Page 1

PC Software for CFN

PC/CFN User’s Guide

MDE-4489

(formerly C36078)

Page 2

Computer Programs and Documentation

Federal Communications Commission (FCC) Warning

All Gasboy computer programs (including software on diskettes and within memory chips) and documentation are copyrighted by, and shall remain the property of, Gasboy. Such

computer programs and documents may also contain trade secret information. The duplication, disclosure, modification, or unauthorized use of computer programs or

documentation is strictly prohibited, unless otherwise licensed by Gasboy.

This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy, and if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense. Changes or modifications not expressly

approved by the manufacturer could void the user’s authority to operate this equipment.

Approvals

Gasboy, Greensboro, is an ISO 9001:2000 registered facility.

Underwriters Laboratories (UL):

UL File# Products listed with UL

MH4314

MH6418

MH7404

MH10581 Key control unit, Model GKE-B Series

All dispensers and self-contained pumping

units

Power operated Transfer Pump Models 25,

25C, 26, 27, 28, 72, 72S, 72SP, 72X, 73 and

1820

Hand operated Transfer Pump Models 1230

Series, 1243 Series, 1520 and 1720 Series

Card reader terminals, Models 1000, 1000P

Site controller, Model 2000S CFN Series

Data entry terminals, Model TPK-900 Series

Fuel Point Reader System

New York City Fire Department (NYFD):

NYFD C of A # Product

4823 9100A, 9140A, 9152A, 9153A,

4997 9822A, 9823A

5046 9100Q, 9140Q, 9152Q, 9153Q,

9800A, 9840A, 9850A, 9852A,

9853A, 9140

9800Q, 9840Q, 9852Q, 9853Q

National Conference of Weights and Measures (NCWM) - Certificate of Compliance (CoC):

Gasboy pumps and dispensers are evaluated by NCWM under the National Type Evaluation Program (NTEP). NCWM has issued the following CoC:

CoC# Product Model # CoC# Product Model # CoC# Product Model #

95-179A2 Dispenser

95-136A5 Dispenser 9800 Series 91-057A3 Controller

9100 Retail Series, 8700

Series, 9700 Series

91-019A2 Dispenser

9100 Commercial

Series

1000 Series FMS,

2000S-CFN Series

California Air Resources Board (CARB):

Executive Order # Product

G-70-52-AM Balance Vapor Recovery

G-70-150-AE VaporVac

Patents

Gasboy products are manufactured or sold under one or more of the following US patents:

Dispensers

5,257,720

Point of Sale/Back Office Equipment

D335,673

Trademarks

Non-registered trademarks

Atlas™

Consola™

Infinity™

Registered trademarks

ASTRA

Fuel Point

Gasboy

Keytrol

Slimline

Additional US and foreign patents pending.

®

®

®

®

®

Additional US and foreign trademarks pending.

Other brand or product names shown may be

trademarks or registered trademarks of their

respective holders.

This document is subject to change without notice. · For information regarding Gasboy Literature, call (336) 547-5661

E-mail: literature@gasboy.com · Internet: http://www.gasboy.com

© 2005 GASBOY · All Rights Reserved

Page 3

Table of Contents

Table of Contents

1 – Introduction 1-1

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Intended Users. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Related Reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Abbreviations and Acronyms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

2 – Installing and Uninstalling PC/CFN 2-3

System Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Fuel Management System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Personal Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Installing PC/CFN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Modem Notice (If Upgrading from a Prior PC Windows Version) . . . . . . . .2-4

Special Instructions for Windows 2000 Professional or

Windows NT Workstation Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Using PC/CFN for the First Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Setting up PC/CFN Fuel Management Software . . . . . . . . . . . . . . . . . . . . .2-6

Uninstalling PC/CFN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Windows 95/98. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Windows 2000 Professional or Windows NT . . . . . . . . . . . . . . . . . . . . . . . .2-7

3 – PC/CFN Basics 3-9

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

A Visual Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Terms to Know. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

DB Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Extra Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Fuel Site Transactions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Inventory Synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

Lockout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

Log Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Lookup Records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Manifolded Tank. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

Polling (Autopolling, Unscheduled, Continuous) . . . . . . . . . . . . . . . . . . . .3-13

MDE-4489 Gasboy® PC/CFN User’s Guide·July 2005 Page 1

Page 4

Table of Contents

RAWTRANS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Tank Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Overview of Tank Inventory Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

What Does Your Fueling Operation Look Like? . . . . . . . . . . . . . . . . . . . . 3-15

How Will the Data be Input? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

How is the Data Processed?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

How Report Data is Accumulated . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Calculating Your Tank Tilt Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

If You are Running PC/COMM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

If you are Running PC/FUEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Recommended Daily Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Recommended Tank Inventory Management . . . . . . . . . . . . . . . . . . . . . . 3-21

Recommended Periodic Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Recommended Year-End Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

RAWTRANS Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Page 2 MDE-4489 Gasboy® PC/CFN User’s Guide·July 2005

Page 5

Purpose Introduction

1 – Introduction

Purpose

The Gasboy Personal Computer (PC)/Commercial Fueling Network (CFN) User’s Guide is

meant to assist you in using the PC/CFN software. It contains the system specifications,

installation instructions, information on getting started and definitions of key terms associated

with PC/CFN and its usage. The User’s Guide is not intended to be an operation manual for

the software. For specific questions on functionality of the software, refer to the Help menu in

your PC CFN software package.

Intended Users

Individuals who have purchased and are authorized to use Gasboy PC Software for CFN,

including site personnel and Authorized Service Contractors (ASCs).

Related Reading

The following documents contain related information and may be helpful when using PC/

CFN:

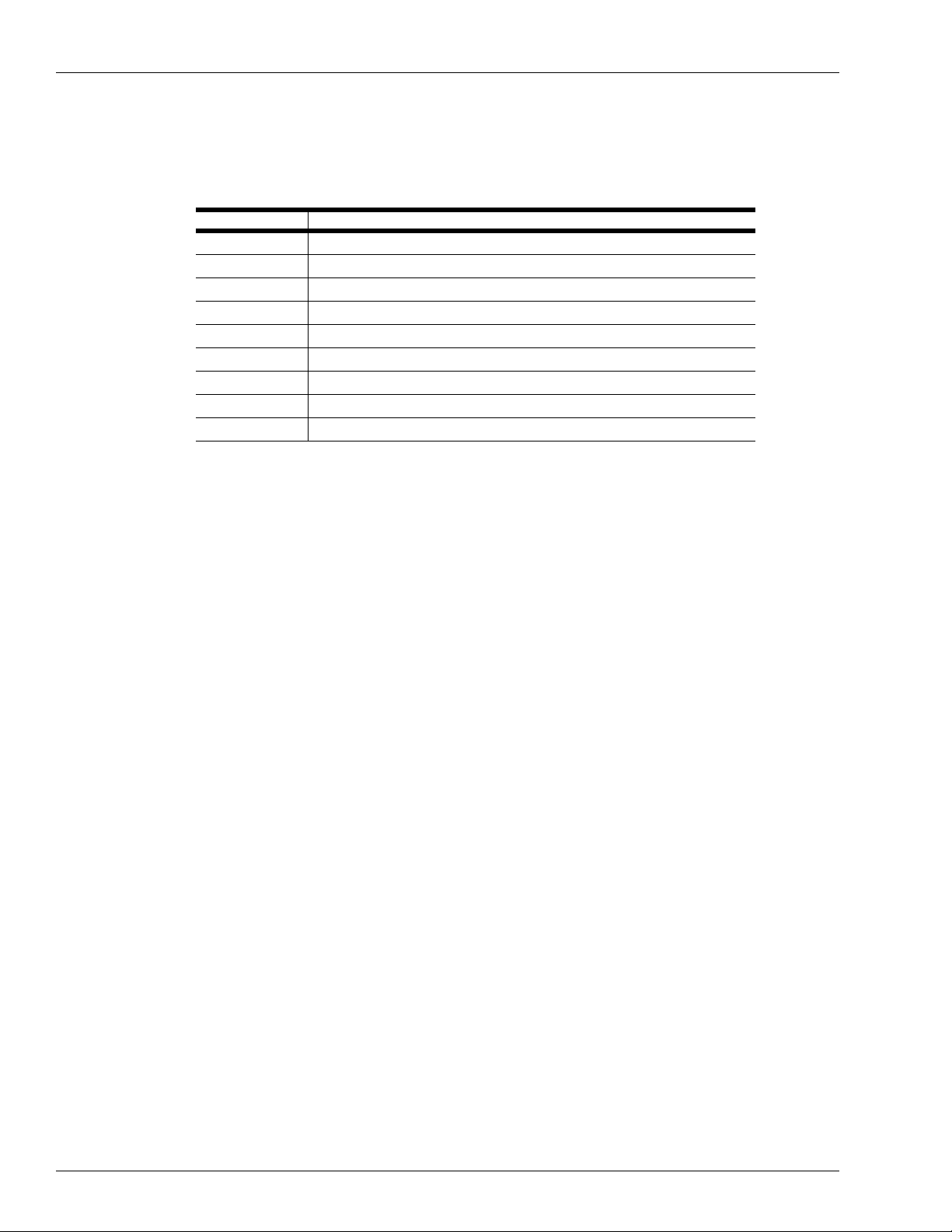

Document Number Title GOLD® Library

MDE-4928 CFN Site Controller II Installation

MDE-4299 CFN Series Profit Point Installation

MDE-4313 CFN III Manager’s Manual for

MDE-4314 CFN III Configuration Manual for

MDE-4315 CFN III Manager’s Manual for

MDE-4316 CFN III Configuration Manual for

Manual

Gasboy Fuel Management Products

Gasboy Fuel Management Products

Manual

Gasboy Fuel Management Products

Windows NT - Version 3.3

Gasboy Fuel Management Products

Windows NT - Version 3.3

Gasboy Fuel Management Products

Windows NT - Version 3.4

Gasboy Fuel Management Products

Windows NT - Version 3.4

MDE-4489 Gasboy® PC/CFN User’s Guide·July 2005 Page 1

Page 6

Introduction Abbreviations and Acronyms

Abbreviations and Acronyms

The following table contains a list of acronyms used in this guide.

Acronym Definition

ASC Authorized Service Contractor

CFN Commercial Fueling Network

FCC Federal Communications Commission

PC Personal Computer

MB Megabyte

®

NT

RAM Random Access Memory

ROM Read-only Memory

UL® Underwriters Laboratories

New Technology

Page 2 MDE-4489 Gasboy® PC/CFN User’s Guide·July 2005

Page 7

System Specifications Installing and Uninstalling PC/CFN

2 – Installing and Uninstalling PC/CFN

System Specifications

Given below are the minimum specifications required for PC/CFN software installation. They

may differ slightly from the specifications printed on your CD-ROM insert, because additional

research has shown that these enhanced specifications will improve the performance of your

PC software.

Fuel Management System

The fuel management systems for Gasboy is configured to work with the following:

• Gasboy CFN II

• Gasboy CFN III

• Gasboy Islander II

Personal Computer

The Personal Computer (PC) is configured to work with the following:

• Microsoft Windows 95 or 98, 2000 or Windows NT Workstation with service pack 4 or

higher

This software has been designed and tested to work with a PC using Windows® English

(United States) regional settings, where the decimal point character is used as the

decimal separator. Ensure that your system is set up properly before using this software.

Gasboy cannot guarantee that the software will work correctly using other regional

settings

• Pentium or faster processor

• 32 MB RAM required, 64 MB recommended

• 100 MB hard disk space available

• 640 x 480, 800 x 600, 1024 x 768; 256-color or higher VGA display (See Note)

•Mouse

•CD-ROM

• Modem for dial-up connection to CFN II/III fuel management system or serial port and

direct connect cable for direct connection to CFN II/III fuel management system

• Windows-compatible laser or inkjet printer, optional (See Note)

IMPORTANT INFORMATION

.

Note: If you encounter problems with this software, check if you have the latest video and

printer drivers installed on your computer, before you contact technical support.

MDE-4489 Gasboy® PC/CFN User’s Guide·July 2005 Page 3

Page 8

Installing and Uninstalling PC/CFN Installing PC/CFN

Installing PC/CFN

Instructions for installing PC/CFN using Microsoft Windows 95/98 or higher are provided

here. If you are using Windows 2000 Professional or Windows NT, ensure that you follow the

additional instructions given in

Windows NT Workstation Installation” on page 5.

To install PC/CFN, proceed as follows:

1 Turn on your computer, and start Microsoft Windows.

2 Insert the Gasboy PC/CFN software CD-ROM into your CD-ROM drive.

3 Click Start>Run.The Run Dialog Box appears.

4 Type D:\Setup.

Note: On most computers, the CD-ROM drive is D. If your CD-ROM drive is not D, type the

appropriate letter.

5 Click OK.

6 Follow the on-screen instructions for installation.

“Special Instructions for Windows 2000 Professional or

Modem Notice (If Upgrading from a Prior PC Windows Version)

When you add, edit or delete modems in the modem database using Setup/Communications

Parameters, the modem information is stored in a file called GBModem.ini. This file is located

in the Program Files\Common Files\Gasboy directory on your PC. If, at any time, you choose

to uninstall the PC/CFN software, the GBModem.ini file will be removed and any changes

that have been made to the modem information will be lost. Before uninstalling PC/CFN,

ensure that you save a copy of GBModem.ini (if you want to save your changes).

In version 3.1.0.7, three new Zoom modem configurations were added to PC/CFN. If you

uninstalled a prior version of PC/CFN and saved the GBModem.ini file and have installed

version 3.1.0.7, you have the following choices:

• If you did not make any changes to the modems in your previous package, simply install

the new software and the new GBmodem.ini file will be installed.

• If you made changes to the modems and saved a copy of the GBModem.ini before

uninstalling, and you are not using one of the new Zoom modems, install the software,

copy the file that you saved into the Program Files\Common Files\Gasboy directory. This

file will replace the new file that was installed with version 3.1.0.7.

• If you made changes to the modems and saved a copy of GBModem.ini before

uninstalling and you also want to use one of the new Zoom modems, install the new

version, then use an editor to open the saved GBModem.ini file and the GBModem.ini file

in Program Files\Common Files\Gasboy directory. Use cut and paste to add any changes

from the saved GBModem.ini file into the GBModem.ini file in the Program

Files\Common Files\Gasboy directory.

If you are using the patch to update your software to version 3.1.0.7, follow the patch

instructions (C36109) for details on the GBModem.ini file.

Page 4 MDE-4489 Gasboy® PC/CFN User’s Guide·July 2005

Page 9

Using PC/CFN for the First Time Installing and Uninstalling PC/CFN

Special Instructions for Windows 2000 Professional or Windows NT Workstation Installation

Instructions for installing PC/CFN using Microsoft Windows 2000 Professional or Windows

NT are given below.

Operating System

To run the PC/CFN software on a Windows NT PC you must be running the Windows NT

Workstation 4.0 (Service pack 4 or higher) operating system.

If you are not sure about which operating system your PC is using, proceed as follows:

1 Click Start>Settings>Control Panel. The Control Panel dialog box appears.

2 Double click the System icon. Your operating system version is displayed on the General tab

of the System Properties program.

Login

To install the PC/CFN application on a Windows 2000 Professional or Windows NT PC, you

must be logged-on to your PC as the NT ADMINISTRATOR user, or as a user who is a

member of the ADMINISTRATOR user account. If you are not sure of how to log-on as one

of these users, contact PC support person for details.

To run the PC/CFN application on a Windows 2000 Professional PC, you must be logged-on

to your PC as a user who is a member of the Administrator or Power Users groups. To run the

PC/CFN application on a Windows NT PC, you must be logged-on to your PC as a user who is

a member of the Administrator, Power Users or Users group.

After doing this setup, perform the steps outlined in “Installing PC/CFN” on page 4.

Using PC/CFN for the First Time

1 Install the PC/CFN software using instructions given in one of the following:

• the inside jacket cover of the Gasboy Fuel Management Software CD-ROM

• “Installing PC/CFN” on page 4

2 Click Start>Programs>PC/CFN folder.

3 When the program is run for the first time, you should select either PC/Comm or PC/Fuel

package. Click Help on this selection screen, if you are unsure of which package you want to

use.

4 After you select the package type, you can choose to register the software (if you have

purchased a license), or run it as a 30-day demo and register it later.

MDE-4489 Gasboy® PC/CFN User’s Guide·July 2005 Page 5

Page 10

Installing and Uninstalling PC/CFN Using PC/CFN for the First Time

IMPORTANT INFORMATION

Before proceeding with the Setup Wizard, close all other applications. If other applications are

active, while PC/CFN is saving critical data, registry keys or database entries can get corrupted.

After completing the registration, enter the PC/CFN Setup Wizard, which will guide you

through the set up of your PC/CFN Fuel Management software.

Setting up PC/CFN Fuel Management Software

To set up PC/CFN Fuel Management software, proceed as follows:

1 On the Setup Wizard's Start tab, click Start.

2 Read all the information on the help screens before continuing.

3 Click Next.

4 When Page 2 of the Start tab appears, click Print Setup Form.This prints a copy of the PC/

CFN Setup form.

Note: If you do not print out this form now, you can print it at another time using an editor,

such as Wordpad. This file is called setup.inf and can be found in the PC/CFN directory.

5 Exit from the Setup Wizard and fill out all applicable pages of this form before continuing. It

will be helpful if you have the card or key layout from your fuel management system handy. It

contains information about field names and sizes.

6 Click Quit to exit the PC/CFN Setup Wizard.

Note: If you are uncertain about any information requested on the Setup form, contact your

Gasboy representative to seek clarifications.

7 After you complete the Setup form, restart the PC/CFN package and proceed through the

Setup Wizard using that information.

8 When you reach the Finish tab of the Setup Wizard, click Print to print a list of your setup

information. Store this information along with your Setup form, in a secure place for future

reference.

Page 6 MDE-4489 Gasboy® PC/CFN User’s Guide·July 2005

Page 11

Uninstalling PC/CFN Installing and Uninstalling PC/CFN

Uninstalling PC/CFN

To uninstall the PC/CFN, proceed as follows:

Windows 95/98

1 If PC/CFN for Windows is running, close the application.

2 To shut down the Interbase Guardian, proceed as follows:

• position the mouse pointer over the Interbase Guardian icon present in the lower right

corner of the Windows Taskbar. The Interbase Guardian icon appears as a green triangle

positioned behind a tower styled PC.

• Click the right mouse button, while pointing at the icon to display the pop-up menu.

• Shut down the Interbase Guardian, by clicking the left mouse button while pointing at

Interbase Shutdown. The Interbase Guardian icon should disappear.

3 To remove PC/CFN using Add/Remove Programs, proceed as follows:

• Click Start>Settings>Control Panel.The Control Panel Window appears.

• Double click on the Add/Remove Programs icon.

• Select PC CFN from the list of available programs to remove and then click Add/

Remove.

• Follow the on-screen instructions.

Windows 2000 Professional or Windows NT

Note: You must be logged-on to your PC as the NT Administrator, to uninstall PC/CFN.

1 If PC/CFN for Windows is running, close the application.

2 Stop the Interbase Guardian and Interbase Server Services.

• For Windows NT: click Start>Settings>Control Panel>Services.

• For Windows 2000 Professional: click Start>Settings>Control Panel>Administrative

Tools>Services.

3 Select Interbase Guardian from the list, and click Stop. Follow the on-screen instructions.

4 To stop the Interbase Server, select Interbase Server from the list and then click Stop. Follow

the on-screen instructions.

5 Remove PC/CFN by proceeding as follows:

• Double click on the Add/Remove Programs icon in Control Panel.

• Select PC CFN from the list of available programs to remove, and click Add/Remove.

• Follow the on-screen instructions.

MDE-4489 Gasboy® PC/CFN User’s Guide·July 2005 Page 7

Page 12

Installing and Uninstalling PC/CFN Uninstalling PC/CFN

This page is intentionally left blank.

Page 8 MDE-4489 Gasboy® PC/CFN User’s Guide·July 2005

Page 13

General PC/CFN Basics

3 – PC/CFN Basics

General

The things you need to know, and the procedures you need to follow differ depending on

whether you are running the software as PC/Comm or PC/Fuel. This section contains a visual

overview of the software, a generic glossary of terms, and a set of tasks for each software

variation. Follow the procedure appropriate to your software selection.

A Visual Overview

Setup

Passwords

Fuel System

Types

Lockouts

Def. Comm.

Parameters

Fuel Mgmt.

System Owner

Administration

Files

Fuel Sites

Lockouts

Tanks

Departments

Vehicles

Employees

Reports

File Maintenance

System Configuration

Unproc. Fuel Trans.

Unproc. Trans. Layout

Lockouts

Fuel Sites

Departments

Employees

Vehicles

Vehicle Specs/Parts

Vehicle Types

Fuel Usage

Dept. Fuel Usage

Employee Fuel Usage

Vehicle Fuel Usage

Site Tank Fuel Usage

Site Prod. Fuel Usage

Proc. Fuel Trans.

Fuel Efficiency

Fuel Efficiency Except.

Inventory

Site Inventory

Site Reconciliation

Tank Synchronization

Meter Reconciliation

PC/CFN Main

Page

CommLink

Setup/Enable

Autopoll

Unscheduled

Polling

Continuous

Polling

View Log Files

Contact Site

Copy Files

Trans

View/Edit/Del

Raw Trans.

Purge Raw

Trans.

View/Del Proc

Fuel Trans.

Process

Transactions

Proc. Trans.

Utilities

Bolded boxes indicate PC/Fuel Functions only

Utilities

PC Database

Convert

DB Maint.

Gen Rawtrans

Backup

Restore

Backup Files?

Quit

MDE-4489 Gasboy® PC/CFN User’s Guide·July 2005 Page 9

Page 14

PC/CFN Basics Terms to Know

Terms to Know

DB Maintenance

PC/CFN has a database maintenance utility that provides periodic maintenance of your

database which minimizes problems, corrects problems that exist, and generally increases

database performance. This happens in two ways: automatically or on demand.

• Automatic database maintenance occurs after polling (Comm package), or after

processing (Fuel package).

• On demand maintenance is selected from the Utilities>DB Maintenance. (The

rundbmaint.exe file that is run as a result of selecting this button, can also be run from

Windows Explorer, or the Run prompt, in case you need to run maintenance without

running the software.)

The database maintenance process is transparent to you as a user, but what occurs internally is,

a verification check is performed. If no errors are detected, the maintenance process does not

continue. If errors or problems are detected, the process continues to repair the database.

Regardless, after nine verification steps, database maintenance is performed on the 10th

occurrence.

Note: If your site encounters frequent problems, you may wish to have this frequency lowered

to every 2nd occurrence or some other setting. Settings for the database can be adjusted

in the dbmaint.ini file which resides in your Windows system directory. Contact Gasboy

technical service before changing this file.

A log of maintenance activity is available in the file dbmaint.log, which is stored in the

\maintenance directory of your PC/CFN application.

Extra Commands

Extra Commands can be up to ten fuel management system commands, that are executed upon

polling. There are two types, namely global and site-specific:

• Global commands are entered on the Fuel System Types form and are executed at all sites

included automatic polling.

• Site-specific commands are entered on the Fuel Sites form and are executed only at that

site upon polling. Refer to your fuel management system manual, for appropriate

commands. Commands do not require user input.

Fuel Site Transactions

Each time a user attempts to obtain fuel at a fuel site, a transaction is generated. Even if the

user encounters errors while doing this a transaction may be generated. Transactions may also

be generated for such events as a fuel delivery, or dipstick reading. Typically, transactions are

accumulated at your fuel management system at the site. You use a PC package, such as PC/

Fuel or PC/Comm to poll or collect the transactions from the fuel management system.Copy

them onto the PC, and process them according to the procedures of your organization.

Polled raw transactions are written to the PC database and stored as part of the RAWTRANS

or RAWTRANS.DAT file. Transactions that occurred outside of your fuel sites or transactions

from sites that could not be successfully polled by the PC may be entered manually through

the PC package.

Page 10 MDE-4489 Gasboy® PC/CFN User’s Guide·July 2005

Page 15

Terms to Know PC/CFN Basics

In PC/Fuel, when processing occurs, valid raw transactions are written to the database and

processed and moved to a processed transaction file and various database files are updated

with totals, etc. depending on the type of transaction.

Transactions that contain errors are not processed and remain in RAWTRANS until you

correct them using the View/Edit/Delete Raw Fuel Transactions option. They can be processed

at the next processing time. When error transactions are present, an error listing gets printed at

the end of transaction processing.

Inventory Synchronization

The Inventory Synchronization function allows you to reconcile your book value with what is

actually in the tank (volume). Book value is the amount of fuel presently on hand calculated

from dispenser transactions or totalizer readings. The book value may be different from the

value that was entered because of any deliveries, any volume changes resulting from

processed dipstick or totalizer transactions and fueling transactions. Before you can perform

an inventory synchronization, you must have an initial inventory (volume) in the tank.

If you have unprocessed raw transactions in the transaction file, you will not be permitted to

perform an inventory synch. You must exit from the tank information forms and process your

transactions first.

Lockout

Lockout is the process of preventing access to the fuel site. Each fuel site should already have

a lockout type and format in place. There are two lockout formats: Bit-mapped and Limited.

With Bit-mapped lockout, lockout is typically by Card Number, but can be by some other userspecified ID field. With Limited lockout, lockout is by Entire Account, which is comprised of

all your ID fields.

The fields used for lockout on the PC software match whatever is configured at your fuel site.

Within each lockout format, there are two ways to set up the lockout file, positive lockout or

negative lockout. With a positive lockout file, all cards, vehicle records, or keys at the site are

locked out and the PC sends only the active numbers. With a negative lockout file, all cards,

vehicle records, or keys at the site are made active and the PC sends only those numbers which

are locked out.

PC/CFN handles lockouts as follows:

• The PC contains a master lockout file which contains the lockouts for every site. This file,

when initially set up, should match the files at each of your fuel sites.

• The PC may also contain a lockout update file for each fuel site.

• All lockout changes must be done on the PC (using Files, Lockout or the Employee or

Vehicle form lockout fields). Locking out at the fuel site will result in non-matching

lockout files which can render lockouts ineffective.

• As you make additions or deletions to your master lockout file, the lockout update files are

updated. This only occurs when the Lockout option is enabled and, when editing the

master lockout file, you respond Yes when asked if you wish to update the site lockout

files.

• When the Lockout Updates polling action is selected, the lockout update file is sent to the

site, thus keeping the lockout file at the fuel site current with the PC's master lockout file.

MDE-4489 Gasboy® PC/CFN User’s Guide·July 2005 Page 11

Page 16

PC/CFN Basics Terms to Know

The lockout update files on the PC are then cleared. If polling is unsuccessful, the lockout

updates are not sent and remain on the PC until the next polling attempt (either at autopoll

time, or at an unscheduled polling).

IMPORTANT INFORMATION

When setting up your fuel sites, lockout will only occur as described above, if the

Lockout option is on. If the Lockout option is switched off, changes made to the master

lockout file will not affect the site update files. This is not recommended

.

Log Files

A polling log is a listing describing the outcome of a polling session. It contains messages for

each site polled stating the date, time and number of transactions polled and the status of all

polling actions. PC/CFN stores polling logs from the last seven polling sessions. These polling

logs are named SESSION1.PLG through SESSION7.PLG. You can have the poll log from the

current session print automatically by clicking on Send Polling Results to Printer on the

Commlink, Setup/Enable Autopoll form or print polling logs later using the View Log Files

option on the CommLink menu.

Each polling log contains date, time polling started, a list of error (status) codes, and the

following:

• Site number - number of the site polled.

• Description - description of the site polled.

• Time polling started

• Connect status - contains OK if connection to site completed successfully or an error

• Trans status - contains OK if transaction polling completed successfully, an error code if

• First Trans - contains number of first transaction polled.

• Last Trans - contains number of last transaction polled.

• Lockout Status - contains OK if lockouts were sent successfully, an error code if

• Lookup Status - contains OK if lookup record updates completed successfully, an error

• Cmds Status - contains OK if site-specific or global commands completed successfully,

Lookup Records

Lookup records are available when the Lookup program is used. The Lookup program is part

of the Fleet options package of the Site Controller. The Lookup program lets you quickly set

up accounts for customers using either codes (manually entered at the keypad), code cards,

club cards, or bank cards. Under the Lookup program, you do not have to encode restrictions

on the cards; restrictions and customer information are stored in a lookup record in the

LOOKUP.DTA file on the site controller. PC/CFN allows you to upload or download an

existing LOOKUP.DTA file.

code if unsuccessful.

unsuccessful, or dashes indicating that the action was not selected or was not executed.

unsuccessful, or dashes indicating that the action was not selected or was not executed.

code if unsuccessful, or dashes indicating that the action was not selected or was not

executed.

an error code if unsuccessful, or dashes indicating that the action was not selected or was

not executed.

Page 12 MDE-4489 Gasboy® PC/CFN User’s Guide·July 2005

Page 17

Terms to Know PC/CFN Basics

Manifolded Tank

A manifolded tank is two tanks containing the same product joined together by a common pipe

and used as a single source for dispensing fuel.

Polling (Autopolling, Unscheduled, Continuous)

Polling is the process by which the PC software contacts a fuel site and extracts the raw

transactions from the fuel management system at the site. Other actions may also be performed

at this time, such as updating lookup records, updating lockouts, and executing extra

commands. There are three polling options available through the Gasboy PC software, namely

autopolling, unscheduled polling, and continuous polling:

• Autopolling is the easiest and most automatic way to poll your sites on a regular basis.

You can include all of your sites, or just selected sites. When you set up your Fuel Sites,

each site that you wish to include in the autopolling process must have the Poll Flag field

set to YES. You can set the PC software to autopoll every hour or set up to four times each

day when the PC will automatically attempt to perform selected polling actions. You

select the actions you wish to run for each polling time. If connection cannot be

established with a site, PC/CFN continues polling other sites and then makes two more

attempts to re-poll the site. If an error occurs during any polling action, the connection is

terminated and no further actions are performed for that site. Upon completion, a polling

log is generated.

• Unscheduled polling is a manual polling option that allows you to poll one or more sites at

any time (on demand). Because autopolling is performed only on sites where the Poll Flag

is set to YES, if you wish to poll other fuel sites (or even one typically scheduled for

autopolling), you would use unscheduled polling. The available polling actions are

identical to those you can select under autopolling.

• Continuous polling allows you to poll a single site continuously for transactions only; no

other polling actions are allowed.

RAWTRANS

When transactions are polled from your fuel sites, they are stored directly to the database.

Each time you generate a RAWTRANS file it serves as a snapshot of the raw transactions in

the PC database at the time of generation. You decide when your file will be generated, which

format you are using, which transactions to include and where the file will be stored on your

PC by selecting settings on the Default Communication Parameters menu.

When Poll Transactions is selected as a polling action either for autopoll, unscheduled poll, or

continuous poll, you can choose to have the file generated automatically at the end of polling.

If you don't choose this, the only way to generate a raw transaction file is to use the Gen

Retrains button on the Utilities form.

When you perform any operation affecting transactions, you alter transactions in the database

but not in the RAWTRANS file that you have generated. If you use automatic file generation,

you'll get an updated RAWTRANS file each time you poll or you can re-run the Gen

RAWTRANS utility from the Utility form. NOTE: Raw transactions are not automatically

purged from the PC database after the RAWTRANS file is generated.

MDE-4489 Gasboy® PC/CFN User’s Guide·July 2005 Page 13

Page 18

PC/CFN Basics Terms to Know

Your raw fuel transaction file may be in one of three formats: standard Windows format (your

file is named RAWTRANS.DAT) or one of two DOS-style formats, V4.992 and above, or

below V4.992 (Your file is named RAWTRANS).

If you currently have a DOS PC/Comm or PC/Fuel version, you may want to select one of the

DOS formats to match the RAWTRANS file currently in use. This will ensure that the file will

be in the correct format for any other application you may be using. The DOS PC/Comm or

PC/Fuel version that you are currently running is listed on the Gasboy banner screen as you

enter the package. Standard windows format is viewable using the Reports menu,

RAWTRANS Layout option. RAWTRANS data from PC software versions above 4.992

contains account field data followed by additional data. RAWTRANS data from PC software

versions below 4.992 contains the account field data as the last field.

Transactions to Include allows you to specify what you want to include in the RAWTRANS

file. All Transactions will include all raw (unprocessed) transactions currently in the PC

database. Latest Polling Session will include those from the latest polling session only.

Tank Table

Tank tables are used to provide gallon equivalents for the inch measurements that are obtained

from a stick reading. Because each tank size and shape are different, there is no set formula for

determining this, so you must rely on tank dimensional data provided by the manufacturer to

build a tank table. A tank table consists of data pairs, which enable the system to determine the

product volume within the tank. These data pairs represent the level of the product (in inches)

and the quantity (gallons) present at that level. For example, a reading of 19 inches might

equate to 1424 gallons. In this case, that data pair would be 19 and 1424. When entering data

into the table, for level 19 you would enter a quantity of 1424. The manufacturer or supplier of

your tank can supply you with tank data, which you can enter manually or import from a data

file. A tank table calculation program is available from the Steel Tank Institute web site (http:/

/www.steeltank.com). This program generates an ASCII file which you can import into the PC

software using Admin, Fuel Tank Tables, Import Tank Tables.

Page 14 MDE-4489 Gasboy® PC/CFN User’s Guide·July 2005

Page 19

Overview of Tank Inventory Management PC/CFN Basics

Overview of Tank Inventory Management

The PC/CFN software, when run as PC/Fuel, enables you to monitor your tank inventory. The

quality of your output however, depends upon your input. The traditional method of tank

inventory management involves manual sticking of your tanks to measure product, matching

the reading up to a printed tank table or manually calculating inches to gallons, and recording

it according to your site's record keeping procedures. Then later, you must perform

reconciliations comparing book inventory to actual. PC/CFN makes this process easier by

automating some of the tasks involved.

What Does Your Fueling Operation Look Like?

The first thing the PC software needs to know is what your fueling operation looks like? What

size tanks do you have, how many do you have, what product is in each tank? You define this

information using different forms. Use the Setup menu, Administration, Fuel Tank Tables

form to define a name and tank table data for each tank type at each of your sites. If all your

tanks are identical, you need only one tank table; if they are different, each unique tank must

have its own table. A tank table contains an inches to gallons conversion for the tank (This

conversion is used for dipstick readings entered in inches). Tank tables are typically available

from the manufacturer or you can use a tank table calculation program (one is available on the

Steel Tank Institute website: http://www.steeltank.com) to generate your own. This tank table

can then be imported into the PC software (Administration, Fuel Tank Tables, Import Tank

Table). Use the Files, Tanks form to define individual tank information. Some things you need

to include are tank number, tank table assignment, capacity, reorder level, tilt offset (see

Calculating Your Tank Tilt Offset later in this section) and whether the tank is manifolded. In

addition, you must supply the product that is in the tank, the pumps that draw from that tank,

and the initial inventory reading (stick reading).

How Will the Data be Input?

There are several ways that your fuel inventory can be monitored and you can select the way

that best suits your application. You must decide how the information will get into the PC

software. This tells the software how to typically expect data. This data is input for each site.

Presently, you are not limited to the choice you make, for example, if you select stick reading

at PC, you can still use dipstick transactions or vice versa. There are slight processing

variations based on some of your choices, but mostly these choices are informational. Your

input choices on the Files, Fuel Sites, Tank Inventory Configuration tab are:

Tank reading source: This tells the PC software whether your tank readings will come from a

dipstick transaction or a manual entry on the Enter Stick Reading portion of the Tank

Information tab. A dipstick transaction occurs when you take a dipstick reading and enter the

data into the fuel management system using a dipstick card or key (or a manually entered

dipstick transaction). The other choice allows you to take the dipstick reading and enter the

data at the PC using the Files, Tanks, Enter Stick Reading form.

Fuel pumped source: This tells the PC software how to calculate your book inventory. The

usual method is by processing fueling transactions and subtracting their quantity. Another

method is by reading the accumulating totalizers on the pump and inputting those readings

into the PC software either by a totalizer transaction or making a totalizer entry on the Files,

Tanks, Enter Totalizer form. A totalizer transaction occurs when you take a totalizer reading

MDE-4489 Gasboy® PC/CFN User’s Guide·July 2005 Page 15

Page 20

PC/CFN Basics Overview of Tank Inventory Management

and enter the data into the fuel management system using a totalizer card or key (or a manually

entered transaction).

Fuel delivery source: This tells the PC software whether to update book inventory based on a

delivery entry at the PC on the Enter Delivery form or a delivery transaction. A delivery

transaction occurs when a delivery is made at the site and the data is entered into the fuel

management system using a delivery card or key (or a manually entered totalizer transaction).

Dipstick entry: This tells the PC software the unit of measure you are using for dipstick

readings: inches or gallons. If you are entering dipstick readings in inches, you must enter a

tank table to convert inches to gallons.

How is the Data Processed?

Once this information is entered, you can begin using the PC software to monitor your

inventory. Some scenarios:

• Stick your tank and input the stick reading using the method of your choice. (If you input

the reading using the Files, Tanks, Enter Stick Reading form, the volume for your stick

reading will be shown immediately. If you use a dipstick transaction, the volume reading

will not be adjusted until transactions are processed.)

• Transactions are processed. Different information within the PC database is updated based

on the type of transactions processed.

• If your Fuel Pumped Source is set to use totalizers (on the Fuel Sites, Tank Inventory

Configuration form) and your input is entered using the Files, Tanks, Enter Totalizer form

or by a totalizer transaction at the site, book value is updated when transactions are

processed. If your Fuel Pumped Source (on the Fuel Sites, Tank Inventory Configuration

form) was configured for Normal Fuel transaction), totalizer transactions or entries on the

Files, Tanks, Enter Totalizer form do not update the book inventory.

• A fuel delivery is received. A delivery transaction is entered at the fuel management

system or a fuel delivery is entered at the PC on the Files, Tanks, Enter Delivery form.

Book inventory is updated when entries are posted or transactions are processed. Tank

volume is not updated until the next dipstick reading/transaction is posted or processed.

• Reordering fuel. When the Reorder field of the Tank Data Summary on the Tank

Information form shows reorder, you must place an order for fuel. Use your site's

established procedures for placing a fuel order, then complete the Fuel Order Information

tab (Files, Tanks, Fuel Order Information) to provide a reference for the order.

How Report Data is Accumulated

As transactions are processed and data is entered into the PC, report data is accumulated. The

following reports provide data from your inventory management functions:

Site Inventory

This report details your fueling operation by providing a snapshot of tank status at the time the

report is printed or displayed. It is useful in determining when reorder is necessary. It can be

run as often as needed according to your site's procedures. It contains the following fields: site

number and name, tank, product, type, capacity, ullage volume, reorder level, volume, level,

water level, inventory date and time, fuel ordered, order placed by, and reorder status.

Page 16 MDE-4489 Gasboy® PC/CFN User’s Guide·July 2005

Page 21

Overview of Tank Inventory Management PC/CFN Basics

Site Reconciliation

This report shows a day-by-day breakdown of actual fuel vs. calculated book value and

provides a means to spot potential discrepancies in the fueling operation. It is based on

dipstick transactions or manual entry of dipstick readings. These readings should be taken

following your site's established procedures. This report contains the following fields: site

number and name, tank and product, date and time of each stick transaction/reading, the

starting level, volume and water level, gallons pumped, gallons delivered, inventory balance,

the ending level, volume and water level, the gallons over or under, and a calculated leak

threshold.

Note: This report has been formatted to match the EPA Inventory control method for leak

detection. It should be run once per day to conform to EPA procedures. Check your

local and federal regulations to determine if this method is an acceptable form of leak

detection for your sites.

Tank Synchronization

This report details each time a tank synchronization occurs. For accurate results, this report

should be run after transaction processing and before purging transactions. It contains the

following fields: site number and name, date, time, tank, book balance, fuel volume, variance,

gallons pumped since last synchronization, leak tolerance, and tolerance results.

Meter Reconciliation

This report details a comparison of the actual pump/dispenser totalizer reading to the gallons

pumped as recorded by processed fuel transactions. It should be run as needed according to

your site's procedures. It contains the following fields: site number and name, pump, product,

date and time of totalizer reading, totalizer reading, gallons pumped by totalizer and

transaction and any variance.

MDE-4489 Gasboy® PC/CFN User’s Guide·July 2005 Page 17

Page 22

PC/CFN Basics Calculating Your Tank Tilt Offset

Calculating Your Tank Tilt Offset

Due to installation or ground settling, the underground storage tank may be tilted. This could

result in inaccurate inventory volume readings. You must measure for tank tilt so that an

Offset can be entered for each tank on the Tank Information Form. Use the following figure

and formula to determine your tank's offset (tilt) factor.

1 Using a dipstick, measure the product level at Tank Opening 1 (a)

2 Using a dipstick, measure the product level at Tank Opening 2 (b).

3 If a=b, the Offset is 0 and no further calculations are needed.

4 Measure the distance between Tank Opening 1 and the tank center line (c).

5 Measure the distance between Tank Opening 1 and Tank Opening 2 (d).

6 Calculate the offset using the following formula:

OFFSET = c (a-b)

d

Page 18 MDE-4489 Gasboy® PC/CFN User’s Guide·July 2005

Page 23

If You are Running PC/COMM PC/CFN Basics

If You are Running PC/COMM

1 Explore the package. Select the icons on the Main Page (Setup, Files, Reports, CommLink,

Trans, and Utilities) and familiarize yourself with what each one does. Each Main Page icon

brings up a menu containing functions that you can perform. Each menu item brings up a form

that you can use to define your application or perform operations on your data. Each form has

a Help button which displays Help screens pertaining to the form or topic displayed. If you get

into an area of the package, from which you cannot proceed, click the Help button for more

information.

2 Go to the Files/Fuel Sites form and verify that all your fuel site information is correct. If it is

not, make any changes at this time.

3 If you intend to use autopolling, display the CommLink Setup/Enable Autopoll form and

select your options.

4 Go to the Files/Lockouts form to enter any lockout information updates you wish to send to

your sites.

5 Go to the CommLink/Contact Site form and make sure that you can successfully contact all

your fuel sites.

6 Once you begin using your PC/CFN package on a regular basis we strongly recommend that

you set up a schedule for performing regular backups of your PC/CFN data. Backups can be

performed from the Utilities form and also when you exit the PC/CFN software.

If you are Running PC/FUEL

General

• Explore the package. Select the icons on the Main Page (Setup, Files, Reports,

CommLink, Trans, and Utilities) and familiarize yourself with what each one does. Each

Main Page icon brings up a menu containing functions that you can perform. Each menu

brings up a form that you can use to define your application or perform operations on your

data. Each form has a Help button which displays Help screens pertaining to the form or

topic displayed. If you get into an area of the package where you feel that you do not know

how to proceed, click the Help button for more information.

• If you did not convert data from an existing PC/Fuel DOS package, you will need to set up

additional information about how you intend to use this package before proceeding

further. This information should be entered on the named forms in the order listed in the

following table:

MDE-4489 Gasboy® PC/CFN User’s Guide·July 2005 Page 19

Page 24

PC/CFN Basics If you are Running PC/FUEL

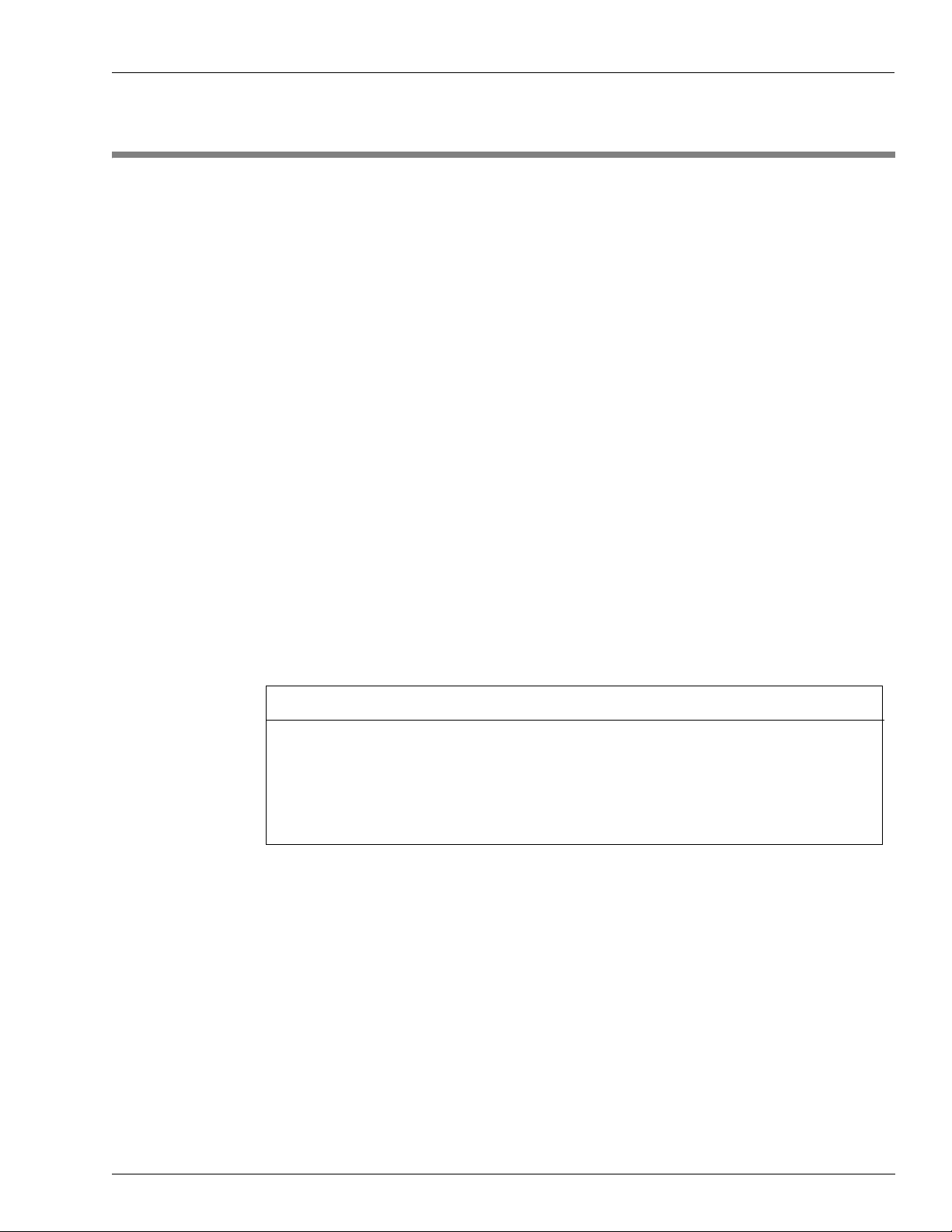

Selection Sequence Enter

Setup/Administration/

Product Types

Setup/Administration/

Vehicle Types

Setup/Administration/

Veh icl e

Specifications

Setup/Administration/

Veh icl e Pa rts

Setup/Administration/

Fuel Tank Tables

Files/Tanks Tank, pump, product assignments, and inventory for your fuel site tanks

Files/Department Department information into the department file

Files/Vehicle Identifying data about each vehicle in your system

Files/Employee Identifying data about each employee that uses your system

Product types

Vehicle types

Vehicle specifications

Vehicle parts information

Tank table data for inches to gallons conversions when using dipstick transactions

• If you intend to use autopolling, display the CommLink Setup/Enable Autopoll form and

select your options.

• Go to the CommLink/Contact Site form and make sure that you can successfully contact

all your fuel sites.

• Follow regular daily, periodic and year-end procedures as suggested in the tables given in

“Recommended Daily Sequence” on page 20.

Recommended Daily Sequence

The following table suggests a sequence of events that should be done on a daily basis. Your

actual site procedures may differ.

Selection Sequence Task

CommLink/View Log

Files

CommLink/

Unscheduled Polling

CommLink/Contact Site Perform fuel site maintenance (price updates, etc.)

CommLink View/Edit/

Del Raw Fuel Trans

Utilities/Backup Perform a Backup of your package data

Reports/Standard/

Unprocessed Fuel

Transactions

CommLink View/Edit/

Del Raw Fuel Trans

CommLink/Process

Transactions

CommLink View/Edit/

Del Raw Fuel Trans

Reports/Standard View/print any reports of interest according to your site's established procedures.

Check the appropriate polling log file to make sure that all fuel sites which were setup

to be autopolled were successfully polled

Perform manual polling of those fuel sites that were unsuccessfully autopolled or not

polled at all.

Enter any transactions that occurred outside your fuel site network.

View/print a list of the polled transactions.

Edit/correct any fuel transactions which have errors.

Process the polled raw transactions

Check the database for any transactions that were not processed. If any are present,

correct the error before attempting to re-process these transactions.

Page 20 MDE-4489 Gasboy® PC/CFN User’s Guide·July 2005

Page 25

If you are Running PC/FUEL PC/CFN Basics

Recommended Tank Inventory Management

The following tank inventory functions may be performed according to your site's established

procedures:

Sticking the Tank - Recommended Interval, Once a Day

1 Ensure that no one is pumping. Block off island, if necessary.

2 Stick the tanks and record the level information. If you are entering data at the PC, be sure to

note date/time and skip to Step 4.

3 Insert the dipstick card/key into the fuel management system and enter the data.

4 Resume fueling at the site.

5 Enter the data at the PC if not using dipstick card/key (Files, Tanks, Enter Stick Reading).

Delivery - Recommended Interval (as needed)

1 Delivery is made to the tank(s).

2 Delivery person provides a receipt with the volume delivered, date, and time. Skip to Step 4 if

entering delivery information at the PC.

3 Insert the delivery card/key into the fuel management system and enter the data.

4 Enter delivery data at the PC (Files, Tanks, Enter Delivery)

Totalizer - Recommended Interval, Once a Day

1 Ensure that no one is pumping. Block off island if necessary.

2 Read the totalizers for each pump. If you are entering data at the PC, take a note of date/time.

3 Stick the tanks and record the level information. If you are entering data at the PC, take a note

of date/time, and skip to Step 6.

4 Insert the totalizer card/key into the fuel management system and enter the data.

5 Insert the dipstick card/key into the fuel management system and enter the data.

6 Resume fueling at the site.

7 Enter the data at the PC if not using totalizer or dipstick card/key (Files, Tanks, Enter Totalizer

and Files, Tanks, Enter Stick Reading).

MDE-4489 Gasboy® PC/CFN User’s Guide·July 2005 Page 21

Page 26

PC/CFN Basics If you are Running PC/FUEL

Recommended Periodic Sequence

The following table suggests a recommended periodic sequence of operations for your PC/

Fuel package. PC/Fuel data is stored and accumulated in the package database. This database

will contain data from the day you start using your system. Many system owners may wish to

retain only set amounts of transaction data, such as a month's worth or maybe a year's worth.

Once you decide how much transaction data you wish to retain, you can establish a routine for

purging transactions from the database. If you choose to retain transaction data for a month,

you can purge transactions at the beginning of a new month. If you choose to retain transaction

data for a year, you can wait until 13 months of transaction data have accumulated and at the

end of each month thereafter, purge transaction data for the oldest month.

Selection Sequence Task

Varies (see previous

table)

Reports/Standard/

selection

Utilities/Backup Back up your package data.

Trans/Processed

Trans Utilities

Perform your daily sequence.

Print any or all of the available reports.

Purge the fuel reporting transaction file according to

your established schedule.

Recommended Year-End Sequence

This section suggests a year-end processing sequence. Your actual year-end processing

operation may differ.

The PC/Fuel package will retain year to date totals for your departments, vehicles and

employees. Depending upon your needs, you may wish to clear these totals on a regular basis

(for annual, semi-annual reporting, etc.) or may not want to clear them at all, thus retaining

lifetime totals. To clear these totals, go to the Trans/Processed Transaction Utilities form and

select Purge Accumulated Totals. Then select which year to date totals you wish to clear.

Once you begin using your PC/CFN package on a regular basis we highly recommend that you

set up a schedule for performing regular backups of your PC/CFN data.

Page 22 MDE-4489 Gasboy® PC/CFN User’s Guide·July 2005

Page 27

RAWTRANS Layout PC/CFN Basics

RAWTRANS Layout

Starting

Length

1 1 N System Type

6 2 N Site ID Number

6 8 N Transaction Number

4 14 N CFN Sequence Number, from Site Controller

1 18 N CFN Status Code

8 19 N Total Price in Hundredths

1 27 N CFN Account to Charge

Column

Typ e CFN Tran Field Description

1 28 N Transaction Type

2 29 N Product Code

4 31 N Unit Price in Thousandths

8 35 N Quantity in Thousandths (See Note 1)

8 43 N Hours in Tenths

8 51 N Odometer in Tenths (See Note 2)

2 59 N Pump Number (See Note 3)

8 61 N Date (YYYYMMDD)

4 69 N Time (HHMM)

2 73 N Error Code

6 75 A CFN Authorization Number

6 81 N Series 1000 Card Number

6 87 N Key 1/VM

6 93 N Key 2

2 99 N Account Field Length

MDE-4489 Gasboy® PC/CFN User’s Guide·July 2005 Page 23

Page 28

PC/CFN Basics RAWTRANS Layout

Starting

Length

30 101 A User Defined ID Fields

20 131 N Manual Entry Number

1 151 A CFN Device Type

1 152 A CFN Device Drop

1 153 N CFN # of Digits After Quantity Decimal Point

1 154 N CFN Kind of Transaction

20 155 N CFN Issuer Field

4 175 A CFN Expiration Date

Column Type CFN Tran Field Description

4 179 N CFN Physical Record Number

4 183 N MPG in Tenths

4 187 N Miles Traveled

5 191 N TopKAT Vehicle Number

4 196 N TopKAT Vehicle Department Number

4 200 N TopKAT Manual Entry Department Number

1 204 N TopKAT Pulse Rate

2 205 N TopKAT Tank Number

6 207 N TopKAT Cum. Vehicle Quantity in Tenths

6 213 N TopKAT Cum. Manual Entry Quantity in

20 219 N Future Expansion

Tenths

Note: The RAWTRANS layout for PC/CFN will contain valid values only in the fields with the

tick marks. The other fields (without the tick marks) will contain zeros.

Note: For a normal fuel transaction or a delivery transaction, Quantity in Thousandths is

true. For a dipstick or a dipstick + water transaction, the decimal portion of the field is

in 8ths. For a totalizer transaction, the totalizer reading is shown with the decimal

portion of the field in tenths.

Note: For a normal fuel transaction, Odometer in Tenths is true. For a dipstick+water

transaction, the decimal portion of the field containing water reading is in 8ths.

Note: For a normal fuel transaction or a totalizer transaction, the Pump Number field

contains pump number. For a dipstick, dipstick+water, or totalizer transaction, this

field contains tank number

Page 24 MDE-4489 Gasboy® PC/CFN User’s Guide·July 2005

Page 29

Page 30

© 2005 GASBOY

7300 West Friendly Avenue • Post Office Box 22087

Greensboro, North Carolina 27420

Phone 1-800-444-5529 • http://www.gasboy.com • Printed in the U.S.A.

Loading...

Loading...