Page 1

TopKAT™ Fuel Management System

Operation Manual

MDE-4338A

Page 2

Computer Programs and Documentation

Federal Communications Commission (FCC) Warning

All Gasboy computer programs (including software on diskettes and within memory chips) and documentation are copyrighted by, and shall remain the property of, Gasboy. Such

computer programs and documents may also contain trade secret information. The duplication, disclosure, modification, or unauthorized use of computer programs or

documentation is strictly prohibited, unless otherwise licensed by Gasboy.

This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy, and if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense. Changes or modifications not expressly

approved by the manufacturer could void the user’s authority to operate this equipment.

Approvals

Gasboy, Greensboro, is an ISO 9001:2000 registered facility.

Underwriters Laboratories (UL):

UL File# Products listed with UL

MH4314

MH6418

MH7404

MH10581 Key control unit, Model GKE-B Series

All dispensers and self-contained pumping

units

Power operated Transfer Pump Models 25,

25C, 26, 27, 28, 72, 72S, 72SP, 72X, 73 and

1820

Hand operated Transfer Pump Models 1230

Series, 1243 Series, 1520 and 1720 Series

Card reader terminals, Models 1000, 1000P

Site controller, Model 2000S CFN Series

Data entry terminals, Model TPK-900 Series

Fuel Point Reader System

New York City Fire Department (NYFD):

NYFD C of A # Product

4823 9100A, 9140A, 9152A, 9153A,

4997 9822A, 9823A

5046 9100Q, 9140Q, 9152Q, 9153Q,

5087 8753K, 8853K, 9153K, 9853K

5091 8752K, 9152K

5129 9122K, 9123K, 9822K, 9823K

9800A, 9840A, 9850A, 9852A,

9853A, 9140

9800Q, 9840Q, 9852Q, 9853Q

(restricted to diesel and nonretail gasoline sales)

National Conference of Weights and Measures (NCWM) - Certificate of Compliance (CoC):

Gasboy pumps and dispensers are evaluated by NCWM under the National Type Evaluation Program (NTEP). NCWM has issued the following CoC:

CoC# Product Model # CoC# Product Model # CoC# Product Model #

95-179 Dispenser

95-136 Dispenser 9800 Series 91-057 Controller

9100 Retail Series, 8700

Series, 9700 Series

91-019 Dispenser

9100 Commercial

Series

1000 Series FMS,

2000S-CFN Series

California Air Resources Board (CARB):

Executive Order # Product

G-70-52-AM Balance Vapor Recovery

G-70-150-AE VaporVac

05-002 Atlas

8700K, 8800K,

9100K, 9200K, 9800K

Patents

Gasboy products are manufactured or sold under one or more of the following US patents:

Dispensers

5,257,720

Point of Sale/Back Office Equipment

D335,673

Trademarks

Non-registered trademarks

Atlas™

Consola™

Infinity™

Registered trademarks

ASTRA

Fuel Point

Gasboy

Keytrol

Slimline

Additional US and foreign patents pending.

®

®

®

®

®

Additional US and foreign trademarks pending.

Other brand or product names shown may be

trademarks or registered trademarks of their

respective holders.

This document is subject to change without notice.

E-mail: literature@gasboy.com · Internet: http://www.gasboy.com

© 2009 GASBOY · All Rights Reserved

Page 3

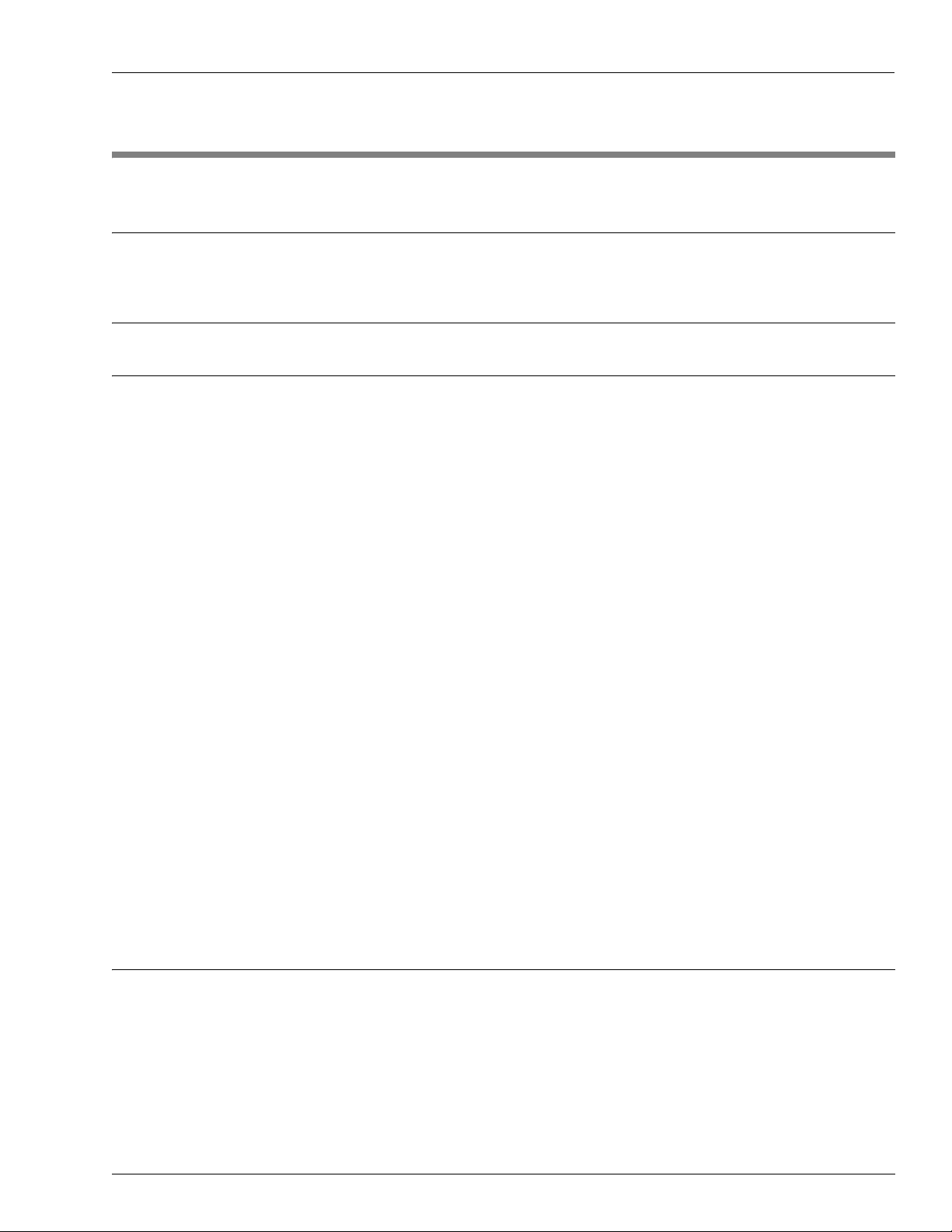

Table of Contents

1 – Introduction 1

Abbreviations and Acronyms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 – Important Safety Information 5

3 – System Overview 9

Hardware Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

CPU Printed Circuit Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

CPU PCB Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

CPU LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Battery Maintenance/Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Communications Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Communications Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Initiating Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

9800 Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Report Printer Interface Option - Standalone or Master Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Accessing the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Printer Controller PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Setting Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Adjusting Contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Loading Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

PCMCIA Interface Option - Standalone or Master Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

PCMCIA Interface PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Master/Satellite (T/Net) Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Mechanical Interface Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Mechanical PCU Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Typical Fueling Sequence - Standalone or Master/Satellite . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Delivery or Dipstick Key Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Supervisor Key Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4 – Getting Started/System Setup 25

Setting Up the System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Navigating the Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Setting Up Your System for the First Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Keypad Setup for Standalone or Master Mode . . . . . . . . . . . . . . . . . . . . 26

Keypad Setup for Satellite Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Terminal Mode Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Accessing the Main Menu Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Accessing the Setup Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

MDE-4338A TopKAT™ Fuel Management System Operation Manual · February 2009 Page i

Page 4

5 – Vehicle File Setup - Keypad 35

About the Vehicle File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Limitation Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Authorization Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Check Digit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Lockout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

PIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Vehicle Record Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Edit/View Record. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Add Vehicle Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Delete Vehicle Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Encode Key. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Initialize File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Clear File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6 – Manual Entry File Setup - Keypad 43

About the Manual Entry File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Manual Entry File Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Accessing the Manual Entry File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Edit/View Manual Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Add Manual Entry Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Delete Manual Entry Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Initialize File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Clear File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7 – Tank, Pump, and PCU File Setup - Keypad 47

About the Tank File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Access the Tank File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Load # of Tanks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Initialize File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Load Tank Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Add to Inventory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Subtract from Inventory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

About the Pump File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Access the Pump File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Initialize File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Load # of Pumps (Standalone TopKAT, Master Electronic,

Master Mechanical PCU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Load Base Pump (Standalone TopKAT and Master Electronic,

Master Mechanical PCU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Load Pump Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Load Pump Timeouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

About the PCU File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Access PCU Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

PCU Setup/PCU Assignments (Standalone, All Electronic; Master,

All Electronic; Mechanical PCUs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

PCU Assignments/Edit PCUs (Master Mechanical I/F,

Master Combination). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Page ii MDE-4338A TopKAT™ Fuel Management System Operation Manual · February 2009

Page 5

8 – Transaction File Setup - Keypad 55

About the Transaction File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Config Trans File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Move Trans Pointer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Load Trans Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Clear Trans in Prog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Clear Trans File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Record Error Trans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Config Trans Logger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Memory Full Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

9 – Modem Initialization - Keypad 59

About Modem Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

PRINT MODEM INIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

INIT MODEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

10 – Serial-to-LAN Configuration 61

11 – Wireless Communications Configuration 63

12 – Reports 65

About Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Printing Reports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Accessing the Report Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Print Date/Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Print System Configuration (PRINT SYS CONFIG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Department/Vehicle Report (DEPT/VEHICLE RPT) or

Account Vehicle Report (ACCT/VEHICLE RPT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Inventory Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Pump Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Vehicle File Report (VEH FILE REPORT). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Vehicle Lockout Report (VEH LOCKOUT REPORT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Manual Entry Lockout Report (MAN LOCKOUT REPORT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Department Manual Entry Report (DEPT MAN ENT RPT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Manual Entry Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Events Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

13 – Diagnostics and Utilities 71

About Diagnostics and Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Accessing the Keypad Diagnostics Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Keypad Diagnostics Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Keypad: PCU STATUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Keypad: RAM TEST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Keypad: ROM TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Keypad: DIP SWITCH TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Keypad: KEYPAD TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Keypad: DISPLAY TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Keypad: KEY READ TOTALIZER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Keypad: PROGRAM VERSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Keypad: PORT TEST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

MDE-4338A TopKAT™ Fuel Management System Operation Manual · February 2009 Page iii

Page 6

Keypad: DATAKEY READ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Keypad: PCMCIA TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Accessing the Utilities Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

PCMCIA Backup/Restore Utility (optional) . . . . . . . . . . . . . . . . . . . . . . . 76

Accessing the Terminal Diagnostics Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Terminal: RAM TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Terminal: ROM TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Terminal: DIP SWITCH TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Terminal: HEALTH LIGHT TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Terminal: BEEPER TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Terminal: DISPLAY TEST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Terminal: KEYPAD TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Terminal: DATAKEY TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Terminal: PORT TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Terminal: DEADMAN TIMER RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Terminal: PCMCIA TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Terminal: PRINTER TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

14 – Terminal Commands 87

About Terminal Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Accessing the Terminal Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Add Inventory (A I) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Add RECord (A REC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

CLear File (CL F) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

CLear Key (CL K) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

CLear Transaction In Progress (CL TIP). . . . . . . . . . . . . . . . . . . . . . . . . 90

COnfigure Bulk (CO B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

COnfigure LOGger (CO LOG). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

COnfigure MAnual (CO MA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

COnfigure PCUs (CO PC) - Standalone Electronic;

Master/Satellite Electronic; Mechanical PCUs . . . . . . . . . . . . . . . . . . . . 92

COnfigure PCus (CO PC) - Master/Satellite Mechanical;

Master/Satellite Combination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

COnfigure PIn (CO PI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

COnfigure SYstem (CO SY) - Standalone Electronic or

Mechanical PCU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

COnfigure SYstem (CO SY) - Standalone Mechanical . . . . . . . . . . . . . . 95

COnfigure SYstem (CO SY) - Master/Satellite Mechanical;

Master/Satellite Combination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

COnfigure SYstem (CO SY) - Master/Satellite Electronic or

Mechanical PCU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

COnfigure Units (CO U) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

DElete RECord (DE REC). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

DIAGnostics (DIAG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

DISable PUmp (DIS PU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

EDit RECord (ED REC). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

ENable PRotection (EN PR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

ENable PUmp (EN PU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

EXit (EX) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Help (H). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

INitialize File (I F) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Initialize MODem (I MOD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Load DAte (L DA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

LOad MODem (LO MOD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Page iv MDE-4338A TopKAT™ Fuel Management System Operation Manual · February 2009

Page 7

Load MOre (L MO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Load PAssword (L PA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Load PUmp (L PU). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Load RAnge (L RA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Load RETry (L RET) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Load TAnk (L TA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Load TIMe (L TIM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Load TRansactions (L TR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Move POinter (M PO). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

PRint DAte (PR DA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

PRint DEPTMan (PR DEPTM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

PRint DEPTVeh (PR DEPTV) or PRint Acctveh (PR A) . . . . . . . . . . . . 106

PRint EVents (PR EV) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

PRint KEy (PR KE). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106

PRint LOCkout (PR LOC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

PRint MAnual (PR MA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

Print MODem (P MOD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

PRint PUmp (PR PU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

PRint SYstem (PR SY). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

PRint TAnks (PR TA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

PRint TRansaction (PR TR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

PRint Vehicle (PR V) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

REcord ERror (RE ER) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

RUN (RUN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

SElect Name (SE N) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

STOP (STOP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

SUbtract Inventory (SU I) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Appendix A: HELP Command A-1

Appendix B: Menu Flow Chart B-1

Appendix C: Display Messages C-1

Appendix D: Transaction Error Codes D-1

Appendix E: Loading TopKAT Files from Microsoft® Excel® E-1

Creating Your TopKAT Vehicle Records in Excel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

Sequential Numbering Hint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-3

Transferring Vehicle Records from Excel to TopKAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-4

Reasons for Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-6

Creating Your TopKAT Manual Entry Records in Excel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-7

Transferring Manual Entry Records from Excel to TopKAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-8

Index Index-1

MDE-4338A TopKAT™ Fuel Management System Operation Manual · February 2009 Page v

Page 8

This page is intentionally left blank.

Page vi MDE-4338A TopKAT™ Fuel Management System Operation Manual · February 2009

Page 9

1 – Introduction

The Gasboy TopKAT is a microprocessor-based fuel control and data acquisition system,

mounted on top of a 9800 pump/dispenser or on a pedestal with the 9820 ASTRA

mechanical pump/dispenser, that is designed to gather and record specific information about

your fuel management operation as well as provide unattended access to your fuel site.

Figure 1-1: Typical TopKAT Installation

Introduction

®

or

Access to the system is controlled by vehicle code keypad entry (also called keyless entry) or

by special data keys that relate to vehicle file records maintained on the system. There are six

possible key types available:

• Vehicle: Key type 0. Linked to the vehicle that will be fueling and the department to

which it belongs. This is the most common key for accessing fuel.

• Supervisor: Key type 3. Provides access for fueling by a supervisor manually entering a

key number or a vehicle number and department number.

• Manager: Key type 8. Provides access to system configuration and setup functions,

utilities and diagnostics, and reports.

• Report*: Key type 9. Provides access to report printing capabilities, while restricting

access to other manager functions.

• Dipstick*: Key type 5. Allows dipstick readings to be entered at the TopKAT keypad.

• Delivery*: Key type 4. Allows delivery transactions to be entered at the TopKAT keypad.

* Available for use at standalone TopKAT or TopKAT master unit.

MDE-4338A TopKAT™ Fuel Management System Operation Manual · February 2009 Page 1

Page 10

Introduction Abbreviations and Acronyms

There are six possible system configurations for the TopKAT:

• Standalone electronic: one TopKAT up to eight electronic hoses

• Standalone mechanical: one TopKAT, one or two mechanical hoses

• Standalone or master/satellite controlling up to eight mechanical hoses (four hoses per

PCU, up to two PCUs). This option is referred to as Mechanical PCU in this manual.

• Master/Satellite, all electronic: Up to eight electronic hoses; one TopKAT acts as the

master and controls all hoses. It also allows up to seven satellite readers which can access

all pumps.

• Master/Satellite, all mechanical, up to 16 hoses; (two hoses per TopKAT)

• Master Satellite, one 9820 or 9800 single or twin, electronic controlled by the master. Up

to 14 mechanical hoses (two hoses per TopKAT) controlled by the satellites.

Abbreviations and Acronyms

Term Description

&F load a read-only factory configuration (a modem command to not be used)

&V display current configuration (a modem command to not be used)

AC Alternating Current

ARP Address Resolution Protocol

ASC Authorized Service Contractor

ASCII American Standard Code for Information Interchange

ATR go off hook (a modem command to not be used)

C

CD Carrier Detect

COMM Communications

CPU Central Processing Unit

CRC Cyclical Redundancy Check (as in CRC1 or CRC2)

CRT Cathode Ray Tube

DC Direct Current

DD (or dd) Day of month (01 - 31)

DIP Dual Inline Package

E1 modem displays keyboard commands (a modem command to not be used)

EIA Electronic Industries Alliance (formerly Electronic Industries Association)

EPROM Erasable Programmable Read-Only Memory

F

HPG Hours Per Gallon

HPL Hours Per Liter

I/F Interface

ID Identification

IEEE Institute of Electrical & Electronics Engineers

IP Internet Protocol

K Kilo or One Thousand (as in 64K, 128K, or 256K)

KM/L Kilometers Per Liter

Celsius (as in 0°C)

Fahrenheit (as in 32°F)

Page 2 MDE-4338A TopKAT™ Fuel Management System Operation Manual · February 2009

Page 11

Abbreviations and Acronyms Introduction

Term Description

L/100KM Liters Per 100 Kilometers

LAN Local Area Network

LCD Liquid Crystal Display

LED Light Emitting Diode

LPH Liters Per Hour

MAC Machine Address Code (also known as Hardware or Ethernet address)

MM (or mm) Month (01 - 12)

Modem Modulator-Demodulator

MPG Miles Per Gallon

N/A Non Applicable

P/N Part Number

PBX Private Branch Exchange

PC Personal Computer

PCB Printed Circuit Board

PCMCIA Peripheral Component Micro Channel Interconnect Architecture

PCU Pump Control Unit

PIN Personal Identification Number

POS Point Of Sale

Q0 displays result codes (a modem command)

Q1 quiet mode, no result codes display (a modem command)

QTY Quantity

RAM Random Access Memory

RDY Ready

ROM Read-Only Memory

RS Recommended Standard of IEEE (as in RS-232 or RS-422)

SNMP Simple Network Management Protocol

SRAM Static Random Access Memory

SW Switch

T/Net TopKAT Network

TCP Transmission Control Protocol

TFTP Trivial File Transfer Protocol

TP Test Point (as in TP1, TP2, and so on)

TPI Transport Service Programmers Interface

TTY Teletypewriter

V Version (as in V1.0, V1.1, or V2.0)

Volt or Volts (as in 5V DC)

VEH Vehicle

VPP (or Vpp) programable power supply

VR Variable Resistor

WP Write Protect

YY (or yy) Year, last two digits (00 - 99)

MDE-4338A TopKAT™ Fuel Management System Operation Manual · February 2009 Page 3

Page 12

Introduction Warranty

Warranty

For information on warranty, refer to MDE-4255 Gasboy’s Warranty Policy Statement. If you

have any warranty-related questions, contact Gasboy’s Warranty Department at its

Greensboro location.

Page 4 MDE-4338A TopKAT™ Fuel Management System Operation Manual · February 2009

Page 13

2 – Important Safety Information

Important Safety Information

This section introduces the hazards and safety precautions

associated with installing, inspecting, maintaining or servicing

this product. Before performing any task on this product, read

this safety information and the applicable sections in this

manual, where additional hazards and safety precautions for

your task will be found. Fire, explosion, electrical shock or

pressure release could occur and cause death or serious

injury, if these safe service procedures are not followed.

Preliminary Precautions

You are working in a potentially dangerous environment of

flammable fuels, vapors, and high voltage or pressures. Only

trained or authorized individuals knowledgeable in the related

procedures should install, inspect, maintain or service this

equipment.

Emergency Total Electrical Shut-Off

The first and most important information you must know is

how to stop all fuel flow to the pump/dispenser and island.

Locate the switch or circuit breakers that shut off all power to

all fueling equipment, dispensing devices, and Submerged

Turbine Pumps (STPs).

!

WARNING

!

The EMERGENCY STOP, ALL STOP, and

PUMP STOP buttons at the cashier’s station

WILL NOT shut off electrical power to the pump/

dispenser. This means that even if you activate

these stops, fuel may continue to flow

uncontrolled.

Read the Manual

Read, understand and follow this manual and any other

labels or related materials supplied with this equipment. If you

do not understand a procedure, call a Gasboy Authorized

Service Contractor or call the Gasboy Service Center at 1800-444-5529. It is imperative to your safety and the safety of

others to understand the procedures before beginning work.

Follow the Regulations

Applicable information is available in National Fire Protection

Association (NFPA) 30A; Code for Motor Fuel Dispensing

Facilities and Repair Garages, NFPA 70; National Electrical

Code (NEC), Occupational Safety and Hazard Association

(OSHA) regulations and federal, state, and local codes. All

these regulations must be followed. Failure to install, inspect,

maintain or service this equipment in accordance with these

codes, regulations and standards may lead to legal citations

with penalties or affect the safe use and operation of the

equipment.

Replacement Parts

Use only genuine Gasboy replacement parts and retrofit kits

on your pump/dispenser. Using parts other than genuine

Gasboy replacement parts could create a safety hazard and

violate local regulations.

Safety Symbols and Warning Words

This section provides important information about warning

symbols and boxes.

Alert Symbol

You must use the TOTAL ELECTRICAL SHUTOFF in the case of an emergency and not the

console’s ALL STOP and PUMP STOP or

similar keys.

Total Electrical Shut-Off Before Access

Any procedure that requires access to electrical components

or the electronics of the dispenser requires total electrical

shut off of that unit. Understand the function and location of

this switch or circuit breaker before inspecting, installing,

maintaining, or servicing Gasboy equipment.

Evacuating, Barricading and Shutting Off

Any procedure that requires access to the pump/dispenser or

STPs requires the following actions:

• An evacuation of all unauthorized persons and vehicles

from the work area

• Use of safety tape, cones or barricades at the affected

unit (s)

• A total electrical shut-off of the affected unit (s)

This safety alert symbol is used in this manual and

on warning labels to alert you to a precaution which must be

followed to prevent potential personal safety hazards. Obey

safety directives that follow this symbol to avoid possible

injury or death.

Signal Words

These signal words used in this manual and on warning

labels tell you the seriousness of particular safety hazards.

The precautions below must be followed to prevent death,

injury or damage to the equipment:

DANGER: Alerts you to a hazard or unsafe practice

!

which will result in death or serious injury.

WARNING: Alerts you to a hazard or unsafe practice

!

that could result in death or serious injury.

CAUTION with Alert symbol: Designates a hazard or

!

unsafe practice which may result in minor injury.

CAUTION without Alert symbol: Designates a hazard

or unsafe practice which may result in property or

equipment damage

Working With Fuels and Electrical Energy

Prevent Explosions and Fires

Fuels and their vapors will explode or burn, if ignited. Spilled

or leaking fuels cause vapors. Even filling customer tanks will

cause potentially dangerous vapors in the vicinity of the

dispenser or island.

MDE-4338A TopKAT™ Fuel Management System Operation Manual · February 2009 Page 5

Page 14

Important Safety Information

No Open Fire

Open flames from matches, lighters, welding torches

or other sources can ignite fuels and their vapors.

No Sparks - No Smoking

Sparks from starting vehicles, starting or using power tools,

burning cigarettes, cigars or pipes can also ignite fuels and

their vapors. Static electricity, including an electrostatic

charge on your body, can cause a spark sufficient to ignite

fuel vapors. Every time you get out of a vehicle, touch the

metal of your vehicle, to discharge any electrostatic charge

before you approach the dispenser island.

Working Alone

It is highly recommended that someone who is capable of

rendering first aid be present during servicing. Familiarize

yourself with Cardiopulmonary Resuscitation (CPR) methods,

if you work with or around high voltages. This information is

available from the American Red Cross. Always advise the

station personnel about where you will be working, and

caution them not to activate power while you are working on

the equipment. Use the OSHA Lockout/ Tagout procedures. If

you are not familiar with this requirement, refer to this

information in the service manual and OSHA documentation.

Working With Electricity Safely

Ensure that you use safe and established practices in working

with electrical devices. Poorly wired devices may cause a fire,

explosion or electrical shock. Ensure that grounding

connections are properly made. Take care that sealing

devices and compounds are in place. Ensure that you do not

pinch wires when replacing covers. Follow OSHA Lockout/

Tagout requirements. Station employees and service

contractors need to understand and comply with this program

completely to ensure safety while the equipment is down.

In an Emergency

Inform Emergency Personnel

Compile the following information and inform emergency

personnel:

• Location of accident (for example, address, front/back of

building, and so on)

• Nature of accident (for example, possible heart attack, run

over by car, burns, and so on)

• Age of victim (for example, baby, teenager, middle-age,

elderly)

• Whether or not victim has received first aid (for example,

stopped bleeding by pressure, and so on)

• Whether or not a victim has vomited (for example, if

swallowed or inhaled something, and so on)

WARNING

!

Gasoline ingested may cause unconsciousness

and burns to internal organs.

Do not induce vomiting.

Keep airway open.

Oxygen may be needed at scene.

Seek medical advice immediately.

WARNING

!

Gasoline inhaled may cause unconsciousness

and burns to lips, mouth and lungs.

Keep airway open.

Seek medical advice immediately.

WARNING

!

Gasoline spilled in eyes may cause burns to eye

tissue.

Irrigate eyes with water for approximately 15

minutes.

Seek medical advice immediately.

WARNING

Hazardous Materials

Some materials present inside electronic enclosures may

present a health hazard if not handled correctly. Ensure that

you clean hands after handling equipment. Do not place any

!

Gasoline spilled on skin may cause burns.

Wash area thoroughly with clear water.

Seek medical advice immediately.

equipment in the mouth.

!

WARNING

The pump/dispenser contains a chemical known to the

State of California to cause cancer.

IMPORTANT: Oxygen may be needed at scene if gasoline

has been ingested or inhaled. Seek medical advice

immediately.

Lockout/Tagout

Lockout/Tagout covers servicing and maintenance of

WARNING

!

machines and equipment in which the unexpected

energization or start-up of the machine(s) or equipment or

The pump/dispenser contains a chemical known to the

State of California to cause birth defects or other

reproductive harm.

release of stored energy could cause injury to employees or

personnel. Lockout/Tagout applies to all mechanical,

hydraulic, chemical or other energy, but does not cover

electrical hazards. Subpart S of 29 CFR Part 1910 - Electrical

Hazards, 29 CFR Part 1910.333 contains specific Lockout/

Tagout provision for electrical hazards.

Page 6 MDE-4338A TopKAT™ Fuel Management System Operation Manual · February 2009

Page 15

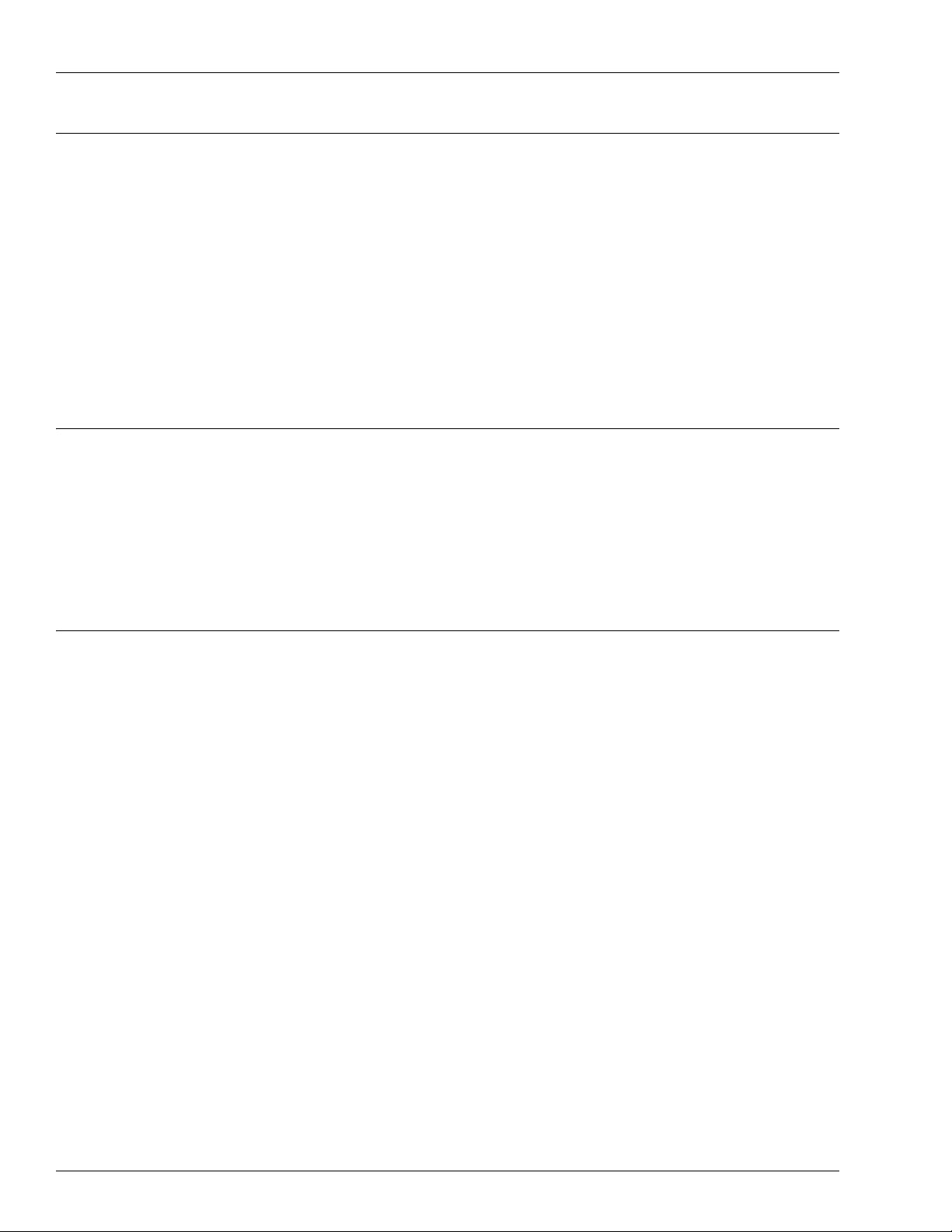

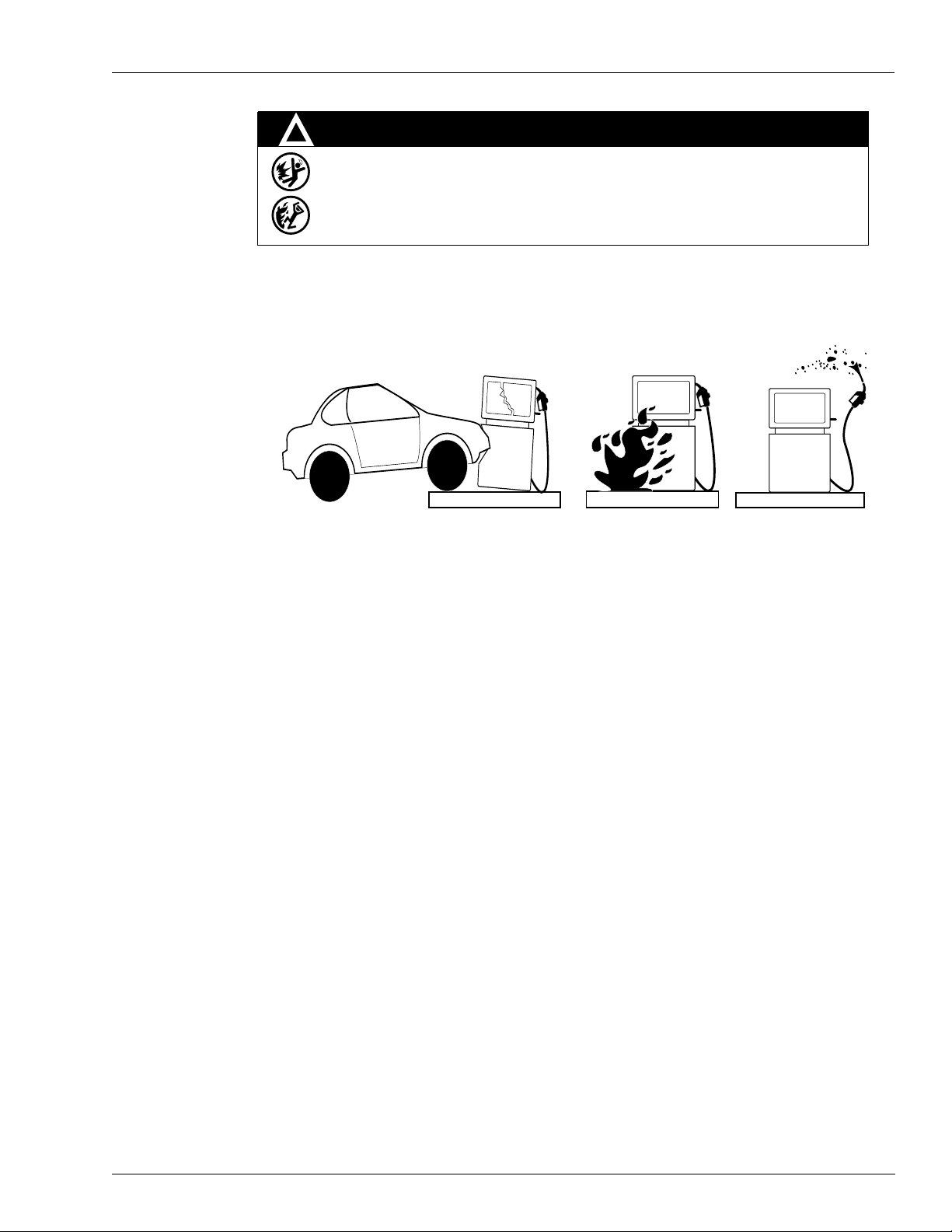

Hazards and Actions

Important Safety Information

!

WARNING

Spilled fuels, accidents involving pumps/dispensers, or uncontrolled fuel flow create a

serious hazard.

Fire or explosion may result, causing serious injury or death.

Follow established emergency procedures.

The following actions are recommended regarding these hazards:

Collision of a Vehicle with Unit Fire at Island Fuel Spill

• Do not go near a fuel spill or allow anyone else in the area.

• Use station EMERGENCY CUTOFF immediately. Turn off all system circuit breakers to the

island(s).

• Do not use console E-STOP, ALL STOP and PUMP STOP to shut off power. These keys do not

remove AC power and do not always stop product flow.

• Take precautions to avoid igniting fuel. Do not allow starting of vehicles in the area. Do not allow

open flames, smoking or power tools in the area.

• Do not expose yourself to hazardous conditions such as fire, spilled fuel or exposed wiring.

• Call emergency numbers.

MDE-4338A TopKAT™ Fuel Management System Operation Manual · February 2009 Page 7

Page 16

Important Safety Information

This page is intentionally left blank.

Page 8 MDE-4338A TopKAT™ Fuel Management System Operation Manual · February 2009

Page 17

Hardware Description System Overview

3 – System Overview

Hardware Description

The TopKAT is totally self-contained in a rugged, well-designed, and attractive weatherized

cabinet. The front bezel and rear of the cabinet are hinged doors secured with locks to prohibit

unauthorized access. The front bezel allows access to the optional report printer and paper.

When installing, be sure to provide adequate clearance to allow easy access to both front and

rear doors for servicing.

The wiring for all equipment connected to the TopKAT is terminated in the head. A

standalone TopKAT can control up to eight electronic hoses or two mechanical hoses. If you

have the master/satellite option, you can control up to eight electronic hoses and seven satellite

readers or up to 16 mechanical (two hoses per TopKAT), or one 9820 or 9800 single or twin

electronic and up to 14 mechanical hoses (two hoses per TopKAT). A standalone or master/

satellite with the mechanical PCU option can control up to eight mechanical hoses (four hoses

per PCU, up to two PCUs). The system can handle quantity pulsing rates of 1000 pulses per

unit of product.

The unit is equipped with a data key receptacle. Visual prompting messages, displayed on the

two-line Liquid Crystal Display (LCD), guide the user through the steps required to activate

the pump/remote dispenser, as well as configure the system. The display is backlit so that it

can be read at night. A 16-position non-tactile keypad is provided on the face of the unit for

entering data such as Personal Identification Number (PIN), odometer reading, pump

selection, and so on. A beeper indicates when a key is pressed.

Power: AC power for the TopKAT comes from the same power connection used to power the

9800 Micro Feed. No customer connections are required between the 9800 and TopKAT.

Connections to the 9820 are made as detailed in MDE-4319 TopKAT Fuel Management

System Installation Manual.

Operating Environment: The unit has been designed to withstand an environment of -22

°

F (-30°C to 50°C), 95% relative humidity, non-condensing.

122

Location: The TopKAT is located on the fueling island. Adequate clearance around the head

of the unit is important to provide room for maintenance of the system. A minimum of 14

inches of clearance from the rear of the unit must be provided to allow the rear door to open.

°

F to

MDE-4338A TopKAT™ Fuel Management System Operation Manual · February 2009 Page 9

Page 18

System Overview CPU Printed Circuit Board

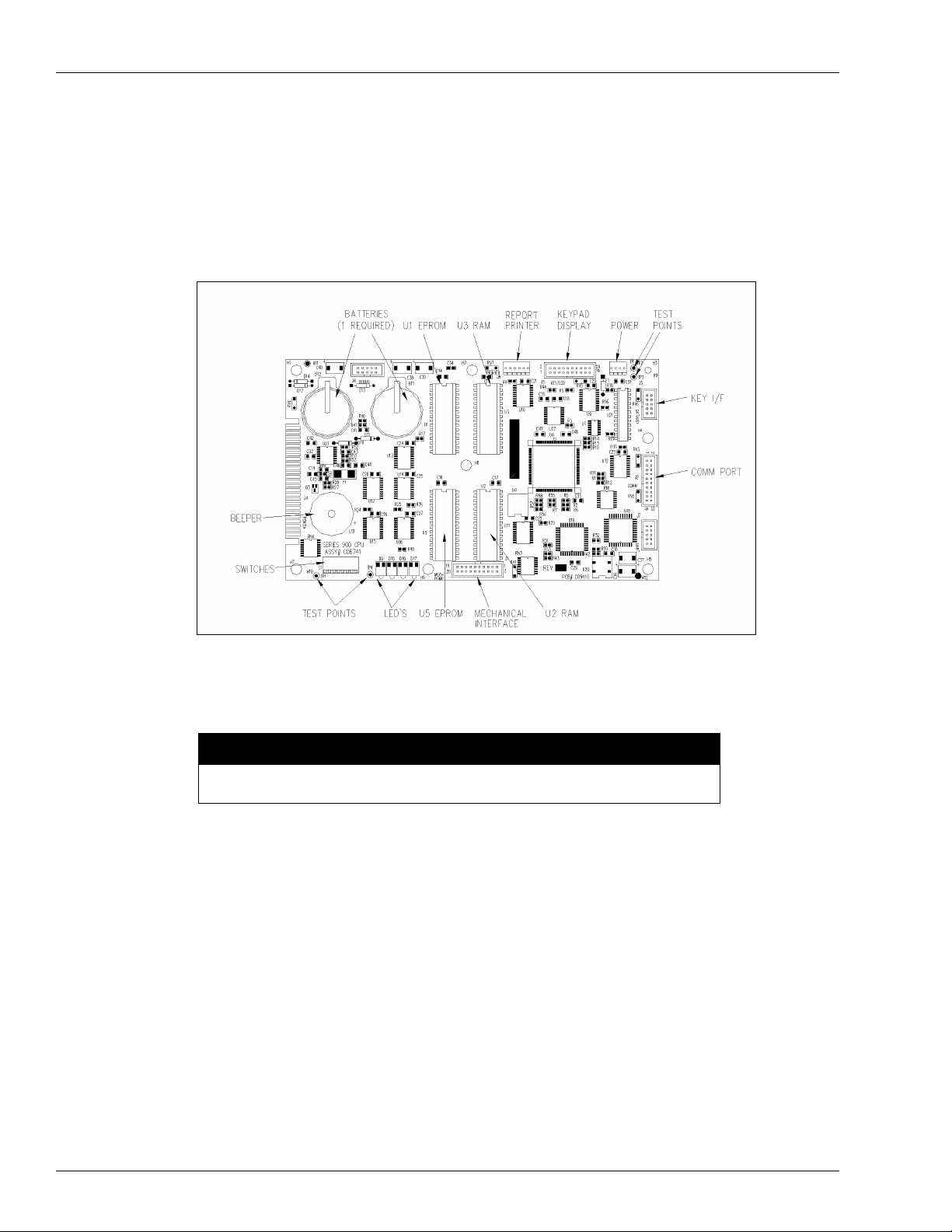

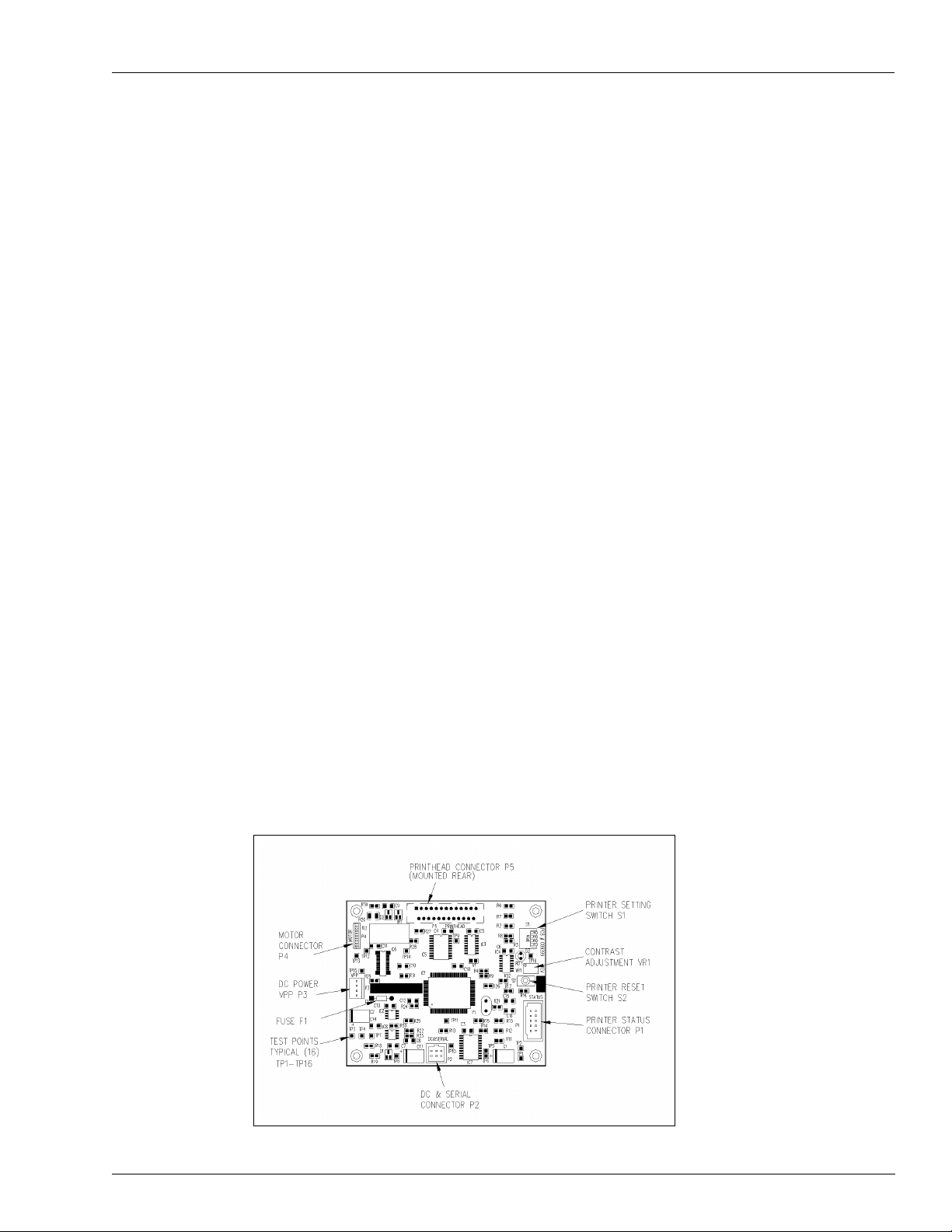

CPU Printed Circuit Board

The Central Processing Unit (CPU) Printed Circuit Board (PCB) and its relevant components

are shown in Figure 3-1.

Figure 3-1: CPU PCB Components

CPU PCB Switch Settings

CAUTION

All switch settings, except SW1-1 should be changed with the system power OFF.

• Switch settings SW1-3 through SW1-8 are read once by the CPU PCB directly after power

is turned on.

• SW1-1 is read by the CPU periodically during normal operation.

• When setting switches, open=up; closed=down.

Page 10 MDE-4338A TopKAT™ Fuel Management System Operation Manual · February 2009

Page 19

CPU Printed Circuit Board System Overview

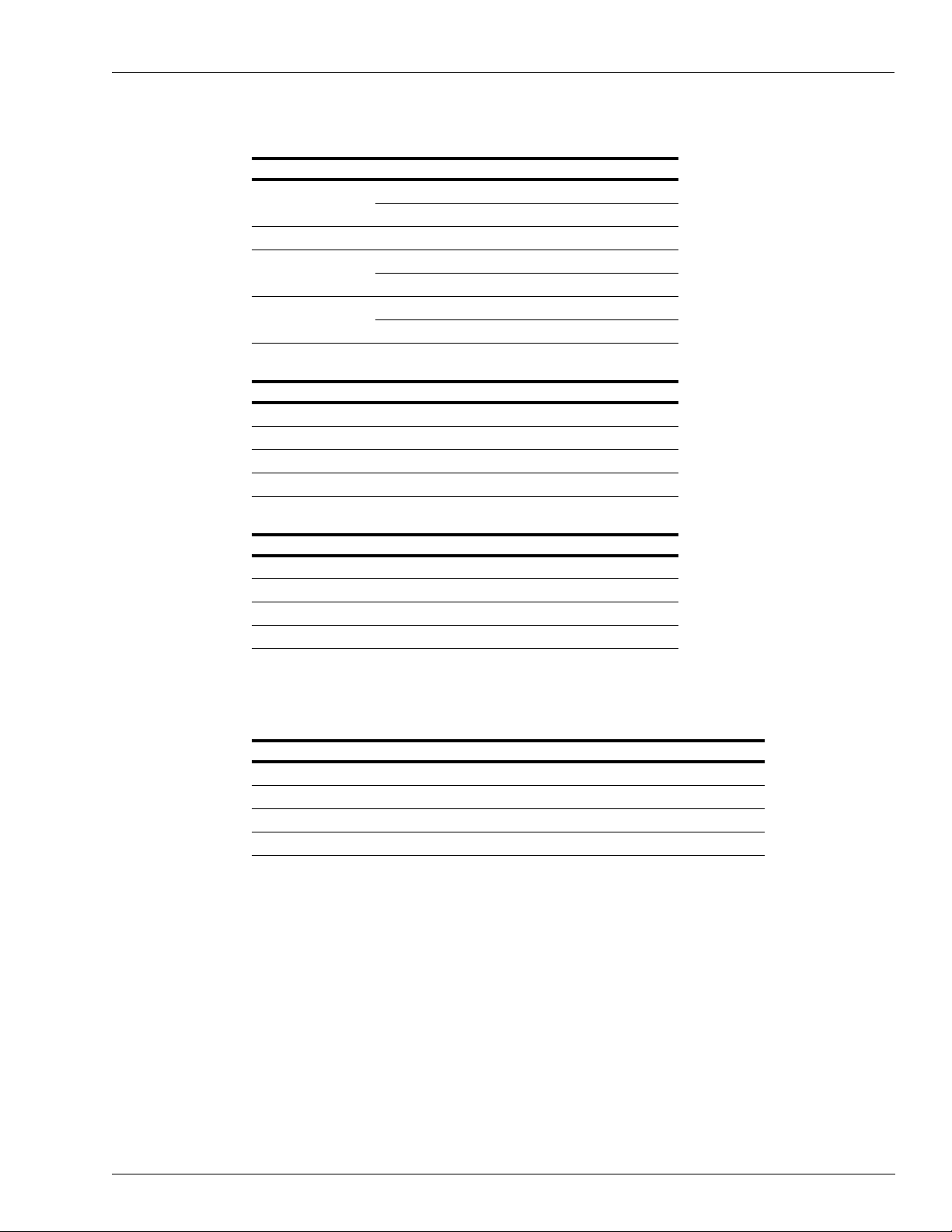

The CPU PCB switches should be set as follows:

Switch Function Setting

SW1-1 Manager Mode Open

Normal Operation Closed

SW1-2 Not used

SW1-3 Report Printer Enabled Open

Report Printer Disabled Closed

SW1-4 Internal Modem Enabled Open

Internal Modem Disabled Closed

Port 2 Baud Rate SW1-5 SW1-6

300 Closed Closed

1200 Closed Open

2400 Open Closed

9600 Open Open

CPU LEDs

Port 3 Baud Rate SW1-7 SW1-8

300 Closed Closed

1200 Closed Open

2400 Open Closed

9600 Open Open

The purpose of the CPU LEDs (left to right) is as follows:

LED Color Indicates

D9 Yellow System Health: should flash approximately 2 times per second

D15 Green Power On

D16 Amber Battery Low

D17 Red CPU PCB Reset Active

MDE-4338A TopKAT™ Fuel Management System Operation Manual · February 2009 Page 11

Page 20

System Overview Communications

Battery Maintenance/Replacement

Check Battery Low LED periodically. If lit, replace the battery using the following procedure.

CAUTION

Do not turn off system power! This could cause irrevocable loss of data.

1 Insert a new battery, C09415, into the empty battery receptacle on the CPU PCB.

2 Remove the old battery from its battery receptacle. Battery Low (Amber) LED should go out.

Communications

Communications Ports

The TopKAT contains three asynchronous ports:

• Port 1 is used for communications to the 9800, mechanical PCU, and satellites via RS-485

lines.

• Ports 2 and 3 can be set for either RS-232 or RS-422 communications to a data terminal or

computer. If used with the 9800, wiring restrictions dictate that only one of these two ports

can be used for terminal/computer communication, unless Port 3 is connected to an

internal modem. The 9820 ASTRA and the mechanical PCU option have no wiring

restrictions.

MDE-4340/MDE-4341 Series 9800 Q/A Installation/Operation Manual, MDE-4319 TopKAT

Installation Manual, MDE-4331 Atlas

Enhanced Communications Installation Manual contain detailed communication requirements

for port wiring and exceptions. Communication is through direct wire, by dial-up phone lines

using an optional internal modem, by serial-to-LAN connection, or wireless communications.

Communications Protocol

Devices that communicate with the TopKAT must be able to transmit and receive full duplex,

ASCII asynchronous data via an EIA RS-232 connection.

The TopKAT supports both a simple and a structured computer protocol. With the simple

terminal protocol, no special characters are transmitted to designate the beginning or end of

data blocks. Data is transmitted in serial bit format per character as follows: one start bit, eight

data bits, one stop bit. Each character is echoed back to the transmitting device. This checks

the integrity and enables the CRT operators to display transmitted data.

The structured computer protocol is covered in a separate manual, C35965 TopKAT Host

Communications Manual.

™

Fuel Systems Installation Manual, and MDE-4520

Page 12 MDE-4338A TopKAT™ Fuel Management System Operation Manual · February 2009

Page 21

Communications System Overview

Initiating Communications

You can communicate with the TopKAT by one of the following methods:

• Via the LCD menu system using SW1-1 Manager Mode switch

• Via the LCD menu system using the Manager’s key

• Via terminal commands using a data terminal or PC

During initial power-up, you must use the Manager Mode switch which is located on the CPU

Board. Setting DIP switch (SW1-1) to the Open position places the system in Manager mode

and activates the LCD Menu System. The system displays COMMAND: SETUP.

You can access the LCD menu system using the Manager key any time after the System ID,

Password, and Vehicle Record for the Manager Key are entered into the Database.

You can access the TopKAT command mode via a data terminal or PC for the first time by

setting the Manager Mode switch (SW1-1) to OPEN and entering terminal commands (no

password is required). Later, when the switch is in its normally closed position, you can access

the commands by entering the correct password at the SIGN ON: prompt then entering

terminal commands. This ensures system security.

Operating Modes

There are two modes of operation, direct printout mode and command mode. In direct printout

mode, the TopKAT displays transactions and system events on the data terminal (or logger) as

they occur.

Note: The Configure Logger command (CO LOG) must be set to enabled for this to occur.

In command mode, you enter terminal commands to input data, change data, or print reports

on the system. When you are in command mode, transactions do not print as they occur,

instead they are stored in memory and printed when the system returns to direct printout mode.

Note: When you sign on in command mode, the system automatically signs off after 5 minutes

of keyboard inactivity and returns the system to direct printout mode.

9800 Switch Settings

The table below contains the proper switch /jumper settings for the 9800 CPU PCB for

operation with the TopKAT. Refer to MDE-4334 Atlas

additional information on setting 9800 switches/jumpers.

Switch SW1/Jumper Function Setting

Old CPU

SW1-1 JP1 9600 Baud Open

SW1-2 JP2 On-Line Mode Open

SW1-3/SW1-4 JP3/JP4 Delay Time Setting

SW1-5 JP5 Not used N/A

SW1-6 JP6 No Authorization Open

SW1-7 JP7 Reset Totalizers Closed

New CPU

(M06333KXXXX)

™

Start-up/Service Manual for

0 seconds Closed/Closed

4 seconds Closed/Open

5 seconds Open/Closed

6 seconds Open/Open

Normal Open

MDE-4338A TopKAT™ Fuel Management System Operation Manual · February 2009 Page 13

Page 22

System Overview Communications

Switch SW1/Jumper Function Setting

New CPU

Old CPU

SW1-8 JP8 RS-485 Pump Stop Detection

N/A JP9 Not used N/A

(M06333KXXXX)

Closed

Disabled

JP3 and JP4 set the delay time used by leak detectors in submersible pump applications. The

delay time is the period between activation of the submersible pump and activation of the slow

flow valve. Set this time according to the type of leak detector installed on the submersible

pump to allow a normal leak test for each transaction. The delay time should be set to 0

seconds for suction pumps.

JP7 should be open for normal operation. When closed, this switch enables the reset of

electronic totalizers.

JP8 is available only with 9800 software, version 5.3 or higher. Switch 1-8 is set to Closed to

disable RS485 pump stop detection. This is necessary because the TopKAT operates in a halfduplex configuration and it is possible for the 98xx to detect a false break character when the

half duplex lines switch from receive mode to transmit mode and vice-versa. These random

false break characters will cause the 98xx to terminate the transaction.

SW2-1 through SW2-4

(Only on M06333KXXXX CPU)

Function Setting

Address 1 All Closed

SW2-5 and SW2-6 - Unit of Measure Selection

(Only on M06333KXXXX CPU)

These two switches set the unit of measure (US gallons, liters, or Imperial gallons) that the

pump/dispenser will be using to meter fuel.

Unit of Measure SW2-5 SW2-6

US Gallons Closed Closed

Liters Open Closed

Imperial Gallons Closed Open

NOT USED (default US Gallons) Open Open

SW2-7 - Electro-mechanical Totalizer Enable

(Only on M06333KXXXX CPU)

This switch is only used on K model dispensers/pumps (excluding the 9850K model). When

closed (“On”), it enables the pump/dispenser to drive electro-mechanical totalizers used on

some K pump models. On A and Q models, this switch is ignored.

EM Totalizer SW2-7

Enabled Closed

Disabled Open

Page 14 MDE-4338A TopKAT™ Fuel Management System Operation Manual · February 2009

Page 23

Report Printer Interface Option - Standalone or Master Only System Overview

SW2-8 - Background Debug Module (BDM) Enable

(Only on M06333KXXXX CPU)

This switch must be OPEN for normal operation.

SW2-9 - Software Load Enable

(Only on M06333KXXXX CPU)

This switch must be OPEN for normal operation. When this switch is closed, it enables

loading the new M06333KXXXX CPU software.

SW2-10

(Only on M06333KXXXX CPU)

This switch is not used. Set to the Open position.

Report Printer Interface Option - Standalone or Master Only

A report printer interface is available as an option for the TopKAT. TopKAT is equipped with

a report printer have a printer controller board and a print mechanism mounted in the lower

right-hand side of the bezel. Printer output exits the base of the bezel through a weatherprotection printer door. This door should remain closed except while printing reports. The

system prompts you to open the printer door before printing reports. The report printer option

is available only at a standalone or master TopKAT unit.

Accessing the Printer

To access the printer, insert the key into the key slot located at the right-hand side of the bezel.

Turn it clockwise, then pull outward to open the bezel.

Printer Controller PCB

Figure 3-2: Printer Controller PCB Components

MDE-4338A TopKAT™ Fuel Management System Operation Manual · February 2009 Page 15

Page 24

System Overview Report Printer Interface Option - Standalone or Master Only

Setting Switches

Setting switches on the Printer Controller PCB can be done with the power ON. When the

required switch settings are made, press S2 Reset on the Printer Controller PCB and the

system will read the new settings. The RDY light on the Printer Controller PCB indicates that

the printer is online and ready to print. If the printer does not print, press Reset and verify that

the RDY light comes on.

Your switches should be set properly at the factory; however, you can verify their settings as

follows:

Switch SW1 Function Setting

SW1-1 Not used N/A

SW1-2 Paper Thickness: 1-ply Open (factory setting)

Paper Thickness: 2-ply Closed

SW1-3, SW1-4 Head Rank: A Open, Open

Head Rank: B Open, Closed

Head Rank: C Closed, Open

SW1-3 and SW1-4 indicate print head resistance. The settings for SW1-3 and SW1-4 must

correspond to the head rank (A, B, or C) indicated on the label on the top left of the printer

mechanism.

Adjusting Contrast

If contrast adjustment is necessary, adjust VR1 on the Printer Controller PCB. It is set to mid

range at the factory. Adjusting the print contrast to darker will slow the print speed; adjusting

the print contrast lighter will increase the print speed.

Page 16 MDE-4338A TopKAT™ Fuel Management System Operation Manual · February 2009

Page 25

Report Printer Interface Option - Standalone or Master Only System Overview

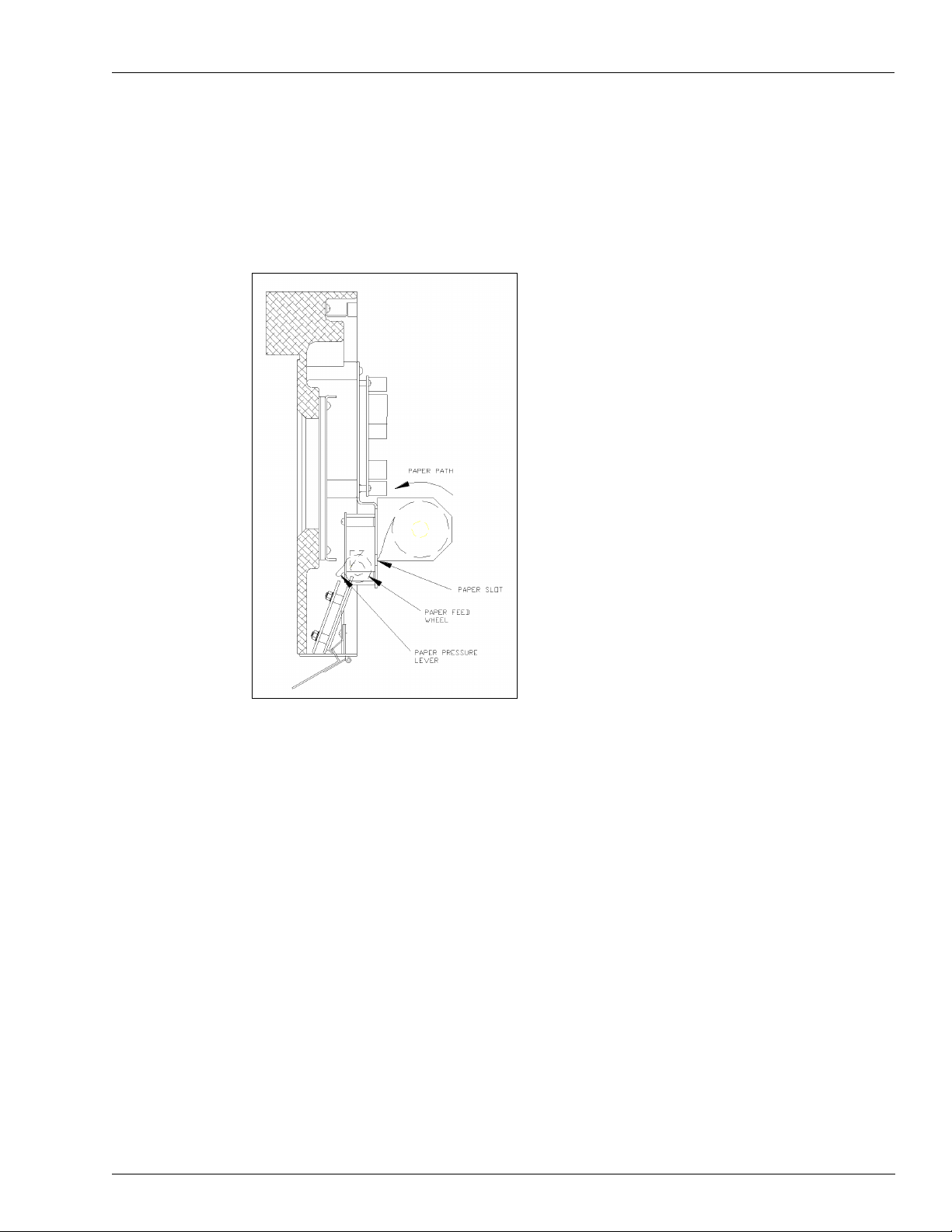

Loading Paper

When printer paper is getting low, a pink band will appear on the edge of the paper.

Replacement paper is available from Gasboy, P/N C01819. Follow these steps to replace the

paper and see

Figure 3-3: Printer - Side View

Figure 3-3.

1 To access the printer, insert the key into the key slot located at the right-hand side of the bezel.

Turn it clockwise, then pull outward to open the bezel.

2 Looking at the rear side of the bezel, locate the printer paper holder and printhead mechanism.

At the right-hand side of the printhead, locate the printhead paper feed wheel.

3 Turn the paper feed wheel counterclockwise until the paper is removed.

Note: If the paper does not move when the paper feed wheel is rotated, the paper pressure

lever is in the pressure release position. Rotate the lever toward you so that it points

straight downward. This places the lever in the pressure engage position.

4 Using a flat-blade screwdriver, remove the screw and the small metal plate securing the left

side of the paper holder. Remove the old paper roll.

5 Take the new paper roll and feed the paper into the paper slot. Turn the paper feed wheel

clockwise until paper catches.

6 Install the paper roll on the spindle with the paper feeding counterclockwise, over the top of

the roll and into the slot.

MDE-4338A TopKAT™ Fuel Management System Operation Manual · February 2009 Page 17

Page 26

System Overview PCMCIA Interface Option - Standalone or Master Only

7 Reattach small metal plate and screw.

8 Press S2 Reset on the printer controller board to put the printer back online. The RDY light

should go on.

9 Close bezel and lock turning the key counterclockwise and pressing the bezel inward until

locked.

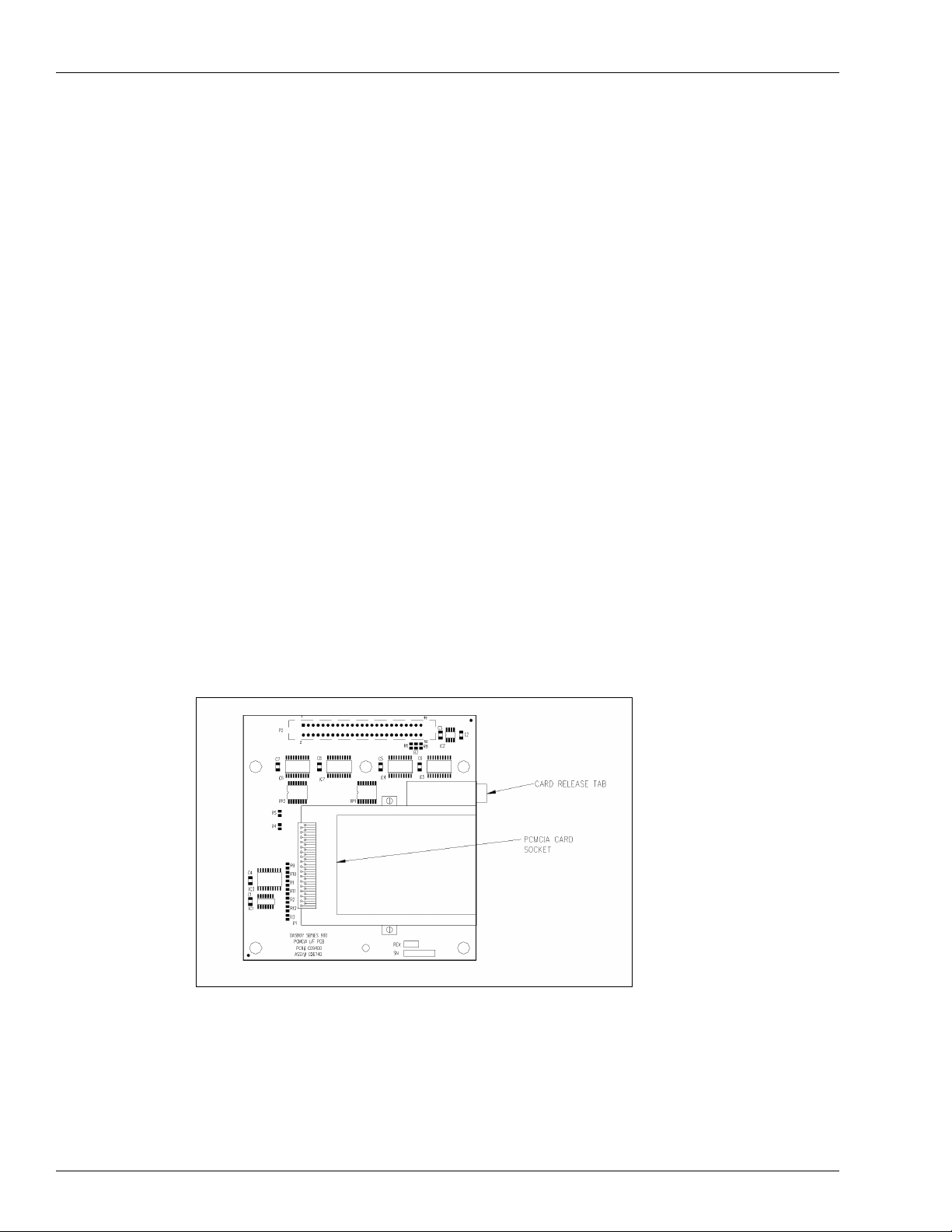

PCMCIA Interface Option - Standalone or Master Only

An optional Peripheral Component Micro Channel Interconnect Architecture (PCMCIA)

interface allows a user to back up and restore all or part of the system’s memory which

includes the vehicle and employee file data, transactions, and system configuration.

The PCMCIA option consists of a PCMCIA interface board with a socket for insertion of a

PCMCIA card. The PCMCIA socket/board is accessible through the back door of the cabinet.

User prompts at the display guide the user through the backup or restore process.

The PCMCIA option is available only at a standalone or master TopKAT unit.

PCMCIA Interface PCB

Figure 3-4: PCMCIA Interface PCB Components

Page 18 MDE-4338A TopKAT™ Fuel Management System Operation Manual · February 2009

Page 27

Master/Satellite (T/Net) Option System Overview

Master/Satellite (T/Net) Option

The master/satellite option (also called the T/Net option), allows you to network up to 8

TopKAT units together to control a maximum of 16 hoses (electronic and mechanical

combination). If all your pumps are 9800 electronic pumps or you have mechanical PCUs, up

to 8 hoses may be controlled. One TopKAT functions as the master unit, the remaining units

function as satellites. A single database resides at the master consisting of system data, vehicle

file data, manual entry file data, transaction, pump, and tank data.

The master TopKAT provides the satellite with the vehicle and (if configured) the manual

entry records required to authorize a transaction. If your configuration is all 9800 electronics

or uses mechanical PCUs, the TopKAT master controls all pumps. If you are using a

combination of 9800 electronic and mechanical pumps, the master controls the electronic

pump (one PCU, single or twin pump) and the satellite controls its local mechanical pump(s)

and returns completed transaction data to the master upon completion of a sale. The master

TopKAT then updates its database with transaction information.

The TopKAT with the master/satellite option is set up and configured slightly differently from

a standalone TopKAT. The differences are as follows:

• Load Mode (refer to “Setup Menu” on page 30)

This new prompt is present in all TopKAT units. When your TopKAT is a standalone

unit, this prompt is set to standalone. When using the master/satellite option, the master

unit is designated as Master. This prompt must be set to Satellite at each satellite unit.

• Poll Address (refer to “Setup Menu” on page 30)

Functions the same as for standalone TopKAT units; however the master must be set as 01

and the satellites must be set as 01 through 07.

• Password (refer to “Setup Menu” on page 30)

Can be loaded at master and at satellites.

• Config Trans File (refer to “Transaction File Setup - Keypad” on page 55)

All functions available at master unit; only Clear Trans in Progress, available at satellite

unit.

• Satellites controlling mechanical pumps are recognized as individual Pump Control Units

(PCUs) and are configured at the TopKAT master, using the PCU SETUP keypad

sequence (refer to

CONFIGURE SYSTEM and CONFIGURE PCUS terminal commands (refer to

“Terminal Commands” on page 87).

• Diagnostics are available at the keypad of both the master and satellite units; however, the

system must be stopped or the satellite must be offline. Enhanced diagnostics from the

terminal are effective only for the master unit.

• Certain options, such as PCMCIA backup and restore and report printing are available

only at the master unit.

“Tank, Pump, and PCU File Setup - Keypad” on page 47) and/or the

MDE-4338A TopKAT™ Fuel Management System Operation Manual · February 2009 Page 19

Page 28

System Overview Mechanical Interface Option

Mechanical Interface Option

The mechanical interface option (Mechanical I/F) allows the TopKAT to control and monitor

up to two mechanical pumps. TopKATs equipped with the mechanical interface can also be

used as part of a master/satellite configuration. Use of this interface results in additional

hardware (Pump Control PCB and solid-state relays) and additional software parameters.

Hardware

The Pump Control PCB is mounted on the inside rear of the chassis; solid state relays which

control power to the pump are located within the chassis. The Pump Control PCB controls all

mechanical pumps by driving the relays which control the pump power, monitors status of the

pump handle to turn relays off, monitors incoming pulses to count quantity, and contains

status LEDs and manual override switches for each hose outlet. Wiring connections and

switch settings for the Pump Control PCB are discussed in more detail in the Installation

Manual.

Software

When a mechanical interface-equipped TopKAT is used as part of a master/satellite

configuration, the TopKAT is configured using PCU assignments (refer to

File” on page 52). When used in standalone mode (one TopKAT controlling two mechanical

hoses), two parameters in the Pump File are used with the mechanical interface option: pump

switch timer and pulse rate. The parameters are loaded via the keypad under LOAD PUMP

TABLE in the Pump file or via the terminal using the L PU (LOAD PUMP) command.

“About the PCU

Pump Switch Timer Parameter

The pump switch timer parameter prevents new fueling transactions at a pump when the

handle has been left on from a previous transaction. In this case, when a new transaction is

initiated, the pump cannot reset and, if pumping is allowed, the quantity shown at the pump

includes the previous transaction quantity.

When the pump switch timer parameter is set, the handle is checked at the beginning of each

transaction. If it is found to be on, the user will see the message TURN OFF PUMP HANDLE

and the transaction will be terminated. A transaction is generated with the message PUMP

SWITCH ERROR. The user must turn off the pump handle and begin a new transaction in

order to fuel.

The pump switch timer parameter sets a time period during which the pump is checked. This

time period must be less than the time that it takes for your pump to reset and transmit a switch

detect signal back to the fuel management system. Nearly all pumps take more than one

second to reset and transmit switch detect, so the values for this option range from .1 to 1

second, in tenths of a second, with .5 being a commonly used value. This value may need to be

adjusted for your pumps. A setting of zero disables this option.

Page 20 MDE-4338A TopKAT™ Fuel Management System Operation Manual · February 2009

Page 29

Mechanical PCU Option System Overview

Pulse Rate Parameter

Set the pulse rate parameter with the appropriate pulse rate for your pump. The mechanical

interface supports pulse rates of 1, 10, 100, 500, and 1000 in gallons; 1, 10, 100, and 250 in

liters. If using a 9800 as a mechanical pump, pulsing should be set to 1000:1 for gallons; 250:1

for liters. If using bulk fueling, the pulse rates for gallons will be 1:1, 10:1 and 100:1 for

gallons and those listed above for liters.

Transaction Changes

If you have the mechanical interface option, the transaction quantity decimal places are

truncated to match the pulse rate (that is 10:1 pulse rate would display xxxxx.x; 100:1 pulse

rate would display xxxxx.xx, and so on).

Mechanical PCU Option

The Mechanical Pump Control Unit (Mechanical PCU) option for the TopKAT allows the unit

to control fueling and gather information from up to eight mechanical hose outlets (four per

PCU, with a maximum of two PCUs). The TopKAT with Mechanical PCU is mounted on top

of a pedestal. All PCUs can be mounted within the pedestal or wall-mounted. All pump/

dispenser wiring connections are made within the TopKAT pedestal, when using internal

PCUs or within the wall-mounted PCUs. The TopKAT with the Mechanical PCU option can

also be used in a master/satellite configuration. Use of this interface results in additional

hardware and software parameters.

Hardware

Software

Each mechanical PCU includes two solid-state relays and one manual override switch per hose

outlet which control power to the fuel dispensing equipment. The TopKAT can handle

quantity pulsing rates as listed below in the Pulse Rate Parameter section. Wiring connections

and switch settings for the Pump Control PCB are discussed in more detail in the Installation

Manual.

When used with the Mechanical PCU option in standalone mode or master/satellite (one

TopKAT controlling up to eight hoses on two mechanical PCUs), two parameters in the Pump

File are used: pump switch timer and pulse rate. The parameters are loaded via the keypad

under LOAD PUMP TABLE in the Pump file or through the terminal using the L PU (LOAD

PUMP) command.

Pump Switch Timer Parameter

The pump switch timer parameter prevents new fueling transactions at a pump when the

handle has been left on from a previous transaction. In this case, when a new transaction is

initiated, the pump cannot reset and, if pumping is allowed, the quantity shown at the pump

includes the previous transaction quantity.

MDE-4338A TopKAT™ Fuel Management System Operation Manual · February 2009 Page 21

Page 30

System Overview Typical Fueling Sequence - Standalone or Master/Satellite

When the pump switch timer parameter is set, the handle is checked at the beginning of each

transaction. If it is found to be on, the user will see the message TURN OFF PUMP HANDLE

and the transaction will be terminated. A transaction is generated with the message PUMP

SWITCH ERROR. The user must turn off the pump handle and begin a new transaction in

order to fuel.

The pump switch timer parameter sets a time period during which the pump is checked. This

time period must be less than the time that it takes for your pump to reset and transmit a switch

detect signal back to the fuel management system. Nearly all pumps take more than one

second to reset and transmit switch detect, so the values for this option range from .1 to 1

second, in tenths of a second, with .5 being a commonly used value. This value may need to be

adjusted for your pumps. A setting of zero disables this option.

Pulse Rate Parameter

Set the pulse rate parameter with the appropriate pulse rate for your pump. The mechanical

interface supports pulse rates of 1, 10, 100, 500, and 1000 in gallons; 1, 10, 100, and 250 in

liters. If using a 9800 as a mechanical pump, pulsing should be set to 1000:1 for gallons; 250:1

for liters. If using bulk fueling, the pulse rates for gallons will be 1:1, 10:1 and 100:1 for

gallons and those listed above for liters.

Transaction Changes

If you have the mechanical interface option, the transaction quantity decimal places are

truncated to match the pulse rate (that is, 10:1 pulse rate would display xxxxx.x; 100:1 pulse

rate would display xxxxx.xx, and so on).

Typical Fueling Sequence - Standalone or Master/Satellite

A typical fueling using a TopKAT vehicle key is accomplished as follows.

1 Position your vehicle adjacent to the fuel dispensing equipment. Be sure to note the odometer

reading (if your system requires you to enter the odometer reading).

2 In its idle state, the TopKAT LCD displays one of the following three messages:

• INSERT KEY

• ENTER VEHICLE CODE

• INSERT KEY OR ENTER VEHICLE CODE

Note: If system is stopped, OUT OF SERVICE displays on master and all satellites.

3 Insert the vehicle key into the key receptacle and turn it clockwise, or enter vehicle code* (if

not using keys). *Vehicle code is key number.

Note: If your daily limit has been exceeded, the message DAILY LIMIT EXCEEDED displays

and fueling is denied.

4 If your key requires an odometer entry, proceed to step 5. If your key requires a Manual Entry

only, skip to step 6. If your key requires a PIN entry only, skip to step 7. If your key requires

neither, skip to step 8.

Page 22 MDE-4338A TopKAT™ Fuel Management System Operation Manual · February 2009

Page 31

Typical Fueling Sequence - Standalone or Master/Satellite System Overview

5 If you are required to enter an odometer reading, the LCD displays: ENTER ODOMETER.

Use the keypad to enter the mileage that appears on your vehicle’s odometer (up to six digits,

no tenths). The digits appear as they are entered. If you make a mistake, press CLEAR and

enter the reading again. When you enter the correct reading, press ENTER. The system

performs a reasonability check and if the reading is accepted, it writes the value to the key

(into the last odometer field). If the entered odometer is not accepted, you can retry entry up to

the number of times specified in the LOAD ODOMETER RETRIES command.

6 If your system requires a manual entry, the LCD displays the prompt for that field. Enter the

data requested using the keypad. The digits appear as they are entered. If you make a mistake,

press CLEAR and reenter the data. When you enter the correct data, press ENTER.

7 If you are required to enter a PIN, the LCD displays: ENTER PIN.

Using the keypad, enter your PIN number and press ENTER. To ensure security, an asterisk

(*) appears for each digit that you press. If you make a mistake while entering your PIN, press

CLEAR and enter it again.

You have three tries to enter the correct PIN. If you have a key system, after the third

unsuccessful try, the display instructs you to TURN KEY LEFT, REMOVE. Turn and remove

your key, then start again at step 3. If you have a non-key system, after the third unsuccessful

try, the display returns to the configured idle message (step 2) and you must restart at step 3.

If your system uses the Auto Pin Lockout feature, the key is automatically locked out

(invalidated) after the third unsuccessful PIN entry.

8 The LCD displays SELECT PUMP. Enter the required pump number and press ENTER. If

you have only one pump, the system automatically selects it and does not prompt.

If the pump you selected cannot be accessed, one of the following messages appears:

• INVALID PUMP

• PUMP IN USE

• PUMP DISABLED

• INVALID FUEL

You have three tries to select a correct pump. If after three attempts, you have not chosen a

correct pump, the display for a key system instructs you to TURN KEY LEFT, REMOVE.

Turn and remove your key, then start again at step 3. For a non-key system, the display returns

to the configured idle message (step 2) and you must restart at step 3.

If the pump is available and you are authorized to use it, the display will show:

PUMP #xx IS READY

TURN KEY LEFT, REMOVE.

Note: Non-key systems will display the top line message only. Skip to step 10.

9 Remove the key from the receptacle. If you leave the key in the receptacle for more than five

seconds, an alarm sounds to remind you to remove it.

MDE-4338A TopKAT™ Fuel Management System Operation Manual · February 2009 Page 23

Page 32

System Overview Delivery or Dipstick Key Sequence