GBO Ultratherm 908i User manual

Short Wave Therapy Unit

ULTRATHERM 908i

Service Manual

gbo Medizintechnik AG 2004 Version 1.2

ULTRATHERM 908i 2

The gbo Medizintechnik AG has taken care in preparation of this service manual, but makes no

expressed or implied warranty of any kind and assume no responsibility for errors or omissions.

All rights reserved. No part of this service manual may be reproduced, in any form or by any

means (electronic, mechanical, or otherwise) without the prior written permission of the gbo

Medizintechnik AG.

gbo Medizintechnik AG 2004

gbo Medizintechnik AG

Kleiststr. 6

D-64668 Rimbach

Germany

Tel. 0 62 53 / 808-0

FAX 0 62 53 / 808-300

gbo Medizintechnik AG 2004 Version 1.2

ULTRATHERM 908i 3

Contents

CONTENTS 3

OVERVIEW 6

1. GENERAL INFORMATION 7

1.1. Purpose 7

1.2. Short User Manual 8

1.2.1. Operation Unit 8

1.2.2. Operation Direction 9

2. TECHNICAL DATA 10

3. ELECTRICAL AND FUNCTIONAL DESCRIPTIONS 11

3.1. Description of the subassemblies 11

3.1.1. Power supply - subassembly A100 11

3.1.2. Power generator - subassembly A200 11

3.1.3. Harmonic filter - subassembly A500 11

3.1.4. Output circuit - subassembly A300 12

3.1.5. Control computer - subassembly A400 12

3.2. Description of the Overall Wiring Diagram 14

4. TEST 15

4.1. Safety instructions 15

4.2. Testing devices and measuring instruments 15

4.3. Pretest 16

4.3.1. Check of earthing connections 16

4.3.2. Check of the fuse elements 16

4.4. Operation test 16

4.4.1. Stand by operation 16

4.4.2. Modes of operation 17

4.4.2.1. „MODE“ and „APPLICATOR“ keys 17

4.4.2.2. „+“ and „-“ keys, „MINUTES“ indicator 17

4.4.2.3. Power selector „INTENSITY“, indicators „WATTS“ and „TUNING“ 17

4.4.2.4. Emergency-off function 18

4.4.2.5. RESET key 18

4.5. Tuning 18

4.6. Check of the operating voltages and currents 19

gbo Medizintechnik AG 2004 Version 1.2

ULTRATHERM 908i 4

4.7. Check of generator frequency and pulse parameters 20

4.7.1. Generator frequency 20

4.7.2. Pulsed operation of „70 Hz“ 20

4.7.3. Pulsed operation of „350 Hz“ 20

4.8. Check of the power output 20

4.8.1. Coil applicator 20

4.8.2. Capacitor-field applicator 21

4.8.3. Auxiliary check of the power output 21

4.9. Check of the internal error recognition circuits 22

4.9.1. Temperature monitoring circuit 22

4.9.3. Generator voltage 22

4.10. Continuous operation 22

4.10.1. Preparation for continuous operation 22

4.10.2. Performance of the continuous operation 22

4.11. Final test 23

4.11.1. High-voltage test 23

4.11.2. Measurement of the leakage current of the casing 23

4.11.3. Earthing conductor test 23

4.11.4. Measurement of the mains current consumption 24

4.11.5. Check of the power values 24

4.11.6. Operation check 24

5. SERVICE INSTRUCTIONS 25

5.1. Function check of the power generator A200 25

5.1.1. Check of the supply voltages 25

5.1.2. Readiness for operation of the A200 subassembly 25

5.1.3. General information on the power loop 26

5.1.3.1. Level control 26

5.1.3.2. Amplification tract 26

5.1.3.3. Power and mismatching meter LFM 27

5.1.3.4. Adding amplifier 27

5.1.3.5. Subtracting amplifier 28

5.1.3.6. Multiplier (N202) 28

5.1.3.7. Setpoint/actual value comparator 28

5.1.3.8. Cable voltage monitoring circuit 29

5.1.3.9. Analogous OR interconnection 29

5.1.4. Operation of the power supply 29

5.1.5. Oscillator 30

5.1.6. Driver 30

5.1.7. RF circuits at the final stage output 30

5.1.8. Typical measurement values with a matched load (50 ohm) 30

5.2. Repair instructions for the control computer (A400) 31

5.2.1. Indication of the error conditions 31

5.2.2. Description of the control computer signals 32

5.3. Power supply (A100) 33

5.4. Output circuit (A300) 33

5.5. Harmonic filter (A500) 33

gbo Medizintechnik AG 2004 Version 1.2

ULTRATHERM 908i 5

6. DISASSEMBLY/ASSEMBLY FLOW CHART 34

7. ORDERING INFORMATION 35

8. PARTS LIST 37

9. WIRING DIAGRAMMS 38

CORRECTION SHEET 39

gbo Medizintechnik AG 2004 Version 1.2

ULTRATHERM 908i 6

Overview

Chapter 1 describes the basic purpose of the ULTRATHERM

908i.

Chapter 2 gives technical data of the unit.

Chapter 3 explains the functions of the subassemblys and the overall wiring diagramm.

Chapter 4 give some safety instructions during the service and describes the test of the whole

unit.

Chapter 5 includes the service instructions and informs about the trobleshooting.

Chapter 6 explains single steps to exchange a part.

Chapter 7 gives ordering information.

Chapter 8 gives a list of parts.

Chapter 9 contains the pictures and the wiring diagramms of the unit.

gbo Medizintechnik AG 2004 Version 1.2

ULTRATHERM 908i 7

1. General Information

1.1. Purpose

The ULTRATHERM 908i is a high performance short wave therapy unit for high frequencey

heat therapy that operates at the well proved frequency of 27,12 Mhz (wave lengh 11 m). It enables

the classical therapy in capacitor-field and electromagnetic coil fields in both the continuous and

the pulsed mode of oparartion and, therfore, it is suited for all heat therapy treatments in clinic as

well as practice.

The use of high frequency energy for the heat therapy has the advantage of larger penetration depth

in contrast to the conventional methods, such as hotpacks, baths, infrared light, heat pillows, and

even to the mirowave.

The heat endogenically generated by this therapy unit induces a whole range of physiological

processes which, for example, spasmodically influence the muscular system, tendons and other

connective tissue structures, increase the cell metabolism, rate of enzyme reaction and improve the

blood circulation in the area under treatment.

As the high frequency energy can be applied in short but high energy shocks (pulsed mode) the

penetration depth can be increased futher, particularly the positive effect on the blood circulation,

while the thermosensitive skin hardly feels the heat.

High frequency heat therapy can by applied in a wide field. It is particularly suited for all

rheumatic ailments of the joints and muscular system, inflammatory ailmants of respiratory

organs, kidnesy and urinary tracts and all ailments caused by blood circulation.

For acute conditions the pulsed mode of operation offers advantages.

gbo Medizintechnik AG 2004 Version 1.2

ULTRATHERM 908i 8

1.2. Short User Manual

1.2.1. Operation Unit

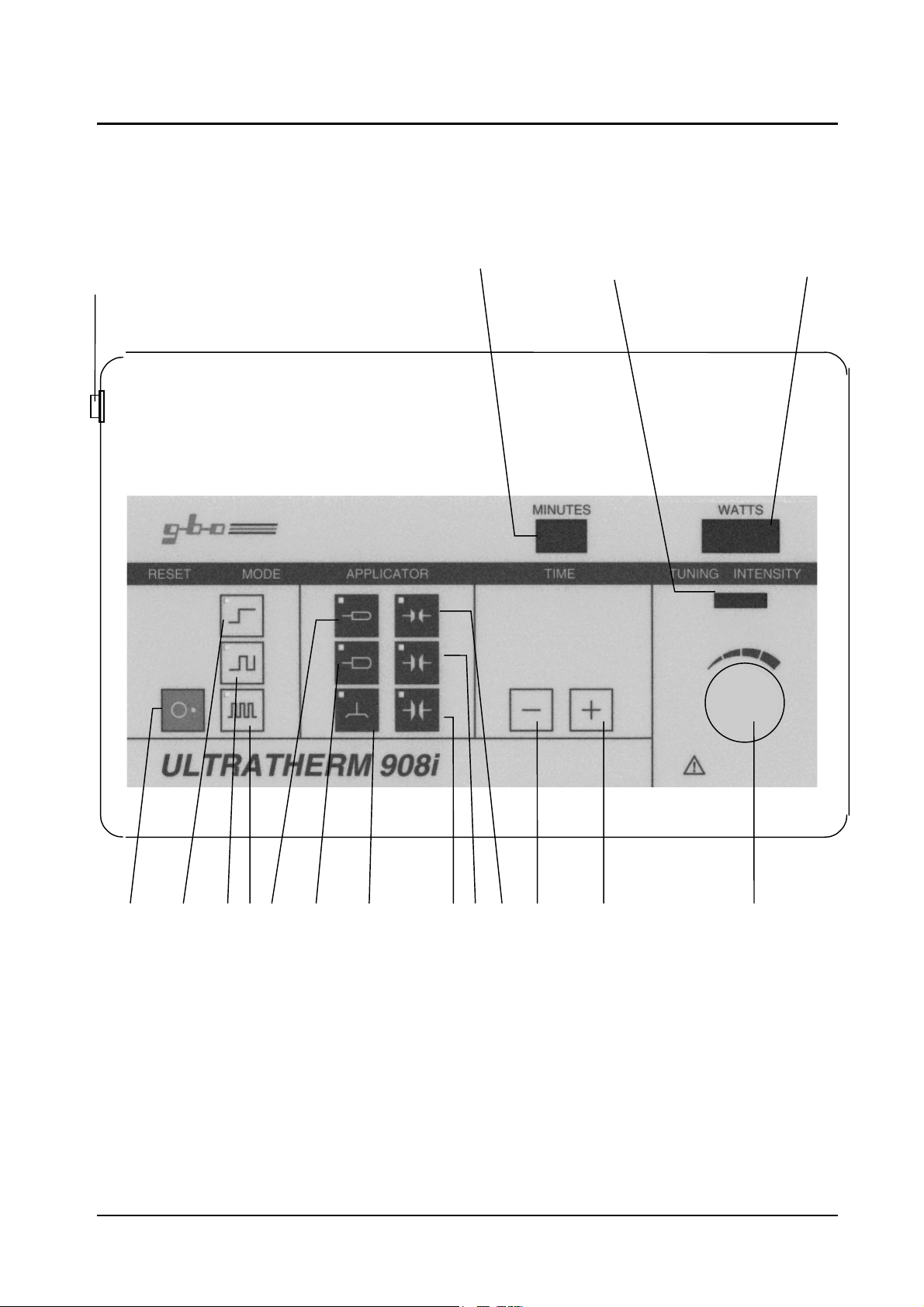

14 16 15

1

2 3 4 5 6 7 8 11 10 9 12 13 17

1 Power switch with light indicator

2 RESET key

3 Key „Continuous mode of operation“ with LED.

4 Key „Pulsed mode of operation“ 70 Hz/2 ms with LED

5 Key „Pulsed mode of operation“ 350 Hz/0.4 ms with LED

6 Key „Coil applicator“ MINODE ∅ 8 cm

7 Key „Coil applicator“ MONODE ∅ 14 cm

gbo Medizintechnik AG 2004 Version 1.2

ULTRATHERM 908i 9

8 Key „Coil applicator“ DIPLODE 18 x 39 cm

9 Key „Capacitor-field applicator“ ∅ 4.2 cm and

„Capacitor-field applicator“, elastic 8 x 12 cm

10 Key „Capacitor-field applicator“ ∅ 8.5 cm

„Capacitor-field applicator“, elastic 12 x 18 cm

11 Key „Capacitor-field applicator“ ∅ 13 cm

„Capacitor-field applicator“, elastic 15 x 25 cm

12 Key „Decrease treatment time“

13 Key „Increase treatment time“

14 Display „treatment time“ in minutes

15 Display „Dosage“

16 Display „Coupling with patient“

17 Dosage knop

1.2.2. Operation Direction

• Connect the therapy unit to the mains socket outlet

• Connect the applicator(s) to the therapy unit

• Attach the applicator(s) to the patient

• Turn on the therapy unit with switch (1)

• Select the mode of operation, buttons (3), (4), (5)

• Select the mode of the applicator(s), buttens (6) to (11)

• Set the treatment time, button (12), (13)

• Set the dosage, knob (17)

• Electric power is applied to the output, the treatment timer starts operation

• After the chosen treatment time has elapsed, the therapy unit automatically turns off and emits

an intermittent acoustic signal for about 10 s. This signal is repeated every minute until the

dosage knob (17) is reset by turning to the left (counterclockwise).

• When an error is displayed (except for FE 0) press RESET button (2) and readjust if required.

• The entire therapy unit is switched off by actuating swich (1) again.

For more imformation please look in the User Manual of the ULTRATHERM 908i.

gbo Medizintechnik AG 2004 Version 1.2

ULTRATHERM 908i 10

2. Technical data

Mains Voltage

On request

Electric fuses (external) 10 A slow acting for 230 V

Protective system Class I

Power consumption maximum

Stand-by oparation

Frequency

RF output power at 50Ω

continuous mode

Pulsed mode

Power equivalent 400 W

Pulse parameters

Peak pulse power

Pulse repetition fequency

Pulse width

230 V a.c. ± 15% 50/60 Hz

115 V a.c. ± 15 %; 50/60 Hz

16 A slow acting for 115 V

about 700 VA

about 100 VA

27,12 MHz ± 0,6 %

200 W

30 W

400 W

70 Hz/350 Hz

2 ms/0,4 ms

Dimensions 85 x 38 x 39 cm³ (HxWxD)

Weight 45 kg

Safety test DIN VDE 0750 Part 1

DIN VDE 0750 Part 204

DIN VDE 0871

MedGV - group 3

gbo Medizintechnik AG 2004 Version 1.2

ULTRATHERM 908i 11

3. Electrical and functional descriptions

3.1. Description of the subassemblies

3.1.1. Power supply - subassembly A100

The A100 subassembly is a mains-frequency clocked switching power supply generating the V1

(+5 V), V2 (+15 V) and V3 (-15 V) supply voltages. The outputs SK4 to SK6 are connected in

parallel to each other. Through plug connector SK7 (terminals 1 and 3) the mains power is fed in;

this connector is designed for 230 V as well as 115 V. The jumper „Link for 115 V operation“ is to

be plugged in accordance with the available mains voltage. The fine adjustment of the V2 supply

voltage is to be performed by means of control P1. When exchanging this subassembly it is to be

observed that the Y capacitors C16/C17 are not provided and that an electrically safe connection

between earthing conductor and base plate is to be ensured.

3.1.2. Power generator - subassembly A200

This module can be subdivided into three main sections. The first one includes the crystalcontrolled generation, amplification and filtration of the 27.12 Mhz high-frequency power. The

second one of this subassembly includes the measurement and control circuits which enable an

exact adjustment of the output power. And the third section contains the control circuit of the

operating voltage of the amplifier.

Any repair work of this subassembly shall only be performed by the manufacturer. That’s why,

this description is restricted mainly to the terminals. The supply power of the subassembly is fed

via the plug connectors X206 (+15 V), X209 (-15 V) and X210 (earth). Additional supply

terminals are X201 to X205 which are used for the regulation of the operating voltage of the

output amplifier. There importance as well as that of the terminals X207, X208, X211 to X213 is

described in detail in clause 3.2. The power is coupled out at the coaxial connector X222. This

A200 subassembly is delivered in the tested and tuned condition. Only the fine adjustment of the

output power is to be performed by means of R202.

3.1.3. Harmonic filter - subassembly A500

A harmonic filter, that additionally attenuates the RF interference spectrum in the frequency range

between 54 Mhz and 100 Mhz, is directly connected to the RF output of the power generator. It’s

adjustment is necessary to ensure being below the interference levels given by law. In case of

erroneous operation this subassembly has to be replaced in any case. Avoid any dismounting of the

air-core chokes L501/L502. The cover on this subassembly is absolutely necessary to maintain the

low RF interference values required by law.

gbo Medizintechnik AG 2004 Version 1.2

ULTRATHERM 908i 12

3.1.4. Output circuit - subassembly A300

The output circuit is provided to match the application part, which is connected to the balanced

output X004/X005, as exactly as possible to the generator. The matching is performed by means of

the adjustable capacitor C302 driven by stepping motor M301, which is a component of a serial

circuit in connection with the coils L302 and L303. The RF power is fed through connection

X301. The RF power flows via the capacitor chain C303 to C305 to the balance-to-unbalance

transformer L301/L302/L303 whose secondary windings are parts of the serial circuit mentioned

above.

The stepping motor is triggered by control computer A400. 4 additional diodes protect the

stepping motor (they are not drawn in the wiring diagramm).

All other parts, given in the layout, are not required.

3.1.5. Control computer - subassembly A400

Subassembly A400 is the central unit which realizes all signal and operation functions as well as

measurement and control operations. The micro-controller 87C196KB, which reduces the

computer hardware to a minimum and, thus, is a very service-friendly solution, is the basis of this

control computer.

The integrated circuit 87C196KB contains clock generator, CPU, program memory, A/D

converter, counter/timer and several different input and output ports. For clock generation (8 Mhz)

only the external components Q401, C406 and C406 are to be connected. After switchingon the

watch-dog circuit D401 generates a reset signal and initiates a defined start of the internal

program. But the generation of the reset signal is also possible by means of key S409. The supply

voltages +5 V, +15 V and -15 V are applied to the subassembly via X403. Mode of operation,

applicator type and treatment time are adjusted by means of the key matrix S401 to S408 and S410

to S412. They are triggered by the output ports P1.4 to P1.7 and evaluated by the input ports P2.1

to P2.3 which are loaded by the pull-up resistors R449 to R451. The output power is adjusted by

means of pulse generator D408, feeding the two direction-of-rotation dependent signals (2) and (4)

to the prosessor via NMI and P0.5. Processor output P2.5/PWM delivers a pulse-duration

modulated signal that is converted to a DC voltage by the two operational amplifier networks

N401A/N401B and used to control the power output of generator A200. The connection C402 to

D402 (P0.6) is used to monitor the D/A conversion. In the pulsed modes of operation the DC

voltage is keyed via processor output pin P4.7/AD15 and transistor T401. The generator control

voltage, the level of which is also monitored by processor (P0.6), applies at plug connector

X401.5. The bar indicator VD401 consists of ten LEDs and signals the degree of matching

between patient circuit and generator output. The individual LEDs VD402 to VD410 have the

following meaning:

VD402 signals the adjustment of the „DIPLODE“ applicator.

VD403 signals the adjustment of the Medium coil-field „MONODE“ applicator.

VD404 signals the adjustment of the Small coil-field „MINODE“ applicator.

gbo Medizintechnik AG 2004 Version 1.2

Loading...

Loading...