Page 1

TopKAT™ PLUS

Installation Manual

MDE-5013C

Page 2

Computer Programs and Documentation

Gasboy, Greensboro, is an ISO 9001:2000 registered facility.

Underwriters Laboratories (UL):

UL File# Products listed with UL

MH4314

All dispensers and self-contained pumping

units

MH10581 Key con t r o l u n i t , M o d e l G K E - B S e r i e s

Card reader terminals, Models 1000, 1000P

Site Controller, Model 2000S CFN Series

Data entry terminals, Model TPK-900 Series

Fuel Point Reader System

National Conference of Weights and Measures (NCWM) - Certificate of Compliance (CoC):

Gasboy pumps and dispensers are evaluated by NCWM under the National Type Evaluation Program (NTEP). NCWM has issued the following CoC:

CoC# Product Model # CoC# Product Model # CoC# Product Model #

95-179 Dispenser

9100 Retail Series, 8700

Series, 9700 Series

91-019 Dispenser

9100 Commercial

Series

05-002 Atlas

8700K, 8800K,

9100K, 9200K, 9800K

95-136 Dispenser 9800 Series 91-057 Controller

1000 Series FMS,

2000S-CFN Series

California Air Resources Board (CARB):

Executive Order # Product

G-70-52-AM Balance Vapor Recovery

G-70-150-AE VaporVac

Non-registered trademarks

Consola

™

Infinity

™

Islander™ PLUS

Registered trademarks

ASTRA

®

Atlas

®

Fuel Point

®

Gasboy

®

Keytrol

®

Slimline

®

Additional US and foreign trademarks pending.

Other brand or product names shown may be trademarks or registered trademarks of their respective holders.

Federal Communications Commission (FCC) Warning

All Gasboy computer programs (including software on diskettes and within memory chips) and documentation are copyrighted by, and shall remain the property of, Gasboy. Such

computer programs and documents may also contain trade secret information. The duplication, disclosure, modification, or unauthorized use of computer programs or

documentation is strictly prohibited, unless otherwise licensed by Gasboy.

This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy, and if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense. Changes or modifications not expressly

approved by the manufacturer could void the user’s authority to operate this equipment.

Approvals

Trademarks

This document is subject to change without notice.

This document is subject to change without notice.

http://www.gasboy.com

E-mail: literature@gasboy.com · Internet: http://www.gasboy.com

2014 GASBOY. All Rights Reserved.

2015 GASBOY. All Rights Reserved.

Page 3

Table of Contents

Table of Contents

1 – Introduction 1-1

Purpose. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Intended Users . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TopKAT PLUS System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Remote Web Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Head Office . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Restrictions and Limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

System Workflow Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

TopKAT PLUS Structure . . . . . . . . . . .

Main Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Electrical Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Available Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Optional Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Dispensers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Security and Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Authorization Security . . . . . . . . . . . . . . . .

Network Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Maintenance Security. . . . . . . . . . . . . . . . .

Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communication Standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Security Standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Using This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Documents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Abbreviations and Acronyms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

. . . . . . . . . . . . . . . . . . . . . 1-13

. . . . . . . . . . . . . . . . . . . . . 1-13

. . . . . . . . 1-1

. . . . . . . . . . . 1-1

. . . . . . . . 1-2

. . . . . . . . . 1-11

. . . . . 1-12

. . . . . 1-13

. . . . . . . . . . 1-13

. . . . . . . . . 1-14

. . . . . . . . . 1-14

. . . . . . . 1-15

. . . . . 1-15

. . . . 1-16

2 – Important Safety Information 2-1

3 – TopKAT PLUS Installation Procedures 3-1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Installation Specifications . . . . . . . . . . . . . . . . . . .

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Precautions and Safety Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Types of Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Types of TopKAT PLUS Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Head Assembly Dimensions . . . .

Pedestal Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Conduits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Conduit Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Barrier Plate Conduit Penetration . . . . . . . . . . . . . . . . .

Sealing Conduits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Safety Distance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

MDE-5013C TopKAT™ PLUS Installation Manual · February 2015 Page i

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

. . . . . . . . . . . 3-4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Page 4

Table of Contents

TopKAT PLUS Pedestal Mounting Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Connections to TopKAT PLUS - Pedestal Mounted

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Types of Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

Wiring Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

Types of Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

Field Wiring Requirements (LAN/WAN) . . . . . . . . . . . . . . . . . . . . . . . .3-12

AC Power Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

Mechanical Pump - Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

Terminal Block - Pin-out Connections for Mechanical Pumps

Mechanical Pump - Required Connections. . . . . . . . . . . . . . . . . . . . . .3-15

Single Suction Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Pump - Pulser Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

RS-485 Electronic - TopKAT PLUS on Gasboy 9800 Atlas

(Factory Installed) .

Electronic Pump Wiring - TopKAT PLUS on Pedest

Mechanical Pulser. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

Electronic Pump - Wiring Description (Pedestal Mount)

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

RS-485 Electronic Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

Electronic Pump - Wiring Description (Atlas Mounted TopKAT PLUS)

Post-installation Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Completion Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-26

TopKAT PLUS Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manager Tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performing a Test Transaction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-27

Disabling Test Transaction Option . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-29

Opening Printer Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-29

Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

. . . . . . . . . . .3-11

. . . .3-14

. . . . . . .3-14

. . . . . .3-18

-19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

al . . . . . . . . . . . . .3-21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

. . . . . . . . . . . . . . . . . . . . . . .3-25

. . . . . . .3-26

. . . . . .3-27

. . . . . . .3-27

4 – Printer 4-1

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printer Connector Pin-out. .

Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Printing Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement - Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Roll Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Thermal Paper Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Jumpers Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Parameters for Printing . .

Cutter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Printing Status Report. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Installing Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

Installing Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

Replacing Paper Roll . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

Releasing Jammed or Crumpled Paper . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

. . . . . . . . . . . . . . . . . . .4-13

. . . . . . . . . . . .4-2

. . . . . . .4-3

. . . . . . . . . . . .4-6

. . . . . . . . . . . .4-6

. . . . . . . . . . . .4-6

. . . . . . . . . .4-6

. . . . . . .4-7

. . . . . . .4-9

. . . . . .4-10

. . . . . . . . .4-13

. . . . . . .4-13

. . . . . .4-14

Page ii MDE-5013C TopKAT™ PLUS Installation Manual · February 2015

Page 5

Table of Contents

5 – Maintenance 5-1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TopKAT PLUS Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

OrPT Troubleshooting . . . . . . . . . . . . . . . .

Printer Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Communication Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Safety Reinforcements. . . . . . .

Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

. . . . . . . . . . . . . . . . . . . . . . 5-5

. . . . . . . . 5-1

Glossary Glossary-1

FuelOmat Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Glossary-1

Communication Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Glo

ssary-1

Appendix A: Wiring Diagrams A-1

Appendix B: Parts List B-1

Appendix C: TopKAT PLUS Parts Illustrated C-1

Index Index-1

MDE-5013C TopKAT™ PLUS Installation Manual · February 2015 Page iii

Page 6

Table of Contents

This page is intentionally left blank.

Page iv MDE-5013C TopKAT™ PLUS Installation Manual · February 2015

Page 7

Purpose Introduction

1 – Introduction

Purpose

This manual provides installation instructions for TopKAT™ PLUS, the complete station

automation solution in a dispenser-mounted compact box. The system must be installed in the

factory as described in this manual to ensure its reliability and proper operation.

This manual includes a general and functional

components, installation requirements, and procedures.

Intended Users

This manual is intended for Authorized Service Contractors (ASCs) of TopKAT PLUS and its

components. It is also intended for the factory and island electricians.

Description

T o pKAT PLUS is a fuel control and data acquisition system. The system is self-contained in a

forecourt compatible and weather-resistant cabinet installed on top of Gasboy

mounted on a post.

TopKAT PLUS (see Figu

small home base gas stations. TopKAT PLUS provides the central function of site controller

adequate for a maximum of two nozzles in a single dispenser. It also fulfills other essential

services on the island such as driver identification system, transaction data storage, and so on.

Its ergonomic design, as well as its user-friendly operating program, enables fast and accurate

service for the driver in the refueling site.

description of the product, its main

®

dispensers or

re 1-1 on page 1-2) is a core component in Gasboy’s solution for

TopKAT PLUS is equipped with the Outdoor Payment Terminal (OrPT), a payment terminal

and communication receptacle. The payment terminal is equipped with an alphanumeric

Liquid Crystal Display (LCD) and a keyboard to interface with the client. This enables

T opKAT PLUS to support all common refueling identification devices such as magnetic cards,

®

contactless Radio Frequency Identification (RFID) tags (also known as MIFARE

keypad entry.

MDE-5013C TopKAT™ PLUS Installation Manual · February 2015 Page 1-1

tags), and

Page 8

Introduction System Overview

Post Mounted Unit for Mechanical and

Electronic Dispensers

TopKAT PLUS mounted on an

Atlas

®

9800 Dispenser

(i)

(ii)

(iii)

TopKAT PLUS - General View

Figure 1-1: TopKAT PLUS - General View

System Overview

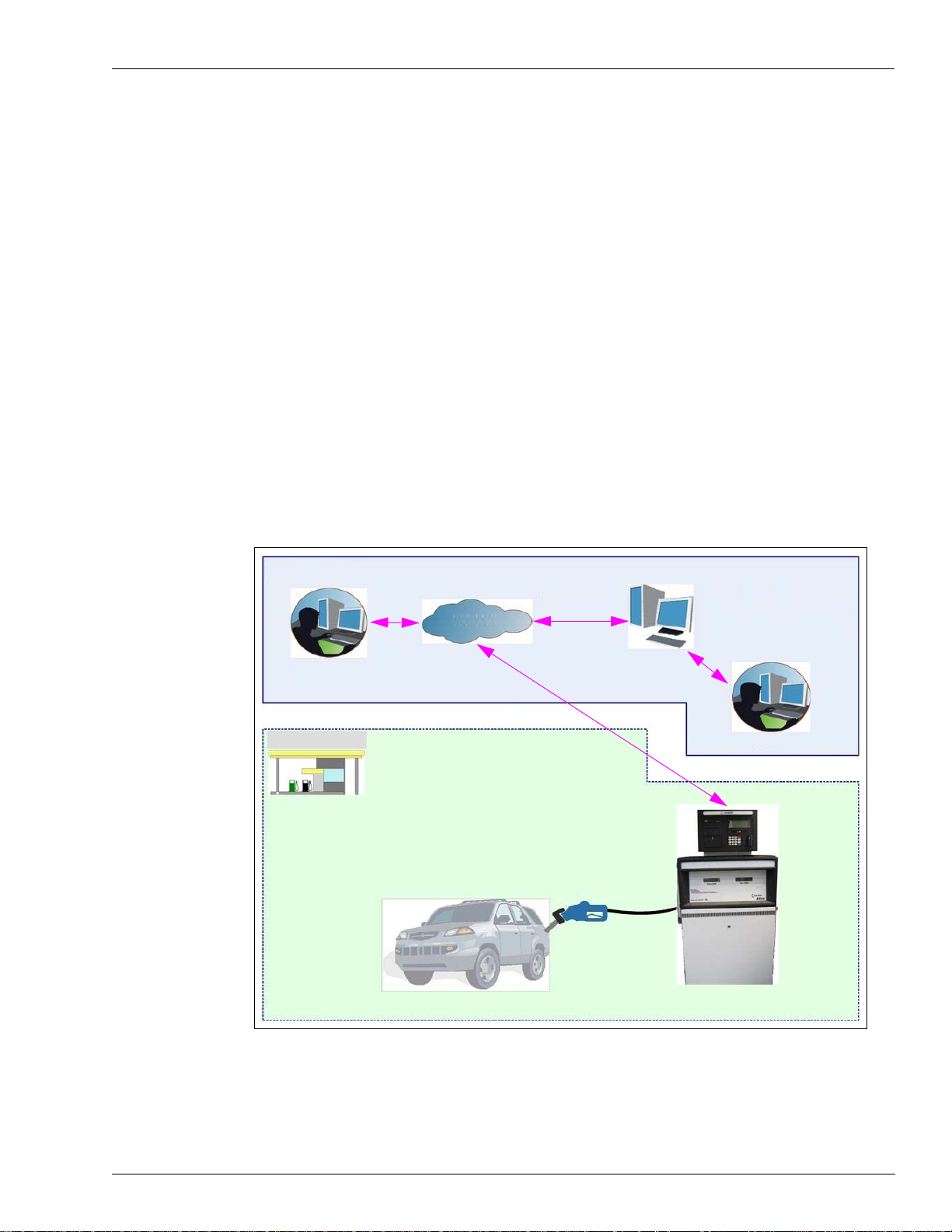

TopKAT PLUS System

TopKAT PLUS is an innovative product that enables refueling in home base gas stations for

fleet authorized vehicles or drivers. T opKAT PLUS electronically locks the dispenser nozzles,

thereby ensuring that only appropriately authorized vehicles and plants receive the required

fuel. The system also ensures accurate recording of each transaction (see Figure 1-2

on page 1-3).

The heart of the home base station solution is the SiteOmat automation software. SiteOmat

ns on an embedded operating system on the Orpak

ru

embedded hardware platform designed to survive the harsh gas station environment. It uses a

solid state flash disk and Real Time Clock (RTC) with backup along with surge suppressors

for transient and noise immunity. The system also includes power failure recovery

mechanisms.

Remote Web Access

Remote web-based capabilities for monitoring, management, and maintenance are available.

A standard PC with Microsoft

locally or remotely (secured). A special management software is not required, thanks to the

built-in web server technology integrated into the station controller and the large variety of

communication links supported.

™

Controller Unit (OrCU). OrCU is an

®

Internet Explorer® is used for management of the site either

Page 1-2 MDE-5013C TopKAT™ PLUS Installation Manual · February 2015

Page 9

System Overview Introduction

Head Office

-Site Manager

- Technician

Management &

Reporting

Fleet Manager

Home Base

Network

Fleet Head Office Web Server

- Issuing Vehicle Identification

- Authorizing Vehicle Identification

- Setting Limits & Restrictions

- Reporting and Management

- Fuel Management (Optional)

Head Office

Centralized management is provided by the optional Fleet Head Office (FHO) and Fuel

Management Software Server. The head office system consolidates the data from multiple

sites and generates reports, including exception reports. It also enables control of the limits

and restrictions placed on the various fleet vehicles. In addition, authorized fleet personnel are

able to login remotely and are always in control. Head office enables authorized users to

control and manage wet stock inventory on all stations including orders, deliveries, and

reports.

Restrictions and Limits

Control of fleet’s fuel expenses can be maximized by defining limits (day, week, month),

maximum number of refueling (day, week, month), and setting restrictions (days of the week,

fuel type, stations, time intervals). In cases where the system is configured for multiple sites,

the centralized FHO must synchronize the data between all sites so that the limits can be

applied to a whole system rather than to an individual site. In case of communication failure,

the specific site is able to refuel for a predefined grace period (parameter) using the most

recent limits stored in its database.

Figure 1-2: TopKAT PLUS in Home Base Station - General Configurat ion Diagram

MDE-5013C TopKAT™ PLUS Installation Manual · February 2015 Page 1-3

Page 10

Introduction TopKAT PLUS Structure

System Workflow Example

Following example depicts the operational workflow for self-service at the home base station:

Refueling Scenario with Magnetic Cards

A motorist stops for fuel at the station. His authorization device for the fueling transaction is a

magnetic card. The client swipes the card through the magnetic card reader on the payment

panel.

The magnetic card information is read and sent to the s

and approval. The client lifts the nozzle and inserts it in the car inlet. On approval, the fueling

transaction starts, at the end of which the transaction data is kept internally. The data is

transferred to the fuel head office for future billing.

The client may add more data to the transaction, by manually entering the information using

the payment panel keyboard. After the refueling is completed, the motorist replaces the nozzle

to pump.

The motorist may print a transaction ticket from the TopKAT PLUS printer (optional).

TopKAT PLUS Structure

Main Components

Following is a short description of the TopKAT PLUS main sub-assemblies:

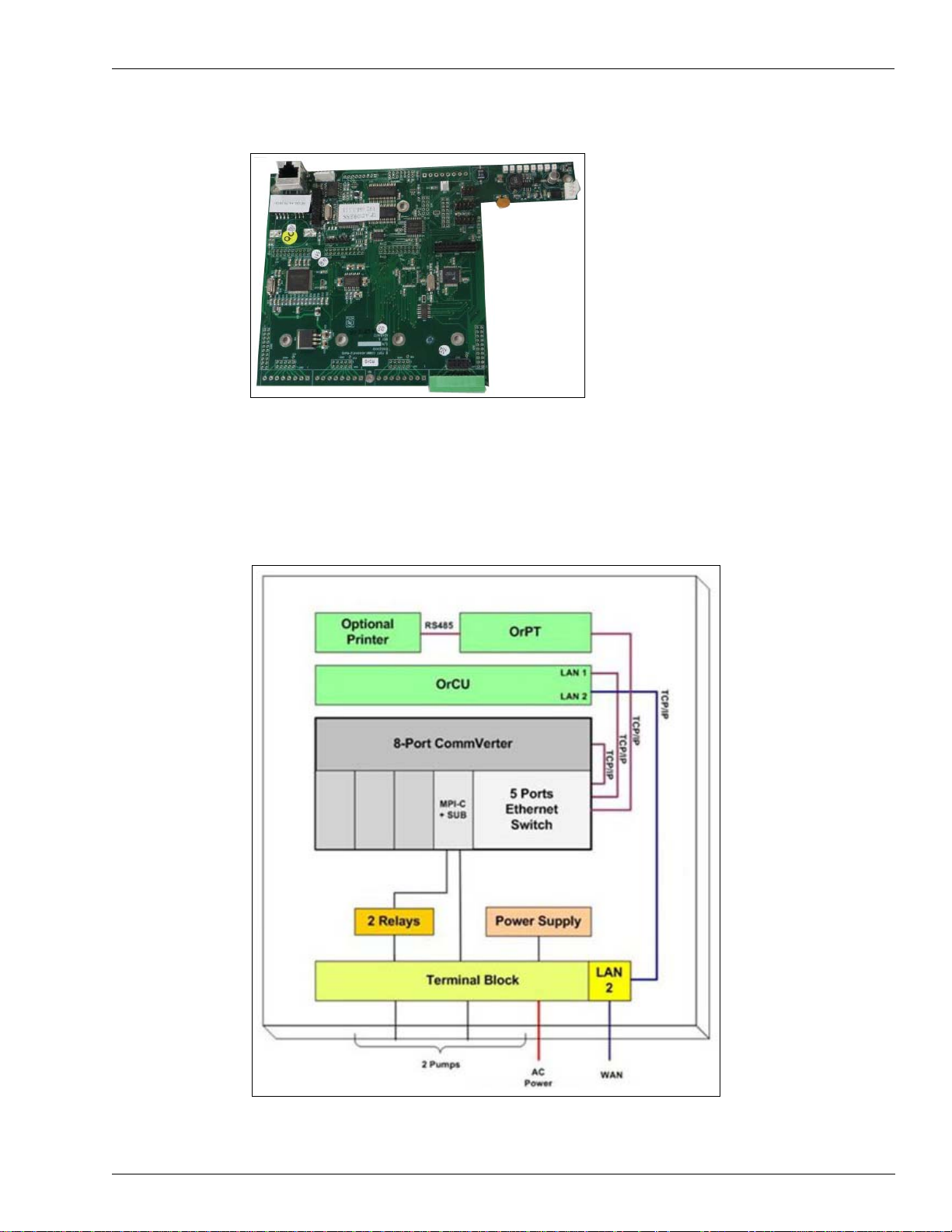

OrCU

OrCU is a complete forecourt controller with its own embedded operating system. The unit

consists of an embedded hardware platform with a solid state flash hard disk, RTC with

backup, along with surge suppressors for transient and noise immunity.

ite controller (OrCU) for authentication

®

OrCU features two separate and isolated networks (TCP/IP over Ethernet

links the TopKAT PLUS system components. The second network is intended for external

remote communication (head office and third-party systems). This network is protected by

Secured Socket Layer (SSL) security.

Page 1-4 MDE-5013C TopKAT™ PLUS Installation Manual · February 2015

). One network

Page 11

TopKAT PLUS Structure Introduction

OrCU includes a built-in server for web access through an Internet browser (Internet

Explorer).

Figure 1-3: OrCU

OrPT Panel

The OrPT consists of a payment panel and communication equipment. The panel is equipped

with an alphanumeric LCD (graphic LCD, optional) and a keyboard to interface with the

client. The payment panel is equipped with several authorization options such as magnetic

card reader and RFID tag reader. These authorization tools enable TopKA T PLUS to accept all

common authorization methods such as credit cards, magnetic cards, and contactless tags.

tho

OrPT supports keyboard entry for au

such as odometer, engine hours, vehicle plate number, and PIN code.

The OrPT panel is connected to the site controller (OrCU) through a Local Area Network

[LAN (Ethernet)] link.

Figure 1-4: OrPT Panel

rization, and other parameters’ input from the user

MDE-5013C TopKAT™ PLUS Installation Manual · February 2015 Page 1-5

Page 12

Introduction TopKAT PLUS Structure

Outdoor Printer (Optional)

TopKAT PLUS includes an optional printer for receipts printout, as well as data output. The

printer is linked to the central payment terminal that sends to it the transaction data for

printout.

n

Printer module G2 is a compact, ruggedized thermal pri

of the gas station. It includes two sensors for paper usage alerts:

• Low paper sensor - activated when there is approximately 25% of

• End paper sensor - activated when printer paper runs out completely

The paper usage and receipt indications include a buzzer sound, Light E

indicators or the combination of both, dependent on its configuration.

Figure 1-5: Outdoor Printer (Optional)

ter suitable for the harsh environment

the paper roll left

m

itting Diode (LED)

8-port CommVerter

The 8-port CommVerter consists of a communication board for all TopKAT PLUS electronic

units and for the peripheral equipment interface.

The CommVerter includes an Ethernet switch, RS-485 port for electronic pumps or an

Mechanical Pump Interface

information, refer to “Printer” on page 4-1. The CommVerter communicates with the site

controller (OrCU) through a LAN (Ethernet) link.

Card (MPI-C) for interface to a mechanical pump. For more

Page 1-6 MDE-5013C TopKAT™ PLUS Installation Manual · February 2015

Page 13

TopKAT PLUS Structure Introduction

Figure 1-6: 8-port CommVerter

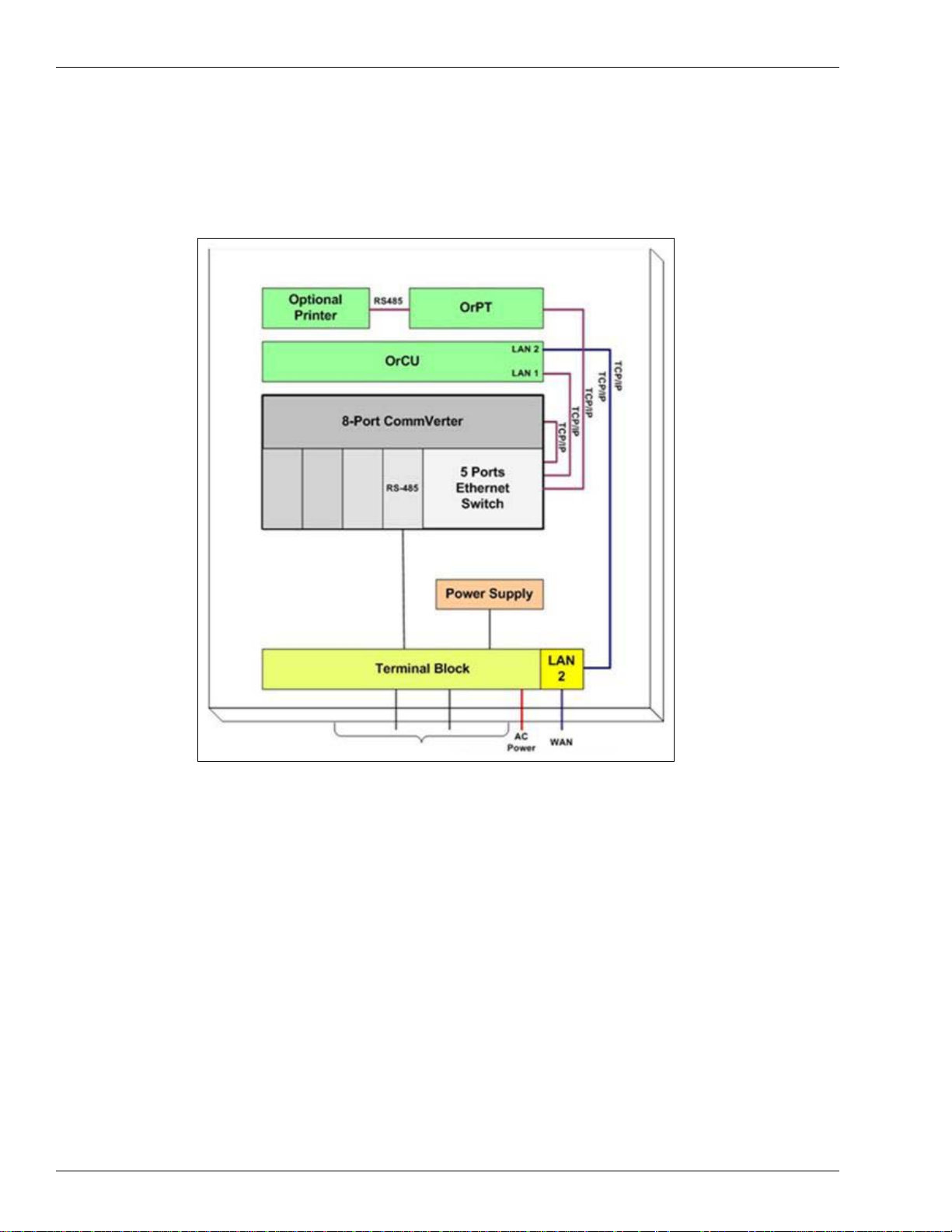

TopKAT PLUS Internal Configuration - Mechanical Pump

Figure 1-7 shows a general configuration diagram of the TopKAT PLUS up to two mechanical

pumps.

Figure 1-7: Internal Configuration Diagram - Two Mechanical Pumps

MDE-5013C TopKAT™ PLUS Installation Manual · February 2015 Page 1-7

Page 14

Introduction TopKAT PLUS Structure

TopKAT PLUS Internal Configuration - Electronic Pump

Figure 1-8 shows a general configuration diagram of the TopKAT PLUS up to two electronic

pumps.

Figure 1-8: Internal Configuration Diagram - Two Electronic Pumps

Page 1-8 MDE-5013C TopKAT™ PLUS Installation Manual · February 2015

Page 15

TopKAT PLUS Structure Introduction

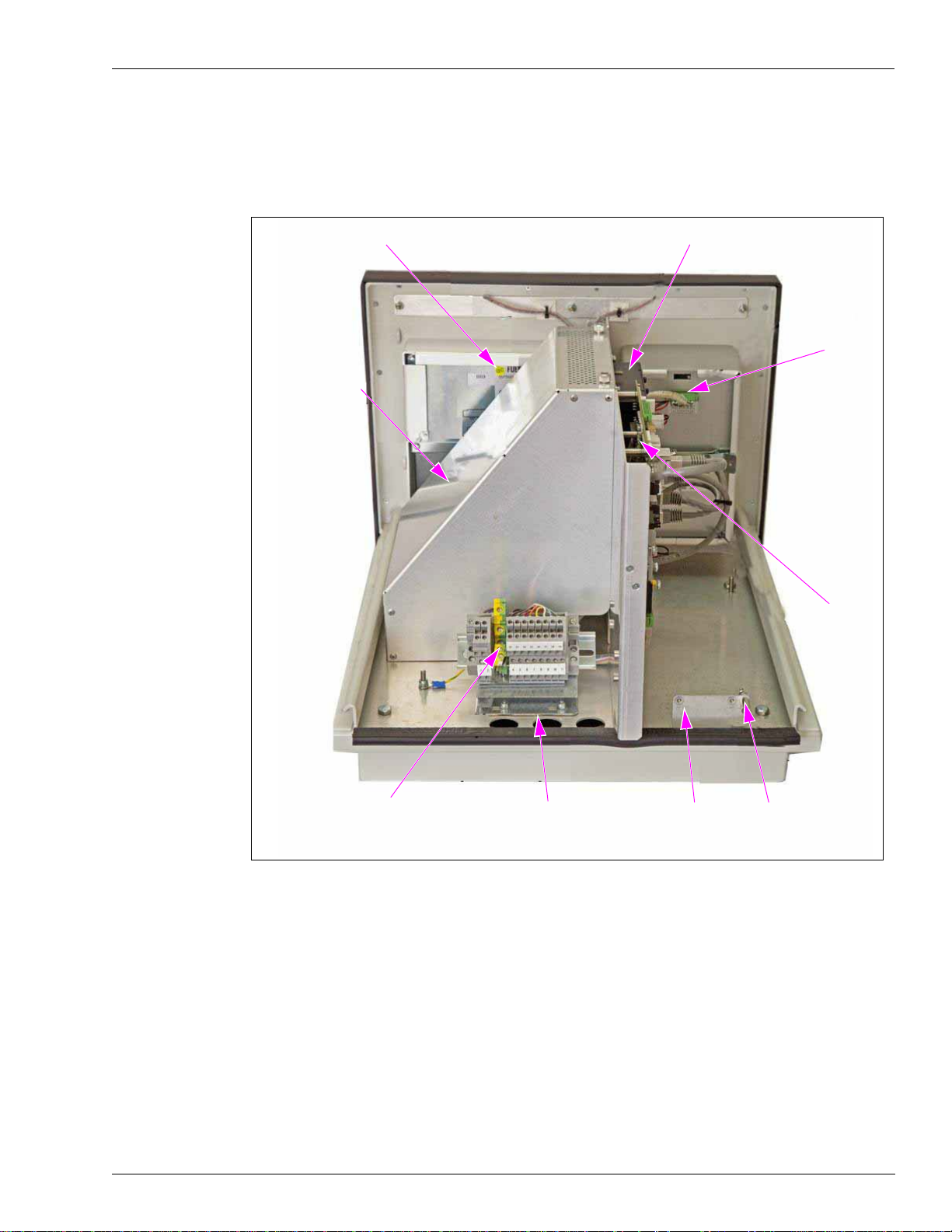

OrPT

OrCU

Printer

8-port

CommVerter

AC

Protective Cover

Terminal Block

Connection

Openings

Cover Opening

Detection

Mechanism

Ground Stud

TopKAT PLUS Main Components Location

Figure 1-9 shows the location of the main components of the TopKAT PLUS.

Figure 1-9: Internal Components Location

MDE-5013C TopKAT™ PLUS Installation Manual · February 2015 Page 1-9

Page 16

Introduction TopKAT PLUS Structure

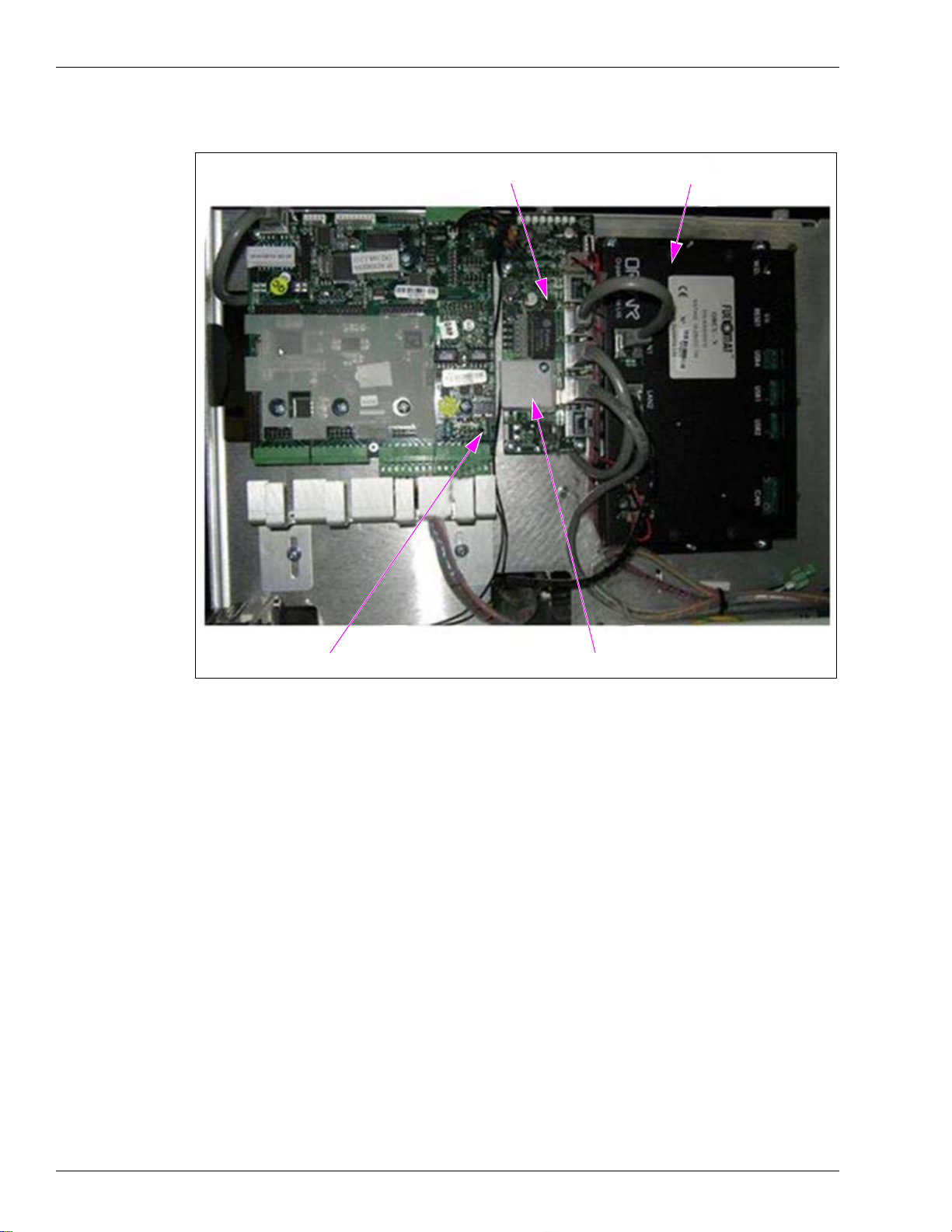

5-port Switch

OrCU

8-port CommVerter Heat Sink Cover

Figure 1-10: Internal Components Location - Right Side

Page 1-10 MDE-5013C TopKAT™ PLUS Installation Manual · February 2015

Page 17

Electrical Setup Introduction

32 V Regulator

(M09680B052)

Line Filter (M09680B008)

24 V Regulator

(M09680B083)

Transformer

(M09680B022)

Terminal Block (M09680B025)

Electrical Setup

TopKAT PLUS electrical components are protected by a dedicated cover to ensure physical

separation between high voltage and low voltage in the box. The mains cable is first connected

to the terminal block. Between the terminal block and transformer, the system uses a line filter

to attenuate conducted radio frequencies - Radio Frequency Interference (RFI),

Electromagnetic Interference (EMI) - between the line and equipment. AC power is then

supplied to an AC/AC high to low transformer - 110/220 to 25 VAC.

Figure 1-11 shows the AC setup in electronic pumps configuration without the prot

cover.

Figure 1-11: AC Setup (Electronic Configuration)

ective

MDE-5013C TopKAT™ PLUS Installation Manual · February 2015 Page 1-11

Page 18

Introduction Available Configurations

Available Configurations

General

TopKAT PLUS is available in several configurations, in accordance with its intended use and

with the components installed. All configurations are manufactured in accordance with

specific customer request and receive a part number (refer to “Configurations”). Following

paragraphs describe the several configurations and t

Optional Printer

The printer in the TopKAT PLUS is provided as an option. The printer issues a printout of the

transaction to the driver.

Dispensers

TopKAT PLUS can support either mechanical or electronic dispensers, in accordance with its

configuration.

heir device composition:

Mechanical dispensers require the installation of

an MPIC card on the 8-port CommVerter.

Electronic dispensers require installation of an interface card (RS-485) on the 8-port

CommVerter.

Configurations

Following table defines all the available product numbers for the different TopKAT PLUS

configurations:

PRN

Part Number Name Dispenser

PA040500000 TopKAT PLUS (E) + - PA040501000 TopKAT PLUS (2M) - + PA040500010 TopKAT PLUS (E, PRN)* + - +

PA040501010 TopKAT PLUS (2M, PRN)* - + +

*TopKAT PLUS with printer is for inst

allation over class 1, division 2.

Note: TopKAT PLUS does not support Tank Level Gauges (TLG) or additional electronic

dispensers. Those devices require an external box or another solution.

Electronic

Mechanic 2

Printer

In the order form, customers are required

to define the part number for the specific pump card

in use (MPI-C or RS-485, refer to the following table).

No. Pump Card Description Gilbarco® Part Number

1 RS-485 Interface (8P) P.B. M09680B014

2 MPI-C + Sub Interface (8P) P.B. M09680B105

Page 1-12 MDE-5013C TopKAT™ PLUS Installation Manual · February 2015

Page 19

Security and Protection Introduction

Security and Protection

General

The transaction activities of the T opKAT PLUS are secured and protected for transmission and

authorization activities.

Authorization Security

The contactless tags include Triple-Data Encryption Standard (TDES) encrypted data for user

identification and billing. Consequently, TopKAT PLUS includes a special Security

Application Module (SAM) for decryption and matching identification. On tag reading,

TopKAT PLUS attempts to decrypt the string from the tag. TopKAT PLUS disregards tags

whose security scheme does not match the TopKAT PLUS internal SAM.

Network Security

The Ethernet LAN is isolated from the external Wide Area Network (WAN) by the site

controller (OrCU). In case of remote maintenance, a firewall must be applied either at the

router level or preferably at the home base station level.

Maintenance Security

T opKAT PLUS maintenance and setup procedures require inserting a user name and password

for access. For more information, refer to MDE-4817 SiteOmat In-House Station Controller

Setup and Maintenance Manual.

Housing

TopKAT PLUS system enclosure is made of a metal cabinet for factory installation on top of

the pump. It includes a front plastic panel and a supportive base.

The enclosure is weather-proof to sustain the harsh env

TopKAT PLUS payment panel is made of rugged plastic. The devices in its front panel are

sealed to prevent humidity and dust penetration.

TopKAT PLUS box is locked by key for safety and security. The key must be kept in a

well-kept, secure, and safe place.

The cabinet also includes an electronic mechanism for preventing unauthorized personnel

from opening the TopKAT PLUS box cover. The detection mechanism is set in the SiteOmat

application, refer to MDE-4817 SiteOmat In-house Station Contro ller Setu p and Maintenance

Manual.

ironment of a home base station.

Note: The top cover and frame are secured by a ground wire. Caution must be taken while

emoving the cover.

r

MDE-5013C TopKAT™ PLUS Installation Manual · February 2015 Page 1-13

Page 20

Introduction Specifications

Specifications

The physical, electrical, and environmental specifications applicable to the TopKAT PLUS are

displayed in the following table.

Description Specification

Supply Voltage 120-240 VAC

Power Consumption 1 A max

Operating Temperature -40 °F to +104 °F (-40 °C to +40 °C)

Storage Temperature -40 °F to +158 °F (-40 °C to +70 °C)

Humidity 80% Non-condensing

Dimensions W X H X D: 16.26 X 11.24 X 17.224” (413 X 285.5 X 437.5 mm)

Communication Interface RS-485 - 9600 bps, Half-duplex

RS-232

Ethernet RJ-45 - 10 mbps

Pump Control Maximum Current [2 Solid State

Relay Channels, (see

Power Supply Output Voltage to Pulser Unit 12 VDC +/- 20%

Power Supply Maximum Output Current 30 mA max

Pulsar Input High Level Voltage 9 to 15 VDC

Pulsar Input High Level Sink Current (at 15 V) 3 mA

In Use “On” Level (Input) 100-240 VAC, 50/60 Hz, 2 W (20 mA)

In Use “Off” Level (Input) 0 to 20 VAC

®

Recognition Suitable for Use Over Class 1, Division 2, Group D

UL

Note: When controlling 230 VAC pumps the solid state relay only con

note)]

Motor Maximum: 3/4 HP at 115 VAC or 1-1/2 HP at 230 VAC

trols one leg of the 230 VAC.

Standards

Communication Standards

TopKAT PLUS communicates, in its different models, over the following standards:

• RS-232 link

• RS-485 link

• TCP/IP over Ethernet

Security Standards

TDES encryption for payment devices (contactless tags, magnetic stripe cards, and so on).

Page 1-14 MDE-5013C TopKAT™ PLUS Installation Manual · February 2015

Page 21

Using This Manual Introduction

An operating procedure, practice, and so on, that if not correctly followed, could

result in an injury or loss of life.

WARNING

An operating procedure, practice, and so on, that if not strictly observed, could

result in damage or destruction of equipment.

CAUTION

More detailed technical/functional information in regard to relevant issue.

IMPORTANT INFORMATION

Using This Manual

This manual includes alerting comments, to draw the reader’s attention to important issues.

The comments are accompanied by symbols for ease of reference. Following comment types

are used:

Related Documents

Document

Number Description GOLD

MDE-4331 Atlas Fuel Systems Installation Manual • Gasboy Atlas

MDE-4333 Atlas Fuel Systems Site Preparation Manual • Gasboy Atlas

MDE-4334 Commercial and Retail Series Atlas Start-up/Service Manual • Gasboy Atlas

MDE-4817 SiteOmat In-House Station Controller Setup and Maintenance Manual Gasboy Fleet PLUS

MDE-4818 SiteOmat In-House Station Controller User’s Manual Gasboy Fleet PLUS

MDE-4819 OrPT Gasboy’s Payment Terminal Inst

Manual for Home-base Stations

MDE-4820 8-port CommVerter Operation and Installation Manual Gasboy Fleet PLUS

PT-1963 Illustrated Spare Parts Manual Gasboy Fleet PLUS System

allation, Setup and Oper

ation

SM

Library

• Pumps/Dispensers

• Pumps/Dispensers

• Pumps/Dispensers

t

ems

Sys

ems

Syst

Gasboy Fleet PLUS

Systems

t

ems

Sys

MDE-5013C TopKAT™ PLUS Installation Manual · February 2015 Page 1-15

Page 22

Introduction Abbreviations and Acronyms

Abbreviations and Acronyms

Term Description

ANSI American National Standards Institute

ASC Authorized Service Contractor

AWG American Wire Gauge

CAT Category

D-Box Distribution Box

DES Data Encryption Standard

EIA Electronic Industries Alliance

EMI Electromagnetic Interference

FHO Fleet Head Office

GOLD Gilbarco Online Documentation

J-box Junction Box

LAN Local Area Network

LCD Liquid Crystal Display

LED Light Emitting Diode

MPI Mechanical Pump Interface

MPI-C Mechanical Pump Interface Card

®

NEC

NFPA National Fire Protection Association

OrCU Orpak Controller Unit

OrPT Orpak/Outdoor Payment Terminal

PS Pump Server

RFI Radio Frequency Interference

RFID Radio Frequency Identification

RTC Real Time Clock

SAM Security Application Module

SSE Site Service Equipment

SSL Secured Socket Layer

STP Submersible Turbine Pump

TCP/IP Transmission Control Protocol/Internet Protocol

TDES Triple-Data Encryption Standard

TIA Telecommunications Industry Association

TLG Tank Level Gauges

UL Underwriters Laboratories

VIT Vehicle Information Transceiver

WAN Wide Area Network

National Electrical Code

Page 1-16 MDE-5013C TopKAT™ PLUS Installation Manual · February 2015

Page 23

2 – Important Safety Information

Notes: 1) Save this Important Safety Information section

in a readily accessible location.

2) Although DEF is non-flammable, diesel is

flammable. Therefore, for DEF cabine ts that are

attached to diesel dispensers, follow all the

notes in this section that pertain to flammable

fuels.

This section introduces the hazards and safety precautions

associated with installing, inspecting, maintaining or servicing

this product. Before performing any task on this product, read

this safety information and the applicable sections in this

manual, where additional hazards and safety precautions for

your task will be found. Fire, explosion, electrical shock or

pressure release could occur and cause death o r serious injury,

if these safe service procedures are not followed.

Preliminary Precautions

You are working in a potentially dangerous environment of

flammable fuels, vapors, and high voltage or pressures. Only

trained or authorized individuals knowledgeable in the related

procedures should install, inspect, maintain or service this

equipment.

Emergency Total Electrical Shut-Off

The first and most important in formation you must know is how

to stop all fuel flow to the pump/dispenser and island. Locate

the switch or circuit breakers that shut off all power to all fueling

equipment, dispensing devices, and Submerged Turbine

Pumps (STPs).

The EMERGENCY STOP, ALL STOP, and

PUMP STOP buttons at the cashier ’s station

WILL NOT shut off electrical power to the

pump/dispenser. This means that even if you

activate these stops, fuel may continue to flow

uncontrolled.

You must use the TOTAL ELECTRICAL

SHUT-OFF in th e cas e of an emerge nc y a nd not

the console’s ALL STOP and PUMP STOP or

similar keys.

!

WARNING

!

Total Electrical Shut-Off Before Access

Any procedure that requires access to electrical component s or

the electronics of the dispenser requires total elect rical shut off

of that unit. Understand the function and location of this switch

or circuit breaker before inspecting, installing, maintaining, or

servicing Gasboy equipment.

Evacuating, Barricading and Shutting Off

Any procedure that requires access to the pump/dispenser or

STPs requires the following actions:

• An evacuation of all unauthorized persons and vehicles from

the work area

• Use of safety tape, cones or barric ades at the affected unit(s)

• A total electrical shut-off of the affected unit(s)

Read the Manual

Read, understand and follow this manual and any other labels

or related materials supplied with this equipment. If you do not

understand a procedure, call a Gasboy Authorized Serv ice

Contractor or call the Gasboy Support Center at

1-800-444-5529. It is imperative to your safety and the safe ty of

oth

e

rs to understand the procedures before beginning work .

Follow the Regulations

Applicable information is available in National Fire Protection

Association (NFPA) 30A; Code for Motor Fuel Dispensing

Facilities and Repair Garages, NFPA 70; National Electrical

Code (NEC), Occupatio nal Safety and Health Administrati on

(OSHA) regulations and federal, state, and local codes. All

these regulations must be followed. Failure to install, inspect,

maintain or service this equipment in accordance with these

codes, regulations and standards may lea d to leg al citation s

with penalties or affect the safe use and operation of the

equipment.

Replacement Parts

Use only genuine Gasboy replacement p art s and re trofit kits on

your pump/dispenser. Using parts other than genuine Gasboy

replacement parts could create a safety hazard and violate

local regulations.

Safety Symbols and Warning Words

This section provides important information about wa rn ing

symbols and boxes.

Alert Symbol

This safety alert symbol is used in this manual and on

warning labels to alert you to a precaution which must be

followed to prev

ent potential personal safety hazards. Obey

safety directives that follow this symbol to avoid possible injury

or death.

Signal Words

These signal words used in this manual and on warning labels

tell you the seriousness of particular safety hazards. The

precautions below must be followe d to prevent death, injury or

damage to the equipment:

DANGER: Al

erts yo

u to a hazard or unsafe practice

which will result in death or serious injury.

WARNING: Alerts

you to a hazard or unsafe practice

that could result in death or serious injury.

CAUTION with Alert symbol: Designates a hazard or

un

safe practice which may result in minor injury.

CAUTION w

i

thout Alert symbol: Designates a hazard or

unsafe practice which may result in property or

equipment damage.

Working With Fuels and Electrical Energy

Prevent Explosions and Fires

Fuels and their vapors will explode or burn, if ignited. Spilled or

leaking fuels cause vapors. Even filling customer tanks will

cause potentially dangerous vapors in the vicinity of the

dispenser or island.

DEF is non-flammable. Therefore, expl

osion and fire safety

warnings do not apply to DEF fluid lines.

!

!

!

Important Safety Information

MDE-5013C TopKAT™ PLUS Installation Manual · February 2015 Page 2-1

Page 24

Important Safety Information

The pump/dispenser contains a chemical known to the

State of California to cause cancer.

WARNING

!

The pump/dispenser contains a chemical known to the

State of California to ca use birth defects or other

reproductive harm.

WARNING

!

Gasoline/DEF ingested may cause

unconsciousness and burns to internal organs.

Do not induce vomiting. Keep airway open.

Oxygen may be needed at scene. Seek medical

advice immediately.

DEF generates ammonia gas at high er temperatures.

When opening enclosed panels, allow the unit to air out to

avoid breathing vapors.

If respiratory difficulties develop, move victim away from

source of exposure and into fresh air. If symptoms persist,

seek medical attention.

WARNING

!

WARNING

!

Gasoline inhaled may cause unconsciousness

and burns to lips, mouth and lungs.

Keep airway open.

Seek medical advice immediately.

WARNING

!

Gasoline/DEF spilled in eyes may cause burns to

eye tissue.

Irrigate eyes with water for approximately

15 minutes.

Seek medical advice immediately.

WARNING

!

Gasoline/DEF spilled on skin may cause burn s.

Wash area thoroughly with clear water.

Seek medical advice immediately.

WARNING

!

DEF is mildly corrosive. Avoid cont act with eyes , skin, and

clothing. Ensure that eyewash stations and safety

showers are close to the work location. Seek medical

advice/recommended treatment if DEF spills into eyes.

WARNING

!

No Open Fire

Open flames from matches, lighters, welding torches or

other sources can ignite fuels and their vapors.

No Sparks - No Smoking

Sparks from starting vehicles, starting or using power tools,

burning cigarettes, cigars or pipes can also ig nite fuels and their

vapors. Static electricity, including an electrostatic charge on

your body, can cause a spark sufficient to ignite fuel vapors.

Every time you get out of a vehicle, touch the metal of your

vehicle, to discharge any electrostatic charge before you

approach the dispenser island.

Working Alone

It is highly recommended that someone who is capab l e of

rendering first aid be present during servicing. Familiarize

yourself with Cardiopulmonary Resuscitation (CPR) methods, if

you work with or around high voltages. This informa tion is

available from the American Red Cross. Always advise the

station personnel about where you will be working, and caution

them not to activate power while you are working on the

equipment. Use the OSHA Lockout/Tagout procedures. If you

are not familiar with this requirement, refer to this information in

the service manual and OSHA documentation.

In an Emergency

Inform Emergency Personnel

Compile the following information and inform emergency

personnel:

• Location of accident (for example, address, front/back of

building, and so on)

• Nature of accident (for example, possible heart attack, run

over by car, burns, and so on)

• Age of victim (for example, baby, teenager, middle-age,

elderly)

• Whether or not victim has received first aid (for example,

stopped bleeding by pressure, and so on)

• Whether or not a victim has vomited (for example, if

swallowed or inhaled something, and so on)

Working With Electricity Safely

Ensure that you use safe and established practices in working

with electrical devices. Poorly wired devices may cause a fire,

explosion or electrical shock. Ensure that grounding

connections are properly made . Take care that sealing devices

and compounds are in place. Ensure that you do not pinch wires

when replacing covers. Follow OSHA Lockout/Tagout

requirements. Station employees and service contrac tors need

to understand and comply with this program complete ly to

ensure safety while the equipment is down.

Hazardous Materials

Some materials present inside electronic enclosures may

present a health hazard if not handled correctly . Ensure that you

clean hands after handling equipment. Do not place any

equipment in the mouth.

Page 2-2 MDE-5013C TopKAT™ PLUS Installation Manual · February 2015

IMPORTANT: Oxygen may be needed at scene if gasoline has

been ingested or inhaled. Seek medical advice immediately.

Lockout/Tagout

Lockout/Tagout covers servicing and maintenance of machines

and equipment in which the unexpecte d energization or sta rt-up

of the machine(s) or equipment or release of stored energy

could cause injury to employees or personnel. Lockout/Tagout

applies to all mechanical, hydraulic, chemical, or other energy,

but does not cover electrical hazards. Subpart S of 29 CFR Part

1910 - Electrical Hazards, 29 CFR Part 1910.333 contains

specific Lockout/Tagout provision for electrical hazards.

Page 25

Hazards and Actions

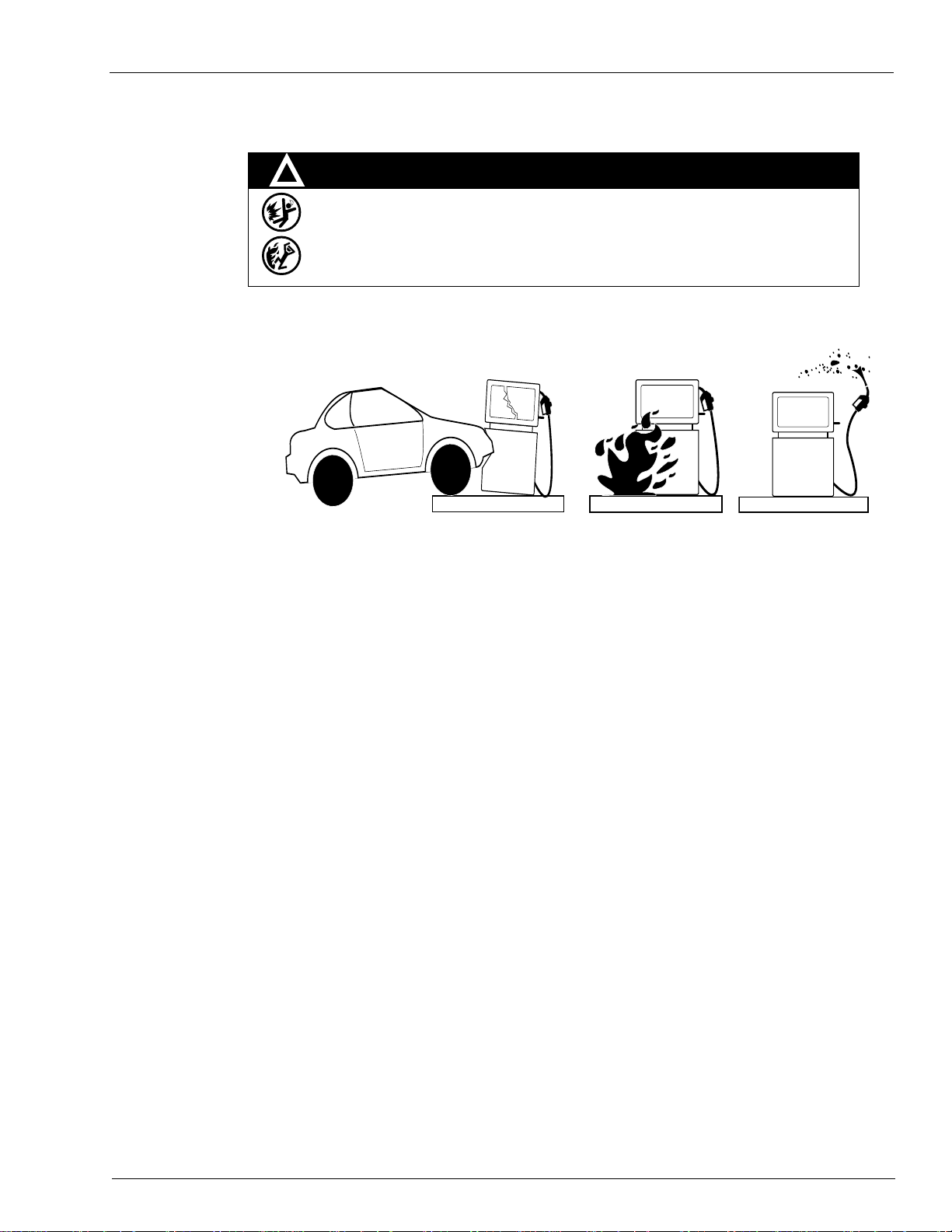

WARNING

Spilled fuels, accidents involving pumps/dispensers, or uncontrolled fuel flow create a

serious hazard.

Fire or explosion may result, causing serious injury or death.

Follow established emergency procedures.

DEF is non-flammable. However it can create a slip hazard. Clean up spills promptly.

!

Collision of a Vehicle with Unit Fire at Island Fuel Spill

The following actions are recommended regarding these hazards:

Important Safety Information

• Do not go near a fuel spill or allow anyone else in the area.

• Use station EMERGENCY CUTOFF immediately . Turn off all system circuit breakers to the island(s).

• Do not use console E-STOP, ALL STOP, and PUMP STOP to shut off power. These keys do not

remove AC power and do not always stop product flow.

• Take precautions to avoid igniting fuel. Do not allow starting of vehicles in the area. Do not allow

open flames, smoking or power tools in the area.

• Do not expose yourself to hazardous conditions such as fire, spilled fuel or exposed wiring.

• Call emergency numbers.

MDE-5013C TopKAT™ PLUS Installation Manual · February 2015 Page 2-3

Page 26

Important Safety Information

This page is intentionally left blank.

Page 2-4 MDE-5013C TopKAT™ PLUS Installation Manual · February 2015

Page 27

General TopKAT PLUS Installation Procedures

Before installing or servicing equipment, carefully observe the warnings and precautions

provided in “Important Safety Information” on page 2-1.

WARNING

3 – TopKAT PLUS Installation Procedures

General

TopKAT PLUS units can be supplied factory mounted on an Atlas pump/dispenser or with a

pedestal for interface to mechanical or electronic register pumps/dispensers. This section

provides installation procedures for both types.

These procedures include:

• TopKAT PLUS box installation

• Wiring

• Post installation check

Installation Specifications

General

Installation procedures and requirements depend, to some extent, on the specific fuel dispenser

models. Therefore, use the information in this section to develop factory installation plans for

each specific dispenser or suction pump.

Precautions and Safety Notes

Before actual installation activities, carefully observe the following precautions and safety

notes:

• Ensure that actual installation is performed by experienced personnel as required by the

National Fire Protection Association-30 (NFP A-30) “Flammable and Combustible Liquids

Code”, NFPA-30A “Code for Motor Fuel Dispensing Facilities and Repair Garages”,

®

NFPA-70A

applicable safety codes and regulations.

• System power may come from more than one source

including pumps, before attempting to work on the system.

• Do not connect power to the TopKAT PLUS or pump, until the complete installation is

inspected and

, National Electric Code (NEC), federal, state, and local codes, and any other

certified.

. Disconnect all power sources,

MDE-5013C TopKAT™ PLUS Installation Manual · February 2015 Page 3-1

Page 28

TopKAT PLUS Installation Procedures Installation Specifications

Allow a minimum of 20-inches clearance at rear of the TopKat PLUS head assembly for

pedestal and Atlas mounted units.

IMPORTANT INFORMATION

Types of Cables

Following table lists the types of cable in use for the wiring of the TopKAT PLUS system:

No. Function Type

2

1 AC Power Power Cable, 3 X 1.5 mm

Control to Pumps (Valves or Engine)

In Use Signal

2 Pulser Data Communication Cable, 300 V RMS, 194 ºF (90 ºC), Shielded

3 LAN Category-5E (CAT-5E), Four Conductor Insulator Cable (042GA00007

4 GND Ground Cable 0.4” (10.8 mm

Note: Use the appropriate gauge wire size for the AC power for pump

standards.

w

isted-pair, Oil-resistant, 24 AWG, Low Capacitance below

T

60 PF/meter similar to Belden

or 042GALF007

300 V RMS, 194 ºF (90 ºC) similar to Belden 121700A

- Gilbarco part number M12673B001) or Shielded,

NYY (14 AWG), in accordance with local

®

9729 Cable

2

)

s, dispensers, and fueling equipment.

Types of TopKAT PLUS Units

There are three types of TopKAT PLUS configurations as follows:

• Electronic TopKAT PLUS mounted on an Atlas 9800 unit

• Electronic TopKAT PLUS mounted on a pedestal

• Mechanical TopKAT PLUS mounted on a pe destal

Head Assembly Dimensions

The T opKat PLUS head assembly that is mounted on a pedestal or Atlas 9800 electronic pump

is 116.5 X 11.4 X 18” (W X H X D).

Page 3-2 MDE-5013C TopKAT™ PLUS Installation Manual · February 2015

Page 29

Installation Specifications TopKAT PLUS Installation Procedures

23

Barrier Plate

11-3/4

48

11-1/2

1-1/4

1-1/4

9-1/4

5-3/4

11-1/2

2-1/2

2-1/2

5-7/8

11-3/4

Bottom View

A

A

AA

B

BB

A = 1/2” Mounting Holes (Bottom Plate)

B = Dual Knockouts For 3/4” or 1” Conduit

(Barrier Plate)

11.4

16.5

Front View

Note: All dimensions are in inches.

9-1/4

Pedestal Dimensions

To ensure a reliable and proper installation it is very important to know the pedestal

dimensions. The mechanical and electronic TopKAT PLUS assembly mounted on the

pedestals are shown in Figure 3-1.

Figure 3-1: Pedestal Dimensions

MDE-5013C TopKAT™ PLUS Installation Manual · February 2015 Page 3-3

Page 30

TopKAT PLUS Installation Procedures Conduits

Mechanical Pump/DispenserMechanical Pump/Dispenser

TopKAT PLUS

Optional

Possible Conduits

in Pedestal

Office

WAN

MCC

UPS

TCP/IP

CAT-5E

Junction

Box

Low Voltage Conduit

TCP/IP

GND

Low Voltage Conduit

High Voltage Conduit

Isle

Junction

Box

High Voltage Conduit

AC

Pulser

In Use

Control

Conduits

General

The installation of the TopKAT PLUS at the island requires digging and setting several

conduits in the station ground. The conduits are required for the routing and protection of the

different types of cables in use in a home base station with TopKAT PLUS. In sites where the

infrastructure is already set up, you can use the existing conduits only if they meet the

requirements defined in “Conduit Requirements”.

Conduit Requirements

Conduits must comply with:

• All conduits must be made and installed according to loca

• High-voltage AC and low-voltage DC must NOT be combined

Junction Box (J-box) or wire through.

• The maximum distance for the LAN communication is 333 feet. Cables must

in a separate low voltage conduit, away from AC wires. Communication range can be

extended with third-party devices.

• All conduits must be inserted in the TopKAT PL

US pedestal through the holes and

knockouts provided in the lower barrier plate.

• After completing the installation, there must not be any unused conduit openings in the

ba

rrier plate. The clearance between conduits and openings in the barrier plate must not be

more than 1/64-inch.

l regulations.

in a common conduit,

be inserted

Figure 3-2: Conduit Layout for Mechanical Pump

Page 3-4 MDE-5013C TopKAT™ PLUS Installation Manual · February 2015

Page 31

Barrier Plate Conduit Penetration TopKAT PLUS Installation Procedures

Electronic Pump/DispenserElectronic Pump/Dispenser

TopKAT PLUS

Possible Conduits

in Pedestal

Office

WAN

MCC

UPS

Optional

TCP/IP

CAT-5E

J-box

J-box

Low Voltage Conduit

TCP/IP

GND

AC

Low Voltage Conduit

High Voltage Conduit

Isle

Figure 3-3: Conduit Layout for Electronic Pump

Barrier Plate Conduit Penetration

The pedestal barrier plate makes the pedestal mounted TopKAT PLUS suitable for installation

over a class 1, division 2 hazardous location. Field installed conduit must run completely up

through the barrier plate. The conduit must be threaded where it passes through the barrier

plate. There must be no unused conduit openings in the barrier plate when installation is

completed. Clearance between conduits and openings in the barrier plate through which

conduit passes must not be more than 1/64-inch.

MDE-5013C TopKAT™ PLUS Installation Manual · February 2015 Page 3-5

Page 32

TopKAT PLUS Installation Procedures Barrier Plate Conduit Penetration

Approved Location for TopKAT PLUS

TopKAT PLUS

Class 1, Division 2 Safety Area

Dispenser

Dispenser

Ground Level

Isle

20”

18”

18”18”18”

Sealing Conduits

The conduits must be sealed in accordance with NFPA requirements and local regulations, to

prevent the passage of gases through conduits, cables, and conductors. The fittings are

requested wherever volatile liquids or gases are present in the surroundings (see Figure 3-4).

Figure 3-4: Conduit Fitting

Safety Distance

Figure 3-5 shows the safety distances required for the installation of the TopKAT PLUS

adjacent to the dispensers. When mounting the

18 inches (0.5 m) between the unit and any of the pumps or the dispensers must be maintained.

This clearance allows room

T opKAT PLUS is designed and approved for installation and use at a convenient location at or

ne

Figure 3-5: TopKAT PLUS - Installation Control Drawing

TopKAT PLUS, a minimum clearance of

for the wiring and maintenance of the system.

ar fuel island in the appropriate hazardous (classified) location:

• Where hazardous location is classified as class 1, division 2 an

d it does not extend higher

than 18 inches (0.5 m) from surface and

• A minimum safety separation of 18 inches (0.5 m) from any nearest

pump/dispenser.

Page 3-6 MDE-5013C TopKAT™ PLUS Installation Manual · February 2015

Page 33

TopKAT PLUS Pedestal Mounting Instructions TopKAT PLUS Installation Procedures

TopKAT PLUS Pedestal Mounting Instructions

The TopKAT PLUS head assembly and pedestal assembly are packaged in their own boxes

and shipped in a large box. After removing them from the large box, the two units must be

connected together using the following procedure.

Parts List

Following parts are required for the TopKAT PLUS pedestal mounting:

• Pedestal and Head Assembly

TopKAT PLUS

Ped

Description

i

TopKAT PLUS Pedestal - Electronic D

TopKAT PLUS Pedestal - Mechanical Dispenser OrTOP (2M) PA040501000 PA040501100 800938972

TopKAT PLUS Pedestal - Electronic D

with Printer

T opKA T PLUS Pedest al - Mechanical Dispenser

with Printer

TopKAT Pedestal M12706002 - -

spenser OrTOP (E) PA040500000 PA040500100 800938970

i

spenser

OrTOP (E, PRN) PA040500010 PA040500110 800938971

OrTOP (2M, PRN) PA040501010 PA040501110 800938973

estal

Assembly

TopKAT PLUS

Head Part

Number

Orpak

OrTOP

Part Number

• Hardware Kit

•Gasket

• Installation Instructions

To install the TopKAT PLUS pedestal, proceed as follows:

1 Install and secure the pedestal to the island using the four holes at the bottom of the pedestal

with anchor bolts before installing the head assembly. This will prevent the completed

assembly from possibly falling over.

Note: To access the four inside bottom mounting holes, re

2 Position the pedestal so that the front side faces the fueling lane. Secure the pedestal to the

move the rear lower door panel.

island using the four mounting holes inside the base of the unit.

3 Install the black rubber gasket on top of the pedestal ensuring that the holes for the wiring are

aligned properly and not blocked.

4 Mount the TopKAT head assembly onto the top of the pedestal using the four threaded studs as

a guide. Secure the head assembly using a flat washer, lockwasher, and 1/4 -20-inch nut onto

each of the four post and tighten.

a Remove the TopKAT cover by unlocking the rear key lock and slide the cover to the rear

side of the unit.

MDE-5013C TopKAT™ PLUS Installation Manual · February 2015 Page 3-7

Page 34

TopKAT PLUS Installation Procedures TopKAT PLUS Pedestal Mounting Instructions

Rear View

Side View

Top Mounting Studs

Facing Front

b Ensure that you do not remove the cover completely until the yellow ground wire that

connects the cover to the grounding lug of the unit is removed.

Note: The front of the pedestal has the over hang, an

d the mounting studs are arranged in such

a manner that the TopKAT head assembly can only be mounted one way, facing

frontwards (see Figure 3-6).

Figure 3-6: TopKAT PLUS Pedestal

Page 3-8 MDE-5013C TopKAT™ PLUS Installation Manual · February 2015

Page 35

Connections to TopKAT PLUS - Pedestal Mounted Units TopKAT PLUS Installation Procedures

Connections to TopKAT PLUS - Pedestal Mounted Units

All connections to the post mounted TopKAT PLUS must be performed to the terminal block

located at the bottom of the TopKAT PLUS box (see Figure 3-7 and Figure 3-8 on page 3-10).

The required connections are:

• Dispenser wiring connections (mechanical

- Pulser (low voltage)

- In use signal (high

- Solenoid valve (high voltage)

• Communications (Atlas 9800 electronic dispensers):

- Pump communication line (RS-485)

• Mains AC power and ground (electronic and mechanical dispensers)

• LAN connection. LAN cable is directly connected to

Figure 3-7: TopKAT PLUS Terminal Block - Mechanical Pump

voltage)

dispensers):

LAN2 connection

on the OrCU.

MDE-5013C TopKAT™ PLUS Installation Manual · February 2015 Page 3-9

Page 36

TopKAT PLUS Installation Procedures Connections to TopKAT PLUS - Pedestal Mounted Units

For the electronic TopKAT factory-installed on top of an Atlas 9800, all the required

wiring for the 9800 electronic pumps including the RS-485 communication, the LAN

communications, and AC power is pre-wired from the factory. No other connections are

made to the terminal blocks.

IMPORTANT INFORMATION

Figure 3-8: TopKAT PLUS Terminal Block - Electronic Pump (Pedestal Mount)

Page 3-10 MDE-5013C TopKAT™ PLUS Installation Manual · February 2015

Page 37

Wiring TopKAT PLUS Installation Procedures

Wiring

Types of Wiring

The wiring in the terminal block differs in accordance with the type of pump controlled by the

TopKAT PLUS. There are several types of pumps:

• Mechanical pumps

• Electronic pumps

Following section provides the “Wiring Requirements” for ea

Wiring Requirements

Before inserting any wire to the terminal block, proceed as follows:

1 Insert the wire with a terminal lug only (see Figure 3-9).

2 Attach the lug to the wire using the proper terminal crimper.

3 For UL-listing, the terminal lug must be a UL recognized component.

Figure 3-9: Terminal Lug

ch type of pump:

Note: Mark each cable at its both ends with a number or sign that will identify its functionality

in the future.

Types of Cables

Following cables are required for the TopKAT PLUS installation:

• Power cable: In accordance with local regulations

• LAN cable: CAT-5E [refer to “Field Wiring Requirements (LAN/WAN)” on page 3-12]

• RS-485/pulser: Communication cable, twisted-pair, separately

For example, Belden 8723 or equivalent.

Note: The shield must be connected to ground on one side of the cable only, preferab ly on the

pKAT PLUS side.

To

MDE-5013C TopKAT™ PLUS Installation Manual · February 2015 Page 3-11

shielded, low capacitance.

Page 38

TopKAT PLUS Installation Procedures Wiring

Field Wiring Requirements (LAN/WAN)

Wiring must be installed in accordance with ANSI/TIA/EIA 568 B standards and

amendments.

Recommendations for CAT-5E Cable

Following are Gasboy recommendations for installing the CAT-5E cable (gas-and

oil-resistant) for Site Service Equipment (SSE):

• The Ethernet cable to the pumps/dispensers

requirements, for example, gas- and oil-resistant, and vapor-resistant properties.

• CAT-5E cable is viable for typical installations un

is not run near the equipment that generates electrical noise such as large motors and

power switching equipment. An example of a noise source to avoid is a variable speed

Submersible Turbine Pump (STP).

• It is crucial that the installer follows the NEC, Article 501 requiremen

outer jacket and spreading the wire pairs at the seal-off points, so that a good vapor seal is

achieved. This is required because most CAT-5E cables will conduct vapors inside their

outer jacket (see Figure 3-10).

Note: This is not required if Four Conductor Insulator Cable (042GA00007 or

042GALF007 - Gilbarco part number M12673B001) is used. This cable will not

conduct vapors inside the outer jacket.

is designed to comply with forecourt wiring

der 280 feet of cable length, if the cable

ts by removing the

Figure 3-10: CAT-5E Cable Installation

• CAT-5E cable must not share the conduit with AC, but can share the conduit with pulsers

or other CAT-5E cables.

• If an Ethernet hub is used, it must be of commercial quality

. Commercial Ethernet

switches are a family of fixed configuration standalone devices that provide desktop.

10/100 fast Ethernet and 10/100/1000 Gigabit Ethernet connectivity for entry level

enterprise

, medium-sized, and branch office networks to enable enhanced LAN services.

• The recommended CAT-5E cable is Fou r Con ductor Insulator Cable (042GA00007 or

042GALF0

07 - Gilbarco part number M12673B001) or an equivalent. The CAT-5E

qualified cable has gas and oil-resistant inner and outer insulation, and vapor resistant

properties.

• A patch panel is recommended (optional) to connect the CAT

-5E cable to the network

RJ-45. The patch panel and LAN wiring must be LAN-certified and follow TIA/EIA LAN

568-

B wiring standards.

Page 3-12 MDE-5013C TopKAT™ PLUS Installation Manual · February 2015

Page 39

Wiring TopKAT PLUS Installation Procedures

TopKAT PLUS is shipped configured for 115 VAC po wer supply. Ensure care to set it

accordingly to your local AC power supply specifications. Failure to do so may result in

damages.

WARNING

AC Power Connection

The AC power input is connected to the terminal block. Between the terminal block and

transformer, the system uses a line filter to attenuate conducted RFI and EMI - between the

line and equipment. AC power is then supplied to an AC/AC high to low

transformer -110/220 to 25 VAC. T ransformer can be fed either to 1 10 or 2 20 VAC. The power

supply setup jumpers shown in Figure 3-11 must be set to match the AC power input to the

TopKAT PLUS. A settings label is also found beside the terminal block. For dispenser

mounted T op KAT PLUS, the power supply setup jumpers must be set to match the micro feed

input to the Atlas pump/dispenser.

• For 115 VAC input (default setting), there must be a jumper wire from position 1 of the

setup jumper to position 5 and from posi

• For 230 VAC input, there must be a jumper wire from position 5

position 2.

tion 2 to position 6.

of the setup jumper to

Figure 3-11: Power Supply Setup Jumpers

MDE-5013C TopKAT™ PLUS Installation Manual · February 2015 Page 3-13

Page 40

TopKAT PLUS Installation Procedures Mechanical Pump - Wiring

Dangerous AC voltages that can cause death or serious personal injury are used to power

the product. Always disconnect power before starting any work.

WARNING

Mechanical Pump - Wiring

General

This device is intended to be connected to UL-listed dispensers equipped with a J-box of

sufficient volume. These connections are not suitable for direct connection to intrinsically safe

devices. All wiring is to be in compliance with NFPA 70 and NFPA 30A.

The wiring for mechanical pumps

is provided in two modes:

• Following table lists the wiring in the sequential order of the terminals. This table provides

signal name and a functional description of the signal.

the

• Figure 3-12 on page 3-15 shows the wiring list for connection to the terminal,

in the wiring label attached to the inner side of the unit. The wiring l

physical location of the wires in the terminal block.

Terminal Block - Pin-out Connections for Mechanical Pumps

Following table lists the TopKAT PLUS terminal block connections for mechanical pumps:

Terminal

No. Signal Name Functional Description

1 LINE_IN_(115/230 V) Line Connection, TopKAT PLUS Power Input

2 NEUTRAL_IN_(115/230 V) Neutral Connection, TopKAT PLUS Power Input

3 GROUND_IN_(115/230 V) Ground Connection, TopKAT PLUS Power Input

4 LINE_1 Pump Control 220/110 VAC Input - Nozzle 1

5 LOAD_1 Pump Control Output - Nozzle 1

6 LINE_2 Pump Control 220/110 VAC Input - Nozzle 2

7 LOAD_2 Pump Control Output - Nozzle 2

8 IN_USE_1_ A(AC) Handle Up - In Use Signal Input - Nozzle 1

9 IN_USE_1_ B(RETURN) Handle Up - AC In Use Signal Return - Nozzle 1

10 IN_USE_2_ A(AC) Handle Up - In Use Signal Input - Nozzle 2

11 IN_USE_2_ B(RETURN) Handle Up - AC In Use Signal Return - Nozzle 2

12 -DC OUT FOR BY-PASS_2 Connection to External Bypass Nozzle 2

13 BY-PASS_2_IN Connection to External Bypass Nozzle 2

14 PULSER_1 Pulser Input - Nozzle 1

15 PULSER_2 Pulser Input - Nozzle 2

16 +12 V_2_P +12 VDC Output to Pulser - Nozzle 2

17 -DC OUT FOR BY-PASS_1 Connection to External Bypass Nozzle 1

18 BY-PASS_1_IN Connection to External Bypass Nozzle 1

19 GND_1_P Nozzle Grounding - Nozzle 1

20 GND_2_P Nozzle Grounding - Nozzle 2

21 +12 V_1_P +12 VDC Output to Pulser - Nozzle 1

as published

abel follows the

Page 3-14 MDE-5013C TopKAT™ PLUS Installation Manual · February 2015

Page 41

Mechanical Pump - Wiring TopKAT PLUS Installa tio n Pro cedures

Figure 3-12: TopKAT PLUS - Mechanical Pump Wiring List Label

Mechanical Pump - Required Connections

This paragraph describes the required wiring connections between the mechanical pump and

TopKAT PLUS. Figure 3-13 and Figure 3-14 on page 3-16 show a schematic diagram of the

connections between the TopKAT PLUS an

on page 3-17 shows a detailed wiring diagram between the TopKAT PLUS terminal block and

pump components.

Pulse Input

es

Wir

Handle Status

Input Wi

res

Authorization

Output Wi

TopKAT PLUS ratings for above signals are as follows:

The dispenser outputs pulses to the system by means of the pulser unit,

installed in accordance with the manufacturer instructions. The pulse rate

per volume (liter/gallon) is determined by the pulser unit. It is programmed

as a “factor” in the SiteOmat.

The handle signal is used to signal the system that the pump is “In Use”

mode. When the dispenser handle is lifted, this contact closes. This signals

the system that the pump is “In Use” or that the transaction ended.

The dispenser requires an authorization signal from the TopKAT PLUS to

res

start a sale transaction. Without this authorization signal, the electric valve

(or pump) does not open and the sale transaction does not begin. The

TopKAT PLUS switches the AC power signal to the valve. When the

dispenser receives the authorization signal, fuel starts to flow. This signal is

also referred to as the LOAD.

d the mechanical pump components. Figure 3-15

Signal TopKAT PLUS Rating

Pulser Input 3 mA, 15 VDC max.

Pulser Power Output 12 VDC, 30 mA max.

In Use Input 100-240 VAC, 50/60 Hz, 2 W (20 mA)

Load 3/4 HP @115 V

1.5 HP @ 240 V

MDE-5013C TopKAT™ PLUS Installation Manual · February 2015 Page 3-15

Page 42

TopKAT PLUS Installation Procedures Mechanical Pump - Wiring

Figure 3-13: Mechanical Pump - Single Dispenser Connections

Figure 3-14: Mechanical Pump - Twin Dispenser Connections

Page 3-16 MDE-5013C TopKAT™ PLUS Installation Manual · February 2015

Page 43

Mechanical Pump - Wiring TopKAT PLUS Installa tio n Pro cedures

Figure 3-15: TopKAT PLUS and Mechanical Pump - Terminal Block Detailed

Connections

MDE-5013C TopKAT™ PLUS Installation Manual · February 2015 Page 3-17

Page 44

TopKAT PLUS Installation Procedures Single Suction Pump

Single Suction Pump

Figure 3-16 shows the connections to the single suction pump.

Figure 3-16: Single Suction Pump 1 HP 115 VAC/230 VAC

GASBOY MECHANICAL PUMP

with VR/TOK Reset Color Codes

Islander Load-1 (TB-31)

SOLENOID

VALVE

OPTIONAL LIGHT ASSEMBLY

ELECTRIC RESET

120 VAC

RESET

RED

MOTOR

SW

NO

NC

NO

NC

WHT

C

C

HANDLE

BRN

BLU

YEL/WHT

BRN/WHT

BLK

SUBM FEED

LIGHT FEED

LIGHT NEUTRAL

RESET MOTOR FEED

TO SUBMERSIBLE

STARTER RELAY

OF PUMP

1 HP AT 120/240 VAC

SUBM DRIVE

FEED NEUTRAL

ORG

RESET COMPLETE

Islander In-use 1A and Line-1 (TB-19 and TB27)

Neutral to In-use 1B (TB-23)

BREAKERS

DISPENSER

Page 3-18 MDE-5013C TopKAT™ PLUS Installation Manual · February 2015

HOT

NEUT

Page 45

Mechanical Pump - Pulser Connections TopKAT PLUS Installation Procedures

Mechanical Pump - Pulser Connections

This paragraph describes the required wiring connections between the pulser in the

mechanical pump and TopKA T PLUS. The sy stem can accept many types of pulsers. For more

information, contact Gasboy. Two types of pulsers can be found in the pumps:

• Electronic pulser

• Mechanical pulser

Connect the TopKAT PLUS to the pulser in a

ccordance with its characteristics.

Following are the TopKAT PLUS ratings for above signals:

Signal TopKAT PLUS Rating

Pulser Input 3 mA, 15 VDC max.

Pulser Power Output 12 VDC, 30 mA max.

In Use Input 100-200 VAC, 50/60 Hz, 2 W (20 mA)

Load 3/4 HP @115 V

1.5 HP @ 240 V

MDE-5013C TopKAT™ PLUS Installation Manual · February 2015 Page 3-19

Page 46

TopKAT PLUS Installation Procedures Mechanical Pump - Pulser Connections

RS-485 Electronic - TopKAT PLUS on Gasboy 9800 Atlas

(Factory Installed)

Figure 3-17 shows the internal wiring connections between TopKAT PLUS and the RS-485

pump nozzle.

Figure 3-17: RS-485 Electronic Pump - Wiring Diagram - 1

Page 3-20 MDE-5013C TopKAT™ PLUS Installation Manual · February 2015

Page 47