Gastite FLASHSHIELD Installation Manual

DESIGN &

INSTALLATION GUIDE

Commercial

Industrial

Residential

FLASHSHIELD

& FLASHSHIELD

+

FLEXIBLE GAS PIPING

™

™

JANUARY 2019

INSTALLER INFORMATION & UPDATES

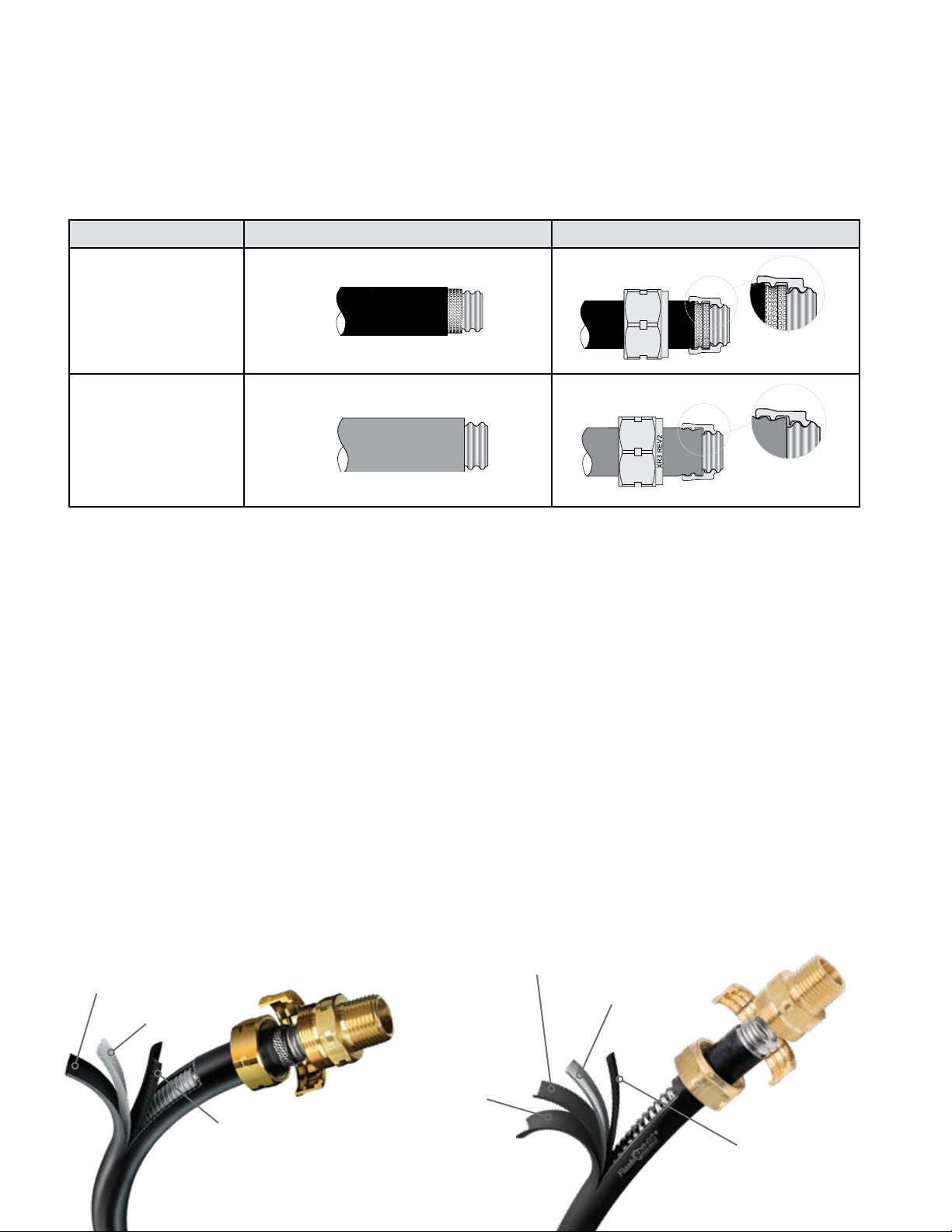

1) e XR3-series fitting is designed to work on Gastite and FlashShield CSSTs. However, CSST end-prep varies by

CSST product type. Reference the chart below for proper CSST end-prep and bushing placement for the product

you have selected.

PRODUCT CSST END-PREP BUSHING PLACEMENT

Two-Step

End-Prep

FlashShield™

CSST

One-Step

End-Prep

FlashShield+™

or Gastite

2) Licensed Installers Only. Every installer of FlashShield™, FlashShield+™, or Gastite® must first meet all applicable

qualifications in accordance with state and/or local requirements as established by the administrative authorities that

enforce the plumbing or mechanical codes where gas piping is installed.

®

CSST

3) Qualified Installers Only. In addition to be licensed in the jurisdiction, FlashShield™, FlashShield+™, or Gastite®

corrugated stainless steel tubing (CSST) flexible gas piping material must only be installed by an installer who has

been successfully trained through the FlashShield™ and Gastite® training program.

4) Check for Updates. Installers should check with their local distributor or at www.gastite.com for technical bulletins

or updated Design & Installation Guides for FlashShield™, FlashShield+™, or Gastite® every year.

5) Proper Installation. Sound engineering principles and practices must be exercised for the proper design of fuel gas

piping systems, in addition to compliance with local codes. e installation instructions and procedures contained

in this Design & Installation Guide must be strictly followed in order to provide a safe and effective flexible fuel gas

piping system or system modification. All installations must pass inspections by the local official having authority

prior to having the gas service turned on. All requirements of the local natural gas utility or propane supplier must

also be met.

FLASHSHIELD FLASHSHIELD+

Electrically Insulative

Polymer

Metallic Shield

High Tensile Polyester

Metallic Shield

Semi-conductive

Polymer

Electrically

Insulative

Polymer

Semi-conductive

Polymer

SECTION 1.0 INTRODUCTION

1.1 GENERAL USER WARNINGS ............................................................................................................. 1

1.2 LIMITATIONS OF THE GUIDELINES .................................................................................................. 3

1.3 STANDARDS, LISTINGS AND CODES ................................................................................................ 3

SECTION 2.0 SYSTEM DESCRIPTIONS & COMPONENTS

2.1 SYSTEM DESCRIPTIONS .................................................................................................................... 4

2.1.2 FLASHSHIELD™ SYSTEM DESCRIPTION ......................................................................................................... 4

2.1.3 FLASHSHIELD+™ SYSTEM DESCRIPTION ...................................................................................................... 5

2.2 COMPONENTS .................................................................................................................................. 6

2.2.1 CORRUGATED STAINLESS STEEL TUBING .................................................................................................. 6–7

2.2.2 FITTINGS ................................................................................................................................................... 8–9

2.2.3 MANIFOLDS ................................................................................................................................................ 10

2.2.4 MODULAR STUB SYSTEM ........................................................................................................................... 10

2.2.5 MOUNTING HARDWARE ..............................................................................................................................11

2.2.6 PIPE SUPPORT SYSTEM .................................................................................................................................11

2.2.7 STRIKE PROTECTION ................................................................................................................................... 12

2.2.8 SHUT- OFF VALVES AND QUICK CONNECTS ............................................................................................... 12

2.2.9 TOO LS ......................................................................................................................................................... 13

2.2.10 BONDING CLAMPS .................................................................................................................................... 13

2.2.11 SYSTEM IDENTIFICATION........................................................................................................................... 13

2.2.12 LINE REGULATORS ..................................................................................................................................... 14

SECTION 3.0 SYSTEM CONFIGURATION

3.1 CONFIGURATION............................................................................................................................16

3.1.1 I N T R O D U CTION ........................................................................................................................................... 16

3.1.2 SYSTEM REQUIREMENTS ............................................................................................................................ 16

3.1.3 REFERENCE DATA FOR PROPER SYSTEM SIZING .......................................................................................... 16

3.1.4 DETERMINING SYSTEM LAYOUT .............................................................................................................17-18

3.1.5 ALLOWABLE PRESSURE DROP ..................................................................................................................... 19

3.1.6 SIZING METHODS ................................................................................................................................... 19 -20

3.1.7 MODIFYING AN E XISTING SYSTEM ............................................................................................................. 20

3.2 SIZING PROCEDURES AND EXERCISES .......................................................................................... 20

3.2.1 SIZING EXAMPLES ....................................................................................................................................... 20

3.2.2 EX AMPLE 1: SERIES SYSTEM – 6"WC ................................................................................................... 21–22

3.2.3 EX AMPLE 2: PARA LLEL SYSTEM – 6"WC .............................................................................................. 23 –24

3.2.4 EX AMPLE 3: PARALLEL SYSTEM – 12-14"WC ....................................................................................... 25–26

3.2.5 EX AMPLE 4: DUAL PRESSURE SYSTEM – 2 PSI TRUNK AN D 8"WC APPLIANCE RUNS .......................... 27–28

3.2.6 EXAMPLE 5: MULTIPLE MANIFOLD SYSTEM ..........................................................................................29-30

3.2.7 EXAMPLE 6: SERIES SYSTEM – 7"WC - HYBRID ..................................................................................... 31-32

3.2.8 EX AMPLE 7: PARALLEL SYSTEM – 7"WC – HYBRID .............................................................................. 33–34

3.2.9 EXAMPLE 8: SUMMATION METHOD FOR PAR ALLEL SYSTEM – 7"WC – HYBRID ................................. 35–36

3.2.10 EXAMPLE 9: SUMMATION METHOD FOR SERIES SYSTEM – 6"WC .................................................... 37–39

3.2.11 EXAMPLE 10: COMMERCIAL ELEVATED PRESSURE SERIES SYSTEM – 2 PSI.........................................40 –41

SECTION 4.0 INSTALLATION PRACTICES

4.1 GENERAL PROVISIONS ................................................................................................................... 42

4.2 FIELD FITTING ASSEMBLY PROCEDURE ......................................................................................... 43

4.2.1 XR3 FIT TING TO FLASHSHIELD+ CSST ................................................................................................... 43– 44

4.2.2 XR3 FIT TING TO FLA SHSHIELD CSST ......................................................................................................45 -4 6

4.2.3 XR3 FITTING TO FLASHSHIELD CSST (WITHOUT STRIPPING TOOL) ........................................................ 47- 48

4.2.4 OTHER ACCESSORY INSTALLATION ............................................................................................................ 49

4.3 ROUTING ........................................................................................................................................ 50

4.3.1 VERTICAL RUNS .......................................................................................................................................... 50

4.3.2 HORIZONTAL RUNS ..................................................................................................................................... 50

4.3.3 INSTALLATION CLEARANCE HOLES ............................................................................................................ 50

4.3.4 CONCEALED FITTI NGS ................................................................................................................................ 51

4.3.5 MODIFICATIONS TO EXISTING SYSTEMS .................................................................................................... 51

4.3.6 OUTDOOR ................................................................................................................................................... 52

GASTITE DIVISION, TITEFLEX CORPORATION / 1116 Vaughn Parkway / Portland, TN 37148

800.662.0208 / www.gastite.com / gastite@gastite.com

iii

4.3.7 FIRE R ATED CONSTRUCTIONS ..................................................................................................................... 52

4.3.8 ROUTING THROUGH MASONRY MATERIAL ............................................................................................... 52

4.3.9 CLEARANCE FROM THE U NDERSIDE OF A ROOF DECK .............................................................................. 53

4.4 STRIKE PROTECTION ...................................................................................................................... 53

4.4.1 STRIKE PLATES ...................................................................................................................................... 53–54

4.4.2 STEEL CONDUIT .......................................................................................................................................... 55

4.5 METER ............................................................................................................................................ 55

4.6 APPLIANCE ..................................................................................................................................... 56

4.6.1 MOVEABLE APPLIANCE .............................................................................................................................. 56

4.6.2 DIRECT CONNECTION – NON-MOVEABLE APPLIANCES ............................................................................. 57

4.6.3 GAS CONVENIENCE OUTLET ...................................................................................................................... 57

4.6.4 SPECIAL APPLICATIONS ........................................................................................................................58– 62

4.7 MANIFOLD ..................................................................................................................................... 62

4.8 PRESSURE REGULATOR .................................................................................................................. 63

4.8.1 INTRODUCTION .......................................................................................................................................... 63

4.8.2 SIZING INSTRUCTIONS .......................................................................................................................... 63 –64

4.8.3 INS TAL L ATIO N ............................................................................................................................................ 65

4.8.4 PERFORMANCE ........................................................................................................................................... 66

4.8.5 REGULATOR OUTLET PRESSURE ADJUSTMENT ........................................................................................... 66

4.8.6 OVER-PRESSURIZATION PROTECTION ......................................................................................................... 66

4.9 UNDERGROUND INSTALLATIONS .......................................................................................... 67

4.10 ELECTRICAL BONDING OF CSST .................................................................................................. 68

SECTION 5.0 INSPECTION, REPAIR & REPLACEMENT

5.1 MINIMUM INSPECTION REQUIREMENTS ...................................................................................... 69

5.2 INSTALLATION CHECKLIST DESCRIPTION ...................................................................................... 70

5.3 REPAIR OF DAMAGED CSST .......................................................................................................... 71

5.3.1 DETERMINE DAMAGE ................................................................................................................................. 71

5.3.2 METHOD OF REPAIR.................................................................................................................................... 71

5.3.3 FLASHSHIELD™ JACKET REPAIR .................................................................................................................. 71

SECTION 6.0 PRESSURE/LEAKAGE TESTING

6.1 GENERAL GUIDELINES FOR PRESSURE TESTING ........................................................................... 72

6.2 ELEVATED PRESSURE SYSTEMS ..................................................................................................... 72

6.3 APPLIANCE CONNECTION LEAKAGE CHECK PROCEDURE........................................................... 73

SECTION 7.0 SIZING TABLES & PRESSURE DROP CHARTS

7.1 CSST CAPACITY TABLES—NATURAL GAS ............................................................................... 74–77

7.2 CSST CAPACITY TABLES—NATURAL GAS—ELEVATED PRESSURE ......................................... 78–79

7.3 CSST CAPACITY TABLES—PROPANE GAS ................................................................................ 80–82

7.4 CSST CAPACITY TABLES—PROPANE GAS—ELEVATED PRESSURE ......................................... 82–83

7.5 GASTITE

®

AND FLASHSHIELD™ CSST PRESSURE DROP TABLES ............................................ 84–87

7.6 IRON PIPE CAPACITY TABLES ........................................................................................................ 88

7.7 IRON PIPE PRESSURE DROP TABLES ......................................................................................... 89-92

7.8 REFERENCE DATA ........................................................................................................................... 93

SECTION 8.0 DEFINITIONS .................................................................... 94–95

SECTION 9.0 DIMENSIONAL & TECHNICAL REFERENCE DATA ................. 96

9.1 FLASHSHIELD™ SPECIFICATION SHEET ......................................................................................... 97

9.2 FLASHSHIELD+™ SPECIFICATION SHEET ....................................................................................... 97

SECTION 10.0 WARRANTY ......................................................................... 98

FLEXIBLE GAS PIPING TRAINING PROGRAM TEST ........................... 101-102

iv

GASTITE DIVISION, TITEFLEX CORPORATION / 1116 Vaughn Parkway / Portland, TN 37148

800.662.0208 / www.gastite.com / gastite@gastite.com

SECTION 1: INTRODUCTION / JANUARY 2019

SECTION 1.0 INTRODUCTION

1.1 GENERAL USER WARNINGS

roughout the guide, the term FlashShield™ will apply to both FlashShield™ and FlashShield ™ CSST systems,

except where FlashShield ™ is specifically referenced.

e installation of FlashShield™ Flexible Gas Piping must be performed by a qualified installer who has successfully

completed the FlashShield™ training program. Certification training is available through qualified distributors, and at

www.gastite.com. e installer must meet all qualifications and requirements to install gas piping as required by the local

administrative authority. Improper installation or operation of a FlashShield™ Flexible Gas Piping system may result in fire,

explosion or asphyxiation.

WARNING: is product can expose you to chemicals including Lead, and Nickel, which are known to the

State of California to cause cancer and birth defects or other reproductive harm. For more information go to

www.P65Warnings.ca.gov.

is document provides the user with general guidance when designing and installing fuel gas piping using FlashShield™

Flexible Gas Piping. is guideline must be used in conjunction with all applicable building standards and codes. In the

event that there is a conflict between this guideline and local code the more stringent requirement will take precedence.

e use of fuel gas can be dangerous. Special attention must be given to the proper design, installation, testing and

application of the gas piping system. Sound engineering practices and principles must be exercised, as well as diligent

adherence to the proper installation procedures to ensure the safe operation of the piping system. All installed systems must

pass customary installation inspections by the local building official having authority prior to being placed into service.

Only the components provided or specified by Gastite® as part of the FlashShield™ flexible fuel piping system are to be

used in the installation. Use of components from other flexible gas piping systems other than those specified as part of

the FlashShield™ system is prohibited and may result in poor system performance and serious bodily injury or property

damage. Where additions, repairs or replacements involve corrugated stainless steel tubing systems from manufacturers

other than Gastite Division, the systems should be joined using standard pipe fittings at the interface.

is manual cannot take into account all situations or locations in which FlashShield™ flexible gas piping will be installed.

Accordingly, installers should also take into account guidance provided by the National Fuel Gas Code, ANSI Z223.1/

NFPA-54, National Standard of Canada, Natural Gas and Propane Installation Code B149.1, the Uniform Plumbing

Code, the International Code Series, the Federal Manufactured Home Construction and Safety Standards, 24 CFR Part

3280, the Manufactured Housing Construction and Safety Standards, ICC/ANSI 2.0 or the Standard on Manufactured

Housing, NFPA 501. Gastite Division shall have no responsibility for any misinterpretation of the information contained

in this guide or any improper installation or repair work or other deviation from procedures recommended in this manual,

whether pursuant to local building codes or engineering specifications or otherwise.

Gastite Division makes no representation or warranty, and nothing contained in this manual shall imply that this manual

contains the best or the only approved method for installing corrugated stainless steel piping systems or that this manual’s

contents are appropriate for all circumstances. In the event that there is a conflict between this guideline and local code the

more stringent requirement will take precedence. Performance of accessory devices, such as pressure regulators and shut

off valves should be reconfirmed by contacting the accessory device manufacturer and receiving the latest technical data on

sizing, installation and performance.

GASTITE DIVISION, TITEFLEX CORPORATION / 1116 Vaughn Parkway / Portland, TN 37148

800.662.0208 / www.gastite.com / gastite@gastite.com

Continued...

1

SECTION 1: INTRODUCTION / JANUARY 2019

1.1 GENERAL USER WARNINGS (CONTINUED)

A FlashShield™ Flexible Gas Piping system offers advantages over other gas delivery systems because of its corrugated

design. In contrast to rigid steel pipe, FlashShield™ does not require intermediate joints in most installations because the

tubing is capable of being installed in one continuous run, reducing not only the total number of joints, but also the

potential for leaks at joints. FlashShield’s flexibility also affords more installation options because an installer can avoid

existing obstacles, and it eliminates the repetitive measuring, cutting, threading and joint assembly that is common with

installation of rigid steel piping systems. FlashShield™ flexibility offers even further safety advantages in geographic areas

that are prone to seismic activity because the tubing is able to move as the ground or the structure shifts.

While FlashShield™ provides significant advantages over more rigid gas delivery systems, its flexible design may make it

more likely than steel pipe to be punctured by a nail or other sharp objects, or damaged by other extraordinary forces such

as lightning strike, depending on the circumstances.

Corrosive substances: Steel piping, brass fittings and valves can be corroded by various chemical substances which may be

present on a jobsite or in a structure. Chlorinated compounds can cause pitting and crevice corrosion of stainless steel.

Ammonia and other nitrogenous compounds can cause stress corrosion cracking of brass. FlashShield's jacket system

provides protection from many harmful substances and should remain intact over the lengths of stainless steel tubing to

maintain this protection.

While not exhaustive, the list below provides guidance of substances which should not come into contact with stainless

steel or brass. If there is a question about the suitability of a certain substance in the environment, the user should refer to

the ingredient list or contact the manufacturer.

Chlorinated compounds (chloride, chlorite, chloric, chlorous, chloro, chlorate):

• Some household soaps*

• Masonry cleaner (Muriatic acid)

• Soldering flux

• Bleach

• Pool chemicals

• Ice melt

• Soils, soil water, concrete

Amonia and ammonium containing compounds:

• Household cleaners

• Fertilizers

Nitrogenous compounds, such as amines:

• Herbicides, pesticides, fungicides, insecticides

* Some household soaps that contactors have used to make leak check solution may contain chlorides which can cause

corrosion to metallic components. Only use leak test solution which are labeled as non-corrosive, for gas piping systems.

Caution: Tube ends are sharp, use care when handling.

2

GASTITE DIVISION, TITEFLEX CORPORATION / 1116 Vaughn Parkway / Portland, TN 37148

800.662.0208 / www.gastite.com / gastite@gastite.com

SECTION 1: INTRODUCTION / JANUARY 2019

1.2 LIMITATIONS OF THE GUIDELINES

is document is intended to aid the professional gas installer in the design, installation and testing of fuel gas piping

systems using corrugated stainless steel tubing (CSST) for residential housing, commercial and industrial buildings.

It would be impossible for this guideline to anticipate and cover every possible variation in building configurations,

construction styles, appliance loads and code restrictions. erefore, there will be applications that will not be covered by

this guideline. For applications that go beyond the scope of this guideline, the installer should exercise sound engineering

principles and practices and/or contact Gastite for engineering assistance.

e techniques outlined within this guideline are recommended practice for generic applications. ese practices must be

reviewed for compliance with all applicable local fuel gas and building codes. In the event that there is a conflict between

this guide and local code, the more stringent requirement will take precedence.

Using components from other flexible gas piping systems other than those specified as part of the FlashShield™ system

is prohibited and may result in poor system performance and serious bodily injury or property damage. Additional

information pertaining to gas piping systems is available from your local gas utility or propane supplier. Please visit the

Gastite web site at www.gastite.com for additional updates and technical bulletins.

1.3 STANDARDS, LISTINGS AND CODES

FlashShield™ corrugated stainless steel tubing systems comply with the following standards, listings and model codes.

STANDARDS

ANSI LC1/CSA 6.26 – Fuel Gas Piping Systems Using Corrugated Stainless Steel Tubing (CSST)

ANSI LC1/CSA 6.26 – 25 PSI operating pressure rating

ANSI LC1/CSA 6.26 Sec. 5.16 – Arc Resistant (AR) Jacket Rating

ICC-ES PMG LC1027 – Protective Jacketed CSST, A Minimum 36-Coulomb Charge Transfer

LISTINGS

• CSA – CSA International - Certificate No. 2728525

• ICC – International Code Council – Evaluation Report Number PMG-1019, PMG-1155

• IAPMO – International Association of Plumbing and Mechanical Officials – File Number 3250, Report #0239

CODE COMPLIANCE

• ICC – International Code Series

• Canada – National Gas & Propane Installation Code B149.1

• NFPA – National Fuel Gas Code (NFPA 54)

• UMC – Uniform Mechanical Code

• UPC – Uniform Plumbing Code

While every effort has been made to prepare this document in accordance with all regional model codes in effect at its

printing, Gastite cannot guarantee that the local administrative authority will accept the most recent version of these

codes. It is the ultimate responsibility of the installer to determine suitability and acceptance of any building component

including gas piping. Gastite assumes no responsibility for labor or material for installations made without prior

determination of local code authority acceptance.

GASTITE DIVISION, TITEFLEX CORPORATION / 1116 Vaughn Parkway / Portland, TN 37148

800.662.0208 / www.gastite.com / gastite@gastite.com

3

SECTION 2: SYSTEM DESCRIPTIONS & COMPONENTS / JANUARY 2019

SECTION 2.0 SYSTEM DESCRIPTIONS & COMPONENTS

2.1 SYSTEM DESCRIPTIONS

2.1.1 FLASHSHIELD™ SYSTEM DESCRIPTION

a) e FlashShield™ Flexible Gas Piping System has been tested in accordance with the American National Standard for Fuel

Gas Systems Using Corrugated Stainless Steel Tubing, ANSI LC1/CSA 6.26. is standard lists performance requirements

for certification of CSST systems for use with all recognized fuel gases, including Natural Gas and Propane. FlashShield™ is

also tested and listed in accordance with ICC-ES PMG LC1027, listing criteria for protective jacketed CSST.

• Electrically insulative polymer jacket

• Metallically shielded CSST

• Shield is electrically continuous through fitting joints.

• System uses corrugated stainless steel tubing (CSST) made of type 304 alloy, ASTM A240.

• e ANSI LC1 standard rates FlashShield for use at pressures up to 25 PSI.

• FlashShield™ is listed to the Arc Resistant (AR) tests of ANSI LC1/CSA 6.26 and ICC-ES PMG LC1027.

b) e tubing is connected using XR3 mechanical brass fittings.

• e self-flaring fitting creates a one step, reusable, metal-on-metal seal.

• Fitting creates metal shield-to-fitting electrical connectivity.

• e jacket is clamped by the fitting (Jacket-Lock™) thereby minimizing the risk of corrosives contacting the CSST.

• Fittings have standard NPT threads and may be used in combination with all approved fuel gas piping materials with

the pipe threads as the interface. System components such as manifolds, tees and stubouts may be fabricated from other

approved materials to be used with FlashShield™ flexible gas piping.

c) e multi-layered jacket is fabricated over the stainless steel tubing to provide a flexible, protective covering. e jacket

and metallic shield are added features of the tubing and do not affect the flaring/sealing process.

• Integrated metallic shield between insulative polymer outer cover and semi-conductive poly inner layer.

• e jacket is engineered with thermal and UV resistant material making it suitable for outdoor use.

• e jacket provides a smooth outside surface; this surface greatly aids in pulling the tube through tight building spaces.

• e polymer jacket blend contains flame and smoke additives making it ASTM E84 and CAN/ULC-S102.2 25/50 compliant.

d) e corrugated stainless steel tubing system has a number of essential hardware and design differences from conventional

gas piping using rigid steel pipe and copper tubing. ese differences are described as follows:

• In many applications, the tubing is sized for individual gas appliance loads and is, therefore, usually small in diameter.

e tubing may also be installed in a parallel fashion from a central distribution manifold rather than a series layout

commonly used for rigid pipe systems.

• Corrugated Stainless Steel Tubing is pulled through the structure similar in fashion to electrical wiring and therefore

requires different handling and installation techniques than rigid pipe.

• Rigid termination of the tube ends is required.

• Flexibility and strike plates protect the CSST allowing it to be run in concealed spaces.

4

GASTITE DIVISION, TITEFLEX CORPORATION / 1116 Vaughn Parkway / Portland, TN 37148

800.662.0208 / www.gastite.com / gastite@gastite.com

SECTION 2: SYSTEM DESCRIPTIONS & COMPONENTS / JANUARY 2019

2.1.2 FLASHSHIELD+™ SYSTEM DESCRIPTION

a) e FlashShield+™ Flexible Gas Piping System has been tested in accordance with the American National Standard

for Fuel Gas Systems Using Corrugated Stainless Steel Tubing, ANSI LC1/CSA 6.26. is standard lists performance

requirements for certification of CSST systems for use with all recognized fuel gases, including Natural Gas and Propane.

FlashShield+™ is also tested and listed in accordance with ICC-ES PMG LC1027, listing criteria for protective jacketed

CSST.

• Electrically insulative polymer cover.

• Metallically shielded CSST.

• Shield is electrically continuous through fitting joints (Arc-Trap™).

• System uses corrugated stainless steel tubing (CSST) made of type 304 alloy, ASTM A240.

• e ANSI LC1 standard rates FlashShield+ for use at pressures up to 25 PSI.

• FlashShield+

™ is listed to the Arc Resistant (AR) jacket tests of ANSI LCI/CSA 6.26 and ICC-ES PMG LC1027

b) e tubing is connected using XR3 REV2-series mechanical brass fittings.

• e self-flaring fitting creates a one step, reusable, metal on metal seal.

• Fitting creates metal shield-to-fitting electrical connectivity (Arc-Trap™).

• e jacket is clamped by the fitting (Jacket-Lock™) thereby minimizing the risk of corrosives contacting the CSST.

• Fittings have standard NPT threads and may be used in combination with all approved fuel gas piping materials

with the pipe threads as the interface. System components such as manifolds, tees and stubouts may be fabricated

from other approved materials to be used with FlashShield+™ flexible gas piping.

c) e metallic laminant jacket is fabricated over the stainless steel tubing to provide a flexible, protective covering.

e jacket is an added feature of the tubing and does not affect the flaring/sealing process.

• Integrated metallic shield between insulative polymer outer cover and semi-conductive poly inner layer.

• e jacket is engineered with thermal and UV resistant material making it suitable for outdoor use.

• e jacket provides a smooth outside surface; this surface greatly aids in pulling the tube through tight building spaces.

• e polymer jacket blend contains flame and smoke additives making it ASTM E84 and CAN/ULC-S102.2 25/50

compliant.

d) e corrugated stainless steel tubing system has a number of essential hardware and design differences from conventional

gas piping using rigid steel pipe and copper tubing. ese differences are described as follows:

• In many applications, the tubing is sized for individual gas appliance loads and is, therefore, usually small in diameter.

e tubing may also be installed in a parallel fashion from a central distribution manifold rather than a series layout

commonly used for rigid pipe systems.

• Corrugated Stainless Steel Tubing is pulled through the structure similar in fashion to electrical wiring and therefore

requires different handling and installation techniques than rigid pipe.

• Rigid termination of the tube ends is required.

• Flexibility and strike plates protect the CSST allowing it to be run in concealed spaces.

GASTITE DIVISION, TITEFLEX CORPORATION / 1116 Vaughn Parkway / Portland, TN 37148

800.662.0208 / www.gastite.com / gastite@gastite.com

5

SECTION 3: SYSTEM CONFIGURATION / JANUARY 2019

2.2 COMPONENTS

2.2.1 CORRUGATED STAINLESS STEEL TUBING

FLASHSHIELD™ CORRUGATED STAINLESS STEEL TUBING (CSST)

Part No. Description Pkg. Qty.

FS-8-250 1/2" FlashShield™ Corrugated Stainless Steel Tubing 250 Ft/Coil

FS-8-25 25 Ft/Coil

FS-8-50 50 Ft/Coil

FS-8-125 125 Ft/Coil

FS-8-500 500 Ft/Coil

FS-8-1000 1000 Ft/Coil

CSST

FS-8-1500 1500 Ft/Coil

FS-11-250 3/4" FlashShield™ Corrugated Stainless Steel Tubing 250 Ft/Coil

FS-11-25 25 Ft/Coil

FS-11-50 50 Ft/Coil

FS-11-125 125 Ft/Coil

FS-11-500 500 Ft/Coil

FS-11-1000 1000 Ft/Coil

FS-16-150 1" FlashShield™ Corrugated Stainless Steel Tubing 150 Ft/Coil

FS-16-50 50 Ft/Coil

FS-16-75 75 Ft/Coil

FS-16-300 300 Ft/Coil

FS-16-500 500 Ft/Coil

FS-20-150 1-1/4" FlashShield™ Corrugated Stainless Steel Tubing 150 Ft/Coil

FS-20-50 50 Ft/Coil

FS-20-75 75 Ft/Coil

FS-20-300 300 Ft/Coil

FS-24-150 1-1/2"

FS-24-50 50 Ft/Coil

FS-24-75 75 Ft/Coil

FS-32-150 2"

FS-32-50 50 Ft/Coil

FS-32-75 75 Ft/Coil

FlashShield™ Corrugated Stainless Steel Tubing 150 Ft/Coil

FlashShield™ Corrugated Stainless Steel Tubing 150 Ft/Coil

APPLICATION

• CSST flexible gas piping supplies natural gas or liquefied petroleum gas to appliances.

MATERIAL / SPECIFICATIONS

• Tubing: ASTM A240 Type 304 Stainless Steel.

• Jacket: Electrically insulative and UV resistant polymer, complying with requirements of ASTM E84 and CAN/ULC-S102.2 25/50

• Protective jacket system, complies with ICC-ES PMG LC1027

FEATURES AND BENEFITS

• Electrically insulative polymer cover.

• Metallically shielded CSST.

• Protective shield is electrically continuous through fitting joints.

• Metal shield layer dissipates and conducts electricity.

• No manufacturer required bonding.

• Flexibility means quick and easy installations. FlashShield™ installs 30-70% faster than traditional piping methods.

• Pre-marked by the foot, there’s no measuring, rigid pipe cutting or threading. is means less waste and fewer fittings.

• 75% fewer fittings in the average installation means a safer system, less leak potential and reduced callbacks.

• FlashShield™ CSST is lightweight — 250 feet of 1/2" CSST weighs approx. 50 lbs and can be easily transported and handled on the job.

6

GASTITE DIVISION, TITEFLEX CORPORATION / 1116 Vaughn Parkway / Portland, TN 37148

800.662.0208 / www.gastite.com / gastite@gastite.com

SECTION 2: SYSTEM DESCRIPTIONS & COMPONENTS / JANUARY 2019

2.2.1 CORRUGATED STAINLESS STEEL TUBING

FLASHSHIELD+™ CORRUGATED STAINLESS STEEL TUBING (CSST)

Part No. Description Pkg. Qty.

FSP-8-250 1/2" FlashShield+™ Corrugated Stainless Steel Tubing 250 Ft/Coil

FSP-8-25 25 Ft/Coil

FSP-8-50 50 Ft/Coil

FSP-8-125 125 Ft/Coil

FSP-8-500 500 Ft/Coil

FSP-8-1000 1000 Ft/Coil

FSP-series

CSST

FSP-8-1500 1500 Ft/Coil

FSP-11-250 3/4" FlashShield+™ Corrugated Stainless Steel Tubing 250 Ft/Coil

FSP-11-25 25 Ft/Coil

FSP-11-50 50 Ft/Coil

FSP-11-125 125 Ft/Coil

FSP-11-500 500 Ft/Coil

FSP-11-1000 1000 Ft/Coil

FSP-16-150 1" FlashShield+™ Corrugated Stainless Steel Tubing 150 Ft/Coil

FSP-16-50 50 Ft/Coil

FSP-16-75 75 Ft/Coil

FSP-16-300 300 Ft/Coil

FSP-16-500 500 Ft/Coil

APPLICATION

• CSST flexible gas piping supplies natural gas or liquefied petroleum gas to appliances.

MATERIAL / SPECIFICATIONS

• Tubing: ASTM A240 Type 304 Stainless Steel.

• Jacket: Electrically insulative and UV resistant polymer, complying with requirements of ASTM E84 and CAN/ULC-S102.2 25/50.

• Protective jacket system, complies with ICC-ES PMG LC1027

FEATURES AND BENEFITS

• Electrically insulative polymer cover.

• Metallically shielded CSST.

• Protective shield is electrically continuous through fitting joints (Arc-Trap™).

• Metal shield layer dissipates and conducts electricity.

• No manufacturer required bonding.

• Flexibility means quick and easy installations. FlashShield+™ installs 30-70% faster than traditional piping methods.

• Pre-marked by the foot, there’s no measuring, rigid pipe cutting or threading. is means less waste and fewer fittings.

• 75% fewer fittings in the average installation means a safer system, less leak potential and reduced callbacks.

• FlashShield+™ CSST is lightweight—250 feet of 1/2" CSST weighs approx. 50 lbs and can be easily transported and handled on the job.

GASTITE DIVISION, TITEFLEX CORPORATION / 1116 Vaughn Parkway / Portland, TN 37148

800.662.0208 / www.gastite.com / gastite@gastite.com

7

SECTION 2: SYSTEM DESCRIPTIONS & COMPONENTS / JANUARY 2019

2.2.2 FITTINGS

Part No. Description Pkg. Qty.

XR3FTG-8-24 1/2" Straight Fitting – 1/2" NPT 24/Box

XR3FTG-11-24 3/4" Straight Fitting – 3/4" NPT 24/Box

XR3FTG-16-12 1" Straight Fitting – 1" NPT 12/Box

XR3FTG-20-6 1-1/4" Straight Fitting – 1-1/4" NPT 6/Box

XR3FTG-24-4 1-1/2" Straight Fitting – 1-1/2" NPT 4/Box

Straight Fitting

XR3FTG-32-4 2" Straight Fitting – 2" NPT 4/Box

XR3 SERIES STRAIGHT FEMALE FITTING (ADAPTER/NUT/BUSHING)

XR3 SERIES STRAIGHT FITTING (ADAPTER/NUT/BUSHING)

Part No. Description Pkg. Qty.

XR3FTGFM-8-24 1/2" Straight Fitting – 1/2" Female NPT 24/Box

XR3FTGFM-11-8-24 3/4" Straight Fitting – 1/2" Female NPT 24/Box

XR3FTGFM-11-24 3/4" Straight Fitting – 3/4" Female NPT 24/Box

Straight Female

Fitting

Part No. Description Pkg. Qty.

XR3 SERIES REDUCING FITTING (ADAPTER/NUT/BUSHING)

XR3REDFTG-8-12-24 1/2" Straight Reducing Fitting – 3/4" NPT 24/Box

XR3REDFTG-11-8-24 3/4" Straight Reducing Fitting – 1/2" NPT 24/Box

XR3REDFTG-16-12-12 1" Straight Reducing Fitting – 3/4" NPT 12/Box

XR3 SERIES TEE FITTING

Part No. Description Pkg. Qty.

Reducing Fitting

XR3T-8-12 1/2" Run x 1/2" Run x 1/2" Tee – Tee Fitting 12/Box

XR3T-11-12 3/4" Run x 3/4" Run x 3/4" Tee – Tee Fitting 12/Box

XR3T-16-6 1" Run x 1" Run x 1" Tee – Tee Fitting 6/Box

Tee

XR3T-11-8-8-6 3/4" Run x 1/2" Run x 1/2" Tee – Tee Fitting 6/Box

XR3T-11-11-8-6 3/4" Run x 3/4" Run x 1/2" Tee – Tee Fitting 6/Box

Run

XR3T-16-11-8-6 1" Run x 3/4" Run x 1/2" Tee – Tee Fitting 6/Box

XR3T-16-11-11-6 1" Run x 3/4" Run x 3/4" Tee – Tee Fitting 6/Box

Run

XR3T-16-16-8-6 1" Run x 1" Run x 1/2" Tee – Tee Fitting 6/Box

XR3T-16-16-11-6 1" Run x 1" Run x 3/4" Tee – Tee Fitting 6/Box

Tee Fitting

XR3 SERIES COUPLING FITTINGS

Part No. Description Pkg. Qty.

XR3CPL-8-12 1/2" Coupling 12/Box

XR3CPL-11-12 3/4" Coupling 12/Box

XR3CPL-16-6 1" Coupling 6/Box

XR3CPL-20-6 1-1/4" Coupling 6/Box

Coupling

APPLICATION

• Straight Fittings connect the flexible gas tubing to gas supply, distribution manifolds or gas appliances.

• Tee Fittings create a branch line on tubing runs.

• Couplings allow for the splicing and additions to the flexible gas tubing.

MATERIAL / SPECIFICATIONS

• Fitting adapter, bushings and nut – Brass.

FEATURES AND BENEFITS

• Tool-less flare design; no special tools are required.

• Metal-to-metal seal, with no split rings, O-rings or gaskets.

• Self-guiding assembly to ensure a perfectly even flare.

• Exclusive, patented Jacket-Lock™ fitting eliminates exposed stainless steel beyond the nut.

• All components are fully reusable.

• Metal-Lock or Arc-Trap™ electrical continuity feature when utilized on FlashShield™ or FlashShield+™ CSST.

XR3CPL-24-4 1-1/2" Coupling 4/Box

XR3CPL-32-4 2" Coupling 4/Box

Note: Fitting Components available. Please contact Customer Service for pricing.

8

GASTITE DIVISION, TITEFLEX CORPORATION / 1116 Vaughn Parkway / Portland, TN 37148

800.662.0208 / www.gastite.com / gastite@gastite.com

SECTION 2: SYSTEM DESCRIPTIONS & COMPONENTS / JANUARY 2019

2.2.2 FITTINGS

XR3 SERIES TERMINATION FITTING (FLANGE/ADAPTER/NUT/BUSHING)

Part No. Description Pkg. Qty.

XR3TRM-8-12 1/2" Term. Fitting-Square Flange – 1/2" NPT 12/Box

XR3TRM-11-12 3/4" Term. Fitting-Square Flange – 3/4" NPT 12/Box

XR3TRM-16-6 1" Term. Fitting-Square Flange – 1" NPT 6/Box

XR3TRM-20-6 1-1/4" Term. Fitting-Square Flange – 1-1/4" NPT 6/Box

XR3TRM-24-4 1-1/2" Term. Fitting-Square Flange – 1-1/2" NPT 4/Box

Termination Fitting

With Square Flange

XR3TRM-32-4 2" Term. Fitting-Square Flange - 2" NPT 4/Box

XR3TRM-8-CB-12 1/2" Term. Fitting-Cast Bronze Flange – 1/2" NPT 12/Box

XR3TRM-11-CB-12 3/4" Term. Fitting-Cast Bronze Flange – 3/4" NPT 12/Box

XR3TRM-16-CB-6 1" Term. Fitting-Cast Bronze Flange – 1" NPT 6/Box

XR3TRM-20-CB-6 1-1/4" Term. Fitting-Cast Bronze Flange – 1-1/4" NPT 6/Box

XR3TRM-24-CB-4 1-1/2" Term. Fitting-Cast Bronze Flange – 1-1/2" NPT 4/Box

XR3 SERIES TERMINATION FITTING WITH NO FLANGE (ADAPTER/NUT/BUSHING)

Part No. Description Pkg. Qty.

XR3TRM-8-NF-12 1/2" Term. Fitting – 1/2" NPT with no Flange 12/Box

XR3TRM-11-NF-12 3/4" Term. Fitting – 3/4" NPT with no Flange 12/Box

XR3TRM-16-NF-6 1" Term. Fitting – 1" NPT with no Flange 6/Box

Termination Fitting

No Flange

XR3TRM-20-NF-6 1-1/4" Term. Fitting – 1-1/4" NPT with no Flange 6/Box

XR3TRM-24-NF-4 1-1/2" Term. Fitting – 1-1/2" NPT with no Flange 4/Box

XR3TRM-32-NF-4 2" Term. Fitting – 2" NPT with no Flange 4/Box

XR3 SERIES TERMINATION BRACKET FITTING (BRACKET/ADAPTER/NUT/BUSHING)

Part No. Description Pkg. Qty.

XR3TRMBKT-8-12 1/2" Term. Bracket Fitting – 1/2" NPT 12/Box

XR3TRMBKT-11-12 3/4" Term. Bracket Fitting – 3/4" NPT 12/Box

XR3TRMBKT-16-6 1" Term. Bracket Fitting – 1" NPT 6/Box

XR3TRMBKT-20-6 1-1/4" Term Bracket Fitting – 1-1/4" NPT 6/Box

Term Bracket Fitting

APPLICATION

• Straight Fittings connect the flexible gas tubing to gas supply, distribution manifolds or gas appliances.

• Tee Fittings create a branch line on tubing runs.

• Couplings allow for the splicing and additions to the flexible gas tubing.

MATERIAL / SPECIFICATIONS

• Fitting adapter, bushings and nut – Brass.

• Square Flange – Steel with zinc coating.

FEATURES AND BENEFITS

• Tool-less flare design; no special tools are required.

• Metal-to-metal seal, with no split rings, O-rings or gaskets.

• Self-guiding assembly to ensure a perfectly even flare.

• Exclusive, patented Jacket-Lock™ fitting eliminates exposed stainless steel beyond the nut.

• All components are fully reusable.

• Metal-Lock or Arc-Trap™ electrical continuity feature when utilized on FlashShield™ or FlashShield+™ CSST.

XR3TRMBKT-24-4 1-1/2" Term. Bracket Fitting – 1-1/2" NPT 4/Box

XR3TRMBKT-32-4 2" Term. Bracket Fitting – 2" NPT 4/Box

GASTITE DIVISION, TITEFLEX CORPORATION / 1116 Vaughn Parkway / Portland, TN 37148

800.662.0208 / www.gastite.com / gastite@gastite.com

9

SECTION 2: SYSTEM DESCRIPTIONS & COMPONENTS / JANUARY 2019

2.2.3 MANIFOLDS

Part No. Description Pkg. Qty.

3-PORTMAN Cast 3 port – 3/4"F x 3 @ 1/2"F x 1/2"F 1 Ea.

3-PORTMAN-1 Cast 3 port – 1/2" x 3 @ 1/2"F x 1/2"F 1 Ea.

4-PORTMAN-10 Cast 4 port – 3/4"F x 4 @ 1/2"F x 1/2"F 10/Box

5-PORTMAN Cast 5 port – 3/4"F x 1 @ 3/4"F x 4 @ 1/2"F x 1/2"F 1 Ea.

5-PORTMAN-1 Cast 5 port – 1"F x 1 @ 3/4"F x 4 @ 1/2"F x 3/4"F 1 Ea.

5-PORTMAN-2 Cast 5 port – 1-1/4"F x 5 @ 3/4"F x 1"F 1 Ea.

Cast Manifolds

5-PORTMAN-3 Cast 5 port – 1-1/4"F x 5 @ 1/2"F x 1"F 1 Ea.

4-PORTMAN-2 Cast 4 port – 1-1/2"F x 4 @ 3/4"F x 1-1/2"F 1 Ea.

4-PORTMAN-3 Cast 4 port – 2"F x 4 @ 1"F x 1-1/2"F 1 Ea.

APPLICATION

• Provides central distribution point for individual runs to each appliance.

MATERIAL / SPECIFICATIONS:

• Coated 4 Port – Welded IPS Schedule 40 pipe.

• Cast 3, 4, and 5 Port – ASTM A47 32510 Malleable Iron.

2.2.4 MODULAR STUB SYSTEM

Part No. Description Pkg. Qty.

XR3-APSTUB-8-10 1/2"M x 1/2"M x 1-1/2" Stub length with 1/2" female fitting 10/Box

XR3-L-APSTUB-8-10 1/2"M x 1/2"M x 2-1/4" Stub length with 1/2" female fitting 10/Box

XR3-Appliance

Stub-Outs

XR3-APSTUB-11-10 1/2"M x 1/2"M x 1-1/2" Stub length with 3/4" female fitting 10/Box

XR3-L-APSTUB-11-10 1/2"M x 1/2"M x 2-1/4" Stub length with 3/4" female fitting 10/Box

XR3-APSTUB-11-11-10 3/4"M x 3/4"M x 1-1/2" Stub length with 3/4" female fitting 10/Box

XR3-L-APSTB-11-11-10 3/4"M x 3/4"M x 2-1/4" Stub length with 3/4" female fitting 10/Box

MULTI-PORT MANIFOLDS

MODULAR STUB SYSTEM

1/2X6STUB-10 1/2"M x 6"L Straight Stub 10/Box

1/2X12STUB-10 1/2"M x 12"L Straight Stub 10/Box

3/4X6STUB-10 3/4"M x 6"L Straight Stub 10/Box

Straight Stub-Outs

Optional Brackets

3/4X12STUB-10 3/4"M x 12"L Straight Stub 10/Box

1X6STUB-10 1"M x 6"L Straight Stub 10/Box

1X12STUB-10 1"M x 12"L Straight Stub 10/Box

1-1/4X6STUB-10 1-1/4"M x 6"L Straight Stub 10/Box

1-1/4X12STUB-10 1-1/4"M x 12"L Straight Stub 10/Box

1-1/2X6STUB-10 1-1/2"M x 6"L Straight Stub 10/Box

1-1/2X12STUB-10 1-1/2"M x 12"L Straight Stub 10/Box

2X6STUB-10 2"M x 6"L Straight Stub 10/Box

2X12STUB-10 2"M x 12"L Straight Stub 10/Box

Angle Stub-Out

ANGLE-STUB-01-10 1/2"M x 4-1/2"L x 72.5° Angle Stub 10/Box

STUB-BRACE Stub Bracket (optional) – Fits All 1 Ea.

DBLSTUB-1-10 3/4" Inlet x 1/2" & 3/4" Outlet 10/Box

DECKSTUB-1/2x3-10 1/2" x 3" Bracket Stub-Out 10/Box

APPLICATION

• All Stubs create a fixed point “stub-out” on a wall or floor surface for meter and appliance attachment.

• Angle Stub-Out mounting plate provided at a 72-1/2° angle to facilitate mounting to angled side of most fireplace inserts.

Deck Stub-Out

MATERIAL / SPECIFICATIONS

• Schedule 40 steel pipe complying with material standard ASTM A-53.

• Exterior plating – Black oxide coating after all threading, forming and welding.

FEATURES AND BENEFITS

• Reduces the number of joints in the system where contractors typically fabricate “stub-outs” from rigid pipe nipples,

elbows and couplings.

Double Stub-Out

• Provides a fixed-point termination for installations where the appliances are not yet installed.

• Creates a more polished look to the overall installation.

10

GASTITE DIVISION, TITEFLEX CORPORATION / 1116 Vaughn Parkway / Portland, TN 37148

800.662.0208 / www.gastite.com / gastite@gastite.com

SECTION 2: SYSTEM DESCRIPTIONS & COMPONENTS / JANUARY 2019

2.2.5 MOUNTING HARDWARE

Part No. Description Pkg. Qty.

LBRACE-1-20 Term. Fitting Mounting Kit – Fits 3/8" - 1" CSST 20/Box

MBRACE-1-10 Manifold Mounting Kit – See below for manifold options 10/Box

MBRACE-3-10 Manifold Mounting Kit – See below for manifold options 10/Box

GLC1 Gas Load Center Kit – 14-1/2" x 24" x 3-1/2" with MBRACE 1 Ea.

MSTRAPS-8-250 Metal Tubing Strap – Fits 1/2" CSST 250/Box

Termination Bracket

Manifold Bracket

Gas Load Center

XR3-Outlet Box

MSTRAPS-11-150 Metal Tubing Strap – Fits 3/4" CSST 150/Box

MSTRAPS-16-100 Metal Tubing Strap – Fits 1" CSST 100/Box

MSTRAPS-20-50 Metal Tubing Strap – Fits 1-1/4" CSST 50/Box

MSTRAPS-24-50 Metal Tubing Strap – Fits 1-1/2" CSST 50/Box

MSTRAPS-32-25 Metal Tubing Strap – Fits 2" CSST 25/Box

XR3OUTLETBOX-8 Recessed gas outlet box kit with 1/2" XR3 Fitting 1 Kit

XR3OUTLETBOX-11 Recessed gas outlet box kit with 3/4" XR3 Fitting 1 Kit

XR3OUTLETBOX-FR8 Firestop gas outlet box kit with 1/2" XR3 Fitting 1 Kit

XR3OUTLETBOX-FR11 Firestop gas outlet box kit with 3/4" XR3 Fitting 1 Kit

APPLICATION

• Termination Bracket provides mounting surface for termination fitting assembly.

• Manifold Bracket provides mounting platform for manifolds, supplied with adhesive port labeling.

• Gas Load Center creates a recessed cabinet for a more polished look to manifold assembly.

• XR3OUTLETBOX creates a secure recessed termination point for connection to moveable appliances.

MATERIAL / SPECIFICATIONS

• Termination Fitting – 16 gauge galvanized sheet metal.

• MBRACE-1 Mounting Kit made of 16 gauge galvanized sheet metal.

- Fits 3-PORTMAN, 4-PORTMAN, 5-PORTMAN and 111596-08.

• MBRACE-3 Mounting Kit made of 14 gauge galvanized sheet metal.

- Fits 5-PORTMAN-1, 5-PORTMAN-2, 5-PORTMAN-3 and 4-PORTMAN-2.

• 4-PORTMAN-3 requires installer supplied mounting brackets.

• Gas Load Center – 20 gauge steel with a white, polyester powder coat finish.

• Metal Tubing Straps – 22, 20 or 18 gauge sheet metal, depending on size.

MOUNTING HARDWARE

2.2.6 PIPE SUPPORT SYSTEM

PIPE SUPPORT SYSTEM

Part No. Description Pkg. Qty.

RB0-10-4 Rubber Support Block (10"L x 4"H) 1 Ea.

RB1-10-5 Rubber Support Block w/ 7/8" Galv Steel Channel (10"L x 5"H) 1 Ea.

RB1-29-5 Rubber Support Block w/ 7/8" Galv Steel Channel (29"L x 5"H) 1 Ea.

RB2-10-12 Rubber Support Block w/Adj height 7/8" Galv Steel Channel (10"L x 5"-12"H) 1 Ea.

APPLICATION

• Effectively anchors and supports lightweight FlashShield™ CSST, as well as other fuel gas piping materials to any roofing

RB2

RB0

RB1

GASTITE DIVISION, TITEFLEX CORPORATION / 1116 Vaughn Parkway / Portland, TN 37148

800.662.0208 / www.gastite.com / gastite@gastite.com

membrane.

MATERIAL / SPECIFICATIONS

• Made of 100% recycled material, UV resistant and waterproof.

• Will not damage expensive roof membranes.

• Installs on any roof with or without standard roof adhesives.

11

SECTION 2: SYSTEM DESCRIPTIONS & COMPONENTS / JANUARY 2019

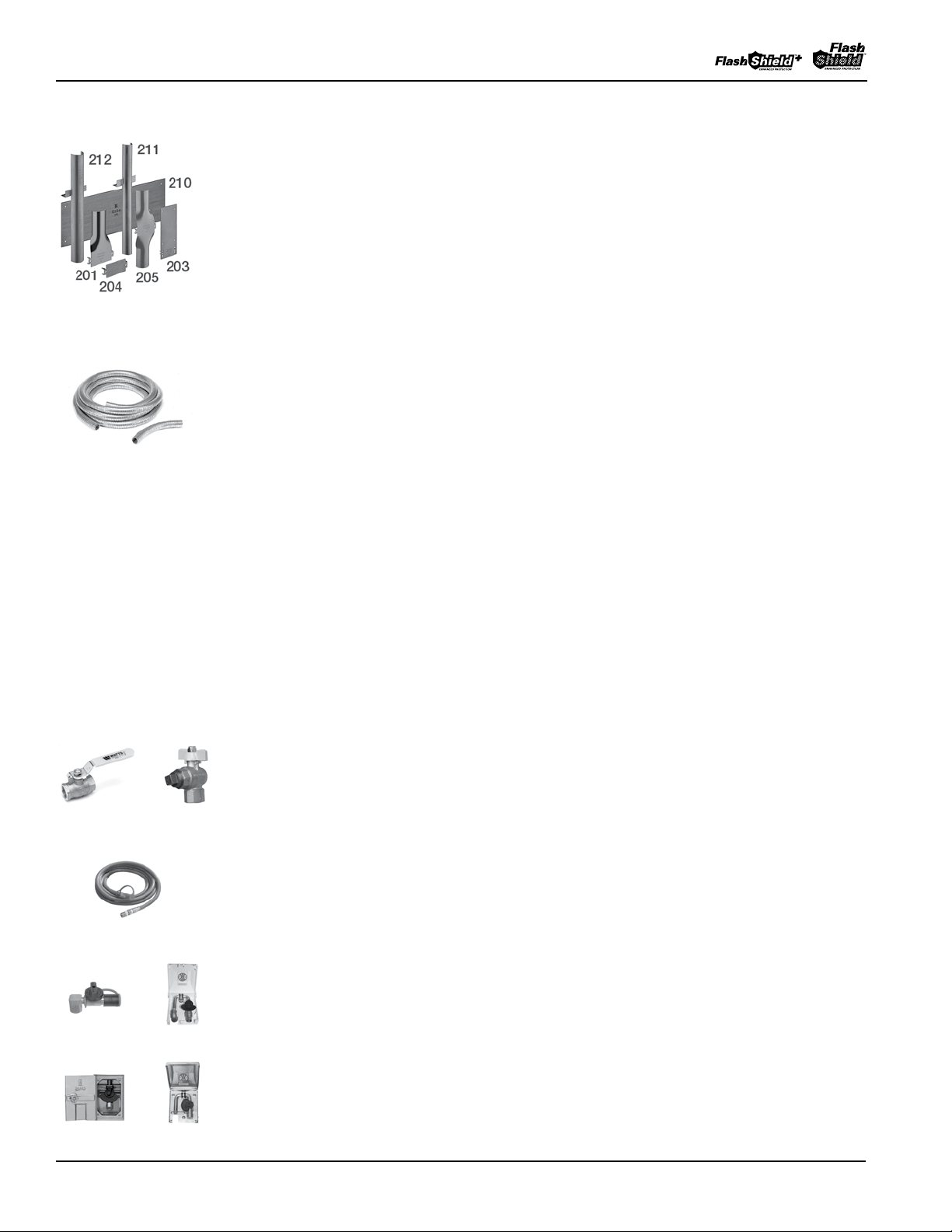

2.2.7 STRIKE PROTECTION

Part No. Description Pkg. Qty.

PROTECTION DEVICES – STRIKER PLATES & SILICONE TAPE

TFM204-100 Quarter Striker Plate – 3" x 2" 100/Box

TFM201-50 Half Striker Plate – 3" x 7" 50/Box

TFM203-50 ree-Quarter Striker Plate – 3" x 8" 50/Box

TFM205-25 Full Striker Plate – 3" x 12" 25/Box

TFM210-10 6" x 17" Striker Plate 10/Box

TFM211-25 Full (Drop-In) Striker Plate – 1/2" & 3/4" CSST 25/Box

TFM212-25 Full (Drop-In) Striker Plate – 1" & 1 1/4" CSST 25/Box

SIL-TAPE Self Bonding Yellow Silicone Tape – 1" x .015" x 12 yd / roll 1 Ea.

SIL-TAPE-B Self Bonding Black Silicone Tape – 1" x .015" x 12 yd / roll 1 Ea.

Striker Plates

Steel Conduit Coil &

Cut Length

APPLICATION

Part No. Description Pkg. Qty.

FLOPPY16 1" Coil steel conduit – Fits 1/2" CSST 50 Ft/Coil

FLOPPY20 1-1/4" Coil steel conduit – Fits 3/4" CSST 25 Ft/Coil

FLOPPY24 1-1/2" Coil steel conduit – Fits 1" CSST 25 Ft/Coil

FLOPPY28 1-3/4" Coil steel conduit – Fits 1-1/4" CSST 25 Ft/Coil

FLOPPY36 2-1/4" Coil steel conduit – Fits 1-1/2" CSST 25 Ft/Coil

FLOPPY48 3" Coil steel conduit – Fits 2" CSST 25 Ft/Coil

Part No. Description Pkg. Qty.

LFLOPPY-16-50 1" – Cut to 1 foot length – Fits 1/2" CSST 50/Box

LFLOPPY-20-25 1-1/4" – Cut to 1 foot length – Fits 3/4" CSST 25/Box

LFLOPPY-24-25 1-1/2" – Cut to 1 foot length – Fits 1" CSST 25/Box

LFLOPPY-28-25 1-3/4" – Cut to 1 foot length – Fits 1-1/4" CSST 25/Box

LFLOPPY 36-25 2-1/4" – Cut to 1 foot length – Fits 1-1/2" CSST 25/Box

LFLOPPY-48-25 3" – Cut to 1 foot length – Fits 2" CSST 25/Box

• Striker plates used for protection where flexible gas piping passes through structural members and is restricted

from moving to avoid nails, screws and other potential puncture threats.

• Steel conduit is used to provide additional protection where striker plates cannot be easily installed.

MATERIAL / SPECIFICATIONS

• Striker Plates – 16 gauge AISI1050 Carbon Steel Hardened to Rc 45.

• Steel Conduit – Strip wound interlocking steel.

2.2.8 SHUT-OFF VALVES AND QUICK CONNECTS

Part No. Description Pkg. Qty.

T100-1/2-20 1/2" Ball Valve rated to 125 PSI 20/Box

T100-3/4-10 3/4" Ball Valve rated to 125 PSI 10/Box

T100-1-1/4-5 1-1/4" Ball Valve rated to 125 PSI 5/Box

Ball Valve 90˚ Ball Valve

T90-1/2-10 1/2" 90 Degree Shut-Off Valve 10/Box

T90-3/4-10 3/4" 90 Degree Shut-Off Valve 10/Box

OUTDOOR FLEX CONNECTOR WITH QUICK CONNECT PLUG

Part No. Description Pkg. Qty.

Outdoor Flex Connector

QC Valve QC Valve Box (PVC)

QC Valve Box (SS)

Recessed

QC Valve Box (SS)

12

OUTFLEX-3/8 3/8" Outdoor Flex Connector, 10-ft, 3/8" Male plug X 3/8"

OUTFLEX-1/2 1/2" Outdoor Flex Connector, 10-ft, 1/2" Male plug X 1/2"

*Capacity of flex connector and QC vlave combination, @ 1" w.c. pressure drop

Part No. Description Pkg. Qty.

T103029 3/8" Quick Connect Valve, 90 deg, 1/2" FPT inlet 1 Ea

T104123 1/2" Quick Connect Valve, Straight, 1/2" FPT inlet 1 Ea

QCBOXPW 3/8" QC Valve Box (white PVC) 1/2" FPT inlet, Surface

QCBOXPG 3/8" QC Valve Box (grey PVC) 1/2" FPT inlet, Surface

QCBBOXSS 3/8" QC Valve Box (S.S.) 1/2" FPT inlet, Recessed,

BBQ-SS-50 1/2" QC Valve Box (S.S.) 1/2" FPT inlet, Surface Mount,

Female Flare Swivel, 3/8" MPT adapter (43 CFH)*

Female Flare Swivel, 1/2" MPT adapter (87 CFH)*

Mount, Lockable

Mount, Lockable

Locking Door

Lockable Door

SHUT-OFF VALVES

1 Ea.

1 Ea.

QUICK CONNECT VALVES

1 Ea

1 Ea

1 Ea

1 Ea

GASTITE DIVISION, TITEFLEX CORPORATION / 1116 Vaughn Parkway / Portland, TN 37148

800.662.0208 / www.gastite.com / gastite@gastite.com

SECTION 2: SYSTEM DESCRIPTIONS & COMPONENTS / JANUARY 2019

2.2.9 TOOLS

Part No. Description Pkg. Qty.

GTCUTTER-SM2 Cutter with flat rollers – 1/2" – 1" Gastite® and FlashShield™ CSST 1 Ea.

GTCUTTER-LG2 Cutter with flat rollers – Up to 2" Gastite® and FlashShield™ CSST 1 Ea.

GTBLADE-SM-5 Replacement blade for GTCUTTER-SM2 (19mm) 5 Ea.

GTBLADE-LG2-5 Replacement blade for GTCUTTER-LG2 (30 mm) 5 Ea.

Tubing Cutters

APPLICATION

• Tubing Cutters, fitted with cutting wheel designed to cut stainless steel, create clean cuts for optimal flaring of tubing.

MATERIAL / SPECIFICATIONS

• Aluminum alloy body.

Part No. Description Pkg. Qty.

STRP3-8 1/2" Jacket Stripper 24/Pkg.

STRP3-11 3/4" Jacket Stripper 24/Pkg.

STRP3-16 1" Jacket Stripper 24/Pkg.

STRP3-20 1-1/4" Jacket Stripper 24/Pkg.

Jacket Stripping Tool

STRP3-24 1-1/2" Jacket Stripper 12/Pkg.

STRP3-32 2" Jacket Stripper 12/Pkg.

TUBING CUTTERS AND ACCESSORIES

JACKET STRIPPING TOOL

2.2.10 BONDING CLAMPS

Part No. Description Pkg. Qty.

CWP1JSH Bonding Clamp for 3/8" and 1/2" Fittings 1 Ea.

CWP2JSH Bonding Clamp for 3/4", 1" and 1-1/4" Fittings 1 Ea.

CWP3JSH Bonding Clamp for 1-1/2" and 2" Fittings 1 Ea.

Bonding Clamps

2.2.11 SYSTEM IDENTIFICATION

Part No. Description Pkg. Qty.

EPAL-1-100 Adhesive Labels for elevated pressure identification 100/Roll

EPMT-1-100 Metal Tags for elevated pressure identification 100/Pkg.

Adhesive Label

Meta l Ta g

BONDING CLAMPS

SYSTEM IDENTIFICATION

GASTITE DIVISION, TITEFLEX CORPORATION / 1116 Vaughn Parkway / Portland, TN 37148

800.662.0208 / www.gastite.com / gastite@gastite.com

13

SECTION 2: SYSTEM DESCRIPTIONS & COMPONENTS / JANUARY 2019

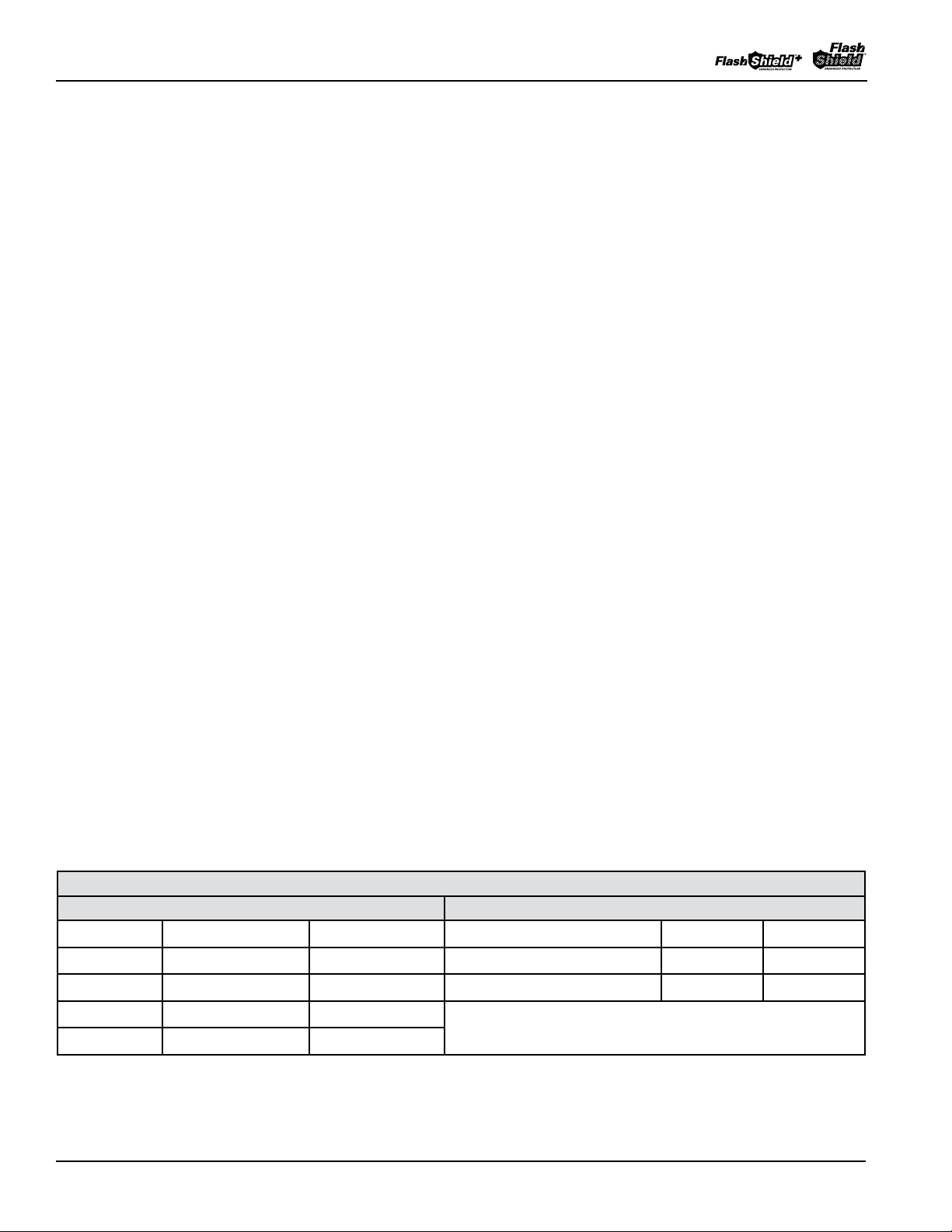

2.2.12 LINE REGULATORS

LINE REGULATORS - NATURAL GAS, 8" W.C. OUTLET SETPOINT

Part No. Regular Application NPT Capacity*(CFH) Pkg. Qty Wt. (Lbs.)

T325-3-44

T325-5-2

T325-5-44

Maxitrol Regulators

Maxitrol Regulators

with OPD

OARA Regulators

Pietro Fiorentini

Regulators

T325-5-3

T325-7AL-NG01

Part No. Regular Application NPT Capacity*(CFH) Pkg. Qty Wt. (Lbs.)

T325-3L48 5 PSI 1/2" 207 1 1.5

T325-5AL600 5 PSI 3/4" 439 1 3.4

T325-7L-210D** 5 PSI 1-1/4" 1,291 1 9.2

Part No. Regular Application NPT Capacity*(CFH) Pkg. Qty Wt. (Lbs.)

REG-8-300 2 PSI 1/2" 238 1 0.8

REG-8-600 2 PSI 3/4" 462 1 1.9

Part No. Regular Application NPT Capacity*(CFH) Pkg. Qty Wt. (Lbs.)

30051-NG 2 PSI 1/2" 552 1 1.7

30052-NG 2 PSI 3/4" 665 1 1.7

30053-NG 2 PSI 1" 893 1 1.6

30153-NG 2 PSI 1-1/4" 3,735 1 7.4

*Natural gas, 0.60 specific gravity. 1 PSI inlet, 8" w.c. outlet

See FlashShield Design & Installation guide, table 4-7 for further sizing info.

**Vent limiter not available for -7 OPD

MAXITROL REGULATORS

2 PSI 1/2" 258 1 0.8

2 PSI 1/2" 516 1 1.8

2 PSI 3/4" 620 1 1.8

2 PSI 1" 620 1 1.8

2 PSI 1-1/4" 1,291 1 3.5

MAXITROL O.P.D.'S

OARA REGULATORS

PIETRO FIORENTINI REGULATORS

Maxitrol Regulators

OARA Regulators

Pietro Fiorentini

Regulators

Vent Protectors

LINE REGULATORS - PROPANE, 11" W.C. OUTLET SETPOINT

MAXITROL REGULATORS

Part No. Regular Application NPT

T325-3-44P

T325-5-44P

T325-5-3P

2 PSI 1/2" 368 1 0.8

2 PSI 3/4" 916 1 1.8

2 PSI 1" 916 1 1.8

Capacity*

(000 BTU/H)

Pkg. Qty

Wt.

(Lbs.)

OARA REGULATORS

Part No. Regular Application NPT

Capacity*

(000 BTU/H)

Pkg. Qty

Wt.

(Lbs.)

REG-11-300 2 PSI 1/2" 344 1 0.8

REG-11-600 2 PSI 3/4" 669 1 1.9

PIETRO FIORENTINI REGULATORS

Part No. Regular Application NPT

Capacity*

(000 BTU/H)

Pkg. Qty

Wt.

(Lbs.)

30052-LP 2 PSI 3/4" 965 1 1.7

*Propane, 1.52 specific gravity. 1 PSI inlet, 11" w.c. outlet

See FlashShield Design & Installation guide, table 4-8 for further sizing info.

VENT PROTECTORS

Pkg.

Part No. Description

VP3 Maxitrol, Outdoor Vent Protector, fits 1/8" NPT vent orifice (fits -3 and 300 series) 1 Ea. 0.1

VP5 Maxitrol, Outdoor Vent Protector, fits 3/8" NPT vent orifice (fits -5 and 600 series) 1 Ea. 0.1

VP14 Pietro Fiorintini, Outdoor Vent Protector, fits 1/4" NPT vent orifice (fits 30051, 52, 53) 1 Ea. 0.1

VP12 Pietro Fiorintini, Outdoor Vent Protector, fits 1/2" NPT vent orifice (fits 30153 and -7) 1 Ea. 0.1

Qty

Wt.

(Lbs.)

14

APPLICATION

Vent protector is used (as one option) when vent-limiter is removed for outdoor regulator installation

GASTITE DIVISION, TITEFLEX CORPORATION / 1116 Vaughn Parkway / Portland, TN 37148

800.662.0208 / www.gastite.com / gastite@gastite.com

SECTION 2: SYSTEM DESCRIPTIONS & COMPONENTS / JANUARY 2019

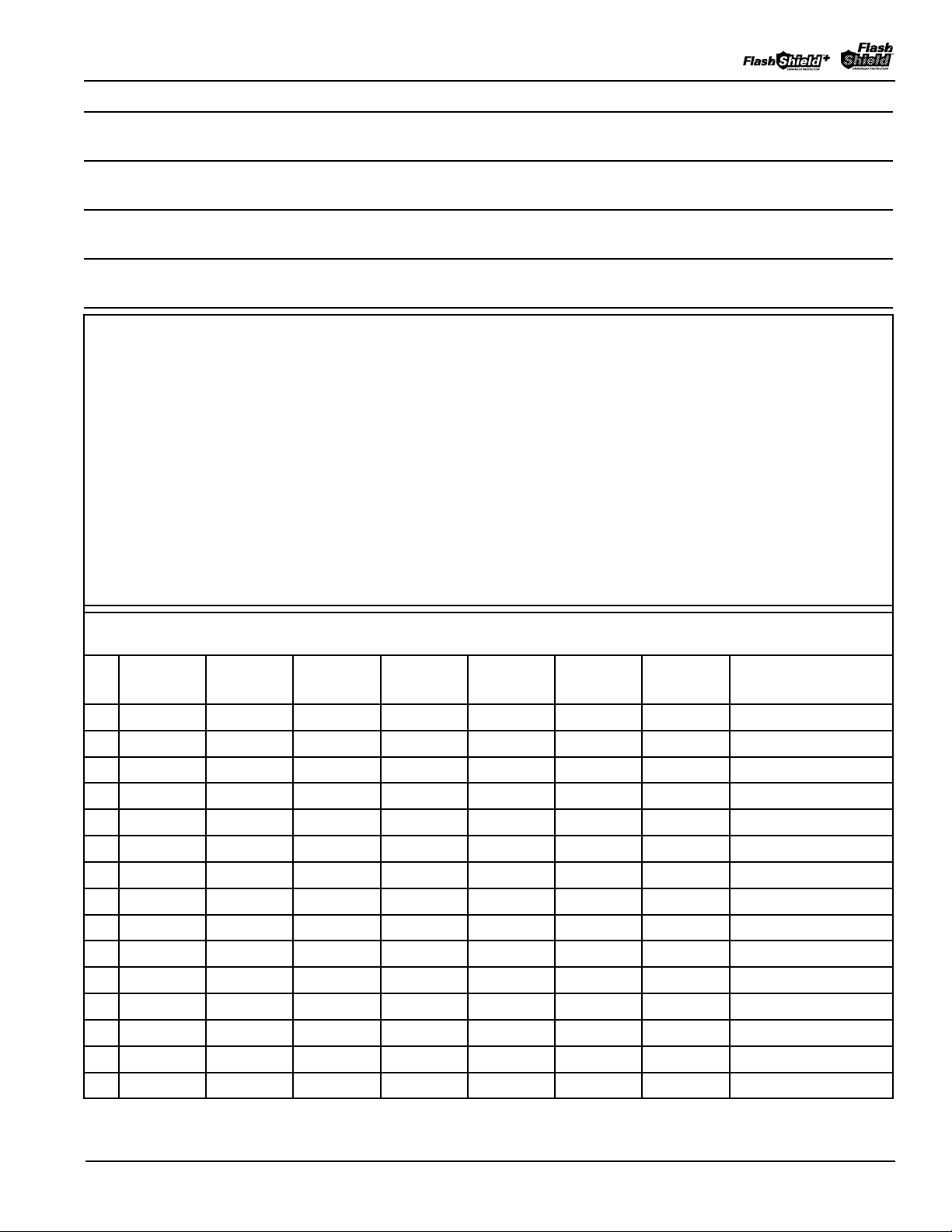

FLASHSHIELD™ CSST WORKSHEET

PROJECT / LOCATION: DR AWN BY:

CONTACT PHONE: DATE:

DESCRIPTION

M

O

SYSTEM DESCRIPTION

SYSTEM DATA AND REQUIREMENTS

NAME OF

RUN

SUPPLY

PRESSURE

(LBS. OR IN.)

LENGTH OF

RUN (FT.)

LOAD OF RUN

(CFH)

PRESS. DROP

(LBS. OR IN.)

TUBE DIAMETER

(SIZE OR IN.)

A

B

C

D

E

F

G

H

I

J

K

L

N

To be copied: For Planning and Design of the FlashShield™ Piping System.

DELIVERY

PRESS. (LBS. OR

IN.)

COMMENTS

GASTITE DIVISION, TITEFLEX CORPORATION / 1116 Vaughn Parkway / Portland, TN 37148

800.662.0208 / www.gastite.com / gastite@gastite.com

15

SECTION 3: SYSTEM CONFIGURATION / JANUARY 2019

SECTION 3.0 SYSTEM CONFIGURATION

3.1 CONFIGURATION

3.1.1 INTRODUCTION

is section is intended to help in the design and sizing of FlashShield™ CSST fuel gas piping systems. e form -printed

on the previous page is to aid in keeping track of the system requirements as well as organizing the system configuration

and sizing numbers. Refer to the Gastite website (www.gastite.com) for additional sizing tools.

e FlashShield™ gas piping system is required to be tested, listed, and installed in accordance with the Standard For Fuel

Gas Piping Systems Using Corrugated Stainless Steel Tubing, ANSI LC1. is standard, among other things, requires the

manufacturer to provide installation instructions including the necessary pipe sizing tables and methods of sizing.

3.1.2 SYSTEM REQUIREMENTS

• Determine the local piping restrictions prior to installing the flexible gas piping. Confirm that the local administrative

authority has accepted the use of flexible gas piping. Corrugated Stainless Steel Tubing has been accepted by all major

code bodies, but local or state adoption of these codes often lags behind. Check with the local administrative authority or

an authorized FlashShield™ distributor for approval in your area.

• Determine metered (supply) pressure. A gauge can be used to measure the supply pressure or the utility will provide a

supply pressure rating.

• Determine appliance demand. Every appliance will have a manufacture’s nameplate containing BTUH or CFH

requirements as well as minimum and maximum operating pressures.

• Refer to building plans or prepare a sketch showing the location of each appliance. When preparing this sketch keep in

mind the safest, easiest, and shortest distance locations to run the piping. Label the pipe segments and the corresponding

lengths. Take note of fittings needed e.g. tees, manifolds, reducers.

3.1.3 REFERENCE DATA FOR PROPER SYSTEM SIZING

• Determine the total capacity needed for all appliances. CFH or BTUH equivalents for natural gas or propane can be

obtained from the local gas utility or propane supplier. e capacity tables within this guide or other approved CSST

tables should be used to determine pipe sizing for FlashShield™ needed to meet BTUH input load requirements.

TABLE 3-1 REFERENCE DATA FOR PROPER SYSTEM SIZING

PRESSURE CONVERSION FACTORS FUEL GAS INFORMATION

1/4 PSI = 6.921"WC = (approx. 7"WC) Natural Gas Propane

1/2 PSI = 13.842"WC = (approx. 14"WC) BTU per Cubic Foot = 1000 2516

1 PSI = 27.684"WC = (approx. 28"WC) Specific Gravity = 0.6 1.52

2 PSI = 55.368"WC = (approx. 56"WC)

5 PSI = 138.42"WC = (approx. 140"WC)

Note: “Pressure Drop Curves are expressed in terms of Cubic Feet per Hour

(CFH). To determine the CFH for Natural Gas, divide the BTU load by 1000.

To determine the CFH for Propane, divide the BTU load by 2516.

Refer to Section 7.0 for gases with a specific gravity other than 0.60.

16

GASTITE DIVISION, TITEFLEX CORPORATION / 1116 Vaughn Parkway / Portland, TN 37148

800.662.0208 / www.gastite.com / gastite@gastite.com

SECTION 3: SYSTEM CONFIGURATION / JANUARY 2019

3.1.4 DETERMINING SYSTEM LAYOUT

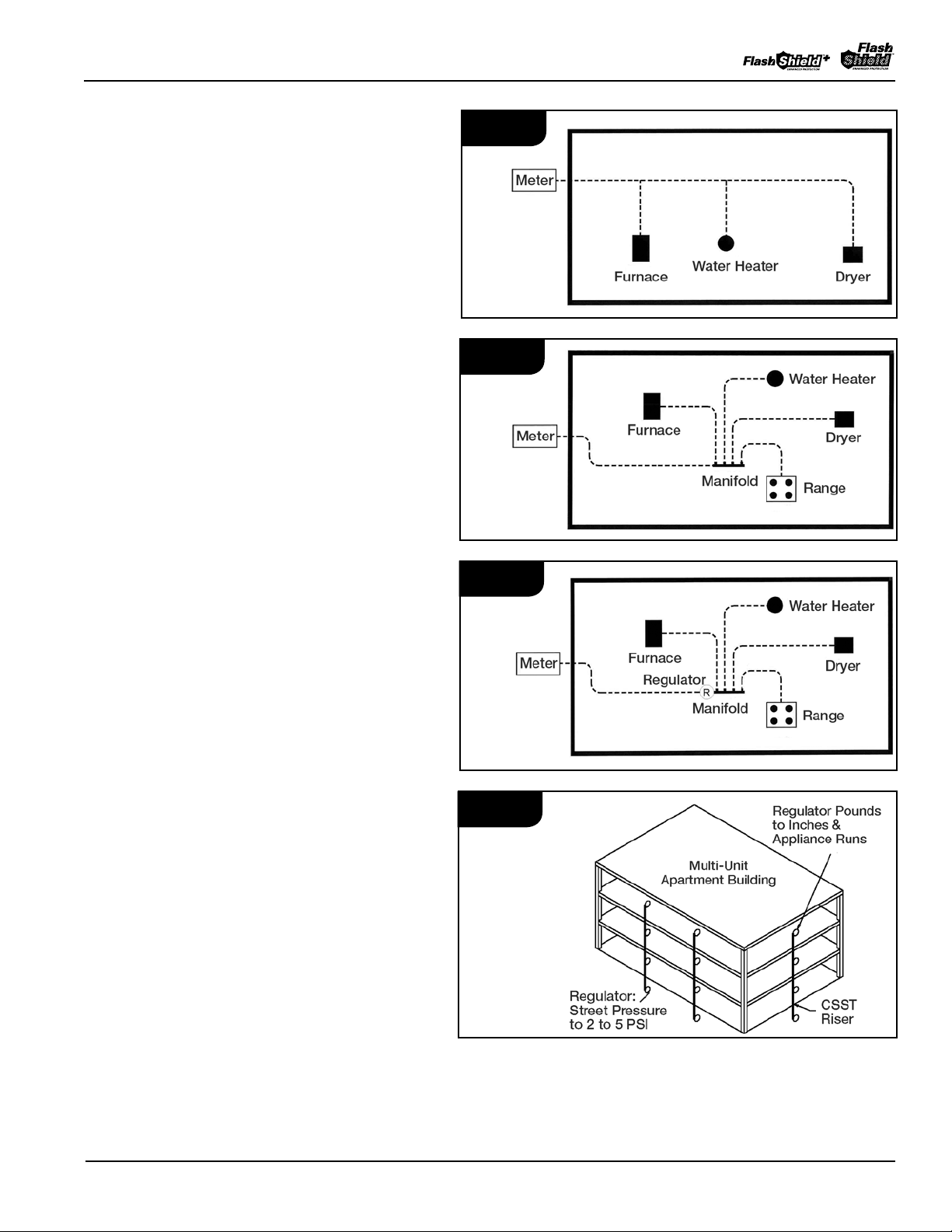

A) SERIES SYSTEMS

A series layout (Fig 3-1) is the most common

arrangement utilized for rigid pipe systems for low

pressure. ese usually consist of a main run (header)

with tees branching off to each appliance. In a

traditional series system, the service pressure down

stream of the meter is typically less than 1/2 PSI.

B) PARALLEL SYSTEMS

In a parallel system (Fig. 3-2) a main run from the

meter supplies a central distribution manifold. e

appliances are serviced by individual runs from the

manifold. e manifold station is best located close

to the greatest load, typically the boiler or furnace.

C) DUAL PRESSURE SYSTEM

A dual pressure system (Fig. 3-3, 3-4) incorporates

two operating pressures downstream from the meter.

e first pressure, set by the service regulator at the

meter, is usually 2 PSI but can be higher or lower

depending on code restrictions and gas company

policy. is part of the system is sized separately and

ends at the pounds-to-inches regulator inlet. Tables

4-7, 4-8 and 4-9 show maximum loads vs. inlet

pressures to the regulator.

Fi g. 3 -1

Fig . 3-2

Fig. 3-3

e second pressure, at the outlet of the pounds-toinches regulator, is under 1/2 PSI; usually 8"WC

for natural gas and 11"WC for propane regulators

supplied by Gastite®. Generally, a parallel system

requires a higher total footage of smaller diameter

tubing and fewer fittings compared to a series layout.

Fig. 3-4

GASTITE DIVISION, TITEFLEX CORPORATION / 1116 Vaughn Parkway / Portland, TN 37148

800.662.0208 / www.gastite.com / gastite@gastite.com

17

SECTION 3: SYSTEM CONFIGURATION / JANUARY 2019

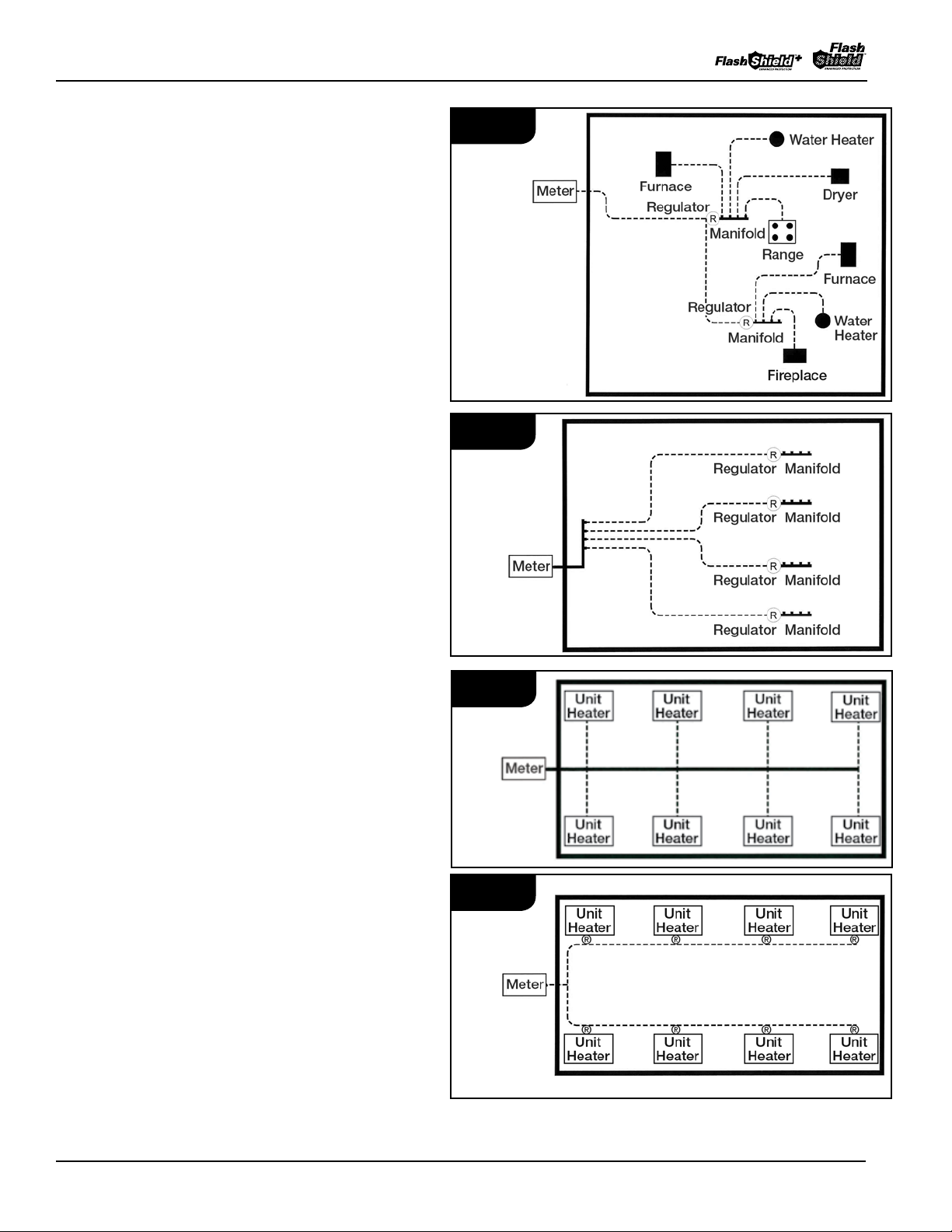

D) MULTIPLE MANIFOLD SYSTEMS

For those installations in which the energy load demand

is large or the appliances are installed throughout the

structure with long distances from the meter, a multiple

manifold system may be used (Fig. 3-5, 3-6). Elevated

pressure systems are a safe, efficient method of providing

for larger BTUH load demands while maintaining

smaller pipe diameters.

E) COMBINATION STEEL / CSST SYSTEM (HYBRID)

In a hybrid system (Fig. 3-7), corrugated stainless steel

tubing is used in combination with rigid pipe or copper

tubing. In lower pressure systems it is often advantageous

to use both CSST and rigid pipe to help minimize

pressure drops typically encountered on systems with

high loads and/or long runs. FlashShield™ flexible Gas

Piping is approved for use in combination with all

approved fuel gas-piping materials by using approved

pipe threads at the interface.

F) ELEVATED PRESSURE SYSTEM

In a complete elevated pressure system (Fig. 3-8),

corrugated stainless steel tubing is used to deliver

pressures in excess of 1/2 PSI to a pounds-to-inches

regulator positioned directly in front of each appliance.

is is an alternate method of installation used to

minimize pipe size on systems with high loads and/or

long runs. Regulators shall be sized per the largest single

appliance, see Table 4-10.

Fig. 3-5

Fig. 3-6

Fig. 3-7

18

Fig. 3-8

GASTITE DIVISION, TITEFLEX CORPORATION / 1116 Vaughn Parkway / Portland, TN 37148

800.662.0208 / www.gastite.com / gastite@gastite.com

SECTION 3: SYSTEM CONFIGURATION / JANUARY 2019

3.1.5 ALLOWABLE PRESSURE DROP

With respect to gas pipe sizing, the intent of all model codes is to ensure that there is sufficient gas volume and pressure

supplied to the appliance for proper operation. Language from the International Fuel Gas Code clearly illustrates this point.

“Allowable Pressure Drop: e design pressure loss on any piping system under maximum probable flow

conditions, from point of delivery to the inlet connection of the equipment, shall be such that the supply

pressure at the equipment is greater than the minimum pressure required for proper equipment operation.”

e FlashShield™ low-pressure tables are intended for use at a system pressure of 1/2 PSI or less, which encompasses the range

of commonly delivered utility pressures and equipment requirements. To determine which table to use determine the system’s

allowable pressure drop. e appropriate pressure drop can be calculated by subtracting the appliance inlet pressure (typically

5"WC for NG, 10.5"WC for LPG) from the gas source pressure (gas meter for NG, secondary regulator for LPG). Use the

FlashShield™ capacity table labeled with the appropriate allowable pressure drop and gas type. Increasing the available pressure

drop will increase the available BTUHs, thus decreasing pipe sizes. It is advantageous to allow for a larger pressure drop.

e Summation Method of pipe sizing calculates the actual pressure loss through each section of pipe. e sum of all the

losses is subtracted from the starting supply pressure to determine the inlet pressure to each appliance. e appliance inlet

pressure must fall within the manufacturer’s range for proper operation.

Note: Regardless of sizing method employed, the typical NG system should be sized for a minimum appliance inlet

pressure of 5"WC and 10.5"WC for LPG system. Pressures less than the typical minimums may be sufficient for proper

appliance operation but should be reviewed with the manufacturers’ input rating and the local administering authority.

Conversely, some modern higher performance appliances require an inlet pressure greater than the typical minimums.

Check the manufacturers’ input rating before sizing.

3.1.6 SIZING METHODS

Capacity Tables from this Guide (Section 7) or appropriate code approved tables must be used when sizing FlashShield™

CSST. e sizing tables used in this manual include losses for four 90-degree bends, and two end fittings. Tubing runs with

larger numbers of bends and/or fittings should be increased by an equivalent length of tubing to the following equation: L

= 1.3 (N): where “L” is additional length of tubing, and “N” is the number of additional fittings, or 90 degree bends.

FlashShield™’s Longest Run tables and Summation tables are produced from the same fluid flow equations. As such, they

will provide the same results taking into account any rounding of distance or capacity. ese fluid equations come from

data produced by a third party laboratory. e testing was performed on actual FlashShield™ CSST while tables in the code

reflect the most restrictive CSST.

THE LONGEST RUN METHOD:

A modified version of the longest run (commonly used in conventional rigid pipe systems) is presented here and used in

Examples 1, 2 & 3. is method may be used for any pressure as listed in the appropriate Capacity Table.

For sizing each length of pipe, determine the total gas load for all appliances serviced by that section and the maximum

distance over which that particular section delivers gas. e maximum distance includes overall length from the meter to

the furthest appliance serviced by that run. Refer to Section 7 Capacity Tables for the maximum flow capacity of CSST at

the required piping length.

For sizing dual-pressure systems, the piping from the meter to the pounds-to-inches regulator is sized separately from the

piping downstream of the regulator outlet. is procedure is shown in Examples 4 & 5.

GASTITE DIVISION, TITEFLEX CORPORATION / 1116 Vaughn Parkway / Portland, TN 37148

800.662.0208 / www.gastite.com / gastite@gastite.com

19

SECTION 3: SYSTEM CONFIGURATION / JANUARY 2019

Sizing for a Hybrid System (one that includes both rigid pipe and CSST) is accomplished by using the longest run method

to determine the appropriate pipe size for a given load and run length. Each segment of the piping system uses the appropriate sizing table for that particular piping material. is procedure is shown in Examples 6 & 7.

SUMMATION METHOD:

An alternative sizing method is the Summation Method which considers a summation of the pressure losses through

each section of piping. is procedure is utilized for the designer whose requirements are not satisfied by the previously

described methods. e summation method can be used for system pressures and pressure drops other than indicated in

the sizing tables for longest run. is method allows full use of the maximum flow capacity of CSST. In this fashion, a

designer can minimize piping size (or maximize flow capacity) with greater accuracy in more complicated arrangements.

e summation method is shown in Examples 8 & 9.

3.1.7 MODIFYING AN EXISTING SYSTEM

XR3-series fittings transition from CSST to pipe thread (NPT) and may be run in conjunction with all other approved

fuel gas piping (iron pipe, polyethylene tubing, copper tubing, etc.). When adding appliances to an existing system the

installer must verify whether the existing system, upstream of the lines to be added, can support the additional load.

A retrofitted line, even when properly sized, added to a system that can’t support the additional load, can adversely effect

all the other appliances in the system.

When the existing system will not support the additional load several installation options exist. A new trunk line(s) can be

run replacing the under-sized system upstream of the retrofitted appliances. A dedicated trunk line can be run from the gas

source to the new appliance. e system pressure may be elevated, thus increasing the allowable pressure drop, after which

the existing trunk lines may afford sufficiently higher flow capacity to handle the existing and new appliances.

If the piping is visible or the existing run lengths are known, the entire system can be resized using either aforementioned

sizing method (Longest Run or Summation). e system shall be resized with an appropriate sizing table based on the

affordable pressure drop. When the piping is not visible or accessible for measurement, approximated lengths should be

rounded up.

3.2 SIZING PROCEDURES AND EXERCISES

3.2.1 SIZING EXAMPLES

While the following examples show typical applications of the sizing methods they do not address all of the system

configurations in which they can be used. In general, Longest Run and Summation can be used with any pressure or

system configuration (series, parallel, dual-pressure, hybrid, etc.).

e following exercises illustrate various design layouts, pressure drops and sizing methods. To further highlight the

differences in methods and designs, examples 1-8 use the same appliance layout and load.

20

GASTITE DIVISION, TITEFLEX CORPORATION / 1116 Vaughn Parkway / Portland, TN 37148

800.662.0208 / www.gastite.com / gastite@gastite.com

SECTION 3: SYSTEM CONFIGURATION / JANUARY 2019

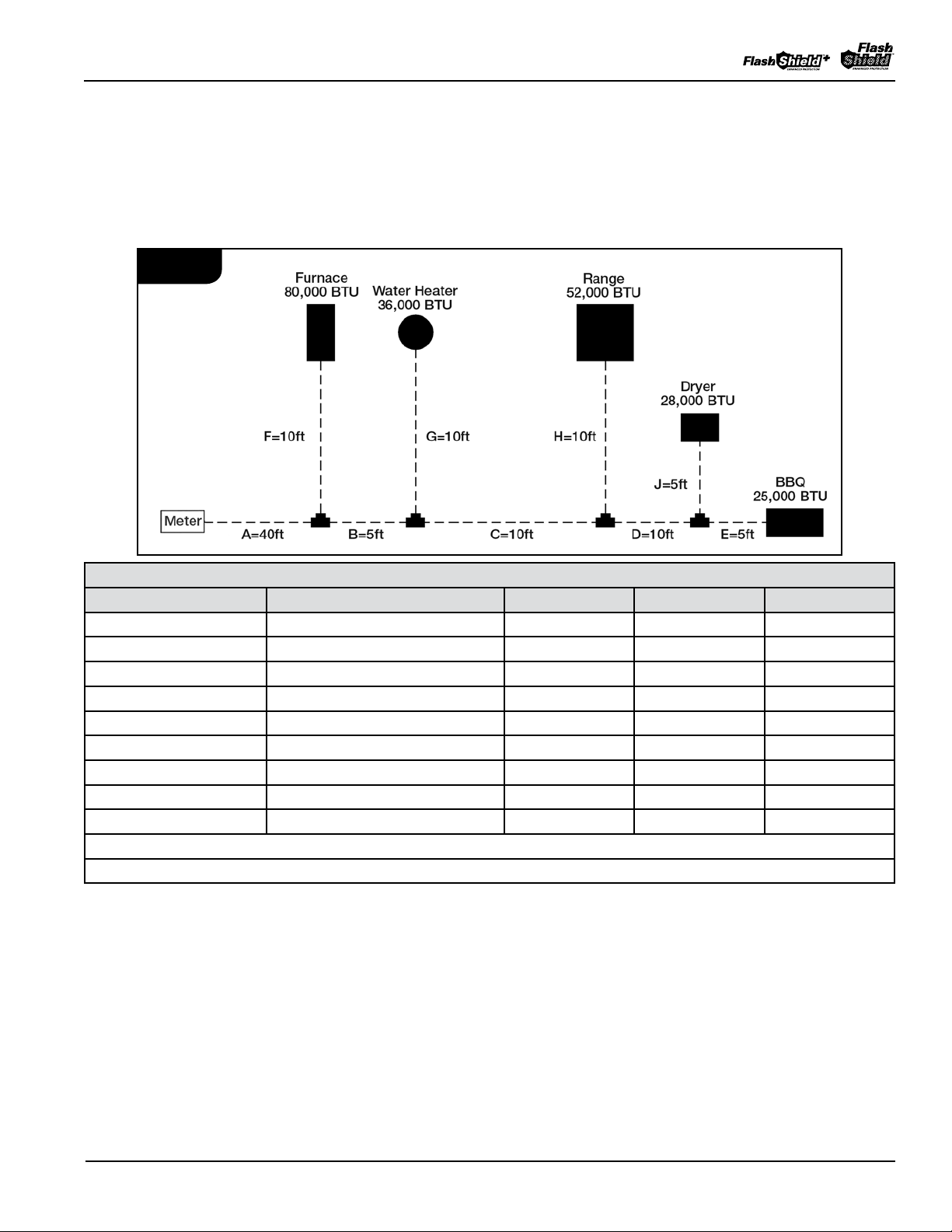

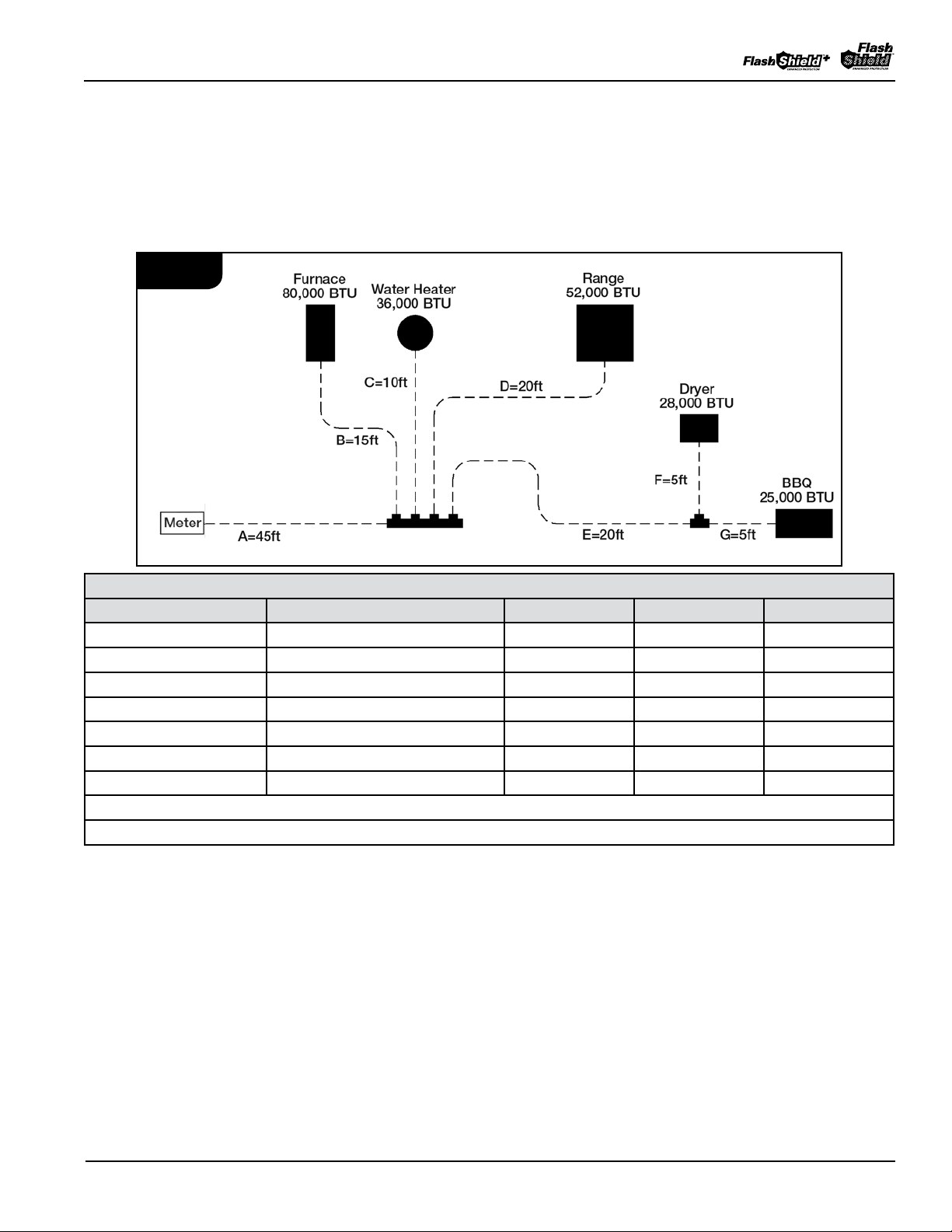

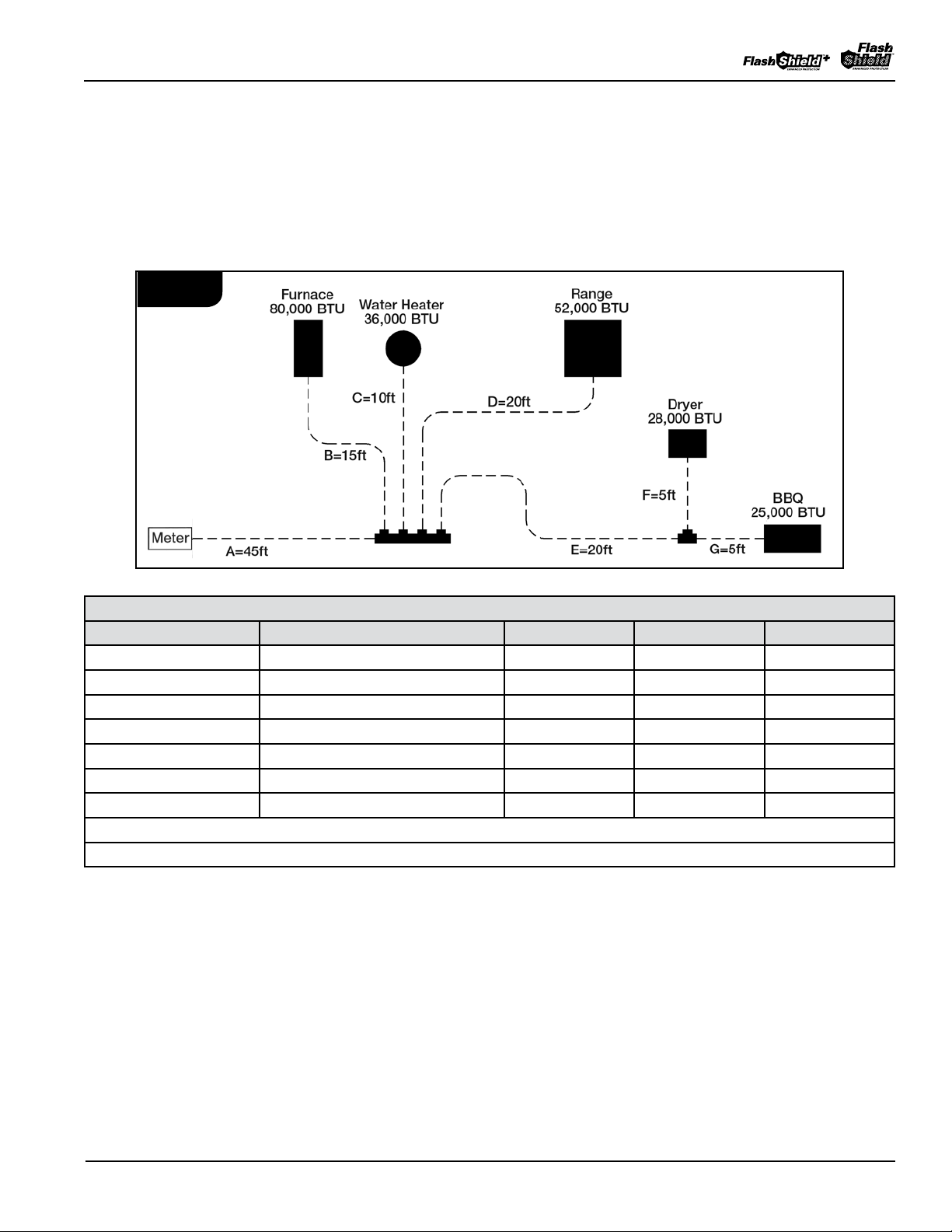

3.2.2 EXAMPLE 1: SERIES SYSTEM – 6"WC

Figure 3-9 below shows a typical single-family house installation with five (5) appliances. e piping is arranged in series

with a main run branching at the appliances. e utility company’s supply pressure (downstream of the meter) is 6"WC.

e utility company advises that the specific gravity of the gas delivered will be 0.60 and the energy content is 1 CFH =

1000 BTUH. e allowable pressure drop across the system has been determined to be 1.0"WC (supply pressure 6"WC –

appliance requirement 5"WC).

Fig. 3-9

TABLE 3-2

SECTION DESCRIPTION LOAD DELIVERED BY SECTION SECTION LENGTH RUN LENGTH TUBE SIZE

“A” – Trunk 221 CFH = 221,000 BTUH 40 feet 70 feet 1" CSST

“B” – Trunk 141 CFH = 141,000 BTUH 5 feet 70 feet 1" CSST

“C” – Trunk 105 CFH = 105,000 BTUH 10 feet 70 feet 1" CSST

“D” – Trunk 53 CFH = 53,000 BTUH 10 feet 70 feet 3/4" CSST

“E” – BBQ 25 CFH = 25,000 BTUH 5 feet 70 feet 1/2" CSST

“F” – Furnace 80 CFH = 80,000 BTUH 10 feet 50 feet 3/4" CSST

“G” – Water Heater 36 CFH = 36,000 BTUH 10 feet 55 feet 1/2" CSST

“H” – Range 52 CFH = 52,000 BTUH 10 feet 65 feet 3/4" CSST

“J” – Dryer 28 CFH = 28,000 BTUH 5 feet 70 feet 1/2" CSST

Run Length for Trunk Sections = Distance from meter to furthest appliance (Longest Run)

Run Length for Appliance Sections = Distance from meter to each appliance

SIZING RUN “A”

• Run “A” is sized by the total load of all appliances and the run length from the meter to the furthest appliance

• e total load of all appliances is 80 + 36 + 52 + 28 + 25 = 221CFH