Page 1

Atlas™ Fuel Systems

Owner’s Manual

MDE-4363A

Page 2

Computer Programs and Documentation

Gasboy , Gr eensbor o, is an ISO 900 1:20 00 regi stered facil ity.

U

U

M

M

M

M

:

N

A

C

I

FCC Warning

All Gasboy computer programs (including software on diskettes and within memory chips) and documentation are copyrighted by, and shall remain the property of, Gasboy. Such

computer programs and documents may also contain trade secret information. The duplication, disclosure, modification, or unauthorized use of computer programs or

documentation is strictly prohibited, unless otherwise licensed by Gasboy.

This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to Part 15 of the FCC Rules. These limits a r e designed to provide

reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy, and if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communic ations. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense. Changes or modifications not expressly

approved by the manufacturer could void the user’s authority to operate this equipment.

Approvals

nderwriters Laboratories:

. L. File# Products listed with U. L.

H4314

H6418

H7404

H10581 Key con t ro l u n it , Mo d e l G K E- B S e ri es

All dispensers and self-contained pumping

units

Power operated Transfer Pump Models 25,

25C, 26, 27, 28, 72, 72S, 72SP, 72X, 73 and

1820

Hand operated Transfer Pump Models 1230

Series, 1243 Series, 1520 and 1720 Series

Card reader terminals, Models 1000, 1000P

Site controller, Model 2000S CFN Series

Data entry terminals, Model TPK-900 Series

Fuel Point Reader System

New York City:

NYFD C of A # Product

4823 9100A, 9140A, 9152A, 9153A,

4997 9822A, 9823A

5046 9100Q, 9140Q, 9152Q, 9153Q,

9800A, 9840A, 9850A, 9852A,

9853A, 9140

9800Q, 9840Q, 9852Q, 9853Q

California Air Resources Board (CARB)

Executive Order # Product

G-70-52-AM Balance Vapor Recovery

G-70-150-AE VaporVac

NCWM - Certificate of Compliance:

Gasboy pumps and dispensers are evaluated by the National Confer ence of Weights and Measures (NCWM) under the National Type Evaluation Program (NTEP).

NCWM has issued the following Certificates of Compliance (COC):

COC# Product Model # COC# Product Model # COC# Product Model #

95-179A2 Dispenser

95-136A5 Dispenser 9800 Series 91-057A3 Controller

Patents

Gasboy products are manufactured or sold under one or more of the following U.S. patents.:

9100 Retail Series, 8700

Series, 9700 Series

91-019A2 Dispenser

9100 Commercial

Series

1000 Series FMS,

2000S-CFN Series

Dispensers

5,257,720

Point of Sale/Back Office Equipment

D335,673

Trademarks

on-registered trademarks

tlas™

onsola™

nfinity™

This document is subject to change without notice. · For information regarding Gasboy Literature, call (336) 547-5661

E-mail: literature@gasboy.com · Internet: http://www.gasboy.com

2005 GASBOY · All Rights Reserved

Registered trademarks

®

ASTRA

®

Fuel Point

®

Gasboy

®

Keytrol

®

Slimline

Additional U.S. and foreign trademarks

pending.

Other brand or product names shown may be

trademarks or registered trademarks of their

respective holders.

Additional U.S. and foreign patents pending.

Page 3

Table of Contents

Table of Contents

Important Safety Information 3

In An Emergency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Introduction 6

Intended User. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Scope. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Acronym Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Pump/Dispenser Components 7

Atlas Pump/Dispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Common Functions 9

Understanding Date Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Pump Totals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Site Preparation 11

Obey the Guidelines in Atlas Fuel Systems Documentation and Other

Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

General Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Hoses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Install Warning Labels and Signs for Customers . . . . . . . . . . . . . . . . . . . 12

Operating Pumps/Dispensers 13

Electronic Component Access (9800 Series Only) . . . . . . . . . . . . . . . . . 13

CPU Switch Settings for Standalone Operation (9800 Series Only) . . . . 14

View/Reset Totalizers (9800 Series Only) . . . . . . . . . . . . . . . . . . . . . . . . 15

Changing the Price. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Programming 8800 Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Shear Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Operating Sequence (9800 Series Only). . . . . . . . . . . . . . . . . . . . . . . . . 25

Standalone Mode Error Handling (Commercial Electronic Unit)(9800

Series Unit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Preparing for Servicing the Pumps/Dispensers 28

Call Gasboy First . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Service Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Replacement Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Specialized Training. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Preventive Maintenance 30

Maintenance of Vender Supplied Parts . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Performing Inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Filter Strainer Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Adjusting the Belts (Suction Pumps Only) . . . . . . . . . . . . . . . . . . . . . . . . 33

Preserve the Finish of Your Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

MDE-4363A Atlas Owner’s Manual· March 2005 Page i

Page 4

Table of Contents

Preventive Maintenance Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Glossary 45

A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

B. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

E. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

G . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

H. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

J . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

L. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

M . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

N. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

P. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

S. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Index Index - 1

MDE-4363A Atlas Owner’s Manual· March 2005 Page ii

Page 5

Important Safety Information

Important Safety Information

This section introduces the hazards and safety precautions

associated with inst alling, ins pecting, maint aining or servicing

this product. Be fore p erfor ming any task on this p roduct , read

this safety information and the applicable sections in this

manual, where additional hazards and safety precautions for

your task will be found. Fire, explosion, electrical shock or

pressure release could occur and cause death or serious

injury if these safe service procedures are not followed.

Preliminary Precautions

You are working in a potentially dangerous environment of

flammable fuels, va pors, and high voltag e or pres s ures . O nl y

trained or authori zed indi viduals k nowled geable i n the rel ated

procedures should install, inspect, maintain or service this

equipment.

Emergency Total Electrical Shut-Off

The first and most important information you must know is

how to stop all fuel flow to the pump and island. Locate the

switch or circuit breakers that shut-off all power to all fueling

equipment, dispensing devices, and submerged turbine

pumps (STPs).

!

WARNING

!

The EMERGENCY STOP, ALL STOP, and

PUMP STOP buttons at the cashier’s station

WILL NOT shut off electrical power to the

pump/dispenser.

This means that even if you activate these

stops, fuel may continue to flow uncontrolled.

You must use the TOTAL ELECTRICAL SHUTOFF in the case of an emergency and not only

these cashier station “stops.”

Total Electrical Shut-Off Before Access

Any procedure requiring access to electrical components or

the electronics of the dispenser requires total electrical shutoff of that unit. Know the function and location of this switch

or circuit breaker b efo re i ns pec tin g, i ns t al lin g, m ai nt a ini ng , or

servicing Gasboy equipment.

Evacuation, Barricading and Shut-Off

Any procedures requiring accessing the pump/dispenser or

STPs requires the following three actions:

Read the Manual

Read, understand and follow this manual and any other

labels or related mat erials suppl ied with this e quipment. If you

do not understand a procedure, call the Gasboy Customer

Service at 1-800-444-5579, Tech Support 1-800-444-5529. It

is imperative to your safety and the safety of others to

understand the procedures before beginning work.

Follow the Regulations

There is applicable information in NFPA 30A; Automotive and

Marine Service Code, NFPA 70; National Electrical Code (NEC),

OSHA regulations and federal, state, and local codes which

must be followed. Failure to install, inspect, maintain or

service this equipment in accordance with these codes,

regulations and standards may lead to legal citations with

penalties or affect the safe use and operation of the

equipment.

Replacement Parts

Use only genuine Gasboy replacement parts and retrofit kits

on your pump/dispenser. Using parts other than genuine

Gasboy replacement parts could create a safety hazard and

violate local regulations.

Safety Symbols and Warning Words

This section provides import ant information about warning

symbols and boxes.

Alert Symbol

This safety alert symbol is used in this manual and on

warning labels to alert you to a precaution which must be

followed to prevent potential personal safety hazards. Obey

safety directives that follow this symbol to avoid possi ble

injury or death.

Signal Words

These signal words used in this manual and on warning labels

tell you the seriousness of particular safety hazards. The

precautions that follow must be followed to prevent death,

injury or damage to the equipment

DANGER - This signal word is used to alert you to a

!

hazard to unsafe practice which will result in death or

serious injury

WARNING - This alerts you to a hazard or unsafe

!

practice that could result in death or serious injury.

CAUTION with Alert symbol - This signal word

!

designates a hazard or unsafe practice which may

result in minor injury.

CAUTION without Alert symbol - When used by itself,

CAUTION designates a hazard or unsafe practice

which may result in property or equipment damage.

- An evacuation of all unauthorized persons and vehicles

using safety tape, cones or barricades to the effected units

- A total electrical shut-off of that unit

MDE-4363A Atlas Owner’s Manual· March 2005 Page 1

Working With Fuels and Electrical Energy

Prevent Explosions and Fires

Fuels and their vapors will become explosive if ignited. Spilled

or leaking fuels cause vapors. Even filling customer tanks will

cause explosive vapors in the vicinity of dispenser or island.

Page 6

Important Safety Information

This area contains a chemical known to the State of

California to cause cancer.

WARNING

!

This area contains a chemical known to the State of

California to cause birth defects or other reproductive

harm.

WARNING

!

No Open Flam es

Open flames from matches, lighters, welding torches

or other sources can ignit e fuels and their vapors.

No Sparks - No Smoking

Sparks from starting vehicles, starting or using power tools,

burning cigarettes, cigars or pipes can also ignite fuels and

their vapors. Static electricity, including an electrostatic

charge on your body, can cause a spark sufficient to ignite

fuels and their vapors. After gettin g out of a vehicl e, touch the

metal of your vehicle to discharge any electrostatic charge

before you approach the dispenser island.

Working Alone

It is highly recommended that someone who is capable of

rendering first aid be present during servicing. Be familiar

with Cardiopulmonary Resuscitation (CPR) methods if you

are working with or around high voltages. This information is

available from the American Red Cross. Always advise the

station personnel about where you will be working, and

caution them not to activate power while you are working on

the equipment. Use the OSHA tag out and lock out

procedures. If you a re not familiar with this re qui remen t, refer

to information in the service manual and OSHA

documentation.

Working With Electricity Safely

Be sure to use safe and establis hed prac tices in working with

electrical devices. Poorly wired devices may cause a fire,

explosion or electrical shock. Be sure grounding connections

are properly made. Make sure that sealing devices and

compounds are in place. Be sure not to pinch wires when

replacing covers Follow OSHA Lock-Out and Tag-Out

requirements. Station employees and service contractors

need to understand and com ply with thi s program comp letely

to ensure safety while the equipment is down.

Emergency First Aid

Informing Emergency Personnel

Compile the following information for emergency personnel:

Location of accident (for example, address, front/back of

building, and so on.)

Nature of accident (for example, possible heart attack, run

over by car, burns, and so on.)

Age of victim (for example, baby, teenager, middle-age,

elderly)

Whether or not victim has received first aid (for example,

stopped bleeding by pressure, and so on.)

Whether or not a victim has vomited (for example, if

swallowed or inhaled something, and so on.)

WARNING

!

Gasoline ingeste d may c ause unc onsciou sness

and burns to internal organs.

Do not induce vomiting.

Keep airway open.

Oxygen may be needed at scene.

Seek medical advice immediately.

WARNING

!

Gasoline inhaled may cause unconsciousness

and burns to lips, mouth and lungs.

Keep airway open.

Seek medical advice immediately.

WARNING

!

Gasoline spilled in ey es may cause bur ns to eye

tissue.

Irrigate eyes with water for approximately 15

minutes.

Seek medical advice immediately

Hazardous Materials

Some materials present inside electronic enclosures may

present a health hazard if not handled correctly. Be sure to

clean hands after handling equipment. Do not place any

equipment in mouth.

WARNING

!

Gasoline spilled on skin may cause burns.

Wash area thoroughly with clear/water.

Seek medical advice immediately.

IMPORTANT: Oxygen may be needed at scene if gasoline

has been ingested or inhaled. Seek medical advice

immediately.

Lockout/Tagout

Lockout/Tagout covers servicing and maintenance of

Machines and equipment in which the unexpected

energization or start up of the machine(s) or equipment or

release of stored energy could cause injury to employees or

personnel. Lockout/Tagout applies to all mechanical,

hydraulic, chemical or other energy, but does not cover

electrical hazards. Re ferenc e Subp art S of 29 CFR Part 191 0

IMPORTANT: Oxygen may be needed at scene if gasoline

has been ingested or inhaled. Seek medical advice

immediately.

Page 2 MDE-4363A Atlas Owner’s Manual· March 2005

- Electrical Hazards, 29 CFR Part 1910.333 contains specific

Lockout/Tagout provision for electrical hazards.

Page 7

In An Emergency

!

Spilled fuels, ac ciden ts invo lving pump s/d ispen se rs, or uncon trolled fuel flow creat es

a serious hazard.

Fire or explosion may result causing serious injury or death.

Follow established emergency procedures.

The following actions are recommended regarding these hazards:

In An Emergency

WARNING

Collision of Vehicle with Unit Fire at Island Fuel Spill

• Do not go near fuel spill or allow anyone else in the area.

• Use station EMERGENCY CUTOFF immediately. Turn off all system circuit breakers to

the island(s).

• Do not use console E-STOP, ALL STOP to shut o ff power . Th ese keys do not remove AC

power and do not always stop product flow.

• Take precautions to avoid igniting fuel. Do not allow starting of vehicles in the area. No

open flames, smoking or power tools in the area.

• Do not expose yourself to hazardous conditions such as fire, spilled fuel or exposed

wiring.

• Call emergency numbers.

MDE-4363A Atlas Owner’s Manual· March 2005 Page 5

Page 8

Introduction

Introduction

This manual provides instructions for safely operating, programming, and maintaining the

Atlas™ Fuel Systems pumps/dispensers.

Intended User

This manual is written for the owners and operators of Atlas Fuel Systems pumps and

dispensers.

Scope

This manual provides the following information about the Atlas Fuel Systems pumps and

dispensers:

• Operating the pumps/dispensers

• Preparing the pumps/dispensers for service

• Maintaining the pumps/dispensers

Acronym Table

The following table contains a list of acronyms used in this manual.

Note: Refer to the glossary for more detailed definitions.

Acronym Definition

ASC Authorized Service Contractor

CFR Code of Federal Regulations

DLT Displaying Last Transaction

IFSF International Forecourt Standards Forum

MOC Major Oil Company

NEC National Electrical Code

NFPA National Fire Protection Association

OSHA Occupational Safety and Health Association

PIN Personal Identification Number

PPU Price Per Unit (i.e., price per gallon or liter)

STP Submerged Turbine Pump

Page 6 MDE-4363A Atlas Owner’s Manual· March 2005

Page 9

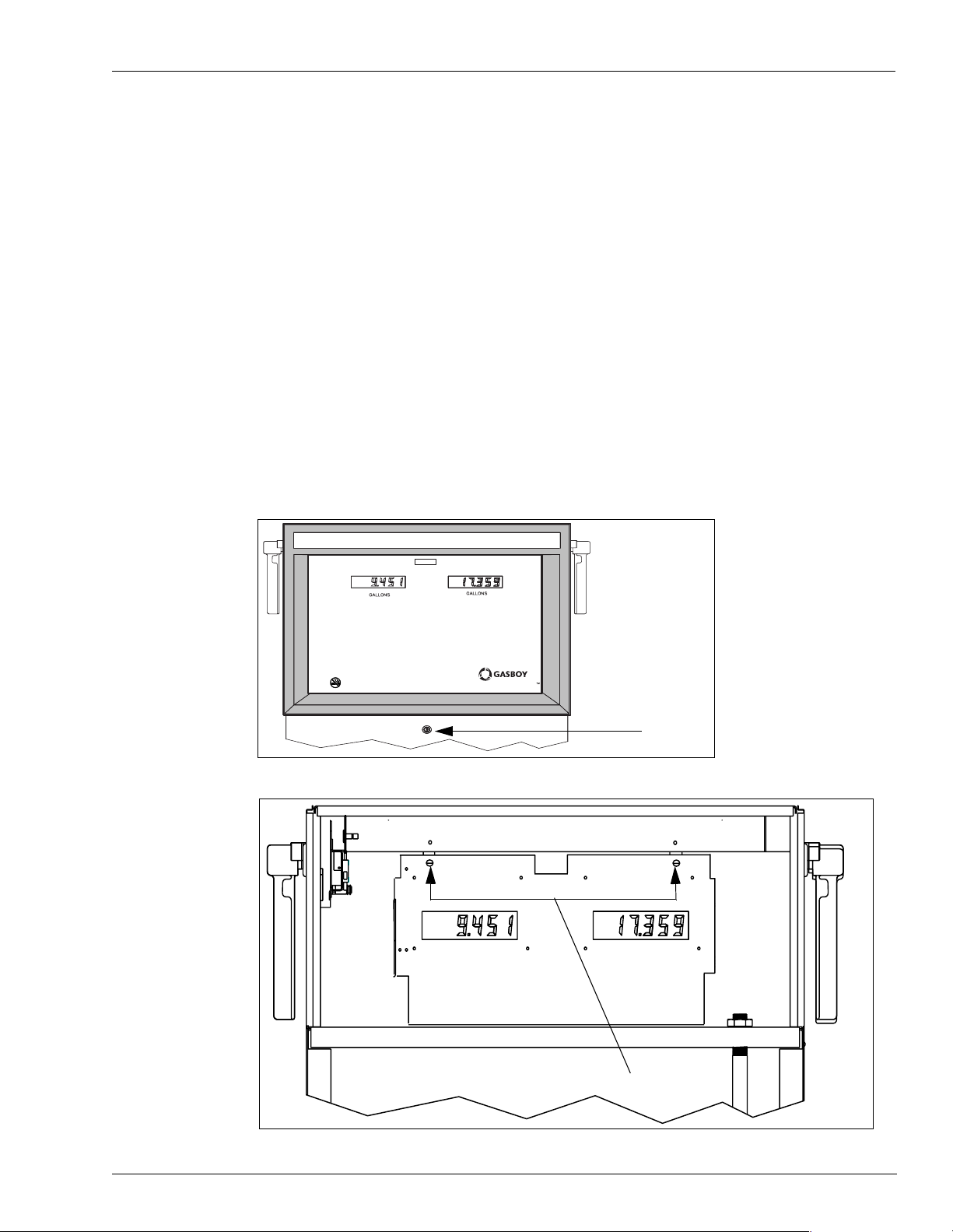

Pump/Dispenser Components

This sectio n provides diagrams that show the internal and external components of pumps and

and provides information about these components. Reference this section as you perform the

procedures in this manual.

Atlas Pump/Dispenser

The following drawing identifies the external components of a Gasboy Atlas pump/dispenser

(Mechanical Retail Unit). Mechanical units ha ve mechanic al digit al type di splays a s opposed

to electronic digital type displays. In units that are Commercial instead of Retail, the external

components are much the same with the exception that there are only totalizers, PPUs and a

Main Display showing the gallons pumped.

Pump/Dispenser Components

Boot Area

Nozzle &

Pump Handle

Lever Control

PPU Display

Totalizers

Mechanical Retail Unit

Cost Display

Gallon Display

Warning Labels

Door Lock

Access Door

MDE-4363A Atlas Owner’s Manual· March 2005 Page 7

Page 10

Pump/Dispenser Components

The following diagram identifies the external componen ts of a Gasboy Atlas pump/dispenser

(Electronic Retail Unit). Electronic units have digital displays as opposed to mechanical

displays. In units t hat are El ectronic Commercial i nstead of Retail th e externa l components are

much the same with the exception that there are only totalizers, PPUs and a Main Display

showing the gallons pumped.

Boot Area

Nozzle & Pump

Handle

Lever

Control

Electro-Mechanical Totalizer

Electronic Retail Unit

Digital Main Display

Gallons Display

PPU

Warning Label

Door Lock

Access Door

Page 8 MDE-4363A Atlas Owner’s Manual· March 2005

Page 11

Common Functions

This subsection provides instructions for common functions on the Gasboy Atlas pumps/

dispensers.

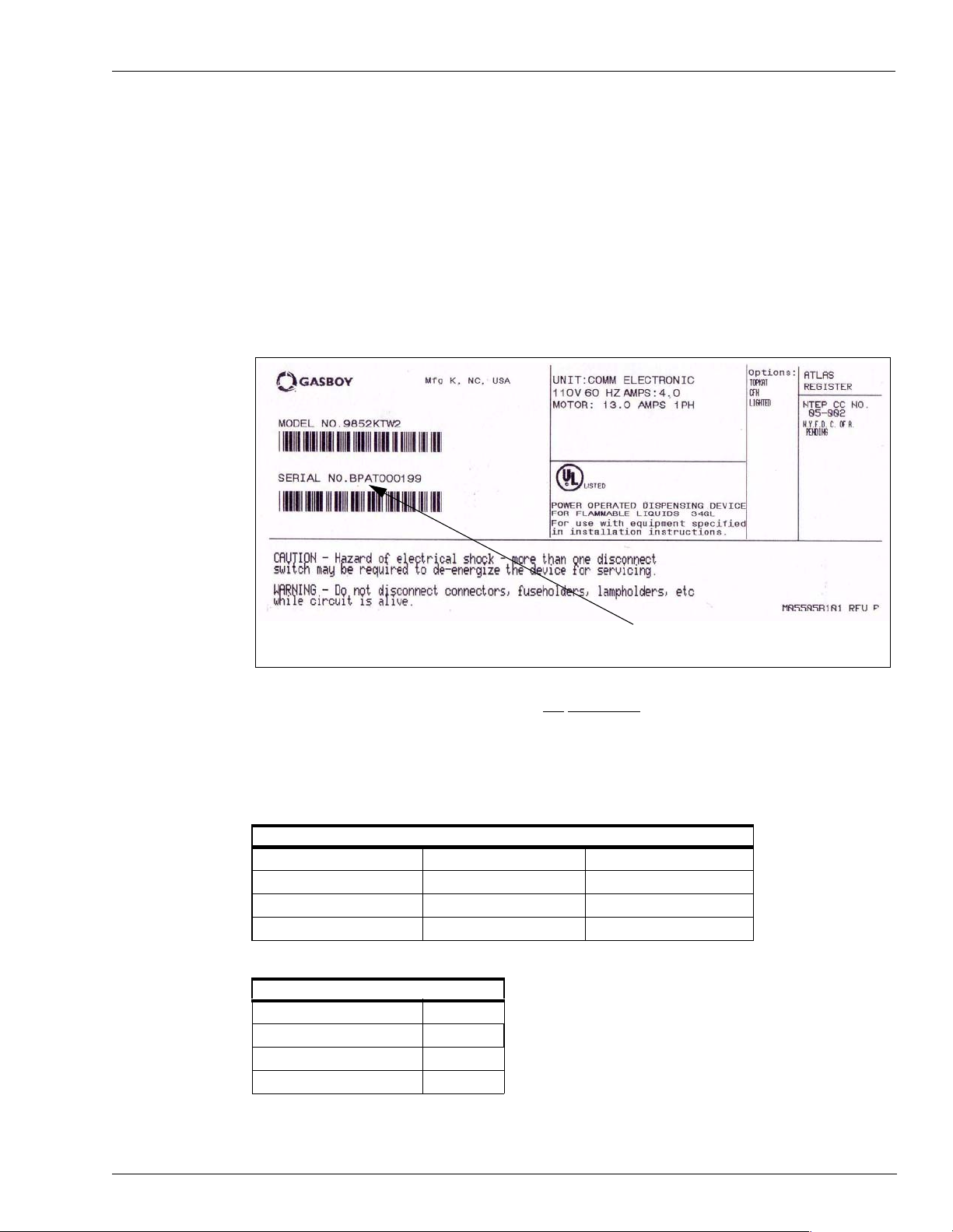

Understanding Date Codes

A two letter date code is stamped on the serial number plate before the serial number. This

code shows the month and year of manufacture. Refer to th e date code to determine the age of

the equipment for wa rr ant y purposes. The serial numbe r pl at e i s located on the “A” side at the

bottom of the unit attached to the inside of the frame.

Common Functions

Serial Number

Example: A serial number plate stamped “BP

AT000199” contains the following information:

• Date code [BP]—This unit was manufactured in B=February P=2005.

• Serial Number [AT000199]

Refer to the following tables to determine the date code on a Gasboy pump or dispenser.

Month Codes

A = January E = May J = September

B = February F = June K = October

C = March G = July L = November

D = April H = August M = December

Year Codes

P = 2005 U = 2009

R = 2006 W = 2010

S = 2007 X = 2011

T = 2008 Y = 2012

MDE-4363A Atlas Owner’s Manual· March 2005 Page 9

Page 12

Common Functions

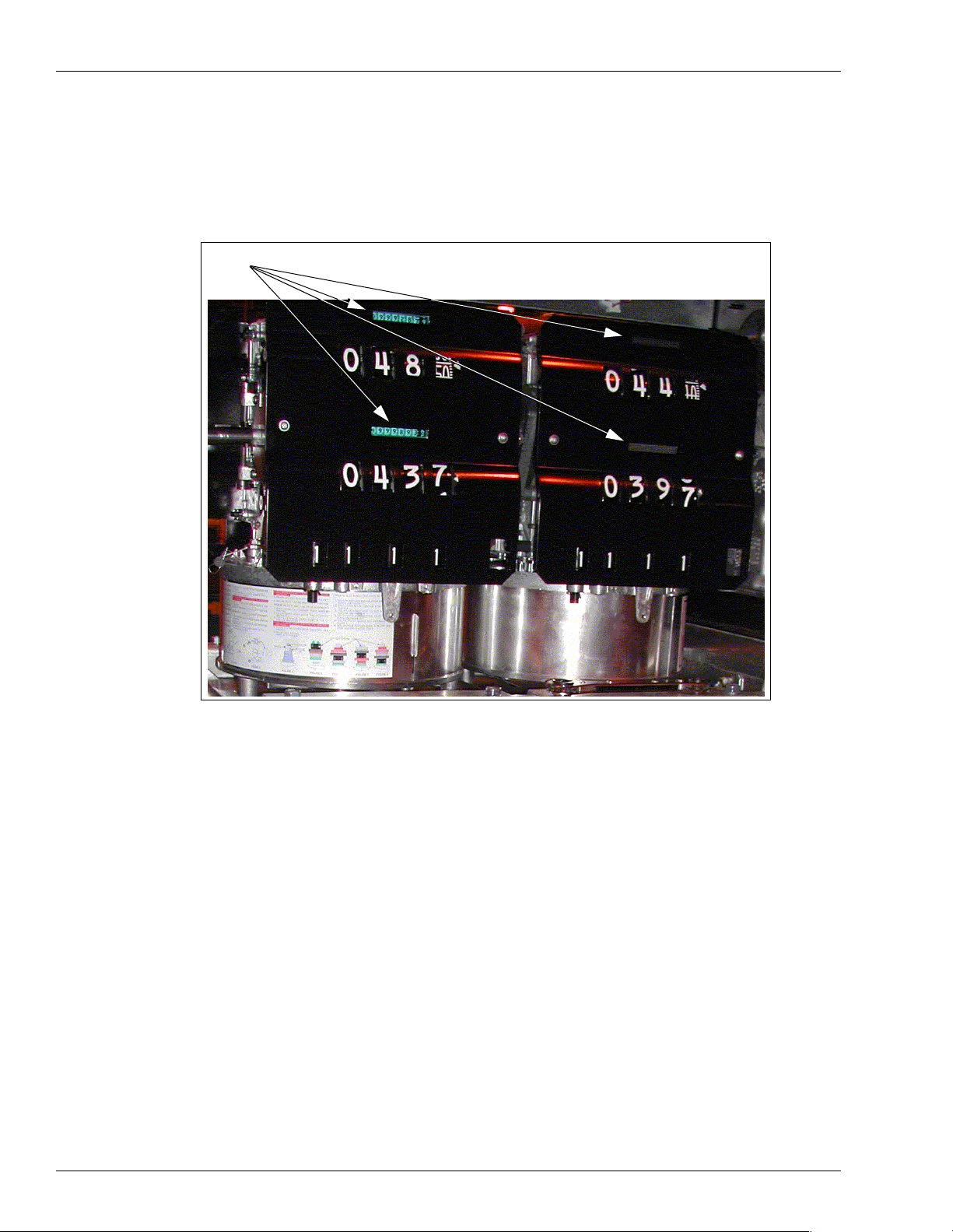

Pump Totals

Pump totals can be read from the totalizers. At the close of each day’s business, the total c an

be read from the unit and subtracted from the day before to obtain the total for that day. If the

unit is in use 24 hours a day, it may be a good idea to also take the readings in the morning so

as to monitor night usage.

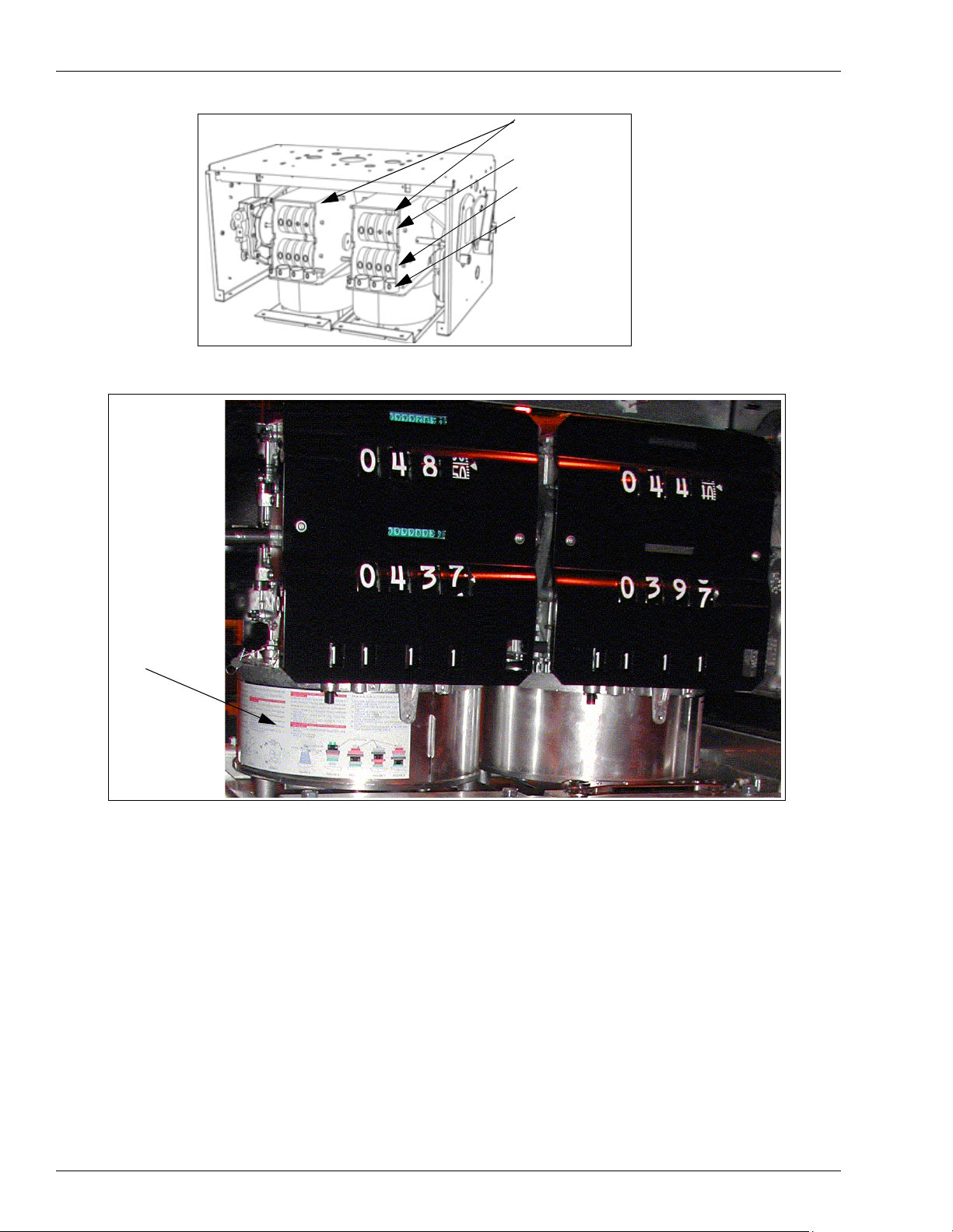

Totalizers

Page 10 MDE-4363A Atlas Owner’s Manual· March 2005

Page 13

Site Preparation

Site Preparat ion

T o ens ur e the sa fety a nd long- term re liabi lit y of your equipmen t, make sur e that your uni ts ar e

properly installed by a knowledgeable ASC. When your units are installed, make sure the

installer takes into consideration the guidelines in the following section.

Obey the Guidelines in Atlas Fuel Systems Documentation and Other Codes

The following manuals provide guidelines for installing Atlas Fuel Systems pumps/

dispensers:

• MDE-4331 Atlas Fuel Systems Installation Manual

• MDE-4333 Atlas Fuel Systems Site Preparation Manual

• FE-356 Atlas Dispenser Wiring Diagram

• FE-357 Atlas Pump Field Wiring Diagram

• FE-361 Atlas Master & Satellite Field Wiring Diagram

Be sure that the installer follows the instructions in those manuals, and adheres to all

applicable local, state and national codes.

General Guidel ines

Be sure the installer, at a minimum, performs the following tasks:

• Attach hose breakaways.

• Follow all manufacturer installation instructions fo r devices attached to the dispenser,

such as hoses, nozzles, and shear valves.

• Install a line leak detection system for all dispensers . (The system must comply with all

local and state codes.)

• Only use UL

• Properly install shear valves for all dispensers and certain above ground tank pump

applications. Be sure to follow all codes.

• Properly bolt units to the island.

• Test hoses for conductivity before use per the manufacturer’s instructions.

• Use appropriate safety signs as outlined in the manuals listed under Obey the Guidelines

in Atlas Fuel Systems Documentation and Other Codes above.

• Use isolation relays for dispensers (required by National Electrical Codes).

• Use the recommended hose lengths for each unit unless you are using hose retrievers.

Note: This is not a complete list. For other requirements, refer the manuals in the above

subsection.

Hoses

Hoses must be UL approved and conductive from end-to-end. Determining hose length is

covered in the table below.

®

-listed or approved attachments with the pump/dispenser.

Note: When determining hose length the effect of adding breakaway s adds significantly to th e

actual hose length.

MDE-4363A Atlas Owner’s Manual· March 2005 Page 11

Page 14

Site Preparation

WARNING

Hoses of excessive length may create a trip hazard.

Serious injury could occur as a result of tripping over an excessively long hose.

Do not use excessive length hoses. Also ensure hose retrievers are installed and

and are in good operating condition.

Do not install soft-wall hoses, they commonly cause a small sale to indicate when the unit is

activated and the nozzle is closed. Refer to the table below for more information about hoses

and hose retrievers.

Determining Hose Length

Refer to the following table to determine the correct hose length for the various types of hoses.

Type Length

Standard hardwall 5/8 or 3/4 ID (without breakaway) 10 feet, 6 inches

Standard hardwall 5/8 or 3/4 ID (with breakaway) 9 feet, 6 inches

Standard breakaway whip hose 1 foot, 0 inches

Install Warning Labels and Signs for Customers

Install wa rning labels and signs to ensure that customers are warned of potential safety

hazards. Make sure the warning label s and si gns ar e rea dily visible. At a minimum, install the

following signs:

• Turn off vehicle before fueling.

• No smoking; do not use matches or lighters nearby.

• Use only non-breakable, approved containers for storing fuel; make sure the container is

metal and properly identified for fuel storage.

• Static electricity hazards during fueling.

Promptly replace any missing, incomplete, or illegible labels or operating instructions.

WARNING

Static electricity can cause an explosion.

Sta tic ele ctricity, inc luding an electrost atic c harge on yo ur body, can ca use a sp ark

sufficient to ignite fuels and their vapors.

After getting out of a vehicle, touch the metal of your vehicle to discharge any

electrostatic charge before you approach the dispenser island.

Page 12 MDE-4363A Atlas Owner’s Manual· March 2005

Page 15

Operating Pumps/Dispensers

This section describes the operation of the pump/remote dispenser. It shows how to:

• access the electronic components

• set the standalone switch

• view and re setting the electronic totalizers

• use the actuator

• use the operating sequences for both pumps and remote dispensers.

If using a point of sale device, reference the manufacturer instructions.

Electronic Component Access (9800 Series Only)

There may be times when you will need to be operated the unit as a standalone. As a

standalone, the pump/dispenser will operate independent of the fuel management system.

1 Unlock and remove the front panel.

2 Remove the two bolts securing the bezel assembly and pivot display panel down.

Operating Pumps/Dispensers

TURN OFF ENGINE

Note: Unit will swing forward and

down after screws are removed.

Atlas

Unlock

Loosen and remove

MDE-4363A Atlas Owner’s Manual· March 2005 Page 13

Page 16

Operating Pumps/Dispensers

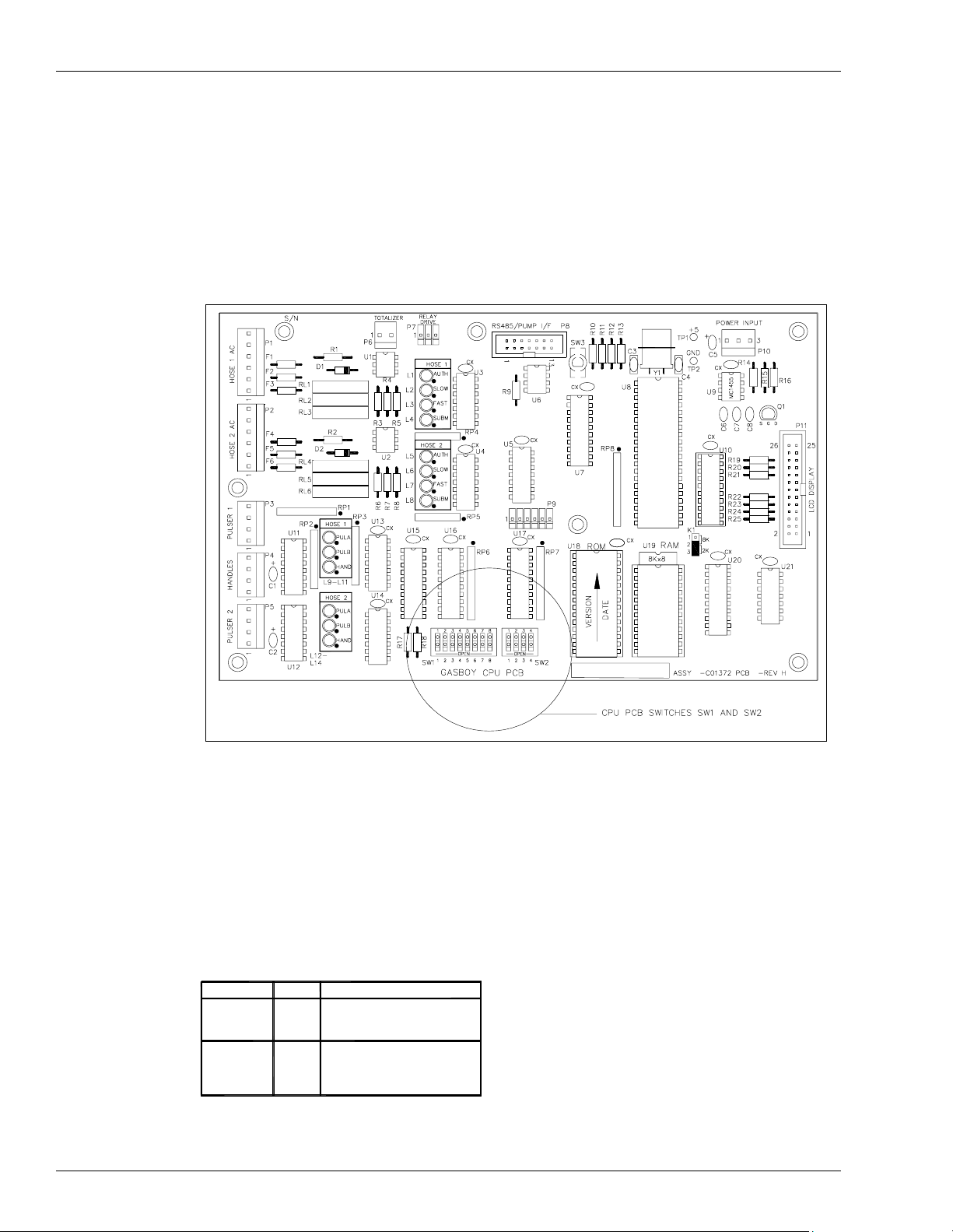

CPU Switch Settings for Standalone Operation (9800 Series Only)

The Atlas can be confi gured for vario us ope rat ing c ondit ions u sing the s witches loca te d on t he

CPU PCB. It is strongly advised that only a Gasboy Service Contractor access any switches

other than those explained here.

Switch settings are only changed with the power OFF. The new settings are read by the CPU

PCB when the power is turned ON again.

CPU Switch Settings (9800 Series Only)

SW1-2 Mode

If the unit is controlled by a GASBOY CFN or Topkat, electronic fuel management system,

the switch should be open (on-l ine mode). If the unit is controlled by a GASBOY Series 1000

or a mechanical system, or controlled by any non-GASBOY system, or not controlled by any

fuel management system at all, the switch should be closed (standalone mode).

Mode

On-line

Standalone

Page 14 MDE-4363A Atlas Owner’s Manual· March 2005

SW1-2

Open

Closed Notcontrolledbyanyfuel

FuelSystem

CFN-ElectronicFuel

ManagmentSystem

managmentsystem

Page 17

3 Onc e the switch set ting has been chang ed, pivot displa y panel to operat ing position and ti ghten

the two screws located on the left and right door support brackets.

4 Place the bezel assembly back into position and secure with the two bolts removed earlier.

5 Place the front panel back into position and lock.

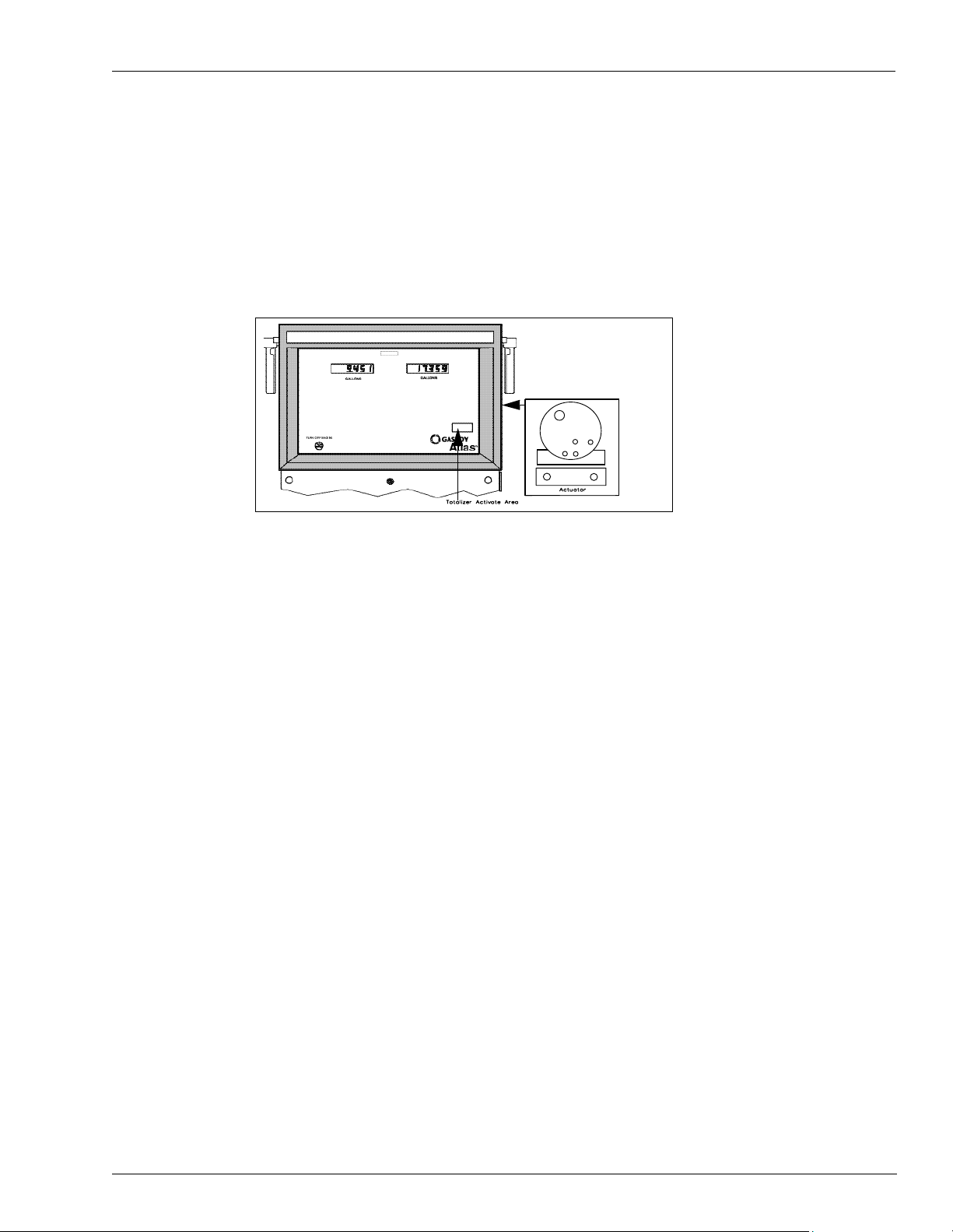

View/Reset Totalizers (9800 Series Only)

Operating Pumps/Dispensers

Commercial Electronic

The Atlas stores a running quantity total for each pump side. These electronic totalizers work

independent of the optional electrical mechanical totalizers that may be installed, and are

shown as whole gallons (liters) on the displays (decimal point is shown, although it is

disregarded). The tota lizer dat a is store d in batter y-backed m emory. The Atlas is supplied wit h

an actuator (shown in the above illustration) which allows you to view and reset electronic

totalizers.

To view the pump totalizers, make sure the pump handles are off and no transactions are in

progress. Locate the GASBOY dial face logo that is on the same pump side as the serial

number tag. (If equipped with the rear totalizer option, the totalizer can be activated from the

GASBOY logo on either side of the pump.) Touch the GASBOY logo with the actuator as

shown. The totalizer data for eac h pump side will be displayed for 10 sec onds . If more time is

needed, touch the actuator to the logo for an additional 10 second period.

Electro-Mech anical Totalizers

Some models of Atlas contain an optional mechanical totalizer for each pump side. Each

totalizer has 7 digits; 6 whole gallons and 1 tenth-wheel, 7 whole digits for liters. The electromechanical totalizers are located below each nozzle hook. Reference Atlas Pump/Dispenser,

Page 7.

MDE-4363A Atlas Owner’s Manual· March 2005 Page 15

Page 18

Operating Pumps/Dispensers

Note: Directions

for changing the

price can be

found on the

outside of the

variator cover.

Mechanical Totalizer

Totalizers

Dollars/Cents

Gallons/Liters

PPU (Price Per

Unit)

NOTE: The unit shown to

the left is an example of a

one type of Totalizer, the

example shown is a

Mechanical Totalizer and

as such is used only in

mechanical units.

Variator

Changing the Price

1 Unlock and remove the front panel. Repeat this procedure for the other side.

2 The variator section of the computer register(s) is exposed to allow for price changes. Slide the

variator cover of the computer register apart to expose the price range arms.

3 To change a setting, grasp the desired range arm (tenths of a cent, one cent, and ten cent arm)

and raise it to clear the range arm locator, move it f oreward or backwards, relocating it at the

desired position so that the range arm is station at it’s new location on the range arm locator.

Assure the range arm is totally bottomed on its setting. Repeat this for all range arm settings if

necessary.

Page 16 MDE-4363A Atlas Owner’s Manual· March 2005

Page 19

Operating Pumps/Dispensers

Range Arm

Range Arm Locator

4 To change the money unit setting, locate the lever control which is located above the variator

section on the same leve l as the price displ ay. There are 3 availa ble posi tion s: 0.00, 1.00 , 2.00.

Remove the cotter pin, grasp the lever and raise it slightly to clear the position locators.

Position the lever to the desired setting and release. Reinsert the cotter pin through the lever

and plate. Note - If the lever wil l not move to the des ired pos iti on, rotat e the ri ght han d money

wheel until the lever is free to move.

5 If you have difficulty reaching the money shift lever when changing prices, remove the two

cap screws located over the tabs of the bezel assembly. Lift the bezel assembly upward and

remove it from the unit. When reattaching the bezel to the dispensing unit, be sure the top

inner edge of the bez el ass embl y sl ides into the "U" shaped chan nel loc at ed on the upper edge

of the dispensing unit.

MDE-4363A Atlas Owner’s Manual· March 2005 Page 17

Page 20

Operating Pumps/Dispensers

Programming 8800 Models

General Programming

Programming the unit is divided into three levels; Level 1, 2 and 3. Level 1 codes will be

explained here. The default code for level 1 is 2222. This code can be changed for station

security, however losing the codes will require a master reset of the unit and reprogramming.

Codes found in Level 1 are included below.

• CC 1 Manual programming of PPU (unit pricing). Pricing can also be downloaded

through the two-wire communication using the POS (Point Of Sale) device.

Note: Levels CC 2 & CC 3 should only be accessed by a trained ASC or improper operation

could result.

• CC 2 Setting mode of operation as being stand alone (isolates sale control from the POS)

or two-wire (unit control through the POS).

• CC 3 Programming Volume Allocation. This basicall y set s the max imum sale size i n unit s

of measure (gallons for example).

• CC 4 Manual Blank and Five-Button Preset. This dual use code allows turning the

displays off manually or is used to activate different preset modes depending upon the

options included with the unit.

• CC 5 Test Programmable Customer Preset. This code is used to initiate testing for the 5

Button Preset option if used.

• CC 6 Memory Clear: This code is only useful to clear a unit displaying an Error Code EC

31 Totals Data Error) or EC 35 Configuration Data Error.

• CC 7 Setting Totals Input. This code allows setting of non zero totals. It is useful for new

installs or service when the station does not want to restart totals for its dispensers at zero

when old dispensers are replaced or receive certain types of service. It can only be

performed after performing a master reset, CC7 or for new units.

• CC 8 display Pump Controller Firmware Version.

Programming the 8800 Series Retail Electronic Units

This section describes the level 1 programming procedures and considerations for the 8800

series.

Page 18 MDE-4363A Atlas Owner’s Manual· March 2005

Page 21

Operating Pumps/Dispensers

Conversion Factor

US Gallons

Imperial Gallons

Liters

1012 Pulses per Gallon

Memory Error

ROM Error

RAM Error

Sides

Single-sided

Dual-sided

Code

0

1

2

3

Code

1

2

Code

1

2

Level 1 Programming and Data Access (8800 Series only)

Pin Code Entry

Unit T ype

1 Grade

2 Grade

3 Grade

4 Grade

Two Wire Pump ID 1-16

Code

0

1

2

3

Press Fl.

Enter 4-digit ID (default 2222) than press ENTER.

Press F1 to exit any command code.

Press F2 to return to normal operation.

From Level 1 after entering pin code (you may enter any command code directly):

Command Code 1: Pr ogram PPU

• Press "1' and then ENTER

• Select Side (1 or 2) and then ENTER

• Select Grade and then ENTER

• Select Price Level and then ENTER

• Enter new PPU and then ENTER

(Repeat for other Side, Grade and Price Level)

Command Code 2: Program Two-Wire/Standalone

• Press “2" and then ENTER

• Press Configuration number and then ENTER where

0 = Standalone

1 = Two-Wire

MDE-4363A Atlas Owner’s Manual· March 2005 Page 19

Page 22

Operating Pumps/Dispensers

Command Code 3: Program Allocation

• Press '3’ and then ENTER

• Select Side (1 or 2) and then ENTER

• Select Hose/Grade and then ENTER

• Select Allocation amount and then ENTER

(Repeat for other Side, Hose and Grade.)

Command Code 4: Program Manual Blank Display Cash/Volume Preset Select

• Press "4" and then ENTER

• Select Function Code (1 or 2) and then press ENTER where

Function Code 1: Manual Blank Displays

Press option code and then ENTER where

0= Display OFF

1= Display ON

Function Code 2: Cash/Volume Preset Select (requires option on dispenser)

Press option code and then ENTER where

0= No 5 Button Preset or PPP Preset installed

1= Money Preset

2= Volume Preset

3= Incremental Preset

Command Code 5: Test Customer Programmable Preset (Requires preset optoin on dispenser)

• Press "5" and then ENTER.

• Select Configuration and then ENTER where

0= STOP Test/Program

1= START Test/Pr ogram

Depending upon the preset option type testing will convey the following when pressing the pr eset

buttons:

Five Button Preset (Non-Customer Programmable Preset) (Requires preset option on unit)

Press ENTER after making selections.

1: Program Button 1 (Default 1)

2: Program Button 2 (Default 5)

3: Program Button 3 (Default 10)

4: Program Button 4 (Default 15)

Page 20 MDE-4363A Atlas Owner’s Manual· March 2005

Page 23

Operating Pumps/Dispensers

Incremental Preset (Non-Customer Programmable Preset) (Requires preset option on unit)

Press ENTER after making selections.

1: Program Button t (Default 1) Money

2: Program Button 2 (Default 5) Money

3: Program Button 3 (Default 10) Money

4: Program Button 1 (Default 1) Volume

5: Program Button 2 (Default 5) Volume

6: Program Button 3 (Default 10) Volume

(After test is complete follow programming steps to setup)

Command Code 6: Memory Clear For Error Code 31 or 35

• Press ”6" and then ENTER

• Press “1” and then ENTER

• Command Code 7: Program Totals Input

• Press “7” and then ENTER

• Select Side (1 or 2) and then ENTER

• Select Grace # and then ENTER

• Press “$ Total”

• Enter money total and then ENTER

(Repeat for other side and grade)

Press “Volume Total” AND repeat above procedure for volume totals.

Command Code 8: Display Version Number

• Enter "8" and then ENTER

• Select Software Option and then ENTER where

1= Pump Controller

3= Customer Programmable Preset

MDE-4363A Atlas Owner’s Manual· March 2005 Page 21

Page 24

Operating Pumps/Dispensers

ATC Programming (8800 Series Only)

At Power-up, units programmed with the ATC option will flash 104 before displaying normal

information. Units with the option but not programmed for ATC will flash 100. The

following procedure is used to program the ATC option:

1 Turn the programming switch on the ATC controller board to “ON”. Note the dispenser must

not be used during this programming and all pump handles must be down or inactive.

2 Press 100 on the keypad, then ENTER

• The money position showing fueling position selected will display 1

• The volume position showing the fuel type selected will display 1 where

a.1= Gasoline

b.2= Diesel

• The PPU position showing fuel density selected will display 730 where

a. 740= Gasoline

b. 840= Diesel

c. Default= 730

3 Select the fuel type and press ENTER

4 The firmware sequence will sequence through each fueling position. Select the fuel type for

each positi on (Diesel or Gasolin e).

5 Turn the programming switch on the ATC controller board to OFF.

6 Press F2 to exit the ATC programming mode.

ATC Inspection Mode (8800 Series Only)

Inspection of ATC states and data collection can be obtained following a similar procedure as

outlined for ATC programming above. Instead of pressing “100” other codes can be used as

described in the following table:

Page 22 MDE-4363A Atlas Owner’s Manual· March 2005

Page 25

Displaying Pump Totals (8800 Series Only)

Operating Pumps/Dispensers

During service it i s of te n required to access pump tota ls. This can be done at the POS or at the

pump/dispenser. Access is simple through the manager keypad:

To view Side 1 totals:

1 Press $TOTAL. Combined cash and credit total will display for grade 1, side 1.

2 Select grade. Read $TOTAL for each grade selected.

3 Press VOL TOTAL. The Volume total will display for the grade selected.

4 Select grade. Read volume totals for grade selected.

5 To view Side 2 totals, press Enter.

6 Press Clear to exit.

Error Codes and Interpretations for 8800 Retail Electronic Units

You may observe t he following. The se codes ar e useful when troubles hooting a pr oblem. Side

A is the Junction box opening side, B is the opposite side.

31 Totals data error - can be cleared through CC 6 programming (reference Pr ogr amming -

8800 series units. If codes repeat frequently, consult a Gasboy ASC.)

35 Configuration Data Error - can be cleared through CC 6 programming (reference

Programming - 8800 series units. If codes repeat fr eque nt ly, consult a Gasboy ASC.)

44 Pump Handle Up at Power Up

To recover, lower pump handle.

MDE-4363A Atlas Owner’s Manual· March 2005 Page 23

Page 26

Operating Pumps/Dispensers

S0000349

Shear Valve

Shear valves, require d by NFPA 30A, are intended to shut-of f t he f low o f f uel at the di spenser

base (hydraulics area ) during vehicl e impact or fir es. A single-poppe t shear valve pr events fuel

from flowing from the underground tank. A double-poppet shear valve prevents fuel from

flowing from the underground tank and draining from the dispenser. In the event that product

fails to exit the dispenser/pump hose, check to ensure that the shear valve is not closed.

The following diagram shows a shear valve, in the open position (allows flow to pass

through). Note it’s location inside the dispenser on the lower cross brace in the pit box area.

Shear Valve in

Open Position

Shear Valve

Lower Cross Brace

WARNING

Shear Valves may stick partially in the open position causing fuel to flow

throug h a she ar val ve tho ught t o be cl osed. Alway s tes t for proper closing

by attempting to dispense fuel into an approved container with the fuel

position authorized. Fuel most not continue to flow after pressure has

been reli ev ed.

For maintenance information, reference the Preventive Maintenance Table, Page 34 of this

manual.

Page 24 MDE-4363A Atlas Owner’s Manual· March 2005

Page 27

Operating Sequence (9800 Series Only)

Operating Pumps/Dispensers

Shear Valve

Shear Valve in the OFF (Closed)

position

The exact sequence of ev ents that occu rs duri ng the opera tion of the pump or remote dispe nser

is determined by various switch settings, inputs, and the user. A typical transaction is

explained below.

Pump Unit - (motor and pump in unit base)

1 Turn on the pump handle. If AC is present on the Control Feed line, the reset cycle begins.

The display (electronic units):

• goes blank for one second

• shows all 8's for one second

• goes to 0.000 (gallons) or 0.00 (liters) until fuel starts.

The display (mechanical units)

• resets to 0.000 (gallons) or 0.00 (liters)

The pump motor turns on and the Reset Complete line becomes active.

2 The pump continu es to run un til on e of the fo llowing co nditions o ccurs. These condi tions tur n

off all relays.

• The handle is turned off.

• The Control Feed line (AC power line to pump/dispenser) is turned off by the POS.

• A pulser error is detected (electronic units only).

• A time-out is reached (if the unit is programmed with a time out value (9800 series only).

If connected to a fuel management system, the time-out loaded into the system will be

used (comm ercial electronic only). Unit will turn off if idle for a preprogramming ti me

when no fuel is flowing.

• A quantity of 990.000 gallons (9900.00 liters) is reached. If connected to a fuel

MDE-4363A Atlas Owner’s Manual· March 2005 Page 25

Page 28

Operating Pumps/Dispensers

management system, the limit set in the system will be used. (9800 Series O nly)

• The pump is halted by an operator of a fuel management system.

• An AC power failure occurs.

• Station Emergency Stop button is pressed.

Dispenser Unit- (fueling unit with no motor and pump in the bottom)

1 Turn on the pump handle. If AC is present on the Control Feed line, the re set cycle begi ns and

the submersible pump turns on. The display (Electronic Unit):

• goes blank for one second

• shows all 8's for one second

• goes to 0.000 (gallons) or 0.00 (liters) and stays until fueling begins.

The display (mechanical units)

• resets to 0.000 (gallons) or 0.00 (liters)

2 The user begins to dispense fuel.

3 The remote dispenser continues to run until one of the following conditions occurs. These

conditions turn off all relays.

• The handle is turned off.

• The Control Feed line is turned off (AC power line to pump/dispenser) is turned off at the

POS.

• A pulser error is detected (electronic unit only).

• A time-out is reached (if the unit is pr ogrammed wit h a time out val ue)(8 800 Serie s Unit).

If connected to a fuel management system, the time-out loaded into the system will be

used (commercial electronic only)(9800 Series Unit). Unit will turn off if idle for a

preprogrammed time when no fuel is flowing.

• (9800 models) A quantit y of 99 0.000 gal lons ( 9900.00 lite rs ) is rea ched. I f conn ected to a

fuel management system, the limit set in the system will be used.

• The pump is halted by an operator of a fuel management system.

• An AC power failure occurs.

• Station Emergency Stop button is pressed.

Standalone Mode Error Handling (Commercial Electronic Unit) (9800 Series Unit)

When operating the pump/dis p en ser in sta nda lone mode (not connected to a fuel mana gemen t

system), the Atlas displays two-digit error transaction codes on the LCD displays when

transactions are terminated abnormally (by a means other than turning off the pump handle).

There are four possible error conditions that may be displayed:

Code Condition

55 Po wer fai lure

56 Pu lser error

57 Timed out

58 Limit cutoff

Page 26 MDE-4363A Atlas Owner’s Manual· March 2005

Page 29

The error codes are displayed for two seconds at the left of the LCD window, alternating with

a five-second display of the last sale amount. The display alternates between the two until a

new transaction begins. When an error occurs, the user should note the error code and relay

the information to the ASC.

Transac tion error cod es are displa yed only when the pump/ dispenser is op erating in st andalone

mode. When connected to a fuel management sys tem, (on-l ine mode) , transa ction error co des

are transmitted back to the fuel management system with the completed transaction data.

Safety Information

Refer to Important Safety Information, Page 3 for safety information before operating pumps/

dispensers.

Operating Pumps/Dispensers

WARNING

Running vehicles can generate sparks, which could ignite fuel.

Running vehicles could create a safety hazard, such as a fire or an explosion.

Never dispense fuel into a vehicle with its motor running.

MDE-4363A Atlas Owner’s Manual· March 2005 Page 27

Page 30

Preparing for Servicing the Pumps/Dispensers

Preparing for Servicing the Pumps/Dispensers

This section provides instructions for preparing your site for servicing by a Gasboy-trained

ASC.

WARNING

The pump/dispenser contains pressurized flammable fuel and lethal voltages.

Servicing a Gasboy unit incorrectly could result in severe injury or death.

Do not attempt to service Gasboy pump/dispenser yourself, and do not allow

untrained pe rsonnel to service Gasboy pumps/dispensers. Only Gasboy-trained

ASCs should service a Gasboy unit.

WARNING

Unapproved modifications could result in hazardous conditions.

Making unapproved modifications could result in improper equipment operation and

violation of state and local codes and could also create a hazardous condition, such

as fire, explosion, or electrical shock.

Do not make unapproved modifications to Gasboy equipment. Consult your ASC,

distributor, or Gasboy for approved modifications and kits.

Call Gasboy First

Before phoning an ASC, call the Gasboy help desk at 1-800-444-5529. The help desk may be

able to resolve the issue for you.

Service Preparation

Use a Gasboy-tra ined ASC to e f fi cient ly s ervice and main tain you r Gasbo y p umps/di spense rs.

Gasboy trains and certifies ASCs to service and maintain Gasboy pumps/dispensers in a safe

manner.

Before Calling For Service

Perform the following tasks bef ore you call for service:

• Obtain complete information from station personnel about the problem.

• Confirm that the tank has fuel.

• Confirm that the power, pump lights, and circuit breakers are on.

• Record Error Codes that may exist on the Main Display (Elec tronic Units only).

Description of Problem

Provide the ASC with a complete pro blem descri ption includi ng all symp toms. Be sure to give

the serviceman as complete and accurate information. Doing so will help ensure faster repairs

and keep downtime costs to a minimum.

Page 28 MDE-4363A Atlas Owner’s Manual· March 2005

Page 31

Warranty Service

All warranty service must be performed by an ASC, failure to do so could result in loss of

warranty coverage.

Replacement Part s

Use only genuine Gasboy replacement parts and retrofit kits on your pump/dispenser.

Preparing for Servicing the Pumps/Dispensers

WARNING

Non-Gasboy replacement parts may create safety hazards and violate local

regulations. Non-Gasboy replacement parts could also affect the pump/

dispenser’s performance, reliability, and warranty.

Use of non-Gasboy replacement parts could create a hazardous condition, such

as fire, explosion, or electrical shock.

Only use Gasboy replacement parts and retrofit kits.

Specialized Training

For safety reasons, do not attempt to service Gasboy pu mp/di spense r yours elf un less y ou have

been trained and certified by Gasboy or an authorized Gasboy certified trainer.

WARNING

The pump/dispenser contains pressurized flammable fuel and lethal voltages.

Servicing a Gasboy unit incorrectly could result in severe injury or death.

Do not attempt to service Gasboy pump/dispenser yourself, and do not allow

untrained pe rsonnel to service Gasboy pumps/dispensers. Only Gasboy-trained

ASCs should service a Gasboy unit.

To receive specialized training for servicing Gasboy pumps/dispensers, contact a Gasboytrained contractor or distributor. Training may be available locally, at various regional centers.

Contractors and distri butors may char ge a nomin al trai ning fe e. For more inf ormati on, conta ct

your nearest distributor.

MDE-4363A Atlas Owner’s Manual· March 2005 Page 29

Page 32

Preventive Maintenance

Preventive Maintenance

Gasboy pumps and remote dispe nsers are designed for many years of re liable service , however

certain dispenser or pump parts will experience normal wear and therefore will require

periodic inspections. For example, detecting fuel leaks that may occur, belt tension and belt

condition, lubrication and strainer cleanliness are all important to maintain safe and efficient

unit operation. To avoid annoying pump shut downs, a periodic preventive maintenance

inspection plan must be established and followed.

Procedures requiring leak repair, shear valve maintenance and disassembly of portions of the

pump/remote dispenser should be performed by an ASC.

WARNING

To avoid electrical shock or hazard of an explosion or fire, when servicing remote dispenser/

pump:

- turn off and lock out all power to the pump/remote dispenser. (In submersible pump

applications turn off and lock out power to the submersible pump and any other remote

dispensers which use that su bmersibl e pump. AC power can feed back into a shut-of f disp enser

when remote dispensers share a commo n subm ersib le pum p or st arte r relay.)

- turn off and lock out all power to the remote dispenser and submerged pumps at the master

panel and clo se and te st a ny im p ac t v al ve before performing any main ten anc e or service to the

remote dispenser, including changing any fuel filters or strainers.

- block island so no vehicles can pull up to the remote dispenser when the dispense is being

worked on.

CAUTION

Moisture from rain can damage the internal components of a pump/dispenser.

Internal components exposed to moisture may not operate correctly.

Do not open the elec tronics cabinet to per form any tasks while it is raining.

Maintenance of Vender Supplied Parts

Certain parts of t he d is p ens er /pu mp ar e pr odu ced by venders for Gasboy (h ose s, nozzles, etc.)

and as such may have docume ntation sepa rate fro m that which Ga sboy suppli es. In thes e cases

it will be necessary to consult the vender documentation for service intervals and any

adjustments if required to your dispenser/pump.

Use Authorized Parts

The use of unauthorized parts can void your warranty, cause you to lose continuity of the

Underwriters Label on the pump, cause inefficient operation and possibly an operational

hazard. Always use new gaskets and seals when servicing or rebuilding Gasboy equipment.

Page 30 MDE-4363A Atlas Owner’s Manual· March 2005

Page 33

Performing Inspections

This section provides instructions for scheduling two types of maintenance inspections:

• General inspections

• Component inspections

Safety Warnings

You are performing inspections and maintenance in a potentially dangerous environment of

flammable fuels/v apors and hi gh volt age . Foll ow all safet y p recaut ions to pre vent i njur y whe n

inspecting a pump/dispenser at the islands.

WARNING

You are performing inspections and maintenance in a potentially dangerous environment of

flammable fuels/vapors and high voltage.

Fire, explosion, or electrical shock could result in severe injury or death if you do not follow

safe procedures.

WARNING

Read and obey all safety precautions in this manual to prevent potential injury or death.

Preventive Maintenance

General Inspections

Perform a general inspection of each pump/dispenser as follows:

• Each week to ensure that all pumps/dispensers are operating properly

• Whenever you receive a complaint about potential unit problems

As part of your general inspection, inspect all areas for signs of damage or sharp edges.

Replace any missing or damaged warning labels. Gasboy also strongly recommends that an

ASC periodically inspect the equipment, as outlined in the next subsection.

WARNING

Leaking fuel can be ignited, causing a fire or explosion.

Fire, explosion, or electrical shock could result in severe injury or death if you continue to use

damaged pumps/dispensers.

If you find any leaks or damage, stop using the pump/dispenser, and contact your local ASC.

WARNING

Personnel servicing a pump /dispe nser c an be in jured i f the pum p/dis pense r is not barrica ded to

all unauthorized personnel and vehicles.

If proper precautions are not taken, the person servicing the unit can be injured by a vehicle.

Before servicing a pump/dispenser, evacuate all unauthorized persons and vehicles; then, use

safety tape or cones as barricades.

MDE-4363A Atlas Owner’s Manual· March 2005 Page 31

Page 34

Preventive Maintenance

Component Inspections

Refer to the Preventive Maintenance table to schedule component inspections. The station

owner should only inspect for problems. For safety reasons, several tasks in the Preventive

Maintenance Table, Page 34, including all repairs, should be performed only by an ASC.

Refer to the column entitled “Who Performs the Inspection/Repair” to determine if an ASC

must perform a task.

WARNING

The pump/dispenser contains pressurized flammable fuel and lethal voltages.

Servicing a Gasboy unit incorrectly could result in severe injury or death.

Do not attempt to s erv ic e G asboy pump/dispenser you rse lf, and do not allow untrained personne l

to service Gasboy pumps/dispensers. Only Gasboy-trained ASCs should service a Gasboy unit.

WARNING

Leaking fuel can be ignited, causing a fire or explosion.

Fire, explosion, or electrical shock could result in severe injury or death if you continue to use

damaged pumps/dispensers.

If you find any leaks or damage, stop using the pump/dispenser, and contact your local ASC.

CAUTION

Improperly installed or maintained e quipment can create a hazard.

Improperly installed or maintained equipment could cause a fire, explosion, or electrical shock.

For any component not supplied by Gasboy (for example, hoses and nozzles), consult and follow

the installation and maintenance instructions provided by the manufacturer.

Filter Strainer Replacement

If the unit is equipped with a straine r and filter, check and change it at regular intervals (see

maintenance table). A dirty strainer and or filter in a pump or remote dispenser will cause a

slower delivery rate. Refer to the accessories section of your parts manual to ensure that you

replace the strai ner of re quired and filter with one d esi gned for your model. Always use a d ri p

pan and abso rbent material directly b elow the filter when removing the cartridge to prevent

contamination of both the soil and the electrical components within the cabinet. This service

must not be done by untrained individuals.

Page 32 MDE-4363A Atlas Owner’s Manual· March 2005

Page 35

Special Setup Required for Aircraft Fueling

CAUTION

Aircraft require finely filtered fuel.

Improperly filtered fuel could cause the engine to fail.

Do not use Gasboy pu mp s/d ispense rs for di rect f ueling of a ircraft wit hout a uxiliary

filters, separators, and other equipment necessary to ensure product purity.

Adjusting the Belts (Suction Pumps Only)

With the proper care, belts will give exceptionally good service. A loose belt not only cuts

down dispensing speed, due to slipping, but also results in excessive wear. Reference the

Preventive Maintenance Table, Page 34 found in this manual. This service must not be done

by untrained individuals.

Preventive Maintenance

Preserve the Finish of Your Pumps

Nearly all gasoline pumps are installed outdoors where their surfaces are subjected to the

weather condition s. As a resul t, it is necessar y to give t he finis h a reason able amount o f care if

an attractive appearance is to be maintained.

The finish on Gasboy pump housings is a high-heat baked synthetic enamel, similar to that

used on automobiles. The life of this finish can be lengthened several years if, at regular

intervals, the pain te d surfac es are th oroughl y cleane d wit h a high grade automo bile pol ish and

then protected with a coat of paste wax. Do not use abrasive cleaners or polish. Do not use

high pressure sprayi ng equipment . Do not use win dow cleaner with ammonia o n the elec tronic

display.

In order to retain the unmarked finish on stainless steel, occasional cleaning is required. In

corrosive atmospheres, such as coastal areas, a more frequent cleaning schedule is necessary.

Under ordinary conditions, washing with detergent or soap and water, followed by a clean

water rinse, is sufficient. If hard water is used, the surface should be wiped dry with a soft

clean cloth to prevent the formation of water spots. Marks or spots, such as grease, oily

fingerprints and smudges which resist soap and detergents, will have to be removed with a

stronger cleaner. (DO NOT us e ordi nary s teel wool a s iro n part icle s may adher e to the su rface

and cause corrosion.) Care should be taken in choosing a cleaner because any cleaning

compounds or powders which contain abrasives can scratch a mill-rolled finish. Care must be

exercised that any polishing is done with the lines in the steel, never across them. After

cleaning, an application of paste wax is recommended to protect the surface and prolong the

interval between cleani ng.

.

MDE-4363A Atlas Owner’s Manual· March 2005 Page 33

Page 36

Preventive Maintenance

WARNING

.

Preventive Maintenance Table

Re c o mm e n d ed

Components

Stainless Steel

sheathing and lower

doors

Hoses, swivels At lease once a

Frequency Recommended Maintenance

Monthly For stains on stainless steel, use a cleaner specifically

week or if a

customer complaint

arises

formulated for cleaning stainless steel. Gasboy recommends

Barkeepers Friend. Be sure to thoroughly rinse off all cleaner.

Be sure not to spray water/cleaner directly at or into card

readers, cash acceptors, or printer chutes.

1 Inspect each hose for leaks abuse and excessive wear.

Leaking fuel can be ignited, causing a fire or explosion.

Fire, explosion, or electrical shock cou ld res ult in sev ere injury or

death if you continue to use damaged pumps/dispensers.

If you find any l eaks or d amage, st op using the pump /dispenser, and

contact your local ASC.

2 Inspect each hose, break away, whip hose, and vapor hose

for the following wear or damage:

• Bulges

• Cracks

• Damage

• Flattened spots

• Holes

3 Make sure vapor recovery hoses do not touch the ground

when the nozzle is seated properly in the nozzle boot.

4 Consult the manufacturer for any additional inspections

required.

5 If repair is needed, call an ASC to make the repairs.

Reinforcement showing

- Soft spots

- Tears

- Weaknesses

- wear through

Who Performs the

Inspection/Repair

Once every three

months (in harsh

environments once a

month)

• Owner—Inspect

• ASC repair and test

• Owner—Inspect

• ASC repair and test

WARNING

The pump/dispenser contains pressurized flammable fuel and lethal voltages

Servicing a Gasboy unit incorrectly could result in severe injury or death.

Do not attempt to service Gasboy pump/dispenser yourself, and do not allow

untrained personnel to service Gasboy pumps/dispensers. Only Gasboytrained ASCs should service a Gasboy unit.

WARNING

Hoses of excessive length may create a trip hazard.

WARNING

Serious injury could occur as a result of tripping over an excessive

length hose.

Do not use excessive length hoses.

Hose retrievers Once a week or if a

customer complaint

arises

1 Inspect hose retrievers for frayed or broken cables.

2 Inspect hose retrievers for cables wrapped around hoses.

3 If repair is needed, call an ASC to make the repairs.

Page 34 MDE-4363A Atlas Owner’s Manual· March 2005

• Owner Inspect

• ASC repair and test

Page 37

Preventive Maintenance

Components

Nozzles and boot area Once a week or as

Re c o mm e n d ed

Frequency Recommended Maintenance

notified about a

potential problem

Who Performs the

Inspection/Repair

WARNING

The pump/dispenser contains pressurized flammable fuel and lethal

voltages.

Servicing a Gasboy unit incorrectly could result in severe injury or death.

Do not attempt to service Gasboy pump/dispenser yourself, and do not

allow untrained personnel to service Gasboy pumps/dispensers. Only

Gasboy-trained ASCs should service a Gasboy unit.

WARNING

Hoses that are not recoiled properly create a trip hazard.

Serious injury could occur as a result of tripping over an excessive

length hose.

Repair or replace broken hose retrievers promptly.

1 Inspect nozzles for the following wear or damage:

• Damage

• Leaks

• Loose nozzle spouts

• Missing parts, such as retainer springs and splash guards

• Owner—Inspect

• ASC only—Repair

and test

WARNING

Leaking fuel can be ignited, causing a fire or explosion.

Fire, explosion, or electrical shock could result in severe injury or

death if you continue to use damaged pumps/dispensers.

If you find any lea ks or damag e, stop us ing the p ump/dis penser, and

contact your local ASC.

2 Inspect vapor recovery boots (bellows) for proper seal and

damage.

3 Consult the nozzle manufacturer for any additional required

inspections.

4 If repair is needed, call an ASC to make the repairs.

WARNING

The pump/dispenser contains pressurized flammable fuel and lethal

voltages.

Servicing a Gasboy unit incorrectly could result in severe injury or death.

Do not attempt to service Gasboy pump/dispenser yourself, and do not

allow untrained personnel to service Gasboy pumps/dispensers. Only

Gasboy-trained ASCs should service a Gasboy unit.

MDE-4363A Atlas Owner’s Manual· March 2005 Page 35

Page 38

Preventive Maintenance

Components

Leaks, external Once a week, or as

Re c o mm e n d ed

Frequency Recommended Maintenance

notified about a

potential leak

Who Performs the

Inspection/Repair

1 Inspect the following for any signs of damage or leaks, such

as cracks and cuts,:

• Couplings

• Hose outlet castings

• Swivels

2 Review all documentation provided by each component’s

manufacturer.

3 If a leak is found, stop using the pump/dispenser, and make

arrangements to repair the leak.

• Owner—Inspect

• ASC only—Repair

and test

WARNING

Leaking fuel can be ignited, causing a fire or explosion.

Fire, explosion, or electrical shock cou ld res ult in sev ere injury or

death if you continue to use damaged pumps/dispensers.

If you find any l eaks or d amage, st op using the pump /dispenser, and

contact your local ASC.

WARNING

The pump/dispenser contains pressurized flammable fuel and lethal

voltages.

Displays (Electro/

Mechanical Units)

Servicing a Gasboy unit incorrectly could result in severe injury or death.

Do not attempt to service Gasboy pump/dispenser yourself, and do not

allow untrained person nel to servic e Ga sb oy pum p s /di sp ens ers . Only

Gasboy-trained ASCs should service a Gasboy unit.

Once a week 1 Inspect displays for proper reading of all digits.

2 Verify that displays are properly backlit.

• Owner—Inspect

• ASC Repair and

test

Page 36 MDE-4363A Atlas Owner’s Manual· March 2005

Page 39

Preventive Maintenance

Components

Breakaways Once a week or after

Note: Not all breakaways are reusable after

separation. Follow manufacturer directions for

inspection and resetting adjustable types.

Re c o mm e n d ed

Frequency Recommended Maintenance

drive-offs

Who Performs the

Inspection/Repair

1 Inspect breakaways for secure connection to hose and for

any leaks.

• Owner—Inspect

• ASC only—Repair

and test

WARNING

Leaking fuel can be ignited, causing a fire or explosion.

Fire, explosion, or el ec trical shock could result i n s ev ere in jury o r de ath if

you continue to use damaged pumps/dispensers.

If you find any leaks or damage, stop using the pump/dispenser, and

contact your local ASC.

2 For units with hose retrievers, position the breakaway

coupling between the retriever connection to the hose and the

nozzle. The breakaway whip hose should be attached to the

nozzle.

3 Consult the breakaway manufacturer for any additional

required inspections.

4 If repair is needed, call an ASC to make the repairs.

WARNING

The pump/dispenser contains pressurized flammable fuel and lethal

voltages.

Servicing a Gasboy unit incorrectly could result in severe injury or death.

Do not attempt to service Gasboy pump/dispenser yourself, and do not

allow untrained personnel to service Gasboy pumps/dispensers. Only

Gasboy-trained ASCs should service a Gasboy unit.

Warning tags and

operating instructions

Hose continuity Once a month Verify that the hose continuity (including breakaway whip hose)

Once a week Inspect for and replace all missing, damaged, or unreadable

warning tags or operating instructions.

complies with the hose manufacturer’s requirements.

WARNING

The pump/dispenser contains pressurized flammable fuel and lethal

voltages.

Servicing a Gasboy unit incorrectly could result in severe injury or death.

Do not attempt to service Gasboy pump/dispenser yourself, and do not

allow untrained personnel to service Gasboy pumps/dispensers. Only

Gasboy-trained ASCs should service a Gasboy unit.

• Owner—Inspect

• Owner or ASC—

Replace

• ASC—Inspect

• ASC only—Repair

MDE-4363A Atlas Owner’s Manual· March 2005 Page 37

Page 40

Preventive Maintenance

UT

Components

Leaks, internal Once a month, after

Re c o mm e n d ed

Frequency Recommended Maintenance

drive-offs, or as

notified about a

potential leak

Who Performs the

Inspection/Repair

1 Whenever possible, Gasboy recommends removing power

to the unit before performing these inspections.

2 Block off the pump/dispenser on both sides to prevent

customers from operating the pump/dispenser during

inspection.

3 Remove the lower panels slowly and carefully.

4 Inspect all hydraulic connections and seals, including the

following:

• Meters

• Valves

5 If wetness or dripping fuel is found, stop using the pump/

dispenser, and make arrangements for repairing the leak.

Note: Some staining of parts around seals is normal and does

not necessarily indicate a leak.

6 Monitor repaired components closely.

• Owner—Inspect

• ASC only—Repair

and test

WARNING

Gasoline or other fuels can dama ge the ey es.

Fuel sprayed into the eye can burn eye tissue.

To prevent potential in jur y, wear eye protectio n when performi ng these

inspections.

CA

WARNING

Self-contained pumps have a pinch point between the belts and the

pulleys.

Severe injury could occur if part of the body is pulled into the pinch

point.

To prevent injury while inspecting self-contained units, do not place

you hands near the belt s, pull eys, or mot ors. T urn of f the pow er before

servicing the unit. Do not operate the unit with the door removed.

WARNING

Leaking fuel can be ignited, causing a fire or explosion.

Fire, explosion, or electrical shock could result in severe injury or

death if you continue to use damaged pumps/dispensers.

If you find any lea ks or damag e, stop us ing the p ump/dis penser, and

contact your local ASC.

WARNING

The pump/dispenser contains pressurized flammable fuel and lethal

voltages.

Servicing a Gasboy unit incorrectly could result in severe injury or death.

Do not attempt to service Gasboy pump/dispenser yourself, and do not

allow untrained personnel to service Gasboy pumps/dispensers. Only

Gasboy-trained ASCs should service a Gasboy unit.

Page 38 MDE-4363A Atlas Owner’s Manual· March 2005

Page 41

Preventive Maintenance

Components

Filter change and

strainer cleaning

Inspect and lubricate

shear valves

Re c o mm e n d ed

Frequency Recommended Maintenance

New Installations—

After 50,000 gallons

(200,000 liters), or

after one month

After first filter

change—Every

300,000 gallons (1.0

million liters), every

six months, or when

fuel delivery rate

significantly slows.

Replace filters, and clean strainers regularly. An ASC must

perform these tasks.

WARNING

The pump/dispenser contains pressurized flammable fuel and lethal

voltages.

Servicing a Gasboy unit incorrectly could result in severe injury or death.

Do not attempt to service Gasboy pump/dispenser yourself, and do not

allow untrained personnel to service Gasboy pumps/dispensers. Only

Gasboy-trained ASCs should service a Gasboy unit.

Every six months To check valve operation, perform the following tasks. If you are

not sure which device is the shear valve, have the ASC inspect

and lubricate this device for you.

Note: Shear valves are typically only used on dispensers. If you

have pumps, consult your installer to determine if they were

installed on your pump.

1 T rip the valve.

2 Authorize the hose at the console, if required.

3 Lift the operating handle.

4 Place the discharge nozzle in an approved container.