Page 1

CFN Series

Site Controller III Start-Up

Manual

MDE-4375

(formerly C35886)

Page 2

Computer Programs and Documentation

FCC Warning

All Gasboy International Inc. computer programs (including software on diskettes and within memory chips) and documentation are copyrighted by, and shall remain the property

of, Gasboy International Inc. Such computer programs and documents may also contain trade secret information. The duplication, disclosure, modification, or unauthorized use of

computer programs or documentation is strictly prohibited, unless otherwise licensed by Gasboy International Inc.

This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy, and if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communic ations. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense. Changes or modifications not expressly

approved by the manufacturer could void the user’s authority to operate this equipment.

Approvals

Gasboy International, Gree nsboro , is an I SO 9001:2 000 r egist ered fa cil ity.

Underwriters Laboratories:

U. L. File# Products li st ed wi th U. L.

MH4314

MH6418

MH7404

MH10581 Key con t ro l u n it , M od e l G K E- B S e ri e s

All dispensers and self-contained pumping

units

Power operated Transfer Pump Models 25,

25C, 26, 27, 28, 72, 72S, 72SP, 72X, 73 and

1820

Hand operated Transfer Pump Models 1230

Series, 1243 Series, 1520 and 1720 Series

Card reader terminals, Models 1000, 1000P

Site controller, Model 2000S CFN Series

Data entry terminals, Model TPK-900 Series

Fuel Point Reader System

New York City:

NYFD C of A # Produc t

4823 9100A, 9140A, 9152A, 9153A,

4997 9822A, 9823A

5046 9100Q, 9140Q, 9152Q, 9153Q,

9800A, 9840A, 9850A, 9852A,

9853A, 9140

9800Q, 9840Q, 9852Q, 9853Q

NCWM - Certificate of Compliance:

Gasboy pumps and dispensers are evaluated by the National Conference of Weights and Measures (NCWM) under the National Type Evaluation Program (NTEP).

NCWM has issued the following Certificates of Compliance (COC):

COC# Product Model # COC# Product Model # COC# Product Model #

95-179A2 Dispenser

95-136A5 Dispenser 9800 Series 91-057A3 Controller

9100 Retail Series, 8700

Series, 9700 Series

91-019A2 Dispenser

9100 Commercial

Series

1000 Series FMS,

2000S-CFN Series

California Air Resources Board (CARB):

Executive Order # Product

G-70-52-AM Balance Vapor Recovery

G-70-150-AE VaporVac

Patents

Gasboy products are manufactured or sold under one or more of the following U.S. patents.:

Dispensers

5,257,720

Point of Sale/Back Office Equipment

D335,673

Trademarks

Non-registered trademarks

Atlas™

Consola™

Infinity™

Registered trademarks

ASTRA

Fuel Point

®

Gasboy

®

Keytrol

Slimline

®

®

®

Additional U.S. and foreign trademarks

pending.

Other brand or product names shown may be

trademarks or registered trademarks of their

respective holders.

Additional U.S. and foreign patents pending.

This document is subject to change without notice. · For information regarding Gasboy Literature, call (336) 547-5661

E-mail: literature@gasboy.com · Internet: http://www.gasboy.com

2005 Gasboy International Inc. · All Rights Reserved

Page 3

Table of Contents

Table of Contents

List of Figures vii

Starting a Site Controller III System 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Start-Up Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

What You Need for Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Filling Out the Start-Up Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Using This Book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Site Information 5

1. Communication Port Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2. Authorize Users . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3. Receipt Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4. Broadcast Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5. Load Product - Fuels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

6. Load Fuel Inventory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

7. Load Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

8. Load Prices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

9. Load Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

10. Load Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

11. Load Cutoff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

12. Load Tax . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

13. Lockout Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

14. Authorization and Limitation Codes . . . . . . . . . . . . . . . . . . . . . . . . 13

15. CRON Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

16. Load Remote Host Phone Number . . . . . . . . . . . . . . . . . . . . . . . . . 14

17. Check Point Default Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

18. Load Merchandise Prods/Depts . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

19. Load Merchandise Inventory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

20. Load Price Lookup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

21. Profit Point Product Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

22. Profit Point Default Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

®

23. Worksheet for Pump/CRIND

Device (if used) . . . . . . . . . . . . . . . . 22

Begin Start-Up Form 23

Parts 1 through 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Physical System Layout 27

Site Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Island Card Reader Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Pump Control Unit(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Checkpoint Console (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Profit Point Console or SC III/POS WS (Optional) . . . . . . . . . . . . . . . . 30

Tank Monitoring System (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Current Loop Interface (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

CRIND Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Fuel Point Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Electronic Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

MDE-4375 CFN Series Site Controller III Start-Up Manual · June 2005 Page i

Page 4

Table of Contents

Jumpers & Switch Settings 33

Site Controller COMM CPU Printed Circuit Board . . . . . . . . . . . . . . . . .33

Site Controller Memory I/O Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Pump Control Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Island Card Reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

RS-232/RS-485 Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

POS Distribution Box (D-Box) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Fuel Point Reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Pumps and Dispensers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Standalone Star Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

System Power 47

Pump/Dispenser Manual Test 49

Verify General Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Manual Override Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Component Power-Up and Configuration 51

Turning On AC Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Configuring the Checkpoint Console . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Configuring the Profit Point Console . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Okidata Printer/Logger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Remote Terminal Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Site Controller Configuration Changes . . . . . . . . . . . . . . . . . . . . . . . . . .57

Series 9800 Electronic Pumps and Dispensers . . . . . . . . . . . . . . . . . . .57

DC Power Measurement and Adjustment 59

Site Controller III . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Pump Control Unit(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Island Card Reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Checkpoint Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Fuel Point Reader (FPR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Profit Point Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Current Loop Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Electronic Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Communication Tests 67

Site Controller III or Remote Terminal . . . . . . . . . . . . . . . . . . . . . . . . . .68

Modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Tank Monitor (Serial Port) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Pump/Dispenser Automatic Test 73

Island Card Reader - Pump Activation Test (optional) . . . . . . . . . . . . . .74

CheckPoint - Postpay Pump Activation Test (optional) . . . . . . . . . . . . .75

CheckPoint - Prepay Pump Activation Test (optional when using

dual-stage solenoid valves) . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Profit Point or SC III/POS WS - Postpay Pump Activation Test

(optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Profit Point or SC III/POS WS - Prepay Pump Activation Test

(optional when using dual-stage solenoid valves) . . . . . . . . . . .76

Before Using Fuel Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Fuel Point Setup for Ground Loop Fueling . . . . . . . . . . . . . . . . . . . . . . .77

Fuel Point - Pump Activation Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Page ii MDE-4375 CFN Series Site Controller III Start-Up Manual · June 2005

Page 5

Table of Contents

Reader Entries and Fuel Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Obtaining a Receipt for Fuel Point Transactions . . . . . . . . . . . . . . . . . . 78

Master/Satellite Dispensers with Fuel Point . . . . . . . . . . . . . . . . . . . . . 78

Using the Chain Pump Feature with Fuel Point . . . . . . . . . . . . . . . . . . 78

Fuel Point - Gate Activation Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Start-up Commands 81

Sign-on and Preliminary Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Receipt Header, Broadcast Messages . . . . . . . . . . . . . . . . . . . . . . . . . 82

Load Fuel Products, Pumps, Tanks, Prices, and Taxes . . . . . . . . . . . . 83

Card Lockout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Card Authorizations, Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Load Merchandise/Departments, Prices, Inventory . . . . . . . . . . . . . . . 88

Enable Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Cash Drawer, Shifts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Optional Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Reset Transaction File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Diagnostics and History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Verification and Backup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Site Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Release, Applications, and System Data . . . . . . . . . . . . . . . . . . . . . . . 95

Standalone Profit Point Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

SC III/POS WS Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Customer Training 99

Finish Start-up 103

Gasboy Motor Fuel Management System S-Form-1

CFN System Start-up Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-Form-1

1. SITE IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-Form-1

2. SYSTEM IDENTIFICATION Site #: 1001 . . . . . . . . . . . . . S-Form-1

3. SYSTEM DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . S-Form-2

4. COMMUNICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-Form-2

5. BREAKER NUMBERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-Form-3

6. SYSTEM ENVIRONMENT . . . . . . . . . . . . . . . . . . . . . . . . . . S-Form-3

7. CONDUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-Form-3

8. SYSTEM POWER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-Form-3

9. DC POWER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-Form-4

10. SYSTEM APPROVALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-Form-4

11. CUSTOMER KNOWLEDGE . . . . . . . . . . . . . . . . . . . . . . . . S-Form-4

12. ATTACH PRINTOUTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-Form-4

13. PARTS USED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-Form-4

14. SITE LAYOUT (include wiring distances) . . . . . . . . . . . . . . S-Form-5

Gasboy Motor Fuel Management System Form-1

CFN System Start-up Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Form-1

1. SITE IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Form-1

2. SYSTEM IDENTIFICATION Site #: . . . . . . . . . . . . . . . . . . . . . Form-1

3. SYSTEM DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Form-2

4. COMMUNICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Form-2

5. BREAKER NUMBERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Form-3

6. SYSTEM ENVIRONMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . Form-3

7. CONDUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Form-3

MDE-4375 CFN Series Site Controller III Start-Up Manual · June 2005 Page iii

Page 6

Table of Contents

8. SYSTEM POWER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Form-3

9. DC POWER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Form-4

10. SYSTEM APPROVALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Form-4

11. CUSTOMER KNOWLEDGE . . . . . . . . . . . . . . . . . . . . . . . . . .Form-4

12. ATTACH PRINTOUTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Form-4

13. PARTS USED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Form-4

14. SITE LAYOUT (include wiring distances) . . . . . . . . . . . . . . . .Form-5

Warranty Warranty-1

General Statements: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Warranty-1

Appendix: Trademark Information A-1

Index Index-1

Page iv MDE-4375 CFN Series Site Controller III Start-Up Manual · June 2005

Page 7

Table of Contents

MDE-4375 CFN Series Site Controller III Start-Up Manual · Ju n e 20 05 Page v

Page 8

Page vi MDE-4375 CFN Series Site Controller III Start-Up Manual · June 2005

Page 9

List of Figures

Figure 2-1: Check Point Default Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 2-2: Profit Point Default Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 5-1: SC III Comm CPU Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 5-2: SC III Memory I/O Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 5-3: Pump Control Unit Component Location. . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 5-4: EXPMUX CPU Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 5-5: Pump Control I/O Cover Plate and PCB . . . . . . . . . . . . . . . . . . . . . . . . 40

List of Figures

Figure 5-6: Fuel Point Reader CPU Printed Circuit Board. . . . . . . . . . . . . . . . . . . . 45

Figure 6-1: AC Output Receptacle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 9-1: PCU +5 VDC Measurement Points. . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 9-2: ICR +5 VDC Measurement Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Figure 9-3: ICR +12 VDC Measurement Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 9-4: Checkpoint +5 VDC Measurement Point. . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 9-5: Fuel Point Reader+5 VDC Measurement Point. . . . . . . . . . . . . . . . . . . 64

Figure 10-1: Sample of Creating TMTST.CMD File for TLS-350. . . . . . . . . . . . . . . 71

Figure 10-2: Sample Tank Monitor Printout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Figure 12-1: Example of SIGN ON Entry with Response . . . . . . . . . . . . . . . . . . . . 81

Figure 12-2: Example of AD SIG Command with Prompts . . . . . . . . . . . . . . . . . . . 82

Figure 12-3: Example of LO DA Command with Prompts . . . . . . . . . . . . . . . . . . . . 82

Figure 12-4: Example of LO H;IC Command with Prompts. . . . . . . . . . . . . . . . . . . 82

Figure 12-5: Example of LO ME;IC Command with Prompts . . . . . . . . . . . . . . . . . 83

MDE-4375 CFN Series Site Controller III Start-Up Manual · June 2005 Page vii

Page 10

List of Figures

Figure 12-6: Example of REM PRO;A Command. . . . . . . . . . . . . . . . . . . . . . . . . . 83

Figure 12-7: Example of LO PRO;AC Command with Prompts . . . . . . . . . . . . . . . 83

Figure 12-8: Example of LO IN;C Command with Prompts . . . . . . . . . . . . . . . . . . 84

Figure 12-9: Example of RE PU Command with Prompt . . . . . . . . . . . . . . . . . . . . 84

Figure 12-10: Example of LO PU;C Command with Prompts. . . . . . . . . . . . . . . . . 84

Figure 12-11: Example of LO TA;C Command with Prompts . . . . . . . . . . . . . . . . 85

Figure 12-12: Example of LO F;C Command with Prompts . . . . . . . . . . . . . . . . . . 85

Figure 12-13: Example of LO CU;C Command with Prompts . . . . . . . . . . . . . . . . 85

Figure 12-14: Example of LO PR;IC Command with Prompts . . . . . . . . . . . . . . . . 86

Figure 12-15: Example of LO TAX Command with Prompts . . . . . . . . . . . . . . . . . 86

Figure 12-16: Example of U CA;A Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Figure 12-17: Example of LOC CA;A Command . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Figure 12-18: Example of LO A;IC Command with Prompts . . . . . . . . . . . . . . . . . 87

Figure 12-19: Example of LO LI;IC Command with Prompts . . . . . . . . . . . . . . . . . 87

Figure 12-20: Example of LO CR;IC Command with Prompts . . . . . . . . . . . . . . . . 88

Figure 12-21: Example of LO PH Command with Prompts . . . . . . . . . . . . . . . . . . 88

Figure 12-22: Example of LO PRO;AC Command with Prompts . . . . . . . . . . . . . . 88

Figure 12-23: Example of LO IN;C Command with Prompts . . . . . . . . . . . . . . . . . 89

Figure 12-24: Example of LO PLU;C Command with Prompts. . . . . . . . . . . . . . . . 89

Figure 12-25: Example of E PRO Command with Prompts . . . . . . . . . . . . . . . . . . 89

Figure 12-26: Example of E PC;I Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Figure 12-27: Example of E PU;I Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Figure 12-28: Example of E RE;I Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Figure 12-29: Example of E CO;I Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Page viii MDE-4375 CFN Series Site Controller III Start-Up Manual · June 2005

Page 11

List of Figures

Figure 12-30: Example of RE TO;A Command with Prompt . . . . . . . . . . . . . . . . . . 90

Figure 12-31: Example of LO DR Command with Prompts. . . . . . . . . . . . . . . . . . . 90

Figure 12-32: Example of LO SH Command with Prompt. . . . . . . . . . . . . . . . . . . . 91

Figure 12-33: Example of REM AL;A Command. . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Figure 12-34: Example of LO AL;C Command with Prompts . . . . . . . . . . . . . . . . . 91

Figure 12-35: Example of LO V;IC Command with Prompts . . . . . . . . . . . . . . . . . . 92

Figure 12-36: Example of Reset Transaction File Command Sequence. . . . . . . . . 92

Figure 12-37: Example of RE DI;I Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Figure 12-38: Example of E HI;I Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Figure 12-39: Example of RUN;I Command with Prompt . . . . . . . . . . . . . . . . . . . . 93

Figure 12-40: Example of P DI Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

MDE-4375 CFN Series Site Controller III Start-Up Manual · June 2005 Page ix

Page 12

List of Figures

Page x MDE-4375 CFN Series Site Controller III Start-Up Manual · June 2005

Page 13

Starting a Site Controller III System

1 – Starting a Site Controller III System

Introduction

This Start-Up Manual is provided to assist you in the start-up of a GASBOY CFN Site

Controller III System. The CFN Series System is a computerized data acquisition system. As

the start-up person, you should already be familiar with all the CFN Site Controller III

manuals. P roper installation according to the C FN Site Controller III Installation Manual is

critical to ensure correct and trouble-free operation. The CFN Site Controller III System

includes a one year parts and labor warranty against defective material and/or workmanship.

See the Warranty page at the back of this book for details.

Note: Noncompliance with th e specific ations of th e CFN Site Controller III Installation

Manual and the checks in the accompanying Start-up Form could void the warranty.

As you are performing t he st art-u p proce ss, any de vi ations from th e speci fica tions list ed in th e

Site Controller II I Ins ta llation Manual should be c orrected. If any tests fail, correct the wiring

or system problem and perform the test again. If you have any questions, cannot proceed to

the next step, or you want authorization for exceptions, please contact GASBOY Technical

Service at:

1-800-444-5529

In addition to this manual, the customer should have these additional GASBOY CFN Series

manuals:

• MDE-4298 Site Controller III Installation Manual, former C35880

Contains instructions, restrictions and guidelines for planning, laying out, and wiring the

Site Controller III System.

• MDE-4299 Profit Point Installation Manual, former C09156

Contains installation instructions for both the Profit Point Console and SC III/POS

workstation.

• MDE-4315 Site Controller III Site Manager's Manual, former C35920

Contains detailed instructions for setting up or maintaining the Site Controller III. It also

contains descriptions of system features, data terminal commands, transaction processing

and system maintenance.

Depending on the site configuration, the customer may also have these manuals:

• CFN Card Encoding Manual, C01687

Describes the cards, field descriptions, layouts, and filling out the card encoding form.

Covers both encoding of mag cards and punching of optical cards.

• Debit and Credit Card Networks Manuals

Each manual describes one of the various network interfaces for the Site Controller III.

MDE-4375 CFN Series Site Controller III Start-Up Manual · Ju n e 20 05 Page 1

Page 14

Starting a Site Controller III System

See your GASBOY representative for information.

• CheckPoint Reference Manual, C09204

Describes the operation of the CheckPoint Console.

• Profit Point Reference Manual, MDE-4356

Describes the operation of the Profit Point.

• Profit Point Clerk's Manual, MDE-4355

Describes all point-of-sale operations for the Profit Point.

• Point of Sale and Shift Change Manual, C09215

Describes POS and shift change operations.

®

• Star

Receipt Printer Manual , C08951

Describes the operation of the Star Re ceipt Printer.

• Series 9800A Installation/Operation Manual, 035235

Describes installation/operation for Series 9800 pumps/dispensers.

• Fuel Point Reader Installation and Retrofit Instructions Manual, C35628

• Fuel Point Dispenser and Hose Retrofit Manual, C35593

• Fuel Point Vehicle Module Installation Manual, C35699

• Fuel Point Vehicle Module Programming Manual, C35629

• Fuel Point Parts Manual, C35709

Start-Up Overview

Start-up for the CFN Site Controller III system consists of:

• gathering site information from customer for loading into system

• verifying the physical system layout

• making sure the system complies with the guidelines and restrictions outlined in the

system Installation Manual and this manual.

• testing the system

• helping the sy stem user execute the commands needed to start the system

• helping the system user back up release disks and explaining backup procedures

• making sure the system user understands how to use the system

• filling out the GASBOY CFN System Start-up Form (55F-066)

What You Need for Testing

To perform the testing portion of start-up, you will need:

• a digital voltmeter

• a 1/4 inch flat blade screwdriver

• a Phillips

• a Phillips head #2 screwdri ver

• a plastic 1/8 inc h or smaller flat blade screwdriver

• socket handle 1/4" drive

Note:A socket bit #2, P/N C04479, for the island card reader is shipped with every CFN

• a tape measure

• diskettes (2-4 blank double- si ded, high-density for the SC II I; 2 blank high density f or th e

Profit Point)

We recommend that you bring all your tools and spare parts with you when doing a

Start-up.

Page 2 MDE-4375 CFN Series Site Controller III Start-Up Manual · June 2005

®

head #1 screwdriver

Site Controller III System. This socket should be left with the end user.

Page 15

Filling Out the Start-Up Form

A sample filled-out Start-up form appears at the end of this manual. You should already have

blank copies of the Start-up form; however, if you do not, you can obtain more by calling

GASBOY Customer Service.

When you encounter an empty box on the form, fill in all the information requested. If an

option is not used or does not apply, fill in N/A (not applicable) in that space. It may be

helpful to have the terminal operator review the Site Controller III Manager’s Manual, if he or

she has not already done so, while you are starting up the system.

The Start-up form must be filled out completely and sent, with the attachments noted in

Section 14 of this manual, to:

GASBOY

Technica l Service Department

7300 West Friendly Avenue

P.O. Box 22087

Greensboro, NC 27420

Starting a Site Controller III System

IMPORTANT

If the Startup Form is not filled out completely, it will be returned to you for completion.

Be sure to keep a copy of the completed form for your own records.

Using This Book

This book is designed to be f ollowed from sta rt to f inish . The proce dures a re lis ted in a logica l

order and correspond to the layout of the Start-up form. Please follow the step-by-step

procedures in this manual.

Note: The Site Controller III can be equipped with a POS Workstation option. This enables it

to work as a Profit Point, as well as control system activity. Throughout the manual,

this configuration is referred to as the SC III/POS WS. If your site has a SC III/POS

workstation, you will ne ed t o refer to both a Site Controlle r I II Installation Manual and

a Profit Point Installation Manual.

MDE-4375 CFN Series Site Controller III Start-Up Manual · Ju n e 20 05 Page 3

Page 16

Starting a Site Controller III System

Page 4 MDE-4375 CFN Series Site Controller III Start-Up Manual · June 2005

Page 17

2 – Site Information

Before the Site Controller III system is operational, you must load in site information. This

section provides a temp late for you to fill in the information needed to pe rform the start-up

commands in the Start-up Commands chapter. Do not perform the commands at this time.

Confirm wi th the custom er and fill in the informa tion that he or she will be using (e.g., fuel

authorizations, limitations, etc.). Successful startup requires coordination between separate

components of the system: installation, card encoding, and operation. Each item contains a

manual reference where you can find additional information. For private-issue cards, the

system identificat ion, f uel a uthori zati on, fue l li mitati on code s, and price le vels are en coded o n

the access cards and then entered into the system via commands. The commands you enter

must match what is encoded on the cards. The Card Encoding Manual explains the encoding

of these items.

The tables in this section are meant to be reused. Make a photocopy of this section

before filling in table data.

Site Information

1. Communication Port Settings

(Reference: Configuration Manual)

Indicate the device connected to each of the ports you will use and the baud rates, if known.

The baud rate must match the baud rate of the device that is being connected to the port. Port

configuration as si gnmen ts and baud rates are don e t hrough the site configur at ion . Po rt wiring

is no longer set by jumpers. You must use the correct cable for the devices connected. Refer

to the Installation Manual for cabling requirem ents.

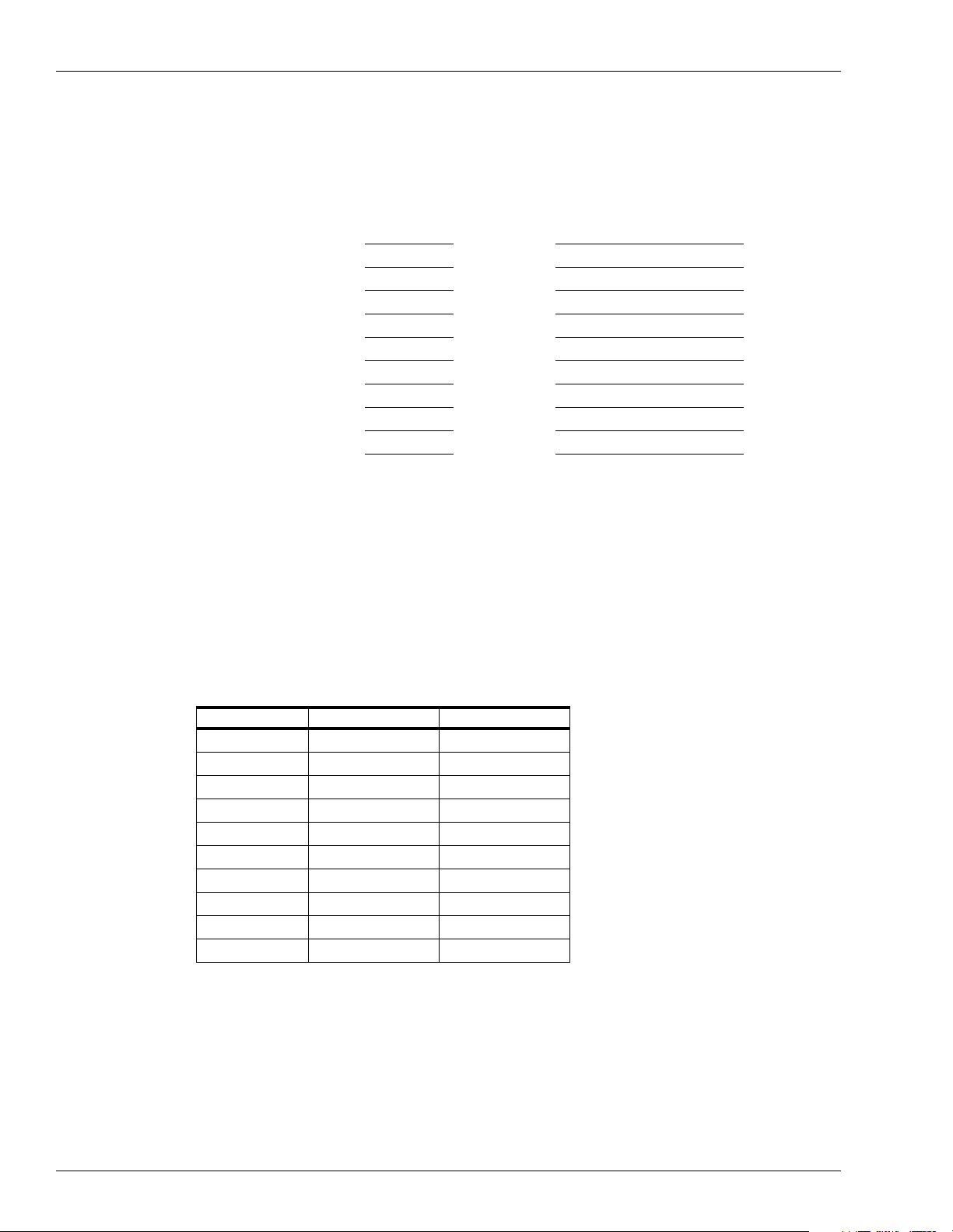

Port Device Baud Rate

1

4

5

6

COM1

COM2

COM3

COM4

COM5

COM6

LPT1 Printer (Y/N) N/A

MDE-4375 CFN Series Site Controller III Start-Up Manual · Ju n e 20 05 Page 5

Page 18

Site Information

CAUTION

If a 2-wire device is connected to a loop that is set for 4-wire communication, the site controller will

not operate correctly. 4-wire devices on a 2-wire loop may not communicate with the site controller.

Note: If your site uses Tokheim® DPTs, 2-wire communication is used. Loop 2 is factory-set

Loop 1 2/4 wire

Loop 2 2/4 wire

2. Authorize Users

(Reference: Site Manager’s Manual: AD SIG command)

Fill in the user name, user number, permission level (0 - 10) and sign-on code for each user

who is authorized to use the data term inal or console (if required).

for 2-wire communicati ons. Indic ate the l oop wiring u sed at the site. See C09146 Pump

Interface Manual for more information.

Note: If you communicate with a remote site using site-to-host protocol, you must identify the

remote host (PC, network, etc.) as user 1, with a permission level of 10. This does not

apply to remote hosts used for authorization only (BUYPASS, VISA, etc.).

User Name User # Permission Sign-on Code

Page 6 MDE-4375 CFN Series Site Controller III Start-Up Manual · June 2005

Page 19

3. Receipt Messages

(Referenc e: Site Manager’s Manual: LO H command)

Line #1

Heading Line

Line #2

Heading Line

Line #3

Heading Line

Line #4

Heading Line

Line #5

Heading Line

Line #6

Heading Line

Line #7

Heading Line

Line #8

Heading Line

Line #9

Heading Line

Site Information

Receipt Heading and Footing Messages

(24 characters maximum)

Heading

Information

Line #10

Footing Line

Line #11

Footing Line

Line #12

Footing Line

Line #13

Footing Line

Line #14

Footing Line

Line #15

Footing Line

Line #16

Footing Line

Line #17

Footing Line

Line #18

Footing Line

Line #19

Footing Line

Line #0

Form Feed

Length (1)

Always 1 with Star Printer

Note: System can be configured with footing lines 10 - 29. Lines 10 - 19 will print on every receipt; lines 20 - 29

(which accomodate such things as customer signature lines, etc.) will print only on POS console receipts.

Footing

Information

MDE-4375 CFN Series Site Controller III Start-Up Manual · Ju n e 20 05 Page 7

Page 20

Site Information

4. Broadcast Messages

(Reference: Site Manager’s Manual: LO ME command)

Display Time in Seconds Message # 1.

Display Time in Seconds Message # 2.

Display Time in Seconds Message # 3.

Display Time in Seconds Message # 4.

Display Time in Seconds Message # 5.

Display Time in Seconds Message # 6.

Display Time in Seconds Message # 7.

Display Time in Seconds Message # 8.

Display Time in Seconds Message # 9.

Display Time in Seconds Message # 10.

5. Load Product - Fuels

(Reference: Site Manager’s Manual, LO PRO command)

Broadcast Message

(20 characters maximum)

Use the following table to list the site's fuel products. Use one product code for each different

fuel product. These product codes can be linked to authorization codes when used with

private-issue cards. They are also used to assign products to tanks and pumps. In addition to

the product code, category, and name, three other prompts appear when you execute this

command: minimum price, maximum price, and tax. These should all be set to zero for fuel

products. If you need additional space, photocopy this chart.

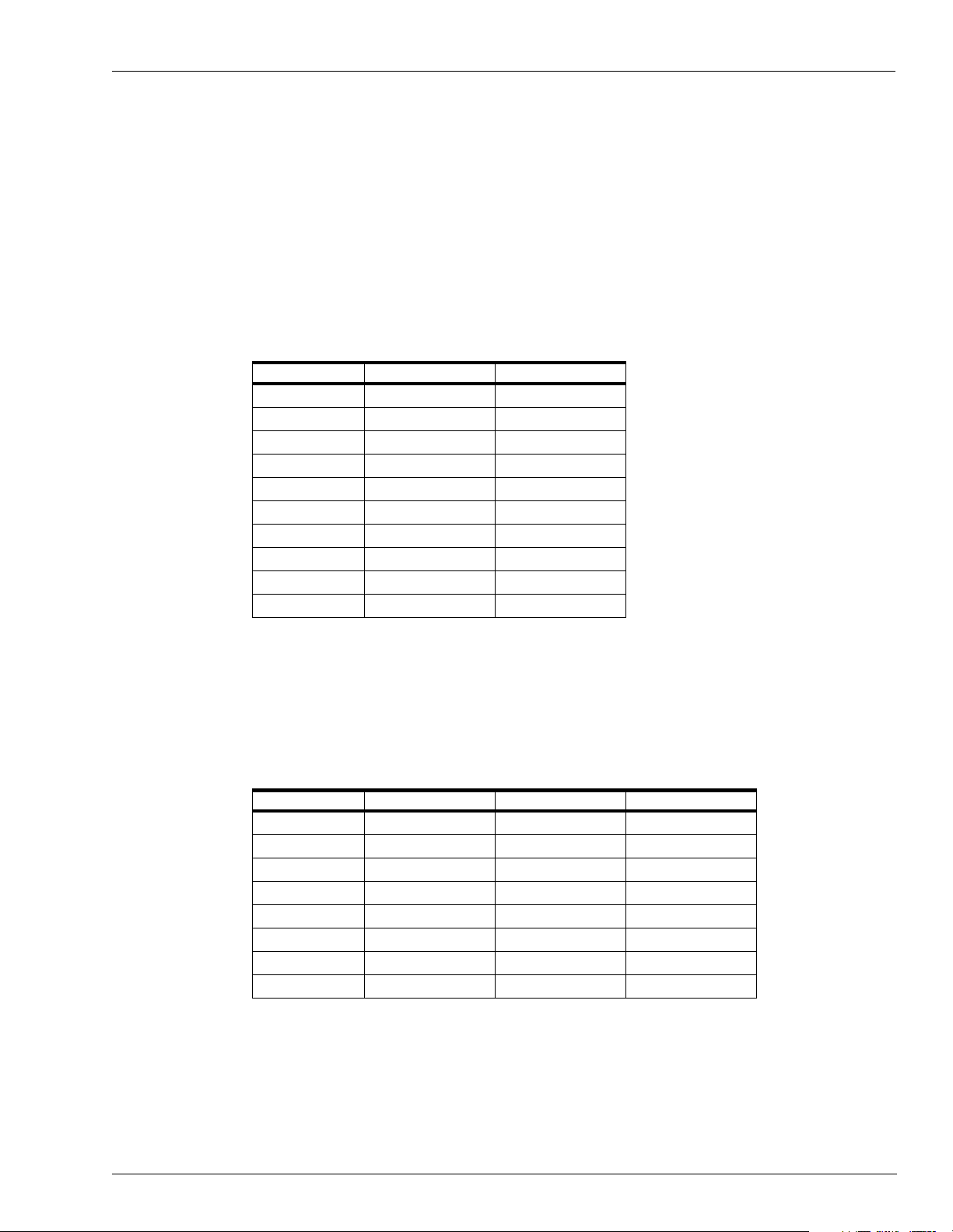

Product Code Product Cat egor y Product Name

Note: Fuel categories are usually 1 or 1 and 2.

Page 8 MDE-4375 CFN Series Site Controller III Start-Up Manual · June 2005

Page 21

6. Load Fuel Inventory

(Referenc e: Site Manager’s Manual, LO IN command)

Use the following table to load the initial inventory amounts and the reorder levels for your

fuel products. Once you have loaded the initial inventory amounts, you will use ADd

INventory to add to the inventory amount for the product. You will also use this command

later when you load inventory for your merchandise products, but you need to define these

products first.

Note: Normally fu el is tracked using the LOad TAnk command (see 7. Load Tank below);

however, this command can also be used.

Product Number Quantity Reorder Level

Site Information

7. Load Tank

(Referenc e: Site Manager’s Manual, LO TA command)

Use this table to enter the initial tank inventory, product code and the reorder level for each

tank. See also 6. Load Fuel Inventory above.

Tank Number Quantity Product Code Reorder Level

MDE-4375 CFN Series Site Controller III Start-Up Manual · Ju n e 20 05 Page 9

Page 22

Site Information

8. Load Prices

(Reference: Site Manager’s Manual, LO PR command; Card Encoding Manual, Price Level)

Use this table to lay out the site' s price co des. Each pric e code may ha ve multiple pr ice levels.

The total number of prices allowed is confi gured i n the Sit e Contro ller. See the explanation in

the above referen ced ma nua ls for the maximum size of price level/ pr ice code tables. Levels 0

through 3 are usually Fallback, Cash, Credit, and Debit respectively. The fallback price is

configurable. Additional price levels may be used for private-issue cards.

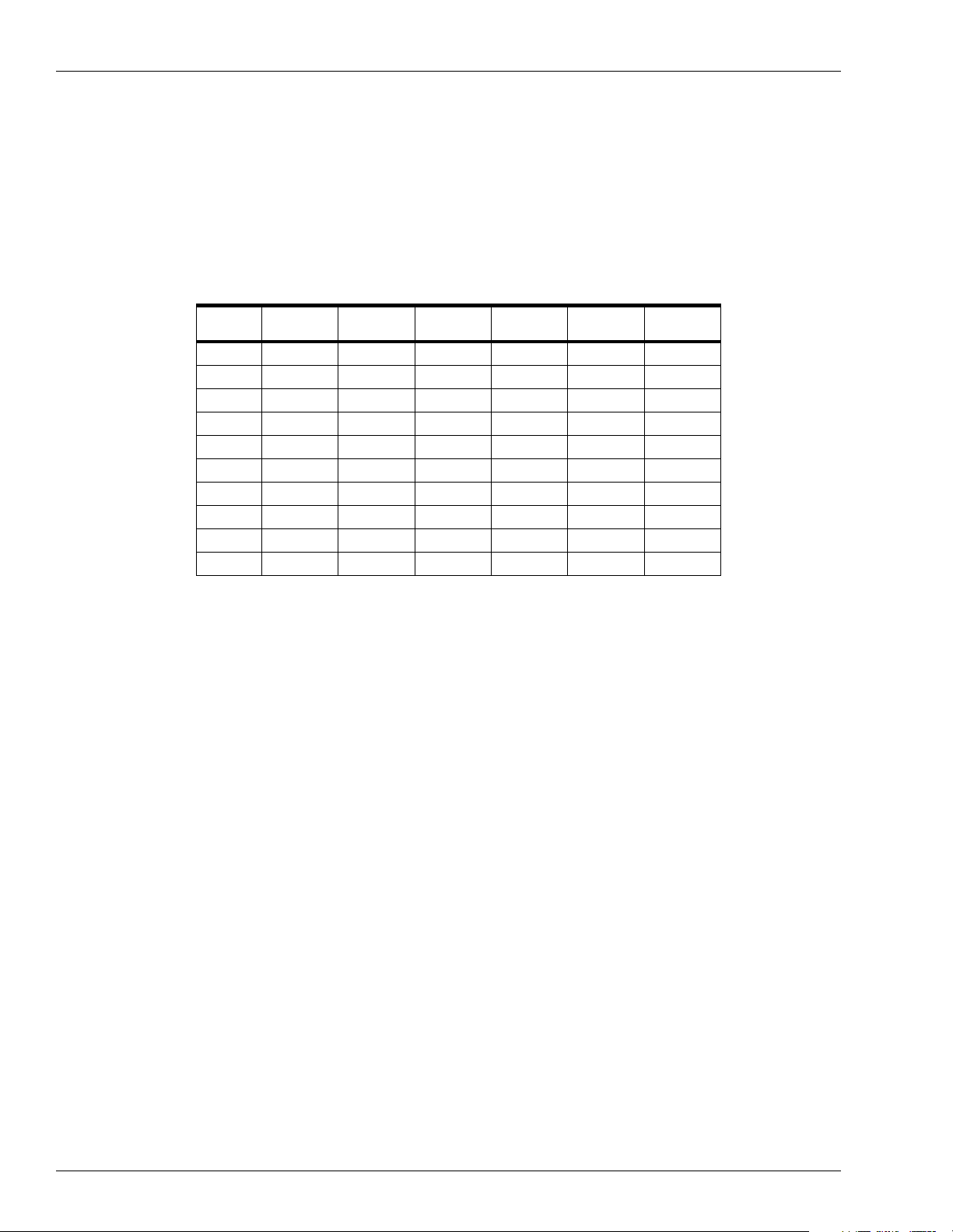

Price

Code

Level 0

(fallback)

Level 1

(cash)

Level 2

(credit)

Level 3

(debit)

Level 4

(additional)

Level 5

(additional)

Page 10 MDE-4375 CFN Series Site Controller III Start-Up Manual · June 200 5

Page 23

9. Load Fuel

Site Information

(Referenc e: Site Manager’s Manual, LO F command)

Use this table to speci fy product s, pric es, and t anks fo r up to f ive hose s per pu mp. If you ne ed

additional space, photocopy this chart.

Pump Number Hose Number Product Code Price Code Tank Number

MDE-4375 CFN Series Site Controller III Start-Up Manual · June 2005 Page 11

Page 24

Site Information

10. Load Pumps

(Reference: Site Manager’s Manual, LO PU command)

Fill in the pump number, hose number (1 to 5 for each pump), the reading from the quantity

totalizer and the reading from the dollar totalizer, if applicable.

Note: Quantity and $Amount are optional. Leave as 0 (zero) if desired. If you need more

Pump Hose Quantity $Amo u nt Pump Hose Quantity $Amount

space, photocopy this table.

11. Load Cutoff

(Reference: Site Manager’s Manual, LO CU command)

Use this table to not e the a mount the Site Cont ro ller wi ll aut horiz e or re quest a uthori zati on for

when a customer requests a FILL. When you encode a limitation code on privately-issued

cards, that code ove rrides t he pump fill l imit. Also i ndicate on this ta ble, the sl ow cutof f point ,

at which the pump will slow prior to reaching the fill limit.

Pump Number Fill Limit Slow Cutoff

Page 12 MDE-4375 CFN Series Site Controller III Start-Up Manual · June 200 5

Page 25

12. Load Tax

Site Information

(Referenc e: Site Manager’s Manual, LO TAX command)

Use the following table to enter the names of th e tax accumulators. Tax accumulators keep a

running total of taxes col lected in up to ei ght cate gor ies. Tax formulas are specified in system

configuration or by using the TAX command.

Tax # Name (up to 7 character)

13. Lockout Type

(Referenc e: Site Manager’s Manual, LOC CA or UN CA command)

Indicate type of lockout: Positive Negative

14. Authorization and Limitation Codes

(Reference: Card Encoding Manual, Site Manager’s Manual, LO A, LO LI commands)

If the customer is us ing pr ivate -iss ue car ds, you may also n eed t o load aut horiz ation codes and

limitation codes for the cards. Values for these codes should have been assigned when the

cards were encoded. Special temp lates for de fining thes e codes appear in the Card Encoding

Manual.

15. CRON Commands

(Referenc e: Site Manager’s Manual, LO CR command)

Use the following table to define any cron commands you wish to have executed. You may

find some crons already loaded.

Command # Command

MDE-4375 CFN Series Site Controller III Start-Up Manual · June 2005 Page 13

Page 26

Site Information

16. Load Remote Host Phone Number

(Reference: Site Manager’s Manual, and Debit and Credit Card Networks Manual, LO PH

command)

Use the following table to indicate the phone number(s) of the remote CFN host (1 and 2),

bank host (3 and 4), or auxiliary numbers (5 and 6).

Main Backup

12

34

56

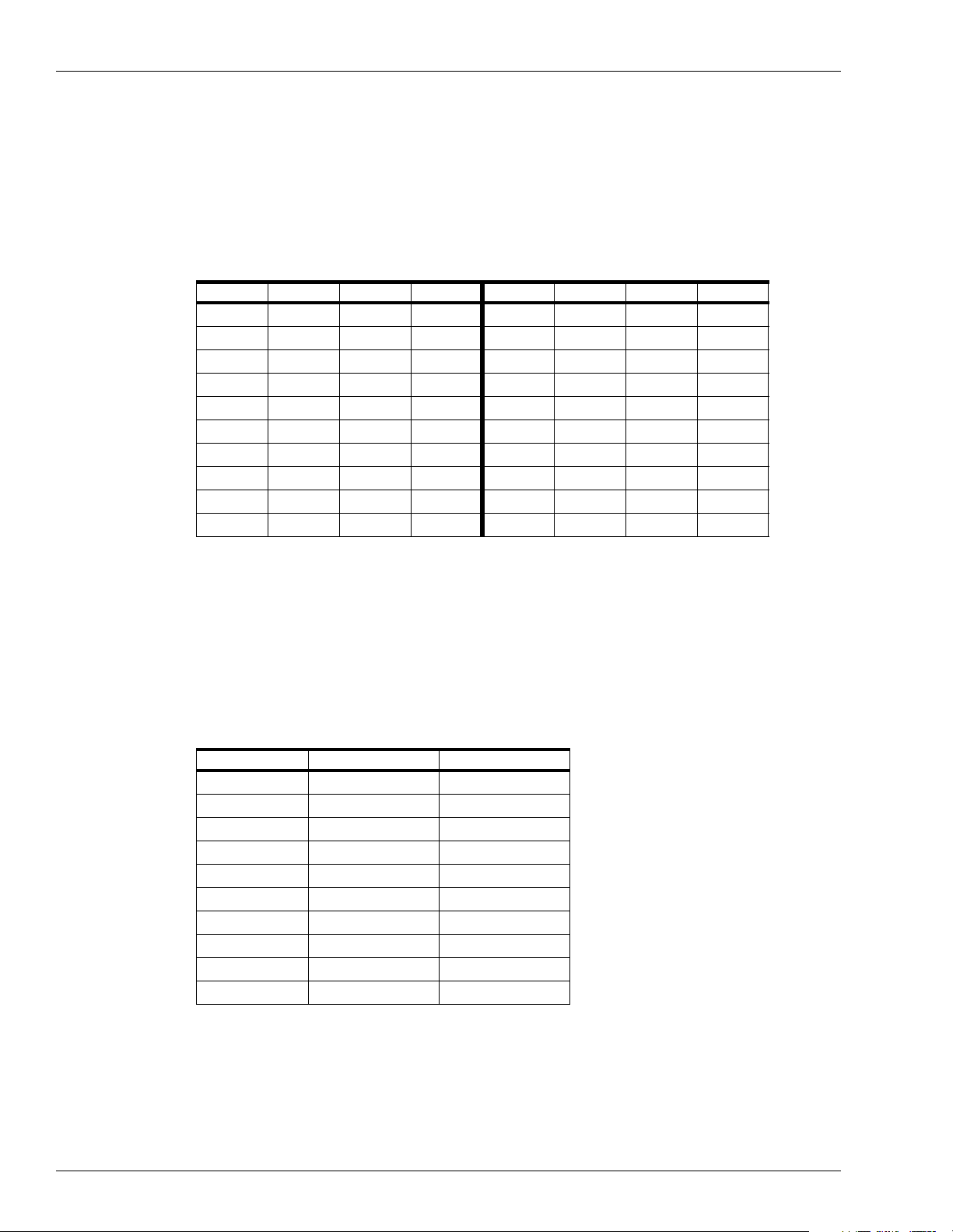

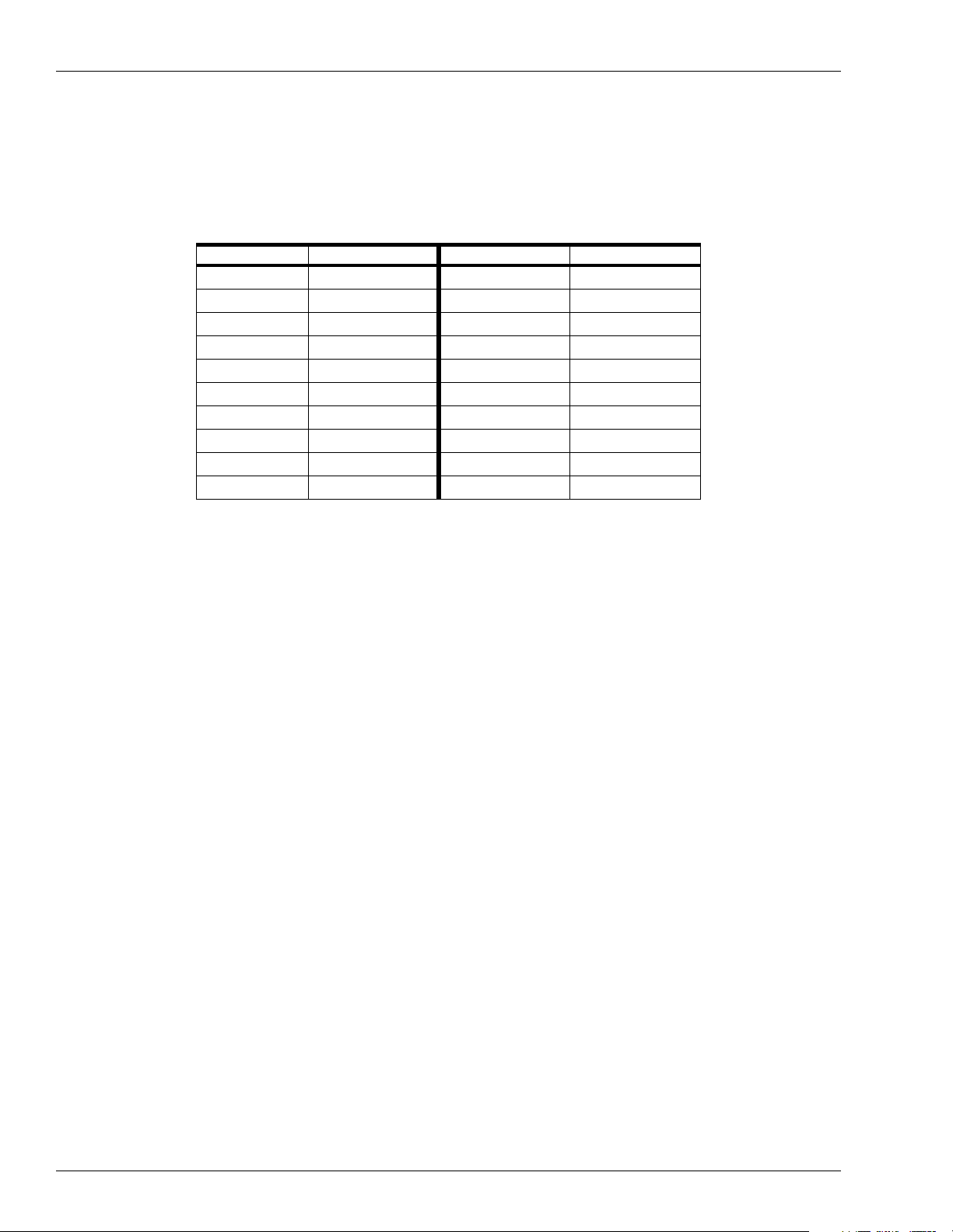

17. Check Point Default Keyboard

This drawing shows the default keyboard for the Check Point. The keyboard can be reconfigured to meet individual needs. See the Check Point Reference Manual and the Site

Controller III Configuration Manual.

Figure 2-1: Check Point Default Keyboard

Page 14 MDE-4375 CFN Series Site Controller III Start-Up Manual · June 200 5

Page 27

18. Load Merchandise Prods/Depts

(Referenc e: Site Manager’s Manual, LO PRO command)

Use the following table to list the site's merchandise products or departments. Use one

product/department code for each different product/department. These codes can be linked to

authorization codes when using private-issue cards.

Site Information

Prd Dpt Cat Name (12)

Prd/Dpt

Cat

Name

$Min

$Max

Tx

Prod Attr

= 2-digit product/department code

= 2-digit category

= 12 character department name

= minimum price for that department (corresponds to floor price on Profit Point)

= maximum price for that department (corresponds to ceiling price on Profit Point)

= tax code for items within that department

= product attribute value (see Site Manager’s Manual for values)

19. Load Merchandise Inventory

(Referenc e: Site Manager’s Manual, LO IN command)

$Min

(Floor)

$Max

(Ceiling) Tx Pro d Attr

Use the following table to load the initial inventory amounts and the reorder levels for your

merchandise products . Once you h ave loade d the initi al i nventor y amount s, you will use ADd

INventory to add to the inventory amount for the product.

Product Number Quantity Reorder Level

MDE-4375 CFN Series Site Controller III Start-Up Manual · June 2005 Page 15

Page 28

Site Information

20. Load Price Lookup

(Reference: Site Manager’s Manual, LO PLU command)

Use the following table to assign pr i ces f or merchandise products that do not have a minimum

or maximum price or as a default price for products that do.

Product # Price Product # Price

21. Profit Point Product Layout

(Reference: Site Manager’s Manual, LO PRO command; Profit Point Reference Manual,

Prompts for PLU Fields)

Before configuring the Profit Point, your site controller should already be set up with the

following: products/departments, prices (fuels only), tanks, pumps, and taxes. You can

transfer this information directly to the Pr ofit Point by using the POS.CMD command. This

will make it easier to enter your MASTER.PLU information on the Profit Point.

The MASTER.PLU file contains three types of data: department numbers, UPC codes, and

stock numbers. Th e charts on the followi ng three pages wi ll help you or ganize the in format ion

for each product.

Notes on Form Entries

The following descr iptio ns ar e abbr eviat ed ver sions of t he entr ies u sed i n the thre e wo rkshee ts

that follow. See MDE-4356 Profit Point Reference Manual for detailed information on these

input requirements.

Dpt = department number corresponding to the site controller’s department (Prd). See Step

19. Will always be present for departments if POS.CMD has been run.

Grp = optional group number assigned to each product.

Vnd = up to 255 vendor numbers can be defined.

Description = description (name) of department or product. See Step 19. Will already be

present for departments if POS.CMD has been run.

Ceiling = corresponds to $MAX price on site controller. See Step 19. Will already be present

for departments if POS.CMD has been run.

Page 16 MDE-4375 CFN Series Site Controller III Start-Up Manual · June 200 5

Page 29

Site Information

Floor = corresponds to $MIN price on site controller. See Step 19. W il l al rea dy be present for

departments if POS.CMD has been run.

Retail Price = selling price of this product (on departments, default price)

Per = unit upon which price is calculated.

Cost + Markup = formula to calculate pri ce: Retail = Cost + (Cost x markup %).

Rounding = no rounding or rounding up to 5 or 9.

Food Stamps = food stamps, enter Y for yes or N for no.

Disct = is discount allowed, enter Y for yes or N for no.

Cust ID = does purchase require ID, enter 1 or 2. See MDE-4356 Profit Point Reference

Manual for assigned values.

Prc Ovr = is price override allowed, enter Y for yes or N for no.

Taxes = tax code for this product (taken from codes defined in the site controller). Will already

be present for departments if POS.CMD has been run.

UPC # = 6- to 12-digit UPC code whi ch can be typed in or scann ed in using the Profit Point or

PC (PC must be set up for scanning).

Stock# = 1- to 5-digit stock number (usually entered when no UPC is available).

Whole Cost = wholesale cost of item to you.

MDE-4375 CFN Series Site Controller III Start-Up Manual · June 2005 Page 17

Page 30

Worksheet for MASTER.PLU File (Dept Entry)

Dpt #Grp #Vnd

# Description

Ceiling

($MAX)

Floor

($MIN)

Retail

Price Per

Cost +

Markup Rounding

Food

Stamps Disct

Cust IDPrc

Ovr

Note: Dpt, Description, Ceiling, and Floor information will be present on the Profit Point if the site controller POS.CMD has been run.

MDE-4375 CFN Series Site Controller III Start-Up Manual · Ju n e 20 05 Page 18

Page 31

Worksheet for MASTER.PLU File (UPC Entry)

UPC #

Dpt #Stock #Grp #Vnd

# Description

Whole

Cost Per

Retail

Price Per

Cost +

Markup Rounding

Food

Stamps Disct

Cust IDPrc

Ovr

MDE-4375 CFN Series Site Controller III Start-Up Manual · Ju n e 20 05 Page 19

Page 32

Worksheet for MASTER.PLU File (Stock Entr y)

Stock #

Dpt #Grp #Vnd

# Description

Whole

Cost Per

Retail

Price Per

Cost +

Markup Rounding

Food

Stamps Disct

Cust IDPrc

Ovr

MDE-4375 CFN Series Site Controller III Start-Up Manual · Ju n e 20 05 Page 20

Page 33

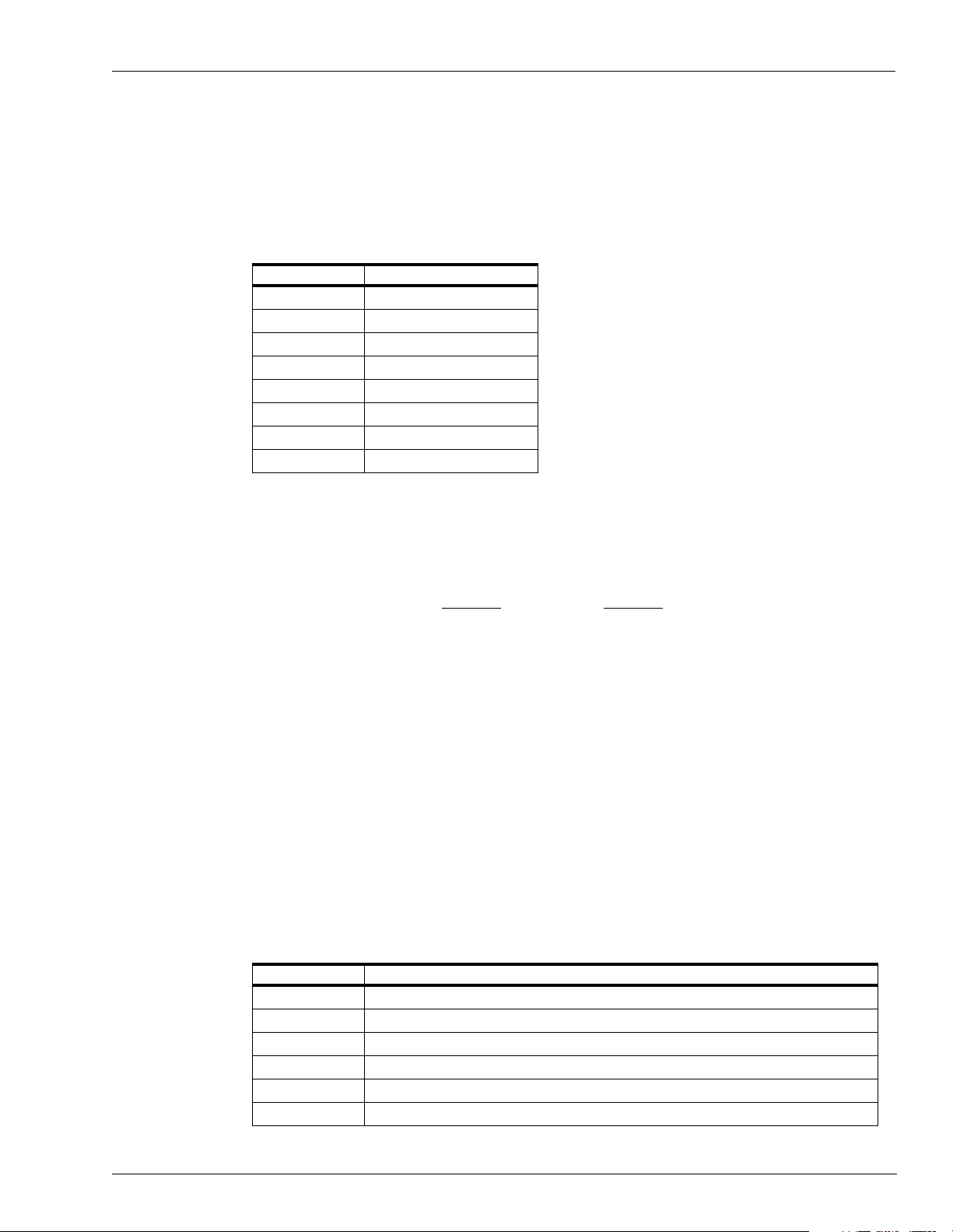

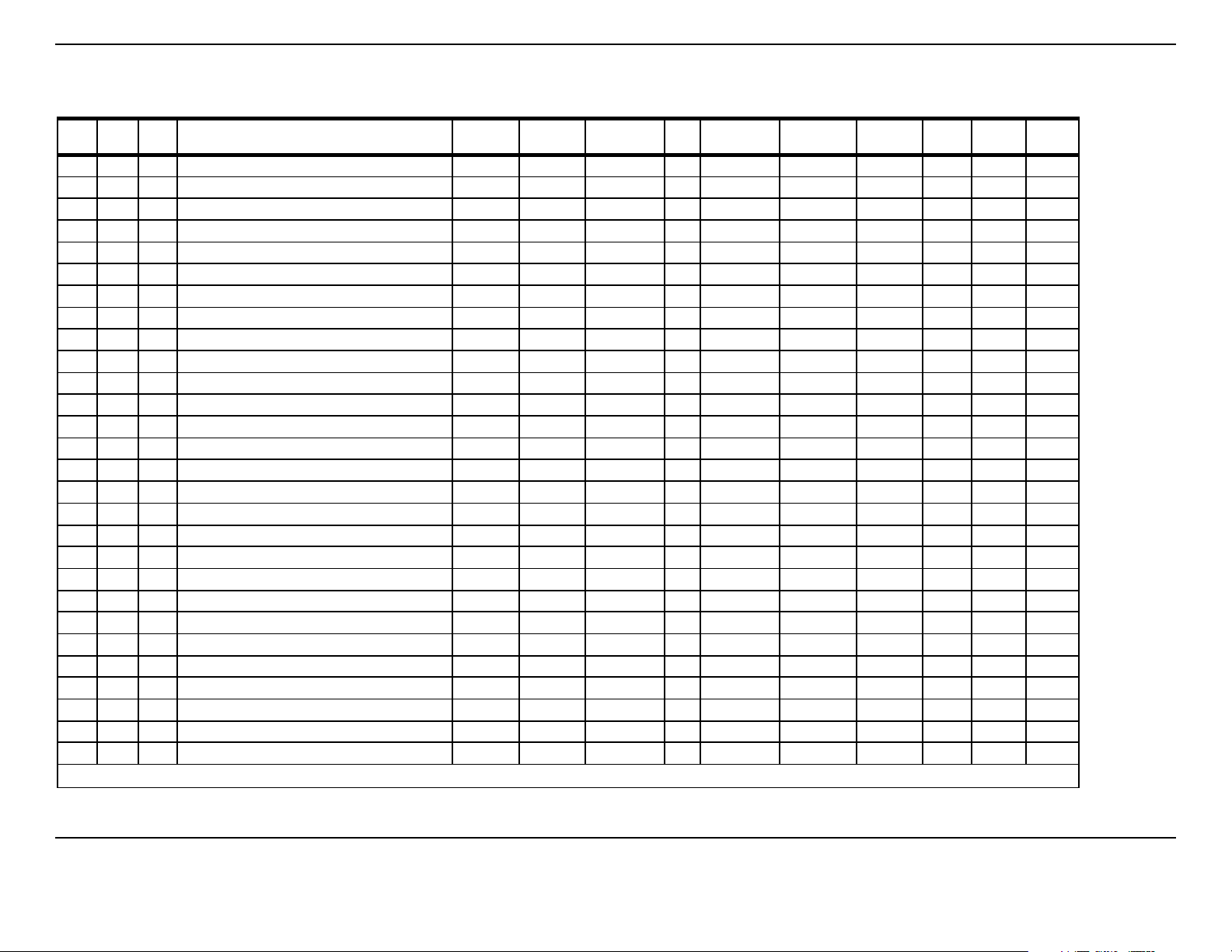

22. Profit Point Default Keyboar d

This drawing shows the default keyboard for the Profit Point. The keyboard can be reconfigured to meet i ndividual needs. See MDE-4356 Pr of it Poi nt Reference Manual for more

information.

Figure 2-2: Profit Point Default Keyboard

Site Information

DEBIT is the default.

This key can be changed to another

function, such as Food Stamps.

See MDE-4356 Profit Point Reference

Manual for details on how to redefine a key.

MDE-4375 CFN Series Site Controller III Start-Up Manual · June 2005 Page 21

Page 34

Site Information

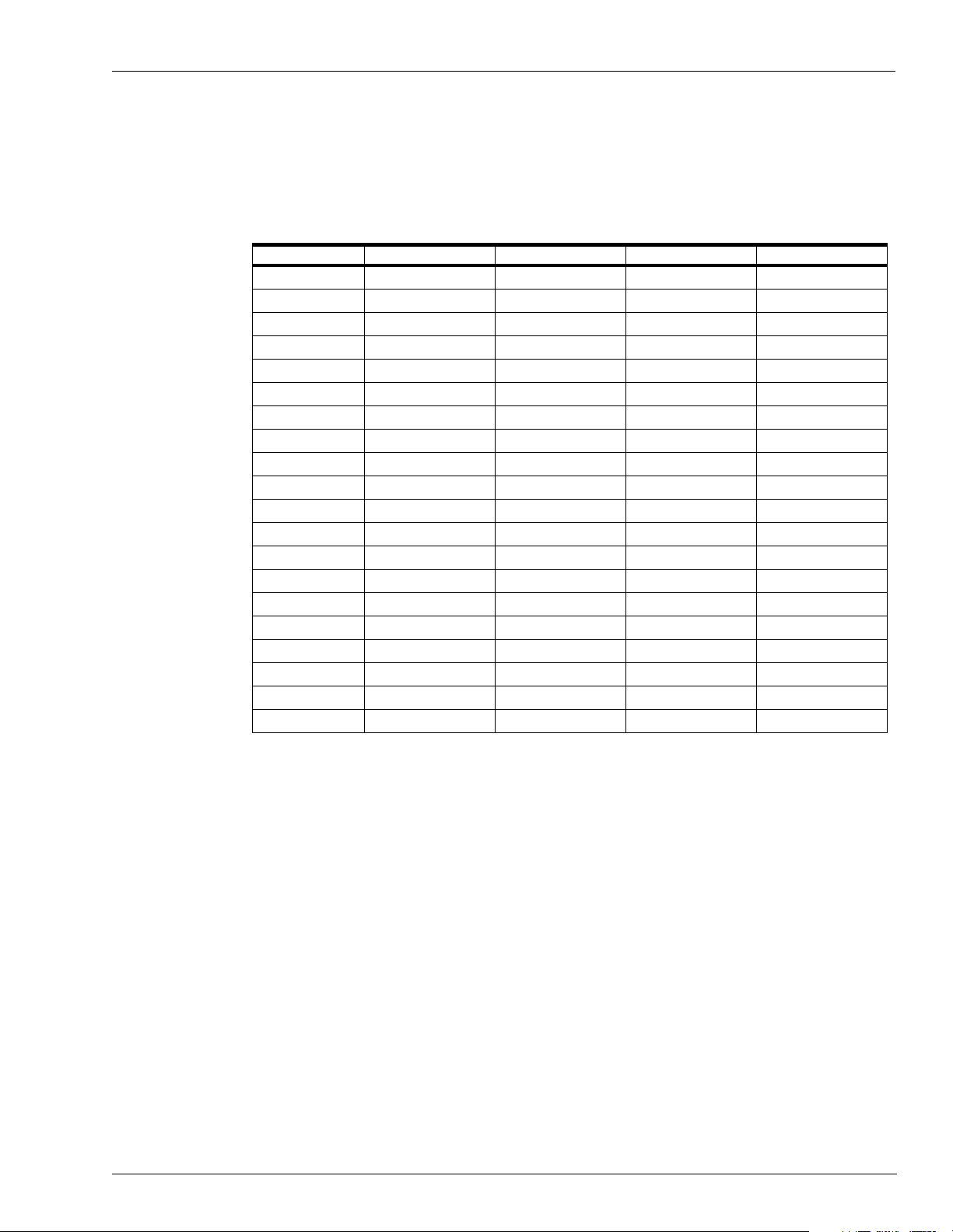

23. Worksheet for Pump/CRIND® Device - PC Interface (if used)

Pump

Number

(Note 1)

11

22

33

44

55

66

77

88

99

10 10

11 11

12 12

13 13

14 14

15 15

16 16

17 1

18 2

19 3

20 4

21 5

22 6

23 7

24 8

25 9

26 10

27 11

28 12

29 13

30 14

31 15

32 16

Notes:

1. Pumps 17 - 32 require a second gilpump.exe session on a separate serial port. In

the parameter file for that session, set

FIRST_CHANNEL_LAST_ADDRESS = 16. Set up the gilpump.exe and crind.exe

sessions using the release diskette for each. See the appropriate installation manual

for each for more information.

2. Pump Type is determined automatically. This column is optional.

3. The Pump Number and the 2-wire Address are the same unless the

FIRST_CHANNEL_LAST_ADDRESS parameter is set. In this case, the 2-wire

Address is the Pump Number minus the FIRST_CHANNEL_LAST_ADDRESS

setting.

Pump Type (Note 2)

(H111, MPD-3, etc.)

2-wire

Address

(Notes 1 & 3)

Number

of Hoses

CRIND Address/

Reader Address

Page 22 MDE-4375 CFN Series Site Controller III Start-Up Manual · June 200 5

Page 35

Site Information

24. Worksheet for Pump/CRIND® Device - Current Loop Interface (if used)

Pump

Number

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

Price levels used at site: 0 1 2 3 4 5 (circle levels)

Price at level 0 is same as price at level 2: Yes No (circle one)

Price at level 0 is same as price at level 1: Yes No (circle one)

Price level for price bars: 1 2 Both None (circle one)

Pump Type

(H111, MPD-3, etc.)

2-wire

Address

PCU

Number

PCU

Slot

Number

of Hoses

CRIND

Address

Reader

Address

MDE-4375 CFN Series Site Controller III Start-Up Manual · June 2005 Page 23

Page 36

Site Information

Page 24 MDE-4375 CFN Series Site Controller III Start-Up Manual · June 200 5

Page 37

3 – Begin Start-Up Form

Parts 1 through 6

This section covers Parts 1 through 6 of the Start-up form. Parts 7 through 13 are covered in

subsequent sections. See “CFN System S tart -up Form” on page Form-1 for a blank copy o f the

Start-up forms.

1. SITE IDENTIFICATION

Customer: The name of the company that owns the system.

Contact: The name of the person who will manage the site operation.

Customer Phone: The phone number where the contact person can be reached.

Site Location: The address of the site where the system is located.

Electrician: The name of the person who did the wiring for the site.

Date/Time of Arrival: Date and time of your arrival at the site.

Date/Time of Departure: Date and time you left the site.

Distributor/Phone: The distributor involved with the sale of the system. Include phone number.

Installer/Phone: The firm that installed the system. Include phone number

Start-up Person: Your name.

Co. Name/Phone: Your company name and phone number.

Begin Start-Up Form

2. SYSTEM IDENTI F ICATION

Site #: Number of the site.

Checkmark the components that this site has.

Indicate the serial number, program version number for each of the following:

Site Controller III: Site Controller III unit. Also indicate the program name and debug version.

PCU (s): Serial number of pump control unit; program version from PCU CPU PCB.

ICR (s): Island Card Readers, program version from Reader CPU PCB.

Console:

Profit Point:

Current Loop Driver:

gilpump PC Driver: (current loop replacement)

CRIND PC Driver: (current loop replacement)

Standalone Receipt Printer:

PIN Pad:

Complete the following section only for Gasboy PC packages.

PC SOFTWARE: if applicable, indicate the version number of the PC software assigned to this site.

PC Make and Model: Indicate the make and model of the PC being used at this site.

DOS Version: Indicate the DOS version that is running on the customer’s PC.

Note: The serial number for each system device can be found on the ID tag located on the outside cover of that

device.

If pedestal pump control unit, program version from PCU CPU PCB.

Also indicate Y or N if the ICR has a receipt printer, has pedestal PCU, or is set up

as a car wash or gate controller.

MDE-4375 CFN Series Site Controller III Start-Up Manual · June 2005 Page 25

Page 38

Begin Start-Up Form

3. SYSTEM DESCRIP TION

PUMP #: Indicates the pump number.

HOSE #: Indicates hose outlet number.

FUEL TYPE: The type of fuel dispensed by that pump or dispenser (for example, No-Lead,

Regular, etc.).

FUEL CODE: The product code number (1 or 2 digits) assigned to that fuel type.

PUMP MAKE: The name of the manufacturer of the pump or dispenser.

MODEL #: The model number of the pump or dispenser.

SERIAL #: The serial number of the pump or dispenser.

RESET: The type of reset used in the pump (Veeder-Root, Tokheim #77, etc.)

TYPE SUC/SUB: The type of pump used to dispense the fuel. Submersible pump (SUB) located

in the tank or is it a suction pump (SUC) located in the pump housing? Circle

one.

PULSER RATE: The pulser rate of the pulser used by that pump or dispenser (for example,

10:1, 100:1)

STARTE R RELAY: Is an external starter relay used to supply power to the pump? Circle Y for yes

or N for no.

4. COMMUNICATIONS

Data Terminal/Logger: Circle the device or devices, if present, and indicate the make and model

Port # Baud Rate

1: Baud rate for port 1.

4: Baud rate for port 4.

5: Baud rate for port 5.

6: Baud rate for port 6.

COM1: Baud rate for COM1.

COM2: Baud rate for COM2.

Loop 1: 2/4 wire.

Loop 2: 2/4 wire.

Short Haul Modem: The make and model number of the short haul modem that is connected to the

Phone Modem: Port The make of the phone modem and the port to which it is connected. Remote

Modem Phone #: The area code and phone number for the external phone modem connected to

Network Name Port The name of the network to which the site is connecting (if appliable) and the

number of the data terminal or logger and which port to which it is connected.

system. If no short haul modems are used, indicate not applicable (N/A).

dial-in, not network.

the system. If a modem is not used, indicate not applicable (N/A).

port through which it is communicating.

Page 26 MDE-4375 CFN Series Site Controller III Start-Up Manual · June 200 5

Page 39

Begin Start-Up Form

5. BREAKER NUMBERS

Indicate the breaker number for each of the following. All breakers pertaining to the system should be in

the OFF position.

Power conditioner:

AC Surge Protector:

(Profit Point)

Islander:

(N/A for SC III)

PCUs:

(pump control units)

ICRs:

(island card readers)

Hose/Brkr #:

(hose outlets 1 to 32)

Answer the following questions:

What components are on power conditioner? Fill in all that apply.

What components are on AC Surge Protector? Fill in all that apply.

Are all Gasboy components on same breaker? Answer Y or N.

Notes:

1. The AC Surge Protector Strip must be on its own separate breaker. The Site Controller, printer, and

monitor must be plugged into the same AC Surge Protector Strip. The Profit Point must also be plugged

into an AC Surge Protector Strip.

2. The optional power conditioner should be on the same breaker as the AC Surge Protector; however, if

this is not possible, it must be in the same phase of power as the AC Surge Protector breaker. The Site

Controller III, modem, standalone receipt printer, and console should be connected to the output of the

power conditioner, if used.

6. SYSTEM ENVIRONMENT

Describe the location and environment of each system component (for example, office, outside, air

conditioned, heated). Make sure the Site Controller III is well ventilated. Nothing should rest on the top of

the Site Controller or around its vents.

MDE-4375 CFN Series Site Controller III Start-Up Manual · June 2005 Page 27

Page 40

Begin Start-Up Form

Page 28 MDE-4375 CFN Series Site Controller III Start-Up Manual · June 200 5

Page 41

4 – Physical System Layout

When verifying physical system layout, be sure power to the system has not been applied and

all power is off. All wiring and conduit runs must also conform with the National Electrical

Code (NFPA 70), the Automotive and Marine Service Stations Code (NFPA 30A), and State

and Local Electrical Codes. See C35880 Site Controller III Installation Manual for more

guidance.

Site Controller

1 Open up the PC. Perform a visual isnpection to verify that all boards are seated properly, all

connections are tight, and there are no loose or unsecured components.

2 Verify that the Site Controller is located in an office-type environment and correctly installed

according to the Site Controller III Installation Manual.

Physical System Layout

3 Verify that all data communication cables located on the back of the SC III/PC are correctly

installed according to the Site Contr oller III Installation Manual. The Site Controlle r III has

four RS-232 ports (1, 4, 5, or 6). All direct connect RS-232 cables over 15 feet must be

installed in m etal conduit separate fr om any AC wires.

Port 3 is used for communication to Tokheim pumps only; one of the RS-232 ports can be

used for communicat ion t hrough a modem or to a co mputer. The others are additional and can

be programmed according to the application. COM1 and COM2 can be programmed

according to the ap pli ca ti on; LPT1 is a parallel port whic h i s c ommonl y connected to a printer.

RS-485 communication cables (C05670, 8-foot modular cable similar to a telephone cord)

must be installed as follows:

LOOP 1 or 2 modular cable must be directly connected to either modular jack of the black

RS-485 junction box. Do not connec t Loop 1 or 2 to t he same RS-48 5 junction b ox. Loop 2 is

factory-set for 2-wire fo r communication to Tokheim DPTs.

CAUTION

If a 2-wire device, such as DPT, is connected to a loop that is set for 4-wire

communication, the site controller will not operate correctly. 4-wire devices on a 2-wire

loop may not communicate with the site controller.

Note: If using Tokheim DPTs, consult C09146 Pump Interface Manual.

LOOP 3 modular cable must be directly connected to the modular jack on the rear of the

Check Point console lab eled Si te Contr oller or to th e conver ter if connect ing to a Prof it Poi nt.

See the Site Controller III Installation Manual and the Profit Point Installation Manual for

remote console wiring considerations. If the SC III will be used as a SC III/POS WS, Loop 3

is used to connect to other POS terminals (Profit Point, CheckPoint) at the site.

MDE-4375 CFN Series Site Controller III Start-Up Manual · June 2005 Page 29

Page 42

Physical System Layout

Island Card Reader Assembly

1 Verify that the island card reader is installed to allow adequate clearance for system

maintenance. For systems with receipt printers or pedestal pump controls, a minimum of 18

inches is required between the post and any of the pumps or dispensers. This clearance meets

the NFPA 30A and NFPA 70 requirements.

2 Remove the two tamper-proof screws from either side of the black bezel, located on the front

of the island card reader head assembly. Unlock and lower the black bezel door.

3 Remove the six screws from the lower back side pedestal cover and remove the cover.

Note: No AC power should be present at TB6 in the island card reader head assembly.

4 Verify that the con dui t and a ll sy stem, pu mp, and dispe nser wi ring i s ins ta lled acc ord ing to th e

specifications detailed in the Site Controller III Installation Manual. Non-compliance with

these specifications and the checks in the accompanying Start-Up Form could void the

warranty.

Pump Control Unit(s)

1 Verify that the pump control unit(s) are installed in an area protected from direct contact with

the weather a ccording to t he Site Controller III Installation Manual.

2 Verify that the con dui t and a ll sy stem, pu mp, and dispe nser wi ring i s ins ta lled acc ord ing to th e

specifications detailed in the Site Controller III Installation Manual. Non-compliance with

these specifications and the checks in the accompanying Start-Up Form could void the

warranty.

7. CONDUIT

All Metal Conduit: Indicate if all conduit is metal and not PVC. Circle Y for yes (all metal) or N for

AC and DC is Separate

Conduit:

Wiring Neatness: Indicate the overall neatness of the installer’s wiring. Is the appearance of the

Is shielded cable used? Indicate if Gasboy C09655 or equivalent cable was used for communications

no (not all metal conduit).

Indicate if all wiring is separated in the appropriate conduits according to the

conduit specifications and exceptions detailed in the SC III Installation Manual.

Circle Y for yes if all AC and DC wiring is in separate conduits. Circle N for no if

AC and DC wiring is combined in conduits where it should not be.

wiring neat and orderly or is it very disorderly? Circle Good, Fair, or Bad.

wiring. Circle Y for yes or N for no.

Page 30 MDE-4375 CFN Series Site Controller III Start-Up Manual · June 200 5

Page 43

Checkpoint Console (Optional)

1 Verify that the CheckPoint and any optional equipment is located in an office type

environment and is correctly installed according to the Site Controller III Installation Manual.

2 Verify that th e AC power cor d fo r the Chec kPoint and the s tandal one rec eip t pri nter i s dire ctly

connected to the output of the AC Surge Protector Outlet Strip (C01218).

3 The RS-485 communication modular cable must be installed as described below. If you are

locating the CheckPoint more than eight feet from the Site Controller, you must use two

additional RS-485 junction boxes to connect the devices. See the Site Controller III

Installation Manual for remote console wiring.

SITE CONTROLLER port modular cable must be directly connected to the modular jack

port on the back of the Site Controller labeled LOOP 3.

4 Optional equipment connection:

RECEIPT PRINTER connection depends upon the type of receipt printer ordered. The

modular cable for an RS-485 printer is connected directly into the RS-485 jack on the rear of

the CheckPo int; no internal cabling is required . For a paralle l printer, the printe r cable is

connected to the D-type 25-pin female connector on the back of the CheckPoint. The cable

from the D-type connector inside the CheckPoint must be attached to P12 of the CheckPoint

PCB.

Physical System Layout

CAUTION

Be sure that the printer cabling is correct before applying power to th e system.

An incorrectly connected pr inter can cause damage to the print er , the CheckPoint,

or both.

CASH DRAWER is connected via cable from the cash drawer whi ch is termi nated by a ro und

4-pin connector and connects to the round 4-pin connector which is keyed.

CUSTOMER DISPLA Y must be installe d according to t he instructi on sheet provided wi th it.

The round 5-pin connector must be threaded as shown in the instructions and must be

connected to the 5-position connector on the back of the CheckPoint.

PIN PAD must be installed according to the Site Controller III Installation Manual. Verify

that the PIN pad is securely connected to the 9-pin connector located on the back of the

CheckPoint.

MDE-4375 CFN Series Site Controller III Start-Up Manual · June 2005 Page 31

Page 44

Physical System Layout

Profit Point Console or SC III/POS WS (Optional)

1 Verify that the Profit Point and any optional equipment is located in an office type

environment and is correctly installed according to the Site Controller III Installation Manual.

2 Verify that the AC power co rd for the Prof it Point is di rectly con nected to the output of th e AC

Surge Protector Strip (C01218).

3 The RS-485 converter must be installed as described below. If you are locating the Profit

Point more than eight feet from the Site Controller, you must use two additional RS-485

junction boxes to connect the devices.

A modular cable must be directly connected to the modular jack port on the back of the Site

Controller labeled LOOP 3. The other end of the modular cable is connected to one of the

modular jacks on the con v er te r. The converter is connected to t he Profit Point port SERIAL1

via a 25-pin to 9-pin cable. The converter power supply must be plugged into the same AC

Surge Protector Strip (C01218) as the Profit Point.

POS Distribution Box (POS D-Box) is connected via a 9-pin cable from the Serial2 port on

the Profit P oint (COM2 on the SCIII/POS WS) to the Serial2 port on the D-Box. If the site

has a PIN Pad, the Serial3 port of the Profit Point (COM3 on the SCIII/POS WS) will be

connected to the Serial3 port of the D-Box. The D-Box power supply must be plugged into

the same AC Surge Protector Strip (C01218) as the Profit Point.

“Old” CASH DRAWER is connected via a 9-pin D-type connector from the cash drawer to

the CASH DRAWER port on the back of the POS D-Box. “New” CASH DRAWER is

connected connects to the receipt printer which connects to the minitower’s 4-port fan-out

cable.

CUSTOMER DISPLAY must be installed according to the Profit Point Installation Manual.

Verify that the Customer Display is connected to the 9-pin CUSTO M ER DISPLAY port on

the POS D-Box.

4 Optional equipment connection:

RECEIPT PRINTER connection depends upon the type of receipt printer ordered. For a

parallel printer, the printer cable is connected to the D-type 25-pin female connector

PRINTER on the back of the Pr ofit Point (LPT1 on SC III/POS WS). For an RS-485 printer,

the modular cable is connected directly into the RS-485 jack on the converter. The receipt

printer must be plugged into the same AC Surge Protector Strip as the Profit Point.

PIN PAD must be installed according to the Profit Point Installation Manual. Verify that the

PIN pad is securely connected to the PIN PAD port located on the POS D-Box.

SCANNER must be installed according to the Profit Point Installation Manual. Verify that

the scanner is securely connected to the 9-pin SCANNER port located on the POS D-Box. If

a scanner is used that needs external power, it must be plugged into the same AC Surge

Protector Str ip as the Profit Point.

Page 32 MDE-4375 CFN Series Site Controller III Start-Up Manual · June 200 5

Page 45

Tank Moni tori ng System (Op tional)

1 Verify that the tank monit oring system is correctly connecte d to the Site Controller according

to the Site Controller III Installation Manual.

2 Refer to the tank monito ring system manufacturer’s installation instru ctions for specific

connection information.

Current Loop Interface (Optional)

Note: Gilbarco pump and CRIND PC interfaces are recommended over the current loop

interface.

1 Verify that the current loop interface unit is located in an office-type environment and is

correctly installed according to its installation sheet.

2 Make sure the special RS-485 communication modular cable is directly connected between

the current loop interface unit (slot labeled RS422) and the RS-485 junction box using the

appropriate RS-485 modular jacks.

Note: The modular cable from the current loop interface unit to the RS-485 junction box is

GASBOY P/N C04500 (cross) modular cable. Other devices (Site Controller, Console

to junction box, etc.) can use GASBOY P/N C05670 (1:1 cable).

Physical System Layout

3 Verify that the two wir e current l oop communicati ons is correctl y wired to the dis tributi on box

according to the Current Loop Interface Unit Ins tallation Manual or Pu mp Interface Manual.

CRIND Connections (with Current Loop Interface only)

For CRIND devices, a universal distribution box must be used. Verify that the modular cable

connects from the second RS-485/RS-422 port on the back of the current loop interface to an

adaptor , and f rom there to a 9-pi n connect or on the distri bution b ox. Refer to the Current Loop

Interface Unit Installation Manual or Pump Interface Manual.

Gilbarco Pump Interface Using PC COM Port

Install according the the Gilbarco Pump PC Interface Manual.

CRIND Interface Using PC COM Port

Install according the the Gilbarco CRIND PC Interface Manual.

Fuel Point Components

1 Verify that all the Fuel Point components are installed according to the applicable Fuel Point

installatio n manuals (listed in sec tion 1).

2 Make sure the N-ring wiring between the Fuel Point Reader and pre-amplifier is in conduit

separate fr om non-intrinsic safe wiring.

MDE-4375 CFN Series Site Controller III Start-Up Manual · June 2005 Page 33

Page 46

Physical System Layout

Electronic Pumps

All electronic pumps must be installed according to the manufacturer’s specifications. Make

sure all interface connections are made according to the SC III Installation Manual or the

Pump Interface Manual.

Page 34 MDE-4375 CFN Series Site Controller III Start-Up Manual · June 200 5

Page 47

5 – Jumpers & Switch Settings

This section covers the jumper and switch settings for the various components of your Site

Controller III system.

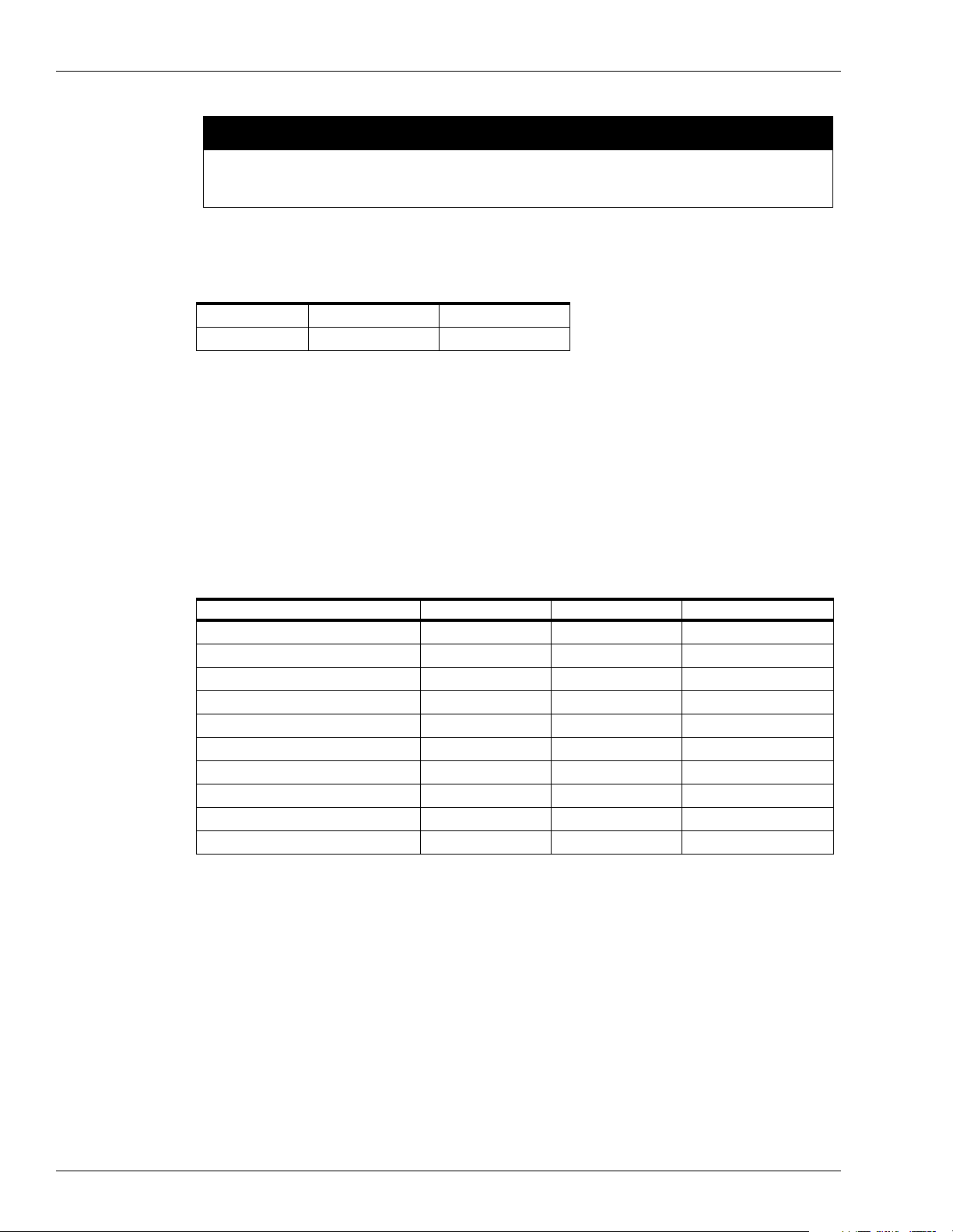

IMPORTANT

It is important that the jumpers and switch settings be set properly to ensure correct

operation.

Site Controller COMM CPU Printed Circuit Board

Figure 5-1: SC III Comm CPU Board

Jumpers & Switch Settings

Jumpers, K3 to K12

Jumper Function Setting

K3 AC power fail sense 2 - 3 to enable

1 - 2 to disable

K4 AC watchdog timer 1 - 2 to enable

K5 SC - Comm CPU (testing only) 1 - 2 to reset

K6 RS-485 loop 1, 2 to 4 wire 2 - 3 for 4 wire

1 - 2 for 2 wire

K7 RS-485 loop 2, 2 to 4 wire 2 - 3 for 4 wire

1 - 2 for 2 wire

MDE-4375 CFN Series Site Controller III Start-Up Manual · June 2005 Page 35

Page 48

Jumpers & Switch Setti ngs

Jumper Function Setting

K8 Rx clock from synchronous modem

K9 ETC output to synchronous modem

K10 Tx clock input from synchronous

K11 EPROM type 2 - 3 for 27256/25128

K12 EPROM type 2 - 3 for 27256/25128

Switches, S1 and S2

Switch S1 - PC IRQ

Indicates the interrupt. Only one can be selected. SC3.EXE assumes interrupt 10. No other

device can use this interrupt.

Switch Function Default

S1-1 IRQ-15 Open

S1-2 IRQ-12 Open

S1-3 IRQ-11 Open

S1-4 IRQ-10 Closed

1 - 2 to connect

(DB25-15)

1 - 2 to connect

(DB25-24)

1 - 2 to connect

modem (DB25-17)

Switch S2 - PC Address

Sets PC Dual RAM address. SC3.EXE currently assumes D0000.

Switch SW3 - Default Sign-On

Position 4 defaults to Open; Closed Normal setting.

Switch SW4 - Weights and Measures Switch

Set to Open fo r enable; Closed for disable.

Switch

Address

C0000 CCCCD6000 OCCC

C3000 CCCOD9000 OCCO

C6000 C C O C DC000 O C O C

C7000 C C O O DF000 O C O O

CC000 C O C C E0000 O O C C

CF000 C O C O E3000 O O C O

D0000 C O O C E6000 OOOC

D3000 C O O O E9000 OOOO

1234 1234

Address

Switch

Page 36 MDE-4375 CFN Series Site Controller III Start-Up Manual · June 200 5

Page 49

Site Controller Memory I/O Board

Figure 5-2: SC III Memory I/O Board

Jumpers & Switch Settings

Jumpers

Jumper Function Setting

K1 Date/Time Clock Speed 1 - 2 for 4 wait state; default

2 - 3 for 1 wait state

K2 Enable A19 to RAM 2 - 3 for 128Kx8; default

1 - 2 for 512Kx8

K3 RAM Size 2 - 3 for 128Kx8; default

1 - 2 for 512Kx8

K5 Tokheim Reset Output Not used

Switches, S1 and S2

Switch S1

Switch Function Setting

S1-1 Boot to monitor after reset Open

Boot to OS after reset; default Closed

S1-2 Debug mode Open

Normal; default Closed

S1-3 Do not talk to PC while in monitor Open

Monitor I/O goes to PC also; default Closed

S1-4 Monito r I/O goes to SC port 1 also Open

No monitor I/O to SC port 1; default Closed

MDE-4375 CFN Series Site Controller III Start-Up Manual · June 2005 Page 37

Page 50

Jumpers & Switch Setti ngs

Switch S2

Switch Function Setting

S2-1 Battery 1 Open = Disabled

S2-2 Battery 2 Open = Disabled; default

S2-3 N /A Unused

S2-4 N /A Unused

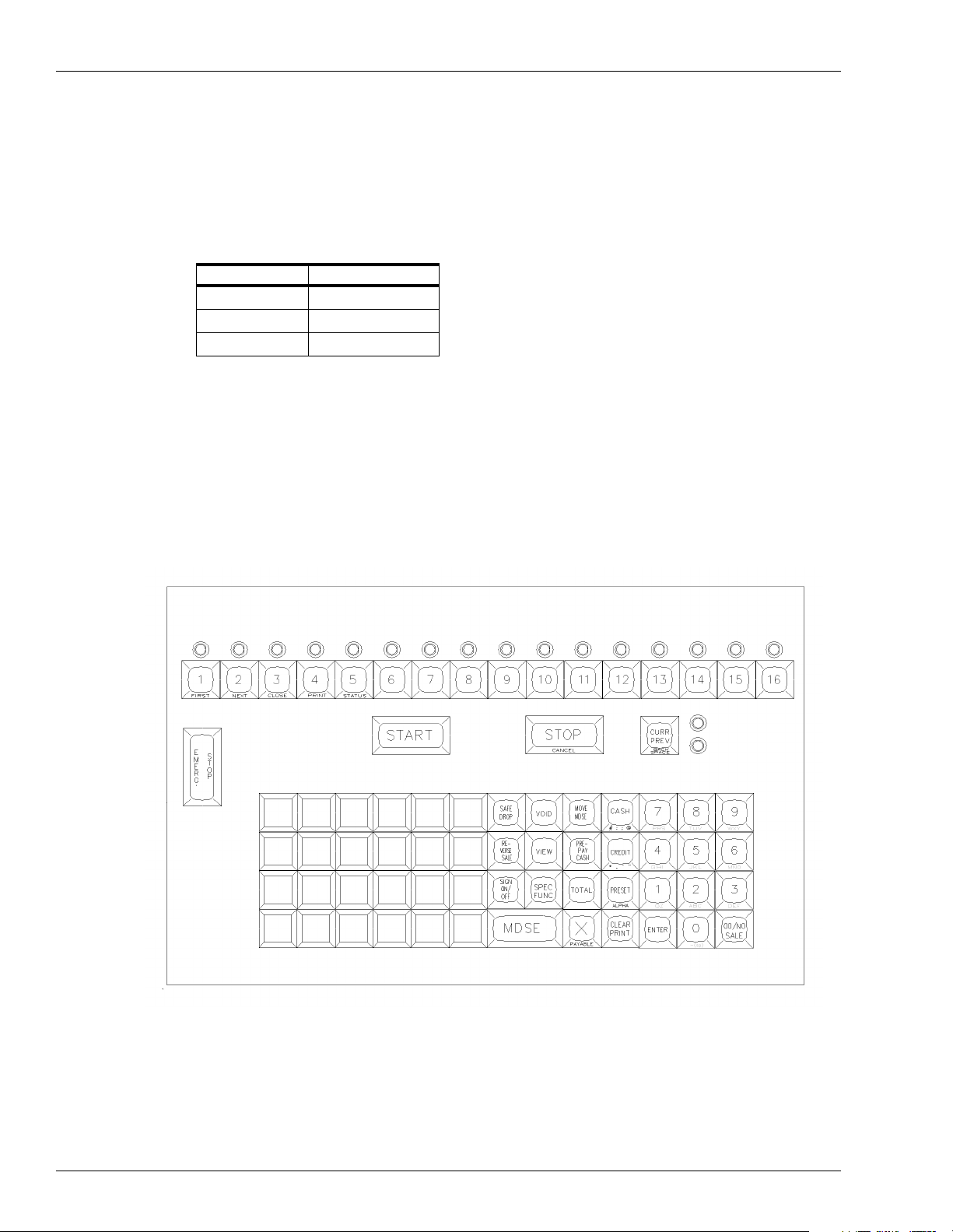

Pump Control Unit

Figure 5-3 shows the pump control unit layout. Refer to this layout when performing steps 1

through 5 under “Pump Control EXPMUX CPU Board” on page 39.

Figure 5-3: Pump Control Unit Component Location

Closed = Enabled; default

Closed = Enabled

Page 38 MDE-4375 CFN Series Site Controller III Start-Up Manual · June 200 5

Page 51

Jumpers & Switch Settings

Pump Control EXPMUX CPU Board

1 Unlock and open the front door of the pump control unit.

2 Make sure all override switches are in the AUTO positi on. See Figure 5-3.

3 Make sure the AC power and battery switches, located in the upper righthand corner of the

power supply are turned OFF (down).

4 Loosen the screw for the card cage section, and swing out the card cage.

5 Remove the pump control EXPMUX CPU board (Figure 5-4), located in the rear portion of

the card cage, by pulling on the top white tab.

Figure 5-4: EXPMUX CPU Board

6

Locate the K1 jumper patch and install the jumper. This jumper allows battery voltage to the

RAM. It should be installed for normal operation and removed for storage to prevent battery

discharge.

7 Add res s: Verify that the pu mp cont rol CPU board switch bank, SB (1 through 4), is se t fo r t he

proper address. An addres s must be se t to identify the pump control unit when it is connected

to the CFN System. This address is a unique identi fier for multiple PCU’s that are connected

on the same RS-485 line. Addressing should start at 1 and continue sequentially through 16.

The physical wiring order does not have to correspond with the address order, that is, the first

unit on the RS-485 line does not have to be address 1.

Switches 1 through 4 denote t he address. This is fa ctory set and may no t have to be correct ed.

MDE-4375 CFN Series Site Controller III Start-Up Manual · June 2005 Page 39

Page 52

Jumpers & Switch Setti ngs

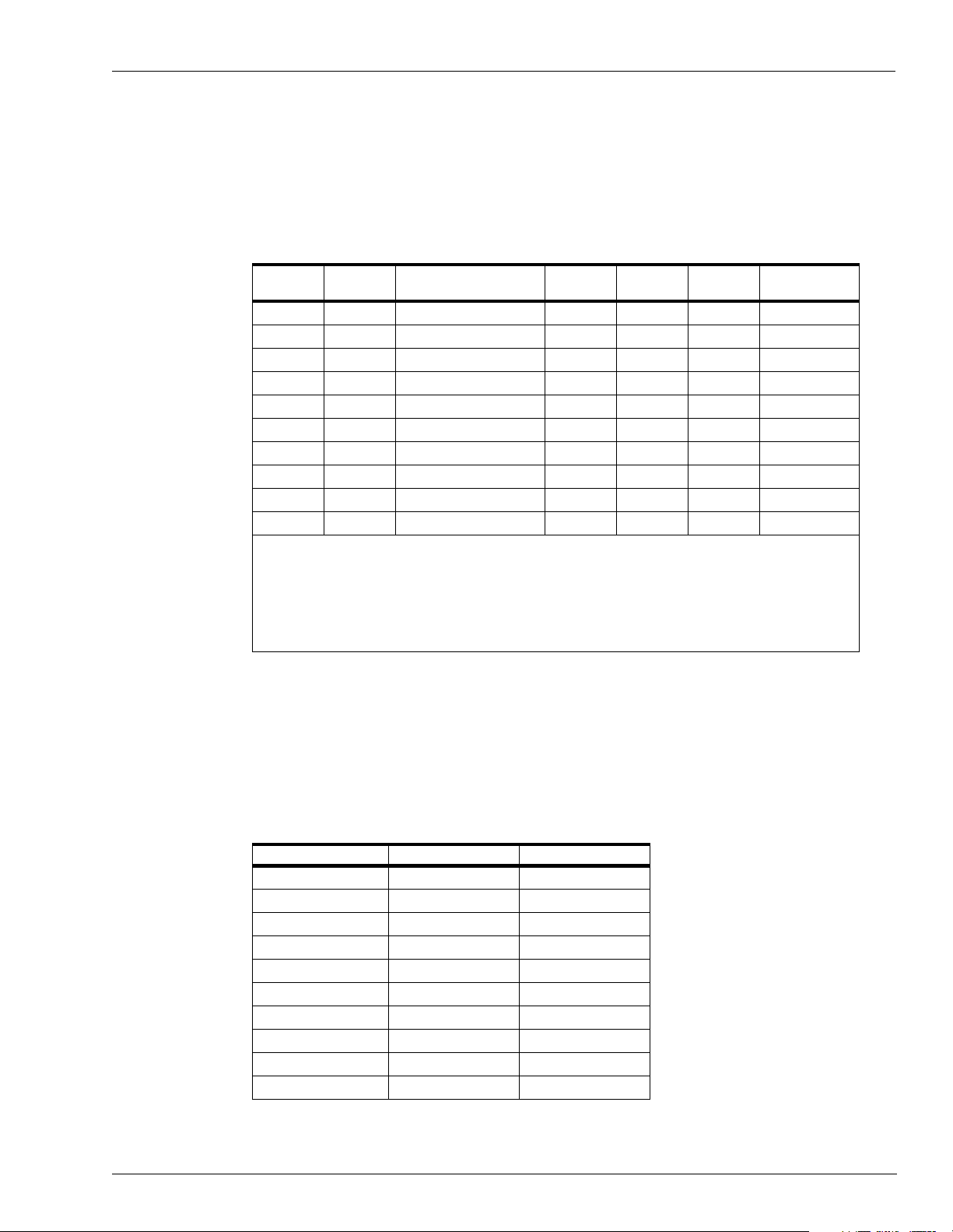

The chart on the right gives the switch settings for the address selections.

Address

1 Closed Closed Closed Closed

2 Open Closed Closed Closed

3 Closed Open Closed Closed

4 Open Open Closed Closed

5 Closed Closed Open Closed

6 Open Closed Open Closed

7 Closed Open Open Closed

8 Open Open Open Closed

9 Closed Closed Closed Open

10 Open Closed Closed Open

11 Closed Open Closed Open

12 Open Open Closed Open

13 Closed Closed Open Open

14 Open Closed Open Open

15 Closed Open Open Open

16 Open Open Open Open

SB-1 SB-2 SB-3 SB-4

ADDR1 ADDR2 ADDR3 ADDR4

8 Pulser Type: Verify that switch SB-5 is set for the proper pulser type, single or dual. Settings

are shown below.

The pulser select switch is set for either single or dual puls ers . If dua l pul se rs are se lected, all