Page 1

At Space-Ray, industrial comfort heating is a challenge we take seriously. We have

been manufacturing gas-fired infrared heating systems since 1958. The quality and

performance of our heaters are based on over 45 years of field experience and exposure to a wide variety of industrial heating problems. Our reputation is built upon a

solid track record for providing radiant ef ficient, easy-to-install, and high quality infrared

heating equipment.

Space-Ray infrared tube heaters are ideal for complete building heat or even spot

heating needs. The best applications include: manufacturing plants, warehouses,

auto dealerships, aircraft hangars, loading docks, weld shops, truck or auto service

areas, car washes, fire stations, greenhouses, gymnasiums, garages, machine

shops, tennis courts, swimming pools, maintenance shops, farm buildings and many

many more.

Space-Ray infrared heaters heat like the sun by transferring radiant heat energy directly to the areas to be heated. Radiant energy is absorbed by concrete floors, objects and

people, and re-radiated to warm the surrounding area. This principle is similar to the

sun’s radiant heat energy heating Earth but not the upper atmosphere. This heating

technology creates a comfort zone at floor level, not at the ceiling, and is much more

efficient than conventional forced air heating systems.

A highly radiant efficient Space-Ray infrared heating system can normally save a

building owner 30% to 50% in annual fuel costs when compared to forced air heating

systems. In fact, some Space-Ray customers report fuel savings as high as 70% with

a payback of less than one year. With a Space-Ray system, your investment payback

accrues not only from reduced energy costs, but from reduced maintenance costs,

too. So when you think industrial heating, think Space-Ray. Call us at 1-800-438-4936

for the name of our representative nearest you.

Infrared Gas Heaters For Industry Since 1958

LOW INTENSITY

ETS/ETU Series Tube Heaters

SPACE-RAY®…A TRUSTED NAME IN INFRARED HEATING

HEATING TECHNOLOGY FOR THE NEXT MILLENNIUM

30%-50% FUEL SAVINGS

SPECIFICATIONS

ETU Series

ETS Series

Page 2

MODEL

BTU/HR

INPUT

MODEL

ETS/U 130 130,000 X X X

ETS/U 140 140,000 X X

ETS/U 150 150,000 X X

ETS/U 160 160,000 X X

ETS/U 175 175,000 X X

ETS/U 180 180,000 X X X X

ETS/U 200 200,000 X X X X

ETS/U 225 225,000 X X X X

ETS/U 250 250,000 X X X X

ETS/U 40 40,000 X X

ETS/U 50 50,000 X X X

ETS/U 60 60,000 X X

ETS/U 75 75,000 X X

ETS/U 80 80,000 X X

ETS/U 90 90,000 X X

ETS/U 100 100,000 X X

ETS/U 110 110,000 X X

ETS/U 120 120,000 X X

ETS/U 125 125,000 X X X

MODEL SELECTIONS

GENERAL FEATURES

• 19 different Btu/hr sizes and more than 100

different configurations to custom design

your infrared heating system.

• CSA design certified

• Vented or indirect vented operation

• Sidewall or through-the-roof venting

• Natural and propane gas models

PULL THROUGH SYSTEM

• Products of combustion are pulled

through the combustion chamber for

increased radiant efficiency and greater

safety

• No draft hoods, totally enclosed

combustion chamber

• Heavy-duty draft inducer with permanently

lubricated, totally enclosed, fan cooled,

and heavy-duty ball bearing motor for

maintenance-free operation

• Draft inducer can be rotated 45° or 90°

for sidewall venting

BURNER SYSTEM

• Heavy-duty cast iron burner

• 10-year limited warranty on burner

• Inside or outside air for combustion

• Up to 50 ft. outside combustion air duct

capability

• Standard 6” combustion air duct opening

• Reliable direct spark ignition system and

100% gas shut-off safety control

• 30-second pre-purge prior to ignition

• State-of-the-art step opening redundant

combination gas valve for quiet ignition

and added safety

• Diaphragm air switch for proof of venting

before gas flow and ignition

• Diagnostic monitoring light system

• Burner inspection sight glass

RADIANT EMITTER TUBE SYSTEM

• 4” O.D. heavy-duty calorized aluminized

steel or alumi-therm steel combustion

chamber (10 feet) and heavy duty hotrolled steel emitter tubes

• 3-year limited warranty on the emitter

tubes

• Suitable for horizontal or angle mounting

up to 45°

• Optional 90° elbows

• Up to 75 feet sidewall vent capacity

REFLECTOR SYSTEM

• Highly efficient aluminum reflectors with

reflectivity rating of 97.5%

• Optional end, corner, side and U-bend

reflectors

• Optional decorative grille

• Individual reflectors can be rotated up to

45° to direct heat where needed

• Easy-to-use mounting brackets

TOTAL EMITTER LUBE LENGTH*

15 FT** 20 FT 30 FT 40 FT 50 FT

ETS/ETU SERIES FEATURES

TOTAL EMITTER LUBE LENGTH*

30 FT 40 FT 50 FT 60 FT 70 FT 80 FT

NOTE: For all installations higher than

2000 ft. above sea level, please consult

the factory regarding recommended

derating of heaters.

GAS

TYPE

NATURAL 3.5” W.C. 5” W.C* 14” W.C.

PROPANE 10” W.C. 11” W.C.** 14” W.C.

BURNER

PRESSURE

VOLTAGE

AMPS

IGNITION

TYPE

MIN MAX

120 VAC

60 HZ

2.6

DIRECT

SPARK

*Indicate model number based on Btu/hr input (e.g., 100,000 Btu/hr), total emitter length, (e.g., 40 feet) and gas type (e.g., natural gas). The

unit selection for a straight tube would be ETS100-40-N and for a U-tube would be ETU100-40-N. **Available only on ETS models.

*7” W.C. for ETS/ETU (180-250) **12” W.C. for ETS/ETU (180-250)

SUPPLY PRESSURE

BTU/HR

INPUT

Page 3

MODEL

ETS AND ETU

DRAFT INDUCER CONTROL BOX

Flue Connection: 4” Round for ETS/U (40-75)

6” Round for ETS/U (80-250)

Fresh Air Connection: 4” Round for ETS/U (40-75)

6” Round for ETS/U (80-250)

ETS OPTIONS

90° ELBOW CORNER REFLECTOR

ETS - BOTTOM VIEW ETS - END VIEW

DIMENSIONS

MINIMUM RECOMMENDED MOUNTING HEIGHTS

MINIMUM CLEARANCES TO COMBUSTIBLES

ETU - BOTTOM VIEW ETU - END VIEW

TOTAL TUBE OVERALL

LENGTH (FT) DIMENSION”L”(FT)

D

E

S

I

G

N

C

E

R

T

I

F

I

E

D

TOTAL TUBE OVERALL

LENGTH (FT) DIMENSION ”L” (FT) MODEL

ETS (40, 50)

ETS (40, 50, 60, 75)

ETS (40, 50, 60, 75, 80, 90,

100, 110, 120, 130)

ETS (80, 90, 100, 110, 120,

125, 130, 140, 150, 160,175)

ETS (125, 130, 140, 150,

160, 175, 180, 200, 225, 250)

ETS (180, 200, 225, 250)

ETS (180, 200, 225, 250)

ETS (180, 200, 225, 250)

15’

20’

30’

40’

50’

60’

70’

80’

17’3”

22’3”

32’3”

42’3”

52’3”

62’3”

72’3”

82’3”

ETU (40, 50, 60, 75)

ETU (50, 60, 75, 80, 90,

100, 110, 120, 130)

ETU (80, 90, 100, 110, 120,

125,130, 140, 150, 160, 175)

ETU (125, 130, 140, 150,

160,175,180,200, 225, 250)

ETU (180, 200, 225, 250)

ETU (180, 200, 225, 250)

ETU (180, 200, 225, 250)

MODEL

MODEL

ETS/U 40

ETS/U 50

ETS/U 60

ETS/U 75

ETS/U 80 & 90

ETS/U 100 & 110

10 feet

11 feet

12 feet

13 feet

13 feet

14 feet

9 feet

10 feet

11 feet

12 feet

12 feet

13 feet

ETS/U 120 & 125

ETS/U 130 & 140

ETS/U 150

ETS/U 160 & 175

ETS/U 180 & 200

ETS/U 225 & 250

14 feet

15 feet

15 feet

16 feet

18 feet

20 feet

13 feet

14 feet

14 feet

15 feet

17 feet

19 feet

HEIGHT AT

HORIZONTAL

HEIGHT AT

45° ANGLE

ETS/U (40, 50)

ETS/U (60, 75)

ETS/U (80, 90)

ETS/U 100

ETS/U (110, 120, 125, 130)

ETS/U (140, 150, 160, 175)

ETS/U (180, 200, 225, 250)

MINIMUM CLEARANCES TO COMBUSTIBLES MODEL NO.

SIDE

CEILING BELOW END

(45°)

FRONT

(45°)

REAR

HORIZONTAL

27”

27”

52”

66”

66”

84”

86”

6”

6”

6”

6”

6”

6”

18”

40”

60”

84”

88”

101”

106”

132”**

30”

30”

30”

40”

40”

48”

48”

48”

48”

52”

66”

66”

84”

84”

12”

12”

12”

20”

20”

24”

24”

*When used indirect vented, clearances to ceiling from top of exhaust hood must be 12” on ETS/U (40-75), and 18” on

ETS/U (80-250). If optional corner or U-bend reflectors are not used, clearance must be 18”. **Clearance below the heater

is 132” for the first 20 ft. of the emitter tube and reduces to 72” 20 ft. downstream from the control box.

Note: Consult factory if reduced clearances are required.

This chart is intended as a guide only, as heaters may be mounted at various heights and angles. Since straight tube heaters are always hotter at the burner end than

at the exhaust end, always observe the minimum recommended mounting heights shown above. Use ETU series for spot heating. Please consult your local SpaceRay Representative for a detailed analysis of your particular infrared heating requirements.

20’

30’

40’

50’

60’

70’

80’

12’9”

17’9”

22’9”

27’9”

32’9”

37’9”

42’9”

L

L

18”

18”

9”

13”

6”

15”

Control

Box

Draft

Inducer

18”

31”

6”

45° ANGLE

(MAXIMUM)

HEIGHT AT

HORIZONTAL

HEIGHT AT

45° ANGLE

1/2

Page 4

COMBUSTION AIR AND VENTILATION

Combustion air and venting requirements for all gas-fired heating equipment must be provided per the National Fuel Gas Code NFPA54 or the authority having jurisdiction over the

installation. In contaminated atmospheres or high humidity areas, optional outside air for combustion can be supplied. Heaters can be common vented, direct vented, or indirect

vented. Refer to the Installation and Operation Instructions for further information. A vented installation must be vented to the outside of the building with a flue pipe. An Indirect

vented installation requires a minimum ventilation flow of 4 CFM per 1000 Btu/hr of total installed heater capacity on natural gas by either gravity or power ventilation (4.18 CFM per

1000 Btu/hr on propane). For indirect vented applications, building exhaust openings must be located above the level of the heaters and inlet air openings must be located below

the level of the heaters.

FOR YOUR SAFETY

OPERATE SPACE-RAY GAS INFRARED HEATERS WITH PROPER CARE AND OBSERVE ALL SAFETY PRECAUTIONS. Installation and service must be performed by a licensed contractor. The installation must conform to local codes. In the absence of local codes, the installation must conform to the National Fuel Gas Code ANSI Z223.1 (latest edition, also known

as NPFA54) or CAN / CSA-B149 installation codes (latest edition). These codes are available from the National Fire Protection Association, Inc., Batterymarch Park, Quincy, MA 02269

or the Canadian Gas Association, 55 Scarsdale Road, Toronto, Ontario MB3 2R3 Canada.

A Division of Gas-Fired Products, Inc.

P.O. Box 36485 Charlotte, NC 28236 Telephone (Toll Free) 1-800-438-4936 (704) 372-3485 Fax (704) 332-5843

Copyright 2003, GFP INC. 10325M FORM#S45504

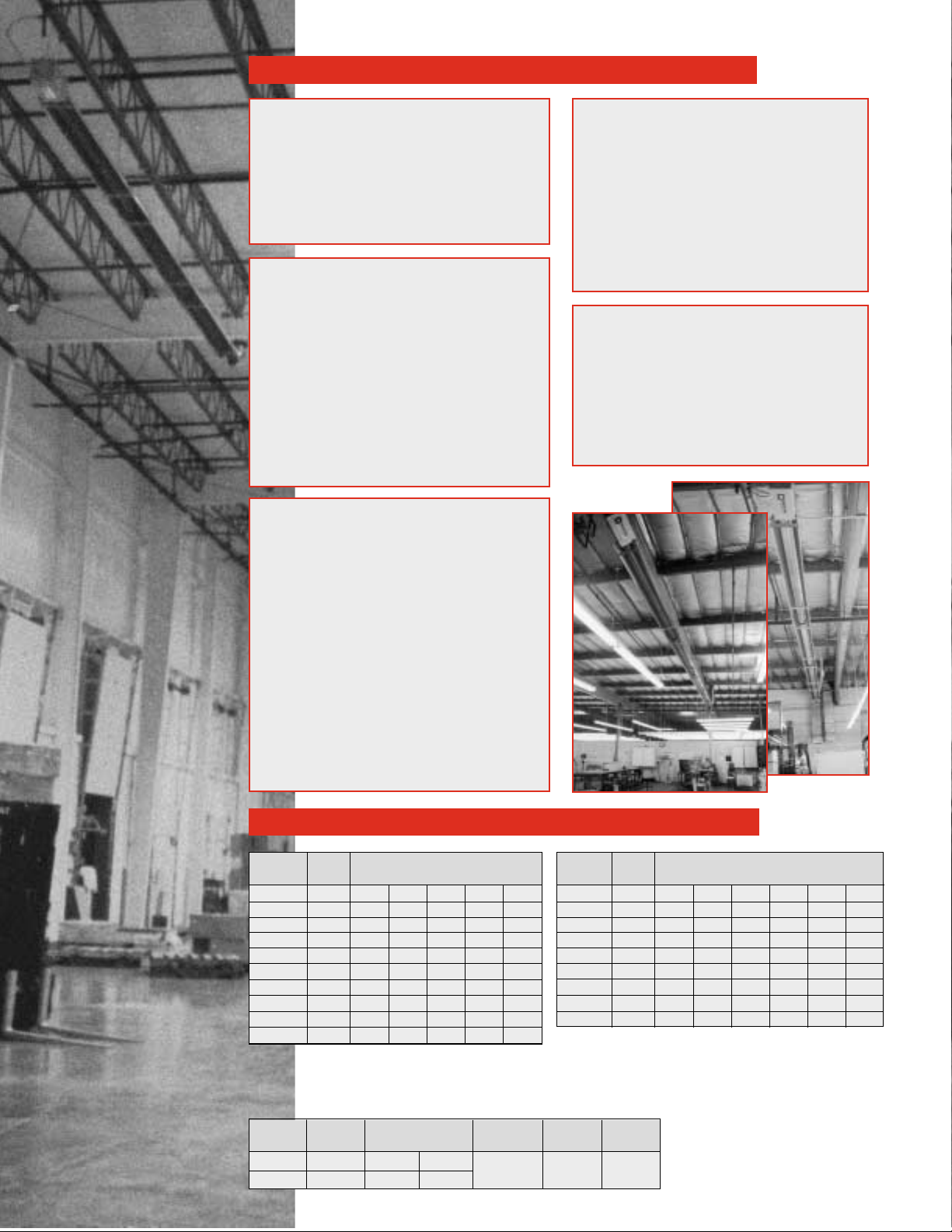

ETS/ETU SERIES LAYOUTS

The ETS/ETU series, with more than 100 different configurations, offers optimum flexibility in custom designing an

infrared heating system. The ETS series is available in multiple configurations (straight, L, Z, and expanded U-shape) with

lengths from 15’ to 80’ long. For added versitality , 90°elbows, corner reflectors, and side reflectors are available for close

area mounting near walls, doors, and corners. The ETU series is available in seven different configurations and provides

more uniform radiant heat energy distribution. The ETU series is ideal for high heat loss areas and spot heating.

ETS/ETU SERIES LAYOUTS

Only 15 ft. to 50 ft. systems are shown. Please refer to the Installation and Operation Instructions for complete layouts.

www.spaceray.com • email: info@spaceray.com

LEGEND

CONTROL UNIT DRAFT INDUCER 10FT. BODYSECTION 5 FT. BODY SECTION 90° ELBOW 180° U BEND

ETS SERIES

STRAIGHT L-SHAPE

EXPANDED

Z-SHAPE STRAIGHT L-SHAPE

EXPANDED

Z-SHAPE

U-SHAPE U-SHAPE

15 FT SYSTEM

40 FT SYSTEM

20 FT SYSTEM

25 FT SYSTEM

45 FT SYSTEM

30 FT SYSTEM

35 FT SYSTEM 50 FT SYSTEM

ETU SERIES

20 FT SYSTEM 30 FT SYSTEM 40 FT SYSTEM 50 FT SYSTEM

Loading...

Loading...