LIMITED LIABILITY COMPANY "AVTOZAVOD "GAZ"

(LLC "AVTOZAVOD GAZ")

VALDAI

VEHICLES FAMILY

OPERATING INSTRUCTIONS

331043902111 ИЭ

RUSSIA

NIZHNIY NOVGOROD

2

Introduction

"VALDAI" vehicles are intended for transportation of goods over differ

ent roads in moderate climate conditions at the ambient air temperature from

plus 45° C to minus 45° C.

1) Service Book for 'VALDAI' vehicle is attached to this Operating Instructions.

"VALDAI" vehicles family presented in this Operating Instructions com

prises the following models:

GAZ33104 vehicle — 4x2 type with threeseat cabin.

GAZ331041 vehicle — 4x2 type with threeseat cabin and extended wheel

base.

GAZ331043 vehicle — 4x2 type with sixseat cabin and extended wheel

base.

The manufacturer reserves the right to constantly alter its vehicle design,

therefore some units and parts may slightly differ from those described in this

Operating Instructions.

You can surely expect reliable operation of the vehicle provided you ob

serve maintenance schedule specified in this Operating Instructions and Serv

ice Book1).

3

1.VEHICLE IDENTIFICATION DATA

Identification number of the vehicle (VIN) and identification numbers of

cabin or allmetal body, engine and cargo body vehicle chassis refer to the ve

hicle identification data.

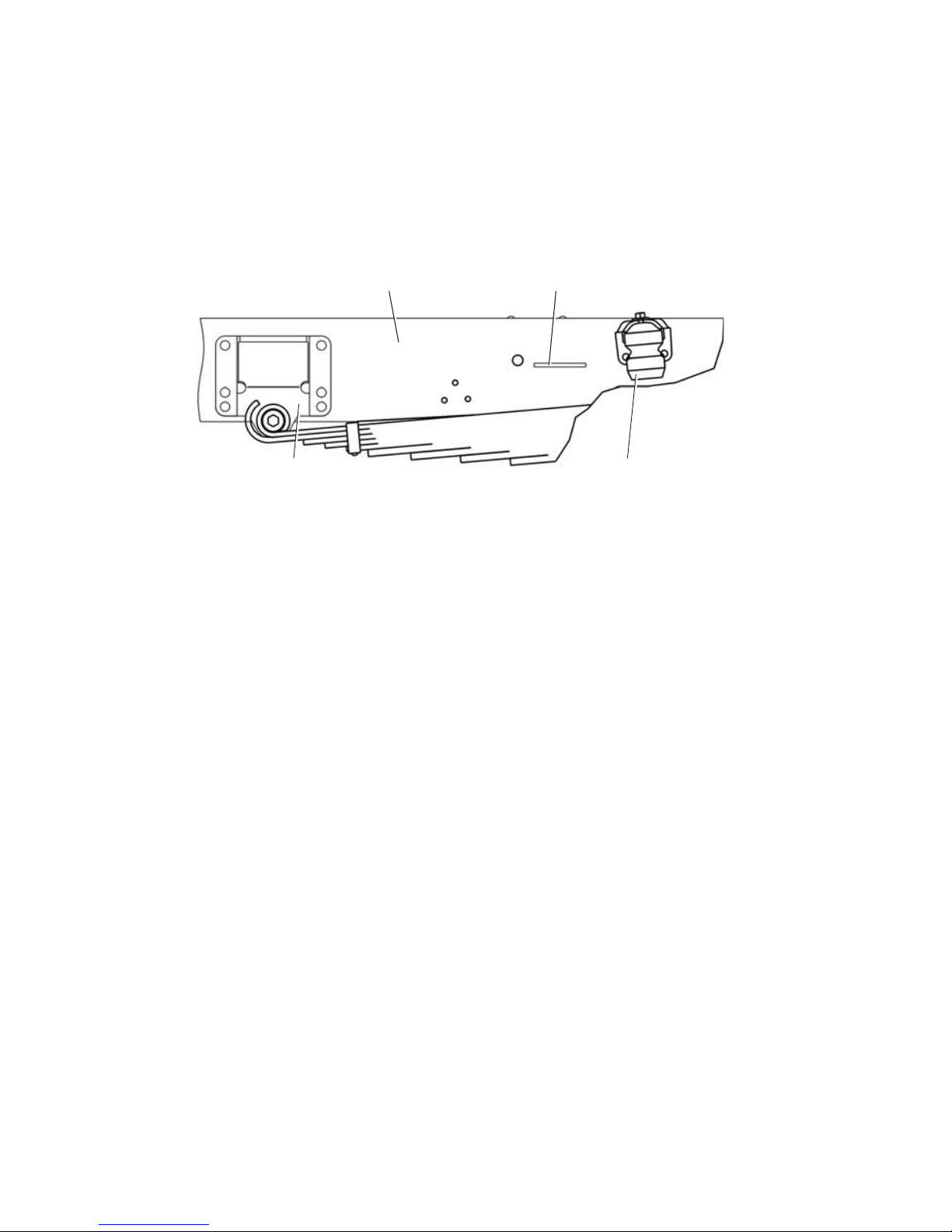

Vehicle Identification Number (VIN) appears on the right frame side

member before the rear spring front bracket (Fig.1.1).

Fig. 1.1. Location of VIN or Chassis Number:

1 — rear spring rear bracket; 2 — frame side member, right; 3 — location of identification number;

4 — rubber restraint cushion

Example of Vehicle Identification Number:

X96 33104050000125, where:

X96 — manufacturer international identification code,

331040 — vehicle index,

5 — model year code,

0000125 — vehicle serial number.

Model year is a period equal on the average to calendar year during which

the vehicles with identical design features are being manufactured.

Chassis identification number is marked on the right side member of the

frame of cargo body vehicles intended for supplying to other plants for manu

facturing special vehicles (Fig. 1.1).

Example of Chassis Number:

33104050000125, where:

331040 — chassis index,

5 — model year code,

0000125 — chassis order number.

Cab identification number is located under the hood on the front outer

panel, on the left in direction of vehicle movement (see Fig. 1.2, arrow "A"

view).

1 4

3

2

4

Example of Cab (Body) Number:

33104050000125, where:

331040 — cabin index

5 — model year code,

0000125 — cabin serial number.

Fig. 1.2. A — Location of Cab Identification Number

Д245.7 E2 engine number is stamped on the nameplate (Fig. 1.3) located

on the cylinder block in the middle portion on the righthand side.

Fig. 1.3. Д245.7 E2 Engine Nameplate

The nameplate contains the following data:

a — engine index;

b — engine serial number

Vehicle identification data also appear on manufacture's plate (Fig. 1.4)

located on the rear pillar of the cab right door.

Chassis, cab and engine numbers refer to the identification data of chassis

and special configuration vehicles for supplying to the other plants for making

their own special vehicles having their own index. Nameplate "GAZ" is not

installed and vehicle identification number does not appear on chassis and the

above vehicles.

5

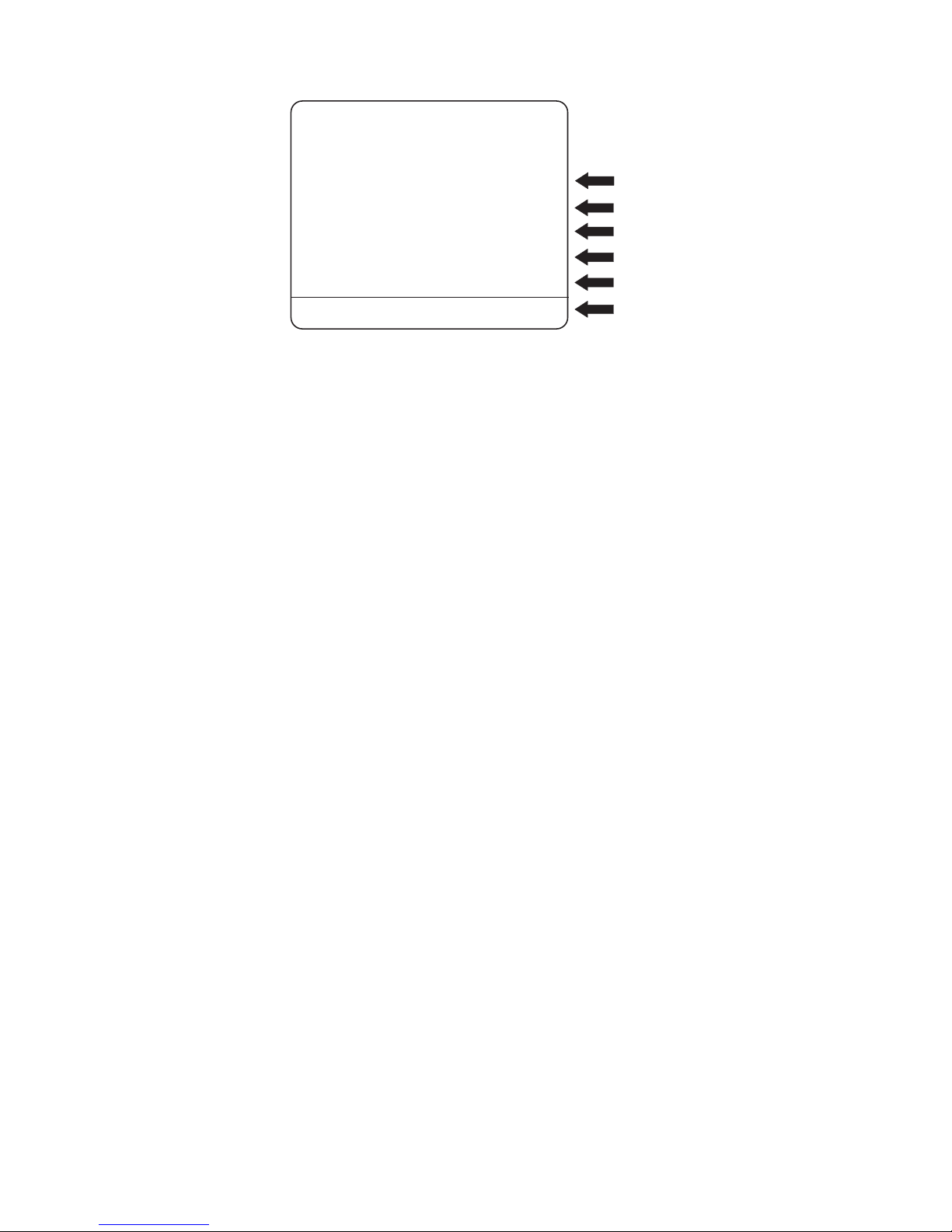

Fig. 1.4. Manufacture's Plate with Vehicle Identification Data, where:

a — vehicle identification number;

b — gross vehicle weight;

c — gross vehicle weight with trailer;

d — maximum front axle weight;

e — maximum rear axle weight;

f — engine index

2. USEFUL HINTS

1. Procedure of engine starting is described in section 6.2. "Engine Start

ing and Stopping".

After cold engine starting do not run it immediately at high speed because

cold oil passes slowly to rubbing surfaces and they may be got damaged at the

engine high speed.

2. The engine efficient performance and its wear mostly depend on engine

operating temperature. It is necessary to maintain coolant temperature within

the limits of 80–95° C. At the ambient air temperature of 5° C and below in

stall cold weather radiator cover.

3. Do not operate the starter continuously for more than 15 seconds. For

the second attempt of engine starting, allow not less than 30 seconds. Not more

than three engine starting attempts are permissible. Should the engine fail to

fire after these attempts, check the starter power circuits, the starter itself, the

engine fuel system and the storage battery for good condition.

Never move the vehicle using the starter and turn on the starter with the

running engine.

4. After cold engine starting do not run it at high speed. Warm the engine

up at 10001400 rpm. Never drive the vehicle with cold engine. Coolant tem

perature before starting movement should be not less than 40° C.

X96

Д-245.7Е2

33104050140794

7500 кг

-кг

2400 кг

1-

2-

540 кг0

a

b

c

d

e

f

LLC AUTOMOBILE PLANT GAZ““”

ENGINE

6

5. If the engine has been operated at heavy duty cycle let it run for 3 min

utes at idle speed before stopping to decrease smoothly the temperature of tur

bocharger to avoid its premature damage.

6. To prevent damaging of the gearbox when towing the vehicle, discon

nect the propeller shaft flange from the axle drive. Then fix reliably the dis

connected end of the propeller shaft via a wooden block to the vehicle nearest

frame element.

7. Do not eliminate free axial displacement of steering arm pin ball head as

to drag link because the travel equal to 3,4 mm with the shutdown engine is

required for power steering drive proper operation.

8. To avoid dislocating of relative position of the steering gear and steer

ing wheels, never set out the adjustment of the drag link length (except for the

cases specified in given Operating Instructions).

9. To avoid overheating of power steering drive system, do not run the en

gine for a long time at high speed (more than 30 minutes) when the vehicle is

at parking place.

10. With operating engine do not keep the steering wheel turned as far as

it will go for more than 15 sec. because it may cause damage of the power steer

ing pump. Never start the engine with power steering tank empty or insuffi

cient oil level.

11. When the ambient air temperature is below 35° C fill the power steer

ing system with special liquid (see subsection "Lubrication Chart").

12. Watch out for tightness of air pipelines, cylinders and pneumatic valves.

Break of air tightness reduces braking efficiency.

13. To avoid storage batteries failure, timely switch over regulated volt

age level.

14. If any of the red pilot lamps lights up on the instrument cluster or buzzer

operates on the run, stop the vehicle, detect and eliminate the trouble.

15. The brake pads are to be replaced at service stations only.

3. SAFETY PRECAUTION RULES

Strictly follow the safety precaution rules during vehicle operation.

Never warm up the engine in the enclosed space. The engine exhaust gases

contain toxic end product of fuel combustion, monoxide carbon including (gas

without fume and color), which, when inhaling, causes severe intoxication and

it may even lead to fatal case. It is also not recommended to turn on the pas

senger compartment ventilation at parking place with the operating engine.

7

4. SPECIFICATIONS

4.1. GENERAL DATA

Vehicle model GAZ33104 GAZ331041 GAZ331043

Vehicle type Biaxial, cargo, with rear axle drive

Vehicle capacity, kg:

— with cargo body without canvas top 3605 3445 3150

— with cargo body and with canvas top 3500 3330 3045

Vehicle gross mass, kg 7400 7400 7400

Vehicle kerb mass, kg:

— with cargo body without canvas top 3500 3730 3800

— with cargo body and with canvas top 3605 3845 3905

Overall dimensions, mm

— length 6050 7565 6770

— width (over mirrors) 2643 2643 2643

— height (over cabin, unladen) 2260 2260 2265

— height (over canvas top, unladen) 3060 3060 3060

Wheelbase, mm 3310 4000 4000

Front wheels track, mm 1740 1740 1740

Rear wheels track (between centres of twin tyres),

mm 1701 1701 1701

Ground clearance, fully laden, mm 177 177 177

Minimum turning radius (front outer track), not

more, m 6,4 7,7 7,7

Maximum speed with full load without trailer on

flat, smooth highway, km/h 95 95 95

Fuel consumption1) when running with constant

speed, l/100km:

— 60 km/h 13,5 13,5 13,5

— 80 km/h 18,0 18,0 18,0

Overhang angles (fully laden), deg.:

— front 27 27 27

— rear 14 10 14

Maximum climable gradient for fully laden vehicle,

% (degree) 25 (14) 25 (14) 25 (14)

Cargo body loading height, mm 1070 1070 1070

4.2. ENGINE AND ITS SYSTEMS

Model D245.7 E2

Type Diesel, 4stroke, with turbocharger, with

supercharged air cooling, liquid cooling

Number of cylinders and their arrangement 4, vertical inline

Cylinders firing order 1—3—4—2

Direction of crankshaft rotation right

1) The fuel consumption specified is not considered to be a rate but serve only for determining

of vehicle technical state.

8

Cylinder bore and piston stroke, mm 110x125

Displacement, l 4.75

Compression ratio 17

Rated power, net, kW (h.p.), not less:

at 2400 min1 engine speed 86.7 (117.2)

Maximum torque, net, N•m (kgf•m):

at 13001600 min1 engine speed 413 (42.1)

Minimum engine idle speed, min

1

800

Maximum idle speed limited by governor, min1,

not more 2600

Ventilation system open

Fuel injection pump Inline, 4plunger, valve type, 7732005

(ЯЗТА) with full range rpm governor and

booster fuel pump

Booster fuel pump Plunger type, for manual and automatic

fuel priming

Injectors ЯЗДА 455.111201050, closed type;

injection point pressure 23,5+1.2MPa

(230 kgf/cm2)

Fuel filters:

— coarse filter Gravitation filter with gauze element

— fine filter With paper renewable filter element

Oil system Combined: under pressure and spraying

Oil cooler Fullflow, constantly operating

Oil filter Fullflow, with renewable filter element

Cooling system Liquid, closed, with forced coolant circula

tion, with expansion tank

Supercharging system Gas turbine, with one turbocharger C14

with radial centripetal turbine, centrifugal

compressor and air cooler of supercharging

air of secondary surface type

4.3. TRANSMISSION

Clutch Singleplate, dry, friction type, with torque

vibration damper on driven plate. With di

aphragm pressure spring. With hydraulic

drive

Gearbox Mechanical, 5speed, with constant gear

mesh, with synchromesh unit on II and III,

IV and V gears

transmission ratios:

— 1st gear 6.555

— 2nd gear 3.933

— 3d gear 2.376

— 4th gear 1.442

— 5th gear 1.000

— reverse gear 5.735

Cardan drive Two open type divided propeller shafts,

three universal joints on needle bearings

9

Final drive Bevel, hypoid type

— transmission ratio 3.417

Differential Bevel, geartype

Axle shafts Full floating

4.4. RUNNING GEAR

Frame Stamped, riveted

Wheels Disk type, with 6,00x17,5 rim

Tires Pneumatic, radial, size 215/75R17,5

Front wheel geometry:

— camber Max. 1°

— pivot transverse inclination 8°

— lengthwise inclination of king pin 5°

— toein (of every wheel to vehicle longitudinal

axis) 7"±3"

Springs Four, longitudinal, semielliptic with ad

ditional springs in rear suspension

Shock absorbers Hydraulic, telescopic, dual acting. Mount

ed on the front axle

4.5. STEERING SYSTEM

Type of steering gear Screwball nut

— transmission ratio 19.8 (in the middle position)

Power steering Hydraulic, integrated, built in steering gear.

Power steering pump is a geartype. НШ14

Steering column Height and tilt adjustable

4.6. BRAKE SYSTEM

Service brake system Doublecircuit, with pneumatic drive

Brake gears Disk type

Emergency brake system Each circuit of service brake system

Parking brake system With pneumatic drive of brake chambers

with spring energy accumulators installed

on rear wheel disk brakes

4.7. ELECTRICAL EQUIPMENT

Wiring system Single wire. Negative terminals are connect

ed to vehicle frame

Rated voltage, V 12

Alternator A/C, with builtin voltage regulator and

rectifier block, 1631.370110

Storage battery Two (6CT 110A)

Starter AZS 3385"Искра"

Headlamps 62.371119

10

Turn indicator repeaters 5302.3726000 or 112.03.30.00.00001

Front marker lights 265.3712

Rear lights 7442.3716.00011 or 8502.371601

Side marker light 4472.3731

Headlamp aiming device control unit БУК24 or 281.3769 or 231.3769

Engine control switch 2126370401050 or 2108370401080

Windshield wiper 60.5205 or 70.5205

Windshield washer 1202.5208, 1102.5208

Horns 22.3721/221.3721

4.8. CABIN AND CARGO BODY

Cabin Metal, three— or sixseat

Cargo body Metal, with rear flap and body sides

Cargo body dimensions (inner), mm: GAZ33104 GAZ331041 GAZ331043

— length 3494 5000 3494

— width 2176 2176 2176

— body side height 518 518 518

4.9. MAIN ADJUSTMENT AND CHECKING DATA

Clearance between valve stems and rocking levers

on cold engine, mm

— intake 0,25

— exhaust 0,45

Oil pressure (at oil temperature of 80–85° C), kPa

(kgf/cm2):

— at rated engine speed 2400 min

1

250–350 (2.5–3.5)

— at minimum idle speed 80 (0.8)

Rated engine coolant temperature, °C 80–95

Minimum engine idle speed, min

1

800

Variable voltage, V 13.3–14.9

Fan and alternator belts sag under 4 daN (4 kgf), mm 12–17

Clutch pedal free travel, mm 10–30

Clutch pedal full travel, mm 190

Brake pedal free travel, mm 9–16

Total play of steering wheel in the position corres

ponding to vehicle straightforward run with run

ning engine, deg., not more 101); 25

Tire air pressure, kPa (kgf/cm2)

— front wheels 530

+10

(5.4

+0.1

)

— rear wheels 620

+10

(6.3

+0.1

)

1) For the vehicle within warranty period.

+0,05

–0,10

+0,05

–0,10

11

5. CONTROLS AND INSTRUMENTS

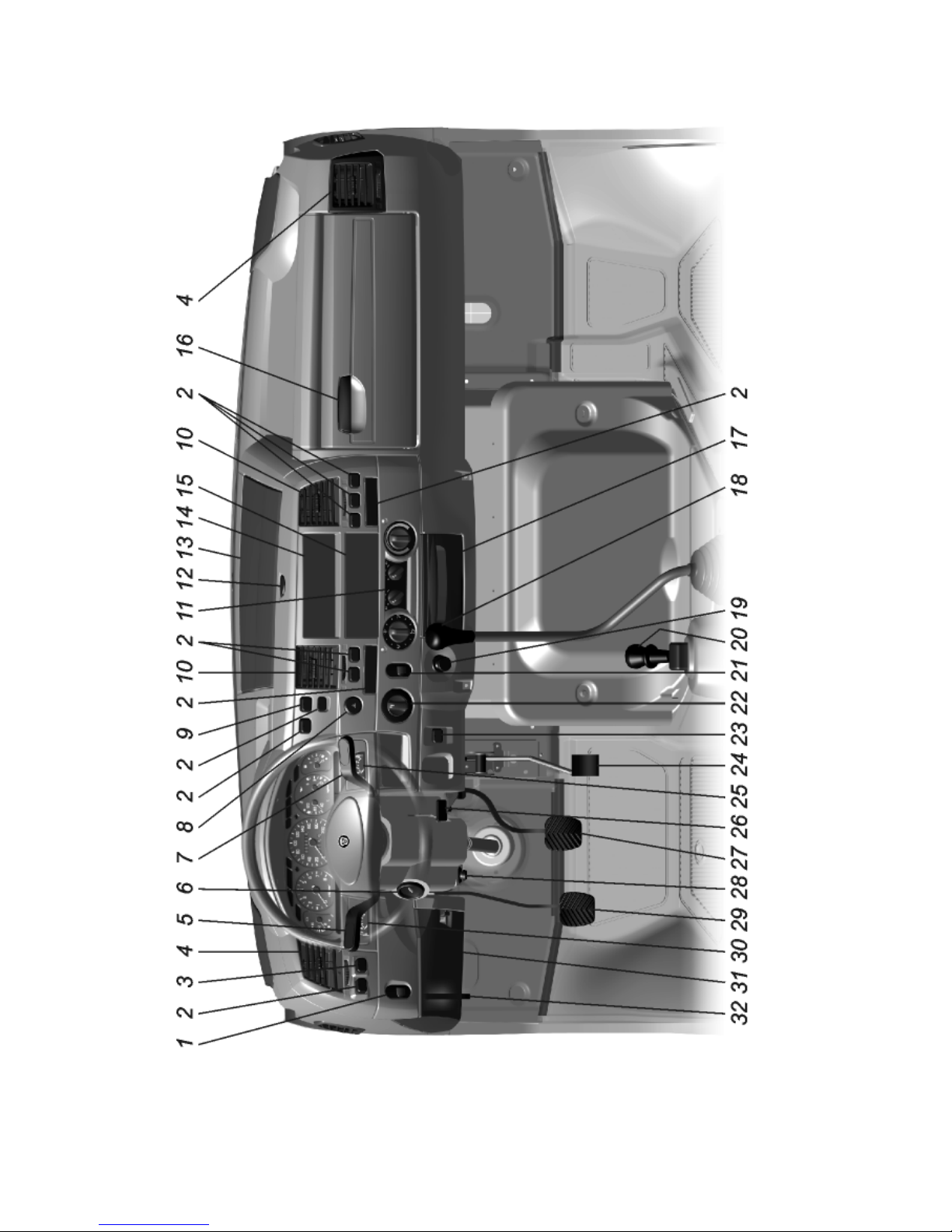

Fig. 5.1. Controls

12

Positions of controls are given in fig. 5.1.

1 — headlamp aiming device control knob depending on vehicle loading

(see subsection 8.5).

2 — plugs.

3 — warning lamps condition checkup switch.

4 — side ventilation grids.

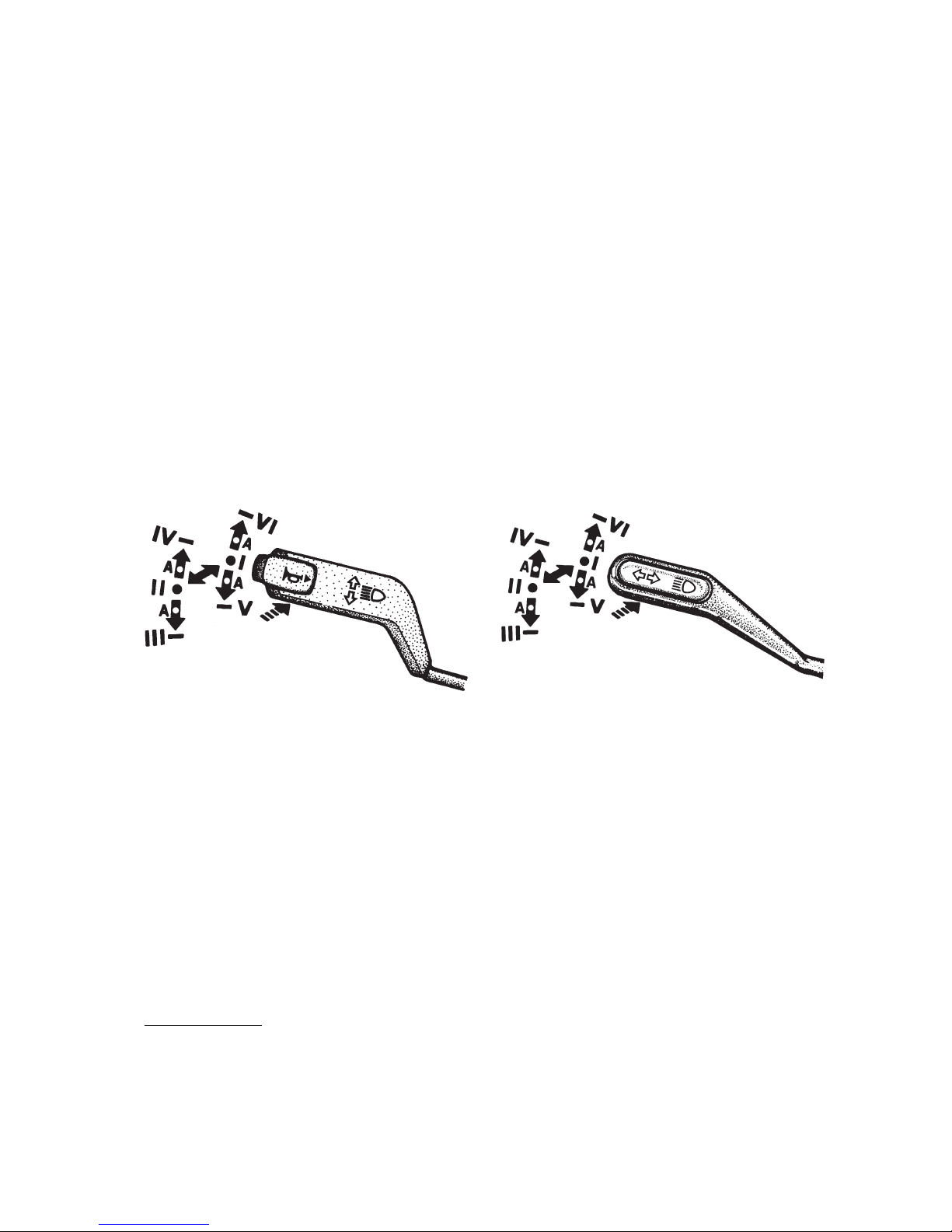

5 — turn indicators, dimmer and horn1) switch lever. The switch lever

has six fixed positions (from I to VI) and four nonfixed positions "A" (fig. 5.2

and 5.3).

If the lever is in position I, and master light switch knob 22 — in position

II, the lower beam is on. When the lever is moved to position II upper beam is

switched on and blue indicator lights up.

Pulling the lever repeatedly from position I along the steering column (non

fixed position) switches on headlamp upper beam for a short time. Depressing

the switch lever button (in any position of the lever) turns on the horn1) (non

fixed position) — see fig. 5.2.

1) On some of the vehicles the horn is switched on by means of windshield wiper and washer

control lever (see Fig. 5.6).

Fig. 5.3. Turn indicator and dimmer

switch lever (without horn)

Fig. 5.2. Turn indicator and dimmer

switch lever (with horn)

To operate turn indicators move the lever from positions I or II up to posi

tions VI or IV (right turn) or down to positions V or III (left turn). A green

warning light comes on flashing on the instrument cluster.

After the turn is completed the switch lever is automatically returned to

position I or II. To switch on turn indicators momentarily shift the switch le

ver to suitable "A" nonfixed position. When released the lever returns to po

sition I or II.

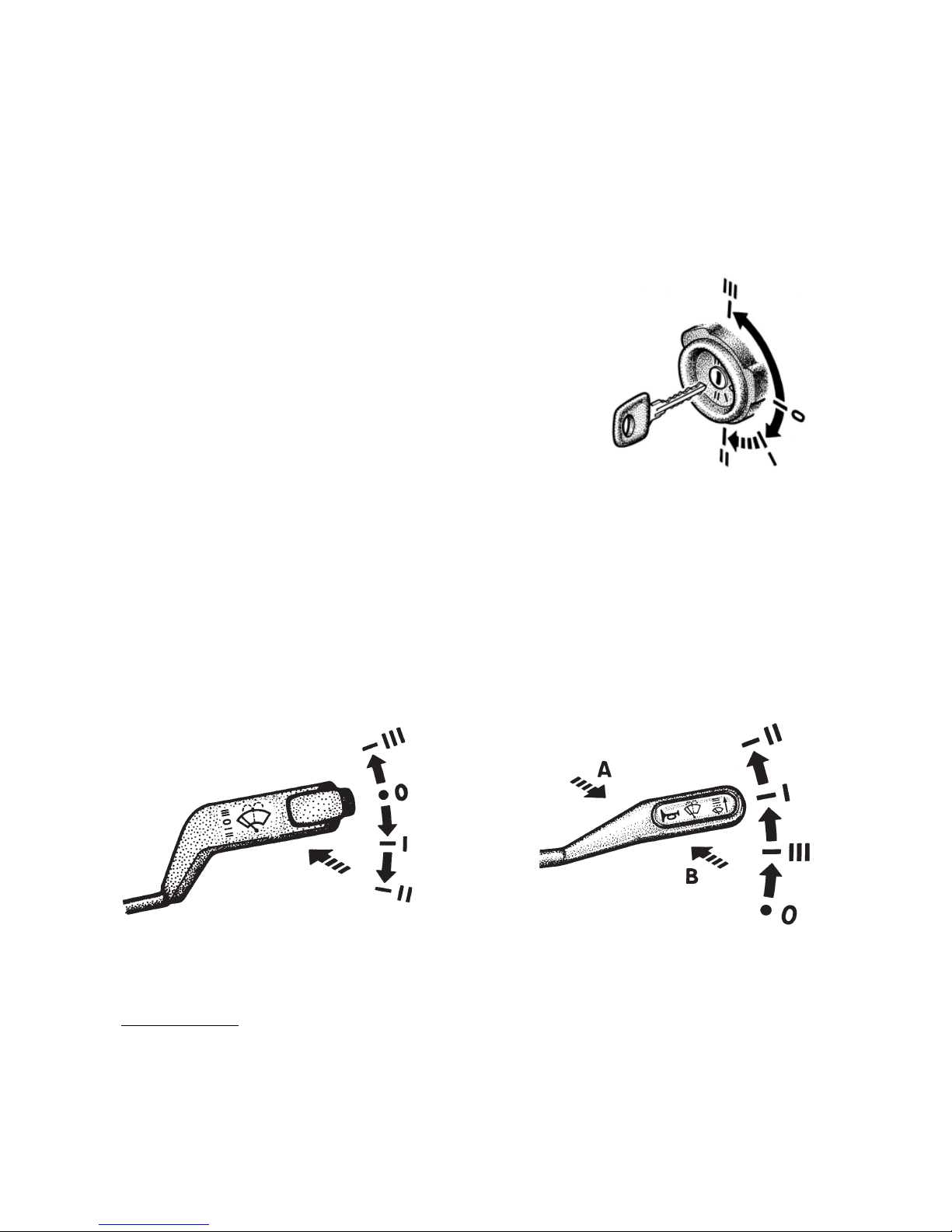

6 — engine control, starter and antitheft device switch.The key posi

tions are given in fig. 5.4:

13

0 — all Off, the key cannot be pulled out, antitheft device is not engaged;

I — engine control switch is On; the key cannot be pulled out;

II — engine control switch and starter are On; the key cannot be pulled out;

III — engine control switch is Off; when the key is withdrawn, the anti

theft device is engaged.

To release the antitheft device fit the key, then gently swinging the steer

ing wheel to both sides turn the key to position 0.

Fig. 5.4. Engine control, starter and antitheft

device switch.

7 — windshield wiper, washer and horn 1) switch lever.

The positions of the lever (fig. 5.5 and 5.6):

0 — windshield wiper is OFF;

I — low speed of windshield wiper;

II — high speed of windshield wiper;

III — intermittent operation of windshield wiper.

In case the control lever is not equipped with horn switch (fig. 5.5), to

turn on windshield wiper and washer momentarily pull the lever (in the direc

tion of the arrow) from position 0.

Fig. 5.6. Windshield wiper and

washer lever positions (with horn)

Fig. 5.5. Windshield wiper and

washer lever positions (without horn)

1) On some of the vehicles the horn is turned on by turn indicators and dimmer switch lever

(see Fig. 5.2).

14

In case the control lever is equipped with horn switch (fig. 5.6), to turn on

windshield wiper and washer momentarily push the lever from position 0 in

the direction of arrow "A" and to turn on the horn pull the lever (from any

position) in the direction of arrow "B".

Windshield washer can be also switched on from all lever positions. Wind

shield wiper operates only when the engine control switch is on.

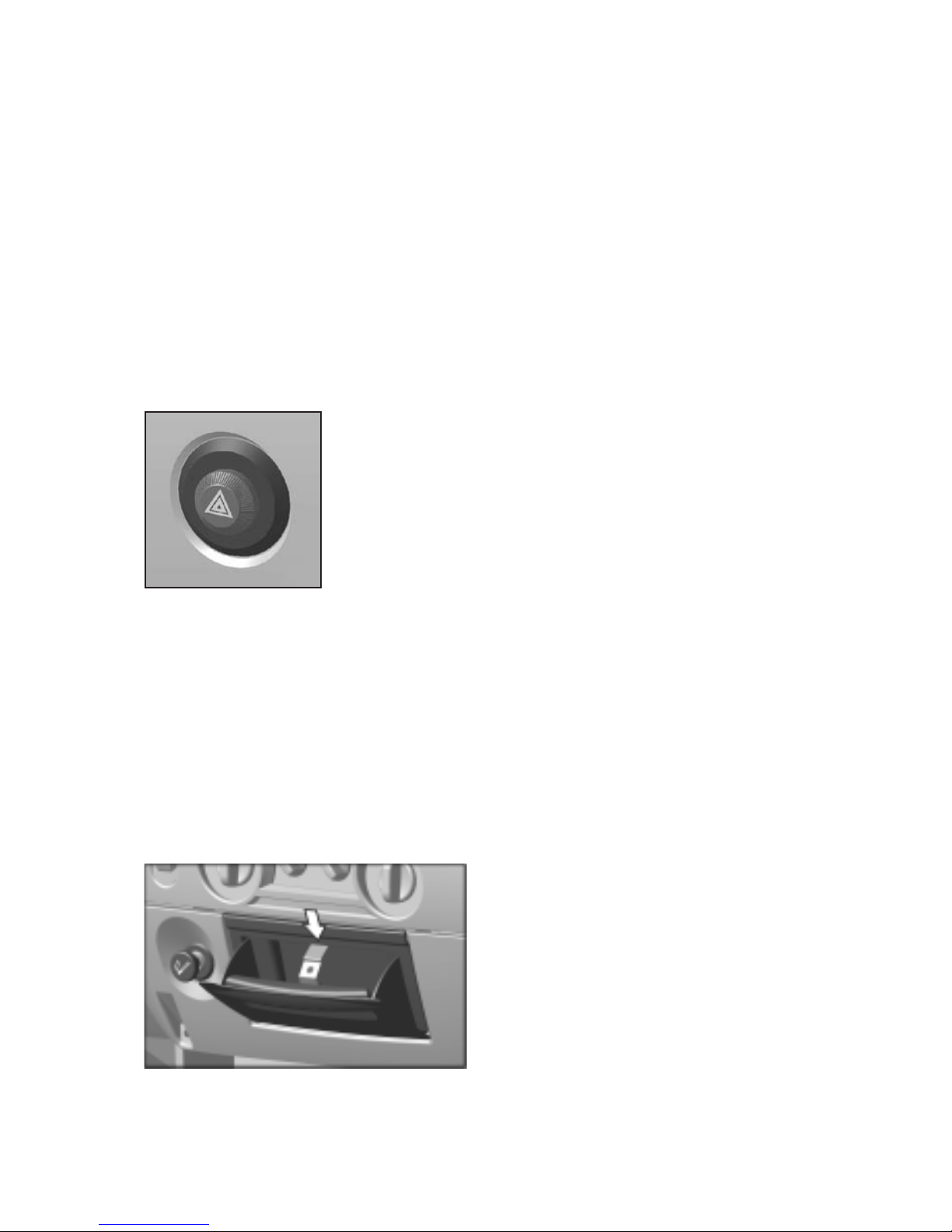

8 — emergency flasher warning system button switch. When in switched

on position all turn indicator bulbs and red bulb inside the button switch

(fig. 5.7) are flashing simultaneously.

Emergency flasher warning system should be switched on in case of vehi

cle accidental stop in order to inform other drivers and maintenance services

about stationary vehicle on the roadway.

Fig. 5.7. Emergency flasher warning system button

switch.

9 — rear row seats dome lamp switch of the cab (for vehicles with two

rows of seats).

10 — central ventilation grids.

11 — heating and ventilation control panel.

12 — lock button for documents box cover.

13 — documents compartment cover.

14 — space for radio set/cassette player.

15 — plug.

16 — glove box lock handle.

17 — ashtray. Removal of ashtray is shown in fig. 5.8.

Fig. 5.8. Ashtray

15

To empty the ashtray pull it, push spring catcher upwards and remove the

ashtray from its slot. Fit the ashtray back liftingup the spring catcher.

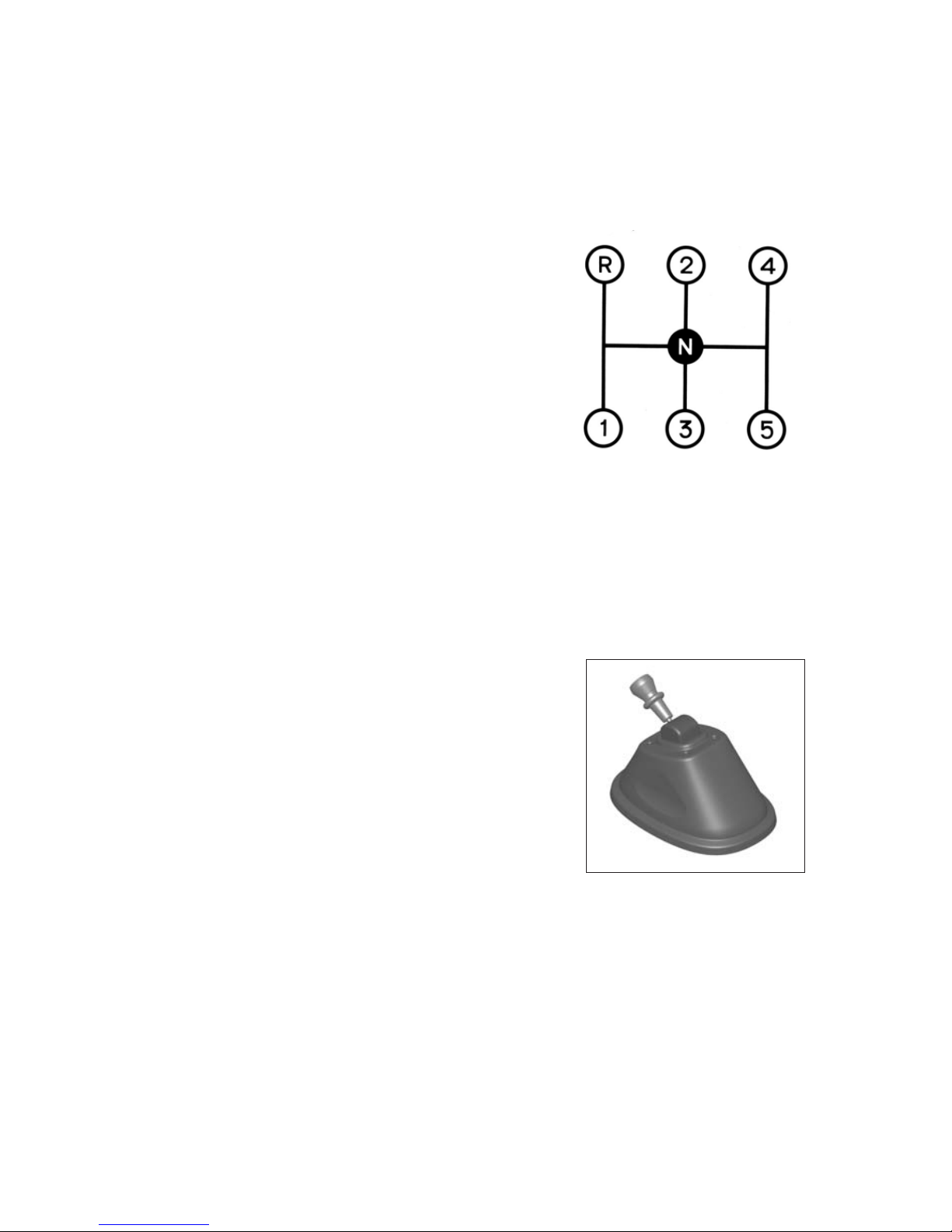

18 — gearbox lever.

Engage reverse gear only after full stop of the vehicle. When reverse gear

is engaged the backing light goes on in the tail lamps.

Fig.5.9. Changeover layout:

19 — cigarette lighter. To use the lighter, push its handle and release it.

The lighter kickout with a click means that the coil is hot. Do not reuse the

lighter sooner that in 30 s.

20 — parking brake lever. For braking the vehicle pull the brake control

lever up. If the engine control switch is on warning lamp 9 (fig. 5.14) is flash

ing on the instrument cluster. For releasing the brake pull up the control lever

lock coupling. With the brake released the warning lamp goes out.

Fig. 5.10. Parking brake lever

21 — instrument lighting control knob.

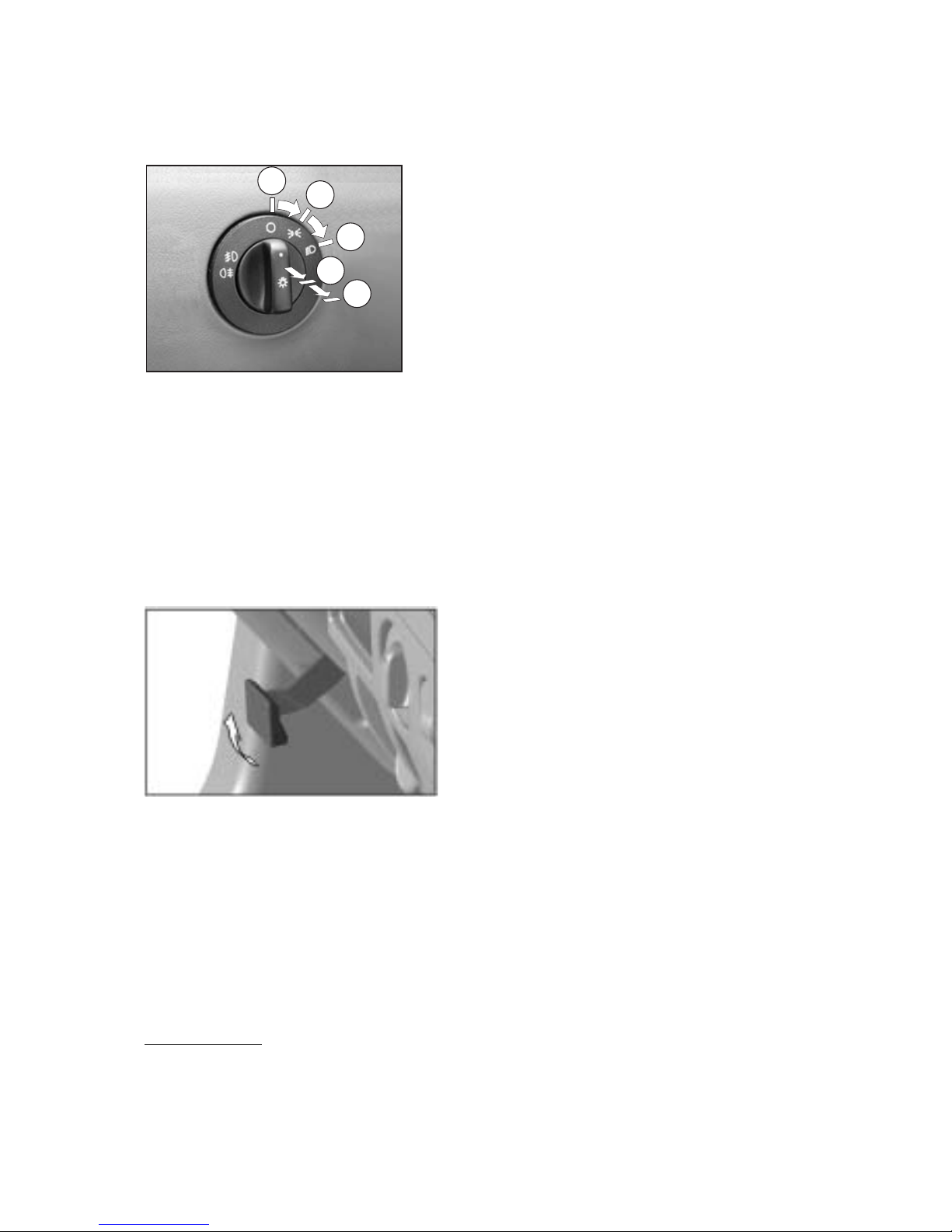

22 — master light switch. The switch has five fixed positions (fig. 5.11):

0 — all external lighting is OFF.

I — clearance lights, instrument cluster lighting, rear license plate lamp

and some electrical equipment controls lighting is ON.

II — additionally upper or lower beam is ON depending on the position of

turn indicators and dimmer switch lever (position I or II correspondingly).

16

III — additionally (from position I or II) front fog lamps1) are ON.

IV — additionally (from position III) rear fog light is ON.

1) Mounted on some of the vehicles

Fig. 5.11. Positions of master light switch

handle.

0

I

II

III

IV

23 — ABS diagnostics button.

24 — accelerator pedal.

25 — brakes rear circuit pressure gauge.

26 — steering column adjustment control lever (fig. 5.12). Pulling the

lever and moving it upwards (within the limits of 90°) results in releasing of

the steering column. After that the steering wheel can be set in the handy po

sition for a driver and locked in this position by setting the lever to the initial

position.

Fig. 5.12. Steering column adjustment

control lever.

27 — service brake pedal.

28 — storage battery remote button switch.

29 — clutch pedal.

30 — brakes front circuit pressure gauge.

31 — fuse blocks.

32 — hood release lever. To open the hood pull lock handle to release the

catch of the lock and open the hood slightly, then push the handle back home.

17

To open the hood completely, move aside the latch mounted on the lower

front edge of the hood (fig. 5.13).

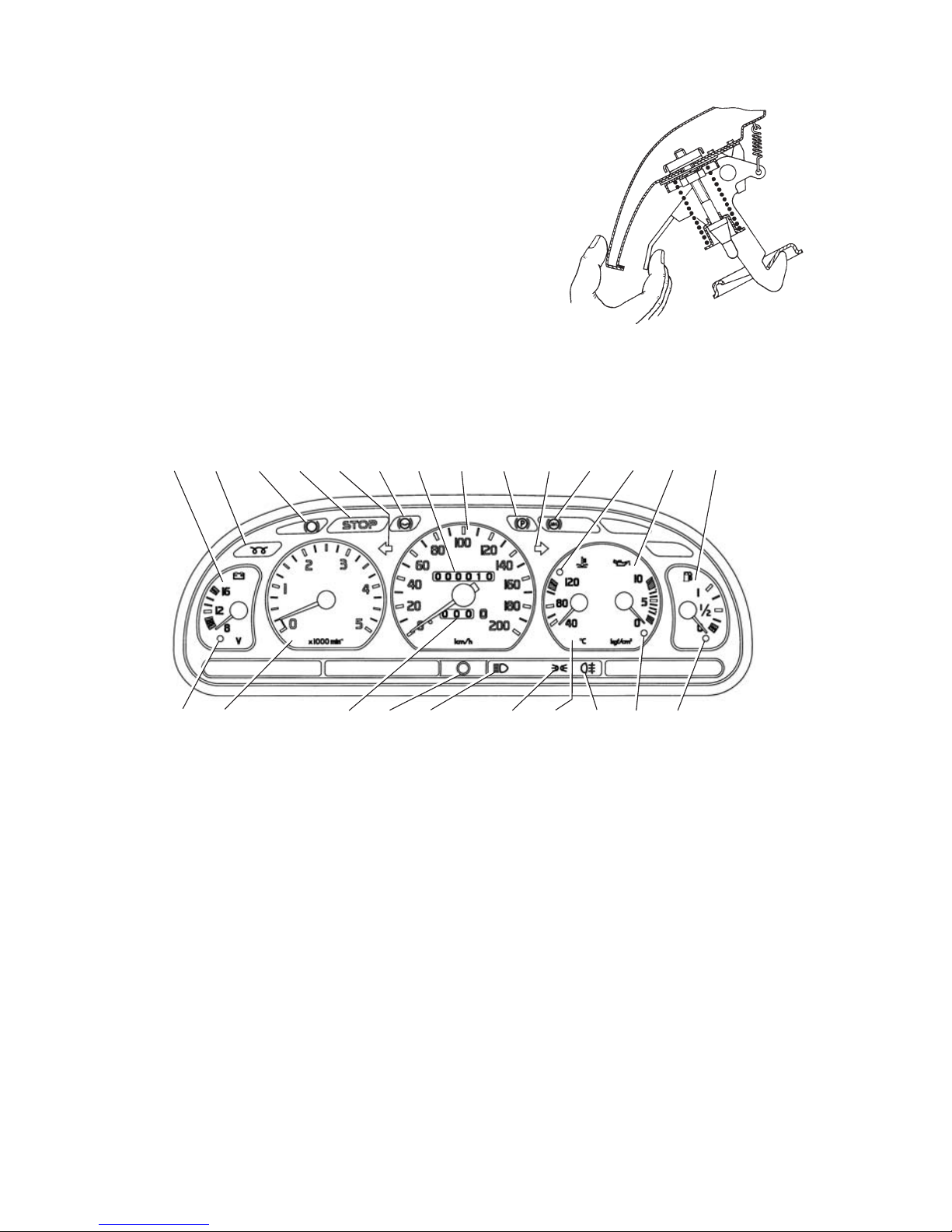

Arrangement of instruments is shown in Fig. 5.14.

Fig. 5.13. Releasing of hood latch.

Fig. 5.14. Instrument cluster.

1234567891011121314

15161718202122

192324

1. Voltmeter.

2. Warning lamp (orange) of glow plugs cuttingin.

3. Warning lamp of brake linings wear.

4. Warning lamp (red) "STOP".

5. Warning lamp (green) of left turn indicators.

6. Reserve warning lamp.

7. Total distance counter.

8. Speedometer.

9. Warning lamp (red) of parking brake engagement.

Starts flashing after turning on the engine control switch, when the park

ing brake is engaged.

18

10. Warning lamp (green) of right turn indicators.

11. Warning lamp (red) of antilock brake system (ABS) malfunction.

12. Warning lamp (red) of engine overheating.

If the lamp lights up shut down the engine and eliminate the reason of over

heating.

13. Oil pressure gauge.

14. Fuel gauge.

15. Warning lamp (orange) of low fuel level in the tank. It lights up,

when less than 10 liters of fuel remain in the tank.

16. Warning lamp (red) of oil pressure drop. Lights up when the engine

control switch is turned on. Should the lamp light up under normal conditions,

shut down the engine immediately and check oil level in the crankcase.

17. Warning lamp (orange) of rear fog light turning on.

18. Coolant temperature gauge.

19. Warning lamp (green) of clearance light turning on.

20. Warning lamp (blue). Lights up when upper beam is on.

21. Trip distance counter reset button.

22. Trip distance counter.

23. Tachometer.

24. Warning lamp (red) of storage battery discharge.

19

6. Doors, Seats and Seat Belts

Doors. To open the door from outside, pull handle 2 (Fig. 6.1). The doors

are equipped with locks that can be locked from outside with key inserted in

lock release 3.

From inside the doors are locked by pushing down button 1.

To open the door from inside pull handle 4 with lock button 1 pulled up only.

Fig. 6.1. Cab Doors

1 — button; 2 — handle; 3 — lock release; 4 — handle

Never drive the vehicle with opened or partially closed doors.

Seats. For seating convenience the

driver seat is adjustable. By turning

handle 2 (Fig. 6.2) the seat can be

moved in lengthwise direction. Re

quired seat backrest tilt is adjusted by

rotation handwheel 3.

For driver's convenience seat tilt is

also adjusted by means of nuts 1.

GAZ331043 vehicle is equipped

with the second row of seats — two

doubleseat passenger seats.

Fig. 6.2. Driver Seat

1 — adjusting nut; 2 — locking handle; 3 —

backrest tilt handwheel.

20

To gain access to the rear passenger seats, the front passenger seat to be

moved in the direction of the driver seat. This seat shifting mechanism is simi

lar to that of the driver's seat. Before driving the vehicle shift the passenger

seat to the extreme right position by all means, otherwise safety belt will be

ineffective.

Seat belts are effective equipment to protect the driver and any passen

gers from severe injury in road accidents.

Vehicles are equipped with two types of seat belts. Inertia reel type with

three anchorage points for driver and passengers of single and outer seats as

well as lap type with two anchorage points for passengers of centre seats. Ad

justment of the inertia reel type belts is not required. As for the lap type belts,

personal adjustment of its length is necessary because intimate mating of web

bing to hips must be ensured. Changing of webbing length is performed by

means of regulator.

To fasten the belt (Fig.6.3) it is necessary to pull the belt webbing slow

ly by the tongue over the shoulder and across the chest and push it into the

buckle nearest the wearer; a click will indicate that the belt is locked.

Upper portion of the belt should pass across the centre of the shoulder so

that it is not resting on your neck or under the arm and must have intimate

mating with the upper part of your body.

Fig. 6.3. Fastening by Seat Belt

Lap portion of the belt should be positioned as low on the hips as possible.

Otherwise release the belt and adjust its length.

To release the belt, press the red panel on the buckle. The belt will auto

matically retract to its stowed position.

Pregnant women should also wear the seat belt. But she should position

the lap portion of the belt low so that it does not come across the abdomen.

21

Warning!

The belts which underwent critical loading in a road accident or they became

frayed, cut and had other damages must be renewed by new ones in assembly.

Never make any changes in the seat belt design.

Never attempt to use the seat belt for more than one person.

Keep hard or fragile objects such as glasses, fountain pens away from the

belt as they may inflict additional injuries.

The belt should not be squeezed or twisted. Keep sharp edges of the objects in

vehicle passenger compartment away from the belt.

If dirty, clean the belt with mild soap and lukewarm water only. Never iron

the belt webbings.

22

7. New Vehicle Runningin

The runningin duration is specified as 1000 km. During this period the

vehicle requires special care and special servicing as well as the following rec

ommendations should be strictly adhered to:

1. After starting until loading the engine, let it run for 2–3 minutes first at

minimum idle speed with the gradual increase up to 1500 rpm.

2. To avoid premature wear of units and parts the vehicle speed should not

exceed 60 km/h.

3. Do not overload the engine. The vehicle load must not exceed 3000 kg.

Driving the vehicle with trailer is prohibited. Besides, driving the vehicle over

tough roads, deep mud and so on should be avoided during this period.

4. Watch the condition of all fastening joints of the vehicle. Loose nuts

should be timely tightened up. Particular emphasis should be placed upon se

curing of pitman arm, propeller shaft wedges, steering knuckle arms, tie and

drag link joints, spring Ubolts, wheels and silencer intake pipes flanges.

5. During runningin period tandem transportation of the vehicles (or their

chassis) by their partial loading of one on the other is permitted when deliver

ing to customer in selfpropelled way over the road of improved type.

In such way of transportation the storage batteries of the trailing vehicle

should be removed and carried on the master vehicle. Then it is necessary to

disconnect propeller shaft flange from axle drive gear and undo screws "А" of

energy storage batteries (see Fig. 8.1).

During runningin period carry out all vehicle maintenance works speci

fied in section "Runningin" of the service book.

23

8. Vehicle Operation

8.1. ENGINE STARTING

8.1.1. Starting of cold engine

Prior to engine starting check coolant level in engine cooling system and

oil level in engine crankcase. When starting from cold, glow plugs bolting in

stalled in cylinder heads turn on automatically.

Engine cold starting is carried out in the following sequence:

1. Turn on the storage batteries switch.

2. After the longterm (for several days) parking before starting the en

gine it is recommended to prime the fuel by hand fuel priming pump.

3. Move the gearshift lever into the neutral position.

4. Depress the clutch pedal all the way down.

5. Turn engine starter key to position I (instrument cluster and engine con

trol system — ON). In doing so red warning lamp in the oil pressure gauge and

warning lamp of turning on glow plugs bolting will illuminate.

6. When warning lamp goes out switch on the starter (for not more than

15 seconds) turning the key to nonfixed position II (instrument cluster and

starter are switched on).

7. Once the engine starts release the key, which will automatically return

to position I. Red warning lamp in the oil pressure gauge goes out.

8. Release the clutch pedal.

Should the engine fail to start it is necessary to make another attempt re

peating the above procedures. Allow not less than 1 minute before the second

attempt. After the third unsuccessful attempt, find and eliminate the trouble.

Do not run the engine at idle speed for more than 15 min.

Load the engine (start driving the vehicle) when the coolant temperature

in the cooling system reaches 40° C.

Start the engine from cold with 15W/40 oil at the ambient air tempera

ture not lower than minus 15° C. When filling the engine with lowviscous

thickened oils of type М4/8П, 5W/40, 5W/50 cold starting temperature may

be lowered up to minus 25° C.

Starting of the warm engine should be carried out in the same sequence,

as the starting of the cold engine, in so doing it is not necessary to disengage

the clutch.

24

8.1.2. Starting of cold engine at low temperatures

At ambient air temperatures below –25° C (when the engine filled with

lowviscous oil) and below –15° C (when the engine filled with winter grade

oils) the following methods of engine warmingup are recommended prior to

engine starting:

a) engine heating with hot water. With the drain cock of the cylinder block

opened, hot water of 70–80° C is being poured in the radiator until water tem

perature reaches 30–40° C in the engine cooling system and warm water flows

from the drain cock. It is recommended to pour the water into the system swiftly

and continuously. To avoid water freezing in the engine radiator, hood the grill

with the radiator cover.

b) filling the engine with hot oil. In this case drain oil from the engine into

clean dishware. The oil should be heated up to 70–80° C and poured into the

engine right before starting.

Never start and run the engine with the empty cooling system. At long

term parking to avoid radiator and engine freezing, drain water from the cool

ing system and watch that all water was drained and it did not freeze in the

radiator and cylinder block drain cocks. For this purpose prick the cocks. To

expedite water drain from the system, open the radiator filler cap. When wa

ter is drained leave the cocks open.

8.1.3. Engine Stopping

Prior to engine stopping let it run for 3–5 min. at medium speed and then

at idle speed so as to reduce the temperature of coolant, oil and turbocharger.

To stop the engine release the accelerator pedal, turn off the instruments

with the key and battery switch.

8.2.VEHICLE DRIVING

It is recommended to start vehicle driving with the engine warmed up. If

there is no such possibility and the engine is warming up on the moving vehi

cle it is advisable at low temperature of ambient air and after prolonged park

ing to drive some time at low gears and low engine speed. As oil warms up it is

necessary to shift to higher gears in succession.

After wading, driving through heavy rain or after washing the vehicle brak

ing surfaces become coated with moisture. This will affect braking efficiency

until disks, drums and brake linings are dried by intermittent light application

of the brakes.

25

When moving over the pools it is necessary to lower the speed to avoid

hydroplaning, which may cause skidding and loss of control; the danger in

creases with the tires worn.

Drive the vehicle where possible without sharp acceleration and decelera

tion for this will lead to the increasing tires wear and higher fuel consumption.

To provide long and troublefree operation of the gearbox, observe the fol

lowing requirements, which will guarantee easy and noiseless gear shifting:

1. When shifting the gears, move the lever smoothly having first completely

disengaged the clutch. Too quick gear shifting will result in premature wear of

synchromesh gears or their breakdown. To increase useful life of the synchro

mesh gears it is recommended to shift from the higher to the lower gear using a

double clutch method with the intermediate increase in the engine speed with

the gearshift lever in the neutral position. Never try to change gears if the clutch

is not disengaged completely. Do not operate the pedal and the lever simulta

neously.

2. Do not engage the clutch if the gear is not changed completely.

8.3. BRAKING AND PARKING

Pneumatic disk brakes ensure steady braking efficiency. Nevertheless brake

the vehicle smoothly avoiding abrupt braking.

Do not turn off the instruments and do not remove the engine control

switch key whilst the vehicle is in motion. With the engine stopped the com

pressed air pressure drops in the brake system receivers as well as the ABS is

deactivated.

Moreover with the key removed the steering shaft will become locked by

the antitheft device and this will result in the loss of vehicle control.

In case one of the brake system circuits goes out of order the second cir

cuit provides the vehicle braking. When the parking brake is engaged, its re

leasing is possible by mechanical means only.

To provide towing of the broken vehicle it is necessary to remove screws

"A" of emergency brake release (see Fig. 8.1).

Fig. 8.1. Vehicle emergency brake release

26

When stopping the vehicle on upgrade or slope, it is necessary to engage

the parking brake and shift, respectively, into the first or reverse gear.

To avoid freezing of the brake pads to the disks after a long driving over a

wet road at sharp temperature variations, it is necessary to dry the pad linings

by smooth braking when moving to the parking place.

8.4. HEATING AND VENTILATION OF THE CAB

Heating

Fig. 8.2. Heating and ventilation control panel:

1 — handle of air distribution control in the cab:

— air flow is directed to the windscreen and door windows;

— air flow is directed to the chest of the driver and passenger;

— air flow is directed to the windscreen and door windows, to the

chest and feet of the driver and passenger;

— air flow is directed only to the feet of the driver and passenger.

2 — control handle of air amount supplied to the cab. It has four positions:

— off;

— slow speed of the blower;

— normal speed of the blower;

— fast speed of the blower.

27

3 — handle of air temperature control in the cab (passenger compartment).

The handle extreme left position (wide part of the blue symbol) activates the

ventilation mode. The intermediate and extreme right positions (wide part of

the red symbol) activate the heating mode.

Defrosting and Demisting

To remove quickly frost and condensate from the windscreen and door win

dows do the following:

— turn handle 1 (Fig. 8.2) of air distribution control to position of direct

ing air to the windscreen and door windows;

— turn handle 3 of air temperature control to the extreme right position

(wide part of the red symbol);

— turn handle 2 of air amount control to the fast speed of the blower.

To achieve a favourable climate in the cab (passenger compartment):

— turn handle 1 of air distribution control to the chosen position;

— set the air temperature you prefer (temperature of outside air or hot air

from the heater) by turning handle 3 of air temperature control;

— turn handle 2 of air amount control from position to one of the three

positions to get the desirable rate of air flow coming to the passenger compart

ment.

Central and side ventilation grids on the instrument panel have handles

(levers) for shutters control. Shifting of them changes the direction of air flow,

increases or decreases the amount of air coming to the passenger compartment

or completely closes the channel of air supply.

Ventilation

Fig. 8.3. Distribution of Air Flows in the Vehicle Cab

Cold or warm air

To cut in the ventilation:

— turn handle 3 (fig. 8.2) to the extreme left position (wide part of the

blue symbol);

28

— choose the mode of air distribution by turning handle 1;

— turn handle 2 to get the desirable rate of the air flow coming to the pas

senger compartment;

— adjust the direction of air flows by turning the shutters of ventilation

grids.

To make heating and ventilation effective be sure that the grid of the hole

for air intake located on the hood before the windscreen is free from leaves,

snow, etc.

8.5. LIGHTING AND LIGHT SIGNALING DEVICES

Caution! Headlampblock with marking ОАО "ОСВАР" lenses are made of

plastic material. That is why never use fuels and other aggressive fluids, as well

as dry brushes and wiping waste for cleaning from dust and dirt.

Remove the dirt from these parts with water jet only.

Headlamps. To replace dipped beam and clearance lamp bulbs it is neces

sary to remove rubber cover 3 (Fig 8.4).

To replace main beam bulb remove rubber covers 3 and 5, and unscrew

connector 1 to replace turn indicator bulb.

Knob 2 is designed to adjust the direction of light beam in horizontal plane.

Vertical adjustment of the light beam is carried out through opening 4 using

hexagon spanner or crosshead screwdriver.

Fig. 8.4. Headlampblock

1 — connector; 2 — light beam horizontal adjust

ment knob; 3 and 5 — rubber covers; 4 — opening

for light beam vertical adjustment

Additional vertical adjustment of the dipped beam depending on vehicle

loading is performed from the cabin by means of the headlamp aiming device

control unit handwheel.

On an unladen vehicle it is necessary to make "0" on the handwheel coin

cident with "•" mark on the control unit housing.

On a fully laden vehicle it is necessary to make "4" on the handwheel coin

cident with "•" mark on the control unit housing.

29

Adjust the headlamps in the following sequence:

— check air pressure in tires. Bring it, if necessary, to the required level;

— place the unladen vehicle on a level ground at 5 m distance from the

screen (Fig.8.5);

— bring "0" on the handwheel into coincidence with the mark on the hous

ing of the headlamp aiming device control unit;

— turn on the dipper beam;

— adjust the light beams by knobs 2 (Fig. 8.4) and through opening 4 for

each headlamp in turn.

Caution! When fitting a halogen bulb in the headlamp, do not touch the

bulb glass with the fingers to avoid luminous flux reduction or bulb rapid de

struction during its operation.

Fig. 8.5. Screen Layout for Headlamps Adjustment:

A — headlamps with "AL" marking on the lenses; B — headlamps with "ОСВАР" marking on

the lenses; h — height of vehicle headlamp dipper beam center; Y–Y — vehicle axis;

The horizontal section of light and shade border of adjusted headlamps must

coincide with line X–X (Fig. 8.5A, 8.5B), the inclined section of the light and

shade border must correspond to Fig. 8.5A (with "AL" marking on the lenses)

and Fig. 8.5B (with "ОСВАР" marking on the lenses), and the points of hori

zontal and inclined sections of the light and shade border intersection must

coincide with G–G and D–D lines.

Turn indicators and hazard light. The vehicle is equipped with electronic

flasher unit of turn indicators and hazard light, which also monitors pilot lamps

serviceability.

If, when switching on the turn indicator, pilot lamp flashes two times fast

er it means that one of the turn indicator bulbs from the vehicle right or left

side is faulty (loose connection or blowing out).

If turn indicator pilot lamp does not illuminate but turn indicator bulbs

are in good repair, the pilot lamp should be checked for serviceability.

30

If, when switching on the turn indicators, its bulbs and pilot lamp do not

light it means that fuse or turn indicator flasher unit (or its circuit) are faulty.

Tail lamps. The vehicle is provided with the tail lamps including: braking

lights, clearance lights, turn indicator lights, backing lights and fog lights.

The provision is made to install a separate fog lamp on buses and vans.

The set of horns 22.3721/221.3721 is installed under the hood on the up

per panel of the radiator cowl.

Carry out fine adjustment of the horn sound, if required. For this purpose

loosen the lock nut of the screw located on the rear side of the horn. Adjust the

sound by turning the screw to the one or the other side. Tighten the lock nut.

8.6. FUSES

Under the hood on the right there is a fuse box БПР4. 90A fuse protects

glow plugs control circuit and alternator circuit.

40 A fuse protects lighting circuit of the vehicle. 60 A fuse protects engine

shutdown solenoid control circuit.

60 A fuse (utmost) protect general positive circuit of the vehicle.

On the left two fuse boxes БПР13 are installed under the instrument

panel.

БПР13 Fuse Boxes

Upper fuse box fuses protect the circuits of:

1. 25A — ABS control unit.

2. 15A — hazard light.

3. 14A — frame switch, radio and cassette player.

4. 10A — windscreen wiper, windscreen washer.

5. 10A — headlamps relay.

6. 10A — braking lights.

7. 20A — horn, horn relay, cigarette lighter.

8. 20A — main heater, heater electric pump.

9. 15A — auxiliary heater.

10. 10A — instrument cluster, boozer, backing light, speed sensor, windshield

wiper relay.

11. 5A — ABS control unit.

12. 15A — dryer relay, starter locking relay, glow plugs control unit, fan elec

tric coupling, engine shutdown solenoid.

13.10A — turn indicators, headlamps relay.

31

Lower fuse box fuses protect the circuits of:

1. 25A — spare.

2. 15A — right headlamp main beam.

3. 15A — left headlamp main beam.

4. 10A — right headlamp dipper beam.

5. 10A — left headlamp dipper beam.

6. 10A — fog lamps, fog lamps pilot lamp.

7. 20A — spare.

8. 20A — spare.

9. 15A — under hood lamp, driver dome lamp, dome lamp of the second row

seats.

10. 10A — illumination (instruments, switches, cigarette lighter).

11. 5A — spare.

12. 15A — right clearance light, headlamp aiming device, licence plate lamp,

glove box lamp.

13. 10A — left clearance light, clearance pilot lamp, marker light on the cab

roof.

Note: Vehicles are provided with the set of spare fuses. A fuse puller is

available in the set of the spare fuses to assist removal of the faulty fuse. The

electric circuits protected by the fuses are also shown on schematic electrical

diagram.

8.7. GENERATOR SET

The vehicle is equipped with AC alternator with builtin rectifier and in

tegral voltage regulator. Maximum current output of alternator is 65A.

During operation check the generator set functioning using voltage indi

cator installed in the instrument cluster.

Basic operation rules

1. Never interconnect the voltage regulator and the alternator leads, and

connect them to the ground even for a short time because it will cause the volt

age regulator failure.

2. Never run the engine with the storage battery disconnected.

3. Never start the engine with the alternator + lead disconnected for it will

cause the generation of high voltage on the alternator rectifier dangerous for

the rectifier diodes.

4. It is prohibited to check the alternator and regulator circuit for good

condition by continuity test using megohmmeter or indicator lamp powered

32

from network exceeding 36 V. Carry out wire insulation check using megohm

meter or lamp powered from network exceeding 36 V when alternator and reg

ulator semiconductor devices are disconnected only.

5. Do not allow the direct water splashing on the alternator and regulator

during vehicle washing.

6. When servicing the alternator brush assembly it is necessary to:

— wipe brush holder and the brushes with clean cloth soaked in gasoline;

— check brushes consistency, absence of their jamming in the brush hold

ers and reliability of their contact with collector;

— brushes worn up to 8 mm are subject to replacement.

8.8 STARTER

The starter is a DC serieswound electric motor with the drive consisting

of a drive gear and a backlash roller clutch. The starter is engaged with the use

of the engine control switch key.

Maintenance service of the starter reduces to periodical checking of start

er and wires fastening and cleanout of dirt.

Starter operation instructions:

1. It is forbidden to set the vehicle in motion by the starter. It may result

in failure of the starter. In case of emergency it is allowed to move the vehicle

for not more than 5 m.

2. In winter do not persist in starting the cold engine by cranking it with

the starter for a long time without preliminary heating of the engine. This may

lead to failure of the starter and storage battery.

8.9. ANTILOCK BRAKE SYSTEM

The vehicles are equipped with antilock brake system (ABS) made by

"KNORRBREMSE". ABS is effective in case of emergency braking on the

roads with diverse road surface (example: asphaltice) and it prevents locking

of the wheels being in the least favorable road adherence condition (on the

ice) ensuring minimum braking distance of the vehicle for this road surface

(ice) while maintaining its stability and response.

Attention!

To get the best effect during emergency braking of the vehicle using ABS

it is necessary to press the brake pedal with maximum effort pushing the clutch

pedal simultaneously.

The electrical part of the ABS consists of 4 speed sensors (located in the

vehicle's wheel assemblies), 3 input choppers (on vehicle frame), control unit

33

(CU) of ABS (in cabin at the right under the instrument panel), ABS diag

nostic button (in the middle of the instrument panel), ABS failure warning

lamp (on the right in the instrument cluster) and ABS harness connecting sen

sors and input choppers with ABS CU.

Two supply circuits are connected to ABS CU: for input choppers via 1st

25A fuse in the upper fuse block and direct for ABS CU via 11th 5A fuse in the

upper fuse block.

The instrument cluster is provided with the warning lamp. It lights up for

several seconds each time the engine control switch is turned on and then goes

out. It evidences that ABS system circuits connected to ABS CU are in sound

condition. If the warning lamp lights continuously or it lights up during vehi

cle movement it indicates that ABS circuits went out of order (but service brake

system maintains serviceability as if without ABS). ABS failure warning lamp

is also lights up automatically at constrained disconnection of supply socket

from ABS control unit.

When ABS failure is confirmed the troubleshooting should be carried out

at service station.

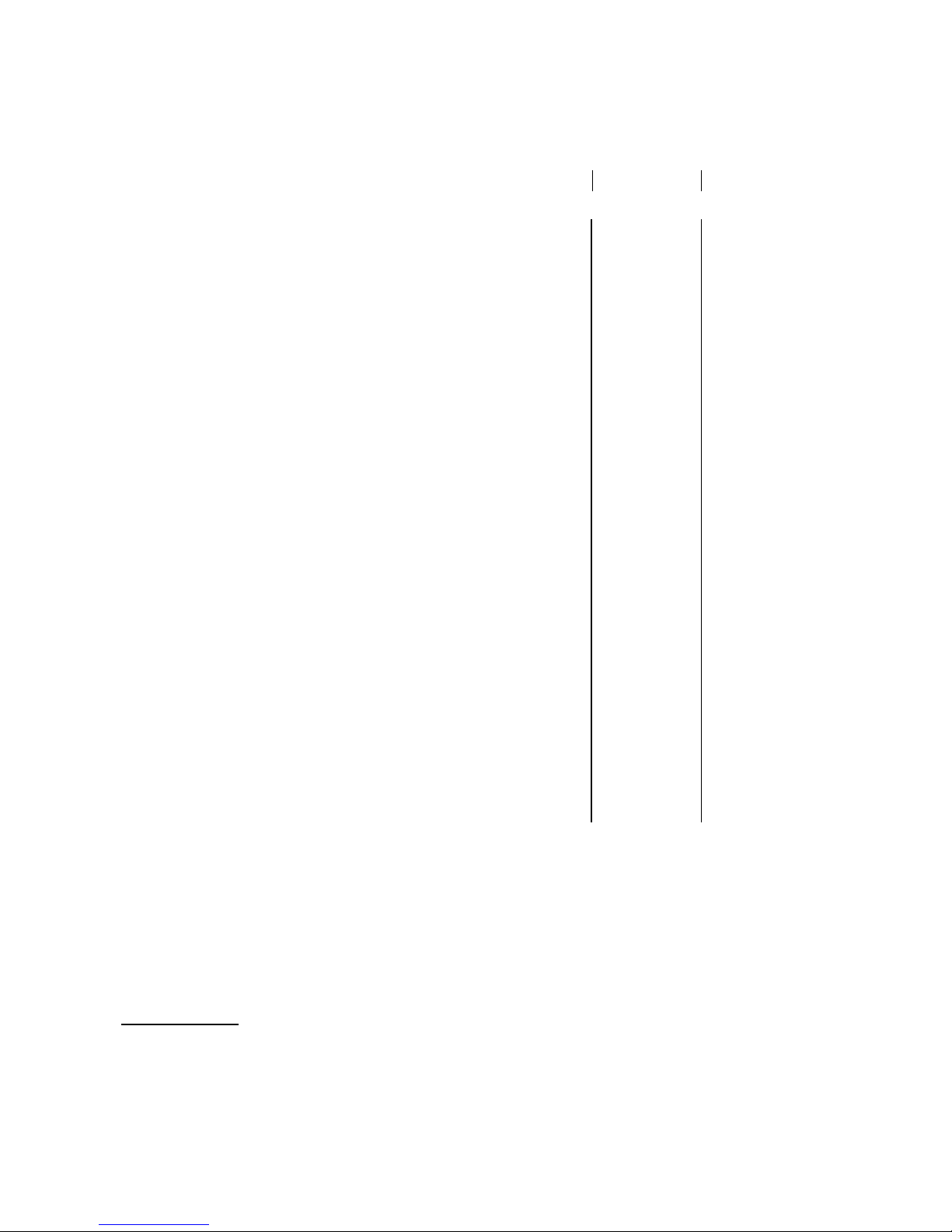

ABS electrical diagram is shown in Fig. 8.6.

Pin

Circuit

ABS CU supply

Input chopper supply

ABS CU common

Input choppers common

Pilot lamp

Pin

D7 - control unit

887 - front, left speed sensor

Y56 - front, left input chopper

888 - front, right speed sensor

Y57 - rear, left input chopper

889 - rear, left speed sensor

890 - rear right speed sensor

Y58 - rear, right input chopper

X1 - 18 pin connector

X2 - 6 pin connector

X3 - 9 pin connector

X4 - 15 pin connector

Fig. 8.6. ABS System Electric Circuit Diagram

See vehicle electrical equipment diagram

1)

Pin

Pin

34

8.10 TOWING DEVICE

Front and rear towing devices consist of towing fork with pivot bolt locked

at below with cotter pin.

Before towing the vehicle remove the front licence plate to make access to

the towing fork. For towing the vehicle in heavy road conditions with small

turning radiuses and so on, it is recommended to remove the bumper to pre

vent its damage. In so doing it is necessary to undo 4 screws of bumper middle

part fastening and one nut (17 mm width across flat) at each side of bumper

sidewalls fastening.

9. Vehicle Maintenance

This section describes the works, which should be carried out regularly

within the intervals between the maintenance operations stated in the Service

Book.

9.1. CHECKING ENGINE OIL LEVEL

Check engine oil daily prior to engine starting. When doing so park the

vehicle on level ground. The oil level must be between "П" and "0" marks on

the oil dipstick (nearer to "П" mark). Bring it to the proper level if required.

Pour fresh engine oil via the filler neck covered with the cap.

9.2. CHECKING OIL LEVEL IN GEARBOX AND REAR AXLE

Check oil level on an unladen vehicle standing on level ground with the

units cold.

Oil level in the gearbox (Fig. 9.1) should be to the level of the filler hole

lower edge.

Fig. 9.1. Checking Oil Level in Gearbox:

1 — drain hole plug

2 — filler hole plug

35

Oil level in the rear axle (Fig. 9.2) should be to the level of the filler hole

lower edge.

9.3. CHECKING COOLANT LEVEL

Checking the coolant level in expansion tank 2 (Fig. 9.3) should be car

ried out only when the engine is cold.

Fig. 9.2. Checking Oil Level in

Rear Axle

1 — drain hole plug;

2 — filler hole plug

Fig. 9.3. Checking Coolant Level in Expansion

Tank:

1 — plug; 2 — tank

The coolant level should be at MIN mark or 30–50 mm above it.

Add antifreeze mixture through the expansion tank hole covered by cap.

If the coolant level falls frequently, inspect the cooling system for leakage.

9.4.CHECKING BRAKE LINING WEAR RATE

On the sliding calipers 1 of all disk brake gears, marking is made (see Fig.

9.4).

According to the position of "P" mark on the sliding caliper 1 against flange

"R" of caliper body 2 it is possible to determine the brake lining thickness with

out wheel removing.

36

In Fig. 9.4 "A" "P" mark position is shown when the brake pads are new.

When mark position corresponds to the position shown in Fig. "B", friction

linings and brake disk thickness should be checked with the wheels removed.

Moreover, brake pad wear indicator is installed in every disk brake to deter

mine friction linings wear. After reaching of any brake pad limiting wear the

indicator lights up on the instrument panel.

9.5. CHECKING BRAKE FLUID LEVEL IN CLUTCH MASTER

CYLINDER TANK

The level of the brake fluid in the clutch master cylinder tank should be

15–20 mm below upper edge of the tank (Fig. 9.5).

Fig. 9.4. Checking Brake Lining Wear Rate

Fig. 9.5. Checking Fluid Level in

Clutch Master Cylinder Tank

1 — service cylinder; 2 — tank; 3 — cap;

4 — reservoir

37

9.6. CHECKING STORAGE BATTERY ELECTROLYTE LEVEL

Storage battery electrolyte level should be between MIN and MAX marks

(Fig. 9.6) on the semitranslucent battery housing and in case of their absence

— to the lower edge of the filler hole.

Fig. 9.6. Storage Battery

1 — cover; 2 — plug; 3 — filler hole

If the electrolyte level is below the standard it is necessary to remove cov

er 1, unscrew plugs 2 and add distilled water through holes 3 up to the re

quired level; then screw in plugs 2 having preliminary checked the vent holes

in them for cleanness and place back cover 1. After that wipe the battery outer

surfaces with clean rugs soaked in 10% solution of ammonia spirit or sodium

bicarbonate.

Always keep the battery terminals and cable clamps clean as well as make

sure that they are securely tightened.

Care should be taken to ensure correct polarity when the battery is recon

nected after removal from the vehicle (positive terminal is bigger than nega

tive).

Prior to installation on the vehicle charge the battery bringing the density

up to 1.25–1.27 g/cm3. Depending on climatic zone of the vehicle operation

the electrolyte density should be corrected (see storage battery operating in

structions).

During the prolong parking of the vehicle disconnect the storage battery

from the vehicle frame to ensure fire safety precautions.

Battery switch. To disconnect the storage battery during the prolong park

ing or the repairing of electric equipment the battery switch is installed under

the hood on the battery plate. It operates by short pressing on the button 28

(See Fig. 5.1), placed on the fuse block bracket.

38

The battery can be switched off or on also by immediate pressing on the

switch button, covered with rubber cap.

To avoid the damage of electric equipment it is not allowed to switch off

the storage battery with the engine running.

9.7. CHECKING OIL LEVEL IN POWER STEERING RESERVOIR

Power steering system reservoir is installed under the hood on the bracket

fastened on the left headlamp case stiffener.

The level of oil should be between MAX and MIN marks available on the

reservoir body.

Fig. 9.7. Checking Oil Level in Power

Steering Reservoir

9.8. ENGINE ACCESSORIES DRIVE BELT TENSION

Fan belt tension (Fig. 9.8) should be checked by pressing with 4,0 daN

(4,0 kgf) force on the side middle between pulleys of crankshaft and alternator

in doing so the belt sag amount must be within 12–17 mm. To adjust the belt

tension it is necessary to loosen alternator fasteners, turn it and tension the

belt. Tighten alternator fasteners.

Fig. 9.8. Checking Fan Belt Tension

39

9.9. WHEELS AND TIRES CARE

In the process of vehicle operation it is necessary to timely tighten the loose

wheel nuts to avoid damaging the fastening holes, remove rust from the wheels

and restore their colour.

To ensure maximum service life of the tires the following rules should be

observed:

— maintain the required air inflation pressure in the tires. Pressure should

be checked when the tires are cold before starting out. When stopping during

a trip carry out visual inspection of the tires and inflation pressure in them.

Never drive the vehicle with the underinflated tires even for a short distance.

Pressure should not be reduced in warm tires because during the vehicle move

ment pressure increase is inevitable due to heating of air inside them;

— check and balance the wheels with tires on a special stand at the service

station. The allowable residual unbalance from each side of the wheel with tire

should not exceed 100 g on the wheel rim;

— on returning from a trip and when at halt inspect the tires and remove

the foreign objects. The vehicle should be parked on clean and dry place. Avoid

oil, gasoline, oil paint getting on the tires;

— prevent vehicle standing with underinflated tires;

— rotate the tires (Fig. 9.9), if necessary to get even wear of all tires, spare

one including, as well as to provide proper selection of the tires for each axle.

The tires on an axle should be of the same tread wear and more reliable tires

should be installed on the front axle of the vehicle.

Fig. 9.9. Tire Rotation

Diagram

Maximum permissible rate of tread wear corresponds to residual depth of

the tread grooves equal to 1.6 mm which is determined by measurement or by

tread wear indicators. These indicators of 1.6 mm high will appear as wide bands

incorporated in the tread pattern and marked on the tire sidewalls by TWI

marks.

40

9.10. CHANGING A WHEEL

Replace the wheel in the following sequence:

— apply the handbrake;

— place chocks under the wheels from the side opposite to the wheel to be

removed;

— loosen six nuts of the wheel to be removed;

— place the jack (Fig. 9.10) under front axle beam or rear axle near the

wheel to be lifted and drive out screw 2 by hand as far as it will go. In case of

loose ground, place a pad or a firm board under the jack base;

Fig. 9.10. Jack

1 — head; 2 — screw; 3 and 4 — operating plungers; 5 —

handle; 6 — delivery plunger; 7 — shutoff needle; 8 — plug

— screw shutoff needle 7 all the way clockwise, insert tommy bar into han

dle 5 and rocking the tommy bar make lifting of the vehicle so that the wheel

clears the ground by 4–5 mm;

In case of failure of lifting by the jack, open shutoff needle 7 and rock the

tommy bar several times to remove air which could get into the working cham

ber.

Plunger liftoff limitation is mechanical, by effort increasing on the handle

at the end of the lifting stop the lifting.

— remove six nuts of the wheel, replace the wheel and fit the nuts;

— lower the vehicle slowly opening shutoff needle 7 of the jack by turn

ing it in a counterclockwise direction;

— tighten six nuts and remove the chocks;

— adjust the tire pressure.

When using and storing the jack the following rules should be observed:

1. To maintain vehicle stability place chocks under the wheels of the op

posite side and apply the handbrake.

41

2. Do not work beneath the vehicle with the lifting jack as the only sup

port.

To carry out adjustment and mounting/dismounting operations lift the

vehicle on the jack and then lower it on suitable stands.

3. In storage jack screw 2 should be driven all the way in, the operating

and delivery plungers must take the lowermost position and shutoff needle 7

be unscrewed through 1 or 2 revolutions.

4. Fill the jack with clear filtered oil ВМГЗС or МГЕ10А up to the level

of the filler hole.

At the ambient air temperature up to – 40° C application of transformer

oil is permissible.

Never use oils of other grades and liquids including brake fluid.

Jack failures should be eliminated timely. Seepage of oil in the plungers

and shutoff needle is eliminated by tightening the packing gland nuts. Oil leak

age through the joints of the body is corrected by tightening the body head.

Worn packing glands should be replaced.

Jack failure results from air presence in the working chamber or due to

valve sticking. To eliminate failure tap lightly on the delivery plunger handle

several times and continue the lifting. To prevent air from getting into the

working chamber of the jack, do not lift the operating plunger by hand with

the shutoff needle closed.

Incomplete lifting of the jack operating plunger occurs due to shortage of

oil. Regularly check the oil level in the jack and replenish, if required. The oil

level in the vertically positioned jack should reach the filler throat closed with

plug 8.

Failure in operation except for mentioned reasons may result from dirt,

which got inside the jack. To clean the jack interior of dirt, unscrew the jack

body head, pour clean kerosene into the body and pump the jack several times

with the shutoff needle open. Drain kerosene and pour fresh oil.

9.11. CAB CARE

Wash the vehicle in a shadow. Do not use soda, kerosene, gasoline as well

as seawater. If after washing with water the cab is not clean enough you may

use shampoo and other vehicle cosmetics available in the market.

Use clean sponge and soft cloth with plenty of water and do not rub too

hard.

Tar spots should be removed with castor or petrolatum oil. A mild soap

solution or pure water may easily clean the plastic parts. Never use gasoline or

solvents for the above purpose.

42

On detecting corrosive spots it is necessary to remove the rust to pure metal,

prime and apply corrosionresisting mastic.

At frosty weather you should not wash the vehicle outofdoor or drive

with wet or just washed cab, because by water freezing cracks may appear on

painted surface.

You should not keep the vehicle under rubberised cover or place rubber

articles on bodywork painted surface because dark spots may appear which

cannot be removed with car polish.

To retain elasticity of rubber seals at low temperatures, it is recommended

to smear them with glycerine at regular intervals.

In the process of vehicle operation noncorrosive coating of the cab may

fail with time that is why it is necessary to perform corrosionresisting treat

ment at regular intervals at service stations.

Hidden pockets additional corrosion protective treatment areas diagram

of the cab is shown in Fig. 9.11.

Fig. 9.11. Hidden Pockets Additional

Corrosion Protective Treatment Areas

Diagram of the Cab

1 — foot steps hidden pockets; 2 — door pock

ets; 3 — front fender with mudguard contact

area; 4 — hood pocket around the periphery;

5 — door hinges area

9.12. TYPES OF MAINTENANCE

The following types of maintenance are established:

1. Daily maintenance (EO).

2. Maintenance one "A" (TO1) — after 10000 km of run.

3. Maintenance two "B" (TO2) — after 20000 km of run.

4. Seasonal maintenance "C" (CO).

Seasonal maintenance is performed once a year along with maintenance

one "A" or two "B".

43

9.13. PROCEDURES CARRIED OUT DURING MAINTENANCE

9.13.1. Daily Maintenance (EO)

Procedure description Specifications

Tools and

materials

12

Check the level of:

— oil in engine crankcase See item 9.1 Visually

— fluid in cooling system See item 9.3 Visually

— fluid in clutch master See item 9.5 Visually

cylinder tank

— oil in power steering See item 9.7 Visually

reservoir

1)

Check service brake sys 1. With the engine running, the Visually

tem for sound condition. brake pedal should not reach the

cab floor.

2. With the engine running, the

buzzer should not work except

for the time necessary for recei

ver feeding after the engine start

ing.

Check operation of parking Parking brake handle should

brake system easy move and securely tune in

parking position.

Check tire inflation pres Check when tires are cold. Air Manometer

sure, bring to the specifi inflation pressure values see in

ed, if required subsection 4.10 "Main adjust

ment and checking data"

Check steering wheel total Total play over steering wheel

play rim should not exceed 25°

(10° — for the vehicles during

the warranty period) in each side

from the neutral position

Check operation of instru With the engine running make Visually

ments, windshield wiper, sure that the devices are in sound

illumination and warning condition by their successive

devices turning on

3

1) In case of oil low level in the reservoir, check power steering system for tightness

44

9.13.2. Periodic Maintenance (TO1, TO2, CO)

Procedures for periodic maintenance are stated in the service book sup

plied with the vehicle.

9.13.3. Vehicle Lubrication

1.Never use fuels, oils and liquids of other grades except for those specified

in subsections 9.13.4 and 9.14.

2.Prior to lubrication remove dirt from grease nipples and plugs to avoid

its penetration into the vehicle's mechanisms.

3.Lubricate with grease gun until fresh lubricant comes out from all joints

and seals.

4.When the engine oil is changed for another grade or company the lubri

cating system should be flushed with flushing oil.

Never mix (top up) engine oil of different grades and different companies.

9.13.4. Lubrication Chart

Description of lubrication

points

Number

of points

Quantity

of lubri

cant

Description of lubricant

1 23 4

Engine oil system 1 12 l In summer — engine oils: М10Г2 or

М10Г2K ААИД1 or engine oil

М10ДМ ААИД2.

In winter — engine oils: М8Г

2

or М

8Г2 ААИД1 or, engine oil: М8ДМ

ААИД2.

Allseason: engine oil SAE 15W40

Api CF4; CF4/SG (up to –15° C);

SAE 5W40 Api CF4; CF4/SG (up

to –25° C);

Gearbox case 1 6 l At the temperature from –25° C to

+40° C — oil "Супер Т3". Substi

tutes — oils ТСп15К, "Девон Супер

Т", "Лукойл ТМ5" SAE 85W90.

At the temperature from –40° C to

+20° C — oil "Лукойл ТМ5" SAE

75W90

Universal joint needle 3 4 g Oil "Супер Т3". Substitute — oil

bearings "Девон Супер Т", "Лукойл ТМ5"

SAE 85W90

45

1 23 4

Propeller shaft slip joint 1 200 g Oil "Супер Т3". Substitute — oil

"Девон Супер Т", "Лукойл ТМ5"

SAE 85W90

Intermediate propeller 1 50 g Grease Литол24. Substitute —

shaft bearing grease ЛИТА

Steering knuckle pivot 4 30 g Solid oil Ж or solid oil C

bearings

Rear axle housing and At the temperature from –25° C to

rear wheels hub bearings 1 8 l +40° C — oil "Супер Т3". Substi

tute — oil "Девон Супер Т", "Лукойл

ТМ5" SAE 85W90

At the temperature from 40° C to

+20° C — oil "Лукойл ТМ5" SAE

75W90

Front wheels hub bear 4 400±30 g Grease Литол24. Substitute —

ings grease ЛИТА

Rear wheel hub seal 2 20 g Grease Литол24

Shock absorbers 4 550 cm

3

АЖ12T. Substitute fluid — spindle

oil AУ

Power steering system 1 1.3 l Hydraulic oil "P"

Steering shaft sealing 1 5 g Grease Литол24. Substitute —

grease ЛИТА

Steering gear universal 3 6 g Grease Литол24. Substitutes —

joints solid oil C, solid oil Ж

Master clutch cylinder 1 0.2 l Brake fluid "РОСДОТ".

refilling tank (system Substitute fluid "Томь"

capacity) class III grade A

Storage battery terminals 4 4 g Lubricant ПВК or solid oil

Door locks and linkages 14 20 g Oil ВМГЗ or МГЕ10А

(inner and outer)

Door lock releases 2 4 g Grease Литол24. Substitute —

grease ЛИТА

Cab door limiters 2 2 g Grease Литол24. Substitute —

grease ЛИТА

Hood lock 1 1 g Oil ВМГЗ or МГЕ10А

Hood lock control 1 15 g Grease Литол24. Substitute —

grease ЛИТА

Hood hinges 2 2 g Oil ВМГЗ or МГЕ10А

Engine cooling system 1 16 l Coolant ТОСОЛА40М, ОЖ40

"Лена", ТЕРМОСОЛА40

46

9.14. EQUIVALENTS OF RUSSIAN AND FOREIGN FUELS, OILS,

LUBRICANTS AND FLUIDS

Russian fuel, oil, lubricant,

fluids

Foreign fuel, oil, lubricant,

fluids

Recommended t° ranges, °C

(ambient)

123

Diesel oil

Л0,5 2D (ASTM97581) Above 0° C

З0,535 1D (ASTM97581) From 0° C to –20° C

Engine oils

М10Г

2

к or ABOVE +5° C

М10Г

2

М10ДМ

М8 Г

2

к or Below –5° C

М8 Г

2

М8 ДМ

APISF 4 ACE 2E2:

SAE 15W40 From +45° C to –15° C

SAE 10W40 From +35° C to –20° C

SAE 5W40 From +35° C to –25° C

Transmission oils

"SUPER T3 (TM5)" or API GL5, SAE 85W90, From –25° C up to +50° C

"UFALUB UNITRANS" MILL2105B

or "DEVON SUPER T

(TM18)"

Lubricants

Litol24 MilG18709A, from –40° C to +60° C

MilG10924C

Fat or synthetic solid oil MilG10924C from –40° C to +50° C

Lubricant (ПВК) MilC11796B From –40° C to +50° C

ЛИТА SM1C4515A (Ford) For cold climatic zone

No.158 NICO GREASE 57

"Nico International Inc."

or Alvania Grease 2 (MoS

2

)"

"Shell International

Petroleum Co. Ltd"

Graphite grease УСcА VVG671d 078.01 (RFA)

47

123

Power steering oil

Oil grade "A" ATF For tropic climatic zone

Oil grade "P" ISO6074HM22 From –35° C to +45° C

Spindle oil АУ ISO6074HH22 From –25° C to +45° C

Oil ВМГЗ ISO6074HV15 For cold climatic zone

Shock absorber fluid

АЖ12т VTL9150033 Above –45° C

Oil МГЕ10A ISO6079HV15 For cold climatic zone

Brake fluids

"РОСДОТ" DOT4 SAE J1703 For all climatic zones

"Toмь" FMVSS 116

DOT3 SAE J1703 For moderate climatic zone

FMVSS 116

Coolants:

ТОСОЛА40М Antifreezing agent with From –40° C to +50° C

ОЖ40 "Лена" corrosion inhibitor complex

ТОСОЛА65М and foamquencher For cold climatic zone

ОЖ65 "Лена"

While choosing the lubricant or fluid give preference to the following com

panies: Shell, Mobil, Castrol, British Petroleum, Agip, Gulf.

9.15. PARTS TO BE REPLACED ON THE VEHICLE DURING

MAINTENANCE

During vehicle maintenance the following parts are subject to replacement:

1. Fine fuel filter element.

Filter element designation is 2401117030.

Fine fuel filter care includes draining sediment at regular intervals and re

placement of filter element.

To drain sediment from fine fuel filter it is necessary to unscrew plug 4

(Fig. 9.12) and drain sediment until clean fuel appears then tighten the plug.

To renew filter element it is necessary to:

— drain fuel from the filter removing plug 4;

— unscrew cover retaining nuts and remove cover 1;

— withdraw filter element 2 from the body;

— clean the inside of the filter body;

— reassemble the filter with new filter element;

48

— unscrew plug 3 (Fig. 9.13) on fuel pump housing to bleed air and un

screw union 1 by 1–2 turns on the fine fuel filter;

— prime the system by means of booster pump 2, when fuel appears screw

in union 1 first and then tighten plug 3.

Fig. 9.12. Fine Fuel Filter Element

Replacement:

1 — filter cover; 2 — filter element; 3 — fil

ter body; 4 — plug

Fig. 9.13. Air Bleeding from Fuel System

1 — union; 2 — booster pump; 3 — plug

2. Air filter element.

Filter element designation is 4301110901310 or 4301.110901320.

49

3. Oil filter, solid, replaceable.

Filter designation is ФМ0091012005.

When installing the filter, lubricate the rubber gasket with engine oil and

screw the filter onto the engine cylinder block.

As soon as the gasket touches the cylinder block, add more 3/4th of the

turn. Installation of the filter is carried out by hands effort only.

Instead of filter ФМ0091012005 it is allowed to use the filterssubsti

tutes X149, firm "ACDelco" (France) and L37198, company "Purolator" (Ita

ly) with basic dimensions:

— diameter — 95–120 mm

— height — 140–153 mm

— mounting thread 3/4" — 16UNF.

4. Filter element of power steering system reservoir ШНКФ 453473.

In case of installation of power steering system reservoir ЯМЗ.993.004 the

latter is replaced in assembly.

5. Filter element of dryer 1117793, firm "KnorrBremse".

50

10. Supplements

Supplement 1

10.1. FILLING CAPACITIES

Fuel tank, 105

Engine cooling system, l 21,5

Engine oil system, l 12

Gearbox case, l 6

Rear axle housing, l 8

Power steering system, l 1,3

Shock absorbers (each), cm

3

137,5

Clutch hydraulic drive system, l 0,2

Lubricant for front wheel hubs (both), g 400±30

Lubricant for rear wheel hubs (both), g 40

Windscreen washer tank, l 4

Supplement 2

10.2. ELECTRIC BULBS USED

Purpose and location Type Quantity

Head lamps:

low beam H7 2

high beam H1 2

clearance light W5W 2

turn indicator PY21W 2

Turn indicator repeater PY21W 2

Front marker lights A125 2

Side clearance lamps W3W 4

Tail lights:

turn indicator A12213 2

stoplight A12213 2

clearance light A1210 2

backing light A12213 2

fog light A12213 2

Side clearance marker light A1210 2

Instrument cluster

pilot lamps A121,21 24

instrument illumination bulbs A122,31 4

Pressure gauge (manometer) AMH1231 2

Cab dome lamp A1251 3

A1231 1

Glove box dome lamp A1251 1

Hood light A1210 1

Licence plate light A125 4

51

Purpose and location Type Quantity

Cab dome lamp for vehicles with twobank cab KЛУ9/ТБЦ1 1

Control unit of head lamp aiming device A121,21 1

Instrument illumination control ACMH120,55 1

Heating and ventilation unit control desk A121,2 4

Cigar lighter socket lighting A121,2 1

Alarm switch pilot lamp A121,1 1

Main light switch A121,2 2

Supplement 3

10.3. ROLLING BEARINGS USED IN THE VEHICLE

LocationType of bearing Bearing No.

Engine

Single seal ball bearing 1160305 2 Water pump

Taper roller bearing 7204A 2 Fuel pump

Thrust ball bearing 8110 1 Fuel pump governor

Thrust ball bearing 8202 1

Singlerow radial ball bearing 205K 2 Power steering pump drive

Singlerow radial ball bearing 6203 or 6203AK 2 Vacuum pump

Singlerow radial ball bearing 207 2 Compressor

Transmission

Radial ball bearing 1280114C23 1 Clutch release sleeve

Singlerow radial ball bearing 6311AKУ 1 Gearbox output shaft, rear

Singlerow radial ball bearing 60205К 1 Gearbox input shaft, front

Singlerow radial ball bearing В6213АКУШ 1 Gearbox input shaft, rear

Radial roller bearing without 64706 1 Gearbox reverse pinion shaft

races

Ball Б 11,112200 306203П 3 Transmission shifter shaft

lock

Ball 10100 296870 4 Transmission shifter shaft

lock plunger

Singlerow taper roller bearing 7207A 2 Intermediate shaft

Radial roller bearing without 264706 1 Gearbox output shaft, front

races

Doublerow needle radial rol 664910E 5 Gearbox output shaft

ler bearing without races pinions

Needle roller bearing with one 804805K1 12 Propeller shaft pivot joints

outer race

Singlerow radial ball bearing 6114 1 Propeller shaft bearing

Singlerow taper roller bearing 27709У4Ш2 1 Rear axle drive pinion, cen

ter

Singlerow taper roller bearing 27308AKУ 1 Rear axle drive pinion, front

Singlerow taper roller bearing У807813А 2 Rear axle differential

Singlerow radial roller bearing 20102605М 1 Rear axle drive pinion, rear

Quantity

52

LocationType of bearing Bearing No. Quantity

Steering gear

Radial ball bearing 6930904FT1C17 2 Steering column

Needle roller bearing with one 904700УС17 10 Steering gear shaft pivot

outer race joints

Running gear

Singlerow taper roller bearing 4807813A 2 Outer support of rear wheel

hub

Singlerow taper roller bearing 67515A 2 Inner support of rear wheel

hub