Gasket Resources Durlon 9000 User Manual

GASKET RESOURCES INC.

APPLICATIONS:

♦

DURLON®9000 STEP RING GASKETS

• GASKET IS CENTERED BY THE

♦

BOLTS

• CLASS 150 RF FLOATING

(LAP JOINT) FLANGES

• MONDI

™

DUCTILE IRON SULFURIC

• LOAD IS CONCENTRATED OVER

THE SMALLER INNER SEALING

AREA

ACID PIPING

• PREVENTS FLUID MIGRATION

FROM INSIDE THE PIPE

• ONE PIECE - NO GLUED JOINT

OR GASKET TO GASKET SEAL

Gasket Installation Procedure:

1. Visually examine and clean flanges, bolts, nuts and washers. Replace components if necessary.

2. LUBRICATE BOLTS, NUTS, AND FLANGE SURFACE AROUND BOLT HOLES. If possible use hardened steel washers.

3. Install new gasket. DO NOT REUSE OLD GASKET, MULTIPLE GASKETS, OR LUBRICATION ON THE GASKET.

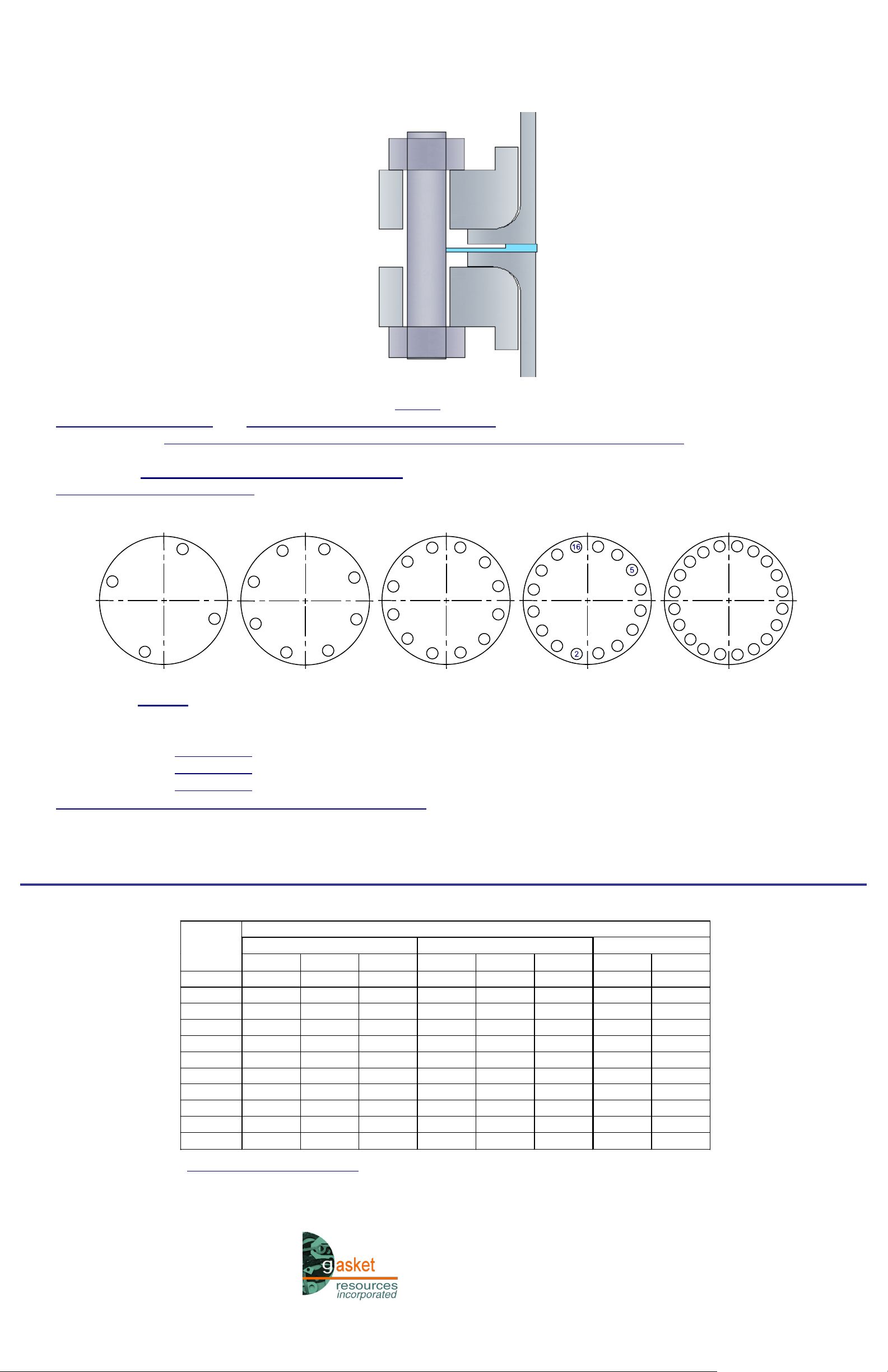

4. Number bolts in cross-pattern sequence according to the appropriate sketch below.

5. IMPORTANT! HAND TIGHTEN; then PRE-TIGHTEN BOLTS to stabilize the flanges, but DO NOT EXCEED 20% of Target Torque

6. CHECK GAP BETWEEN FLANGES for uniformity.

7. Use the APPROPRIATE CROSS-PATTERN TIGHTENING SEQUENCE in the sketch below for ROUNDS 1, 2, and 3 and/or ROUND 4

(each sequence constitutes a “Round”).

1

1

1

4

3

2

8

4

6

2

1

5

3

7

4

10

4-bolt 8-bolt

12

8

6

2

5

9

3

7

11

8

12

4

14

6

10

12-bolt 16-bolt 20-bolt

1

9

16

13

3

11

7

15

4

10

18

12

20

8

6

14

13

5

17

9

3

15

7

19

2

11

Final Torque: ft-lbs (see chart below)

• BOLTS / NUTS: LUBRICATE, HAND TIGHTEN,

• PRETIGHTEN: to 10-20 ft-lbs (but not greater than 20% of bolt yield)

• Round 1 - Tighten to ft-lbs - 1st torque value in chart below (25% of final torque)

• Round 2 - Tighten to ft-lbs - 2nd torque value in chart below (50% of final torque)

• Round 3 - Tighten to ft-lbs - Final torque value in chart below (100% of final torque)

Check gap around the circumference between each of these rounds, measured at every other bolt. If the gap is not reasonably

uniform around the circumference, make the appropriate adjustments by selective bolt tightening before proceeding.

• Round 4 - ROTATIONAL ROUND: Tighten at the Final Torque (same as Round 3 above) using a ROTATIONAL, clockwise tightening sequence,

starting with the No. 1 Bolt. Continue tightening around until no further nut rotation occurs at 100% of the Final Torque value for any nut.

• NOTE – If possible, after 4 hours rotational retightening at ambient temperature and pressure can compensate for bolt or gasket relaxation.

Torque Values - 1/8” DURLON®9000 Step Gaskets for Class 150 Floating Flanges

Nominal

Pipe

Size

F593 316SS, dry SAE Gr. 5, lubricated Tighten Seq Dwg *

1st 2nd Final 1st 2nd Final Bolt No. Bolt Dia.

Durlon 9000 Step Gaskets - Torque / Round (ft-lbs)

3" 20 40 75 25 50 100 4-bolt 5/8"

4" 15 30 70 15 30 70 8-bolt 5/8"

6" 30 60 120 30 60 120 8-bolt 3/4"

8" 25 50 110 40 80 160 8-bolt 3/4"

10" 35 70 150 40 80 160 12-bolt 7/8"

12" 45 90 180 45 90 180 12-bolt 7/8"

14" 65 130 260 90 180 370 12-bolt 1"

16" 69 139 210 75 150 310 16-bolt 1"

18" 65 130 260 100 200 400 16-bolt 1-1/8"

20" 85 170 350 85 170 350 20-bolt 1-1/8"

24" 115 230 460 115 230 460 20-bolt 1-1/4"

Note: It is assumed that new studs or bolts and nuts are used and studs, nuts and the flange facings on the nuts are

lubricated with a never-seize type paste

* Refer to the appropriate bolt tightening sequence drawing for the number of bolts listed.

** A raised step is not required on sizes under 3" ID and standard ANSI ring gaskets should be used.

These torque values are considered reliable but care should be taken on ductile iron to not crack or damage the flanges.

using the installation and bolt tightening practices outlined above.

GASKET RESOURCES INC.

Downingtown, PA – Toll Free: (866) 707-7300

E-mail: sales@durlon.com

Technical Services – Houston, Texas

PH: (713) 856-9445

E-mail: tech@durlon.com

©2014 Gasket Resources Inc.®All rights reserved www.gasketresources.com DURLON® is a registered Trademark of Gasket Resources Inc.

Loading...

Loading...