Page 1

ProCut Paper Cutter

Model 20P

INSTALLATION &

OPERATION MANUAL

Document Number: 1729247 Rev. A

Do not duplicate without written permission from ACCO Brands.

Store this instruction manual in a safe place for future reference.

Page 2

ProCut 20P – Installation and Operating Instructions

Page i

ACCO Brands reserves the right to make changes

to this publication and to the products described in

it without notice. All specications and information

concerning products are subject to change without

notice. Reference in this publication to information or

products protected by copyright or patent does not

convey any license under the rights of ACCO Brands

or others. ACCO Brands assumes no liability arising

from infringements of patents or any other rights of third

parties.

This publication is copyrighted © 2015 by ACCO Brands.

All rights reserved.

© 2015 ACCO Bran ds. All rights res erved. ACCO® is a registered tradem ark of

ACCO Bran ds. GBC® is a registered trad emark of General B inding Co rporation.

1729247 Rev. A 2015/03

ACCO Brands Canada Inc.

7381 Bramalea Road

Mississauga ON L5S1C4

800.263.1063

www.gbccanada.com

ACCO Mexicana

Neptuno 43, Fraccionamiento Nueva Industrial Vallejo

México 07 700 D.F.

Delagación Gustavo A.

Madero

(55) 1500 5778

www.accomexico.mx

ACCO Brands

4 Corporate Drive

Lake Zurich, IL 60047

In USA call 800.772.9281

www.gbcconnect.com

IntroductIon

The equipment is designed to provide you with improved

productivity, versatility, and quality.

Note: Depending on the model and its version, the

photos in this manual may not look like your machine.

However, the components and functions are the same.

Features

• Intuitive user LCD display

• Programmable for up to 80 programs with up to

99 steps

• Electric blade, clamp and back gauge

BeneFIts

• LED optical cut line ensures accuracy

• Reset button recalibrates machine for accuracy

• Full programmability increases speed of cutting

saFety

• Two handed cut and clamp activation buttons

• Mechanical safety latch and light curtain safety

shield

• Push-out feature moves media forward after the

cut is complete

Page 3

Page ii

ProCut 20P – Installation and Operating Instructions

Introduction ................................................................ i

Features ................................................................ i

Benets ................................................................. i

Safety .................................................................... i

1. Safety

Cautions ................................................................ 1-2

General .................................................................. 1-2

Electrical ................................................................ 1-2

GBC Technical Service ......................................... 1-2

2. Warranty

Limited One Year Parts, 90 Days Labor Warranty;

USA, Mexico, and Canada .................................... 2-1

3. Specications

FCC Class A Notice .............................................. 3-2

Canada Class A Notice - Avis Canada, Classe A . 3-2

Modications ......................................................... 3-2

4. Installation

GBC Technical Service ......................................... 4-1

Prior to Installation ................................................. 4-1

Installation ............................................................. 4-1

Location ............................................................ 4-2

5. Feature Guide

Infrared Safety Walls ............................................. 5-1

Jogging Aid ............................................................ 5-1

Back Gauge ........................................................... 5-1

The Clamp & Cutting Blade ................................... 5-1

Cut Stick ................................................................ 5-1

Control Panel ......................................................... 5-2

A. LCD Display .................................................. 5-2

B. Keypad .......................................................... 5-2

C. Operation Buttons ........................................5-3

E. Blade Adjustment.......................................... 5-3

6. Operation

Powering Up the Machine ..................................... 6-1

Operating the Machine .......................................... 6-1

Manual Operation ............................................. 6-1

Programming the Machine .................................... 6-1

Entering a Program ........................................... 6-1

7. Operator Maintenance

Caring for the ProCut 20P ......................................7-1

Cleaning The Paper Cutter ................................7-1

Cut Stick Rotation and Replacement .................7-1

Blade Replacement ............................................7-1

8. Function Values

Changing Function Values .................................... 8-2

taBle oF contents

Page 4

ProCut 20P – Installation and Operating Instructions

Page iii

Page 5

Page 1-1

ProCut 20P – Installation and Operating Instructions

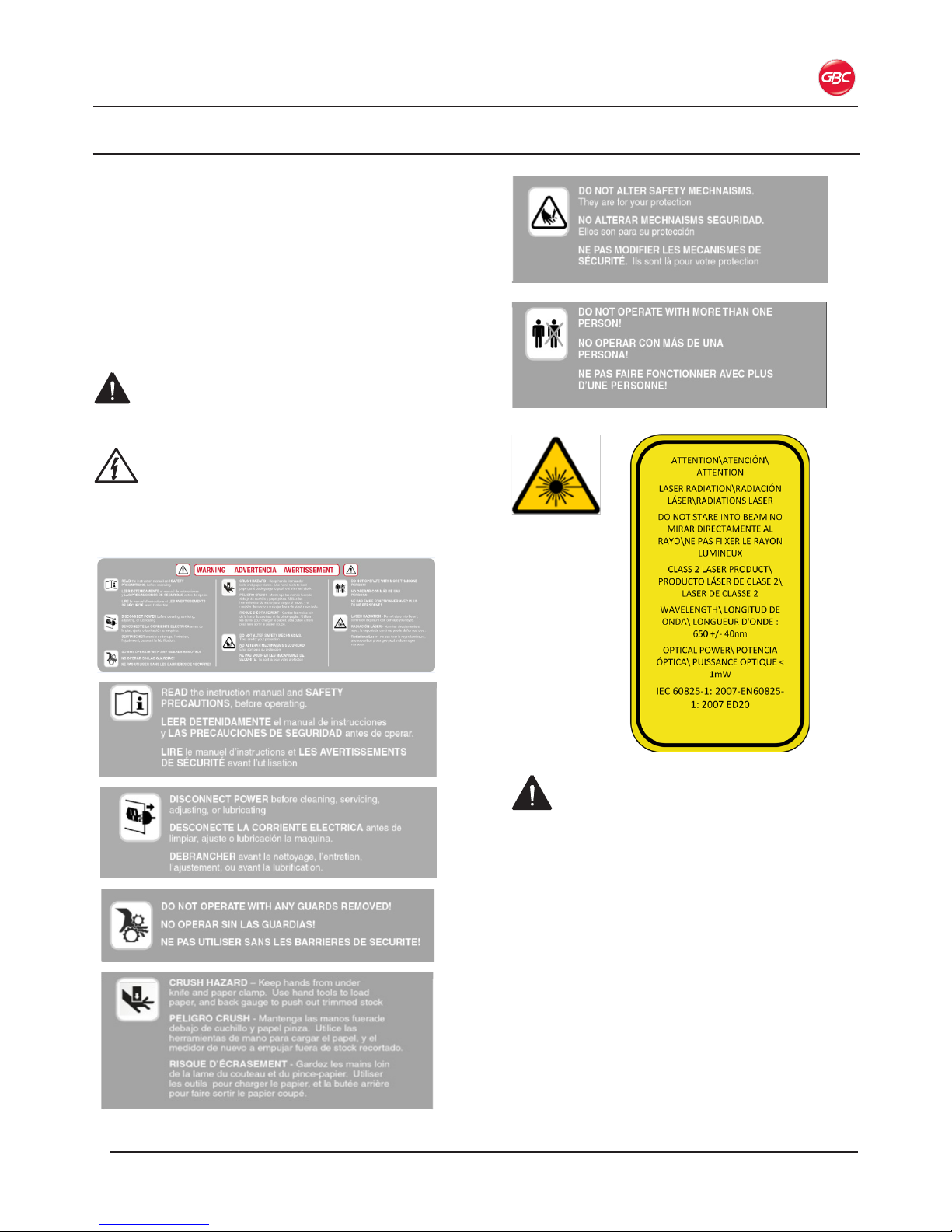

Your safety, as well as the safety of others, is

important. Before you install or use the machine,

read and follow all the safety notices carefully in

this chapter. In this instruction manual, and on the

machine, you will nd important safety notices

related to the use of the product. Observe all the

safety information provided.

Read all of the instructions and save these

instructions for further use. Also make sure you have

been fully trained before operating.

The safety alert symbol precedes each

safety notice in this manual. The symbol indicates a

potential personal safety hazard to you or others.

This safety alert symbol indicates a potential

electrical shock. It warns you not to open the

machine and expose yourself to hazardous voltage.

The following warnings are found on the equipment.

WarnInGs

• Do not attempt to service or repair the

machine.

• Do not open the machine. There are no

serviceable parts inside. Refer service to

qualified service personnel.

• Do not attempt to modify this equipment.

• Do not connect to an electrical supply or

attempt to operate until you have completely

read these instructions. Maintain these

instructions in a convenient location for future

reference.

• Entrapment hazard. Do not operate when

alone. More than one person is required to be

in the area when operating the machine.

• To guard against injury, the general safety

precautions must be observed when installing

and using the machine.

1. saFety

Page 6

ProCut 20P – Installation and Operating Instructions

Page 1-2

WarnInGs (cont’d)

• Consider the work area. A cluttered work area

can lead to accidents. The machine must be

placed on a sturdy level floor surface. Allow

sufficient access to the front, back, and sides.

Keep the work area well lit.

• Plastic bags must be kept out of reach of

children.

Failure to observe these warnings could result in

severe personal injury or death.

cautIons

Caution indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury or

cause damage to the machine.

General

• Keep ngers, hands clothing, jewelry, and long

hair away from the front of the Working Table,

Clamp, and Cutting Blade.

• Use only sufficiently stable and compatible

stands. Make certain the equipment is installed

securely and cannot fall down.

• Do not use the machine for other than its

intended purpose.

• Avoid quick stops, excessive force and uneven

floor surfaces when moving the machine.

• The cutter and stand are separate components.

The cutter and stand will need to be lifted and

moved separately.

• Do not defeat or remove electrical and

mechanical safety equipment such as interlocks,

shields and guards.

• Do not insert objects unsuitable for the purpose

of this machine or expose the equipment to

liquids.

• The cabinet should remain locked at all times

and only be opened by approved personnel.

• Do not store flammable items in the cabinet.

Before you operate this machine, it is important that

you read and understand the entire contents of these

instructions.

electrIcal

The machine should be connected only to a source

of power as indicated in these instructions and on the

nomenclature plate located on the side of the machine.

Contact an electrician should the attachment plug

provided not match the receptacles at your location.

After plugging in, check that the power cord does not

create a tripping hazard.

WARNING: Do not attempt to service or repair.

Failure to observe this warning could result severe

personal injury or death.

Disconnect the plug from the receptacle and contact

your dealer or distributor, or GBC Technical Service at

1-800-723-4000, when one or more of the following has

occurred.

• The power supply cord or attachment plug is

damaged.

• Liquid has been spilled into the machine.

• The machine is malfunctioning.

• The machine does not operate as described in

these instructions.

Opening the machine exposes you to hazardous

voltage, which can seriously hurt or kill you.

There are no user serviceable parts inside. Refer

service to qualied service technician.

CAUTION: The receptacle must be located near the

equipment and must be easily accessible.

Disconnect the attachment plug from the receptacle to

which it is connected and keep the power supply cord in

your possession when moving.

GBc technIcal servIce

To order replacement accessories, service, parts, or

an Equipment Maintenance Agreement, please contact

GBC Technical Service and Support at:

unIted states

ACCO Brands

GBC Technical Service and Support

4 Corporate Drive

Lake Zurich, IL 60047-8997

www.gbcconnect.com

1-800-723-4000

canada

Ontario and Quebec – 1-800-268-3310

All other Provinces – 1-800-268-3447

Local 905-595-3100

Callcentre@GBCCanada.com

MexIco

(55) 1500 5778

Lada SIN costo: 01 800 759 6825

serviciotecnico@acco.com.mx

Page 7

Page 2-1

ProCut 20P – Installation and Operating Instructions

2. Warranty

lIMIted one year Parts, 90 days

laBor Warranty; usa, MexIco,

and canada

ACCO Brands USA LLC, ACCO Brands, 4 Corporate

Drive, Lake Zurich, IL 60047 (in Mexico, ACCO

Brands Mexicana,Neptuno 43, Fraccionamiento Nueva

Industrial Vallejo México 07700 D.F. México), (in

Canada, ACCO Brands Canada Inc., 7381 Bramalea

Road, Mississauga ON L5S1C4) (each, respectively,

“ACCO Brands”) warrants to the original purchaser

that this ACCO Brands product is free from defects

in workmanship and material under normal use and

service for a period of: one (1) year for parts and ninety

and (90) days for labor after purchase.

ACCO Brands’ obligation under this warranty is limited

to replacement or repair, at ACCO Brands’ option, of

any warranted part found defective by ACCO Brands

without charge for material or labor. Any replacement,

at ACCO Brands’ option, may be the same product

or a substantially similar product that may contain

remanufactured or refurbished parts. This warranty

shall be void in the following circumstances:

(i) if the product has been improperly installed or

misused,

(ii) if the product has been damaged by negligence or

accident, or

(iii) if the product has been altered by anyone other

than ACCO Brands or ACCO Brands’ authorized

agents.

Without limiting the generality of the previous

paragraph, ACCO Brands’ obligation under this limited

warranty does not include:

(a) damage caused to the rollers by knives, razors,

or other sharp tools; by any foreign objects falling

into the working area of the laminator; or by cleaning

the laminator with solutions or materials that harm its

surfaces;

(b) damage caused by adhesives; nor

(c) damage caused by lifting, tilting or attempting to

position the laminator other than rolling it on its castors

across even surfaces. For warranty execution, please

contact ACCO Brands at:

800-723-4000 or www.gbcconnect.com in the USA

800-263-1063 or www.gbccanada.com in Canada

(55) 1500 5578 or www.accomexico.mx in Mexico

TO THE EXTENT ALLOWED BY APPLICABLE

LAW, THIS WARRANTY IS IN LIEU OF ALL OTHER

EXPRESSED WARRANTIES. REPRESENTATIONS

OR PROMISES INCONSISTENT WITH OR

IN ADDITION TO THIS WARRANTY ARE

UNAUTHORIZED AND SHALL NOT BE BINDING ON

ACCO BRANDS. TO THE EXTENT PERMITTED BY

APPLICABLE LAWS, ANY IMPLIED WARRANTIES

(IF APPLICABLE) ARE LIMITED IN DURATION

TO THE DURATION OF THIS WARRANTY.

SOME STATES AND JURISDICTIONS DO NOT

ALLOW LIMITATIONS ON HOW LONG AN

IMPLIED WARRANTY LASTS, SO THE ABOVE

LIMITATION MAY NOT APPLY TO YOU. TO THE

EXTENT PERMITTED BY APPLICABLE LAW, IN

NO EVENT SHALL ACCO BRANDS BE LIABLE

FOR ANY SPECIAL, INCIDENTAL, PUNITIVE,

EXEMPLARY, CONSEQUENTIAL OR SIMILAR

DAMAGES, WHETHER OR NOT FORESEEABLE.

SOME STATES AND JURISDICTIONS DO NOT

ALLOW THE EXCLUSION OR LIMITATION OF

SPECIAL, INCIDENTAL, PUNITIVE, EXEMPLARY,

CONSEQUENTIAL, OR SIMILAR DAMAGES, SO

THE ABOVE EXCLUSION OR LIMITATION MAY NOT

APPLY TO YOU.

FOR CONSUMERS WHO HAVE THE BENEFIT

OF CONSUMER PROTECTION LAWS OR

REGULATIONS IN THEIR JURISDICTION OF

PURCHASE OR, IF DIFFERENT, IN THEIR

JURISDICTION OF RESIDENCE, THE BENEFITS

CONFERRED BY THIS WARRANTY ARE IN

ADDITION TO ALL RIGHTS AND REMEDIES

CONVEYED BY SUCH CONSUMER PROTECTION

LAWS AND REGULATIONS.

To the extent permitted by law, this warranty is not

transferable and will automatically terminate if the

original product purchaser sells or otherwise disposes

of the product.

This warranty gives you specic legal rights. Other

rights, which vary from jurisdiction to jurisdiction, may

exist. In addition some jurisdictions do not allow

(i) the exclusion of certain warranties, (ii) limitations

on how long an implied warranty lasts and/or (iii) the

exclusion or limitation of certain types of costs and/ or

damages, so the above limitations may not apply.

Page 8

ProCut 20P – Installation and Operating Instructions

Page 2-2

Page 9

Page 3-1

ProCut 20P – Installation and Operating Instructions

Model

ProCut 20P

Control

Programmable

Minimum Cut Length

1.19 in. (30 mm)

Maximum Cut Length

20.43 in. (519 mm)

Maximum Cut Thickness

2.5 in. (64 mm)

Maximum Cut Width

20.43 in. (519 mm)

Dimensions:

• Width

• Height

• Depth

• Work Table Height

34.5 in. (876 mm)

52.5 in. (1334 mm)

45.5 in. (1156 mm)

39.5 in. (1003 mm)

Weight

419 lbs. (190 kg).

Electrical Requirements:

• Voltage

• Current

• Power

• Receptacle

208-240V 60 Hz

8A

1400 Wat ts

NEMA 6-15P

Cycle Time

Operating time = 7 seconds

Rest time = 3 seconds

Paper Press Method/Clamp

Automatic

Paper Pusher/Back Gauge

Automatic

3. sPecIFIcatIons

W

i

d

t

h

De

pt

h

Height

Figure 1. ProCut 20P Dimensions

Page 10

ProCut 20P – Installation and Operating Instructions

Page 3-2

Fcc class a notIce

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

• This device may not cause harmful interference.

• This device must accept any interference

received, including interference that may cause

undesired operation.

Note: This equipment has been tested and found to

comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC rules. These limits are

designed to provide reasonable protection against

harmful interference when the equipment is operated

in a commercial environment. This equipment

generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance

with the instruction manual, may cause harmful

interference to radio communications. Operation

of this equipment in a residential area is likely to

cause harmful interference in which case the user

will be required to correct the interference at his own

expense.

canada class a notIce - avIs

canada, classe a

This Class A digital apparatus complies with Canadian

ICES-003.

Cet appareil numérique de la classe A est conforme à

la norme NMB-003 du Canada.

ModIFIcatIons

Any modications made to this device that are not

approved by ACCO Brands may void the authority

granted to the user by the FCC and/or by Industry

Canada to operate this equipment.

Toutes modications apportées à ce dispositif et non

approuvées par ACCO Brands annuleront le droit

accordé à l’utilisateur par le FCC et/ou par Industrie

Canada de faire fonctionner cet équipement.

Page 11

Page 4-1

ProCut 20P – Installation and Operating Instructions

WARNING: Do not attempt to service or repair

the machine. Failure to observe this warning could

result in severe personal injury or death.

Disconnect the plug from the receptacle and contact

GBC Technical Service when one or more of the

following has occurred.

• The power supply cord or attachment plug is

damaged.

• Liquid has been spilled into the machine.

• The machine is malfunctioning.

• The machine does not operate as described

in these instructions.

GBc technIcal servIce

United States

1-800-723-4000

Canada

Ontario and Quebec – 1-800-268-3310

All other Provinces – 1-800-268-3447

Local 905-595-3100

Mexico

(55) 1500-5778

PrIor to InstallatIon

Inspect the crate and machine for damage. Shipping

damage should be brought to the immediate

attention of the delivering carrier.

WARNING: Do not attempt to move the

machine across anything other than a at, level

surface without trained and qualied riggers. You

can be severely injured or crushed.

The ProCut 20P Series Cutter is a large and heavy

piece of equipment. It is not designed to be tipped

up or tipped sideways in anyway.

Prepare the site:

1. Allow enough room to access all sides of the

machine. Refer to the illustration on the next

page.

2. Ensure the floor is stable and a flat surface

capable of supporting the weight of the machine

and any materials. All four foot pads should be

able to be positioned completely on a level and

smooth surface.

InstallatIon

There are no operator serviceable parts to the

machine other than periodic cleaning. Refer to the

Operator Maintenance chapter.

During installation, observe the safety regulations

applicable for your country.

WARNING: A trained GBC Technician MUST

install the machine for the rst time. Failure to

observe this warning could result in severe bodily

injury or death.

CAUTION: Do not attempt to install the machine

yourself for the rst time. You could damage the

machine.

4. InstallatIon

Page 12

ProCut 20P – Installation and Operating Instructions

Page 4-2

locatIon

The ProCut 20P should be located in a space that allows

adequate room to operate the machine. Allow at least

six inches behind the machine. It is recommended that

a media table be used to stage the sheets to be cut.

A second media table is recommended for nished

material. Keep the working area of the cutter free from

clut ter.

Avoid locating the cutter in a high trafc area. When not

in use, the ProCut 20P can be unplugged.

Operator

Media Table Media Table

6 inches

12 inches

Figure 2. ProCut 20P Location

Page 13

Page 5-1

ProCut 20P – Installation and Operating Instructions

5. Feature GuIde

This chapter identies the main components of the

machine.

InFrared saFety Walls

Figure 3. Infrared Safety Walls

The side walls on the working table contain infrared

sensors which prevent the machine from operating when

the sensors are obstructed. If an obstruction occurs, up

to 65mm above the working table, an alarm sounds and

the cut and clamp functions will not operate.

JoGGInG aId

Figure 4. Jogging Aid

The Jogging Aid is used to register the paper against the

Back Gauge.

Back GauGe

Figure 5. Back Gauge

Sets the proper position for cutting based on the values

entered through the Control Panel. Media is then pushed

against the Back Gauge using the Jogging Aid, to ensure

a straight and accurate cut. Laser Cut Line

Figure 6. Red LED Laser Cut Line

The cut line, as shown in the photo above, is visible

only when the machine is turned ON. The line indicates

where the paper stack will be cut.

the claMP & cuttInG Blade

Figure 7. The Clamp (dark grey) and Cutting Blade

The Clamp activates rst, pressing and holding down the

media to ensure a clean cut. The Cutting Blade then cuts

the stack. The blade should be sharpened or replaced

every 2000 – 3000 cuts based on 20 lb. bond paper.

Cutting Blades can be sharpened multiple times but it

is recommended not to remove more than 8mm off the

blade. The number of times you can sharpen the blade

will depend on the types of media being cut.

cut stIck

Figure 8. Cut Stick (red) and Removal Tool

The Cut Stick provides a clean cut as the Cutting Blade

makes contact with it. The Cut Stick can be rotated to

provide eight cutting surfaces.

Page 14

ProCut 20P – Installation and Operating Instructions

Page 5-2

WARNING: Keep hands and ngers away from

the Clamp and Cutting Blade. Failure to observe

this warning could result in severe personal

injury.

control Panel

In addition to the manual cut settings, the ProCut 20P

can be programmed for in front and behind the blade

cutting. Up to 80 programs, containing 99 steps each,

can be stored for reuse.

The Control Panel includes an LCD display and keypad.

The LCD shows the current and programmed settings of

the cutter and the keypad is used to set up and program

the cutting programs.

a. lcd dIsPlay

The display shows the current settings of the machine.

The values shown can be displayed in millimeters or

inches.

01 00.00

00.00 00.00 00.00

00.00

00.00

00.0000.00

05 06

02

07

03

08

04

x

10.00

5 inch 0716 00

Figure 9. Rendering of LCD Display

claMPInG Force:

Indicates the amount of pressure applied to the media.

The pressure can be set from 1 (highest) to 9 (lowest)

with the default being 5. You must be in the Clamping

Force setting screen to adjust the pressure.

saFety curtaIn alarM:

Indicates whether the alarm buzzer is enabled or disabled.

reBladInG Mode:

Used when changing the blade.

WARNING: Blade removal should only be done

by a GBC Technician. Failure to observe this

warning could result in severe personal injury.

BehInd the Blade:

Cut value is measured from behind the blade to the Back

Gauge.

In Front oF the Blade:

Cut values are measured by the amount of media

the Back Gauge pushes in front of the blade from the

previous cut.

Back GauGe value:

The numeric value displayed is the current position of the

Back Gauge.

ProGraMMInG values:

Displays the programmed cuts entered for each step.

count value:

Provides the total cuts performed during the lifetime of

the machine.

B. keyPad

The keypad is used to:

• Set the cutting size when operating in manual

mode

• Change cutter settings

• Select or create programs

Figure 10. Keypad

Use the numeric keypad to enter the cut values in

manual mode or when entering programs. To add a

decimal, press the decimal button.

When display is in menu mode, the Up and Down arrow

buttons are used to scroll through the menu and to

increase or decrease selected values.

set:

Use the Enter button to access the menu mode. Once

in menu mode, use the numeric buttons to set the value

when programming or changing cutter settings.

Page 15

Page 5-3

ProCut 20P – Installation and Operating Instructions

cancel:

The Cancel button is used to:

• Delete current values

• Return to the home screen from the menu mode

• Stop a warning condition

c. oPeratIon Buttons

Figure 11. Operation Buttons on Machine Front

1. claMP cut

This button must be pressed simultaneously with

either

the Clamp or Cut button.

2. on/oFF sWItch

The On/Off Switch must be in the ON position to supply

power to the machine. When the machine is not in use,

switch to the OFF position.

3. reset

This button resets the Blade and Back Gauge to the

default position. When the machine is initially turned ON,

the Reset button must be pressed before the blade will

cycle.

4. Back GauGe control dIal

Used to move the back gauge. Turn left to move forward

or right to move backward. Continuously holding in one

direction will move the back gauge more quickly for

larger adjustments.

5. Push

Use the push button to move the cut sheets out from

under the clamp and blade. This is a safety feature to

keep your hands away from the clamp and blade.

6. claMP

Press the Clamp and Clamp Cut buttons simultaneously

to engage the Clamp.

7. cut

Press the Cut and Clamp Cut buttons simultaneously to

engage the Blade.

1 2 3 5 6 7

4

d. cIrcuIt Breaker

Figure 12. Circuit Breaker

If the machine experiences an overload, or short circuit,

the Circuit Breaker will trip removing power from the

machine. If this happens, conrm that the switch is in the

OFF position, reset the Circuit Breaker, then move the

switch to the ON position to apply power to the machine.

e. Blade adJustMent

Figure 13. Blade Adjustment Hole and Hex Wrench

In the event the Blade is not cutting through the entire

stack, the cut stick needs to be rotated. See “Cut Stick

Rotation and Replacement” If after rotating the cut stick

the Blade is still not cutting through the entire stack, then

adjust the depth of the Blade.

Insert the 6mm Hex wrench into the blade adjustment

hole and rotate clockwise to lower the blade. Refer to

“Blade Depth Adjustment” for more information.

Page 16

ProCut 20P – Installation and Operating Instructions

Page 5-4

Page 17

Page 6-1

ProCut 20P – Installation and Operating Instructions

6. oPeratIon

The ProCut 20P Paper Cutter follows standard SGS

safety design specications. The infrared photoelectric

protection and two hand operation provides operators

with more safety.

WARNING: This machine is designed for one

person operation only. The operator must use both

hands to operate the cutter. Failure to observe this

warning could result in severe personal injury.

The ProCut 20P Paper Cutter is ideal for small to

medium sized operations, to cut stacks of photocopies,

printed materials, books, pictures, documents, and other

non-metal materials to specied sizes.

CAUTION: Do not cut staples, paper clips, or other metal

items with the cutter. Failure to observe this caution can

damage the Cutting Blade.

Note: Grease from the Cutting Blade may transfer to

the media when using the machine the rst time. It is

recommended to cut scrap media until the grease is no

longer being transferred.

PoWerInG uP the MachIne

When the machine is powered on, the LCD Display

illuminates. The Control Panel shows the machine’s

current condition.

1. Plug the power cord into an approved electrical

outlet.

2. Move the Circuit Breaker, on the machine, to the up

position.

3. Turn the switch to the ON position.

oPeratInG the MachIne

After powering on the machine the word RESET appears

on the LCD. Press the yellow Reset Button to set the

Cutting Blade to the HOME position and calibrate the

Back Gauge by returning to the home position and

returning to the last used numeric setting.

Place the media on the Working Table and use the

Jogging Aid to push the leading edge against the Back

Gauge and align the sheets.

Using both hands, simultaneously press and hold the

Clamp Cut and Cut buttons until it nishes cutting.

Manual oPeratIon

1. Using the Keypad, enter the length of the cut.

2. Press Enter.

ProGraMMInG the MachIne

The ProCut 20P can be programmed for in front and

behind the blade cutting. Up to 80 programs, containing

99 steps each, can be stored for reuse.

There are two modes:

• Front Blade

• Behind Blade

enterInG a ProGraM

1. Power up the machine.

2. Press the yellow Reset Button.

• The Home screen is displayed on the LCD.

01 00.00

00.00 00.00 00.00

00.00

00.00

00.0000.00

05 06

02

07

03

08

04

x

10.00

5 inch 0716 00

Figure 14. Rendering of Home Screen

3. To select the menu mode, press SET on the Keypad.

4. Press the Up or Down arrow for your desired mode,

which is displayed on the LCD:

• Behind Blade

• Front Blade

5. Press ENTER on the Keypad.

• Double 00 flashes.

Figure 15.

01 00.00

00.00 00.00 00.00

00.00

00.00

00.0000.00

05 06

02

07

03

08

04

00

Behind blade program

Pressing Enter on the Keypad

6. Press the Up or Down arrow buttons to select a

program number 00 - 80.

7. Press ENTER to select the program.

• The LCD displays the program number and cut

values associated with the program. The first cut

is highlighted.

Page 18

ProCut 20P – Installation and Operating Instructions

Page 6-2

01

00.00 00.00 00.00

00.00

00.00

6.008.00

05 06

02

07

03

08

04

01

Behind blade program

10.00

Figure 16. Rendering of Sample Program

8. Using the Keypad, enter the value for the first cut.

• Use the Down arrow to proceed to and enter

the next cut value.

• Continue this process until all cut values are

entered.

9. After the last cut value has been entered, key in a

value of 0.00. This signifies the end of your program

and will return the Back Gauge to your first cut value

position.

Figure 17. 00 Signies End of Program

10. Press the Enter button once to signify program

is complete and press Enter again to return the

machine to the home screen and auto setup for the

first cut of your program.

• The first step is highlighted.

• You are now ready to begin your job.

11. Make the first cut by simultaneously pressing the

Clamp Cut and Cut buttons until it finishes cutting.

01

10.00

00.00 00.00 00.00

00.00

00.00

6.008.00

05 06

02

07

03

08

04

01

Behind Blade program

• The Back Gauge then moves to the second step

cut position, which is highlighted on the LCD.

Figure 18. Operating the Machine

• Once all cuts in the program have been completed,

the Back Gauge and LCD return to the rst step in the

program.

12. Press the Set button to exit the program.

13. Press the arrow to select the mode used in the

program and press the Enter button.

• The program number blinks.

14. Use the Up or Down arrow to select program 00.

15. Press the Enter button.

16. Press the “C” button.

• The cutter is back in manual mode.

Page 19

Page 7-1

ProCut 20P – Installation and Operating Instructions

7. oPerator MaIntenance

carInG For the Procut 20P

The only maintenance required by the operator is to

perform what is described in this section. Perform

only

the routine maintenance procedures referred to

in these instructions.

WARNINGS:

• Before performing maintenance on the machine,

turn the Circuit Breaker and Switch to OFF.*

• Do not attempt to repair the machine. Refer

service to qualied service personnel.

• Do not lift, tilt, or attempt to move the machine.

You can be severely injured or crushed.

Failure to observe these warnings could result in

severe personal injury or death.

*If rotating or replacing the Cut Stick, see the

instructions, shown below, before turning the

machine OFF.

CAUTIONS:

• Do not place materials on the table or near the

Cutting Blade other than paper.

• Do not cut through metal objects such as paper

clips or staples.

• Do not allow foreign objects to fall into the working

area of the machine.

Failure to observe these cautions could result in

damage to the machine.

cleanInG the PaPer cutter

At the end of the day or project, clean up all waste

and extra scraps off the working table.

cut stIck rotatIon and rePlaceMent

The Cut Stick provides a clean cut as the Cutting

Blade makes contact with it. When the Cut Stick is

badly abraded and the paper is not cut cleanly, either

rotate or replace the Cut Stick. The Cut Stick can be

rotated to provide eight cutting surfaces.

1. Turn the Circuit Breaker and Switch to OFF.

2. Insert the Stick Removal Tool into the end of the

Cut Stick and pull up.

Figure 19. Cut Stick Removal Tool

3. From the front of the machine, lift the Cut Stick

out of the groove.

WARNING: Keep ngers and hands clear of

the Cutting Blade. Failure to observe these

warnings could result in severe personal injury.

Figure 20. Cut Stick Removal

4. Do one of the following:

• Rotate the Cut Stick

• Turn the Cut Stick end-to-end

• Replace the Cut Stick if all eight surfaces

are abraded.

5. Put the Cut Stick back into the groove of the

machine, making sure that both ends are level

with the Working Table.

6. With the machine powered ON, press the Reset

button.

• The Cutting Blade and Clamp move to home

position.

Blade rePlaceMent

The Cutting Blade can be sharpened for re-use

or replacement. The blade should be sharpened

professionally. It will need to be sharpened or

replaced under any of the following conditions.

• Media is cut poorly

• Cutting sounds abnormal

• After approximately 2,000 cuts

CALL YOUR LOCAL SERVICE TECH OR DEALER

FOR BLADE REMOVAL OR SHARPENING.

WARNING: Do not attempt to service the

Cutting Blade. Failure to observe these warnings

could result in severe personal injury.

Page 20

ProCut 20P – Installation and Operating Instructions

Page 7-2

Blade dePth adJustMent

If the Cutting Blade does not cut through the paper,

the blade may need to be adjusted or the Cut Stick

may need to be changed. See “Cut Stick Rotation

and Replacement”.

The blade can be adjusted up to approximately

.9 inch (23mm). Adjustment is made with a number

6mm hex wrench on the upper right corner of the

machine above the Cutting Blade housing.

Insert a number 6mm hex wrench in the blade

adjustment hole and turn the screw clockwise. Rotate

45 degrees, or a quarter turn, then check for proper

cutting.

• Counter-clockwise raises the blade

• Clockwise lowers the blade

Figure 21. Blade Adjustment

At the end of its useful life, your product is considered to

be Waste Electrical and Electronic Equipment (WEEE).

As such, it is important to note that:

• WEEE is not to be disposed of as unsorted

municipal waste. It is to be collected

separately such that it can be disassembled so

its components and materials can be recycled,

re-used, and recovered (burned for energy

content in electricity production).

• Public collection points have been set up by

municipalities for the collection of WEEE, free

of charge to you.

• Please return your WEEE to the collection

facility nearest your home or office.

• If you have difficulty locating a collection

facility, the retailer that sold you the product

should accept your WEEE.

• If you are no longer in contact with your

retailer, please contact ACCO for assistance

with this matter.

• Recycling of WEEE is geared toward

protecting the environment, protecting

human health, preserving raw materials,

improving sustainable development, and

ensuring a better supply of commodities in

the European Union. This will be achieved by

retrieving valuable secondary raw materials

and reducing the disposal of waste. You can

contribute to the success of these goals by

returning your WEEE to a collection facility.

• Your product is marked with the WEEE

symbol (wheelie bin with an X through it). This

symbol is to inform you that WEEE is not to be

disposed of as unsorted municipal waste.

Page 21

Page 8-1

ProCut 20P – Installation and Operating Instructions

There are eight functions which are as follows:

Function Name &

Rendered Drawing

Description When to Use

Behind Blade Program

01 00.00

00.00 00.00 00.00

00.00

00.00

00.0000.00

05 0602070308

04

00

Behind blade program

Behind Blade cutting

used in program setup.

When doing large jobs with multiple cuts.

In Front Blade Program

01

00.00

00.00 00.00 00.00

00.00

00.00

00.0000.00

05 0602070308

04

00

Front blade program

In Front Blade cutting

used in program setup

.

When doing large jobs with multiple cuts.

Unit of Measurement

01 00.00

00.00 00.00 00.00

00.00

00.00

00.0000.00

05 0602070308

04

inch

Units

Measurements can be in

millimeters or inches

.

Use either option depending on personal preference.

Buzzer Mode

Mute

01 00.00

00.00 00.00 00.00

00.00

00.00

00.0000.00

05 0602070308

04

x

Ability to turn on/off the

audio warning for the

Safety Curtain.

You are turning off an audible warning for a safety

feature, use at your own discretion.

Reblading Mode

Blade change mode OFF

01 00.00

00.00 00.00 00.00

00.00

00.00

00.0000.00

05 0602070308

04

Service mode used when

replacing the blade.

CALL YOUR LOCAL SERVICE TECH OR DEALER

FOR BLADE REMOVAL OR SHARPENING

.

Reset Service adjustment to

optimize performance.

Used by the Service Technician.

Count Value

01 00.00

00.00 00.00 00.00

00.00

00.00

00.0000.00

05 0602070308

04

000715

Total count

Provides the total cuts

performed during the

lifetime of the machine

.

After approximately 2,000 cuts the blade should be

sharpened.

Clamping Force

01 00.00

00.00 00.00 00.00

00.00

00.00

00.0000.00

05 0602070308

04

5Press

Numeric value of

pressure applied to the

media by the Clamp.

When the paper is pulling out from under clamp during

cutting process or if too much pressure being applied

is leaving clamp marks on the media.

01 00.00

00.00 00.00 00.00

00.00

00.00

00.0000.00

05 0602070308

04

OFF

Reset

8. FunctIon values

Page 22

ProCut 20P – Installation and Operating Instructions

Page 8-2

chanGInG FunctIon values

Once the Function is selected, enter the value by

pressing the Up or Down arrow keys.

1. Press the Set button once to access the

Functions. Use the Up or Down arrows to

scroll through the Functions.

2. When the desired Function is highlighted on the

LCD, press the Enter button again.

• The value is highlighted.

01 00.00

00.00 00.00 00.00

00.00

00.00

00.0000.00

05 06

02

07

03

08

04

00

Behind blade program

Figure 22. Value to Change

3. Press the Up or Down arrow keys to change

the value.

• Each time the arrow key is pressed the

changed value is displayed.

4. Press Enter when your desired value is shown.

01

12.50

00.00 00.00 00.00

00.00

00.00

5.258.75

05 06

02

07

03

08

04

24

Behind blade program

Figure 23. Value Highlighted

Page 23

Page 24

© 2015 ACCO Bran ds. All rights res erved. ACCO® is a registered tradem ark of

ACCO Bran ds. GBC® is a registered trad emark of General B inding Co rporation.

1729247 Rev. A 2015/03

ACCO Brands Canada

5 Precidio Court

Brampton, ON L6S -6B7

800.263.1063

www.gbccanada.com

ACCO Mexicana

Neptuno # 43, Colonia Nu eva Industrial

Vallejo

Delagac ion Gustavo A. Madero, CP 07700

México, D F. (55) 1500 5578

www.accomexico.mx

ACCO Brands

4 Corporate Drive

Lake Zurich, IL 60047

In USA call 800.772.9281

www.gbcconnect.com

Loading...

Loading...