Gaymar TP-500, TP-500C User manual

®

T/PUMP

TP500 / TP500C

Heat Therapy System

®

LISTED 304L

STANDARD (NORME)

C22.2 NO. 125 RISK

CLASS (CATEGORIE

DE RISQUES) NO. 2G

SERVICE MANUAL

P/N 11950-000 9/03

CONTENTS

CONTENTS

Safety Precautions ..................... 1

Introduction ......................... 2

Features ............................ 3

Specifications ........................ 4

Operating Instructions .................. 5

Storage/Cleaning ...................... 7

Theory of Operation ................... 8

Functional Check and Safety Inspeciton ....... 10

Inspection Form ...................... 15

Disassembly/Reassembly ................. 16

Calibration .......................... 19

Troubleshooting ...................... 21

Replacement Parts ..................... 27

Warranties .......................... 30

ILLUSTRATIONS

1 T/Pump® Heat Therapy System ........ 2

2 Features/Specifications .............. 3

3 Clik-Tite® Connectors .............. 5

4 Colder-style Connectors ............ 5

5 T/Pump Components .............. 9

6 Motor ........................ 11

7 TPC1 Test Covers ................ 22

8 Functional Check Test Diagram ....... 23

9 Circuit Diagram for T/Pump .......... 24

10 Circuit Diagram for TPC1 Test Cover .. . 25

11 Exploded View of T/Pump ........... 26

SERVICE MANUAL

TP500/TP500C T/PUMP

BEFORE YOU BEGIN . . .

Read and understand this

T/PUMP SERVICE MANUAL and all

PRECAUTIONS (see page 1) prior to

servicing the T/Pump.

The purpose of this manual is to provide operation,

service, and repair information for GAYMAR heat

therapy pumps.

RECEIVING INSPECTION

Check the shipping carton for damage immediately

upon receipt. If package damage is discovered, the

device should be unpacked with the carrier's agent

present. Any claims for shortage or damage must be

filed with the delivering carrier by the purchaser. Do

not return pumps damaged in shipment to GAYMAR

without contacting our Technical Service

Department for advice (see phone numbers below).

If damaged goods are returned to GAYMAR without

notifying the carrier, GAYMAR will assume the

repairs will be made at the customer's expense.

TO RETURN PUMPS TO FACTORY

FOR REPAIR OR EXCHANGE

Merchandise returned to GAYMAR must be

accompanied by a Return Goods Number (RG#),

issued by GAYMAR, authorizing goods to be

returned. Call Customer Service or Technical

Service at

(716) 662-2551

1 800 828-7341

Advise model, serial number, and nature of problem.

You will be given a Return Goods Number (RG#).

The serial number is on the back of the T/Pump

(see figure 2, p. 3).

T/PUMP, T/PAD, Mul•T•Pad, Clik-Tite, and Gaymar are registered trademarks of Gaymar Industries, Inc. U. S. PATENT 4,068,870

© 2001. Gaymar Industries, Inc. All rights reserved. www.gaymar.com

SERVICE MANUAL

DANGER

CAUTION

WARNING

TP500/TP500C T/PUMP

SAFETY PRECAUTIONS

• Risk of explosion. Do not use in the presence of flammable

anesthetics.

• Risk of electric shock. Disconnect power before servicing

the T/Pump.

• This device pumps warmed water through a pad. Set pad

temperature only as prescribed by and under the guidance of a

physician. Monitor the patient's temperature and skin condition

every 20 minutes or as directed by a physician. Failure to

adhere to these warnings could result in patient injury.

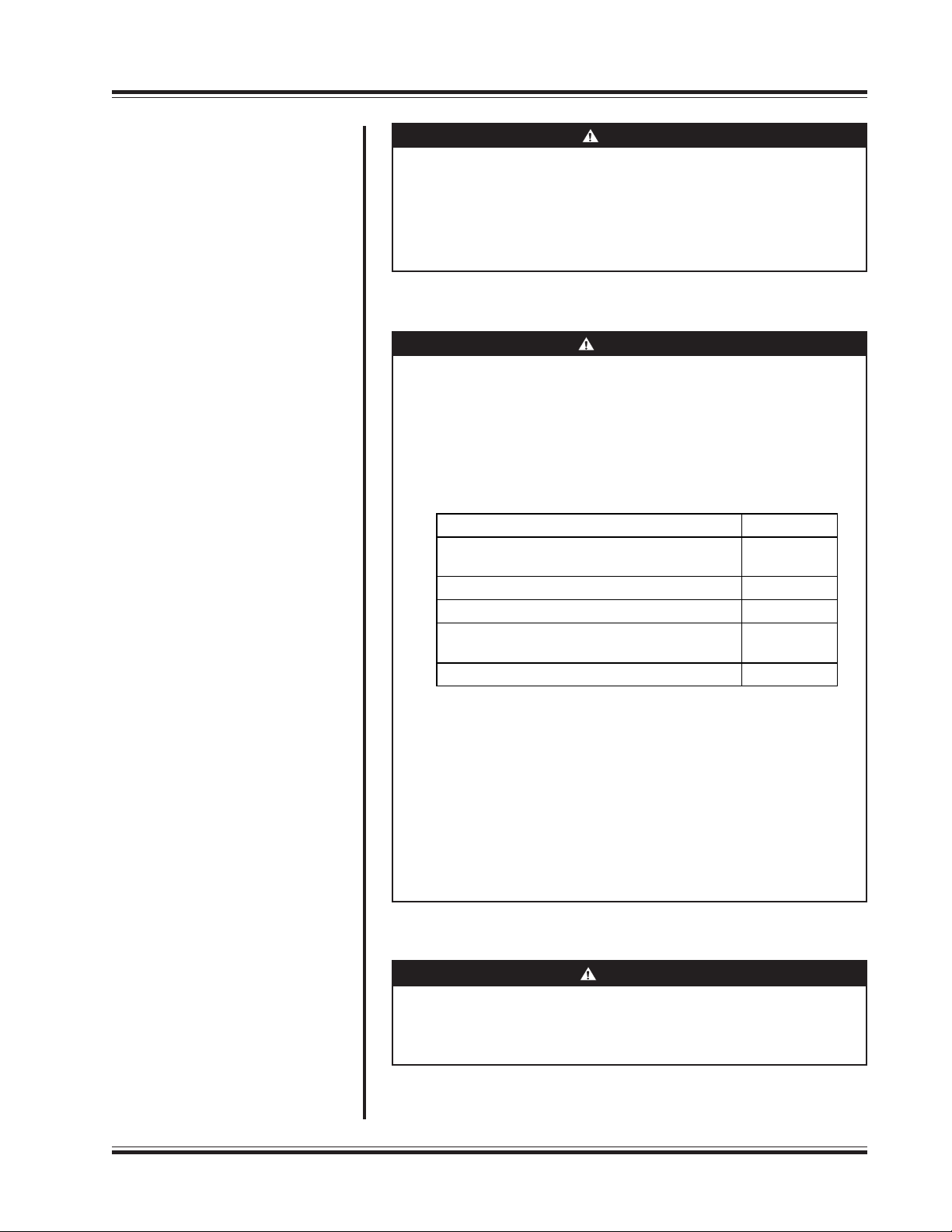

The following Groups/Conditions require additional surveillance:

Group/Condition at risk Potential injury

Pediatric patients Hyperthermia/

hypothermia

Patients with impaired circulation Ischemia

Areas of application are under pressure Ischemia

In combination with topical solutions whose toxicity

may be affected by the application of heat

In combination with other heat sources Thermal injury

Chemical

injury

• Only qualified medical service personnel should repair the

T/Pump. Improper repair may result in death or

serious injury, equipment damage, or malfunction.

• Always perform the

INSPECTION

(pp. 10-14) after making repairs and before

FUNCTIONAL CHECK AND SAFETY

returning the T/Pump to patient use. Document your

findings on the

INSPECTION FORM

(p. 15). Improper

repair may result in death or serious injury,

equipment damage, or malfunction.

• Do not perform any powered tests with the reservoir empty.

Damage to the T/Pump may result.

1

INTRODUCTION

SERVICE MANUAL

TP500/TP500C T/PUMP

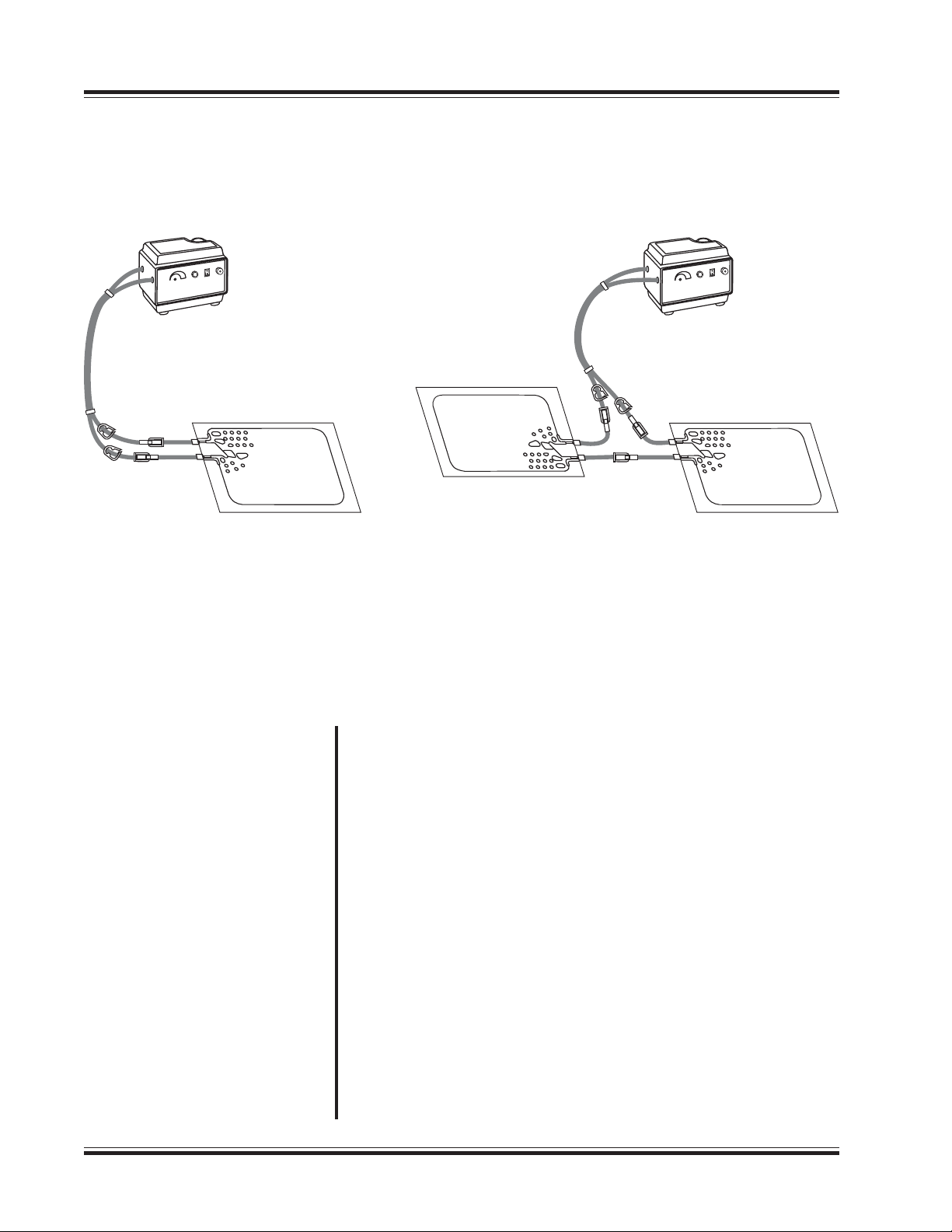

Single Pad Multiple Pads

Figure 1—T/Pump Heat Therapy System

Heat therapy is effective in the dilation of blood vessels, thereby increasing

the blood flow to the heated area. Heat therapy has a variety of uses, the

most common being treatment of aches and pains in joints and muscles.

The GAYMAR T/Pump® Heat Therapy System provides a means of

applying heat therapy by supplying temperature-controlled water through a

connector hose to a Gaymar T/Pad®. The hose is terminated in easy-to-use

Clik-Tite® or Colder-style connectors.

The T/Pad provides the interface for delivering the heat therapy. The

unique button design allows water to flow and provides trouble-free

operation when the pad is folded. This reduces the number of pads your

facility must keep in inventory. The pads are applied to the part of the

body requiring heat therapy, and the circulating water maintains the pad at

the set point temperature. The temperature setpoint is key-operated to

prevent tampering.

The T/Pads can be interconnected (on model TP500 only) to provide

therapy to more than one body site at a time.

2

SERVICE MANUAL

TP500/TP500C T/PUMP

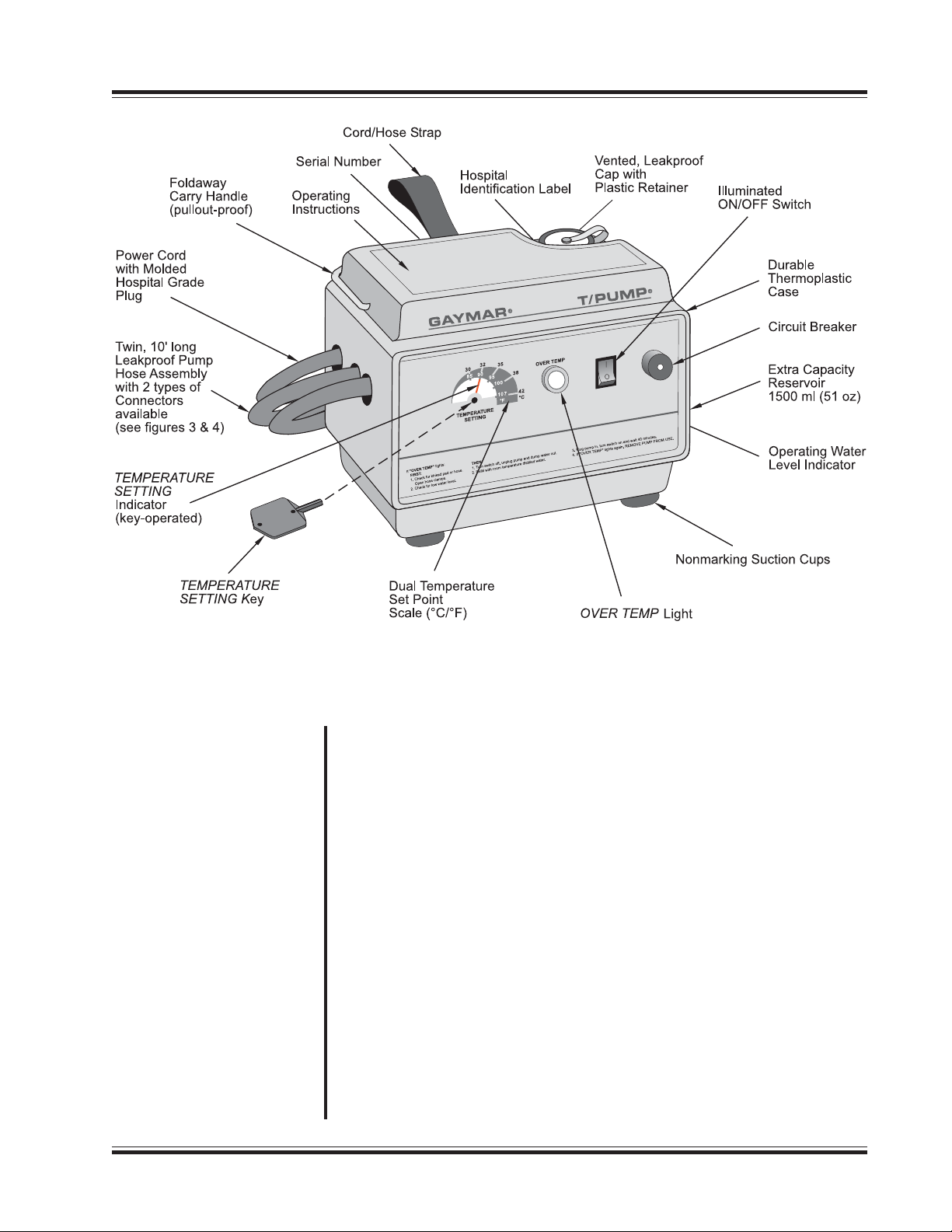

FEATURES

FEATURES

Figure 2—T/Pump Features

Attached Hose 10 ft (305 cm) dual hose. Connectors allow pads to be

connected to the pump (see figs. 3 and 4, p. 5).

Tip-over Turns heater off if pump is tipped.

Switch NOTE: This does not activate the

Hospital ID A label is provided on the back of the T/Pump for your

Label convenience. Use a felt tip or ball point pen to add any

required hospital identification.

OVER TEMP

Light This light is activated by the two

Circuit Breaker When the circuit breaker trips, the small button in

OVER TEMP

Safety if the high temperature limit is exceeded. The

Thermostats light will glow. Refer to the

Indicates the pump and heater have been turned off.

thermostats. Refer to the

the center will extend 1/4", exposing a white band.

Refer to the

Either of two limit thermostats will shut off pump and heater

TROUBLESHOOTING

OVER TEMP

OVER TEMP

TROUBLESHOOTING

section.

TROUBLESHOOTING

light.

safety

section.

OVER TEMP

section.

3

SPECIFICATIONS

SERVICE MANUAL

TP500/TP500C T/PUMP

SPECIFICATIONS

Size (approx.) 8-1/8" x 5-5/8" x 6-1/4"

(20.6 cm x 14.3 cm x 15.9 cm)

Weight (empty) 5 lbs, 2 oz (2.3 kg)

Reservoir capacity 51 oz (1500 ml) maximum

Flow rate 9 gph (34 lph) minimum with pad attached

Ambient operating 60°F to 90°F (15.6°C to 32.2°C)

temperatures

Storage temperatures -30°F to 160°F (-34.4°C to 71.1°C)

(empty)

Temperature set point 85°F to 107°F (29.4°C to 41.7°C)

range

Average operating ±2°F at 107°F setting

temperature accuracy

Power cord 18 AWG, 3 conductor, 9 ft (274 cm), Type SJT

with molded, hospital grade plug

Circuit breaker 3 amperes

1st backup limit Bimetallic (trip point fixed)

thermostat 110°F to 117°F (43.3°C to 47.2°C)

(manifold mounted)

2nd backup limit Bimetallic (trip point fixed)

thermostat 110°F to 122°F (43.3°C to 50°C)

(well mounted)

Current leakage 100 microamperes maximum

Ground resistance 0.5 ohm maximum

Electrical requirements

Voltage (VAC) 120

Frequency (Hz) 60

Current (amps) 1.8

Power req'd (watts) 200

Safety approvals Tested to UL 544 and CSA C22.2, No. 125

4

SERVICE MANUAL

TP500/TP500C T/PUMP

T/Pumps are supplied with one of two types of hose connectors:

TP500 T/Pumps have Clik-Tite® connectors;

TP500C T/Pumps have Colder-style connectors.

CLIK-TITE® CONNECTORS

(on TP500):

To attach Clik-Tite connectors from hose to pad:

1. Insert male fittings into female fittings with

a twisting motion (figs. 3A and 3B).

2. When fittings are fully inserted, snap locking

ring into place (figs. 3C and 3D).

3. To disconnect, simply reverse the procedure.

4. To open or close the hose pinch clamps:

OPERATING INSTRUCTIONS

• Open the clamp by pushing the serrated

end (fig. 3E).

• Close the clamp by pressing the clamp

together (fig. 3F).

NOTE: Refer to figure 1 (p. 2) and

item 9 (p. 6) when connecting

multiple pads.

COLDER-STYLE CONNECTORS

(on TP500C):

1. To attach Colder-style connectors to a pad,

push the male coupling onto the female coupling. When you hear an audible “click”, the

connectors are joined (fig. 4A).

2. To disconnect Colder-style connectors, press

down on the thumb tab of the female coupling.

The couplings will partially disconnect. Pull the

male coupling out fully to disconnect (fig. 4B).

3E

4A

Figure 3A–3D—Clik-Tite® Connectors

3F

Figure 3E–3F—Hose Pinch Clamps

4B

Figure 4—Colder-style Connectors

5

OPERATING INSTRUCTIONS

SERVICE MANUAL

TP500/TP500C T/PUMP

START-UP PROCEDURE

1. Before filling, always attach a T/Pad to the T/Pump connector hose (see

figs. 3 and 4, p. 5). Unkink pad and hose. Open hose clamps.

2. Open the fill cap on top of the pump. Fill the pump with room

temperature (i.e., not hot) distilled water to the operating level

indicated on the side of the pump.

NOTE: Using tap water will decrease the life of the pump.

3. Insert temperature setting key. Set temperature as prescribed by the

physician. Remove key to prevent tampering.

4. Plug the pump into a properly grounded outlet.

5. Turn on the power switch. The selected water temperature will be

reached in approximately 20 minutes.

6. If the water level drops below the operating level, add water. Do not

overfill. Overfilling can result in reduced pump motor life.

7. Apply T/Pad to the patient. Follow T/Pad instructions.

8. For specified performance, keep the pump at or above the level of the

pad.

9. If the pump is placed below the pad(s), water will drain into the pump

when it is shut off. If the pump has been overfilled or if multiple pads

are connected, excess water can leak out onto the floor or cause

reduced motor life.

SHUTDOWN PROCEDURE

1. Turn off pump before disconnecting pad. Close all hose clamps.

To prevent water spillage, always disconnect pad from pump with

connectors raised above the level of the pad and pump.

2. Connect the T/Pad Clik-Tite connectors together, where applicable.

3. Connect the ends of the T/Pump connector hose together

(TP500 only).

6

SERVICE MANUAL

TP500/TP500C T/PUMP

STORAGE / CLEANING

Storage (Short term)

Storage (Long term)

Draining

Cleaning

Disconnect pad. Connect ends of the connector hoses together,

where applicable. Open hose clamps. Leave water in the reservoir.

To prevent hose kinks, coil the hose rather than folding it. Fasten the hose

and cord with strap.

Connect pad. Open hose clamps. Add 1/4 ounce GAYMAR MTA33

germicidal or equivalent to water already in reservoir. Run for two (2)

minutes. Drain pump. Close hose clamps. Disconnect pad. To prevent hose

kinks, coil the hose rather than folding it. Fasten the hose and cord with

strap and store pump.

Unplug the power cord. Disconnect the pad or hoses from one another,

keeping hoses at or above the level of the T/Pump. Remove the fill cap and

invert the T/Pump over a sink. When all fluid has drained from the hoses

and reservoir, replace the fill cap and connect the hoses together, where

applicable.

Unplug the power cord.

To clean the external surfaces, use a non-abrasive cleaning solution (such

as warm, soapy water) and a damp cloth.

Pads / Accessories

To clean the fluid system, drain the pump. Fill the reservoir to the operating level indicated on the side of the pump. Add 1/4 ounce GAYMAR

catalog MTA33 germicidal or equivalent. Set the temperature indicator to

its lowest setting (fully counterclockwise). Start the T/Pump and circulate

the solution for one hour. Drain the solution and refill the pump with

distilled water. Using distilled water retards algae growth and mineral

buildup.

Change the distilled water monthly or more often depending upon use.

For best results use only GAYMAR T/Pads® or Mul•T•Pads®. The unique

button design allows water to flow and provides trouble free operation

when the pad is folded. This reduces the number of different sizes of pads

your facility must keep in inventory. The T/Pads can be interconnected (on

model TP500 only) to provide therapy to more than one body site at a

time (see fig. 1, p. 2). For a brochure listing the various pads, contact the

GAYMAR Customer Service Department (see inside cover for telephone

numbers).

An optional bed bracket (model TP20A) is available to mount the T/Pump

on the footboard of a bed.

7

THEORY OF OPERATION

SERVICE MANUAL

TP500/TP500C T/PUMP

WATER TEMPERATURE

CONTROL

There are four devices that control the operation of the heater in the

GAYMAR T/Pump:

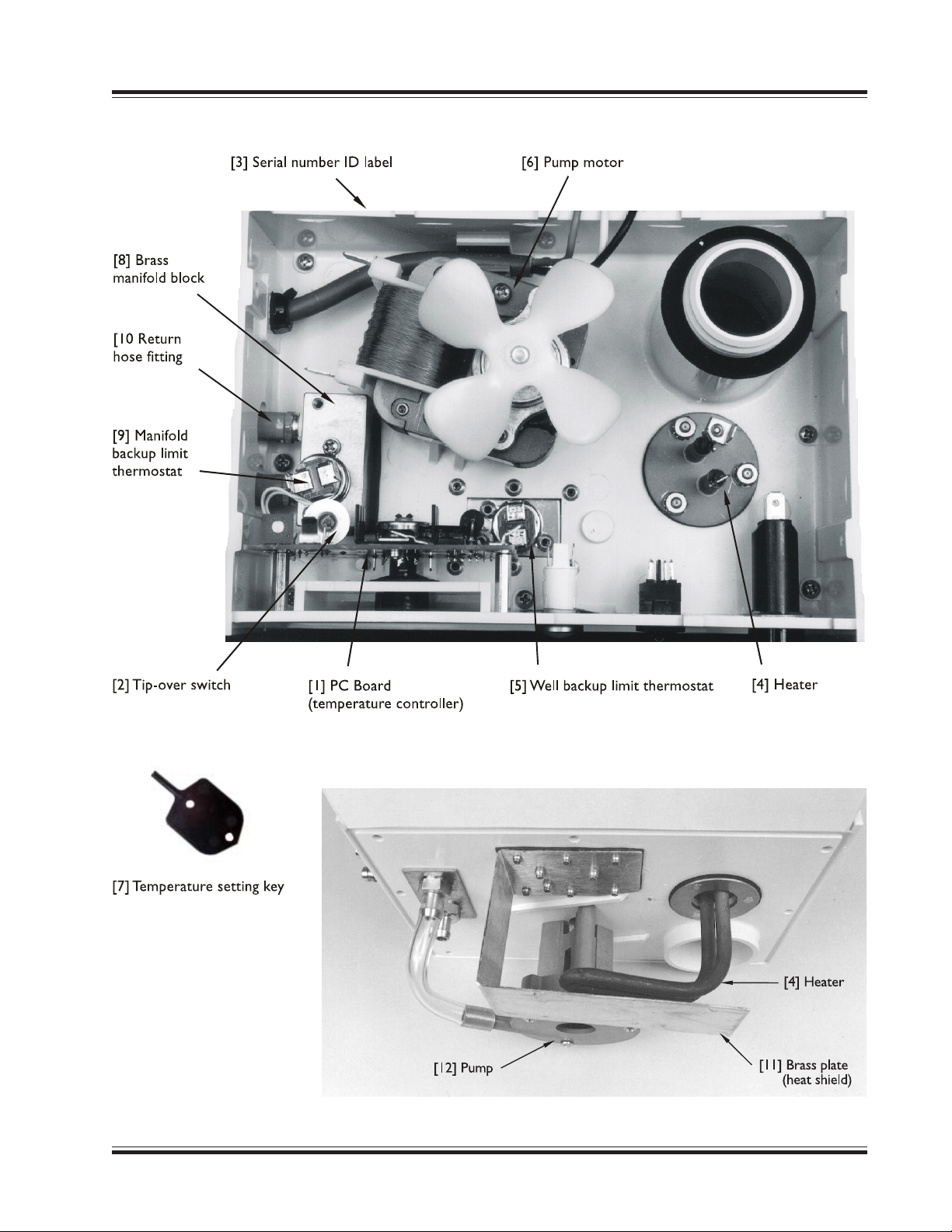

• The temperature controller is thermistor actuated (fig. 5, item 1, p. 9).

This controller is adjustable over a temperature range of 85°F to 107°F

(29.4°C to 41.7°C). The desired water temperature is set with a special

removable key (fig. 5, item 7). To prevent unauthorized temperature

setting changes, remove the key after the temperature has been set.

• The manifold backup limit thermostat (fig. 5, item 9) is mounted on the

brass manifold block (fig. 5, item 8). This thermostat senses water

temperature flowing to the pad and will shut off the pump and heater

and activate the

specific limits. The purpose of the manifold backup limit thermostat is to

prevent the pump from providing water at too high a temperature to

the pad.

• The well backup limit thermostat (fig. 5, item 5) is mounted on the brass

plate (fig. 5, item 11) that extends along and under the heater (fig. 5,

item 4) near the bottom of the reservoir. This thermostat senses water

temperature in the reservoir and will shut off the pump and heater and

activate the

specific limits. The purpose of the well backup limit thermostat is to

both prevent the pump from providing water at too high a temperature

to the pad and to protect the pump from high temperature damage due

to a low water level.

OVER TEMP

OVER TEMP

light if the water temperature exceeds

light if the reservoir temperature exceeds

FLUID SYSTEM

• The tip-over switch (fig. 5, item 2; see also fig. 12, item 64, p. 27) is

mounted on the PC board. This mercury-type switch will shut off the

heater if the pump is tipped more than 45° from the vertical position.

NOTE: The tip-over switch does not shut off the pump

motor or activate the

The pump (fig. 5, item 12) is a sump configuration driven by an impedance

protected, shaded pole AC motor (fig. 5, item 6).

The return hose fitting (fig. 5, item 10) is machined internally to act as an

orifice. This maintains a back pressure in the pad to make it resistant to

flow restrictions.

OVER TEMP

light.

8

SERVICE MANUAL

TP500/TP500C T/PUMP

FIGURE 5—T/PUMP COMPONENTS

T/PUMP COMPONENTS

TOP

(wire harness removed for clarity)

BOTTOM

9

Loading...

Loading...