GBS FOOD SERVICE EQUIPMENT GBS721 G1 User Manual

•

GAS, COMBI OVEN

MODEL GBS721 [G1], [G2], [G3]

MODEL GBS721 E3 SHOWN

Standard Features:

• Constructed of 20 gauge #316 and #304 Stainless

Steel

• Easy to operate electronic controls with digital

readout

• Ability to select from four languages, metric or

imperial measure

• Instantaneous steam generation within oven cavity

• Low (saturated) temperature and superheated (187

to 257 ) steam generation

• Autoreverse fan with Automatic oven cooldown

• Electronic self-diagnosis with malfunction alarms for

key operating areas

• Automatic pre-heat function

• HCCAP printout interface

• Tamper proof cooking programe protection

• Manual steam injection – great for artisan breads

• Slightly (6-7 psi) pressurized cooking chamber

reduces cooking times increases efficiency

• NEW Patented burner TDM system with automatic

firing pilot light (gas only)

• Double step safety “robust” safety handle

• Tempered double glazed window system coupled

with half and full position safety hinges

• Integrated door drip tray functions whether the door

is open or closed

• Magnetic door switch to energize oven

7 Sheet Pans

14 Hotel Pans

Oven Highlights:

• Advanced patented design eliminates the need for conventional type

• No boiler also allows the user to employ Reverse Osmosis (RO) water

• Highest quality materials used including #316 Stainless Steel oven cavity

• Airtight cooking chamber along with the reversible fan (motor) and

• CIBUS PLUS System = Closed Inertia Balanced Upright System imparts

• Patented TDM (Turbolet Double Mixing) gas/heat exchanger construction

Level ONE Features (F) and Options (O)

• Semi Automatic cleaning – use your own

• Six cooking programs, three steps each (F)

• Single point cooking probe (O)

• Spray gun (hanging or recoil style) (O)

• Printer with cable connection for HACCP data

Level TWO Features (F) and Options (O)

• Automatic cleaning – use your own cleaning

• Six cooking programs, three steps each (F)

• Single point cooking probe (F)

• Spray gun (hanging or recoil style) (O)

• Printer with cable connection for HACCP data (O)

Level THREE Features (F) and Options (O)

• SC3 Automatic cleaning system with triple action sanitizing using

• 150 cooking programs with up to 18 steps per program – custom program

• Multipoint (4) cooking probe for self directed “eyes off” cooking (F)

• Low Temperature, Banqueting, Delta T and Holding Programs (F)

• 3 speed fan for multiple purpose cooking/baking (F)

• Delayed Start, delayed cleaning timers (F)

• Interface for downloading/uploading data – including new cooking

• Adjustable display contrast (F)

• Spray gun (hanging or recoil style) (O)

boilers thereby eliminating typical boiler related problems; no more boiler

de-scaling, no more hidden problems, no duplicity of parts, less items

subject to failure, easier to maintain

systems further reducing maintenance issues and enhancing oven

performance

with a polished mirror finish to aid in durability and cleaning, #304 SS in

oven (turbine, shroud, guards), 20 gauge weight #304 stainless steel

used on all exterior oven components, gently coved interior corners,

airtight cooking chamber with a tempered double-glazed opening window,

water protection rating of IPX5, heat exchangers constructed of ICOLOY

800 and #316 Stainless Steel

aerodynamic divergent intake angle constantly replaces oven

environment to assure the correct heat and humidity are present allowing

for more accurate heat/humidity levels

a slight “overpressure” to the oven chamber thereby decreasing cooking

times while reducing energy consumption

increases fuel efficiency by as much as 20 percent

.

cleaning detergents (F)

(O)

detergents (F)

manufacturers detergents (F)

naming (F)

program details (F)

Printer with cable connection for HACCP data (O)

951 Matheson Blvd. E, ● Mississauga, Ont ● L4W 2R7

Tel.: (905) 897-2333 ● Fax: (905) 897-2334

www.gbscooks.com

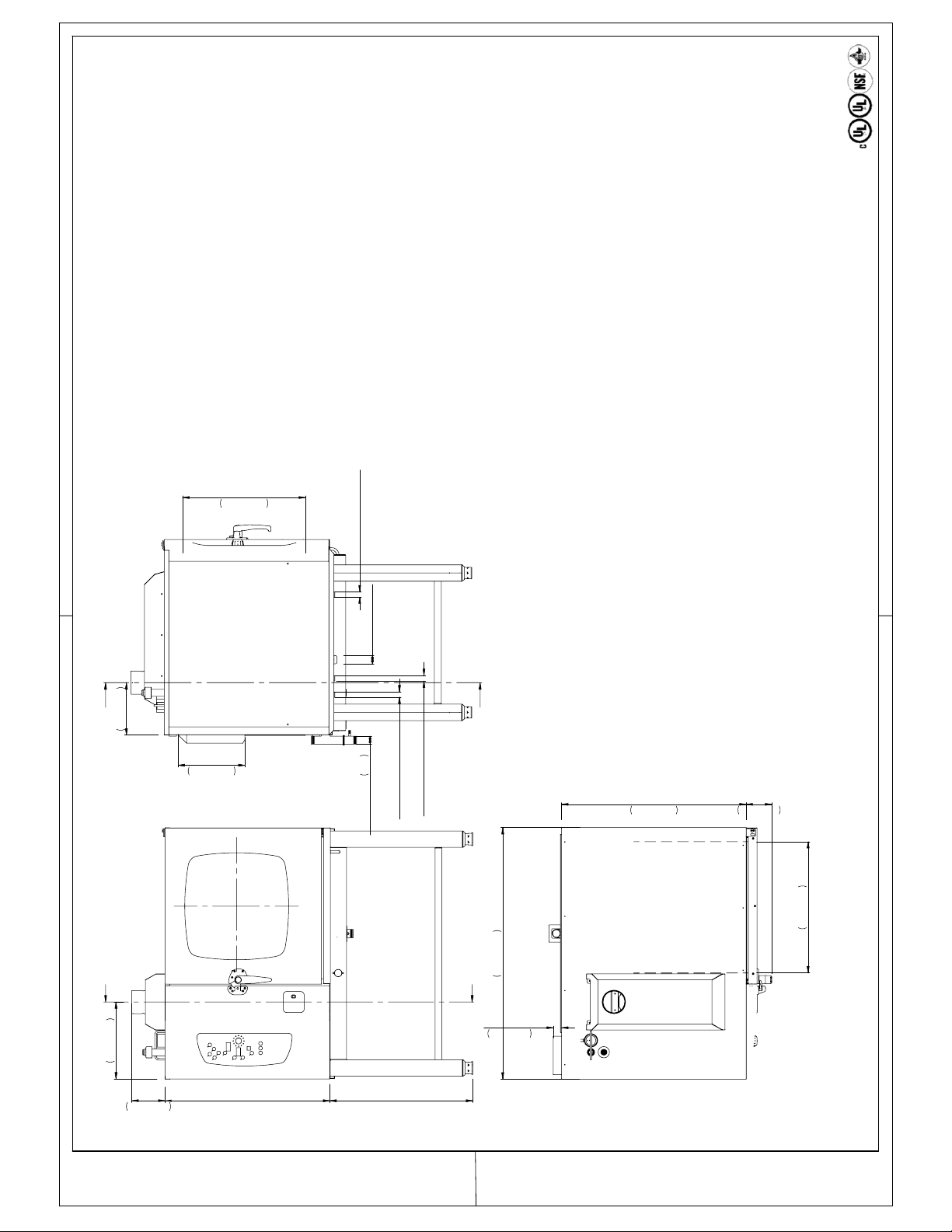

49 x 38 x 67 in

36 x 33 x 27 in

7 X 2/1

Outside Dimensions: 1225 x 955 x 1690mm

DIMENSIONS (W x D x H):

23,62 ±0,16

600 ±4

Gas conn. O3/4 NPT

Electrical conn.

Cooking Chamber 893 x 828 x 685 mm

ELECTRICAL CONNECTION:

Power: 1260 W, 120 V, 10.5 A, 1 Phase, 60 Hz

GAS:

91,000 BTU

NET WEIGHT:

266 kg

587 lbs.

CAPACITY

GN Containers: 14 X 1/1

B

B

255 ±5

10,04±0,2

12,82 ±0,12

326±3

A

375 ±5

14,77 ±0,2

6,38 ±0,08

162 ±2

800u5Minimum hight 690

40

1,57Drain conn.

O

Water conn. G3/4"

Water conn. G3/4"

35,45 ±0,16

901 ±4

1227 ±4

48,31 ±0,16

A

1,58 ±0,08

40 ±2

4,93 ±0,12

125 ±3

640 ±4

25,2 ±0,16

Loading...

Loading...