Page 1

Introduction

This manual provides installation instructions for the Automatic Temperature Compensation

(ATC) Kits on Retail Atlas™ (8800K) units.

Note: Filters are required for installation but are not contained in the kits.

Contents

Section Page ...

Introduction 1

Important Safety Information 5

Installation 7

Programming the ATC Option 18

MDE-4556

Gasboy ATC Kits M06875K00X

Installation Manual

July 2006

• M06875K001 for Single-Sided 8800K Unit

• M06875K002 for Two-Sided 8800K Unit

Required Reading 1

Required Tools 2

Abbreviations and Acronyms 2

Parts Lists 2

Preparing Site and Dispenser for ATC Option 7

Installing Filter Manifold and Probe 7

Installing the T-Meter Module and Cables 9

Installing I.S. Barrier Assembly 11

Installing ATC Controller Board 12

Connecting ISB Wires and Cable 15

Completing Installation 16

Required Reading

Before installing a kit, the installer must read, understand, and follow:

• This manual

• NFPA 30A, The Automotive and Marine Service Station Code

• NFPA 70, The National Electrical Code

• Applicable Canadian, federal, state and local codes and regulations

Failure to do so may adversely affect the safe use and operation of the equipment.

Note: This kit must be installed by a Gasboy Authorized Service Contractor (ASC) to ensure

warranty.

MDE-4556 Gasboy ATC Kits M06875K00X Installation Manual • July 2006 Page 1

Page 2

Introduction

Required Tools

The following tools are needed to install the ATC Kits:

• Open-end wrench set

• 1/2-inch socket wrench

• Flat blade screwdriver

®

• Phillips

• Allen

screwdriver

®

wrench set

• Sealant, SAF-T-LOK

Abbreviations and Acronyms

The following are abbreviations and acronyms used in this document.

Abbreviation or

Acronym Expansion

AT C

ASC Authorized Service Contractor

CFR Code of Federal Regulations (http://www.gpoaccess.gov/cfr/index.html)

DIP Dual Inline Package

ESD Electrostatic Discharge

IC Integrated Circuit

I.D. Inside Diameter

IS Intrinsic Safety

ISB Intrinsic Safety Barrier

NEC National Electrical Code (NFPA 70)

NFPA National Fire Protection Association (http://www.nfpa.org/Home/index.asp)

OSHA Occupational Safety & Health Administration (http://www.osha.gov/)

PCB Printed Circuit Board

RTD Resistance Temperature Detector

STP Submerged Turbine Pump

TPS Teflon Pipe Sealant

VAC Volts Alternating Current

Automatic Temperature Compensation (reference of 15

(http://strategis.ic.gc.ca/epic/internet/inmc-mc.nsf/en/lm01094e.html)

®

polytetrafluroethylene (Teflon® ) Pipe Sealant (TPS), or equivalent

° C = 59° F)

Parts Lists

M06875K001 - ATC Kit for 115 VAC Single-Sided Unit (Pulse Out)

Part Number Description Quantity

K81105-20 Wire Nut Connector, Length 18 mm, Blue 2

K94160-01 ATC Software Kit (includes Q11594-23 28-pin DIP IC) 1

M00414B001 M5 Metric Nut, Hex Serrated Flange 2

M04607B003 2-Stage Solenoid Valve and Filter Manifold, Low Voltage with ATC 1

MDE-4556 Gasboy ATC Kits M06875K00X Installation Manual (this document) 1

Q10068-09 O-Ring, 1.234” I.D. 2

Q10068-14 O-Ring, 1.609” I.D. 1

Q10178-03 Cable Tie 6

Page 2 MDE-4556 Gasboy ATC Kits M06875K00X Installation Manual • July 2006

Page 3

Introduction

Part Number Description Quantity

Q13130-01 Thermowell, Meter Cover 1

Q13131-01 RTD Probe Assembly 1

Q13306-02 Meter Identification Decal Set (for probes 1 - 8) 1

R19457 High-Capacity Strainer Insert 1

R19527-G1 34-conductor Calibration Switch Cable Assembly (J204/P802/P204A) 1

R19667-G1 34-conductor Ribbon Cable Assembly (P204/P304 and P205/P405) 2

R19951-G1 10-conductor Ribbon Cable Assembly (J203/J901) 1

R20128-G1 Power Data Cable Assembly (J307) 1

R20146-G2 10-conductor Keypad Interface Cable Assembly (J203/J303) 1

T19405-G4 T-Meter Module Assembly

This includes the following cables as well as other hardware:

• R20148-G3, T-Meter Probe Cable Assemblies, quantity 2

• R20147-G1 T-Meter ISB Cable Assembly (J201/PS1), quantity 1

T19428-G1 115 VAC ISB Assembly (J1S) 1

T20569-G1 ATC Controller Printed Circuit Assembly 1

1

M06875K002 - ATC Kit for 115 VAC Two-Sided Unit

Part Number Description Quantity

K81105-20 Wire Nut Connector, Length 18 mm, Blue 2

K94160-01 ATC Software Kit (includes Q11594-23 28-pin DIP IC) 1

M00414B001 M5 Metric Nut, Hex Serrated Flange 2

M04607B003 2-Stage Solenoid Valve and Filter Manifold, Low Voltage with ATC 2

MDE-4556 Gasboy ATC Kits M06875K00X Installation Manual (this document) 1

Q10068-09 O-Ring, 1.234” I.D. 4

Q10068-14 O-Ring, 1.609” I.D. 2

Q10178-03 Cable Tie 6

Q13130-01 Thermowell, Meter Cover 2

Q13131-01 RTD Probe Assembly 2

Q13306-02 Meter Identification Decal Set (for probes 1 - 8) 1

R19457 High-Capacity Strainer Insert 2

R19527-G1 34-conductor Calibration Switch Cable Assembly (J204/P802/P204A) 1

R19667-G1 34-conductor Ribbon Cable Assembly (P204/P304 and P205/P405) 2

R19951-G1 10-conductor Ribbon Cable Assembly (J203/J901) 1

R20128-G1 Power Data Cable Assembly (J307) 1

R20146-G2 10-conductor Keypad Interface Cable Assembly (J203/J303) 1

T19405-G4 T-Meter Module Assembly

This includes the following cables as well as other hardware:

• R20148-G3, T-Meter Probe Cable Assemblies, quantity 2

• R20147-G1 T-Meter ISB Cable Assembly (J201/PS1), quantity 1

T19428-G1 115 VAC ISB Assembly (J1S) 1

T20569-G1 ATC Controller Printed Circuit Assembly 1

1

MDE-4556 Gasboy ATC Kits M06875K00X Installation Manual • July 2006 Page 3

Page 4

Introduction

Related Documentation

Document

Number Description GOLD Library

MDE-4404 Atlas Technician Programming Quick Reference Card Gasboy

PT-1949 Commercial and Retail Series Atlas Pump and Dispenser Illustrated Parts Manual

Commercial &

Retail Pumps

Page 4 MDE-4556 Gasboy ATC Kits M06875K00X Installation Manual • July 2006

Page 5

Important Safety Information

Important Safety Information

This section introduces the hazards and safety precautions

associated with installing, inspecting, maintaining or servicing

this product. Before performing any task on this product, read

this safety information and the applicable sections in this

manual, where additional hazards and safety precautions for

your task will be found. Fire, explosion, electrical shock or

pressure release could occur and cause death or serious

injury if these safe service procedures are not followed.

Preliminary Precautions

You are working in a potentially dangerous environment of

flammable fuels, vapors, and high voltage or pressures. Only

trained or authorized individuals knowledgeable in the related

procedures should install, inspect, maintain or service this

equipment.

Emergency Total Electrical Shut-Off

The first and most important information you must know is

how to stop all fuel flow to the pump and island. Locate the

switch or circuit breakers that shut-off all power to all fueling

equipment, dispensing devices, and submerged turbine

pumps (STPs).

!

WARNING

!

The EMERGENCY STOP, ALL STOP, and PUMP

STOP buttons at the cashier’s station WILL NOT

shut off electrical power to the pump/dispenser.

This means that even if you activate these stops, fuel

may continue to flow uncontrolled.

You must use the TOTAL ELECTRICAL SHUTOFF in the case of an emergency and not only these

cashier station “stops.”

Read the Manual

Read, understand and follow this manual and any other

labels or related materials supplied with this equipment. If

you do not understand a procedure, call a Gasboy Authorized

Service Contractor or call the Gasboy Service Center at 1800-444-5529. It is imperative to your safety and the safety of

others to understand the procedures before beginning work.

Follow the Regulations

There is applicable information in NFPA 30A; Automotive and

Marine Service Code, NFPA 70; National Electrical Code (NEC),

OSHA regulations and Canadian, federal, state, and local

codes which must be followed. Failure to install, inspect,

maintain or service this equipment in accordance with these

codes, regulations and standards may lead to legal citations

with penalties or affect the safe use and operation of the

equipment.

Replacement Parts

Use only genuine Gasboy replacement parts and retrofit kits

on your pump/dispenser. Using parts other than genuine

Gasboy replacement parts could create a safety hazard and

violate local regulations.

Safety Symbols and Warning Words

This section provides important information about warning

symbols and boxes.

Alert Symbol

This safety alert symbol is used in this manual and on

warning labels to alert you to a precaution which must be

followed to prevent potential personal safety hazards. Obey

safety directives that follow this symbol to avoid possible

injury or death.

Signal Words

These signal words used in this manual and on warning labels

tell you the seriousness of particular safety hazards. The

precautions that follow must be followed to prevent death,

injury or damage to the equipment.

Total Electrical Shut-Off Before Access

Any procedure requiring access to electrical components or

the electronics of the dispenser requires total electrical shutoff of that unit. Know the function and location of this switch

or circuit breaker before inspecting, installing, maintaining, or

servicing Gasboy equipment.

Evacuation, Barricading and Shut-Off

Any procedures requiring accessing the pump/dispenser or

STPs requires the following three actions:

- An evacuation of all unauthorized persons and vehicles

- using safety tape, cones or barricades to the effected units

- A total electrical shut-off of that unit

MDE-4556 Gasboy ATC Kits M06875K00X Installation Manual • July 2006 Page 5

!

DANGER - This signal word is used to alert you to a

hazard to unsafe practice which will result in death or

serious injury.

!

WARNING - This alerts you to a hazard or unsafe

practice that could result in death or serious injury.

!

CAUTION with Alert symbol - This signal word

designates a hazard or unsafe practice which may

result in minor injury.

CAUTION without Alert symbol - When used by itself,

CAUTION designates a hazard or unsafe practice

which may result in property or equipment damage.

Working With Fuels and Electrical Energy

Prevent Explosions and Fires

Fuels and their vapors will become explosive if ignited. Spilled

or leaking fuels cause vapors. Even filling customer tanks will

cause explosive vapors in the vicinity of dispenser or island.

Page 6

Important Safety Information

No Open Flames

Open flames from matches, lighters, welding torches

or other sources can ignite fuels and their vapors.

No Sparks - No Smoking

Sparks from starting vehicles, starting or using power

tools, burning cigarettes, cigars or pipes can also ignite fuels

and their vapors. Static electricity, including an electrostatic

charge on your body, can cause a spark sufficient to ignite

fuels and their vapors. After getting out of a vehicle, touch the

metal of your vehicle to discharge any electrostatic charge

before you approach the dispenser island.

Working Alone

It is highly recommended that someone who is capable of

rendering first aid be present during servicing. Be familiar

with Cardiopulmonary Resuscitation (CPR) methods if you

are working with or around high voltages. This information is

available from the American Red Cross. Always advise the

station personnel about where you will be working, and

caution them not to activate power while you are working on

the equipment. Use the OSHA tag out and lock out

procedures. If you are not familiar with this requirement, refer

to information in the service manual and OSHA

documentation.

Working With Electricity Safely

Be sure to use safe and established practices in working with

electrical devices. Poorly wired devices may cause a fire,

explosion or electrical shock. Be sure grounding connections

are properly made. Make sure that sealing devices and

compounds are in place. Be sure not to pinch wires when

replacing covers. Follow OSHA Lock-Out and Tag-Out

requirements. Station employees and service contractors

need to understand and comply with this program completely

to ensure safety while the equipment is down.

Emergency First Aid

Informing Emergency Personnel

Compile the following information for emergency personnel:

Location of accident (for example, address, front/back of

building, and so on.)

Nature of accident (for example, possible heart attack, run

over by car, burns, and so on.)

Age of victim (for example, baby, teenager, middle-age,

elderly.)

Whether or not victim has received first aid (for example,

stopped bleeding by pressure, and so on.)

Whether or not a victim has vomited (for example, if

swallowed or inhaled something, and so on.)

WARNING

!

Gasoline ingested may cause unconsciousness and

burns to internal organs.

Do not induce vomiting.

Keep airway open.

Oxygen may be needed at scene.

Seek medical advice immediately.

WARNING

!

Gasoline inhaled may cause unconsciousness and

burns to lips, mouth and lungs.

Keep airway open.

Seek medical advice immediately.

WARNING

!

Gasoline spilled in eyes may cause burns to eye

tissue.

Irrigate eyes with water for approximately 15

minutes.

Seek medical advice immediately.

Hazardous Materials

Some materials present inside electronic enclosures may

present a health hazard if not handled correctly. Be sure to

clean hands after handling equipment. Do not place any

equipment in mouth.

!

WARNING

This area contains a chemical known to the State of

California to cause cancer.

WARNING

!

Gasoline spilled on skin may cause burns.

Wash area thoroughly with clear/water.

Seek medical advice immediately.

IMPORTANT: Oxygen may be needed at scene if gasoline

has been ingested or inhaled. Seek medical advice

immediately.

Lockout/Tagout

WARNING

!

This area contains a chemical known to the State of

California to cause birth defects or other reproductive harm.

Lockout/Tagout covers servicing and maintenance of

machines and equipment in which unexpected energizing or

start up of the machine(s) or equipment or release of stored

energy could cause injury to employees or personnel.

Lockout/Tagout applies to all mechanical, hydraulic, chemical

or other energy, but does not cover electrical hazards.

Reference Subpart S of 29 CFR Part 1910 - Electrical

IMPORTANT: Oxygen may be needed at scene if gasoline

has been ingested or inhaled. Seek medical advice

Hazards, 29 CFR Part 1910.333 contains specific Lockout/

Tagout provision for electrical hazards.

immediately.

Page 6 MDE-4556 Gasboy ATC Kits M06875K00X Installation Manual • July 2006

Page 7

Installation

Preparing Site and Dispenser for ATC Option

1 Record all electronic and mechanical totals.

2 Isolate each unit to have ATC kit installed at distribution box.

3 Open door to hydraulics area.

4 Turn off (close) shear valve.

5 Test shear valve for proper closure by activating fueling position nozzle and verifying no flow

occurs.

6 Turn OFF associated STP circuit breakers for the unit(s) being upgraded.

This may require multiple STP disconnects.

Installation

7 Turn OFF all power to unit at system circuit breaker, including unit lights.

8 Disconnect power cable to the following boards:

• M05200A001 Retail Pulse Out

• T20011-G1 Pump Controller

CAUTION

Maintaining power to the boards during installation could result in board failures. Do not rely on the circuit

breakers to disconnect power to the boards.

9 Turn off system battery by pressing CLEAR then ENTER on manager keypad.

10 Tag shear valve according to OSHA lock-out and tag-out requirements.

Installing Filter Manifold and Probe

The kit parts used in this section are:

• M04607B003 2-Stage Solenoid Valve and Filter Manifold with Probe Port

• Q10068-09 O-Ring, 1.234-inch I.D.

• Q10068-14 O-Ring, 1.609-inch I.D.

• Q13130-01 Thermowell, Meter Cover

• Q13131-01 RTD Probe Assembly

• R19457 High-Capacity Strainer Insert

WARNING

!

Residual pressure may exist in the hydraulic system. Wear eye protection.

1 Remove filter from current M04607B001 Valve and Filter Manifold.

MDE-4556 Gasboy ATC Kits M06875K00X Installation Manual • July 2006 Page 7

Page 8

Installation

2 Unbolt and carefully remove current M04607B001 Valve and Filter Manifold.

3 Note orientation of check valve assembly located between manifold and meter.

4 Discard two O-rings located on each side of check valve assembly.

5 Clean meter surface where new M04607B003 Valve and Filter Manifold will be mounted.

6 Place new Q10068-09 O-Ring (1.234-inch I.D.) into meter opening.

7 Place new Q10068-14 O-Ring (1.609-inch I.D.) into opening of new M04607B003 Valve and

Filter Manifold.

8 Properly orient the check valve between the meter body and new M04607B003 Valve and

Filter Manifold and bolt the new manifold to the meter.

9 Carefully remove the plugs from the ATC ports (Figure 1).

Figure 1: M04607B003 Valve and Filter Manifold

coil

RTD probe port

Thermowell port

10

Insert the Q13131-01 RTD Probe Assembly into the RTD probe port on the filter manifold.

Note: The connection to the probe assembly will be made in the Installing Filter Manifold and

Probe section which follows.

11 Insert the new Q13130-01 Thermowell into the Thermowell port in the filter manifold.

12 Fully insert the new R19457 High-Capacity Strainer Insert into the filter cavity of the

manifold with the pull tabs properly oriented.

13 Install a new filter onto the new filter manifold.

14 Replace the connection from the coil on the old manifold with the connection from the coil on

the new maniold.

15 If installing the M06875K002 - ATC Kit for Two-Sided Unit, repeat steps 1 through 14 for the

other side of the dispenser.

Page 8 MDE-4556 Gasboy ATC Kits M06875K00X Installation Manual • July 2006

Page 9

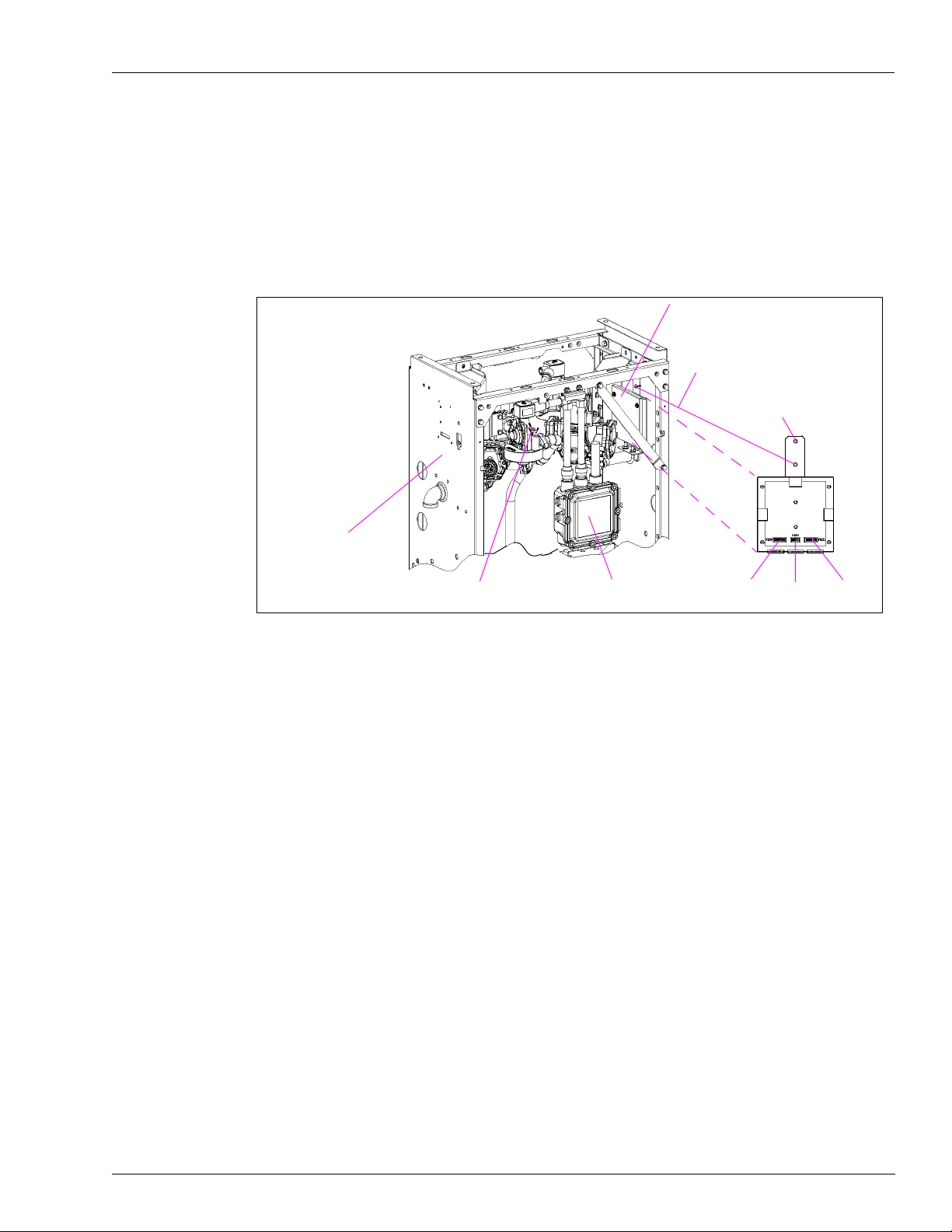

Installing the T-Meter Module and Cables

The cables used in this section are included with the T19405-G4 T-Meter module.

1 Install the T-Meter module onto two clinch studs located on the inside of the side column

(Figure 2, install on either side).

Note: Locate T-Meter module so cables can reach appropriate probe connectors.

Figure 2: Example of Installed T-Meter Module

Installation

T19405-G4 T-Meter Module

lower clinch stud location

upper clinch stud

mounting hole

side column

probe location

(another on other side)

2

Connect the T-Meter module cables as follows (Figure 3):

junction box

P200 P201 P202

• J200 connector on first R20148-G3 cable to P200 connector on T19405-G4 module

• PTP1 connector on first R20148-G3 cable to RTD Probe A1 connector

• J202 connector on second R20148-G3 cable to P202 connector on T19405-G4 module

• PTP5 connector on second R20148-G3 cable to RTD Probe B1 connector

• J201 connector on R20147-G1 cable to P201 connector on T19405-G4 module

Note: The P1S connector on the R20147-G1 cable is not connected at this time; it will be

connected in the Installing I.S. Barrier Assembly section which follows.

MDE-4556 Gasboy ATC Kits M06875K00X Installation Manual • July 2006 Page 9

Page 10

Installation

R20148-G3

R20147-G1

R20148-G3

Figure 3: Cable Block Diagram for T-Meter Module

Route the T-Meter module cables using the following considerations:

3

• Place cables along bottom of hydraulic support rail to prevent damage from screws.

• Be careful to not damage cables when routing over brackets.

• Foam blocks will help to keep cables from falling during routing.

• Use Sealant, TPS or equivalent, to seal ends of any unused connectors to prevent damage

by moisture.

• Use up to four Q10178-03 cable ties to secure cables so connectors are located inside rail

away from moisture and cables do not have excessive slack.

• Adjust foam blocks into final position after cables and connectors are in place.

• All cables should be clear of moving components.

Page 10 MDE-4556 Gasboy ATC Kits M06875K00X Installation Manual • July 2006

Page 11

Installing I.S. Barrier Assembly

The kit parts used in this section are:

• K81105-20 Wire Nut Connector

• Two Q10178-03 Cable Ties

• T19428-G1 115 VAC ISB Assembly

1 Remove 3/4-inch plug from far right-hand opening on top of junction box.

2 Install ISB directly into junction box as shown in Figure 4.

Figure 4: ISB Installation

Junction Box

Installation

T19428-G1

I.S. Barrier

3

Route ISB wires (with connector P1S) back onto ISB and secure with a Q10178-03 cable tie.

4 Run these wires up the junction box conduit and secure to conduit with Q10178-03 cable tie.

5 Connect P1S of the R20147-G1 cable (Figure 3) to J1S of the ISB cable (Figure 7 on page 15).

Locate connector in rail away from moisture.

The green, orange, and grey wires from the ISB are not connected at this time; they will be

connected later in “Connecting ISB Wires and Cable” on page 15.

MDE-4556 Gasboy ATC Kits M06875K00X Installation Manual • July 2006 Page 11

Page 12

Installation

Installing ATC Controller Board

CAUTION

The printed circuit boards (PCBs) and integrated circuits (ICs) within the dispenser are sensitive to

electrostatic discharge (ESD) caused by static electricity. ESD damages electronic parts.

Use the following guidelines when installing the K94160-01 software or handling sensitive

parts.

• Touch an unpainted metal surface to discharge any static electricity buildup.

• Use a wrist strap connected to a grounded metal frame or chassis. Dispenser must be

connected to an AC source with power OFF.

wrist strap

• Place removed PCBs or ICs, if any, on a grounded antistatic mat or in an antistatic bag.

The kit parts used in this section are:

• K94160-01 ATC Software Kit

• R19527-G1 34-conductor Calibration Switch Cable Assembly

• R19667-G1 34-conductor Ribbon Cable Assembly

• R20146-G2 10-conductor Keypad Interface Cable Assembly

• T20569-G1 ATC Controller Board

1 Insert K94160-01 software from kit into position U5 on the T20569-G1 ATC Controller board

(Figure 5).

Figure 5: T20569-G1 ATC Controller Board

P307

Install K94160-01

software in position U5.

JP1

used in “Completing

Installation” on page 16

programming switch

· left = OFF (normal use)

· right = ON (program use only) – used in “Programming the ATC Option” on page 18

Page 12 MDE-4556 Gasboy ATC Kits M06875K00X Installation Manual • July 2006

Page 13

Installation

2 Insert ATC Controller board into top slot of card cage.

If necessary, rearrange boards in the following order, top to bottom:

• T20569-G1 ATC Controller

• M05200A001 Retail Pulse Out

• T20011-G1 Pump Controller

3 Connect existing R17995-G7 cable to the following connectors (Figure 6 on page 14):

• P301 on T20569-G1 ATC Controller board

• P101 on M05200A001 Retail Pulse Out board

• P201 on T20011-G1 Pump Controller board

4 Unplug existing R19667-G1 cable from connector P205 of T20011-G1 Pump Controller board

(leaving other end connected to connector P105 of M05200A001 Retail Pulse Out board) and

connect loose end to connector P305 on T20569-G1 ATC Controller board (Figure 6).

5 Connect new R19667-G1 cable from kit to the following connectors (Figure 6):

• P405 on T20569-G1 ATC Controller board

• P205 on T20011-G1 Pump Controller board

6 Unplug existing R19951-G1 keypad cable from connector P203 of T20011-G1 Pump

Controller board and connect it to connector P303A on T20569-G1 ATC Controller board

(Figure 6).

7 Connect new R20146-G2 cable from kit to the following connectors (Figure 6):

• P303 on T20569-G1 ATC Controller board

• P203 on T20011-G1 Pump Controller board

8 Unplug existing T17768-G1 display cable from connector P204 on T20011-G1 Pump

Controller board and connect it to new R19527-G1 calibration switch cable from the kit

(Figure 6); connect the other end of the new R19527-G1 calibration switch cable to the P204A

connector on T20569-G1 ATC Controller board (Figure 6).

9 Connect other new R19667-G1 cable from kit to the following connectors (Figure 6):

• P304 on T20569-G1 ATC Controller board

• P204 on T20011-G1 Pump Controller board

10 Connect the existing R20128-G1 cable from the conduit to connector P307 on T20569-G1

ATC Controller board (Figure 6).

MDE-4556 Gasboy ATC Kits M06875K00X Installation Manual • July 2006 Page 13

Page 14

Installation

Figure 6: Cable Connections Between Boards for ATC

To conduit

existing R20128-G1

To d i s p l a y

existing T17768-G1

new R19527-G1

To k e y pad

existing R19951-G1

Page 14 MDE-4556 Gasboy ATC Kits M06875K00X Installation Manual • July 2006

Page 15

Connecting ISB Wires and Cable

1 Remove junction box cover using 1/2-inch socket wrench. Save all bolts.

2 Run grey and orange wires of R20128-G1 cable down conduit into junction box (Figure 7).

3 Connect wires using K81105-20 wire nut connectors as shown below and in Figure 7.

ISB Wires Junction Box R20128-G1 Wires Function

Orange – Orange Power

Grey – Grey

Green Ground stud –

Figure 7: Wiring Diagram for ISB and R20128-G1 Cable in Junction Box

Installation

Ground

ground

orange wire

R20128-G1

green wire

J1S

T19428-G1

ISB Assembly

junction box

grey wire

Connect J307 on R20128-G1 cable (Figure 7) to connector P307 on T20569-G1 ATC

4

Controller board (Figure 8).

J307

conduit

K81105-20

wire nut

connector

(1 of 2)

MDE-4556 Gasboy ATC Kits M06875K00X Installation Manual • July 2006 Page 15

Page 16

Installation

Figure 8: ISB to ATC Controller and T-Module Assembly Connections

Note: For simplification, the J1S-to-P1S and junction box connections are not shown.

R20128-G1

(existing)

T19428-G1 ISB

Assembly

R20147-G1

R20148-G3

side A probe

Notes:

1. Installed in “Installing I.S. Barrier Assembly” on page 11.

2. Installed in “Installing ATC Controller Board” on page 12.

3. Installed in “Installing the T-Meter Module and Cables” on page 9.

4. Installed in “Installing Filter Manifold and Probe” on page 7.

1

3

J201 to P201

3

4

3

J307 to P307

T20569-G1 ATC

Controller

T19405-G4 T-Meter

Module Assembly

R20148-G3

side B probe

2

3

4

3

Completing Installation

!

WARNING

!

Spilled or leaking fuels in the vicinity of electrical junction boxes can be hazardous if

boxes are not properly closed.

Serious fire/explosion and injury/death could result.

Replace all bolts and tighten junction box cover before turning on unit AC power. Do not

use gaskets on junction box covers.

1 Place conversion labels, nameplates, any extra cable ties, and additional hardware on upper

shelf.

2 Securely attach junction box cover with all bolts using the 1/2-inch socket wrench.

3 Turn power ON (including lights) as follows:

• Reconnect multiple disconnects.

• Turn system circuit breakers on.

• Turn on associated STP power.

• Turn on power to all pumps/dispensers on same isolation relay, if used.

• Turn on system battery.

• Remove OSHA lock-outs and tag-outs.

• Turn on shear valve.

Page 16 MDE-4556 Gasboy ATC Kits M06875K00X Installation Manual • July 2006

Page 17

Installation

4 Do an ATC master reset on T20569-G1 ATC Controller board by installing a jump jack on JP1

(Figure 5 on page 12) and powering the unit up. Wait for the ATC to completely come up and

display error code 110; then remove the jump jack from JP1.

5 Do a pump master reset on the appropriate display board.

6 Reprogram the unit.

7 Test unit for correct operation.

8 Check for leaks around M04607B003 Filter Manifold and probe/thermowell.

9 Close hydraulics area door.

10 Close electronics area door.

MDE-4556 Gasboy ATC Kits M06875K00X Installation Manual • July 2006 Page 17

Page 18

Programming the ATC Option

Programming the ATC Option

Switch ON the programming switch located on ATC Controller board (Figure 5 on page 12).

At power up:

• Programmed units will flash “104” and then, normal information.

• Non-programmed units will flash “100” which indicates the units must be programmed

per How To Program Each Fueling Position below.

How To Program Each Fueling Position

Note: If programming switch is set to OFF, this procedure will not work.

1 Press 1 0 0.

2 Press ENTER.

Money Position will display “1”.

Money Position shows which meter is selected.

(Meter: 1 through 8)

Volume Position will display “1”.

Volume Position shows which fuel type has been selected.

(Fuel Type: 1-gasoline, 2-diesel)

PPU Position will display “730”.

PPU Position shows which fuel density has been selected for the corresponding meter.

[Fuel Density (kg/m

Note: The Fuel Density default is 730.

Main Display

Information

The software will sequence through each meter position for you to assign the fuel type desired.

3 Select fuel type and press ENTER.

4 Sequence through each meter position and verify desired fuel type by pressing ENTER.

3

): gasoline-730, diesel-840]

1

1

730

Money Position:

Current Meter

Volume Position:

Fuel Type

PPU Position:

Fuel Density

5 Switch OFF the programming switch on ATC controller board (Figure 5 on page 12).

6 Press F2 to exit ATC programming mode.

7 Weights and Measures auditor will put a seal on the programming switch (Figure 5).

8 Close electronics door.

Page 18 MDE-4556 Gasboy ATC Kits M06875K00X Installation Manual • July 2006

Page 19

How To Access ATC Mode Information

Example of How To View Last Transaction

1 Enter 3-digit keypad code for information type desired

(see Definition/Function of ATC Codes below).

2 Press ENTER.

3 Press 1 for Meter Position One information.

4 Press ENTER.

5 Record the information.

6 Continue to press each position number for corresponding position information.

7 Press ENTER.

Programming the ATC Option

8 Press F2 to exit ATC Mode.

(Wait for 1-minute timeout if F2 is nonfunctional.)

Definition/Function of ATC Codes

100 Programming Code

Instructions for programming ATC option are given in “How To Program Each Fueling

Position” on page 18.

200 Inspection Mode

Access this mode to obtain a precise reading of ATC system operation during an actual

transaction. This is the most accurate means of checking ATC system accuracy because

temperature readings are displayed during transaction.

Pure product only: Program a blender for 100%, otherwise the PPU display shows error code

105-product error.

• Money display-shows uncompensated volume

• Volume display-shows compensated volume

• PPU display-shows real-time temperature (in degrees Celsius).

300 View Last Transaction

Access this mode after a transaction. This mode can be used as a basic check to make sure

ATC system is operating properly. Temperature displayed in this mode is an average during

the last transaction. Do not use this mode to verify the accuracy of ATC system.

There are no blender restrictions.

• Money display-shows uncompensated volume.

• Volume display-shows compensated volume.

• PPU display-shows average temperature (in degrees Celsius).

MDE-4556 Gasboy ATC Kits M06875K00X Installation Manual • July 2006 Page 19

Page 20

Programming the ATC Option

301 Display Volume Correction Factor (VCF)

• Money display-shows product number.

• PPU display- shows volume correction factor.

302 Display Density

PPU display-shows programmed density information for selected meter.

303 Display Temperature

PPU display-shows current product temperature for selected meter.

304 Display Gross Volume Totals

Volume and PPU displays-shows a 10-digit number representing the cumulative

uncompensated volume total of the selected meter for a pure product.

500 Software Version

Main display-shows software version number.

600 Troubleshoot Probe

Access this mode to troubleshoot probes. There should be a small change in readings every

second if T-Meter and controller board are working properly. Each probe can be checked by

entering meter number.

• Money display-pulse width in terms of counts

• Volume display-probe resistance in ohms

• PPU display-shows the temperature of probe (in degrees Celsius)

601 Probe History

Use this mode to display probe history since ATC was installed. This is useful for

troubleshooting intermittent probes or probe connections. Access each probe by entering

meter number.

• Money display-shows probe number entered

• Volume display-shows total number of probe range errors logged

• PPU display-shows total number of missing probe pulse errors

Page 20 MDE-4556 Gasboy ATC Kits M06875K00X Installation Manual • July 2006

Page 21

ATC Error Codes

The following list describes ATC error codes that you may observe. These codes are useful

when troubleshooting a problem.

Error Code Error Displayed Description

Programming the ATC Option

00 NO ERROR No errors - no code displayed

100 PROGRAMMING ERROR All fuel types not programmed

101 ROM CHECKSUM Controller ROM checksum error

102 RAM ERROR Controller RAM write/read error

103 T-METER DEAD Not receiving any T-meter pulses

104 T-METER SYNC Receiving T-meter pulses, but with errors

105 PRODUCT ERROR Multiple product selected

106 RAMP RANGE ERROR Gasboy use only

107 RANGE ERROR FOR PROBE Probe out of range

108 MISSING ERROR Probe information missing

109 PULSER ERROR Pulser fail

110 RESET JJ ERROR Reset jump jack is installed

111 RAM CORRUPTED RAM data corrupted

112 NO INPUT TIMER No timer A interrupts occurring

113 NO OUTPUT TIMER No timer B interrupts occuring

114 POWER FAIL ERROR Power fail signal stuck

115 RECURSION ERROR Read T-meter interrupt recursion

MDE-4556 Gasboy ATC Kits M06875K00X Installation Manual • July 2006 Page 21

Page 22

Programming the ATC Option

Pump Error Codes

The following list describes pump error codes that you may observe. These codes are useful

when troubleshooting a problem.

Error Code Description

22 Not Used

23 Grade Assignment Changed

24 Conversion Factor Changed/ Not Programmed

25 Two-Wire/Stand- Mode Changed

26 No Conversion Factor Table

27 Side A* Two-Wire ID Changed

28 Side B* Two-Wire ID Changed

29 Pump Timeout Error

30 Not Used

31 Totals Data Error

32 Pulser Count Error

34 Not Used

35 Configuration Data Error

36 Unit Type Configuration Code Changed

37 PIN Code 1 Changed

38 PIN Code 2 Changed

39 Cast/Credit Option Changed

41 Side Exists Option Changed

42 PPU Options Changed

43 Not Used

44 Pump Handle Up at Power Up

* Side A is the Junction box opening side; side B is the opposite side.

Atlas™ is a trademark of Gasboy Inc.

®

Allen

is a registered trademark of Industrial Fasteners, Inc.

Phillips® is a registered trademark of Phillips Screw Company.

®

SAF-T-LOK

Teflon

is a registered trademark of SAF-T-LOK Chemical Corporation.

®

is a registered trademark of E.I. Du Pont de Memours and Company.

© 2006 GASBOY

7300 West Friendly Avenue • Post Office Box 22087

Greensboro, North Carolina 27420

Phone (800) 444-5529 • http://www.gasboy.com • Printed in the U.S.A.

MDE-4556 Gasboy ATC Kits M06875K00X Installation Manual • July 2006

Loading...

Loading...