GBS FOOD SERVICE EQUIPMENT GBS2011 E2 User Manual

ELECTRIC, COMBI OVEN

MODEL GBS2011 [E2], [E3]

MODEL GBS2011 E3 SHOWN

20 Hotel Pans

. Oven Highlights:

• Advanced patented design eliminates the need for conventional type

boilers thereby eliminating typical boiler related problems; no more boiler

de-scaling, no more hidden problems, no duplicity of parts, less items

subject to failure, easier to maintain

• No boiler also allows the user to employ Reverse Osmosis (RO) water

systems further reducing maintenance issues and enhancing oven

performance

• Highest quality materials used including #316 Stainless Steel oven cavity

with a polished mirror finish to aid in durability and cleaning, #304 SS in

oven (turbine, shroud, guards), 20 gauge weight #304 stainless steel

used on all exterior oven components, gently coved interior corners,

airtight cooking chamber with a tempered double-glazed opening window,

water protection rating of IPX5, heat exchangers constructed of ICOLOY

800 and #316 Stainless Steel

• Airtight cooking chamber along with the reversible fan (motor) and

aerodynamic divergent intake angle constantly replaces oven

environment to assure the correct heat and humidity are present allowing

for more accurate heat/humidity levels

• CIBUS PLUS System = Closed Inertia Balanced Upright System imparts

a slight “overpressure” to the oven chamber thereby decreasing cooking

times while reducing energy consumption

Standard Features:

• Constructed of 20 gauge #316 and #304 Stainless

Steel

• Easy to operate electronic controls with digital

readout

• Ability to select from four languages, metric or

imperial measure

• Instantaneous steam generation within oven cavity

• Low (saturated) temperature and superheated (187

to 257 ) steam generation

• Autoreverse fan with Automatic oven cooldown

• Electronic self-diagnosis with malfunction alarms for

key operating areas

• Automatic pre-heat function

• HCCAP printout interface

• Tamper proof cooking programe protection

• Manual steam injection – great for artisan breads

• Slightly (6-7 psi) pressurized cooking chamber

reduces cooking times increases efficiency

• NEW Patented burner TDM system with automatic

firing pilot light (gas only)

• Double step safety “robust” safety handle

• Tempered double glazed window system coupled

with half and full position safety hinges

• Integrated door drip tray functions whether the door

is open or closed

• Magnetic door switch to energize oven

Level TWO Features (F) and Options (O)

• Automatic cleaning program – use your own

cleaning detergents (F)

• Six cooking programs, three steps each (F)

• Single point cooking probe (F)

• Spray gun (hanging or recoil style) (O)

• Printer with cable connection for HACCP data

(O)

Level THREE Features (F) and Options (O)

• SC3 Automatic cleaning system with triple

action sanitizing using manufacturers

detergents (F)

• 150 cooking programs with up to 18 steps per

program – custom program naming (F)

• Multipoint (4) cooking probe for self directed “eyes off” cooking (F)

• Low Temperature, Banqueting, Delta T and Holding Programs (F)

• 3 speed fan for multiple purpose cooking/baking (F)

• Delayed Start, delayed cleaning timers (F)

• Interface for downloading/uploading data – including new cooking

program details (F)

• Adjustable display contrast (F)

• Spray gun (hanging or recoil style) (O)

• Printer with cable connection for HACCP data (O)

951 Matheson Blvd. E, ● Mississauga, Ont ● L4W 2R7

Tel.: (905) 897-2333 ● Fax: (905) 897-2334

www.gbscooks.com

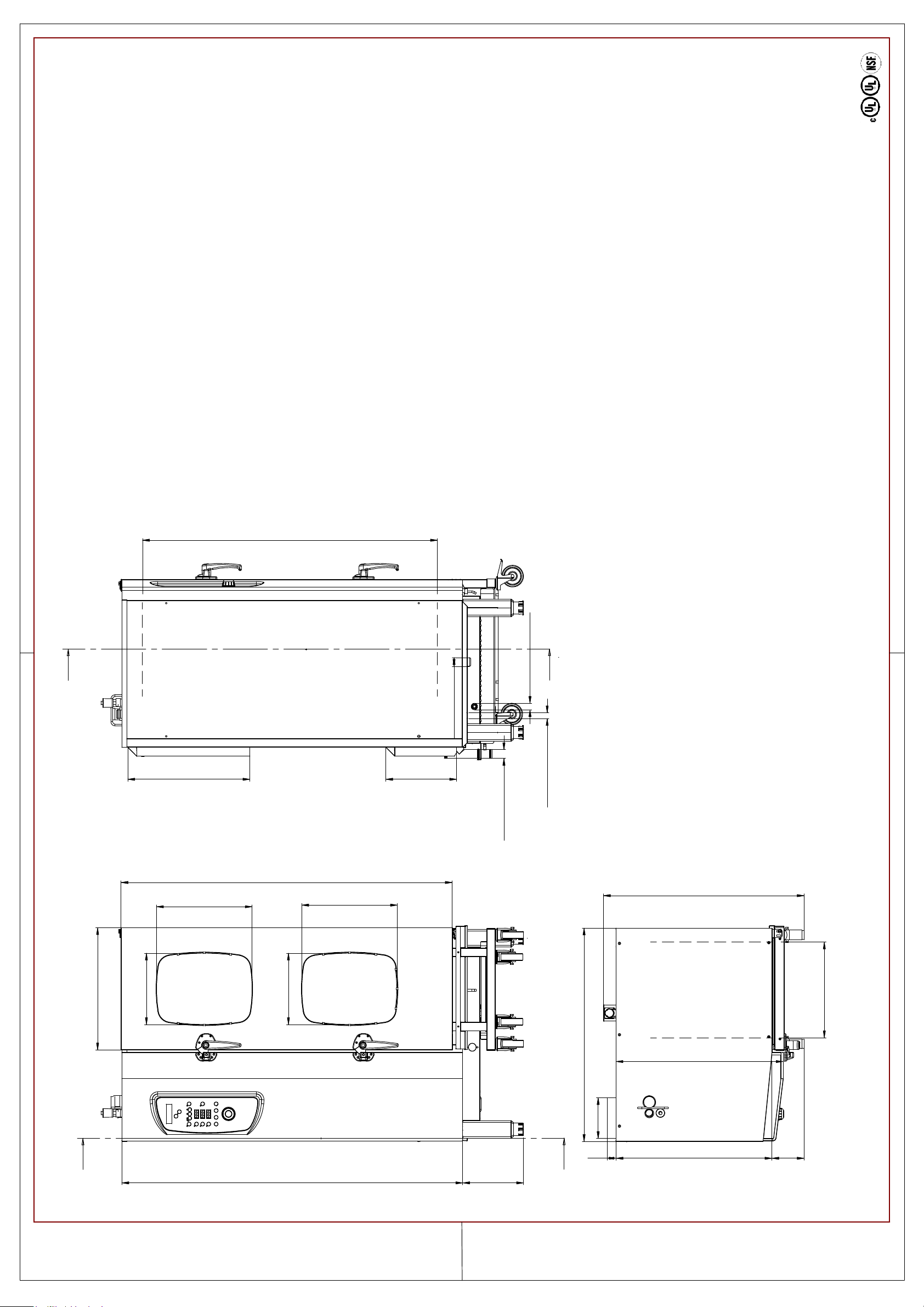

MODEL GBS2011 [E2], [E3]

DI9MENSIONS (W x D x H):

Outside Dimensions: 976 x 770 x 1835mm

39 x 31 x 73 in

Cooking Chamber 647 x 652 x 1420 mm

26 x 26 x 56 in

480 V; 3Ph; 60 Hz

ELECTRICAL CONNECTION:

Power:

NET WEIGHT:

340 kg

750 lbs.

CAPACITY

GN Containers: 20 X 2/1

1355

B

B

Water conn G3/4"

Electrical conn.

561326

40Drain conn. O

Water conn. G3/4"

1522

922

440

440

560

330

440

330

980

768,2

188

A

A

40

716148

270 1566

Loading...

Loading...