Page 1

INSTALLATION AND OPERATION INSTRUCTIONS

OWNER / INSTALLER: For your safety this manual must be carefully and thoroughly read

and understood before installing, operating or servicing this heater.

INFRARED RADIANT TUBE HEATER

Two Stage Push Through System (Positive Pressure)

Models

:

PTS SERIES: (40, 50, 75, 100, 125, 150, 175, 200) – N7/L7

PTU SERIES: (40, 50, 75, 100, 125, 150, 175, 200) – N7/L7

!INSTALLER: This manual is the property of the owner. Please present this manual to

the owner when you leave the job site.

WARNING: Improper installation, adjustment, alteration, service, or maintenance can

cause property damage, injury or death. Read the installation, operation and maintenance

instructions thoroughly before installing or servicing this equipment.

IF YOU SMELL GAS:

^ DO NOT try to light any appliance.

^ DO NOT touch any electrical switch; DO NOT use any

telephone in your building.

^ IMMEDIATELY call your gas supplier from a neighbor's

telephone. Follow the gas supplier's instructions. If you

cannot reach your gas supplier, call the fire department.

!IMPORTANT

Post Office Box 36485 (28236) 305 Doggett Street (28203) Charlotte, North Carolina

Phone (704) 372-3485 Fax (704) 332-5843 www.spaceray.com email: info@spaceray.com

Form #43343530

July 08

FOR YOUR SAFETY

: SAVE THIS MANUAL FOR FUTURE REFERENCE.

SPACE-RAY

DO NOT store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

Page 2

TABLE OF CONTENTS

SECTION

DESCRIPTION PAGE

1.0) Safety........................................................................................................................................ 2

2.0) Installer Responsibility........................................................................................................... 2

3.0) General Information ............................................................................................................... 2

4.0) Minimum Clearances to Combustibles ............................................................................... 4

5.0) Specifications .......................................................................................................................... 5

6.0) Packing List ............................................................................................................................. 5

6.1) Accessory Packages ............................................................................................................... 9

7.0) Typical Layouts – PTS/U Series ........................................................................................... 11

7.1) Typical Assembly Layout........................................................................................................ 12

8.0) Dimensions – PTS Series....................................................................................................... 13

8.1) Dimensions – PTU Series ..................................................................................................... 14

8.2) Heater Assembly / Joining of Tube Sections...................................................................... 15

9.0) Typical Suspension Methods................................................................................................. 17

10.0) Assembly of Tube Sections.................................................................................................... 18

10.1) Assembly of Extension Section............................................................................................. 19

10.2) Inserting Turbulators .............................................................................................................. 20

10.3) Adding Body Reflectors.......................................................................................................... 21

11.0) Adding Optional 90º Elbow (PTS Only) ............................................................................... 22

11.1) Adding Optional Corner Reflector (PTS Only) .................................................................... 22

11.2) Adding 180º U-Bend (PTU Only)........................................................................................... 23

11.3) Adding Optional U-Bend Reflector (PTU Only) ................................................................... 23

12.0) Attaching Control Box Assembly .......................................................................................... 24

12.1) Connecting The TISS System ............................................................................................... 25

13.0) Gas Connections And Regulations ....................................................................................... 28

14.0) Instructions For Pressure Test Gauge Connection............................................................. 30

15.0) Electrical Connections............................................................................................................ 31

16.0) Venting...................................................................................................................................... 34

17.0) Air For Combustion ................................................................................................................. 38

17.1) Direct Outside Air For Combustion....................................................................................... 38

18.0) Lighting and Shutdown Instructions .................................................................................... 40

19.0) Sequence of Operation .......................................................................................................... 40

20.0) Burner Component Location ................................................................................................. 41

21.0) Cleaning And Annual Maintenance...................................................................................... 42

22.0) Troubleshooting Guide ........................................................................................................... 43

23.0) Replacing Parts ....................................................................................................................... 46

23.1) Removal of Main Burner And Electrodes ............................................................................ 46

23.2) Removing Gas Valve And Manifold Assembly ................................................................... 47

23.3) Air Switch Pressure Check .................................................................................................... 47

23.4) Ignition System Checks.......................................................................................................... 48

24.0) Installation Data...................................................................................................................... 49

25.0) Replacement Parts Guide...................................................................................................... 49

This heater complies with ANSI Z83.20 (current standard) and CSA 2.34. Copies of the National Fuel Gas Code (ANSI

Z223.1-latest edition) are available from the CSA at 8501 East Pleasant Valley Road, Cleveland, Ohio 44131 or 55 Scarsdale

Road, Don Mills, Ontario M3B 2R3. All NFPA codes are available from the National Fire Protection Association, Batterymarch

Park, Quincy, Massachusetts 02269.

Form #43343530

July 08 –1–

Page 3

1.0) SAFETY

This heater is a self-contained two stage infrared radiant tube heater. Safety information required during installation

and operation of this heater is provided in this manual and the labels on the product. The installation, service and

maintenance of this heater must be performed by a contractor qualified in the installation and service of gas fired

heating equipment.

All personnel in contact with the heater must read and understand all safety information, instructions and labels

before operation. The following symbols will be used in this manual to indicate important safety information.

Warning instructions must be followed to prevent or avoid hazards which

may cause serious injury, property damage or death.

Caution instructions must be followed to prevent incorrect operation or

installation of the heater which may cause minor injury or property damage.

2.0) INSTALLER RESPONSIBILITY

The installer is responsible for the following:

• The heater and venting, as well as electrical and gas supplies must be installed in accordance with these

installation instructions and any applicable codes and regulations.

• Every heater shall be located with respect to building construction and other equipment so as to permit access to

the heater.

• Each installer must follow the clearances to combustible materials for the heaters.

• Install the heater so that the supports and hangers are correctly spaced in accordance with these instructions. The

heater must be supported by materials having a working load limit of at least 115lbs.

• Ensure that the tube integrity safety system TISS™ supplied is installed in accordance with these instructions and

that the tension is correct.

• Supply the owner with a copy of these Installation and Operation Instructions.

• Where unvented heaters are used, gravity or mechanical means shall be provided to supply and exhaust at least 4

CFM per 1,000 Btu/hr input of installed heaters.

• Never use the heater as a support for a ladder or other access equipment. Do not hang anything from the heater.

• Supply all installation materials necessary that are not included with the heater.

• Check the nameplate to make sure that the burner is correct for the gas type in the building and the installation

altitude.

3.0) GENERAL INFORMATION

This heater is a self-contained two stage infrared radiant tube heater for use in locations where flammable gases or

vapors are not generally present (as defined by OSHA acceptable limits) and is intended for the heating of

nonresidential spaces.

INSTALLATION REQUIREMENTS

The installation must conform to local building codes or in the absence of local codes, with the National Fuel Gas

Code ANSI Z223.1/NFPA54 or the Natural Gas and Propane Installation Code CSAB149.1. Heaters shall be installed

by a licensed contractor or licensed installer. Clearances to combustibles as outlined in this manual should always

be observed. In areas used for storage of combustible materials where they may be stacked below the heater,

NFPA54 requires that the installer must post signs that will “specify the maximum permissible stacking height to

maintain the required clearances from the heater to combustibles.”

Form #43343530

–2– JJuly 08

Page 4

Every heater shall be located with respect to building construction and other equipment so as to permit access to the

heater. Each installer shall use quality installation practices when locating the heater and must give consideration to

clearances to combustible materials, vehicles parked below, lights, overhead doors, storage areas with stacked

materials, sprinkler heads, gas and electrical lines and any other possible obstructions or hazards. Consideration also

must be given to service accessibility.

The heater, when installed in aircraft hangars and public garages, must be installed in accordance with ANSI/NFPA

409-latest edition (Standard for Aircraft Hangars), ANSI/NFPA 88a-latest edition (Standard for Parking Structures),

and ANSI/NFPA 88b-latest edition (Standard for Repair Garages) with the following clearances:

a. At least 10 feet above the upper surfaces of wings or engine enclosures of the highest aircraft that may be

housed in the hangar and at least 8 feet above the floor in shops, offices, and other sections of hangars

communicating with aircraft storage or service areas.

b. At least 8 feet above the floor in public garages. WARNING

: Minimum clearances marked on the heater must

be maintained from vehicles parked below the heater.

a. Installation of this appliance is to be in accordance with latest edition of CAN 1-B149.1 (Installation Code for

(FOR CANADA ONLY)

Natural Gas Burning Appliances and Equipment), and/or CAN B149.2 (Installation Code for Propane Gas Burning

Appliances and Equipment).

b. For installation in public garages or aircraft hangars, the minimum clearances from the bottom of the infrared

heater to the upper surface of the highest aircraft or vehicle shall be 50 percent greater than the certified

minimum clearance, but the clearance shall not be less than 8 feet.

Although these heaters may be used in many applications other than space heating (e.g., process heating), SpaceRay will not recognize the warranty for any use other than space heating.

This heater is for Indoor Installation and Covered Patio Installation only and can be used in either Vented or Unvented

mode. The term Unvented actually means Indirect Vented. While the products of combustion are expelled into the

building, national codes require ventilation in the building to dilute these products of combustion. This ventilation

may be provided by gravity or mechanical means.

This heater is not an explosion proof heater. Where the possibility of exposure to volatile and low flash point

materials exists, it could result in property damage or death. This heater must not be installed in a spray booth where

the heater can operate during the spraying process. Consult your local fire marshal or insurance company.

PTS Series Only

: Since straight tube heaters are always hotter at the control end than at the flue terminal end,

always observe the minimum recommended mounting heights shown on the specification sheets and in Section

5.0 of this manual. Use U-tube configuration instead of straight tubes for spot or area heating (e.g., where a single

heater is utilized for space heating).

HOT

WARM

WARM

HOT

WARM

WARM

High Altitude

:

Appliances are supplied as standard for altitudes of O to 2,000 feet (0-610 m). High-altitude ratings are obtained

by a change in the orifice size. When ordered for high altitude installations, burners are supplied by the factory

ready for high altitude installation. Check the nameplate for altitude before proceeding with the installation. In

Canada the adjustment for altitude is made in accordance with Standard CGA 2.17, Gas-Fired Appliances for Use

at High Altitudes.

Form #43343530

July 08 –3–

Page 5

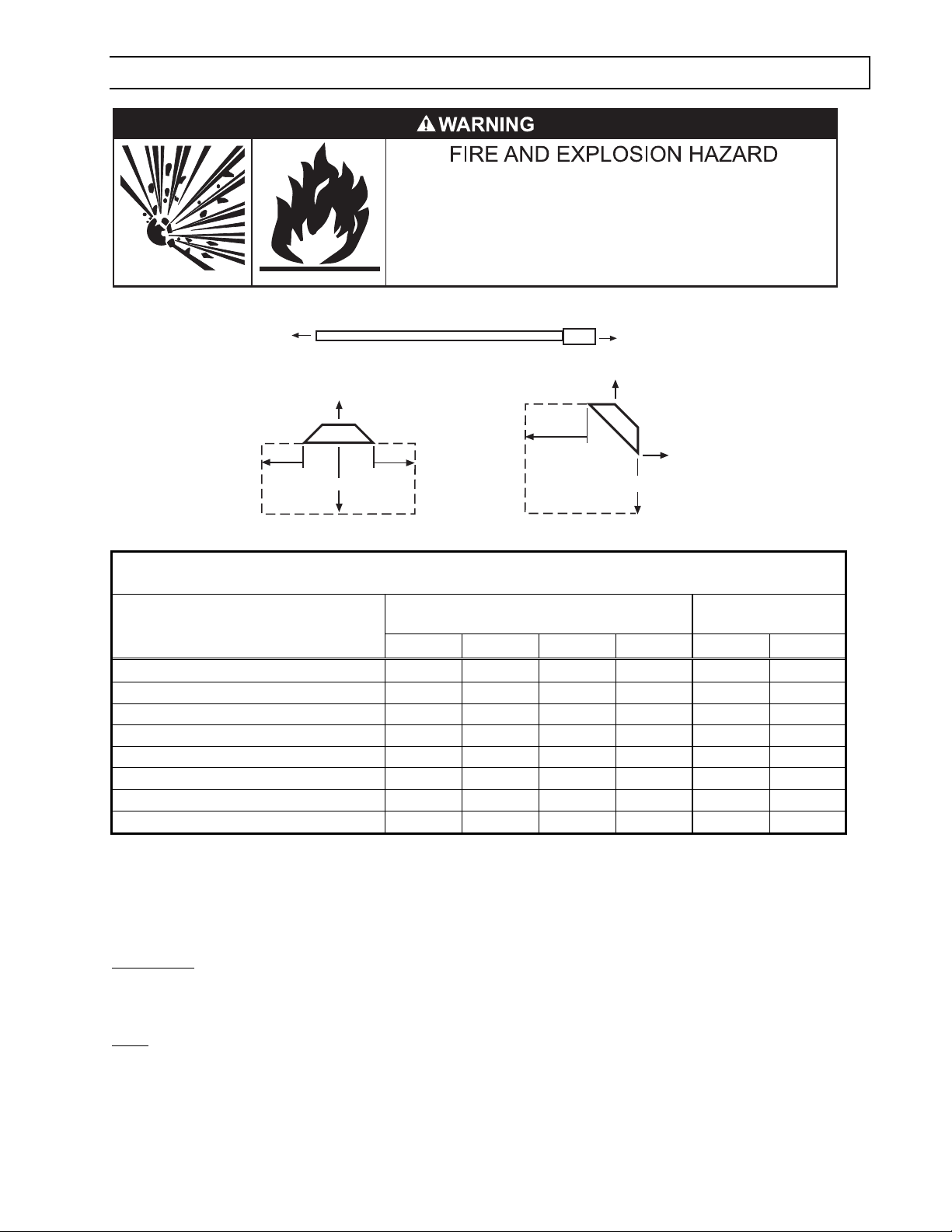

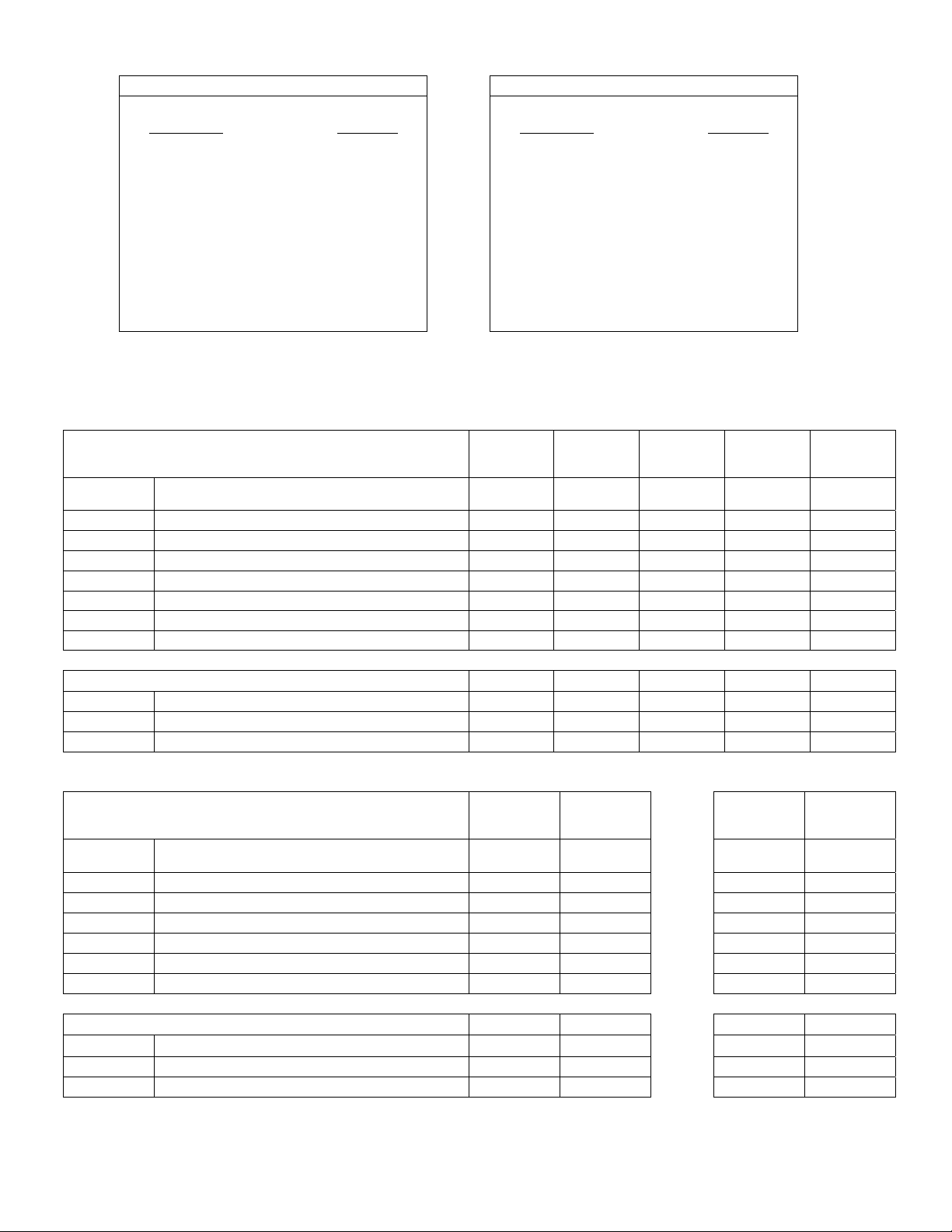

4.0) MINIMUM CLEARANCES TO COMBUSTIBLES

Combustible material must be located outside the

clearance dimensions listed.

Failure to do so may result in death, serious injury or

property damage.

Minimum clearances to combustibles shall be measured from the outer surfaces as shown in the following diagram:

End

End

* Ceiling

Ceiling

Side

Below

Horizontal

Side

Front

Below

45° Angle (Maximum)

Rear

MINIMUM CLEARANCES TO COMBUSTIBLES

Angle Mounted at

Model No.

PTS/PTU 40/25

PTS/PTU 50/30

PTS/PTU 75/50

PTS/PTU 100/65

PTS/PTU 125/80

PTS/PTU 150/100

PTS/PTU 175/110

PTS/PTU 200/125

Mounted Horizontally

Sides Ceiling* Below Ends 45º Front 45º Rear

27” 6” 40” 30” 48” 12”

27” 6” 40” 30” 48” 12”

27” 6” 60” 30” 48” 12”

66” 6” 88” ** 40” 66” 20”

66” 6” 101” ** 40” 66” 20”

84” 6” 106” ** 48” 84” 24”

84” 6” 106” ** 48” 84” 24”

84” 6” 106” ** 48” 84” 24”

45º

* When used indirect vented, minimum clearance for CEILING must be: 12” for PTS/PTU 50-75 and 18” for

PTS/PTU 100-200. If optional corner and u-bend reflectors are not used, the clearance must be 18”.

** Maximum clearance below reduces to 72” once you are 20ft. downstream from the control box.

WARNING

: Certain materials or objects, when stored under the heater, will be subjected to radiant heat and

could be seriously damaged. Observe the Minimum Clearances to Combustibles listed in the manual and on the

heater at all times.

NOTE

: The clearances specified above must be maintained to combustibles and other materials that may be

damaged by temperatures 90ºF above ambient temperature. Clearances to combustibles are posted on the

control box. In areas used for storage of combustible materials where they may be stacked below the heater,

NFPA54 requires that the installer must post signs that will “specify the maximum permissible stacking height to

maintain the required clearances from the heater to combustibles.” Space-Ray recommends posting these signs

adjacent to the heater thermostat or other suitable location that will provide enhanced visibility.

Form #43343530

–4– JJuly 08

Page 6

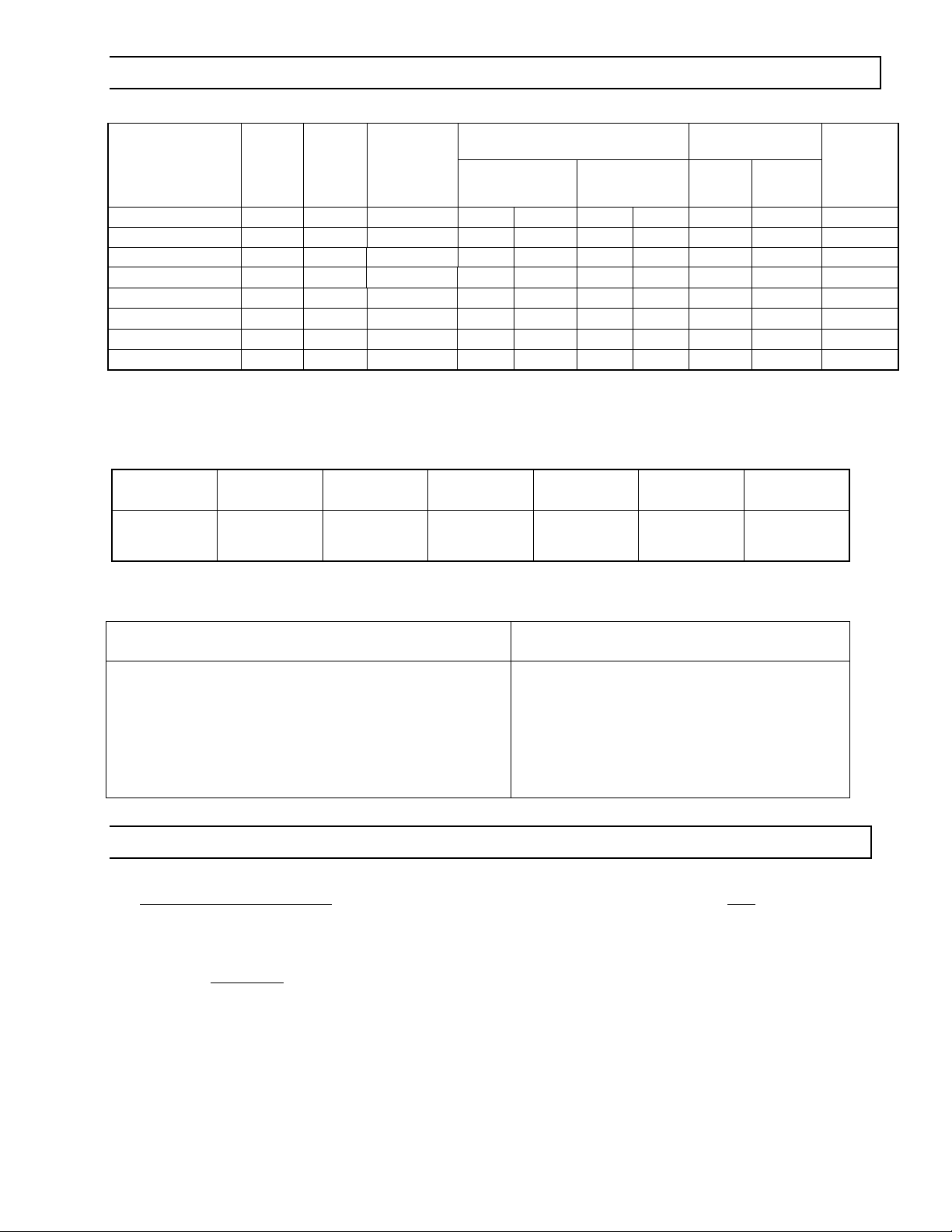

5.0) SPECIFICATIONS

High

Btu/hr

Model No.

PTS/PTU 40/25 40,000 25,000 #44140061 #32

PTS/PTU 50/30 50,000 30,000 #44140064 3.5mm

PTS/PTU 75/50 75,000 50,000 #44140063 #21

PTS/PTU 100/65 100,000 65,000 #44140062 #12

PTS/PTU 125/80 125,000 80,000 #44140066 #4

PTS/PTU 150/100 150,000 100,000 #44140067 “A”

PTS/PTU 175/110 175,000 110,000 #44140067 “E”

PTS/PTU 200/125 200,000 125,000 #44140068 6.9mm

Input

Low

Btu/hr

Input

Combustion

Air Plate

Part #

Natural Gas Propane Gas

Orifice Size

(0.116)

(0.138)

(0.159)

(0..189))

(0..209)

(0.234)

(0.250)

(0.272)

#49

46

2.5mm

#32

#30

#27

#23

4.1mm

(0.073)

(0.081)

(0.098)

(0.116)

(0.129)

(0.144)

(0.154)

(0.161)

Minimum *

Mounting Height

@

Horizonta

l

45º Angle

10 ft. 9 ft. 4

11 ft. 10 ft. 5

13 ft. 12 ft. 5

14 ft. 13 ft. 3

14 ft. 13 ft. 7

15 ft. 14 ft. 4

16 ft. 15 ft. 0

18 ft. 16 ft. 1

@

Turbulator

* MOUNT HEATERS AS HIGH AS POSSIBLE. Minimums are shown as a guideline for human comfort and uniform

energy distribution for complete building heating applications. Consult your Space-Ray representative for the

particulars of your installation requirements.

Type

Gas:

Natural

or Propane

Gas-Pipe

Connection:

Diameter:

Tube

Flue

Connection: 1

Fresh Air

Connection: 1

½” MPT

(Male) 4” 4” Round 4” Round

Electrical

Supply:

Current

Rating:

120 Volt,

60Hz, 1 Phase 1.74 Amp

1) See Section 16 for vent sizes when multiple heaters are connected into a common vent.

Module Electrical Rating:

Input Power-Control: 18-30 VAC 50/60 Hz (class 2

transformer)

Input Power-Line: 120 VAC (L1, IND contacts only)

Gas Valve Rating: 2.0 A @ 24 VAC (max.)

Combustion Blower Rating: 3.0 FLA @ 120 VAC

Ignition System (direct spark):

15 second trial for ignition period

15 second pre-purge period

60 second inter-purge period

30 second post-purge period

3 tries for ignition (separate flame sensor).

1/4 H.P. Motor

Flame Sensitivity: 0.7 microamps minimum

Qty.

6.0) PACKING LIST

A) PTS/PTU Burner Package QTY

Burner Box Assembly (Refer to the following chart for Package Part Numbers) 1

4”ID x 4”Lg Flue Adapter Collar (#30504500) ...................................................................1

Fastener Kit – Burner Box Attachment/Flue Adapter Collar (#42907040)....................1

containing

¼ - 20 Locknuts (#02167010)..............................................................3

Tube Flange Gasket (#42921000).......................................................................................1

Turbulator 24” Long (#44152240) *See chart above for required quantities. *

Installation & Operation Instructions (#43343530)..........................................................1

Turnbuckle (#30545040) ......................................................................................................1

Gas connector 5/8” OD x 36” (#30302360) .......................................................................1

Form #43343530

July 08 –5–

: #10 x 1/2” Self-Drilling Screws (#02189020)..............................2

Page 7

BURNER PACKAGE NUMBERS:

NATURAL GAS PROPANE GAS

MODEL NO PART NO.

PTS/U 40-N7 #44149510

PTS/U 50-N7 #44149530

PTS/U 75-N7 #44149550

PTS/U 100-N7 #44149570

PTS/U 125-N7 #44149590

PTS/U 150-N7 #44149610

PTS/U 175-N7 #44149630

PTS/U 200-N7 #44149650

MODEL NO

PART NO.

PTS/U 40-L7 #44149520

PTS/U 50-L7 #44149540

PTS/U 75-L7 #44149560

PTS/U 100-L7 #44149580

PTS/U 125-L7 #44149600

PTS/U 150-L7 #44149620

PTS/U 175-L7 #44149640

PTS/U 200-L7 #44149660

B) PTS 40-200 Body Package Descriptions

(Package Part Number is indicated on the outside of each corresponding carton.)

System Lengths

PTS Body Packages – Aluminized/Hot Rolled or

Alumi-Therm/Hot Rolled

10 Ft.

44134020

20 Ft. pkg

44135000

30 Ft. pkg

44136000

40 Ft. pkg

44137100

50 Ft. pkg

44138100

Part # Each Body Package Includes: Qty. Qty. Qty. Qty. Qty.

42912080 10 Ft. Tube with 24 Hole Flange (Aluminized) 1 1 1 - 42912169 10 Ft. Tube with 6 Hole Flange (Alumi-Therm) - - - 1 1

41932101 10 Ft. Tube less Flanges (Hot Rolled) - 1 2 3 4

43319100 Reflector, 9’ 11½” 1 2 3 4 5

30462980 Tube Coupling - 1 2 3 4

43318000 Tube Hanger/Support Bracket, 13” 1 2 3 4 5

43980010 Wire Hanger 1 2 3 4 5

Body Fastener Kit (included in body packages) 42907280 42907190 42907200 42907210 42907220

42873000 U-Bolt 1 2 3 4 5

02127110 Hex Nut, 5/16-18 3 5 6 8 10

02189020 HWHSM Screw, #10-16 x ½” TEKS 4 8 10 14 18

60Ft. System 70Ft. System

PTS Body Packages – Alumi-Therm/Hot Rolled

40 Ft. Pkg

44137100

20 Ft. Pkg

44135010

40 Ft. Pkg.

44137100

30 Ft. Pkg

44136040

Part # Each Body Package Includes: Qty. Qty. Qty. Qty.

42912169 10 Ft. Tube with 6 Hole Flange (Alumi-Therm)

1 - 1 41932101 10 Ft. Tube less Flanges (Hot Rolled) 3 2 3 3

43319100 Reflector, 9’ 11½” 4 2 4 3

30462980 Tube Coupling 3 2 3 3

43318000 Tube Hanger/Support Bracket, 13” 4 2 4 3

43980010 Wire Hanger 4 2

4 3

Body Fastener Kit (included in body packages) 42907210 42907190 42907210 42907200

42873000 U-Bolt 4 2 4 3

02127110 Hex Nut, 5/16-18 8 5 8 6

02189020 HWHSM Screw, #10-16 x ½” TEKS 14 8

14 10

Form #43343530

–6– JJuly 08

Page 8

C) PTS 40-200 Series Body Package Descriptions – ALC Option (Aluminized Calorized)

(Package Part Number is indicated on the outside of carton.)

System Lengths

PTS Body Packages – Aluminized/Aluminized or

Alumi-Therm/Aluminized

10 Ft. Pkg

44134020

20 Ft. Pkg

44135020

30 Ft. Pkg

44136020

40 Ft. Pkg

44137090

50 Ft. Pkg

44138080

Part # Each Body Package Includes: Qty. Qty. Qty. Qty. Qty.

42912080 10 Ft. Tube with 24 Hole Flange (Aluminized) 1 1 1 - 42912169 10 Ft. Tube with 6 Hole Flange (Alumi-Therm) - - - 1 1

41932100 10 Ft. Tube less Flanges (Aluminized) - 1 2 3 4

43319100 Reflector, 9’ 11½” 1 2 3 4 5

30462980 Tube Coupling - 1 2 3 4

43318000 Tube Hanger/Support Bracket, 13” 1 2 3 4 5

43980010 Wire Hanger 1 2 3 4 5

Body Fastener Kit (included in body packages) 42907280 42907190 42907200 42907210 42907220

42873000 U-Bolt 1 2 3 4 5

02127110 Hex Nut, 5/16-18 3 5 6 8 10

02189020 HWHSM Screw, #10-16 x ½” TEKS 4 8 10 14 18

60Ft. System 70Ft. System

PTS Body Packages – Alumi-Therm/Aluminized

40 Ft. Pkg

44137090

20 Ft. Pkg

44135030

40 Ft. Pkg

44137090

30 Ft. Pkg

44136050

Part # Each Body Package Includes: Qty. Qty.

42912169 10 Ft. Tube with 6 Hole Flange (Alumi-Therm)

1 - 1 -

Qty. Qty.

41932100 10 Ft. Tube less Flanges (Aluminized) 3 2 3 3

43319100 Reflector, 9’ 11½” 4 2 4 3

30462980 Tube Coupling 3 1 3 3

43318000 Tube Hanger/Support Bracket, 13” 4 2 4 3

43980010 Wire Hanger 4 2

4 3

Body Fastener Kit (included in body packages) 42907210 42907190 42907210 42907200

42873000 U-Bolt 4 2 4 3

02127110 Hex Nut, 5/16-18 8 5 8 6

02189020 HWHSM Screw, #10-16 x ½” TEKS 14 8

14 10

D) PTU 40-200 Body Package Descriptions

(Package Part Number is indicated on the outside of each corresponding carton.)

System Lengths

PTU Body Packages – Aluminized/Hot Rolled or

Alumi-Therm/Hot Rolled

20 Ft. Pkg.

44135000

30 Ft. Pkg

44136010

40 Ft. Pkg

44137100

50 Ft. Pkg

44138110

Part # Each Body Package Includes: Qty. Qty. Qty. Qty.

42912080 10 Ft. Tube with 24 Hole Flange (Aluminized) 1 1 - 42912169 10 Ft. Tube with 6 Hole Flange (Alumi-Therm) - - 1 1

41932101 10 Ft. Tube less Flanges (Hot Rolled) 1 1 3 3

41932051 5 Ft. Tube less Flanges (Hot Rolled) - 2 - 2

43319100 Reflector, 9’ 11½” 2 2 4 4

43319050 Reflector, 4’ 11 ½” - 2 - 2

30462980 Tube Coupling 1 3 3 5

43318000 Tube Hanger/Support Bracket, 13” 2 4 4 6

43980010 Wire Hanger 2 4 4 6

Form #43343530

July 08 –7–

Page 9

Body Fastener Kit (included in body packages) 42907190 42907210 42907210 42907221

42873000 U-Bolt 2 4 4 6

02127110 Hex Nut, 5/16-18 5 8 8 13

02189020 HWHSM Screw, #10-16 x ½” TEKS 8 14 14 24

U-Bend Package 43208020 43208020 43208020 43208020

42873000 U-Bend 1 1 1 1

43318500 31” Tube Support/Hanger Bracket 1 1 1 1

30462980 Tube Coupling 1 1 1 1

02189020 HWHSM Screw, #10-16 x ½” TEKS 2 2 2 2

60Ft. System 70Ft. System

PTU Body Packages – Alumi-Therm/Hot Rolled

40 Ft. Pkg.

44137100

20 Ft. Pkg.

44135010

40 Ft. Pkg.

44137120

30 Ft. Pkg.

44136040

Part # Each Body Package Includes: Qty. Qty. Qty. Qty.

42912169 10 Ft. Tube with 6 Hole Flange (Alumi-Therm)

1 - 1 41932101 10 Ft. Tube less Flanges (Hot Rolled) 3 2 2 3

41932051 5 Ft. Tube less Flanges (Hot Rolled) - - 2 43319100 Reflector, 9’ 11½” 4 2 3 3

43319050 Reflector, 4’ 11 ½’ - - 2 30462980 Tube Coupling 3 2 4 3

43318000 Tube Hanger/Support Bracket, 13” 4 2 5 3

43980010 Wire Hanger 4 2

5 3

Body Fastener Kit (included in body packages) 42907210 42907219 42907220 42907200

42873000 U-Bolt 4 2 5 3

02127110 Hex Nut, 5/16-18 8 5 10 6

02189020 HWHSM Screw, #10-16 x ½” TEKS 14 8

18 10

U-Bend Package 43208020 43208020

42873000 U-Bend 1 1

43318500 31” Tube Support/Hanger Bracket 1 1

30462980 Tube Coupling 1 1

02189020 HWHSM Screw, #10-16 x ½” TEKS 2

2

E) PTU 40-200 Series Body Package Descriptions – ALC Option (Aluminized Calorized)

(Package Part Number is indicated on the outside of each corresponding carton.)

System Lengths

PTU Body Packages –Aluminized/Aluminized or

Alumi-Therm/Aluminized

20 Ft. Pkg.

44135020

30 Ft. Pkg.

44136030

40 Ft. Pkg.

44137090

50 Ft. Pkg.

44138090

Part # Each Body Package Includes: Qty. Qty. Qty. Qty.

42912080 10 Ft. Tube with 24 Hole Flange (Aluminized) 1 1 - 42912169 10 Ft. Tube with 6 Hole Flange (Alumi-Therm) - - 1 1

41932100 10 Ft. Tube less Flanges (Aluminized) 1 1 3 3

41932050 5 Ft. Tube less Flanges (Aluminized) - 2 - 2

43319100 Reflector, 9’ 11½” 2 2 4 4

43319050 Reflector, 4’ 11 ½” - 2 - 2

30462980 Tube Coupling 1 3 3 5

43318000 Tube Hanger/Support Bracket, 13” 2 4 4 6

43980010 Wire Hanger 2 4 4 6

Form #43343530

–8– JJuly 08

Page 10

13

(33cm)

13

(33cm)

6

(15cm)

12

(30cm)

END REFLECTOR

Body Fastener Kit (included in body packages) 42907190 42907210 42907210 42907221

42873000 U-Bolt 2 4 4 6

02127110 Hex Nut, 5/16-18 5 8 8 13

02189020 HWHSM Screw, #10-16 x ½” TEKS 8 14 14 24

U-Bend Package 43208020 43208020 43208020 43208020

42873000 U-Bend 1 1 1 1

43318500 31” Tube Support/Hanger Bracket 1 1 1 1

30462980 Tube Coupling 1 1 1 1

02189020 HWHSM Screw, #10-16 x ½” TEKS 2 2 2 2

60Ft. System 70Ft. System

PTU Body Packages – Alumi-Therm/Aluminized

40 Ft. Pkg.

44137090

20 Ft. Pkg.

44135030

40 Ft. Pkg.

44137110

30 Ft. Pkg.

44136050

Part # Each Body Package Includes: Qty. Qty. Qty. Qty.

42912169 10 Ft. Tube with 6 Hole Flange (Alumi-Therm) 1 - 1 41932100 10 Ft. Tube less Flanges (Aluminized) 3 2 2 3

41932050 5 Ft. Tube less Flanges (Aluminized) - - 2 43319100 Reflector, 9’ 11½” 4 2 3 3

43319050 Reflector, 4’ 11 ½’ - - 2 30462980 Tube Coupling 3 2 4 3

43318000 Tube Hanger/Support Bracket, 13” 4 2 5 3

43980010 Wire Hanger 4 2

5 3

Body Fastener Kit (included in body packages) 42907210 42907219 42907220 42907200

42873000 U-Bolt 4 2 5 3

02127110 Hex Nut, 5/16-18 8 5 10 6

02189020 HWHSM Screw, #10-16 x ½” TEKS 14 8

18 10

U-Bend Package 43208020 43208020

42873000 U-Bend 1 1

43318500 31” Tube Support/Hanger Bracket 1 1

30462980 Tube Coupling 1 1

02189020 HWHSM Screw, #10-16 x ½” TEKS 2

2

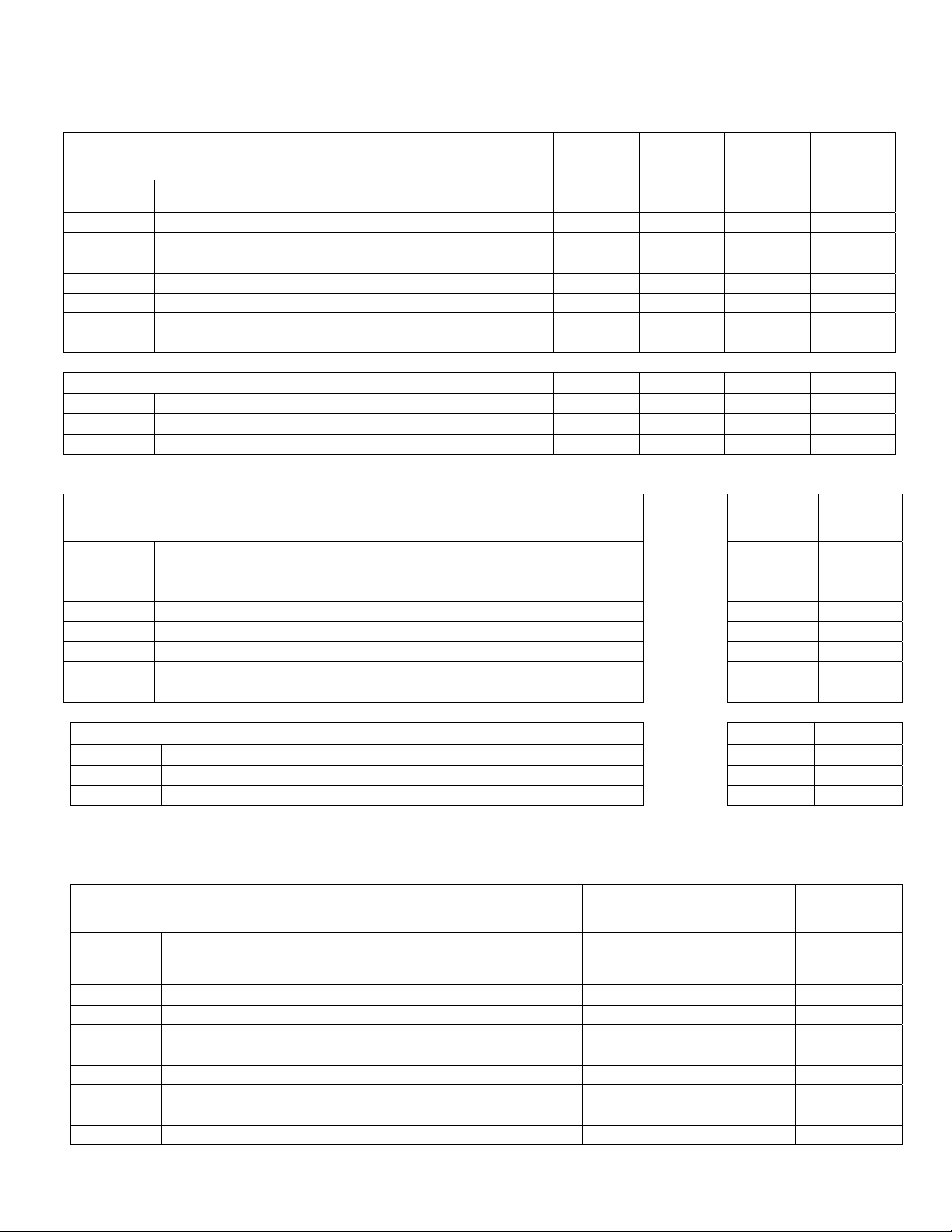

6.1) ACCESSORIES

A) End Reflector Accessory Package, Part #43341010

(1 pkg. per PTS Series or 2 pkgs. per PTU Series)

Contains

End Reflector, #43320000……QTY–2

Speed Clips, #02266010……QTY–4

B) Elbow Accessory Package, Part #43208010

Form #43343530

July 08 –9–

(Option for PTS Series Only)

Contains

Elbow, #431750010……QTY–1

#10-16 x ½ Self-Drilling Screws, #02189020……QTY–2

Tube Coupling, #30462980……QTY–1

:

:

Page 11

18

(46cm)

30 3/4 (78cm)

Length = 24 (61cm)

C) Corner Reflector Accessory Package, Part #43342000

(Option for PTS Series Only)

Contains

:

Corner Reflector Assembly, #43345000……QTY–1

Speed Clips, #02266010……QTY–4

24

(61cm)

D) U-Bend Package, Part #43208020

(Option for PTU Series Only)

Contains:

U-Bend, #42913020……QTY–1

#10-16 x ½ Self-Drilling Screws, #02189020……QTY–2

Tube Coupling, #30462980……QTY–1

31” Hanger/Tube Support, #43318500……QTY–1

E) U-Bend Reflector Package, Part #43488000

(Option for PTU Series Only)

Contains:

U-Bend Reflector, #43490000……QTY–1

U-Bend End Reflector, #43490050……QTY–1

Speed Clips, #02266010……QTY–11

#10-16 x ½ Self-Drilling Screws, #02189020……QTY–4

F) 31” Hanger/Tube Support, Part #43318500

(Option for Angle Mounting of PTU Series)

31

(79cm)

18

(46cm)

Tube Centers

G) Exhaust Hood Package, Part #42924000

Contains

Exhaust Hood Assembly, #42925540……QTY–1

#10-16 x ½ Self-Drilling Screws, #02189020……QTY–2

:

4 (10cm)

7 1/2

(19cm)

3 3/4 (10cm)

3 1/2 (9cm)

Side View

24

(61cm)

7 1/2

(19cm)

Bird

Screen

Front View

Form #43343530

–10– JJuly 08

Page 12

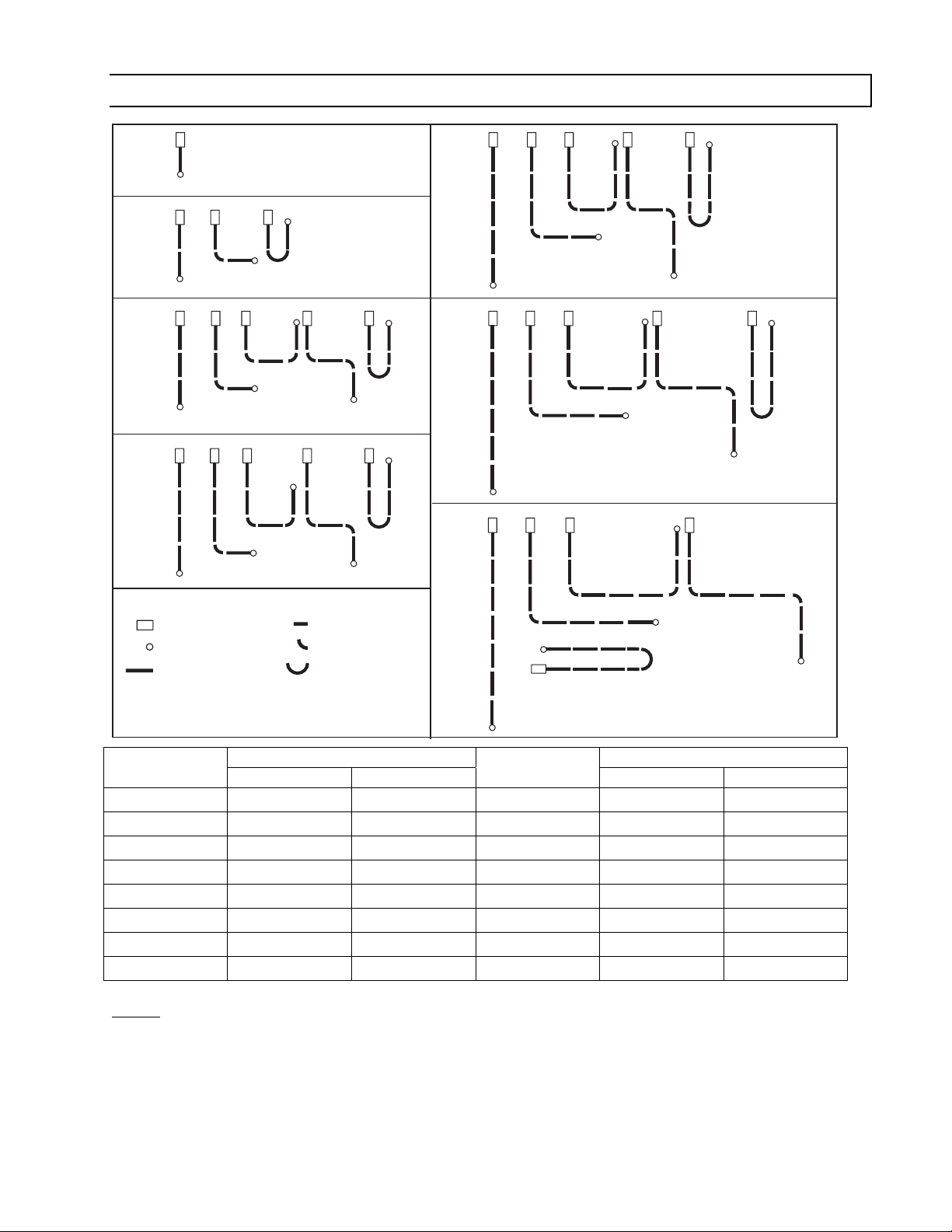

7.0) TYPICAL LAYOUTS – PTU / PTS Series

10FT.

SYSTEM

50 FT.

SYSTEM

20 FT.

SYSTEM

30 FT.

SYSTEM

60 FT.

SYSTEM

40 FT.

SYSTEM

LEGEND

Burner Box

Flue Termination

10 FT. Body Section

5 FT. Body Section

90 Deg. Elbow

180 Deg. U-Bend

70 FT.

SYSTEM

EMITTER LENGTH BODY LENGTH

MODEL

PTS 40/25

PTS 50/30

PTS 75/50

PTS 100/65

PTS 125/80

PTS 150/100

PTS 175/110

PTS 200/125

Min. Max.

10 Ft. 20 Ft.

20 Ft 30 Ft.

20 Ft. 30 Ft.

30 Ft. 40 Ft.

30 Ft 50 Ft.

40 Ft. 60 Ft.

50 Ft. 70 Ft.

50 Ft. 70 Ft.

MODEL

PTU 40/25

PTU 50/30

PTU 75/50

PTU 100/65

PTU 125/80

PTU 150/100

PTU 175/110

PTU 200/125

Min. Max.

10 Ft. 10 Ft.

10 Ft. 15 Ft.

10 Ft. 15 Ft

15 Ft. 20 Ft.

15 Ft. 25 Ft.

20 Ft. 30 Ft.

25 Ft. 35 Ft.

25 Ft. 35 Ft.

NOTES:

1) In all configurations, the control unit must be connected directly to either a) the 24-hole flange of the 10 ft.

aluminized steel starting body section (for 10 ft., 20 ft., and 30 ft. systems) or b) the 6-hole flange of the 10 ft.

alumi-therm steel starting body section (for 40 ft., 50 ft., 60 ft., and 70 ft. systems.

2) Joining of two 90º elbows directly together to form a “Z” shape IS NOT permitted.

3) PTS / U 175/110 - 40 ft length available for special applications.

4) 5 Ft. Body Packages may be utilized on any of these heaters to yield heater lengths from 15 ft. to 70 ft.

5) Any configuration of components not shown in the illustrations may be used except as noted in 1 and 2

Form #43343530

July 08 –11–

Page 13

above.

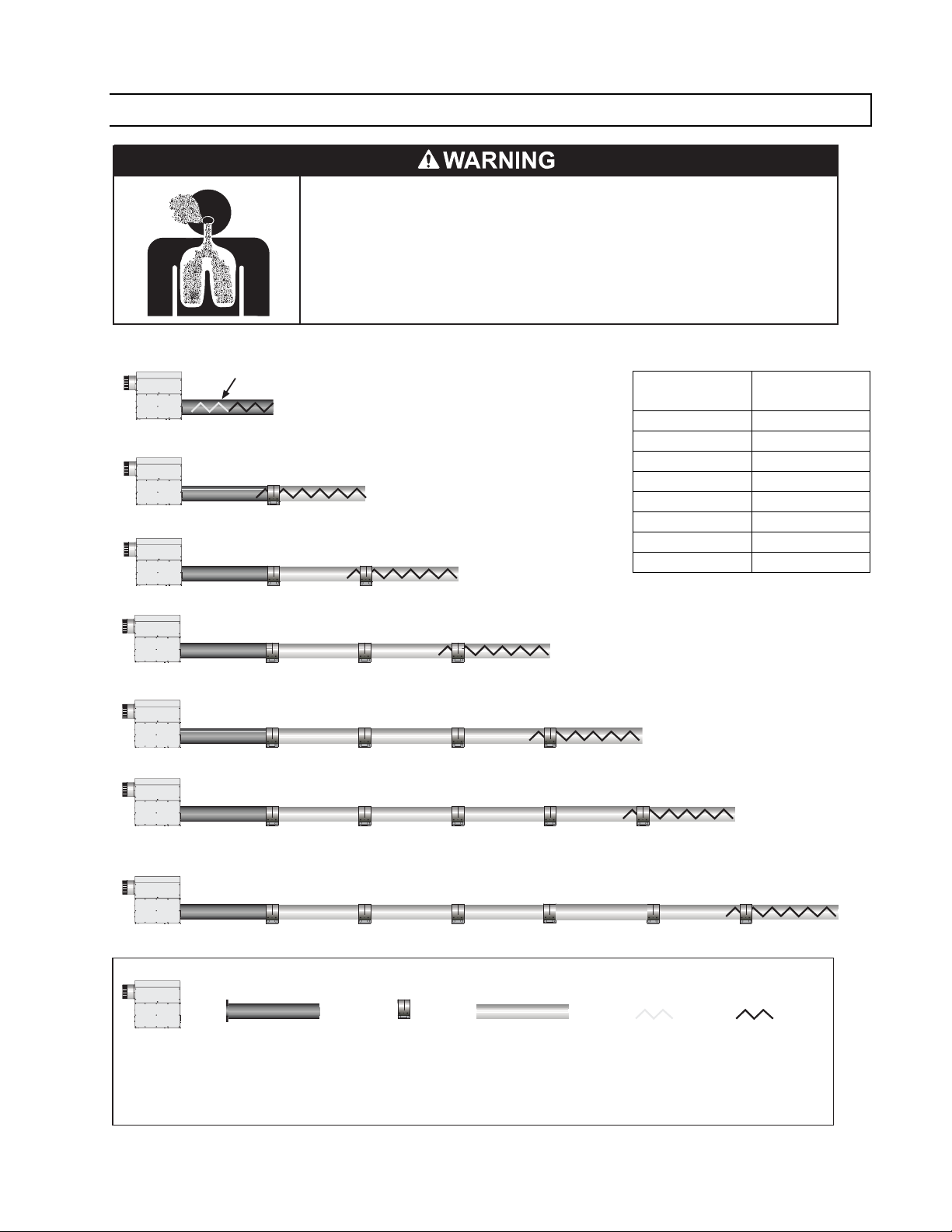

7.1) TYPICAL ASSEMBLY LAYOUT

POISONOUS GAS AND SOOT HAZARD

The heater must be assembled with the correct number of turbulator sections

and tube length for the rated heat input.

The turbulator must be installed in the last tube section as shown.

Failure to do so may result in death, serious injury, property damage or illness

from Carbon Monoxide poisoning.

10 FT. SYSTEM

20 FT. SYSTEM

30 FT. SYSTEM

40 FT. SYSTEM

50 FT. SYSTEM

60 FT. SYSTEM

70 FT. SYSTEM

Burner Box 10ft Aluminized Tube 24

Form #43343530

–12– JJuly 08

Stainless Steel Turbulator

closest to burner PTS / U

40 only.

Hole Flange

or

10ft Alumi-Therm Tube

6 Hole Flange

LEGEND

Coupling 10ft Aluminized or HRS

Tube model dependent

MODEL

PTS/U 40/25

PTS/U 50/30

PTS/U 75/50

PTS/U 100/65

PTS/U 125/80

PTS/U 150/100

PTS/U 175/110

PTS/U 200/125

2ft Stainless

Steel

Turbulator

sections

2 Ft. Turbulator

Sections

2ft Aluminized

Steel

Turbulator

sections

4

5

5

3

7

4

0

1

Page 14

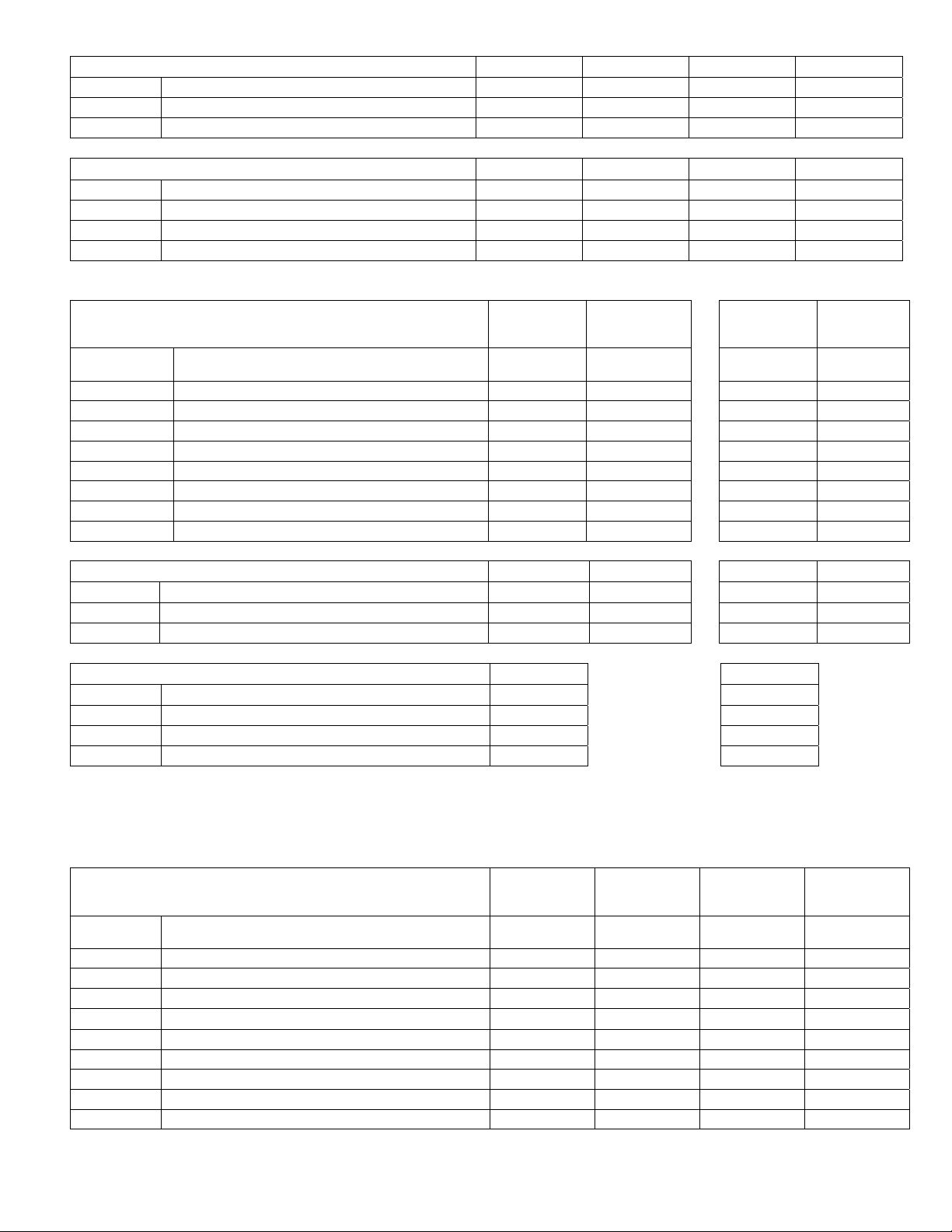

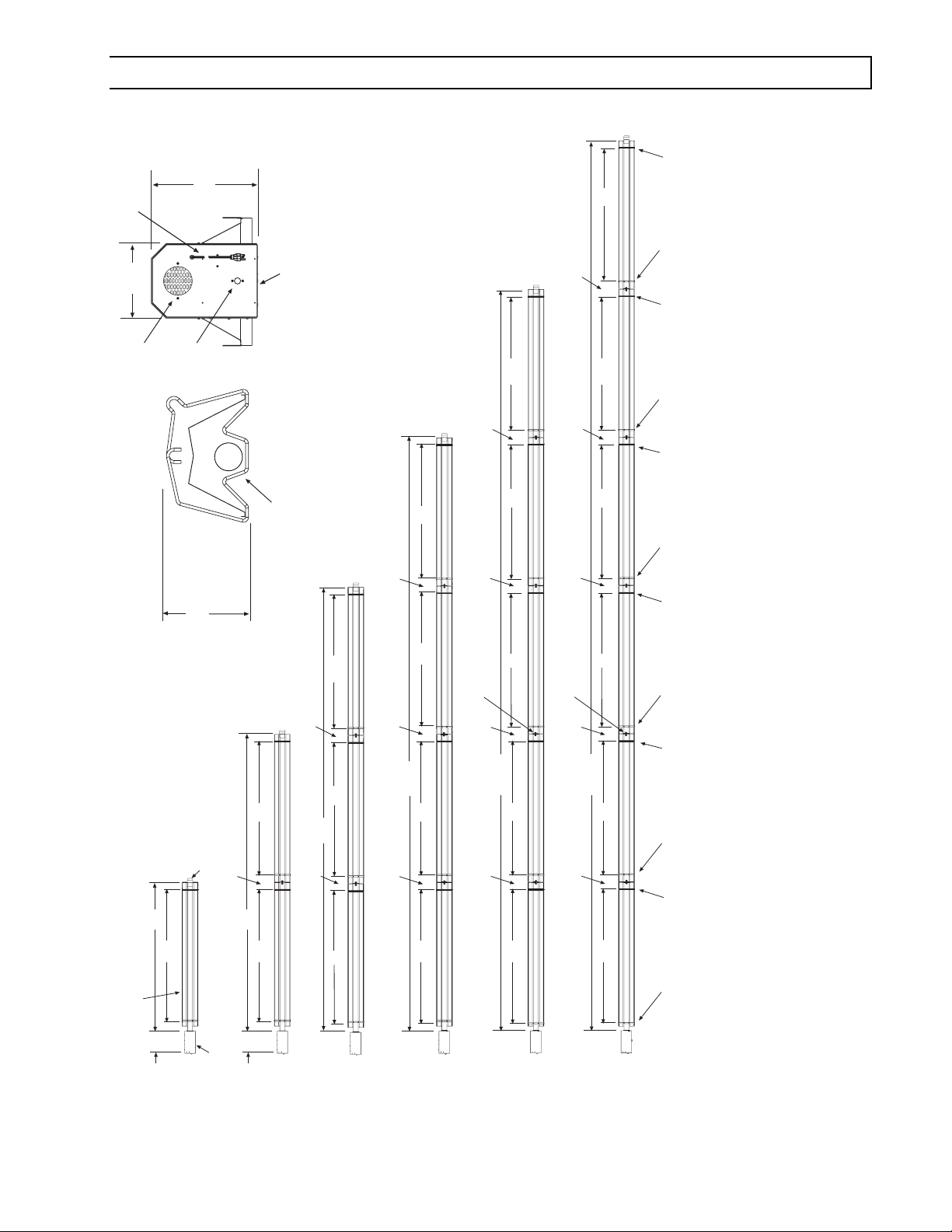

8.0) DIMENSIONS – PTS Series

Typical Dimensions Up to 60 Ft. Shown.

120VAC

Power Supply Cord

10

(25cm)

Fresh Air

Inlet

1/2 MPT Gas

(37cm)

14-1/2

Connection

9-1/4

(24cm)

Burner

Box

End View

Flue Terminal

12

(30cm)

108

(274cm)

12

12

(30cm)

(30cm)

108

108

(274cm)

(274cm)

12

12

(30cm)

(30cm)

108

108

108

(274cm)

(274cm)

(274cm)

Wire Hanger

13 Tube Support/

Hanger Bracket

Wire Hanger

13 Tube Support/

Hanger Bracket

Wire Hanger

13 Tube Support/

Hanger Bracket

Wire Hanger

10 FT Tube

Assembly

120

(typical)

14

(305cm)

108

(274cm)

(36cm)

Models:

PTS 40

Flue

Terminal

Burner

Box

12

(30cm)

240

(610cm)

14

108

(274cm)

108

(274cm)

(36cm)

Models:

PTS 40, 50,

75

12

12

(30cm)

360

(30cm)

108

(274cm)

108

(274cm)

(914cm)

108

(274cm)

Models:

12

12

PTS 50, 75,

100, 125

(30cm)

480

(30cm)

108

(274cm)

(1219cm)

108

(274cm)

108

(274cm)

Models:

PTS 100, 125

150

108

4 Tube Coupling

(typical)

12

(30cm)

600

(1524cm)

108

12

(30cm)

108

(274cm)

(274cm)

(274cm)

Models:

PTS 125, 150,

175, 200

4 Tube Coupling

(typical)

12

(30cm)

720

12

(30cm)

Bottom View

108

(274cm)

(1829cm)

108

(274cm)

108

(274cm)

Models:

PTS 150, 175,

200

13 Tube Support/

Wire Hanger

13 Tube Support/

Wire Hanger

Bottom View

13 Tube Support/

Hanger Bracket

Hanger Bracket

Hanger Bracket

Form #43343530

July 08 –13–

Page 15

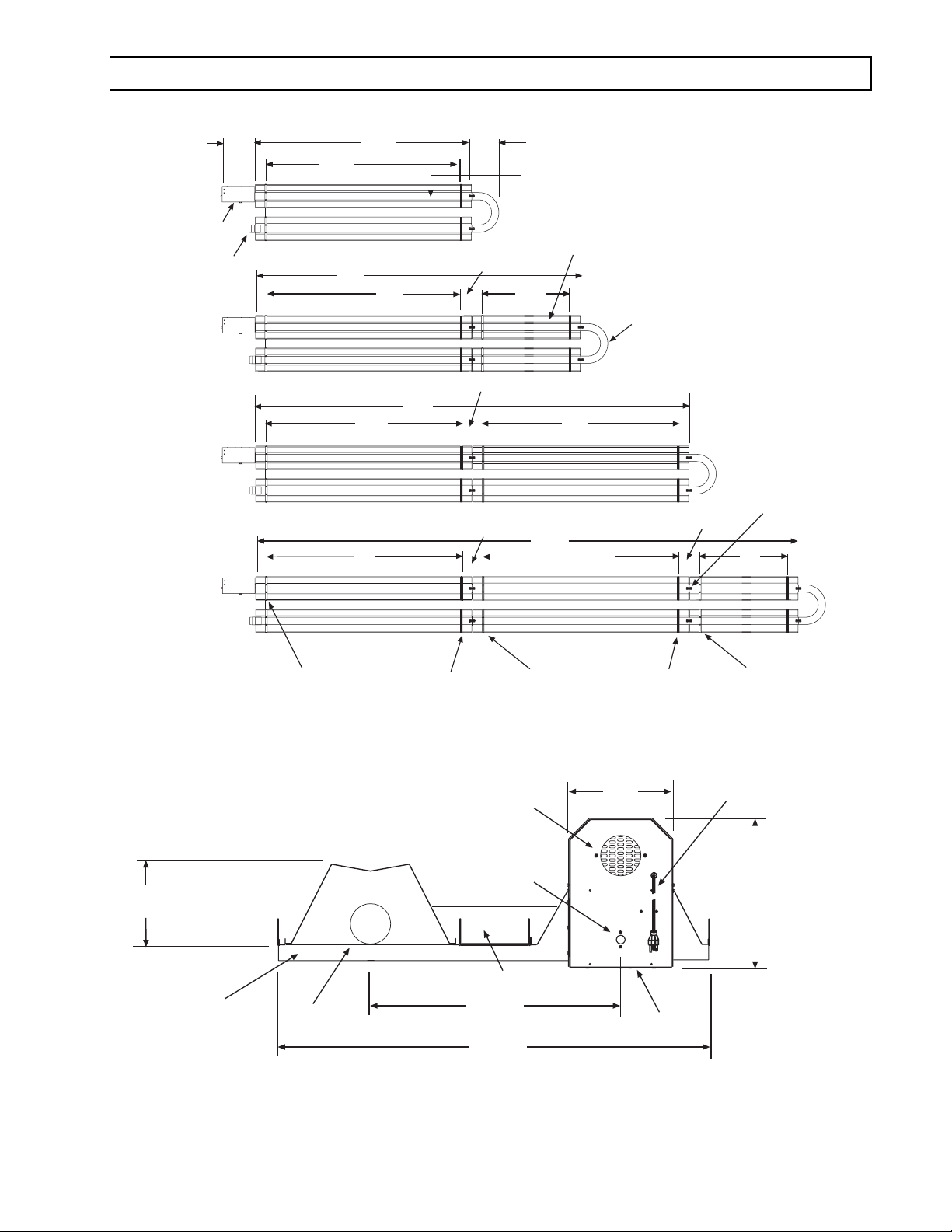

8.1) DIMENSIONS – PTU Series

Typical Dimensions Up to 50 Ft. Shown.

(36cm)

Models:

PTU 40, 50,

75

Models:

PTU 50, 75,

100, 125

Models:

PTU 100, 125,

150, 175

Models:

PTU 125, 150,

175, 200

14

Burner

Box

Flue

Terminal

(274cm)

(305cm)

108

180

(457cm)

(274cm)

108

(274cm)

120

108

(274cm)

108

240

(610cm)

12

(30cm)

12

(30cm)

12

(30cm)

15

(38cm)

10 FT Tube

Assembly

(typical)

48

(122cm)

300

(762cm)

5 FT Tube

Assembly

108

(274cm)

(274cm)

108

U-Bend

12

(30cm)

(122cm)

4 Tube Coupling

(typical)

48

6

(16cm)

31 Tube Support/

Hanger Bracket

Bottom View

31 Tube Support/

Hanger Brackets

(typical at control end)

Shipped with

U-Bend Package

Flue Terminal

Wire Hangers

(typical)

1/2 MPT Gas

Connection

18 (46cm)

31 (79cm)

PTU (end view)

13 Tube Support/

Hanger Brackets

(typical)

Fresh Air

Inlet

U-Bend

10

(25cm)

Wire Hangers

(typical)

120VAC

Power Supply Cord

Burner

Box

13 Tube Support/

Hanger Brackets

(typical)

14-1/2

(37cm)

Form #43343530

–14– JJuly 08

Page 16

8.2) HEATER ASSEMBLY / JOINING OF TUBE SECTIONS

a

Flue

Termin

Turbulator

(See specifications

section 5 for required

quantities.)

Typical

Overlap

Not Less

Than 10

#10 Self-Drill Screws

(Typical all tube supports,

tube couplings and flue

terminal.)

Wire Hanger

Tube Support Bracket

Tube Coupling

)

.

8 - 10

(Typical each tube joint

8 - 10

5 hanging points to be used for suspension for a typical 40ft

long system. There must be two hanging points on the first

tube and one on each of the other tubes

U-Bolt Clamp &

5/16" Hex Nuts

Tube

7

8 - 9 ¼

4"OD x 10Ft.

for required tubes.

See section

Flange

24 Hole for Aluminized Steel Tubes

6 Hole for Alumi-Therm Steel Tubes

Mounting

Gasket

(PTS 40FT Shown)

Burner

Box

Maximum 6 distance

from burner box to the

Typical Assembly Overview

tube support/hanger

Burner Box

bracket.

Suspension

Chain

Form #43343530

July 08 –15–

Page 17

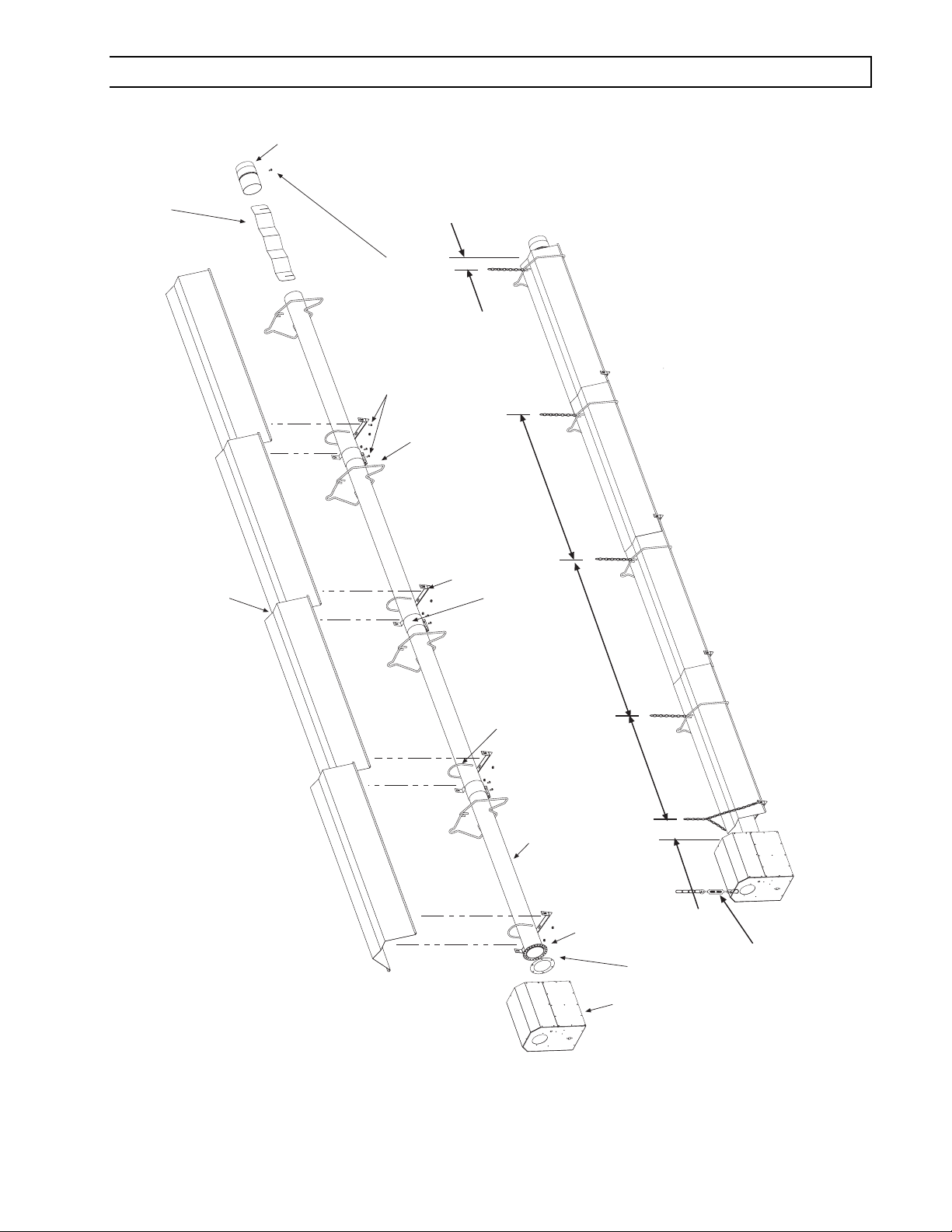

Typical Assembly Overview

(PTU 40FT Shown)

Turbulator

(See specifications

section 5 for required

quantities.)

#10 Self-Drill

Screws

(2 each)

Flue

Terminal

Burner Box

Gasket

Typical

Overlap

31 Tube Support Brk.

with U-Bolt Clamp

& 5/16" Hex Nuts

Mounting Flange

24 Hole for Aluminized Steel Tubes

6 Hole for Alumi-Therm Steel Tubes

Reflector

Wire Hanger

4"OD x 10Ft. Tube

See section 7

for required tubes.

13 Tube Support Brk.

with U-Bolt Clamp

& 5/16" Hex Nuts

U-Bend

Tube Coupling

(Typical each tube joint.)

#10 Self-Drill Screws

(Typical all tube supports,

tube couplings and flue

terminal.)

8 - 10

8 - 9 ¼

Maximum 6 distance

from burner box to the

tube support/hanger

bracket.

Burner Box

Suspension

Chain

6 hanging points to be used for suspension for a typical

40ft long system. There must be two hanging points

on the first tube and one on each of the other tubes

Form #43343530

–16– JJuly 08

Page 18

9.0) TYPICAL SUSPENSION METHODS

SUSPENSION HAZARD

Burner must be secured to the mounting flange with nuts.

All materials used to suspend the heater must have a minimum working load

of 115 lbs.

All S Hooks must be crimped closed.

Never use the heater to support a ladder or other access equipment.

Failure to do so may result in death, serious injury or property damage.

Various means of suspending the heater can be used. See the following drawings for typical examples.

1. Use only noncombustible materials for hangers and brackets.

2. A minimum No. 2 chain with a working load limit of 115 lbs. is required.

3. Turnbuckles can be used with chains to allow leveling of the heater. All “S” hooks and eye bolts must be

manually crimped closed by the installer.

4. When using rigid means for heater suspension (rod, flat bar, etc.) provide sufficient lengths or swing joints to

compensate for expansion. See Figures b and c.

5. Heaters subject to vibration must be provided with vibration isolating hangers.

6. Heaters must not be supported by gas or electric supply lines and must be suspended from a permanent

structure with adequate load capacity.

Space-Ray recommends that the body sections be suspended using chains with turnbuckles. This will allow slight

adjustments after assembly and heater expansion/ contraction during operation.

If a “trapeze” method is used (shown below), the minimum chain length for the two connecting chains is 36”. If these

chains must be less than 36”, then do not use the trapeze method and, instead, use individual chains on each tube

support/hanger bracket.

Minimum

No. 2 Chain

Eyebolt

Turnbuckle

Eyebolt

Failure to install the burner box suspension

chain will void the manufacturers warranty.

Turnbuckle

Minimum

No. 2 Chain

S-Hook crimped

closed (typical)

Wire Hanger

3/16 x 1

wideFlat Bar

Threaded

Rod

Turnbuckle

Eyebolt

Eye bolt

36 (91cm) Minimum

Burner Box Suspension

Form #43343530

July 08 –17–

a.

b.

Tube Support/

Hanger Bracket

c.

Wire

Hanger

d.

Page 19

10.0) ASSEMBLY OF TUBE SECTIONS

CUT HAZARD

Sheet metal parts, particularly reflectors and vent have sharp

edges. Always use gloves when handling.

Failure to do so may result in death, serious injury or property

damage.

During field assembly of the heater body sections, the recommended procedure is as follows:

1. Before hanging heater sections, first determine the actual layout of the system (see Sections 7.0 & 8.0 for

details). Consideration must also be taken for flue pipe, fresh air ducting, gas piping, clearances to combustibles,

etc. before hanging heater. Typical suspension methods are shown in Section 9.0.

2. Hang each tube section individually. DO NOT

attach the heater tube sections together on the ground and attempt

to hang the entire system.

3. In all configurations, the burner box must be connected directly to either a) the 24-hole flange of the 10 ft.

aluminized steel starting body section (for 10 ft., 20 ft., and 30 ft. systems) or b) the 6-hole flange of the 10 ft.

alumi-therm steel starting body section (for 40 ft., 50 ft., 60 ft., and 70 ft. systems.

4. Assemble a tube support/hanger bracket 4” from the end of the heat exchanger tube having the mounting

flange. Align the tube such that the welded seam is facing down toward the ground.

FAILURE TO ASSEMBLE THE TUBE WITH THE SEAM FACING DOWN

WILL VOID THE MANUFACTURER’S WARRANTY.

8 to 9 1/4

1

S Hooks

U-Bolt Clamp

& 5/16 Hex Nuts

Wire Hanger

2

4"OD x 10Ft. Heat

Treated Aluminized

Steel Tube

Tube Support/

Control Box

Mounting Flange

Maximum 6 distance from

control box mounting flange

to tube support bracket.

Hanger Bracket

5. Suspend the chain to attach the wire hanger and the tube support bracket. Insert the tube into the wire hanger

and then raise the tube support bracket end up to the suspension chain, use “S” hooks to attach the wire hanger

and tube support bracket to the chain.

Form #43343530

–18– JJuly 08

END VIEW

Weld seam to the

bottom of tube.

Page 20

10.1 ASSEMBLY OF EXTENSION SECTION

MIN 8 MAX 10 BETWEEN HANGERS

Coupling

1

2

Wire Hanger

U-Bolt Clamp

& 5/16 Hex Nuts

3

Tube Support/

Hanger Bracket

See typical assembly overview (Section 8.0) for typical complete assembly. Assemble additional extension

sections as required for all systems. (See Sections 7.0, and 8.0 for typical layout details.)

Join the tube sections together and secure with tube couplings as described below:

Tube Support/

Hanger Bracket

6 approx.

WARNING: THE FOLLOWING COUPLING TIGHTENING INSTRUCTIONS MUST

1. Place the compression coupling over the end of the tube.

2. Use the small hole at the centerline of the coupling to check that the coupling is inserted correctly.

3. Partially tighten the bolt nearest the end of the tube (approximately half closed).

BE FOLLOWED PROPERLY TO AVOID FUTURE PROBLEMS.

1

Tube

Center end of

Tube with hole

2

Tube

Coupling

Partially tighten this bolt

Form #43343530

July 08 –19–

3

Page 21

4

Center both

tubes with hole

Tube

Coupling

4. Slide the next tube into the coupling.

5. Make sure both tube ends are butted together.

6. Finish tightening both bolts to 40-60 ft.lbs. torque to ensure a complete seal.

7. Use the two Self-drilling screws through the pre-punched holes to secure the tubes in the coupling.

Band

#10 Self-Drilling

Screws

(QTY 2)

5

7

6

Force

Bars

Reaction

Block

8. Check to ensure that the hardware is completely closed and the band is seated on the reaction block and

interference pins as illustrated above.

9. Once all the heater body sections are attached, make sure that the heater system is level

adjustments can be made using the turnbuckles. (See Section 9.0)

Bolt

Interference

Pins

CORRECT

INSTALLATION

IMPORTANT: NEVER REUSE A COUPLING. Always install a new

coupling only and torque as per instructions above and the diagrams

above.

INCORRECT

INSTALLATION

. If it is not, slight

10.2) INSERTING TURBULATORS

POISONOUS GAS AND SOOT HAZARD

The heater must be assembled with the correct number of turbulator sections

and tube length for the rated heat input.

The turbulator must be installed in the last tube section as shown.

Failure to do so may result in death, serious injury, property damage or illness

from Carbon Monoxide poisoning.

1. Assemble the turbulators together by interlocking the slotted end portions. Slide these into the last tube

section until they are flush with the tube end. Note: Refer to the table below for quantities of turbulators

required for each heater model.

Form #43343530

–20– JJuly 08

Page 22

Turbulators

MODEL 2 Ft. Turbulator Sections

PTS/U 40/25

PTS/U 50/30

PTS/U 75/50

PTS/U 100/65

PTS/U 125/80

PTS/U 150/100

PTS/U 175/110

PTS/U 200/125

4

5

5

3

7

4

0

1

ASSEMBLY HAZARD

The PTS / U 40 has one stainless steel

turbulator. This must be installed

closest to the burner.

Failure to do so may result in

deterioration of the turbulator material

and invalidate the warranty.

10.3) ADDING REFLECTORS

1. Slide the reflectors on the tube support/hanger brackets and through the wire hangers.

2. The tube at the coupling joints must be covered. Slide the reflectors together and provide an overlap of two (2”)

inches for the first reflector overlap after the control unit. All remaining reflector overlaps will be approximately

one (1”) inch. This will allow for the natural expansion and contraction of the heater when in operation. Note: The

heaters can expand and contract up to 1-3/4” of an inch.

3. Secure the reflectors as shown in Detail “A” using #10 x 1/2” self-drilling sheet metal screws at each tube

support/hanger bracket.

40 FT SYSTEM SHOWN

The reflector overlap must be

able to slide at this joint for

expansion of the heater

3 Gap

(between burner box

and reflector)

2 OVERLAP

Burner Box

Suspension

Chain

BURNER

BOX

CORRECT INSTALLATION INCORRECT INSTALLATION

DETAIL A

REFLECTOR

OVERLAP

(offset from tube

hanger support brackets)

REFLECTOR

DETAIL B

DETAIL B

REFLECTOR

OVERLAP

(positioned over tube

hanger support brackets)

1 OVERLAP

1 OVERLAP

DETAIL A

#10 x 1/2 SHEET

METAL SCREW

(Typical all tube

hanger/

support brackets.)

FLUE

TERMINAL

Form #43343530

July 08 –21–

Page 23

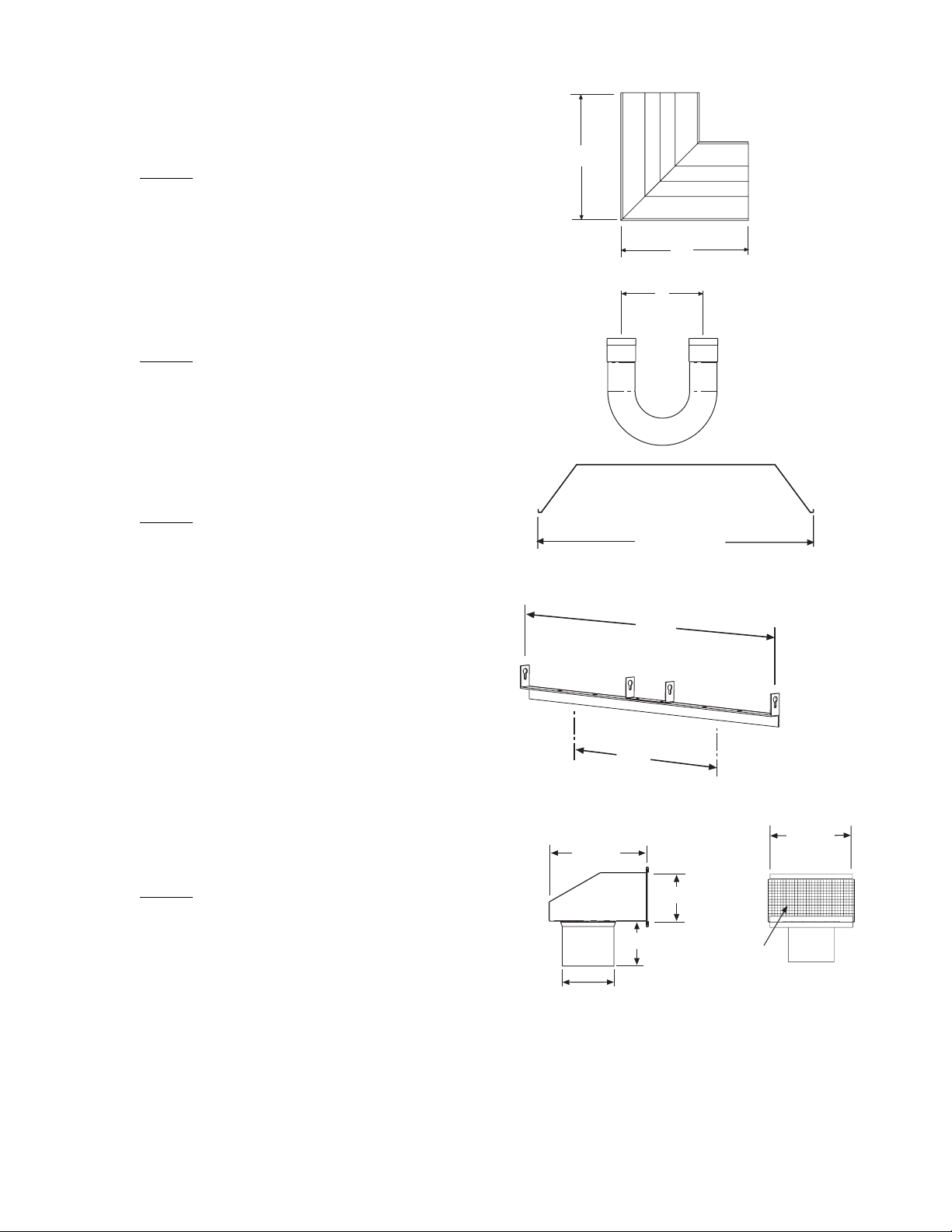

11.0) ADDING OPTIONAL 90º ELBOW (PTS ONLY)

1. The optional 90º elbow must be located a minimum of 10 ft. after the control box.

2. Hang th e body secti ons in a 90º ( "L") sh aped pattern. Allow spacing for the elbow. The distance from one end of

the elbow to the centerline of the opposite leg is 13" as shown.

3. Join the tube ends of the body sections and the elbow together and secure with tube couplings as described in

Section 10.1.

Self-Drilling Screws

(QTY-2 per coupling)

13 (330mm)

Tube

Coupling

90 Deg. Elbow

13 (330mm)

11.1) ADDING OPTIONAL CORNER REFLECTOR (PTS ONLY)

1. Place the corner reflector over the reflectors of both body sections.

2. Secure by sliding speed clips on the reflector edges. One speed clip is required for each side of reflector.

3. The corner reflector can be used only when the long axis of the heater is level and mounted in a horizontal

position.

Speed Clip

(QTY-4)

Corner

Reflector

Form #43343530

–22– JJuly 08

Page 24

11.2) ADDING 180°U-Bend (PTU ONLY)

1. Hang body sections parallel with each other. The centerline distance from tube at each body section should be

18” as shown.

2. Join tube ends of body sections and the U-Bend together and secure with tube couplings as described in Section

10.1.

Self-Drilling Screws

(QTY-2 per coupling)

18

(457mm)

Tube Coupling

U-Bend

11.3) ADDING OPTIONAL U-BEND REFLECTOR (PTU ONLY)

1. Place the U-Bend Reflector over the reflectors of each body section with the end resting next to the tube wire

hangers as shown.

2. Slide the speed clips on the reflector edges towards the end of the body section reflectors. Two speed clips are

required for each side of the U-Bend Reflector. Make sure that the speed clips fit tightly over both the U-Bend

Reflector and the reflector on each body section. Use two self-drilling screws to permanently secure both sides to

the reflectors.

3. Place the End Reflector flush with the U-Bend Reflector as shown. Note: Clearance between end of the U-Bend

Reflector and the U-Bend must be a minimum of 1”. Secure by sliding speed clips onto the end reflector edges.

Evenly space the speed clips on the sides (two each side) and top (three each) of the reflectors to provide a snug

fit.

Form #43343530

July 08 –23–

U-Bend Reflector

Part No. 43490000

End Reflector

Part No. 43490050

Speed Clip

Part No. 02266010

(QTY-7)

1 Clearance

(between end reflector

and u-bend)

Speed Clip

Part No. 02266010

(QTY-4)

#10 Self-Drill Screws

Part No. 02189020

(QTY-4)

Wire Hangers

Page 25

12.0) ATTACHING BURNER BOX ASSEMBLY

1. Attach the burner box and gasket to end of tube flange and secure with 1/4-20 locknuts.

2. Assemble the optional end reflector flush with the end of the main body reflector. Secure by sliding speed clips

onto the reflector edges. Evenly space the speed clips on the sides (one each side) and top (two required) of the

reflectors to provide a snug fit. Leave a 3" space between the end reflector and the burner box assembly.

3. The heater can be mounted horizontally or at an angle of up to 45 degrees maximum from horizontal.

When angle mounting, the burner box unit must be positioned upright as shown below. FAILURE TO INSTALL THE

BURNER BOX IN AN UPRIGHT POSITION WILL VOID THE MANUFACTURER’S WARRANTY.

Speed Clip

(QTY-4)

DO NOT lift burner or support its

weight using the TISS wire. It will

break under heavy load.

Burner Box

Optional

End

Reflector

1/4-20 Locknut

(QTY-3 per flange)

Failure to install the burner box

suspension chain will void

manufacturers warranty.

Turnbuckle

Eye bolt

Burner Box Suspension

Tube Flange

Gasket

Upright Position

Burner

Box

Angle Mounting

Straight Tube Heaters

Reflector

Mounting Flange

24 Hole for Aluminized Steel Tubes

6 Hole for Alumi-Therm Steel Tubes

Upright Position

Burner

Box

Angle Mounting

U-Tube Heaters

Form #43343530

–24– JJuly 08

Page 26

12.1) CONNECTING THE TISS SYSTEM

Description: The TISS (Tube Integrity Safety System) is designed to shut the main burner off in the event that a

burnout occurs in the first 10ft. section of firing tube. Note: When replacing the firing tube a new TISS wire assembly

PN 44176010 must also be installed.

Instructions:

1. Make sure that the gap between the burner box and end of reflector is 3” and the reflector is securely

attached to the reflector support bracket. Make adjustments if necessary.

TISS Assembly.

#10 x 1/2 Screws

must securely attach

reflector to the bracket

3 Gap (between

burner box and end

of reflector)

Step 1

2. Un-roll the TISS wire assembly from the spool. Be careful not to kink the wires.

Spool with

TISS Wire

Assembly

Step 2

Form #43343530

July 08 –25–

Page 27

3. Hold the spring retainer clamp and pull the TISS wire assembly to end of reflector at overlap joint.

Slide spring retainer clamp over end of reflector as shown.

Step 3

Spring

Thimble

TISS Wire Assembly

PN 44176000

End View

Spring

Retainer Clamp

4. After attachment of the TISS, check to make sure that there is sufficient tension on the wire. Follow the

diagram below to increase or decrease the tension as necessary.

1. Measure the extension of the spring from the end of the reflector to the thimble as shown below.

11 extension

Thimble

Wire & Sleeving

Assembly

Wire & Sleeving

Assembly

Step 4

Spring

Retainer Clamp

Reflector End

2. Tape one end of the sleeve to the burner box

or use a marker.

3. Mark the other end of the sleeve with tape or

other marker. Use the top of the retainer as a

reference.

4. Loosen screws.

Spring

If the extension is less than 11 follow the

instruction below to increase the extension.

5. Pull one end of the sleeve and wire inside until

the marker is raised by the total adjusment length.

ie. if the extension is 10 then pull through 1 to

increase the exension to 11.

6. Tighten screws.

7. Check extension using the method in step 1.

Form #43343530

–26– JJuly 08

Page 28

ANGLE MOUNTED HEATERS ONLY

5. If heaters are to be angle mounted, the TISS wire holder clamp must first be re-positioned as shown

using the bottom hole pattern of the clamp. Follow procedures described earlier for all other

adjustments.

End View

Re-position wire clamp using

bottom hole pattern.

Angle Mounted Body Section

Step 5

Form #43343530

July 08 –27–

Page 29

13.0) GAS CONNECTIONS AND REGULATIONS

Tighten flexible gas hose and components securely.

Flexible metal gas hoses must be installed without any twists or

kinks in them. The hose will move during operation of the heater

and it can crack if it is twisted.

Failure to do so may result in death, serious injury or property

damage.

IMPORTANT BEFORE CONNECTING THE GAS TO THE HEATER

1. Connect to the supply tank or manifold in accordance with the latest edition of National Fuel Gas Code (ANSI

Z223.1), and local building codes. Authorities having jurisdiction should be consulted before the installation

is made. (In Canada, refer to the latest edition of CAN Standard B.149-1 & -2, Installation Codes for Gas

Burning Appliances and Equipment.)

2. Check that the gas fuel on the burner rating plate matches the fuel for the application.

3. Check that the gas supply piping has the capacity for the total gas consumption of the heaters and any other

equipment connected to the line.

4. Check that the calculated supply pressure with all gas appliances and heaters operating will not drop below

the minimum supply pressure required for these heaters. Check inlet supply pressures on Section 14.

5. All gas supply lines must be located in accordance with the required clearances to combustibles from the

heater as listed on the clearances label of the heater and section 4 of this manual.

6. Pipe joint compounds must be resistant to the action of liquefied petroleum gases.

7. Tube heaters will expand/contract during operation. Where local codes do not prohibit, a CSA or U.L.

approved flexible connector supplied with this heater is required for connections between the rigid piping

and the heater. A union should be installed before the burner box inlet. An approved shut off valve should

be installed within 6 feet of the union.

8. The gas pipe, flexible hose and connections must be self supporting. The gas pipe work must not bear any of

the weight of the heater or any other suspended assembly.

9. This appliance is equipped with a step-opening, combination gas valve. The maximum supply pressure to

the appliance is 14” W.C. or 1/2 P.S.I. If the line pressure is more than the maximum supply pressure, then

a second stage regulator which corresponds to the supply pressure must be used.

10. After all gas connections have been made, make sure the heater and all gas outlets are turned off before

the main gas supply is turned on slowly. Turn the gas supply pressure on and check for leaks. To check for

leaks, check by one of the methods listed in Appendix D of the National Fuel Gas Code.

11. If a 2

DO NOT USE AN OPEN FLAME OF ANY KIND TO TEST FOR

nd

stage regulator is used, the ball valve down stream in the supply line must be closed when purging

the gas lines to prevent gas seeping through it. If initial gas pressure is higher than 14” w.c. the redundant

combination gas valve is designed to lock out. Pressure build-up in the supply lines prior to the heater must

be released before proper heater operation.

LEAKS.

Form #43343530

–28– JJuly 08

Page 30

KEY DIMENSIONS AND COMPONENTS OF THE GAS CONNECTIONS

Gas Pressure

Approved

Flexible Connector

14 to 17

(36 to 43cm)

2 (5cm) Max.

Displacement

*Second Stage Regulator with

Vent Leak Limiter to reduce the

Supply Pressure below 14 W.C.

* Available as Accessories

Burner Movement

RECOMMENDED GAS CONNECTION POSITIONS WITH 36 FLEXIBLE GAS HOSE

Alternate Positions

DO NOT install gas connector

vertically if fresh air is to be

connected.

Adaptor 1/2 NPT male

= 2 PSIG

Gas Supply

Piping

*Manual Gas

Shut Off Valve

Sediment Trap

(Drip Leg)

7 5/8

3 7/8 (10cm)

Adaptor 1/2 NPT female

6

END VIEW

Gas pipe work must not restrict

opening of hinged service doors.

Burner Movement

Minimum 1 (25cm)

SIDE VIEW

Certified connectors are recommended to be installed as shown, in one plane, and without sharp bends, kinks or

twists.

INCORRECT POSITIONS

Movement

Movement

WRONG

WRONG

Movement

WRONG

Movement

WRONG

Form #43343530

July 08 –29–

Page 31

14.0) INSTRUCTIONS FOR PRESSURE TEST GAUGE CONNECTION

Never operate the heater with the access panel open or removed.

The access panels must be closed tightly with all the necessary

screws during operation.

Failure to do so may result in death, serious injury or property

damage.

The access doors on either side of the burner must

be securely fastened before operating the heater.

DANGER

FIRE HAZARD

Never operate the heater with the

access panel open or removed.

This access panel must be closed

tightly with all the necessary screws

during operation.

Failure to do so may result in death,

serious injury or property damage

43269050 Rev. A 03/08

SIDE VIEW

SUPPLY PRESSURE

1. The installer will provide a 1/8” N.P.T. tapped plug, accessible for test gauge connection immediately upstream

of the gas supply connection to the heater.

MANIFOLD PRESSURE– COMBINATION GAS VALVE IS FACTORY SET

Two-stage valves require that you check and adjust both high and low pressure regulator settings.

1. Turn the gas valve to the “OFF” position. Remove the 1/8” plug from the combination gas valve at the outlet

pressure tap and connect a 1/8” nipple to the tapped hole. Connect the gauge to the nipple. Turn on the gas

supply.

2. Set the heater to operate on high. With the main burner operating, check the full rate (high) burner manifold

pressure using a water manometer. Gauges that measure pressure in pounds per square inch are not accurate

enough to measure or set the manifold pressure. All measurements MUST BE made when this heater and all

other gas burning equipment that is connected to the gas supply system are operating at maximum capacity.

3. The combination gas valve is factory set and should not require adjustment. If high pressure adjustment is

required, remove the pressure regulator adjustment cap. Using a 3/32” hex Allen wrench, turn the inner

adjustment screw for HI pressure clockwise to increase or counterclockwise to decrease the gas pressure

to the burner.

4. After high pressure has been checked, check low pressure regulation.

5. Using a 3/32” hex Allen wrench, turn the inner adjustment screw for LO pressure clockwise to increase or

counterclockwise to decrease the gas pressure to the burner.

6. Once high and low pressures have been checked and adjusted, replace pressure regulator adjustment cap.

Gas pressures are shown in the table below.

GAS PRESSURE TABLE

SUPPLY PRESSURE

GAS TYPE

MANIFOLD PRESSURE

High Low

Minimum* Maximum

Natural Gas 3.5” W.C. 1.4” W.C. 5” W.C. 14” W.C.

Propane Gas 10.0” W.C. 4.0” W.C. 11” W.C. 14” W.C.

* Minimum permissible gas supply pressure for purpose of input adjustment.

Form #43343530

–30– JJuly 08

Page 32

HI-LO

Adjustment Screws

Electric

Solenoid

Coil

Regulator

Vent Cover

(use 3/32 Hex

Allen Wrench)

INLET

HI

LO

1/8 NPT

Inlet Pressure

Tap with 3/16 Hex

Allen Wrench Plug

TWO-STAGE

GAS CONTROL VALVE

OFF

Gas Control

Knob

15.0) ELECTRICAL CONNECTIONS

ON

CAUTION

Never jumper these terminals. This

shorts out valve coil and may burn

out heat anticipator in thermostat.

Wiring

Terminals (3)

Ground

Terminals (2)

OUTLET

1/8NPT

Outlet Pressure

Tap with 3/16 Hex

Allen Wrench Plug

LO

C

HI

ELECTRIC SHOCK HAZARD

Disconnect electrical power and gas supply before servicing.

This appliance must be connected to a properly grounded electrical source.

Failure to do so may result in death or serious injury.

1. All electric wiring shall conform to the latest edition of the National Electrical Code (ANSI/NFPA No. 70), or

the code legally authorized in the locality where the installation is made.

2. The unit must be electrically grounded in accordance with the National Electrical Code (ANSI/NFPA No.

70-latest edition). In Canada, refer to current standard C22.1 Canadian Electrical Code Part 1.

3. The wiring providing power to the heater shall be connected to a permanently live electrical circuit, one that

is not controlled by a light switch.

4. The power supply to the unit should be protected with a fused disconnect switch or circuit breaker. A service

switch, as required by local codes, shall be located in the vicinity of the heater (check local codes for

allowable distances) and should be identified as Heater Service Switch. All electrical wiring must be located

in accordance with the required Clearances to Combustibles below the heater as listed on the nameplate on

the heater.

5. Connection to the power supply is provided by a 18/3 gauge x 72” long cord with grounded 3 prong plug.

6. The post purge function of the burner (fan on for 30 seconds after the call for heat) will only be enabled

when using a 24 Volt thermostat. With the line Voltage thermostat post purge operation is disabled.

2-Stage Thermostat

24V 2 stage thermostat connection

HI

43269060 rev A

The two stage heater terminals must

only be supplied with 24V

C

LO

72 grounded 3 prong

electrical cord

Liquid tight fitting

must be tight to

prevent ingress of

moisture

Form #43343530

July 08 –31–

Page 33

INTERNAL CONNECTION WIRING DIAGRAM — Direct Spark Ignition

CONNECTION WIRING DIAGRAM

Schéma de circuit de connexion

Ignition Module (Fenwal)

Bloc d'allumage

(W)TH

P.SW

V1

NC

IND

L1

(R) 24VAC

V2

GND

S1

HV

FACTORY WIRING

Circuit d'origine

FIELD WIRING

Connexions client

MONITORING LIGHTS

Lampes témoins

Red

Orange

Blue

Black

Black

Red

Blue

Green

Violet

Red

Light

Robinet à gaz

HI

Amber

Lights

Violet

High Voltage

Cable

Haute tension

Air Switch

pressostat

Gas Valve

LO

C

Flame Sensor

Terminal Block

(2-stage thermostat

connections)

LO

Red

Fuse 2A

Red

Transformer

Primary

120V

Secondary

Electrode

Gap 1/8

Écartement

d'électrode

3,2Êmm

HI

C

Red

Transformateur

bobine primaire 120ÊV

bobine secondaire 24ÊV

Fusible

24V

White

If any of the original wire as

supplied with the appliance must

be replaced. It must be replaced

with wiring material having a

temperature rating of at least

105oC. (18 AWG. - UL / CSA 600V

Type TEW)

When connecting the supply circuit

to the heater, wiring material

having a minimum size of 14 AWG

and a temperature rating of at least

90oC shall be used.

TISS

(Tube Integrity

Safety System)

Red

Black

White

Blower

Moteur

d'amorce

d'aspiration

Green

Green

Terminal

Block

Plaque

Black

(ribbed)

Terminal

Block

Plaque

L1 Black

L2 Black

(ribbed)

GROUND

L1 (hot) 120V

L2 NEUTRAL

CONTINUE TO

ADDITIONAL

HEATERS

Vers les

autres

radiateurs

NOTES

:

IGNITION MODULE TERMINAL DESIGNATIONS

24VAC/R 24 VAC Supply to Module

TH/W Thermostat Input

PS/W Pressure Switch Input

GND System Ground

V1 Valve Power

V2 Valve Ground

L1 120/240 VAC Input (Hot)

IND Blower Output

NC Alarm (if equipped)

S1 Remote Flame Sensor

1. If any of the original wire as supplied with the appliance must be replaced, it must be replaced with wiring

material having a temperature rating of at least 105ºC. (18 Ga. CSA 600V Type TEW)

2. When connecting the supply circuit to the heater, wiring material having a minimum size of 14 AWG and a

temperature rating of at least 90ºC shall be used.

Form #43343530

–32– JJuly 08

Page 34

FIELD CONNECTION WIRING DIAGRAMS

A. LOW VOLTAGE (24V) THERMOSTAT CONNECTIONS – SINGLE HEATER

Ground

N Neutral

L1 Hot (120V)

Fused

Disconnect

Switch

HI

C

LO

Receptacle

Continue To

Additional

Heaters

Power Supply

Cord (120V)

High FireLow Fire

Burner Control Box

B. LOW VOLTAGE (24V) THERMOSTAT CONNECTIONS – MULTIPLE HEATERS

Ground

N Neutral

L1 Hot (120V)

Fused

Disconnect

Switch

Terminal Block

(thermostat

connections)

Burner Control Box

HI

C

LO

Receptacle

Power Supply

Cord (120V)

1/4 Quick connect

terminals

Two-Stage Thermostat

(field supplied)

Receptacle

Burner Control Box

HI

C

LO

Continue To

Additional

Heaters

Power Supply

Cord (120V)

HI

24V

CHI

HI

FIRE

Relay Kit externally

mounted

(PN 44195000)

LO

FIRE

24V

LO

RELAY BOARD

LO

CHI

HI

3/16 Quick

HI

connect terminals

FIRE

LO

FIRE

LO

RELAY BOARD

LO

Continue To

24V Transformer

(field supplied)

Additional

Heaters

24V

C

High FireLow Fire

Two-Stage Thermostat

(field supplied)

Form #43343530

July 08 –33–

Page 35

16.0) VENTING

CARBON MONOXIDE HAZARD

Heaters installed in an unvented mode require a minimum ventilation flow of

4 CFM per 1,000 Btu/hr of total installed capacity.

In buildings with airborne contamination such as poultry houses the heater

must be installed with fresh air for combustion.

Failure to do so may result in death, serious injury, property damage or illness

from Carbon Monoxide poisoning.

A. BASIC FLUE VENTING — Venting must comply with the latest edition of the National Fuel Gas Code (ANSI

Z223.1-latest edition) or the authority having jurisdiction. Other venting references are in the equipment volume of

the ASHRAE Handbook.

Model Heat

exchanger

Maximum vent length ft.

(4” diameter)

length ft

Maximum Fresh air

intake length ft (4”

diameter)

Max. combination of

fresh air and vent ft. (4”

diameter)

PTS/U 40/25 20 45 50 75

PTS/U 50/30 20 45 50 75

PTS/U 50/30 30 35 40 65

PTS/U 75/50 20 45 50 75

PTS/U 75/50 30 35 40 65

PTS/U 100/65 30 45 50 75

PTS/U 100/65 40 35 40 65

PTS/U 125/80 30 60 50 75

PTS/U 125/80 40 50 40 65

PTS/U 125/80 50 40 30 55

PTS/U 150/100 40 60 50 75

PTS/U 150/100 50 50 40 65

PTS/U 150/100 60 40 30 55

PTS/U 175/110 50 60 50 75

PTS/U 175/110

PTS/U 175/110

PTS/U 175/110

60 50 40 65

70 40 30 55

50 60 40 65

PTS/U 200/125 60 50 30 55

PTS/U 200/125

70 40 30 45

Vent lengths shown in the table are for horizontal and vertical venting. If a longer length of vertical or horizontal

venting is required contact the manufacturer for assistance with vent sizing.

SINGLE HEATER VENTING (VERTICAL THROUGH THE ROOF)

1. When venting the heater to outside of building through a roof, use single-wall metal pipe. This is to be

constructed of galvanized sheet metal or other approved noncombustible corrosion-resistant material as

allowed by state or local codes.

2. A vent passing through a combustible roof shall extend through an approved clearance roof thimble.

Double-wall, Type B vent must be used for the portion of the vent system which passes through the roof. An

approved vent cap (Leslie “VersaCap”-Type B or equal) must be attached to end of the flue.

3. The maximum equivalent length of vent pipe should be carefully observed. A safety switch in the heater is

designed to shut the heater off before excessive flue restriction causes bad combustion. Refer to the Vent

Sizing Table for maximum vent lengths and vent pipe diameter.

4. Joints between sections of piping shall be fastened by sheet metal screws or other approved means and

should be sealed to prevent leakage of flue gas into building. Aluminum or Teflon tape suitable for 550ºF

(3M Company tapes 433 or 363) or silicone sealant is recommended.

5. All portions of the vent pipe shall be supported to prevent from sagging (6’ spacing is recommended).

6. When the vent pipe passes through areas where the ambient temperature is likely to induce condensation of

Form #43343530

–34– JJuly 08

Page 36

the flue gases, the vent pipe should be insulated and a condensation drain should be provided.

7. Minimum clearance for single-wall flue pipe to combustible material shall be 6 inches. This may be reduced

when the combustible material is protected as specified in the National Fuel Gas Code or the authority

having jurisdiction.

8. Single-wall metal pipe shall not originate in any unoccupied attic or concealed space and shall not pass

through any attic, inside wall or concealed space, or through any floor. For the installation of a single-wall

metal pipe through an exterior combustible wall, refer to latest edition of the National Fuel Gas Code or the

authority having jurisdiction.

9. A venting system shall terminate at least 3 ft. above any forced air inlet located within 10 ft.

2 ft (77cm) minimum

(when no wall or

parapet exists)

or less

Vent

2 ft (77cm)

minimum

Wall or

Parapet

4 Vent Pipe

(vertical position)

#10 Self-Drill

Screws

(typical)

Flue Adapter

Collar

4 Vent Elbow

Vent Cap (Leslie

VersaCap Type B)

Flashing

2 (5cm)

Clearance

Thimble

Seal Joint

and Annular

Space

10 ft (305cm)

4 Diameter

SINGLE HEATER VENTING (HORIZONTAL THROUGH SIDEWALL)

When venting the heater horizontally through a combustible outside sidewall, the same requirements listed

previously for venting Vertical Through The Roof apply except as follows:

1. A vent passing through a combustible wall must pass through an approved clearance thimble (Air-Jet #4VT

or Ameri-Vent #4EWT or other thimbles that are listed by a nationally recognized testing agency.

2. An approved vent cap (Breidert-Type L or equal) must be attached to the end of the vent pipe.

NOTE

: To minimize problems associated with condensation in long horizontal runs, vent pipe can be insulated.