Page 1

Quarles NBS

Configuration and Software

Installation Manual

MDE-4643

Page 2

Computer Programs and Documentation

Federal Communications Commission (FCC) Warning

All Gasboy computer programs (including software on diskettes and within memory chips) and documentation are copyrighted by, and shall remain the property of, Gasboy. Such

computer programs and documents may also contain trade secret information. The duplication, disclosure, modification, or unauthorized use of computer programs or

documentation is strictly prohibited, unless otherwise licensed by Gasboy.

This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy, and if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense. Changes or modifications not expressly

approved by the manufacturer could void the user’s authority to operate this equipment.

Approvals

Gasboy, Greensboro, is an ISO 9001:2000 registered facility.

Underwriters Laboratories (UL):

UL File# Products listed with UL

MH4314

MH1941

MH6418

MH7404

MH10581 Key con t r o l u n i t , M o d e l G K E - B S e r i e s

All dispensers and self-contained pumping

units

Power operated Transfer Pump Models 25,

25C, 26, 27, 28, 72, 72S, 72SP , 72X, 73 and

1820

Hand operated Transfer Pump Models 1230

Series, 1243 Series, 1520 and 1720 Series

Card reader terminals, Models 1000, 1000P

Site controller, Model 2000S CFN Series

Data entry terminals, Model TPK-900 Series

Fuel Point Reader System

New York City Fire Department (NYFD):

NYFD C of A # Product

4823 9100A, 9140A, 9152A, 9153A,

4997 9822A, 9823A

5046 9100Q, 9140Q, 9152Q, 9153Q,

5087 8753K, 8853K, 9153K, 9853K

9800A, 9840A, 9850A, 9852A,

9853A, 9140

9800Q, 9840Q, 9852Q, 9853Q

(restricted to diesel and nonretail gasoline sales)

National Conference of Weights and Measures (NCWM) - Certificate of Compliance (CoC):

Gasboy pumps and dispensers are evaluated by NCWM under the National Type Evaluation Program (NTEP). NCWM has issued the following CoC:

CoC# Product Model # CoC# Product Model #

95-179A2 Dispenser

95-136A5 Dispenser 9800 Series 91-057A3 Controller

9100 Retail Series, 8700

Series, 9700 Series

91-019A2 Dispenser

9100 Commercial

Series

1000 Series FMS,

2000S-CFN Series

California Air Resources Board (CARB):

Executive Order # Product

G-70-52-AM Balance Vapor Recovery

G-70-150-AE VaporVac

Patents

Gasboy products are manufactured or sold under one or more of the following US patents:

Dispensers

5,257,720

Point of Sale/Back Office Equipment

D335,673

Trademarks

Non-registered trademarks

Atlas™

Consola™

Infinity™

Registered trademarks

ASTRA

Fuel Point

Gasboy

Keytrol

Slimline

Additional US and foreign patents pending.

®

®

®

®

®

Additional US and foreign trademarks pending.

Other brand or product names shown may be

trademarks or registered trademarks of their

respective holders.

This document is subject to change without notice. · For information regarding Gasboy Literature, call (336) 547-5661

E-mail: literature@gasboy.com · Internet: http://www.gasboy.com

© 2007 GASBOY · All Rights Reserved

Page 3

Table of Contents

Table of Contents

1 – Introduction 1

Purpose. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Abbreviations and Acronyms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

2 – Important Safety Information 3

3 – Configuration and Installation 5

Confirmation of Version Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Site Controller (SC) III Operating Software . . . . . . . . . . . . . . . . . . . . . . . .5

Network Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Card Handler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Site Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

SYS_PAR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

READER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Site Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Limitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Authorization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Product Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

NBS Network Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Network Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Card Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Modem Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Product Cross Reference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Appendix A - Port Wiring 13

Appendix B - System Parameters Listing 15

*** Page 1: *** System Parameters ***. . . . . . . . . . . . . . . . . . . . . . . . . . .15

*** Page 2: *** Club Card Format - Field Widths ***. . . . . . . . . . . . . . . . .15

*** Page 3: *** Club Card Format - Offsets ***. . . . . . . . . . . . . . . . . . . . .16

*** Page 4: *** Reader Verification and Miscellany ***. . . . . . . . . . . . . . .16

*** Page 5: *** Console Verification *** . . . . . . . . . . . . . . . . . . . . . . . . . .17

*** Page 6: *** Gate Verification and Miscellany ***. . . . . . . . . . . . . . . . .17

*** Page 7: *** Fuel Point Verification and Miscellany *** . . . . . . . . . . . .18

*** Page 8: *** Serial Port Configuration ***. . . . . . . . . . . . . . . . . . . . . . .18

*** Page 9: *** Miscellany *** . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

*** Page 10: *** Tank Gauge *** . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

*** Page 11: *** Transaction Miscellany *** . . . . . . . . . . . . . . . . . . . . . . .20

*** Page 12: *** Receipt Configuration *** . . . . . . . . . . . . . . . . . . . . . . . .21

*** Page 13: *** Miles per Gallon (MPG) Package *** . . . . . . . . . . . . . . .22

Appendix C - 3.3 to 3.4K Upgrade Instructions 23

Creating Backups. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

MDE-4643 Quarles NBS Configuration and Software Installation Manual · March 2007 Page i

Page 4

Table of Contents

Preparing the System for Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Installing the Upgraded Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Restoring the Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Index Index-1

Page ii MDE-4643 Quarles NBS Configuration and Software Installation Manual · March 2007

Page 5

1 – Introduction

Purpose

This document provides the general setup information for Quarles fueling sites. The

information in this document is based on the use of the Cash Flow Network (CFN) III

operating system V3.4K with NBS router V1.2.3.7. All settings and parameters are subject to

change based on the on-site preference.

Abbreviations and Acronyms

Term Description

CFN Cash Flow Network

ICR Island Card Reader

ID Identification

MPG Miles per Gallon

NBS National Bankcard Services

PIN Personal Identification Number

POS Point of Sale

RAM Random Access Memory

SC Site Controller

Introduction

Warranty

For information on warranty, refer to MDE-4255 Gasboy’ s Warranty Policy Statement. If you

have any warranty-related questions, contact Gasboy’s Warranty Department at its Greensboro

location.

MDE-4643 Quarles NBS Configuration and Software Installation Manual · March 2007 Page 1

Page 6

Introduction

This page is intentionally left blank.

Page 2 MDE-4643 Quarles NBS Configuration and Software Installation Manual · March 2007

Page 7

2 – Important Safety Information

Important Safety Information

This section introduces the hazards and safety precautions

associated with installing, inspecting, maintaining or servicing

this product. Before performing any task on this product, read

this safety information and the applicable se cti o ns in th is

manual, where additional hazards and safety precautions for

your task will be found. Fire, explosion, electrical shock or

pressure release could occur and cause death or serious

injury if these safe service procedures are not followed.

Preliminary Precautions

You are working in a potentially dangerous environment of

flammable fuels, vapors, and high voltage or pressures. Only

trained or authorized individuals knowledgeable in the related

procedures should install, inspect, maintain or service this

equipment.

Emergency Total Electrical Shut-Off

The first and most important information you must know is

how to stop all fuel flow to the pump and island. Locate the

switch or circuit breakers that shut-off all power to all fueling

equipment, dispensing devices, and submerged turbine

pumps (STPs).

!

WARNING

!

The EMERGENCY STOP, ALL STOP, and

PUMP STOP buttons at the cashier’s station

WILL NOT shut off electrical power to the

pump/dispenser.

This means that even if you activate these

stops, fuel may continue to flow uncontrolled.

You must use the TOTAL ELECTRICAL SHUTOFF in the case of an emergency and not only

these cashier station “stops.”

Total Electrical Shut-Off Before Access

Any procedure requiring access to electrical components or

the electronics of the dispenser requires total electrical shutoff of that unit. Know the function and location of this switch

or circuit breaker before inspecting, installing, maintaining, or

servicing Gasboy equipment.

Evacuation, Barricading and Shut-Off

Any procedures requiring accessing the pump/dispenser or

STPs requires the following three actions:

Read the Manual

Read, understand and follow this manual and any other

labels or related materials supplied with this equipment. If you

do not understand a procedure, call the Gasboy Customer

Service at 1-800-444-5579, T ech Support 1-800-444-5529. It

is imperative to your safety and the safety of others to

understand the procedures before beginning work.

Follow the Regulations

There is applicable information in NFPA 30A; Automotive and

Marine Service Code, NFPA 70; National Electrical Code (NEC),

OSHA regulations and federal, state, and local codes which

must be followed. Failure to install, inspect, maintain or

service this equipment in accordance with these codes,

regulations and standards may lead to legal citations with

penalties or affect the safe use and operation of the

equipment.

Replacement Parts

Use only genuine Gasboy replacement parts and retrofit kits

on your pump/dispenser. Using parts other than genuine

Gasboy replacement parts could create a safety hazard and

violate local regulations.

Safety Symbols and Warning Words

This section provides important information about warning

symbols and boxes.

Alert Symbol

This safety alert symbol is used in this manual and on

warning labels to alert you to a precaution which must be

followed to prevent potential personal safety hazards. Obey

safety directives that follow this symbol to avoid possible

injury or death.

Signal Words

These signal words used in this manual and on warning labels

tell you the seriousness of particular safety hazards. The

precautions that follow must be followed to prevent death,

injury or damage to the equipment

DANGER - This signal word is used to alert you to a

!

hazard to unsafe practice which will result in death or

serious injury

WARNING - This alerts you to a hazard or unsafe

!

practice that could result in death or serious injury.

CAUTION with Alert symbol - This signal word

!

designates a hazard or unsafe practice which may

result in minor injury.

CAUTION without Alert symbol - When used by itself,

CAUTION designates a hazard or unsafe practice

which may result in property or equipment damage.

- An evacuation of all unauthorized persons and vehicles

using safety tape, cones or barricades to the effected units

- A total electrical shut-off of that unit

MDE-4643 Quarles NBS Configuration and Software Installation Manual · March 2007 Page 3

Working With Fuels and Electrical Energy

Prevent Explosions and Fires

Fuels and their vapors will become explosive if ignited. Spilled

or leaking fuels cause vapors. Even filling customer tanks will

cause explosive vapors in the vicinity of dispenser or island.

Page 8

Important Safety Information

No Open Flames

Open flames from matches, lighters, welding torches

or other sources can ignite fuels and their vapors.

No Sparks - No Smoking

Sparks from starting vehicles, starting or using power tools,

burning cigarettes, cigars or pipes can also ignite fuels and

their vapors. Static electricity, including an electrostatic

charge on your body, can cause a spark sufficient to ignite

fuels and their vapors. After getting out of a vehicle, touch the

metal of your vehicle to discharge any electrostatic charge

before you approach the dispenser island.

Working Alone

It is highly recommended that someone who is capable of

rendering first aid be present during servicing. Be familiar

with Cardiopulmonary Resuscitation (CPR) methods if you

are working with or around high voltages. This information is

available from the American Red Cross. Always advise the

station personnel about where you will be working, and

caution them not to activate power while you are working on

the equipment. Use the OSHA tag out and lock out

procedures. If you are not familiar with this requirement, refer

to information in the service manual and OSH A

documentation.

Working With Electricity Safely

Be sure to use safe and established practices in working with

electrical devices. Poorly wired devices may cause a fire,

explosion or electrical shock. Be sure grounding connections

are properly made. Make sure that sealing devices and

compounds are in place. Be sure not to pinch wires when

replacing covers Follow OSHA Lock-Out and Tag-Out

requirements. Station employees and service contractors

need to understand and comply with this program completely

to ensure safety while the equipment is down.

Emergency First Aid

Informing Emergency Personnel

Compile the following information for emergency personnel:

Location of accident (for example, address, front/back of

building, and so on).

Nature of accident (for example, possible heart attack, run

over by car, burns, and so on).

Age of victim (for example, baby, teenager, middle-age,

elderly)

Whether or not victim has received first aid (for example,

stopped bleeding by pressure, and so on).

Whether or not a victim has vomited (for example, if

swallowed or inhaled something, and so on).

WARNING

!

Gasoline ingested may cause unconsciousness

and burns to internal organs.

Do not induce vomiting.

Keep airway open.

Oxygen may be needed at scene.

Seek medical advice immediately.

WARNING

!

Gasoline inhaled may cause unconsciousness

and burns to lips, mouth and lungs.

Keep airway open.

Seek medical advice immediately.

WARNING

!

Gasoline spilled in eyes may cause burns to eye

tissue.

Irrigate eyes with water for approximately 15

minutes.

Seek medical advice immediately

Hazardous Materials

Some materials present inside electronic enclosures may

present a health hazard if not handled correctly. Be sure to

clean hands after handling equipment. Do not place any

equipment in mouth.

!

WARNING

This area contains a chemical known to the State of

California to cause cancer.

WARNING

!

Gasoline spilled on skin may cause burns.

Wash area thoroughly with clear/water.

Seek medical advice immediately.

IMPORTANT: Oxygen may be needed at scene if gasoline

has been ingested or inhaled. Seek medical advice

immediately.

Lockout/Tagout

WARNING

!

This area contains a chemical known to the State of

California to cause birth defects or other reproductive

harm.

Lockout/Tagout covers servicing and maintenance of

Machines and equipment in which the unexpected

energization or start up of the machine(s) or equipment or

release of stored energy could cause injury to employees or

personnel. Lockout/Tagout applies to all mechanical,

hydraulic, chemical or other energy, but does not cover

electrical hazards. Reference Subpart S of 29 CFR Part 1910

IMPORTANT: Oxygen may be needed at scene if gasoline

has been ingested or inhaled. Seek medical advice

- Electrical Hazards, 29 CFR Part 1910.333 contains specific

Lockout/Tagout provision for electrical hazards.

immediately.

Page 4 MDE-4643 Quarles NBS Configuration and Software Installation Manual · March 2007

Page 9

Confirmation of Version Information

3 – Configuration and Installation

Confirmation of Version Information

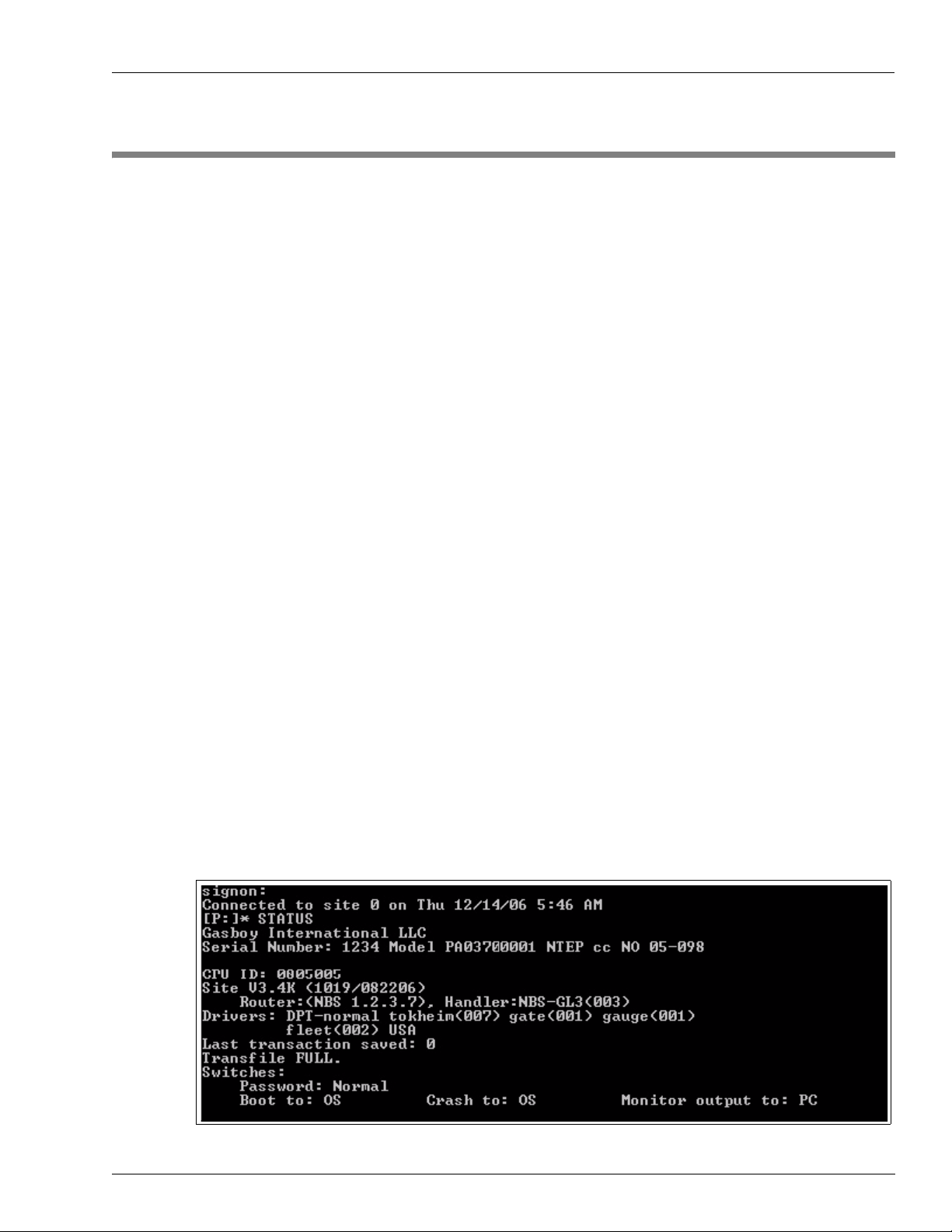

Use the STATUS command to view the current software revisions. Each Gasboy CFN

operating system contains three sections.

Site Controller (SC) III Operating Software

The SC III operating software is the top layer software that controls all operations. It performs

the following:

• Communicates with pump interfaces, network routers, and card handlers.

• Acts as the trail guide for all data that passes in and out of the system.

Network Router

The network router receives credit card/network-authorized Fleet Card information from the

card handler and communicates it to the designated network ho st.

Card Handler

The card handler receives the card data from the operating system and distributes it according

to the card type. The Quarles network uses the NBS-GL3 handler. When a Quarles Fleet Card

is swiped at the reader, the SC III operating software sends the Q-card information to the card

handler. Here, the data is verified and routed to the network router.

Example: The following screen capture of the STATUS command shows the information that

is required to determine the version of the software that is running. The current Quarles

installation displays Site 3.4K operating software, Router NBS 1.2.3 .7 an d Hand ler NBS GL3

003. If you are at a Quarles site and do not have these minimum versions, you must upgrade.

To order the software and enquire about other details, call Gasboy’s Customer Service

Department.

MDE-4643 Quarles NBS Configuration and Software Installation Manual · March 2007 Page 5

Page 10

Site Configuration

This section highlights the configuration parameters that are required for the proper operation

of Quarles locations. Not all parameters are specified since many of the default parameters are

acceptable. Use the installation procedures in this manual to automatically load the appropriate

configuration, network and site data information. The following information is required to

verify if the installation has been performed properly.

Table

Match your table setup to the following screen capture. Items 6-12 may vary depending on the

number of devices at each site. For more information on these parameters, refer to

MDE- 4316 Site Controller III Configuration Manual.

Always run SYSBACK and TRANBACK prior to changing the table parameters. This

configuration program directly affects the way data is written to the memory. Changing this

table will redefine the memory allocation and could result in data loss. Proper backups are the

only way to ensure recovery after memory table reconstruction.

Site Configuration

SYS_PAR

Page 1

• 2. Site ID - This number will vary from site to site and is designated by Quarles. Contact

Quarles at (877) 444-3835 if you are unsure of the number that is to be entered here.

• 7. PIN Key - This number will vary from site to site and is designated by Quarles. Contact

Quarles at (877) 444-3835 if you are unsure of the number that is to be entered here.

• All other items on Page 1 can retain their default settings.

Page 2+3

• All items on these pages can retain their default settings. Standard Gasboy Club Card

formats are not used with Quarles.

Page 6 MDE-4643 Quarles NBS Configuration and Software Installation Manual · March 2007

Page 11

Site Configuration

Page 4

• 35. Use remote verification (reader) - Credit

®

• 50. Keypads - If Gilbarco

CRIND®, Tokheim® DPT or Wayne® CATS are used, this

parameter will be filled in. If Gasboy Island Card Readers (ICRs) are used, this line can be

left blank. Refer to MDE-4316 Site Controller III Configuration Manual for the

appropriate entries when using third party (Gilbarco, Wayne or Tokheim) readers.

• All other items on Page 4 can retain their default value.

Page 5

• Quarles sites are currently card reader-access only. The default settings on Page 5 can be

used.

Page 6

• If a gate reader is used, refer to MDE-4316 Site Controller III Configuration Manual for

information on setting up this page.

Page 7

• If Fuel Point is used, refer to MDE-4316 Site Controller III Configuration Manual for

information on setting up this page.

Page 8

• 85. Remote port channel - 6 (can be 4, 5 or 6). Refer to “Appendix A - Port Wiring” on

page 13 to identify appropriate port numbers.

• 86. Log printer channel - 1

• 88. Remote port baud rate - 2400

• 94. Host handler channel - 4

• 95. Host handler baud rate -2400

• 96. Verification timeout (routers) - 95

• 100. Send requests to host handler - Credit

• All other items on Page 8 can retain their default settings.

CAUTION

The Host Handler Channel (94), Host Handler BAUD rate (95), and Host Handler Data (101)

should not be changed here. Changes in network parameters pertaining to modem type and

other configuration settings that are important to credit verification will automatically change

this parameter. Making changes here may render the credit verification system inoperable.

This operation should only be performed at the suggestion of the Gasboy Technical

Assistance Center.

CAUTION

Page 9

• 107. Blank pump display after - Never

• All other items on Page 9 can retain their default settings.

Page 10+1 1

• All items on Page 10+11 can retain their default settings.

MDE-4643 Quarles NBS Configuration and Software Installation Manual · March 2007 Page 7

Page 12

READER

Site Configuration

Page 12

• 148. Print manual # on receipt - Yes

• 155. Text used on receipt for manual number - Job Number

• All other items on Page 12 can retain their default settings.

Page 13

• 166. Use aux info field for vehicle number - Club

• All other items on Page 13 can retain their default settings.

Note: Ensure that you quit, save and reboot the system when you make changes to the system

parameters or any configuration setup utility, for the changes to take effect. Refer to

“Appendix B - System Parameters Listing” on page 15 for a list of system parameters

for Quarles locations.

Reader Program - Match the Reader program to the following screen capture.

Reader parameters may vary from site to site. Refer to MDE-4316 Site Controller III

Configuration Manual for information on setting up the Reader parameters appropriately.

PUMP

Pump options will vary from site to site. Refer to MDE-4316 Site Controller III Configuration

Manual for information on setting up the Pump parameters appropriately.

Page 8 MDE-4643 Quarles NBS Configuration and Software Installation Manual · March 2007

Page 13

Site Data

TRFMT

Field Letter Field Type Offset Number of Digits Title

A 1 Not used AUTO SET to 4 Tran

B 21 Not used Not used SEQ

C20 19 Card

D 3 Not used Not used Auth

E 4 Not Used Not Used Date

F 6 Not used Not used Time

G 7 Not used Not used P#

H 8 Not used Not used Pr

I 9 Not used Not used Quantity

J 17 Not used Not used Odom

K 19 Not used Not used JOB

L 13 Not used Not used Error

The following screen capture helps you verify the settings in TRFMT. This screen capture

should match your screen when you have entered the appropriate fields.

Site Data

Limitation

Limitations for Quarles can be loaded by typing QLIMITS at the command prompt. After

running the command type PR LIM, ensure that the limits loaded match the following data:

1 10.000 2 20.000 3 30.000 4 50.000

6 70.000 8 100.000 9 200.000 80 250.000

81 10.000 82 20.000 83 30.000 84 40.000

85 50.000 86 70.000 87 100.000 88 150.000

89 200.000 90 250.000

MDE-4643 Quarles NBS Configuration and Software Installation Manual · March 2007 Page 9

Page 14

Authorization

Site Data

Use the LO AU command to load the following authorization codes with the appropriate

products.

Code Allowed Product

80 3 4 9 11 14 15

81 14

82 11

83 3 4

84 5

85 11 14

86 11 14 15

87 3 4 11

88 3 4 14

89 3 4 15

93 4

94 4 11

Product Codes

Listed below are the current Quarles product codes.

Note: Different product codes use the same description. This is to account for reformulated

Refer to “Product Cross Reference” on page 11 for the appropriate NBS cross reference

number for referencing the network setup.

Prices

Each fuel product will have a price of 1 dollar.

Local Code Description NBS Cross Reference #

3Diesel 18

4 Ultra Low DI 25

6 Off-road 30

9 Mid-grade 3

10 Super 4

11 Regular 14

12 Regular 2

14 Mid-grade 15

15 Super 16

fuels and is managed by Quarles and NBS.

Page 10 MDE-4643 Quarles NBS Configuration and Software Installation Manual · March 2007

Page 15

NBS Network Configuration

NBS Network Configuration

Type NBS at the command prompt to access the NBS main menu.

Network Parameters

Match the network parameters to the following screen capture.

Card Parameters

For Quarles sites, all other credit card verification parameters are set to Not Allow (N/A). Set

the Quarles Card (#25 on the list in the edit card parameter menu) parameters as follows:

CARD OK Auth Fill Amt Price Level OK Rtn OK Voice OK Ovrid OK Loc Auth

Quarles Y $250 0 Y Y N Y

ALL OTHERS N N/A N/A N/A N/A N/A N/A

Modem Parameters

Set the modem parameters as follows:

• Modem Name - Select the appropriate modem from the list provided in the software. The

current production model is a Gasboy Quick Connect 2400 (#23 on the list).

• Baud Rate - 2400

• Port Number - (can be 4, 5 or 6). Refer to “Appendix A - Port Wiring” on page 13 to

identify the appropriate port numbers.

Product Cross Reference

Refer to “Product Codes” on page 10 for the appropriate NBS cross reference numbering.

MDE-4643 Quarles NBS Configuration and Software Installation Manual · March 2007 Page 11

Page 16

This page is intentionally left blank.

NBS Network Configuration

Page 12 MDE-4643 Quarles NBS Configuration and Software Installation Manual · March 2007

Page 17

Appendix A - Port Wiring

Gasboy CFN III Tower Port Diagram

MDE-4643 Quarles NBS Configuration and Software Installation Manual · March 2007 Page 13

Page 18

This page is intentionally left blank.

Page 14 MDE-4643 Quarles NBS Configuration and Software Installation Manual · March 2007

Page 19

Appendix B - System Parameters Listing

*** Page 1: *** System Parameters ***

1. Power up - Quarles

2. Site ID - 807

3. System ID - 0

4. Second System ID - 0

5. Network poll address - 1

6. Manager key permission - 10

7. PIN key - ****

8. Backup password - GASBOY

9. Lockout - Bit mapped, 4 digits, in RAM tables

10. Disk journal - No

11. Send generic log messages to disk journal - No

12. Locale code for site - USA

*** Page 2: *** Club Card Format - Field Widths ***

13. Digits in system ID - 6

14. Digits in account # - 19

15. Digits in allocation - 4

16. Digits in vehicle # - 4

17. Digits in expiration date - 4

18. Digits in limitation code - 1

19. Digits in authorization code - 2

20. Digits in price level - 1

21. Digits in restriction code - 1

MDE-4643 Quarles NBS Configuration and Software Installation Manual · March 2007 Page 15

Page 20

22. Digits used in PIN calculation - 19

23. Digits in checking PIN - 4

24. Digits in savings PIN - 4

25. Digits in credit PIN - 4

*** Page 3: *** Club Card Format - Offsets ***

26. Allocation account offset - 0

27. Vehicle account offset - 0

28. Limitation code offset - 0

29. Authorization code offset - 1

30. Price level offset - 3

31. Restriction code offset - 4

32. PIN calculation offset - 0

33. Extra card digit offset - 0

34. CLUB bit-mapped account offset - 0

*** Page 4: *** Reader Verification and Miscellany ***

35. Use remote verification (reader) - Credit

36. Use local verification (reader) - Club

37. Require PIN (reader) - None

38. Check PIN (reader) - Club

39. Check mod 10 (reader) - None

40. Check expiration date (reader) - Club Checking Savings Credit

41. Lockout on local verification (reader) - Club Credit

42. Lockout on remote verification (reader) - Club Checking Savings Cred it

43. Reader default payment is - Credit

44. Show product price on reader display - Checking Savings Credit

Page 16 MDE-4643 Quarles NBS Configuration and Software Installation Manual · March 2007

Page 21

45. Pump must be on hook for reader transaction - No

46. Auto receipt: When reentering the card, ICR prints without asking - No

47. Auto receipt: Duplicate receipts printed - No

48. Reader types that print receipt without asking after the sale - None

49. Reader ignores PIN restriction on the card - No

50. Keypads:

51. Requires clerk approval for reader transactions - No

52. Reader requires attendant card for transactions - No

53. Reader requires patron/loyalty card for transactions - No

*** Page 5: *** Console Verification ***

54. Use remote verification (console) - Credit

55. Use local verification (console) - Club

56. Require PIN (console) - None

57. Check PIN (console) - Club

58. Check mod 10 (console) - None

59. Check expiration date (console) - None

60. Lockout on local verification (console) - Club Credit

61. Lockout on remote verification (console) - Club Checking Sav i ngs Credit

62. Where to send Profit Point broadcast messages - PC loop 3 when PP is up

63. Console requires attendant card for transactions - No

64. Console requires patron/loyalty card for transactions - No

*** Page 6: *** Gate Verification and Miscellany ***

65. Use remote verification (gate) - None

66. Use local verification (gate) - None

67. Require PIN (gate) - None

MDE-4643 Quarles NBS Configuration and Software Installation Manual · March 2007 Page 17

Page 22

68. Check PIN (gate) - Club

69. Check mod 10 (gate) - Credit

70. Check expiration date (gate) - Club Credit

71. Lockout on local verification (gate) - Club Credit

72. Lockout on remote verification (gate) - Club Credit

73. Log gate openings - Yes

74. All gate openings make transaction - No

75. Select gate message - Select gate number

*** Page 7: *** Fuel Point Verification and Miscellany ***

76. Use remote verification (Fuel Point) - None

77. Use local verification (Fuel Point) - None

78. Require PIN (Fuel Point) - None

79. Check PIN (Fuel Point) - Club

80. Check mod 10 (Fuel Point) - Checking Savings Credit

81. Check expiration date (Fuel Point) - Club Checking Savings Credit

82. Lockout on local verification (Fuel Point) - Club Credit

83. Lockout on remote verification (Fuel Point) - Club Checking Savings Credit

84. Require sys-ID match for track-II vehicle module - Yes

*** Page 8: *** Serial Port Configuration ***

85. Remote port channel - 6

86. Log printer channel - 1

87. Special pump handler channel - None

88. Remote port baud rate - 2400

89. Remote port terminal type - 2

90. Remote port modem type - Direct or Dumb Modem (Full Duplex)

Page 18 MDE-4643 Quarles NBS Configuration and Software Installation Manual · March 2007

Page 23

91. Additional Hayes remote port command(s) - No

92. Pumps on first Tokheim channel - 16

93. Poll split Tokheim loops fast - No

94. Host handler channel - 4

95. Host handler baud rate - 2400

96. Verification timeout (routers) - 95

97. Verification timeout (CFN host) - 0

98. Host router data:

99. More router data:

100. Send requests to host handler - Credit

101. Host handler data - 16 14 00 00 00 00 00 00 00 00 00 00 00 78 02 00

CAUTION

The Host Handler Channel (94), Host Handler BAUD rate (95), and Host Handler Data (101) should

not be changed here. Changes in network parameters pertaining to modem type and other

configuration settings that are important to credit verification will automatically change this

parameter. Making changes here may render the credit verification system inoperable. This

operation should only be performed at the suggestion of the Gasboy Technical Assistance Center.

*** Page 9: *** Miscellany ***

102. Null pad CR/LF - 0

103. Switch timeout - 80

104. Pulser timeout - 80

105. Fall-back price level - 0

106. STOP pumps on RS422 break - No

107. Blank pump display after - Never

108. Blank pump price display - No

109. Command search path - r:,.,p:bin

110. Zero quantity disable after - 5

MDE-4643 Quarles NBS Configuration and Software Installation Manual · March 2007 Page 19

Page 24

111. Reuse current sale on POS if prev unpaid - Yes

112. Log remote port commands executed - No

113. Unique shift #'s for every console - Yes

114. Hours required between NEXT SHIFT/DAY - 0

115. Initial drawer value after NEXT SHIFT/DAY - 300

116. Buffered cumulative totalizers on RESET TOTALS - No

117. Blank lines for page break - 0

118. Lines of text per page on direct printout - 66

119. Logger initialization - 00 00 00 00 00 00 00 00 00 00

*** Page 10: *** Tank Gauge ***

120. Log gauge delivery - Yes

121. Transaction for gauge delivery - No

122. Add to tank inventory after gauge delivery - No

123. Log fuel drop card - No

124. Transaction for fuel drop card - No

125. Add to tank inventory after fuel drop card - No

126. Log dipstick reading - No

127. Transaction for dipstick reading - No

*** Page 11: *** Transaction Miscellany ***

128. Bank PIN D.E.S.- No

129. CFN PIN unencrypted - No

130. Cumulative limit time - 0

131. Cumulative fuel limit - 0

132. Save cash transactions - No

133. Save HAND transactions - Yes

Page 20 MDE-4643 Quarles NBS Configuration and Software Installation Manual · March 2007

Page 25

134. Allow supervisor cards - No

135. Allow cardless use of code file - No

136. Alternate expiration date - 00 00

137. Number to add to club price level - 0

138. Transaction file full warning percentage - 80

139. Fuel authorization code for bank cards - None

140. Check fuel authorization codes on post-pay - No

141. Always request dollars from CFN host - None

142. Send transactions to CFN host - None

143. Use new format for CFN auth request - No

144. Generate card swipe event - No

*** Page 12: *** Receipt Configuration ***

145. System volume units - G

146. Minutes until ICR receipts expires - 20

147. Print MPG on receipt - No

148. Print manual # on receipt - Yes

149. Print cost per mile on receipt - No

150. Print odometer tenths on receipt - No

151. Print remaining allocation on receipt - No

152. Print transaction time on receipts - Yes

153. Print dollar amount for fuel on CLUB receipts - Yes

154. Text used on receipt for odometer - Odometer

155. Text used on receipt for manual number - Job Number

156. Text used on receipt for vehicle number - Vehicle #

MDE-4643 Quarles NBS Configuration and Software Installation Manual · March 2007 Page 21

Page 26

*** Page 13: *** Miles per Gallon (MPG) Package ***

157. MPG package used for club cards - No

158. MPG package used for bank cards - No

159. Low MPG - 3

160. High MPG - 20

161. Maximum miles between fuelings - 500

162. Club odometer tries allowed - 2

163. Bank odometer tries allowed - 2

164. Accept Club odometer - Yes

165. Accept Bank odometer - Yes

166. Use aux info field for vehicle number - Club

Page 22 MDE-4643 Quarles NBS Configuration and Software Installation Manual · March 2007

Page 27

Appendix C - 3.3 to 3.4K Upgrade Instructions

The upgrade instructions should be used by trained CFN technicians when upgrading a

Quarles location from version 3.3X to 3.4K. They are not universal installation instructions.

The following procedures are applicable only for Quarles locations and should not be

attempted with any other site software.

Creating Backups

To stop the site and create a backup, proceed as follows:

1 Clear the fuel island.

2 Type STOP at the command prompt to shut down the site.

3 Settle all pending network transactions.

4 Type TRANBACK to create a backup of the transactions.

Note: Transactions will not be restored after the upgrade.

5 Type SYSBACK to create a backup of the site data.

Preparing the System for Upgrade

To prepare the system for upgrade, proceed as follows:

1 Log on to the CFN as the Administrator.

2 Close the CFN III program.

3 Insert the 3.4K customer disk.

4 Navigate to Start > Run, type CMD and press Enter.

5 Type A: Backup.

Installing the Upgraded Software

To install the software upgrade, proceed as follows:

1 Insert the 3.4K CD. Wait for 15 seconds for the Auto Run screen to appear.

2 Click Install. The Open option is highlighted.

3 Click Ok. The Welcome window appears.

4 Click Next.

MDE-4643 Quarles NBS Configuration and Software Installation Manual · March 2007 Page 23

Page 28

5 Enter the name and company, and click Next.

Note: Do not leave the name and/or company field blank.

6 Check only CFN III programs and click Next.

®

Note: Do not select Citgo

7 Click Next at the Check Setup Information window. You are prompted to insert the customer

or Profit Point software for Quarles locations.

disk.

8 Click Ok.

9 Enter the Unit Serial Number and click Next.

Note: The Serial Number, Model Number and Ntep Number can be found on the front of new

black SMTC towers and on the right panel near the back on older beige towers.

10 Enter the Unit Model Number and click Next.

11 Enter the Ntep Number (if prompted) and click Next.

Note: This option may not be available on the older towers. If not available, leave the field

blank.

12 Click Ok when a message “Post copy update batch successfully executed” appears.

13 Click Finish at the SC III Dip Setup window.

14 Click Finish when prompted to restart the computer. The CD must remain in the drive. The

floppy should be removed.

15 After restart, remove the CD and click Finish to restart the PC for the final time.

Note: When the CFN III system restarts, some network halted messages will appear prior to

the sign-on prompt. This is normal and occurs because the NBS network setup is not yet

complete.

16 Sign on to the SC III system.

17 Type REBOOT;A and press Enter to load the new operating system and configuration into

the RAM. After the reboot, sign back on and type STATUS. The status report should now

reflect SC III V3.4K and NBS Router 1.2.3.7. Refer to “Confirmation of Version Information”

on page 5 for information on the status report.

Page 24 MDE-4643 Quarles NBS Configuration and Software Installation Manual · March 2007

Page 29

Restoring the Data

To restore the data, proceed as follows:

1 Type NBS–I. When prompted, save the changes and reboot the system.

2 Insert the customer floppy.

3 Type NBS–R A:NBSQUARLES.TXT and press Enter.

4 Type NBS–M and configure the modem.

5 Press S to save and press Return.

Note: Do not start the reboot process.

6 Type RESTORE EV FR A:SYSBACK.DTA and press Enter.

7 Sign on and type NBS–X. Load the appropriate product cross reference information.

8 Type NBS–E and load the appropriate terminal number.

9 Set the maximum time in fall back to 120.

10 Type SYS_PAR and set the appropriate system ID number on “*** Page 1: *** System

Parameters ***” on page 15.

11 Reboot the system to complete the installation.

12 Refer to “Site Configuration” on page 6 to ensure that all the settings are correct.

13 Run several test transactions and confirm the following:

• Authorization is successful

• Appropriate dispensers are activated

• Receipt information is correct

MDE-4643 Quarles NBS Configuration and Software Installation Manual · March 2007 Page 25

Page 30

This page is intentionally left blank.

Page 26 MDE-4643 Quarles NBS Configuration and Software Installation Manual · March 2007

Page 31

Index

Index

A

Alert symbol 3

B

Barricading 3

C

Card Handler 5

Cash Flow Network

Caution warnings

3

D

Danger warnings 3

E

Electrical

Shut-off

Emergency

Electrical shut-off

Personnel (contacting)

Evacuation

Explosions

Preventing

3

3

3

F

Fires

Preventing

3

N

NBS 1

NBS Network

Card

Modem

Parameters

Product

Network Router

11

11

11

11

11

5

3

4

4

3

3

PUMP

TRFMT

9

17

21

15

3

3

4

3

3

3

3

3

3

4

3

3

6

8

8

8

6

5

10

9

10

15

15

18

17

22

16

18

20

20

Evacuation

NFPA regulations

Open flames

Preventing explosions and fires

Regulations

Replacement parts

Safety symbols

Shut-off

Signal words

1

Smoking

Sparks

Warning words

Working alone

Safety symbols

Shut-off

Emergency electrical

Signal words

Safety

Site Configuration

READER

3

4

SYS_PAR

Site Controller (SC) III

Site Data

Authorization

Limitation

Product Codes

System Parameter Listing

Club card

Console

Fuel Point

Gate verification

Miles per gallon

Reader verification

Receipt

Serial port

System

Tank Gauge

Transaction

P

Personnel

Emergency (informing)

Port Wiring

13

4

S

Safety Information 3

Alert symbol

Barricading

Emergency electrical shut-off

Emergency personnel

MDE-4643 Quarles NBS Configuration and Software Installation Manual · March 2007 Index-1

3

3

3

4

U

Upgrade 23

3.3 to 3.4K

Install

23

Restoring

25

W

Warning words 3

Warnings

3

23

Page 32

Index

Citgo® is a registered trademark of Citgo Petroleum Corporation. CRIND® and Gilbarco® are registered trademarks of Gilbarco Inc.

Tokheim

®

is a registered trademark of Tokheim Holding B.V. Corporation. Wayne® is a registered trademark of Dresser Equipment Group

Inc.

© 2007 GASBOY

7300 West Friendly Avenue · Post Office Box 22087

Greensboro, North Carolina 27420

Phone 1-800-444-5529 · http://www.gasboy.com · Printed in the U.S.A.

MDE-4643 Quarles NBS Configuration and Software Installation Manual · March 2007

Loading...

Loading...