Page 1

MDE-4816A

GGiillbbaarrccoo’’ss TTaagg RReeaaddeerr ((TTaagg RReeaaddeerr))

INSTALLATION MANUAL

Page 2

Page 3

SAFETY CONSIDERATIONS

Read all warning notes and instructions carefully. They are included to help you installing the Product safely

in the highly flammable environment of the fuel station. Disregarding these warning notes and instructions

could result in serious injury or property damage. It is the installer responsibility to install, operate and

maintain the equipment according to the instructions given in this manual, and to conform to all applicable

codes, regulations and safety measures. Failure to do so could void all warranties associated with this

equipment. Remember that the fuel station environment is highly flammable and combustible. Therefore,

make sure that actual installation is performed by experienced personnel, licensed to perform work in fuel

station and at a flammable environment, according to the local regulations and relevant standards.

WARNING - EXPLOSION HAZARD

Use separate conduit for the intrinsically safe. Do not run any other wires or cables through this conduit,

because this could create an explosion hazard.

Use standard test equipment only in the non- hazardous area of the fuel station, and approved test equipment

for the hazardo us areas.

In the installation and maintenance of the Product, comply with all applicable requirements of the National

Fire Protection Association NFPA-30 “Flammable and Combustible Liquids Code”, NFPA-30A “Automoti ve

and Marine Service Station Code”, NFPA-70 “National Electric Code”, federal, state and local codes and any

other applicable safety codes and regulations. Do not perform metal work in a hazardous area. Sparks

generated by drilling, tapping and other metal work operations could ignite fuel vapors and flammable

liquids, resulting in death, serious personal injury, property loss and damage to you and other persons.

CAUTION - SHOCK HAZARD

Dangerous AC voltages that could cause death or serious personal injury are used to power the Product.

Always disconnect power before starting any work. The Product has more than one power supply connection

points. Disconnect all power before servicing.

WARNING – PASSING VEHICLES

When working in any open area of fuel station, beware of passing vehicles that could hit you. Block off the

work area to protect yourself and other persons. Use safety cones or other signaling devices.

WARNING

Components substitutions could impair intrinsic safety.

Attaching unauthorized components or equipment will void your warranties.

Page 4

CAUTION

Do not attempt to make any repair on the printed circuit boards residing in the Product, as this will void all

warranties related to this equipment.

PROPRIETY NOTICE

This document contains propriety and confidential information. It is the property of Orpak SYSTEMS Ltd.

It may not be disclosed or reproduced in whole or in part without written consent of Orpak SYSTEMS. The

information in this document is current as of the date of its publication, but is subject to change without

notice.

DISCLAIMER

This document is provided for reference only. Although every effort has been made to ensure correctness,

ORPAK SYSTEMS does not guarantee that there are no errors or omissions in this document.

FCC Compliance Statement

The FCC Wants You to Know:

This equipment has been tested and found to comply with the limits for a Class B & C digital device,

pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment generates uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures :

a) Reorient or relocate the receiving antenna.

b) Increase the separation between the equipment and receiver.

c) Connect the equipment to an outlet on a circuit different from that to which the receiver is connected.

d) Consult the dealer or an experienced radio/TV technician.

FCC Warning

Modifications not expressly approved by the manufacturer could void the user authority to operate the

equipment under FCC Rules.

This document is the property of:

ORPAK SYSTEMS Ltd.

ISRAEL

Page 5

TABLE OF CONTENTS

Paragraph Page

SECTION 1 GENERAL DESCRIPTION

1-1. SCOPE................................................................................................................................ 4

1-2. DESCRIPTION .................................................................................................................. 4

1-2.1. General........................................................................................................................... 4

1-2.2. Description..................................................................................................................... 4

1-3. FUNCTIONAL DESCRIPTION........................................................................................ 6

1-3.1. Main Features................................................................................................................. 6

1-3.2. Supported Cards/Tags Options...................................................................................... 6

1-3.2.1. MiFare Tag/Card....................................................................................................... 6

1-3.2.2. Magnetic Stripe Fuel Cards....................................................................................... 7

1-3.2.3. Payment Contact Less Cards (optional).................................................................... 7

1-3.3. Serial Communication Interface .................................................................................... 7

1-3.4. Assigning Tag Reader RS-485 Address......................................................................... 8

1-3.5. Assigning TR RS-485 Address...................................................................................... 8

1-4. POWER SUPLY................................................................................................................. 8

1-5. HOUSING .......................................................................................................................... 9

1-6. SPECIFICATIONS.............................................................................................................9

1-6.1. Operational..................................................................................................................... 9

1-6.2. Communication Interface............................................................................................... 9

1-6.3. Physical.......................................................................................................................... 9

1-6.4. Power ............................................................................................................................. 9

1-6.5. Environmental................................................................................................................ 10

1-7. TYPES................................................................................................................................ 10

1-8. STANDARDS .................................................................................................................... 11

1-8.1. Communication Standard............................................................................................... 11

1-8.2. Security Standards.......................................................................................................... 11

1-9. MANUAL STRUCTURE .................................................................................................. 11

1-10. USING THIS MANUAL.................................................................................................... 12

SECTION 2 INSTALLATION

2-1. GENERAL.......................................................................................................................... 13

Tag Reader Installation Guide

i

Page 6

TABLE OF CONTENTS

Paragraph Page

2-2. TOOLS AND ACCESSORIES .......................................................................................... 14

2-3. LOCATIONS...................................................................................................................... 14

2-4. SAFETY LIMITATIONS...................................................................................................14

2-5. INSTALLATION INSTRUCTIONS.................................................................................. 15

2-5.1. Preparation .....................................................................................................................15

2-5.2. General Instructions .......................................................................................................16

2-5.3. Mechanical Installation.................................................................................................. 16

.

2-5.4.

.

5 Post-Installation Checks and Programming of Tag Reader Address

2-5.5.

g.............................................................................................................................17 2-5.4 Wirin

Wiring

Post-Installation Checks and Programming of Tag Reader Address

.............................19 2-5.

SECTION 3 USING TAG READER

3-1. GENERAL.......................................................................................................................... 21

3-2. ERROR CONDITIONS...................................................................................................... 22

SECTION 4 MAINTENANCE

4-1. GENERAL.......................................................................................................................... 23

4-2. CLEANING........................................................................................................................ 23

4-2.1. General........................................................................................................................... 23

4-2.2. Cleaning Instructions......................................................................................................23

4-3. TROUBLESHOOTING...................................................................................................... 24

ii

Tag Reader Installation Guide

Page 7

LIST OF ILLUSTRATIONS

Figure Page

Figure 1-1. Tag Reader, General view ................................................................................................5

Figure 1-2. MiFare Tag, General view................................................................................................ 6

Figure 1-3 Tag Reader. Power and Communication Cable................................................................. 8

Figure 1-4. Tag Reader – Dimensions............................................................................................... 10

Figure 2-1 – Tag Reader beneath CFN PLUS................................................................................... 13

Figure 2-2. Tag Reader, Outdoor Installation Control Drawing....................................................... 15

Figure 2-3. Tag Reader Installation Holes, Internal View ................................................................16

Figure 2-4. Tag Reader Installation Holes and Grommet Cap, Rear View....................................... 17

Figure 2-5. Tag Reader with Cables.................................................................................................. 18

Figure 2-6. Host OrPT Main Screen..................................................................................................19

Figure 2-7. Scan/Set New Address Dialog Box................................................................................ 20

Figure 3-1. Starting Fuel Dispensing.................................................................................................21

LIST OF TABLES

Table Page

Table 4-1. Tag Reader, Troubleshooting Procedures....................................................................... 24

Tag Reader Installation Guide

iii

Page 8

0

SECTION 1

SECTION 1

GE

GE

NERAL DESCRIPTION

1-1.

1-1.

This manual is provided to assist you in installing the Gilbarco TR- Tag Reader . The Tag Reader

must be installed as described in this manual to ensure unit reliability and normal operation.

This manual includes a general and functional description of the Tag Reader. It provides the

installation requirements and procedures for the Tag Reader.

This manual is intended for qualified authorized installers of the Tag Reader. It is also intended for

the Island electrician.

1-2.

1-2.

1-2.1. General

The Gilbarco Tag Reader (P/Ns: Tag Reader - PA04020000, Tag and Magnetic Card Reader PA04020001) is a standalone reader unit for contactless cards and tags intended for vehicle or

driver tag identification in gas stations and other applications. In addition, it can also be equipped

with an optional magnetic card reader, at the right-hand side of the unit. The TR includes a

Security Application Module (SAM) used to handle encrypted contactless cards and tags. The TRis

within easy reach of the customer wishing to refuel, and transmits the information to the station

automation system (CFN PLUS) over an RS-485 shielded cable.

The TR is designed to be installed in a non hazardous location in the station.

SCOPE

DESCRIPTION

SCOPE

DESCRIPTION

NERAL DESCRIPTION

1-2.2. Description

The Tag Reader has a modern, stylish-look, with a clean panel, which includes two indicators

(green and red) and a large LCD. Its operation is very simple: to start a fuel purchase, the cus

waves the tag or card in front of the unit. After the tag is recognized and validated, clear messages

shown on the display guide the customer and help him to complete the transaction. In addition to

the LCD, an internal buzzer beeps to provide audio feedback and the status of the current operation

is indicated by the green and red indicators.

One or several TRs can be installed in a single station for improved service. In this case, all TRs in

the station should be connected to the same single CFN PLUS (e.g. Fuel Truck Controller or others)

via RS-485.connection.

4

Tag Reader Installation Guide

tomer

Page 9

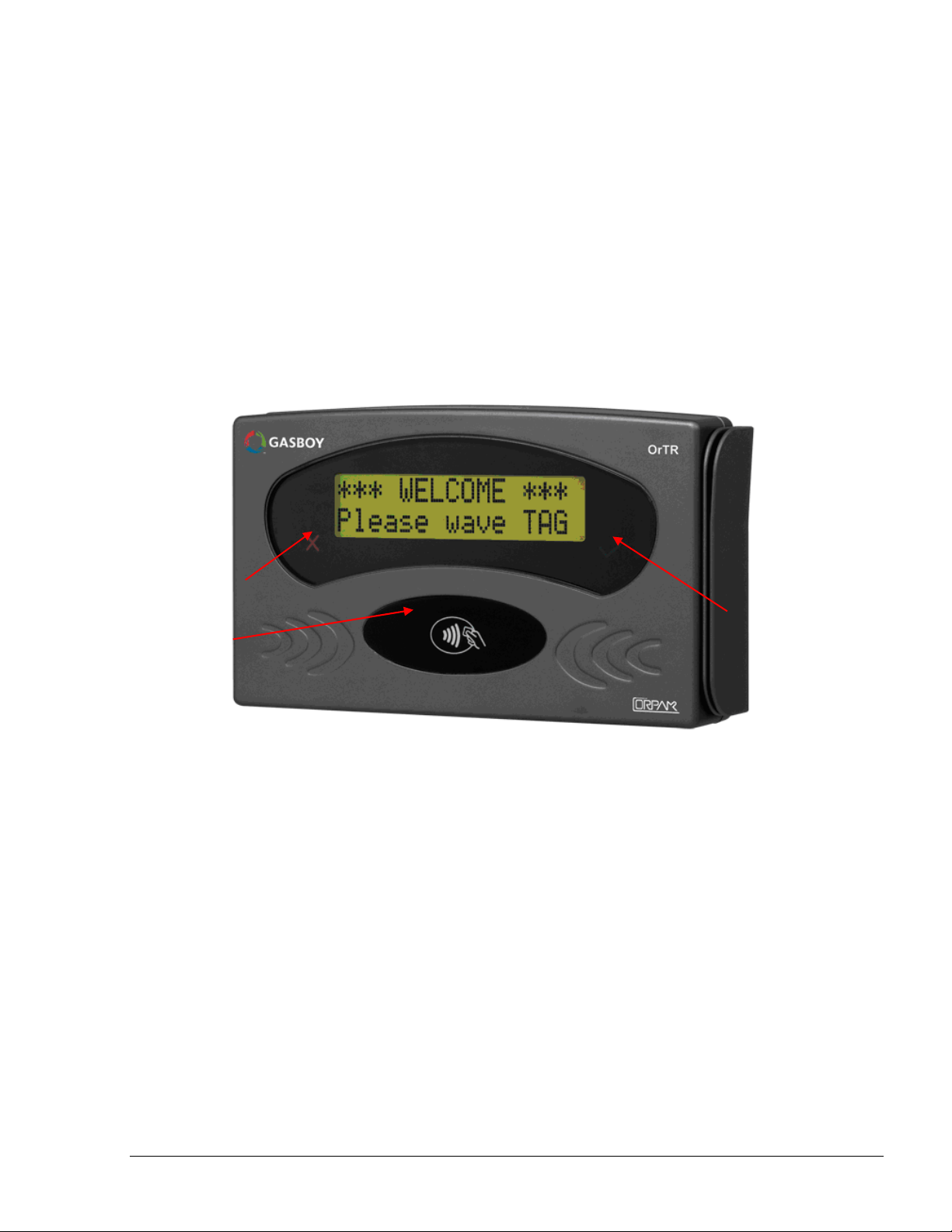

Two LEDs on the Tag Reader front panel indicate the transaction status:

Green – - Positive recognition, transaction was authorized

Red – - Negative recognition, transaction is not authorized.

The indicators are automatically activated by the station Controller when the customer places the

tag or card near the tag reader, close to the sensing component located at the bottom of the front

panel (see Figure 1-1).

A welcome message is displayed on the TR display, and is replaced by messages which indicate the

progress of the transaction. The display is backlit for improved readability under poor lighting

conditions. An internal speaker provides audio feedback.

Red LED

Contactless

Reader

Green

LED

Figure 1-1. Tag Reader, General view

Tag Reader Installation Guide

5

Page 10

1-3.

1-3.

FUNCTIONAL DESCRIPTION

FUNCTIONAL DESCRIPTION

1-3.1. Main Features

The TR is based on advanced technology, implemented by two microcomputer subsystems: one for

handling the secure communication protocol with the tag/card, and the other for communication

with the station Controller and for controlling the operation of TR.

The Tag Reader includes a single cable carrying power and RS485 communication.

The Tag Reader user interface (UI) can easily be adapted to the customer requirements. For

flexibility, the Tag Reader uses a standard communication protocol, and the displayed messages are

controlled by the station Controller.

The message contents and language can be selected by the system operator, and the microcomputer

application software can be updated in the field.

1-3.2. Supported Cards/Tags Options

Tag Reader has several configurations and can support various cards and tags, including: MiFare,

magnetic fuel and fleet cards and optional payment contact less cards.

1-3.2.1. MiFare Tag/Card

This is a contact less card that can be used as a fueling card by the driver at the gas station. When

the card is presented next to the TR, it reads the card / tag data and transmits it to the station controller

in the gas station. Upon verification and approval, the station Controller activates and releases the pump

valve, so fuel can be dispense to the vehicle.

Four types of tags are recognized:

Driver’s tag: this tag is used to identify a specific driver. Therefore, fuel dispensing is

allowed only after the vehicle has been identified by means of its Vehicle Identification Unit

(VIU).

Vehicle’s tag: this tag is used to authorize fuel dispensing and charging.

Attendant’s tag: permits operation of any fuel nozzle from the TR, by a station attendant.

Technician tag: this tag is used to setup TR RS-485 address, as explained in para. 1-3.4.

Figure 1-2. MiFare Tag, General view

6

Tag Reader Installation Guide

Page 11

1-3.2.2. Magnetic Stripe Fuel Cards

If the TR is equipped with an optional magnetic card reader, at the right-hand side of the unit, the

driver can use a magnetic stripe card.

A magnetic stripe card is a type of card capable of storing data. The magnetic stripe is read by

physical contact and swiping past a reading head.

The driver may have a vehicle fuel card or personal driver card.

1-3.2.3. Payment Contact Less Cards (optional)

Payment contactless cards such as the PayPass® cards enable the driver to pay using a standard

credit or debit card which has contact less capabilities.

This allows the home-base station to be semi-public and accept payment from occasional customers

and process the transaction through the bank or local processing network.

TR has an optional PayPass reader to support these types of cards

1-3.3. Serial Communication Interface

The TR has a balanced bidirectional RS-485 communication interface, which connects to the CFN

PLUS of the gas station or tanker truck.

This interface is used to communicate with the station controller.

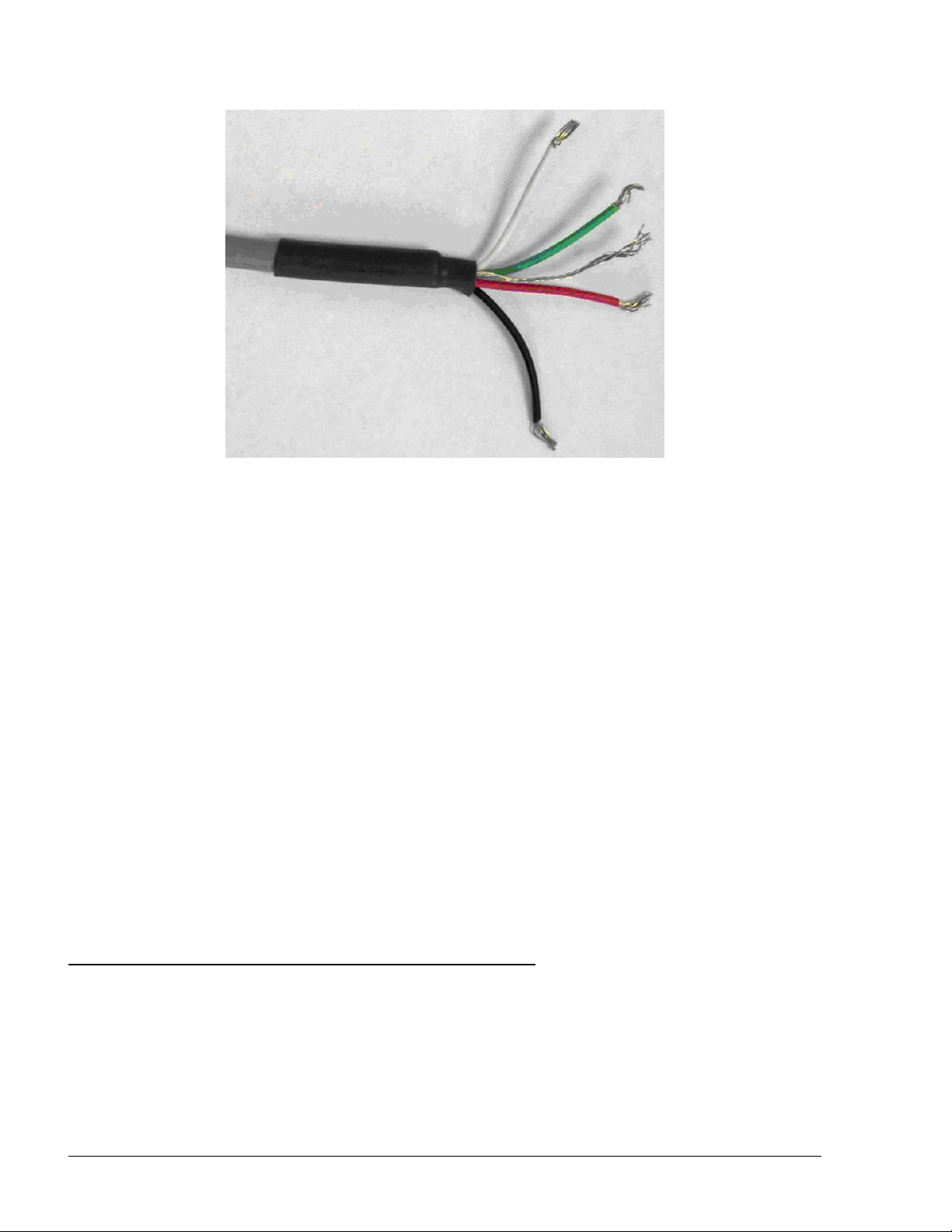

The power and communication cable has five wires: two power supply wires, two wires for the

communication interface and one Ground Wire (see

Figure 1-3).

Wire Color Functional Description

Green Power (+)

White Power (-)

Red RS-485 (+)

Black RS-485 (-)

Shield Shield

Tag Reader Installation Guide

7

Page 12

Figure 1-3 Tag Reader. Power and Communication Cable

The same interface can be used for maintenance purposes, e.g., to download software updates,

configure various parameters, select the RS-485 communication address, etc. For such purposes,

1-3.4. Assigning Tag Reader RS-485 Address

1-3.5. Assigning TR RS-485 Address

To enable communication with the station controller, the TR must be assigned a unique RS-485

address. This address must be selected by the system operator, during the planning stages of the

system installation or upgrading.

The RS-485 address of the TR can be programmed in two ways:

Contact less mode: the address is selected using the Technician tag. The selection is

performed using a simple interactive process: The Technician tag is brought close to be read

by the TR, which then starts sequentially displaying the addresses in the allowed range.

When the prescribed address is displayed, the Technician tag is removed.

By a PC directly connected to TR RS-485 interface.

1-4.

1-4.

POWER SUPLY

POWER SUPLY

The TR requires 12 to 24 VDC power input. Power can be provided by the CFN PLUS or an

external power supply. If an external power supply is used, it should be approved in accordance

with local regulations.

8

Tag Reader Installation Guide

Page 13

In North America, use a NEC Class 2 power supply, low voltage and low current [maximum

100 VA even under fault conditions]. The adaptor can be installed in the office, in the installation

pole or pedestal, or in a separate box.

The TR is provided with DC connection cables protruding from the rear panel for easy connection.

NNOOTTEE

If the power supply is installed far from the TR box,

make sure the TR receives a correct voltage! There

may be a power failure on the lines!

1-5.

1-5.

HOUSING

HOUSING

The Tag Reader system enclosure is made of rugged plastic, in the form of a small box. The

enclosure is weather-proof in order to sustain the harsh environment of a Home Base Station. The

devices in its front panel are sealed to prevent humidity and dust penetration.

1-6.

1-6.

SPECIFICATIONS

SPECIFICATIONS

1-6.1. Operational

User Interface – Alphanumeric LCD

Dual-LED green and red indicators

Piezoelectric speaker

Readers - Contactless MiFare reader

Magnetic card reader (optional)

Payment contactless cards reader (optional)

Display Type – Backlit alphanumeric LCD with 5×7 dot matrix display units

Display Size – 2 rows of 16 characters each

1-6.2. Communication Interface

RS- 485

1-6.3. Physical

Height – 140 mm (5.1 in.)

Width – 210 mm (8.3 in.)

Depth – 38 mm (1.5 in.)

Weight – 480 gram (1.1 lb.)

(see Figure 1-4).

1-6.4. Power

Operating voltage - 12 - 24 V DC.

Tag Reader Installation Guide

9

Page 14

Operating current - 0.5 A

Figure 1-4. Tag Reader – Dimensions

1-6.5. Environmental

Operating temperature : -40 - +70 °C (-40 – 158 °F)

Storage temperature : -40 - +70 °C (-40 – 158 °F)

Humidity – 95% RH

Degrees of Protection - IP66

1-7.

1-7.

TYPES

TYPES

The TR can be obtained in several contact less models, in accordance with the functional options:

Contactless readers: MiFare, or PayPass

Connectivity: RS485

With or without magnetic card reader

10

Tag Reader Installation Guide

Page 15

1-8.

1-8.

STANDARDS

STANDARDS

1-8.1. Communication Standard

The Tag Reader communicates, in its different models, over the following standard:

RS-485 link

1-8.2. Security Standards

Tag Reader has a Security Authentication Module (SAM) used to decrypt the card/tag data.

1-9.

1-9.

MANUAL STRUCTURE

MANUAL STRUCTURE

This manual comprises of the following sections:

Section 1: General Description

This section provides a general description of the Tag Reader system.

Section 2: Installation Procedures

This section provides the preliminary installation requirements and procedures to be performed

before installing Tag Reader.

Section 3: Maintenance and Troubleshooting

This section provides basic troubleshooting procedures for the Tag Reader.

Tag Reader Installation Guide

11

Page 16

1-10.

1-10.

USING THIS MANUAL

USING THIS MANUAL

This manual includes alerting comments inserted along the document, in order to draw the reader’s

attention to important issues. The comments are accompanied by symbols for ease of reference.

The following comment types are used:

WWAARRNNIINNGG

An operating procedure, practice, etc', that if not

correctly followed, could result in injury or loss of

life.

CCAAUUTTIIOONN

An operating procedure, practice, etc', that if not

strictly observed, could result in damage to, or

destruction of equipment.

TTIIPP

This note is aimed for using the system in better

efficiently way.

NNOOTTEE

This comment is of importance for emphasizing.

IINNSSIIGGHHTT

More detailed technical/ functional information in

regard relevant issue.

12

Tag Reader Installation Guide

Page 17

0

SECTION 2

SECTION 2

IN

IN

STALLATION

2-1.

2-1.

This section provides installation and configuration instructions for the Tag Reader, and instructions

for solving problems that may occur during installation and operation

The Tag Reader is designed to be installed in a non hazardous location in the station or tanker truck

in both indoors and outdoors installation. The Tag Reader is intended for installation outside the

associated fuel pump, on the side accessible to the customer (at an area defined as safe area).

The Tag Reader is designed to be installed in a non hazardous location in the station.

Three installation alternatives are available:

GENERAL

1. Installation on a wall or pole

2. Together with the CFN PLUS station controller. See Figure 2-3 for instructions.

3. In fueling trucks, as part of the TC solution

GENERAL

STALLATION

Figure 2-1 – Tag Reader beneath CFN PLUS

Tag Reader Installation Guide

13

Page 18

2-2.

2-2.

TOOLS AND ACCESSORIES

TOOLS AND ACCESSORIES

Tag Reader can be provided with an installation kit for the Tag Reader, which includes a rubber

seal, P/N 8149-27400, and four M4 × 20 screws, P/N 8152-03120, with spring washers.

No special tools are required for installing the Tag Reader. Make sure you have 4 mm, 4.4 mm and

5mm drill bits.

2-3.

2-3.

LOCATIONS

LOCATIONS

The Tag Reader can be installed in several Unclassified/Non-Hazardous Locations:

Attached to a station controller box (CFN PLUS) and Over Class 1 Division 2 Group D

Attached to a Tanker Truck controller box and Over Class 1 Division 2 Group D

On a pole or wall mounted close to the station dispensers.

Connected to the station controller box (CFN PLUS) in the station office or in any other

non-explosive environment.

If no suitable walls or poles are available, the Tag Reader can be installed on a dedicated

pole. In that case, setting the pole in the island must comply with the UL/EU or any local

regulations requirements such as cementing the pole to the island floor, laying cables and

keeping the Tag Reader Box outside Class I zone, as described in paragraph 2-4.

Inside the driver compartment of a tanker truck

NNOOTTEE

Maximum distance of the RS-485 communication

line between Tag Reader and Controller box is 330

feet (100m).

More than one Tag Reader can be mounted in one station for improved service. In this case all Tag

Readers shall be connected to the same, single CFN PLUS via RS-485.

The preferred installation method depends on the layout and configuration of the gas station. Any of

the above selected methods must comply with UL and EU requirements.

CCAAUUTTIIOONN

The Tag Reader must NOT be installed on the

dispenser or in any other hazardous environment.

2-4.

2-4.

SAFETY LIMITATIONS

SAFETY LIMITATIONS

Due to safety requirements, the Tag Reader box can be installed only in non-hazardous areas/

non-classified area. Hazardous areas are shown in grey in the control drawing (see Figure 2-2).

Therefore, the Tag Reader must be installed within the following boundaries:

14

Tag Reader Installation Guide

Page 19

1. Above 18” (0.5 meter) from the island floor

2. At least 18” (0.5 meter) away from the dispenser

Figure 2-2 shows various possible installation locations for the Tag Reader Box.

Figure 2-2. Tag Reader, Outdoor Installation Control Drawing

2-5.

2-5.

INSTALLATION INSTRUCTIONS

INSTALLATION INSTRUCTIONS

2-5.1. Preparation

The Tag Reader is fastened by means of four M4 × 16 screws to the mounting surface or flange.

The fastening screws pass through holes in the bottom plate of the Tag Reader. In addition, a 0.474"

hole is required to pass the connection cable. The Tag Reader support flange is provided with holes

suitable for attaching the Tag Reader to it. Figure 2-3 shows the drilling marking template for the

Tag Reader.

Tag Reader Installation Guide

15

Page 20

Figure 2-3. Tag Reader Installation Holes, Internal View

2-5.2. General Instructions

The following paragraph provides step by step instructions for installation of the Tag Reader box.

1. Install the Tag Reader in a non-hazardous area in accordance with Figure 2-2.

2. Install the Tag Reader at a height suitable for LCD screen reading by an average driver.

3. Link the Tag Reader to the Controller (CFN PLUS, Islander Plus, Fuel Truck Controller or

other) with the RS-485 wires.

4. Connect Tag Reader to power supply

5. The installation procedures must meet all safety regulations in accordance with local state

regulations.

2-5.3. Mechanical Installation

In this configuration, the Tag Reader is installed on a pole or a wall. Proceed as follows:

1. Verify that the Tag Reader support flange is provided with holes suitable for attaching the

Tag Reader to it (see Figure 2-3)

2. Remove the four M4 x16 screws at the rear panel attaching the rear panel (see

Figure 2-4)

3. Rem

ove the Grommet cap at the center of rear panel and pull out cable from the Tag Reader

4. Insert the free end of the Tag Reader cable through the 12 mm hole, and then place the Tag

Reader rear (with the rubber seal) in the prescribed position on the support flange

5. Attach the unit using four M4 x16 screws from

16

Tag Reader Installation Guide

the rear side

Page 21

6. Install the Tag Reader with support flange to the installation site: Smooth flat surface/Pole/

Dedicated Pole/CFN PLUS (with special flange)

7. Secure the Tag Reader support flange at installation location using the appropriate screws,

spring washers and flat washers. Make sure the rubber seal remains properly seated under

the Tag Reader base.

8. In case of installation to the CFN PLUS, attach a special flange to CFN PLUS lower plate

with two appropriate screws

9. Proceed with the wiring connections (paragraph 2-5.4).

Figure 2-4. Tag Reader Installation Holes and Grommet Cap, Rear View

2-5.4.

2-5.4.

Wiring

The Tag Reader is equipped with a single cable c

Wiring

arrying the Power and Serial Communication

cable. The Tag Reader requires power input and data input/output connections. The RS-485 wires

should be connected to the appropriate CFN PLUS serial communication ports. The cables must be

inserted through dedicated conduits that comply with UL/EU regulations and any other local

regulations. The cables enter the CFN PLUS from the sealing glands that ensure the box sealing.

Proceed as follows:

Tag Reader Installation Guide

17

Page 22

1. Remove appropriate length of cable coating for connection to power supply and RS-485

ports

2. Connect the Tag Reader power wires to a 12-24 VDC (stabilized), 500 mA (minimum)

power supply or to CFN PLUS DC connection ports

3. Connect Tag Reader serial communication wires to the CFN PLUS RS-485 ports

4. Connect coax (shield) wire of RS-485 cable to Ground inside CFN PLUS

5. When installing cables into CFN PLUS Controller, do not damage unit sealing (IP66

protection)

6. Verify that Tag Reader is powered on.

Figure 2-5. Tag Reader with Cables

1.

18

Tag Reader Installation Guide

Page 23

2-5.5.

2-5.5.

Tag Reader Address

Tag Reader Address

Post-Installation Checks and Programming of

Post-Installation Checks and Programming of

Proceed as follows:

1. Restart the CFN PLUS

2. Monitor the power-up indications provided by the Tag Reader:

Check that the green and red indicators turn on for a few seconds and then turn

off.

Check that a single beep is heard.

Check that the LCD displays Tag Reader

software version, followed by the welcome

message.

3. Observe the default OrTR address as displayed on the screen as the device is powered-up,

and then set the new OrTR address using the Host ORPT application, as follows:

a. Connect a PC on which the Host OrPT application was previously installed to OrTR

RS-485 connector via 8-Port Commverter or any other RS-485/RS-232 convertor

b. Run the Host OrPT application. The following screen is displayed (see Figure 2-6):

Figure 2-6. Host OrPT Main Screen

c. Click on the Scan button. The Scan/Set New Address dialog box appears (see Figure

2-7)

Tag Reader Installation Guide

19

Page 24

Figure 2-7. Scan/Set New Address Dialog Box

d. Enter the address range to be scanned using the Scan From and To spin boxes and

then click on the Scan button

e. The application displays all the allowed addresses in ascending order on the bottom

of the screen

f. Click on the required address and then click Choice

g. The selected address in displayed on the New Address spin box. Click Set to assign

the new address to the device

h. Click Close to exit the dialog box

i. Click Exit on the OrPT Host Main Screen to close the application

The OrTR is now ready for use.

20

Tag Reader Installation Guide

Page 25

0

SECTION 3

SECTION 3

US

US

ING TAG READER

3-1.

3-1.

This section provides a description of the customer's interaction with the Tag Reader.

For a regular Fuel Dispensing procedure, proceed as follows:

GENERAL

1. When ready for service, the Tag Reader displays a

welcome message, and its two indicators, green and

red , are both off.

2. A customer wishing to start fuel dispensing needs to bring his tag/card near the ”tap” icon

on the Tag Reader, as shown in Figure 3-1.

GENERAL

S

NNOOTTEES

The following messages are usually displayed.

However, they may be changed at the setup of the

Station Controller

ING TAG READER

Figure 3-1. Starting Fuel Dispensing

Tag Reader Installation Guide

21

Page 26

3. The two Tag Reader indicators, green and red ,

flash for a few seconds to indicate that it reads the

tag/card, a beep is heard, and the customer sees a

notification message:

4. After the tag/card is successfully read, only the green

indicator continues to flash. The Tag Reader waits for a

confirmation or rejection message from the station

controller, and notifies the customer to wait:

5. After tag/card OK is displayed, the customer can remove the tag/card.

6. If everything is OK, the station controller confirms the

transaction within 10 seconds. The green indicator

turns on (or flashes) and the customer is notified to start

refueling:

7. After refueling is ended by returning the refueling nozzle

to its cradle, the customer see the following message:

3-2.

3-2.

ERROR CONDITIONS

ERROR CONDITIONS

In case an error occurs after the customer starts a refueling in accordance with para. 3-1, the red

indicator turns on (or starts flashing) and a beep is heard. The cause of the error is displayed on the

LCD.

Error during the reading of information from the tag or

card. In this case, after step 3 the following message is

displayed: In this case, the customer should wait until the

welcome message appears, and bring again the tag/card

close to Tag Reader.

In case the problem occurs again, the customer should contact one of the station attendants.

The tag/card is rejected by the station controller. In this

case, after step 5 the following message is displayed: In

this case, the customer should contact one of the station

attendants.

22

Tag Reader Installation Guide

Page 27

0

SECTION 4

SECTION 4

MA

MA

INTENANCE

4-1.

4-1.

This section provides general maintenance and troubleshooting instructions for the Tag Reader.

4-2.

4-2.

4-2.1. General

The Tag Reader itself as a standalone unit should be cleaned periodically at short intervals, due to

the harsh environment of the Home Base Station where they operate.

GENERAL

CLEANING

GENERAL

CLEANING

CCAAUUTTIIOONN

INTENANCE

DO NOT use any solvents such as thinner or

benzene.

4-2.2. Cleaning Instructions

The Tag Reader should be cleaned periodically, preferably once every two (2) weeks, in order to

ensure proper operation. The cleaning purpose is to remove any dust or foreign body that may

harm the reader and consequently prevent the completion of a sale.

Proceed as follows:

Clean the Tag Reader with a damp cloth only.

Tag Reader Installation Guide

23

Page 28

4-3.

4-3.

TROUBLESHOOTING

TROUBLESHOOTING

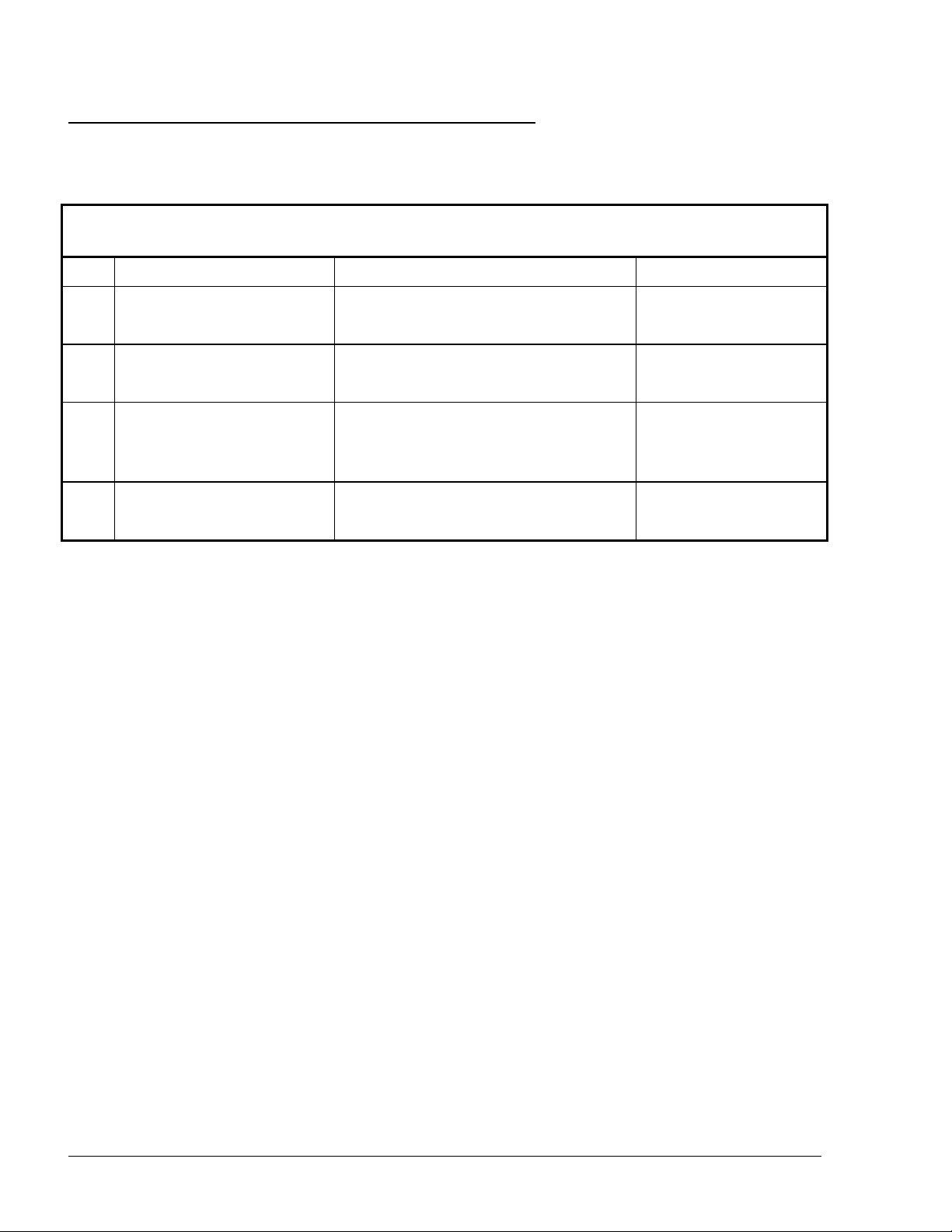

Table 4-1 lists the recommended procedures for troubleshooting the Tag Reader.

Table 4-1. Tag Reader, Troubleshooting Procedures

No. Symptom Troubleshooting Procedure Recommended Action

1 Display is off Check DC Voltage power supply

output

Check the proper connection between

the Power Supply and Tag Reader

2 No communication

between Tag Reader and

the controller

Check RS-485 and CAT-5E cables

connection between Tag Reader and

controller

3 LEDs are not operating Check DC Voltage power supply

output

Replace DC Voltage

power supply

Wire the unit anew.

Replace Tag Reader

Replace DC Voltage

power supply

24

Tag Reader Installation Guide

Loading...

Loading...