GatesAir CZF Users Manual

TECHNICAL MANUAL

888-2687-001

Ranger™ Mobile SeriesUHF

Transmitter

Ranger™ Mobile Series

UHF Transmitter

T.M. No. 888-2687-001

© Copyright Harris Corporation 2002,2003, 2007

All rights reserved

Rev. A, October, 2007

PRELIMINARY

Returns And Exchanges

Damaged or undamaged equipment should not be returned unless written approval

and a Return Authorization is received from HARRIS Broadcast Communications

Division. Special shipping instructions and coding will be provided to assure proper

handling. Complete details regarding circumstances and reasons for return are to be

included in the request for return. Custom equipment or special order equipment is

not returnable. In those instances where return or exchange of equipment is at the

request of the customer, or convenience of the customer, a restocking fee will be

charged. All returns will be sent freight prepaid and properly insured by the

customer. When communicating with HARRIS Broadcast Communications

Division, specify the HARRIS Order Number or Invoice Number.

Unpacking

Carefully unpack the equipment and preform a visual inspection to determine that

no apparent damage was incurred during shipment. Retain the shipping materials

until it has been determined tha t all re ceived equipment i s not d amaged. Locate and

retain all PACKING CHECK LISTs. Use the PACKING CHECK LIST to help

locate and identify any components or assemblies which are removed for shipping

and must be reinstalled. Also remove any shipping supports, straps, and packing

materials prior to initial turn on.

Technical Assistance

HARRIS Technical and Troubleshooting assistance is available from HARRIS

Field Service during normal business hours (8:00 AM - 5:00 PM Central Time).

Emergency service is available 24 hours a day. Telephone 217/222-8200 to contact

the Field Service Department or address correspondence to Field Service

Department, HARRIS Broadcast Communications Division, P.O. Box 4290,

Quincy, Illinois 62305-4290, USA. Technical Support by e-mail:

tsupport@harris.com. The HARRIS factory may also be contacted through a FAX

facility (217/221-7096).

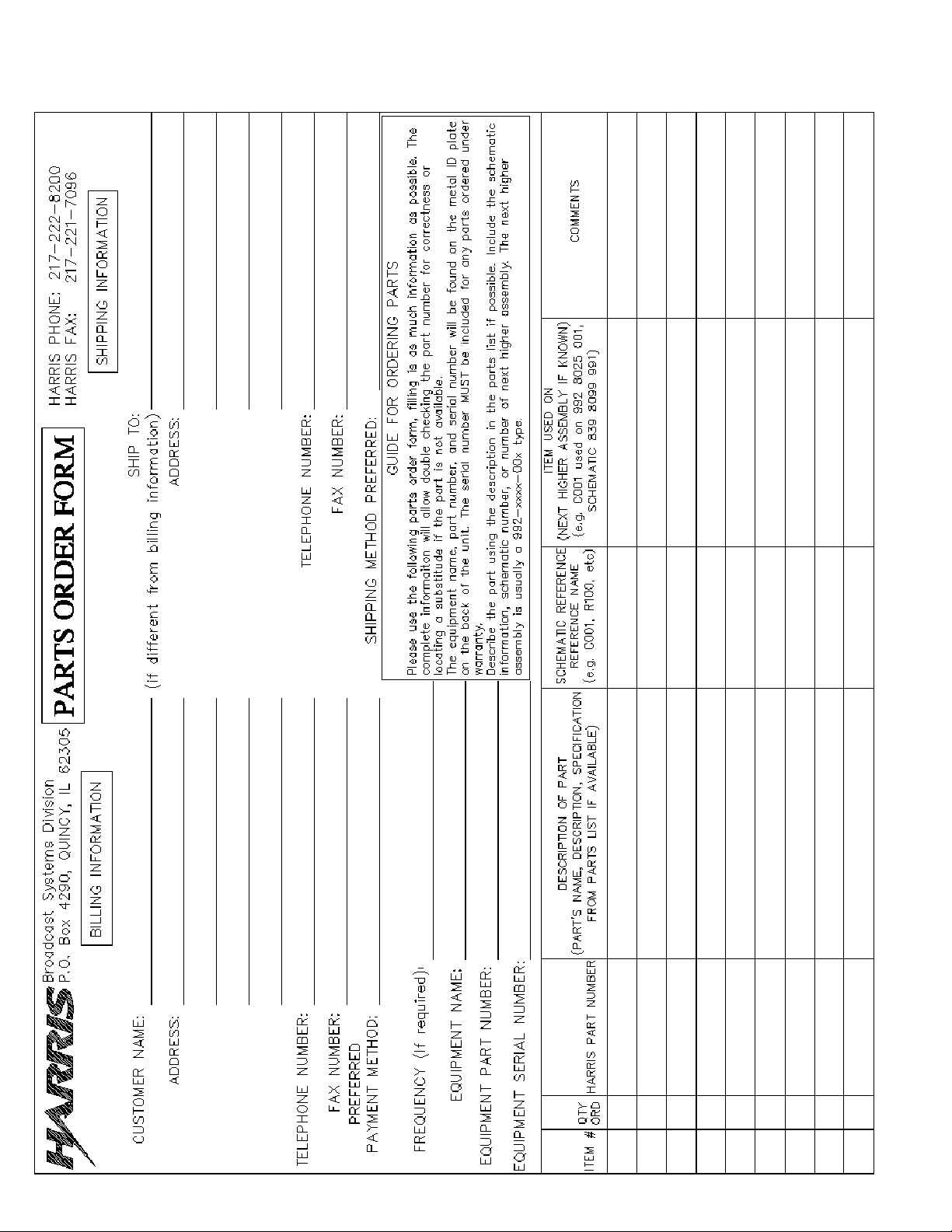

Replaceable Parts Service

Replacement parts are available 24 hours a day, seven days a week from the

HARRIS Service Parts Department. Telephone 217/222-8200 to contact the service

parts department or address correspondence to Service Parts Department, HARRIS

CORPORATION, Broadcast Systems Division, P.O. Box 4290, Quincy, Illinois

62305-4290, USA. The HARRIS factory may also be contacted through a FAX

facility (217/221-7096).

NOTE:

The # symbol used in the parts list means used with (e.g. #C001 = used with C001).

888-2687-001 10/19/07

WARNING: Discon nect primar y power prior to servicing.

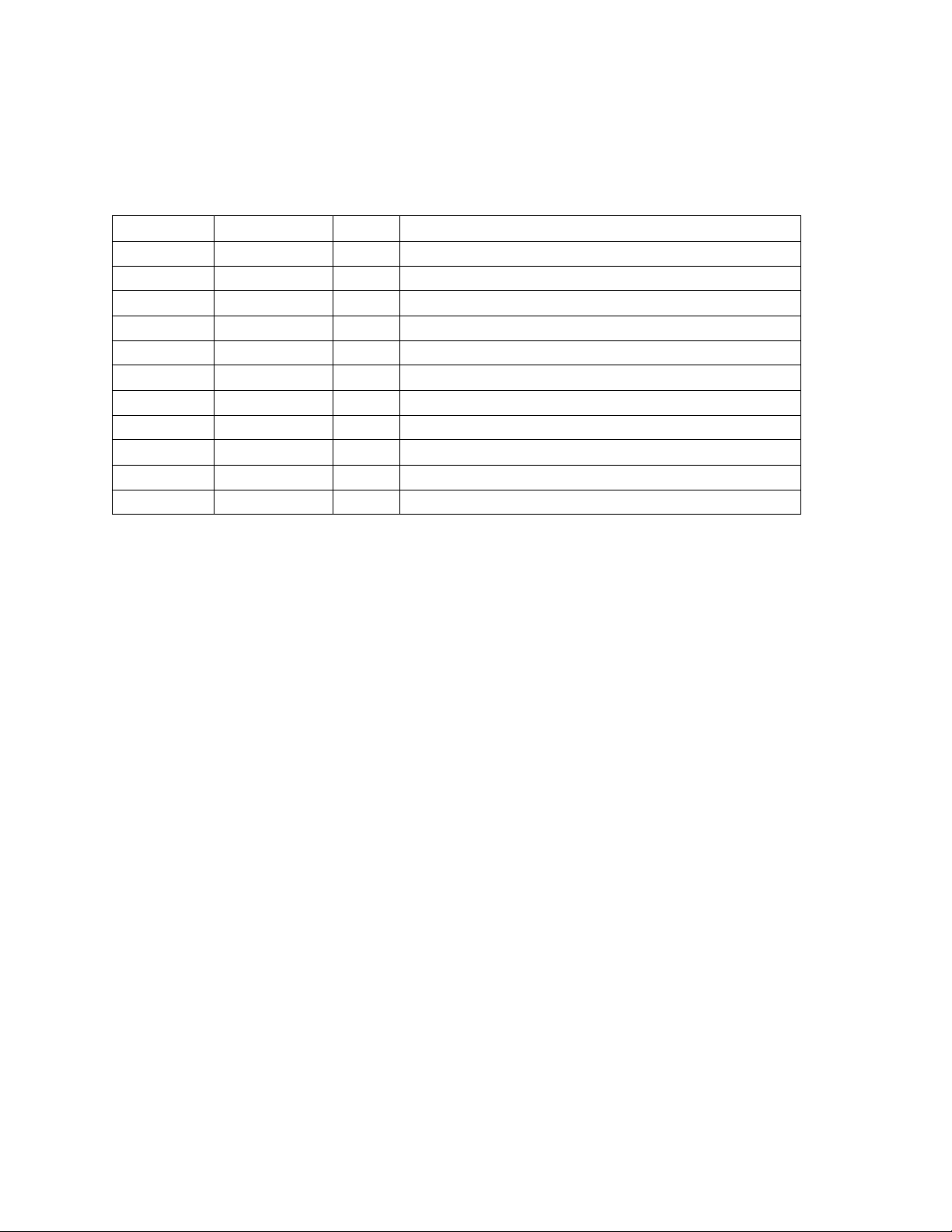

Manual Revision History

Ranger™ Mobile Series

REV. DATE ECN Pages Affected

Preliminary Oct. 19, 2007 Added power supply note. Section 4.

10/19/07 888-2687-001

WARNING: Discon nect primar y power prior t o servicing .

MRH-1

MRH-2

888-2687-001 10/19/07

WARNING: Discon nect primar y power prior to servicing.

10/19/07 888-2687-001

WARNING: Discon nect primar y power prior t o servicing .

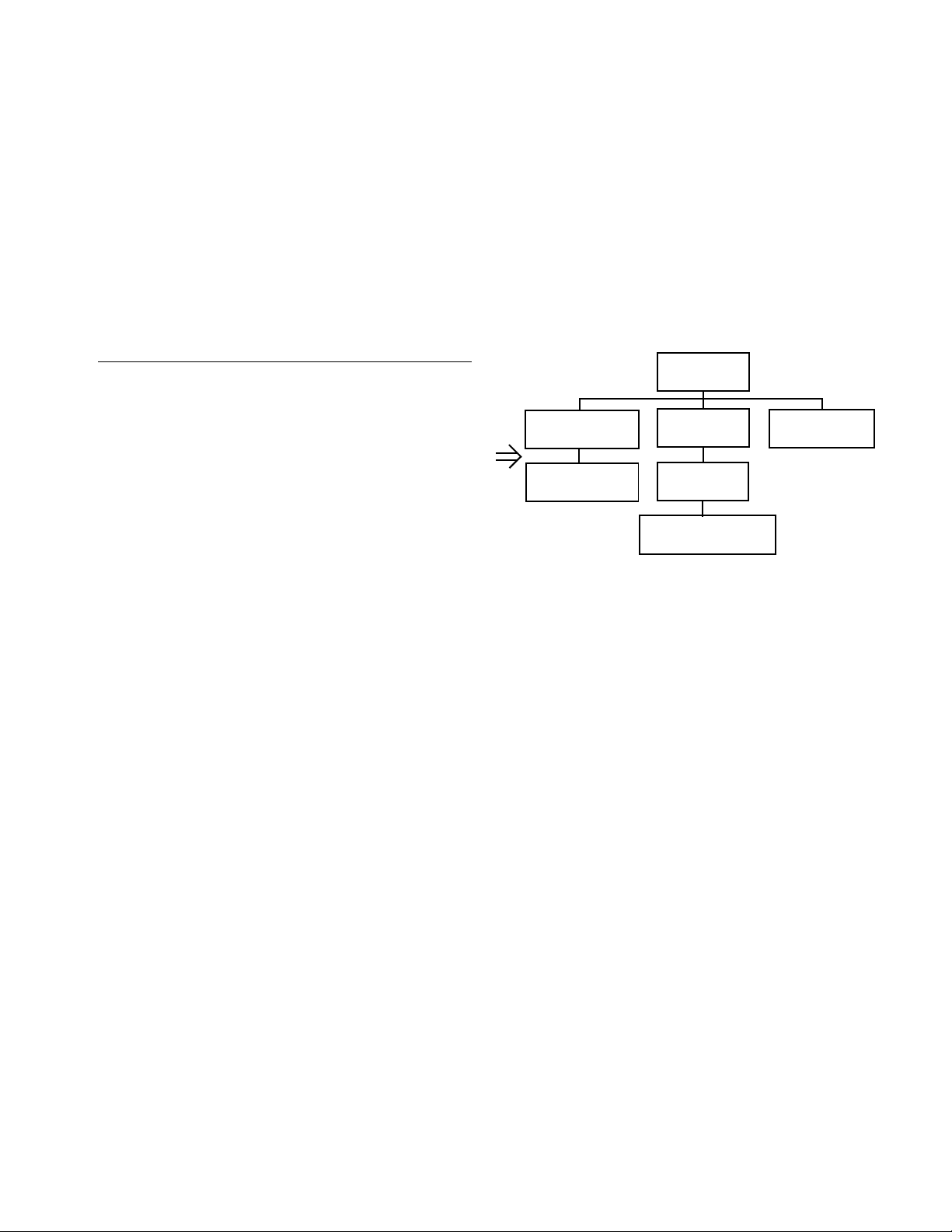

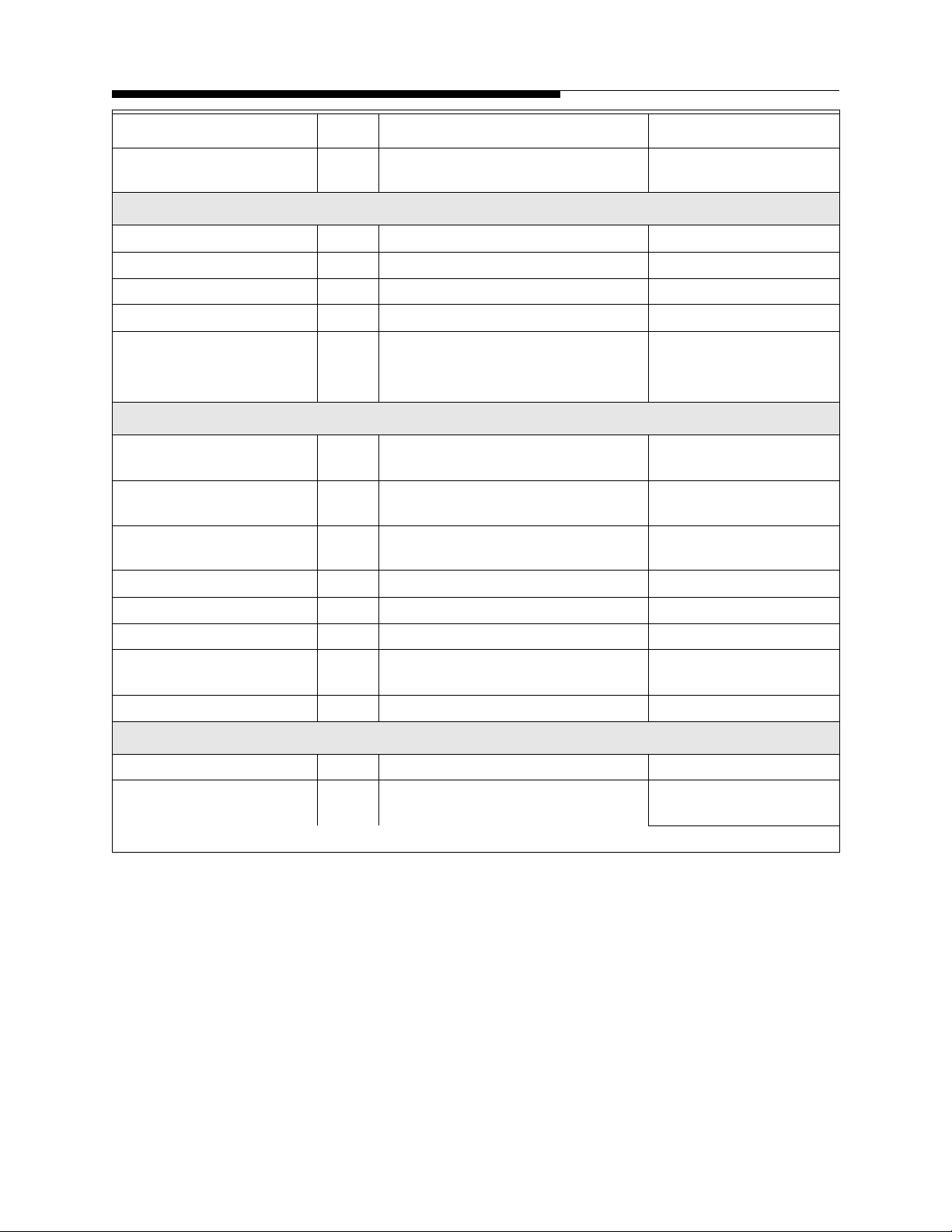

Guide to Using Har ris Parts List Information

t

The Harris Replaceable Parts List Index portrays a tree structure with the major items being leftmost in the index. The

example below shows the Transmitter as the highest item in the tree structure. If you were to look at the bill of materials

table for the Transmitter you would find the Control Cabinet, the PA Cabinet, and the Output Cabinet. In the Replaceable

Parts List Index the Control C abinet, PA Cabinet, an d Output Ca binet show up one in dentation l evel below the T ransmi tter

and implies that they are used in the Transmitter. The Controller Board is indented one level below the Control Cabinet so

it will show up in the bill of material for the Control Cabinet. The tree structure of this same index is shown to the right of

the table and shows indentation level versus tree structure level.

Example of Replaceable Parts List Index and equivalent tree structure:

Replaceable Parts List Index Part Number Page

Table 7-1. Transmitter 994 9283 001 7-2

Table 7-2. Control Cabinet 992 9244 002 7-3

Table 7-3. Controller Board 992 8344 002 7-6

Table 7-4. PA Cabinet 992 9400 002 7-7

Table 7-5. PA Amplifier 994 7894 002 7-9

Table 7-6. PA Amplifier Board 992 7904 002 7-10

Table 7-7. Output Cabinet 992 9450 001 7-12

The part number of the item is shown to the right of the description as is the page in the manual where the bill for that part

number starts. Inside the actual tables, four main headings are used:

Control Cabinet

992 9244 002

Controller Board

992 8344 002

Transmitter

994 9283 001

PA Cabinet

992 9400 002

PA Amplifier

992 7894 002

PA Amplifier Board

992 7904 002

Output Cabine

992 9450 001

• Table #-#. ITEM NAME - HARRIS PART NUMBER - this line gives the information that corresponds to the

• Replaceable Parts List Index entry;

• HARRIS P/N column gives the ten digit Harris part number (usually in ascending order);

• DESCRIPTION column gives a 25 character or less description of the part number;

• REF. SYMBOLS/EXPLANATIONS column 1) gives the reference designators for the item (i.e., C001, R102,

etc.) that corresponds to the number found in the schematics (C001 in a bill of material is equivalent to C1 on the

schematic) or 2) gives added information or further explanation (i.e., “Used for 208V operation only,” or “Used

for HT 10LS only,” etc.).

Inside the individual tables some standard conventions are used:

• A # symbol in front of a component such as #C001 under the REF. SYMBOLS/EXPLANATIONS column

means that this item is used on or with C001 and is not the actual part number for C001.

• In the ten digit part numbers , if the last th ree numbers are 000, t he item is a part that Harris has pu rchased and has

not manufactured or modified. If the last three numbers are other than 000, the item is either manufactured by

Harris or is purchased from a vendor and modified for use in the Harris product.

• The first three digits of the ten digit part number tell which family the part number belongs to - for example, all

electrolytic (can) capacitors will be in the same family (524 xxxx 000). If an electrolytic (can) capacitor is found

to have a 9xx xxxx xxx part number (a number outside of the normal family of numbers), it has probably been

modified in some manner at the Harris factory and will therefore show up farther down into the individual parts

list (because each table is normally sorted in ascending order). Most Harris made or modified assemblies will

have 9xx xxxx xxx numbers associated with them.

The term “SEE HIGHER LEVEL BILL” in th e d escript ion column imp lies that the reference designated part number will

show up in a bill that is higher in the tree structure. This is often the case for components that may be

frequency determinant or voltage determinant and are called out in a higher level bill structure that is more

customer dependent than the bill at a lower level.

WARNING: Discon nect primar y power prior to servicing.

888-2687-001 10/19/07

!

WARNING:

THE CURRENTS AND VOLTAGES IN THIS EQUIPMENT ARE DANGEROUS. PERSONNEL MUST AT ALL TIMES OBSERVE SAFETY WARNINGS, INSTRUCTIONS AND REGULATIONS.

This manual is intended as a general guide for trained and qualified personnel who are aware of the

dangers inherent in handling potentially hazardous electrical/electronic circuits. It is not intended to

contain a complete statement of all safety precautions which should be observed by personnel in

using this or other electronic equipment.

The installation, operation, maintenance and service of this equipment involves risks both to

personnel and equipment, and must be performed only by qualified personnel exercising due care.

HARRIS CORPORATION shall not be responsible for injury or damage resulting from improper

procedures or from the use of improperly trained or inexperienced personnel performing such tasks.

During installation and operation of this equipment, local building codes and fire protection

standards must be observed.

The following National Fire Protection Association (NFPA) standards are recommended as reference:

- Automatic Fire Detectors, No. 72E

- Installation, Maintenance, and Use of Portable Fire Extinguishers, No. 10

- Halogenated Fire Extinguishing Agent Systems, No. 12A

!

WARNING:

ALWAYS DISCONNECT POWER BEFORE OPENING COVERS, DOORS, ENCLOSURES, GATES, PANELS OR SHIELDS. ALWAYS USE GROUNDING STICKS AND

SHORT OUT HIGH VOLTAGE POINTS BEFORE SERVICING. NEVER MAKE INTERNAL

ADJUSTMENTS, PERFORM MAINTENANCE OR SERVICE WHEN ALONE OR WHEN

FATIGUED.

Do not remove, short-circuit or tamper with interlock switches on access covers, doors, enclosures,

gates, panels or shields . K e ep away from li ve circui ts , k now your equ ip ment and do n’t take chances.

!

WARNING:

IN CASE OF EMERGENCY ENSURE THAT POWER HAS BEEN DISCONNECTED.

!

WARNING:

IF OIL FILLED OR ELECTROLYTIC CAPACITORS ARE UTILIZED IN YOUR EQUIPMENT, AND IF A LEAK OR BULGE IS APPARENT ON THE CAPACITOR CASE WHEN

THE UNIT IS OPENED FOR SERVICE OR MAINTENANCE, ALLOW THE UNIT TO COOL

DOWN BEFORE ATTEMPTING TO REMOVE THE DEFECTIVE CAPACITOR. DO NOT

ATTEMPT TO SERVICE A DEFECTIVE CAPACITOR WHILE IT IS HOT DUE TO THE

POSSIBILITY OF A CASE RUPTURE AND SUBSEQUENT INJURY.

888-2687-001 10/19/07

WARNING: Discon nect primar y power prior to servicing.

10/19/07 888-2687-001

WARNING: Discon nect primar y power prior t o servicing .

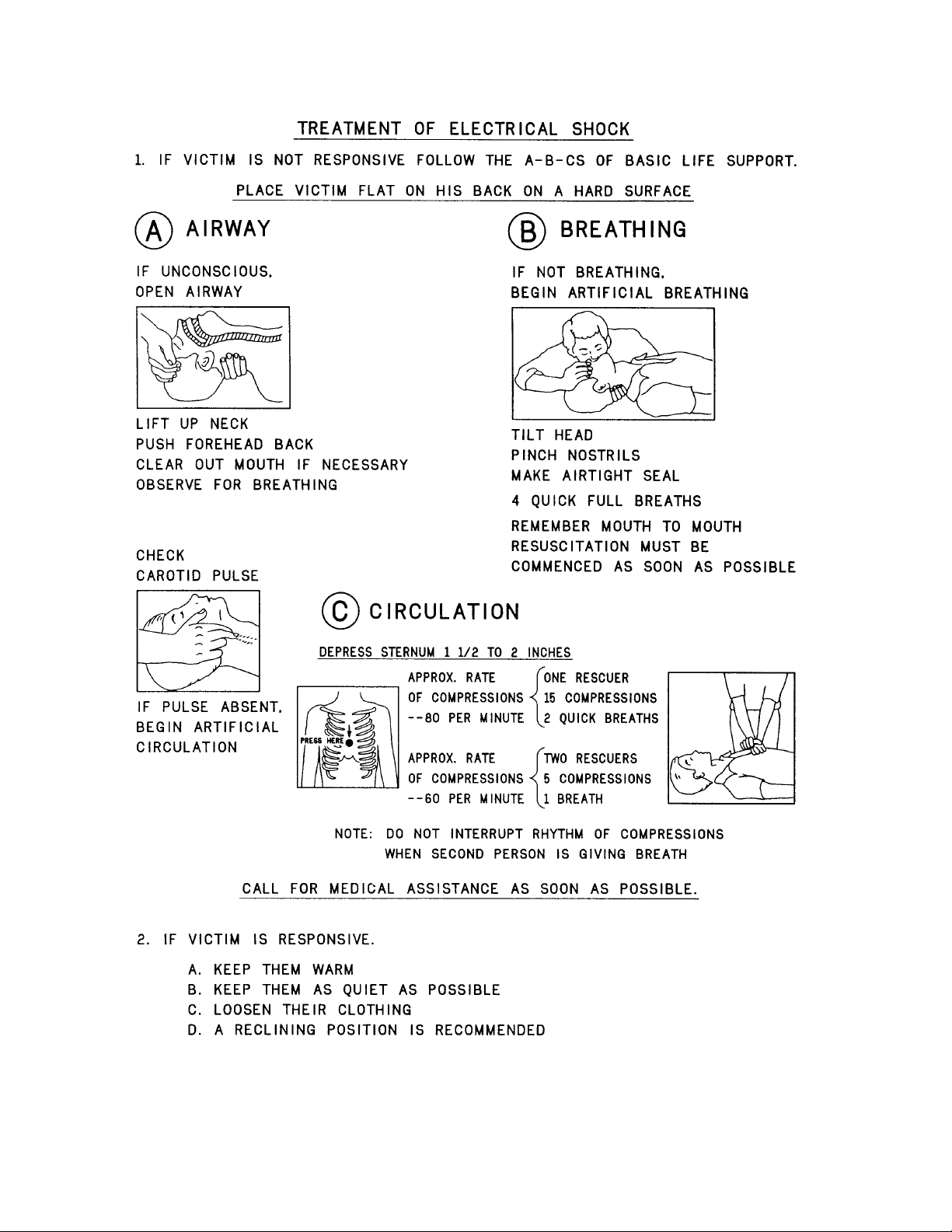

FIRST-AID

Personnel engaged in the installation, operation, maintenance or servicing of this equipment

are urged to become famil iar with fi rst -aid the ory and practices. The following information is

not intended to be complete first-aid procedures, it is a brief and is only to be used as a

reference. It is the duty of all personnel using the equipment to be prepared to give adequate

Emergency First Aid and there by prevent avoidable loss of life.

Treatment of Electrical Burns

1. Extensive burned and broken skin

a. Cover area with clean sheet or cloth. (Cleanest available cloth

article.)

b. Do not break blisters, remove tissue, remove adhered particles of

clothing, or apply any salve or ointment.

c. Treat victim for shock as required.

d. Arrange transportation to a hospital as quickly as possible.

e. If arms or legs are affected keep them elevated.

NOTE:

If medical help will not be available within an hour and the victim is conscious and

not vomiting, give him a weak solution of salt and soda: 1 level teaspoonful of salt

and 1/2 level teaspoonful of baking soda to each quart of water (neither hot or

cold). Allow victim to sip slowly about 4 ounces (a half of glass) over a period of

15 minutes. Discontinue fluid if vomiting occurs. (Do not give alcohol.)

2. Less severe burns - (1st & 2nd degree)

a. Apply cool (not ice cold) compresses using the cleanest available

cloth article.

b. Do not break blisters, remove tissue, remove adhered particles of

clothing, or apply salve or ointment.

c. Apply clean dry dressing if necessary.

d. Treat victim for shock as required.

e. Arrange transportation to a hospital as quickly as possible.

f. If arms or legs are affected keep them elevated.

REFERENCE:

ILLINOIS HEART ASSOCIATION

AMERICAN RED CROSS ST ANDARD FIRST AID AND PERSONAL SAFETY

MANUAL (SECOND EDITION)

888-2687-001 10/19/07

WARNING: Discon nect primar y power prior to servicing.

888-2687-001 10/19/07

WARNING: Discon nect primar y power prior to servicing.

Table of Contents

Section 1

Introduction

Purpose of This Manual . . . . . . . . . . . . . . . . . . . . 1-1

General Description. . . . . . . . . . . . . . . . . . . . . . . . 1-2

System Block Diagrams. . . . . . . . . . . . . . . . . . . 1-4

Transmitter Control System . . . . . . . . . . . . . . . . 1-6

Graphical User Interface . . . . . . . . . . . . . . . . . 1-6

Control System Communications . . . . . . . . . . 1-6

In-System Programming or ISP. . . . . . . . . . . . 1-7

Remote Control . . . . . . . . . . . . . . . . . . . . . . . . 1-7

PA Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Power Supplies. . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Apex™ Exciter. . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

General Specifications. . . . . . . . . . . . . . . . . . . . . . 1-9

Section 2

Installation /

Initial Turn-On

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Installation Drawings . . . . . . . . . . . . . . . . . . . . . 2-1

Installation Checkboxes . . . . . . . . . . . . . . . . . . . . 2-2

Transmitter Cabinet Placement. . . . . . . . . . . . . . . 2-2

Transmitter AC Connection . . . . . . . . . . . . . . . . . 2-3

Signal and Ground Connections . . . . . . . . . . . . . . 2-5

Interlock Connections . . . . . . . . . . . . . . . . . . . . . . 2-5

External Interlocks . . . . . . . . . . . . . . . . . . . . . . . 2-6

RF Mute Interlock . . . . . . . . . . . . . . . . . . . . . . . 2-6

3 Port Patch Panel . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Motorized RF Switch Connections. . . . . . . . . . . . 2-8

Install PA and PS Modules . . . . . . . . . . . . . . . . . . 2-9

Initial Turn-On . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

RF Initial Turn ON. . . . . . . . . . . . . . . . . . . . . . 2-14

Parallel Remote Control Connections. . . . . . . . . 2-16

Transmitter Control Functions, J13 and J14. . . 2-17

Remote Status Outputs, J15 & J16 . . . . . . . . . . . 2-19

Remote Power Metering, J17. . . . . . . . . . . . . . 2-20

Section 3

Operation/Adjustments

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Transmitter Control Panel. . . . . . . . . . . . . . . . . . . .3-1

Main Menu “Hardware” Buttons. . . . . . . . . . . . .3-2

Graphical User Interface (GUI) . . . . . . . . . . . . . . .3-2

Global Status and Navigation. . . . . . . . . . . . . . . .3-3

GUI Home Page . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Drive Chain Main Menu. . . . . . . . . . . . . . . . . . . . .3-5

Drive Service . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Drive Meter Calibration. . . . . . . . . . . . . . . . . . . .3-6

Power Amp Main Menu . . . . . . . . . . . . . . . . . . . . .3-7

PA Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Module 3 strike Routine . . . . . . . . . . . . . . . . . .3-8

PA Meters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

PA Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

PA Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

PA Setup (Gain Balance). . . . . . . . . . . . . . . . .3-14

Output Main Menu . . . . . . . . . . . . . . . . . . . . . . . .3-15

Output Service . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

Module Phasing Procedure. . . . . . . . . . . . . . . . .3-18

Output Setup . . . . . . . . . . . . . . . . . . . . . . . . . .3-19

Forward and Reflected Power Calibrations . . . .3-20

Power Supply Main Menu . . . . . . . . . . . . . . . . . .3-21

PS Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

AC Mains Meter Calibration. . . . . . . . . . . . . .3-22

System Main Menu. . . . . . . . . . . . . . . . . . . . . . . .3-23

Control System. . . . . . . . . . . . . . . . . . . . . . . . . .3-24

System Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-25

System Service. . . . . . . . . . . . . . . . . . . . . . . . . .3-26

System Setup . . . . . . . . . . . . . . . . . . . . . . . . . .3-27

System Configuration . . . . . . . . . . . . . . . . . .3-28

Control Setup . . . . . . . . . . . . . . . . . . . . . . . .3-28

Touch Screen Calibration . . . . . . . . . . . . . . .3-29

Software Revisions (SW REVs) . . . . . . . . . . .3-31

Hardware Revisions . . . . . . . . . . . . . . . . . . .3-31

GUI Menu Structures . . . . . . . . . . . . . . . . . . . . . .3-32

Section 4

Theory of Operation

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Block Diagram Descriptions. . . . . . . . . . . . . . . . . .4-1

Transmitter Control System . . . . . . . . . . . . . . . . . .4-2

Active Logic Symbols . . . . . . . . . . . . . . . . . . . . .4-3

Micro Module. . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

CPLD, Complex Programmable Logic Device . . 4 -4

I/O Expansion . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

1

Table of Contents (continued)

Life Support Backup. . . . . . . . . . . . . . . . . . . . . 4-4

Controller Area Network (CAN) Bus. . . . . . . . . 4-5

System Control Bus. . . . . . . . . . . . . . . . . . . . . . . 4-6

Main Controller. . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Transmitter Control . . . . . . . . . . . . . . . . . . . . . 4-8

Graphical User Interface (GUI) . . . . . . . . . . . 4-8

Remote Controls . . . . . . . . . . . . . . . . . . . . . . 4-8

Life Support Mode, Main Controller . . . . . . . . 4-9

Manual RF MUTE . . . . . . . . . . . . . . . . . . . . . . 4-9

External I/O Board . . . . . . . . . . . . . . . . . . . . . . . 4-9

External Interlocks . . . . . . . . . . . . . . . . . . . . . 4-10

RF Mute Interlock . . . . . . . . . . . . . . . . . . . . . 4-11

Transmitter RF System . . . . . . . . . . . . . . . . . . . . 4-12

CZ500F RF System Description. . . . . . . . . . . . 4-12

CZ1000F RF System Description. . . . . . . . . . . 4-13

ApexR Exciter. . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Backplane Interface Board . . . . . . . . . . . . . . . . 4-14

Control Distribution . . . . . . . . . . . . . . . . . . . . 4-14

Low Voltage Power Supply Distribution . . . . 4-14

PA Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Phase and Gain Board . . . . . . . . . . . . . . . . . . 4-16

Automatic Gain Control (AGC). . . . . . . . . . . 4-17

RF Pallets . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

RF Splitter and Combiner. . . . . . . . . . . . . . . . 4-18

Module Controller . . . . . . . . . . . . . . . . . . . . . 4-18

PA Module Circulators . . . . . . . . . . . . . . . . . . . 4-18

PA Module Combiner (CZ1000F only) . . . . . . 4-19

Combiner Isolation Load (CZ1000F only). . . 4-19

RF Monitor Board. . . . . . . . . . . . . . . . . . . . . . . 4-19

RF Detectors. . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Reject Load RF Detector (Relative). . . . . . . . 4-21

PA Module Phase Alignment. . . . . . . . . . . . 4-21

Precision RF Power Detectors . . . . . . . . . . . . 4-22

Normal Mode / Life Support Mode . . . . . . . . 4-22

Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

AC Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

PA Power Supply Module. . . . . . . . . . . . . . . . . 4-23

Low Voltage Power Supply (LVPS) . . . . . . . . . 4-23

Power Supply Monitor Board. . . . . . . . . . . . . . 4-24

LVPS Interface . . . . . . . . . . . . . . . . . . . . . . . . 4-24

PA Power Supply Monitoring and Control. . . 4-24

AC Line Monitoring. . . . . . . . . . . . . . . . . . . . 4-24

Cabinet Cooling System Sensors . . . . . . . . . . 4-25

Ambient Temperature . . . . . . . . . . . . . . . . . 4-25

Air Pressure . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

PS Monitor LEDs. . . . . . . . . . . . . . . . . . . . . . 4-26

Section 5

Replacement Procedures

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

PA Module Removal . . . . . . . . . . . . . . . . . . . . . . . 5-1

CZ1000F PA Module Air Block. . . . . . . . . . . . . 5-1

PA Module Pallet Replacement. . . . . . . . . . . . . . . 5-3

Power Supply Module Replacement. . . . . . . . . . . 5-6

Circulator Removal/Replacement. . . . . . . . . . . . . 5-7

Blower Assembly Removal. . . . . . . . . . . . . . . . . . 5-9

Section 6

ISP (In-System Programming)

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Installing the ISP Program. . . . . . . . . . . . . . . . . . . 6-2

ISP Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Control System ISP Procedure . . . . . . . . . . . . . . 6-3

PA Module ISP Procedure . . . . . . . . . . . . . . . . . 6-8

ISP Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Section 7

Parts List

Parts List Index . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

2

Ranger ™ Mobile Series

Section 1 Introduction

1.1 Purpo se of This Manual

This technical manual contains the information pertaining to the Ranger™ Mobile

Series UHF solid-state transmitter, with Apex exciter, featuring FLOR technologies.

The various sections of this technical manual provide the following types of

information.

• Section 1, Introduction, provides general manual layout, frontispiece, equipment

description, block diagram and performance specifications.

1

• Section 2, Installation/Initial Turn-on, provides physical and electrical installation

procedures for the transmitter and RF systems and basic remote control connections.

• Section 3, Operation/Adjustments, provides information encompassing all uses of the

Graphical User Interface or GUI. These include:

a. Operation and navigation information for the Graphical User Interface and front

panel controls.

b. Since almost all alignments are done from the GUI, this section also provides for

all alignment procedures which are done using the GUI

c. Lastly, it provides information on the use of the GUI for diagnostics and trouble-

shooting of all faults which will show up on the GUI.

• Section 4, Theory of Operation, provides block diagram and detailed theory of opera-

tion.

• Section 5, Replacement Procedures, provides procedures for replacement of PC

boards and mechanical components and any alignments which may be required as a

result of the replacement.

• Section 6, ISP (In-System Programming), provides procedures for the use of the ISP

software for updating transmitter firmware.

• Section 7, Parts List, provides a parts list for the overall transmitter as well as indi-

vidual modules.

10/19/07 888-2687-001 1-1

WARNING: Disconnect primary power prior to servicing.

Section 1 Introduction

1.2 General Description

This section contains a general description of the Ranger™ Mobile Series Solid State

UHF Digital television transmitters featuring FLOR Technologies. Included in this

section are descriptions of the:

• Control System

• Power Amplifier

• System Block Diagram

• System Specifications

Ranger™ Mobile Series solid state UHF FLO™ transmitters share many of the unique

features and field-proven benefits that have made Harris digital transmitters the

industry standard. Ranger transmitters employ ultra-reliable air-cooled LDMOS FET

power amplifier modules and the Harris APEX exciter. A redundant control system

combined with a serial bus architecture assure the highest levels of reliability and on-air

availability.

Ranger ™ Mobile Series

Transmitter Features:

• Low loss external filter.

• Remote transmission monitoring with eCDi

TM

• Real-Time Adaptive Correction (RTAC) system provides continuous and automatic

correction for linear distortions including mask filter

• Straightforward diagnostics using a 320x240 pixel color touch-screen

• On air servicing of PA modules (1kW model)

• Air-cooled amplifiers for ease of installation and maintenance

• Field-proven Apex Exciter using FLO

R

technologies.

• Standard Parallel remote control interfaces

The Ranger Series™ transmitter is available in 2power levels as listed in T able 1-1. It is

also available with external (low loss) mask filters for applications where the full 500W

or 1000W output (after the filter) is required.

1-2 888-2687-001 10/19/07

WARNING: Disconnect prim ary power prior to servic ing.

Ranger ™ Mobile Series

Section 1 Introduction

Table 1-1 Ranger ™ Mobile Series Transmitter Models

Power

Tx Models PA Modules Power Supplies

CZ500F 1 1 375W External

CZ1000F 2 1 750W External

NOTE: All power levels given in average power assuming the use of FLO technology modulation

before Filter Filter location

The Ranger ™ Mobile series transmitter is a low

power FLOR transmitter which utilizes

components from existing, proven transmitter

designs. The PA Modules and power supply are

from the Diamond Series UHF DTV transmitter

and as such are completely interchangeable with

a Diamond transmitter or Sigma IOT transmitter

with Diamond Drive IPA. This provides the

opportunity for upgrade to a higher power

Diamond or Sigma IOT transmitter in the future

where the PA modules, power supply and the

Apex exciter can be transferred to the new

transmitter or used as spares.

The control system is adapted from the state-ofthe-art Atlas Series UHF (COFDM) solid state

transmitter using a very simple control panel and

easy to use Graphical User Interface or GUI.

It consists of a single cabinet with a single power

supply and one or two P A modules depending on

the model.

Figure 1-1 at right, shows a front view of the

Ranger transmitter. All models look identical due

to the use of false module covers for the 2 or 3

right-hand slots.

Figure 1-1 Transmitter Front View

10/19/07 888-2687-001 1-3

WARNING: Discon nect primar y power prior t o servicing .

Section 1 Introduction

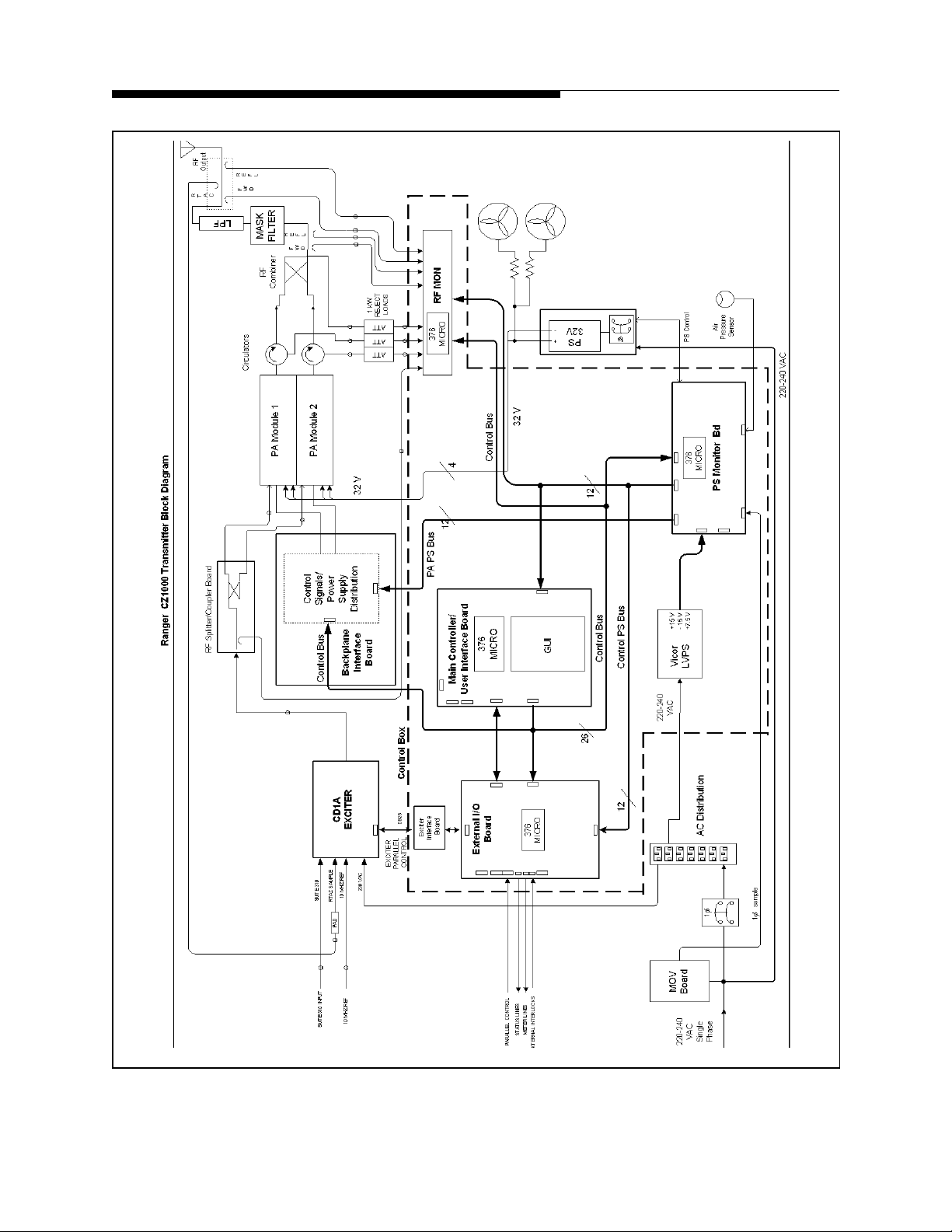

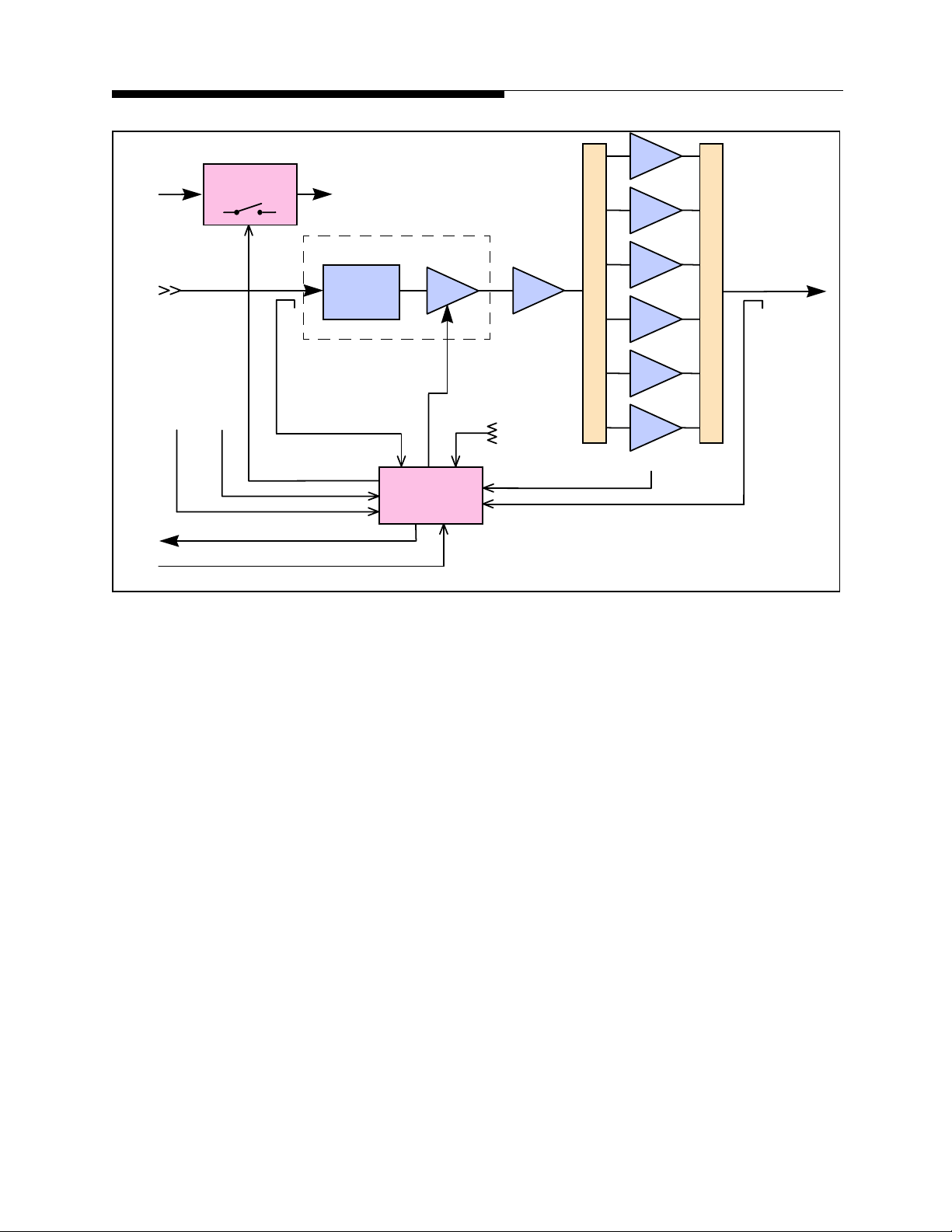

1.2.1 System Block Diagrams

The Figure 1-2 contains the system block diagram of the CZ1000F Ranger T ransmitter.

The CZ500F has only 1 PA Module and is therefore identical with the following items

deleted: (CZ500F and CZ1000F both use external filters)

• PA Module 2, along with its circulator and reject attenuator

• 3dB Hybrid Combiner and Reject attenuator

NOTE:

For components locations refer to Figure 2-11 on page 2-21 and Figure 2-12 on

page 2-22.

Ranger ™ Mobile Series

1-4 888-2687-001 10/19/07

WARNING: Disconnect prim ary power prior to servic ing.

Ranger ™ Mobile Series

Section 1 Introduction

Figure 1-2 Ranger Series™ System Block Diagram

10/19/07 888-2687-001 1-5

WARNING: Discon nect primar y power prior t o servicing .

Section 1 Introduction

1.2.2 Transmitter Control System

The transmitter uses a distributed architecture control system. This means that each

transmitter sub-system is responsible for its own monitoring and protection and simply

reports back to the Main Controller for display on the GUI (Graphical User Interface) or

to a remote interface. The heart of the system is the 376 Micro Module which is used in

all of the transmitter systems for control, monitoring and protection. The Micro Module

is used on each of the following controllers and sub-systems:

a. Main Controller Board - This board is responsible for transmitter control and

monitoring. However, with the distributed control architecture, it is not directly

responsible for protection of the individual transmitter components. It merely

gathers all status and fault data from the individual sub-systems and reports that

information to the operator. The Main Controller is responsible for system level

control (issues which effect multiple systems) since it is the only part of the control system which can monitor the entire transmitter.

b. RF Monitor Board - Responsible for cabinet VSWR protection and monitoring of

combiner reject loads. Reports directly to the Main Controller.

Ranger ™ Mobile Series

c. Power Supply Monitor Board - Responsible for control and monitoring of the PA

power supply and distribution of the low voltage. Also responsible for monitoring

the cooling system including temperature and air pressure. Reports directly to the

Main Controller.

d. External I/O Board - Provides all customer interface connections including paral-

lel remote control. Reports directly to the Main Controller.

e. PA Module Controllers (1 in each module) - This is not actually a 376 micro

module but is a micro controller and is responsible for protection and control of

the PA Module. Reports directly to the Main Controller Board via the CAN bus.

1.2.2.1 Graphical User Interface

The front panel user interface is a 1/4 VGA, LCD touchscreen display. The touchscreen

display is used to monitor the transmitter. Hardware buttons for the primary transmitter

functions such as ON, OFF , RAISE and LOWER are provided on the overlay panel next

to the display.

1.2.2.2 Control System Communications

The control system uses a serial communications system called a CAN bus. CAN stands

for Controller Area Network. The CAN bus is a closed loop serial network operated by

the Main Controller Board. Each circuit board and module connected to the CAN bus is

1-6 888-2687-001 10/19/07

WARNING: Disconnect prim ary power prior to servic ing.

Ranger ™ Mobile Series

considered a node and therefore has a specific address. This allows the Main Controller

to gather information from all parts of the transmitter and display it on the GUI. One big

advantage of the CAN bus is that it requires only 2 wires of the system control ribbon

cable, eliminating a large amount of discret e wiring which would otherwise be required.

For redundancy, the CAN bus is backed up by parallel, hardwired, control lines that

allow the transmitter to stay on the air even if the CAN bus fails. The parallel control

lines also provide the instantaneous OFF and RF MUTE commands necessary for

transmitter protection.

1.2.2.3 In-System Programming or ISP

The use of the CAN bus for communication between the various Micro Modules in the

transmitter also allows for easy updating of the software used in each transmitter subsystem via a serial port connection to an external computer. This is referred to as InSystem Programming or ISP.

Section 1 Introduction

The real benefit of In-System Programming is that it allows any or all of the transmitter

software to be updated without removing or replacing any firmware ICs. The Harris ISP

program is provided on the CD-ROM accompanying this manual along with all of the

transmitter software as it shipped from the factory. The Harris ISP program is easy to

use and it only takes a few minutes to load or update software.

NOTE:

Software does not need to be loaded into the transmitter unless new components

are installed or an update is sent from Harris. The transmitter , as shi pped from the

factory, is preloaded and ready to run.

1.2.2.4 Remote Control

The Ranger™ Mobile Series transmitter has all of the standard parallel remote control,

status and analog metering connections for use with a third party remote control system.

For a complete listing of the remote control connections, see Table 2-1, Table 2-2 and

Table 2-3 at the end of section 2.

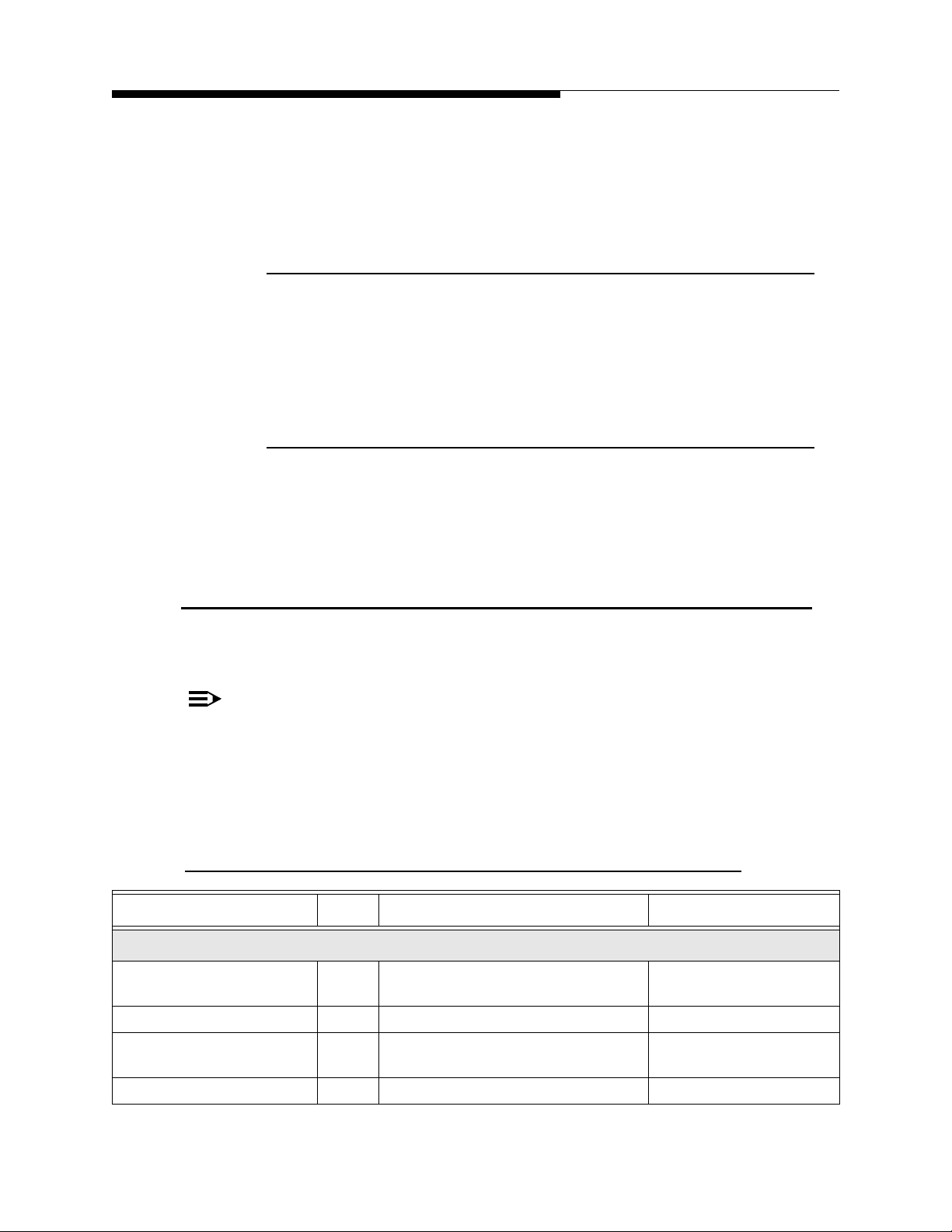

1.2.3 PA Module

The Ranger Mobile Series™ P A Module utilizes the same LDMOS amplifier mod ule as

used in the Diamond Series DTV transmitter. Each PA Module will produce up to

400W average power output. A block diagram of the P A module is shown in Figure 1-3.

10/19/07 888-2687-001 1-7

WARNING: Discon nect primar y power prior t o servicing .

Section 1 Introduction

Ranger ™ Mobile Series

AB

32V

SS RELAY

DC

SHORT

+32V

RF IN

MON

TO MAIN CONTROLLER

MODULE ENABLE

ON/OFF

Pin

SWITCHED

+32V

PHASE

&

AB A

GAIN

BIAS

TEMP

LDMOS FAULT

CONTROL

BOARD

Figure 1-3 PA Module Block Diagram

AB

AB

AB

AB

AB

RF

OUT

FWD

Each PA module consists of the following components:

a. PA Module Controller Board - Responsible for all monitoring and protection of

the module. Reports to the transmitter Main Controller via the CAN bus but is

also connected to the parallel control lines in case the CAN bus is not operational.

Also provides for FET switching and distribution of the +32Vdc power to the

driver and PA pallets and sensing of driver and pallet currents.

b. Phase and Gain Board - Provides for module phase and gain adjustments to mini-

mize the PA module combiner reject power for the CZ1000F.

c. One LDMOS Driver Pallet - Provides enough power to drive the 6 way splitter

and the inputs to the power amplifier pallets.

d. Six-way Pallet Splitter and Combiner.

e. Six (6) LDMOS Amplifier Pallets - When combined, they provide up to 400

watts of average power at the output of the module. These pallets are field

replaceable.

f. RF Output Directional Coupler - Samples both Forward and Reflected power for

metering, module ALC and module VSWR protection.

1-8 888-2687-001 10/19/07

WARNING: Disconnect prim ary power prior to servic ing.

Ranger ™ Mobile Series

Each Ranger Series™ PA Module is a self-contained transmitter (except for the power

supply) with its own internal control, monitoring and protection. The modules only

receive basic On/Off, Mute, Restart, Phase and Gain commands from the transmitter

control system. This means that each module will protect itself without relying on the

system controller.

1.2.4 Power Supplies

A single +32 Vdc switching power supply is used to provide the DC voltage to the PA

modules within each PA cabinet. The power supply can provide power for 1 or 2 PA

modules. The control system in the PA Cabinet is powered by a self contained low

voltage power supply with +/-15Vdc and +7.5Vdc outputs.

1.2.5 Apex™ Exciter

For information on setup and operation of the Apex Exciter utilizing FLOR

technologies refer to the separate exciter manual, 888-2604-001. The exciter manual is

bundled with the transmitter documentation for shipment

Section 1 Introduction

1.3 General Specifications

Table 1-2 provides the performance specifications for the Ranger series transmitters.

NOTE:

All specifications subject to change without notice

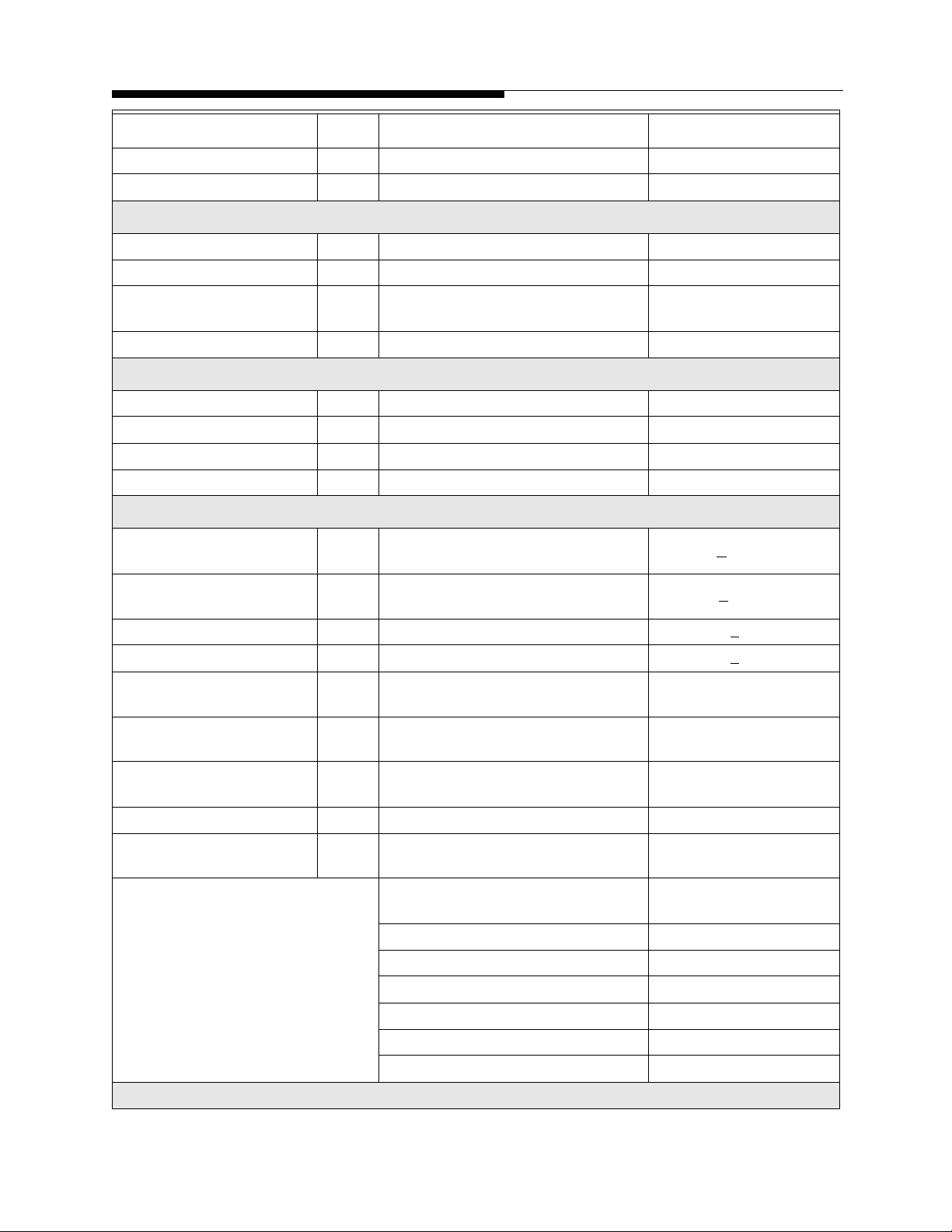

Table 1-2 Ranger Performance Specifications

Item Units Conditions Value

General

Frequency Range Mhz Any specified FCC

Channel 14-69

Channel Bandwidth Mhz FLO Technologies COFDM standard 6, 7, or 8 Mhz

470-806 Mhz

Output Power before System

Filters

RF Load Impedance Ohms 50 Ohms

10/19/07 888-2687-001 1-9

WARNING: Discon nect primar y power prior t o servicing .

W At 36 dB shoulders (measured +/-3.00

MHz from center of 6 MHz channel)

CZ500F - 550W

CZ1000F - 1090W

Section 1 Introduction

Item Units Conditions Value

RF Load VSWR Over specified TV channel 1.1:1

Output Connector 1-5/8” EIA Flanged

Data Input

Input Rate Mb/s 270

Impedance Ohms 75

Ranger ™ Mobile Series

Standard DVB-

ASI

Connector BNC Female

External Frequency Reference Input

Frequency Mhz 10 Mhz

Impedance Ohms 50 Ohms

Level dBm Sinusoidal Waveform 0 to +10 dBm

Connector BNC Female

Performance

Modulation Error Ration

(MER)

Shoulder Level dB

Carrier Suppression dB > 20

I/Q Imbalance dB Residual Sideband Level > 50

Frequency Tolerance (without

external reference)

Frequency Tolerance (with

external reference)

Frequency Tolerance (with

external reference)

dB Measured at transmitter output

Measured at transmitter output before

filter, for 6 MHz channel, F

Hz for at least 24 hrs. 1 x 10

Hz for at least 24 hrs. 1 x 10

Hz for at least 24 hrs. 1 x 10

+/- 3 MHz

c

EN 50083-9

> 3 3dB

> 36 dB

-8

-9

-9

Pilot Frequency Stability Hz With External Reference Less than +/- 3 Hz

Stability of Output Power %

Phase Noise

Spurious Radiation

Over entire operating temperature range

and indefinite time period

Frequency Offset Relative to Carrier

Frequency

100 Hz -80

1 kHz -90

10 kHz -95

100 kHz -110

1 MHz -120

> 1 MHz -120

+/-10%, or less

Phase Noise

1-10 888-2687-001 10/19/07

WARNING: Disconnect prim ary power prior to servic ing.

Ranger ™ Mobile Series

Item Units Conditions Value

Section 1 Introduction

Conducted Spurious

Radiation

Measured at transmitter outptut before

filter

< -30

AC Line

AC Line Voltage VAC Single Phase 50/60 Hz 208/240 VAC

AC Line Voltage Variation % +/-10%

Power Factor > 0.97

Overall Efficiency (Typical) % AC power to RF average power 20% (for CZ500 & 1000F)

Power Consumption

(Typical)

kW 2.5kW for CZ500F

5 kW, for CZ1000F

Environmental

Operational Temperature

Range

Operational Relative

Humidity

Guaranteed Specification

Temperature Range

Storage Temperature

Maximum Altitude Ft. AMSL (Above Mean Sea Level) 7500

o

C Derate 2 degree C per 300m AMSL 0 - 45

% Non-condensing 0 - 90

o

C 5-45

o

C -20+60

Cooling M ethod Air Cooled

Residual Heat Transferred to

Room

Acoustic Noise dBA Measured 1m from front of cabinet <67 dBa

kW Normal operating conditions

4.0 kW, for CZ1000F

Physical

Dimensions In Cabinet only 72H x 27.6W x 40D

Weight Lbs Does not include options

Cl-PS-02-003 Ranger Performance Spec

2.0kW for CZ500F

CZ500F 600 Lbs

CZ1000F 1000 Lbs

10/19/07 888-2687-001 1-11

WARNING: Discon nect primar y power prior t o servicing .

Section 1 Introduction

Ranger ™ Mobile Series

1-12 888-2687-001 10/19/07

WARNING: Disconnect prim ary power prior to servic ing.

Ranger ™ Mobile Series

Section 2 Installation / Initial Turn-On

2.1 Introduction

This section includes the information necessary for installation and initial turn on of a

Ranger™ Mobile Series FLOR, solid state UHF transmitter. Information is included for

single and dual PA module configurations. Due to the modular nature of the Ranger, all

models have the same basic cabinet level installation and testing procedures, with

additional information given for dual PA module testing in CZ1000F.

NOTE:

For component locations, refer to Figure 2-11 and Figure 2-12 at the end of this

section.

2

2.1.1 Installation Drawings

The following is a list of documentation that ships with the transmitter. This

documentation should be available for reference during the commissioning process.

The top level Document Package numbers for each transmitter model are shown below:

• CZ500F & CZ1000F: 988-2687-001

A Document Package includes:

1. 888-2685-001 Commissioning Manual (this technical manual)

2. 888-2497 RangerTM Mobile Series Transmitter Manual

3. 888-2604-001 Apex Exciter using FLOR Technology Operating Manual

It is recommended that you look through the drawing package to familiarize yourself

with the information available. Although drawings are provided for all assemblies in the

transmitter, most of the installation and planning information is given in the following

drawings (in the supplied drawing package):

10/19/07 888-2687-001 2-1

WARNING: Disconnect primary power prior to servicing.

Section 2 Installation / Initial Turn-On

a. Trans mitter Outline Drawing - 843-5560-071 - S hows physical connection points

for AC and control conduits and RF output. Also gives cabinet dimensions,

required cabinet clearances and a table of basic requirements for both models.

b. Transmitter Wiring Diagram - 843-5560-001 - Interconnection wiring diagram

for all assemblies inside the transmitter cabinet.

c. AC Flow Diagram - 843-5560-098 - Shows external AC wiring requirements

along with minimum wire and breaker sizing for each model.

d. RF Flow Diagram - 843-5560-097 - Shows external RF connections and possible

layout for patch panel and dummy load.

e. Ranger External I/O Connections - 843-5560-105 - Shows connections to the

External I/O board for an RF patch panel or motorized switch.

The included CD-ROM contains:

1. Transmitter control software files of the same revision as loaded into the

transmitter at the factory

2. ISP (In-System Programming) software application which is used to install

software upgrades into the transmitter controllers.

Ranger ™ Mobile Series

3. An Acrobat (pdf) version of the transmitter Technical Manual.

2.2 Ins tallation Checkboxes

Located to the left of each important step in the installation procedure is a checkbox like

the one to the left of this paragraph. As each step in the procedure is completed, the box

should be checked. This provides a quick confidence check at the end of the procedure

that no steps were skipped. The primary goal of each step is also in bold letters, with

the rest of the paragraph being support information toward that goal.

NOTE:

In case of discrepancy between the connections listed in the schematics versus

the information given in this installation section, the wiring information in the

schematics should be considered the most accurate. All connections listed in this

section should be verified with the schematics before initial turn on.

2.3 Transmitter Cabinet Placement

The transmitter cabinet should be placed where it will have approximately 3 feet of

clearance on each side and in the back. The front of the transmitter should have a

clearance of at least 5 feet to allow for access to the PA and power supply modules. The

2-2 888-2687-001 10/19/07

WARNING: Disconnect prim ary power prior to servic ing.

Ranger ™ Mobile Series

Section 2 Installation / Initial Turn-On

transmitter outline, 843-5560-001 drawing gives all cabinet dimensions and required

clearances as well as conduit connections and cabinet layout.

Remove the transmitter from the wooden pallet. The transmitter is bolted to the

pallet with 2 bolts. One is accessible via the back door, the other can be removed by

pulling the PA Power supply out the front of the cabinet. The power supply is held in

place by the 2 screws, one on each side of the PS breaker.

Use shims or flat washers to make sure the transmitter is level and solid (not

rocking).

Secure the transmitter to the floor as required by local codes.

2.4 Transmitter AC Connection

!

WARNING:

DISABLE AND LOCK OUT STATION PRIMARY POWER BEFORE PRIMARY POWER

CABLES ARE CONN ECTED TO THE EQUIPMENT.

NOTE:

The Ranger transmitter is equipped for single phase 208/240Vac at 50/60Hz. If

voltage variations in excess of +/-10% are anticipated, the transmitter power

input must be equipped with automatic voltage regulators (optional equipment)

capable of correcting the mains voltage.

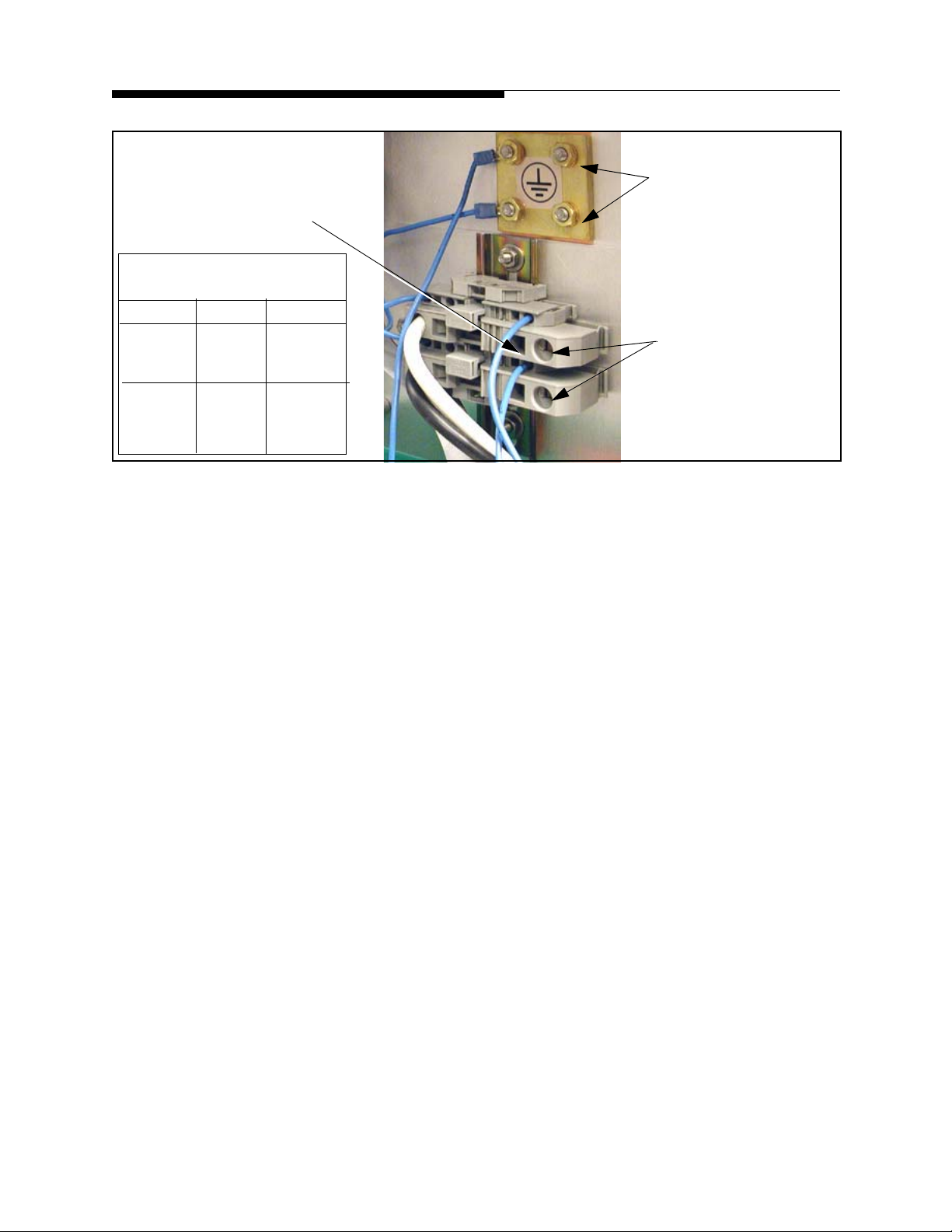

Connect the Primary AC conduit to the top of the transmitter cabinet. The top of

the transmitter cabinet has a pre-cut hole for a 3/4” conduit connection. For Conduit

connections to the transmitter refer to the Transmitter Outline Drawing 843-5560-071,

Top View. The AC input is the routed straight down to TB1, shown in Figure 2-1.

Connect the AC wires to TB1-2 and TB1-4. The AC Flow diagram shows ac wiring

to the transmitter along with recommended wire gauge and breaker size. Wire gauge

and breaker size are also given in the Figure 2-1.

Connect the safety ground wire to one of the terminals on the grounding block.

10/19/07 888-2687-001 2-3

WARNING: Discon nect primar y power prior t o servicing .

Section 2 Installation / Initial Turn-On

Place flat blade screwdriver into

square hole and gently pry toward

front of transmitter until connector

in round hole is open far enough

to insert the AC input wire

Recommended Wire and

Breaker Sizes:

Model Breaker Wire size

CZ500F 20A 10 awg

CZ1000F 40A 8 awg

Figure 2-1 AC and Safety Ground Connections

Ranger ™ Mobile Series

Safety Ground Connection

Safety Ground Connection

TB1 AC Connections

TB1 AC Connections

2-4 888-2687-001 10/19/07

WARNING: Disconnect prim ary power prior to servic ing.

Loading...

Loading...