Page 1

'

This document is based on Orpak’s SiteOmat In-House Station Controller

MDE-4818E

SiteOmat In-House Station Controller

USER’S MANUAL

This manual supports released version 6.4.45

manual P/N 817423751

Page 2

SAFETY CONSIDERATIONS

Read all warning no tes and instructions carefully. They are included to help y ou installing the Produc t safely

in the highly flammable env ironment of the fuel st ation. Disregarding these warning notes and instructions

could result in serious injury or property damage. It is the installer responsibility to install, operate and

maintain the equipment a ccording to the instructi ons given in this manual, a nd to conform to all applicable

codes, regulations and safety measures. Failure to do so could void all warranties associated with this

equipment.

Remember that the fuel station environment is highly flammable and combustible. Therefore, make sure

that actual installation is performed by experienc ed personnel, licensed to perform work in fuel station and at

a flammable environment, according to the local regulations and relevant standards.

WARNING - EXPLOSION HAZARD

Use separate conduit for the intrinsically safe. Do not run any other wires or cables through this conduit,

because this could create an explosion hazard.

Use standard test equipment only in the non- ha z ardous area of the fuel station, and approved test equipment

for the hazardous areas.

In the installation and maintenance of the Pro duc t, comply with all applicable re qui r ements of the National

Fire Protection Association NFPA-30 “Flammable and C ombustible Liquids Code” , NFPA-30A “Automotive

and Marine Servic e Station Code”, NFPA-70 “National Electric Code”, federal, state and local codes and any

other applicable safety codes and regulations.

Do not perform metal work in a hazardous area. Sparks generated by drilling, tapping and other metal work

operations could ignit e fuel vapors and flammable l iquids, resulting in death, serious personal injury,

property loss and damage to you and other persons.

CAUTION - SHOCK HAZARD

Dangerous AC voltages that could cause death or serious personal injury are used to power the Product.

Always disconnect power before starting any work. The Product has more tha n one power supply co nne c tion

points. Disconnect all power before servicing.

WARNING – PASSING VEHICLES

When working in any open area of fuel station, beware of passing vehicles that could hit you. Block off the

work area to protect yourself and other persons. Use safety cones or other signaling devices.

WARNING

Components substitut i ons could impair intrinsic safety.

Attaching unauthoriz e d c omponents or equipment will void your war r anties.

Page 3

CAUTION

Do not attempt to make any repair on the printed circ uit boards residing in t he Product, as this will void all

warranties related to this equipment.

PROPRIETY NOTICE

This document contains propriety and confidenti al information. It is the prope r ty of ORPAK SYSTEMS

Ltd. It may not be disclosed or reproduced in who le or in part without writt en consent of ORPAK

SYSTEMS. The information in this document is current as of the date o f its publication, but is subject to

change without no tice.

DISCLAIMER

This document is provided for reference only. Although every effort has been made to ensure correctness,

ORPAK SYSTEMS does not guarantee that there are no errors or omissions in this document.

FCC Compliance Statement

The FCC Wants You to Kno w:

This equipment has been t ested and found to comply with the limits for a Cla ss B & C digital device,

pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment generates uses and can radiate radio

frequency energy and, if not installed and used in accordance with the i nst ructions, may cause harmfu l

interference to radio communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment o ff and on, the user is encouraged to try to co r rect the

interference by one or more of the following measures :

a) Reorient or relocate the receiving antenna.

b) Increase the separation between the equipment and receiver.

c) Connect the equipment to an outlet on a circuit different from that to which the receiver is connected.

d) Consult the dealer or an experienced radio/TV technician.

FCC Warning

Modifications not expressly approved by the manufacturer could void the user authori ty to operate the

equipment under FCC Rules.

This document is the prop erty of:

ORPAK Systems Ltd.

ISRAEL

Page 4

Page 5

Paragraph

Page

TABLE OF CONTENTS

1

GENERAL DESCRIPTION

1-1. INTRODUCTION .............................................................................................................. 11

1-2. SITEOMAT ........................................................................................................................ 12

1-2.1. Overview ........................................................................................................................ 12

1-2.2. Interfaces ........................................................................................................................ 12

1-2.3. Internal Communication Alternatives ............................................................................ 14

1-2.4. External Communication Alternatives ........................................................................... 14

1-2.5. Data Access Methods ..................................................................................................... 14

1-3. ORCU ................................................................................................................................. 14

1-4. SYSTEM WORKFLOW – EXAMPLES ........................................................................... 16

1-4.1. General ........................................................................................................................... 16

1-4.2. Refueling Scenario with FuelPoint PLUS ..................................................................... 16

1-4.3. Refueling Scenario with Magnetic Cards ...................................................................... 16

1-4.4. Refueling Scenario with 2 devices (2 stage authorization) ............................................ 16

1-5. MANUAL STRUCTURE .................................................................................................. 17

1-6. USING THIS MANUAL .................................................................................................... 18

1-7. REFERENCES ................................................................................................................... 19

2 COMMON FUNCTIONAL PRINCIPLES

2-1. GENERAL .......................................................................................................................... 20

2-2. TERMINOLOGY ............................................................................................................... 20

2-3. COMMON ACTIONS ........................................................................................................ 21

2-3.1. Selecting a Row in a Grid .............................................................................................. 21

2-3.2. Sorting a Grid ................................................................................................................. 22

3 GETTING STARTED

3-1. GENERAL .......................................................................................................................... 23

3-2. SITEOMAT STARTUP ..................................................................................................... 23

3-3. LOGIN ................................................................................................................................ 24

3-4. NAVIGATING THROUGH THE SITEOMAT ................................................................ 25

SiteOmat User’s Manual– MDE 4818

I

Page 6

TABLE OF CONTENTS

Paragraph

Page

4 MONITORING STATION STATUS

4-1. GENERAL .......................................................................................................................... 28

4-2. STATION MONITORING ................................................................................................. 28

4-3. PUMP STATUS .................................................................................................................. 29

4-3.1. Pump Status Window Elements ..................................................................................... 29

4-3.1.1. Pump Heads Gauge ................................................................................................... 30

4-3.1.2. Pump Head On-Line Data ......................................................................................... 30

4-3.1.3. Fueling Transactions History Log ............................................................................. 32

4-4. REFUELING THROUGH SCREENS ............................................................................... 33

4-4.1. Starting Refueling .......................................................................................................... 33

4-4.2. Stopping Refueling ......................................................................................................... 34

4-5. TANK STATUS ................................................................................................................. 36

4-5.1. Tank Status Window Elements ...................................................................................... 36

4-5.1.1. Tanks Gauge .............................................................................................................. 37

4-5.1.2. Tank Head On-Line Data .......................................................................................... 37

4-5.1.3. Fuel Tank Transactions History Log ......................................................................... 38

4-6. ORPT STATUS .................................................................................................................. 39

4-7. DEVICE STATUS .............................................................................................................. 40

5-1. GENERAL .......................................................................................................................... 41

5-2. LOCAL MANAGEMENT OVERVIEW ........................................................................... 41

5-2.1. Devices Definition.......................................................................................................... 41

5-2.2. Workflow ....................................................................................................................... 42

5-3. DEFINING VEHICLE MODELS ...................................................................................... 42

5-3.1. General ........................................................................................................................... 42

5-3.2. Vehicle Models Screen................................................................................................... 42

5-3.3. Defining a New Model ................................................................................................... 43

5-3.4. Modifying a Model Properties ....................................................................................... 45

5-3.5. Deleting a Model ............................................................................................................ 45

5-4. DEFINING RULES ............................................................................................................ 46

5-4.1. Creating a New Rule ...................................................................................................... 47

5-4.1.1. Time Range Rule ....................................................................................................... 48

5-4.1.2. Limits Rule ................................................................................................................ 50

II

SiteOmat User’s Manual– MDE 4818

5 LOCAL MANAGEMENT

Page 7

TABLE OF CONTENTS

Paragraph

Page

5-4.1.3.

Visits Rule ................................................................................................................. 52

5-4.1.4. Fuel Rule ................................................................................................................... 53

5-4.2. Rule Properties ............................................................................................................... 54

5-4.3. Deleting a Rule .............................................................................................................. 54

5-5. CREATING GROUP RULES ............................................................................................ 55

5-5.1. Creating a New Group Rule ........................................................................................... 55

5-5.2. Group Rules Properties .................................................................................................. 57

5-5.3. Deleting a Group Rule ................................................................................................... 57

5-6. FLEET MANAGEMENT .................................................................................................. 58

5-6.1. Creating a New Fleet ..................................................................................................... 58

5-6.2. New Fleet – General Tab ............................................................................................... 59

5-6.3. New Fleet – Information Tab ......................................................................................... 60

5-6.4. New Fleet – Account Tab .............................................................................................. 60

5-6.5. New Fleet – Validation Tab ........................................................................................... 62

5-6.6. Fleet Functional Buttons ................................................................................................ 63

5-6.6.1. Changing a Fleet's Status (Active/Block) ................................................................. 63

5-6.6.2. Fleet Properties .......................................................................................................... 64

5-6.6.3. Deleting a Fleet ......................................................................................................... 64

5-6.6.4. Finding a Fleet ........................................................................................................... 64

5-6.6.5. History of a Fleet ....................................................................................................... 65

5-6.7. Saving a Fleet Definition ............................................................................................... 66

5-7. DEPARTMENTS MANAGEMENT ................................................................................. 66

5-7.1. Displaying the Departments List Dialog Box ................................................................ 67

5-7.2. Adding a New Department ............................................................................................ 67

5-7.3. New Department –General Tab ..................................................................................... 67

5-7.4. New Department – Information Tab .............................................................................. 68

5-7.5. New Department – Validation Tab ................................................................................ 69

5-7.6. Department Functional Buttons ..................................................................................... 69

5-7.6.1. Changing a Department's Status (Active/Block) ....................................................... 70

5-7.6.2. Department Properties ............................................................................................... 70

5-7.6.3. Deleting a Department .............................................................................................. 70

5-7.6.4. Finding a Department ................................................................................................ 71

5-8. DEVICES MANAGEMENT .............................................................................................. 72

5-8.1. Creating a New Device .................................................................................................. 73

5-8.1.1. New Device – General Tab ....................................................................................... 73

SiteOmat User’s Manual– MDE 4818

III

Page 8

TABLE OF CONTENTS

Paragraph

Page

5-8.1.2.

New Device – Information Tab ................................................................................. 74

5-8.1.3. New Device – Validation Tab ................................................................................... 77

5-8.1.4. New Device – Format Tab ........................................................................................ 79

5-8.1.5. New Device – Two Stage Tab ................................................................................... 81

5-8.2. Device Properties ........................................................................................................... 82

5-8.3. Deleting a Device ........................................................................................................... 82

5-8.4. Changing a Device's Status ............................................................................................ 83

5-8.5. Importing Device Data ................................................................................................... 83

5-8.6. Exporting Devices Data ................................................................................................. 84

5-8.7. Printing Devices Report ................................................................................................. 84

5-8.8. Clearing the Device Filters ............................................................................................. 85

5-8.9. Gasboy Magnetic Cards Format ..................................................................................... 85

6 WET STOCK MANAGEMENT

6-1. GENERAL .......................................................................................................................... 86

6-2. PRICE UPDATE TAB ....................................................................................................... 86

6-2.1. Edit Product .................................................................................................................... 87

6-2.2. Price History ................................................................................................................... 88

6-2.3. Price Lists ....................................................................................................................... 88

6-2.3.1. General ...................................................................................................................... 88

6-2.3.2. Setup .......................................................................................................................... 89

6-3. DELIVERY TAB ................................................................................................................ 91

6-4. INVENTORY TAB ............................................................................................................ 96

6-5. RECONCILIATION TAB .................................................................................................. 98

6-6. TRANSACTION RECONCILIATION TAB ..................................................................... 99

6-7. MANUAL TOTALIZER ENTRY ...................................................................................... 100

7-1. GENERAL .......................................................................................................................... 104

7-2. CUSTOM REPORTS ......................................................................................................... 105

7-2.1. Report Header ................................................................................................................ 105

7-2.2. Rows in Reports ............................................................................................................. 106

7-2.3. Report Criteria ................................................................................................................ 106

7-2.4. Multi Select .................................................................................................................... 108

7-2.5. Template Options ........................................................................................................... 109

IV

SiteOmat User’s Manual– MDE 4818

7 PRODUCING REPORTS

Page 9

TABLE OF CONTENTS

Paragraph

Page

7-2.6.

Report Structure Options ............................................................................................... 109

7-2.7. Functional Buttons ......................................................................................................... 109

7-2.8. Custom Report Production Example.............................................................................. 110

7-3. EXPORT SCREEN ............................................................................................................ 111

7-3.1. Defining Templates ........................................................................................................ 111

7-3.2. Setting Export Range ..................................................................................................... 119

7-3.3. Scheduling Automatic Exports ...................................................................................... 119

7-3.4. Executing Manual Exports ............................................................................................. 120

8 EVENTS

8-1. GENERAL .......................................................................................................................... 121

8-2. EVENT VIEWER ............................................................................................................... 121

8-3. LOG VIEWER .................................................................................................................... 122

8-4. ALARMS SCREEN ........................................................................................................... 124

9 REFUELING SCENARIOS FOR DRIVER

9-1. GENERAL .......................................................................................................................... 126

9-2. BASIC PAYMENT MODES FOR SITEOMAT INHOUSE ............................................. 126

9-2.1. Payment Means and Terminal ....................................................................................... 126

9-2.2. Detailed Scenarios ......................................................................................................... 127

9-2.2.1. Fuel Ring only scenario ............................................................................................. 127

9-2.2.2. Fuel Ring Transactions Options ................................................................................ 127

9-2.2.3. OrTR - Tag reader scenario (Without swipe) ............................................................ 128

9-2.2.4. OrTR (Orpak tag reade r) S cenari o ............................................................................ 129

9-2.2.5. OrPT Scenarios ......................................................................................................... 130

9-2.2.6. Active Keys & Devices for PIN Authorization: ........................................................ 131

9-2.2.7. Active Keys & Devices for Pump Number Entry ..................................................... 132

9-2.2.8. Printing rules for all scenarios ................................................................................... 132

10 GLOSSARY

10-1. SITEOMAT GLOSSARY .................................................................................................. 133

10-2. COMMUNICATION GLOSSARY ................................................................................... 134

APPENDIX A – GENERAL GUIDE FOR WEB CLIENT USER

SiteOmat User’s Manual– MDE 4818

V

Page 10

TABLE OF CONTENTS

Paragraph

Page

A-1. ACCESSING FROM WEB .................................................................................................... 136

A-1.1. Pop ups Blockers ................................................................................................................. 136

A-1.2. Removing Full URL Display ............................................................................................... 142

VI

SiteOmat User’s Manual– MDE 4818

Page 11

LIST OF ILLUSTRATIONS

Figure

Page

Figure 1-1 – Islander PLUS in Home Base Station - General Configuration Diagram .................... 13

Figure 1-2 - OrCU - General View .................................................................................................... 15

Figure 2-1. Selecting a Row in a Grid .............................................................................................. 22

Figure 3-1. SiteOmat Login Dialog Box .......................................................................................... 24

Figure 3-2. Updating Data Message .................................................................................................. 25

Figure 3-3. SiteOmat Opening Screen .............................................................................................. 27

Figure 4-1. Status – Pumps Screen ................................................................................................... 28

Figure 4-2. Station Monitoring – Pump Status View ....................................................................... 29

Figure 4-3. Start Refueling Confirmation Message.......................................................................... 33

Figure 4-4. Pump Busy Message ...................................................................................................... 33

Figure 4-5. Authorize Pump Dialog Box ......................................................................................... 34

Figure 4-6. Money Limit Confirmation Message ............................................................................. 34

Figure 4-7. Volume Limit Confirmation Message ........................................................................... 34

Figure 4-8. Close All Pumps Confirmation Message ....................................................................... 35

Figure 4-9. Station - Tanks Screen ................................................................................................... 36

Figure 4-10. Station Monitoring – OrPT Status View ..................................................................... 39

Figure 4-11. Status– Devices Screen ................................................................................................ 40

Figure 5-1. Local Management Models Main Screen ...................................................................... 43

Figure 5-2. Model Properties Dialog Box ........................................................................................ 44

Figure 5-3. Rules Main Screen ......................................................................................................... 47

Figure 5-4. Rule Properties Screen ................................................................................................... 48

Figure 5-5. Time Range Rule Detail Tab ......................................................................................... 49

Figure 5-6. Rule Time Range Dialog Box ........................................................................................ 50

Figure 5-7. Limits Rule Detail Tab .................................................................................................. 51

Figure 5-8. Visits Rule Detail Tab ................................................................................................... 52

Figure 5-9. Fuel Rule Detail Tab ...................................................................................................... 53

Figure 5-10. Group Rules Screen ..................................................................................................... 55

Figure 5-11. Group Rule Properties – General Tab.......................................................................... 56

SiteOmat User’s Manual– MDE 4818

VII

Page 12

LIST OF ILLUSTRATIONS

Figure

Page

Figure 5-12. Group Rule Properties – Detail Tab ............................................................................. 57

Figure 5-13. Local Management Fleets Screen ................................................................................ 58

Figure 5-14. Fleet Properties Dialog Box – General Tab ................................................................. 59

Figure 5-15. Fleet Properties – Information Tab ............................................................................... 60

Figure 5-16. Fleet Properties Screen – Account Tab ........................................................................ 61

Figure 5-17. Fleet Properties – Account Tab - Wrong Value Message ............................................ 62

Figure 5-18. Fleet Properties – Validation Tab ................................................................................. 63

Figure 5-19. Deleting a Fleet– Departments Delete Warning Message ........................................... 64

Figure 5-20. Find Fleet Dialog Box .................................................................................................. 65

Figure 5-21. Fleet History Dialog Box ............................................................................................. 66

Figure 5-22. Department Definition – Error Message ...................................................................... 66

Figure 5-23. Departments Dialog Box .............................................................................................. 67

Figure 5-24. Department Properties Dialog Box – General Tab ....................................................... 68

Figure 5-25. Department Properties Dialog Box – Information Tab ................................................. 69

Figure 5-26. Finding a Department................................................................................................... 71

Figure 5-27. Devices Screen ............................................................................................................. 72

Figure 5-28. Device Properties Screen – General Tab ..................................................................... 73

Figure 5-29. Device Properties Screen – Information Tab ............................................................... 74

Figure 5-30. Device Properties Screen – Employee Device Information Tab ................................. 76

Figure 5-31. Devices Properties Screen – Validation Tab ................................................................. 77

Figure 5-32. Validation Prompt Including Pump Number ................................................................ 78

Figure 5-33. Device Properties Screen – Format Tab ...................................................................... 81

Figure 5-34. Device Properties Screen – Two Stage Tab ................................................................. 82

Figure 5-35. Delete Device Approval Message ................................................................................ 83

Figure 5-36. Import Device Data ...................................................................................................... 84

Figure 5-37. Devices Report - Example ........................................................................................... 84

Figure 6-1 Wet Stock Management Screen – P ri ce Upd ate .............................................................. 86

Figure 6-2. Setup Fuel Products Dialog Box ..................................................................................... 88

VIII

SiteOmat User’s Manual– MDE 4818

Page 13

LIST OF ILLUSTRATIONS

Figure

Page

Figure 6-3. Price History Window ................................................................................................... 88

Figure 6-4. Wet Price Lists Dialog Box ........................................................................................... 90

Figure 6-5. Delivery Screen ............................................................................................................. 92

Figure 6-6. Wet Delivery Details Dialog Box .................................................................................. 93

Figure 6-7. Wet Delivery Detailed Data Entry Using Manual Source ............................................. 94

Figure 6-8. Wet Delivery TLG Reading Dialog Box ....................................................................... 95

Figure 6-9. Wet Delivery Detailed Data Screen Based on TLG Reading ......................................... 96

Figure 6-10. Inventory Screen .......................................................................................................... 97

Figure 6-11. Wet Inventory Dialog Box ........................................................................................... 97

Figure 6-12. Reconciliation Screen .................................................................................................. 99

Figure 6-13. Transaction Reconciliation Window ......................................................................... 100

Figure 6-14. Manual Totalizer Entry Screen .................................................................................. 101

Figure 7-1. Custom Report Screen ................................................................................................. 105

Figure 7-2. Multi Select Box .......................................................................................................... 109

Figure 7-3. Custom Report (Typical) ............................................................................................. 110

Figure 7-4. Reports – Export Transactions Screen ......................................................................... 111

Figure 7-5. Reports - Export Transactions Dialog Box .................................................................. 112

Figure 7-6. Fleet List Dialog Box ................................................................................................... 113

Figure 7-7. Station List Dialog Box ............................................................................................... 114

Figure 7-8. Export – Automatic Export Transaction Dialog Box .................................................. 119

Figure 8-1. Event Viewer ............................................................................................................... 122

Figure 8-2. History Login Logs Viewer ......................................................................................... 123

Figure 8-3. History Reports Logs Viewer ...................................................................................... 123

Figure 8-4. Alarm Screen ................................................................................................................ 124

Figure 8-5. Alarm Comment Entry Screen ...................................................................................... 125

Figure 8-6. Alarm Already Acknowledge Message ....................................................................... 125

Figure 8-7. Alarm will be Ended and Acknowledged Message ..................................................... 125

SiteOmat User’s Manual– MDE 4818

IX

Page 14

Table

Page

Table 2-1. Common Terms ............................................................................................................... 20

LIST OF TABLES

Table 3-1. Navigation Bar Buttons .................................................................................................... 25

Table 4-1. Fueling Transactions History Log Fields ........................................................................ 32

Table 4-2. Fuel Tank Transactions History Log Fields .................................................................... 38

Table 4-3. Devices Status ................................................................................................................. 40

Table 5-1. Model Properties Fields.................................................................................................... 44

Table 5-2. Devices ............................................................................................................................. 79

Table 6-1. Wet Delivery Details Fields ............................................................................................. 93

Table 6-2. Wet Delivery Detailed Data Fields .................................................................................. 95

Table 7-1. Custom Report Fields .................................................................................................... 106

Table 7-2. Export Fields .................................................................................................................. 114

Table 7-3. Export Field Formats ...................................................................................................... 118

Table 9-1. Station Configuration for Payment Means ..................................................................... 126

Table 9-2. Active Keys for PIN Authorization ................................................................................ 131

Table 9-3. Active Keys for Pump Number Entry ............................................................................ 132

x

SiteOmat User’s Manual– MDE 4818

Page 15

1

SECTION

GENERAL DESCRIPTION

1-1. INTRODUCTION

This manual describes the web-based software application of the SiteOmat In House Station

Controller, which is a part of the FuelPoint PLUS system, including the usage of the various

features offered by the application, such as real-time gas station monitoring, data reporting, fleet

and vehicle management, fueling restriction setting and more.

This manual is targeted toward any authorized user of the SiteOmat Station Controller’s web-based

application (i.e. gas station managers, gas company managers, fleet owners). For technical

information regarding the SiteOmat Station Controller installation and setup, please refer to the

SiteOmat Station Controller Setup and maintenance Manual - MDE-4817.

SiteOmat software can be installed in the following Island Controllers:

• Islander PLUS - A self-contained pedestal that provides a complete island solution in a

forecourt compatible and weather-resistant cabinet. Islander PLUS is equipped with the

OrPT, a Payment Panel with an alphanumeric LCD (graphic LCD, optional) and a keyboard

to interface with the client. This enables the Islander PLUS to support all common refueling

identification devices such as: Vehicle/Driver Identification/FuelPoint PLUS Unit ,

FuelPoint PLUS, magnetic cards, contact-less RFID tags, keypad entry and others

• CFN PLUS - A sealed wall-mount, complete station automation

system in one compact, durable box for internal or external

installations. It interfaces with the forecourt devices, including

dispensers, Tank Level Gauge (TLG), payment terminals and Nozzle

Readers (for optional vehicle identification)

• Fuel Truck Controller - A sealed, metal box installed on mobile

tanker trucks, Fuel Truck Controller has been especially designed to

address the heavy or stationary equipment refueling needs at the site.

Fuel Truck Controller is connected to the nozzle equipment on the

tanker truck and controls the tanker's electric valve. The heavy or

stationary equipment is identified by the Fuel Ring (Vehicle

Identification Unit) component of FuelPoint PLUS or a driver

contactless Tag

SiteOmat User’s Manual– MDE 4818

11

Page 16

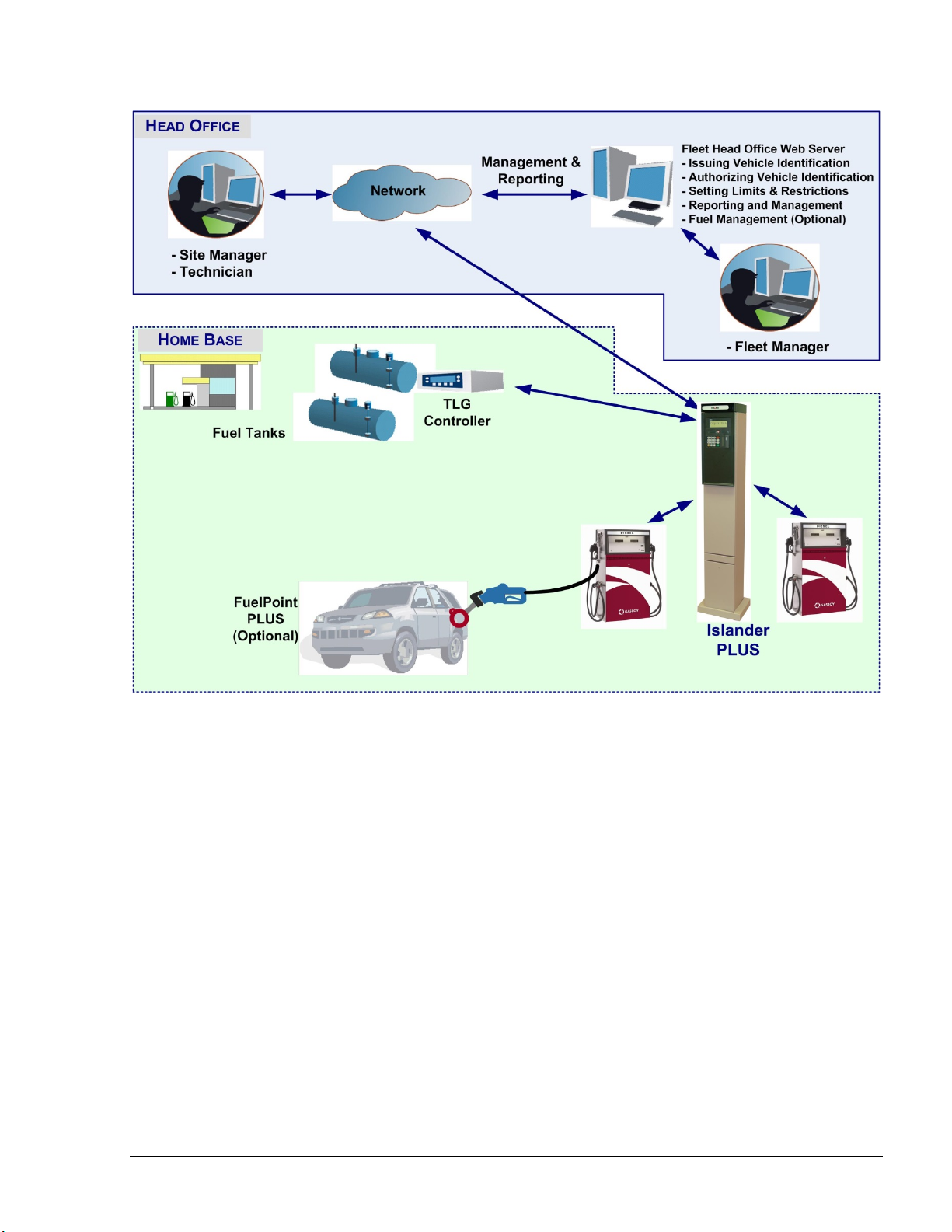

1-2. SITEOMAT 1-2.1. Overview

Island Controllers are innovative products that enable refueling in Home Base Fueling Stations for

fleets' authorized vehicles or drivers. They electronically lock all dispensers and pumps thereby

ensuring that only appropriately authorized vehicles and personnel receive the required fuel. These

fuel control and data acquisition systems also ensures accurate recording of each transaction (see

Figure 1-1).

The heart of the Home Base Station solution is the SiteOmat automation software. SiteOmat runs

on an embedded operating system on the OrCU. This controller uses a solid state Flash disk and

RTC (Real Time Clock) with back-up, along with surge suppressors for transient and noise

immunity. It also includes power fail recovery mechanisms.

SiteOmat ensures accurate recording of each transaction. The dispenser is authorized to refuel after

a positive identification of the vehicle or the driver. All transaction information, including the

vehicle’s odometer or engine hour, is automatically recorded. A combined vehicle and driver

identification is also possible for a tight tracking.

SiteOmat features a comprehensive set of setup screens for easy and fast configuration and

modification in accordance with the client’s changing needs.

1-2.2. Interfaces

SiteOmat Station Controller provides the following operational features for a comprehensive Home

Base Station management:

• Supports over 50 different types of dispensers

• Advanced electronic support of electronic and mechanical dispensers

• Tank Level Gauging System (TLG) available for several brands

• Outdoor Payment Terminal and printer (OrPT)

• Contactless Tag Reader (OrTR)

• Vehicle Identification Terminals (Wireless Gateway)

• Support of large variety of communication links: cellular dial-in modem, VPN, satellite,

ADSL and more

• Interface to Head Office Systems - The system has an interface for authorization and

for sending transaction to 3rd party head office/ SiteOmat Fleet Head Office using a

single export format (Web Services).

12

SiteOmat User’s Manual– MDE 4818

Page 17

Figure 1-1 – Islander PLUS in Home Base Station - General Configuration Diagram

SiteOmat User’s Manual– MDE 4818

13

Page 18

1-2.3. Internal Communication Alternatives

OrCU can communicate with the other modules in the Island Controller system over:

a. TCP/IP Ethernet over CAT5e wires (some modules require the CommVerter Module as the

interface)

b. RS-485 links (segmentation to several links is available)

c. 8 Port CommVerter system

1-2.4. External Communication Alternatives

Communication with external management and data processing systems, for reports and

clearinghouse, can be provided by:

a. Direct - Ethernet or RS-232

b. ADSL/ISDN Modem

c. Dial-Up Modem (not recommended)

d. GPRS, Cellular modem.

1-2.5. Data Access Methods

OrCU is a web server over an SQL transaction database. It uses a secured link with several levels

of authentication. Logging into the SiteOmat is done with a standard browser from any PC and a

static IP address. Data is available in real time using pre-defined active forms.

Real-time data is available via an on-line connection, a dedicated line or Internet/Intranet (Secured)

link. The Station Controller system with SiteOmat enables real-time monitoring of a vehicle

refueling process including Volume, Price and all vehicle details.

The SiteOmat Station Controller supports exporting (transactions) and importing (Negative/Positive

lists) data using a pre-defined format.

1-3. ORCU

Orpak Controller Unit (OrCU) is a complete forecourt controller with its own embedded operating

system (see Figure 1-2). The unit consists of an embedded hardware platform with a solid state

Flash hard disk, Real Time Clock (RTC) with back up, along with surge suppressors for transient

and noise immunity. It also includes power fail recovery mechanisms.

OrCU features two separate and isolated networks (TCP/I P over Ether net) . One network l inks the

Islander PLUS syste m componen ts. The sec o nd ne t wor k is in tende d for external remote

communication (Head Office, 3rd party systems). This network is protecte d b y SSL security.

OrCU includes a Security Access Module (SAM) for enhanced data protection and safe security key

storage (Triple DES encry ptio n). OrCU includes a built-in server for Web access through Internet

Explorer 7.0 or higher.

14

SiteOmat User’s Manual– MDE 4818

Page 19

OrCU includes the following communication ports:

• LAN 1 / LAN 2 for TCP/IP over Ethernet

• RS-232 ( DB9-female ) for serial communication

• The other ports (CAN, USB) are currently not in use

NOTE

This note is relevant for the Islander PLUS system

only:

The connection (RS-485) to the optional printer is

done through the OrPT device. OrPT is connected to

the OrCU via LAN.

Figure 1-2 - OrCU - General View

SiteOmat User’s Manual– MDE 4818

15

Page 20

1-4. SYSTEM WORKFLOW – EXAMPLES 1-4.1. General

This section provides examples of different operational workflow, refueling, scenarios for selfservice at the Home Base Station. These examples are a function of the payment and transaction

devices available in each Station Controller system.

1-4.2. Refueling Scenario with FuelPoint PLUS

A motorist stops for fuel at the station. His authorization device for the fueling transaction is a

vehicle identification unit (VIU) mounted in his car. The client lifts the nozzle and inserts it into

the car’s fuel inlet.

The VIU information is automatically read and sent to the Site Controller (OrCU) for

authentication and approval. Upon approval the fueling transaction starts, once refueling is

completed, the motorist replaces the nozzle back to pump. At this point the transaction data is

kept internally. Data is periodically transferred to the Fleet Head Office (FHO) for future billing.

1-4.3. Refueling Scenario with Magnetic Cards

A motorist stops for fuel at the station. His authorization device for the fueling transaction is a

magnetic card. The client swipes the card through the magnetic card reader on the payment

terminal.

The magnetic card information is read and sent to the Site Controller (OrCU) for authentication

and approval. The client lifts the nozzle and inserts it into the car’s fuel inlet. Upon approval,

the fueling transaction starts, once the refueling is completed, the motorist replaces the nozzle

back to the pump. At this point the transaction data is kept internally. Data is periodically

transferred to the Fleet Head Office (FHO) for future billing.

During the authorization process the motorist may be prompted to enter more data to the

transaction (PIN code, Odometer, Vehicle No., Etc.). This is done by manually entering the

information using the payment terminal keypad.

1-4.4. Refueling Scenario with 2 devices (2 stage authorization)

A motorist stops for refueling at the gas station. His authorization devices for the refueling

transaction include any two devices. One represents the vehicle and the other represent the

driver (e.g. two cards, two tags, card and tag, card and manual entry, etc.). The refueling

scenario for each device is the same as with magnetic cards (see above). For each device, the

motorist may be requested to add more relevant data to the transaction (PIN for the driver,

Odometer recording for the vehicle, etc.). The OrCU opens the dispenser for refueling only after

successful authorization of the two devices.

For all options above, the motorist may print a transaction ticket from the Islander PLUS printer

(optional).

16

SiteOmat User’s Manual– MDE 4818

Page 21

1-5. MANUAL STRUCTURE

This manual comprises of the following sections:

Section 1: General Description

This section provides a general description of the FuelPoint PLUS system in general, and the

SiteOmat Station Controller in particular.

Section 2: Common Functional Principles

This section explains generic principles, which the user must be familiar with for proper operation

of the SiteOmat Station Controller application, and which will not be detailed in each occurrence.

Section 3: Getting Started

This section provides initial instructions needed for the user to start using the SiteOmat Station

Controller, namely application launch, login and general orientation of the application. This section

gives references to the following sections, which discuss the different operative parts of the

SiteOmat Station Controller.

Section 4: Monitoring Station Status

This section provides instructions for monitoring the gas station in real-time using the SiteOmat

Station Controller application. The SiteOmat Station Controller is connected to all FuelPoint PLUS

modules in the gas station, and receives on-line fueling information and status from each of the

pumps deployed in the gas station.

Section 5: Local Management

This section provides instructions for managing the fleets, devices, rules, group rules and models in

the SiteOmat Station Controller database, as well as setting limits for each vehicle per day, week,

month and year.

Section 6: Wet Stock Management

This section provides instructions for adding, controlling, tracking and updating the price of a

product in all pumps and nozzles.

Section 7: Producing Reports

This section provides instructions for generating data reports using the SiteOmat Station Controller

application.

Section 8: Events

This section provides all the events that occurred during the operation, history of login events and

reports history logs.

Section 9: Scenario in Basic Payment Modes

This section explains the basic payment modes for SiteOmat In-house.

Section 10: Glossary

This section provides a glossary of abbreviation used in the FuelPoint PLUS manuals.

Appendix A: General Guide for Web Client User

SiteOmat User’s Manual– MDE 4818

17

Page 22

This appendix provides instructions to enhance the connection from a web client to the SiteOmat

application.

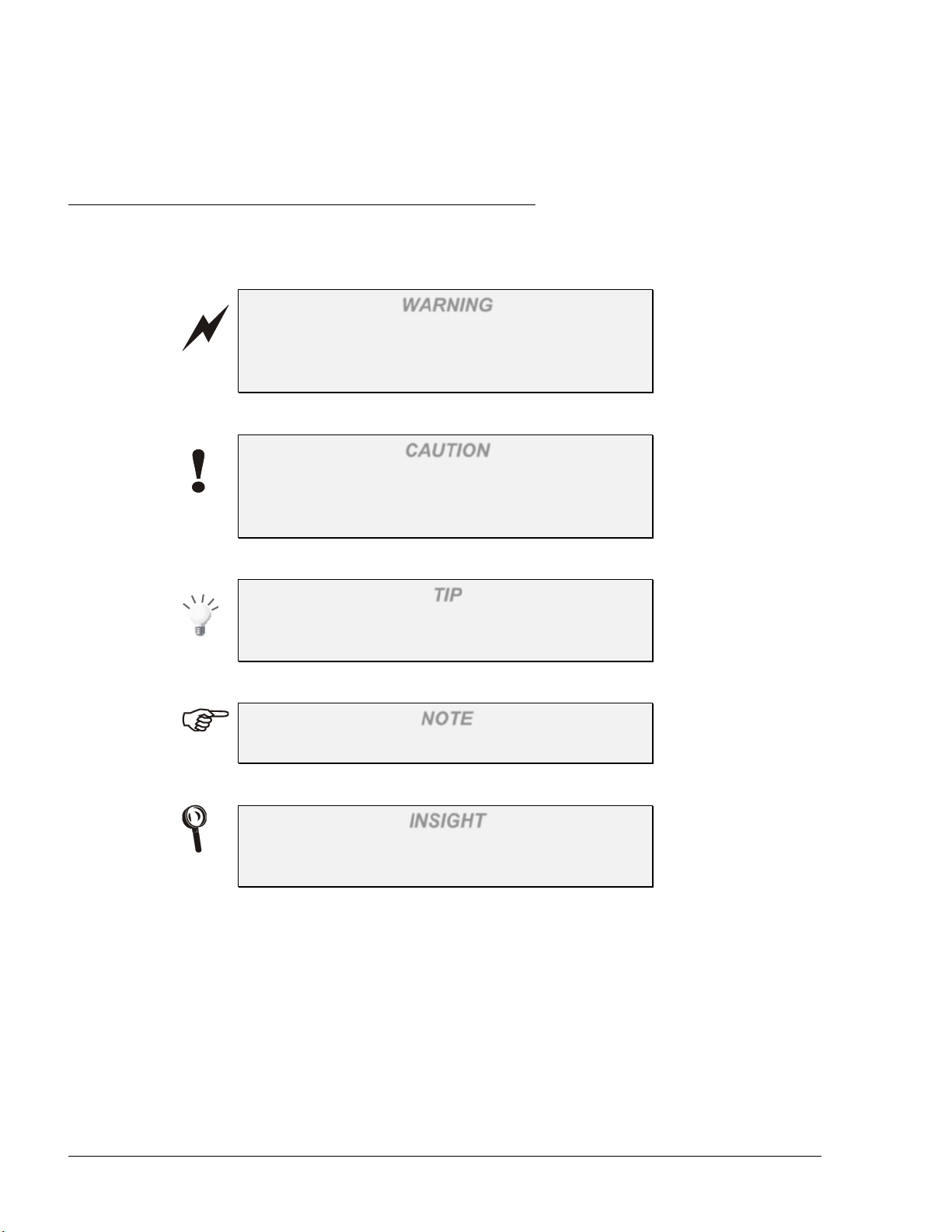

1-6. USING THIS MANUAL

This manual includes comments planted along the text, in order to draw the reader’s attention to

important issues. The comments are accompanied by symbols for ease of reference. The following

comment types are used:

WARNING

An operating procedure, practice, et cetera, which if

not correctly followed, could result in injury or loss

of life.

CAUTION

An operating procedure, practice, etcetera, which if

not strictly observed, could result in damage to, or

destruction of equipment.

TIP

A useful guidance, whose purpose is to use the

system in a more efficient way.

NOTE

A relevant and important comment.

INSIGHT

More detailed technical/ functional information

regarding relevant issues.

18

SiteOmat User’s Manual– MDE 4818

Page 23

1-7. REFERENCES

For additional and complementary information regarding Gasboy’s home base solution, please refer

to the following manuals:

• SiteOmat Station Controller Setup Manual, Document No. MDE-4817

• Islander PLUS installation Manual, Document No. MDE-4811

• CFN PLUS installation Manual, Document No. MDE-4813

• Fuel Truck Controller installation Manual, Document No. MDE-4814

• Wireless Gateway installation Manual, Document No. MDE-4815

• OrPT User’s Manual, Document No. MDE-4819

• 8-Port CommVerter User’s Manual, Document No. MDE-4820

• FHO installation and setup guide Document No. MDE-4821

• Fuel Point PLUS Installation and Configuration Manual, Document No. MDE-4851

SiteOmat User’s Manual– MDE 4818

19

Page 24

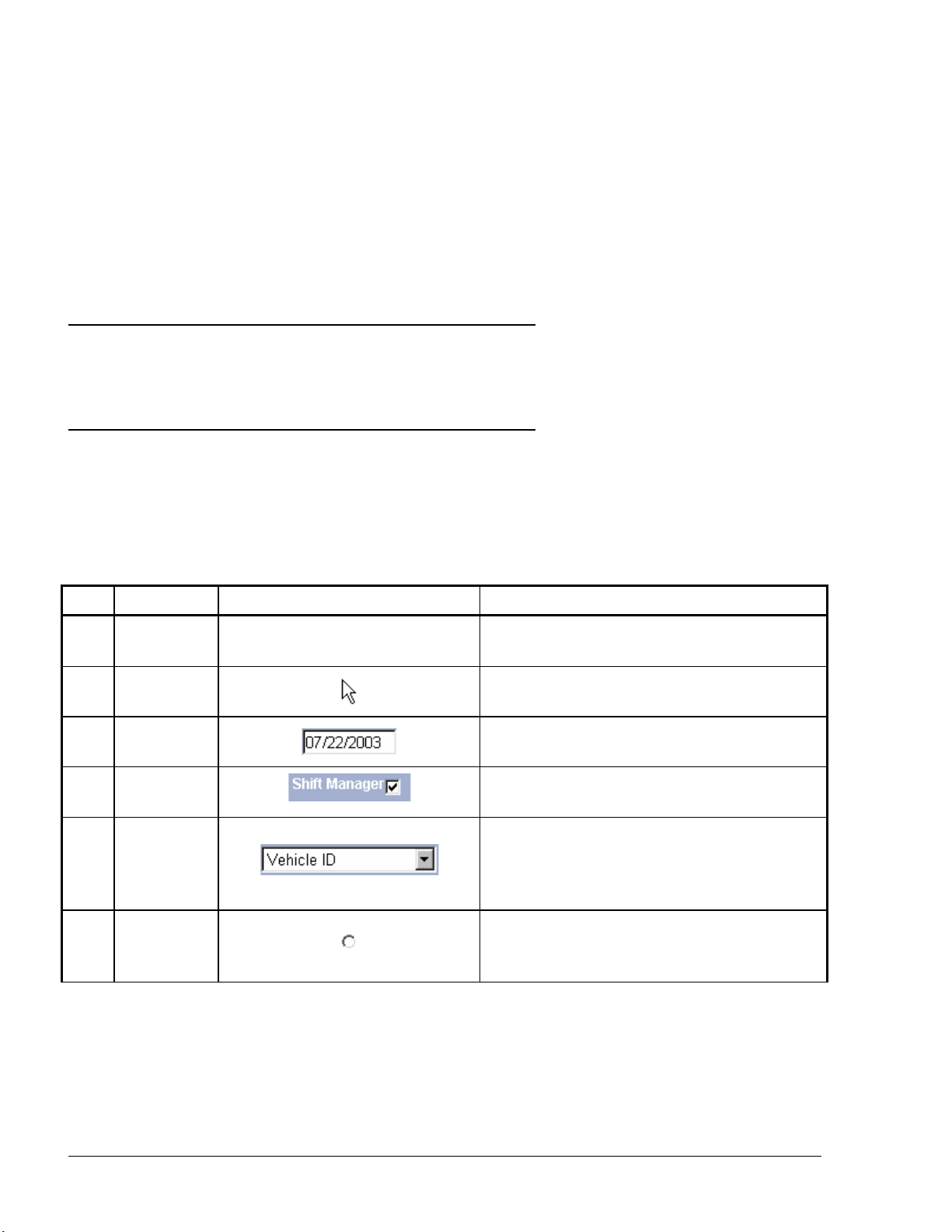

0

No.

Name

Appearance (Typical)

Description

1.

Checkbox

2.

Combo

3.

Radio

SECTION

2

COMMON FUNCTIONAL PRINCIPLES

2-1. GENERAL

This section explains generic principles, which the user must be familiar with for proper operation

of the SiteOmat Station Controller application that are not to be detailed in each occurrence.

2-2. TERMINOLOGY

The SiteOmat is a user-friendly, window-based application with a graphical interface similar to

other Windows® applications.

A number of common terms are used in this manual under the assumption that their meaning is

obvious, as depicted in Table 2-1.

Table 2-1. Common Terms

1.

2.

3.

Cursor

Pointer

Text Box

Box

Buttons

|

Indicator pointing where text is to be

inserted

Indicator pointing where the mouse is

located on the screen

An element allowing the user to input text

information

An element permitting the user to enable/

disable a specific option.

An element allowing the user to choose one

value from a list. Clicking on the arrowshaped button in the combo box opens the

list of values.

An element allowing the user to choose a

single value from a predefined set of

options.

20

SiteOmat User’s Manual– MDE 4818

Page 25

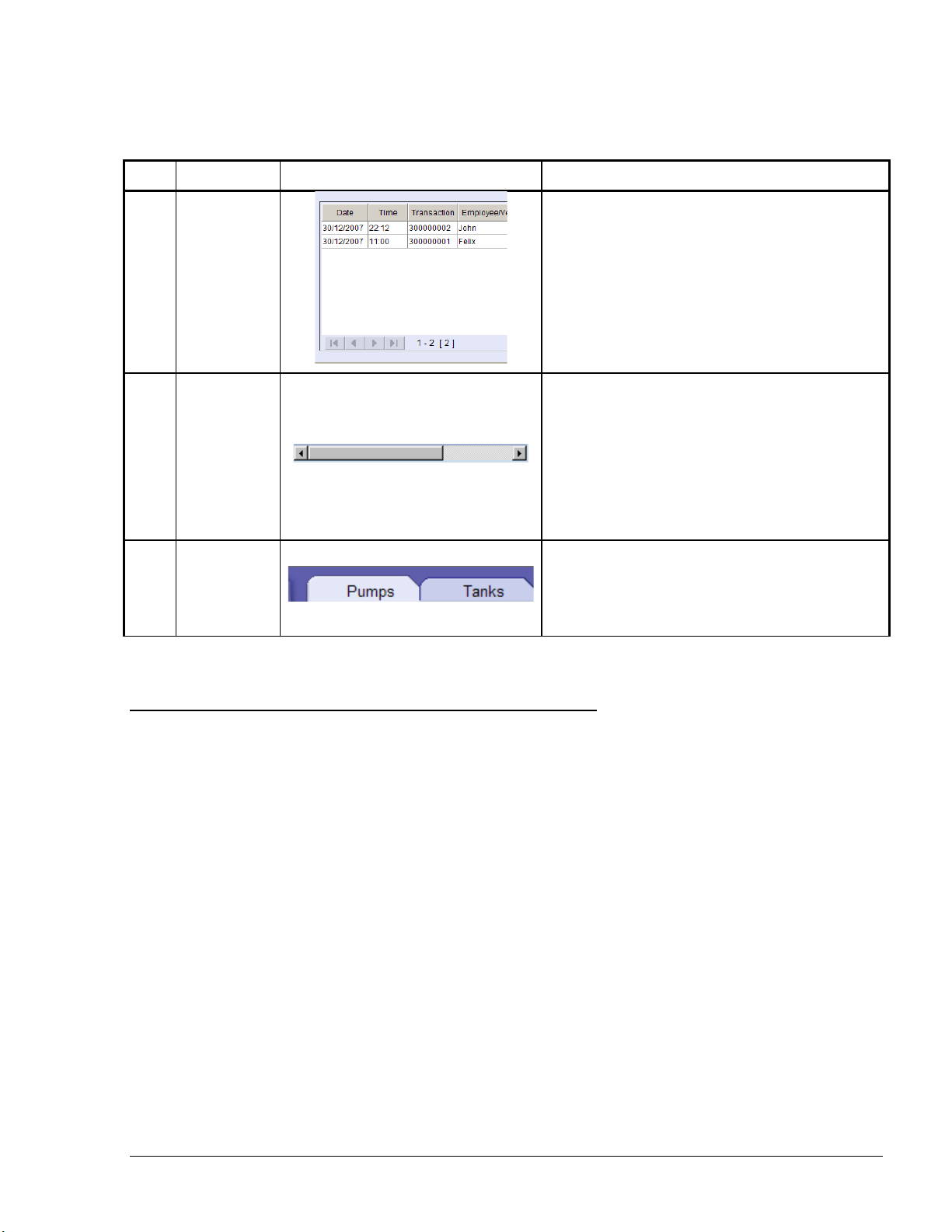

Table 2-1. Common Terms

No.

Name

Appearance (Typical)

Description

4.

Grid

5.

Scroll Bar

6.

Tab

An element, usually located on the top of a

A database consisting of columns (fields)

and rows (records). Grids are a common

way of displaying and handling data in the

SiteOmat application.

A bar allowing continuous text to be

viewed even if it does not fit into the space

in the window. Clicking the arrow-shaped

buttons in the ends allows users to move the

body of the document.

Scroll bars may be either horizontal or

vertical.

window, allowing the user to switch from

multiple documents located in a single

window.

2-3. COMMON ACTIONS

The user-interface of the SiteOmat Station Controller is intuitive and requires little experience for

using it. The operative actions are common and generic across the various windows. The common

actions in the SiteOmat application are as follows:

a. Selecting a row in a grid

b. Marking row(s ) in a grid

c. Sorting a grid

2-3.1. Selecting a Row in a Grid

Selecting a row in a grid serves several purposes, such as displaying the data associated with the

grid. To select a row, click on the applicable row. Consequently, the row is highlighted in a gray

color (as seen in Figure 2-1), indicating that the row is currently selected.

SiteOmat User’s Manual– MDE 4818

21

Page 26

Figure 2-1. Selecting a Row in a Grid

2-3.2. Sorting a Grid

Sorting a grid is done simply by clicking on a column header. The records are consequently sorted

by the selected column in an ascending order. A second click arranges the records by descending

order. The small triangle in the right-side of the selected header indicates the current sorting order.

NOTE

Sorting applies only to the currently displayed

screen.

22

SiteOmat User’s Manual– MDE 4818

Page 27

SECTION

3

GETTING STARTED

3-1. GENERAL

This section provides initial instructions needed for the user to start using the SiteOmat, namely

launching the application, login and familiarizing with the general orientation of the application.

This section provides references to the subsequent sections, which discusses the different operative

parts of the System.

NOTE

The SiteOmat application has been designed and

tested to run properly on Microsoft Internet Explorer

7 and up. On any other browser (or version), the

application may not function properly.

3-2. SITEOMAT STARTUP

The SiteOmat Application can be logged into using a standard browser from any PC. The

application is launched from the SiteOmat computer and may be accessed from any networked

computer (directly connected to the SiteOmat via the LAN) or from a remote computer with an

Internet browser over the Internet.

To access the application, launch the Internet browser and enter the address (IP address or domain

name) of the SiteOmat as provided by Gasboy as follows:

https://IPaddress

(Each customer’s IP address may differ based on their network.)

NOTE

Before proceeding, go to Appendix A, and follow

the procedure. This enables the connection from a

web client to the SiteOmat and improves browsing

capabilities.

SiteOmat User’s Manual– MDE 4818

23

Page 28

Once a link is established, the SiteOmat login window is displayed. The system grants access to

authenticated users only. It sets its clearance level in accordance with the organizational level of

the user. Information regarding the login is given in the following paragraph.

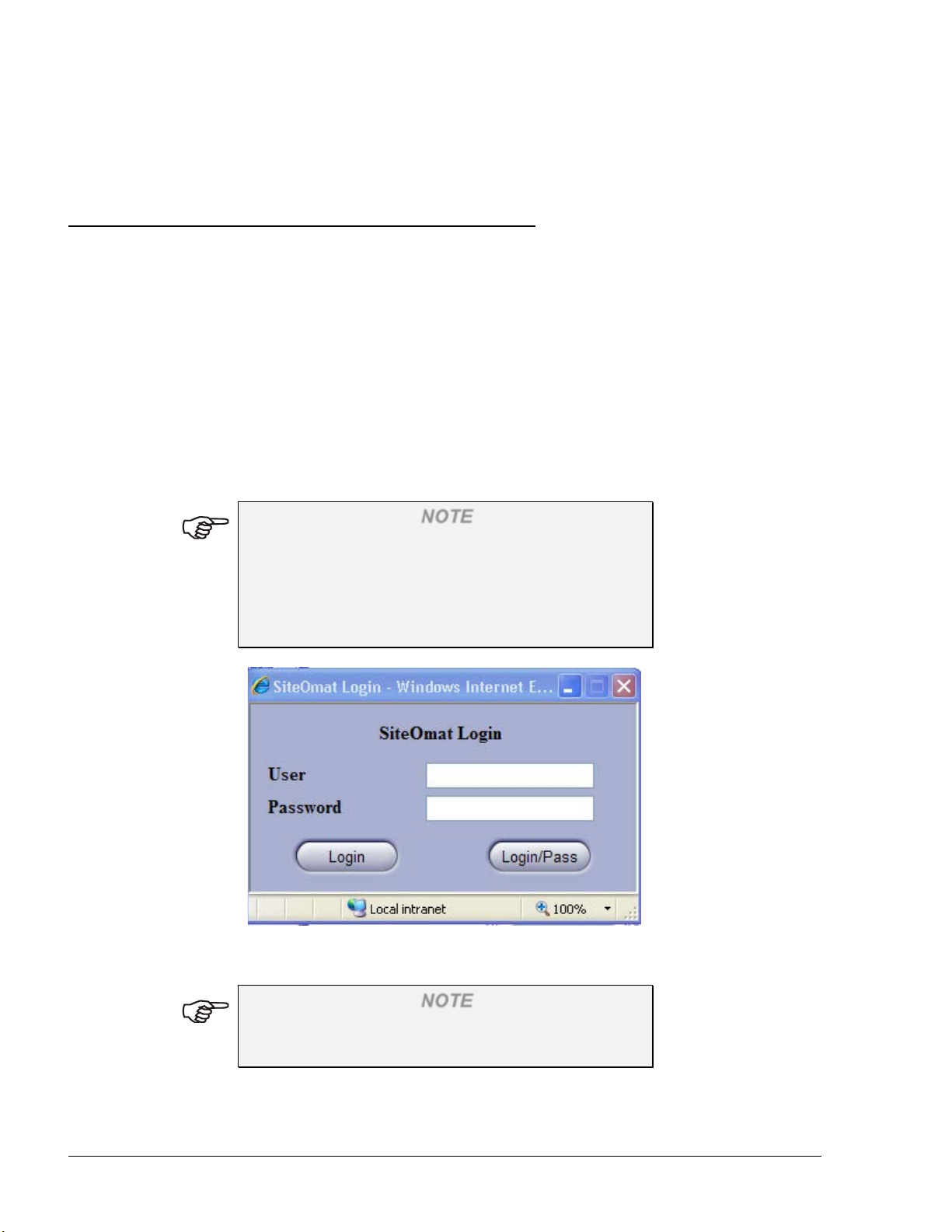

3-3. LOGIN

The SiteOmat Station Controller incorporates powerful SSL mechanisms to allow only authorized

users to view and alter its contents. The SiteOmat application opens with a login dialog box, for

entering the username and password (see Figure 3-1).

The accessible contents and privileges of the user depend upon its clearance level, as set in the User

Management definitions of the SiteOmat application (refer to Section 5 – Local Management). The

application is designed to grant each user with his suitable privileges and block other capabilities.

For example, a gas station manager is not allowed to manage vehicle fleets.

Enter the username and password and click on the Login button. The SiteOmat Station Controller

checks the entered information against the users listed in the system. If the user and the password

are authenticated, the user logs into the SiteOmat Station Controller with its applicable clearance

level.

NOTE

The default username is “Admin” and password is

“Admin” (lowercase sensitive).

It is highly recommended for the administrator to

change the password once the system is running (the

user "Admin" cannot be deleted or renamed).

Figure 3-1. SiteOmat Login Dialog Box

NOTE

Disable any sort of pop-up blockers, because it

interferes with the operation of the application.

24

SiteOmat User’s Manual– MDE 4818

Page 29

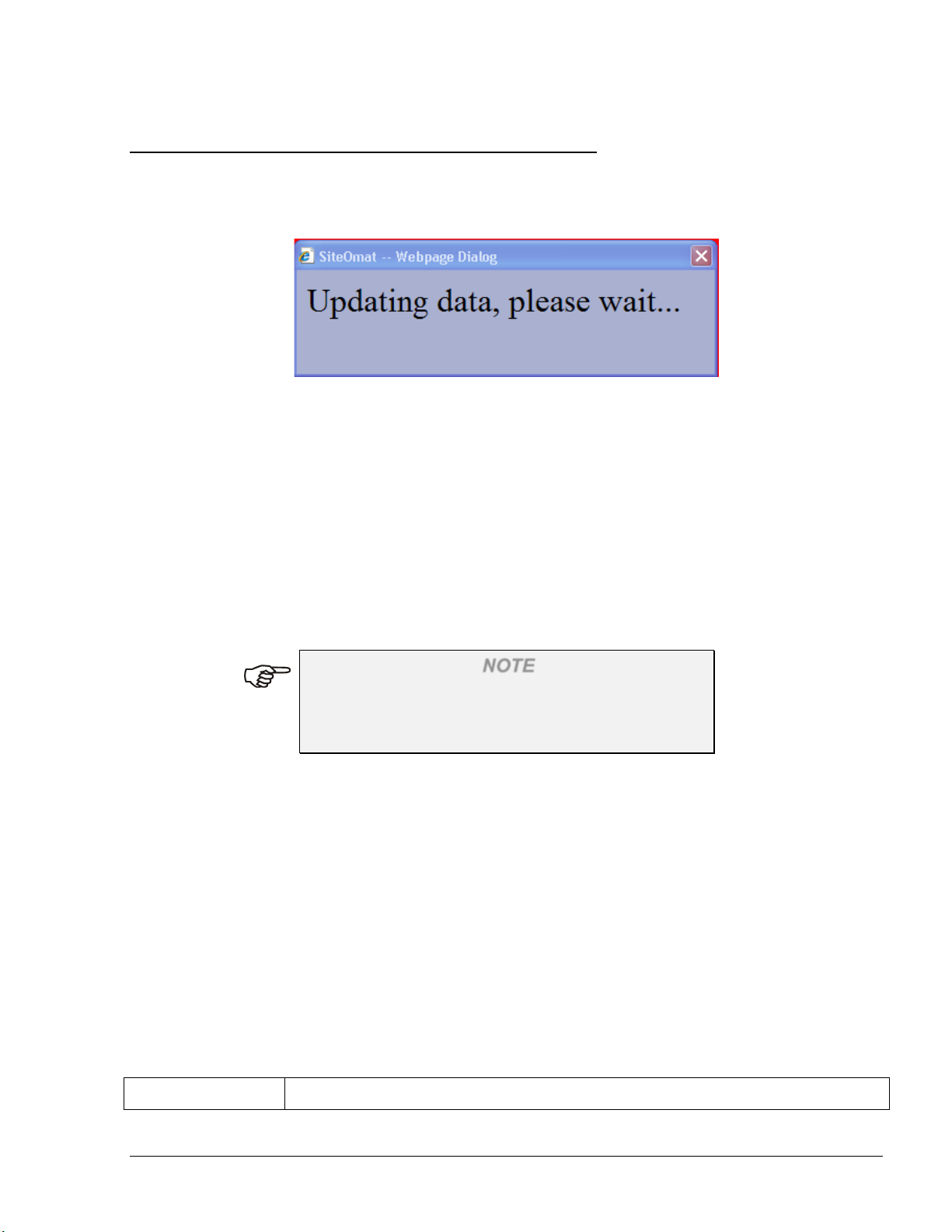

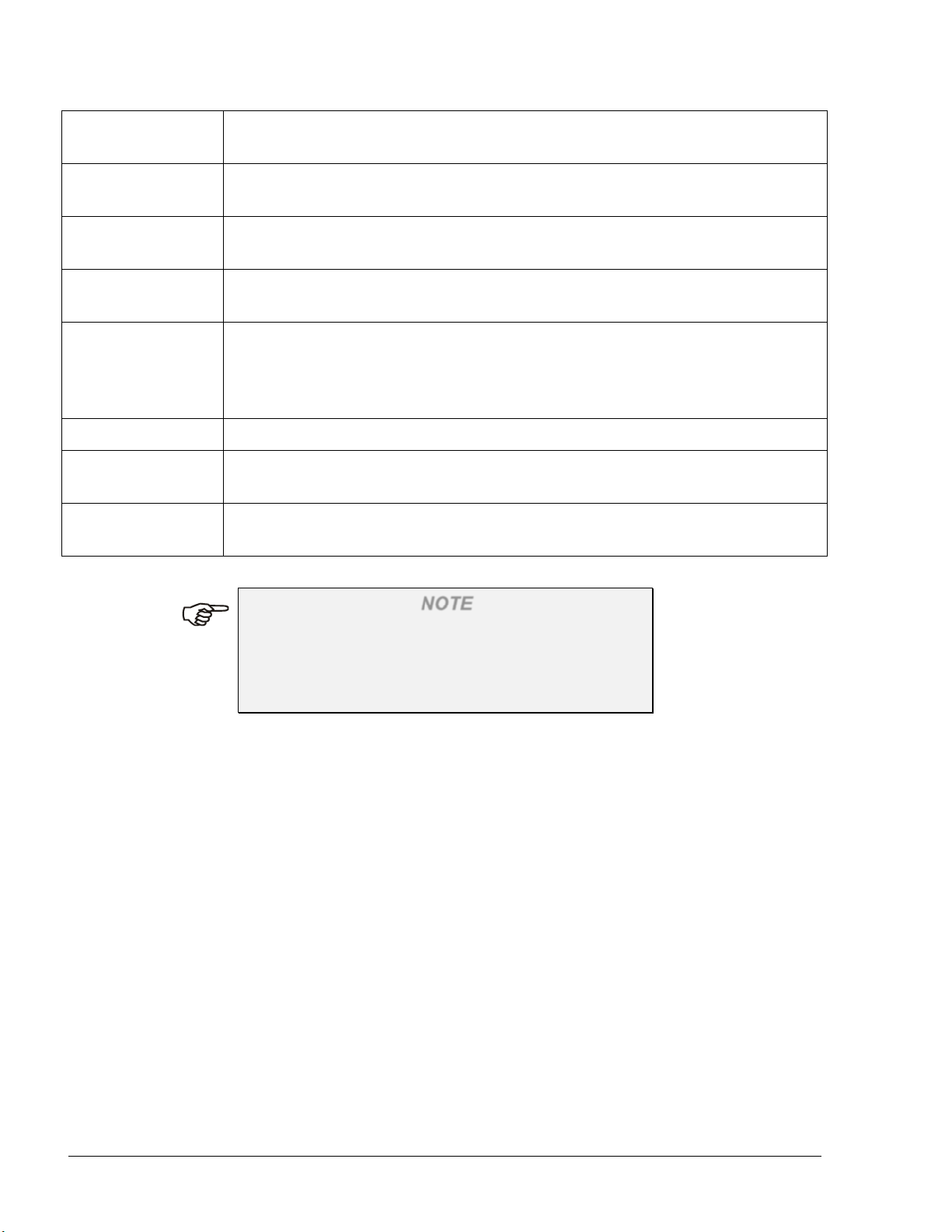

3-4. NAVIGATING THROUGH THE SITEOMAT

Button

Description

After successful login, the opening screen (see Figure 3-3) appears. When entering the program for

the first time, the opening screen appears after the system data is uploaded (it may take a few

seconds). Meanwhile the following message appears (see Figure 3-2):

Figure 3-2. Updating Data Message

The SiteOmat interface includes three sections:

a. Navigation Bar – Accessing the various capabilities of the SiteOmat application is done using

the Navigation Bar on the left-hand side of the window. The Navigation Bar appears throughout

the SiteOmat application and contains buttons, which lead to the various screens of the

application within the boundaries of the user’s clearance level

b. Alarm Line– The alarm line is constantly displayed on the bottom of the window, indicating

the most critical fault in the system

c. Work Area – The main user interface located in the center of the screen

NOTE

The login name of the current user is displayed in

the information bar at the bottom of the screen

"Login User Name" (see Figure 3-3).

Clicking on a button in the Navigation Bar opens the subsequent contents in the work area; while

the Navigation Bar is fixed, the work area is dynamic and changes according to the requested

option. The objective of each button in the Navigation Bar is depicted as follows (see Table 3-1):

Table 3-1. Navigation Bar Buttons

SiteOmat User’s Manual– MDE 4818

25

Page 30

Status

Enables real-time monitoring of the gas station fuel pumps. This part is

Reports

A report generator tool, which facilitates producing a wide variety of reports

Wet Stock Mgmt

Manages and updates the price of a product in all pumps and nozzles

Local

Management

Defines all authorized fleets and devices in the tank-fuel station

Setup

Leads to SiteOmat setup definitions, which map the gas station for the

Event Viewer

Enables viewing system warnings and logins.

Admin

The admin section contains system properties and diagnostics tools, meant for

Exit

Closes the current window and opens the login dialog - Used for exiting the

detailed in Section 4 – Monitoring Station Status

on the data in the SiteOmat

including a product price history report for tracking price changes

SiteOmat Station Controller. These definitions are beyond the scope of the

user, and are described in the SiteOmat In-House Installation & Setup

Manual

the SiteOmat Controller administrator/technician.

SiteOmat Application.

NOTE

Not all navigation buttons are available to all users

(i.e. Setup and Admin navigation buttons are

available to users with ADMIN clearance level

only).

26

SiteOmat User’s Manual– MDE 4818

Page 31

Figure 3-3. SiteOmat Opening Screen

SiteOmat User’s Manual– MDE 4818

27

Page 32

4

SECTION

MONITORING STATION STATUS

4-1. GENERAL

This section provides instructions for monitoring the gas station in real-time using the SiteOmat

application. The SiteOmat Station Controller is connected to all FuelPoint PLUS modules in the

gas station, and receives on-line fueling information and status from each of the pumps deployed in

the gas station. The Status feature also enables monitoring the status of the fuel tanks in the station.

4-2. STATION MONITORING

Enter the station-monitoring window by clicking on the Status navigation button on the SiteOmat

Navigation Bar. This section is divided into four sub-sections which are accessed through the

following tabs: Pumps, Tanks, OrPT, and Devices, as seen in Figure 4-1

28

SiteOmat User’s Manual– MDE 4818

Figure 4-1. Status – Pumps Screen

Page 33

4-3. PUMP STATUS

The application presents the data received from each of the fuel pumps in the station, as seen in

Figure 4-2.

The station-monitoring window, aside from displaying an overall picture regarding the fuel

dispensing activity in the gas station, also allows users to remotely initiate a fuel dispensing

transaction, by clicking on the applicable pump head indicator or stops the fuel dispensing

transaction, by clicking the emergency stop icon on the right side.

Figure 4-2. Station Monitoring – Pump Status View

In order to display information in a readable size, the Pump Status window enables monitoring a

group of eight pump heads simultaneously. Switching between the groups of pump heads is done

by clicking on the gauges in the upper part of the window.

NOTE

A pump may consist of one or two pump heads, each

pump head including a number (one or more) of

nozzles. Only a single nozzle in a pump head can be

used in a given time.

4-3.1. Pump Status Window Elements

The Status window comprises several elements, each serves a different role in the monitoring of the

gas station, as follows:

a. Pump Heads Gauge × 4

SiteOmat User’s Manual– MDE 4818

29

Page 34

b. Pump Head On-Line Data × 8 for each group (total of 32)

c. Fueling Transactions History Log

4-3.1.1. Pump Heads Gauge

The four Pump Heads Gauges (see Figure 4-2) serve two functions:

a. Switching between the four groups of eight pump heads, by clicking on the applicable

gauge:

1. First (leftmost) Gauge: Pump heads 1 to 8

2. Second Gauge: Pump heads 9 to 16

3. Third Gauge: Pump heads 17 to 24

4. Forth Gauge: Pump heads 25 to 32

b. Indicating whether a fueling transaction is currently performed in one of the pump heads.

The gauge contains eight indicators, each representing a pump head (the leftmost is the first

pump head in the group and the rightmost is the last one). The color indications are as

follows:

1. Gray: No pump head is assigned to the indicator

2. Blue: The pump head is Idle – awaiting fueling request

3. Yellow: The pump head is in Call status – the fuel nozzle was lifted

4. Purple: The pump head is in Ready status – fueling was authorized but the

nozzle was not lifted yet

5. Green: The pump head is in In-Use - fuel is being dispensed; or Pay status -

the transaction is completed and the transaction is being charged

6. Orange: Fueling was stopped (e.g.: fuel limit is reached, or fueling is stopped in

automatic fueling, in cases where the nozzle was taken out of the vehicle fuel inlet

during the fueling)

7. Red: A problem of some sort occurred (i.e. error in pump, communication

error)

NOTE

The color indicators display the status of all the

pump heads, even though the Status window only

shows eight pump heads each time.

4-3.1.2. Pump Head On-Line Data

30

SiteOmat User’s Manual– MDE 4818

Page 35

The Pump Head On-Line Data is displayed in five text boxes and two indicators. The fueling

process is viewed in real-time, as if watching the display on the fuel pump. The textual information

displayed on-line is as follows:

a. USD: The amount of money, which should be collected for the fuel dispensed so

far

b. Gallon: The fuel volume dispensed so far

c. Emp/Veh: The Employee name or plate number of the vehicle being fueled

d. Nz: The number of the nozzle dispensing the fuel

e. Fleet: The number of the fleet, to which the fueled vehicle belongs

4-3.1.2.1. Pump Head Indicator

The pump head indicator displays the number of the pump head. The following states are displayed

by the pump head color indicator:

Red: The pump head is not defined

Green: The pump head is monitored

Black: The pump head is blocked (deactivated)

4-3.1.2.2. Nozzle Indicator

The nozzle indicator displays the state of the nozzle of each pump head. The nozzle icon changes

according to the nozzle state, as follows:

a. Idle – awaiting fueling request

b. Call status – the fuel nozzle was lifted

c. In-Use – fuel is being dispensed

d. Pay status – transaction is completed and money is collected

e. Ready – fueling was authorized but the nozzle was not lifted yet

f. Stop – Fueling is stopped (e.g. nozzle is pulled out before fueling was completed)

g. Attention – A problem of some sort occurred (i.e. pump in error, communication error)

SiteOmat User’s Manual– MDE 4818

31

Page 36

4-3.1.3. Fueling Transactions History Log

2.

Time

Time of the transaction

4.

Employee/Vehicle

The license plate number of the fueled vehicle. The vehicle number

9.

Fuel type

Type of fuel supplied in the transaction

11.

Nozzle

Number of the nozzle in the pump head, used to supply the fuel in

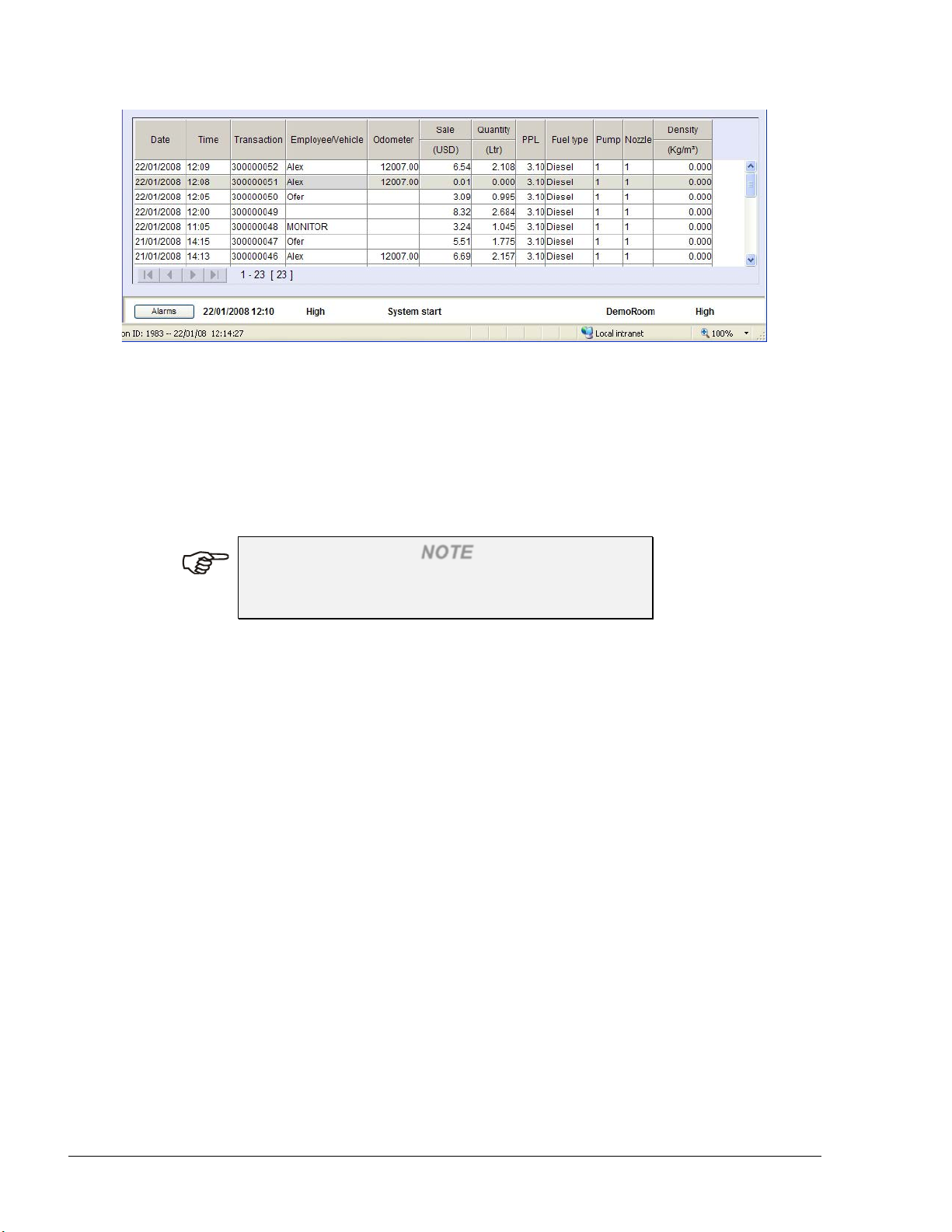

The Fueling Transactions History Log is a grid listing all the fueling transactions that took place in

the gas station.

The grid is sorted by the date and time of the transaction, so the most recent transaction appears

first. However, the grid may be sorted by any other field (see paragraph 2-3.2). The fields

appearing in the Fueling Transactions History Log are described in Table 4-1.

Table 4-1. Fueling Transactions History Log Fields

No. Field Name Description

1. Date Date of the transaction

3. Transaction A unique transaction ID ordinal number given by the SiteOmat

Station Controller to each transaction

appears in the transaction only if provided from the Fuel Ring or

entered by the authorizer in the OrPT

5. Odometer Odometer reading of the vehicle in the transaction

6. Sale (USD) The sum of money collected in the transaction

7. Quantity (Gallons) The fuel volume dispensed in the transaction

8. PPV Price Per Volume (PPV) i.e the ratio between the Gallon value and

the Amount value.

10. Pump Number of the pump head, from which the transaction was

performed

the transaction

12. Density (Kg/m3) Fuel density

32

SiteOmat User’s Manual– MDE 4818

Page 37

4-4. REFUELING THROUGH SCREENS

The SiteOmat Controller enables users to remotely initiate and stop refueling transactions. The

start/stop refueling is done through the Status window (see Figure 4-2), by click on the pump head

icon, from which the refueling transaction should be performed.

NOTE

The remote refueling option is available only if

enabled in the setup of the SiteOmat Controller. For

more information about the setup of this feature,

refer to the SiteOmat In-House Installation &

Setup Manual.

4-4.1. Starting Refueling

To start a refueling transaction from a certain pump head, click on the applicable pump head icon in

the Status window. The SiteOmat presents a confirmation box, as seen in Figure 4-3.

Figure 4-3. Start Refueling Confirmation Message

In cases where the pump head is currently occupied with a refueling transaction, a proper

notification message is displayed (see Figure 4-4).

Figure 4-4. Pump Busy Message

In cases where the pump head is available for refueling, the SiteOmat prompts for the money or

volume limit for the requested refueling, as seen in Figure 4-5. Enter the applicable money/volume

value and click Money or Volume, accordingly.

SiteOmat User’s Manual– MDE 4818

33

Page 38

Figure 4-5. Authorize Pump Dialog Box

The SiteOmat requests confirmation for the given money/volume amount (see Figure 4-6 and

Figure 4-7). Confirming the limit starts the refueling transaction for the given pump.

Figure 4-6. Money Limit Confirmation Message

Figure 4-7. Volume Limit Confirmation Message

4-4.2. Stopping Refueling

All pump heads currently engaged in a refueling transaction can be remotely stopped through the

Pump Status window of the SiteOmat Controller. Click on the emergency stop icon at the

middle-right side of the Pump Status window to stop all current refueling transactions.

A confirmation box is displayed prior to actually stopping the refueling.

34

SiteOmat User’s Manual– MDE 4818

Page 39

Figure 4-8. Close All Pumps Confirmation Message

SiteOmat User’s Manual– MDE 4818

35

Page 40

4-5. TANK STATUS

The Tank Status window (see Figure 4-9) is accessed by clicking the Status navigation button, then

clicking the Tanks tab. This window enables visual inspection of the current fuel level in each

tank. The visual and textual data displayed for each tank is obtained from the last inventory

measurement (for details, refer to the Wet Stock management in Section 6 ), without the fuel

consumption according to the registered transactions. This data can also be provided from the TLG

readout.

Figure 4-9. Station - Tanks Screen

In order to display information in a readable size, the Tanks Status window enables monitoring a

group of four tanks simultaneously. Switching between groups of tanks is done by clicking on the

gauges in the upper part of the screen.

4-5.1. Tank Status Window Elements

The Status window is comprised of several elements, each serving a different role in the gas station

monitoring as follows:

a. Tanks Gauge × 6

b. Tanks On-Line Data × 4 for each group (total of 24)

c. Capacit y Trans acti on s Hist ory Log.

36

SiteOmat User’s Manual– MDE 4818

Page 41

4-5.1.1. Tanks Gauge

The four Tanks Gauges (see Figure 4-9) have two functions:

a. Switching between the four groups of eight Tanks, by clicking on the applicable gauge:

1. First (leftmost) Gauge: pump heads 1 to 4

2. Second Gauge: pump heads 5 to 8

3. Third Gauge: pump heads 9 to 12

4. Forth Gauge: pump heads 13 to 16

5. Forth Gauge: pump heads 17 to 20

6. Forth Gauge: pump heads 21 to 24

b. Indicating whether a fuel tank is currently specified. Each of the gauges contains four

indicators, each representing a tank (the leftmost is first tank in the group and the rightmost

is the last one). The color indications are as follows:

1. Gray: No tank is assigned to indicator

2. Blue: The tank is Idle

4-5.1.2. Tank Head On-Line Data

The Tank On-Line Data is displayed in six text boxes and a single indicator. The tank fuel volume

is displayed in real-time. The textual information displayed online is as follows:

a. Fuel Level: Displays the height of fuel in the tank

b. Fuel Volume: The fuel volume remained so far

c. Water Level: Displays the height of the water in the fuel tank

d. Temp: Displays the temperature inside the fuel tank

e. Density at 150C: Displays the fuel density in kg/m3 at this temperature

f. Flow Rate: Flow rate calculated over a period of time as defined in the setup. The units

are volume per hour, and it is based on two measurement points over the

defined period. A negative value indicates level drop

SiteOmat User’s Manual– MDE 4818

37

Page 42

Some of the data may not be available depending on the TLG type and probes (such as density).

2.

Capacity

Product capacity

If the TLG reports on delivery status, a relevant indication appears.

4-5.1.2.1. Tank Indicator

The tank's fuel indicator indicates whether the tank fuel is currently specified. The following states

are shown by the fuel tank indicator:

a. Green: Displays the tank fuel volume

b. Red: Displays the water level in the tank. If the water level is above zero, at least one

red line is displayed

4-5.1.3. Fuel Tank Transactions History Log

The Fuel Tank Transactions History Log is a grid listing all the fuel tanks transactions that took

place in the gas station.

The grid is sorted by product. However, the grid may be sorted by any other field (as instructed in

page 22 – Sorting a Grid). The fields appearing in the Fuel Tank Transactions History Log are

described in Table 4-2.

Table 4-2. Fuel Tank Transactions History Log Fields

No. Field Name Description

1.

3.

Product Fuel type name

Volume Volume of all the tanks containing the specific product in the gas

station

38

SiteOmat User’s Manual– MDE 4818

Page 43

4-6. ORPT STATUS

The application presents the display of the OrPT as seen in Figure 4-10.

The OrPT status screen allows users in the back/head office to view the information currently

displayed on any of the OrpT defined in the system.

NOTE

The current message displayed on the selected OrPT

is displayed. Data entered by drivers/attendants

(such as odometer) is not displayed in this screen.

Select the OrPT to be displayed utilizing the adjacent drop-down list.

The screen can be refreshed manually, by clicking on the Refresh button, or automatically by

selecting the Auto refresh checkbox and defining the refreshment intervals from the Refresh every