Hydraulic Ram Unit

HRE 1000 / HRE 3000 / HRE 4000

Translation of the original operating instructions

Hydraulic Ram Unit HRE

Issue 06.2016

Gayk Baumaschinen GmbH

Dieselstraße 3

D-63762 Großostheim

Telephone: +49-6026 97885-0

Telefax: +49-6026 9788529

E-mail: info@gayk-baumaschinen.de

Internet: www.gayk-baumaschinen

Publisher's copyright:

These operating instructions are intended for installation, operations and maintenance personnel. They may

be duplicated, translated or made available to others only with the expressed approval of the publisher. Also,

the operating instructions contain regulations and drawings of a technical nature which may not be

duplicated, in their entirety or partially, modified or utilised for the purposes of unauthorised competition, or

given to others.

Table of contents

Hydraulic Ram Unit HRE

Issue 06.2016

1

Table of contents

1 Basic information ................................................................................................................. 5

1.1 Notes on the operating instructions ........................................................................ 5

1.2 Explanations in the operating instructions .............................................................. 5

1.3 Proper use .............................................................................................................. 5

1.4 Usage conditions .................................................................................................... 6

1.5 Guarantee and liability ............................................................................................ 6

2 Safety instructions ............................................................................................................... 7

2.1 Standards and guidelines ....................................................................................... 7

2.2 Explanation of labels in the operating instructions ................................................. 8

2.3 Safety labels on the machine ................................................................................. 8

2.4 Safety labels at the setup location .......................................................................... 9

2.5 Basic safety measures ......................................................................................... 10

2.6 Safety instructions for transport ............................................................................ 10

2.7 Safety instructions for installation ......................................................................... 11

2.8 Safety instructions for operation ........................................................................... 11

2.9 Safety instructions for maintenance and repair .................................................... 12

2.10 Operator responsibility.......................................................................................... 12

2.11 Requirements of personnel .................................................................................. 14

2.12 Personal protective work clothing ......................................................................... 14

2.13 Behaviour in an emergency .................................................................................. 15

2.14 Disposal ................................................................................................................ 16

3 Technical data .................................................................................................................... 19

4 Technical description ........................................................................................................ 21

4.1 Chassis ................................................................................................................. 22

4.2 Drive motor ........................................................................................................... 23

4.3 Hydraulic aggregate ............................................................................................. 28

4.4 Mast (carriage) ..................................................................................................... 31

4.5 Hydraulic hammer ................................................................................................ 32

4.6 Control console..................................................................................................... 33

4.7 Electrical system................................................................................................... 35

4.7.1 Battery .................................................................................................................. 36

4.7.2 Automatic self-regulation ...................................................................................... 37

4.7.3 Electrical switch box ............................................................................................. 38

Table of contents

2

Issue 06.2016

Hydraulic Ram Unit HRE

5 Transport ............................................................................................................................. 41

5.1 General transport instructions ............................................................................... 41

5.2 Incoming inspections by the operator ................................................................ ... 41

6 Assembly and start-up ....................................................................................................... 43

6.1 General assembly instructions .............................................................................. 43

6.2 Aligning the machine ............................................................................................ 43

7 Operating the machine ....................................................................................................... 45

7.1.1 General instructions .............................................................................................. 45

7.1.2 Operating procedure ............................................................................................. 45

7.1.3 Ramming the profiles ............................................................................................ 46

8 Maintenance and repair ..................................................................................................... 49

8.1 General instructions .............................................................................................. 49

8.2 Maintenance and repair measures ....................................................................... 50

9 Disruptions .......................................................................................................................... 57

Table of figures

Hydraulic Ram Unit HRE

Issue 06.2016

3

Table of figures

Fig. 1: Nameplate ................................................................................................................... 19

Fig. 2: Main assemblies with optional accessories ................................................................. 21

Fig. 3: Chassis ........................................................................................................................ 22

Fig. 4: Machine in the transport position ................................................................................. 22

Fig. 5: Locking and positioning lever ...................................................................................... 23

Fig. 6: Drive motor .................................................................................................................. 24

Fig. 7: Motor oil fill opening with oil dipstick ............................................................................ 24

Fig. 8: Electric starter and speed adjustment lever ................................................................. 25

Fig. 9: Ignition switch with message lights .............................................................................. 25

Fig. 10: Fuel tank ...................................................................................................................... 26

Fig. 11: Fuel tank shut-off valve ................................................................................................ 26

Fig. 12: Hydraulic tank .............................................................................................................. 28

Fig. 13: Vent filter with contamination display ........................................................................... 29

Fig. 14: Visual fill level display .................................................................................................. 29

Fig. 15: Cooling package .......................................................................................................... 30

Fig. 16: Functioning principle of the cooling package ............................................................... 30

Fig. 17: Mast (carriage) with hydraulic hammer ........................................................................ 31

Fig. 18: Hydraulic hammer ........................................................................................................ 32

Fig. 19: Control console (optional) ............................................................................................ 33

Fig. 20: Gear lever .................................................................................................................... 34

Fig. 21: Control console (standard)........................................................................................... 35

Fig. 22: Tool box for battery and tool kit.................................................................................... 36

Fig. 23: Electrical switch box with automatic self-regulation (option) ........................................ 37

Fig. 24: Exterior of the electrical cabinet (optional) ................................................................... 38

Fig. 25: Interior of the electrical cabinet (optional) .................................................................... 38

Fig. 26: Electrical cabinet (standard) ........................................................................................ 39

Fig. 27: Circular level ................................................................................................................ 44

Fig. 28: Limit switch for shutting off the automatic ramming function ....................................... 46

Table of figures

4

Issue 06.2016

Hydraulic Ram Unit HRE

Basic information

Hydraulic Ram Unit HRE

Issue 06.2016

5

NOTE

Hydraulic ram unit HRE 1000/ HRE 3000/ HRE 4000 is only called a machine in the

following chapters of these operating instructions.

1 Basic information

1.1 Notes on the operating instructions

These operating instructions are provided to educate the user concerning the design,

function, operation, setup, maintenance and upkeep of hydraulic ram unit HRE 1000/

HRE 3000/ HRE 4000. The hydraulic ram unit HRE 1000/ HRE 3000/ HRE 4000 was

developed and built by Gayk Baumaschinen GmbH. Before using hydraulic ram unit

HRE 1000/ HRE 3000/ HRE 4000, please carefully read through the operating

instructions. They must be available at the machine at all times for operating personnel.

The operating instructions will allow you to quickly understand the technical details, and

contains necessary information on important technical data and on the expert use of

the machine. Hydraulic ram unit HRE 1000/ HRE 3000/ HRE 4000 is only intended to

be used for the purposes listed in the operating instructions. The manufacturer cannot

be responsible for claims arising from improper use and insufficient maintenance of the

equipment. The component documentation located in the appendix, as well as all other

1.2 Explanations in the operating instructions

documentation provided with the equipment, must be adhered to.

1.3 Proper use

The machine may only be operated in its technically proper state and only for its

intended purpose, in accordance with these operating instructions. The machine is

operated fully-hydraulically and its exclusive purpose is to precisely ram steel or

wooden profiles into earthen soil. The profiles are rammed into the ground through

repeated impacts depending on the ramming depth and the soil characteristics.

No other use of the machine beyond this qualifies as proper use. Any other use can be

dangerous and is not allowed. The manufacturer is not liable for any consequences

arising from improper use of the machine or for any use not in accordance with the

instructions in these operating instructions. If the machine is altered without the

approval of the manufacturer, the manufacturer is not liable for any damages that may

result. Adherence to inspection and maintenance specifications is also part of the

proper use of this equipment. Connection data must be adhered to. If changes are

made to the system by the operator, the CE certificate of compliance will become

invalid.

Basic information

6

Issue 06.2016

Hydraulic Ram Unit HRE

1.4 Usage conditions

Before beginning work, check the area to make sure it meets the following criteria:

Make sure there are no cables, lines, sewer lines, etc., in the area that could

present a hazard.

Prepare the work area according to how it is found. If necessary, re-route,

disconnect, or secure existing lines.

The ground must be free of any contaminants and explosive ordinance.

The ground must be evenly supportive of construction machines being driven on it.

Establish traffic routes and storage areas and identify them.

All necessary operating materials such as oils, greases and the like must be made

available in sufficient amounts and qualities prior to start-up corresponding to the

specifications contained in the operating instructions.

The manufacturer must be timely notified of any environmental and operating

conditions that are out of specification at the set-up location of the machine. The

deviating environmental and operating conditions must be listed.

1.5 Guarantee and liability

The “General Conditions of Sale and Delivery” submitted by the manufacturer to the

operator apply fundamentally. Guarantee and liability claims for personal injury and

property damages are not valid if they can be attributed to one or more of the following

causes:

Use of the machine in a manner that is not intended.

Improper start-up, operating and maintenance of the machine.

Alterations to the machine without prior consultation with the manufacturer.

Operation of the machine with defective safety equipment or improperly attached

safety and protective equipment.

Non-adherence to the instructions in these operating instructions with regard to

operation and maintenance.

Insufficient monitoring of machine assemblies that are subject to wear.

Safety instructions

Hydraulic Ram Unit HRE

Issue 06.2016

7

2 Safety instructions

2.1 Standards and guidelines

The machine is designed according to the current state of the art according to

recognised safety rules. The machine was designed according to basic safety

requirements, standards and guidelines. All safety information refers to currently

applicable ordinances of the European Union (EU). In countries outside of the EU, the

applicable laws and ordinances of those countries must be adhered to. In addition to

the safety instructions contained in these operating instructions, the generally

applicable regulations concerning accident prevention and environmental protection

must be followed and adhered to. All information in the operating instructions must be

followed fully. The machine was designed according to the following basic safety

requirements, standards and guidelines.

Machine Guidelines 2006/42/EC dated 17.05.2006

Applied harmonised norms, in particular

DIN EN-ISO 12100

“Machine Safety - General Structural Guidelines - Risk Assessment and Risk

Minimization” (ISO 12100:2010), German Version EN ISO 12100:2010

DIN EN 60204-1

“Machine Safety – Electrical Equipment in Machines”

DIN EN 13849

“Machine Safety – Safety-related Parts in Control Systems”

DIN EN 13850

“Machine Safety – EMERGENCY STOP Structural Guidelines”

DIN EN 13857

“Machine Safety – Safe distances to prevent reaching into dangerous areas with

upper and lower extremities”

DIN EN 1037

“Machine Safety – Preventing unexpected starting of moving elements”

DIN EN 13478

“Machine Safety – Fire protection”

DIN EN 414

“Rules for the drafting and presentation of safety standards”

DIN EN 4844-1

“Graphical Symbols - Safety colours and safety signs Part 1: Structural

fundamentals for safety signs for use in workshops and in public areas”

DGUV [German Social Accident Insurance] Regulation 3 “Portable and fixed

operating resources

Accident prevention regulation “Electrical systems and resources”

BGV A8 / DGUV Regulation 9

“Safety and health protection signage at the workplace”

Safety instructions

8

Issue 06.2016

Hydraulic Ram Unit HRE

DANGER

Type and source of danger!

Immediate danger with high risk of death or serious bodily injuries. Measures to avoid

danger.

WARNING

Type and source of danger!

Possible danger with medium risk of death or serious bodily injuries. Measures to

avoid danger.

CAUTION

Type and source of danger!

Dangers with low risk of medium bodily injuries or property damage. Measures to

avoid danger.

NOTE

User tips and useful information.

NOTE

User tips and useful information on environmental protection.

DANGER

Type and source of danger!

Dangers with risk of environmental damages. Measures to avoid danger.

DANGER

Warning of dangerous electrical voltage.

2.2 Explanation of labels in the operating instructions

2.3 Safety labels on the machine

The instructions attached to the machine identify the sources of danger and must be

adhered to absolutely. They must be attached in an easily recognizable area and

maintained in fully legible condition. If these labels are destroyed, new ones must be

attached. The following symbols are attached to the equipment and must be adhered

to:

Safety instructions

Hydraulic Ram Unit HRE

Issue 06.2016

9

DANGER

Warning of crush injuries.

DANGER

Warning of rotating parts.

DANGER

Warning of crushing at chain drives.

DANGER

Warning of hot surfaces.

DANGER

Warning of flammable materials.

DANGER

Warning of explosive materials.

DANGER

Warning of corrosive materials.

DANGER

Risk of accidents!

Unauthorised personnel access to the machine is forbidden.

DANGER

Fire and explosion danger!

The starting of fires and handling of open flames is strictly forbidden. Areas must be

labelled accordingly.

2.4 Safety labels at the setup location

The operator of the machine must make sure that the entire work area in which the

machine is set up is identified appropriately according to operational conditions,

respectively, by means of the following instructions.

Safety instructions

10

Issue 06.2016

Hydraulic Ram Unit HRE

During installation, maintenance and repair work, the entire danger area surrounding

the machine must be blocked off with the following identifying tape:

2.5 Basic safety measures

The following must be adhered to:

The machine may only be used as intended.

All safety instructions in these operating instructions and in other documents must

be followed and adhered to.

The machine may only be set up, installed, operated and maintained by trained

expert personnel. The personnel must have read and understood these operating

instructions. This includes in particular the understanding of how risk of injury can

be averted for the operator and others.

Unauthorised personnel may not have any direct access to the machine.

Downtime and environmental impairments due to incorrect handling must be

avoided.

During transport, installation/removal, operation and care and maintenance, the

pertinent work safety regulations and environmental protection regulations must be

adhered to.

All work on the machine must be carried out with care and with a perspective on

safety.

2.6 Safety instructions for transport

The following must be adhered to:

The machine is transported, set up and installed as a complete machine. The

danger area must be blocked off with a wide berth and identified as such.

Safety regulations as to the transport materials used must be adhered to.

Unauthorised transport work is not permitted. Significant dangers and property

damages can result.

Transport activities may only be carried out by trained personnel.

Only approved lifting equipment and attachment means with sufficient support

capacity may be used.

Ropes and belts must meet safety requirements. No torn ropes or ropes with

abraded areas may be used. Do not let ropes and belts sit against sharp edges and

corners, do not knot or twist them. When fastening, be aware of the centre of

gravity of the machine.

Safety instructions

Hydraulic Ram Unit HRE

Issue 06.2016

11

2.7 Safety instructions for installation

The following must be adhered to:

The machine may only be installed by trained, instructed expert personnel.

Unauthorised assembly is not permitted.

To avoid dangerous situations, and to ensure optimum performance, no

modifications or alterations may be made to the machine.

The set-up area for the machine must be of such dimensions that sufficient support

is guaranteed.

Before beginning work, sufficient freedom of installation must be ensured. Maintain

order and cleanliness at the work place. Any components and tools lying around

must be removed.

Be aware of the dimensions and weight data for the machine. An operational

environment suitable for use of the machine must be guaranteed.

The machine must be checked each time prior to being turned on for damages and

proper condition. Any modifications to the machine that affect operational safety

must be reported. The causes must be remedied immediately.

The machine may only be connected to supply lines that are provided and designed

specifically for it.

2.8 Safety instructions for operation

The following must be adhered to:

The operational safety of the machine must be guaranteed at all times.

The machine must be immediately shut down if changes are detected during

operation. Listen for any unusual noise.

Proper attachment and connection of the control console, safety equipment

(EMERGENCY OFF switch, safety switches sensors).

The machine must be checked each time prior to being turned on for damages and

proper condition. Any modifications to the machine must be reported. The causes

must be remedied immediately.

Proper connection of all supply media (electrical energy bonding for safe contact,

hydraulics).

Safety instructions

12

Issue 06.2016

Hydraulic Ram Unit HRE

CAUTION

Damage to the machine!

Operational disruptions caused by insufficient or improper maintenance can cause

very high repair costs and long downtimes of the machine. The manufacturer assumes

no liability for damages caused by improper maintenance and care. Maintenance

intervals must be recorded and maintained in a maintenance plan.

2.9 Safety instructions for maintenance and repair

The following must be adhered to:

All maintenance and repair work on the machine may only be carried out with the

machine turned off.

The machine may only be maintained and repaired by service personnel from the

manufacturer or personnel specially trained and instructed in the same.

Unintentional turning of the machine back on must be prevented (shut of the main

switch, attach a warning sign to the main switch, block off the area).

During maintenance and repair work, sometimes safety equipment needs to be

turned off. This equipment must be properly re-installed immediately after the

maintenance and repair work and checked for proper functioning.

After the maintenance work, the following checks must be carried out prior to

turning the machine back on, during which time safety regulations are adhered to:

– Check that all bolted connections are tight.

– Ensure that all tools, materials and other equipment used have been removed

from the work area.

– Clean the work area and remove any materials, such as liquids, processing

materials, etc.

2.10 Operator responsibility

The operator of the machine is subject to legal obligations with regard to work safety. In

addition to the safety instructions in these instructions, the applicable safety, accident

prevention and environmental protection regulations must be adhered to.

The operator must be aware of the applicable work safety specifications. Any

additional dangers that arise from special working conditions at the point of use

must be recorded in an overview. The additional dangers determined to exist must

be recorded by the operator in its operating instructions and incorporated in the

daily handling instructions for the machine.

During the entire time of use of the machine, the operator must check whether its

operating instructions correspond to the current version of the regulatory policies,

and if not, modify them as needed.

The operator must use the machine in good, operationally safe condition. The

technical condition must correspond to the legal requirements and regulations.

The operator must clearly regulate and establish responsibilities for installation

operation, maintenance and cleaning.

Safety instructions

Hydraulic Ram Unit HRE

Issue 06.2016

13

CAUTION

Risk of injury if personnel is insufficiently qualified!

Improper handing can result in serious personal injury and property damage. All

activities must be carried out by qualified personnel only.

Operating personnel

The instruction as to the tasks to be assumed and

possible risks from improper behaviour is done by the

operator.

Maintenance and repair

personnel

Maintenance and repair personnel must be capable, as a

result of expert training, experience and knowledge of the

pertinent specifications, of autonomously carrying out

maintenance and repair work, and of recognising possible

risks and avoiding them. Maintenance personnel are to be

specially trained for this.

Electrician

The electrician must be capable, as a result of expert

training, experience and knowledge of the pertinent

specifications, of autonomously working on electrical

machines and of recognising possible risks and avoiding

them. The electrician is specially trained for this.

The operator must make sure that all employees handling the machine have read

and understood these instructions. Also, the operator must train its personnel at

regular intervals and make the aware of the risks. Training by the operator must be

recorded.

The operator must provide its personnel with the required work safety clothing.

The operator must make sure that the listed maintenance intervals are being

adhered to.

The operator must check all safety equipment regularly for functionality and

completeness.

As to requirements to be placed on personnel, the operator must adhere to the

following criteria:

Safety instructions

14

Issue 06.2016

Hydraulic Ram Unit HRE

DANGER

Risk of accidents!

Unauthorised persons who do not meed the requirements described must be kept

away from the work area.

PROTECTIVE WORK CLOTHING

Wear snugly-fitting protective work clothing to protect against getting caught by

moving parts. However, the clothing must not restrict the freedom of movement of

personnel.

SAFETY SHOES

To protect from falling parts and slipping on floors that are not non-slip surfaces and

when current-carrying components could possibly be touched.

2.11 Requirements of personnel

The following must be adhered to:

Smoking, eating and drinking in the area of the machine are not allowed.

Working on the machine while tired, under the influence of alcohol and medications

is not allowed.

Personnel may not have any physical limitations that would temporarily or

permanently impair their attentiveness and ability to evaluate a situation.

Operating personnel must have mastered the national language of the operator

verbally and in written form enough to allow all tasks pertaining to the machine and

the contents of the operating instructions to be understood and internalised.

Personnel must wear appropriate clothing for the work at hand.

All safety instructions in these operating instructions and in all other documents

must be followed and adhered to in unlimited extent.

If danger is recognised which could result in personal injury, the machine must be

shut off immediately.

Personnel must have thorough understanding of operational procedures,

regulations and processes.

– Operational processes of the machine

– Setting up of perimeters, securing and identifying the area of danger

– Behaviours and actions in case of emergency

The machine may only be operated and maintained by authorised personnel. If

additional qualifications of personnel are necessary to perform certain work, the

operator must meet all prerequisites for it.

2.12 Personal protective work clothing

The operator will determine which protective work clothing must be worn by personnel.

Safety instructions

Hydraulic Ram Unit HRE

Issue 06.2016

15

SAFETY GLOVES

To protect the skin from friction, scrapes, punctures or deeper injuries of the hands

and to protect against the touching of hot surfaces and substances that are hazardous

to a person's health.

HEARING PROTECTION

Hearing protection offers protection against injury to the auditory system due to excess

and sustained noise.

SAFETY GLASSES

Safety glasses protects the eyes against flying parts (dust particles, liquid and acid

sprays).

FIRST AID AND FIRE-FIGHTING EFFORTS

The locations for first aid equipment and fire-fighting agents must be identified with

information signs. The user must be familiar with these resources. The user must be

able to correctly use and operate them in the event of accidents.

2.13 Behaviour in an emergency

In emergencies or accidents, the machine must be shut off immediately!

Since in the event of an accident quick reaction can save lives, the following actions

must be introduced:

Immediately initiate the EMERGENCY SHUT-DOWN system.

Initiate first aid measures. Operating personnel must know where safety equipment,

accident and danger alarms, and first aid and life-saving equipment are located and

must be familiar with how to handle them.

Remove injured persons from the danger zone.

Notify responsible parties at the location of use.

Notify first responders.

Open access routes to allow access to ambulance vehicles.

The operator is responsible for appropriate training of its operations personnel. All first

aid equipment (first aid kits, stretchers, etc.) and fire-fighting agents (fire extinguishers)

must be maintained in accessible locations and must always be available. All

equipment must be in proper condition and regularly checked.

Safety instructions

16

Issue 06.2016

Hydraulic Ram Unit HRE

DANGER

Environmental hazard!

If environmentally hazardous materials are handled incorrectly, in particular if they are

disposed of incorrectly, serious damages to the environment can occur.

The following must be adhered to:

The information contained in the operating instructions concerning environmental

protection must be followed at all times.

If environmentally-hazardous materials accidentally come in contact with the

environment, suitable measures must be taken immediately. The appropriate

authorities must be notified of the damages.

CAUTION

For all auxiliary materials and cleaning agents used, the regulations and EC safety

data sheets of the respective manufacturer with regard to storage, handling, use and

disposal must be adhered to.

CAUTION

Electrical scrap and electronic assemblies require hazardous waste treatment and

may only be disposed of by approved expert operators.

2.14 Disposal

Legal fundamentals on disposal:

Recycling and Waste Management Act (KrW/AbfG)

State Waste Act for each of the federal states (LAbfG)

Ordinance for determining wastes that require monitoring (BestbüAbfV)

Waste Oil Ordinance (AltölV)

Packaging Ordinance (VerpackV)

Battery Ordinance (BattV)

Commercial Waste Ordinance (GewAbfV)

Chemicals Act (ChemG)

Hazardous Materials Ordinance (GefStoffV)

Industrial Safety Ordinance (BetrSichV)

Water Management Act (WHG)

Technical Rules for Hazardous Materials, TRGS 201 Classification and

identification of wastes for disposal while handling

GUV-SR-2005 Handling hazardous materials in industry

Safety instructions

Hydraulic Ram Unit HRE

Issue 06.2016

17

The following must be adhered to:

No materials may be used if their physical properties are unknown. A consultation

with the manufacture is required.

If there is no take-back or disposal agreement in place, the disassembled

components must be sent to a recycling facility after proper disassembly.

– Metallic material residue is scrapped.

– Plastic components are sent to a recycling facility.

– Sort other components according to material properties and dispose of

accordingly.

Cleaning agents and their containers may not be disposed of as domestic waste or

allowed to flow to sewer systems and to the soil. Applicable disposal regulations

must be adhered to.

Safety instructions

18

Issue 06.2016

Hydraulic Ram Unit HRE

Technical data

Hydraulic Ram Unit HRE

Issue 06.2016

19

General data

Name

Hydraulic Ram Unit

Type

HRE 1000 / HRE 3000 / HRE 4000

Serial number

9950216

Model

2016

Dimensions (transport dimensions)

Length

4000 mm / 5000 mm

Width

2000 mm

Height

2200 mm / 2500 mm

Weight with hydraulic hammer

3100 kg / 3600 kg (depending on the design of

the hammer IM 150, IM 304, IM 305)

Operating data

Operating conditions

Manual and automatic operation

Post height

3200 m / 4200 mm

Transverse grade

20°

Operating hydraulic fluid pressure

200 bar

Oil amount

180 l

Fuel tank volume

60 l

Motor output

22.5 kW (depending on the motor design;

2-, 3-, 4-cylinder motor

Weight of the hydraulic hammer

76 kg - 136 kg

(depending on the hammer design)

Impact rate

670 min-1 - 1450 min

-1

(depending on the hammer design)

Noise emissions

117 dB

3 Technical data

The nameplate is located below the hydraulic aggregate at the air/hydraulic fluid cooler.

Fig. 1: Nameplate

Technical data

20

Issue 06.2016

Hydraulic Ram Unit HRE

Technical description

Hydraulic Ram Unit HRE

Issue 06.2016

21

1 Chassis

2 Control console

3 Hydraulic hammer

4 Mast (carriage)

5 Hydraulic cylinder

6 Fuel tank

7 Electrical cabinet with control elements

8 Drive motor

9 Hydraulic aggregate

regulation

4 Technical description

The hydraulic ram unit is a machine for ramming steel profiles or posts into terrain,

even under severe conditions. Areas of use include guardrail supports along streets,

frames for solar energy facilities, wood profile palisades, supports for earthen slopes

and water bank straighteners. The machine consists of the following main groups:

Fig. 2: Main assemblies with optional accessories

The rugged and stable design of the machine can also facilitate pulling out profiles or

posts, or drilling holes with a drill (optional). At a 1.9 m advancement from the forward

edge of the chain to the middle of the hydraulic hammer and a working height of 4 m,

even large posts can be rammed in effortlessly.

Technical description

22

Issue 06.2016

Hydraulic Ram Unit HRE

NOTE

The chassis of the machine is an out-sourced assembly. Construction, function,

maintenance and repair are not described in these operating instructions. Detailed

instructions can be found in the manufacturer's technical documents.

4.1 Chassis

The fully-hydraulic ram unit has a stable crawler chassis with a slewing ring and

rubber-coated chain. A Hatz diesel motor is installed as a drive motor. The chassis

supports all machine assemblies. A drive gear of the chassis moves the chain links

forward in the direction of travel. The rest of the vehicle is pulled along on the runners

and guide wheels. The chain drives on both sides move independently of one another.

In some designs, the chain drives can move in opposite directions and the chassis can

be rotated on the spot.

Fig. 3: Chassis

The machine can be rotated on the chassis by 90°. When it is transported to the work

location, the machine is in its transport position (the hydraulic hammer is parallel to the

direction of travel lengthwise) and during operation it is in its working position (the

hydraulic hammer is perpendicular to the direction of travel).

Fig. 4: Machine in the transport position

Technical description

Hydraulic Ram Unit HRE

Issue 06.2016

23

CAUTION

Avoid injuries and machine damage!

When the machine is rotated in a different direction, make sure that the stopping point

has been reached. The lever must be returned back to its proper locking position.

NOTE

When operated over long periods of time without load or very small loads, the running

behaviour of the motor can become worse. A motor load of at least 15%

is required. Under low-load operation, the motor must be operated under a much

higher load for a short period of time before turning it off.

When the locking and positioning lever is moved by 90° (lever position is vertical), the

lock is released and the machine can be manually rotated on the chassis until it rests

against a stop. When it is rotated to another position (such as the working position), the

lever must be moved downward and clamped in this position. Rotation back to the

transport direction is done in the same sequence.

Fig. 5: Locking and positioning lever

4.2 Drive motor

The drive motor is an air-cooled, diesel-operated four-stroke motor with direct injection.

The type and size of the drive motor depends on the type of machine. It is a drive

assembly for the chassis, the slewing ring drive and the hydraulic pump. To dampen

the vibration and noise, the motor is supported on rubber bumpers and fastened to the

chassis.

Technical description

24

Issue 06.2016

Hydraulic Ram Unit HRE

1 Drive motor

2 Oil fill nozzle and oil level dipstick

3 Fuel tank

4 Tool box for battery and tool kit

5 Exhaust gas muffler

1 Handle

2 Oil dipstick (MAX/MIN indicator)

Fig. 6: Drive motor

The drive motor must be filled with motor oil before initial start-up. The holding capacity

is 4 l - 8 l, depending on the type. So pay attention to the different types of motors. The

types of motor oils to be used are those with the following specifications:

ACEA – B2 / E2 and

API – CD / CE / CF / CF-4 / CG-4

If other motor oils are used, the manufacturer must first be consulted. Unsuitable motor

oil reduces the time between oil change intervals and leads to significant shortening of

the motor lifespan.

Fig. 7: Motor oil fill opening with oil dipstick

The oil level is measured using the oil dipstick located in the fill opening. Fill up to the

MAX marking when filling.

Technical description

Hydraulic Ram Unit HRE

Issue 06.2016

25

1 Motor “ON” illuminated display

2 Charge Check illuminated display

3 Oil Pressure illuminated display

4 Ignition key

5 Motor temperature illuminated display

6 Air Filter Maintenance illuminated display

The drive motor is started using an electric starter. The speed adjustment lever (gas

lever) is located right next to the ignition switch.

Fig. 8: Electric starter and speed adjustment lever

The ignition switch with key switch for the electric starter has 3 switch positions “0, I, II”.

When the key is rotated to the “I” position, the installed “Check Charge 2” and “Oil

Pressure Display 3” control lamps light up. To start the motor, the key is turned to the

“II” position. When the motor is running, the key is released. The key will turn back to

the “I” position by itself and will remain in this position during operation. The charge

check and oil pressure display go out immediately after the drive motor starts.

Fig. 9: Ignition switch with message lights

Technical description

26

Issue 06.2016

Hydraulic Ram Unit HRE

A fuel tank with a holding capacity of 180 l is installed to supply diesel fuel. All diesel

fuels are suitable, provided that they meet the minimum requirements of the following

specifications.

EN 590

BS 2869 A1 / A2

ASTM D 975 - 1D / 2D

Fig. 10: Fuel tank

When work with the machine is finished, the speed adjustment lever must be moved to

the stop position. The motor will run at idle. Close the shut-off valve at the lower end of

the diesel fuel tank. Turn the start key to the “0” position and remove it. The start key

must be protected against unauthorised access.

Fig. 11: Fuel tank shut-off valve

Technical description

Hydraulic Ram Unit HRE

Issue 06.2016

27

DANGER

Warning of hot surfaces!

During longer operating durations, various components become very hot, such as the

hydraulic tank, hydraulic hoses (sometimes over 80 °C). Direct contact should be

avoided until the unit cools down completely.

DANGER

Motor damages due to low-quality fuel!

Use of fuel that does not meet the specifications above can lead to motor damage.

Use of fuels with deviating specifications may be used only after prior approval by the

HATZ motor factory.

DANGER

Warning of escaping diesel fuel!

When finished working with the machine and after shutting off the motor, the shut-off

valve at the diesel fuel tank must be closed as well. If this is not done, the diesel fuel

might spill onto the ground.

CAUTION

Machine damage!

Diesel fuel stops flowing at low temperatures. This can cause clogging in the fuel

system. When outside temperatures are below 0 °C, winter fuel should be used or

petroleum should be added.

CAUTION

Danger of poisoning and explosion!

Never run the motor in closed or poorly ventilated rooms. Before starting, make sure

that no other people are in the area of danger around the machine. All safety

equipment should be installed and functional.

NOTE

The drive motor for the chassis is a supplier assembly. Construction, function,

maintenance and repair are not described in these operating instructions. Detailed

instructions can be found in the manufacturer's technical documents. They are part of

the overall documentation.

Technical description

28

Issue 06.2016

Hydraulic Ram Unit HRE

1 Hydraulic fluid/air cooler

2 Hydraulic tank

3 Fluid fill level display

4 Visual contamination display

5 Fill and vent opening with replaceable filter insert

6 Warning light

4.3 Hydraulic aggregate

The purpose of the hydraulic aggregate is to provide the necessary fluid pressure for

operating the hydraulic cylinders of the mast (carriage) and the hydraulic hammer. The

hydraulic aggregate consists of a gear pump and a hydraulic tank. The gear pump is

attached to the drive motor. It draws in hydraulic fluid until it has reached the required

operating pressure. The hydraulic tank is a steel container with a holding capacity of

180 l. It may only be filled with hydraulic fluid that meets specification

ISO-VG 46 DIN 51 524 / Part 2. Unsuitable fluid can considerably shorten the lifespan

of the machine. Feet with struts are welded to the hydraulic tank. They are used to

fasten the hydraulic tank to the hydraulic fluid/air cooler. The hydraulic tank consists of

a steel container with a cleaning opening, a drain screw at the bottom of the tank, a

visual fluid level display, a fill and vent opening with a replaceable filter insert and a

visual contamination display.

Fig. 12: Hydraulic tank

The vent filter (tank vent filter) of the hydraulic tank has a corrosion-resistant housing

with an inlet opening on top. A cover with a protective edge prevents splashing water

and allows the filter element to be quickly replaced. The vent filter is used to filter air

when the volume changes in the hydraulic fluid tank and prevents contamination from

ambient air from penetrating into the fluid. The vent filter is equipped with a filling

screen. The filling screen is a support basket that keeps the shape of the filter element

stable. When the fluid tank is filled, coarse contaminants are held back.

A contamination display attached to the vent filter shows the degree of contamination

of the fluid.

Technical description

Hydraulic Ram Unit HRE

Issue 06.2016

29

Fig. 13: Vent filter with contamination display

The visual fill level display mounted to the side wall of the tank shows the operator of

the machine the current hydraulic fluid level in the tank. The two markings on the sight

glass indicate the maximum and the minimum fill level.

Fig. 14: Visual fill level display

The air/hydraulic fluid cooler contains a compact cooling package. It consists of

rectangular aluminium profiles in series. Aluminium sheet lamella are inserted between

the individual layers. They enlarge the surface to be cooled. A fan motor with a fan

impeller is located below the air/hydraulic fluid cooler. The fan motor is protected by a

fuse and a protective relay. A thermostat is installed in the air/hydraulic fluid cooler. It

turns on the fan motor with fan impeller at 60 °C. It cools the hydraulic fluid down to 40°

and is then turned off again.

Technical description

30

Issue 06.2016

Hydraulic Ram Unit HRE

WARNING

Machine damage!

The hydraulic fluid cooler must always be free of particulates and other contaminants.

Hydraulic assemblies can be damaged by an impaired cooling effect.

Air

Oil

The medium to be cooled (hydraulic fluid) flows through the profiles of the cooling

package. The cooling air flows through the lamella perpendicular to the cooling

package. The medium dissipates heat to the cooler environment and is blown away.

Fig. 15: Cooling package

Fig. 16: Functioning principle of the cooling package

Technical description

Hydraulic Ram Unit HRE

Issue 06.2016

31

1 Hydraulic hammer

2 Mast (carriage)

3 Post guide

4.4 Mast (carriage)

The mast (carriage) is a stable steel structure. Pulleys are mounted at both ends. The

drive chains (upper and lower) are guided on the pulleys. At one end, the drive chains

are fastened to the hydraulic hammer sled and at the other end to a chain holder. The

chain attachments at the sled are spring-loaded. The chain tension can be adjusted by

tightening or loosening the nut. Various hydraulic cylinders are attached to the mast.

They are controlled from the control console. With these hydraulic cylinders, the mast

and hydraulic hammer can be moved to the following positions:

Hydraulic hammer up and down

Mast upright and store

Mast set and place

Mast left and right

Fig. 17: Mast (carriage) with hydraulic hammer

Technical description

32

Issue 06.2016

Hydraulic Ram Unit HRE

1 Hydraulic hammer

2 Ram head

NOTE

The hydraulic hammer is a supplier assembly. Construction, function, maintenance

and repair are not described in these operating instructions. Detailed instructions can

be found in the manufacturer's technical documents. They are part of the overall

documentation.

4.5 Hydraulic hammer

The hydraulic hammer has a sled to which it is attached. The rolls of the sled run

frictionlessly in a guide of the mast. The drive chains are fastened at both ends of the

sled. They move the entire hydraulic hammer up and down depending on the motion of

the hydraulic cylinder. The hydraulic hammer converts the work output from the

machine into kinetic energy and transfers it to the upper ram head of the hydraulic

hammer. Hydraulic fluid pressure is built up and is released suddenly to the impact

piston located below it, causing the piston to move. The energy transmitted with each

impact is called impact energy and the number of individual impacts per unit time is

called the impact rate. The impact rate is 670 min-1 - 1450 min-1. It is adjustable. When

the impact piston hits the upper ram head, it conveys the energy to the profile material

to be rammed. The lower ram head guides the rammed material. The shape of the ram

heads depend on the geometry of the rammed material or is specified by the operator

off the machine.

Fig. 18: Hydraulic hammer

Technical description

Hydraulic Ram Unit HRE

Issue 06.2016

33

Pos. No.

Process

Figure

1

Turning the hydraulic hammer on

and off

2

Moving the hydraulic hammer up

and down

3

4

Chassis left back and forth

Chassis right back and forth

4.6 Control console

The control console is the workplace for the operator of the machine. All movements of

the entire machine can be controlled from here. By actuating the individual shift levers,

the following functions can be executed:

Fig. 19: Control console (optional)

Technical description

34

Issue 06.2016

Hydraulic Ram Unit HRE

Pos. No.

Process

Figure

5

Mast up and down

6

Mast upright and store

7

Mast left and right

8

Advance in and out

9

Not assigned

10

Operating pressure manometer

1 Gear lever

2 Fast rate

3 Slow rate

Fig. 20: Gear lever

Technical description

Hydraulic Ram Unit HRE

Issue 06.2016

35

DANGER

If the electrical insulation becomes damaged, immediately shut off the power supply

and have the problem repaired!

In all work on the electrical system, the system must be de-energised and checked

to make sure of it.

Do not bypass any fuses or take them out of service. When replacing fuses, make

sure the correct current rating in amperage is used.

Avoid moisture on live parts. Short-circuiting can occur.

DANGER

Danger of non-functioning safety equipment!

Safety is only ensured when safety equipment is functioning.

Before beginning work, check to make sure that the safety equipment is functionally

and correctly installed.

Never shut down or bypass safety equipment.

Ensure that safety equipment such as EMERGENCY STOP switches, limit

switches, sensors, etc. are always accessible.

Fig. 21: Control console (standard)

4.7 Electrical system

The electrical system for the machine is a 12 V system. It consists of the following

assemblies:

12 V battery

Automatic self-regulation

Electrical switch box with control elements

Sensors, safety switches and electrical connection elements

Technical description

36

Issue 06.2016

Hydraulic Ram Unit HRE

DANGER

Danger due to uncontrolled turn-on!

Uncontrolled turn-on can lead to serious personal injury. The following must be

adhered to:

Prior to turning the machine back on, all faults must be remedied, all safety

equipment must be installed and functional.

An EMERGENCY STOP is initiated by pressing the EMERGENCY STOP button.

After an EMERGENCY STOP button has been pressed, it must be pulled back

again to turn the machine back on.

DANGER

Danger of explosion due to flammable materials!

There is a danger of explosion due to flammable gases. Keep batteries away from

open flames and ignition sparks. Do not smoke when handling batteries.

CAUTION

Danger of corrosion!

When installing and removing batteries for electrical operation, and when filling them

with battery acid, corrosive burning can occur. Protect eyes, skin and clothing from

corrosive battery acid. In the event of acid spray, immediately rinse with clear water

thoroughly and, if necessary, seek medical attention.

4.7.1 Battery

The electrical energy for starting the drive motor is provided by a 12 V, 90 Ah battery.

It is located under a cover in the tool box.

Fig. 22: Tool box for battery and tool kit

Technical description

Hydraulic Ram Unit HRE

Issue 06.2016

37

DANGER

Environmental hazard!

If batteries and battery acids are handled incorrectly, serious damages to the

environment can occur. The following must be adhered to:

Proper disposal of unusable batteries must be done according to the battery

ordinance.

Prevent battery acid from leaking.

Store and transport battery acid in containers designed for them.

1 Manual controller

2 Self-regulation On

3 Automatic self-regulation (controller)

4 Automatic self-regulation ON

5 Automatic self-regulation OFF

6 Set zero

4.7.2 Automatic self-regulation

Automatic self-regulation is an option and can be installed at customer request. It

allows the self driving distance to be adjusted. In other words, the machine will travel a

pre-set distance by itself. This distance is input in the associated control system.

Fig. 23: Electrical switch box with automatic self-regulation (option)

The manual controller for automatic self-regulation is equipped with a longer

connection cable. This makes it possible to control the machine from a different

location. If the controller is no longer needed, it can be attached to a flat wall using the

attached magnetic feet.

Technical description

38

Issue 06.2016

Hydraulic Ram Unit HRE

1 Hydraulic hammer ON

2 Hydraulic hammer OFF

3 EMERGENCY OFF button

4 Automatic alignment OFF

5 Working headlights ON/OFF

6 Warning light ON/OFF

7 Automatic alignment ON

1 Controls for automatic alignment

2 Fuses, plug connectors, connection elements

4.7.3 Electrical switch box

The machine has an electrical cabinet (optional). It is mounted above the control

console of the hydraulic machine controls. All the control elements, machine

protections and main machine assemblies are installed in the electrical cabinet. All

terminal and connecting elements are also kept there. Every load is separately fused.

Connecting the power and control voltage for the machine is done through terminal

elements directly in the electrical cabinet.

Fig. 24: Exterior of the electrical cabinet (optional)

Fig. 25: Interior of the electrical cabinet (optional)

Technical description

Hydraulic Ram Unit HRE

Issue 06.2016

39

Fig. 26: Electrical cabinet (standard)

Technical description

40

Issue 06.2016

Hydraulic Ram Unit HRE

Transport

Hydraulic Ram Unit HRE

Issue 06.2016

41

DANGER

Risk of accidents!

Before performing transport work, check to see that the machine is stable enough.

To securely load the machine, a loading ramp is always required. It must not be

damaged and must have sufficient support capacity.

DANGER

Risk of accidents!

Falling parts must be removed prior to transport. Standing below a suspended load is

strictly forbidden.

Crush injuries can occur between moving parts. No unauthorised persons are allowed

in the work area of the machine.

5 Transport

5.1 General transport instructions

For transport to the set-up location, VDI 2700 “Process Instructions for Securing Loads

for Road Traffic” must be followed. A vehicle must be prepared. Lashing straps must

also be provided. The loader and the driver of the vehicle are responsible for properly

loading and securing the machine for transport on a vehicle.

5.2 Incoming inspections by the operator

The machine must be checked immediately after transport.

The following must be checked:

any transport damages

proper scope of delivery

loose bolted connections

other defects

A delivery record is required, with the signature of the driver of the transport vehicle.

Complaints must be submitted to the manufacturer or supplier immediately within

24 hours.

If the machine is not set up and installed immediately after delivery at the customers

location, it must be stored in a protected location. For longer periods of storage

(>3 months), the general condition of the machine and its packing should be checked

regularly. If required, renew or replace preservative.

Transport

42

Issue 06.2016

Hydraulic Ram Unit HRE

Assembly and start-up

Hydraulic Ram Unit HRE

Issue 06.2016

43

DANGER

Unauthorised set-up, assembly and initial start-up is not permitted. Set-up, assembly

and initial start-up of the machine should be done by service personnel or other

authorised personnel of Gayk Baumaschinen GmbH, and all safety regulations must

be observed.

6 Assembly and start-up

6.1 General assembly instructions

The following must be adhered to:

Before beginning work, sufficient freedom of installation must be ensured.

Be aware of the dimensions and weight data for the machine.

Proper assembly procedure. Improperly fastened components can fall off or topple.

Install assemblies and components properly. Maintain prescribed bolt torques.

In the assembly of the machine, the following protective clothing must be worn:

Protective work clothing

Protective safety helmet

Protective work gloves

Safety shoes

6.2 Aligning the machine

Before setting up the mast, the machine must always be placed in its work position.

The lock is released and the entire upper structure of the machine is rotated to its

working position and locked. The lock may only move slightly against the stop. The

mast is raised by about 50 cm by actuating the corresponding control lever. When the

vertical position is reached, the mast may not be pressed into the soil. The machine

can be aligned automatically and manually. Automatic operation is turned on by

pressing the “Automatic Alignment ON” button. To check alignment, check the attached

bubble level to see whether the mast of the machine is exactly vertical. Automatic

operation is turned on by pressing the “Automatic Alignment ON” button.

When aligning by hand, the “Mast up and down” shift lever is actuated until the exact

alignment is indicated at the bubble level.

Assembly and start-up

44

Issue 06.2016

Hydraulic Ram Unit HRE

CAUTION

Aligning the machine!

Improper alignment of the machine and thus all assemblies can lead to damage of the

rammed material and wear of the respective machine parts.

Fig. 27: Circular level

Operating the machine

Hydraulic Ram Unit HRE

Issue 06.2016

45

DANGER

Risk of accidents when turning on the machine!

Any damages found must be reported before turning on the machine. The machine is

only ready to operate after all defects are remedied.

DANGER

Risk of accidents when turning on the machine!

Actuating control devices causes a mechanical movement at the machine. The

following must be adhered to:

The control device should be actuated slowly. No uncontrolled movements are

allowed.

No unauthorised personnel are allowed in the work area of the machine.

Obstructions or other objects near the machine must be removed.

7 Operating the machine

7.1.1 General instructions

7.1.2 Operating procedure

1. The following checks must be done before beginning work:

check and, if necessary, top up the motor oil level.

check and, if necessary, top up the fuel.

check and, if necessary, top up the hydraulic fluid level.

degree of contamination of the fill and vent filter and, if necessary, change

filter.

check and, if necessary, replace hydraulic fluid hoses and connectors.

check chain tension and tighten if necessary.

2. Rotate and lock the upper structure of the machine in the working position.

3. Set ignition key to the “I” position, the check charge and fluid pressure control

lamps will light.

4. Rotate the ignition key to “II”. The motor will start. The charge check and oil

pressure control lamps will go out.

5. Lightly actuate the speed adjustment lever.

6. Bring the machine to the position at which the profile is to be rammed.

7. To move, actuate the two corresponding control levers.

Move straight forward → both control lever are moved in the same direction. To

go around a curve → move the control lever in opposite directions.

When driving the machine, the hydraulic hammer may never be higher than one

meter above the ground.

8. Drive until the correct position is reached.

9. Erect the mast. Move the hydraulic hammer to its centre position.

10. Align the mast automatically or manually (optional).

Operating the machine

46

Issue 06.2016

Hydraulic Ram Unit HRE

1 Limit switch

2 Switch roll

11. Optionally, the corresponding distance can be established in the automatic selfregulation system.

12. Ramming position has been reached.

13. Move the hydraulic hammer upward using the control lever until the profile can be

inserted into the ram head.

14. Place the profile into the post guide and then align it, then move the hydraulic

hammer downward until the profile is pressed into the ground.

15. Before beginning the ramming process, check to see whether the profile is

standing vertically in the machine

7.1.3 Ramming the profiles

1. The ramming process can be done manually with the control levers or using the

automatic ramming function.

2. In the manual ramming process, the “Hammer down” control lever is always

actuated first before the ramming process is begun. The control levers are held

until the desired depth of the profile is reached. To end the ramming process, the

control lever “Hammer in” is released first and then the control lever “Hammer

down”.

3. If the correct depth is not yet reached, the process is repeated until the desired

depth is reached.

4. The hydraulic hammer is lifted far enough that it does not get caught in the

profile.

5. In the ramming process using the automatic ramming function, the height of the

automatic shut-down is adjusted on the mast.

Fig. 28: Limit switch for shutting off the automatic ramming function

Operating the machine

Hydraulic Ram Unit HRE

Issue 06.2016

47

6. The profile is placed under the hydraulic hammer. To start the ramming process,

the green button on the control panel of the electrical cabinet (optional) is

pressed. The machine automatically turns off the ramming process when the

height setting is reached.

7. If the automatic ramming process is stopped, the red button on the control panel

of the electrical cabinet is pressed. Only the ramming process is interrupted, but

the machine continues to run. If a dangerous situation arises during ramming, the

emergency stop button must be pressed immediately. The machine is shut down

completely.

8. At the end of the work, the machine must be placed in the transport position. The

lock is opened and the chassis structure is rotated. The lock is re-set.

9. Move the hydraulic hammer all the way downward.

10. The mast must be brought to the transport position. It is folded backward onto its

storage position. Before the mast is fully stored, it must be moved all the way

downward. Otherwise it might damage the hydraulic cylinder.

Operating the machine

48

Issue 06.2016

Hydraulic Ram Unit HRE

Maintenance and repair

Hydraulic Ram Unit HRE

Issue 06.2016

49

DANGER

Risk of accidents!

In all work involving operation, installation and maintenance, the shut-off procedures

described in these operating instructions must be followed, as well as any required

safety measures. After all work on the machine, check whether all safety equipment

has been installed and is functioning properly. Safety equipment may not be bypassed

or shut down.

CAUTION

Maintenance and testing of machine functions may only be performed by qualified

personnel according to the instructions in the operating instructions. The maintenance

intervals established by the manufacturer of the machine must be adhered to. The

operation of the machine must not be affected by a power loss.

CAUTION

Only perform maintenance work with the machine shut off and after it has been

secured against being turned back on. Statutory disposal regulations for waste oil,

lubricants, cleaning agents and filters must be followed. To protect against

unauthorised access, the ignition key must be removed and the negative terminal of

the battery disconnected. At the end of the maintenance work, all tools and

miscellaneous objects must be removed from the machine.

DANGER

Risk of accidents!

After the maintenance work, the following checks must be carried out prior to turning

the machine back on, during which time safety regulations must be adhered to.

Check that all loose bolted connections are tightened.

Properly re-install all removed safety equipment. Ensure that all safety equipment

for the machine is properly functioning again.

Clean the work area and remove any escaped process materials.

CAUTION

Do not use aggressive cleaning agents!

Cleaning agents must not damage the paint and the components of the machine. Use

a lint-free cleaning cloth. Only work with dry, filtered compressed air up to max. 2 bar.

After cleaning work on the machine, perform a visual and functional inspection.

8 Maintenance and repair

8.1 General instructions

Maintenance and repair

50

Issue 06.2016

Hydraulic Ram Unit HRE

NOTE

The life of the machine depends to a large degree on the quality of the maintenance

measures being performed.

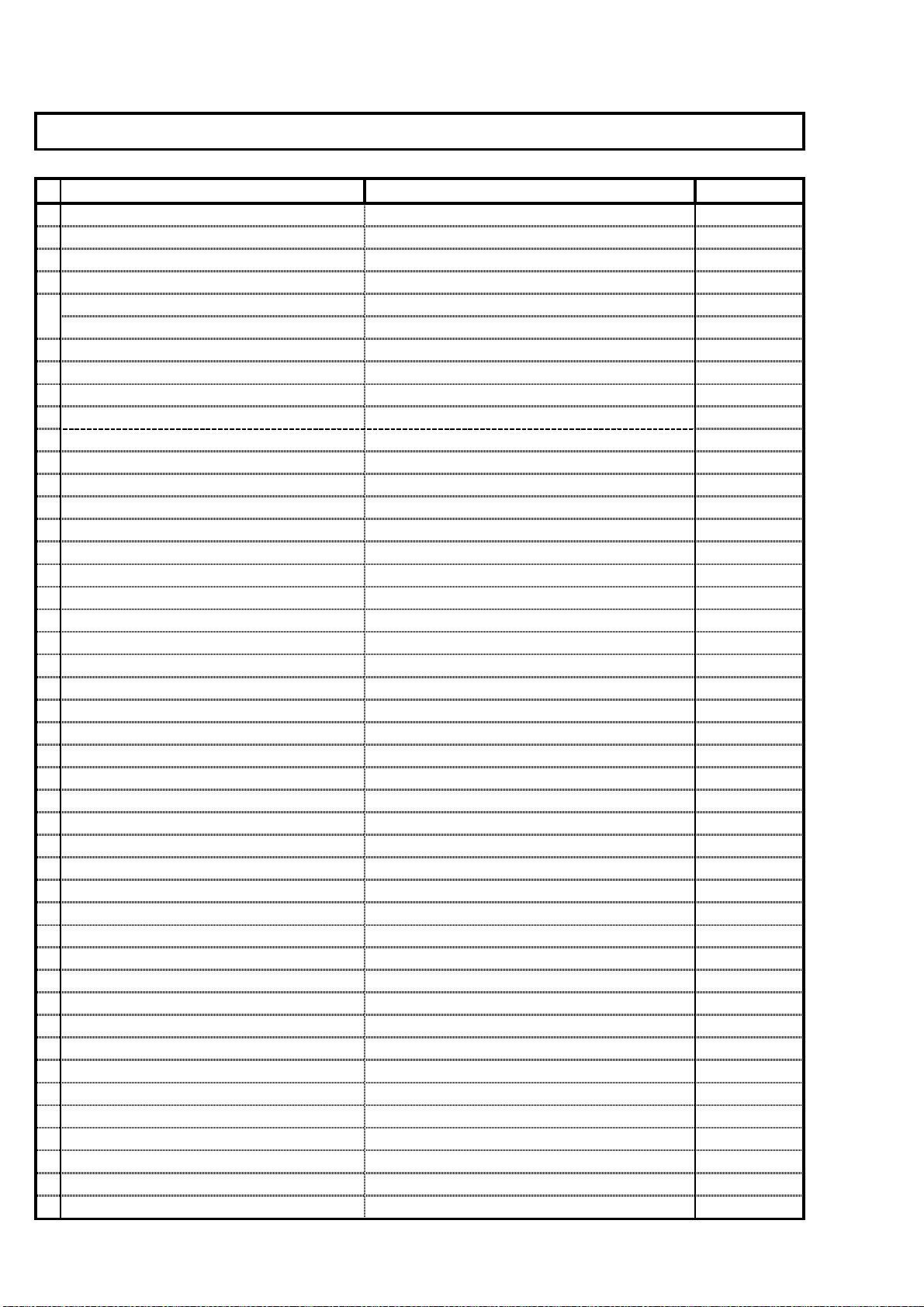

Maintenance and repair measures

Work to be performed

Interval

Figure

Upper mast lubrication

(carriage)

2 to 3 pumps of highpressure grease

30-50

operating

hours

Mast lubrication (carriage)

2 to 3 pumps of highpressure grease

1.

Lubricant nipple

at the centre of the mast

(carriage)

2.

Sight holes for

positioning the return

pulleys

30-50

operating

hours

Lower mast lubrication

(carriage) 2 to 3 pumps of

high-pressure grease

30-50

operating

hours

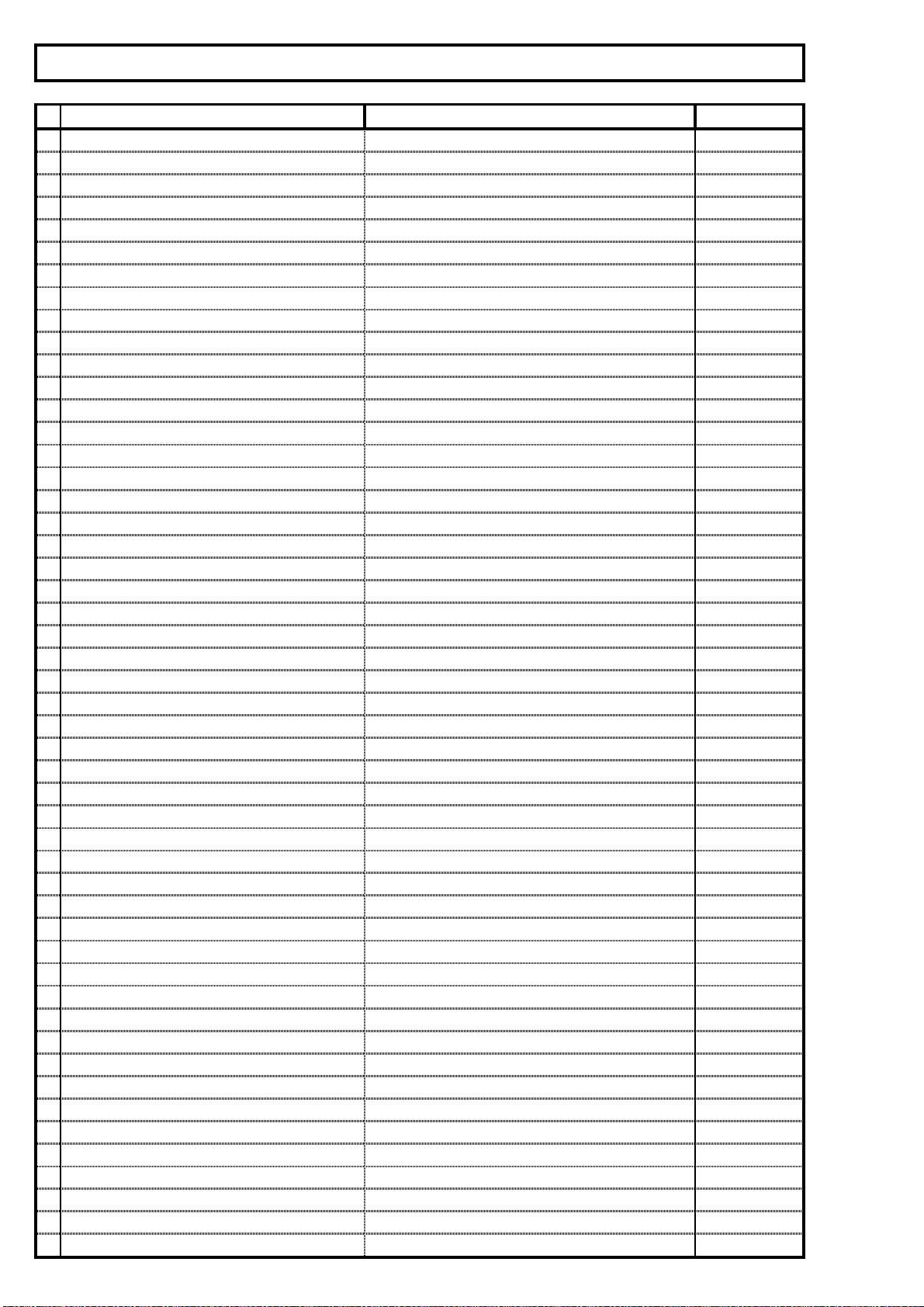

8.2 Maintenance and repair measures

Maintenance and repair

Hydraulic Ram Unit HRE

Issue 06.2016

51

Maintenance and repair measures

Work to be performed

Interval

Figure

Mast lubrication (carriage) at

hinge 2 to 3 pumps of highpressure grease

30-50

operating

hours

Lubrication at lower

hydraulic cylinder 2 to 3

pumps of high-pressure

grease

30-50

operating

hours

Lubrication at upper

hydraulic cylinder 2 to 3

pumps of high-pressure

grease

30-50

operating

hours

Lubrication at the hydraulic

hammer

Lay the hydraulic hammer on

a post and push the chisel

completely into the hydraulic

hammer.

2 – 3 times

per day

1 – 2 pumps

Maintenance and repair

52

Issue 06.2016

Hydraulic Ram Unit HRE

Maintenance and repair measures

Work to be performed

Interval

Figure

Adjusting bolts at sled (4x)

Check the bolted

connections

250 operating

hours

Adjusting bolts at the

advance (8x)

Check the bolted

connections

250 operating

hours

Tensioning bolts at the sled

Check the bolted

connections

250 operating

hours

Slide rails

Adjust play

Maintenance and repair

Hydraulic Ram Unit HRE

Issue 06.2016

53

Maintenance and repair measures

Work to be performed

Interval

Figure

Check tubing for leaks

Ongoing

checks.

Replace as

necessary.

Chains

Check tension and oil

Gear oil replacement at

vehicle motor

1.

Oil dipstick

2.

Oil fill nozzle

500 operating

hours

Tensioning the vehicle tracks

500 operating

hours

Maintenance and repair

54

Issue 06.2016

Hydraulic Ram Unit HRE

Maintenance and repair measures

Work to be performed

Interval

Figure

Hydraulic hoses

Visual check for damages,

abrasions, cracks.

Every 6 years

under normal

loads. Under

increased

demands,

after 2 years.

Blow out cooling fins with

compressed air.

Do not set the compressed

air gun onto the cooling fins.

250 operating

hours

Change motor oil

During motor oil change,

place a collection vessel for

the waste oil underneath. It

should not be allowed to

drain to the environment, or

the ground. Danger of

slipping.

The drained waste oil must

be disposed of according to

the waste oil ordinance

(AltölV).

Manufacturer'

s operating

instructions

Replace hydraulic fluid

During a hydraulic fluid

change, place a collection

vessel for the waste fluid

underneath. It should not be

allowed to drain to the

environment, or the ground.

Danger of slipping.

The drained waste oil must

be disposed of according to

the waste oil ordinance

(AltölV).

500 operating

hours

Maintenance and repair

Hydraulic Ram Unit HRE

Issue 06.2016

55

Maintenance and repair measures

Checking the chain tension

1.

Check on a flat surface.

2.

Rotate the chassis to the working position and lift using the mast until the chain is free.

3.

Lift the opposite side using a suitable forklift below the bracket until the chain is free (make

sure that the machine is secured against slippage).

4.

Never lift both sides at the same time.

5.

Sag of the chain between the pulley and the chain (the distance should be 15-20 mm).

Tensioning the chains

1.

Remove bolts on the cover to the right and left at the drive support and place the manual

grease pump over the lubrication nipple.

2.

Re-tension the chain.

3.

Do not use any chisel paste to tension the chain.

4.

Move the chain and check the chain tension again.

5.

For new rubber tracks, check the sag of the rubber tracks 2-3 times. Tension the rubber

tracks if necessary.

De-tensioning the chains

1.

Slowly loosen the valve with the lubrication nipple and allow grease to flow out until the

correct chain tension is reached.

2.

Re-tighten the valve with the lubrication nipple.

3.

Remove grease and dispose of it properly.

Removing the rubber track

1.

Remove the fenders and raise the chassis.

2.

Loosen the valve until the rubber chain is entirely de-tensioned.

3.

Use a long pry bar to remove the chain.

4.

The lower end at the sagging chain must reach in front of the rear pulley. A lateral force

will be exerted on the chain.

5.

Now slowly move the chain forward using the drive motor and exert more pressure on the

chain. The chain will now move downward from the guide bracket of the guide pulley and

can be pulled backward and removed from the drive pulley.

Installing the rubber track

The rubber track is installed in the same sequence as its removal, but in reverse.

1.

Place the chain completely against the cogging of the drive pulley.

2.

Lay the lower end of the chain onto the guide pulley.

3.

Push on the chain using the pry bar.

4.

Slowly move the chain forward until it is seated on the guide pulley and drive pulley

completely.

5.

Tension the chain according to the description.

Adjusting the slide rails

The slide rails are seated using adjusting bolts at the sled and the base tube.

There are 4 adjusting bolts at the sled with lock nuts, and 8 adjusting bolts at the base tube

with lock nuts.

1. Adjusting the slide rails at the sled

Set the mast in the vertical position. Loosen the lock nut. Tighten the adjusting bolt hand tight

against the lock nut. Check the play in the sled by moving it up and down.

The sled should have a constant speed in each direction. If not, the adjusting bolt must be

readjusted.

Check whether the sled is sitting firmly against the mast by shaking it.

Maintenance and repair

56

Issue 06.2016

Hydraulic Ram Unit HRE

2. Adjusting the slide rails at the base tube

Set the mast in the vertical position. Lock nuts are loose. Tighten the bolts until resistance is

felt. Tighten the lock nuts and check the play by slowly moving the advancement and the leftright cylinder of the mast one after the other. If there is still play in the slide rails, the

adjustment must be repeated at the adjusting bolts.

Disruptions

Hydraulic Ram Unit HRE

Issue 06.2016

57

Type of disruption

Possible causes

Remedy

Motor does not start

Emergency Stop button

activated

Unlock the Emergency Stop

button.

Follow the Hatz operating

instructions.

Hydraulic hammer is not

making impact

Loose quick coupling

Tighten the quick coupling

Follow the Atlas Copco

operating instructions.

9 Disruptions

Disruptions

58

Issue 06.2016

Hydraulic Ram Unit HRE

Ersatzteilliste HRE / Spare Parts List HRE

A=Aufbau, E=Elektrik, HY=Hydraulik, M= Motor, B=Bohreinheit

A=Assembly, E=Electric, HY=Hydraulic, M=Motor, B=Drilling Unit

Bezeichnung (d) Name (engl) Art-Nr/ArtNo

Große Inspektion Large service 09575274

Kleine Inspektion Minor service 09575174