Gas Measurement Instruments 2-500 User Manual

GAS MEASUREMENT INSTRUMENTS LTD.

CHECKLIST

1. Check the instrument has no obvious faults.

2. Check accessories.

3. Read and understand handbook before use.

4. Switch ON (see overleaf)

5. Check battery levels.

6. Check “ZERO” in fresh air.

SAFETY

• The instrument must be regularly serviced and calibrated

by fully trained personnel in a safe area.

• Batteries: Alkaline batteries must be exchanged in a

safe area and fitted correctly before use. Never use

damaged batteries or expose to extreme heat.

• Only GMI replacement parts should be used.

• If the instrument detects gas, follow your own organisa

tion’s procedures and operational guidelines.

• The combustion chamber is a flameproof assembly and

must not be opened in the presence of a flammable

atmosphere.

• Gascoseeker 2-500 instruments are certified as:

EEx iad IIC T4 (-20oC

BAS01ATEX2292 II 2 G.

UL Class 1 Groups A, B, C and D.

• This equipment is designed and manufactured to protect

against other hazards as defined in paragraph 1.2.7 of

Annex II of the ATEX Directive 94/9/EC

Any right of claim relating to product liability or consequential

damage to any third party against GMI is removed if the warnings

are not observed.

Part Number: 13889 Issue 2 (15/03/2004)

GASCOSEEKER 2-500

OPERATING INSTRUCTIONS

<

Tamb < 50

AREAS OF USE

Exposure to certain chemicals can result in a loss of sensitivity of the flammable

sensor. Where such environments are known or suspected it is recommended

that more frequent response checks are carried out. The chemical compounds

that can cause loss of sensitivity include Silicones, Lead, Halogens and Sulphur.

Do not use instrument in potentially hazardous atmospheres containing greater

than 21% Oxygen. The enclosure material is polypropylene and must not be

exposed to environments which are liable to result in mechanical or thermal

degradation or to damage caused by contact with aggressive substances.

Additional protection may be required in environments where the instrument

enclosure is liable to damage.

OPERATOR MESSAGES / FAULT FLAGS

Various messages can appear on the LCD screen to indicate instrument status.

‘SAMPLE’

Indication that the pump is running and the instrument is sampling.

’OFF’

Indication that the instrument is about to switch OFF. Can be reset by pressing

MEASURE button once.

‘SAMPLE FAULT’

Indication that the instrument sample flow is incorrect due to sample path

blockage or pump failure.

‘CHECK ZERO’

Indication that there may have been a zero shift due to the presence of gas.

Switch off the instrument and switch on again in fresh air.

o

C).

‘ZERO FAULT’

Indication that zero is outside calibration limits. Switch instrument OFF and

initiate ZERO sequence with instrument in fresh air to reset zero.

‘BAT’ (Flashing)

Indication that the batteries will soon require replacement as indicated by BAT

FAULT flag.

‘BAT FAULT’

Indication that the batteries require replacement.

‘ZERO’

Indication that the instrument is in the ZERO mode.

GASCOSEEKER 2-500

OFF

MEASURE

PUMP ON

PUMP OFF

%

10080

60

40200

OFF

MEASURE

ZERO

GASCOSEEKER 2-500

%

10080

60

40200

ZERO

PUMP ON

BUTTON 1

OPERATION

BUTTON 2

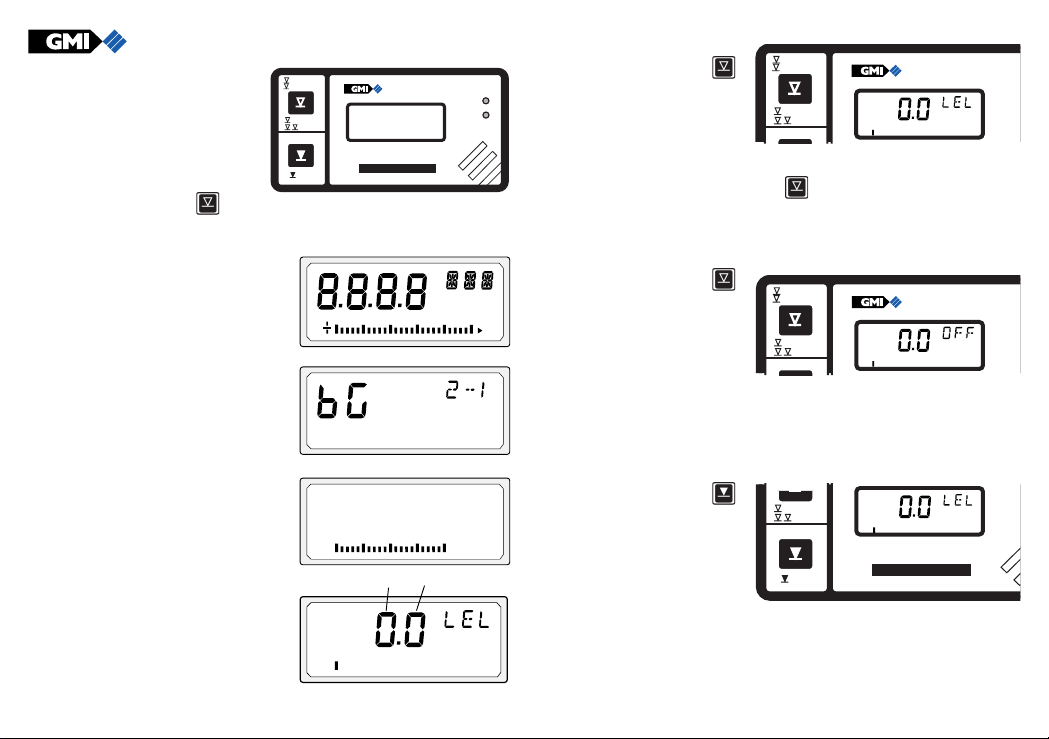

Switch ON

Press MEASURE Button

once to switch instrument ON. Instrument performs self-check and start-up

sequence. Pump also operates for a short period during this sequence.

All LCD segments are displayed:

The following display indicates instrument

version identifier and software version

number:

A bar graph indicates battery capacity and

background illumination is activated:

After a few seconds the instrument is

ready for use, indicated by a flashing

digital display:

PUMP OFF

MEASURE

OFF

ZERO

GASCOSEEKER 2-500

6000

400020000

60

40200

Display flashing

60

40200

%

V

SAMPLE STORE

CHECK

ZERO

BAT

FAULT

10000PPM8000

V

BAT

10080

%

10080

Sample Start

Press MEASURE Button

once to switch on pump.

‘SAMPLE’ flag indicates that

pump is running and display

shows analysis of sample:

PUMP ON

PUMP OFF

MEASURE

OFF

%

SAMPLE

60

40200

10080

Sample Finish

A single press of the MEASURE button , when the pump is running, stops

the pump and stops sampling. This is indicated by the absence of both ‘SAMPLE’

flag and flashing display.

Switch OFF

Press the MEASURE button

twice in rapid succession to

switch the instrument OFF.

‘OFF’ appears in the display and

the instrument will shut down.

(To cancel this action, press the

MEASURE button once).

Switch off is automatic after 30 minutes running.

Zero Mode

Make sure that the instrument is switched OFF and in FRESH AIR before

zeroing.

Press the ZERO button

once to enter zero mode.

The instrument will enter zero

mode with similar test sequence

to measure mode except for

‘ZERO’ flag, indicated in the

status display as shown.

The instrument is then zeroed automatically.

If this operation does not reset the zero and remove the ‘ZERO FAULT’ or

‘CHECK ZERO’ flags, the instrument should be returned to the service centre

for checking.

The instrument switches OFF automatically from the ZERO mode.

The instrument can only be zeroed by switching OFF from the MEASURE mode.

Loading...

Loading...