Page 1

TopKAT™ Fuel Management System

Installation Manual

MDE-4319E

Page 2

Computer Programs and Documentation

Federal Communications Commission (FCC) Warning

All Gasboy computer programs (including software on diskettes and within memory chips) and documentation are copyrighted by, and shall remain the property of, Gasboy. Such

computer programs and documents may also contain trade secret information. The duplication, disclosure, modification, or unauthorized use of computer programs or

documentation is strictly prohibited, unless otherwise licensed by Gasboy.

This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy, and if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense. Changes or modifications not expressly

approved by the manufacturer could void the user’s authority to operate this equipment.

Approvals

Gasboy, Greensboro, is an ISO 9001:2000 registered facility.

Underwriters Laboratories (UL):

UL File# Products listed with UL

MH4314

MH6418

MH7404

MH10581 Key con t r o l u n i t , M o d e l G K E - B S e r i e s

National Conference of Weights and Measures (NCWM) - Certificate of Compliance (CoC):

Gasboy pumps and dispensers are evaluated by NCWM under the National Type Evaluation Program (NTEP). NCWM has issued the following CoC:

CoC# Product Model # CoC# Product Model # CoC# Product Model #

95-179 Dispenser

95-136 Dispenser 9800 Series 91-057 Controller

All dispensers and self-contained pumping

units

Power operated Transfer Pump Models 25,

25C, 26, 27, 28, 72, 72S, 72SP , 72X, 73 and

1820

Hand operated Transfer Pump Models 1230

Series, 1243 Series, 1520 and 1720 Series

Card reader terminals, Models 1000, 1000P

Site controller, Model 2000S CFN Series

Data entry terminals, Model TPK-900 Series

Fuel Point Reader System

9100 Retail Series, 8700

Series, 9700 Series

New York City Fire Department (NYFD):

NYFD C of A # Product

4823 9100A, 9140A, 9152A, 9153A,

4997 9822A, 9823A

5046 9100Q, 9140Q, 9152Q, 9153Q,

5087 8753K, 8853K, 9153K, 9853K

5091 8752K, 9152K

5129 9122K, 9123K, 9822K, 9823K

91-019 Dispenser

9800A, 9840A, 9850A, 9852A,

9853A, 9140

9800Q, 9840Q, 9852Q, 9853Q

(restricted to diesel and nonretail gasoline sales)

9100 Commercial

Series

1000 Series FMS,

2000S-CFN Series

California Air Resources Board (CARB):

Executive Order # Product

G-70-52-AM Balance Vapor Recovery

G-70-150-AE VaporVac

05-002 Atlas

8700K, 8800K,

9100K, 9200K, 9800K

Patents

Gasboy products are manufactured or sold under one or more of the following US patents:

Dispensers

5,257,720

Point of Sale/Back Office Equipment

D335,673

Trademarks

Non-registered trademarks

Atlas™

Consola™

Infinity™

Pr

el

Registered trademarks

ASTRA

Fuel Point

Gasboy

Keytrol

Slimline

imin

®

®

®

®

®

ry

a

Additional US and foreign patents pending.

Additional US and foreign trademarks pending.

Other brand or product names shown may be

trademarks or registered trademarks of their

respective holders.

This document is subject to change without notice. · For information regarding Gasboy Literature, call (336) 547-5661

E-mail: literature@gasboy.com · Internet: http://www.gasboy.com

© 2008 GASBOY · All Rights Reserved

Page 3

Table of Contents

1 – Introduction 1

Purpose. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Abbreviations and Acronyms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

General Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Communication Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Using this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Related Documents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 – Important Safety Information 5

3 – FCC and DOC Customer Information 9

FCC Part 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

FCC Part 68 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

General Requirements for All Equipment . . . . . . . . . . . . . . . . . . . . . . . . . 9

DOC Certification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4 – General Installation 11

Rules for Proper Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Component Location and Installation Spe cif ications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Data Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

External Modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Internal Modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Power Conditioner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Conduit Layout/Installation Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Conduit Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

AC Power to the TopKAT System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

TopKAT Peripheral Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Suction Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Dispensers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Wire Size. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Mechanical Interface Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Communication Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

RS-485 - ASTRA and Mechanical PCUs. . . . . . . . . . . . . . . . . . . . . . . . . 19

RS-485 - Master/Satellite Option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

RS-485 - Standalone TopKAT System or Wall-Mount PCU . . . . . . . . . . 20

RS-232 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

RS-232 - Termination Box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

RS-422 - SHMs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Terminal Block ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5 – Series 9820 ASTRA Installation 25

MDE-4319E TopKAT™ Fuel Management System Installation Manual · August 2008 Page i

Page 4

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

ASTRA to TopKAT Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Port Communication Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

TopKAT Master/Satellite Communications Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Wiring for a CRT Terminal and Okidata Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Wiring for Modems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

External Modems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Internal Modem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6 – TopKAT Master/Satellite 33

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

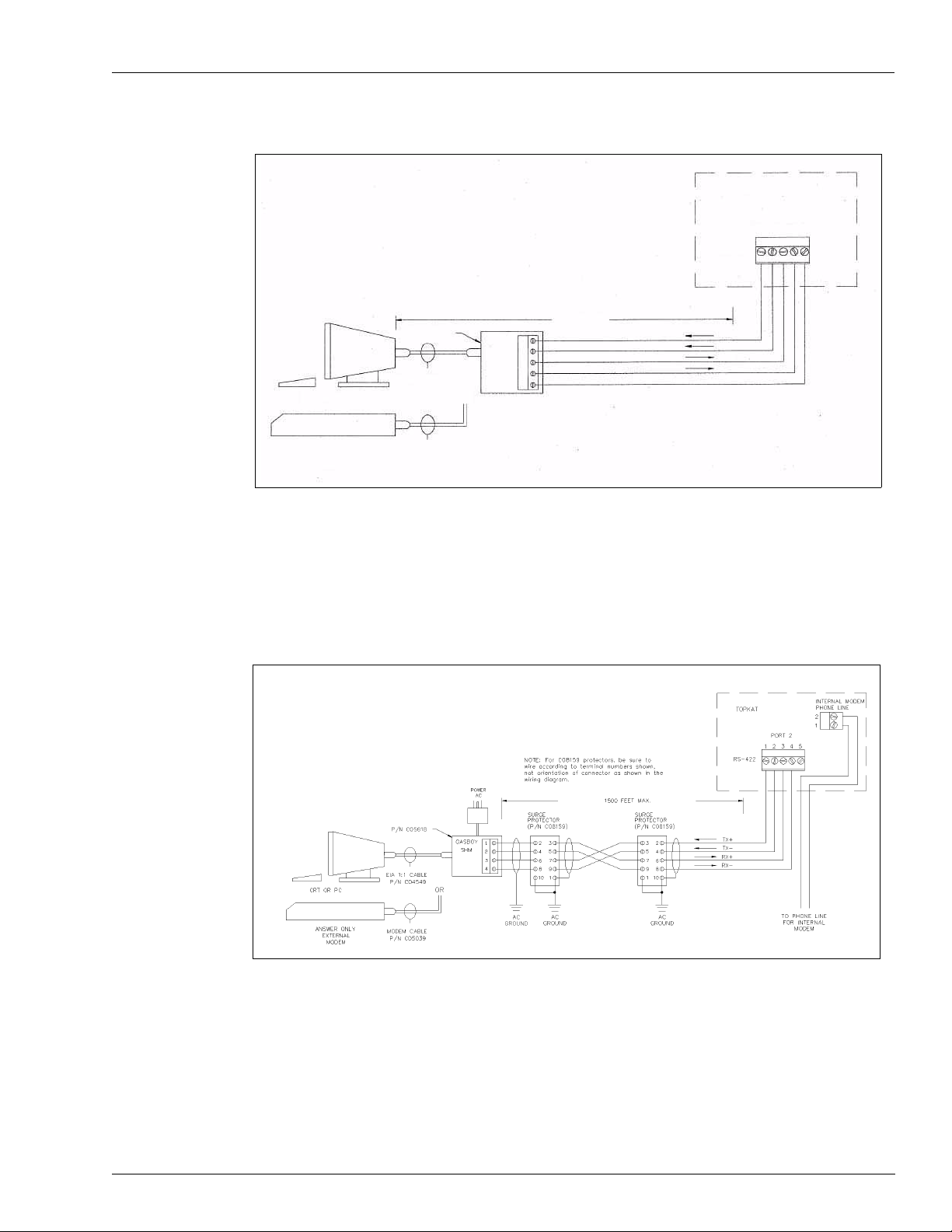

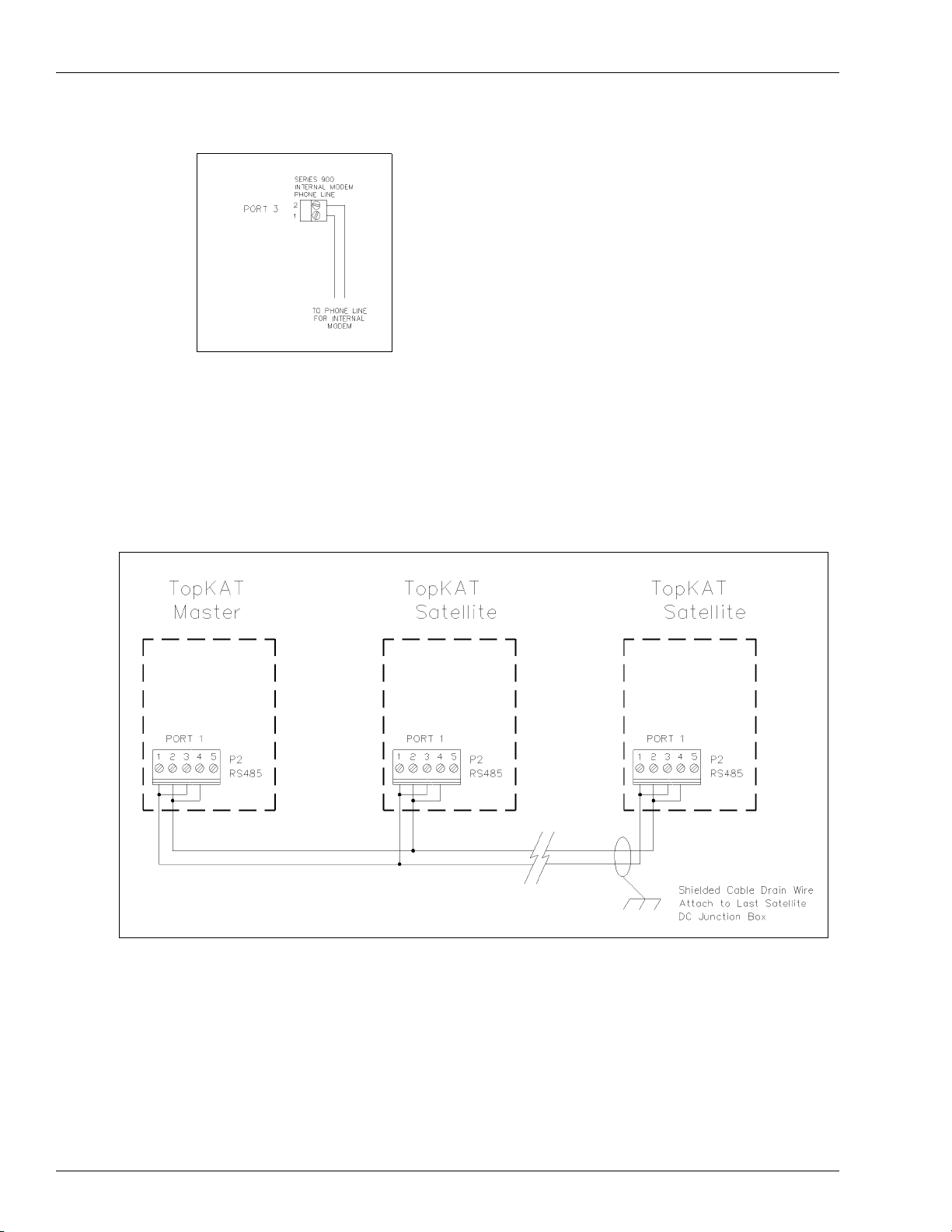

Wiring for Modems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

External Modems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Internal Modems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7 – Mechanical Interface Option 39

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Conduit Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Terminal Block ID. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

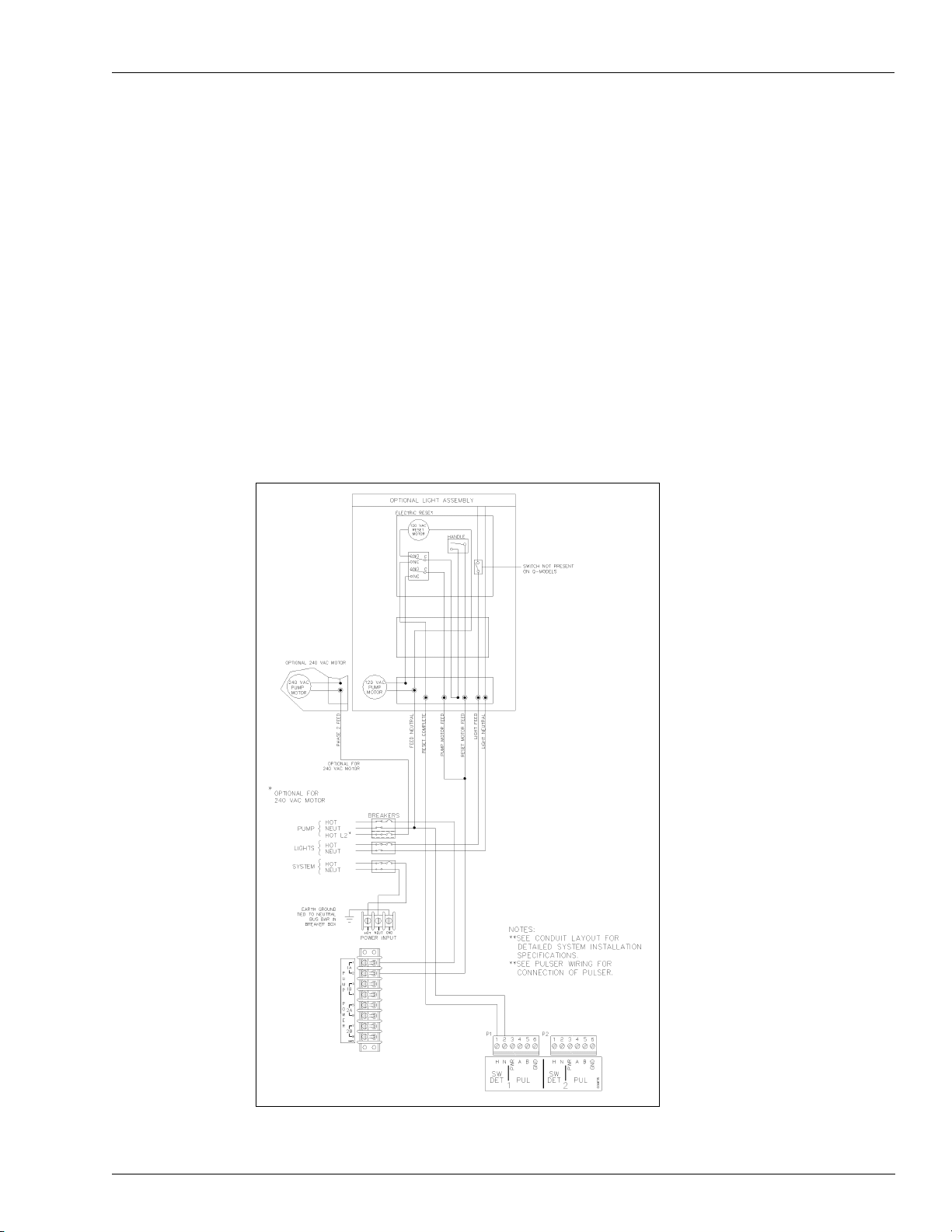

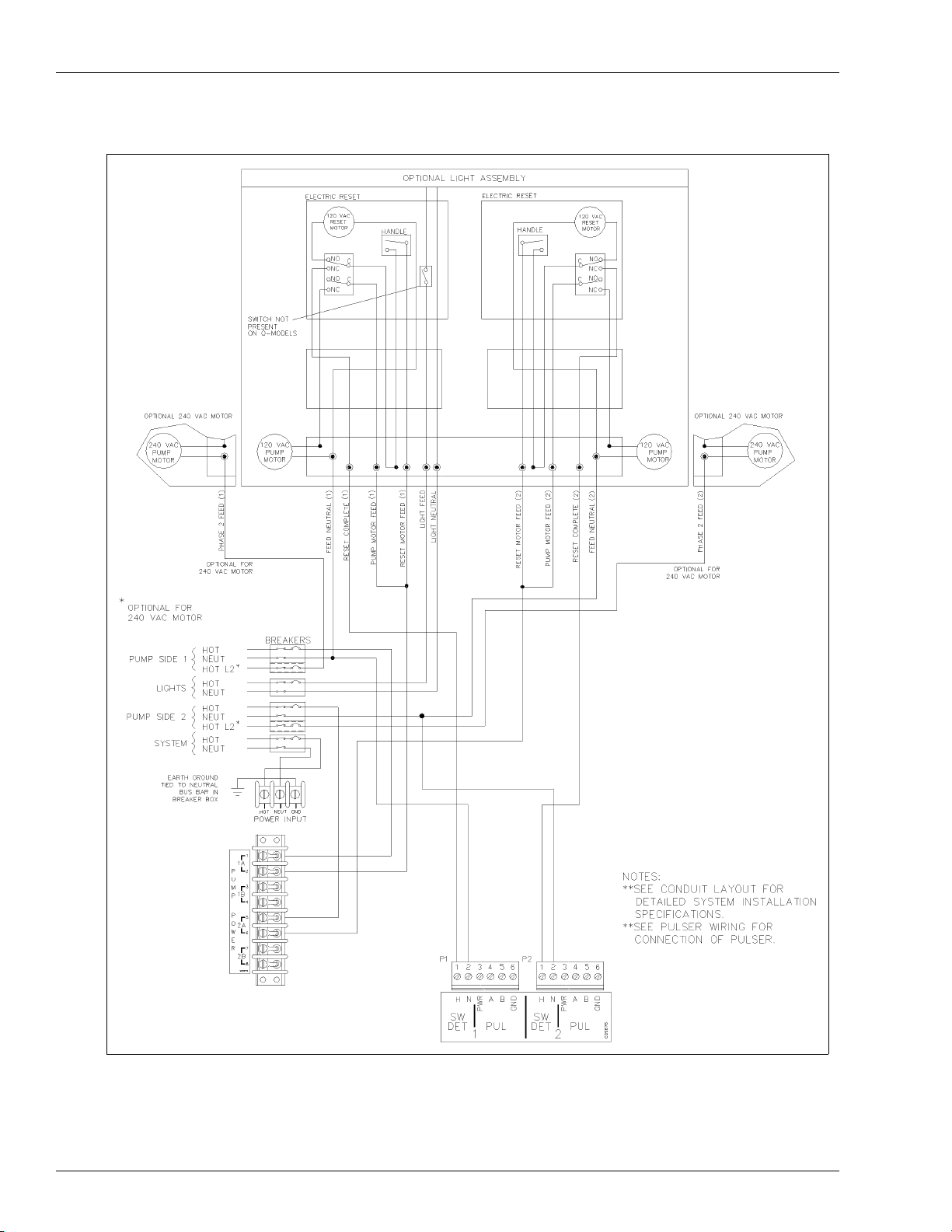

System Pump and Dispenser Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Wiring Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Control Lines for Mechanical Pumps/Dispensers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Reset Motor Feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Pump Motor Feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Neutral Feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Submersible Feed, Submersible Drive . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Reset Complete (Switch Detect). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Light Feed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Light Neutral . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Phase 2 Feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Pulser - Mechanical Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Control Lines for Gasboy 9800 or 9820 Electronic Pumps/Dispensers . . . . . . . . . . . . . . . . . . . . . . . . 46

Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Micro Feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Micro Neutral. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Control/Pump Motor Feed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

External Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Neutral Feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Control/Submersible Feed (Control/Subm Feed) . . . . . . . . . . . . . . . . . . 47

Submersible Starter Drive (Subm Starter Drive). . . . . . . . . . . . . . . . . . . 48

Submersible Drive (Subm Drive). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Reset Complete (Switch Detect)/Slow Flow . . . . . . . . . . . . . . . . . . . . . . 48

Phase 2 Feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Light Feed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Light Neutral . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Pulser - 9800/9820 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Wiring Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Pulser Wiring Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Wiring for Modems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

External Modems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Internal Modem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Page ii MDE-4319E TopKAT™ Fuel Management System Installation Manual · August 2008

Page 5

8 – Mechanical PCU Option 75

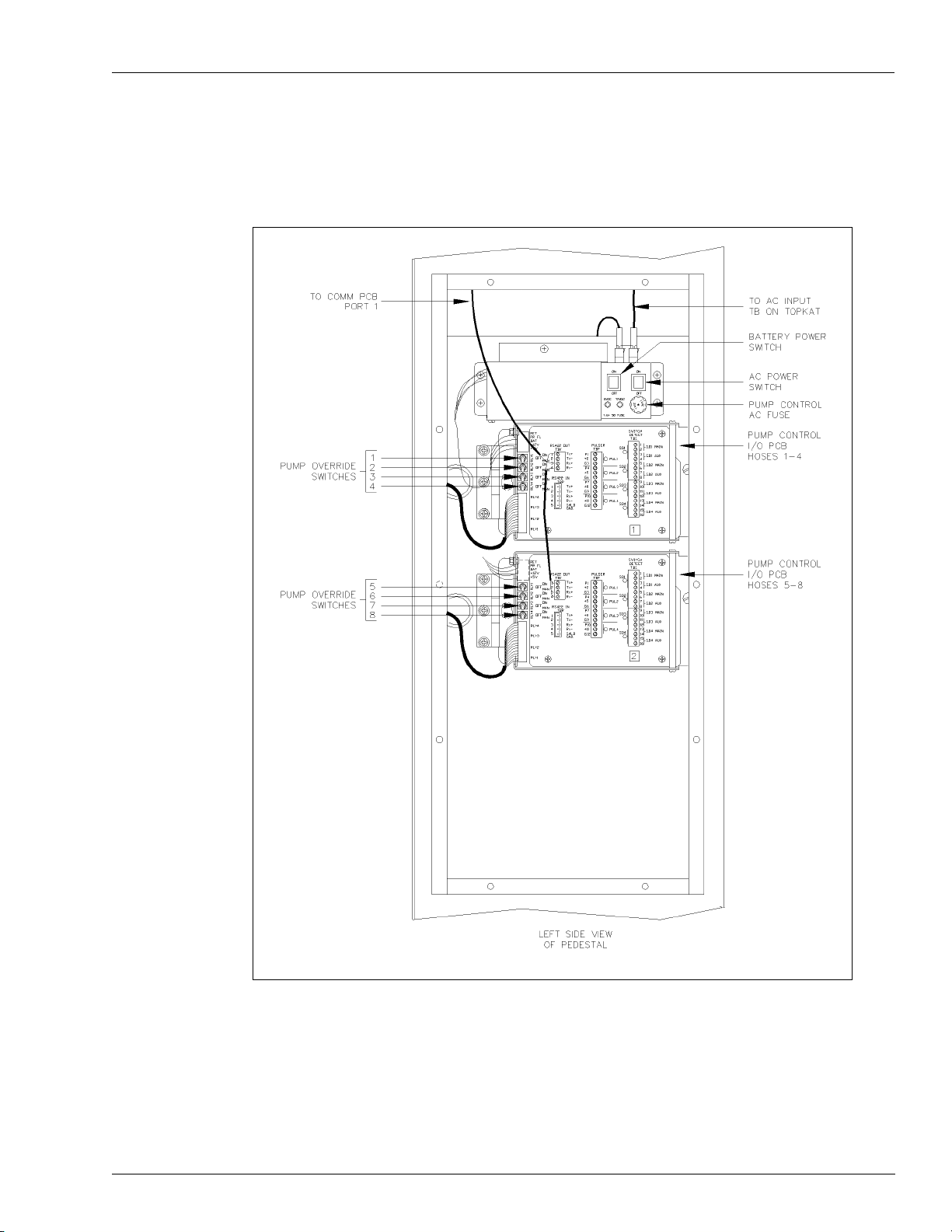

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

PCU Dimensions and Layouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Terminal Block ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

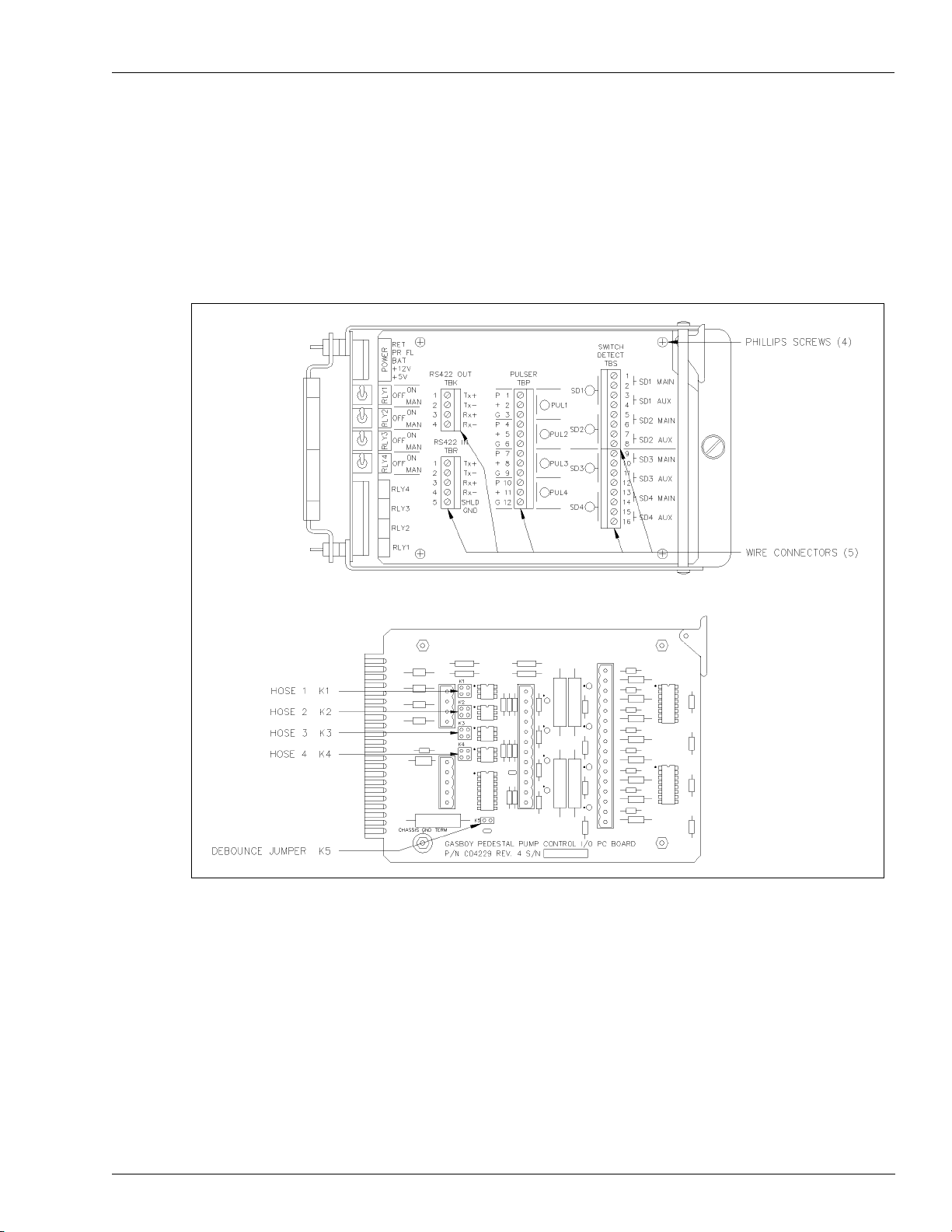

Pump Control EXPMUX CPU Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Pump Control I/O PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

System Pump and Dispenser Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Wiring Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Control Lines for Mechanical Pumps/Dispensers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Reset Motor Feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Pump Motor Feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Neutral Feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Submersible Feed, Submersible Drive . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Reset Complete (Switch Detect) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Light Feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Light Neutral . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Phase 2 Feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Pulser - Mechanical Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Wiring Diagrams: Pulsers, Pumps, Dispensers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Pulser Wiring Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Wiring Diagrams: Port Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

TopKAT Master/Satellite Communications Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Wiring for a CRT Terminal and Okidata Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Wiring for Modems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

External Modems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Internal Modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

9 – Series 9800 Field Installation 111

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Conduit Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Series 9800 to TopKAT Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Port Communication Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

TopKAT Master/Satellite Communications Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Wiring for a CRT Terminal and Okidata Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Wiring for Modems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

External Modems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Internal Modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

10 – Wireless Communications Installation 121

11 – Serial-to-LAN Connection Installation 123

12 – Testing 125

Completion Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Manual Override Test - 2-hose Mechanical Interface Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Manual Override Test - 4-hose Mechanical PCU Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Appendix A: Base Layout for Shelf Mounting A-1

MDE-4319E TopKAT™ Fuel Management System Installation Manual · August 2008 Page iii

Page 6

Appendix B: Atlas CPU Board Jumper Settings B-1

Old Style (C09634). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

New Style CPU (M06333) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Index Index-1

Page iv MDE-4319E TopKAT™ Fuel Management System Installation Manual · August 2008

Page 7

Purpose Introduction

1 – Introduction

Purpose

The Gasboy® Series 900 TopKAT™ Installation Manual is provided to assist you in installing

the TopKAT system. This manual should be supplied to the electrician prior to the installation

of the conduit and wiring to ensure that the TopKAT System is installed properly. Faulty

installations are the major cause of system malfunctions. The TopKAT system must be

installed exactly as described in this manual to ensure its reliability and proper operation.

Note: Gasboy provides a toll-free number for customers and installers who may have

questions pertaining to the installation: 1-800-444-5529.

Abbreviations and Acronyms

Term Description

AC Alternating Current

CRT Cathode Ray Tube

DC Direct Current

DOC Department of Communication

FMS Fuel Management System

FCC Federal Communications Commission

ICR Island Card Reader

LAN Local Area Network

LCD Liquid Crystal Display

PCB Printed Circuit Board

PCU Pump Control Unit

PIN Personal Identification Number

PVC Polyvinyl Chloride

RAM Random Access Memory

REN Ringer Equivalence Number

SHM Short Haul Modem

®

UL

Underwriters Laboratories

MDE-4319E TopKAT™ Fuel Management System Installation Manual · August 2008 Page 1

Page 8

Introduction Description

Description

General Information

Figure 1-1: Typical TopKAT Installation

Figure 1-2: TopKAT Dimensions

The Gasboy Series 900 TopKAT is a microprocessor-based fuel control and data acquisition

system. The TopKAT system is totally self-contained in a rugged, well-designed, and

attractive weatherized cabinet. It is mounted on one of the following:

• 9800 pump/dispenser

• 9820 ASTRA® pedestal

• Pedestal

Page 2 MDE-4319E TopKAT™ Fuel Management System Installation Manual · August 2008

Page 9

Description Introduction

A standalone TopKAT system can control up to eight electronic hoses or two mechanic al

hoses. A master/satellite option allows multiple units to be linked together, with one acting as

the master controlling unit. If you have the master/satellite option, you can control the

following:

• Up to eight electronic hoses and seven satellite readers

• Up to 16 mechanical hoses (two hoses per TopKAT)

• One 9820 or 9800 single or twin electronic hose and up to 14 mech anical hoses (two hoses

per T o pKAT).

A standalone or master/satellite with a mechanical Pump Control Unit (PCU) option can

control up to eight mechanical hoses (four hoses per PCU and up to two pedestal or wallmounted PCUs).

The TopKAT is equipped with a data key receptacle. Visual prompting messages that are

displayed on the Liquid Crystal Display (LCD) guide the user through the steps required to

activate the pump/dispenser. The display is backlit so that it can be read at night. A 16-posit ion

membrane keypad is provided on the face of the unit to enter data such as Personal

Identification Number (PIN), odometer reading, pump selection, and so on. The unit may also

be equipped with an optional report printer.

The front bezel and rear of the cabinet are hinged doors secured with locks to prohibit

unauthorized access. The front bezel allows access to the optional report printer and paper.

The one-piece hood can be removed for total accessibility during installation and servicing.

When installing the system, ensure that you provide adequate clearance to allow easy access to

both front and rear doors for servicing.

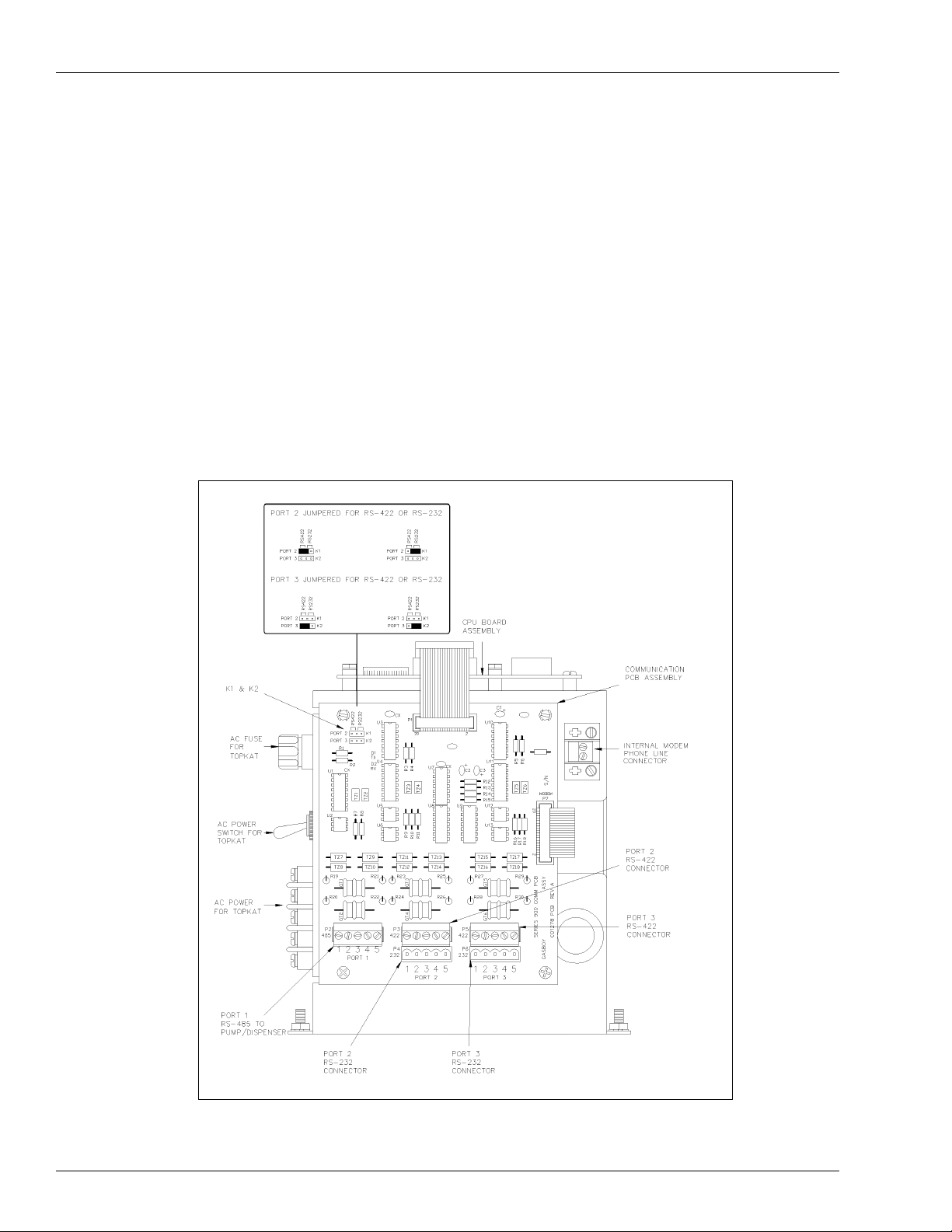

Communication Ports

The TopKAT system contains three asynchronous ports. Typically, Port 1 is used for

communications to a 9800, ASTRA, or Mechanical PCU via RS-485 lines. Ports 2 and 3 can

be set for either RS-232 or RS-422 communications to a data terminal or computer. Refer to

the port wiring diagrams in

of installation. Communication is through direct wire, or by dial-up phone lines using an

optional built-in modem.

If the TopKAT system is equipped with the master/satellite option, the master is the only unit

that will need to have a data communication link. This will collect all transactions and

maintain the complete data base for the entire site. Refer to

on page 19 for more communication requirements.

If the TopKAT is equipped with the wireless option, refer to “Wireless Communications

Installation” on page 121 and MDE-4520 Enhanced Communications Installation Manual.

“Communication Requirements” on page 19 for your specific type

“RS-485 - Master/Satellite Option”

MDE-4319E TopKAT™ Fuel Management System Installation Manual · August 2008 Page 3

Page 10

Introduction Using this Manual

Using this Manual

The TopKAT system can be installed in the following ways:

• Mounted on a pedestal with a Series 9820 ASTRA

• Mounted on a free-standing pedestal for use with mechanical pumps, electronic 9800s or

ASTRAs

• As part of a master/satellite configuration

• Mounted atop a 9800 pump/dispenser

• Mounted on a freestanding pedestal, for use with internal 4-hose Mechanical PCUs or

external wall-mounted 4-hose Mechanical PCUs.

Note: The 4-hose mechanical PCU option is referred to as the Mechanical PCU option in this

manual; the 2-hose Mechanical Interface is called the Mechanical Interface option.

Related Documents

The following manuals provide additional information about the TopKAT Fuel Management

System (FMS).

Document

Number

C35965 TopKAT Host Communications Manual Series 1000/Fleetkey and TopKAT

MDE-4338 TopKAT Operation Manual Series 1000/Fleetkey and TopKAT

MDE-4490 PC/TopKAT User’s Guide CFN Series Controllers and POS

MDE-4520 Enhanced Communications Installation Manual RFID Wireless and TCP/IP Equipment

PT-1957 TopKAT Parts Manual CFN Series Controllers and POS

Title GOLD Library

Warranty

For information on warranty, refer to MDE-4255 Gasboy’s Warranty Policy Statement. If you

have any warranty-related questions, contact Gasboy’s Warranty Department at its

Greensboro location.

Page 4 MDE-4319E TopKAT™ Fuel Management System Installation Manual · August 2008

Page 11

2 – Important Safety Information

Important Safety Information

This section introduces the hazards and safety precautions

associated with installing, inspecting, maintaining or servicing

this product. Before performing any task on this product, read

this safety information and the applicable sections in this

manual, where additional hazards and safety precautions for

your task will be found. Fire, explosion, electrical shock or

pressure release could occur and cause death or serious

injury, if these safe service procedures are not followed.

Preliminary Precautions

You are working in a potentially dangerous environment of

flammable fuels, vapors, and high voltage or pressures. Only

trained or authorized individuals knowledgeable in the related

procedures should install, inspect, maintain or service this

equipment.

Emergency Total Electrical Shut-Off

The first and most important information you must know is

how to stop all fuel flow to the pump/dispenser and island.

Locate the switch or circuit breakers that shut off all power to

all fueling equipment, dispensing devices, and Submerged

Turbine Pumps (STPs).

!

WARNING

!

The EMERGENCY STOP, ALL STOP, and

PUMP STOP buttons at the cashier’s station

WILL NOT shut off electrical po wer to the p ump/

dispenser. This means that even if you activate

these stops, fuel may continue to flow

uncontrolled.

Read the Manual

Read, understand and follow this manual and any other

labels or related materials supplied with this equipment. If you

do not understand a procedure, call a Gasboy Authorized

Service Contractor or call the Gasboy Service Center at 1800-444-5529. It is imperative to your safety and the safety of

others to understand the procedures before beginning work.

Follow the Regulations

Applicable information is available in National Fire Protection

Association (NFPA) 30A; Code for Motor Fuel Dispensing

Facilities and Repair Garages, NFPA 70; National Electrical

Code (NEC), Occupational Safety and Hazard Association

(OSHA) regulations and federal, state, and local codes. All

these regulations must be followed. Failure to install, inspect,

maintain or service this equipment in accordance with these

codes, regulations and standards may lead to legal citations

with penalties or affect the safe use and operation of the

equipment.

Replacement Parts

Use only genuine Gasboy replacement parts and retrofit kits

on your pump/dispenser. Using parts other than genuine

Gasboy replacement parts could create a safety hazard and

violate local regulations.

Safety Symbols and Warning Words

This section provides important information about warning

symbols and boxes.

Alert Symbol

You must use the TOTAL ELECTRICAL SHUTOFF in the case of an emergency and not the

console’s ALL STOP and PUMP STOP or

similar keys.

Total Electrical Shut-Off Before Access

Any procedure that requires access to electrical components

or the electronics of the dispenser requires total electrical

shut off of that unit. Understand the function and location of

this switch or circuit breaker before inspecting, installing,

maintaining, or servicing Gasboy equipment.

Evacuating, Barricading and Shutting Off

Any procedure that requires access to the pump/dispenser or

STPs requires the following actions:

• An evacuation of all unauthorized persons and vehicles

from the work area

• Use of safety tape, cones or barricades at the affected

unit (s)

• A total electrical shut-off of the affected unit (s)

This safety alert symbol is used in this manual and

on warning labels to alert you to a precaution which must be

followed to prevent potential personal safety hazards. Obey

safety directives that follow this symbol to avoid possible

injury or death.

Signal Words

These signal words used in this manual and on warning

labels tell you the seriousness of particular safety hazards.

The precautions below must be followed to prevent death,

injury or damage to the equipment:

DANGER: Alerts you to a hazard or unsafe practice

!

which will result in death or serious injury.

WARNING: Alerts you to a hazard or unsafe practice

!

that could result in death or serious injury.

CAUTION with Alert symbol: Designates a hazard or

!

unsafe practice which may result in minor injury.

CAUTION without Alert symbol: Designates a hazard

or unsafe practice which may result in property or

equipment damage

Working With Fuels and Electrical Energy

Prevent Explosions and Fires

Fuels and their vapors will explode or burn, if ignited. Spilled

or leaking fuels cause vapors. Even filling customer tanks will

cause potentially dangerous vapors in the vicinity of the

dispenser or island.

MDE-4319E TopKAT™ Fuel Management System Installation Manual · August 2008 Page 5

Page 12

Important Safety Information

No Open Fire

Open flames from matches, lighters, welding torches

or other sources can ignite fuels and their vapors.

No Sparks - No Smoking

Sparks from starting vehicles, starting or using power tools,

burning cigarettes, cigars or pipes can also ignite fuels and

their vapors. Static electricity, including an electrostatic

charge on your body, can cause a spark sufficient to ignite

fuel vapors. Every time you get out of a vehicle, touch the

metal of your vehicle, to discharge any ele c tro static charge

before you approach the dispenser island.

Working Alone

It is highly recommended that someone who is capable of

rendering first aid be present during servicing. Familiarize

yourself with Cardiopulmonary Resuscitation (CPR) methods,

if you work with or around high voltages. This information is

available from the American Red Cross. Always advise the

station personnel about where you will be working, and

caution them not to activate power while you are working on

the equipment. Use the OSHA Lockout/ Tagout procedures. If

you are not familiar with this requirement, refer to this

information in the service manual and OSHA documentation.

Working With Electricity Safely

Ensure that you use safe and established practices in working

with electrical devices. Poorly wired devices may cause a fire,

explosion or electrical shock. Ensure that grounding

connections are properly made. Take care that sealing

devices and compounds are in place. Ensure that you do not

pinch wires when replacing covers. Follow OSHA Lockout/

Tagout requirements. Station employees and service

contractors need to understand and comply with this program

completely to ensure safety while the equipment is down.

In an Emergency

Inform Emergency Personnel

Compile the following information and inform emergency

personnel:

• Location of accident (for example, address, front/back of

building, and so on)

• Nature of accident (for example, possible heart attack, run

over by car, burns, and so on)

• Age of victim (for example, baby, teenager, middle-age,

elderly)

• Whether or not victim has received first aid (for example,

stopped bleeding by pressure, and so on)

• Whether or not a victim has vomited (for example, if

swallowed or inhaled something, and so on)

WARNING

!

Gasoline ingested may cause unconsciousness

and burns to internal organs.

Do not induce vomiting.

Keep airway open.

Oxygen may be needed at scene.

Seek medical advice immediately.

WARNING

!

Gasoline inhaled may cause unconsciousness

and burns to lips, mouth and lungs.

Keep airway open.

Seek medical advice immediately.

WARNING

!

Gasoline spilled in eyes may cause burns to eye

tissue.

Irrigate eyes with water for approximately 15

minutes.

Seek medical advice immediately.

Hazardous Materials

WARNING

Some materials present inside electronic enclosures may

present a health hazard if not handled correctly. Ensure that

you clean hands after handling equipment. Do not place any

equipment in the mouth.

!

WARNING

The pump/dispenser contains a chemical known to the

State of California to cause cancer.

!

Gasoline spilled on skin may cause burns.

Wash area thoroughly with clear water.

Seek medical advice immediately.

IMPORTANT: Oxygen may be needed at scene if gasoline

has been ingested or inhaled. Seek medical advice

immediately.

Lockout/Tagout

WARNING

!

Lockout/Tagout covers servicing and maintenance of

machines and equipment in which the unexpected

The pump/dispenser contains a chemical known to the

State of California to cause birth defects or other

reproductive harm.

energization or start-up of the machine(s) or equipment or

release of stored energy could cause injury to employees or

personnel. Lockout/Tagout applies to all mechanical,

hydraulic, chemical or other energy, but does not cover

electrical hazards. Subpart S of 29 CFR Part 1910 - Electrical

Hazards, 29 CFR Part 1910.333 contains specific Lockout/

Tagout provision for electrical hazards.

Page 6 MDE-4319E TopKAT™ Fuel Management System Installation Manual · August 2008

Page 13

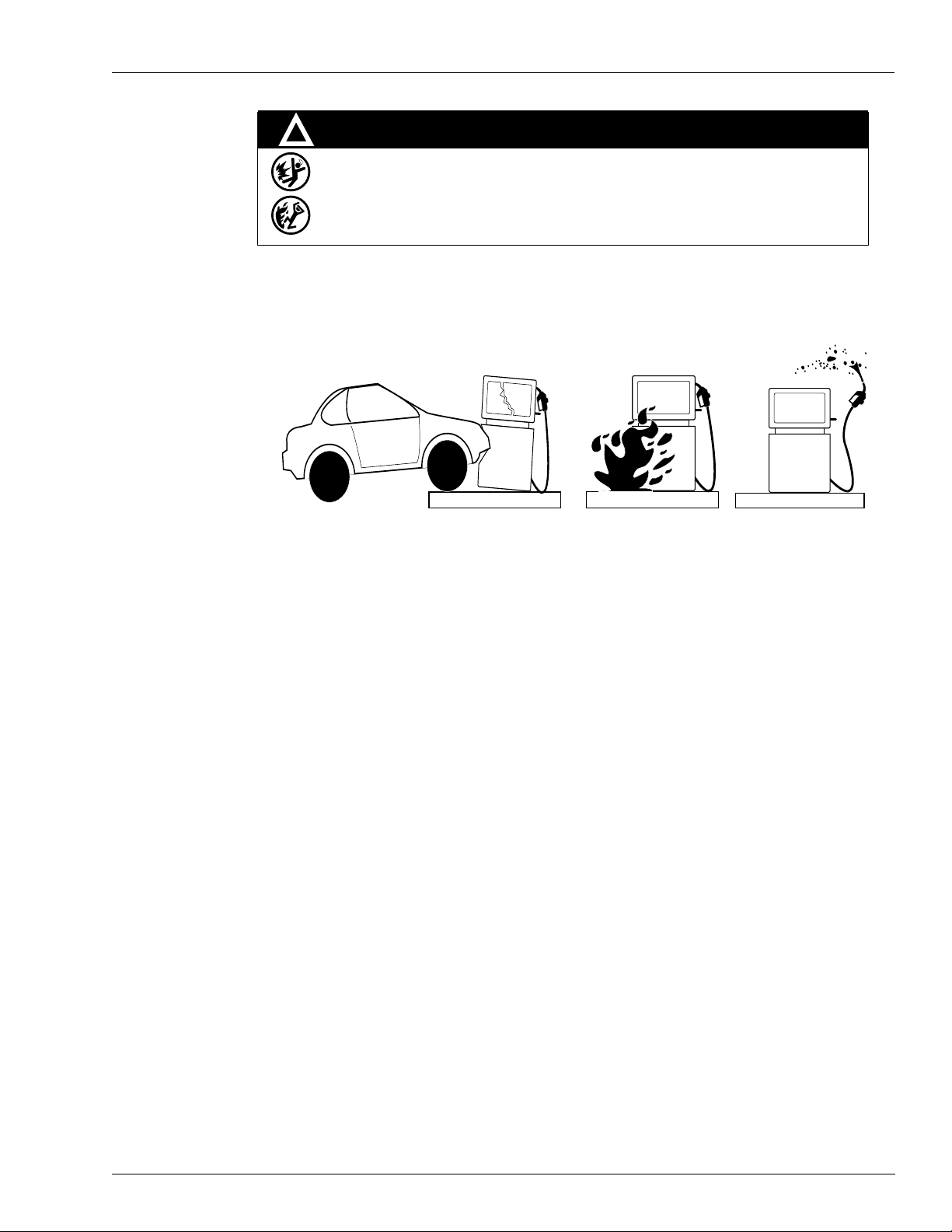

Hazards and Actions

Important Safety Information

!

WARNING

Spilled fuels, accidents involving pumps/dispensers, or uncontrolled fuel flow create a

serious hazard.

Fire or explosion may result, causing serious injury or death.

Follow established emergency procedures.

The following actions are recommended regarding these hazards:

Collision of a Vehicle with Unit Fire at Island Fuel Spill

• Do not go near a fuel spill or allow anyone else in the area.

• Use station EMERGENCY CUTOFF immediately. Turn off all system circuit breakers to the

island(s).

• Do not use console E-STOP, ALL STOP and PUMP STOP to shut o ff power. These keys do not

remove AC power and do not always stop product flow.

• Take precautions to avoid igniting fuel. Do not allow starting of vehicles in the area. Do not allow

open flames, smoking or power tools in the area.

• Do not expose yourself to hazardous conditions such as fire, spilled fuel or exposed wiring.

• Call emergency numbers.

MDE-4319E TopKAT™ Fuel Management System Installation Manual · August 2008 Page 7

Page 14

Important Safety Information

This page is intentionally left blank.

Page 8 MDE-4319E TopKAT™ Fuel Management System Installation Manual · August 2008

Page 15

FCC Part 15 FCC and DOC Customer Information

3 – FCC and DOC Customer Information

Both the US Federal Communications Commission (FCC) and the Canadian Department of

Communication (DOC) require that specific information be supplied to the users of any

equipment that may emit radio frequency energy. Read the following information for details.

FCC Part 15

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of FCC rules. These limits are designed to provide reasonable

protection against harmful interference when the device is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if

not installed in accordance with the instruction manual, may cause harmful interference to

radio communications. Operation of this equipment in a residential area is likely to cause

harmful interference, in which case, users will be required to correct the interference at their

own expense.

FCC Part 68

General Requirements for All Equipment

• This equipment complies with Part 68 of the FCC rules. The Gasboy Internal Modem is

contained within a Gasboy FMS. On the outside of the rear access door of the FMS is a

label that contains, among other information, the FCC registration number and Ringer

Equivalence Number (REN) for this equipment. If requested, this information must be

provided to the telephone company.

• The Gasboy Internal Modem should be connected to a USOC RJ-11C jack.

• An FCC-compliant telephone cord and modular plug is provided with the equipment. This

equipment is designated to be connected to the telephone network or premises wiring

using a compatible modular jack, which is Part 68 compliant.

• The REN is used to determine the quantity of devices that may be connected to the

telephone line. Excessive RENs on the telephone line may result in the device not ringing

in response to an incoming call. In most, but not all areas, the sum of RENs should not

exceed five (5.0). To be certain of the number of devices that may be connected to a line,

as determined by the total RENs, contact the local telephone company.

• If the Gasboy Internal Modem causes harm to the telephone network, the telephone

company will notify you in advance that temporary discontinuance of service may be

required. But if the advance notice is not practical, the telephone company will notify the

customer as soon as possible. Also, you will be advised of your right to file a complaint

with the FCC if you believe it is necessary.

• The telephone company may make changes in its facilities, equipment, operations or

procedures that could affect the operation of the equipment. If such a case, the telephone

company will provide advance notice for you to make necessary modifications to maintain

uninterrupted service.

MDE-4319E TopKAT™ Fuel Management System Installation Manual · August 2008 Page 9

Page 16

FCC and DOC Customer Information FCC Part 68

• If trouble is experienced with the Gasboy Internal Modem, contact Gasboy at

1-800-444-5529 for repairs or warranty information. If the equipment is causing harm to

the telephone network, the telephone company may request that you disconnect the

equipment until the problem is resolved.

• The Gasboy Internal Modem does not have any easily repairable or replaceable parts.

Contact Gasboy in case you are experiencing trouble.

• The equipment cannot be used on the public coin phone service provided by the telephone

company . Connection to the party line service is subject to state tariffs. (Contact your state

Public Utility Commission, Public Service Commission or Corporation Commission for

information).

DOC Certification

Industry Canada Ringer Equivalence Number Notice

The Canadian Department of Communications label identifie s the certified equipment. This

certification indicates that the equipment meets certain telecommunications network

protective, operational, and safety requirements. The department does not guarantee that the

equipment will operate to the user's satisfaction.

Before installing this equipment, you should ensure that it is permissible to be connected to the

facilities of the local telecommunications company. The equipment must also be installed

using an acceptable method of connection. In some cases, the company's inside wiring

associated with a single line individual service may be extended by means of a certified

connector assembly (telephone extension cord). The customer should be aware that

compliance with the above condition may not prevent degradation of the service in some

situations.

Repairs to the certified equipment should be made by an authorized maintenance facility

designated by the supplier. Any repairs or alterations made to this equipment, or equipment

malfunctions may give the telecommunications company cause to request you to disconnect

the equipment.

You should ensure for your protection that the ground connections of the power utility,

telephone lines and internal metallic water pipe system are connected together. This

precaution may be particularly important in rural areas.

!

CAUTION

Users should not attempt to make such connections themselves and should contact the

electric inspection authority or electrician, as appropriate.

The REN assigned to each terminal device denotes the percentage of the total load to be

connected to a telephone loop that is used by the device, to prevent overloading. The

termination on a loop may consist of any combination of devices subject only to the

requirement that the total of the REN of all devices does not exceed five.

The REN for the Gasboy Internal Modem is 0.8B.

Page 10 MDE-4319E TopKAT™ Fuel Management System Installation Manual · August 2008

Page 17

Rules for Proper Installation General Installation

4 – General Installation

Rules for Proper Installation

!

WARNING

To reduce the risk of electrical shock when servicing, turn off all power to the pump/remote

dispenser. In submersible pump applications, turn off all power to the submersible pump

and any other remote dispensers that use the submersible pump. AC power can feed back

into a shut-off remote dispenser when dispensers share a common submersible pump or

starter relay.

!

AVERTISSEMENT

Pour réduire le risque de choc électrique lors de l'entretien/révision, coupez totalement le

courant à la pompe/distributeur éloigné. Dans les applications de pompe immersible, coupez

totalement le courant à la pompe immersible et tous autres distributeurs éloigné qui utilisent la

pompe immersible. Le courant alternatif peut alimenter de nouveau un distributeur éloigné à

l'arrêt quand les distributeurs partagent une pompe immersible commune ou un relais de

démarrage.

To ensure proper installation, follow these rules:

• Read this entire manual before starting installation.

• Internationally and domestically: All wiring is to be installed and used in accordance with

all applicable national, state, and local building/fire/electrical codes. Additionally, in the

USA, installations must comply with the National Electrical Code (NFPA 70), NFPA 30,

and the Automotive and Marine Service Station Code (NFPA 30A) codes and regulations.

Canadian installations must comply with the Canadian Electrical Code.

• All wiring must be in a threaded, rigid, metal conduit to provide the necessary shielding.

DO NOT use a PVC conduit.

• High-voltage AC and low-voltage DC must not be combined in a common conduit,

Junction box, or wire trough unless the cable is used as specified in

“RS-422 - SHMs” on

page 22.

• Power for the TopKAT system (when used with a mechanical interface), da ta terminal,

and external modem must come from a separate, dedicated, circuit breaker.

• The TopKAT system and peripheral equipment must be properly grounded.

• Use terminal connectors on stranded wire.

• Test pumps in the manual override position prior to the startup of the system.

• DO NOT turn on the system power switch located in the head assembly. Power will be

applied to the system by the person performing the system startup. Turning on this switch

prematurely may result in damage to the system and may void your warranty.

Note:When the TopKAT system is supplied with a Mechanical Pump Interface (2-hose

Mechanical or 4-hose PCU), it is necessary to turn on system power in order to test.

Refer to

“Testing” on page 125 for more details.

• Check through all boxes and cartons for manuals, cables, connectors, and so on before

disposing them off.

MDE-4319E TopKAT™ Fuel Management System Installation Manual · August 2008 Page 11

Page 18

General Installation Component Location and Installation Specifications

Component Location and Installation Specifications

Careful planning for the layout of the site will help eliminate possible problems with the

startup of your system and will ensure continued, reliable system operation.

System

Regardless of your installation option, the TopKAT system must be located on the fuel island.

Data Terminal

°

The unit has been designed to withstand an environment of -22

F to 122° F (-30

95% relative humidity (non-condensing). When mounting the un it, a minimum clearance of 18

inches between the post and any of the pumps or dispensers must be maintained. This

clearance meets the NFPA 30A and NFPA 70 re quirements and allows room for the wiring

and maintenance of the system. Adequate clearance around the head of the unit is important to

provide room for the maintenance of the system. A minimum of 14 inches of clearance from

the rear of the unit must be provided to allow the rear door to open.

When a data terminal is used with the system it must be UL-listed and should be located in a

clean, office type of environment. Do not install the data terminal over a hazardous location.

Data terminals supplied by Gasboy have an operative temperature range of 32

(0° C to 40° C). Locating the terminal in a dirty environment may cause premature failure.

Refer to

“Port Communication Wiring” on page 28 for your installation type to connect the

data terminal.

°

C to 50° C),

°

F to 104° F

External Modem

When an external modem is used with the system it must be UL-listed and should be located in

an office type of environment. However, if this is not possible, it should be housed in a

protective enclosure. Do not install the modem over a hazardous location. External modems

supplied by Gasboy have an operative temperature range of 32

type of phone line required for communication via an external modem is dependant on the

type of modem used and the method of communication desired. Consult the manual that

comes with the modem for specific requirements. Refer to

page 28 for your installation type to connect the external modem.

°

F to 104° F (0° C to 40° C). The

“Port Communication Wiring” on

Page 12 MDE-4319E TopKAT™ Fuel Management System Installation Manual · August 2008

Page 19

Component Location and Installation Specifications General Installation

Internal Modem

When the TopKAT system is equipped with the optional internal modem, the Port 3

communication is routed through the modem in place of being wired at the DC Junction box.

Jumper K2 should be removed. Refer to

jumpers K1 and K2. The phone line for the internal modem can be installed in the DC conduit.

If you are installing the phone line in a DC conduit, the cable must be two twisted-pair

shielded cables as specified in

“Communication Requirements” on page 19 and the shield

drain wire must be connected to the system AC ground. Check with your local phone company

for proper installation of the phone line.

If you order your TopKAT system with an optional internal modem, the modem is mounted

within the TopKAT system at the factory and power for the modem is supplied by the

TopKAT system. The 2400 baud modem is designed for 300, 1200, or 2400 baud, full duplex,

asynchronous communication. The 33600 baud modem is designed for 1200, 2400, or 9600

baud, full duplex, asynchronous communication. This modem meets or exceeds the direct

connection registration requirements of the FCC rules. The modem will connect directly

through a phone line supplied by the phone company. The customer is required to order this

phone line and have it installed.

To order this equipment from the phone company, specify:

“Terminal Block ID” on page 24 for the location of

1 The registration number of 6BHUSA-2479 3-DT-E.

2 The data transmission rate of 300 baud, 1200 baud, 2400 baud, or 9600 baud.

3 The Bell equivalent of 103J/212A.

Power Conditioner

When used, a UL-listed power conditioner helps provide clean power to the TopKAT system.

Poor power conditions are a key cause to system malfunction or failure. The power

conditioner provides transient and common mode protection for the TopKAT system,

although it cannot totally compensate for extremely poor power conditions. The power

conditioner must be located in an area protected from direct contact with the weather

(typically near the system circuit breakers) and should be no further than 50 feet from the

TopKAT system for optimum protection. It must not be used over a hazardous location.

When used with a TopKAT system that is installed on a 9800 or ASTRA, the Micro Feed line

from the pump/dispenser is routed through the power conditioner and then to the breaker . W ith

a mechanical installation, the TopKAT system is directly connected to the power conditioner

and then to the breaker. The power conditioner is designed for an operating temperat ure range

of -20

°

C to 48

°

C.

MDE-4319E TopKAT™ Fuel Management System Installation Manual · August 2008 Page 13

Page 20

General Installation Conduit Layout/Installation Specifications

Conduit Layout/Installation Specifications

• Internationally and domestically: All wiring must be installed and used in accordan ce with

all applicable national, state, and local building/fire/electrical codes. Additionally, in the

USA, installations must comply with the National Electrical Code (NFPA 70), NFPA 30,

and the Automotive and Marine Service Station Code (NFPA 30A) codes and regulations.

Canadian installations must comply with the Canadian Electrical Code.

• All peripheral equipment connected to the RS-232 ports must be listed, have an

Electronics Industrial Association (EIA) standard RS-232 communications protocol and

not be installed over a hazardous location.

• Power for the data terminal and external modem must come from a separate circuit

breaker rated at no less than 10A.

• All conduits must be made of metal to provide the necessary shielding.

• Use the Conduit Size Chart to determine the proper conduit size.

• RS-232 communication must not exceed 100 feet. RS-232 communication wires must be

in a separate metal conduit away from AC wires.

• For communication distances exceeding 100 feet, you must use a Gasboy RS-422 Short

Haul Modem.

• It is recommended that high voltage AC power wires be installed in a separate conduit,

away from the low voltage DC signal wires. However, if AC and DC wires share the

conduit, communication wiring must use the cable specified in “RS-422 - SHMs” on

page 22.

• DC RS-422 communication wires can be combined in the same conduit.

• When using the master/satellite configuration, the maximum field wiring cable length

between the first and last unit must not exceed 1500 feet (455 m). It is recommended that

high voltage AC wires be installed in a separate conduit, away from the low voltage DC

signal wires. However, if AC and DC wires share the conduit, communication wiring must

use the cable specified in

“Communication Requirements” on page 19.

Conduit Requirements

All wiring (AC and DC) connecting different components of the Gasboy FMS must be

installed in threaded, rigid, metal conduit except as noted in

on page 19 and “RS-422 - SHMs” on page 22. PVC IS NOT ACCEPTABLE. Components of

the system include pumps, dispensers, submersible pumps, submersible starter relays, circuit

breaker panels, optional wall-mount PCUs and the TopKAT system. Communications

equipment signal wires must also be run in the metal conduit, except for RS-422 wiring, as

noted in

Communication equipment signal wires must also be run in metal conduits. High-voltage

(AC) and low-voltage (DC) must not be combined in a common conduit, Junction box, or wire

trough unless the cable is used as specified in

All conduits must be connected to the TopKAT pedestal through the holes and knockouts

provided by the factory. Do not make any other holes in this unit. If you must make holes at

locations other than those provided, contact Gasboy for approval.

Page 14 MDE-4319E TopKAT™ Fuel Management System Installation Manual · August 2008

“Communication Requirements” on page 19.

“Communication Requirements” on page 19.

“Communication Requirements”

Page 21

Conduit Requirements General Installation

All wiring and conduit runs must conform to all building/fire codes, all Federal, State, and

Local codes, the National Electrical Code (NFPA 70), NFPA 30, and the Automotive and

Marine Service Stations Code (NFPA 30A). Canadian users must also comply with the

Canadian Electrical Code.

Use the tables below as a guideline to determine the proper conduit sizes for the Gasboy

TopKAT FMS. When planning the o r ientation of wiring runs, follow the applicable Gasboy

wiring diagram and consider the layout of components at the site. Long runs or a large number

of bends may require you to increase the conduit size over what is listed here.

To determine the conduit size required, use the “THHN/THWN Wire Areas” table to find the

area for each wire gauge. Add up all wire areas. Use the “Areas of Trade Size Conduit” table

to select the smallest number in the 25% fill area (based on NEC 501-1) that comes closest

without exceeding the total wire area.

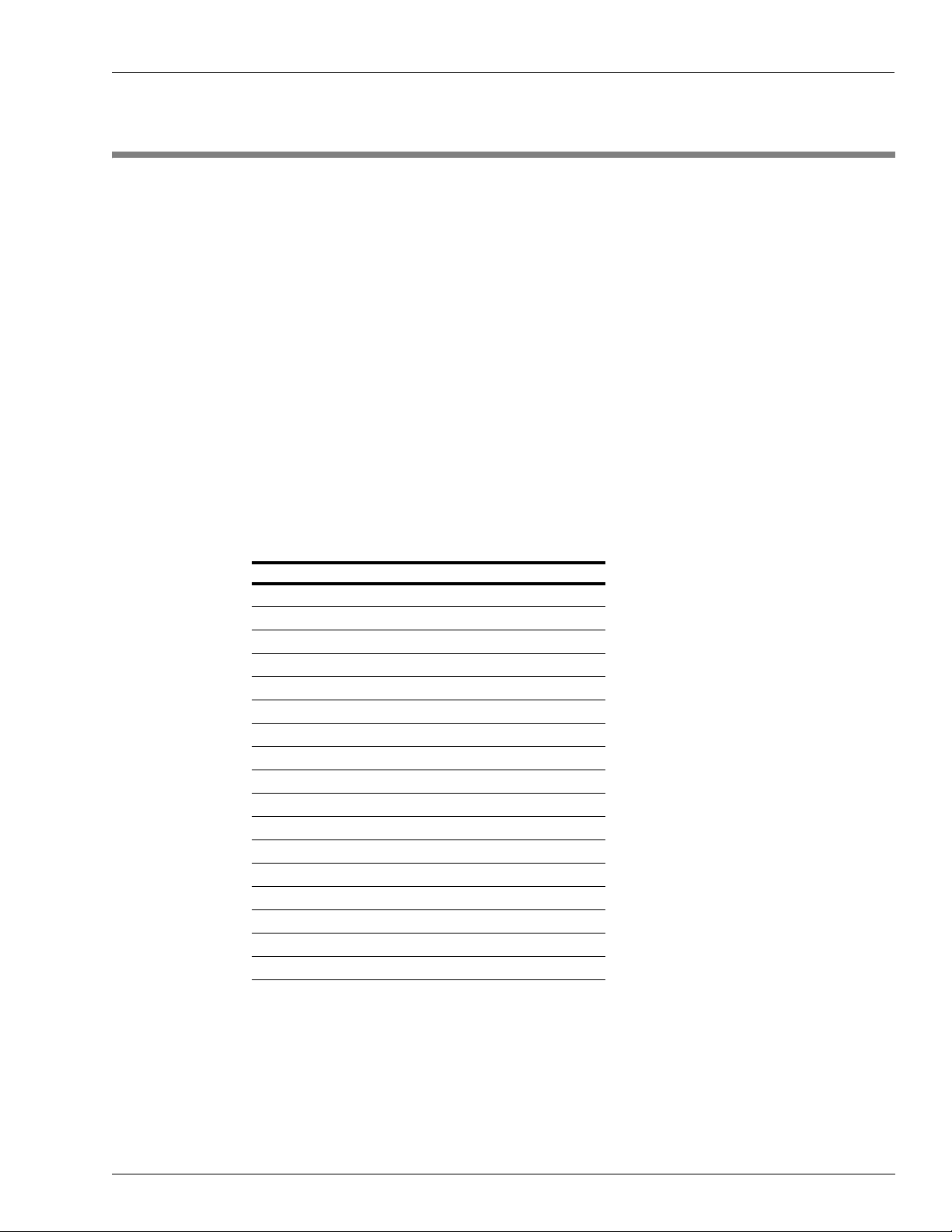

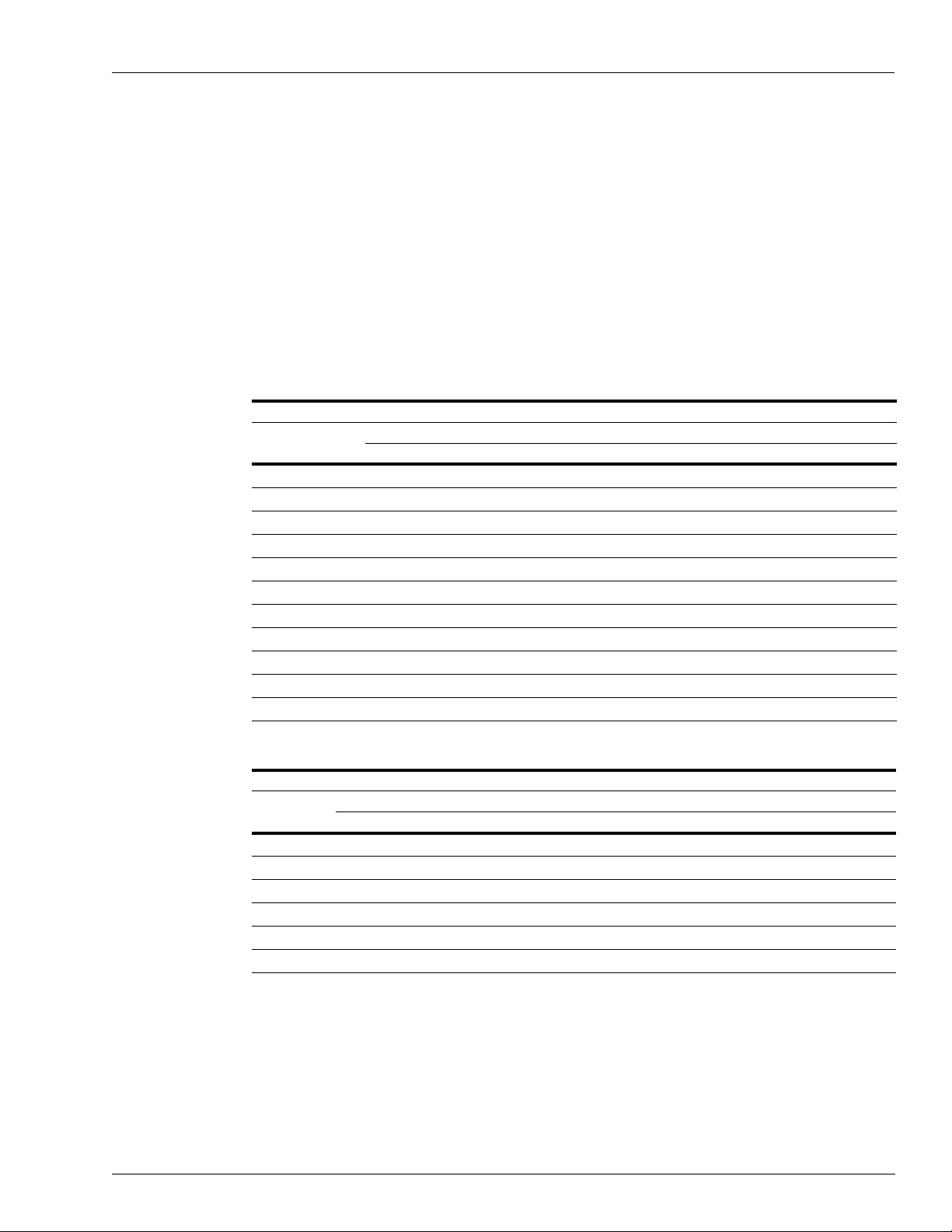

THHN/THWN Wire Areas

Gauge

18 .090 2.29 .007 4.1

16 .104 2.64 .009 5.5

14 .118 2.95 .011 6.8

12 .135 3.43 .014 9.2

10 .169 4.29 .022 14.5

8 .216 5.49 .037 23.7

6 .259 6.60 .053 34.2

4 .331 8.41 .086 55.5

3 .359 9.14 .102 65.6

2 .394 10.01 .122 78.7

1063A .417 10.59 .137 88.4

Inches Millimeters Inches Millimeters

Diameter Area (square units)

Areas of Trade Size Conduit

Internal Diameter Area (square units) Fill Area (square units) 25% fill

Trade Size

1/2 .629 16 .303 196 .076 49

3/4 .826 21 .532 343 .133 86

1 1.063 27 .862 556 .215 139

1-1/4 1.378 35 1.50 968 .375 242

1-1/2 1.614 41 2.04 1314 .509 329

2 2.087 53 3.36 2165 .839 541

MDE-4319E TopKAT™ Fuel Management System Installation Manual · August 2008 Page 15

Inches Millimeters Inches Millimeters Inches Millimeters

Page 22

General Installation Power Requirements

Power Requirements

AC Power to the TopKAT System

When mounted to a 9800 or ASTRA, AC power for the TopKAT system is supplied from the

same power source used to power the 9800 or ASTRA Micro Feed. A wiring cable for AC

power from the 9800 or ASTRA to the TopKAT is supplied with the TopKAT. Refer to

“ASTRA to T opKAT Cabling” on page 27 for more information.

When mounted on a pedestal, AC power for the TopKAT system must come from a separate,

dedicated circuit breaker. No other equipment, including the system's pumps or dispensers,

may be powered from this breaker.

When the TopKAT system is pedestal-mounted with internal PCUs, AC power for the

TopKAT system must be supplied from the same power source used to power the PCUs. A

wiring cable for AC power from the TopKAT system to the PCUs is supplied. When the

TopKAT system is pedestal-mounted but is being used with wall-mounted PCUs, the AC

power for the TopKAT system and PCUs must come from a separate, dedicated circuit

breaker. No other equipment, including the system's pumps and dispensers may be powered

from this breaker.

TopKAT Peripheral Equipment

When used with a 9800 or ASTRA, AC power for the data terminal or external modem must

come from a separate, dedicated circuit breaker. No other equipment, including the system's

pump or remote dispenser control may be powered from this breaker. However, for 9800 and

ASTRA applications, it is acceptable to power the data terminal or external modem from the

breaker that supplies power to the electronic register (Micro Feed on 9800 or ASTRA). This

breaker is the same one that supplies power to the TopKAT system. Whenever possible, one

breaker should be used to supply the Micro Feed and the data terminal or external modem.

However, it is acceptable to supply power to both from multiple breakers within the same

breaker panel and the same phase of power. When necessary, power for the data terminal or

modem may be supplied from a separate, dedicated breaker located in a different breaker

panel.

When used with a pedestal TopKAT system, power for a data terminal or external modem can

come from the same breaker as the TopKAT system.

The system requires 115 VAC + 10% 47-63 Hz, or optional 230 VAC + 10% 47-63 Hz of

power. The system draws a maximum of 95 Watts.

Grounding

Proper system grounding is an extremely important part of system installation. As with the AC

power, the grounds for all system components should return to the same breaker panel. This

helps you to assure a common ground throughout the system, which is necessary for protection

of the RS-485 data loop circuitry. Grounds for all system devices should be wired to the

breaker panel ground bus bar, which in turn should be grounded to a ground rod. A conduit

ground does not provide sufficient ground. It is recommended that the neutral and ground bus

bars be bonded together when it is not prohibited by local codes.

Page 16 MDE-4319E TopKAT™ Fuel Management System Installation Manual · August 2008

Page 23

Wire Size General Installation

Suction Pumps

The TopKAT system, with Mechanical Interface or Mechanical PCU options, is capable of

directly driving pump motors up to 3/4 HP at 115 VAC or 1-1/2 HP at 230 VAC. A starter

relay must be used with pump motors that exceed this limitation. A separate circuit breaker

should be supplied for each pump to meet the current requirements and to allow isolated

control with the circuit breaker panel in case of problems.

Dispensers

The TopKAT system with the Mechanical Interface option is capable of directly driving

submersible pumps up to 3/4 HP at 115 VAC or 1-1/2 HP at 230 VAC. A dispenser with a

submersible pump exceeding this limitation requires the use of a submersible starter relay. A

separate circuit breaker should be supplied for each dispenser in cases where it will directly

drive the submersible pump. Dispensers may be grouped together on a single breaker when the

submersible pump has its own breaker . It is recommended that no mo re than two dispen sers be

powered from one breaker to maintain isolated control with the circuit breaker panel in case of

problems.

Wire Size

A wiring cable for AC power from the 9800 or ASTRA to the TopKAT system is supplied

with the TopKAT system. If you are wiring a pedestal TopKAT system or wall-mount

Mechanical PCUs, the AC power wire size must be 14 AWG or larger for runs of up to 300

feet from the breaker panel to the system. Sites with distances over 300 feet must use 12 A WG

wire or larger.

The AC wire size for power of the system data terminal or external modem must be 14 AWG

or larger. This gauge of wire will be sufficient for runs of up to 300 feet (91m) from the

breaker panel to the system. Components with distances over 300 feet (91m) must use 12

AWG wire or larger. All wires should be stranded.

The specifications for the communication wire/cable size can be found in RS-485

“Communication Requirements” on page 19 and/or “RS-422 - SHMs” on page 22 in this

chapter.

MDE-4319E TopKAT™ Fuel Management System Installation Manual · August 2008 Page 17

Page 24

General Installation Wire Size

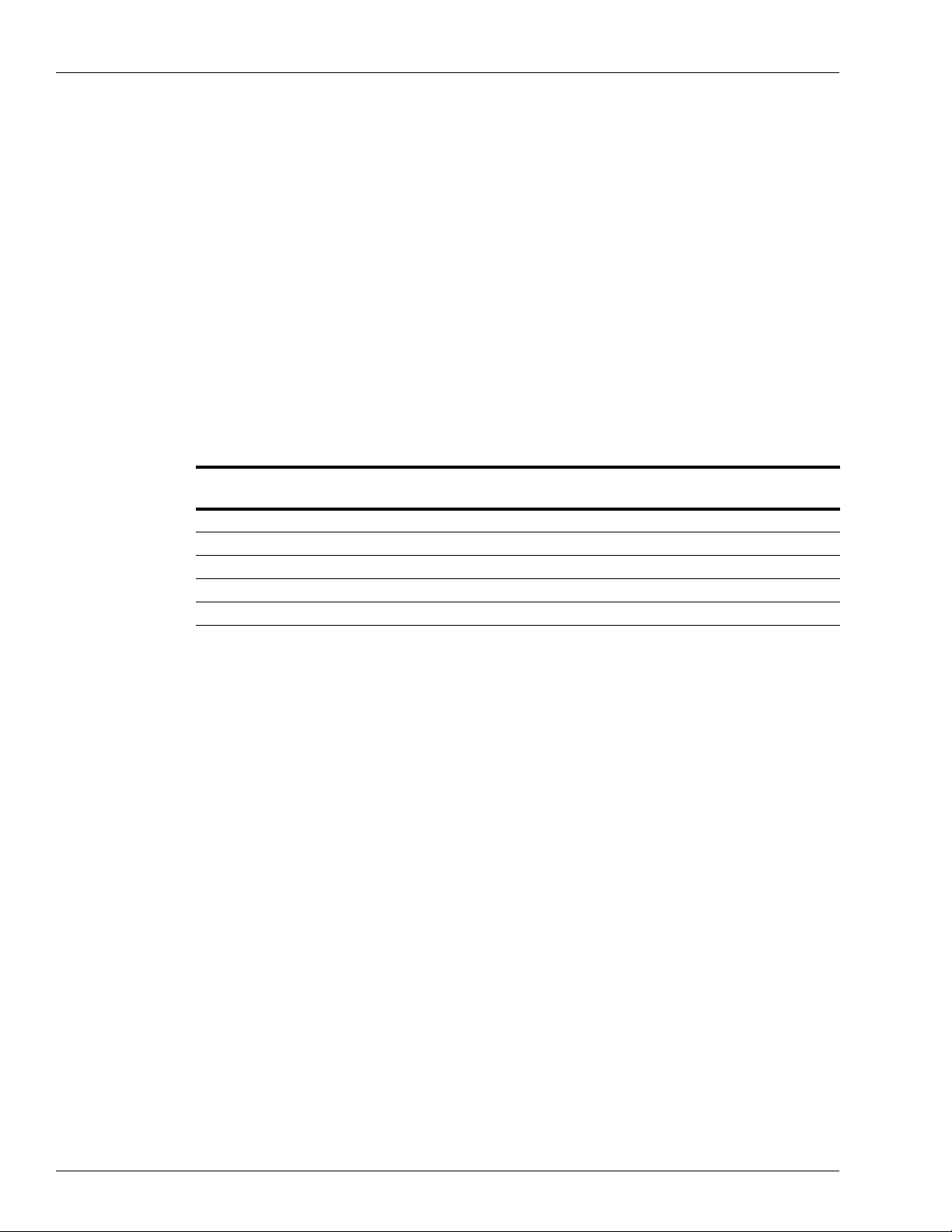

Mechanical Interface Option

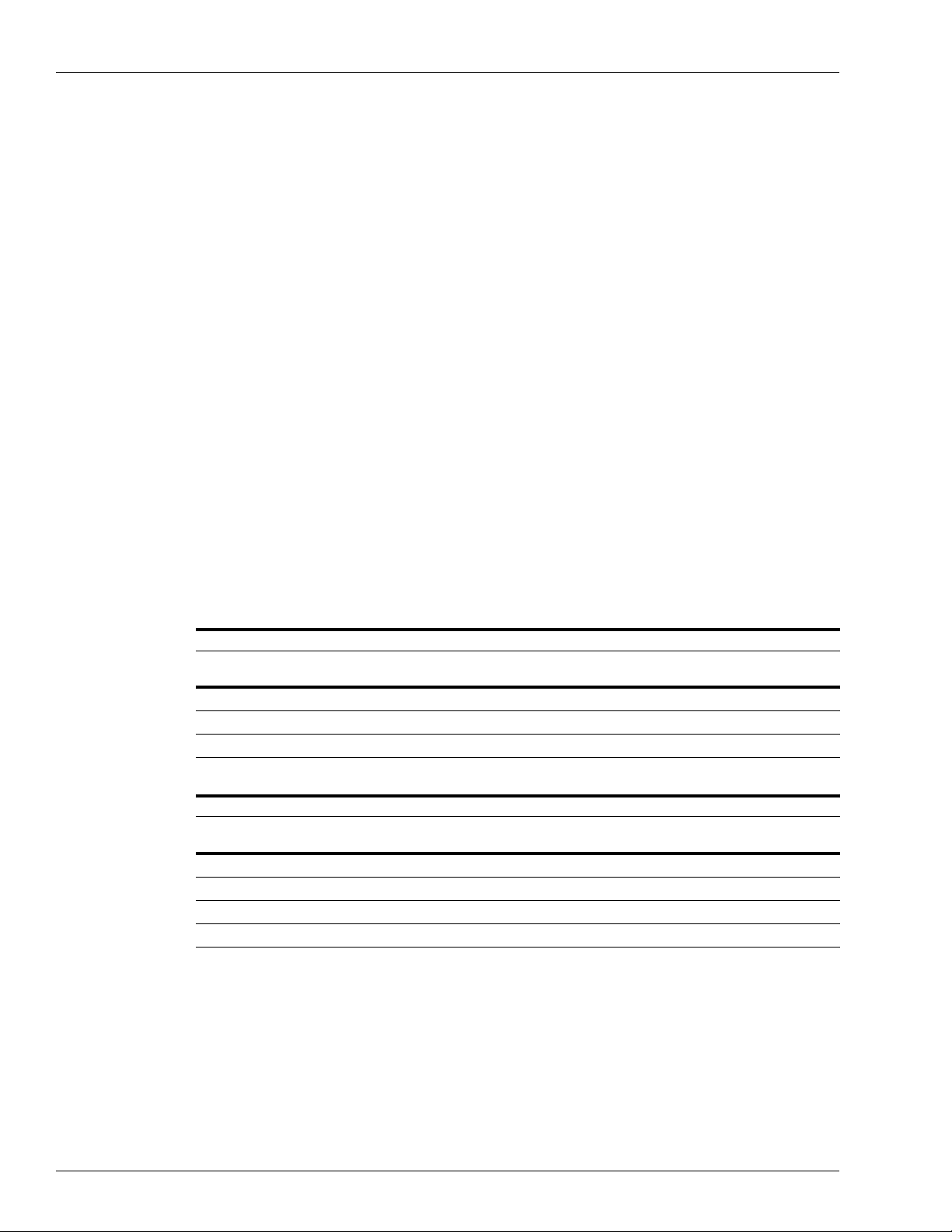

The AC wire size for a suction pump is dependent on the HP rating of the pump motor, the

voltage at which the pump will be operated (115/230), and the distance from the circuit

breaker panel to the pump. The chart below may be used as a guide to select the proper size

wire according to the specific installation requirements. The wire size for the Reset Complete

from the pump should be 14 AWG. All wires should be stranded.

The AC wire size for the control lines of a dispenser should be 12 AWG. These control lines

supply power for the reset mechanism, solenoid valve, and submersible starter relay (when the

submersible pump is not directly powered by the dispenser). The wire size for the submersible

pump power depends on the HP rating of the pump motor, the voltage at which it will be

operated (115/230), and the distance from the circuit breaker to the pump. Use the following

table as a guide to select the proper wire size according to specific installation requirements.

The wire size for the Reset Complete from the dispenser should be 14 AWG. All wires should

be stranded.

The DC wire size for the pulser must be 18 AWG (when they are used). Shielded cables, as

described in

The DC wire size for RS-422 lines should be 18 AWG and meet the specifications outlined in

“Communication Requirements” on page 19.

“Pulser Wiring Notes” on page 50 allows pulser lines to run with AC wires.

Refer to “Communication Requirements” on page 19 to determine the wire size and type for

communication wiring of your specific application.

115 Volt Wire Gauge Sizes per Feet/Meters of Run (Note)

Motor H.P.

1/2 14 12 10 8 8 8 8

3/4 14 12 10 8 8 6 4

Note: For runs over 300 feet, use the relay at the motor location.

25’

7.6M

50’

15.2M

100’

30.5M

150’

45.7M

200’

61M

250’

76.2M

300’

91.4M

230 Volt Wire Gauge Sizes per Feet/Meters of Run (Note)

25’

Motor H.P.

1/2 14 12 12 12 10 10 10

3/4 14 12 12 10 10 10 8

1-1/2 12 12 10 10 8 8 8

Note: For runs over 300 feet, use relays at the motor location.

7.6M

50’

15.2M

100’

30.5M

150’

45.7M

200’

61M

250’

76.2M

300’

91.4M

Page 18 MDE-4319E TopKAT™ Fuel Management System Installation Manual · August 2008

Page 25

Communication Requirements General Installation

Communication Requirements

The TopKAT system utilizes RS-485, RS-232, and RS-422 modes of communication for

communicating to the ASTRA, 9800, Mechanical PCUs and peripheral equipment. The

TopKAT has three ports:

• Port 1 is an RS-485 port that is dedicated to communicate with the ASTRA or satellite

TopKAT system.

• Ports 2 and 3 are configurable for either an RS-232 or RS-422 for communication with a

data terminal, modem, or PC.

Phone line (modem) communication may also be used when remote communication to the site

is desired. If a TopKAT internal modem is used, Port 3 is not available for external

communication wiring. The specific requirements for each of these modes of communication

are listed below.

RS-485 - ASTRA and Mechanical PCUs

RS-485 wiring is used for communication between the TopKAT system, ASTRA, and

Mechanical PCUs. This communication takes place over the RS-485 wiring that is supplied

with the TopKAT when the TopKAT system is mounted on an ASTRA or the Mechanical

PCU is mounted in the TopKAT pedestal.

RS-485 - Master/Satellite Option

The master/satellite option uses four wires to operate a full-duplex RS-485 communication

loop. Ports 2 and 3 of the master can be set for either RS-232 or RS-422 communications to a

data terminal or computer or used to communicate with an optional built-in modem.

• All wiring is to be installed and used in accordance with all building/fire codes, Federal,

State and Local codes, National Electrical Code (NFPA 70), NFPA 30, and Automotive

and Marine Service Station Code (NFPA 30A) codes and regulations. Wiring must also

conform to the wiring diagram supplied with the pump/remote dispenser. Canadian users

must comply with the Canadian Electrical Code.

• Power: The AC power for the short haul modem should come from the same breaker that

supplies the peripheral device or the system (Micro Feed).

• Cable: A twisted-pair shielded cable is highly recommended for RS-485 wiring. Although

it is recommended that wires be run in a conduit away from AC wires, they can be

combined in the same conduit with AC wires, provided that a UL-listed cable with the

following specifications is used:

- Conductor: 18 AWG stranded wire; one twisted-pair

- Shield: Foil-wrapped 100% coverage and/or tinned copper braid 90% coverage

- Drain Wire: Stranded, tinned copper, 20 AWG or larger/or braided shield

- Voltage Rating: Maximum operating voltage of 600 V

- Environmental: Gas and oil-resistant; suitable for wet or dry locations.

Gasboy can supply Belden® 1120A (part number C09672) that is a UL-listed, 2-conductor

cable that meets the requirements listed above.

Belden 1120A is UL-listed but not CSA-listed.

Cables with a voltage rating of less than 600 V must be installed in a conduit away from

all AC wires.

MDE-4319E TopKAT™ Fuel Management System Installation Manual · August 2008 Page 19

Page 26

General Installation Communication Requirements

• Conduit: When you use the recommended shielded twisted-pair cable, RS-485 wires can

be run with AC wires in the metal conduit. The shield drain wire must be connected to the

system AC ground. Only AC wires for the system and pumps can be installed in the AC

conduit. Do not run the cable outdoors without the use of metal conduit. Do not run this

cable overhead when outdoors.

The cable can be run indoors without the use of a metal conduit. The shield drain wire

must be connected to the system AC ground (at one end only).

If you use cables other than the ones that are recommended above, the RS-485 field wires

must be installed in a metal conduit away from AC wires.

• Distance: The maximum overall field wiring cable length between all units must not

exceed 1500 feet (455 m).

RS-485 - Standalone To pKAT System or Wall-Mount PCU

When the TopKAT system must communicate to a 9800 or wall-mount PCU through Port 1

(RS-485) of the TopKAT system and the TopKAT is not directly mounted on the 9800, the

appropriate interconnect cable must be used. It must always be used in this configuration. A

distance of up to 1500 feet (455 m) is allowed. Refer to “Port Communication Wiring” on

page 28 for the wiring diagrams.

Installation Requirements

• Internationally and domestically: All wiring is to be installed and used in accordance

with all applicable national, state and local building/fire/electrical codes. Additionally, in

the USA, installations must comply with the National Electrical Code (NFPA 70), NFPA

30, and the Automotive and Marine Service Station Code (NFPA 30A) codes and

regulations. Canadian installations must comply with the Canadian Electrical Code.

• Cable: A twisted-pair shielded cable is highly recommended for RS-485 wiring. Although

it is recommended that wires be run in a conduit away from AC wires, they can be

combined in the same conduit with AC wires, provided that a UL-listed cable with the

following specifications is used:

- Conductor: 18 AWG stranded wire; one twisted-pair

- Shield: Foil-wrapped 100% coverage and/or tinned copper braid 90% coverage

- Drain Wire: Stranded, tinned copper, 20 AWG or larger/or braided shield

- Voltage Rating: Maximum operating voltage of 600 V

- Environmental: Gas and oil-resistant; suitable for wet or dry locations.

Gasboy can supply Belden 1120A (part number C09672) which is a UL-listed,

2-conductor cable that meets the requirements listed above.

Note: Belden 1120A is UL-listed but not CSA-listed.

Cables with a voltage rating of less than 600 V must be installed in a conduit away from

all AC wires.

• Conduit: When you use the recommended shielded twisted-pair cable described

previously, RS-485 wires can be run with AC wires in a metal conduit. The shield drain

wire must be connected to the system AC ground. Only AC wires for the system and

pumps can be installed in the AC conduit. Do not run the cable outdoors without the use of

a metal conduit. Do not run this cable overhead when outdoors.

Page 20 MDE-4319E TopKAT™ Fuel Management System Installation Manual · August 2008

Page 27

Communication Requirements General Installation

The cable can be run indoors without the use of a metal conduit. The shield drain wire

must be connected to the system AC ground (at one end only).

If you are using a cable other than what was recommended previously, the RS-485 field

wires must be installed in a metal conduit away from AC wires.

• Distance: The maximum field wiring cable length must not exceed 1500 feet (455 m).

RS-232

RS-232 wiring can be used for communication between the TopKAT system and EIA RS-232

compatible peripheral devices (CRT/printer , modem, and so on). The remote end of the wiring

can be terminated with either an RS-232D connector or a Gasboy termination box. You must

follow these installation requirements when installing the RS-232 communication lines:

• All peripheral equipment connected to the RS-232 ports must be UL-listed, have an EIA

standard RS-232 communication protocol and not be installed over a hazardous location.

• Distance: The following distances must be adhered to when installing the RS-232

communication lines:

- 1 - 100 feet (1 - 31 meters): RS-232 can be directly connected to a peripheral device.

- 101 - 1500 feet (32 - 455 meters): RS-422 and Gasboy Short Haul Modem (SHM) are

required. Refer to “RS-422 - SHMs” on page 22 for details.

• Conduit: All direct connect RS-232 cables over 15 feet (5 m) must be in a metal conduit

away from any AC wires. For conduit requirements of SHMs, Refer to the installation

sheet that applies to the device being used.

• Cables: RS-232 cables can either be purchased from Gasboy or made by the installer. The

type of cable needed will vary according to the device it connects. When making cables,

the wire used must be stranded and not a solid core.

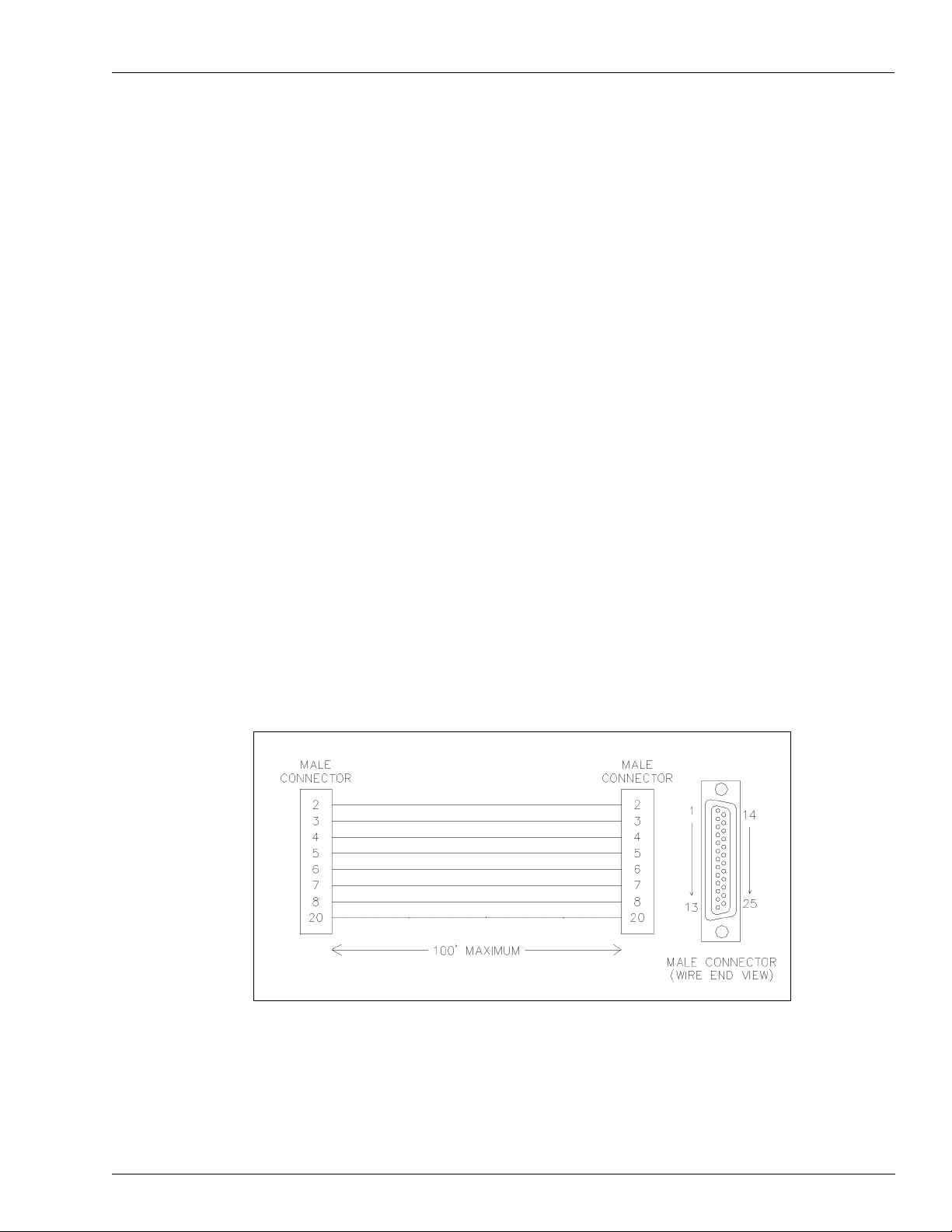

Figure 4-1: RS-232 1:1 Cable (Part Number C04549: 8 feet M/M)

MDE-4319E TopKAT™ Fuel Management System Installation Manual · August 2008 Page 21

Page 28

General Installation Communication Requirements

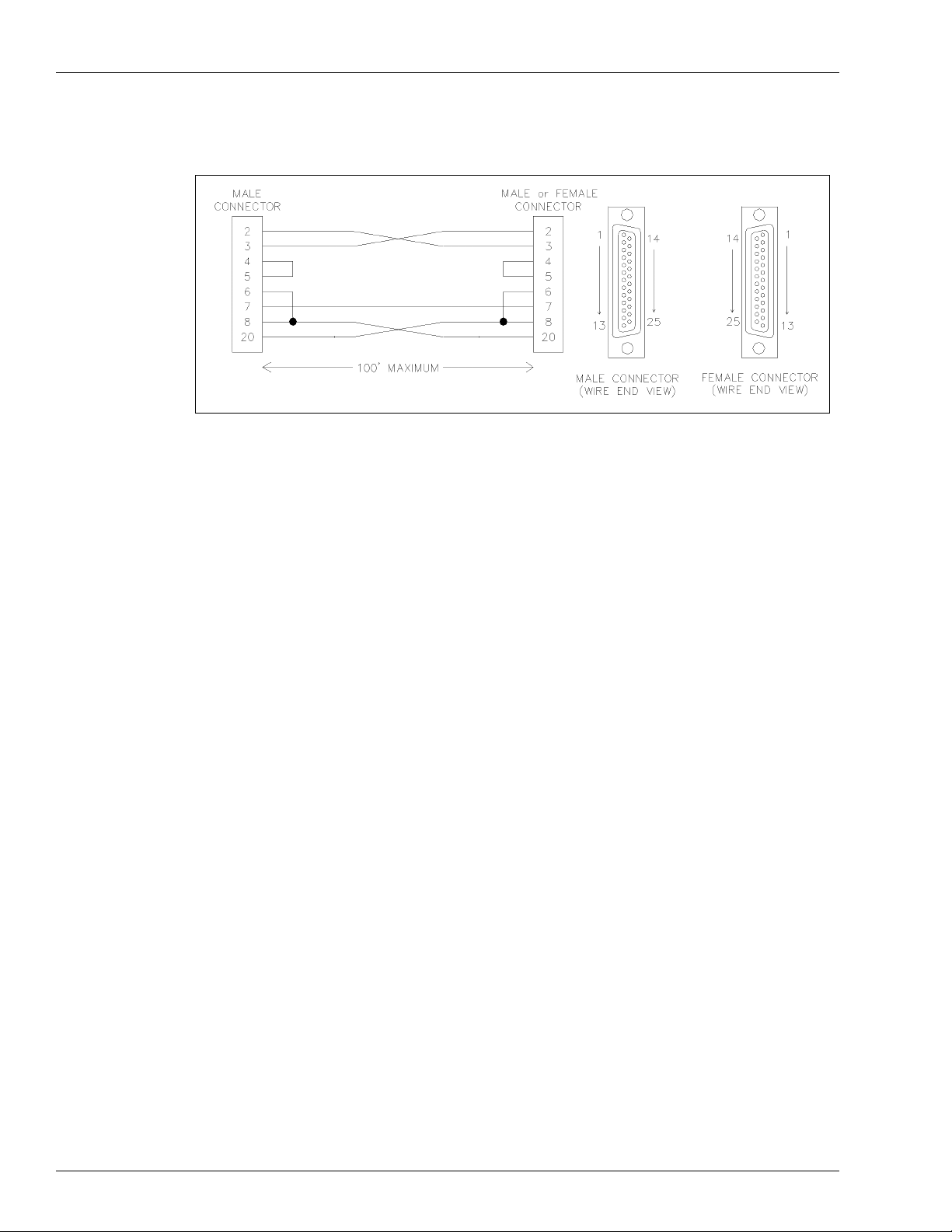

Figure 4-2: DTE Cross Cable (Part Number C05039: 8 feet M/M, Part Number C05928:

8 feet M/F)

RS-232 - Te rmination Box

A termination box can be purchased from Gasboy. Gasboy provides the installer with an easyto-wire terminal block connected to the proper pins on an RS-232D female connector. The

terminal block will accept up to 18 AWG wire.

RS-422 - SHMs

A Gasboy SHM and the appropriate interconnect cable must be used when the RS-422

communication mode is being used to communicate to the ports of the TopKAT system. It

must be used for distances between 100 and 1500 feet (31 and 455 meters). It can be used for

distances under 100 feet in place of RS-232 wiring. One SHM is required at the remote end of

the communication wiring. Refer to

diagrams.

“Port Communication Wiring” on page 28 for wiring

Page 22 MDE-4319E TopKAT™ Fuel Management System Installation Manual · August 2008

Page 29

Communication Requirements General Installation

Installation Requirements

• Internationally and domestically: All wiring is to be installed and used in accordance

with all applicable national, state and local building/fire/electrical codes. Additionally, in

the USA, installations must comply with the National Electrical Code (NFPA 70), NFPA

30, and the Automotive and Marine Service Station Code (NFPA 30A) codes and

regulations. Canadian installations must comply with the Canadian Electrical Code.

• Power: The AC power for the SHM must come from the same breaker that supplies the

peripheral device or the system (micro feed).

• Cable: A twisted-pair shielded cable is highly recommended for RS-422 wiring. Although

it is recommended that wires be run in a conduit away from AC wires, they can be

combined in the same conduit with AC wires, provided a UL-listed cable with the

following specifications is used:

- Conductor: 18 AWG stranded wire; two twisted-pairs

- Shield: Foil-wrapped 100% coverage and/or tinned copper braid 90% coverage

- Drain Wire: Stranded, tinned copper, 20 AWG or larger/or braided shield

- Voltage Rating: Maximum operating voltage of 600 V

- Environmental: Gas and oil-resistant; suitable for wet or dry locations

Gasboy can supply Belden 1063A (Part Number C09655) which is a UL-listed, 4conductor cable that meets the requirements listed above.

Note:Belden 1063A is UL-listed but not CSA-listed.

Cable with a voltage rating of less than 600 V must be installed in a separate conduit away

from all AC wires.

These modems must be connected with priv ate lines and will not work if connected into a

telephone network.

• Conduit: When you use the recommended shielded twisted-pair cable described

previously, RS-422 wires can be run with AC wires in a metal conduit. The shield drain

wire must be connected to the system AC ground. Only AC wires for the system and

pumps can be installed in the AC conduit. Do not run the cable outdoors without the use of

metal conduit. Do not run this cable overhead when outdoors.

• The cable can be run indoors without the use of a metal conduit. The shield drain wire

must be connected to the system AC ground (at one end only).

• If you use a cable other than what was recommended previously, the RS-422 field wires