Page 1

MDE-481

7G

SiteOmat In-House Station Controller

SETUP and MAINTENANCE MANUAL

This manual supports released version 6.4.45

This document is based on Orpak’s SiteOmat setup and maintenance

manual P/N 817423756

Page 2

Page 3

SAFETY CONSIDERATIONS

Read all warning notes and instructions carefully. They are included to help you installing the Product safely

in the highly flammable environment of the fuel station. Disregarding these warning notes and instructions

could result in serious injury or property damage. It is the installer responsibility to install, operate and

maintain the equipment according to the instructions given in this manual, and to conform to all applicable

codes, regulations and safety measures. Failure to do so could void all warranties associated with this

equipment.

Remember that the fuel station environment is highly flammable and combustible. Therefore, make sure

that actual installatio

a flammable environment, according to the local regulations and relevant standards.

Use separate conduit for the intrinsically safe. Do not run any other wires or cables through this conduit,

because this could create an explosion hazard.

Use standard test equipment only in the non- hazardous area of the fuel station, and approved test equipment

for the hazardous areas.

In the installation and maintenance of the Product, comply with all applicable requirements of the National

Fire Protection Association NFPA-30 “Flammable and Combustible Liquids Code”, NFPA-30A “Code for

Motor Fuel Dispensing Facilities and Repair Garages”, NFPA-70 “National Electric Code”, federal, state and

local codes and any other applicable safety codes and regulations.

Do not perform m

operations could ignite fuel vapors and flammable liquids, resulting in death, serious personal injury,

property loss and damage to you and other persons.

Dangerous AC voltages that could cause death or serious personal injury are used to power the Product.

Always disconnect power before starting any work. The Product has more than one power supply connection

points. Disconnect all power before servicing.

When working in any open area of fuel station, beware of passing vehicles that could hit you. Block off the

work area to protect yourself and other persons. Use safety cones or other signaling devices.

n is performed by experienced personnel, licensed to perform work in fuel station and at

WARNING - EXPLOSION HAZARD

etal work in a hazardous area. Sparks generated by drilling, tapping and other metal work

CAUTION - SHOCK HAZARD

WARNING – PASSING VEHICLES

WARNING

Components substitutions could impair intrinsic

Attaching unauthorized components or equipment will void your

safety.

warranties.

Page 4

CAUTION

Do not attempt to make any repair on the printed circuit boards residing in the Product, as this will void all

warranties related to this equipment.

PROPRIETY NOTICE

This document contains propriety and confidential information. It is the property of ORPAK SYSTEMS

Ltd. It may not be disclosed or reproduced in whole or in part without written consent of ORPAK

SYSTEMS. The information in this document is current as of the date of its publication, but is subject to

change without notice.

DISCLAIMER

This document i

ORPAK SYSTEMS does not guarantee that there are no errors or omissions in this document.

s provided for reference only. Although every effort has been made to ensure correctness,

FCC Compliance Statement

The FCC Wants You to Know:

This equipment

pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment generates uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does caus

which can be determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures :

a) Reorient

b) Increase the separation between the equipment and receiver.

c) Connect the equipment to an outlet on a circuit different from that to which the receiver is connected.

d) Consult the dealer or an experienced radio/TV technician.

has been tested and found to comply with the limits for a Class B & C digital device,

e harmful interferen

or relocate the receiving antenna.

FCC Warning

Modifications not expressly approved by the manufacturer could void the user authority to operate the

equipment under FCC Rules.

ce to radio or television reception,

This document is the property of:

ORPAK Systems Ltd.

ISRAEL

Page 5

SiteOmat Setup and Mainte nance Manual – MDE 4817G

TABLE OF CONTENTS

Paragraph

1 GENERAL

DESCRIPTION

Page

1-1. INTRODUCTION .............................................................................................................. 21

1-2. SITEOMAT ........................................................................................................................ 22

1-2.1. Overview ........................................................................................................................ 22

1-2.2. Interfaces ........................................................................................................................ 22

1-2.3. Internal Communication Alternatives ............................................................................ 24

1-2.4. External Communication Alternatives........................................................................... 24

1-2.5. Data Access Methods..................................................................................................... 24

1-3. ORCU ................................................................................................................................. 24

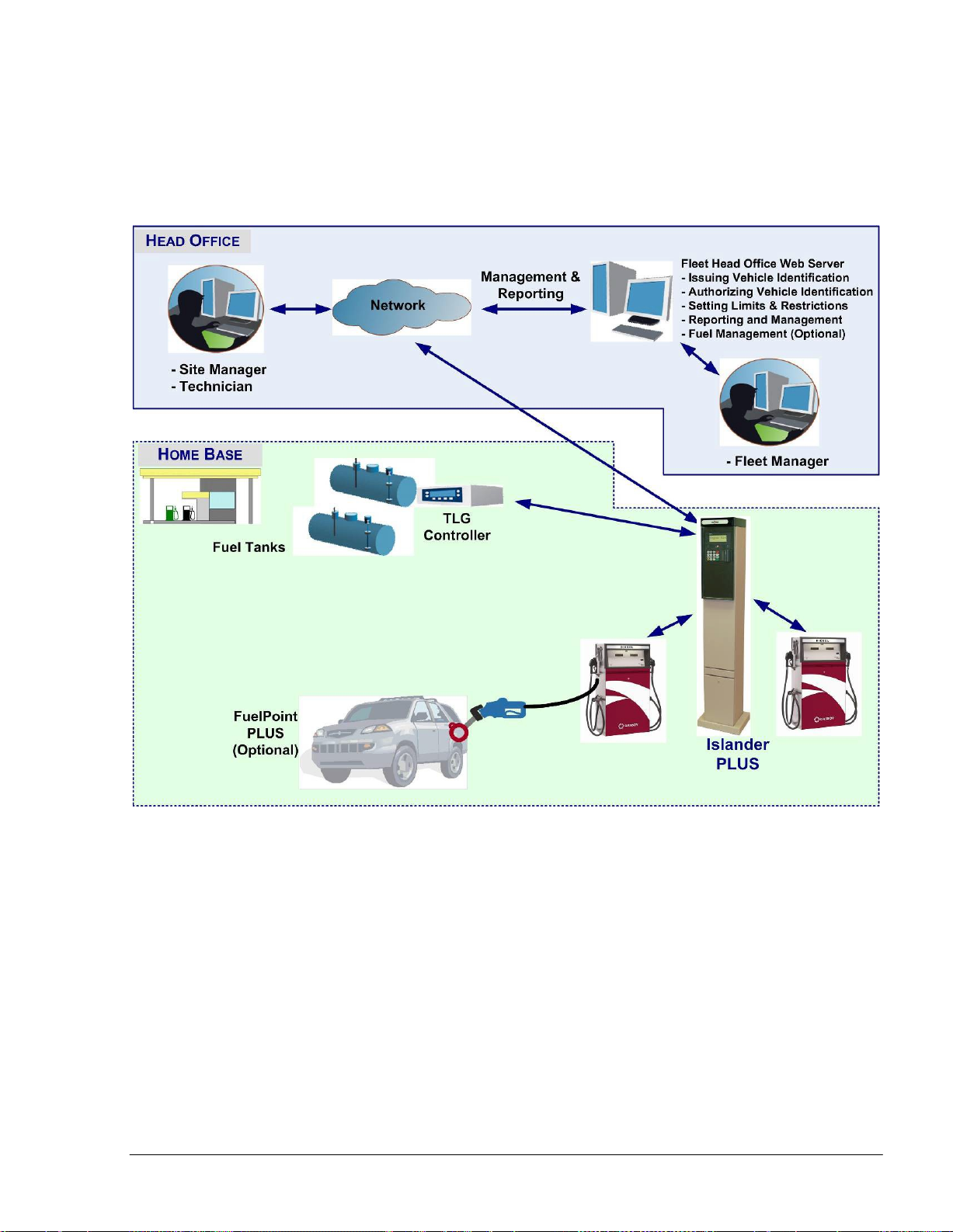

1-4. SYSTEM WORKFLOW – EXAMPLES ........................................................................... 26

1-4.1. General ........................................................................................................................... 26

1-4.2. Refueling Scenario with FuelPoint PLUS ..................................................................... 26

1-4.3. Refueling Scenario with Magnetic Cards ...................................................................... 26

1-4.4. Refueling Scenario with 2 devices (2 stage authorization)............................................ 26

1-5. MANUAL STRUCTURE .................................................................................................. 27

1-6. USING THIS MANUAL.................................................................................................... 28

1-7. REFERENCES ................................................................................................................... 29

2 PRE-SETUP

2-1. GENERAL.......................................................................................................................... 30

2-2. SETUP DEFINITION INFORMATION ........................................................................... 30

2-2.1. Required Setup Information........................................................................................... 30

2-2.2. Required Setup Information – Example......................................................................... 30

2-3. SITE SURVEY ................................................................................................................... 31

2-4. ETHERNET NETWORK ADDRESSES ........................................................................... 32

2-4.1. Network Addresses for Controller Internal Devices...................................................... 32

2-4.2. Serial Addresses for Controller Devices ........................................................................ 32

2-5. NAVIGATION NOTES ..................................................................................................... 38

2-5.1. Not Saving Change ........................................................................................................ 38

2-5.2. Saving Data .................................................................................................................... 38

2-5.3. Errors.............................................................................................................................. 38

INFORMATION

I

Page 6

II

SiteOmat Setup and Mainte nance Manual – MDE 4817G

TABLE OF

CONTENTS

Paragraph Page

2-5.4. Confirmation .................................................................................................................. 39

2-5.5. Success ........................................................................................................................... 40

2-6. CONFIGURATION AND SETUP PROCEDURES .......................................................... 40

2-7. BYPASS FEATURE FOR MECHANICAL PUMPS ........................................................ 42

3 OrCU ADMINSTRATION

SCREEN

3-1. GENERAL .......................................................................................................................... 43

3-2. TECNICIAN PC SOFTWARE REQUIRMENTS ............................................................. 43

3-3. INITIAL SETUP PROCEDURES...................................................................................... 43

3-4. SYSTEM INFORMATION ................................................................................................ 45

3-4.1. Versions Screen.............................................................................................................. 46

3-4.2. Largest Files Screen ....................................................................................................... 47

3-4.3. Mini Terminal Screen..................................................................................................... 47

3-4.4. Reboot Unit .................................................................................................................... 48

3-5. SETUP SCREENS .............................................................................................................. 48

3-5.1. Networking..................................................................................................................... 49

3-5.2. Time ............................................................................................................................... 49

3-5.3. Password......................................................................................................................... 50

3-5.4. Serial/ Modem ................................................................................................................ 50

3-5.5. UPS................................................................................................................................. 51

3-6. INSTALLATION SCREENS ............................................................................................. 53

3-6.1. SiteOmat......................................................................................................................... 53

3-6.2. OrData ............................................................................................................................ 55

3-6.3. Pump Server ................................................................................................................... 56

3-6.4. PAIS ............................................................................................................................... 57

3-6.5. Operating System (BSP) ................................................................................................ 57

3-6.5.1. BSP Upgrade Schema................................................................................................ 58

4 SETUP

WIZARD

4-1. GENERAL .......................................................................................................................... 60

4-2. SOFTWARE REQUIREMENTS ....................................................................................... 61

4-3. ACCESSING THE WIZARD............................................................................................. 61

4-3.1. Microsoft Silverlight Installation ................................................................................... 62

4-4. SETUP WIZARD PROCEDURE....................................................................................... 65

4-4.1. Validation of Parameters ................................................................................................ 65

Page 7

III

SiteOmat Setup and Mainte nance Manual – MDE 4817G

TABLE OF

CONTENTS

Paragraph Page

4-4.2. Page 1 - Welcome .......................................................................................................... 65

4-4.3. Page 2 – Global Parameters ........................................................................................... 66

4-4.4. Page 3 - Forecourt Controller Type ............................................................................... 67

4-4.5. Page 4 - Forecourt Setting.............................................................................................. 70

4-4.6. Page 5 - Products ........................................................................................................... 72

4-4.7. Page 7 - Pumps............................................................................................................... 75

4-4.8. Page 8 – Payment ........................................................................................................... 77

4-4.8.1. Product Map .............................................................................................................. 78

4-4.9. Page 9 – Printer .............................................................................................................. 80

4-4.10. Page 10 – Series 1000 Upgrade ..................................................................................... 81

4-4.11. Page 11 – Series 1000 Upgrade ..................................................................................... 82

4-4.12. Page 12 – Backup........................................................................................................... 83

4-4.13. Finalizing the Wizard..................................................................................................... 84

4-5. MAIN SETUP SCREEN – BASIC MODE........................................................................ 85

4-5.1. Functional B

uttons ......................................................................................................... 87

4-6. SETUP WIZARD DEFAULTS.......................................................................................... 87

4-6.1. Ethernet Network Default Addresses............................................................................. 87

4-6.2. Cluster Port Allocation .................................................................................................. 88

4-6.3. Pump Clustering Conventions ....................................................................................... 88

4-6.4. TLG Settings .................................................................................................................. 91

4-6.5. Naming Conventions ..................................................................................................... 91

4-6.6. Cluster Log Port Conventions........................................................................................ 91

4-6.7. Loading Existing Setup .................................................................................................. 92

5 SPECIFIC PARAMETER

SETTINGS

5-1. GENERAL.......................................................................................................................... 93

5-2. MANAGING USERS......................................................................................................... 93

5-2.1. Login .............................................................................................................................. 96

5-2.1.1. Password Change ...................................................................................................... 96

5-2.2. Adding a User ................................................................................................................ 96

5-2.3. Delete a User .................................................................................................................. 98

5-2.4. Updating a User ............................................................................................................. 98

5-3. ACCESS LEVELS ............................................................................................................. 99

5-4. PASSWORD POLICY ....................................................................................................... 100

5-5. REGISTRATION ............................................................................................................... 102

Page 8

IV

SiteOmat Setup and Mainte nance Manual – MDE 4817G

TABLE OF

CONTENTS

Paragraph Page

5-6. PRICE UPDATE ................................................................................................................ 103

5-6.1. Price Lists ....................................................................................................................... 104

5-6.1.1. General ...................................................................................................................... 104

5-6.1.2. Setup .......................................................................................................................... 104

6 ADVANCED SETUP PROCEDURES – GLOBAL

PARAMETERS

6-1. GENERAL .......................................................................................................................... 107

6-2. GLOBAL PARAMETERS ................................................................................................. 109

6-3. ADVANCED STATION PARAMETERS......................................................................... 110

6-3.1. Open Door Detection ..................................................................................................... 114

6-3.2. Payment Terminal Setup ................................................................................................ 114

6-3.2.1. Product Translation ................................................................................................... 116

6-4. RECEIPT ............................................................................................................................ 116

6-4.1. General Settings ............................................................................................................. 117

6-4.2. Defining Formats............................................................................................................ 118

6-5. ALARMS ............................................................................................................................ 122

6-6. COMM (FCC)..................................................................................................................... 123

6-6.1. General ........................................................................................................................... 123

6-7. BACKUP ............................................................................................................................ 126

6-8. SERIES 1000 ...................................................................................................................... 127

6-9. UI TEXT LOCALIZATION............................................................................................... 128

7 ADVANCED SETUP PROCEDURES -

FORECOURT

7-1. GENERAL .......................................................................................................................... 129

7-2. MAIN SETUP SCREEN – ADVANCED MODE ............................................................. 130

7-3. BUSES ................................................................................................................................ 131

7-3.1. General ........................................................................................................................... 131

7-3.2. Settings ........................................................................................................................... 132

7-3.3. Finalizing........................................................................................................................ 133

7-4. PRINTERS.......................................................................................................................... 134

7-5. ORPT .................................................................................................................................. 135

7-5.1. General ........................................................................................................................... 135

7-5.2. Additional Features ........................................................................................................ 135

7-5.3. Finalizing........................................................................................................................ 136

7-6. TAG READERS ................................................................................................................. 137

Page 9

V

SiteOmat Setup and Maintenance Manual – MDE 4817G

TABLE OF

CONTENTS

Paragraph Page

7-7. TANK LEVEL GAUGE – TLG ......................................................................................... 138

7-7.1. General ........................................................................................................................... 138

7-7.2. Probes............................................................................................................................. 138

7-7.2.1. Strapping ................................................................................................................... 140

7-7.2.2. Oil/Water Separator Probe Setting ............................................................................ 141

7-7.2.3. Finalizing Probes Settings ......................................................................................... 142

7-7.3. Sensors ........................................................................................................................... 143

7-7.4. Finalizing Settings ......................................................................................................... 143

7-7.5. Auto Calibration............................................................................................................. 144

7-7.5.1. Tank Calibration Graphs ........................................................................................... 146

7-8. TANKS AND PRODUCTS ............................................................................................... 147

7-8.1. General ........................................................................................................................... 147

7-8.2. Properties ....................................................................................................................... 147

7-8.3. Products.......................................................................................................................... 148

7-8.3.1. General ...................................................................................................................... 148

7-8.3.2. Defining a Base Product............................................................................................ 148

7-8.3.3. Defining a Blended Product ...................................................................................... 149

7-8.4. Defini

ng a Virtual Tank for Blended Fuel ..................................................................... 149

7-8.5. Tank Alarm Settings ...................................................................................................... 150

7-8.5.1. Fuel Leak ................................................................................................................... 150

7-8.5.2. Fuel Volume .............................................................................................................. 150

7-8.5.3. Fuel Density, Fuel Temperature, Water Level .......................................................... 150

7-8.6. Probes Definition ........................................................................................................... 151

7-8.7. Finalizing Settings ......................................................................................................... 151

7-9. VIS AND WGT .................................................................................................................. 152

7-10. PUMP SERVERS ............................................................................................................... 153

7-10.1. General ........................................................................................................................... 153

7-10.2. Additional Features ........................................................................................................ 155

7-10.3. Finalizing the Settings in the Pump Servers Screen ...................................................... 157

7-11. DISPENSERS ..................................................................................................................... 157

7-11.1. General ........................................................................................................................... 157

7-11.2. Message Factors ............................................................................................................. 159

7-11.3. Specific .......................................................................................................................... 159

7-11.3.1. Mechanical Pump Specific Parameters ..................................................................... 160

7-11.3.2. Gasboy Pump Specific Parameters ........................................................................... 161

Page 10

VI

SiteOmat Setup and Mainte nance Manual – MDE 4817G

TABLE OF

CONTENTS

Paragraph Page

7-11.3.3. Gilbarco Pump Specific Parameters .......................................................................... 161

7-11.3.4. Tokheim Pump Specific Parameters ......................................................................... 162

7-11.3.5. Wayne Dart Pump Specific Parameters .................................................................... 162

7-11.4. More Pump Options ....................................................................................................... 163

7-11.5. Finalizing Pump Settings ............................................................................................... 165

7-11.6. Deleting Pump................................................................................................................ 165

7-12. EXPORT/ IMPORT ............................................................................................................ 166

7-12.1. General ........................................................................................................................... 166

7-12.2. Exporting / Saving Setup................................................................................................ 166

7-13. APPLYING THE SETUP SETTINGS ............................................................................... 167

7-14. VERIFYING DEVICES STATUS ..................................................................................... 168

7-15. PIPE FLOW MEASUREMENT......................................................................................... 169

8

MAINTENANCE

8-1. OVERVIEW ....................................................................................................................... 172

8-1.1. Tools and Utilities .......................................................................................................... 173

8-1.2. IP Addresses and Connections ....................................................................................... 175

8-1.3. Regular FCC Maintenance Operation ............................................................................ 175

8-1.3.1. FCC Transaction Limit .............................................................................................. 175

8-1.3.2. Disk Usage Thresholds .............................................................................................. 175

8-1.3.3. Purging Old Data ....................................................................................................... 176

8-1.4. Management File Locations ........................................................................................... 176

8-1.4.1. /usr/local//orpak/BOS/bin .......................................................................................... 176

8-1.4.2. /usr/local/orpak/BOS/bin/log..................................................................................... 176

8-1.4.3. /usr/local/orpak/BOS/DB/patches ............................................................................. 176

8-1.4.4. /usr/local/orpak/BOS/htdocs/* .................................................................................. 176

8-1.4.5. /usr/local/orpak/BOS/reports ..................................................................................... 176

8-1.5. FCC File Locations ........................................................................................................ 176

8-1.6. FCC Loader – Watchdog................................................................................................ 176

8-1.6.1. Pump Server .............................................................................................................. 177

8-1.6.2. Pump Server ‘ini’ Files.............................................................................................. 177

8-1.6.3. Pump Server Factor Settings ..................................................................................... 178

8-2. SYSTEM COMMANDS .................................................................................................... 180

8-2.1. Logging Settings ............................................................................................................ 181

8-3. BACKUP AND RECOVERY ............................................................................................ 185

Page 11

VII

SiteOmat Setup and Mainte nance Manual – MDE 4817G

TABLE OF

CONTENTS

Paragraph Page

8-3.1. Recovery ........................................................................................................................ 186

8-4. LOG FILES ........................................................................................................................ 188

8-4.1. Log File Rotation ........................................................................................................... 188

8-4.2. Log File Format ............................................................................................................. 188

8-4.2.1. General ...................................................................................................................... 188

8-4.2.2. Date/Time Stamp and Thread ID .............................................................................. 189

8-4.2.3. Locating Object ID .................................................................................................... 189

8-4.3. Critical log file ............................................................................................................... 189

8-4.4. BOS Log Files................................................................................................................ 190

8-4.4.1. BOS_REMOTE_HO.log........................................................................................... 190

8-4.4.2. Database Logs (DATA.log, META_DATA.log, LANG.log)................................... 190

8-4.4.3. Web Server Access Logs (WebAccessxxxx.log) ...................................................... 190

8-4.4.4. Web Server Communications Logs (WebCommxxxx.log) ...................................... 190

8-4.4.5. Debug Log (debug.log) ............................................................................................. 191

8-4.5. FCC Log File

s ................................................................................................................ 191

8-4.5.1. FCC_AUTH.log ........................................................................................................ 191

8-4.5.2. Database Logs (DATA.DB.log, META_DATA.DB.log)......................................... 191

8-4.5.3. Bus Logs (BUS_xxx.log) .......................................................................................... 192

8-4.5.4. Pump Server Log FIles.............................................................................................. 194

8-4.5.5. FCC Loader Log (fccloader.log) ............................................................................... 194

8-4.5.6. Web Server Monitor Log (WebAccess6000.log, WebComm6000.log) ................... 195

8-4.5.7. Web Server Watchdog Log (WebAccess6001.log, WebComm6001.log) ................ 195

8-4.5.8. Web Server Access Logs (WebAccessxxxx.log) ...................................................... 195

8-4.5.9. Web Server Communications Logs (WebCommxxxx.log) ...................................... 196

8-4.5.10. Debug Log (debug.log) ............................................................................................. 197

8-4.5.11. Lock Miss use Log (DebugLock.log) ....................................................................... 205

8-5. FCC MONITOR ................................................................................................................. 206

8-5.1. Basic Navigation ............................................................................................................ 206

8-5.2. Starting the FCC Monitor from a putty Window ........................................................... 206

8-5.3. Starting the FCC Monitor from the Windows Command Prompt ................................. 208

8-5.4. FCC Monitor Command Menu ...................................................................................... 209

8-5.4.1. Pumps Overview ....................................................................................................... 209

8-5.4.2. Tanks Overview ........................................................................................................ 210

8-5.4.3. Device Status ............................................................................................................. 210

8-5.4.4. Monitor Buses ........................................................................................................... 214

Page 12

VIII

SiteOmat Setup and Mainte nance Manual – MDE 4817G

TABLE OF

CONTENTS

Paragraph Page

8-5.4.5. Debug Log ................................................................................................................. 217

8-5.4.6. Admin Commands..................................................................................................... 218

8-5.4.7. System Information ................................................................................................... 219

8-5.4.8. Change Password....................................................................................................... 219

8-5.4.9. Exit ............................................................................................................................ 219

8-6. LINUX COMMANDS........................................................................................................ 220

8-6.1. df (Displays file-system information) ............................................................................ 220

8-6.2. ifconfig (Command line tool to check all network cards/interfaces) ............................. 220

8-6.3. Ping (Sends test packets to a specified server to check if it is responding properly)..... 220

8-6.4. ps (Lists all existing processes on the server) ................................................................ 221

8-6.5. top (Displays many system statistics and details regarding active processes) ............... 221

8-6.6. grep (Filter output of other programs)............................................................................ 221

8-6.7. vim (

Text editor) ............................................................................................................ 222

8-6.8. less (Text file viewer)..................................................................................................... 222

8-6.9. tail (Display continuously file added lines).................................................................... 222

8-6.10. cd (Change current directory) ........................................................................................ 222

8-6.11. pwd (Show current directory) ........................................................................................ 222

8-6.12. ls (List directory) ............................................................................................................ 223

8-6.13. history (Show last typed commands) ............................................................................. 223

8-6.14. telnet (Open connection to IP port) ................................................................................ 223

8-6.15. script ............................................................................................................................... 223

8-6.16. Useful Linux Files .......................................................................................................... 223

8-7. SQLITE HANDLING......................................................................................................... 223

8-7.1. Getting Inside the Directory of the DB Files & Start a Session of SQLite .................... 224

8-7.2. Display all the Tables that are Inside a DB file.............................................................. 226

8-7.3. Display the Types of each Field inside the Table .......................................................... 227

8-7.4. Display all the Content that is Stored inside a Table ..................................................... 228

8-8. FHO HANDLING FOR SMALL SITES ........................................................................... 231

8-9. EVENTS / ALARMS ......................................................................................................... 231

8-9.1. Events ............................................................................................................................. 231

8-9.2. Logs ................................................................................................................................ 232

8-9.3. Alarms ............................................................................................................................ 233

8-10. ORCU BOX LEDS ............................................................................................................. 235

8-11. RS-232 CONNECTOR ....................................................................................................... 238

8-12. ORCU CONNECTION VIA RS-232 ................................................................................. 239

Page 13

IX

SiteOmat Setup and Mainte nance Manual – MDE 4817G

TABLE OF

CONTENTS

Paragraph Page

8-12.1. OrCU Ethernet Failure – Data Base Recovery .............................................................. 245

9 ORCU EXTERNAL

COMMUNICATION

9-1. GENERAL.......................................................................................................................... 246

9-2. OVERVIEW ....................................................................................................................... 246

9-3. ADSL/INTRANET CONNECTIONS................................................................................ 246

9-3.1. Overview ........................................................................................................................ 246

9-3.2. Router Settings ............................................................................................................... 247

9-3.3. OrCU Settings ................................................................................................................ 247

9-3.3.1. Additional Network Commands................................................................................ 248

9-4. DIAL UP MODEMS .......................................................................................................... 249

9-4.1. Overview ........................................................................................................................ 249

9-4.2. OrCU Settings ................................................................................................................ 249

9-4.3. Siemens MC35 GSM Modem........................................................................................ 251

9-4.4. Wavecom Fastrack GSM Modem.................................................................................. 252

9-4.5. U.S ROBOTICS 56K Faxmodem.................................................................................. 253

9-4.6. OrCU - Modem Harness Specification .......................................................................... 254

9-4.7. AT COMMANDS.......................................................................................................... 254

9-5. GPRS MODEM .................................................................................................................. 255

9-6. 3G MODEMS CONNECTIONS........................................................................................ 255

9-6.1. Overview ........................................................................................................................ 255

9-6.2. Hardware Requirements................................................................................................. 256

9-6.3. Router Settings ............................................................................................................... 257

9-6.4. OrCU Settings ................................................................................................................ 259

9-6.5. Connecting to OrCU from an External PC .................................................................... 260

10

GLOSSARY

10-1. FUELOMAT GLOSSARY ................................................................................................ 265

10-2. COMMUNICATION GLOSSARY ................................................................................... 266

APPENDIX A SITE SURVEY

APPENDIX B SITE SURVEY FORM – HOME BASE

FORMS

STATION

Page 14

X

SiteOmat Setup and Mainte nance Manual – MDE 4817G

TABLE OF

Paragraph Page

APPENDIX C SITE SURVEY FORM – FUEL TRUCK

APPENDIX D HOW TO OPEN ZIP OR RAR

APPENDIX E SETTING THE IP

APPENDIX F WEIGHT AND MEASURES SECURITY

F-1. GENERAL .......................................................................................................................... 280

F-2. INSTALLATION KIT ........................................................................................................ 280

F-3. INSTALLATION PROCEDURE....................................................................................... 281

F-4. SETUP ................................................................................................................................ 283

APPENDIX G DISCOVERY

CONTENTS

STATION

FILES

ADDRESS

MODE

PLUG

G-1. GENERAL .......................................................................................................................... 286

G-2. SETUP ................................................................................................................................ 286

G-3. OPERATION PROCEDURE ............................................................................................. 290

G.3.1. PIN Feature .......................................................................................................................... 293

G.3.2. Odometer Feature................................................................................................................. 293

G.3.3. Card Number Generation ..................................................................................................... 294

G.3.4. Editing the Devices .............................................................................................................. 294

G.3.5. Final Wrap Up...................................................................................................................... 294

Page 15

XI

SiteOmat Setup and Mainte nance Manual – MDE 4817G

LIST OF ILLUSTRATIONS

Figure

Page

Figure 1-1 – Islander PLUS in Home Base Station - General Configuration Diagram .................... 23

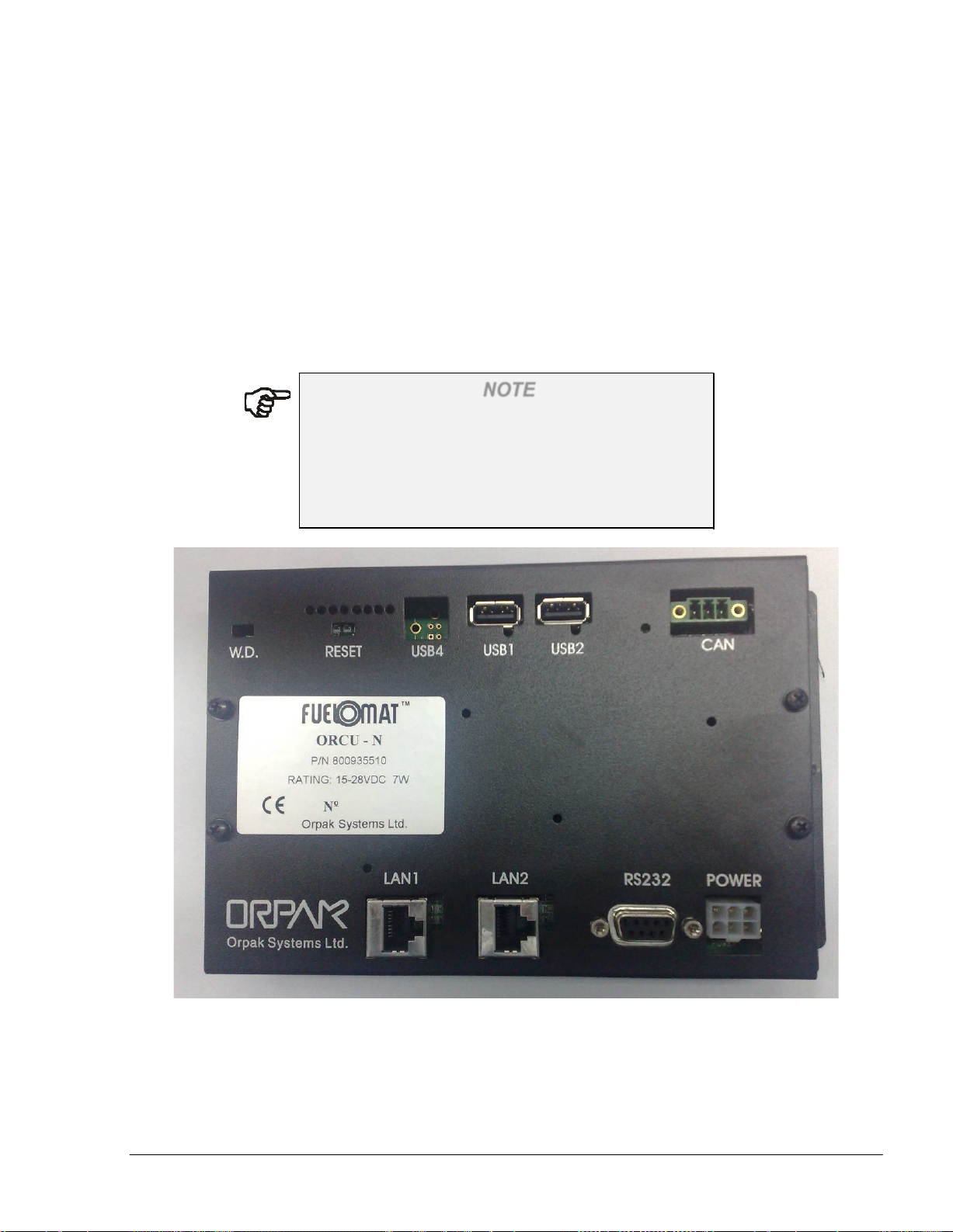

Figure 1-2 - OrCU - General View.................................................................................................... 25

Figure 2-1. Setup Requirement – Example (Pump) .......................................................................... 31

Figure 2-2. System Address Example - Islander PLUS .................................................................... 34

Figure 2-3. System Address Example – CFN PLUS........................................................................ 35

Figure 2-4. System Address Example - Extension Box .................................................................... 36

Figure 2-5. System Address Example – ICR PLUS .......................................................................... 37

Figure 2-6. Cancel Warning Message ............................................................................................... 38

Figure 2-7. Processing Message ........................................................................................................ 38

Figure 2-8. Same Name Error Message............................................................................................. 39

Figure 2-9. IP Port Error Message..................................................................................................... 39

Figure 2-10. Device with Same Address Error Message................................................................... 39

Figure 2-11. Cannot Delete Message ................................................................................................ 39

Figure 2-12. Confirmation Message .................................................................................................. 40

Figure 2-13. Operation Successful Message ..................................................................................... 40

Figure 3-1. Login Dialog Box ........................................................................................................... 44

Figure 3-2. OrCU Administrator –Home Screen .............................................................................. 44

Figure 3-3. System Information Screen............................................................................................. 46

Figure 3-4. Versions Screen .............................................................................................................. 46

Figure 3-5. Largest Files Screen........................................................................................................ 47

Figure 3-6. Mini Terminal Screen ..................................................................................................... 48

Figure 3-7. Unit Reboot Warning Message....................................................................................... 48

Figure 3-8. Time Setup Screen .......................................................................................................... 50

Figure 3-9. OrCU Password Screen .................................................................................................. 50

Figure 3-10. Serial/Modem Settings Screen...................................................................................... 51

Figure 3-11. UPS Setup Screen ......................................................................................................... 52

Figure 3-12. W&M Security Plug Message ...................................................................................... 54

Figure 3-12. Install SiteOmat Screen ................................................................................................ 54

Page 16

X

SiteOmat Setup and Mainte nance Manual – MDE 4817G

LIST OF

ILLUSTRATIONS

Figure Page

Figure 3-13. Installation Warning Message....................................................................................... 55

Figure 3-14. Install OrData Screen .................................................................................................... 55

Figure 3-15. Install Pump Server Screen ........................................................................................... 56

Figure 3-16. Install PAIS Screen ....................................................................................................... 57

Figure 3-17. Install Operating System (BSP) Screen ........................................................................ 58

Figure 3-18. BSP Service Pack Upgrade Warning Message ............................................................. 58

Figure 3-19. BSP Upgrade Schema ................................................................................................... 59

Figure 4-1. Setup Screen.................................................................................................................... 62

Figure 4-2. Setup Wizard – Setup Override Warning Message ........................................................ 62

Figure 4-3. Setup Wizard – Microsoft Silverligth Download Link ................................................... 63

Figure 4-4. Microsoft Silverligth Update Message ........................................................................... 63

Figure 4-5. File Download Security Warning Message .................................................................... 64

Figure 4-6. IE Security Warning Message......................................................................................... 64

Figure 4-7. Install Silverlight Message.............................................................................................. 64

Figure 4-8. Silverlight Installation Successful Message.................................................................... 65

Figure 4-9. Restart Browser Message................................................................................................ 65

Figure 4-10. SiteOmat Setup Wizard, Page 1 .................................................................................... 66

Figure 4-11. SiteOmat Setup Wizard, Page 2 .................................................................................... 67

Figure 4-12. SiteOmat Setup Wizard, Page 3 .................................................................................... 68

Figure 4-13. SiteOmat Setup Wizard, Page 4 .................................................................................... 70

Figure 4-14. SiteOmat Setup Wizard, Page 5 .................................................................................... 72

Figure 4-15. SiteOmat Setup Wizard, Page 6 .................................................................................... 73

Figure 4-16. SiteOmat Setup Wizard, Page 7 .................................................................................... 75

Figure 4-17. SiteOmat Setup Wizard, Page 8 .................................................................................... 77

Figure 4-18. SiteOmat Setup Wizard – Product Mapping Dialog Box ............................................. 79

Figure 4-19. SiteOmat Setup Wizard, Page 9 .................................................................................... 80

Figure 4-20. SiteOmat Setup Wizard, Page 10 .................................................................................. 81

Figure 4-21. SiteOmat Setup Wizard, Page 11 .................................................................................. 82

Page 17

XIII

SiteOmat Setup and Mainte nance Manual – MDE 4817G

LIST OF

ILLUSTRATIONS

Figure Page

Figure 4-22. SiteOmat Setup Wizard, Page 12.................................................................................. 83

Figure 4-23. Wizard Processing and Successful Message ................................................................ 84

Figure 4-24. Main Setup Screen – Basic Mode................................................................................. 85

Figure 4-25. Setup Pump Settings Dialog Box ................................................................................. 86

Figure 5-1. SiteOmat Station Controller – User Authorization Process .......................................... 94

Figure 5-2. Administration Screen – User Management Tab........................................................... 95

Figure 5-3. Login Dialog Box ........................................................................................................... 96

Figure 5-4. Change Password Window ............................................................................................ 96

Figure 5-5. User Properties Window ................................................................................................ 97

Figure 5-6. Policy Tab .................................................................................................................... 100

Figure 5-7. Registration Screen ...................................................................................................... 102

Figure 5-8 Wet Stock Management Window .................................................................................. 103

Figure 5-9. Wet Price Lists Dialog Box ......................................................................................... 105

Figure 6-1. Station Parameters Screen – Global Tab ...................................................................... 108

Figure 6-2. Station Parameters, Additional Options........................................................................ 111

Figure 6-3. Setup PAIS Dialog Box –FiPay Processor Specifics ................................................... 114

Figure 6-4. Product Translation Dialog Box ................................................................................... 116

Figure 6-5. Receipt Format Selection Dialog Box .......................................................................... 117

Figure 6-6. Format Receipt Header/Footer Dialog Box .................................................................. 118

Figure 6-7. Alarm Management Dialog Box................................................................................... 122

Figure 6-8. Setup Comms ................................................................................................................ 123

Figure 6-9. Setup Backup ................................................................................................................ 126

Figure 6-10. Save Data Message ..................................................................................................... 127

Figure 6-11. Text Translation Dialog Box ...................................................................................... 128

Figure 7-1. Setup Screen - Advanced Mode.................................................................................... 130

Figure 7-2. Buses Dialog Box ......................................................................................................... 132

Figure 7-3. Bus Selection ................................................................................................................ 133

Figure 7-4. Printers Dialog Box ...................................................................................................... 134

Page 18

XIV

SiteOmat Setup and Maintenance Manual – MDE 4817G

LIST OF

ILLUSTRATIONS

Figure Page

Figure 7-5. OrPT Dialog Box .......................................................................................................... 135

Figure 7-6. OrPT Features Dialog Box............................................................................................ 136

Figure 7-7. Tag Reader Dialog Box................................................................................................. 137

Figure 7-8. TLG Dialog Box ........................................................................................................... 138

Figure 7-9. Probes Dialog Box ........................................................................................................ 140

Figure 7-10. Strapping Table Screen ............................................................................................... 141

Figure 7-11. Strapping File Selection .............................................................................................. 141

Figure 7-12. Probes Oil/Water Separator Dialog Box ..................................................................... 142

Figure 7-13. Oil/Water Separator Initial and Alarm Levels ............................................................ 142

Figure 7-14. Sensors Dialog Box..................................................................................................... 143

Figure 7-15. Tank Status Screen ...................................................................................................... 144

Figure 7-16. Auto Calibration Data Dialog Box.............................................................................. 145

Figure 7-17. Tank Calibration Graphs Dialog Box ......................................................................... 146

Figure 7-18. Setup Tanks Dialog Box ............................................................................................. 147

Figure 7-19. Setup Fuel Products Dialog Box ................................................................................. 148

Figure 7-20. Tanks Probes Dialog Box ........................................................................................... 151

Figure 7-22.Setup VIT with WGT................................................................................................... 153

Figure 7-23. Pump Server Flow....................................................................................................... 154

Figure 7-24. Setup Pump Server Dialog Box .................................................................................. 155

Figure 7-25. Pump Server Settings Screen ...................................................................................... 156

Figure 7-26. Setup Pump Settings Dialog Box................................................................................ 158

Figure 7-27. Setup Pump Settings (more) Dialog Box .................................................................... 164

Figure 7-28. Setup Screen – Application Buttons ........................................................................... 166

Figure 7-29. Open or Save File Message......................................................................................... 166

Figure 7-30. Importing Setup Confirmation Message ..................................................................... 167

Figure 7-31. Setup Import Screen.................................................................................................... 167

Figure 7-32. Processing Message .................................................................................................... 168

Figure 7-33. Devices Tab in Status Page ......................................................................................... 169

Page 19

XV

SiteOmat Setup and Mainte nance Manual – MDE 4817G

LIST OF

ILLUSTRATIONS

Figure Page

Figure 7-34. Defining a Virtual Pump - Pump Server Settings Dialog Box ................................... 170

Figure 7-35. Defining a Virtual Pump – Setup Pump Settings Dialog Box .................................... 171

Figure 7-36. Virtual Pump Status .................................................................................................... 171

Figure 8-1. SiteOmat Modules ........................................................................................................ 173

Figure 8-2. Scheduling LogRotate................................................................................................... 174

Figure 8-3. Sys Commands Screen ................................................................................................. 181

Figure 8-4. Logging Settings Dialog Box ....................................................................................... 182

Figure 8-5. Backup Screen .............................................................................................................. 185

Figure 8-6. Putty Configuration Screen - 1 ..................................................................................... 206

Figure 8-7. Putty Configuration Screen - 2 ..................................................................................... 207

Figure 8-8. Putty Configuration Screen - 3 ..................................................................................... 207

Figure 8-9. Putty Configuration Screen - 4 ..................................................................................... 208

Figure 8-10. FCC Monitor Command Menu................................................................................... 209

Figure 8-11. Pump Summary........................................................................................................... 209

Figure 8-12. Tank Summary............................................................................................................ 210

Figure 8-13. Device Status .............................................................................................................. 210

Figure 8-14. Pump Status - 1 ........................................................................................................... 211

Figure 8-15. Pump Status - 2 ........................................................................................................... 211

Figure 8-16. Pump Status - 3 ........................................................................................................... 212

Figure 8-17. OPOS .......................................................................................................................... 212

Figure 8-18. Printer - 1 .................................................................................................................... 213

Figure 8-19. Printer - 2 .................................................................................................................... 213

Figure 8-20. List of Busses.............................................................................................................. 214

Figure 8-21. Bus Running Logs in XML ........................................................................................ 214

Figure 8-22. Bus Running Logs in Hexadecimal ............................................................................ 215

Figure 8-23. Raw Logs - 1............................................................................................................... 216

Figure 8-24. Raw Logs - 2............................................................................................................... 216

Figure 8-25. Raw Logs - 2............................................................................................................... 217

Page 20

XVI

SiteOmat Setup and Mainte nance Manual – MDE 4817G

LIST OF

ILLUSTRATIONS

Figure Page

Figure 8-26. Display of raw logs ..................................................................................................... 218

Figure 8-27. Administrator Commands Screen ............................................................................... 218

Figure 8-28. System Information Screen ......................................................................................... 219

Figure 8-29. Change Password Screen ............................................................................................ 219

Figure 8-30. Logging into the System via “Putty” .......................................................................... 224

Figure 8-31. Logging into the System via “Putty” .......................................................................... 225

Figure 8-32. Display all Tables inside a DB File ............................................................................ 226

Figure 8-33. Display Types of each Filed inside the Table ............................................................. 227

Figure 8-34. Display all the Content Stored inside a Table ............................................................. 228

Figure 8-35. Display Content of a Table with Specific Value......................................................... 229

Figure 8-36. Display All Available Commands .............................................................................. 230

Figure 8-37. Event Viewer............................................................................................................... 232

Figure 8-38. Log Viewer – Login List............................................................................................. 233

Figure 8-39. Log Viewer – Reports List.......................................................................................... 233

Figure 8-40. Alarm Screen............................................................................................................... 235

Figure 8-41. OrCU box – LED’s Configuration.............................................................................. 237

Figure 8-42. OrCU Internal Drawing – LED’s Configuration ........................................................ 237

Figure 8-43. RS-232 Connector Pinout ........................................................................................... 238

Figure 8-44. Connection Description Dialog Box ........................................................................... 239

Figure 8-45. OrCU Properties Dialog Box ...................................................................................... 240

Figure 8-46. COM1 Properties Dialog Box ..................................................................................... 240

Figure 8-47. OrCU HyperTerminal Screen ..................................................................................... 241

Figure 8-48. OrCU HyperTerminal Screen after Restart................................................................. 241

Figure 8-49. OrCU HyperTerminal Screen – Enter Password Message ......................................... 242

Figure 8-50. OrCU HyperTerminal Screen – Password OK ........................................................... 243

Figure 8-51. OrCU HyperTerminal Screen - Login ........................................................................ 243

Figure 8-52. OrCU HyperTerminal Screen – Successful Login...................................................... 244

Figure 8-53. OrCU HyperTerminal screen – ifconfig Command.................................................... 244

Page 21

XVII

SiteOmat Setup and Mainte nance Manual – MDE 4817G

LIST OF

ILLUSTRATIONS

Figure Page

Figure 8-54. Zmodem with Crash Recovery Dialog Box................................................................ 245

Figure 9-1. Intranet Connection and ADSL Modem ....................................................................... 246

Figure 9-2. Port Forwarding Rules .................................................................................................. 247

Figure 9-3. OrCU Networking Screen............................................................................................. 248

Figure 9-4. Example of Advanced Network Settings...................................................................... 249

Figure 9-5. OrCU Serial/ Modem Settings Screen .......................................................................... 250

Figure 9-6. Siemens MC35 GSM Modem ...................................................................................... 251

Figure 9-7. Wavecom Fastrack GSM Modem ................................................................................ 252

Figure 9-8. U.S ROBOTICS 56K Faxmodem................................................................................. 253

Figure 9-9. Modem Setting Screen.................................................................................................. 255

Figure 9-10. 3G Modem Connections ............................................................................................. 256

Figure 9-11. Router with USB Support ........................................................................................... 257

Figure 9-12. Air Card USB.............................................................................................................. 257

Figure 9-13. New Connection Wizard – Network Connection Type Screen .................................. 260

Figure 9-14. New Connection Wizard – Getting Ready Screen...................................................... 260

Figure 9-15. New Connection Wizard – Internet Connection Screen ............................................. 261

Figure 9-16. New Connection Wizard – Select a Device Screen .................................................... 261

Figure 9-17. New Connection Wizard – Connection Name Screen ................................................ 262

Figure 9-18. New Connection Wizard – Phone Number to Dial Screen......................................... 262

Figure 9-19. New Connection Wizard – Connection Availability Screen ...................................... 263

Figure 9-20. New Connection Wizard – Internet Account Information Screen.............................. 263

Figure 9-21. Connecting to OrCU ................................................................................................... 264

Figure E-1. Control Panel Screen .................................................................................................... 276

Figure E-2. Network Connections Screen ....................................................................................... 277

Figure E-3. Local Connection Properties Dialog Box..................................................................... 278

Figure E-4. Internet Protocol (TCP/IP) Properties Dialog Box....................................................... 279

Figure F-1. W&M Security Plug ..................................................................................................... 280

Figure F-2. Removing Spacers from RS-232 Connector ................................................................ 281

Page 22

XVIII

SiteOmat Setup and Mainte nance Manual – MDE 4817G

LIST OF

ILLUSTRATIONS

Figure Page

Figure F-3. Placing the Bracket ....................................................................................................... 282

Figure F-4. Securing the Bracket ..................................................................................................... 282

Figure F-5. Installing the Security Plug........................................................................................... 283

Figure F-6. OrCU Administrator Login Dialog Box ....................................................................... 283

Figure F-7. OrCU Administrator –Home Screen............................................................................. 284

Figure F-8. Serial/Modem Settings Screen ...................................................................................... 284

Figure F-9. System Information Screen........................................................................................... 285

Figure F-10. Unit Reboot Warning Message................................................................................... 285

Figure G-1. Station Parameters Screen............................................................................................ 287

Figure G-2. Setup Wizard Page 4 – Upgrade Information Section ................................................. 287

Figure G-3. Setup Wizard Page 5 – Products List ........................................................................... 288

Figure G-4. Setup Wizard Page 10 – Series 1000 Upgrade............................................................. 288

Figure G-5. Setup Wizard Page 11 – Series 1000 Upgrade............................................................. 289

Figure G-6. Series 1000 Upgrade Button ........................................................................................ 290

Figure G-7. Station Status – Success ............................................................................................... 291

Figure G-8. Station Status – Pulling Remote................................................................................... 291

Figure G-9. FHO Devices Screen .................................................................................................... 292

Figure G-10. FHO Rules Screen...................................................................................................... 292

Figure G-11. Devices Properties Dialog – Validation Tab – PIN Code Section............................. 293

Figure G-12. Odometer Validation Section ..................................................................................... 293

Figure G-13. Generated Card Numbers ........................................................................................... 294

Page 23

XIX

SiteOmat Setup and Mainte nance Manual – MDE 4817G

LIST OF

TABLES

Table

Page

Table 2-1. Network Addresses for Controller Devices .................................................................... 32

Table 2-2. Serial (HEX) Addresses for Devices............................................................................... 33

Table 3-1. OrCU Status Screen Elements ......................................................................................... 45

Table 3-2 UPS Setup Parameters ...................................................................................................... 52

Table 4-1. Payment Clearing System Parameters ............................................................................. 77

Table 4-2. Network Addresses for Controller Devices .................................................................... 88

Table 4-3. Electronic Pump Default Settings ................................................................................... 90

Table 5-1. Access Levels................................................................................................................... 99

Table 5-2. Policy Screen Fields ....................................................................................................... 101

Table 6-1. Global Tab Parameters ................................................................................................... 109