjust the manifold pressure using the Maxitrol gas

pressure regulator located upstream of the automatic gas valve (remove the dust cover cap to

expose the adjustment screw).

c. Replace the manifold pressure adjustment screw caps

8. With the manifold gas pressure set per step 6 above, observe the main burner flame characteristics.

The burner flame should be blue at the base, with yellow at the tips permissible. An excessive amount

of yellow flame suggests a lack of combustion air or inadequate vent draw.

Page 16

9. Verify the water flow switch opens at the minimum water flow rate by slowly closing a manual ball valve

installed in the water outlet piping, until the difference between the water inlet and outlet reaches 95 –

100 oF (53 – 55 oC). Note: The operating thermostat may have to be turned to its highest setting in

order to conduct this test. If the main burner does not shut down when this temperature difference is

achieved, adjust the flow switch set point until the flow switch opens (refer to Operating Section for

instructions concerning setting the flow switch).

10. Fully open the manual ball valve in the water outlet piping.

11. After the main burner has been in operation for at least five (5) minutes, inspect the venting for spillage.

Draft tests must be done with the appliance firing. Proper draft or airflow in the venting may be

determined by either of the following means:

o Smoke Test – Place a source of smoke or other visible fumes under the opening of the draft

hood. If the fumes are all drawn up the draft hood opening, the appliance is drafting properly. If

any fumes roll outside of the vent hood there is a problem with the drafting or make-up air.

o Draft Gauge – A draft pressure gauge can be inserted into the vent pipe directly above the draft

hood. The draft gauge must show a constant negative pressure.

12. Turn the operating thermostat down to its lowest setting. The pilot and main burner will shut off. Close

the manual gas valve immediately upstream of the heater/boiler.

13. Remove the gas pressure manometers and replace all plugs. Use an appropriate pipe thread sealant

(do not use Teflon tape).

14. Open the manual gas valve immediately upstream of the heater/boiler and set the operating thermostat

at the desired temperature.

NOTE: Low inlet water temperatures on start-up may create flue gas condensation which may

gather on the floor under the heater. THIS IS NOT A LEAK. The unit will stop condensating when it

reaches standard operating temperatures.

Main Burner Flame

Pilot Burner Flame

SHUT DOWN PROCEDURE

1. Set the operating thermostat to lowest setting and turn the gas valve to “OFF.”

o For A2-(H,B)-035/050 models, rotating the control knob on top of the combination regulating gas

valve to the “OFF” position turns off the gas.

o For all other models, the gas is turned off by rotating the handle on the separate manual gas

valve to a position perpendicular to the gas piping.

2. Switch off all electrical power to the system.

Page 17

OPERATION

The A2000 models are simple ON/OFF water heater/boilers. The units are turned ON and OFF by the

application or removal of 120 VAC power to the control panel. Normally, this 120 VAC power is provided

through an operating thermostat. Safety controls (such as a flow switch and manual reset water high limit

temperature switch) installed between the operating thermostat and the heater/boiler prevent power from

reaching the control panel if water flow is not present, or the outlet water temperature has been exceeded.

When 120 VAC power is applied to the heater/boiler control panel on a call for heat from the operating

thermostat, 24 VAC is applied to the Ignition Control Module via a transformer. The ICM provides spark to the

igniter, opens the pilot burner operating valve providing gas flow to the pilot burner, and looks for flame

verification through the spark igniter electronics. Once pilot flame is verified, the ICM opens the automatic main

burner valve(s), which provides gas flow to the main burner, which is ignited by the pilot burner.

Ignition Control Module (ICM)

normally closed pilot valve and main burner valves close.

Operating Thermostat Setting: A separate operating temperature controller is required for proper operation of

this appliance. Failure to install a separate operating temperature controller will result in short cycling. Water

heaters are expected to operate at temperatures between 120 °F and 155 °F (49 to 68 oC) Water boilers can

operate with return water temperature up to 190 °F (88 oC) and a supply temperature up to 240 oF (115 oC).

Return water temperatures must be kept above 120 °F to prevent condensation. Refer to the DIAGRAMS

section for recommended piping for lower operating water temperatures. Frequent operation below 120°F (49

o

C) return water temperature will damage the heat exchanger and void the warranty.

Do not operate your A2000 heater/boiler with return water temperatures lower than

120 oF (49 0C). Consistent operation below these temperatures will cause heat

exchanger corrosion and void the warranty.

Water Temperature - Scald Relationship

Water Time to Produce

Temperature 2nd & 3rd Degree

deg F deg C

> 170 > 77

160 71

150 65

140 60

130 54

120 49

Water High Limit Switch: Every A2000 model is equipped with a manual reset, High Limit Switch on the hot

water outlet. For water heater models, the high limit has a factory stop of 200 oF (93 oC). For boiler models, the

factory stop is set at 240 oF (115 oC). The high limit switch must always be present and must never be bypassed. If the High Limit Switch trips, it must be manually reset by pressing the red button, located on the front

cover of the High Limit Switch.

Burns on Adult Skin

Nearly Instantaneous

About 1/2 Second

About 1-1/2 Second

Less Than 5 Seconds

About 30 Seconds

More Than 5 Minutes

If the pilot flame is not verified, the ICM will try to light the pilot burner two

more times (see CSD-1 Section below for control differences specific to

CSD-1 models). After the third try, the ICM will go into lock-out. The ICM

can be reset by removing power to the heater/boiler. The pilot burner

remains ON the entire time the main burner is ON. If pilot flame verification

is lost while the main burner valves are ON, the ICM will close the main

burner valves and try to re-establish pilot burner flame.

When the operating thermostat is satisfied, the 120 VAC is removed, and the

When the heater/boiler is used for potable water heating, use a

mixing valve or similar means to reduce the potable water

supply temperature to avoid scald injuries. The mixing valve

should be set at the lowest possible temperature that provides

useful service for the application. For potable water uses, 120

– 125o F (49 – 51o C) is recommended.

Water temperatures higher than 125 oF

(51 oC) can cause severe burns,

personal injury or loss of life. The

temperature at which injury occurs

varies with a persons age and the time of exposure. Never

allow small children to use a hot water tap or draw their

own bath water.

Page 18

Gas Pressure Regulator: A gas pressure regulator is provided on all A2000 water heater/boilers. This regulator

is preset at 4 inches water column for natural gas or 10.5 inches water column for Propane gas. For

A2(H,B)035/050 models, the pressure may be adjusted using the adjustment screw located on the combination

gas valve (see Figure on page 16). For all other models, except 2-Stage, a Maxitrol gas pressure regulator is

provided. If a pressure adjustment is required, remove plug and turn screw clockwise to increase pressure,

counterclockwise to decrease pressure. One complete turn will change the pressure approximately ¼ inch of

water column. For 2-Stage models, see the Items Specific to 2-Stage Models below.

Flow Switch: A flow switch is required to be installed in the outlet water line, wired so that the heater/boiler will

not fire unless the minimum water flow through the heat exchanger is present. The minimum flow rate for each

model the flow that will provide a 100 oF (55 oC) temperature rise through the heat exchanger (see table in

Water Pump: All A2000 models require forced circulation of the water through the heat exchanger. Selection

and installation method of the pump depends upon the design of the system and intended use (see DIAGRAMS

section for water pump location suggestions). The pump electrical power must be wired independently and

should be adequate for the amp rating of the pump motor. Refer to the INSTALLATION section for pressure

losses through the A2000 heat exchangers. The maximum flow rate through the A2000 heat exchanger is

56 gpm due to velocity induced tube erosion. A list of acceptable water pumps and manufacturers for

the A2000 models is listed on the following page.

Water High Limit Switch –

Manual Reset

Operation of the A2000 heater/boiler at gas manifold pressures greater than 4.0” w.c.

for Natural Gas, and 10.5” w.c. for Propane Gas, will cause the unit to be over-fired,

which may cause premature heat exchanger failure, serious injury, or loss of life.

INSTALLATION Section). The set point for the flow switch can be

changed using the adjustment screw located under the electrical house

cover of the switch. Rotate the screw clockwise to increase the flow

set point, counter-clockwise to decrease the flow set point. With the

heater/boiler firing (make sure 2-Stage models are firing on HIGH),

slowly close the manual valve in the water outlet piping, until the

temperature rise through the heat exchanger approaches 100 °F (or

lower based on specific installation or requirements). Adjust the switch

set point so that the switch opens at this flow rate. Slowly open the

water valve so that the switch closes, then repeat the process to

ensure the switch is set correctly.

Risk of electrical shock. Be careful not to touch live electrical parts or bare wires

inside the flow switch housing. The voltage to the flow switch is 120 VAC.

Maxitrol Gas Pressure Regulator

Page 19

A2000 Pump Selection Chart

MODEL: A2*035* A2*050* A2*070* A2*097* A2*120* A2*140*

Flow Rate &

Head Loss

Pump Vendor

GOULDS : 1ST2C1D4 1ST2C1D4 1ST1C1E4 2ST1E1E4

Horsepower 1/2 1/2 1/2 1 1-1/2 1-1/2

RPM 1750 1750 3450 3450 3450 3450

Electric 115/230 VAC 115/230 VAC 115/230 VAC 115/230 VAC 115/230 VAC 115/230 VAC

Impeller 4-3/4" 4-3/4" 4-7/16" 4-1/4" 4-5/8" 4-5/8"

B & G :

Horsepower 1/2 1/2 1 2 3 3

RPM 1750 1750 3500 3500 3500 3500

Electric 115 VAC 115 VAC 115 VAC 115 VAC 115 VAC 115 VAC

Impeller 3-7/8” 3-7/8” 3-7/8” 4-5/8” 4-3/4” 4-3/4”

GRUNDFOS :

Horsepower 1/12 1/6

RPM 3450 3450

Electric 115 VAC 115 VAC

Impeller One Size Only One Size Only

TACO :

Horsepower 1/8 1/8

RPM 3250 3250

Electric 115 VAC 115 VAC

Impeller One Size Only One Size Only

BURKS :

Horsepower 1/3 1 1 1

RPM 3500 3500 3500 3500

Electric 115/230 VAC 115/230 VAC 115/230 VAC 115/230 VAC

Impeller 3-1/8” 4-1/8” 4-1/8” 4-1/8”

MEPCO :

Horsepower 1/2 1 1-1/2 1-1/2

RPM 3450 3450 3450 3450

Electric 115/230 VAC 115/230 VAC 115/230 VAC 115/230 VAC

Impeller 3-1/2" 4-1/2" 5" 5"

23GPM @

11.3 FT.

3530

1-1/4x1-1/2x6

UP26-96BF UP43-75BF Not Available Not Available Not Available Not Available

0012BF4 0012BF4 Not Available Not Available Not Available Not Available

Not Available Not Available 3GA5-1 1/4AB 10GA5-1 1/4AB 10GA5-1 1/4AB 10GA5-1 1/4AB

Not Available Not Available RC05-10

23GPM @

11.3 FT.

3530

1-1/4x1-1/2x6

40GPM @

34.6 FT.

3530

1-1/4x1-1/2x6

-005-34-1

49GPM @

54.8 FT.

3530

1-1/4x1-1/2x6

RC05-10

-010-34-1

54GPM @

70.7 FT.

2ST1F1D4

3530

1-1/2x2x6

RC05-10

-015-34-1

40GPM @

70.7 FT.

2ST1F1D4

1-1/2x2x6

RC05-10

-015-34-1

3530

Page 20

Relief Valve Operation: Each boiler/water heater is equipped with an ASME approved pressure relief valve,

with a standard setting of 125 psi (862 kPa). The outlet of the relief valve must be piped to a drain or other

suitable safe place in accordance with local codes. When the heater/boiler is connected to a storage tank, a

separate temperature/pressure relief valve must be provided on the tank.

Items Specific To CSD-1 Models: A2000 models equipped with ASME CSD-1 gas train and controls (model

numbers start with “A2C”) include a factory installed water flow switch in the water hot water outlet, and an

operating thermostat (240 oF (115 oC) maximum setting) in the cold water inlet. CSD-1 models are also

equipped with an Ignition Control Module (ICM) that waits five minutes before trying to re-light the pilot burner.

The CSD-1 ICM will not lock out on flame failure; it will continually try to re-light the pilot burner every five

minutes.

Items Specific to 2-Stage Models: Natural Gas A2000 models equipped with a 2-Stage gas valve (model

numbers starting with “A2T” or “A2X”) include an electronic temperature controller with its temperature sensor

installed in the inlet water line. 24 VAC power for the automatic gas control valve, from the ICM, passes through

electronic temperature controller, to either the LOW or HIGH terminal of the 2-Stage gas valve. The 2-Stage

gas valve is factory set to provide 4 inches w.c. gas pressure in HIGH fire mode, and 2.0 inches w.c. in the LOW

fire mode (approximately 70% of nameplate input).

The electronic controller is factory set with both stages in Heating Mode, with Stage 2 set for HIGH fire, and

Stage 1 set for LOW fire. The factory temperature and differential settings are provided in the table below.

Electronic 2-Stage

Temperature Controller

2-Stage Controller - Factory Set Points

Stage 1 (Low Fire OFF) Set Point 180 oF

Stage 1 Differential 45 oF

Stage 2 (High Fire OFF) Set Point 135 oF

Stage 2 Differential 95 oF

Low Fire Range: 135 oF to 180 oF

High Fire Range: 40 oF to 135 oF

When the control is in heating mode, the differential is below the set point.

The relay will de-energize as the temperature rises to the set point.

To change the settings, press the SET button. The screen will display oF or

o

C, press the ▲or ▼key to change the mode. Press the SET button again to

display the Stage 1 (S1) set point. Press the ▲or ▼key to change the set

point, then press SET. The S1 differential will not be displayed. Press the

▲or ▼key to change the differential, then press SET. The heating (H1) or

cooling mode (C1) will be displayed. Press SET to keep the control in heating

Electronic 2-Stage Temp

Controller – Heating Mode

mode. Press SET again to display the Stage 2 (S1) set point. After setting the

desired temperature, press SET again to display the S2 differential. Press set

again to display heating (H2) or cooling (C2) mode. Press SET to keep control

in heating mode.

Programming is now complete. Programming mode will end if no keys are

pressed for 30 seconds. Any changes will be saved. Settings are stored in

non-volatile memory and will not be lost with power failure.

Page 21

MAINTENANCE & INSPECTION

This manual must be thoroughly reviewed and understood before servicing your A2000

heater/boiler. Installation and Service must be completed by a Qualified Installer, Service

Agency or Qualified Gas Supplier. If you have any questions which are not covered in the

manual, please contact Green Boiler Technologies or your local Representative.

Keep the area clear and free from combustible materials, flammable liquids and

vapors. Do not block the flow of combustion air by blocking air vents or by storing

boxes or other items near the appliance.

Label all wires before disconnection when servicing controls. Wiring errors can

cause improper and dangerous operation.

Verify proper operation of the heater/boiler after any inspection or servicing the

appliance.

Heat Exchanger: The heat exchanger should be visually checked at least once a year, or whenever necessary.

The heat exchanger can be viewed from the top of the unit by removing the draft hood. The fins on the heat

exchanger tubing should extend about 27/64 of an inch. Excessive burn off of fin height indicates poor heat

transfer, commonly caused by scaling (deposits of lime and other minerals) inside the tube. Look for corrosion

(usually a rusty-brown coating) commonly caused by cleaning solvent vapors or fumes in the combustion air

supply), or sooting (a fine black-gray powder caused by improper combustion, usually due to a partially blocked

stack or insufficient combustion air), or the affect of excessive condensation (usually evidenced by a greenishblack cupro oxide caused by the acid formed by the mixing of combustion gases with the condensate).

Before removing draft hood, ensure that the gas and electrical power to the

heater/boiler is shut off.

Burner & Pilot Flame: The burner and pilot flame should be checked frequently (it is recommended that the

unit be checked at least annually by a professional service technician). A yellow flame commonly indicates poor

combustion, and may cause soot deposits on the heat exchanger or inside the venting. When an excessively

yellow flame is present, inspect the burner orifices and heat exchanger for carbon deposits and foreign particles.

Yellow flame and sooting may be caused by inadequate combustion air, venting, or incorrect gas manifold

pressure. Refer to the burner and pilot flame Figure in the START-UP Section of this manual.

Gas Manifold Pressure: Check the gas manifold pressure at least once per year to make sure it matches that

specified on the Name Plate, using an manometer (refer to START-UP Section for checking manifold pressure).

Vent System: Inspect the venting system for proper size, horizontal pitch and determine there is no blockage or

restriction, leakage, corrosion or any other deficiencies which could cause an unsafe condition. Check the inside

of the vent system for excessive sooting.

In so far as practical, close all building doors between the space in which the appliances are connected

to a common venting system and any area where any appliance which is not connected to the common

venting system is located. Test the system by turning on clothes dryers and any other appliance not

connected to the common venting system. Turn on all exhaust fans, including those used in range

hoods and bathroom exhausts, so they will operate at their maximum speed. Close fireplace dampers.

Place the appliance being tested into operation by following the proper lighting instructions. Adjust the

aquastat so the appliance will remain in operation for the duration of the test. After the main burner has

been in operation for at least five (5) minutes. inspect the venting for spillage. When it is determined the

unit is working without exhaust gasses spilling into the room, return doors, windows, fans, fireplace

dampers and any other gas-burning device to their normal condition of use.

Draft tests must be done with the appliance firing. Proper draft or airflow in the venting may be

determined by either of the following means:

Page 22

o Smoke Test – Place a source of smoke or other visible fumes below the opening of the draft

hood. If the fumes are all drawn up the draft hood opening, the appliance is drafting properly. If

any fumes roll outside of the vent hood there is a problem with the drafting or make-up air.

o Draft Gauge – A draft pressure gauge can be inserted into the vent pipe directly above the draft

hood. The draft gauge must show a constant negative pressure.

Any improper operation of common venting systems should be corrected so the installation conforms to

the National Fuel Gas Code, ANSI-Z223.1, Latest Edition. When any portion of the venting system is

changed it must conform to the National Fuel Gas Code, ANSI-Z223.1, Latest Edition.

Burner & Flue Passageway: Do not allow the burner, burner orifices, or the floor shield to accumulate foreign

matter. Clean periodically by brushing or blowing any dust or debris from the area. Orifices should be checked

for size and reamed as required. The flue gas passageway can be cleaned by simply sliding the burner out and

flushing the finned tubing with water.

Before disconnecting the burner, be sure to shut off all gas valves and electrical

switches then let cool for 30 minutes. After cleaning, reinstall the burner. Water must

be circulating before turning on the gas valve to prevent heat exchanger damage.

Pressure Relief Valve: A pressure relief valve is supplied on the outlet of the heat exchanger. The relief valve

should be tested at least annually by lifting the test handle.

When testing the valve extremely hot water and/or steam may be released.

High Temperature Switch: The manual reset High Temperature switch, located in the water outlet piping,

should be checked annually for proper function. To test the switch, slowly close the valve in the water outlet

piping until the water temperature exceeds the set point of the switch. The temperature switch should open

before the water temperature reaches 210 oF (99 oC) for a water heater, and 250 oF (121 oC) for a boiler. Note:

The operating thermostat and/or flow switch may have to be temporarily by-passed in order to conduct this test.

Ensure all operating and safety controls are put back into proper operation before

putting the heater/boiler back into service.

Flow Switch: The water Flow Switch should be checked annually for proper function. To test the Flow Switch,

slowly close the valve in the water outlet piping until the temperature rise through the heat exchanger

approaches 100 oF (55 oC). The Flow Switch should open before the temperature rise exceeds 105 oF (58 oC).

Refer to the OPERATION Section of this manual for more information regarding the water Flow Switch.

Heat Exchanger Protection: Either very soft or very hard water will shorten the life of the heat exchanger. The

water to be heated should be between 5 and 15 grains per gallon. Harder water should be softened to prevent

scaling, reduced efficiency and ultimately melting the heat exchanger. Softer water must have buffers added to

prevent erosion of the heat exchanger. NOTE: FAILURE TO PROPERLY OBSERVE THE ABOVE WILL VOID

THE WARRANTY AND MAY RESULT IN A VERY SHORT LIFE OF THIS BOILER/HEATER.

Condensation: Condensation of the flue gas may result if the inlet water temperature is under 120° F.

Condensation will form on the outside of the heat exchanger and drip down onto the burner and possibly the

floor below the heater/boiler, often mistaken for a leaking coil. After the boiler has been in operation long

enough for the temperature of the water in the system to reach 120° F, the condensation will stop dripping from

the heat exchanger. The A2000 and the venting connected to it are not designed to withstand repeated

condensation. Low operating temperatures and frequent cold start-ups must be prevented. Frequent operation

below 120°F return water temperature will damage the heat exchanger and void the warranty. If low operating

temperatures cannot be avoided, a feedback loop (by-pass) must be installed as shown in the DIAGRAMS

section.

Noise During Operation: Knocking sounds produced by the heater/boiler may indicate scale build-up in the

heat exchanger waterway. De-liming is recommended. Scale thickness as thin as 1/16 inch can increase fuel

consumption by 15%. Refer to procedure provided with de-liming kit part number W3700001. Extended

operation with a scaled heat exchanger may cause early heat exchanger failure and will void warranty.

Page 23

Removal of Existing Appliance: If an existing appliance is removed from a common venting system, the

common venting system is likely to be too large for proper venting of the appliances remaining connected to it.

At the time of removal, the following steps shall be followed with each appliance remaining connected to the

common venting system placed in operation, while the other appliances remaining connected to the common

venting system are not in operation.

(a) Seal any unused openings in the common venting system.

(b) Visually inspect the venting system for proper size and horizontal pitch, and determine there is no

blockage or restriction, leakage, corrosion and other deficiencies which could cause an unsafe

condition.

(c) Insofar as is practical, close all building doors and windows and all doors between the space in which

the appliances remaining connected to the common venting system are located and other spaces of the

building. Turn on clothes dryers and any appliance not connected to the common venting system. Turn

on any exhaust fans, such as range hoods and bathroom exhausts, so they will operate at maximum

speed. Don not operate a summer exhaust fan. Close fireplace dampers.

(d) Place in operation the appliance being inspected. Follow the lighting instructions. Adjust thermostat so

appliance will operate continuously.

(e) Test for spillage at the draft hood relief opening after 5 minutes of main burner operation. Use the flame

of a match or candle, or smoke from a cigarette, cigar or pipe.

(f) After it has been determined that each appliance remaining connected to the common venting system

properly vents when tested as outlined above, return doors, windows, exhaust fans, fireplace dampers

and any other gas-burning appliance to their previous condition of use.

(g) Any improper operation of the common venting system should be corrected so the installation conforms

with the National fuel Gas Code, ANSI Z223.1/NFPA 54 and/or CAN/CSA B149.1, Natural Gas and

Propane Installation Code. When resizing any portion of the common venting system, the common

venting system should be resized to approach the minimum size as determined using the appropriate

tables in Part 11 of the National fuel Gas Code, ANSI Z223.1/NFPA 54 and/or CAN/CSA B149.1,

Natural Gas and Propane Installation Code.

Page 24

SYMPTOM POSSIBLE CAUSE CHECKS & REMEDIES

Short Cycling (Unit

Turns ON And OFF

Every 30 seconds Or

So).

The Unit Will Not

Operate

Operating Aquastat Not

Operating Aquastat

Installed In The Wrong

System Mis-Wired Or

Operating Aquastat

Has Failed

Pilot Burner Is Not

Pilot Lights But Main

Burner Will Not Come

No Power To The Unit

No Power To The

Transformer

No Power To The

Ignition Module

TROUBLESHOOTING

Install An Operating Aquastat Or Boiler Sequencer To

Installed

For a Storage Tank Installation, Install the Operating

Aquastat in the Tank. Otherwise, the Operating Aquastat

Location

Being Lit

On

Must Be Installed Upstream of the A2000 In A Place That

Will Have Constant Water Flow Across The Sensor

When The Desired Operating Temperature has Been

Reached, The 120 VAC Electrical Power Supplied To the

Appliance Should Be Interrupted. If The Power Is Not

Stopped At The Desired Operating Temperature, Correct

The Wiring Or Replace The Defective Temperature Switch.

Refer to “Pilot Burner Not Lighting” In The Symptoms Listed

Refer To “Main Burner Not Lighting” In the Symptoms Listed

Use A Multimeter To Check For 120 VAC Power To The

Unit When It is Supposed To Be Turned ON. Trace The

Check The Manual Reset High Temperature Switch. Reset

Verify 120 VAC Power To The Transformer. Replace

Page 25

Control The Water Temperature

Below.

Below.

Interruption Of Power Back To the Source.

Or Replace As Necessary

Transformer If Needed.

SYMPTOM POSSIBLE CAUSE CHECKS & REMEDIES

Pilot Burner Not

Lighting

The Pilot Is Lit, But

Goes Out After 15

Seconds Or Less. The

Main Burner Never

Comes On

The Ignition Module Is

Not Generating A Spark

The Spark Is Not Arcing

In The Proper Location