Gates Corporation GT2 User Manual

Drive Design Manual

Rac ehor se

Rac ehor se

PowerGrip®GT®2 Belt Drives

For more power at less

cost in high-speed

applications.

THE DRIVING FORCE IN POWER TRANSMISSION

Table of Contents

Description Page Description Page

Introduction to PowerGrip®Belt Drives . . . . . . . . . 2-7

PowerGrip

®

Belt Drive Selection Procedure . . . . . . 8-9

High Speed Drive Survey

and Energy Savings Worksheet . . . . . . . . 10

®

PowerGrip

PowerGrip

GT2®Belt Pitch Selection Guide. . . 11

®

Timing Belt Pitch Selection Guide . . 11

NEMA Minimum Recommended

Sprocket Outside Diameters . . . . . . . . . . 12

PowerGrip GT2 Belt Drives . . . . . . . . . . . . . . . 13

Stock Lengths and Widths. . . . . . . . . . . . . 14

Basic PowerGrip Service Factors . . . . . . . . . 15

Belt Drive Selection Tables

5mm Pitch Belts . . . . . . . . . . . . . . 16-29

8mm Pitch Belts . . . . . . . . . . . . . . 30-35

14mm Pitch Belts . . . . . . . . . . . . . 36-43

Power Rating Tables

5mm Pitch Belts . . . . . . . . . . . . . . 44-45

8mm Pitch Belts . . . . . . . . . . . . . . 46-48

14mm Pitch Belts . . . . . . . . . . . . . 49-51

Drive Selection Tables . . . . . . . . . . . . . 52-55

Power Rating Tables

20mm Pitch Belts . . . . . . . . . . . . . 56-58

PowerGrip Timing Belt Drives. . . . . . . . . . . . . . 59

Stock Lengths and Widths. . . . . . . . . . . . . 60

Drive Selection Tables

XL, 0.200″ Pitch Belts . . . . . . . . . . . 61-64

L, 0.375″ Pitch Belts . . . . . . . . . . . . 65-70

H, 0.500″ Pitch Belts . . . . . . . . . . . . 71-74

Horsepower Rating Tables

XL, 0.200″ Pitch Belts . . . . . . . . . . . 75-76

L, 0.375″ Pitch Belts . . . . . . . . . . . . 77-79

H, 0.500″ Pitch Belts . . . . . . . . . . . . 80-84

Long Length Belting . . . . . . . . . . . . . . . . . 85-94

PowerGrip Twin Power Belts . . . . . . . . . . . . 95-97

Drive Selection Procedure . . . . . . . . . . . 98-99

PowerGrip GT2 Sprocket Specifications. . . . . . . . 100

Sprocket Specifications Tables

5mm Pitch Sprockets . . . . . . . . . . 101-102

8mm Pitch Sprockets . . . . . . . . . . 103-106

14mm Pitch Sprockets . . . . . . . . . 107-111

®

PowerGrip HTD

Sprocket Specifications . . . . . . . 112

20mm Pitch Sprockets . . . . . . . . . 113-114

PowerGrip Timing Belt Pulleys . . . . . . . . . . . . 115

Sprocket Specifications . . . . . . . . . . . 116-118

Taper-Lock Bushings . . . . . . . . . . . . . . . . . 119

QD Bushings. . . . . . . . . . . . . . . . . . . . . . 120

Bushing and Keyseat Information. . . . . . . . . 121-122

Taper-Lock Type Sprocket Installation

and Removal . . . . . . . . . . . . . . . . . . . . 123

QD Type Sprocket Installation

and Removal . . . . . . . . . . . . . . . . . . . . 124

Belt Drive Tensioners . . . . . . . . . . . . . . . . . 125

PowerGrip GT2 Idler Sprockets . . . . . . . . . . . . 125

Sprocket Specification Tables. . . . . . . . 126-129

Engineering Data . . . . . . . . . . . . . . . . . . . 130

Section I—Application Design Considerations. . 130

1. Gear Motors/Speed Reducer Drives . . . 130

2. Electric Motor Dimensions . . . . . . . . 131

3. Minimum Recommended Sprocket

Diameters for General Purpose

Electric Motors . . . . . . . . . . . . . . 132

4. High Driven Inertia . . . . . . . . . . . . 132

5. Air Moving Drives . . . . . . . . . . . . 132

6. Linear Motion Drives . . . . . . . . . . . 133

7. High Performance Vehicle Applications . 133

8. Belt Drive Registration . . . . . . . . . . 133

9. Belt Drive Noise . . . . . . . . . . . . . 134

10. Use of Flanged Sprockets . . . . . . . . 134

11. Fixed (non-adjustable) Center Distance . 134

12. Use of Idlers . . . . . . . . . . . . . . . 135

13. Minimum Belt Wrap and

Tooth Engagement . . . . . . . . . . . . 135

14. Adverse Operation Conditions . . . . . . 136

Section II—Engineering Design Considerations . 136

1. Belt Storage and Handling . . . . . . . . 136

2. Center Distance and Belt Length. . . . . 136

3. Tooth Profiles . . . . . . . . . . . . . . 137

4. Static Conductivity . . . . . . . . . . . . 137

5. Sprocket Diameter—Speed . . . . . . . 138

6. Efficiency . . . . . . . . . . . . . . . . . 138

7. Belt Tolerances. . . . . . . . . . . . . . 139

8. Belt Installation Tension . . . . . . . 139-140

9. Center Distance Allowances

for Installation and Testing . . . . . . . . 141

10. Drive Alignment . . . . . . . . . . . . . 141

11. Belt Installation . . . . . . . . . . . . . . 142

12. Belt Pull Calculations. . . . . . . . . . . 142

13. Bearing/Shaft Load Calculations . . . . . 142

14. Self-Generated Tension . . . . . . . . . 143

Technical Data

Made-To-Order (MTO) PowerGrip Belts . . . . . 144

Trouble Shooting . . . . . . . . . . . . . . 145-146

Standard Calculations . . . . . . . . . . . . . . 147

Useful Formulas and Calculations . . . . . 148-149

Synchrounous Belt Product Design Catalogs . . . . . 150

Synchronous Belt Standard Product Line Listing . 150-164

Application Examples . . . . . . . . . . . . . . . 165-168

Copyright 2000

The Gates Rubber Company

Denver, Colorado 80217 Printed in U.S. of America

R

Low speed. Hig h speed. And any speed in between.

Gates has your tota l synchr onous belt drive system solution!

Synchronous belt drives are

being used more extensively than

ever for the transfer of power from

one shaft to another, multiplication

of torque,speed reduction or

increase, and synchronization

of shaft operations.

Gates, the world’s recognized

leader in synchronous belt

technology, continues to meet all

your needs for synchronous belts,

sprockets and bushings across

the broadest range of industry

applications. Choose from a full

line of quality products featuring

leading-edge technologies

that deliver the advantages

you’re looking for:

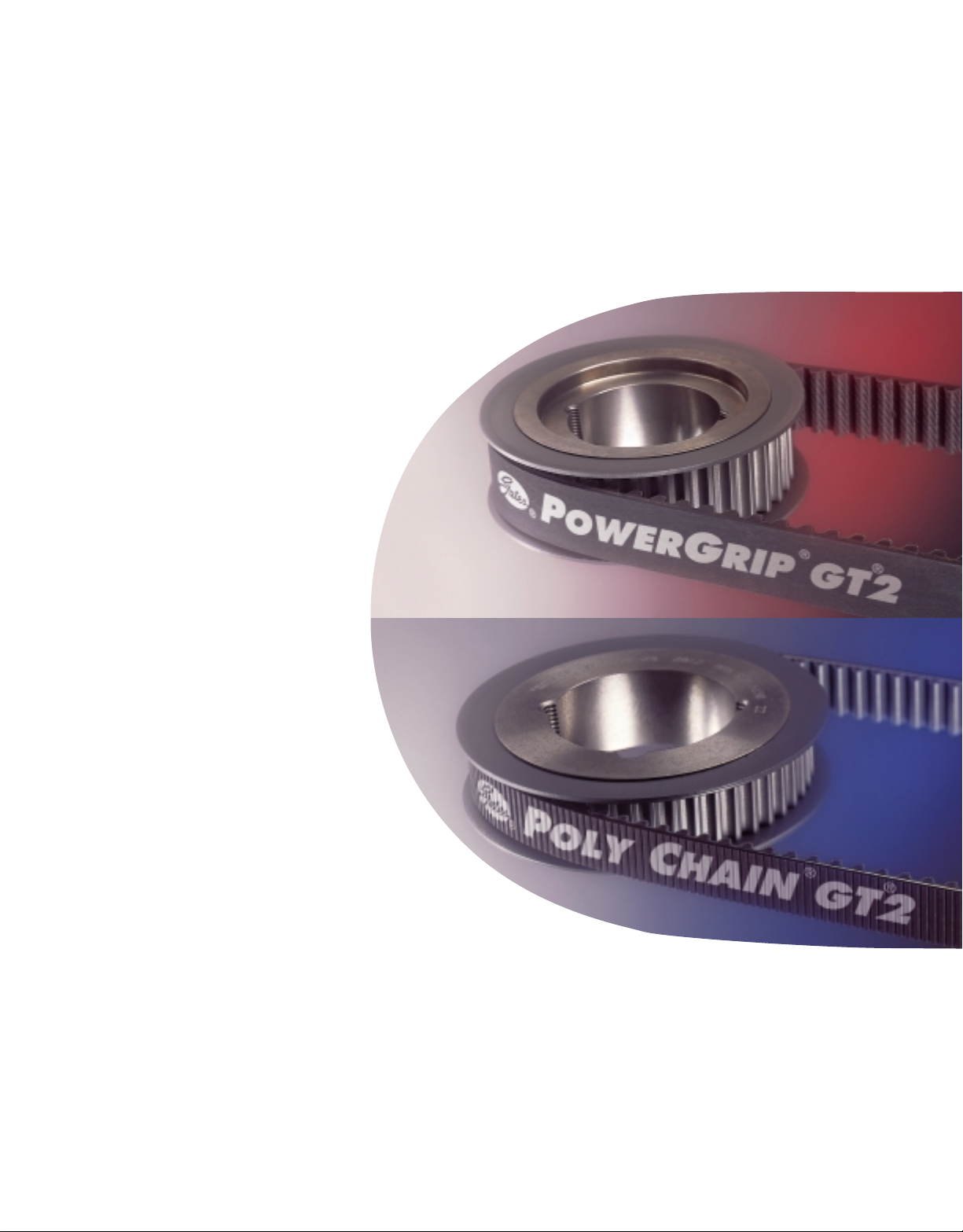

PowerGrip® GT®2

The Racehorse. This is the perfor mance choice for a wide

variety of high-speed (above 500 rpm) drive applications.

PowerGrip GT2 will deliver more power at a lower overall

cost than any other rubber synchronous belt

drive system available.

●

Reduced downtime

●

Reduced over-all drive cost

●

Reduced drive package size

●

Increased component life

●

Increased per formance

●

Energy savings

●

Reduced acquisition costs

●

Reduced transaction costs

●

Increased drive design options

New, improved

synchronous belt l ines.

The latest innovations in Gates

synchronous drive systems are two

redesigned and reengineered belt

and sprocket lines. They are the

clear winners in overall cost, drive

selection options and performance

when compared to any other belt

drive products on the market today.

Poly Chain® GT®2

The Workhorse. This is the optimal choice in meeting your

needs for low-speed (below 500 rpm), high-torque drive applications.

The powerful Poly Chain GT2 polyurethane belt drive system will

outperfor m roller chain drives and any rubber belt drive system

on the market today, delivering the lowest-cost belt drive

system available for low-speed, high-torque applications.

And we can prove it!

Taper-Lock

®

sprockets & bushings.

Poly Chain GT2 and PowerGrip GT2

belt drive systems feature TaperLock bushings. Advantages of

the Taper-Lock system include:

●

Industry -pr oven robustness

●

True running, concentric

●

Extensive use in

roller chain sprockets

●

Easy installation and removal

●

Allows compact

sprocket hub designs

●

Short length-thr u-bore

dimensions

●

Flush mount with

no protruding hubs

●

Installs with less axial

sprocket movement than

other bushing systems

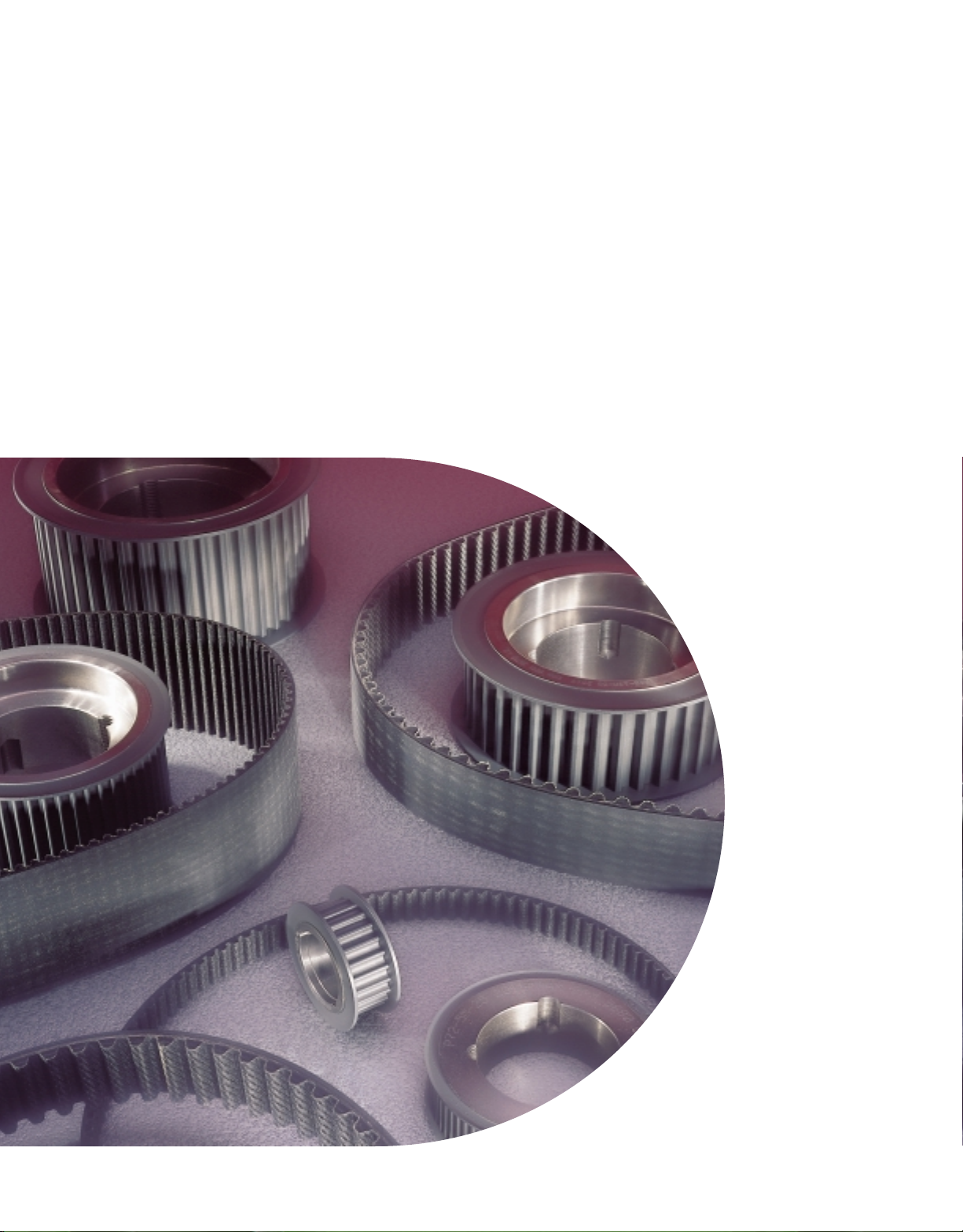

Made - to -or der sp rockets.

Gates Made-to-Order (MTO)

Metal Depar tment supports

synchronous MTO sprockets with

90% of Requests For Quote (RFQ)

provided within 48 hours and 84%

of quotes provided within 24

hours. Quoted deliver y dates

are met at a 97% rate and most

deliveries are made within four

weeks. Call 800-709-6 001

for more information.

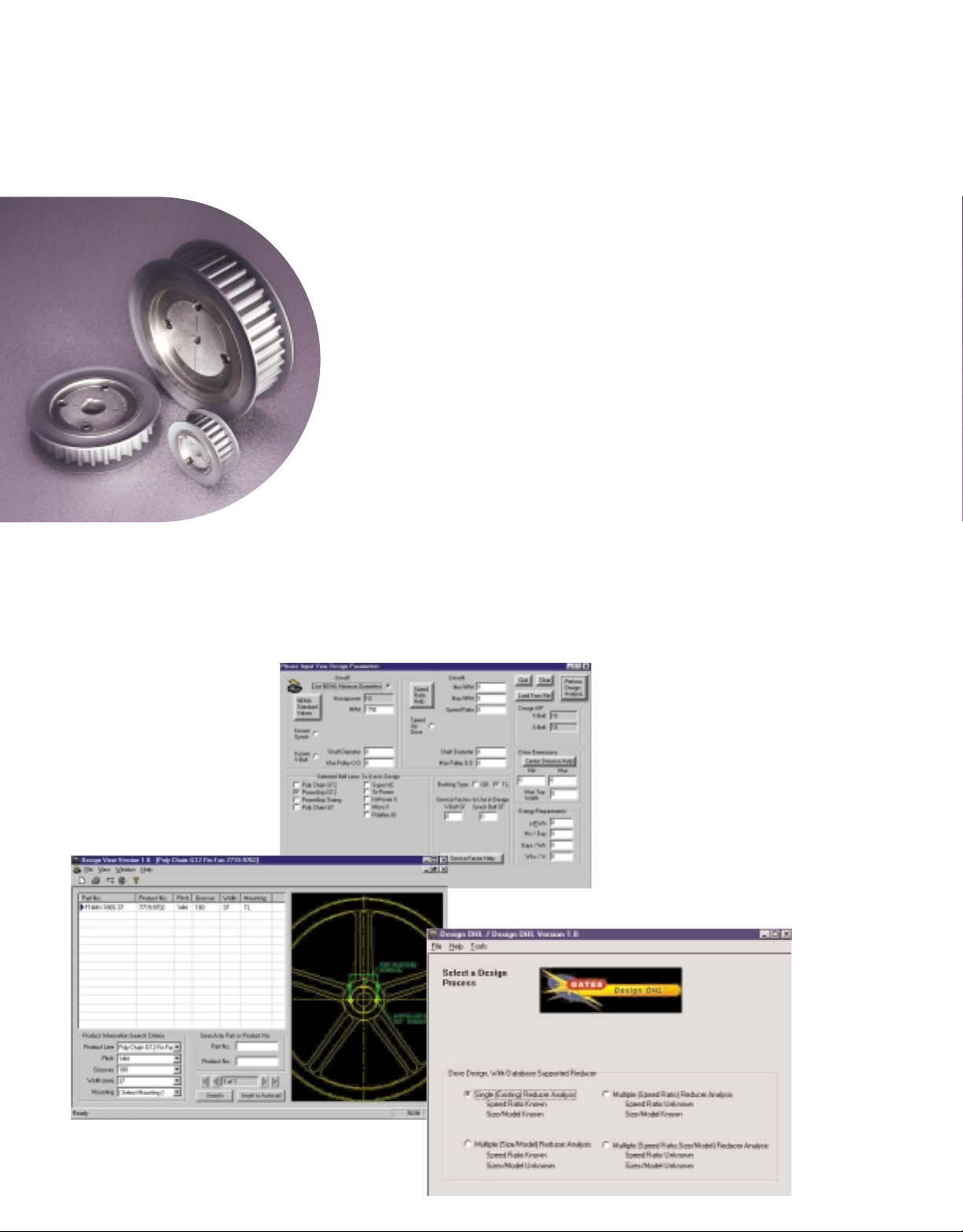

Gates Compass®CD-ROM:

selection, maintenance,

and design tool.

The Gates Compass CD-ROM

is a powerful tool offering a

variety of useful information and

features. It makes choosing the

right drive system fast and easy.

Compass contains

Design View

™

invaluable assistance in product

selection, drive design, energy savings calculations, installation and

system cost savings. The CD also

contains eight instructional videos

covering topics such as belt drive

Design Flex™II,

and Design OHL

▲ Design Flex II

™

for

troubleshooting, tensioning, safety

and installation. The Compass

CD-ROM is available through

authorized Gates Industrial

Power Transmission Distributors.

A partnersh ip commitment.

To ensure that you get the

synchronous drive systems

that are right for your applications,

Gates provides the industry’s

leading suppor t pr ogram and the

largest distributor network. You

get local inventor y availability and

a single source for all your needs.

You also get access to Gates

Product Application Engineering

Suppor t for unmatched design and

problem-solving expertise in every

aspect of synchronous drive operation. You’re backed by the industr y’s largest manufacturer’s field

sales force, voted number one in

a recent

Selling Power

magazine

sur vey. Your Gates representatives

are experts in the products they

market and provide a variety of

in-house and on-site training programs. Nobody is as committed

to suppor ting you as Gates!

It’s obvious !

Gates is your total

synchronous drive solution.

With industr y-leading technologies,

a complete line of high quality,

top-performing products, and

unmatched customer suppor t,

it’s easy to see that Gates is

the par tner to choose in meeting

all your needs for synchronous

™

belt drive systems.

▲ Design View

®Taper-Lock is a register ed trademark

of the Reliance Electric Corporation.

™

Design OHL

▲

™

PowerGrip GT2

The new PowerGrip GT2 drive

system combines an innovative

rubber compound with Gates’

industr y-leading belt engineering

technology. The result is a belt that

provides extraordinary load-car rying

capacity in high-speed applications

(above 500 rpm). It transmits up

to 200% more power than previous

PowerGrip GT, PowerGrip HTD

or other first generation cur vilinear

synchronous belts. Because of

the increase in horsepower, size

for size, PowerGrip GT2 allows for

the design of belt drive systems

that are small and compact.

®

With over 42,000 possible drive

combinations available, there’s

no need to over-design your drives.

And with Gates as your system

supplier, inventory, transaction

and acquisition costs can be

significantly reduced.

If you are using PowerGrip GT,

PowerGrip HTD or similar cur vilinear first generation synchronous

belts, you can lower your costs

by replacing them with PowerGrip

GT2. The increased capacity of

Power Grip GT2 allows the use

of the next narrower belt size

than the current size with no

sacrifice in ser vice life.

Whether it’s a new or existing

application, the PowerGrip GT2

belt is the only belt you need for

your high-speed drive applications.

PowerGrip GT2

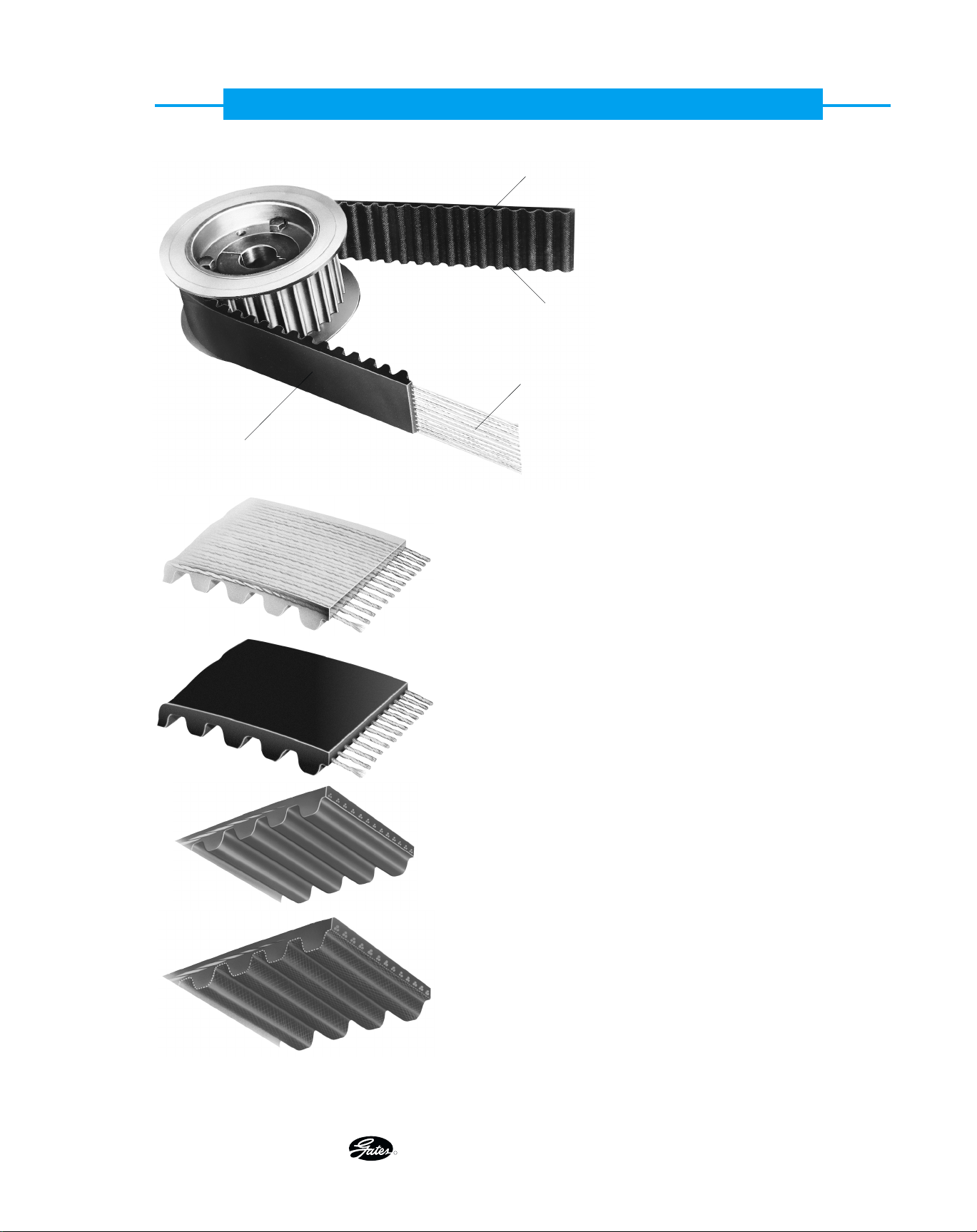

Construction Features

1. Tensile cord—

tensile member provides high

strength, excellent flex life and

high resistance to elongation.

The fiberglass tensile member

provides greater length stability

than competitive belts using

aramid tensile members.

2. Neoprene backing—

neoprene is bonded to the tensile

member for protection against

grime, grease, oil and moisture.

It also protects from frictional

wear if idlers are used on the

back of the belt.

A fiberglass

Strong

3. Neoprene teeth —

neoprene compound is molded

integrally with the neoprene

backing. The teeth are

precisely formed and pre-

cision-spaced to assure

smooth meshing with

the sprocket grooves,

minimizing tooth

interference with

the mating sprocket.

Minimizing tooth

meshing interference

greatly increases

belt life by prevent-

ing tooth wear and

distor tion. Audible

drive noise is also

minimized.

High-strength

4. Nylon facing—

Tough nylon fabric with

a low coef ficient of friction

covers the wearing surfaces

of the belt. It protects the tooth

surfaces and provides a durable

wear surface for long service life.

Advantages of the Gates

PowerGrip GT2 drive system:

PowerGrip GT2 drives provide

positive, trouble-free power

transmission and of fer many

advantages over conventional

gears and rubber belt drives.

●

Higher capacity

●

Improved registration

●

Reduced noise

●

No lubrication required

●

No stretching due to wear

●

Corrosion resistance

●

Excellent abrasion resistance

●

Clean operation

●

Long trouble-free ser vice

●

Low vibration

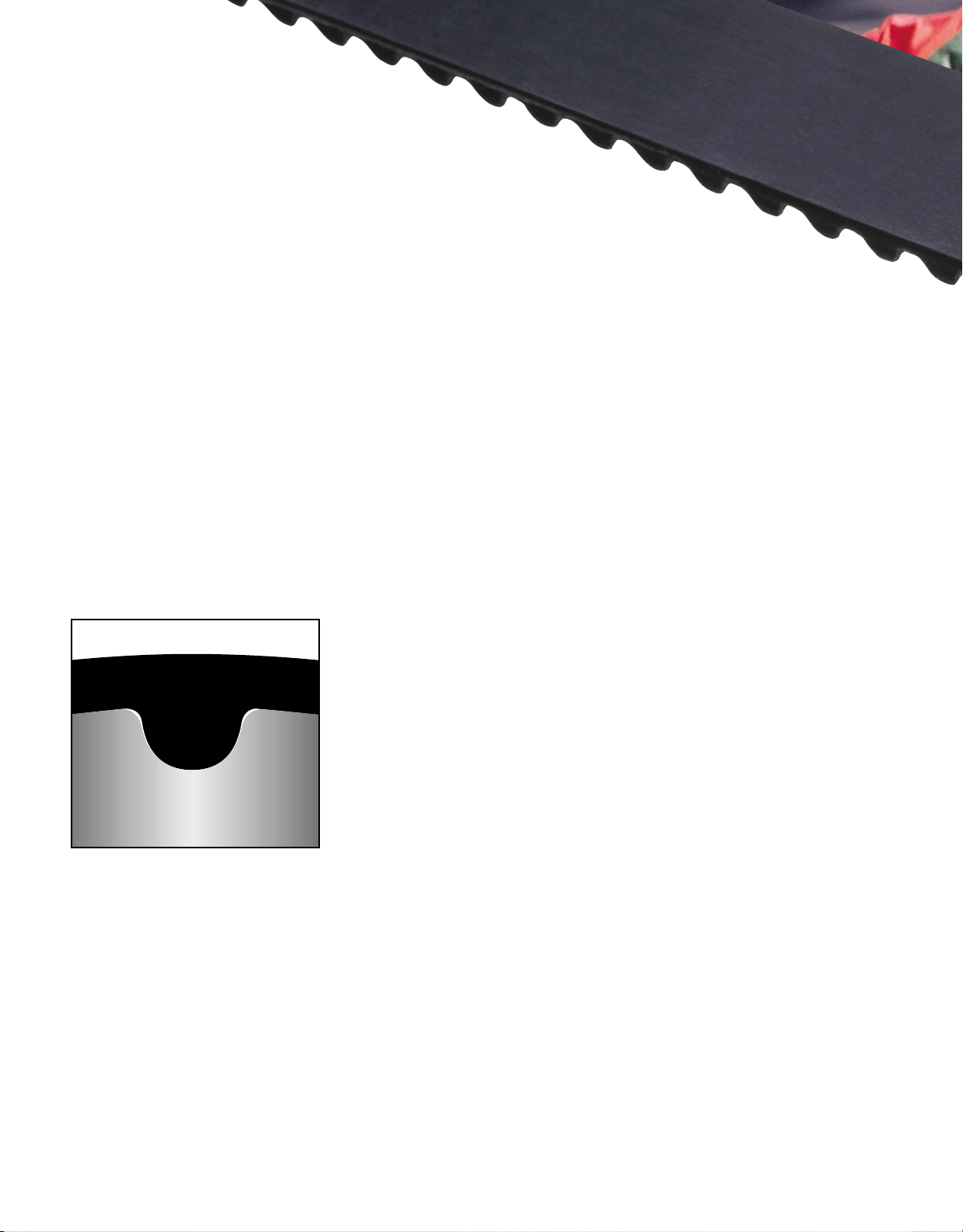

The profile f it.

PowerGrip GT2 belts and sprockets

were specially designed to work

together as a system in providing

the best possible performance.

The belt teeth have a deep design

for robustness and excellent ratcheting resistance, yet enter and exit

the sprocket grooves cleanly with

minimal interference. This results

in minimal wear and low noise.

The key to the PowerGrip GT2

system is the fit of the belt teeth

in the sprocket grooves. The flank

contact area of the belt teeth has

been increased significantly over

other cur vilinear belt drive systems. This greatly increases surface contact area and prevents

belt tooth distor tion in the spr ocket grooves under heavy torque

loads. This results in long, trouble free service. The belt tooth and

sprocket groove curvatur es were

also designed to fit closely together with a minimum of backlash.

This means more accurate positioning and less lost motion than

in other belt drive systems.

Precision registration.

PowerGrip GT2 drive systems

provide timing and synchronization

accuracy that make for excellent

registration. They are ideal for

applications where precision is

critical, such as robotics, conveyors and machine tools. Gates

of fers belts in a full range of

standard configurations. Custombuilt constructions are also available for individual applications that

require maximum perfor mance.

Quiet operation.

The PowerGrip GT2 belt’s specially

engineered teeth mesh cleanly

with sprocket grooves to reduce

noise and vibration. Clean meshing

results in significant noise reduction when compared to PowerGrip

Timing, PowerGrip HTD and some

other rubber belts. PowerGrip

GT2’s high load capacity also

allows narrower drive designs,

fur ther r educing noise.

The operating noise reduction in

comparison with first generation

cur vilinear tooth belts is r emarkable. PowerGrip GT2 belts are

made to work hard, yet quietly.

Whether or not an application

requires low noise levels,

PowerGrip GT2 belts deliver

a quieter, longer running life—

with no sacrifice in performance.

Taper-Lock

®

sprockets & bushings.

PowerGrip GT2 belt drive systems

feature a new line of sprockets

that have been specially designed

to handle the new increased belt

power ratings. These sprockets

utilize Taper-Lock bushings, a bushing system with an industr y-pr oven

track record of robustness and

reliability.

Taper-Lock bushings allow easy

sprocket installation and removal.

Their compact design allows narrow sprocket hubs for compact

drive systems. They assure secure

sprocket mounting and run tr ue,

eliminating any concern for

reliable operation at both

low and high speeds.

The bottom line:

For: From: Gates Rubber Company

900 So. Broadway

Denver, Colorado 80217-5887

303 - 744 - 5800

Application: ENERGY SAVINGS - 50 HP

Motor HP: 50.00

RPM: 1750

Motor Efficiency: 0.90%

Hours Per Day: 24

Days Per Week: 7

Weeks Per Year: 50

¢/KWh: 8.00

Price Price

S-Belt PartNo: 2600-8MGT-50 $ 102.80 V-Belt Part No: 4 / 5VX1000 $ 73.30

DriveR Sprocket: P72-8MGT-50 $ 120.94 DriveR Sheave: QD4/5V7.10 $ 90.05

DriveR Bushing: 2517 2.1/8 $ 13.85 DriveR Bushing: SF 2.1/8 $ 18.57

DriveN Sprocket: P112-8MGT-50 $ 187.88 DriveN Sheave: TL4/5V10.30 $ 128.64

DriveN Bushing: 3020 2.1/8 $ 20.82 DriveN Bushing: 3020 2.1/8 $ 20.82

Total Cost: $ 446.29 TotalCost: $ 331.38

KWh Per Year: 348133 KWH/yr.

Energy Savings: $ 1392.53 /yr.

Cost of Replacing Existing V-Belt Drive

Where Existing Drive is Operational: $ 446.29 Payback Period: 4 months.

Where V-Belt Needs Replacement: $ 372.99 Payback Period: 3 months.

Where Entire Drive Needs Replacement: $ 114.91 Payback Period: 1 months.

NOTES

- Drive Design by Design Flex II.

- KWh Per Year are calculated using the following formula:

(Motor HP) x (0.746) x (Hours/Year) / (Motor Efficiency)

- Energy Savings are calculated using the following formula:

(KWh Cost) x (KWh Per Year) x 0.05

I

N

P

U

T

D

R

I

V

E

S

R

E

S

U

L

T

S

INDUSTRIAL BELT DRIVE DESIGN - Energy Report

Using Design Flex II by the Gates Rubber Company

™

Compared to other rubber belt

drive systems, PowerGrip GT2

drives of fer you:

●

●

●

●

●

PowerGrip GT2

Energy Savings Calculator.

The sample calculator here

illustrates the energy savings

of a PowerGrip GT2 drive system.

This energy savings program is

available exclusively on the Gates

Compass PT CD-ROM (version

2.0). Use it to estimate energy

savings of a PowerGrip GT2 drive

system in your application. For

more information on Compass

and Gates’ Design Flex II drive

design program, contact your

local Gates representative.

A smaller, more compact design

Lowest cost drive system

for high speed applications

Longest life, width for width

More belt and sprocket

combinations to choose from

Easier installation and removal

Gates PowerGrip GT2 belts are protected by U.S.

patents 4,605,389, 4,403,979, 4,662,863,

5,362,281 and U.S. and foreign patents pending.

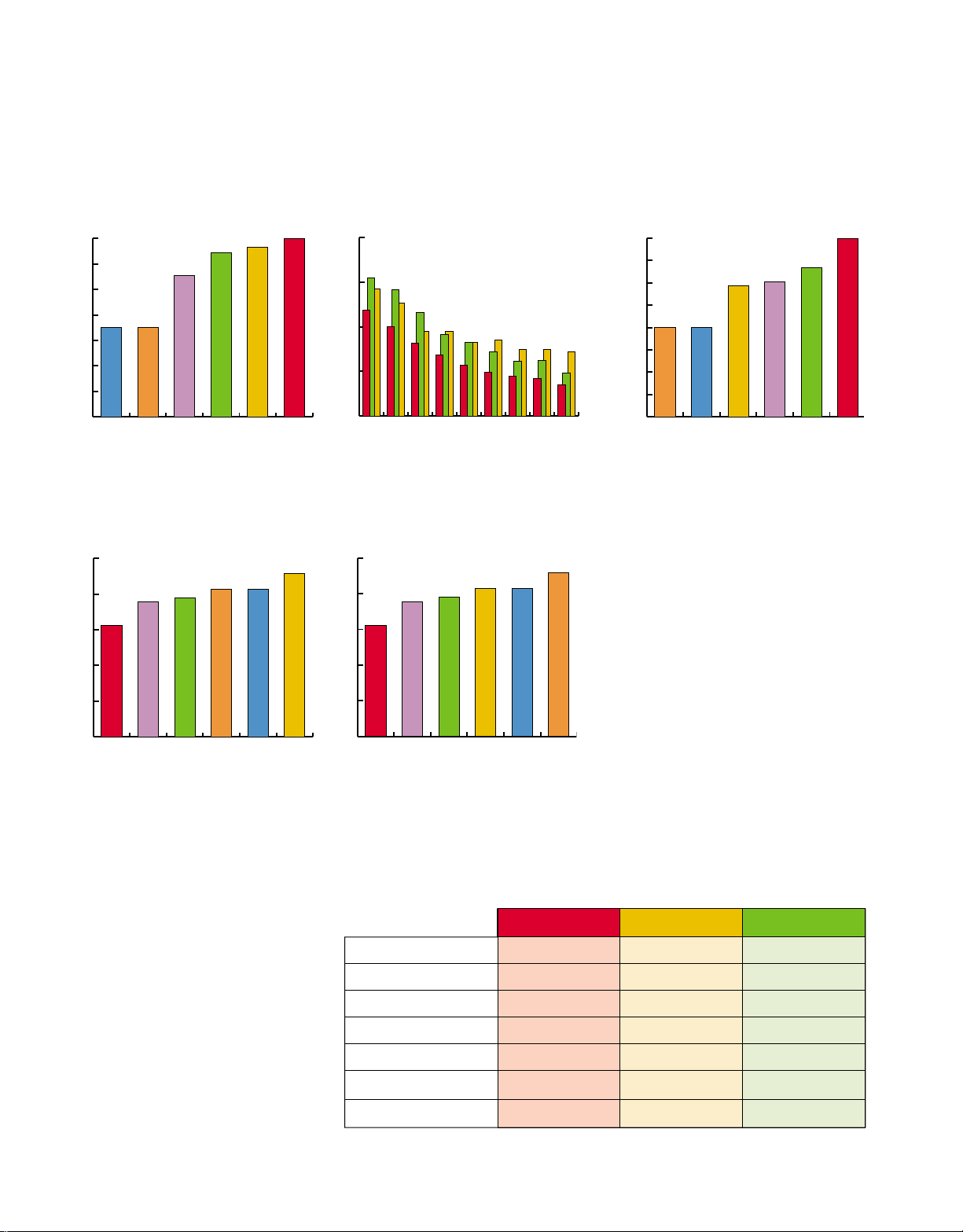

PowerGrip GT2 drive systems provide the lowest initial cost compar ed to

0

5

10

15

20

25

30

35

PGGT2EaglePantherRPP PlusPGGTHTD

Published Horsepower Ratings

$0$0

$5$5

$10$10

$15$15

$20$20

60504030252015107.5

Motor Horsepower

Relative Cost

$0

$2

$4

$6

$8

$10

EagleHTDPGGTPantherRPP PlusPGGT2

Relative Cost

$0

$2

$4

$6

$8

$10

PGGTHTDEaglePantherRPP PlusPGGT2

Relative Cost

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

PGGT2PantherRPP PlusEagleHTDPGGT

Horsepower Per mm Belt Width

Center Distance Range

Maximum Speed Ratio

Belt Length Selections

Belt Length Range

Belt Width Selections

Total Drive Combinations

Goodyear

Eagle Pd

Dayco

RPP Panther

Gates

PowerGrip GT2

3.46 – 83.15 5.51 – 44.09 3.78 – 83.15

6.545:1 11.200:1 8.730:1

33 14 26

384 – 4400mm 640 – 2400mm 480 – 4400mm

20-30-50-85 16-32 12-22-35-60

20000+ 7000+ 16500+

Sprocket Diameters

19 26 20

any other high-speed rubber belt synchr onous system.

PowerGrip®GT®2

■

PowerGrip®GT

■

®

Goodyear®Eagle Pd

■

®

RPP®Plus

■

®

■

And here’s pr oof!

®

HTD

Dayco®Panther

■

®

Published Horsepower Ratings

(8mm Pitch, 56 Groove Sprocket,

1750 rpm Motor Speed, 1” Belt Width)

Relative Drive Cost

Per Motor Horsepower

(8mm Pitch, 56 Groove Sprocket, 1750 rpm

Motor Speed, Ser vice Factor Added)

Relative Drive Cost

For Motor Horsepowers

(1750 rpm Motor Speed, 8mm Pitch)

Relative Drive Cost

Per Inch of Belt Width

(8mm Pitch, 56 Groove Sprocket,

1750 rpm Motor Speed)

8mm Pitch Product

Line Comparison

Horsepower Capacity

Per mm Belt Width

(8mm Pitch, 56 Groove Sprocket, 1750 rpm

Motor Speed, Ser vice Factor Added)

®™ Eagle PD is a trademark of The Goodyear Tire & Rubber

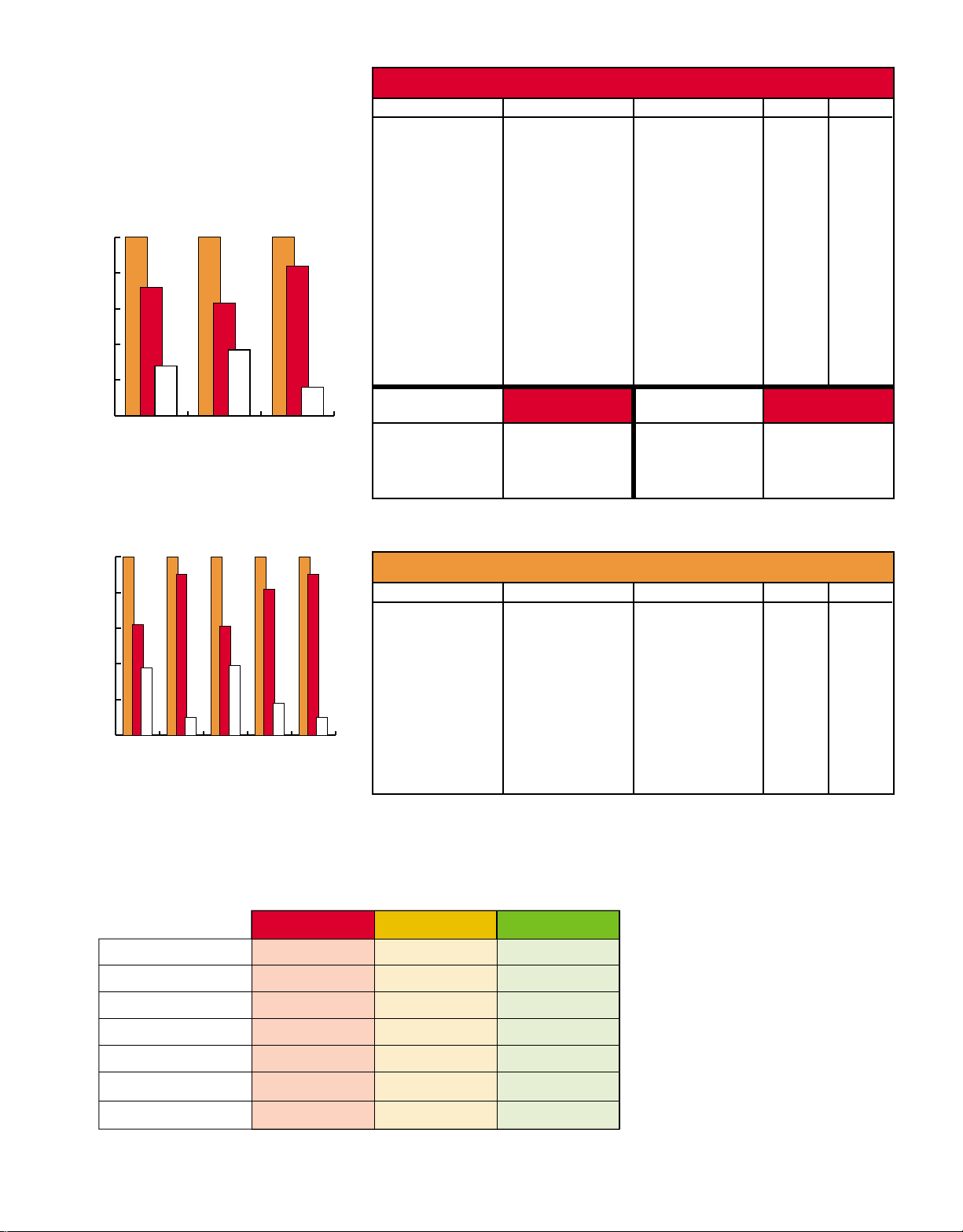

Company. Dayco and Panther are registered trademarks

and RPP is a trademark of Dayco Products Inc.

$0

$20

$40

$60

$80

$100

28%

37%

16%

30mm to 20mm50mm to 30mm85mm to 50mm

Belt Width

Replacement Cost

Replacement Belt Cost Saving %

$0

$20

$40

$60

$80

$100

38%

10%

39%

18%

10%

55mm

to 40mm

85mm

to 55mm

115mm

to 55mm

115mm

to 85mm

170mm

to 85mm

Belt Width

Replacement Cost

Center Distance Range

Maximum Speed Ratio

Belt Length Selections

Belt Length Range

Belt Width Selections

Total Drive Combinations

Goodyear

Eagle Pd

Dayco

RPP Panther

Gates

PowerGrip GT2

7.99 – 127.32 8.54 – 47.40 7.99 – 89.84

6.857:1 6.00:1 7.71:1

22 14 18

966 – 6860mm 994 – 2800mm 966 – 4956mm

40-55-85-115-170 35-53-70-105 20-42-65-90-120

22000 8,000+ 17,500+

Sprocket Diameters

23 21 23

Design Performance Grouping – PowerGrip GT2

PowerGrip GT2 – 8 & 14mm Belts can be used to replace other non-Gates curvilinear belts in the next smallest width

Company Product Trade Name Nomenclature Belt-Pitch Profile

Bando Synchro-Link® – HT 1600-8M-20-H 8 & 14mm HTD

Dodge HT100™ 1600-8M-20 HT100 8 & 14mm GT

Electron EHT® 1600-8M-20 8 & 14mm HTD

Gates HTD® 1600-8M-20 8 & 14mm HTD

Jason HTB® 1600-8M-20 8 & 14mm HTD

MBL HTT™ 1600-8M-20 8 & 14mm HTD

Opti Belt HTD® 1600-8M-20 8 & 14mm HTD

Browning HPT® 1600-8M-20 14mm RPP

Dayco RPP® 1600-8M-20 14mm RPP

Goodyear HPPD™ 1600-8M-20 14mm RPP

T.B. Woods RPP® 1600-8M-20 14mm RPP

Thermoid Synchro-Curve® Timing 1600-8M-20 14mm RPP

Dayco RPP Plus™ 1600-8M-20 14mm RPP

Dayco HPR™ 1600-8M-20 14mm RPP

Dodge HT150™ 1600-8M-20 8 & 14mm GT

T.B. Woods RPP Plus™ 1600-8M-20 14mm RPP

T.B. Woods HPR™ 1600-8M-20 14mm RPP

Competitors Width PowerGrip GT2 – Width Competitors Width PowerGrip GT2 – Width

8mm – Pitch 8mm – Pitch 14mm – Pitch 14mm – Pitch

20 20 40 40

30 20 55 40

50 30 85 55

85 50 115 85

170 115

Design Performance Grouping – PowerGrip GT

PowerGrip GT – 8 & 14mm Belts can be used to replace other non-Gates curvilinear belts in the same width

Company Product Trade Name Nomenclature Belt-Pitch Profile

Bando Synchro-Link® - HT 1600-8M-20-H 8 & 14mm HTD

Dodge HT100™ 1600-8M-20 HT100 8 & 14mm GT

Electron EHT® 1600-8M-20 8 & 14mm HTD

Gates HTD® 1600-8M-20 8 & 14mm HTD

Jason HTB® 1600-8M-20 8 & 14mm HTD

MBL HTT™ 1600-8M-20 8 & 14mm HTD

Opti Belt HTD® 1600-8M-20 8 & 14mm HTD

Browning HPT® 1600-8M-20 14mm RPP

Dayco RPP® 1600-8M-20 14mm RPP

Goodyear HPPD™ 1600-8M-20 14mm RPP

T.B. Woods RPP® 1600-8M-20 14mm RPP

Thermoid Synchro-Curve® Timing 1600-8M-20 14mm RPP

(HTD & PowerGrip GT to PowerGrip GT2,

8mm Pitch)

Replacement Belt Cost Saving %

(HTD & PowerGrip GT to PowerGrip GT2,

14mm Pitch)

14mm Pitch Product

Line Comparison

Make the switch

to PowerGrip GT2.

PowerGrip GT2 drives will

provide greater horsepower

capacity at less cost than any

other synchronous belt drive

system in a wide variety of

industr y applications including:

Lumber, Pulp & Paper

Conveyors, repulpers,

sentr y scr eens, effluent

systems, presses, waxers,

chippers, debarkers,

slashers, chip ‘n saws,

edgers, roll grinders,

screw conveyors, flotation

cells, cut-of f saws, hour glass

rolls, dryers, agitators,

calendars, pumps, winders

Food Processing

Pumps, bucket elevators,

belt conveyors, icing machines,

elongators, dough mixers,

cookers, mills, bottling machines,

meat grinders, hog dehairers

Packaging

Box makers, car ton sealers,

case palletizers, and live roll,

apron, belt, chain and

screw conveyors

Aluminum/Steel

Bucket elevators, shot blasters,

conveyor drives, scrap cutters,

sand seals, drag-out machines,

polishers, cooling chambers,

muf fler fur naces,

mandrel stripping rods,

spinner cars, gray iron

foundries, sand conveyors,

bucket elevators, grinders

Petrochemical Industries

Air coolers, fin fans,

chlorine compressors,

processing, centrifuges,

dr yers, compr essors,

pumps

Sand, Gravel & Concrete

Feeder drives, conveyor drives,

elevators, screw conveyors

Glass

Manufacturing/Bottles

Conveyors, crushers,

grinders, car ton sealers,

case palletizers

HVAC

Air blower fan drives,

ventilating fans, exhaust fans

SAFETY POLICY

WARNING! Be Safe! Gates belt drive systems are very reliable when used safely and

within Gates application recommendations. However, there are specific USES THAT

MUST BE AVOIDED due to the risk of serious injury or death. These prohibited mis

uses include:

Primary In-Flight Aircraft Systems

Do not use Gates belts, pulleys or sprockets on aircraft, propeller or rotor drive sys

tems or in-flight accessory drives. Gates belt drive systems are not intended for aircraft

use.

Lift Systems

Do not use Gates belts, pulleys or sprockets in applications that depend solely upon

the belt to raise/lower, support or sustain a mass without an independent safety

backup system. Gates belt drive systems are not intended for use in applications re

quiring special “Lift” or “Proof” type chains with minimum tensile strength or certi

fied/test tensile strength requirements.

Braking Systems

Do not use Gates belts, pulleys or sprockets in applications that depend solely upon

the belt to slow or stop a mass, or to act as a brake without an independent safety

backup system. Gates belt drive systems are not intended to function as a braking device in “emergency stop” systems.

-

-

-

-

R

The Driving Force in Power Transmission. Page 1

Introduction — PowerGrip®GT®2 Belt Drives

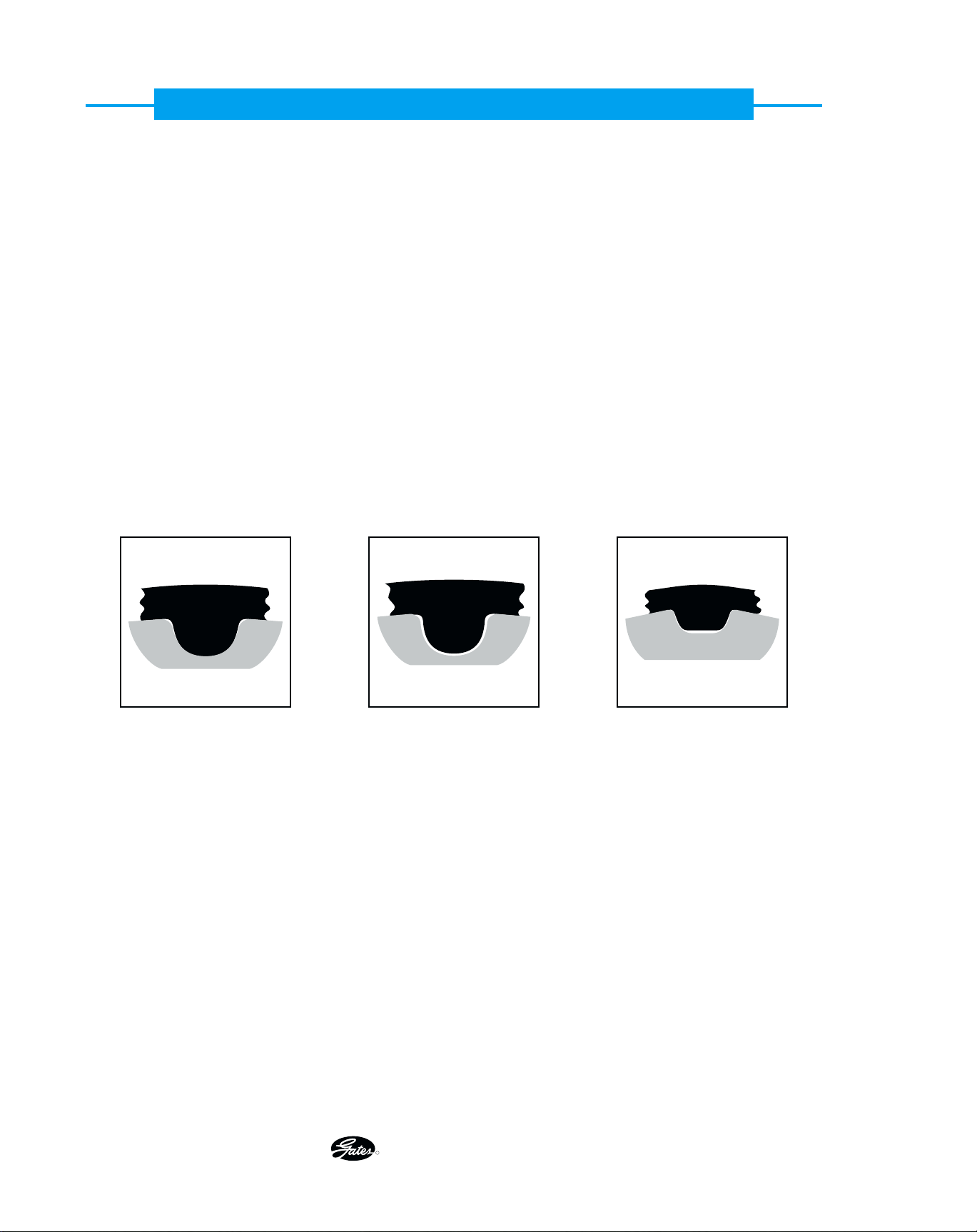

There’s nothing like a good set of teeth

when it comes to synchronous belts.

The advantages of Gates PowerGrip GT2 belt drives are overwhelming

The PowerGrip GT2 Belt Drive System is an advance in product design over Gates older, standard HTD system.

The PowerGrip GT2 System, featuring a modified curvilinear belt tooth profile, provides timing and indexing accu

racy equivalent to the conventional PowerGrip Trapezoidal Belt System. Plus, PowerGrip GT2 Belts have a higher

capacity and longer belt life than trapezoidal belts.

It’s difficult to make a true quantitative comparison between the backlash of a trapezoidal tooth drive and PowerGrip

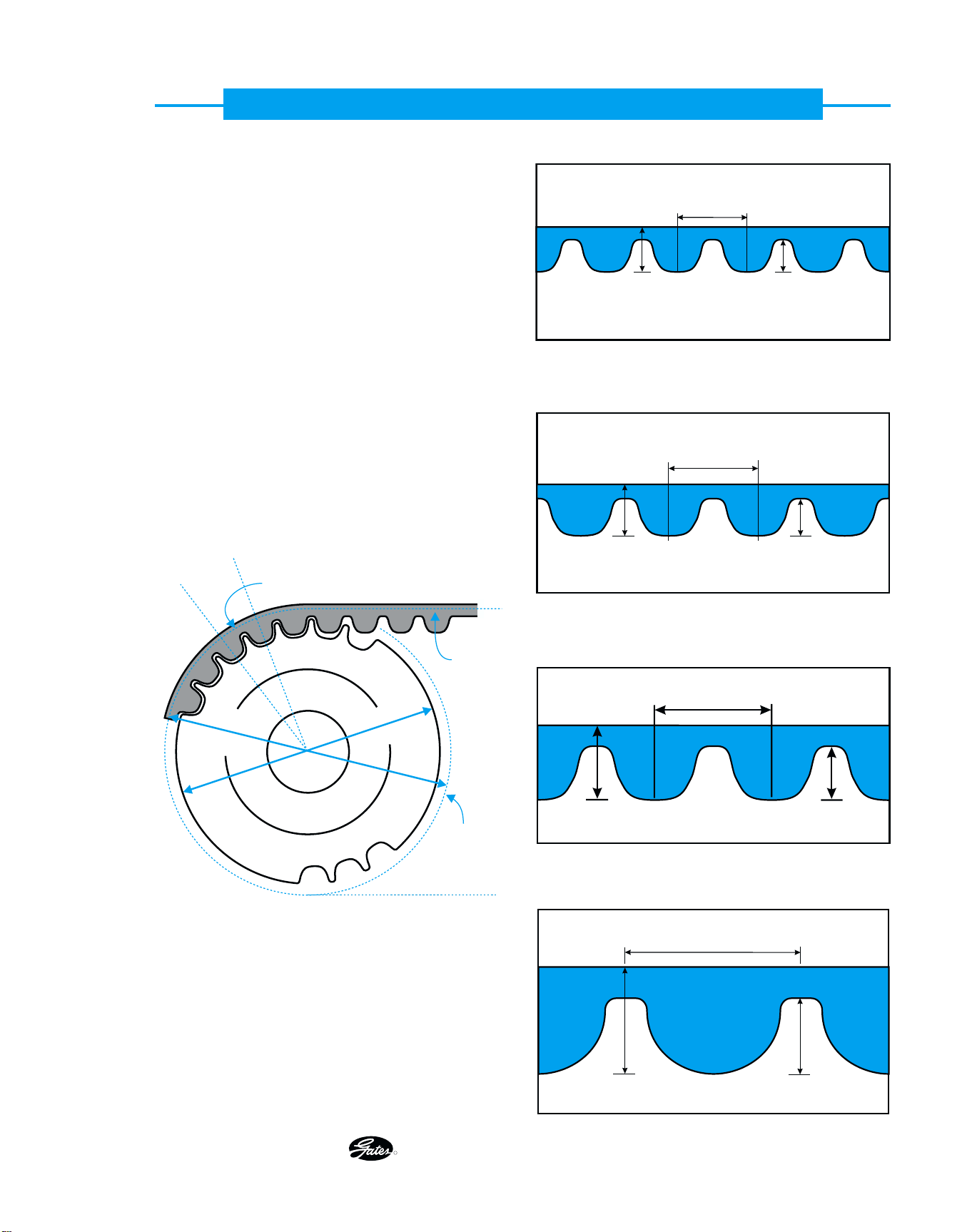

GT2 tooth drive due to the difference in “sprocket to belt tooth” fit. (See illustrations below). Trapezoidal belts contact

the sprocket in the root radius– upper flank area only, while the PowerGrip GT2 system permits full flank contact.

The main stress line in a trapezoidal tooth timing belt is at the base of the teeth. During operation this stress greatly

reduces belt life. The PowerGrip GT2 system overcomes this condition with its complete tooth flank contact which

eliminates the tooth stress line area. This greatly increases belt life and prevents tooth distortion caused by drive

torque. In addition, the conventional timing belt has a chordal effect as it wraps small sprockets. This is significantly

reduced in the PowerGrip GT2 system because there’s full tooth support along the sprocket. Full support improves

meshing, reduces vibration and minimizes tooth deformation.

On drives using a low installation tension, small pulleys, and light loads, the backlash of the PowerGrip GT2 system

will be slightly better than the trapezoidal timing belt system. However, with increased tension and/or loads and/or

sprocket sizes the performance of the PowerGrip GT2 system becomes significantly better than the trapezoidal tim

ing belt system.

-

-

PowerGrip®GT2®Belt

Tooth/Groove Contact

The PowerGrip GT2 system is an extension of the HTD system with improved load-carrying capacity. HTD was de

veloped for high torque drive applications, but is not acceptable for most precision indexing or registration applica

tions. The HTD design requires substantial belt tooth to sprocket groove clearance (backlash) to perform. As smaller

diameter sprockets are used, the clearance required to operate properly is increased. HTD drive clearance, using

small diameter sprockets, is approximately four times greater than than an equivalent timing belt drive.

PowerGrip®HTD®Belt

Tooth/Groove Contact

PowerGrip®Timing Belt

Tooth/Groove Contact

-

-

Deep tooth profile makes the difference

The PowerGrip GT2 system’s deep tooth design increases the contact area which provides improved resistance to

ratcheting. The modified curvilinear teeth enter and exit the sprocket grooves cleanly resulting in reduced vibration.

This tooth profile design results in parallel contact with the groove and eliminates stress concentrations and tooth de

formation under load. The PowerGrip GT2 design improves registration characteristics and maintains high torque

carrying capability.

-

Page 2 The Gates Rubber Company

R

Introduction — PowerGrip®GT®2 Belt Drives

The choice of the industry

for ultimate durability and precision

The Gates PowerGrip GT2 combines the

very best in technology and construction

design to give improved performance

and extended product life.

Last longer than competitive belts

The PowerGrip GT2 belt has been tested

against the competition, under equivalent

conditions, at speeds up to

9,000 RPM. It outlasted the competition more than

two to one. Strong fiberglass tensile cords wrapped in

a durable neoprene body gives it flexibility and in

creases service life. A deep tooth profile provides su

perior load-carrying strength and greatly reduces

ratcheting when used with Gates designed sprockets.

Precision registration

PowerGrip GT2 Belt Drive Systems provide timing

and synchronization accuracy that make for flawless

registration, with no loss of torque carrying capability.

Increases load-carrying capacity

Performance far exceeds HTD and trapezoidal belt

capabilities making PowerGrip GT2 belts the choice

for accurate registration, heavy loads

and small sprockets.

Sounds this quiet……

The PowerGrip GT2 belt’s specially engi

neered teeth mesh cleanly with sprocket

grooves to reduce noise and vibration.

Clean meshing results in significant

noise reduction when compared to

PowerGrip Timing and HTD belts.

-

When precision is critical,

depend on PowerGrip GT2 belts

PowerGrip GT2 belts are specifically designed for ap

-

plications where precision is critical. Applications such

as robotics, conveyors and machine tools. We offer

belts in a variety of sizes… custom built constructions

are also available for individual applications that re

quire maximum performance. Gates worldwide manu

facturing capabilities assures you of prompt service

for important markets.

PowerGrip GT2 belts are currently available in 5mm,

8mm, 14mm and 20mm pitches.

See Pages 7-58 for PowerGrip GT2 Belt Drives.

-

-

-

Here are just some of the many applications of PowerGrip GT2 belts:

n

machine tools

n

hand power tools

n

DC stepper/servo applications

n

pumps

n

floor care equipment

n

medical diagnostic equipment

n

centrifuges

n

fans

n

robotics equipment

n

vending equipment

n

conveyors

n

compressors

R

The Driving Force in Power Transmission. Page 3

Introduction — PowerGrip®Timing Belt Drives

Provide positive,

non-slip power transmission

PowerGrip Timing Belts are a good stan

dard line product with a history of reliabil

ity. Around since the late 1940’s, this

product line has been the flagship of syn

chronous power transmission prior to

Gates introduction of PowerGrip HTD

and GT2 Belts.

-

-

-

PowerGrip Timing Belts are recommended for these types of applications:

Gates timing belts are made with a true

design pitch, a standard of the Rubber

Manufacturers’ Association and the Inter

national Standards Organization.

-

office equipment

n

appliances

n

medical equipment

n

data processing equipment

n

power tools

n

robotics

n

spindles

n

mailing equipment

n

See pages 59-84 for PowerGrip Timing Drives.

Page 4 The Gates Rubber Company

R

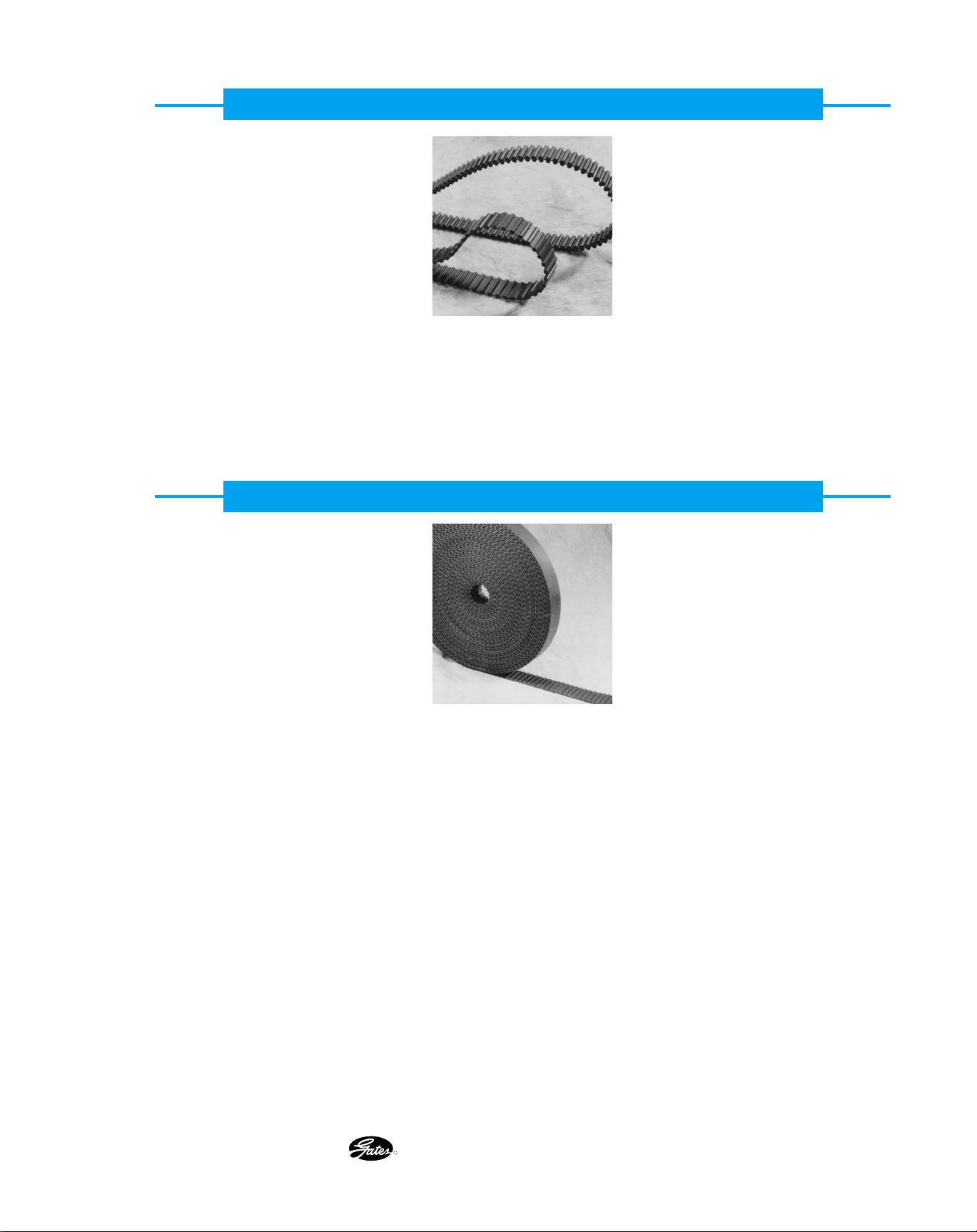

Introduction — PowerGrip®Twin Power®Belt Drives

Dual driving surfaces allow for unique,

problem solving drive designs

Gates Twin Power Belts have teeth on

both sides to provide synchronization from

both driving surfaces. This special feature

makes possible unique drive designs such

as multipoint drives, rotation reversal with

one belt, serpentine drives, etc. They may

also provide solutions to other difficult de

-

sign problems.

Some typical PowerGrip Twin Power applications are:

serpentine drives

n

reversing rotations

n

See pages 95-99 for PowerGrip Twin Power Belting.

Introduction — PowerGrip®Long Length Belting

For drives that require belt lengths

longer than can be produced in conventional endless form.

Long-length PowerGrip Belting has the

same basic construction as conventional

Gates synchronous belts.

Twin Power Belts are similar in construc

tion to regular synchronous belts, includ

ing nylon-faced teeth on both sides.

NOTE: Twin Power Belts are available in

GT2 and Timing Belt configurations, so

designers can use them in a wide variety

of applications.

For information or assistance on any

long length belt problem, contact Gates

Application Engineering.

NOTE: Long-length PowerGrip Belting

is available in GT, HTD, Timing Belt and

Synchro-Power Polyurethane configurations.

-

-

Typical PowerGrip Long Length Belting uses are:

n

reciprocating carriage drives

n

rack and pinion drives

R

The Driving Force in Power Transmission. Page 5

n

large plotters

See pages 85-94 for PowerGrip Long Length Belting.

PowerGrip®GT®2 Belt Drives

The operating noise comparison with first generation

curvilinear tooth belts is remarkable. PowerGrip GT2

belts are made to do the work quietly. Whether or not

an application requires low noise levels, PowerGrip

GT2 belts give quieter, longer running life —with no

sacrifice in performance like other competitive belts.

Using a mulitmillion-dollar manufacturing process that

features breakthrough belt building technology, Gates

assures each belt meets the highest standards of pre

cision construction.

-

Test Conditions

Belt Length 1400mm

Width 40mm

Sprockets DriveR 36 Grooves

DriveN 36 Grooves

Load 36 HP

Speed 1750 rpm

All tests in HTD Sprockets

Please note the “Annoyance Zone” in the graph

above. This zone, roughly 2,000-4,000 Hz, is the

frequency range to which the human ear is the

most sensitive. The PowerGrip GT2 belt has an

obvious advantage in this zone. Also note the

Total Sound Pressure Level (SPL) depicted in

the adjoining bar graph. Here again, the overall

noise level (SPL) is dramatically lower for the

PowerGrip GT2 belt.

Page 6 The Gates Rubber Company

R

Belt Construction

2. Neoprene Backing

PowerGrip®GT®2 Belt Drives

3. Neoprene Teeth

4. Nylon Facing

1. Tensile Member

PowerGrip GT2 drives provide positive, trou

ble-free power transmission in low speed —

high torque applications and offer many advan

tages over conventional chain, gear and other

belt drives.

Advantages:

n

n

n

n

n

n

n

n

n

-

-

Higher capacity

Improved registration

Reduced noise

No lubrication required

No stretching due to wear

Corrosion resistance

Excellent abrasion resistance

Clean operation

Long trouble-free service

Construction Features

The tooth design substantially improves stress distribution and allows extra high loading. The molded teeth enter and leave the sprocket grooves

smoothly with negligible friction — functioning in much the same way as

teeth on a gear.

Construction consists of these components:

1.

Tensile Member — Provides high strength, excellent flex life and

high resistance to elongation.

2.

Neoprene Backing — Strong Neoprene bonded to the tensile

member for protection against grime, oil and moisture. It also pro

tects from frictional wear if idlers are used on the back of the belt.

3.

Neoprene Teeth — Shear-resistant Neoprene compound is

molded integrally with the Neoprene backing. They are precisely

formed and accurately spaced to assure smooth meshing with the

sprocket grooves.

4.

Nylon Facing — Tough nylon fabric with a low coefficient of friction

covers the wearing surfaces of the belt. It protects the tooth sur

faces and provides a durable wearing surface for long service.

-

-

R

The Driving Force in Power Transmission. Page 7

PowerGrip®Belt Drive Selection Procedure

Selection of a stock PowerGrip Belt Drive System in

-

volves these five steps:

1.

Calculate design horsepower.

2. Select belt pitch

3. Select sprockets and belt.

4. Select belt width.

5. Determine bushing and bore requirements.

Sample Problem

A gear pump is to be driven by a 30 hp normal torque

electric motor with an output speed of 1160 rpm. The

gear pump is to be driven at 580 rpm ±5%. The center

distance is to be approximately 30 inches, but can be

altered ±3 inches, if necessary. The motor shaft is 2

1

8

inches and the pump shaft is 3 inches. The pump will op

erate 16 hours a day, five days a week. The pump

sprocket is limited to 18 inches OD. There are no unusual

drive conditions. Design using PowerGrip GT2.

Step 1 Determine Design Horsepower

Procedure

To calculate the design hp, first determine the relative

severity or service factor of the drive. Average hours

per day of service also should be considered. Locate

the power source and the driveN unit in the Service

Factors table on Page 15. The design hp then is determined by multiplying the rated hp (usually the

nameplate rating) by the service factor determined

above.

Example

Using the Service Factor Chart, the driveR would be

found in the first group. Since the pump will run 16

hours per day, follow the continuous service column

down to the driveN machines group for gear pumps.

This gives a 1.7 Service Factor. Since this is not a low

speed or speedup drive, no additional service factor is

required.

Design HP = 30 1.7 = 51DHP×

Step 2 Select Belt Pitch

Procedure

Using the design hp and the rpm of the faster shaft,

select from Belt Pitch Selection Guide graph on Page

11.

Example

Locate 1160 rpm on the RPM of Faster Shaft scale

and move over to where the Design Horsepower of 51

Dhp line intersects. The intersection falls at the 8mm

and 14mm pitch overlap area. Both 8mm and 14mm

pitches should be considered.

Step 3 Select Sprockets and Belt Length

Procedure

a. Determine speed ratio.

The speed ratio can be determined by dividing the

rpm of the faster shaft by the slower shaft rpm.

Example

rpm of faster shaft

rpm of slower shaft

1160

580

=2.0

=

b. Select sprocket combination and belt length. Turn

to the Stock Drive Selection Tables (pages 16 through

43, 52 through 55 and 61 through 74) and in the

proper pitch tables find the chosen speed ratio.

Moving over within the speed ratio block, find the

stock sprocket combinations available for that speed

ratio. Selection of the proper combination will depend

on the center distance required, minimum or maxi

mum required sprocket diameter and the recom

-

-

mended minimum sprocket diameter for electric

-

motors (See table on Page 12).

After selecting possible sprocket combinations and

center distances, record belt length (top of column)

Length Factor (bottom of column), and the Teeth In

Mesh Factor if applicable.

Example

First, using the Stock Drive Selection Tables for 8mm

pitch belts on pages 30 through 35, we locate the

speed ratio of 2.0 to 1 on pages 32 and 33. The various sprocket combinations with a center distance

within the required tolerance range is 8. Of these,

three are closest to the desired 30 inches. These are

72 to 144, 56 to 112 and 40 to 80. The minimum

sprocket diameter of 6.1 inches for a 30 hp motor at

1160 rpm (See table on Page 12) eliminates the 56 to

112 and 40 to 80 sprocket combinations. Only the

8mm pitch, 72 to 144 sprocket combination will be

considered further. On the line for the 72 to 144

sprocket combination, the center distance of 30.02

inches uses a 2400mm (94.49-inch), 8mm pitch belt.

The belt length factor is 1.2.

Secondly, using the Stock Drive Selection Tables for

14mm pitch belts on pages 36 through 43, locate the

speed ratio of 2.0 to 1 on page 40. Several combina

-

tions are shown which will meet the 30 ±3-inch center

distance requirement. The maximum OD limit of 18

inches on the driveN sprocket eliminates two of the

combinations and the preference for as close to 30

inches center distance would favor the 36 to 72 and

28 to 56 combinations. However, the 4.912-inch diam

eter of the 28-groove sprocket is less than the recom

-

mended minimum diameter of 6.1 inches for the

electric motor. So the 36 to 72 sprocket combination

is chosen for further consideration.

For the 36 to 72, 14-mm pitch sprocket combination,

the belt length used for the 30.42-inch center distance

is a 2310mm (90.94-inch), 14mm pitch belt. The belt

length factor is 1.0.

continued

Page 8 The Gates Rubber Company

R

PowerGrip®Belt Drive Selection Procedure—continued

Procedure

c. Check belt speed.

Do not exceed 6500 fpm with stock sprockets. Belt

Speed is determined using the following formula:

V(fpm) =

PD (inches) Speed (rpm)

×

3.82

Example

Determining belt speed for each of the drive systems

shows that the belt speed does not exceed 6500 fpm

and can be considered further.

8mm Drive:

×

7.218 1160

V=

3.82

= 2191.9 fpm

14mm Drive:

×

6.316 1160

V=

3.82

= 1917.9 fpm

Step 4 Select Belt Width

Procedure

Belt Width Selection Tables (pages 44 through 51, 56

through 58 and pages 75 through 84) show the horsepower ranges of stock belt widths. The left-hand column

shows the speed of the smaller sprocket. Across the top

are various stock sprockets. The base rated horsepower

capacity of a given sprocket at a specific rpm is at the

point of intersection of the rpm row and sprocket column.

This base horsepower rating must be corrected for

the belt length selected and for the number of teeth in

mesh (if less than 6). Multiply the base table rating by

the applicable Length Factor and Teeth In Mesh Factor (if applicable), both determined in Step 3b. The

corrected horsepower rating must equal or exceed

design hp.

Where there are several choices, drive limitations

may control the selection. In addition, the following

rules must be observed.

1.

Larger sprockets mean less belt width.

2. Larger sprockets yield extra long service life.

3. Avoid drives where the belt width exceeds sprocket

diameter.

4. Avoid drives where center distance is greater than 8

times the diameter of the smaller sprocket. Refer to

Section II, Drive Alignment on Page 141 for additional

details.

Example

Referring to the 8mm pitch Belt Width Selection tables

on page 47, locate the 1160 rpm line in each table in

turn. Proceeding across to the 72-groove sprocket

column (Smaller sprocket groove number), note the

base belt horsepower capacity in each table. The

50mm (1.97-inch) width belt has a base horsepower

rating which, when multiplied by the length factor of

1.2, exceeds the design horsepower.

68.5 hp 1.2 = 82.2 hp×

And, repeating the procedure for the 14mm pitch belt

horsepower tables on pages 49 through 51, we

find the 55mm (2.16-inch) width belt has an 77.1 base

horsepower rating for a 36-groove sprocket. This,

multiplied by the length factor of 1.0, gives a corrected

horsepower rating of 77.1 which also exceeds the de

sign horsepower.

Since there is now a choice between the 8mm pitch,

72 to 144 ratio drive components, and the 14mm

pitch, 36 to 72 ratio drive components, the rules as

given in the procedure column must be considered.

Rules 1 and 2 would dictate larger sprockets. Width is

unaffected. Rules 3 and 4 would not apply, so the

8mm pitch drive system is the choice.

Step 5 Check and Specify Stock Drive Components

Procedure

a. Check the sprockets selected in steps 3 and 4

against the design requirements using the dimensions

given in the Sprocket Specification Tables on pages

100 through 114. Use flange diameter in checking

against maximum diameter requirements.

Example

From the table on Page 105, we find the

P144-8MGT-50 driveN sprocket has an overall

diameter of 14.383 inches which is less than the

18-inch maximum specified.

Procedure

b. Determine the type of bushing and check bore

sizes by using the Sprocket Specification Tables; find

the bushings to be used with the required sprockets.

From the Stock Bushing Tables on pages 119 through

122, check the bore range and keyway dimensions

against the design requirements.

Example

Also from the sprocket data on Page 105 we note that

the P72-8MGT-50 sprocket takes a 2517 bushing and

the P144-8MGT-85 sprocket takes a 3020 bushing.

On Page 119 in the bushing data table, a 2517 bush

1

ing has a bore range of

cludes the 2

1

-inch bore required for the driveR shaft.

8

The 3020 bushing has a bore range form

2

to 2

11

inches which in

16

7

to 3

8

-

-

1

4

inches which meets the 3-inch bore required for the

driveN shaft.

Procedure

c. Specify stock drive components

Example

They are as follows:

1—2400-8MGT-50 PowerGrip GT2 belt

1—P72-8MGT-50 driveR sprocket

1—2517 Bushing with a 2

1

-inch bore

8

1—P144-8MGT-50 driveN sprocket

1—3020 Bushing with a 3-inch bore

-

R

The Driving Force in Power Transmission. Page 9

High Speed Drive Survey and Energy Savings Worksheet

Customer Information

Distributor _______________________________________________________________________________

Customer ________________________________________________________________________________

Drive Information

I.D. of Drive (location, number, etc.) ___________________________________________________________

Description of DriveN Equipment ____________________________________________________________

Manufacturer of DriveN Equipment __________________________________________________________

Horsepower Rating of Motor _________ DriveN HP Load (Peak) ______________ (Normal) _____________

Motor Frame Size _________ Motor Shaft Dia. ___________ DriveN Shaft Dia. ___________________

Speed:

DriveR RPM _____________ RPM Measured with Contact or Strobe Tachometer

DriveN RPM _____________ RPM Measured with Contact or Strobe Tachometer

Speed Ratio _____________ Speed Up ________________ or Speed Down ____________________

Center Distance: Minimum _______________ Nominal ________________ Maximum ________________

Existing Drive Components: DriveR _______________________ DriveN ___________________________

Belts _____________________________ Belt Manufacturer __________________________________

Ambient Conditions:

Temperature _____________ Moisture __________________Oil, etc. ___________________________

Abrasives __________________________________________ Shock Load _______________________

Static Conductivity Required?

Maximum Sprocket Diameter (OD) and Width Limitations (for guard clearance):

DriveR: Max. OD _________ Max. Width _______ DriveN: Max. OD ________ Max. Width _______

Guard Description _____________________________________________________________________

Motor Mount:

q

Yes

q

No

q

q

Yes

Yes

q

q

No

No

q

q

Yes

Yes

Double Screw Base?

Adequate Structure?

Start Up Load:

%Motor Rating at Start Up________ AC Inverter?

Duty Cycle:

Number of Starts/Stops ______________________ times per ________________ (hour, day, week, etc.)

q

No Motor Mounted on Sheet Metal?

q

No Floating/Pivot Motor Base?

q

Yes

q

No Soft Start?

q

Yes

q

Yes

q

q

No

q

Yes

No

q

No

Energy Savings Information

Energy Cost per KW-Hour __________________________________________________________________

Hours of Operation: _______Hours per Day _______Days per Week ________Weeks per Year _________

Page 10 The Gates Rubber Company

R

RPM

of

F

aster

Shaft

7000

5000

3450

1750

1160

870

600

400

200

100

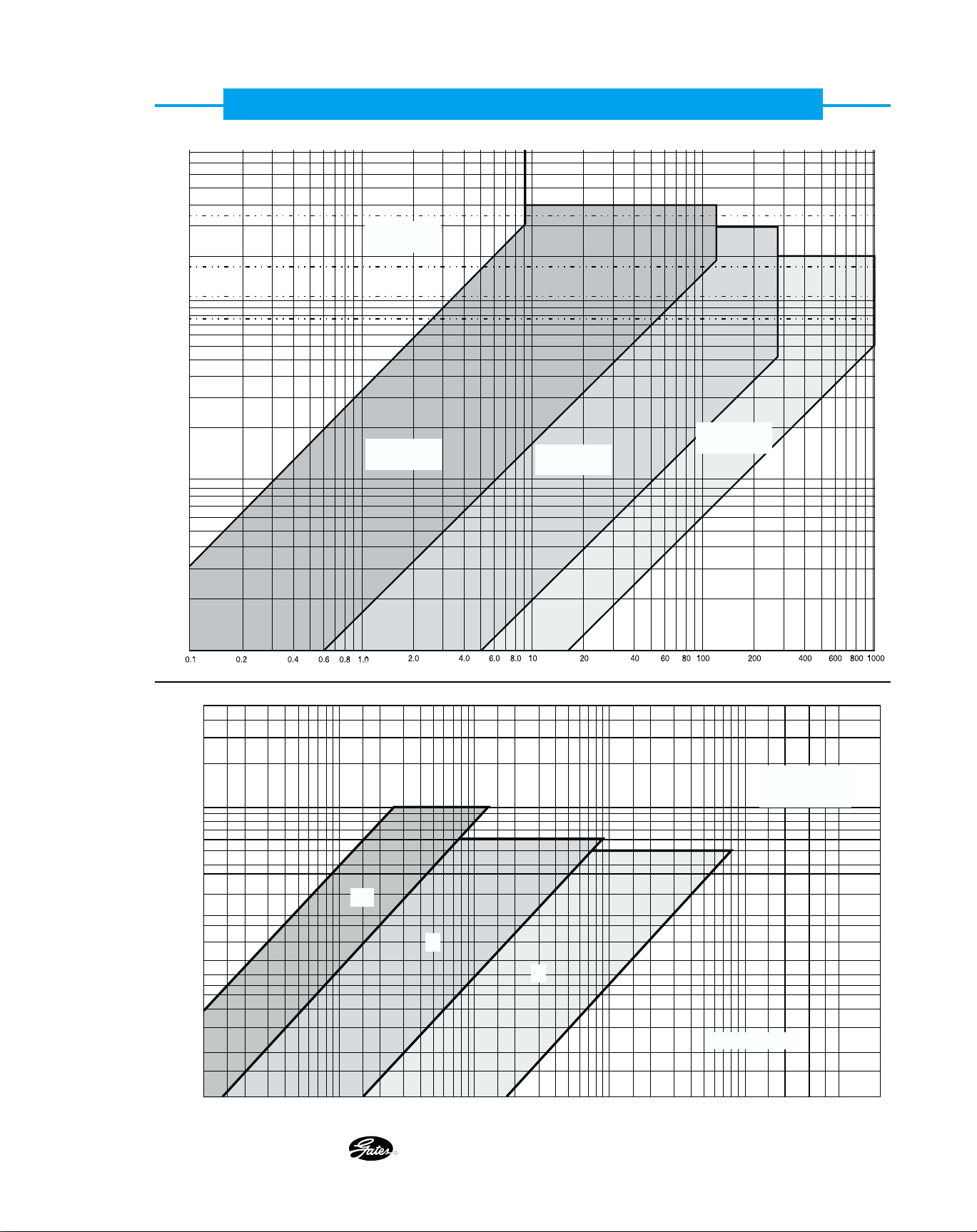

PowerGrip®Belt Drives

PowerGrip®GT®2 Belt Pitch Selection Guide

5mm

PowerGrip GT2

20mm

8mm

PowerGrip GT2

80

60

14mm

PowerGrip GT2

PowerGrip GT2

40

20

10

PowerGrip®Timing Belt Pitch Selection Guide

20,000

10,000

5,000

4,000

3,450

2,500

1,750

1,160

870

RPM OF Faster Shaft

690

575

400

300

200

150

100

0.01 0.050.15 .02 .03 .04 .07 0.1 .15 .2 .3 0.5 1.0 1.5 2.0 3.0 4.0 5.0 7.0 10 20 200 300 400 50030 40 50 70 100 1,00015015.7

XL

Design Horsepower

L

Design Horsepower

=

XL

0.200 Pitch

"

=

L

0.375 Pitch

"

=

H

0.500 Pitch

"

H

NONSTOCK

R

The Driving Force in Power Transmission. Page 11

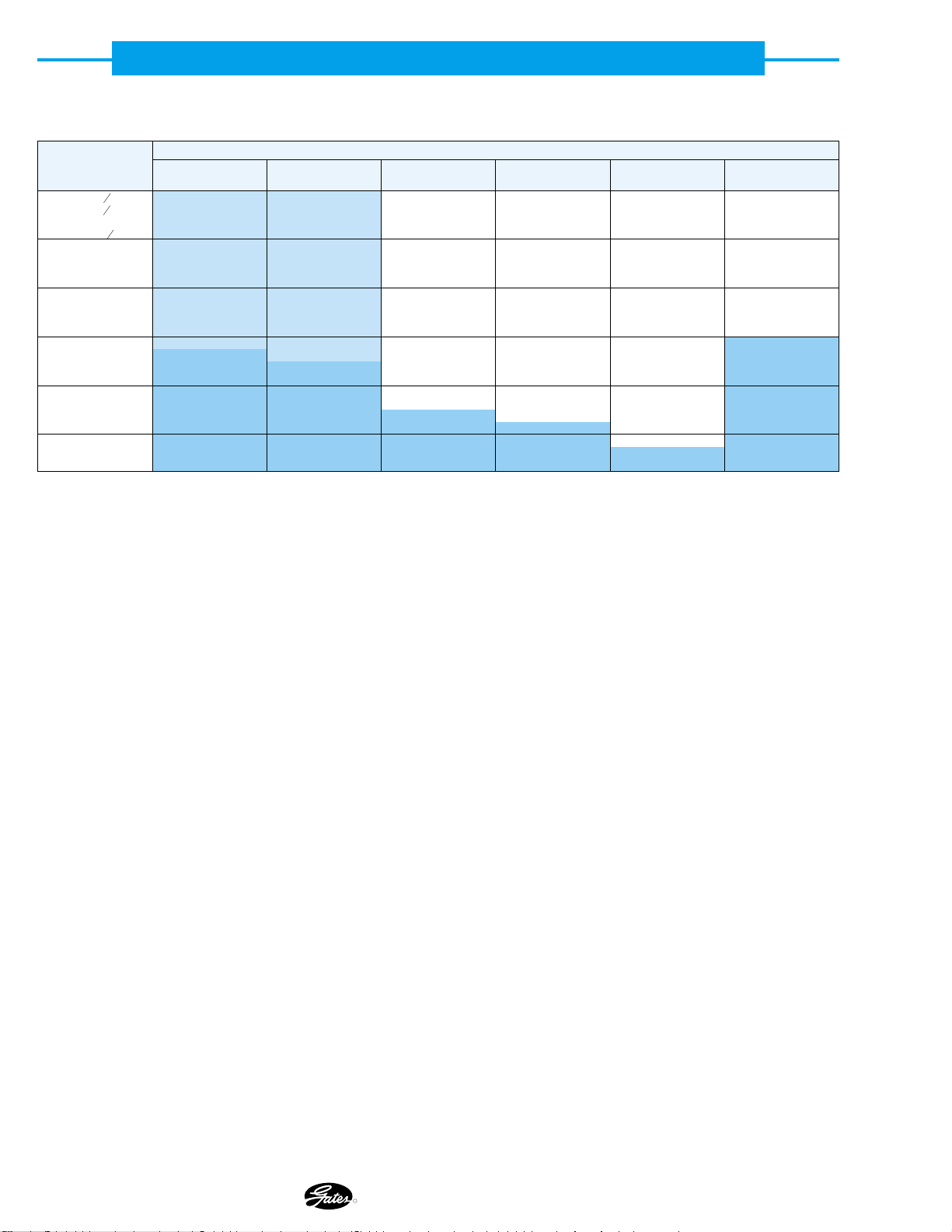

PowerGrip®Belt Drives

Mimimum Recommended Sprocket Outside Diameters

for General Purpose Electric Motors — Synchronous Belts

Motor RPM (60 Cycle and 50 Cycle Electric Motors

Motor

Horsepower

1

2

3

4

1 2.7 2.3 2.2 2.2 2.0 —

1

1

2

2 3.4 2.7 2.7 2.2 2.2 2.2

3 4.1 3.4 2.7 2.7 2.2 2.2

5 4.1 4.1 3.4 2.7 2.7 2.2

7 4.7 4.1 4.0 3.4 2.7 2.7

10 5.4 4.7 4.0 4.0 3.4 2.7

15 6.1 5.4 4.7 4.0 4.0 3.4

20 7.4 6.1 5.4 4.7 4.0 4.0

25 8.1 7.4 6.1 5.4 4.0 4.0

30 9.0 8.1 6.1 6.1 4.7 —

40 9.0 9.0 7.4 6.1 5.4 —

50 9.9 9.0 7.6 7.4 6.1 —

60 10.8 9.9 9.0 7.2 6.7 —

75 12.5 11.7 8.5 9.0 7.7 —

100 16.2 13.5 10.8 9.0 7.7 —

125 18.0 16.2 13.5 10.8 9.5 —

150 19.8 18.0 16.2 11.7 9.5 —

200 19.8 19.8 19.8 — 11.9 —

250 19.8 19.8 ————

300 24.3 24.3 ————

* These RPM are for 50 cycle electric motors.

# Use 8.6 for Frame Number 444 T only.

Data in the white area are from NEMA Standard MG-1-14-42, June, 1972, while data in the light blue area are from MG-1-14-43, January,

1968.

The dark blue area is a composite of electric motor manufacturers data. They are generally conservative, and specific motors and bearings

may permit the use of a smaller motor sprocket. Consult the motor manufacturer. See Engineering Section II-13, Bearing/Shaft Load

Calculations on Page 142.

NOTE: For a given motor horsepower and speed, the toal belt pull is related to the motor sprocket size. As this size decreases, the total belt

pull increases. Therefore, to limit the resultant load on motor shaft and bearings, NEMA lists minimum sprocket sizes for the various motors.

575

485*

——2.0———

— — 2.2 2.0 — —

2.7 2.7 2.2 2.2 2.2 2.0

690

575*

870

725*

1160

950*

1750

1425*

3450

2850*

Page 12 The Gates Rubber Company

R

PowerGrip®GT®2 Belt Drives

Gates 5mm, 8mm, 14mm and 20mm pitch GT2 belts

have helically-wound fiberglass tension members em

bedded in a Neoprene body with the belt teeth faced

with a tough wear-resistant nylon fabric.

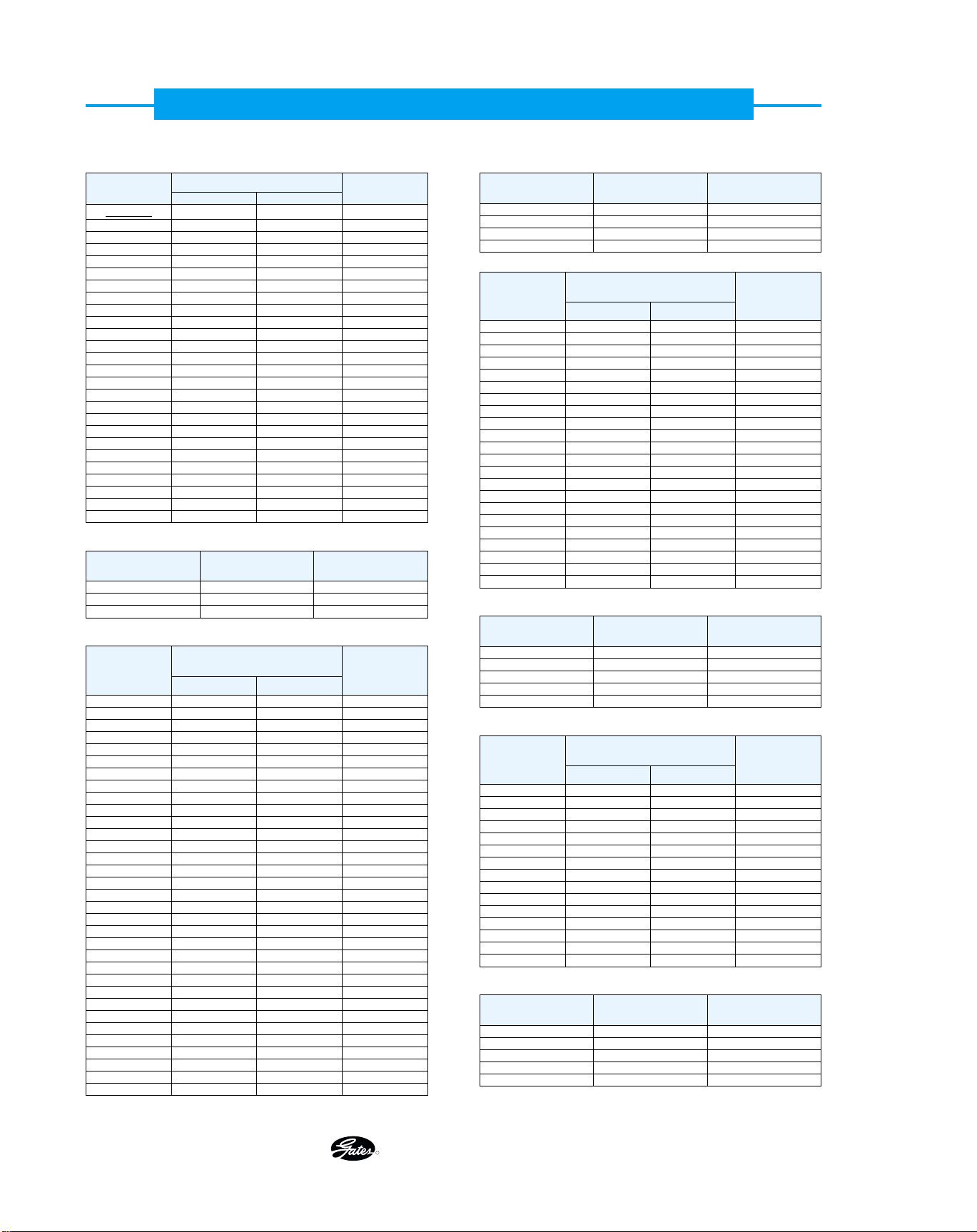

The three principal dimensions of a belt are

Pitch Pitch Length Width

Belt pitch is the distance in millimeters between two

adjacent tooth centers as measured on the pitch line of

the belt. Belt pitch length is the total length (circumference)

in millimeters as measured along the pitch line. The the

oretical pitch line of a PowerGrip GT2 belt lies within the

tensile member.

The part number designations for PowerGrip GT2 belts

depend on the pitch of the belt. Belt designations are

shown below for each of the available pitches.

5mm PowerGrip GT2

Example: 5mm pitch, 1600mm pitch length, 25mm belt width

Belt Designation: 5MR-1600-25

8mm, 14mm PowerGrip GT2

Example: 14mm pitch, 1610mm pitch length, 55mm belt width

Belt Designation: 1610-14MGT-55

20mm PowerGrip GT2

Example: 20mm pitch, 2000mm pitch length, 230mm belt width

Belt Designation: 2000-20M-230

Pitch (circular pitch)

-

5mm Pitch −Reference Dimensions

5mm

.197 In.

3.81mm

-

.150 In.

8mm Pitch −Reference Dimensions

1.93mm

.76 In.

8mm

.315 in.

5.59mm

.220 in.

3.28mm

.129 in.

Belt

Pitch

Line

Pitch

Diameter

The part number designations for PowerGrip GT2

sprockets depend on the pitch of belt. Sprocket desig

nations are shown below for each of the available

pitches.

5mm, 8mm, 14mm PowerGrip GT2

Example: 14mm pitch, 48 grooves, 55mm belt width

Sprocket Designation: P48-14MGT-55

20mm PowerGrip GT2

Example: 20mm pitch, 52 grooves, 230mm belt width

Belt Designation: P52-20M-230

NOTE: 20mm pitch PowerGrip GT2 belts use 20mm pitch HTD

sprockets.

Outside

Diameter

Sprocket

Pitch

Circle

14mm Pitch - Reference Dimensions

14mm

.552 in.

9.91mm 5.84mm

.390 in. .230 in.

20mm Pitch − Reference Dimensions

-

13.2mm

.520 in.

20mm

.787 in.

8.4mm

.330 in.

R

The Driving Force in Power Transmission. Page 13

PowerGrip®GT®2 Belt Drives

The following tables list the stock Industrial Belts and their essential specification.

5mm Pitch PowerGrip GT2 Stock Belt Lengths

Designation

5MR-300 300 11.81 60

5MR-355 355 13.98 71

5MR-375 375 14.76 75

5MR-400 400 15.75 80

5MR-425 425 16.73 85

5MR-450 450 17.72 90

5MR-405 405 15.99 81

5MR-500 500 19.69 100

5MR-535 535 21.06 107

5MR-565 565 22.24 113

5MR-580 580 22.83 116

5MR-600 600 23.62 120

5MR-625 625 24.61 125

5MR-650 650 25.59 130

5MR-700 700 27.56 140

5MR-750 750 29.53 150

5MR-800 800 31.50 160

5MR-850 850 33.46 170

5MR-900 900 35.43 180

5MR-1000 1000 39.37 200

5MR-1150 1150 45.28 230

5MR-1300 1300 51.18 260

5MR-1450 1450 57.09 290

5MR-1600 1600 62.99 320

5MR-1720 1720 67.72 344

5MR-2100 2100 82.67 420

Pitch Length

(mm) (in)

No. of

Teeth

5MR Stock Belt Widths

Belt Width

Code

09 9 0.354

15 15 0.591

25 25 0.984

Belt Width

(mm)

Belt Width

(in)

8mm Pitch PowerGrip GT2 Stock Belt Lengths

Pitch

Length

Designation

384-8MGT 384 15.12 48

480-8MGT 480 18.89 60

560-8MGT 560 22.05 70

600-8MGT 600 23.62 75

640-8MGT 640 25.20 80

720-8MGT 720 28.35 90

800-8MGT 800 31.50 100

840-8MGT 840 33.07 105

880-8MGT 880 34.65 110

920-8MGT 920 36.22 115

960-8MGT 960 37.80 120

1040-8MGT 1040 40.94 130

1064-8MGT 1064 41.89 133

1120-8MGT 1120 44.09 140

1160-8MGT 1164 45.67 145

1200-8MGT 1200 47.24 150

1224-8MGT 1224 48.19 153

1280-8MGT 1280 50.39 160

1440-8MGT 1440 56.69 180

1512-8MGT 1512 59.53 189

1584-8MGT 1584 62.36 198

1600-8MGT 1600 62.99 200

1760-8MGT 1760 69.29 220

1800-8MGT 1800 70.87 225

2000-8MGT 2000 78.74 250

2200-8MGT 2200 86.61 275

2400-8MGT 2400 94.49 300

2600-8MGT 2600 102.36 325

2800-8MGT 2800 110.24 350

3048-8MGT 3048 120.00 381

3280-8MGT 3280 129.13 410

3600-8MGT 3600 141.73 450

4400-8MGT 4400 173.23 550

No. of

Teeth(mm) (in)

8MGT Stock Belt Widths

Belt Width

Code

20 20 0.787

30 30 1.181

50 50 1.969

85 85 3.346

Belt Width

(mm)

Belt Width

(in)

14mm Pitch PowerGrip GT2 Stock Belt Lengths

Pitch

Length

Designation

966-14MGT 966 38.03 69

1190-14MGT 1190 46.85 85

1400-14MGT 1400 55.12 100

1610-14MGT 1610 63.39 115

1778-14MGT 1778 70.00 127

1890-14MGT 1890 74.41 135

2100-14MGT 2100 82.68 150

2310-14MGT 2310 90.94 165

2450-14MGT 2450 96.46 175

2590-14MGT 2590 101.97 185

2800-14MGT 2800 110.24 200

3150-14MGT 3150 124.02 225

3360-14MGT 3360 132.28 240

3500-14MGT 3500 137.80 250

3850-14MGT 3850 151.57 275

4326-14MGT 4326 170.32 309

4578-14MGT 4578 180.24 327

4956-14MGT 4956 195.12 354

5320-14MGT 5320 209.45 380

5740-14MGT 5740 225.98 410

6160-14MGT 6160 242.52 440

6860-14MGT 6860 270.08 490

No. of

Teeth(mm) (in)

14MGT Stock Belt Widths

Belt Width

Code

40 40 1.575

55 55 2.165

85 85 3.346

115 115 4.528

170 170 6.693

Belt Width

(mm)

Belt Width

(in)

20mm Pitch PowerGrip GT2 Stock Belt Lengths

Pitch

Length

Designation

2000-20M 2000 78.74 100

2500-20M 2500 98.43 125

3400-20M 3400 133.86 170

3800-20M 3800 149.61 190

4200-20M 4200 165.35 210

4600-20M 4600 181.10 230

5000-20M 5000 196.85 250

5200-20M 5200 204.72 260

5400-20M 5400 212.60 270

5600-20M 5600 220.47 280

5800-20M 5800 228.35 290

6000-20M 6000 236.22 300

6200-20M 6200 244.09 310

6400-20M 6400 251.97 320

6600-20M 6600 259.84 330

No. of

Teeth(mm) (in)

20M Stock Belt Widths

Belt Width

Code

115 115 4.528

170 170 6.693

230 230 9.055

290 290 11.417

340 340 13.386

Belt Width

(mm)

Belt Width

(in)

Page 14 The Gates Rubber Company

R

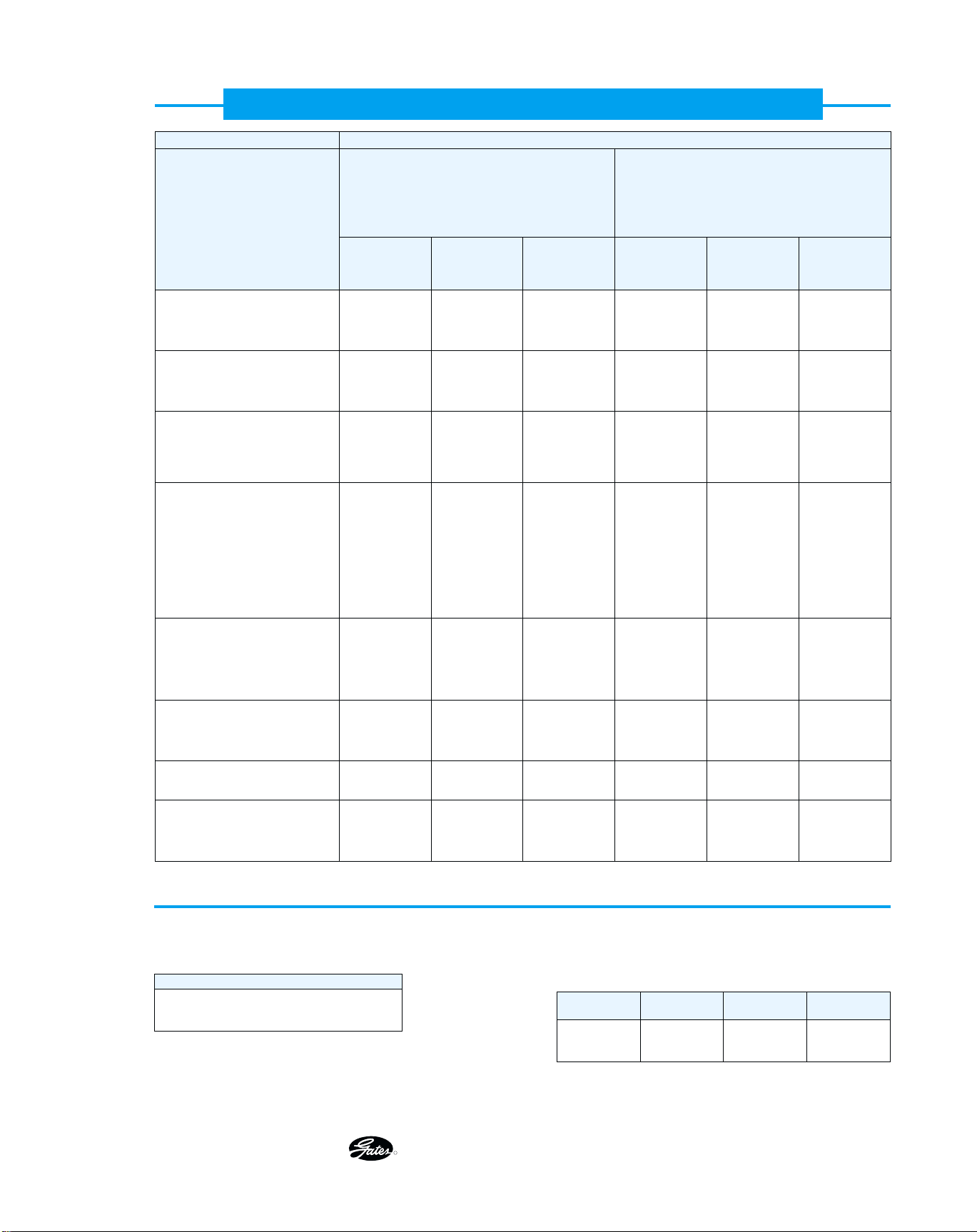

Basic PowerGrip®Service Factors

DriveN Machine DriveR

AC Motors: Normal Torque, Squirrel Cage, Synchronous,

Split Phase, Inverter Controlled

The driveN machines listed below are

representative samples only. Select a

driveN machine whose load characteris

tics most closely approximate those of

the machine being considered.

Display, Dispensing Equipment

Instrumentation

Measuring Equipment

Medical Equipment

Office, Projection Equipment

Appliances, Sweepers, Sewing Ma

chines

Screens, Oven Screens, Drum, Conical

Woodworking Equipment (Light):

Band Saws, Drills, Lathes

Agitators for Liquids

Conveyors: Belt, Light Package

Drill Press, Lathes, Saws

Laundry Machinery

Wood Working Equipment (Heavy):

Circular Saws, Jointers, Planers

Agitators for Semi-Liquids

Compressor: Centrifugal

Conveyor Belt: Ore, Coal, Sand

Dough Mixers

Line Shafts

Machine Tools: Grinder, Shaper,

Boring Mill, Milling Machines

Paper Machinery (except Pulpers):

Presses, Punches, Shears

Printing Machinery

Pumps: Centrifugal, Gear

Screens: Revolving, Vibratory

Brick Machinery (except Pug Mills)

Conveyor: Apron, Pan, Bucket, Elevator

Extractors, Washers

Fans, Centrifugal Blowers

Generators & Exciters

Hoists

Rubber Calender, Mills, Extruders

Centrifuges

Screw Conveyors

Hammer Mills

Paper Pulpers

Textile Machinery

Blowers: Positive Displacement,

Mine Fans

Pulverizers

Compressors: Reciprocating

Crushers: Gyratory, Jaw,

Roll Mills: Ball, Rod, Pebble, etc.

Pumps: Reciprocating

Saw Mill Equipment

DC Motors: Shunt Wound Stepper Motors

Engines: Multiple Cylinder Internal Combustion

-

Intermittent

Service

(Up to 8 hours

Daily or Seasonal)

1.0 1.2 1.4 1.2 1.4 1.6

-

1.1 1.3 1.5 1.3 1.5 1.7

1.2 1.4 1.6 1.6 1.8 2.0

1.3 1.5 1.7 1.6 1.8 2.0

1.4 1.6 1.8 1.8 2.0 2.2

1.5 1.7 1.9 1.9 2.1 2.3

1.6 1.8 2.0 2.0 2.2 2.4

1.7 1.9 2.1 2.1 2.3 2.5

Normal

Service

(8 - 16

hours Daily)

Continuous

Service

(16 - 24

hours Daily)

These service factors are adequate for most belt drive applications. Note that service factors cannot be substituted for good engineering judg

ment. Service factors may be adjusted based upon an understanding of the severity of actual drive operating conditions.

AC Motors: High Torque, High Slip, Repulsion-Induction,

Single Phase, Series Wound, Slip Ring

DC Motors: Series Wound, Compound Wound Servo Motors

Engines: Single Cylinder Internal Combustion

Line Shafts Clutches

Intermittent

Service

(Up to 8 hours

Daily or Seasonal)

Normal

Service

(8 - 16

hours Daily)

Continuous

Service

(16 - 24

hours Daily)

-

Additional Service Factors

Low Speed Drives

8mm / 14mm / 20mm Belts Only

Up to 200 rpm Add 0.3

201 to 400 rpm Add 0.2

401 to 600 rpm Add 0.1

Unusual Conditions

Additional service factors are required for unusual condi

tions—such as load reversal, heavy shock, plugged motor

stop, electric brake. These should be determined by a

transmission specialist.

Smaller Sprocket Speed

-

R

The Driving Force in Power Transmission. Page 15

Speedup Drives

For speedup drives, add to the basic service factor the

additional factor given below.

Speedup

Ratio Range

1 to 1.24 none 2.50 to 3.49 .30

1.25 to 1.74 .10 3.50 & over .40

1.75 to 2.49 .20

Additional

Factor

Speedup

Ratio Range

Additional

Factor

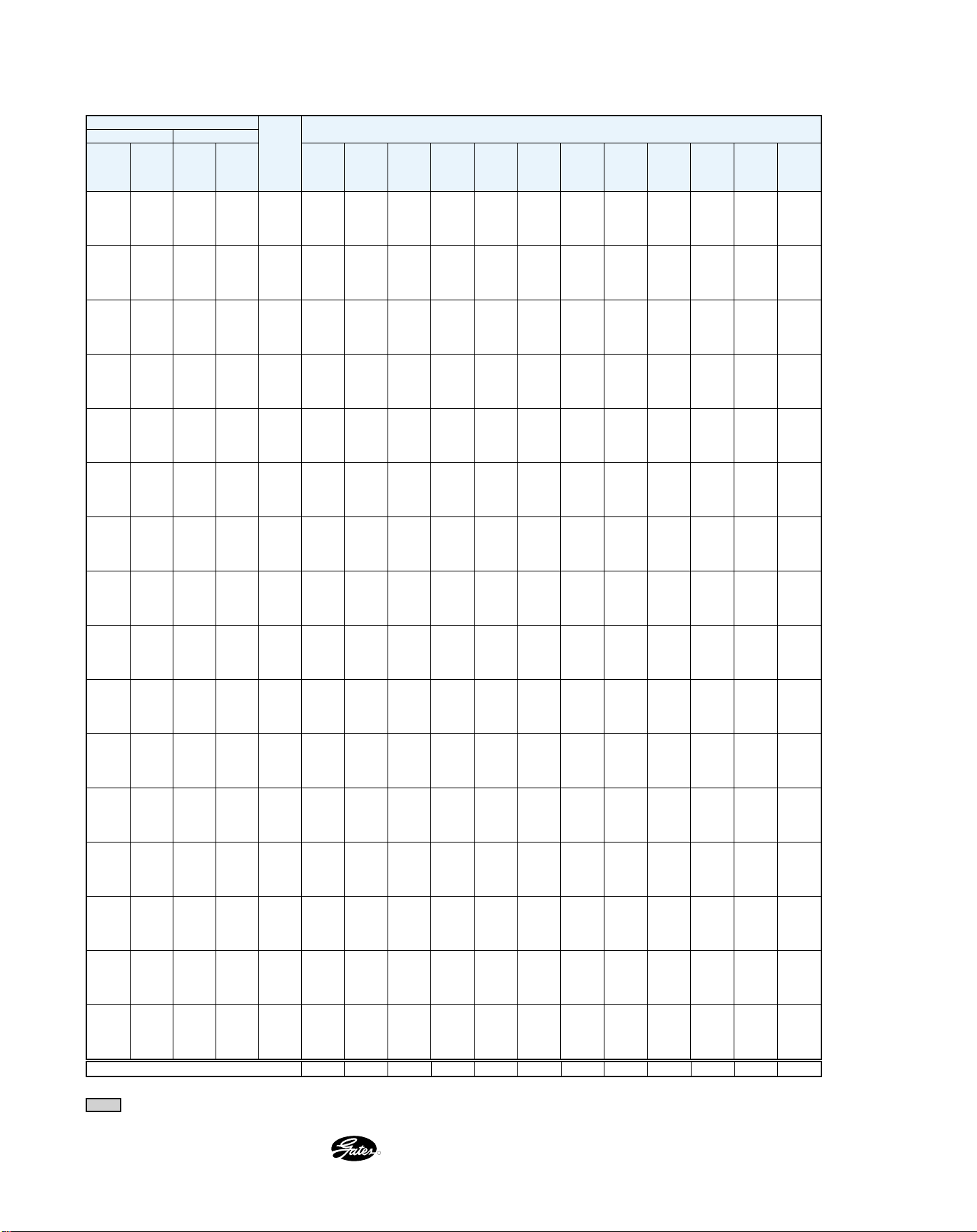

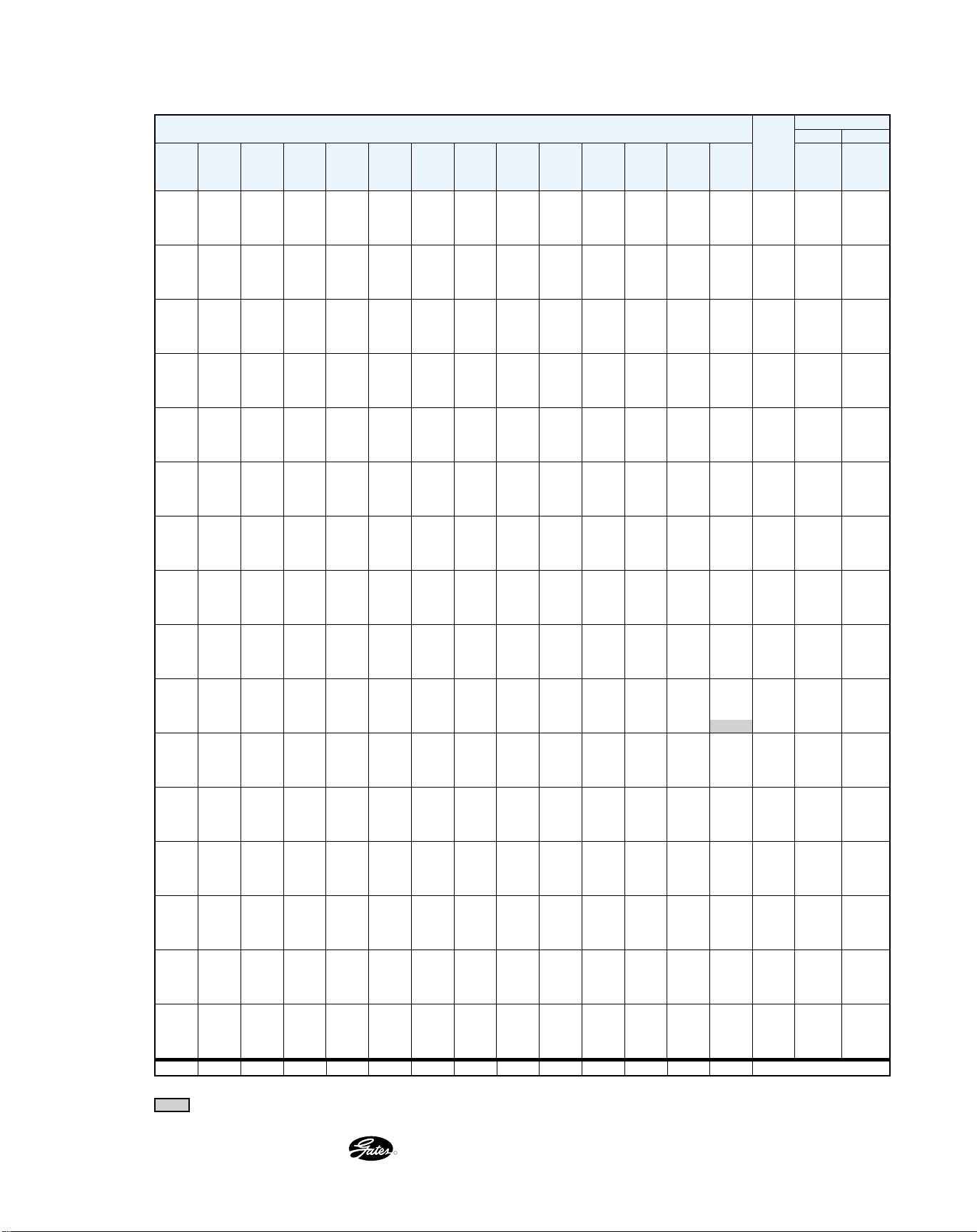

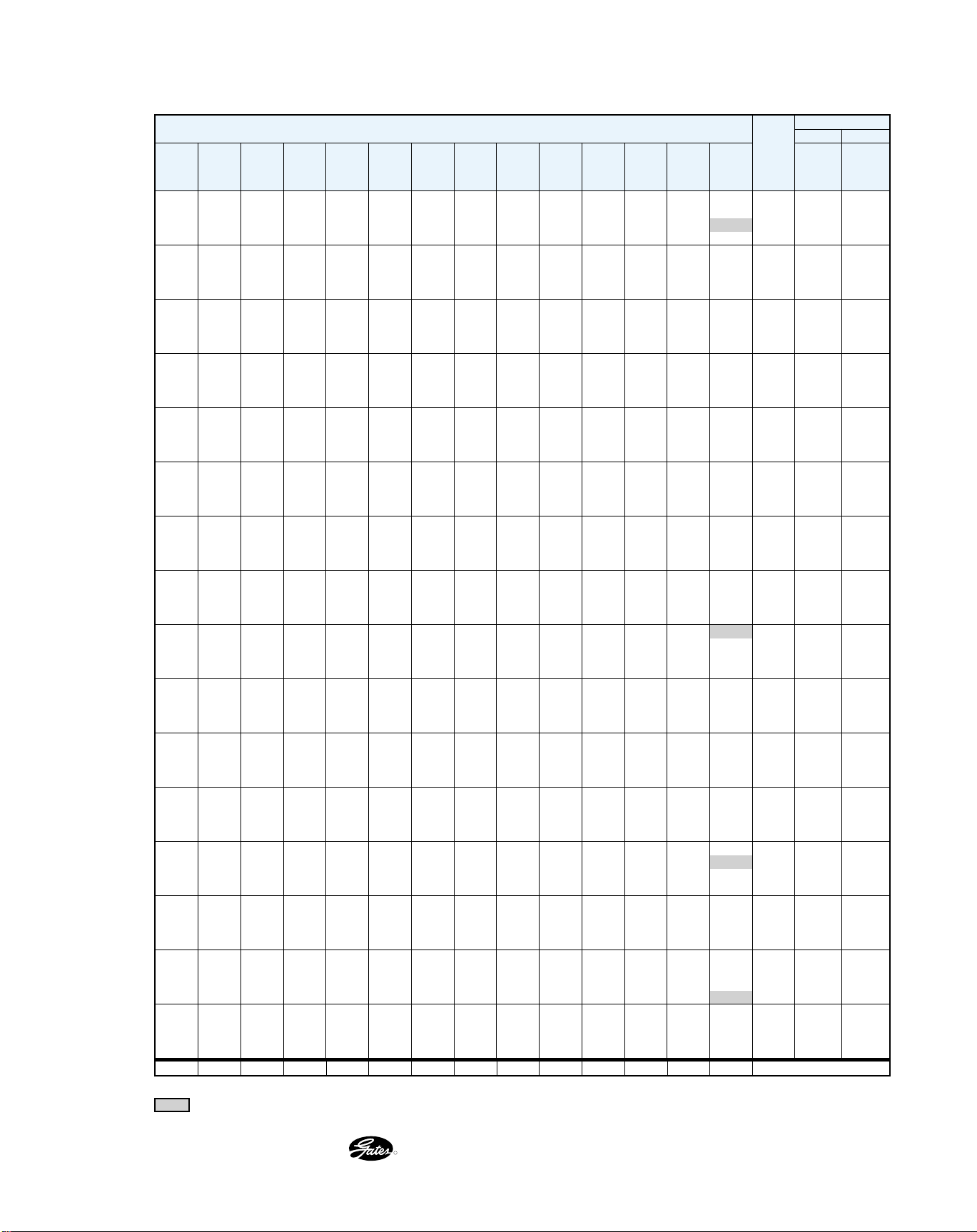

5mm Pitch PowerGrip®GT®2 Belts Drive Selection Table

Sprocket Combinations

DriveR DriveN

No.

of

Grooves

Pitch

Diameter

(Inches)

No.

of

Grooves

Pitch

Diameter

(Inches)

Speed

Ratio

5MR-300

P.L 11.811

60 teeth

5MR-355

P.L 13.976

71 teeth

5MR-375

P.L 14.764

75 teeth

18 1.128 18 1.128 1.000 4.13 5.22 5.61 6.10 6.20 6.59 7.09 8.07 8.76 9.35 9.64 10.04

19 1.191 19 1.191 1.000 4.03 5.12 5.51 6.00 6.10 6.49 6.99 7.97 8.66 9.25 9.54 9.94

20 1.253 20 1.253 1.000 3.94 5.02 5.41 5.91 6.00 6.40 6.89 7.87 8.56 9.15 9.45 9.84

21 1.316 21 1.316 1.000 3.84 4.92 5.31 5.81 5.90 6.30 6.79 7.77 8.46 9.05 9.35 9.74

22 1.379 22 1.379 1.000 3.74 4.82 5.21 5.71 5.80 6.20 6.69 7.67 8.36 8.95 9.25 9.64

23 1.441 23 1.441 1.000 3.64 4.73 5.12 5.61 5.71 6.10 6.60 7.58 8.27 8.86 9.15 9.55

24 1.504 24 1.504 1.000 3.54 4.63 5.02 5.51 5.61 6.00 6.50 7.48 8.17 8.76 9.05 9.45

25 1.566 25 1.566 1.000 3.45 4.53 4.92 5.42 5.51 5.91 6.40 7.38 8.07 8.66 8.96 9.35

26 1.629 26 1.629 1.000 3.35 4.43 4.82 5.32 5.41 5.81 6.30 7.28 7.97 8.56 8.86 9.25

28 1.754 28 1.754 1.000 3.15 4.23 4.62 5.12 5.21 5.61 6.10 7.08 7.77 8.36 8.66 9.05

30 1.880 30 1.880 1.000 2.95 4.04 4.43 4.92 5.02 5.41 5.91 6.89 7.58 8.17 8.46 8.86

32 2.005 32 2.005 1.000 2.76 3.84 4.23 4.73 4.82 5.22 5.71 6.69 7.38 7.97 8.27 8.66

34 2.130 34 2.130 1.000 2.56 3.64 4.03 4.53 4.62 5.02 5.51 6.49 7.18 7.77 8.07 8.46

36 2.256 36 2.256 1.000 3.45 3.84 4.33 4.43 4.82 5.32 6.30 6.99 7.58 7.87 8.27

38 2.381 38 2.381 1.000 3.25 3.64 4.13 4.23 4.62 5.12 6.10 6.79 7.38 7.67 8.07

40 2.506 40 2.506 1.000 3.05 3.44 3.94 4.03 4.43 4.92 5.90 6.59 7.18 7.48 7.87

44 2.757 44 2.757 1.000 3.54 3.64 4.03 4.53 5.51 6.20 6.79 7.08 7.48

45 2.820 45 2.820 1.000 3.45 3.54 3.94 4.43 5.41 6.10 6.69 6.99 7.38

48 3.008 48 3.008 1.000 3.64 4.14 5.12 5.81 6.40 6.69 7.09

50 3.133 50 3.133 1.000 3.94 4.92 5.61 6.20 6.49 6.89

52 3.258 52 3.258 1.000 3.74 4.72 5.41 6.00 6.30 6.69

56 3.509 56 3.509 1.000 4.33 5.02 5.61 5.90 6.30

60 3.760 60 3.760 1.000 4.62 5.21 5.51 5.90

64 4.010 64 4.010 1.000 4.82 5.12 5.51

68 4.261 68 4.261 1.000 4.72 5.12

44 2.757 45 2.820 1.023 3.49 3.59 3.98 4.48 5.46 6.15 6.74 7.03 7.43

25 1.566 26 1.629 1.040 3.40 4.48 4.87 5.37 5.46 5.86 6.35 7.33 8.02 8.61 8.91 9.30

50 3.133 52 3.258 1.040 3.84 4.82 5.51 6.10 6.40 6.79

24 1.504 25 1.566 1.042 3.49 4.58 4.97 5.46 5.56 5.95 6.45 7.43 8.12 8.71 9.00 9.40

48 3.008 50 3.133 1.042 3.54 4.04 5.02 5.71 6.30 6.59 6.99

23 1.441 24 1.504 1.043 3.59 4.68 5.07 5.56 5.66 6.05 6.55 7.53 8.22 8.81 9.10 9.50

22 1.379 23 1.441 1.045 3.69 4.78 5.17 5.66 5.76 6.15 6.65 7.63 8.32 8.91 9.20 9.60

21 1.316 22 1.379 1.048 3.79 4.87 5.26 5.76 5.85 6.25 6.74 7.72 8.41 9.00 9.30 9.69

20 1.253 21 1.316 1.050 3.89 4.97 5.36 5.86 5.95 6.35 6.84 7.82 8.51 9.10 9.40 9.79

19 1.191 20 1.253 1.053 3.99 5.07 5.46 5.96 6.05 6.45 6.94 7.92 8.61 9.20 9.50 9.89

38 2.381 40 2.506 1.053 3.15 3.54 4.04 4.13 4.53 5.02 6.00 6.69 7.28 7.58 7.97

18 1.128 19 1.191 1.056 4.08 5.17 5.56 6.05 6.15 6.54 7.04 8.02 8.71 9.30 9.59 9.99

36 2.256 38 2.381 1.056 3.35 3.74 4.23 4.33 4.72 5.22 6.20 6.89 7.48 7.77 8.17

34 2.130 36 2.256 1.059 3.54 3.93 4.43 4.52 4.92 5.41 6.39 7.08 7.67 7.97 8.37

68 4.261 72 4.511 1.059 4.92

32 2.005 34 2.130 1.063 2.66 3.74 4.13 4.63 4.72 5.12 5.61 6.59 7.28 7.87 8.17 8.56

64 4.010 68 4.261 1.063 4.62 4.92 5.31

30 1.880 32 2.005 1.067 2.85 3.94 4.33 4.82 4.92 5.31 5.81 6.79 7.48 8.07 8.36 8.76

45 2.820 48 3.008 1.067 3.30 3.39 3.79 4.28 5.26 5.95 6.54 6.84 7.23

60 3.760 64 4.010 1.067 4.43 5.02 5.31 5.71

28 1.754 30 1.880 1.071 3.05 4.14 4.53 5.02 5.12 5.51 6.01 6.99 7.68 8.27 8.56 8.96

56 3.509 60 3.760 1.071 4.13 4.82 5.41 5.70 6.10

26 1.629 28 1.754 1.077 3.25 4.33 4.72 5.22 5.31 5.71 6.20 7.18 7.87 8.46 8.76 9.15

52 3.258 56 3.509 1.077 4.52 5.21 5.80 6.10 6.49

24 1.504 26 1.629 1.083 3.44 4.53 4.92 5.41 5.51 5.90 6.40 7.38 8.07 8.66 8.95 9.35

48 3.008 52 3.258 1.083 3.94 4.92 5.61 6.20 6.49 6.89

23 1.441 25 1.566 1.087 3.54 4.63 5.02 5.51 5.61 6.00 6.50 7.48 8.17 8.76 9.05 9.45

22 1.379 24 1.504 1.091 3.64 4.73 5.12 5.61 5.71 6.10 6.60 7.58 8.27 8.86 9.15 9.55

44 2.757 48 3.008 1.091 3.34 3.44 3.84 4.33 5.31 6.00 6.59 6.89 7.28

21 1.316 23 1.441 1.095 3.74 4.82 5.21 5.71 5.80 6.20 6.69 7.67 8.36 8.95 9.25 9.64

20 1.253 22 1.379 1.100 3.84 4.92 5.31 5.81 5.90 6.30 6.79 7.77 8.46 9.05 9.35 9.74

40 2.506 44 2.757 1.100 3.24 3.74 3.83 4.23 4.72 5.71 6.40 6.99 7.28 7.68

19 1.191 21 1.316 1.105 3.94 5.02 5.41 5.91 6.00 6.40 6.89 7.87 8.56 9.15 9.45 9.84

18 1.128 20 1.253 1.111 4.03 5.12 5.51 6.00 6.10 6.49 6.99 7.97 8.66 9.25 9.54 9.94

36 2.256 40 2.506 1.111 3.25 3.64 4.13 4.23 4.62 5.12 6.10 6.79 7.38 7.67 8.07

45 2.820 50 3.133 1.111 3.29 3.69 4.18 5.16 5.85 6.44 6.74 7.13

34 2.130 38 2.381 1.118 3.44 3.84 4.33 4.43 4.82 5.32 6.30 6.99 7.58 7.87 8.27

25 1.566 28 1.754 1.120 3.30 4.38 4.77 5.27 5.36 5.76 6.25 7.23 7.92 8.51 8.81 9.20

50 3.133 56 3.509 1.120 3.64 4.62 5.31 5.90 6.20 6.59

Length Factor* 0.77 0.81 0.83 0.84 0.85 0.86 0.88 0.90 0.92 0.94 0.95 0.95

*This length factor must be used to determine the proper belt width.

Center Distance is greater than eight times the small diameter and the large sprocket is not flanged. See Engineering Section I-10, Use of Flanged

Sprockets, on page 134.

Center Distance, Inches

5MR-400

P.L 15.748

80 teeth

5MR-405

P.L 15.945

81 teeth

5MR-425

P.L 16.732

85 teeth

5MR-450

P.L 17.716

90 teeth

5MR-500

P.L 19.685

100 teeth

5MR-535

P.L 21.063

107 teeth

5MR-565

P.L 22.244

113 teeth

5MR-580

P.L 22.835

116 teeth

5MR-600

P.L 23.622

120 teeth

Page 16 The Gates Rubber Company

R

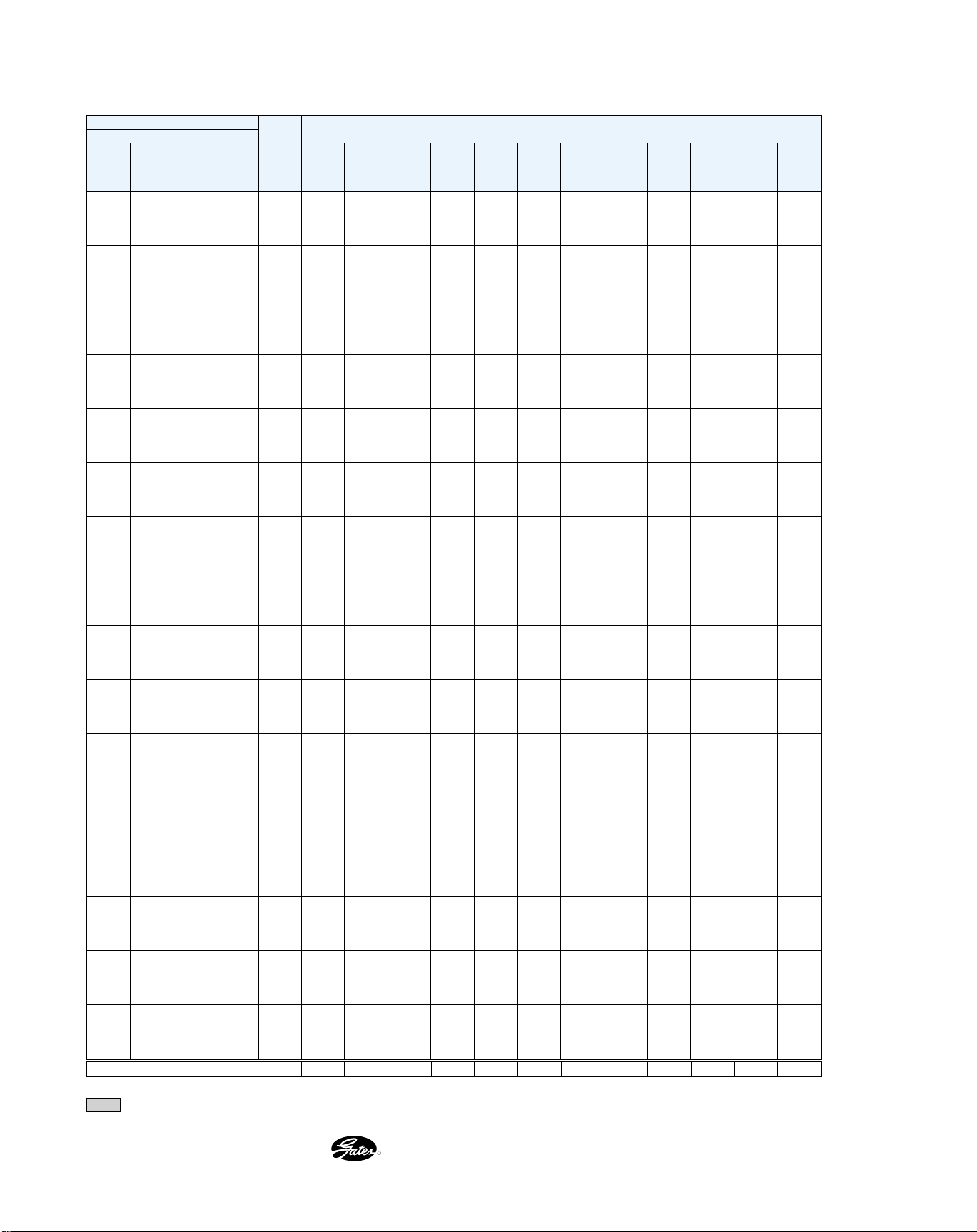

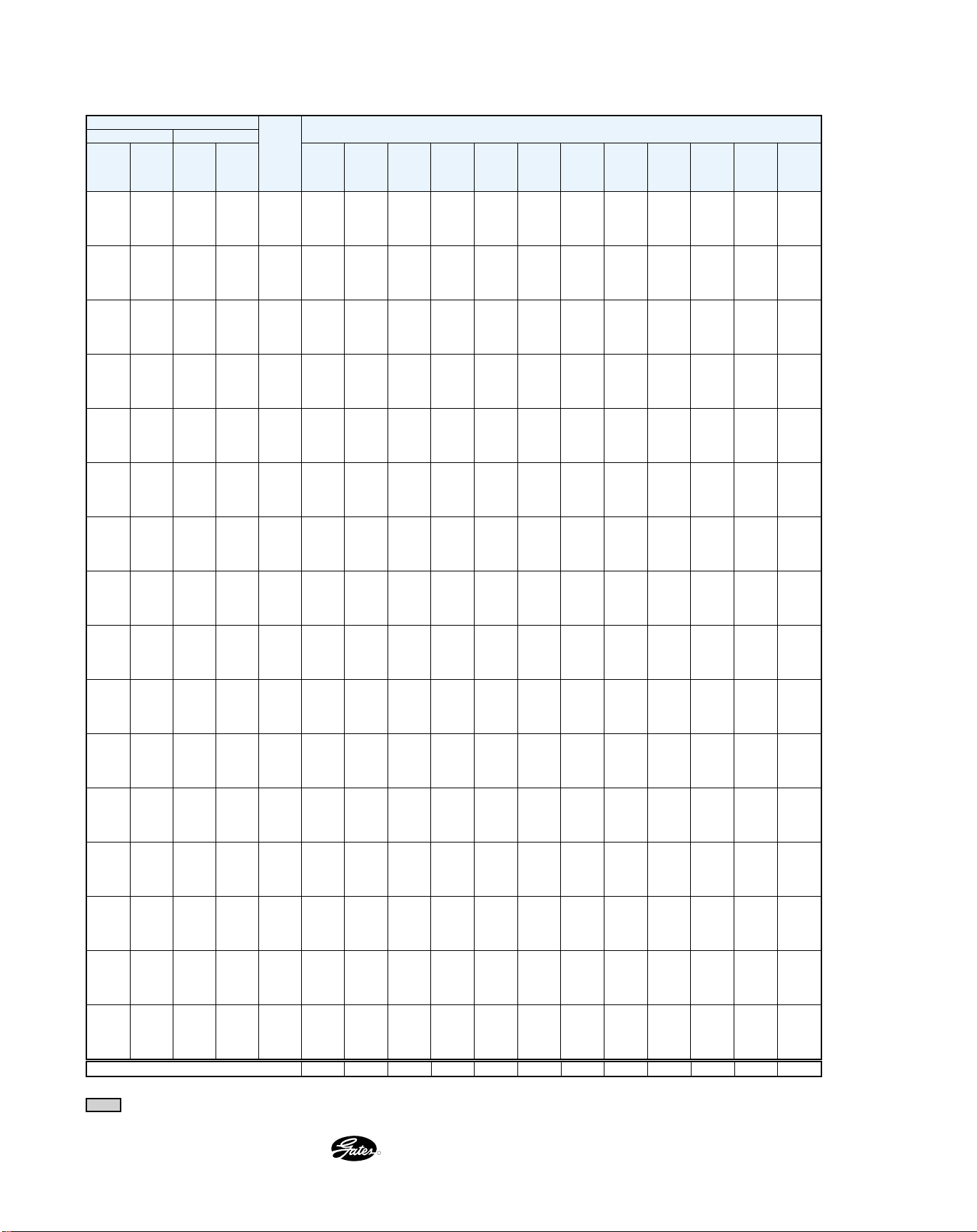

5mm Pitch PowerGrip®GT®2 Belts Drive Selection Table

Center Distance, Inches

Sprocket Combinations

DriveR DriveN

5MR-625

P.L 24.606

125 teeth

5MR-650

P.L 25.590

130 teeth

5MR-700

P.L 27.559

140 teeth

5MR-750

P.L 29.528

150 teeth

5MR-800

P.L 31.496

160 teeth

5MR-850

P.L 33.465

170 teeth

5MR-900

P.L 35.433

180 teeth

5MR-1000

P.L 39.370

200 teeth

5MR-1150

P.L 45.276

230 teeth

5MR-1300

P.L 51.181

260 teeth

5MR-1450

P.L 57.087

290 teeth

5MR-1600

P.L 62.992

320 teeth

5MR-1720

P.L 67.716

344 teeth

5MR-2100

P.L 82.677

420 teeth

Speed

Ratio

No. of

grooves

10.53 11.02 12.01 12.99 13.98 14.96 15.94 17.91 20.87 23.82 26.77 29.72 32.09 39.57 1.000 18 18

10.43 10.92 11.91 12.89 13.88 14.86 15.84 17.81 20.77 23.72 26.67 29.62 31.99 39.47 1.000 19 19

10.34 10.83 11.81 12.80 13.78 14.76 15.75 17.72 20.67 23.62 26.58 29.53 31.89 39.37 1.000 20 20

10.24 10.73 11.71 12.70 13.68 14.66 15.65 17.62 20.57 23.52 26.48 29.43 31.79 39.27 1.000 21 21

10.14 10.63 11.61 12.60 13.58 14.56 15.55 17.52 20.47 23.42 26.38 29.33 31.69 39.17 1.000 22 22

10.04 10.53 11.52 12.50 13.49 14.47 15.45 17.42 20.38 23.33 26.28 29.23 31.60 39.08 1.000 23 23

9.94 10.43 11.42 12.40 13.39 14.37 15.35 17.32 20.28 23.23 26.18 29.13 31.50 38.98 1.000 24 24

9.85 10.34 11.32 12.31 13.29 14.27 15.26 17.23 20.18 23.13 26.09 29.04 31.40 38.88 1.000 25 25

9.75 10.24 11.22 12.21 13.19 14.17 15.16 17.13 20.08 23.03 25.99 28.94 31.30 38.78 1.000 26 26

9.55 10.04 11.02 12.01 12.99 13.97 14.96 16.93 19.88 22.83 25.79 28.74 31.10 38.58 1.000 28 28

9.35 9.84 10.83 11.81 12.80 13.78 14.76 16.73 19.69 22.64 25.59 28.54 30.91 38.39 1.000 30 30

9.16 9.65 10.63 11.62 12.60 13.58 14.57 16.54 19.49 22.44 25.40 28.35 30.71 38.19 1.000 32 32

8.96 9.45 10.43 11.42 12.40 13.38 14.37 16.34 19.29 22.24 25.20 28.15 30.51 37.99 1.000 34 34

8.76 9.25 10.24 11.22 12.21 13.19 14.17 16.14 19.10 22.05 25.00 27.95 30.32 37.80 1.000 36 36

8.56 9.05 10.04 11.02 12.01 12.99 13.97 15.94 18.90 21.85 24.80 27.75 30.12 37.60 1.000 38 38

8.37 8.86 9.84 10.83 11.81 12.79 13.78 15.75 18.70 21.65 24.61 27.56 29.92 37.40 1.000 40 40

7.97 8.46 9.45 10.43 11.42 12.40 13.38 15.35 18.31 21.26 24.21 27.16 29.53 37.01 1.000 44 44

7.88 8.37 9.35 10.34 11.32 12.30 13.29 15.26 18.21 21.16 24.12 27.07 29.43 36.91 1.000 45 45

7.58 8.07 9.06 10.04 11.03 12.01 12.99 14.96 17.92 20.87 23.82 26.77 29.14 36.62 1.000 48 48

7.38 7.87 8.86 9.84 10.83 11.81 12.79 14.76 17.72 20.67 23.62 26.57 28.94 36.42 1.000 50 50

7.19 7.68 8.66 9.65 10.63 11.61 12.60 14.57 17.52 20.47 23.43 26.38 28.74 36.22 1.000 52 52

6.79 7.28 8.27 9.25 10.24 11.22 12.20 14.17 17.13 20.08 23.03 25.98 28.35 35.83 1.000 56 56

6.40 6.89 7.87 8.86 9.84 10.82 11.81 13.78 16.73 19.68 22.64 25.59 27.95 35.43 1.000 60 60

6.01 6.50 7.48 8.47 9.45 10.43 11.42 13.39 16.34 19.29 22.25 25.20 27.56 35.04 1.000 64 64

5.61 6.10 7.09 8.07 9.06 10.04 11.02 12.99 15.95 18.90 21.85 24.80 27.17 34.65 1.000 68 68

7.92 8.41 9.40 10.38 11.37 12.35 13.33 15.30 18.26 21.21 24.16 27.11 29.48 36.96 1.023 44 45

9.80 10.29 11.27 12.26 13.24 14.22 15.21 17.18 20.13 23.08 26.04 28.99 31.35 38.83 1.040 25 26

7.29 7.78 8.76 9.75 10.73 11.71 12.70 14.67 17.62 20.57 23.53 26.48 28.84 36.32 1.040 50 52

9.89 10.38 11.37 12.35 13.34 14.32 15.30 17.27 20.23 23.18 26.13 29.08 31.45 38.93 1.042 24 25

7.48 7.97 8.96 9.94 10.93 11.91 12.89 14.86 17.82 20.77 23.72 26.67 29.04 36.52 1.042 48 50

9.99 10.48 11.47 12.45 13.44 14.42 15.40 17.37 20.33 23.28 26.23 29.18 31.55 39.03 1.043 23 24

10.09 10.58 11.57 12.55 13.54 14.52 15.50 17.47 20.43 23.38 26.33 29.28 31.65 39.13 1.045 22 23

10.19 10.68 11.66 12.65 13.63 14.61 15.60 17.57 20.52 23.47 26.43 29.38 31.74 39.22 1.048 21 22