Page 1

FedEx Islander PLUS FMS

Installation Manual

MDE-5067

Page 2

Computer Programs and Documentation

Gasboy, Greensboro, is an ISO 9001:2000 registered facility.

Underwriters Laboratories (UL):

UL File# Products listed with UL

MH4314

All dispensers and self-contained pumping

units

MH10581 Key con t r o l u n i t , M o d e l G K E - B S e r i e s

Card reader terminals, Models 1000, 1000P

Site Controller, Model 2000S CFN Series

Data entry terminals, Model TPK-900 Series

Fuel Point Reader System

National Conference of Weights and Measures (NCWM) - Certificate of Compliance (CoC):

Gasboy pumps and dispensers are evaluated by NCWM under the National Type Evaluation Program (NTEP). NCWM has issued the following CoC:

CoC# Product Model # CoC# Product Model # CoC# Product Model #

95-179 Dispenser

9100 Retail Series, 8700

Series, 9700 Series

91-019 Dispenser

9100 Commercial

Series

05-002 Atlas

8700K, 8800K,

9100K, 9200K, 9800K

95-136 Dispenser 9800 Series 91-057 Controller

1000 Series FMS,

2000S-CFN Series

California Air Resources Board (CARB):

Executive Order # Product

G-70-52-AM Balance Vapor Recovery

G-70-150-AE VaporVac

Registered trademarks

ASTRA

®

Fuel Point

®

Gasboy

®

Keytrol

®

Slimline

®

Additional US and foreign trademarks pending.

Other brand or product names shown may be

trademarks or registered trademarks of their

respective holders.

Non-registered trademarks

Atlas

™

Consola

™

Infinity

™

Federal Communications Commission (FCC) Warning

All Gasboy computer programs (including software on diskettes and within memory chips) and documentation are copyrighted by, and shall remain the property of, Gasboy. Such

computer programs and documents may also contain trade secret information. The duplication, disclosure, modification, or unauthorized use of computer programs or

documentation is strictly prohibited, unless otherwise licensed by Gasboy.

This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy, and if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense. Changes or modifications not expressly

approved by the manufacturer could void the user’s authority to operate this equipment.

Approvals

Trademarks

This document is subject to change without notice.

E-mail: literature@gasboy.com · Internet: http://www.gasboy.com

2013 GASBOY. All Rights Reserved.

Page 3

Table of Contents

Table of Contents

1 – Introduction 1-1

Purpose. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Intended Users . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Abbreviations and Acronyms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

2 – Important Safety Information 2-1

3 – Installation Procedure 3-1

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Pre-installation Power Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Pre-installation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Shutting Down Island. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Removing Existing Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Mounting Dry Islander PLUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Installing FedEx Islander PLUS FMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Downloading Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Installing Islander PLUS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Connecting to FedEx Islander PLUS FMS Corporate Network. . . . . . 3-14

4 – SiteOmat Software Set Up 4-1

Software Set Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Process Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

OrCU Set Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Setting SiteOmat. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Pump Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Tank Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Setting Fuel Price . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Unblocking or Activating Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Weights & Measures (W&M) Dongle Activation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Process Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

Synchronizing with Fleet Head Office (FHO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

HOCOMM User . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Synchronizing FedEx Islander PLUS FMS . . . . . . . . . . . . . . . . . . . . . 4-32

Test Sequences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

Testing Procedure for Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

Finalizing Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

Appendix A: Commissioning A-1

Appendix B: Multiple Controller Sites B-1

Installing Multiple Controller FedEx Islander PLUS FMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Gasboy 9800 Series Pumps Business Inventory Reconciliation (BIR) Set Up . . . . . . . . . . . . . . . . . . B-2

MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013 Page i

Page 4

Table of Contents

Appendix C: FedEx Project Site Information Form (Example Only) C-1

Index Index-1

Page ii MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013

Page 5

Purpose Introduction

Verify that you have all the required equipment and software to complete the installation.

IMPORTANT INFORMATION

1 – Introduction

Purpose

This manual provides instructions for installing the FedEx Islander PLUS Fuel Management

System (FMS) in the off-site server.

Intended Users

This manual is intended for facility personnel (Operations Manager) who installs the FedEx

Islander PLUS FMS.

Required Equipment

Following equipment is required to install the FedEx Islander PLUS FMS:

• FedEx Custom Islander PLUS FMS (PA039400801FX)

• Contents of the FedEx project folder from ftp.gilbarco.com:

- Board Support Package (BSP) - Version 1.08 Service Pack 8

- SiteOmat - Version 6.4.33.098

- Payment Application Interface Service (P

Note: To report any missing or damaged equipment, contact Bob Grif

AIS) - 4.31.1.58

fith at 1-336-547-5654.

MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013 Page 1-1

Page 6

Introduction Abbreviations and Acronyms

Abbreviations and Acronyms

Term Description

BIR Business Inventory Reconciliation

BSP Board Support Package

DEF Diesel Exhaust Fluid

DNS Domain Name System

FHO Fleet Head Office

FMS Fuel Management System

GW Gateway

HOCOMM Head Office Communicator

LAN Local Area Network

OrCU Orpak Controller Unit

OrPT Orpak Payment Terminal

OS Operating System

PAIS Payment Application Interface Service

POE Power Over Ethernet

STP Submersible Turbine Pump

WAN Wide Area Network

W&M Weights & Measures

Page 1-2 MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013

Page 7

2 – Important Safety Information

The EMERGENCY STOP, ALL STOP, and

PUMP STOP buttons at the cashier’s station

WILL NOT shut off electrical power to the

pump/dispenser. This means that even if you

activate these stops, fuel may continue to flow

uncontrolled.

You must use the TOTAL ELECTRICAL

SHUT-OFF in the case of an emergency and not

the console’s ALL STOP and PUMP STOP or

similar keys.

!

WARNING

!

Important Safety Information

Note: Although DEF is non-flammable, Diesel is

flammable. Therefore, for DEF cabinets that are

attached to Diesel dispensers, follow all the notes

in this section that pertain to flammable fuels.

This section introduces the hazards and safety precautions

associated with installing, inspecting, maintaining or servicing

this product. Before performing any task on this product, read

this safety information and the applicable sections in this

manual, where additional hazards and safety precautions for

your task will be found. Fire, explosion, electrical shock or

pressure release could occur and cause death or serious injury,

if these safe service procedures are not followed.

Preliminary Precautions

You are working in a potentially dangerous environment of

flammable fuels, vapors, and high voltage or pressures. Only

trained or authorized individuals knowledgeable in the related

procedures should install, inspect, maintain or service this

equipment.

Emergency Total Electrical Shut-Off

The first and most important information you must know is how

to stop all fuel flow to the pump/dispenser and island. Locate

the switch or circuit breakers that shut of f all p ower to all fueling

equipment, dispensing devices, and Submerged Turbine

Pumps (STPs).

Read the Manual

Read, understand and follow this manual and any other labels

or related materials supplied with this equipment. If you do not

understand a procedure, call a Gilbarco Authorized Se rvice

Contractor or call the Gilbarco Support Ce nte r at

1-800-800-7498. It is imperative to your safety and the sa fety of

ot

hers to understand the procedures before beginning work.

Follow the Regulations

Applicable information is available in National Fire Protection

Association (NFPA) 30A; Code for Motor Fuel Dispensing

Facilities and Repair Garages, NFPA 70; National Electrical

Code (NEC), Occupational Safety and Health Administration

(OSHA) regulations and federal, state, and local codes. All

these regulations must be followed. Failure to install, inspect,

maintain or service this equipment in accordance with these

codes, regulations and standards may lead to legal citations

with penalties or affect the safe use and operat ion of the

equipment.

Replacement Parts

Use only genuine Gilbarco replacement parts and retrofit kits on

your pump/dispenser. Using parts other than genuine Gilbarco

replacement parts could create a safety hazard and violate

local regulations.

Safety Symbols and Warning Words

This section provides important information about warn ing

symbols and boxes.

Alert Symbol

Total Electrical Shut-Off Before Access

Any procedure that requires access to electrical co mponent s or

the electronics of the dispenser requires total electrical shut off

of that unit. Understand the function and location of this switch

or circuit breaker before inspecting, installing, maintaining, or

servicing Gilbarco equipment.

Evacuating, Barricading and Shutting Off

Any procedure that requires access to the pump/dispenser or

STPs requires the following actions:

• An evacuation of all unauthorized persons and vehicles from

the work area

• Use of safety tape, cones or barrica

• A total electrical shut-off of the affected unit(s)

MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013 Page 2-1

des at the affected unit(s)

This safety alert symbol is used in this manual and on

warning labels to alert you to a precaution which must be

ed to prevent potential personal safety hazards. Obey

follow

safety directives that follow this symbol to avoid possible injury

or death.

Signal Words

These signal words used in this manual and on warning labels

tell you the seriousness of particular safety hazards. The

precautions below must be followed to prevent death, injury or

damage to the equipment:

s

DANGER: Alert

!

which will result in death or serious injury.

WARNING: A

!

that could result in death or serious injury.

CAUTION with Alert

!

unsafe practice which may result in minor injury.

CAUTION without Alert symbol: Designates a hazard or

un

safe practice which may result in property or

equipment damage.

you to a hazard or unsafe practice

lerts you to a hazard or unsafe practice

sy

mbol: Designates a hazard or

Working With Fuels and Electrical Energy

Prevent Explosions and Fires

Fuels and their vapors will explode or burn, if ignited. Spilled or

leaking fuels cause vapors. Even filling customer tanks will

cause potentially dangerous vapors in the vicinity of the

dispenser or island.

DEF is non-flammable. Therefore, explosion and fire safety

rnings do not apply to DEF fluid lines.

wa

Page 8

Important Safety Information

The pump/dispenser contains a chemical known to the

State of California to cause cancer.

WARNING

!

The pump/dispenser contains a chemical known to the

State of California to cause birth defects or other

reproductive harm.

WARNING

!

Gasoline/DEF ingested may cause

unconsciousness and burns to internal organs.

Do not induce vomiting. Keep airway open.

Oxygen may be needed at scene. Seek medical

advice immediately.

DEF generates ammonia gas at high er temperatures.

When opening enclosed panels, allow the unit to air out to

avoid breathing vapors.

If respiratory difficulties develop, move victim away from

source of exposure and into fresh air. If symptoms persist,

seek medical attention.

WARNING

!

WARNING

!

Gasoline inhaled may cause unconsciousness

and burns to lips, mouth and lungs.

Keep airway open.

Seek medical advice immediately.

WARNING

!

Gasoline/DEF spilled in eyes may cause burns to

eye tissue.

Irrigate eyes with water for approximately

15 minutes. Seek medical advice immediately.

WARNING

!

Gasoline/DEF spilled on skin may cause burn s.

Wash area thoroughly with clear water.

Seek medical advice immediately.

WARNING

!

DEF is mildly corrosive. Avoid contact with eyes, skin, and

clothing. Ensure that eyewash stations and safety

showers are close to the work location. Seek medical

advice/recommended treatment if DEF spills into eyes.

WARNING

!

No Open Fire

Open flames from matches, lighters, welding torches or

other sources can ignite fuels and their vapors.

No Sparks - No Smoking

Sparks from starting vehicles, starting or using power tools,

burning cigarettes, cigars or pipes can also ignite fuels and

their vapors. Static electricity, including an electrostatic charge

on your body , can ca use a sp ark su f ficient to ign ite fuel vapors.

Every time you get out of a vehicle, touch the metal of your

vehicle, to discharge any electrostatic charge before you

approach the dispenser island.

Working Alone

It is highly recommended that someone who is capable of

rendering first aid be present during servicing. Familiarize

yourself with Cardiopulmonary Resuscitation (CPR) methods, if

you work with or around high voltages. This information is

available from the American Red Cross. Always advise the

station personnel about where you will be working, and caution

them not to activate power while you are working on the

equipment. Use the OSHA Lockout/Tagout procedures. If you

are not familiar with this requirement, refer to this information in

the service manual and OSHA documentation.

In an Emergency

Inform Emergency Personnel

Compile the following information and inform emergency

personnel:

• Location of accident (for example, addres

building, and so on)

• Nature of accident (for example, poss

over by car , burns, and so on)

• Age of victim (for example, baby, teenager, middle-age,

elderly

)

• Whether or not victim has receiv

ed f

stopped bleeding by pressure, and so on)

• Whether or not a victim has vomited (for example, if

swal

lowed or inhaled something, and so on)

s, front/back of

ible heart attack, run

irst aid (for example,

Working With Electricity Safely

Ensure that you use safe and established practices in workin g

with electrical devices. Poorly wired devices may cause a fire,

explosion or electrical shock. Ensure that grounding

connections are properly made. Take care that sealing devices

and compounds are in place. Ensure that you do not pinch

wires when replacing covers. Follow OSHA Lockout/Tagout

requirements. Station employees and service con tra ctors need

to understand and comply with this program completely to

ensure safety while the equipment is down.

Hazardous Materials

Some materials present inside electronic enclosures may

present a health hazard if not handled correctly. Ensure that

you clean hands after handling equipment. Do not place any

equipment in the mouth.

Page 2-2 MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013

IMPORTANT: Oxygen may be needed at scene if gasoline has

been ingested or inhaled. Seek medical advice immediately.

Lockout/Tagout

Lockout/Tagout covers serv icing and maintenance o f machines

and equipment in which the unexpected energization or

ipme

start-up of the machine(s) or equ

nt or release of stored

energy could cause injury to employ ee s or personnel.

Lockout/Tagout applies to all mechanical, hydraulic, chemical,

or o

ther energy , but does not cover electrical hazards.

Subpart S of 29 CFR Part 1910 - Electrical Hazards, 29 CFR

Part 19

10.333 contains specific Lockout/Tagout provision for

electrical hazards.

Page 9

Hazards and Actions

WARNING

Spilled fuels, accidents involving pumps/dispensers, or uncontrolled fuel flow create a

serious hazard.

Fire or explosion may result, causing serious injury or death.

Follow established emergency procedures.

DEF is non-flammable. However it can create a slip hazard. Clean up spills promptly.

!

Collision of a Vehicle with Unit Fire at Island Fuel Spill

The following actions are recommended regarding these hazards:

Important Safety Information

• Do not go near a fuel spill or allow anyone else in the area.

• Use station EMERGENCY CUTOFF immediately. T urn of f all

• Do not use console E-STOP, ALL STOP, and PUMP STOP to shut off power. These keys do not

ve AC power and do not always stop product flow.

remo

• Take precautions to avoid igniting fuel. Do not allow starting of vehicles in the area. Do not allow

open flames, smoking or power tools in the area.

• Do not expose yourself to hazardous conditions such as fire, spil

• Call emergency numbers.

system circuit breakers to the island(s).

led fuel or exposed wiring.

MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013 Page 2-3

Page 10

Important Safety Information

This page is intentionally left blank.

Page 2-4 MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013

Page 11

3 – Installation Procedure

AC power is present on the Terminal Blocks in the pedestal. Electrical shock may occur if

the operator comes in contact with these connections.

WARNING

If any readings are NOT within the acceptable ranges, then STOP. For further instructions,

call Gasboy TAC at 1-800-444-5529.

IMPORTANT INFORMATION

Before You Begin

Use the following checklist to verify you have all the required equipment to complete the

installation.

Pre-installation Power Inspection

Installation and reliability issues during the initial roll out of the FedEx project have revealed a

high number of sites with electrical issues, excessive noise, due to improper system and panel

grounding, and other issues. These issues have made it necessary to verify the quality of the

AC power at the island before removing the existing equipment and checking again post

installation to verify no issues have been introduced during the installation process.

These checks/tests are simple to complete and must not add

entire installation.

Following checks/tests pre-install are designed to identify additional work required, not

currently part of the installation scope.

1 Verify that the AC Power for the Islander PLUS System comes from a separate, dedicated

circuit breaker. No other equipment must be powered from this breaker. The system’s pumps

or dispensers must not be on this breaker. Power for the system must be 115 VAC + 10%,

47-63 HZ. The system draws 135 watts

Before You Begin

more than 10-15 minutes to the

maximum.

2

Locate the SYSTEM POWER Terminal Block in the pedestal on the existing system. Use a

digital AC voltmeter to measure the following voltages.

Hot to Neutral measured at: ____________ (fill in value) measured by: ____________ (print name)

This voltage must be 115 VAC + 10% (104 VAC to 126 VAC).

Hot to Ground measured at: ____________ (fill in value) measured by: ____________ (print name)

This voltage must be 115 VAC + 10% (104 VAC to 126 VAC).

Neutral to Ground measured at: ____________ (fill in value) measured by: ____________ (print name)

This voltage must be 0 VAC + 500 millivolts (-500 mV to 500 mV).

Note: If power is not within these specifications,

3

Put ALL PUMPS into manual override and activate the pumps [ensure Submersible Turbine

correct it before continuing.

Pumps (STPs)/pumping units are ON]. Use a digital AC voltmeter to measure the following

voltages

Hot to Neutral measured at: ____________ (fill in value) measured by: ____________ (print name)

This voltage must be 115 VAC + 10% (104 VAC to 126 VAC).

Hot to Ground measured at: ____________ (fill in value) measured by: ____________ (print name)

This voltage must be 115 VAC + 10% (104 VAC to 126 VAC).

Neutral to Ground measured at: ____________ (fill in value) measured by: ____________ (print name)

This voltage must be 0 VAC + 500 millivolts (-500 mV to 500 mV).

.

Note: If power is not within these specifications, correct it before continuing.

MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013 Page 3-1

Page 12

Before You Begin

DO NOT remove existing system before verifying that there are NO BARRIERS to

complete the Islander PLUS installation.

If issues are found, call Bob Griffith at 336-547-5654 IMMEDIATELY to discuss optio ns.

WARNING

4 Grounding Method: Proper system grounding is an extremely important part of the system

installation. Grounds for all system devices must be wired to the breaker panel ground bus bar

which, in turn, must be grounded to a ground rod. A conduit ground does not provide a

sufficient ground. It is recommended that the neutral and ground bus bars be bonded together

unless prohibited by local codes.

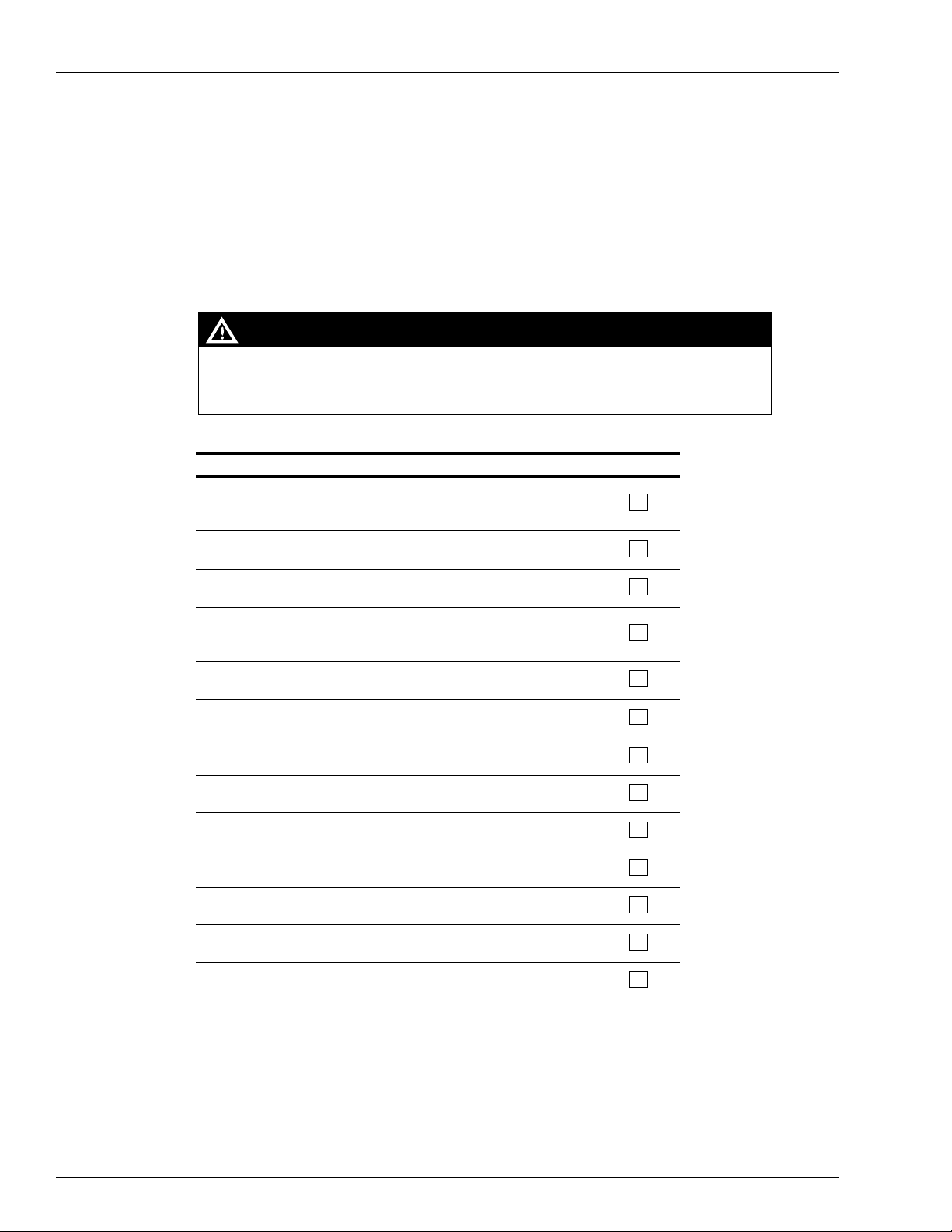

Pre-installation Checklist

Following pre-installation checklist is designed to ensure proper installation:

Description Checkbox

Check that you have the correct Gasboy Supplied parts:

• PA093400810FX - Islander PLUS FedEx CUSTOM.

• Stage 2 FedEx Islander PLUS Install Guide.

Check the conduit layout, and ensure you have the proper supplies and

clearances to complete the installation.

Check all fueling positions for proper operation.

Check all hose reels for proper operation - All hose reels connected to the

existing system MUST be connected and controlled by the Gasboy Fleet

PLUS system.

Check the E-STOP system for proper operation.

Find the circuit controlling the current FMS. Verify this is a dedicated

circuit.

Trace and identify control wires in the existing system.

Know the function of the control wires.

Identify and label the handle switch (in-use), if available.

Identify and label the (line/load) or authorize wires.

Identify and label the pulser wires.

Identify and label the LAN/WAN connections.

Mark all control wires for use when installing the Islander PLUS system.

Page 3-2 MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013

Page 13

Shutting Down Island

For issues locating the FedEx Fleet Manager, contact Travis Langston at 1-870-704-5230.

IMPORTANT INFORMATION

The circuit panel must be locked out, tagged out as per normal Gilbarco® safety procedures

found in the Gilbarco LMS training module http://wise.gilbarco.com. For more information,

refer to GVRSAFEUS50-012 GVR Fueling Site Safety.

CAUTION

Ensure that the facility personnel (Operations Manager) is aware of these steps before the old

equipment is removed. Name and contact information for the Operations Manager and site

installation parameters will be sent to you by Bob Griffith (1-336-547-5654).

FedEx Project Site Information Form, includes the following [for an example, refer to “FedEx

Project Site Information Form (Example Only)” on page C-1]:

• Operations Manager’s Name and Phone Number.

• Fipay Server IP Address, Subnet Mask, and Gateway IP Address.

• SiteOmat Wide Area Network [WAN Local Area Network (LAN2)] IP Address, Subnet

Mask, a

• FedEx Alpha code - SiteOmat St

• Site Number - SiteOmat Station Code.

Before You Begin

nd Gateway IP Address.

ation Name or Description.

Removing Existing Equipment

The Gasboy Fleet PLUS system will use some of the same control and communication wiring

as other third-party FMS. To aid in efficient installation, all control wiring in an existing

system must be labeled before disconnection.

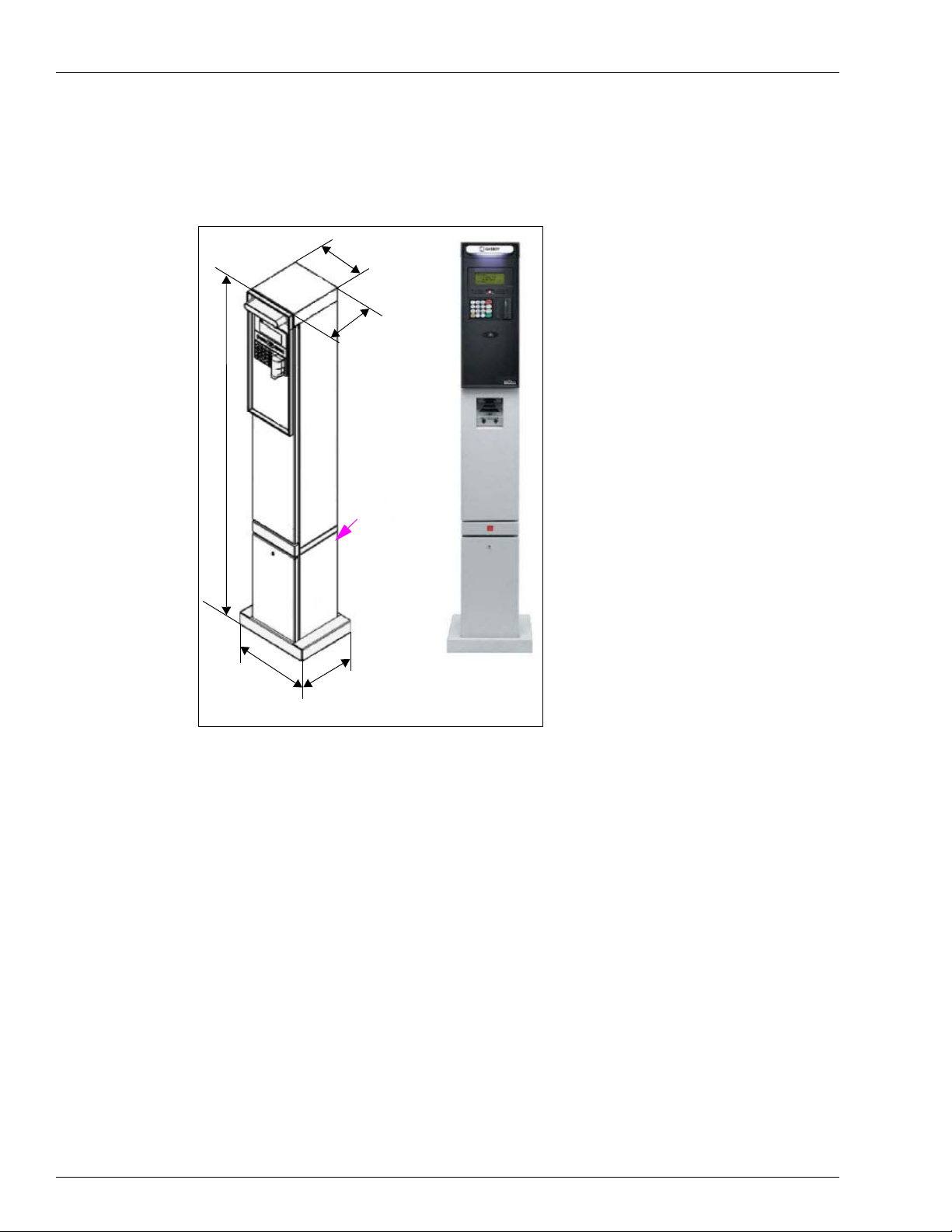

Mounting Dry Islander PLUS

To mount the Islander PLUS in the facility, proceed as follows:

1 When installing the Gasboy Islander PLUS at a facility with existing conduits at the fuel

island, it is important to note the dimensions of the pedestal to determine if special fabrication

is required for the conduits (see Figure 3-1 on page 4).

2 The pedestal can be cut within UL parameters from the base plate up to 18 inches. Any holes

drilled in the pedestal must only be large enough to fit conduit elbows and must not be inserted

above the IS Barrier Plate.

3 Following conduits are required for the Gasboy Islander PLUS pedestal:

• High Voltag e (AC power, pump control, ground, in-use for me

• Low Volta ge (pulser, tank gauge, and LAN).

chanical dispensers).

MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013 Page 3-3

Page 14

Before You Begin

9

.1

7

3

9

.4

8

8

61.728

1

3

.6

5

4

1

0

.

7

0

1

I/S Barrier Plate

Note: Dimensions are in inches.

4 Depending on the installation, you may need to modify the existing conduit wiring to

accommodate the required feeds.

Figure 3-1: Installing Gasboy Islander PLUS

Page 3-4 MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013

Page 15

Before You Begin

A3

φ 11 (X4)

With Knockout Cover

φ Insert PEM CLS-M4X1

From Other Side (X4)

A3 φ 28.5 (X4) With Knockout Cover

Front of Base - Wide Side

Wide Side

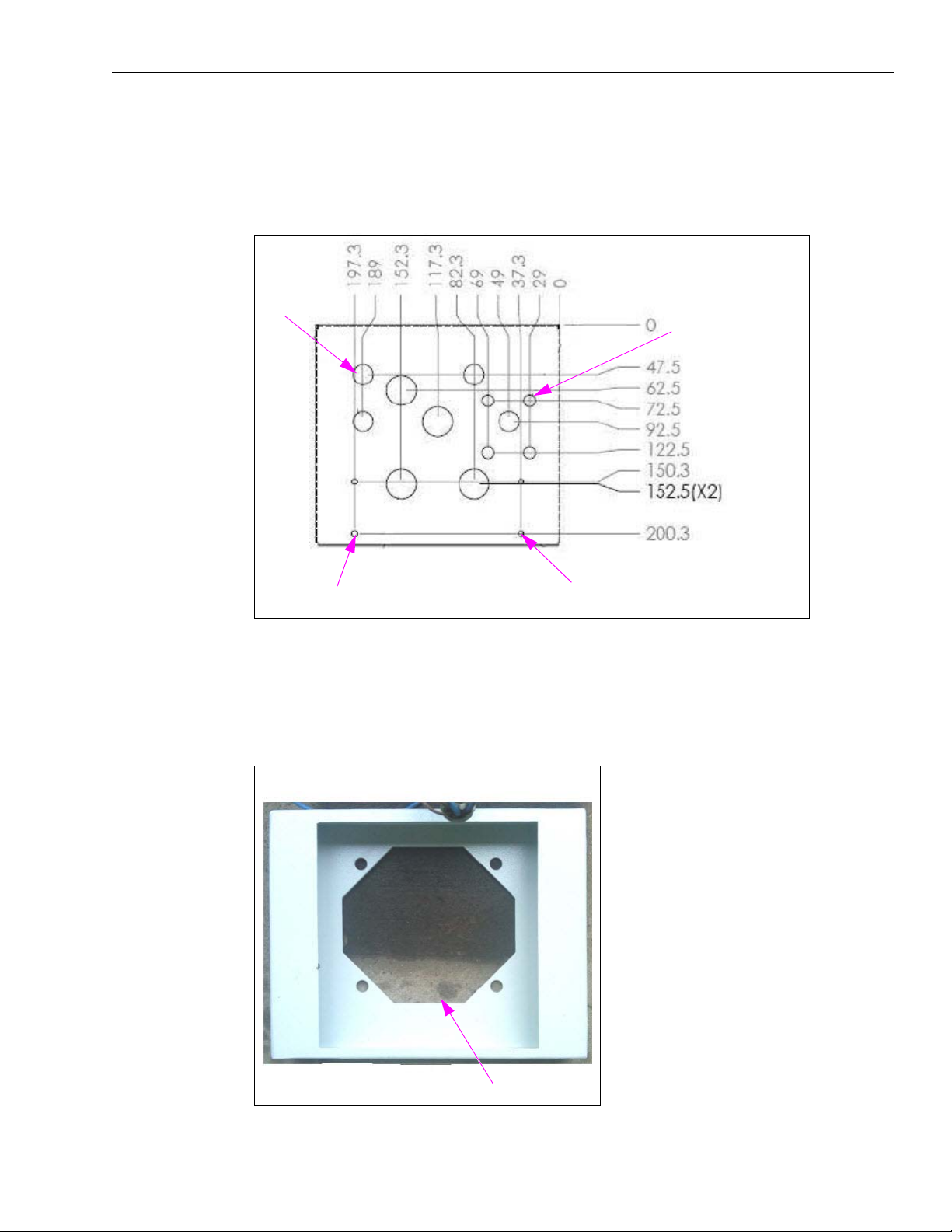

5 Make a template of the conduit configuration for the cutouts in the barrier plate. The cutouts in

the plate must only be cut large enough for the wiring to be pulled through. You will also want

to install conduit gaskets to prevent wire damage (see Figure 3-2).

Figure 3-2: Conduit Configuration in Barrier Plate

6 After the pedestal and conduit needs are addressed, place the base plate over the conduits,

wider side faced towards the front of the unit, and mark the island along the outside edge of the

base plate as well as the inside holes for the lag bolt placement (see Figure 3-3).

Figure 3-3: Base Plate on Conduits

MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013 Page 3-5

Page 16

Installing FedEx Islander PLUS FMS

Installing FedEx Islander PLUS FMS

To install the FedEx Islander PLUS FMS, proceed as follows:

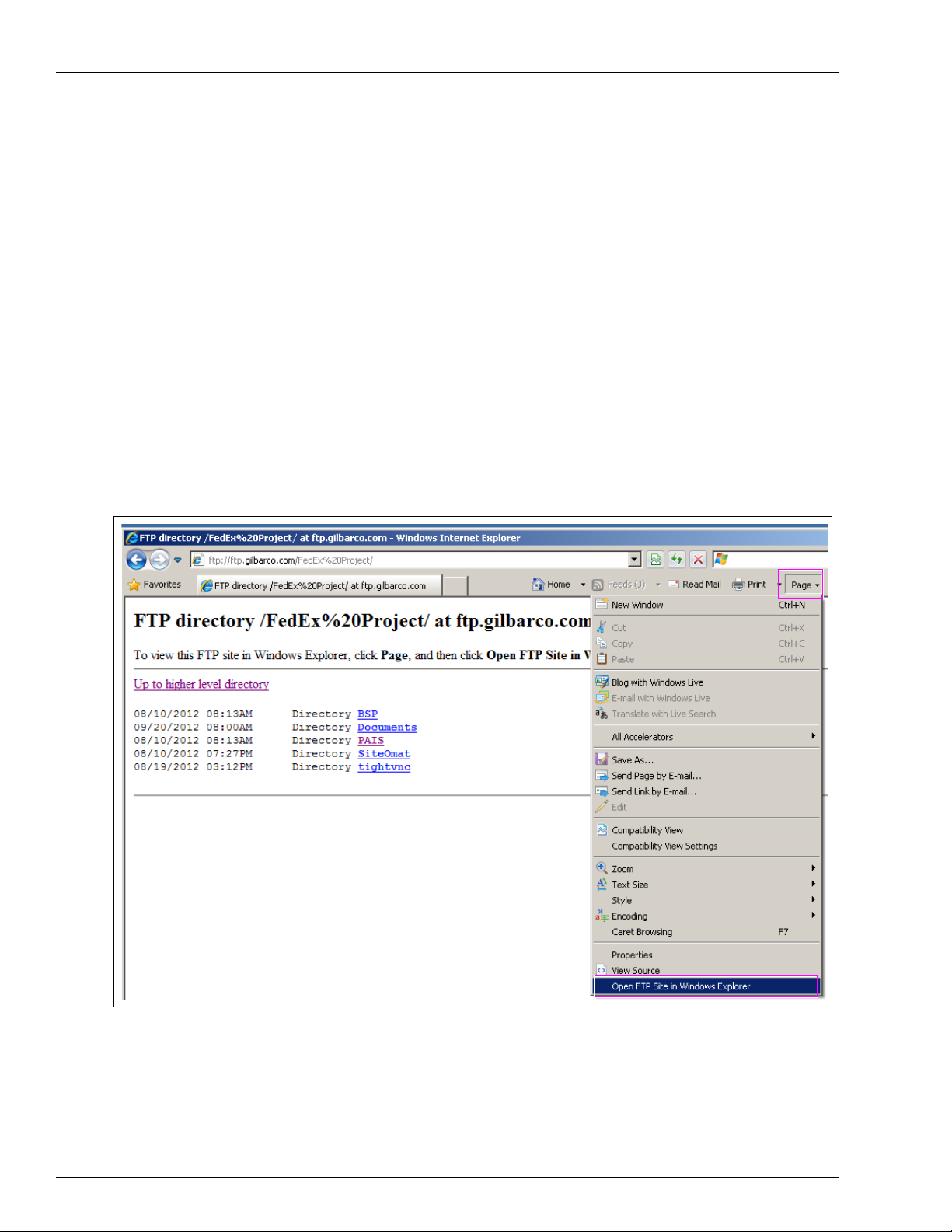

Downloading Software

To download the software, proceed as follows:

1 Download all software and documents required for installation:

•Site: ftp.gilbarco.com

• ID: -

• Password: -

Note: If the ID and Password are not known, contact Gasboy TAC at 1-800-444-5529.

2 Navigate to the FedEx folder and download the entire contents of this folder.

3 Click the Page button and select Open FTP Site in Internet Explorer

Figure 3-4: Opening FTP Site in Internet Explorer

®

.

Page 3-6 MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013

Page 17

Installing Islander PLUS

To install the Islander PLUS, proceed as follows:

1 After lag bolts are inserted in the island, position the base plate over the lag bolts, wide-side

facing front. The pedestal is then placed over conduit and into the base plate. To avoid

pinching wires, two technicians are required for this step. Tighten the nuts over the lag bolts to

secure to the island (see Figure 3-5).

Figure 3-5: Installing Islander PLUS

Installing FedEx Islander PLUS FMS

MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013 Page 3-7

Page 18

Installing FedEx Islander PLUS FMS

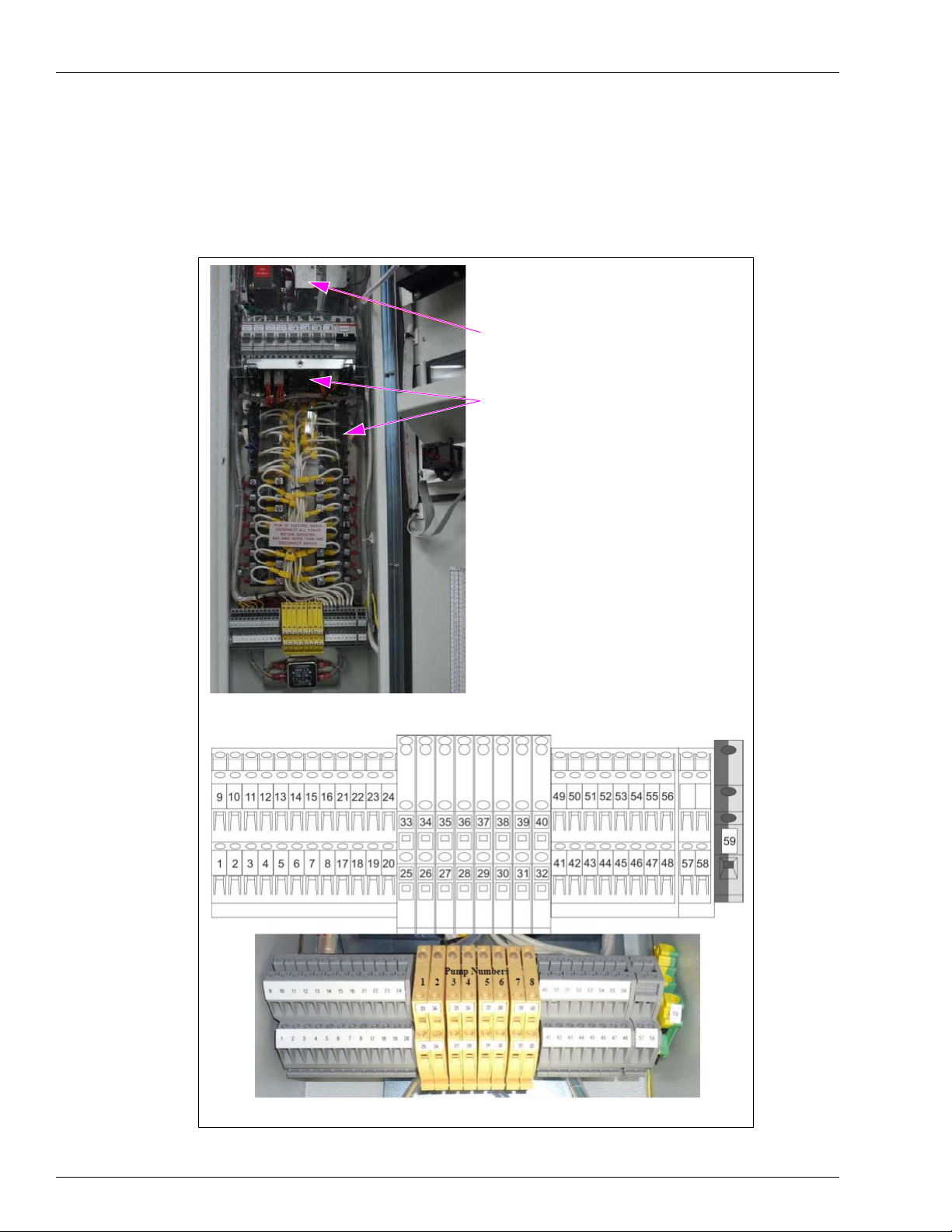

PCB Assembly P.S-24 VDC

[8-hose (M09680B083)]

PCB Assembly, SSR

[8-hose (M09680B084)]

(i)

(ii)

2 The control wiring must be attached to the Terminal Block after the pedestal is secure

(see Figure 3-6). System power, dispenser communication,

connected based on the Terminal

(see Figure 3-8 on page 10).

Figure 3-6: Connecting Control Wiring to Terminal Block

LAN, and so on, must be

Block diagram on the inside door of the pedestal

Page 3-8 MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013

Page 19

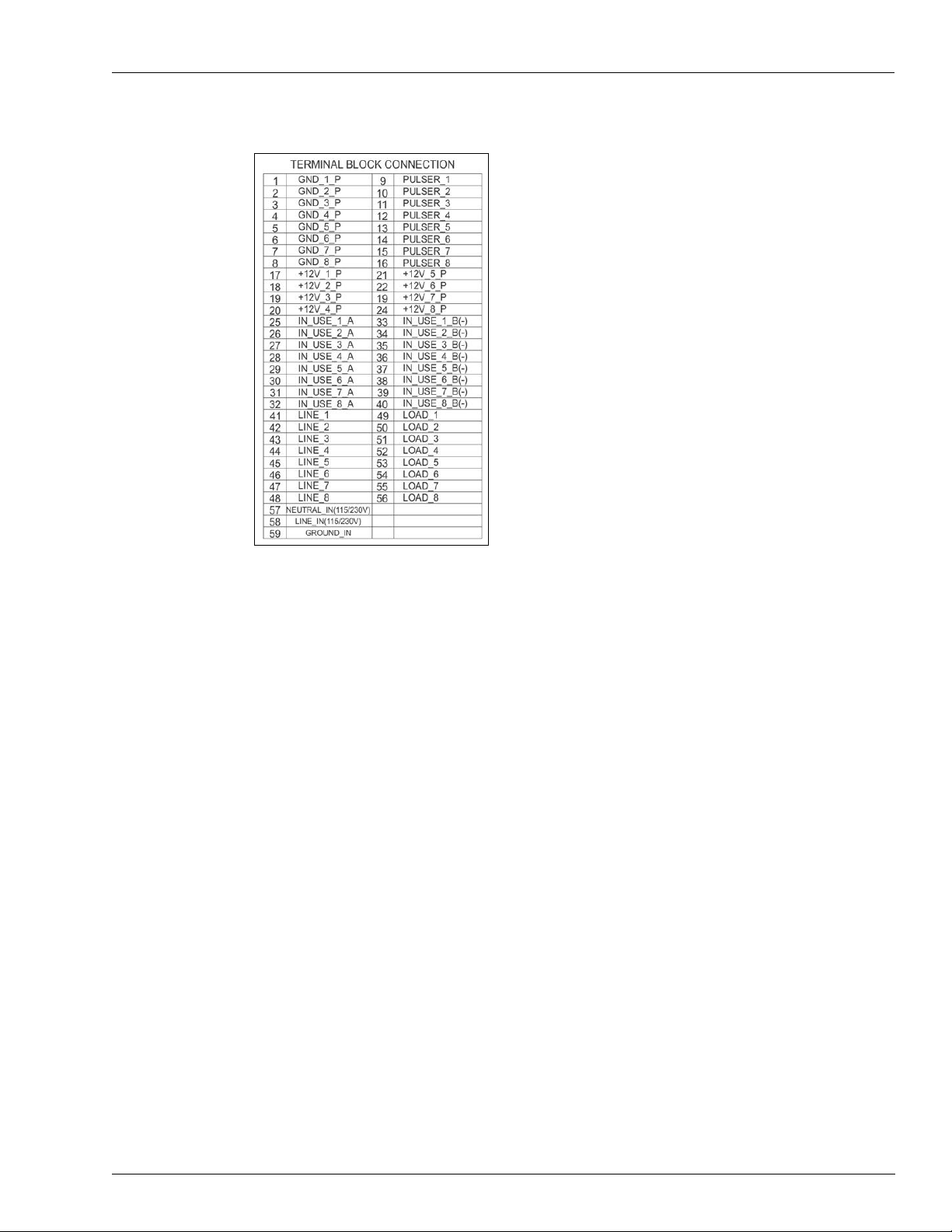

Figure 3-7: Terminal Block Connection

Installing FedEx Islander PLUS FMS

3 For pumps that are NOT Gasboy 9800’s, follow the wiring diagrams for electronic and

mechanical per your specific application.

MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013 Page 3-9

Page 20

Installing FedEx Islander PLUS FMS

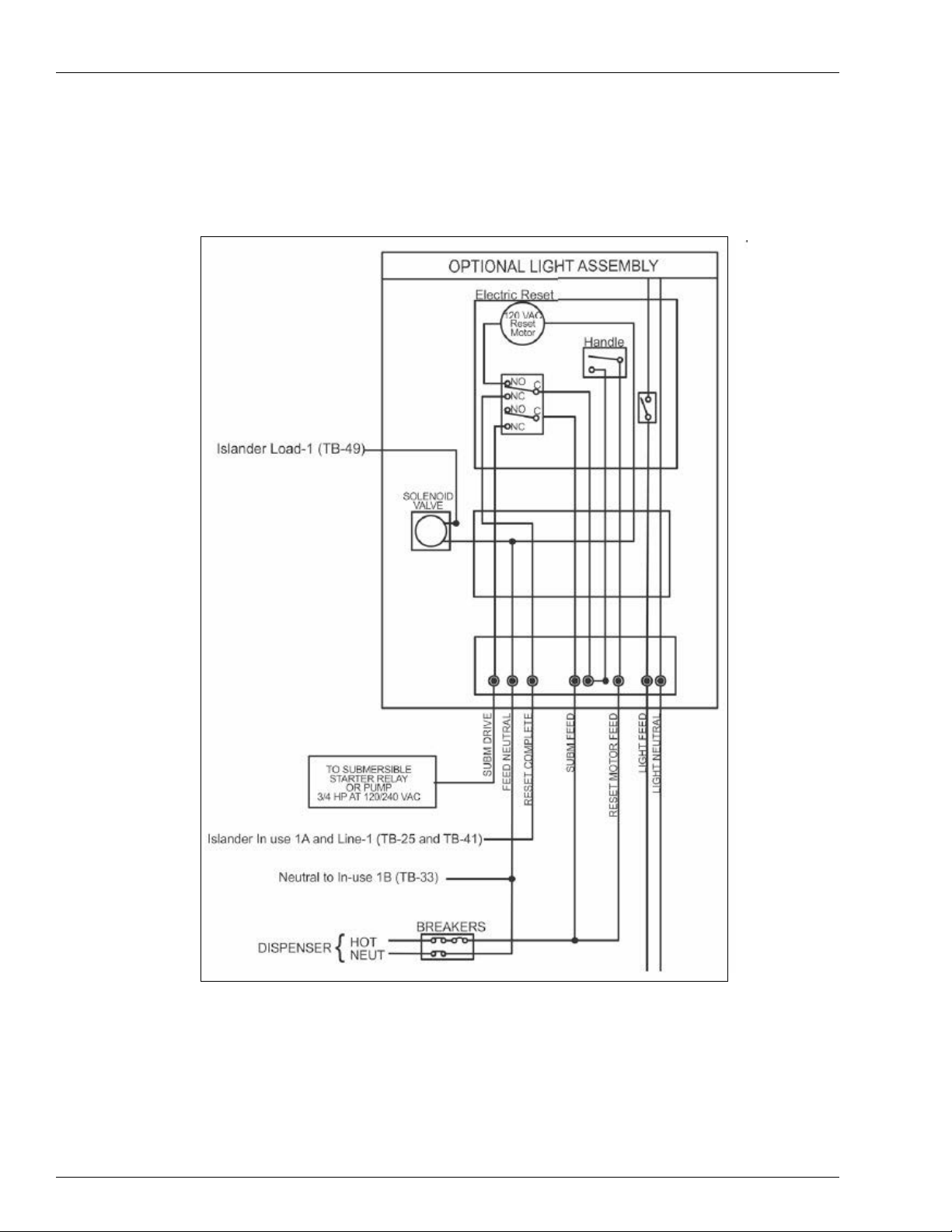

4 Mechanical dispenser: Note that instead of the solenoid lead tying to the Reset Complete wire;

it now connects directly to Terminal Block for the Gasboy PLUS. Also, note that the Reset

Motor and Submersible Feeds tie together in the junction box of the dispenser (see Figure 3-8).

Figure 3-8: Wiring Diagram - Mechanical Dispenser

Note: Reset Complete is the in-use line, this jumpers to line and the load line, which comes

back and run the solenoid valves. Pulse wires are polarized.

Page 3-10 MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013

Page 21

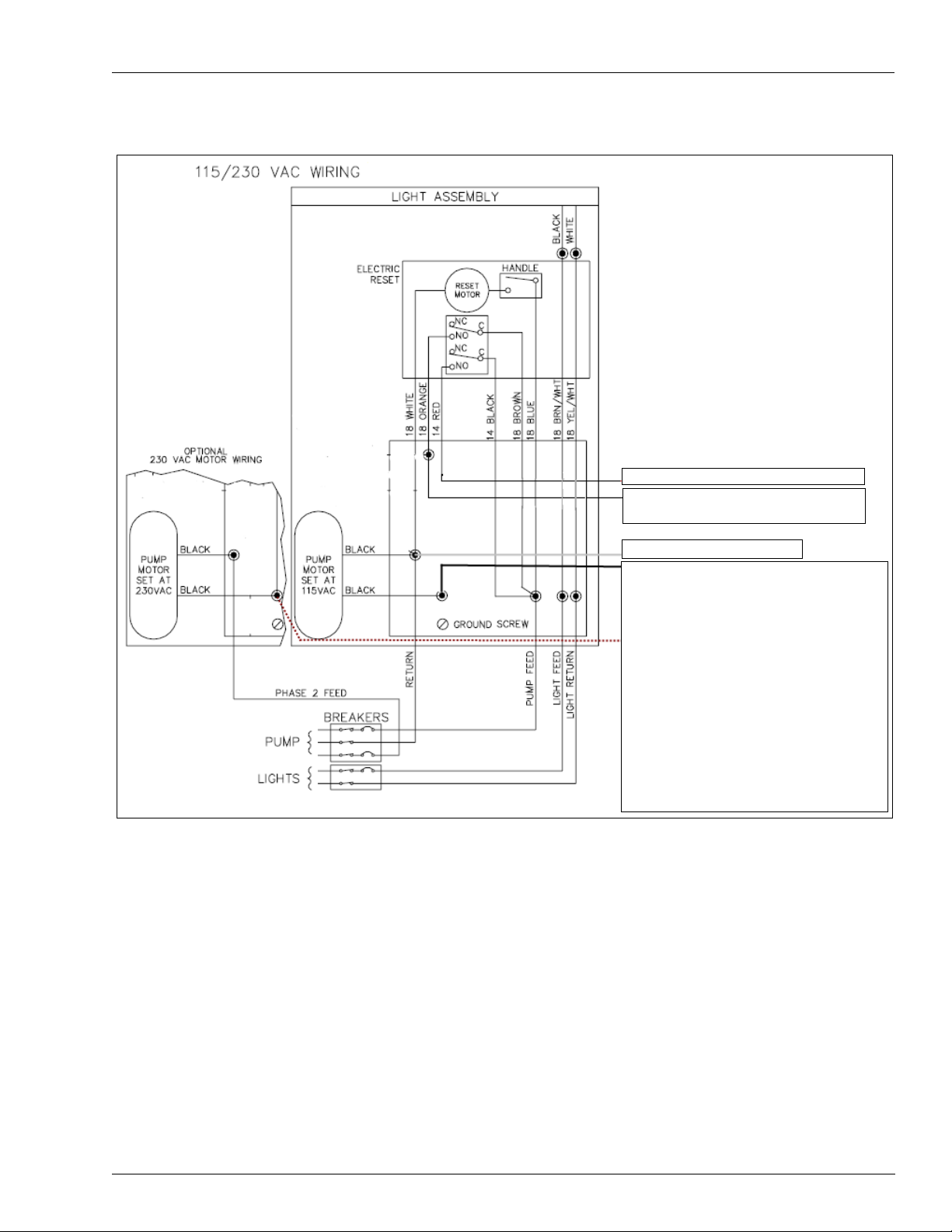

Figure 3-9: Mechanical Pump without Solenoid Valve

Disconnect from motor feed and cap wire.

Islander IN_Use_1A and Line (TB-25 and

TB-41)

Islander Load 1 (TB-49)

Pump Control Maximum Current

Pedestal with up to 4-hose mechanical pumps:

Motor Max: 1 HP @ 115 VAC

~OR~

2 HP @ 230 VAC

Additional relay must be used if pump motor

exceeds these limitations.

Pedestal with up to 8-hose mechanical pumps:

Motor Max: 3/4 HP @ 115 VAC

~OR~

1.5 HP @ 230 VAC

Additional external relay must be used if pump

motor exceeds these limitations.

Neutral to IN_Use 1B (TB-33)

Installing FedEx Islander PLUS FMS

MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013 Page 3-11

Page 22

Installing FedEx Islander PLUS FMS

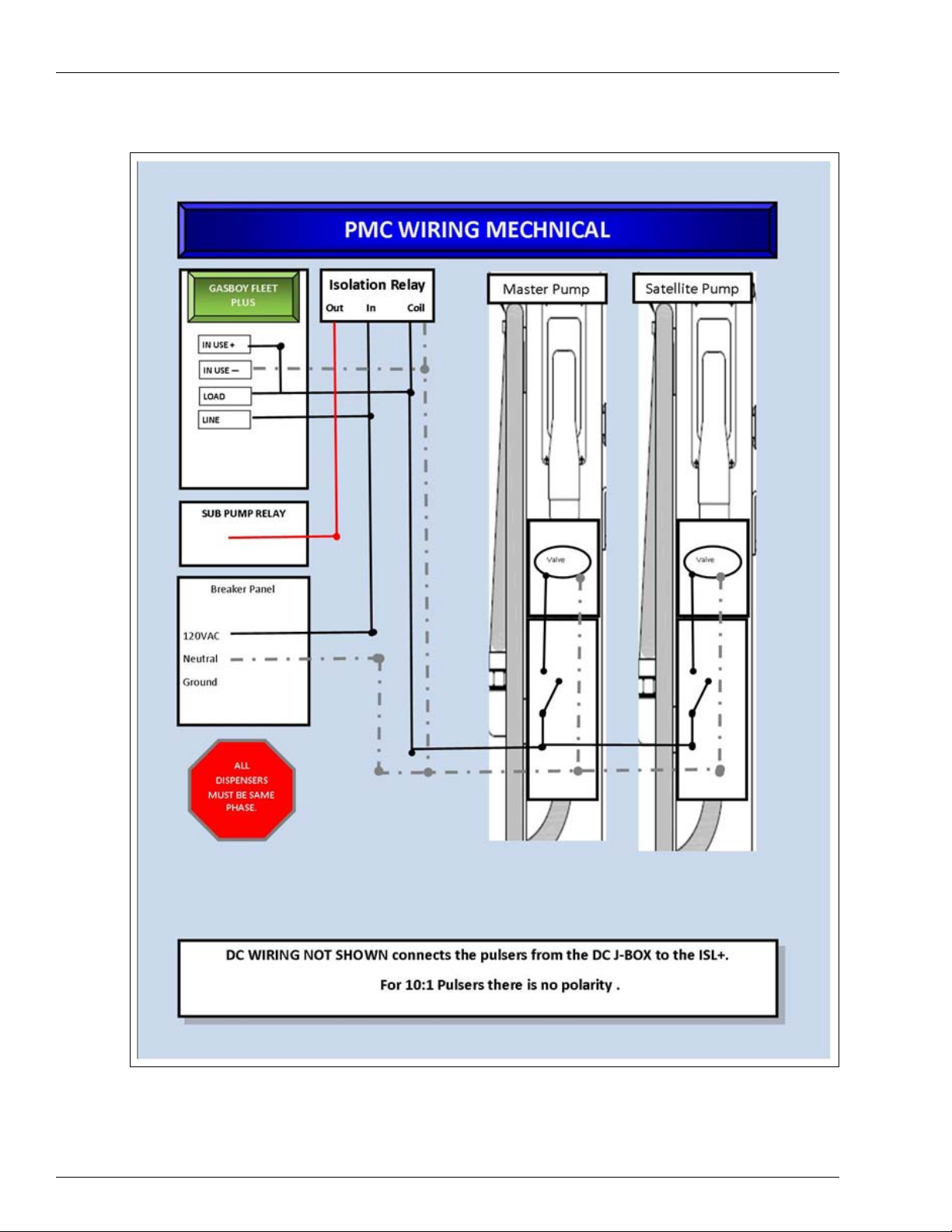

Figure 3-10: Mechanical Pumps On Stick - PMC Pumps

Page 3-12 MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013

Page 23

Figure 3-11: Hose Reels Using 24 V Solenoids

Installing FedEx Islander PLUS FMS

MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013 Page 3-13

Page 24

Installing FedEx Islander PLUS FMS

OrCU - Connect FedEx

WAN to LAN2

POE Adapter

Black Cable

“FedEx Islander PLUS FMS wireless networking equipment - DO NOT DISCARD”

This is a POE Adapter that FedEx Islander PLUS FMS uses for it wireless connections.

This will have a 12-24 V Power Adapter and an Ethernet connection. The black cable

shown in Figure 3-13 will commonly be found inside the existing FMS.

IMPORTANT INFORMATION

Connecting to FedEx Islander PLUS FMS Corporate Network

To connect to the FedEx Islander PLUS FMS corporate network, proceed as follows:

5 Locate the networking cable used in the existing FMS. Typical equipment is shown in

Figure 3-12 through Figure 3-14 on page 15. FedEx Islander PLUS FMS uses Power Over

Ethernet (POE) and fiber optics.

6 After you have located the WAN Cable, connect this to the LAN2 Port of the Orpak Controller

Unit (OrCU). The OrCU is located on the door of the 8-hose mechanical unit.

Figure 3-12: Connecting WAN Cable to LAN2 Port

Figure 3-13: POE

Page 3-14 MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013

Page 25

Installing FedEx Islander PLUS FMS

(i)

(ii)

Termination Box

Switch

7 FedEx Islander PLUS FMS also uses fiber optic termination boxes and switches for

connecting to the corporate network. These devices are shown in Figure 3-14.

Figure 3-14: Fiber Optic Termination Box and Switch

MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013 Page 3-15

Page 26

Installing FedEx Islander PLUS FMS

This page is intentionally left blank.

Page 3-16 MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013

Page 27

Software Set Up SiteOmat Software Set Up

LAN1 - Configure

software using 5-port

switch.

4 – SiteOmat Software Set Up

Software Set Up

FedEx Islander PLUS FMS installation requires specific software to support T-Check Fleet

Cards. FedEx uses only T -Check Fleet Cards in its fueling operati ons to authorize transactions.

T-Check Fleet Cards are processed as any credit cards.

Process Check

Before you begin to configure software, verify that the correct software versions are loaded in

the SiteOmat.

To configure the SiteOmat software, proceed as follows:

1 Connect your laptop and Ethernet Cable to the LAN1 Port next to the 8-port CommVertor

Board (see Figure 4-1).

Figure 4-1: Configuring SiteOmat Software

MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013 Page 4-1

Page 28

SiteOmat Software Set Up Software Set Up

2 Change the IP Address scheme on your laptop to align with the IP address scheme set in

OrCU. An IP 192.168.1.10 as your laptop IP will work (see Figure 4-2).

Figure 4-2: Setting IP Address

3 To log on to OrCU Administrator page, enter http://192.168.1.104:8090 in your browser. A

logon pop-up box appears.

4 Type the User name (as admin) and Password (as admin). See Figure 4-3.

Figure 4-3: Entering User Name and Password

5 Click OK.

Page 4-2 MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013

Page 29

Software Set Up SiteOmat Software Set Up

The OrCU Administrator home page appears (see Figure 4-4).

Figure 4-4: OrCU Administrator Home Page

6 In the home page, verify that the correct OrCU FW and SiteOmat Versions appear.

• OrCU FW Version: 1.08 (SP8)

• SiteOmat Version: 6.4.33.098

7 Click MODIFIED (see Figure 4-4) to open the versions page. Verify the PAIS Version

[4.31.1.58 (see Figure 4-5)].

Figure 4-5: Verifying PAIS Version

MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013 Page 4-3

Page 30

SiteOmat Software Set Up Software Set Up

OrCU Set Up

Before you begin verify you have SiteOmat WAN (LAN2) IP Address, Subnet Mask, and

Gateway IP Address. These are supplied on the FedEx Project Site Information Form.

To update the OrCU set up, proceed as follows:

1 Log into the OrCU Administration home page to see the IP, Net Mask, and MAC addresses of

both LAN ports. You will also notice the date and time of the system (see Figure 4-6).

2 Ensure that the softwares mentioned in step 6 on page 4-3 are installed before set up.

3 Click the Networking button (see Figure 4-6) to set the IP Address of LAN1 and LAN2. The

OrCU Networking screen appears as shown in Figure 4-6.

Figure 4-6: OrCU Networking Screen

Page 4-4 MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013

Page 31

Software Set Up SiteOmat Software Set Up

4 Verify the LAN1 Network settings:

• IP: 192.168.1.104

• Mask: 255.255.0.0

• MAC: default setting (do not change)

Figure 4-7: V erifying LAN1 Network Settings

5 Set the LAN2 Network Settings according to the information supplied by FedEx in the FedEx

Project Site Information Form.

Column Name

Network Settings

IP OrCU Lan 2 IP Address

Mask OrCU Lan 2 Subnet Mask

MAC Default setting (do not change)

Gateway (GW)* OrCU Lan 2 GW (Gateway)

* Failure to set the gateway results in the

6 Set the Primary and Secondary Domain Name System [DNS (see Figure 4-7)], if provided.

Note: This is not currently used but may be implemented

7 Click the Save networking settings button, the notification text appears (see Figure 4-8).

Figure 4-8: Saving Networking Settings

(from where the data must be added)

inability t

o connect to the SiteOmat.

in the near future.

MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013 Page 4-5

Page 32

SiteOmat Software Set Up Setting SiteOmat

Ensure all fueling activities are stopped at the island before applying the time settings.

IMPORTANT INFORMATION

8 Click the Apply Changes button to save the changes and power cycle the unit to activate the

new networking settings.

Figure 4-9: Applying Changes

9 Click the Time button to set the local Time, Date, and Time Zone information. The OrCU

Time Setup screen appears (see Figure 4-10).

Figure 4-10: Setting Time, Date, and Time Zone

10 In the OrCU Time Setup screen (see Figure 4-10), set the following:

• Time - Based on a 24-hour clock.

• Date - Format is DD/MM/YYYY.

• Time Zone - Set to Central for all sites.

11 Click the Change time settings button (see Figure 4-10).

12 On the System Information webpage, click the Reboot button to reboot OrCU.

~OR~

Power

cycle the SiteOmat.

Setting SiteOmat

To set the SiteOmat, proceed as follows:

1 Verify that the PC connection to the SiteOmat has the following:

• Operating System (OS) - Microsoft Windows

• Microsoft Internet Explorer 7 or later.

• Sun Microsystems Java

Note: Upgrade to the latest Java version if you experien

SiteOmat webpages (visit http://java.com).

™

application.

®

2000/XP®/2003/Win7.

ce any display issues with

Page 4-6 MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013

Page 33

Setting SiteOmat SiteOmat Software Set Up

2 Enter https://192.168.1.104 in your browser to login to the SiteOmat webpage. The SiteOmat

Login screen appears (see Figure 4-11).

3 Type the User (as Admin) and Password (as Admin), and click Login (see Figure 4-11).

Figure 4-11: Entering Username and Password

The Pump Status screen of the SiteOmat appears.

• FedEx sites will have a default set up file loaded, there is no need t

• Default configuration - Status screen (see Figure 4-12).

- 4 - Mechanical pumps

irtual in use enabled - Nozzle points up

- V

- All pumps are blocked - Black pump head

Figure 4-12: Pump Statu s Screen

o run the wizard.

MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013 Page 4-7

Page 34

SiteOmat Software Set Up Setting SiteOmat

4 Click the Setup button. The Setup screen appears (see Figure 4-13).

Figure 4-13: Setup Screen

5 Click the Advanced Mode button to continue (see Figure 4-14). The screen as shown in

Figure 4-15 appears.

Figure 4-14: Selecting Advanced Mode

Figure 4-15: Setup Screen

6 Click the Global tab to open the Station Parameters screen.

Page 4-8 MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013

Page 35

Setting SiteOmat SiteOmat Software Set Up

The Global Station Parameters screen appears (see Figure 4-16).

Figure 4-16: Station Parameters Screen

MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013 Page 4-9

Page 36

SiteOmat Software Set Up Setting SiteOmat

7 Set the following in the Station Parameters screen (see Figure 4-17):

• Description - Add the station description (stati

on name), which is available in the

SiteOmat Station Description column of the FedEx Project Site Information Form.

Note: Memphis as example: FXFMEM (FXF is FedEx Islander P

LUS FMS and MEM is

the location code).

• Code - Add the station code, which is available in the Sit

eOmat Station Code column of

the FedEx Project Site Information Form.

• City - Enter station city.

• Date format - Click the drop-down list from

Figure 4-17: Station Parameters Setting

Date format and select MM/DD/YYYY.

Page 4-10 MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013

Page 37

Setting SiteOmat SiteOmat Software Set Up

8 In the General section (see Figure 4-18), enter the following:

• User Inactivity timeout - Set this to 60

seconds.

• Zero transactions - Select 5 from the drop-down list.

• Authorization Timeout - Set this to 60 seconds.

Figure 4-18: Global Parameters Section

9 Click the Save button to save the changes. A pop-up Processing box will display for few

seconds while saving (see Figure 4-19).

Figure 4-19: Global Parameter Processing

MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013 Page 4-11

Page 38

SiteOmat Software Set Up Setting SiteOmat

10 In the Global screen, click the Advanced button.

Figure 4-20: Selecting Advanced Parameter

Page 4-12 MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013

Page 39

Setting SiteOmat SiteOmat Software Set Up

The Advanced Station Parameters screen appears with the advanced options (see Figure 4-21).

Figure 4-21: Advanced Station Parameter

11 In the Formats section, set the Decimal point precision for volume to 2 (see Figure 4-21).

12 In the Payment Terminal section, click Setup. The Setup PAIS screen appears

(see Figure 4-22).

Figure 4-22: Setup PAIS Page

MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013 Page 4-13

Page 40

SiteOmat Software Set Up Setting SiteOmat

Local Product Codes

set in the SiteOmat

13 Change the following on the Setup PAIS screen (see Figure 4-22 on page 4-13):

• Timeout - Set this to 45 seconds, this is

• Card may not be reused within - Set this to 0 mi

the time allowed to contact the host network.

nutes, which allows the same card to be

used again for oil or Diesel Exhaust Fluid (DEF) to be dispensed.

• Pre-authorize amount - Set this to $400.

• Credit processor - Select T-C

• Device Port - Enter the Device Port, which is available in the

heck from the drop-down list.

Fipay Port Number column

of the FedEx Project Site Information Form.

• Device IP - Enter the Device IP, which is available

in the Fipay Server IP Address column

of the FedEx Project Site Information Form.

14 Click the ProductMap button to map the local product codes that you have loaded into the

site to those which are predetermined by network processor. The Translate Product Codes

screen appears (see Figure 4-23).

Figure 4-23: Translate Product Codes

15 Verify that T-Check is available in Translation group drop-down list.

Page 4-14 MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013

Page 41

Setting SiteOmat SiteOmat Software Set Up

16 Set the following in the Translate Product Codes screen based on the table:

• Product name - code: Select local product loaded in the Islander PLUS

system from the

Product name - code drop-down list.

• External code: Enter the correspon

ding network code for the local product set in the

Product name - code box.

External code Product name - code

62 DEF - 2000

63 Oil - 1

99 Diesel - 1200

Note: Repeat step 16 to add product codes.

17 After completing the entries, click OK to save (see Figure 4-23 on page 4-14); click Cancel to

exit the screen without saving.

18 Verify that the Daily run enabled check box is not selected (see Figure 4-22 on page 4-13).

19 Click the Save button (see Figure 4-21 on page 4-13) to save your changes and return to the

Station Parameters screen with the advanced options.

Figure 4-24: Setting Station Parameter

20 Click the Modify button to save the changes and return to the Global tab (see Figure 4-24).

21 From the Global tab (step 12 on page 4-13), click the Save button.

MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013 Page 4-15

Page 42

SiteOmat Software Set Up Setting SiteOmat

(i)

(ii)

22 Click the Forecourt tab.

Figure 4-25: Selecting Forecourt

23 Before you continue, click the Save or Reload button to load the new configuration changes

into the system in the Forecourt tab.

Figure 4-26: Configuring Forecourt Tab

Clicking the Reload button displays a pop-up box as shown in Figure 4-27.

24 Click OK when reloading is complete.

Figure 4-27: Reloading SiteOmat Process

Page 4-16 MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013

Page 43

Pump Configuration SiteOmat Software Set Up

Pump Configuration

To configure the pumps, proceed as follows:

1 To verify the pump configuration, click the Setup button from the status screen

(see Figure 4-28).

Figure 4-28: Verifying Pump Configuration

2 Click ... [ellipse (see Figure 4-28)]. The Setup Pump Settings screen appears.

Figure 4-29: Setup Pump Settings - General

3 In the General section, verify the following (see Figure 4-29):

• Pump Number - This is the number of the pump.

• Pump Head - For example, Pump Head is 1 for the first pump on th

e cluster and 2 for the

second pump on the cluster.

• Number of nozzles - For example, Number of nozzles will always be 1.

•

Mode - Select Need

Authorize from the drop-down list.

• Pump server - Select PumpServer from the drop-down list.

•

Cluster - Set 1 for the first two master pumps, 2 for the next two master pumps

.

MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013 Page 4-17

Page 44

SiteOmat Software Set Up Pump Configuration

Following table shows the Cluster information for Mechanical Pumps.

Pump # Head Cluster

111

221

312

422

513

623

• Orpak Payment Terminal (OrPT) - Select ORPT from the drop-down list.

Note: This setting causes beeps at the isl

Figure 4-30: Verifying Pump Server - Message Factors

and when a ring or tag is read and authorized.

4 In the Message Factors section, verify that the details are set as shown in Figure 4-30.

• If transaction amount and volume are not being recorded properly this setting may need to

be

changed.

• Do not change until the Pulse Factor and DIP switches

Figure 4-31: Verifying Mechanical Pump - Card

have been verified and corrected.

Page 4-18 MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013

Page 45

Pump Configuration SiteOmat Software Set Up

(i)

(ii)

The More Options button is not used for FedEx Islander PLUS FMS installations.

IMPORTANT INFORMATION

5 In the Specific section, verify the following is set up for the installed pumps

(see Figure 4-31 on page 4-18).

• Pulser Type - Select Half Cycle Count Pu

• Pulse Factor - Enter the correct setting for the inst

lse from the drop-down list.

alled pumps (as 10 or 100).

- 10 - 10:1 Pulser on PUMP

- 100 - 100:1 Pulser on PUMP

• Virtual In Use - Select Enable when a

handle switch is not available and select Disable at

all other times.

- This is always required for hose

- This is required for some dispensers (PMC Pu

reels for oil and lubricants.

mps) without proper handle-switch wires.

• Flow Protection timeout - Set this to 70 seconds.

Note: Flow protection timeout controls the active tim

e (70 seconds) of the Virtual In Use

after pulses stop.

6 Repeat steps 1 (on page 4-17) to 5 for all pumps and oil reels.

7 To save the pump configuration settings, click Save, the Setup screen appears.

Figure 4-32: Saving Pump Configuration

8 In the Setup screen, click Save (see Figure 4-32).

9 To load new configuration changes into the system, click Reload, a pop-up box appears as

shown in Figure 4-33 (i).

10 Click OK when reloading is complete [see Figure 4-33 (ii)].

Figure 4-33: Reloading Configuration

MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013 Page 4-19

Page 46

SiteOmat Software Set Up Tank Configuration

Ta nk Configuration

To configure the tanks, proceed as follows:

1 To verify the tank configuration, from the status screen click the Setup button

(see Figure 4-34), the Setup screen appears.

Figure 4-34: Setup Screen

2 To view the additional options, click the Advanced Mode button.

Figure 4-35: Selecting Advanced Mode

Page 4-20 MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013

Page 47

Tank Configuration SiteOmat Software Set Up

3 In the Setup screen, select the Forecourt > Tanks tab (see Figure 4-36). The Setup Tanks

screen appears (see Figure 4-37)

Figure 4-36: Setup Screen - Tanks Tab

Figure 4-37: Setup Tanks Screen

4

In the Setup Tanks screen, verify that the following Tanks are set up.

Capacity

Description Number

Tank_1 1 20000.00 Diesel

Tank_2 2 55.00 Oil

Tank_3 3 5000.00 DEF

MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013 Page 4-21

(in Gallon) Fuel Type

Page 48

SiteOmat Software Set Up Tank Configuration

5 To verify that the products are set up, in the Tank Properties section, click the Products button

(see Figure 4-37 on page 4-21). The Setup Fuel Products screen appears (see Figure 4-38).

Figure 4-38: Setup Fuel Products Screen

6

Verify that the following Names (fuel types) are set up with the Codes.

Name Code

Oil 1

Diesel 1200

DEF 2000

Page 4-22 MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013

Page 49

Setting Fuel Price SiteOmat Software Set Up

Setting Fuel Price

To set the fuel price, proceed as follows:

Pricing must be loaded for the pumps to properly op

erate. Use $1.00 for all products at this

time.

1 From the status screen, click the Wet Stock Mgmt button (see Figure 4-39), the Wet Price

screen appears (see Figure 4-40).

Figure 4-39: Selecting Wet Stock Management

2 From the Wet Price screen, click the Price Update tab. The available products screen appears

(see Figure 4-40).

Figure 4-40: Verifying Price Update

3 Click the name of the Product that you want to change (for example, change the price of

Diesel).

Figure 4-41: Modifying Price Update

4 Enter the updated price in the Price Update field (for example, $1.000).

5 Select the Update price now check box, click the Modify button to update the price.

MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013 Page 4-23

Page 50

SiteOmat Software Set Up Unblocking or Activating Pumps

Pumps Status Screen

Pumps Setup Screen

(i)

(ii)

Unblocking or Activating Pumps

To unblock or activate pumps, proceed as follows:

After the SiteOmat is configured, unblock or activate the pumps/oil reel

s that are on the site.

All the pumps not being used will remain blocked.

1 Determine the pumps/reels that need to be activated and identify how they are numbered.

• For example, the island has tw

o master pumps with satellites and one oil reel.

• Master and satellites are numbered 1 and 2.

• Oil reel is numbered 4.

2 In this example, Pumps 1, 2, and 4 are active. Pump 3 is blocked.

• For example, Status screen [see Figure 4-42 (i)]

• For example, Setup screen [see Figure 4-42 (ii)]

Figure 4-42: Setup and Status Screen of Pump

3 On the Pump Status screen, right-click the pump that you want to unblock and select the

Unblock pump option from the list.

Note: Right-clicking at the black rectangle of the pump w

Figure 4-43: Unblocking Pump

Page 4-24 MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013

orks best.

Page 51

Unblocking or Activating Pumps SiteOmat Software Set Up

If unsure which dispensers to unblock or which additional pumps to add, call Gasboy

Technical Support at 1-800-444-5529.

IMPORTANT INFORMATION

4 To activate the pump, in the Setup screen, select the Active check box for the pump that you

want to activate (see Figure 4-44).

Note: For example, only Pump 1 is active

Figure 4-44: Activating Pump

in the following screen.

MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013 Page 4-25

Page 52

SiteOmat Software Set Up Weights & Measures (W&M) Dongle Activation Procedure

Mechanical pumps will not authorize if the W&M Dongle is NOT installed and set up.

IMPORTANT INFORMATION

Weights & Measures (W&M) Dongle Activation Procedure

To activate the W&M Dongle, proceed as follows:

1 Verify that the W&M Dongle is installed in OrCU.

Figure 4-45: W&M Dongle Installation

2 To log on to OrCU Administrator screen, enter https://192.168.1.104:8090 in your browser. A

logon pop-up box appears (see Figure 4-46).

Figure 4-46: OrCU Admin Login Dialog Box

Page 4-26 MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013

Page 53

Weights & Measures (W&M) Dongle Activation Procedure SiteOmat Software Set Up

3 Enter User name (as admin) and Password (as admin).

4 Click OK. The OrCU Administrator home page appears (see Figure 4-47).

Figure 4-47: OrCU Administration Home Page

5 Click the Serial/Modem button (see Figure 4-48), the OrCU Serial/Modem setting screen

appears (see Figure 4-49 on page 4-28).

Figure 4-48: Serial/Modem Setup

MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013 Page 4-27

Page 54

SiteOmat Software Set Up Weights & Measures (W&M) Dongle Activation Procedure

Figure 4-49: OrCU Serial/Modem Settings

6 In the OrCU Serial/Modem settings screen, perform the following:

• Select the Use port for External Devices (TLG) (Com2) button.

• Click the Set Serial/Modem s

After clicking the Set Serial/Modem settings

ettings button.

button, the following notification appears

(see Figure 4-50).

Figure 4-50: Serial/Modem Warning Screen

7 Power cycle Islander PLUS unit for the changes to take effect. Power cycle takes 2 to 3

minutes to complete.

Page 4-28 MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013

Page 55

Weights & Measures (W&M) Dongle Activation Procedure SiteOmat Software Set Up

8 Verify that the W&M Dongle is activated. The pulse factor drop-down list will no longer be

present on the Setup screen.

Figure 4-51: Setting Pulse Factor

Process Check

After the wiring connections have been made, test the dispensers using the bypass switches on

the Terminal Block.

MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013 Page 4-29

Page 56

SiteOmat Software Set Up Synchronizing with Fleet Head Office (FHO)

Synchronizing with Fleet Head Office (FHO)

Head Office Communicator (HOCOMM) user is added to communicate to the FHO. This user

is automatically added from the Setup screen.

HOCOMM User

To verify that the HOCOMM user is added to communicate to the FHO, proceed as follows:

1 From SiteOmat Status screen, click the Admin button. The Users SiteOmat screen appears

(see Figure 4-52).

Figure 4-52: SiteOmat Status Screen

2 Verify that the HOCOMM user is displayed in the list of users.

Page 4-30 MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013

Page 57

Synchronizing with Fleet Head Office (FHO) SiteOmat Software Set Up

3 If the HOCOMM user does not exist, proceed to step 4 and add the HOCOMM user.

Figure 4-53: Adding HOCOMM User

4 Click the New button to add a user, the User properties screen appears (see Figure 4-54).

Figure 4-54: User Properties

5 Set the User Properties as follows (see Figure 4-54):

• Login name - Set the login name as HOCOMM (all capital letters).

• Password - Set the password as 123456.

• Confirm password - Enter the same password

• User is part of group - Select HO Com

6 Click the OK button to save the User Properties.

municator from the drop-down list.

(as 12345).

MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013 Page 4-31

Page 58

SiteOmat Software Set Up Synchronizing with Fleet Head Office (FHO)

HOCOMM User Added

After saving the user properties, the newly added HOCOMM user displays in the list of users

(see Figure 4-55).

Figure 4-55: Verifying HOCOMM User

Synchronizing FedEx Islander PLUS FMS

To synchronize the FedEx Islander PLUS FMS, proceed as follows:

7 After completing hardware installation and software configuration, contact Travis Langston

(or delegated person) at 1-870-704-5230 to begin the syncing process.

8 Provide the FedEx Location Name information when calling for a download.

9 End User set up.

At this time… End Users will not have access to the FHO or SITE application. All

access will

be controlled specifically by the FedEx headquarters.

Page 4-32 MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013

Page 59

Test Sequences SiteOmat Software Set Up

Test Sequences

After completing hardware installation and software configuration, test each pump and verify

transaction details.

Testing Procedure for Pumps

To test the pumps, proceed as follows:

1 Verify the fuel price has been downloaded to the SiteOmat from the FHO and is set to $1.000.

2 Ensure pumps are no longer in bypass mode.

3 Run a transaction using a T-Check Card. Record the transaction information and verify the

following:

• Transaction information is captured correctly in the S

• Quantity is recorded correctly and

• Correct pump numbers and nozzle numbers are dis

matches the pump.

iteOmat Status screen.

played in the SiteOmat Status screen.

Finalizing Installation

To ensure that the installation is complete, the Gasboy Fleet PLUS system must be online and

communicating with the FHO, and all the dispensers and satellites must be online and

operational.

Commission all serialized equipment (Islander

Installation Service Request with Gilbarco Claims. Have this information available before

communicating. You are also expected to commission and close the installation with Gilbarco

Claims before leaving the facility.

PLUS and FiPay Server) to close the

MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013 Page 4-33

Page 60

SiteOmat Software Set Up Finalizing Installation

This page is intentionally left blank.

Page 4-34 MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013

Page 61

Appendix A: Commissioning

*All installations for the FedEx Islander PLUS FMS require signed verification that the

installation is complete and the customer is satisfied. Per the ASC Notification Letter, no

payment will be remitted to the installer until required documentation is received.

AC Power confirmed to be within specification. T est at Idle. For more information, refer to “Pre-installation

Power Inspection” on page 3-1.

Neutral to Ground: measured at: ______________ (fill in value).

Hot to Ground: measured at: ______________ (fill in value).

Hot to Neutral: measured at: ______________ (fill in value).

AC Power confirmed to be within specification. Test at load (ALL PUMPS ON). For more information,

refer to “Pre-installation Power Inspection” on page 3-1.

Neutral to Ground: measured at: ______________ (fill in value).

Appendix A: Commissioning

Hot to Ground: measured at: ______________ (fill in value).

Hot to Neutral: measured at: ______________ (fill in value).

Fleet Manager trained in operation and manual bypass.

FiPay Server ground cable installed.

Program the SiteOmat.

Reboot SiteOmat.

Pumps and oil reels blocked and unblocked as needed.

Set up networking in the FiPay Server.

Set up T-Check information in the FiPay Server.

Perform all tests per the “Test Sequences” on page 4-33.

Commission equipment with Gilbarco claims via the Gilbarco extranet

(http://www.gilbarco.com/interactive/login.cfm), log into your account. If you do not currently have access

to the extranet, see your company gatekeeper for a username and password.

The Gasboy Fleet Plus system is operational and equipment has been commissioned with the

Gilbarco Claims Department.

Signature of Installer: _______________________________________________

ature of Fleet Manager/Director: ________________________________

Sign

Date: ___________________________

MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013 Page A-1

Page 62

Appendix A: Commissioning

This page is intentionally left blank.

Page A-2 MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013

Page 63

Installing Multiple Controller FedEx Islander PLUS FMS Appendix B: Multiple Controller Sites

(i) In the SiteOmat, if Pumps 2 and 4 are blocked, Pumps are wired at slots 1 and 3 in the Terminal Block.

(ii) In the SiteOmat, if Pumps 1 and 3 are blocked, Pumps are wired at slots 2 and 4 in the Terminal Block.

Oil Reel # 3

Pump # 1

Pump # 2

Oil Reel # 4

Appendix B: Multiple Controller Sites

Installing Multiple Controller FedEx Islander PLUS FMS

To keep pump numbering consistent with the existing scheme, extra pumps need to be added

to the system. Unused pumps will be blocked in the SiteOmat.

For example,

• A site has two Islander PLUS system

• There are two islands each with an Islander PLUS

• Pumps are numbered 1 - 2. Oil reels are numbered 3 - 4.

Figure B-1: Pump Statu s - SiteOmat and Terminal Block

s and two pumps and oil reels.

controlling, a pump and an oil reel.

MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013 Page B-1

Page 64

Appendix B: Multiple Controller Sites Gasboy 9800 Series Pumps Business Inventory Reconciliation (BIR) Set Up

Gasboy 9800 Series Pumps Business Inventory Reconciliation (BIR) Set Up

Gasboy 9800 Series pumps need to be wired as mechanical pumps to maintain the BIR

interface to the tank gauge as shown in Figure B-2 and Figure B-3 on page B-3.

Figure B-2: Gasboy 9800 Series Pumps BIR Set Up - 1

Page B-2 MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013

Page 65

Gasboy 9800 Series Pumps Business Inventory Reconciliation (BIR) Set Up Appendix B: Multiple Controller Sites

Figure B-3: Gasboy 9800 Series Pumps BIR Set Up - 2

MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013 Page B-3

Page 66

Appendix B: Multiple Controller Sites Gasboy 9800 Series Pumps Business Inventory Reconciliation (BIR) Set Up

This page is intentionally left blank.

Page B-4 MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013

Page 67

Appendix C: FedEx Project Site Information Form (Example Only)

FedEx Project Site Information Form

Following is the necessary information about the installation of 8 HOSE ISL+ w/FiPAY system for Federal Express Freight. You will be

provided a play book with all the necessary instruction that along with this information will allow you to successfully complete the

installation.

Take a few moments before you go to the site to read through this as well as the playbook. If you have any questions or concerns, do not

hesitate to call us so we can work through them before the day of installation.

GVR Site ID - 125644

Site Specific Information (You will need a separate one of these for each ISL + units).

OrCU Lan

2 IP

Address

OrCU Lan 2

Subnet

Mask

OrCU Lan

2 GW

(Gateway)

SiteOmat

Station

Description

SiteOmat

Station

Code

Fipay

ALPHA

Code

Fipay

Port

No.

Fipay

Server IP

Address

Fipay Server

Subnet Mask

Fipay

Server

Gateway

Fipay

Site

No.

xx.x.x.xx xxx.xxx.xxx.x xx.x.x.x xxxxxxx xxxxxx xxx xxxxx xx.x.x.xx xxx.xxx.xxx.x xx.x.x.x xxxxx

Note: This table is ONLY a sample.

Tasks to Perform While On-site

Inspect site for any obvious problems with Wiring, Hoses, Nozzles and so on. Alert Project Manager immediately in the event

issues are found you feel will not allow you to complete the project at this time.

Verify proper operation of existing equipment.

Verify E-Stop is working properly.

Verify you have all required Equipment/Tools/Supplies/Personnel to complete the work before you begin.

De-energize all power to existing island card reader and remove existing FMS system.

Clearly mark all wiring to existing system.

Install new ISL+ unit and wire.

Install FiPAY server retrofit kit into ISL+ unit.

Power up unit and program unit as per Playbook.

Verify proper operation.

Train on-site personnel on proper operation.

Important Contact Information

Gilbarco/Gasboy FedEx Freight Corporate Offices

Bob Griffith - 1.336.547.5654

Gasboy TAC - 1.800.444.5529

Travis Langston - 1.870.704.5230

Justin Hudson - 1.870.416.6482

Appendix C: FedEx Project Site Information Form

(Example Only)

MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013 Page C-1

Page 68

Appendix C: FedEx Project Site Information Form (Example Only)

This page is intentionally left blank.

Page C-2 MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013

Page 69

Index

Index

A

A

Admin 7

Advanced Mode 8

Alert symbol 1

Authorization Timeout 11

B

Barricading 1

Black pump head 7

Board Support Package 1

BSP 2

Bypass Switches 29

C

Caution warnings 1

Cluster 17

Com2 28

Corporate Network 14

Credit card 1

Credit processor 14

D

Danger warnings 1

DEF 14

Device IP 14

Device Port 14

DNS 2

E

Electrical

Shut-off 1

Electronic 9

Emergency

Electrical shut-off 1

In Case Of 3

Personnel (contacting) 2

Evacuation 1

Explosions

Preventing 1

F

FedEx 5

FedEx Islander PLUS FMS 1

FedEx Project Site Information

Form 1

FHO 2

Fiber Optic 15

FiPay Server 33

Fires

Preventing 1

FMS 2

Forecourt 16

Fuel Management System 1

Fueling Site Safety 3

G

Gasboy 9

Gasboy Technical Support 25

Gilbarco Claims 1

Global Station Parameters 9

GW 2

H

Half Cycle Count Pulse 19

HOCOMM 2

Hose Reels 13

J

Junction box 10

L

LAN 2

LAN1 1

LAN2 4

M

MAC addresses 4

Mechanical 9

Memphis 10

Message Factors 18

N

Nozzle 7

O

Operations Manager 1

OrCU 2

OrCU Administrator 2

OrCU FW Version 3

OrCU Networking 4

OrPT 2

OS 6

P

PAIS 2

PAIS version 3

Payment Application Interface

Service 1

Personnel

Emergency (informing) 2

PMC Pumps 12

POE 2

Power adaptor 14

Power cycle 28

Power Over Ethernet 14

Process Check 29

ProductMap 14

Pulse Factor 18

Pulse wires 10

Pump Head 17

Pump Number 17

Pump server 17

R

Reset Complete 10

Reset Motor 10

S

Safety Information 1

Alert symbol 1

Barricading 1

Emergency electrical shut-off

1

MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013 Index-1

Page 70

Index

Emergency personnel 2

Evacuation 1

NFPA regulations 1

Open flames 2

Preventing explosions and

fires 1

Regulations 1

Replacement parts 1

Safety symbols 1

Shut-off 1

Signal words 1

Smoking 2

Sparks 2

Warning words 1

Working alone 2

Safety symbols 1

Serial/Modem setting 27

Setup Pump Setting 17

Shut-off 1

Emergency electrical 1

Signal words

Safety 1

Site Number 3

SiteOmat 1

SiteOmat Status 33

SiteOmat Version 3

Solenoid lead 10

Solenoid valves 10

Specific 19

STP 2

Subnet Mask 3

Synchronizing 32

V

Version 1

W

W&M dongle 26

WAN 2

Warning words 1

Warnings 1

Wet Stock Management 23

Z

Zero transactions 11

T

Tank configuration 20

Tank gauge 2

T-Check 14

T-Check Fleet cards 1

Terminal Block 8

Terminal Block Connection 9

Time Zone 6

Translation group 14

U

User Inactivity timeout 11

User properties 31

Index-2 MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013

Page 71

This page is intentionally left blank.

Index

MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013 Index-3

Page 72

Gilbarco® is a registered trademark of Gilbarco Inc. Internet Explorer®, Windows®, and XP® are registered trademarks of Microsoft

™

Corporation. Java

is a trademark of Sun Microsystems, Inc.

© 2013 GASBOY

7300 West Friendly Avenue · Post Office Box 22087

Greensboro, North Carolina 27420

Phone 1-800-444-5529 · http://www.gasboy.com · Printed in the U.S.A.

MDE-5067 FedEx Islander PLUS FMS Installation Manual · March 2013

Loading...

Loading...