Gaymar MTA-4700, MTA-4701, MTA-4702 Service manual

GAYMAR:

MEDI-THERM

SERVICE

AUTOMATIC/MANUAL

MODELS

MANUAL

MTA-4700/MTA-4701/MTA-4702

Hyper/Hypothermia

CONTROL

LISTED

303L

P/N

06686-000

PLEASE

NOTE

IMMEDIATELY

BEFORE

PLEASE

CEDURES

Objective

This

publication

characteristics

has

been

of

the

incorporation

are

publication

or

matter

made

variations

contingencies

not

should

both

of

necessarily

in

whole

problems

should

is

intended

of

equipment

to

in

which

design

be

referred

PROCEEDING

REFER

SECTION

IN

to

incorporated

present

or

information

the

equipment

might

changes

reflected

in

part

arise

which

to

in

without

Technical

UPON

TO

provide

itself

arise

to

improve

the

prior

are not

RECEIVING

IN

RECEIVING

THE

3.1

the

reader

in

the

which

is

and

in

in

its

installation,

performance

information

notice

covered

Service-Gaymar

READING

PAGE

ON

with

significant

Gaymar

both

complete

its

application

operation,

or

provided.

is

reserved.

sufficiently

YOUR

MEDI-THERM,

THIS

INSPECTION

3-1.

Medi-therm.

data

and

current,

make

it

or

reliability

The

Should

for

Industries,

maintenance.

may

right

further

the

purchaser's

MANUAL,

PRO-

regarding

Although

the

impossible

occur

at

to

revise

or

information

Inc.

the

essential

every

attempt

large

number

to

cover

In

addition,

any

time

change

be

desired

purposes,

all

and

this

the

of

First

Printing

Second

"АО

РИА

July,

1989

— _ TOT

и

μα.

E

REUSABLE

USAGE

CONTAINER

INSTRUCTIONS

RC-1

Le

26

3;

4.

5,

6.

The

8.

With

unit

unfasten

Using

base

Remove

handles provided

section.

accessories.

Lift unit

If

transformer

base

Follow

Manual.

To

diagram

To

with

section

start-up

repack,

clean

water/soap

in

upright

container

out

and

reverse

for

positioning

reusable

TRANSFORMER

position

sections.

of

base

is

included,

follow

instructions

unpacking

container,

solution.

USAGE

lift

upper

section.

remove

transformer

in

instructions.

of

components.

wipe

MODEL

INSTRUCTIONS

rotate

container

Operating

with

XFM-1

latches

transformer

usage

instructions.

Instruction

cloth

to

section

from

See

inside

wetted

off

Note:

la

2

Be

4.

Sis

6.

This unit

MTA-4700

Place

of

MTA-4700

Make

certain

MTA-4700

Plug

Plug

side

Turn

power

power

of

circuit

Follow

XMF-1

and

XFM-1.

start-up

unit

unit.

that

XFM-1

cord

cord

breaker

is

for

only.

onto

the

units

of

XMF-1

MTA-4700

of

instructions

use

with

shoulder

circuit

are

into

XMF-1

of

Gaymar

bolts

breaker,

in

220V,

unit

to

for

the

off

50/60

into

position.

on

MTA-4700

Medi-Therm

provided

on-off switch

position.

HZ

outlet.

receptacle

unit.

on

model

rear

of

on

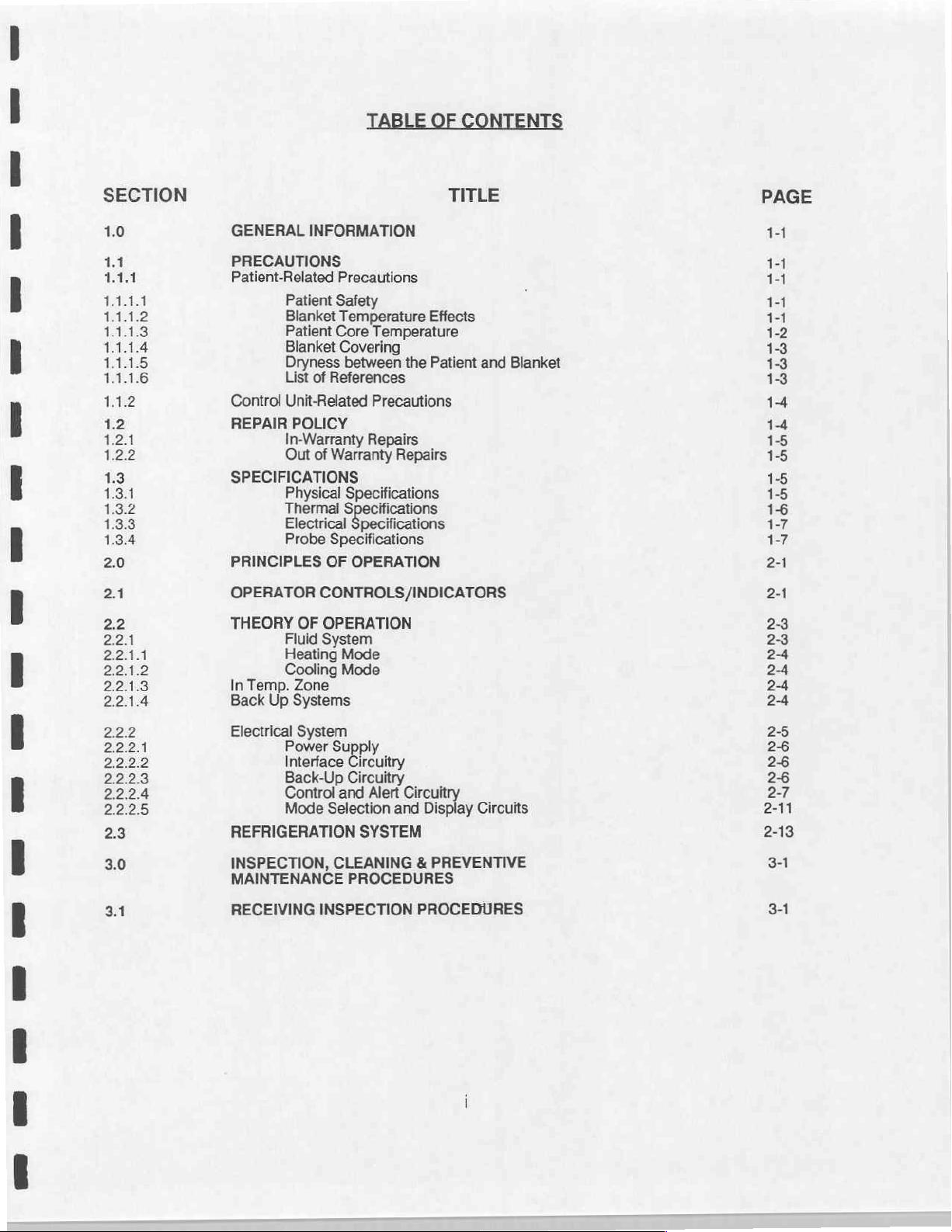

TABLE

OF

CONTENTS

SECTION

o

ak

Lu

E

=

ee

Falla

ニニ ニニ ーー ニニ

Ono

ー

RY

+

ニュ

ニニ

Nit

NA

ニニ

ニー

Boh-

ニニ

bbebü

NN

©

Ν

OS

oo

090000000000

に

GENERAL

PRECAUTIONS

Patient-Related

Control

REPAIR POLICY

SPECIFICATIONS

PRINCIPLES

OPERATOR

THEORY

In

Temp.

Back

INFORMATION

Precautions

Patient

Blanket

Patient

Blanket

Dryness

List

Unit-Related

In-Warranty

Out

Physical

Thermal

Electrical

Probe

Fluid

Heating

Cooling

Up

Safety

Temperature

Core

Covering

of

References

of

Warranty

Specifications

OF

CONTROLS/INDICATORS

OF

OPERATION

System

Zone

Systems

Temperature

between

Precautions

Repairs

Specifications

Specifications

Specifications

OPERATION

Mode

Mode

Effects

the

Patient

Repairs

TITLE

and Blanket

EO

МЮ

NNNNN

© R

o b

E

>

Electrical

System

Power

Interface

Back-Up

Control

Mode

Supply

Selection

REFRIGERATION

INSPECTION,

MAINTENANCE

RECEIVING

CLEANING & PREVENTIVE

INSPECTION

Circuitry

Circuitry

and

Alert

and

SYSTEM

PROCEDURES

Circuitry

Display

PROCEDURES

Circuits

TABLE

OF

CONTENTS

SECTION

6606066000606

ONDA

DDR

EGG

bo

Wow

VEEE

ARR

boa

OH

VE

CLEANING

FUNCTIONAL

P.C.

BOARD

REFRIGERATION

FLOW

TROUBLESHOOTING

TROUBLESHOOTING

REPAIR

Thermostats

Cover

Top

SPARE

PROCEDURES

Fluid

System

Compressor

Pump

Panel

Exterior

Blankets

Probe

Check

Probes,

Probes,

CHECK-OUT

Procedures/Equipment

Inspection

CALIBRATION

A3

Power

A2

Control

A1

Display

Primary

SWITCH

PROCEDURES

Recharging

Replacing

Replacing

Replacing

PARTS

TITLE

Well

Reusable

Disposable

AND

SAFETY

Form

Supply

PROCEDURES

Board

Board

Board

CONTROLLER ADJUSTMENT

Back-Up

CLEANING

A3

A2

A1

Adjustment

PROCEDURE

&

SERVICE

GUIDE

Refrigeration

Power

Control

Display

Unit

Supply

Board

Board

DATA

Board

INSPECTION

PAGE

3-2

3-2

3-3

3-3

3-3

3-3

3-3

34

34

3-4

3-4

3-13

3-15

3-15

3-16

3-17

3-18

3-19

3-19

4-1

4-1

46

46

4-9

4-9

4-10

4-10

410

412

SHIPPING/REPACKING

REFERENCE

CELSIUS-FAHRENHEIT

RESISTANCE

Patient

Primary

Water

Probe

Water Probe

Probe

Back-Up

(RT2

(RT3

TABLES

VALUE-TEMPERATURE

Thermistor

ILLUSTRATIONS

INSTRUCTIONS

CONVERSION

(RT1)

TABLE

CONVERSION

TABLES

4-15

5-1

5-1

5-2

5-2

5-2

5-3

54

TABLE

OF

CONTENTS

DESCRIPTION

Warm-Up

Cool

ADP-10B

Operator

Heating

Cooling

Electrical

Electrical

Electrical

Electrical

Refrigeration

Test

Refrigeration

Flow

Recharging

Unit

P.C.

Spare

Spare

P.C.

A1

Display

P.C.

A2

Control

P.C.

A3

Power

Shipping/Repackaging

Rate

Graph

Down

Rate

Graph

Circuit

Controls/Indicators

Mode

Mode

Schematic-A1

Schematic-A2

Schematic-A3

Schematic-A3

Set-Up

Switch

Disassembly

Board

Parts

Parts

Board

Board

Board

Diagram

System

Procedures

Controller

Cleaning

Refrigeration

Connections

Diagram

Diagram

Component

Board

Component

Board

Component

Supply

(Chassis)

(Top

Board

Display

Control

Power

Power

Adjustment

Procedure

Unit

Listing . . .

Listing . . .

Listing...

Instructions

Board

Board

Supply

Supply

Cover)

Board

(MTA-4700/4701)

Board

(MTA-4702)

FIGURE

NO.

6.1

6.2

6.3

6.4

6.5

66

67

68

69

6.10

6.11

6.12

6.13

6.13

6.15

6.16

6.17

6.18

6.19 6-12

6.20

6.21

6.22

6.23

6.24

6.25

PAGE

6-1

6-1

6-1

6-2

63

63

64

65

66

67

68

6-9

69

69

6-10

6-10

6-11

6-11

6-13

6-14

6-15

6-16

6-17

6-18

GENERAL

INFORMATION

1.0

11

1.1.1

1.1.1.1

11612

GENERAL

PRE

TIENT-RELATED

PATIENT

Maximum

thorough

cation

AND

of

ALL

REVIEWED.

MINUTES

AUTION:

BLANKET

INFORMATION

TION

P

SAFETY

benefit

knowledge

the

PRECAUTIONS

CHECK

OR

AS

to

unit.

THE

THE

OFTEN

POWER

INTO

RESETTING

CONTINUED.

the

and

TEMPERATURE

AUTION

patient

understanding

OPERATOR

PRIOR

PATIENT

AS

STANDBY

TO

AND

DIRECTED

INTERRUPTION

BY

EFFECTS

at

the

MUST

USE.

BLANKET

BY

MODE

THE

greatest

of

the

margin

correct

UNDERSTAND

PRECAUTIONS

WATER

THE

PHYSICIAN.

WILL

(NO

THERAPY)

USER

BEFORE

of

safety

operation

THE

OPERATING

SHOULD

BE

TEMPERATURE

CAUSE

UNIT

AND

THERAPY

requires

and

appli-

MANUAL

CAREFULLY

EVERY

TO

GO

REQUIRE

CAN

BE

a

20

BLANKET

THE

TEMPERATURE,

AND

DIRECTED

OPERATING

A.

TEMPERATURE

GUIDANCE

THE

BLANKET

BY

Operating

inadequate

of

peripheral

external

B.

Temperature

circulation

tated

more

chord

blanket

OF A PHYSICIAN.

SKIN

CONDITION

WATER

THE

PHYSICIAN.

ROOM

PATIENTS

Room

Patients - Patients

heart

blood

application

Sensitive

caused

may

be

more

normal

injury)

circulation.

should

is

in

use.

SHOULD

TEMPERATURE

CHECK

MORE

BE

SET

ONLY

CHECK

IN

FREQUENTLY.

PATIENT,

AN

AREA

PEDIATRIC,

with

function,

vessels

of

heat

reduction

may

deviate

and

cold.

Patients - Patients

by

vascular

sensitive

Patients

always

diseases

to

temperature

unable

be

closely

AS

IN

EVERY

TEMPERATURE

poor

in

blood

from

with

and

to

monitored

PRESCRIBED

INCLUDING

CONTACT

20

MINUTES

circulation

volume,

the

normal

impaired

patients

changes

detect

temperature

when a temperature

BY

AND

PATIENT’S

WITH

THE

OR

AS

OFTEN

SENSITIVE,

associated

and

constriction

response

peripheral

who

are

than

patients

(i.e.

UNDER

CORE

BLANKET

AS

AND

with

to

the

blood

incapaci-

with

spinal

ο.

Pediatrics - The

responsive

patient

skin

to

the

more

contact

core

surface

pronounced

area

to

temperature

heating and

the

body

volume.

in

infants

cosa

effect

GENERAL

and

tan

in

adults.

because

INFORMATION

children

The

of

their

is

smaller

higher

more

the

ratio

of

1.1.1.3

Additional

arise

for

example,

trode,

itself

injurious.1*

PATIENT

Localized

pressed

associated

temperatures

injury

Local

capillary

enhanced

forces,

vation.

EXCESSIVE

FORCES-ESPECIALLY

ATIENT

If

the

patient's

Heat

Sources - Heat

in

skin

could

may

AND

Skin

between

temperature

to

electrosurgical

be

sufficient

be

completely

DO

NOT

THE

BLANKET.

Injury - Localized

boney

with

prolonged

well

below

in

to

safe;

PLACE

prominences

the

threshold.2,3,4,5,6

ischemia

pressure,

and

Pathological

CORE

core

can

follow

resulting

by

generalized

increased

AND/OR

TEMPE

temperature

the

impairment

metabolic

changes

PROLONGED

OVER

BONEY

RE

is

being

the

applied

area

of

contact.

currents

cause

tissue

however,

ADDITIONAL

skin

injury

and

cardiovascular

scientifically

application

in

tissue

necrosis.

of

demand

may

begin

TISSUE

PROMINENCES.

not

responding

by

the

blanket

Additional

flowing

injury.

HEAT

to

the

the

Each

additive

thermal

SOURCES BETWEEN

corresponding

fluid-filled

channels

procedures

established

of

pressures

This

local

the

circulation,

because

in

PRESSURE

and/or

two

of

temperature

hours.”

does

could

heat

result

rise

dispersive

effect

effect

to

may

tissue

has

and

blanket

epidermal

exceeding

effect

local

may

shearing

PREVENT

AND

SHEARING

not

reach

in

due,

elec-

by

be

THE

com-

been

burn

mean

be

ele-

the

*

Numbered

prescribed

scribed

TOR

superscripts

temperature

THE

PATIENT’S

temperature

range,

CORE

refer

to

references

in

the

prescribed

the

attending

TEMPERATURE

in

Section

time

physician

FREQUENTLY.

1.1.1.6

of

and/or

this

manual.

deviates

should

from

be

notified.

the

MONI-

pre-

GENERAL

INFORMATION

1.1.1.4

1.1.1.5

1.1.1.6

BLANKET

A

dry

cotton

sanitary

barrier

distribution

PLACE A DRY,

SURFACE.

WHICH

AN

INTERPOSED

RY

The

application

solutions

patients

res.8,9

LIST

REFERENCES

have

and a water-circulating

KEEP

OF

Electrosurgery,

Scott,

2.

Vol.

94,

COVERING

sheet

and

absorbs

of

heat

and

COTTON

GAYMAR'S

В

EEN

of

heating

been

THE

AREA

Stewart

181,

p.

placed

between

perspiration. A sheet

contributes

SHEET

to

BETWEEN

MUL-T-BLANKET”

SHEET

THE

reported

BETWEEN

AMM

Thermal

M.

Feb.

IS

PATIENT

or

cooling

to

310

(6/76),

1978.

NOT

injure

heating blanket

THE

Blanket

the

patient

the

reduction

THE

PATIENT

ALSO

PROVIDES A FABRIC

REQUIRED.

AND

may

the

affect

skin

when

BLANKET

PATIENT AND

Ritter

Co.,

the

Injury

in

and

the

blanket

also

promotes a more

of

localized

AND

THE

the

toxicity

allowed

during

THE

prolonged

BLANKET

Rochester,

Operating

provides

tissue

PLASTIC

SURFACE

of

solutions.

to

remain

DRY.

NY.

Room.

Arch.

a

even

pressure.

BLANKET

FOR

Prep

between

procedu-

Surg.

3

Crino,

ating Room.

4.

Gendron,

19-26,

5.

Moritz,

TERME

6.

Stoll,

of

Nov.

Kosiak,

7.

and

8.

Llorens,

radical

1972.

Marjanne

H.

Anesthesiology,

Francis

January-March

A.R.

and

Am.

J.

Alice

M.

and

Thermal

Protection.

1969.

Michael.

Rehabilitation,

Alfred

pelvic

S.

operations.

Thermal

G.

Journal

Burns

Vol.

29,

of

Clinical

Caused

1980.

Henriques,

Path,

Chianta,

Aerospace

Etiology

p.

Reaction

providone-iodine

23:695,

of

19,

Jan.

to

Am.

13

Jr.,

Не

1947.

Maria

A.

Method

Medicine,

Decubitus

Ulcers,

1961.

Obstet.

J.

by

Warming

pp.

149-50,

Engineering,

des

of

and

Rating

Vol.40,

Archives

surgical

Gynecol.,

Blankets

Jan.-Feb.

Vol.

1980.

5,

henne!

System

No.

of

scrub

pp.

for

11,

pp.

Physical

associated

834-835,

in

the

Oper-

No.

1,

pp..

jury

Il

Evaluation

1232-1238,

Medicine

with

14,

Nov.

GENERAL

INFORMATION

112

1.2

9. © Hodgkinson,

NTROL

A.

B.

6.

D.

REPAIR

Burns

and

Skin

pp.

17,

Val.,

UNIT-RELATED

|IMPORTANT-

Donotrunthe

may

result.

water.

Gaymar

rectal/esophageal

check,

sheath

Use

POLICY

Medi-Therm

use a disposable

or

YS!

400

Darryl

J.,

Preparation

534-536,

machine

Use

equivalent)

Series

Oct.

ALWAYS

AND

REPAIRS

THERM

COULD

distilled

machines

temperature

to

patient

Irons,

George

Solutions.

1978.

PRECAUTI

PERFORM

SAFETY

AND

FOR

PATIENT

RESULT

without

water

probe

prevent

water,

only.

are

probes.

sheath

cross

probes

or

B.

and

Williams,

Surgery,

INSPECTION

BEFORE

IN

PATIENT

as

Alcohol

provided

(B-D

contamination.

equivalent.

Gynecology

FUNCTIONAL

RETURNING

USE.

damage

should

with a means

When

catalog

Tiffany

4

an

CHECK-OUT

AFTER

IMPROPER

INJURY.

to

internal

not

performing

#3700

components

be

thermometer

J.

Chemical

Obstetrics,

MAKING

MEDI-

REPAIR

added

of

to

the

checking

the

probe

The

Medi-Therm

material

of

the

Hyper/Hypothermia

customer

to

For

this

familiar

Service

available

sentative.

and

unit

has

request, a shipping

Gaymar

customers

manual

or a qualified

with

training

from

workmanship

contains

practices

Hyper/Hypothermia

an

additional

who

for

Gaymar.

for a period

four

(4)

Units

elect

the

can

be

carton

Service

to

information

for

servicing

Hyper/Hypothermia

For

Center.

repair

to

medical

specific

14

Unit

is

warranted

of

one

(1)

year.

year

pro-rated

repaired

will

Gaymar

allow a qualified

at

the

be

provided

Medi-Therm

devices,

Unit

details,

contact

The

compressor

warranty.

factory

to

or

to

safely

Units

bio-medical

make

is

recommended

your

free

of

defects

The

Medi-Therm

in

the

field.

return

at

their

location,

technician,

necessary

Gaymar

in

portion

Upon

the

unit

repairs.

and

is

repre-

GENERAL

INFORMATION

1.2.1

122

IN-WARRANTY

All

in-warranty

Department

A.

Replacement

period.

uncommon

B.

OUT-OF

The

A.

Unit

calibration

and

is

WARRANTY

following

Defective

Gaymar

B.

Defective

for

refurbished

C.

Defective

base)

REPAI

field

before

Since

repairs

proceeding.

lamps

must

will

average

be

be

furnished

lamp

occurrence.

is

considered

not

covered

by

Gaymar’s

REPAIRS

repair

options

are

available

Component - Replacement

part

number;

Printed Circuit

boards

Top

Module - The

to

the

factory

reference

(PC)

Board - Defective

at a fixed

defective

or

qualified

authorized

at

life

is

14,000

part

of

preventive

Warranty.

when

parts

Parts

cost

List

directly

top

module

Service

by

Gaymar's

no

charge

hours,

maintenance

local

can

be

in

Section 4 of

PC

boards

from

can

Center

during

lamp

unit

servicing

ordered.

can

the

be

for

repair.

Technical

the

warranty

failure

procedures

is

elected:

Specify

this

manual.

be

exchanged

factory.

returned

(without

Service

is

an

the

1.3

1.3.1

D.

Unit

Repairs - If a Hyper/Hypothermia

cause

returned

expensive

of

the

to

problem

the

factory

repair

option.

cannot

for

PECIFICATI

P

A.

B. © Weight - MTA-4700/4701:

ICA

ECIFI

Dimensions:

(full);

lbs.

145

(empty);

56.25

kg

37

(93.98

Ibs.

124

Shipping

ION

inches

(empty);

be

servicing.

x

high

high

cm.

Sniping

Wt.:

1-5

Unit

becomes

determined,

This

normally

17-1/8

43.50

x

inches

cm.

Wt.:

68.04

kg.

the

deep

deep

150

defective

complete

represents

inches wide

14

x

x

35.56

Ibs.

cm.

65.77

and

unit

can

the

wide)

kg

the

be

most

(full);

155

Ibs.

70.31

(full);

kg.

(full);

134

60.78

Ibs.

kg.

(empty);

(empty);

Shipping

Shipping

GENERAL

Wt.:

Wt.:

160

72.58

lbs.

INFORMATION

kg.

1.3.2

Reservoir

D.

Pressure,

E:

Flow;

THERMAL

A.

Flow

Check

SPECIFICATIONS

High

T

1.

Adjustable:

2.

Fixed:

I

1.

Adjustable:

2.

Fixed:

Switch

12 + 2

GPH

Probe

Below

250C

Capacity: 9 quarts

Dead

Head:

16

GPH

H/H

Blanket.

Actuation

(45.42 + 7.6

Activation

or

above

7.0 + 1.0

(60.57

419С + 0.50C

430C

47°C

re

Cut

Cut

2.50C

liters/hour)

=

to

46.50C

to

50°C

in

5.29 - 6.50C

out

3.90 - 4,500

to - 3.09C

Level

liters)

Temperature

450C

(8.52

liters)

psi

(48.23 + 6.89

(Whenever

distilled

minimum

(Average

(Unit

will

DOWN

and

Audible

(Will

turn

probe

water.

kPa).

through a full

Water

Temperature)

go

into

MACHINE

FROM

heater

SERVICE

Alarm

off

is

used.)

will

be

and

size

condition

on.))

on

only.)

GAYMAR

SHUT-

Patient

25°C

to

Blanket

40C

to

410C

Warm-up

See

Figure

Cool

Down

See

Figure

Temperature

Control

419C

Water

Temperature

Rate

Curve

6.1,

Page

6-1

Rate

Curve

6.2,

Page

6-1

Range

Control

for

Range

1-6

Automatic

for

Mode

Manual

Mode

GENERAL

INFORMATION

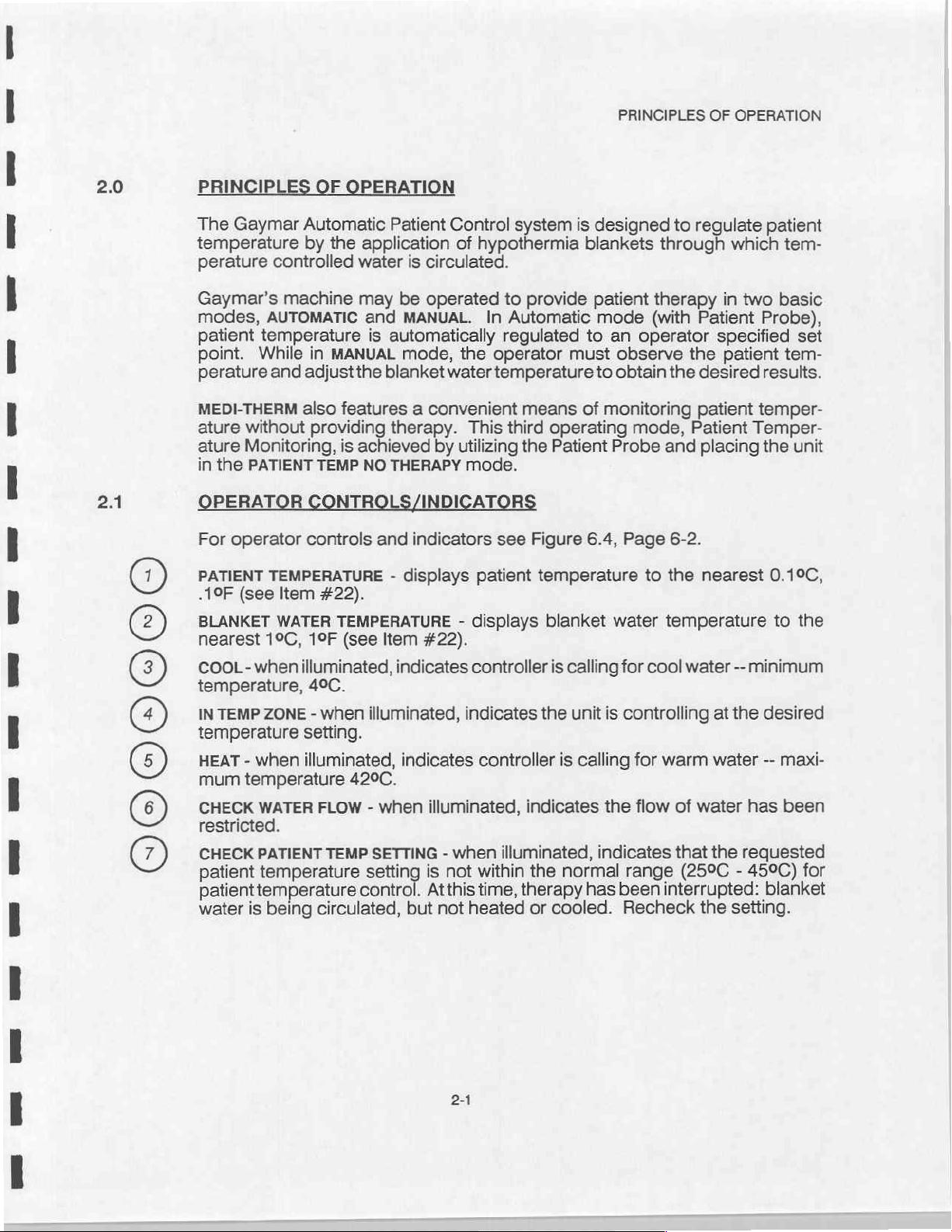

1.3.3

ELECTRICAL

A.

Display

B.

Controller

Current

Chassis

Patient

Microamps

Input

Voltage

Frequency

a

Power

Input

Current

--with

--with

-With

SPECIFICATIONS

Accuracy:

Accuracy:

Leakage:

Microamps

Probe

(Grounded)

Maximum

(Volts)

(Hz)

Consumption

(AMPS)

compressor

compressor

heater

ON

Maximum

(WATTS)

and heater

ON

ON

Water

Temperature

Patient

Water

Patient

Temperature

Temperature

Temperature

MTA-4700

100

50

120 + 10

50/60

1325

11.5

75

4.0

+1

+

0.5°C, + .90F

+

.759C,

«0.590, + .90F

MTA-4701

100

50

100

(+10)

65

50/60

1150 1188

10.0

65

3.5

°C, + 1.80F

+1.30F

MTA-4702

200

100

220 + 20

50/60

5.5

3.0

25

1.3.4

PR

PECIFICATION

Disposable

1.

DP-400 - Disposable

length

2.

ADP-10 - Reusable

or

Probes

(requires

Cincinnati

3. | ADP-10B - Reusable

can

Medical

TWO

ADDITIONAL

USE

WITH

ADAPTOR

Reusable

1.

2.

3.

Probes

PAT-101 - Patient

PAT-102 - Patient

PAT-108 - Patient

adaptor).

Sub-Zero

Systems

RESISTORS

AMERICAN

CIRCUIT

probe--Rectal/Esophageal - Adult

probe--Rectal/Esophageal - Pediatric

probe--Skin Surface

Rectal/Esophageal--Adult/Small

adaptor

cable

for

DP-400

(connects

equipment).

adaptor

equipment).

MEDICAL

DIAGRAM,

1-7

cable

TO

PROVIDE

SYSTEMS

FIGURE

for

DP-400

NOTE:

TEMPERATURE

6.3,

PAGE

(10’

(connects

THIS

ADAPTOR

EQUIPMENT

6-1.

long).

Child - 3°

to

to

CONTAINS

OFFSET

ONLY.

(10'

long).

(10°

Gaymar

Ameri-

FOR

SEE

long).

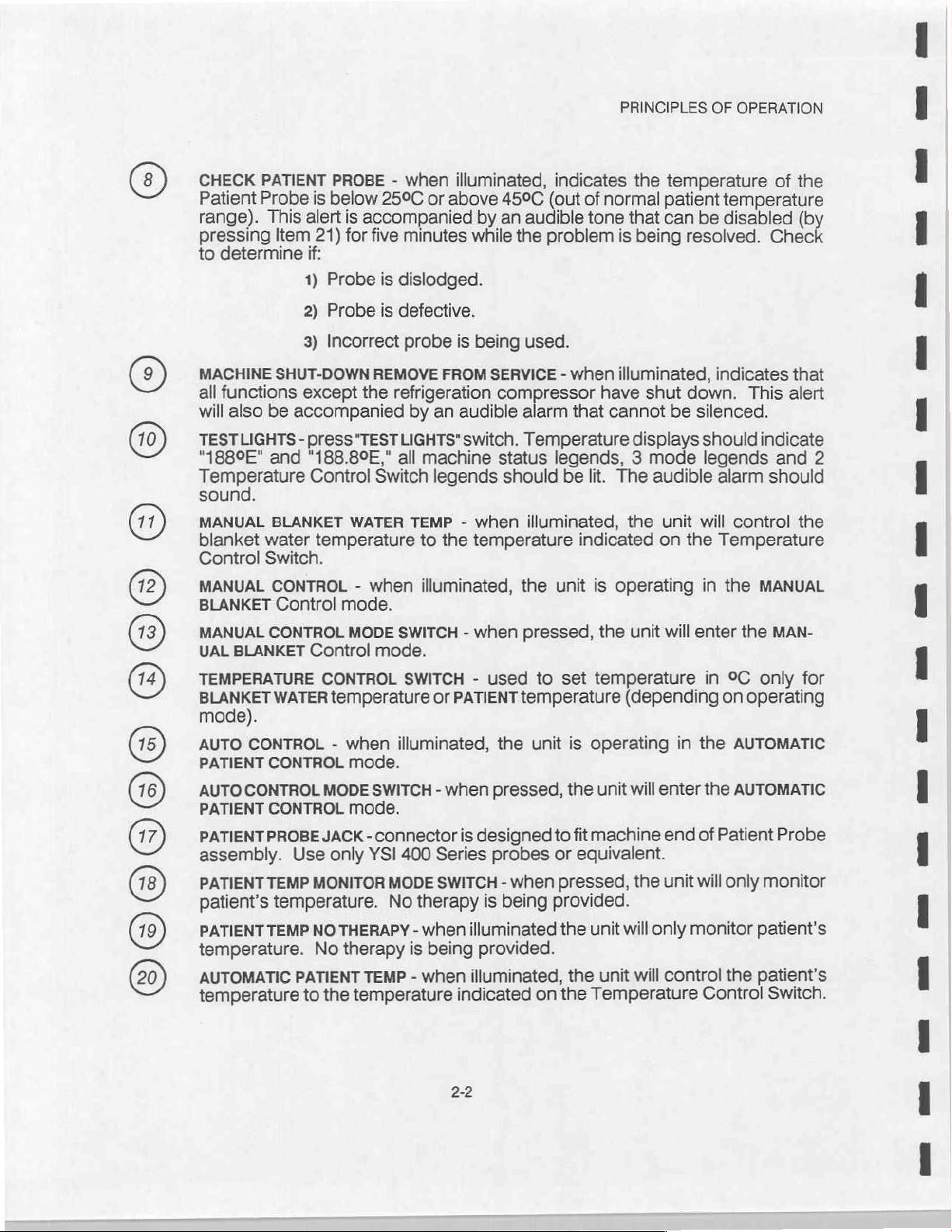

PRINCIPLES

OF

OPERATION

2.0

201

PRIN

The

Gaymar

temperature

perature

Gaymar's

modes,

patient

point.

perature

controlled

machine

AUTOMATIC

temperature

While

and

MEDI-THERM

ature

ature

in

For

PATIENT

.19F

BLANKET

nearest

without

Monitoring,

the

PATIENT

PERATOR

operator

TEMPERATURE - displays

(see

WATER

10C,

Item

F

OPERATION

Automatic

by

the

in

MANUAL

adjust

also

features a convenient

providing

is

TEMP

NTR

controls

Patient

application

water

may

is

circulated.

be

operated

and

MANUAL.

is

automatically

mode,

the

blanket

therapy.

achieved

NO

and

by

THERAPY

INDICATOR

indicators

Control

of

the

water

This

utilizing

mode.

#22).

TEMPERATURE - displays

10F

(see

ltem

#22).

system

hypothermia

to

provide

In

Automatic

regulated

operator

must

temperature

means

third

operating

the

Patient

see

Figure

patient

temperature

blanket

is

designed

blankets

patient

mode

to

an

operator

observe

to

obtain

of

monitoring

mode,

Probe

6.4,

Page

water

to

regulate

through

therapy

(with

in

Patient

specified

the

patient

the

desired

patient

Patient

and

placing

6-2.

to

the

nearest

temperature

patient

which

two

Probe),

results.

temper-

Temper-

the

0.10C,

to

tem-

basic

set

tem-

unit

the

COOL-

when

illuminated,

temperature,

IN

TEMP

temperature

HEAT - when

mum

ZONE - when

setting.

illuminated,

temperature

CHECK WATER

restricted.

CHECK

OVOS)

patient

PATIENT

temperature

patienttemperature

water

is

being

indicates

4°C.

illuminated,

42°C.

FLOW - when

TEMP

SETTING - when

setting

control.

circulated,

controller

indicates

indicates

controller

illuminated,

is

not

within

Atthis

but not

time,

heated

2-1

is

calling

the

unit

is

is

calling

indicates

illuminated,

the

therapy

or

cooled.

the

indicates

normal

has

for

cool

water

controlling

for

warm

flow

range

been

interrupted:

Recheck

at

water

of

water

that

the

(25°C - 45°C)

the

--

minimum

the

desired

--

maxi-

has

been

requested

blanket

setting.

for

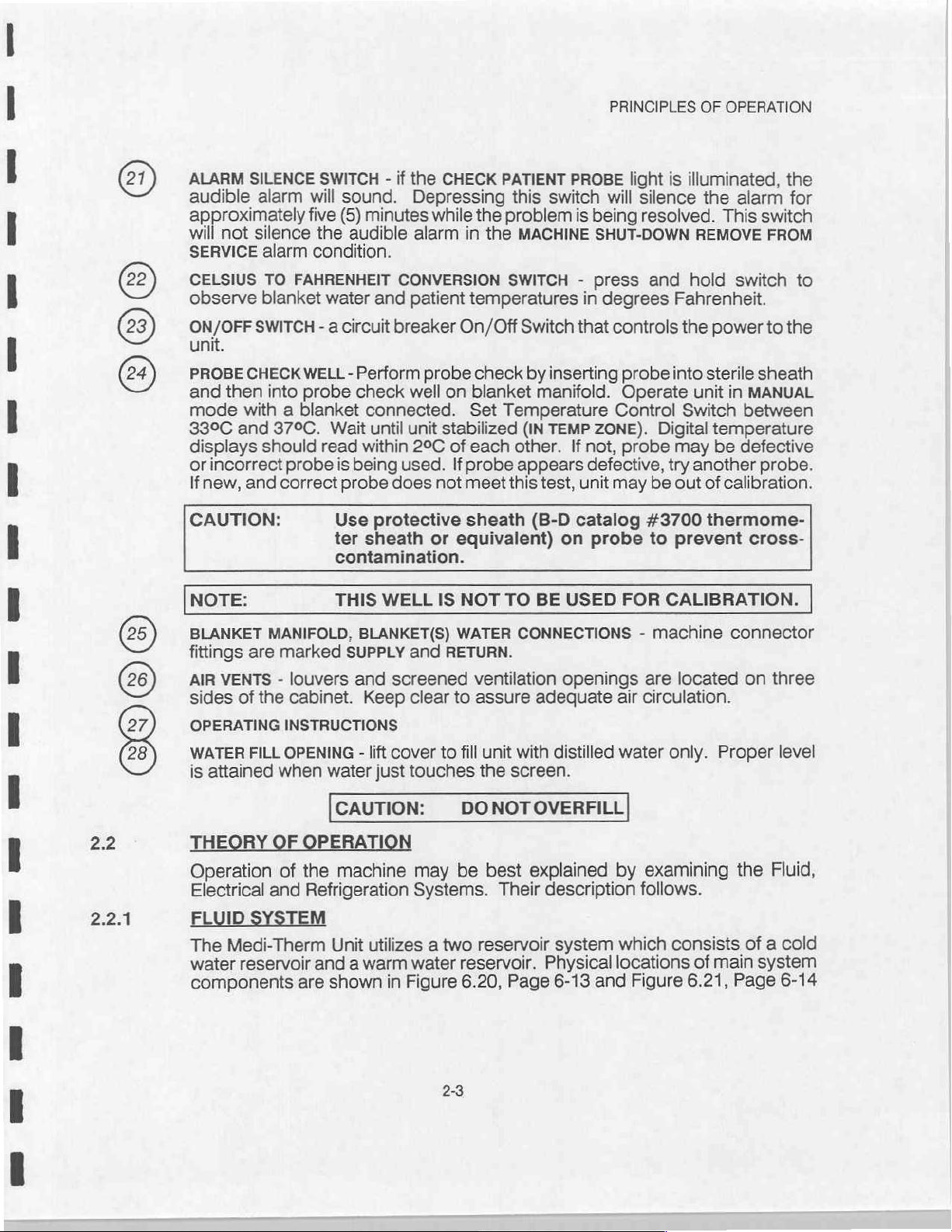

PRINCIPLES

OF

OPERATION

©

CHECK

Patient

range).

pressing

to

determine

MACHINE

all

functions

will

also

TEST

"1880E"

Temperature

sound.

MANUAL

©

blanket water

Control

MANUAL

BLANKET

PATIENT

Probe

This

Item

SHUT-DOWN

be

LIGHTS - press

and

BLANKET

Switch.

CONTROL - when

Control

PROBE - when

is

below

alert

is

21)

for

if:

1)

Probe

2)

Probe

3)

Incorrect

except

accompanied

"188.80E,"

Control

temperature

mode.

25°C

or

accompanied

five

minutes

is

dislodged.

is

defective.

probe

REMOVE

the

refrigeration

by

an

"TEST

LIGHTS"

all

machine

Switch

WATER

legends

TEMP - when

to

illuminated,

illuminated,

above

FROM

the

45°C

by

an

audible

while

the

is

being

audible

switch.

temperature

used.

SERVICE - when

compressor

alarm

Temperature

status

should

illuminated,

the

indicates

(out

of

problem

that

legends, 3 mode

be

indicated

unit

the

normal

tone

that

is

being

illuminated,

have

shut

cannot

displays

lit.

The

audible

the

is

operating

patient

can

unit

on

temperature

temperature

be

disabled

resolved.

indicates

down.

be

silenced.

will

the

This

should

legends

in

indicate

alarm

control

Temperature

the

MANUAL

of

the

(by

Check

that

alert

and

2

should

the

MANUAL

UAL

TEMPERATURE

006

BLANKET WATER

mode).

AUTO

PATIENT

AUTO

PATIENT

PATIENT

assembly.

PATIENT

patient’s

PATIENT

temperature.

AUTOMATIC

000000

temperature

CONTROL

BLANKET

CONTROL - when

CONTROL

Control

CONTROL

CONTROL

MODE

CONTROL

PROBE

TEMP MONITOR MODE

temperature.

TEMP

JACK - connector

Use

NO

No

PATIENT

to

the

MODE

temperature

mode.

SWITCH - when

mode.

SWITCH - used

or

illuminated,

SWITCH - when

mode.

only

YSI

400

Series

SWITCH - when

No

therapy

THERAPY - when

therapy

is

being

TEMP - when

temperature

pressed,

to

PATIENT

is

illuminated

temperature

the

unit

pressed,

designed

probes

is

being

provided.

to

or

provided.

illuminated,

indicated

on

the

unit

set

temperature

(depending

is

operating

the

unit

will

fit

machine

equivalent.

pressed,

the

the

the

the

unit

will

unit

will

Temperature

will

enter

in

in

the

enter

the

end

of

unit

will

only

monitor

control

Control

the

MAN-

°C

only

on

operating

AUTOMATIC

AUTOMATIC

Patient

only

the

Probe

monitor

patient's

patient's

Switch.

for

22

PRINCIPLES

OF

OPERATION

ALARM

O

audible

approximately

will

not

SERVICE

CELSIUS

observe

ON/OFF

unit.

PROBE

000

and

then

mode

33°C

displays

or

If

CAUTION:

NOTE:

BLANKET

©

fittings

with a blanket

and

incorrect

new,

SILENCE

alarm

silence

alarm

blanket

SWITCH - a

CHECK

should

and

are

will

five

condition.

TO

FAHRENHEIT

WELL - Perform

into

probe

37°C.

probe

correct

MANIFOLD,

marked

SWITCH - if

sound.

(5)

the

audible

water

circuit

check

Wait

read

within

is

being

probe

Use

ter

sheath

contamination.

THIS

BLANKET(S)

SUPPLY

the

Depressing

minutes

CONVERSION

and

patient

breaker

well

connected.

until

unit

2°C

used.

does

protective

WELL

and

CHECK

while

the

alarm

in

temperatures

On/Off

probe

check

on

blanket

Set

stabilized

of

each

If

probe

not

meet

sheath

or

equivalent)

IS

NOT

WATER

RETURN.

PATIENT

this

problem

the

MACHINE

SWITCH - press

Switch

Temperature

(IN

other.

appears

this

TO

CONNECTIONS - machine

PROBE

switch

is

being

SHUT-DOWN

in

that

by

inserting

manifold.

TEMP

test,

(B-D

BE

ZONE).

If

not,

defective,

unit

catalog

on

probe

USED

light

will

silence

resolved.

degrees

controls

probe

Operate

Control

probe

may

#3700

FOR

is

illuminated,

the

alarm

This

REMOVE

and

hold

switch

Fahrenheit.

the

power

into

sterile

unit

in

Switch

Digital

be

to

CALIBRATION.

temperature

may

be

try

another

out

of

calibration.

thermome-

prevent

defective

connector

the

for

switch

FROM

to

to

the

sheath

MANUAL

between

probe.

cross-

2.2

2.2.1

AIR

©

sides

OPERATING

WATER

DO

is

attained

THEORY

Operation

Electrical

FLUID

The

water

components

VENTS - louvers

of

the

cabinet.

INSTRUCTIONS

FILL

OPENING - lift

when

OF

and

water

CAUTION:

OPERATION

of

the

machine

Refrigeration

SYSTEM

Medi-Therm

reservoir

Unit

and a warm

shown

are

and

screened

Keep

clear

cover

just

touches

may

Systems.

utilizes a two

water

Figure

in

ventilation

to

assure

to

fill

unit

the

screen.

DO

NOT

be

best

Their

reservoir

reservoir.

6.20,

2-3

Page

openings

adequate

with

distilled

OVERFILL

explained

description

system

Physical

6-13

are

air

circulation.

water

by

examining

follows.

which

locations

Figure

and

located

only.

consists

Proper

of

main

6.21,

the

Page

on

three

level

Fluid,

of a cold

system

6-14

of

this

manual.

senses

water

TEMP

10C

The

liters)

eration

The

heat

cartridge

the

temperature

ZONE

of

the

cold

water

of

water

controller

warm

is

called

heater.

reservoir

In

the

temperature

is

condition

BLANKET

reservoir

at

4°C.

(S4).

water

reservoir

for,

water

The

is

41.50C.

MANUAL

of

within

and

will

WATER

system

This

contains

in

maximum

mode,

the

water

1°C

remain

of

going

the

desired

there

temperature

maintains

reservoir

temperature

only a small

the

reservoir

attainable

the

Blanket

to

the

blanket.

setting,

so

long

as

setting.

approximately

is

reserve

is

quickly

water

temperature

PRINCIPLES

Water

Probe

When

the

Unit

will

the

temperature

nine

(9)

maintained

of

water,

heated

by

inthe

OF

OPERATION

IZA

the

enter

quarts

by

the

and

means

warm

blanket

the

IN

is

within

(8.52

refrig-

when

of

the

water

22411

22.12

2.2.1.3

2.2.1.4

HEATING

See

Figure

COOLING

See

Figure

IN

When

TEMP

the

between

BACK-UP

Several

patient

MAX

To

A.

safety.

limit

The

circuitry

the

6.5,

6.6,

ZONE

Medi-Therm

heating

SYSTEM

back-up

maximum

primary

limit

warm

water

Page

6-3.

Page

6-3.

(Figure

systems

TER

water

high

the

reservoir

is

in

the

IN

TEMP

6.5,

Page

are

incorporated

ΤΕΜΡΕΒΑΤΙ

temperature,

temperature

maximum

average

to

410 + 0.50C.

ZONE,

6-3)

and

the

back-up

the

water

cooling

into

the

following

controls

sensor

water

temperature

path

(Figure

unit

to

assure

(RT1)

alternates

6.6,

Page

maximum

are

utilized:

and

associated

flowing

6-3).

through

24

B.

C.

The

second

bimetallic

thermostat

associated

FROM

the

Bimetallic

(47°to

off

SERVICE

refrigeration

thermostat

50°C).

and

on

again

high

temperature

control

circuitry,

circuit

compressor.

Ifthis

when

back-up

(S2).

which

(S3)

thermostatis

If

this

will

activate

automatically

is

the

third

activated,

it

cools

and

sensor

thermostat

the

MACHINE-SHUTDOWN

shuts

high

temperature

it

will

resets.

PRINCIPLES

(439

to

is

activated,

down

all

turn

the

OF

OPERATION

46.59C)

it,

along

REMOVE

functions

back-up

except

sensor

cartridge

is

the

with

heater

222

MINIMUM WATER

Temperature

controller

perature

SHUT-DOWN

all

functions

ELECTRICAL

The

unit’s

for

operator

selection),

tems.

temperature

The

of

water

(S4)

(3.9°

back-up

REMOVE

except

SYSTEM

electronics

input

status

controller

probe,

probe.

The

solid-state

modular

while

The

electrical

and

Safety

and

Display

design

construction

system

Circuits,

Circuits.

TEMPERATURE

in

the

to

6.5°C).

(-2.5°

to

+3.0°C)

FROM

the

SERVICE

refrigeration

package

(temperature

and

alert

displays,

controls

or

controls

assures

provides

consists

Control

cold

reservoir

The

bimetallic

for

Circuitis

is

controlled

thermostat

(S4).

If

triggered,

compressor.

utilizes a closed-loop

set

and

blanket

water

patient

temperature

reliability

for

of

the

Power

Circuits,

Alert

point

selection

redundant

temperature

and

accurate

easy and

Supply,

Circuits,

by

the

(S1),

S1

activates,

which

in

turn

controller

and

back-up

using

using a patient

control

convenient

Interface

Mode

with

operating

and

an

at

serviceability.

Circuits,

Selection

refrigeration

is a low

the

shuts

tem-

MACHINE

down

provisions

mode

safety

internal

connected

the

water

set

sys-

point

Back-Up

Circuits,

Component

6-17.

The

layout

electrical

and

schematics

parts

designation

are

25

are

shown

shown

on

Pages

on

Pages

6-4, 6-5,

6-15,

6-6,

and

6-16,

6-7.

and

PRINCIPLES

OF

OPERATION

2.2.2.1

2222

2.2.2.9

POWER

With

the

exception

contained

rectified,

Q11,

rectified

filtered,

is

controlled

lamp

INTERFACE

Interface

of

(A3)

(A3)

respective

low

(A3)

the

while

BACK-UP

The

on/off

RT1

perature

disables

to

turn

0.50C.

Circuitry

U1

U1

through

voltage

A1

control

hot

solenoid

(A3)

CIRCUITRY

A3

Board

controller

located

of

Q5.

the

SUPPLY

of

on

the

A3

Power

and

at

output

supply

(L.S.)

CIRCUITRY

is

also

through

triacs;

control

U1

and

in

the

This

heater

(A3)

(A3)

these

circuits

the

cold

valve

(A3)

also

contains

consisting

the

heater

output water

circuit

off

Transformer

Supply

by

means

levels

is

used

of

located

U4,

(A3)

U4

are

optically

combinations

and

the

solenoid

K2.

(A3)

U3

Q4

control

the

Primary

of

(A3)

manifold

exceeds

operates

to

limit

the

T-1,

the

unit’s

Printed

on-board

of

+5, + 12,

to

illuminate

on

the

Q1

coupled

line

valve

and

power

Wiring

regulators

-12,

A3

Power

through

triac

provide

voltage

K1

while

(A3)

G3

to

the

status,

(A3)

electrical

Back-Up

U7,

(A3)

A5,

surrounding

in

the

machine

419 + 0.5°C,

independently

average

output

Power

Board.

and

-5

alert,

Supply

Q4

and

drivers

power

(A3)

circuits.

U2

control

heat

circuit.

Circuit.

base.

(adjustable

from

the

water

Supply

The

(A3)

volts

Board

is

output

Q8

through

D.C. A full

and

legend

and

completely

associated

used

to

control

isolation

and

the

This

between

(A3)

(A3)

A2

circulating

is a solid

components,

Whenever

by

A3R1),

main

control

temperature

of

T-1

is

(A3)

wave

lamps.

consists

parts.

their

the

U4

and

control

pump

state

and

the

tem-

U7

circuits

to

410

+

Finally,

circuitry,

interconnected

inthe base.

of

blanket

into

(A3)

the

the

A3

which

R19,

water

range

Board

components,

Under

(A3)

temperature

from

includes

includes

normal

C11 and

43°C

the

MACHINE

(A3)

O6,

and

fixed,

conditions

(A3)

CR10

falls

into

to

46.5°C,

26

SHUT-DOWN

(A3)

U6,

(A3)

non-adjustable

(A3)

Q6

and

completes

the

range

S1

or

S2

REMOVE

U5,

(A3)

G7,

thermostats

is

kept

turned

the

heater

from

-30C

to

respectively

will

FROM

(A3)

CR9,

on

by

circuit.

+2.50C

open

SERVICE

their

S1

and

the

action

If

or

rises

and

full

S2

the

line

voltage

couplers

turning

output

returns

REMOVE

on

of

the

FROM

(A3)

(A3)

SHUT-DOWN

cleared

only

condition

SHUT-DOWN

The

final

protective

the

heater

from

47°C

SERVICE

circuit.

will

appear

U6

and

even

after S1

U5,

buffered

controller

SERVICE

REMOVE

by

turning

still

exists,

REMOVE

device,

and

would

to

50°C,

but

between

(A3)

U5

will

(or

S2)

by

(A3)

to

standby

indicator

FROM

SERVICE

the

machine

attempting

FROM

SERVICE

bimetallic

regulate

will

the

not

activate

(A3)

P1

be

turned

has

closed

Q7,

results

status,

and

enables

condition

off.

to

apply

to

reoccur.

thermostat

heater

the

pins 7 and

on.

(A3)

again.

in a signal

turns

the

on

audible

remains

If,

upon

machine

therapy

S3,

for

water

MACHINE

PRINCIPLES

1.

In

U6

prevents

The

to

the

MACHINE

alarm.

latched

will

cause

is

wired

OF

this

case,

(A3)

electrically

the

controller

This

up

turn

the

only

temperatures

SHUT-DOWN

REMOVE

OPERATION

optical

Q6

from

isolated

which

SHUT-DOWN

MACHINE

and

can

on,

the

fault

MACHINE

in

series

in

the

with

range

FROM

be

2.2.2.4

INTROL

The

Control and

exceptions

the

machine

Patient

Probe.

Circuitry:

A.

Reference

transistors

temperature

levels

used

the

effect

B.

Blanket

the

feedback

and

(A2)

linear

AND

are

ALERT

Alert

the

base,

The

Circuits

Flow

the

ALARM

following

Diode

(A2)

Qi

stable

of

+5

and

-5

here

and

throughout

of

ambient

water

temperature

loop

R12

is a linearly

temperature

CIRCUITRY

reside

Switch

and

SILENCER

is a brief

(A2)

CR1,

and

(A2)

references

volts,

respectively.

and

temperature

sensing

of

(A2)

U3.

temperature

sensitive

primarily

Blanket

Water Probe

Switch,

description

integrated

Q2,

and

associated

voltages

circuitry,

changes

thermistors

The

combination

voltage

results

on

the

A2

Temperature

of

the

circuits

(A2)

components

(+Vref

and

Temperature

where

appropriate,

on

system

RT2

of

dependent

at

the

output

Main

Control

Assembly

Set

Switch,

Control and

U1

and

-Vref)

stable

at

resistors

to

operation.

and

RTS

RT2,

RT3,

resistive

network.

of

(A2)

Board;

located

and

Alert

(A2)

U2,

generate

nominal

are

minimize

are

part

(A2)

R11

U3

with

in

of

A

2-7

zero

and

at

(A2)

TP4

Water

the

A

in

Probe

A1

Display

circuit

its

feedback

PATIENT

range

of

(A2J2

from

the

required

pin

span

adjustments

is

thus

linearly

Assembly.

Board.

(A2)

(U4)

similar

loop

to

temperature.

+300C

to

+410C

accuracy

3)

to

the

A1

provided

dependent

This

signal

to

that

by

(A2)

on

goes

described

generate a signal

(A2)

R19

linearizes

so

that

patient

can

be

achieved.

Display

Board.

PRINCIPLES

R9

and

the

temperature

off

the

in

"B"

uses

at

(A2)

the

probe

temperature

This

signal

(A2)

board

the

TP5

response

goes

OF

OPERATION

R6.

The

voltage

of

the

Blanket

(A2J2

that

determinations

pin

Patient

Probe

represents

over

off

the

board

6) to

the

Transistors

switch;

pin

1)

under

this

switch

temperature

by

voltage

The

controller

Switch.

(A2)

R24

span

The

output

selected

two

levels

the

output

and

sense

perature.

associated

error

whenever

mode.

signal

The

difference

follower

This

through

and

zero

probe

are

of

of

R120

components

amplifier;

the

Otherwise,

from

the

(A2)

Q3

through

command

selects

as

the

input

(A2)

set

point

setting

is

converted

(A2)

adjustments,

from

the

controller

circuit

are

unequal,

(A2)

U11.

the

difference

provides

the

integrator

machine

the

error

amplifier.

signal

and

(A2)

of

the

Mode

either

to

the

controller.

U12;

R117

is

determined

R34

and

(A2)

respectively.

compared

an

output

This

error

between

offset

is

an

integrator

is

is

in

standby

output

of

the

integral

Q7

form a single

Selection

blanket

water

The

allows

offset

by a three

to a voltage

U5.

(A2)

set

point

of

appropriate

signal

by

is

the

circuit

error

thus

set

correction

operating

reset

(A2)

(A2)

by

mode

U20

U21

(A2)

or

is

provides

signal

Circuits

temperature

switch

correction

digit

Temperature

by

resistor

R35

and

(E)

amplifier

polarity

related

point

for

U11.

on

014

in

PATIENT

the

integral

are

summed

pole

(by

output

ladder

(A2)

and

(A2)

is

to

the

and

the

(A2)

the

through

TEMP

of

unity

gain

double

way

of

throw

of

A2J2

or

patient

is

buffered

U12.

Control

network

R38

provide

that

from

U11.

If

developed

magnitude

actual

U20

output

tem-

and

of

(A2)

NO

THERAPY

the

difference

inversion.

and

offset

the

the

at

its

the

916

28

by

the

circuit

U8A

and

(A2)

The

outputs

whose

signal.

time

between

either

on

probe

enable

modes

Transistors

heater,

17,

The

to

equal

from

Therefore,

by

a

HEAT

Celsius

outputs

a

light

indicators

selected

duty

That

is

proportional

set

on

or

and

off

with

temperature

the

as

hot

and

16

output

voltages

to

the error

the

set

more

than

high

output

status

difference

of

(A2)

high

output

on.

(A2)

only

(low

off.

controller

commanded

(A2)

solenoid

respectively.

of

of

ifthe

including

U8B,

compared

of

(A2)

U8A

cycle

is,

while

depends

the

to

point

and

For

differences

the

on

equal

Q10

and

(A2)

U11

plus

two

amplifier

point

temperature

actual

one

degree

on

(A2)

light

on.

between

U14

will

on

(A2)

U16B,

when

level

input

(A2)

U10.

to a low

and

(A2)

on

the

outputs

the

control

probe

and

outputs

and

volts

temperatures,

approaching

off

times

to

the

set

only

by

mode

(A2)

Q11

cold

solenoid

is

tied

to

inputs

and

minus

outputs

by

temperature

Celsius,

J9

pin 9 or

If,

on

the

other

set

be

high, the

J3

pin

10

will

C,

and D provide

AUTOMATIC

on

A2J3

The

resulting

frequency

U8B

are

magnitude

are

either

signal

automatically

point.

in

on

amplitude.

Gates

the

manual

selection

buffer

the

through

of

(A2)

two

volts;

when

minus

differs

one output

11

point

HEAT

the

from

will

hand,

and

and

or

command

there

command

the logic

or

MANUAL

pin

1).

PRINCIPLES

control

OF

signal

sawtooth

complementary

and

or

off,

For

the

controller

zero,

the

adjusted

(A2)

and

circuits

gate

outputs

outputs

U14

where

these

actual

plus

the

set

of

(A2)

sense

one

of

the

ratio

larger

outputs

outputs

U7A

and

automatic

via

on

A2P2

it

two

temperature

degree

point

U14

will

either

is

less

than

actual

COOL

CONTROL

temperatures,

lights

the

IN

TEMP ZONE

to

enable

mode

will

OPERATION

is,

at

(A2)

from

(A2)

U9.

pulse

the

to

on

trains

control

to

differences

will

will

switch

to

maintain

(A2)

U7D

control

A2J3

and

pin

drive

pins

is

compared

voltages

differs

Celsius.

temperature

be

low

and

the

COOL

one

degree

both

be

off,

and

status

these

has

status

been

off

be

a

1.

the

18,

are

or

When

enabled.

is

automatic

more

Thus,

than

one

outputs a pulse

control

when

degree

is

in

AUTOMATIC

different

waveform.

2-9

selected

than

(low

mode

the

level

at

and

the

set

point,

A2J3

pin

patient

U17

2)

U16A

temperature

is

enabled

is

and

A2J3

pin 3 is

also

be a pulse

to

flash

on

display,

Alert

the

Circuits

low

anytime

waveform

and

off.

display

For

will

the

Patient

that

all

other

remain

Probe

will

cause

conditions

on

without

PRINCIPLES

is

in

use;

the

patient

requiring

flashing.

OF

OPERATION

A2J3

pin 4 will

temperature

patient

temperature

then

display

“CHECK

of

circuit

these

45°C.

probe

be

limits,

the

PROBE

audible

pressing

which

operator

(A2

"CHECK

PATIENT

the

patient

(A2)

limits

Inthe

temperature

high.

probe

one

When

output

is

light

alarm

the

will

disable

approximately

U15B

is

PATIENT

Regardless

heater

solenoid.

patient

reason

In

diode

so

and

This

probe

appears

addition

(A2)

CR15,

that

there

PROBE" - The

probe

U4

are

normal

system.

is

brought

set

to

case

correspond

between

the

probe

of

(A2)

in

use

(A2J3

on

(A2J3

on.

ALARM

enabled

of

what

close

that

to

discontinuing

pin 12

One-half

SILENCER

U7C

only

PROBE“

the

the

cold

will

prevent

is

disconnected,

to

be

at a temperature

disables

is

also

no

function

To

this

to

(A2)

U6

where

the

the

two

appears

U6

will

go

pin

3low),

willthen

high).

of

(A2)

Switch,

thereby

five

minutes

in

condition

turning

the

AUTOMATIC

then

controller

solenoid

the

machine

therapy,

the

HEAT,

indication

of

of

this

circuit

end,

the

where

to

patient

output

limits,

to

low.

it

of

(A2)

the

be

at a temperature

(A2)

command

The

output

U18

is a nominal

S6,

momentarily

off

of

silence

will

turn

is

requiring,

while

from

dislodged,

less

the

output

COOL,

and

therapy.

is

to

verify

output

is

of

the

compared

temperatures

U4

represents a patient

outputs

of

(A2)

U15C, enabled

the

CHECK

of

(A2)

U7C

five

will

the

alarm

to

investigate

mode

on

(A2)

(A2)

Q9

(A2J3

(A2)

Q8

will

tone

08

will

controlling

defective,

than

25°C

of

IN

TEMP ZONE

(A2)

or

or

U15B,

the

integrity

patient

to

of

two

25°C

U6

probe

limits;

and

will

both

outside

whenever

PATIENT

will

drive

minute

start

the

timer;

the

timer

giving

problem.

pin 2 low);

and

(A2)

O9.

turn

off

open

the

based

for

any

above

on

other

45°C.

through

status

lights

the

the

the

a

the

hot

a

“CHECK

the

PATIENT

machine

abnormal.

TEMP

from

controlling

SETTING" - The

patient

2-10

function

of

temperature

this

circuitry

at a set

is

to

prevent

point

that

is

The

output

the

limits

correspond

pointis

between

one output

mode,

PATIENT

turns

functions

provides a high

TEMP

off

the

are

automatic

25°C

or

above

of

the

set

these

will

go

low

SETTING

status

as

described

control,

the

41°C.

point

circuit

to

temperatures

limits,

and

the

(A2)

output

light

on.

lamps;

it

in

controller

is

outputs

U15A,

at

This

also

turns

the

CHECK

will

compared

of

25°C

of

enabled

A2J3

pin

same

on

not

PRINCIPLES

to

and

(A2)

U13

13

to

output,

(A2)

Q8

PATIENT

respond

two

limits

41°C.

are high.

only

in

command

through

and

PROBE

to a set

OF

OPERATION

by

(A2)

When

the

Otherwise,

the

AUTOMATIC

the

CHECK

(A2)

CR23,

(A2)

Q9

whose

discussion.

point

below

U13;

set

In

2.2.2.5

"CHECK

the

flow

ERS/HR.).

MATIC

U5C.

signal

indicator.

"MACHINE

J.

Whenever

turns

8

to

flash the

(A2)

generates

sounder

CHECK

TEST

MODE

SELECTION

Mode

selection

WATER

through

mode.

The

is

then

SHUT-DOWN

off

and

U19

provides

alow

AA1.

PATIENT

LIGHTS.

FLOW" - The

the

This

indicator

This

enable

contacts

fed

any

one-half

ALERT

of

to

alert

condition

light

of

the

frequency

This

entire

PROBE,

AND DISPLAY

is

accomplished

unit

drops

can

is

the

flow

(A1)

Q9 which

REMOVE

(A2)

on

signal

square

circuit

MACHINE

function

only

of

below

be

controlled

switch,

enables

FROM

occurs,

U18

and

to

SERVICE" - (See

A2J3

outputs a pulse

off.

drive

AA1,

wave

to

is

turned

SHUT-DOWN

CIRCUITS

by

momentary

this

circuitry

12 + 2

enabled

by

(A1)

S5,

are

the

pin

the

turn

on

on

by

REMOVE

operation

is

GPH

in

U2C,

closed

(45.42 + 7.57

the

MANUAL

(A1)

CHECK

Section

14

goes

waveform

audible

and

offthe

(A2)

Q13

to

indicate

or

U3D,

with

low

and

flow.

WATER

2.2.2.3)

low,

(A2)

on

A2J3

alarm.

(A2)

piezoelectric

in

response

FROM

of

SERVICE

one

of

when

LIT-

AUTO-

(A1)

A

FLOW

Q12

pin

U19

to

or

three

pressure

sensitive

momentary

retainthe

to

assure

turn

selected

on.

signals

that

the

mode

set

and

mode.

These

standby

switches

reset

the

latch

mode

is

attached

to

appropriate

circuits

include

established

the

A1

Display

latch

circuits

power-on-reset

at

the

time

Board.

of

of

initial

These

(A1)

U2

networks

machine

to

(A1)

U3A,

allow

B,

use

of a patient

C, D buffer

the

probe

latch

outputs.

during

manual

(A2)

U4A,

control.

Latch

PRINCIPLES

OF

B, C provide

outputs

OPERATION

the logic

to

the

control

to

circuits

panel

REMOVE

standby

respective

Amplifier

perature

version

(equivalent

R73

to

function

The

the

amplifier

and

passes

are

legends

FROM

condition.

requires

allows

derive

for

input

input

and output

inputs

become

through

provided

driver

circuit

from

to

adjustment

the

PATIENT

to

where

and

displays

SERVICE

condition

The

transistors

(A1)

U17

degrees

multiplication

offset).

(A1)

of

offset

voltage.

temperature.

and output

of

from

(A1)

(temperatures

inputs

to

(A1)

the

U18

required;

as

required.

(A1J2

various

status

in

response