Gilbarco® Global Pumping Unit

Operation and Service Manual

MDE-4447A

Computer Programs and Documentation

Federal Communications Commission (FCC) Warning

All Gilbarco Inc. and/or Veeder Root Company computer programs (including software on diskettes and within memory chips) and documentation are copyrighted by, and shall

remain the property of, Gilbarco Inc. and/or Veeder Root Company. Such computer programs and documents may also contain trade secret information. The duplication, disclosure,

modification, or unauthorized use of computer programs or documentation is strictly prohibited, unless otherwise licensed by Gilbarco Inc. and/or Veeder Root Company.

This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy, and if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user will be re quired to correct the inte rference at his own exp ense. Changes or modifications not expressly approved by

the manufacturer could void the user’s authority to operate this equipment.

Approvals

Gilbarco is an ISO 9001:2000 registe red company.

Underwriters Laboratories (UL):

U L File# Products listed with U L

MH1941

MH8467 Transac System 1000 and PAM 1000

All Gilbarco pumps and dispensers that bear

the UL listing mark.

New York City Fire Department (NYFD):

NYFD C of A # Product

4805

4986 Encore and Eclipse

The Advantage Series and

Legacy Series

E105106 Dell DH M M i n i t o w e r

E165027 G-SITE a n d P a s s p o r t S y s t e m s

National Conference of Weights and Measures (NCWM) - Certificate of Conformance (CoC):

Gilbarco pumps and dispensers are evaluated by NCWM under the National Type Evaluation Program (NTEP). NCWM has issued the following CoC:

CoC# Product Model # CoC# Product Model # CoC# Product Model #

02-019 Encore Nxx 02-026 H111B Series AC, RAC 02-034 External Mount CRIND CECXXXXXXX

02-020 Eclipse Exx

02-021

T-12C Console PA0188, RA0188 Fixed Blender

T-12C Console PA0203, RA0203 Dispenser - Low Profile AR, RAR

02-022 T-12G Console PA0180, RA0180

T-15 Console PA0189 Outdoor Card Q11891 G-SITE Keyboard PA0304

02-023

T-15 Controller C2 PA0211 02-029 CRIND — G-SITE Mini Tower PA0301

02-027

02-028

T-15 Controller PA0190

ProBlender AU, RAU TS-1000 Controller PA0241 G-SITE Printer (Citizen) PA0308

02-024

Precision Blender AE, RAE Distribution Box PA0242 02-038 C+ Meter T19976

Dispenser - Standard AK, RAK Micro-T Console PA0250 02-039 Passport PA0324

02-030

Dispenser - Low Profile AL, RAL Meter - EC Series PA024EC10 02-040 Ecometer T20453

Fixed Blender AP, RAF VaporVac Kits CV

02-025

Meter - C Series PA024NC10 02-031 The Advantage Series Bxx, RBxx

Meter - C Series PA024TC10 02-032 Trimline Series AA, RAA

Salesmaker ProBlender AB, RAB 02-033 Meter - C Series PA024XC10

99-165 Salesm a k e r S e r i e s 2 / 2 H /4 /4A AM MPD-A3 Series AD, RAD

MPD-1 Series AN, RAN 02-035 Dimension Dxx

AF, RAF, AG,

RAG

Indoor Card Q11640 G-SITE Distribution Box PA0306

TS-1000 Console PA0240 G-SITE Monitor PA0303

California Air Resources Board (CARB):

Executive Order # Product

G-70-52-AM Balance Vapor Recovery

G-70-150-AE VaporVac

02-036 Legacy Jxxx

G-SITE Printer (Epson) PA0307

02-037

Patents

Gilbarco Inc. products are manufactured or sold under one or more of the following US patents:

Dispensers

4,566,504 4,556,927 4,570,686 4,687,033 4,728,788 4,748,846 4,799,940 4,805,453 4,876,653 4,890,210 4,913,813 4,930,655 4,934,565 4,938,054

4,938,251 4,939,730 4,967,366 4,986,445 5,040,577 5,098,179 5,134,548 5,156,199 5,269,353 5,228,084 5,325,706 5,345,979 5,355,915 5,363,988

5,384,850 5,407,115 5,417,256 5,448,638 5,450,883 5,464,466 5,501,246 5,535,130 5,542,458 5,543,849 5,546,981 5,557,084 5,571,310 5,602,745

5,626,649 5,630,528 5,708,580 5,719,779 5,719,781 5,720,325 5,724,067 5,734,851 5,755,854 5,782,275 5,794,667 5,798,931 5,803,136 5,843,212

5,857,500 5,868,179 5,871,651 5,890,520 5,954,080 5,956,259 5,969,691 5,971,042 5,979,705 5,980,090 6,026,866 6,052,629 6,073,840 6,078,888

6,078,896 6,082,415 6,085,775 6,087,954 6,089,284 6,092,410 6,098,879 6,102,085 6,109,477 6,112,134 6,113,039 6,116,505 6,119,110 6,123,118

6,149,033 6,167,923 6,176,421 6,184,846 6,185,307 6,185,893 6,196,065 6,227,227 6,244,310 6,250,151 6,253,779 6,263,319 6,275,746 6,296,148

6,302,165 6,313,737 6,325,112 6,326,934 6,336,479 6,338,369 6,347,649 6,352,176 6,357,493 6,360,137 6,363,299 6,364,206 6,380,853 6,381,514

6,386,246 6,418,983 6,421,616 6,422,464 6,431,226 6,438,452 6,460,579 6,463,389 6,466,842 6,470,233 6,493,440 6,499,516 6,505,134 6,522,947

6,523,744 6,529,800 6,532,999 6,535,726 6,546,882 6,571,151 6,571,201 6,573,884 6,574,603 6,578,145 6,618,362 6,644,360 6,681,814 6,685,089

6,690,275 6,697,705 6,704,774 6,708,797 6,710,701 6,712,101 6,721,669 6,736,313 6,741,909 6,745,104 6,761,190 6,763,974 6,766,949 RE35,238

D262,971 D265,092 D306,719 D309,144 D316,471 D413,124 D413,311 D413,336 D413,337 D413,610 D413,901 D413,902 D414,192 D414,501

D414,778 D414,779 D414,780 D414,781 D414,782 D415,166 D415,167 D415,168 D415,169 D415,170 D415,171 D415,172 D415,501 D415,777

D416,915 D416,916 D417,226 D418,523 D420,684 D421,612 D422,285 D422,604 D426,555 D428,424 D428,897 D429,739 D429,740 D431,039

D431,252 D431,573 D432,140 D432,141 D432,548 D432,552 D433,031 D433,032 D433,033 D433,034 D433,035 D433,036 D433,037 D433,420

D433,421 D433,422 D433,423 D433,424 D433,685 D433,686 D433,687 D433,688 D434,424 D434,780 D435,051 D440,579 D443,624 D456,820

D457,084

Point of Sale/Back Office Equipment

4,967,366 5,228,084 5,448,638 5,798,931 5,980,090 5,708,580 5,719,779 5,719,781 5,724,067 5,734,851 6,073,840 6,078,888 6,116,505 6,185,307

6,263,319 6,275,746 6,326,934 6,360,137 6,363,299 6,364,206

Trademarks

Non-registered trademarks

™

C-PAM

™

CIM

™

ECR

™

EMC

™

G-CAT

™

Gilbert

G-SITE® Link™SMART CRIND™Val u e L i n e

G-SITE® Lite

This document is subject to change without notice. For information regarding Gilbarco Inc. Literature, call (336) 547-5661

E-mail: literature@gilbarco.com Internet: http://www.gilbarco.com

© 2008 Gilbarco Inc. All Rights Reserved

™

™

Highline

MultiLine

SMART Meter

™

SmartPad

Optimum™ Series Surge Management System

PAM™ 1000 Tank Monitor

™

PAM

TCR

SMART Connect™Ultra-Hi

SMART

Merchandising

™

™

™

™

™

™

™

Registered trademarks

Dimension® Series The Advantage® Series Encore

®

Gilbarco

™

InfoScreen

®

Legacy

Making Things Better®G-SITE

®

MPD

®

®

Transac

®

Trimline

®

Vap o r Va c

®

Transac® System 1000 Performer

Eclipse

TRIND

Passport

CRIND

e-CRIND

®

®

Additional US and foreign trademarks pending.

®

®

Other brand or product names shown may be

®

trademarks or registered trademarks of their

®

respective holders.

®

Table of Contents

1 – Introduction 1

Purpose. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Pumping Unit Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Revision History. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Determining the Model Number. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

2 – Important Safety Information 3

3 – Pumping Unit Operation and Maintenance 5

Flow of Liquid Through Pumping Unit and Air Eliminator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Float and Air Separator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Adjustable Bypass Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Air Separator Float Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Control Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Lip Seal Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Pumping Units with Throw-Out Rings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4 – Parts Lists and Kits 11

Model M04920B003 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Model M04920B003 - Pumping Unit Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Adjustable Bypass Parts Breakdown . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Plug and Fitting Parts Breakdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Model M04920B015 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Model M04920B015 - Pumping Unit Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Air Eliminator Parts Breakdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Adjustable Bypass Parts Breakdown . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Air Eliminator Float Assembly Parts Breakdown . . . . . . . . . . . . . . . . . . .18

Kits for M04920B003 and M04920B015 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Kit Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Kit Component Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

5 – Troubleshooting 21

General Vacuum and Pressure Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Vacuum Gauge Readings (Inches of Mercury) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Conversion Factors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Use Gauge Readings to Troubleshoot Self-Contained Dispensers . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Testing Pump Vacuum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Testing Pump Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Troubleshooting Using Gauge Readings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Resolving Problems on Pumping Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

6 – Vapor Lock Causes 31

Reasons for Vapor Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Atmospheric Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Vapor Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

MDE-4447A Global Pumping Unit Operation and Service Manual · May 2008 Page i

Table of Contents

Working Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Measuring Suction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Installation is the Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Vapor Lock Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Page ii MDE-4447A Global Pumping Unit Operation and Service Manual · May 2008

Purpose Introduction

1 – Introduction

Purpose

This manual provides service information regarding mechanical and hydraulic components for

the following Gilbarco Global Pumping Unit models:

• M04920B003 - United States Version, Heavy Duty, (20-24 gpm)

• M04920B015 - European Version, Heavy Duty, (20-24 gpm)

• M04920B011 - United States Version, Alternate Fuel Version, Heavy Duty, (20-24 gpm)

• M04920B012 - European Version, Alternate Fuel Version, Heavy Duty, (20-24 gpm)

Pumping Unit Identification

The following chart shows features of the models covered in this manual.

Where Used

United States M04920B003 X Heavy Duty

Europe M04920B015 X X X X Heavy Duty

United States M04920B011 X Heavy Duty

Europe M04920B012 X X X X Heavy Duty

Model

Number

Heavy

Duty Standard

Revision History

Old Pump Part Number New Pump Part Number

M04920B001 M04920B003

M04920B002 M04920B003

M04920B008 M04920B015

M04920B010 M04920B015

Inlet Check

Valve

Air Vent

Float

Air

Separator

Device

Bypass

Spring

Determining the Model Number

The model number appears on the serial number tag attached to the front of the global

pumping unit. Use the chart under Pumping Unit Identification to determine your model.

MDE-4447A Global Pumping Unit Operation and Service Manual · May 2008 Page 1

Introduction Determining the Model Number

This page is intentionally left blank.

Page 2 MDE-4447A Global Pumping Unit Operation and Service Manual · May 2008

2 – Important Safety Information

Important Safety Information

This section introduces the hazards and safety precautions

associated with installing, inspecting, maintaining or servicing

this product. Before performing any task on this product, read

this safety information and the applicable sections in this

manual, where additional hazards and safety precautions for

your task will be found. Fire, explosion, electrical shock or

pressure release could occur and cause death or serious

injury, if these safe service procedures are not followed.

Preliminary Precautions

You are working in a potentially dangerous environment of

flammable fuels, vapors, and high voltage or pressures. Only

trained or authorized individuals knowledgeable in the related

procedures should install, inspect, maintain or service this

equipment.

Emergency Total Electrical Shut-Off

The first and most important information you must know is

how to stop all fuel flow to the pump/dispenser and island.

Locate the switch or circuit breakers that shut off all power to

all fueling equipment, dispensing devices, and Submerged

Turbine Pumps (STPs).

!

WARNING

!

The EMERGENCY STOP, ALL STOP, and

PUMP STOP buttons at the cashier’s station

WILL NOT shut off electrical po wer to th e pump/

dispenser. This means that even if you activate

these stops, fuel may continue to flow

uncontrolled.

Read the Manual

Read, understand and follow this manual and any other

labels or related materials supplied with this equipment. If you

do not understand a procedure, call a Gilbarco Authorized

Service Contractor or call the Gilbarco Support Center at

1-800-800-7498. It is imperative to your safety and the safety

of others to understand the procedures before beginning

work.

Follow the Regulations

Applicable information is available in National Fire Protection

Association (NFPA) 30A; Code for Motor Fuel Dispensing

Facilities and Repair Garages, NFPA 70; National Electrical

Code (NEC), Occupational Safety and Hazard Association

(OSHA) regulations and federal, state, and local codes. All

these regulations must be followed. Failure to install, inspect,

maintain or service this equipment in accordance with these

codes, regulations and standards may lead to legal citations

with penalties or affect the safe use and operation of the

equipment.

Replacement Parts

Use only genuine Gilbarco replacement parts and retrofit kits

on your pump/dispenser. Using parts other than genuine

Gilbarco replacement parts could create a safety hazard and

violate local regulations.

Safety Symbols and Warning Words

This section provides important information about warning

symbols and boxes.

Alert Symbol

You must use the TOTAL ELECTRICAL SHUTOFF in the case of an emergency and not the

console’s ALL STOP and PUMP STOP or

similar keys.

To tal Electrical Shut-Off Before Access

Any procedure that requires access to electrical components

or the electronics of the dispenser requires total electrical

shut off of that unit. Understand the function and location of

this switch or circuit breaker before inspecting, installing,

maintaining, or servicing Gilbarco equipment.

Evacuating, Barricading and Shutting Off

Any procedure that requires access to the pump/dispenser or

STPs requires the following actions:

• An evacuation of all unauthorized persons and vehicles

from the work area

• Use of safety tape, cones or barricades at the affected

unit (s)

• A total electrical shut-off of the affected unit (s)

This safety alert symbol is used in this manual and

on warning labels to alert you to a precaution which must be

followed to prevent potential personal safety hazards. Obey

safety directives that follow this symbol to avoid possible

injury or death.

Signal Words

These signal words used in this manual and on warning

labels tell you the seriousness of particular safety hazards.

The precautions below must be followed to prevent death,

injury or damage to the equipment:

DANGER: Alerts you to a hazard or unsafe practice

!

which will result in death or serious injury.

WARNING: Alerts you to a hazard or unsafe practice

!

that could result in death or serious injury.

CAUTION with Alert symbol: Designates a hazard or

!

unsafe practice which may result in minor injury.

CAUTION without Alert symbol: Designates a hazard

or unsafe practice which may result in property or

equipment damage.

Working With Fuels and Electrical Energy

Prevent Explosions and Fires

Fuels and their vapors will explode or burn, if ignited. Spilled

or leaking fuels cause vapors. Even filling customer tanks will

cause potentially dangerous vapors in the vicinity of the

dispenser or island.

MDE-4447A Global Pumping Unit Operation and Service Manual · May 2008 Page 3

Important Safety Information

No Open Fire

Open flames from matches, lighters, welding

torches or other sources can ignite fuels and their vapors.

No Sparks - No Smoking

Sparks from starting vehicles, starting or using power tools,

burning cigarettes, cigars or pipes can also ignite fuels and

their vapors. Static electricity, including an electrostatic

charge on your body, can cause a spark sufficient to ignite

fuel vapors. Every time you get out of a vehicle, touch the

metal of your vehicle, to discharge any electrostatic charge

before you approach the dispenser island.

Working Alone

It is highly recommended that someone who is capable of

rendering first aid be present during servicing. Familiarize

yourself with Cardiopulmonary Resuscitation (CPR) methods,

if you work with or around high voltages. This information is

available from the American Red Cross. Always advise the

station personnel about where you will be working, and

caution them not to activate power while you are working on

the equipment. Use the OSHA Lockout/ Tagout procedures. If

you are not familiar with this requirement, refer to this

information in the service manual and OSHA documentation.

Working With Electricity Safely

Ensure that you use safe and established practices in

working with electrical devices. Poorly wired devices may

cause a fire, explosion or electrical shock. Ensure that

grounding connections are properly made. Take care that

sealing devices and compounds are in place. Ensure that you

do not to pinch wires when replacing covers. Follow OSHA

Lockout/T agout requirements. S t ation employees and service

contractors need to understand and comply with this program

completely to ensure safety while the equipment is down.

Hazardous Materials

Some materials present inside electronic enclosures may

present a health hazard if not handled correctly. Ensure that

you clean hands after handling equipment. Do not place any

equipment in the mouth.

!

WARNING

The pump/dispenser contains a chemical known to the

State of California to cause cancer.

In an Emergency

Inform Emergency Personnel

Compile the following information and inform emergency

personnel:

• Location of accident (for example, address, front/back of

building, and so on)

• Nature of accident (for example, possible heart attack, run

over by car, burns, and so on)

• Age of victim (for example, baby, teenager, middle-age,

elderly)

• Whether or not victim has received first aid (for example,

stopped bleeding by pressure, and so on)

• Whether or not a victim has vomited (for example, if

swallowed or inhaled something, and so on)

WARNING

!

Gasoline ingested may cause unconsciousness

and burns to internal organs.

Do not induce vomiting.

Keep airway open.

Oxygen may be needed at scene.

Seek medical advice immediately.

WARNING

!

Gasoline inhaled may cause unconsciousness

and burns to lips, mouth and lungs.

Keep airway open.

Seek medical advice immediately.

WARNING

!

Gasoline spilled in eyes may cause burns to eye

tissue.

Irrigate eyes with water for approximately 15

minutes.

Seek medical advice immediately.

WARNING

!

Gasoline spilled on skin may cause burns.

Wash area thoroughly with clear water.

Seek medical advice immediately.

IMPORTANT: Oxygen may be needed at scene if gasoline

has been ingested or inhaled. Seek medical advice

immediately.

WARNING

!

Lockout/Tagout

Lockout/Tagout covers servicing and maintenance of

The pump/dispenser contains a chemical known to the

State of California to cause birth defects or other

reproductive harm.

machines and equipment in which the unexpected

energization or start-up of the machine(s) or equipment or

release of stored energy could cause injury to employees or

personnel. Lockout/Tagout applies to all mechanical,

hydraulic, chemical or other energy, but does not cover

electrical hazards. Subpart S of 29 CFR Part 1910 - Electrical

Hazards, 29 CFR Part 1910.333 contains specific Lockout/

Tagout provision for electrical haza rd s.

Page 4 MDE-4447A Global Pumping Unit Operation and Service Manual · May 2008

Flow of Liquid Through Pumping Unit and Air Eliminator Pumping Un it Operation and Maintenance

3 – Pumping Unit Operation and Maintenance

Flow of Liquid Through Pumping Unit and Air Eliminator

The Model M04920 Pumping Unit moves the product from the storage tank to the vehicle or

container in the following manner:

Note: The numbers within parentheses in the procedural steps below refer to the numbers in

Figure 3-1.

1 The fuel is drawn from the storage tank through the strainer screen or filter (1).

2 The rotary vane pumping unit (2) pressurizes the fluid.

3 Fuel enters the centrifugal air separator assembly (3). Any air that is present is forced out of

the air tube along with a small amount of liquid into the atmospheric chamber.

4 When the liquid level in the chamber lifts the float and valve assembly (4), the liquid collected

in the atmospheric chamber is returned to the pump intake. Air is then vented to the

atmosphere through the end tube (5).

5 Air-free fuel leaving the air separator opens the control valve (6) and is pumped into the meter.

The control valve includes a built-in relief valve (7) which relieves excess pressure caused by

hot weather expansion.

6 Fuel passes through the meter where it is accurately measured, then through the hose and

nozzle to the vehicle or container being fueled.

7 Whenever the nozzle is not fully opened, some liquid is relieved into the pump through the

bypass valve (8).

Figure 3-1: Flow Diagram

Vent Tube

Atmospheric

Chamber

Discharge

Pressure

Relief

Valve

Inlet

MDE-4447A Global Pumping Unit Operation and Service Manual · May 2008 Page 5

Pumping Unit Operation and Maintenance Float and Air Separator

Float and Air Separator

IMPORTANT INFORMATION

Before gasoline can be accurately measured by the meter, air and vapors must be eliminated.

The pumping unit eliminates air and vapor by using the air separator and float assembly. The

float assembly employed is as shown in Figure 3-2.

Figure 3-2: Float Assembly

Enlarge Top Hole to

7/16 inch

Flat Side Pointing

Away from Float

Adjustable Bypass Valve

The pumping unit uses an adjustable bypass valve assembly in order to limit the pumping unit

pressure when the motor is running and no fuel is being dispensed. The adjustable bypass

assembly includes the following:

• Valve spring

•Guide

•Cover

• Adjustment screw

• Brass cap

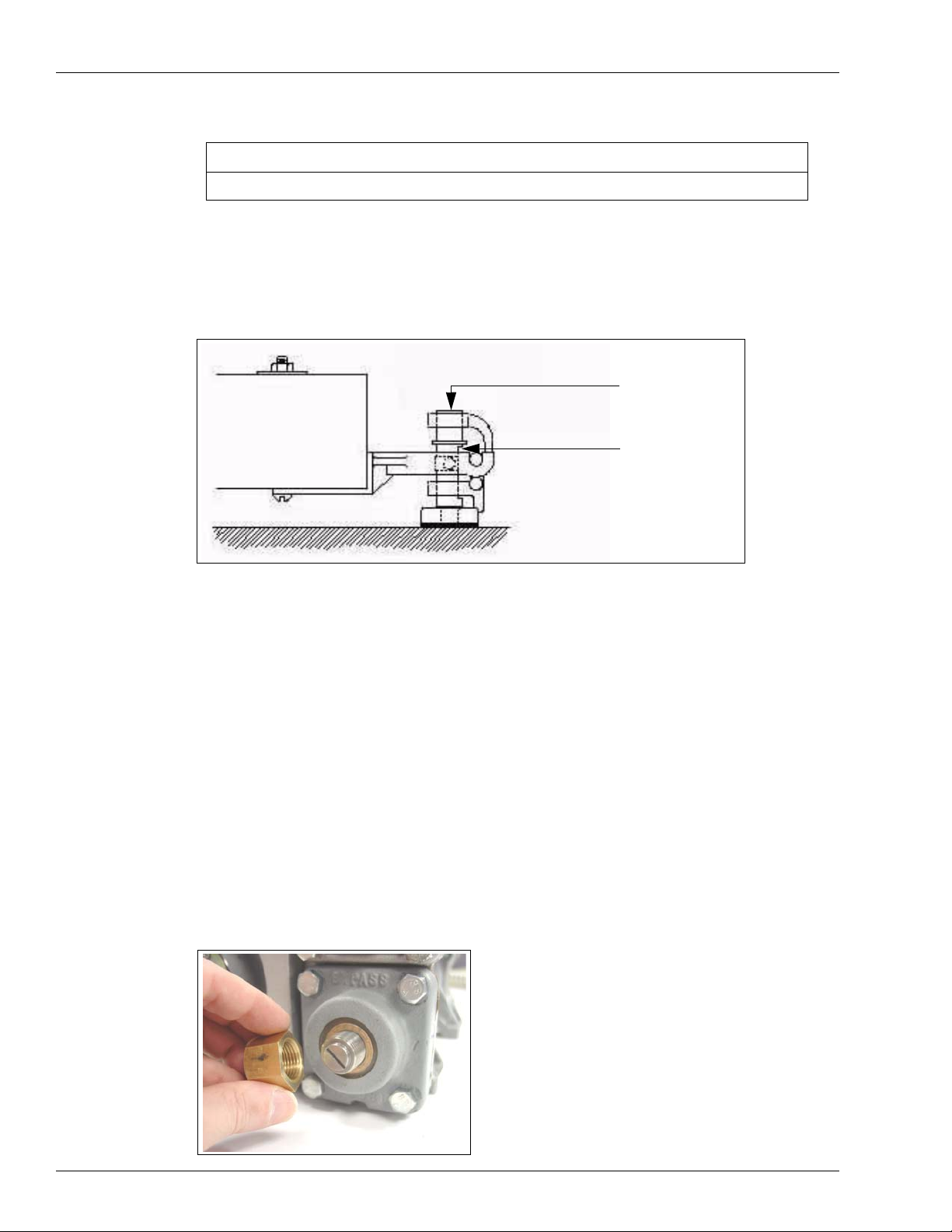

Note: The same bypass assembly is used on all pumping units. See Figure 3-3.

Figure 3-3: Bypass Valve

Page 6 MDE-4447A Global Pumping Unit Operation and Service Manual · May 2008

Air Separator Float Device Pumping Unit Operation and Maintenance

Air Separator Float Device

On OIML Euro versions of the pumping unit, a float assembly is provided on the pumping unit

vent opening. This assembly is used to prevent liquid from escaping through the vent pipe. See

Figure 3-4.

Figure 3-4: Air Separator Float Device

Control Valve

The pumping unit uses a control valve that aids in the elimination of air by producing a back

pressure and is also used as a check valve for any fuel above it.

The control valve also contains a pressure relief valve. This valve relieves excess hose

pressure, which may result from the expansion of fuel in the hose during hot weather, to the air

eliminator chamber. This action prevents hoses from bursting and helps prevent pumping unit

leaks.

Figure 3-5: Control Valve

MDE-4447A Global Pumping Unit Operation and Service Manual · May 2008 Page 7

Pumping Unit Operation and Maintenance Lip Seal Replacement

Lip Seal Replacement

To replace the lip seal, proceed as follows:

1 Remove the belt, pulley, and shaft key.

2 Remove the three screws that hold the seal retainer. See Figure 3-6. Carefully pry the old seal

from the recess in the cover plate.

Note: Do not scratch the shaft.

3 Wipe the shaft clean.

4 With a small plastic plug tool (furnished with new seal), slip the new seal over the shaft.

Remove the tool.

5 Reinstall the seal retainer screws, key, pulley, and belt.

Figure 3-6: Lip Seal Replacement

Stator

Seal

Retainer

Remove Plastic Plug

After Assembling Lip

Seal to Rotor Shaft

Lip

Seal

Screw

Inner

Seal

A 52 5702

Page 8 MDE-4447A Global Pumping Unit Operation and Service Manual · May 2008

Pumping Units with Throw-Out Rings Pumping Unit Operation and Maintenance

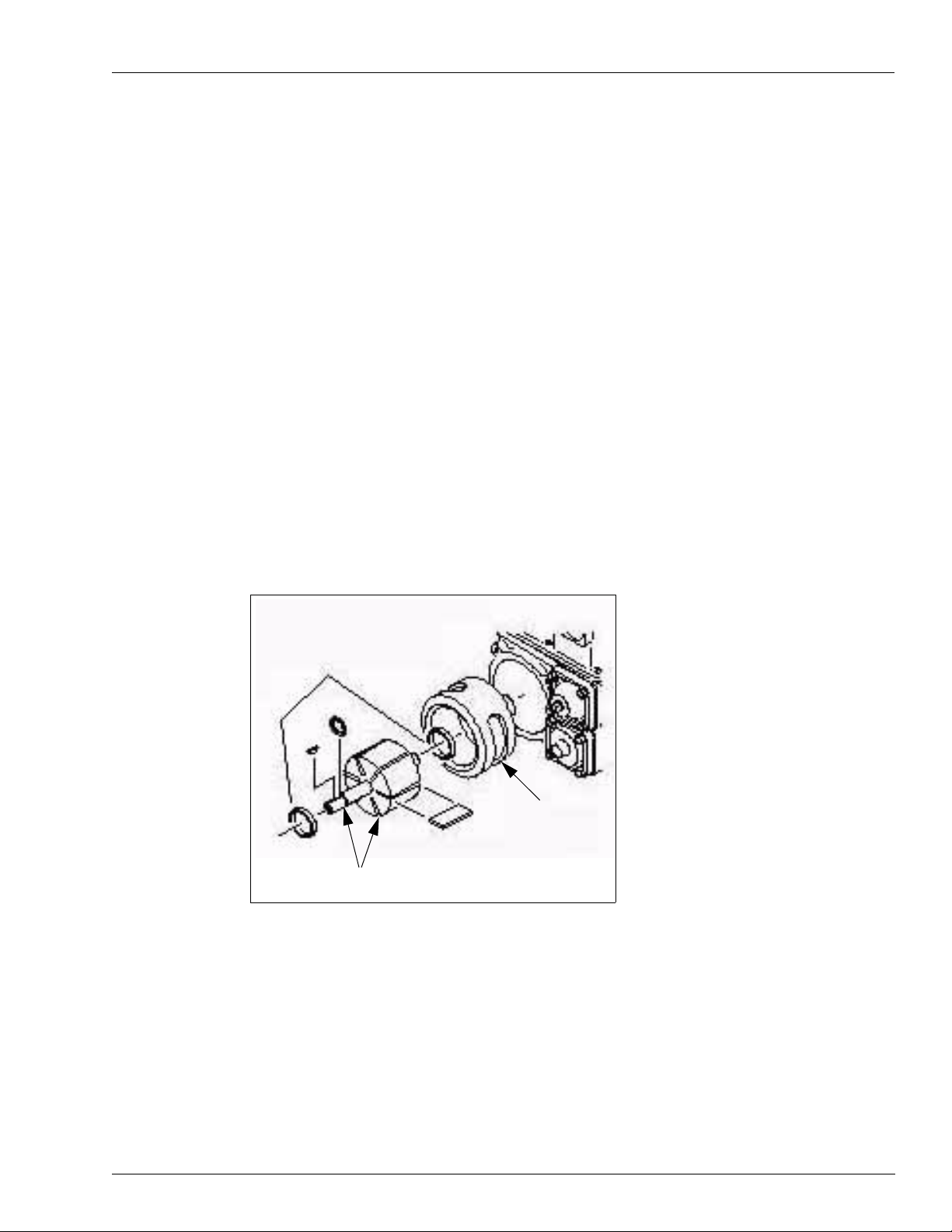

Pumping Units with Throw-Out Rings

All pumping units have rotors with throw-out rings and carbon blades.

Note: Studies conclude that pumping units with throw-out rings produce greater vacuum and

are more resistant to vapor lock.

To replace blades in rotors with throw-out rings, proceed as follows:

1 Install throw-out rings in the recesses of the rotor.

2 Install the rotor in the stator assembly.

3 Rotate the rotor until a blade slot is at the 12:00 o'clock position. Install a blade.

4 Rotate the rotor two slots from the installed blade. Ensure that the second slot is at the 12:00

o'clock position. Install a blade.

5 Repeat step 4 for the third blade.

6 Repeat steps 1 to 3 for the three remaining blades. See Figure 3-7.

Figure 3-7: Pumping Units with Throw-Out Rings

Blade Slot at 12:00 o’clock Position

Throw-out Rings

Stator

Rotor and Shaft

Assembly

MDE-4447A Global Pumping Unit Operation and Service Manual · May 2008 Page 9

Pumping Unit Operation and Maintenance Pumping Units with Throw-Out Rings

This page is intentionally left blank.

Page 10 MDE-4447A Global Pumping Unit Operation and Service Manual · May 2008

Parts Lists and Kits Model M04920B003

4 – Parts Lists and Kits

Model M04920B003

Figure 4-1: Pumping Unit - United States

MDE-4447A Global Pumping Unit Operation and Service Manual · May 2008 Page 11

Model M04920B003 - Pumping Unit Parts List Parts Lists and Kits

Model M04920B003 - Pumping Unit Parts List

Notes:1) Parts listed in the following table are not available for individual purchase. Repair

kits may be purchased. Refer to “Kits for M04920B003 and M04920B015” on

page 19.

2) Refer to “Adjustable Bypass Parts Breakdown” on page 13 and “Plug and Fitting

Parts Breakdown” on page 14 for additional parts and graphics.

Item Part Description Quantity Item Part Description Quantity

1 Body (non-reverse

float)

Body (reverse float) 1 32 Seal, Retainer 1

2 Blade, Rotor 10, see Note 2 33 Seal, Square 1

3 Clamp (see Note 1) 1 34 Rotor and Shaft Assembly 1, see Note 2

4 Connector, Male 1 19 • Key 1

5 Cover, Atmos.

Chamber

6 Cover, Bypass Valve 1 36 Screw (see Note 1) 1

7 Cover, Control Valve 1 37 Screw, M8 1.25x15mm 1

8 Cover, Filter 1 38 Screw, M8 1.25x20mm

9 Float, Non-Reversing 1 39 Screw, M8 1.25x25mm 24

11 Gasket, Atmos. Cham.

Cover

12 Gasket, Bypass Valve 1 41 Separator & Air Eliminator 1

13 Gasket, Clamping

Ring

14 Gasket, Control Valve

Cover

15 Gasket, Filter Cover 1 44 Spring, Filter 1

16 Gasket, Inlet

(separator)

17 Gasket, Outlet

(separator)

18 Inse rt 1 47 Strainer Assembly-149

19 Key 1 • Strainer, 70 Micron 1

20 Nut, Tube (see Note 1) 1 • Paper Filter (not

21 Nut 1 48 Tube, Vent Assy- 9024

22 O-ring 1 Tube, Vent Assy- 9033

23 Plug, Pipe 1/4” 2 Tube, Vent Assy- 9044

24 Pulley 1 49 Valve Assembly, Bypass 1

25 Ring, Throw Out

(H.D.)

1 31 Seal, Lip (with plug) 1

1 35 • Ring, Retaining 1

(see Note 1)

1 40 Screw, M6 1x20mm 6

1 42 Sleeve, Tube (see Note 1) 1

1 43 Spring, Control Valve

(H.D.)

1 45 Stator, H.D. 1

1 46 Stop, Filter Insert 1

micron

shown)

(see Note 1)

and 9036

and 9048

2 50 Valve Assembly, Control 1

-

1

1

1

2

3

4

Page 12 MDE-4447A Global Pumping Unit Operation and Service Manual · May 2008

Parts Lists and Kits Model M04920B003 - Pumping Unit Parts List

Item Part Description Quantity Item Part Description Quantity

26 Ring, Clamping 1 51 Valve, Relief 30-50 PSI 1

27 Ring, Retaining 1 52 Valve Assembly, Float 1

28 Rotor Support

Assembly

29 Cover, Rotor 1 54 Washer (see Note 1) 2

30 Screw, M3.5 Flat Hd 3 55 Washer, Lock 1

Notes:

1. Not part of the pumping unit.

2. Current pumping units use a 10-blade assembly. If you have a 6 or 8-blade rotor assembly, you can replace

blades, but the replacement rotor assembly uses a 10-blade design. When you need to replace the blades, it

is also recommended that you replace 6 or 8-blade rotor assemblies with a 10-blade rotor assembly for

quieter operation and better performance.

1 53 Washer 1

Adjustable Bypass Parts Breakdown

Refer to the table below Figure 4-3 on page 14 for a parts listing.

Figure 4-2: Adjustable Bypass Parts Breakdown

58

60

61

59

MDE-4447A Global Pumping Unit Operation and Service Manual · May 2008 Page 13

Model M04920B003 - Pumping Unit Parts List Parts Lists and Kits

Plug and Fitting Parts Breakdown

Refer to the table below Figure 4-3 on page 14 for a parts listing.

Figure 4-3: Plug and Fitting Parts Breakdown

56

57

Item Part Description

56 Fitting

57 Pipe Plug

58 Nut

59 Screw - Adjustable

60 Cover

61 Gasket - screw

Page 14 MDE-4447A Global Pumping Unit Operation and Service Manual · May 2008

Parts Lists and Kits Model M04920B015

Model M04920B015

Figure 4-4: Pumping Unit (Euro and Heavy Duty OIML Euro)

MDE-4447A Global Pumping Unit Operation and Service Manual · May 2008 Page 15

Model M04920B015 - Pumping Unit Parts List Parts Lists and Kits

Model M04920B015 - Pumping Unit Parts List

Notes:1) Parts listed in the following table are not available for individual purchase. Repair

kits may be purchased. Refer to “Kits for M04920B003 and M04920B015” on

page 19.

2) Refer to “Adjustable Bypass Parts Breakdown” on page 17, “Air Eliminator Float

Assembly Parts Breakdown” on page 18 and “Air Eliminator Float Assembly Parts

Breakdown” on page 18 for additional parts and graphics.

Item Part Description Quantity Item Part Description Quantity

1 Body (non-reverse

float)

Body (reverse float) 1 32 Seal, Retainer 1

2 Blade, Rotor 10, See Note 2 33 Seal, Square 1

3 Clamp (see Note 1) 1 34 Rotor and Shaft Assembly 1, See Note 2

4 Connector, Male 1 19 • Key 1

5Cover, Atmos.

Chamber

6 Cover, Bypass Valve 1 36 Screw (see Note 1) 1

7 Cover, Control Valve 1 37 Screw, M8 1.25x15mm 1

8 Cover, Filter 1 38 Screw, M8 1.25x20mm

9 Float, Non-Reversing 1 39 Screw, M8 1.25x25mm 24

11 Gasket, Atmos. Cham.

Cover

12 Gasket, Bypass Valve 1 41 Separator & Air Eliminator 1

13 Gasket, Clamping Ring 1 42 Sleeve, Tube (see Note 1) 1

14 Gasket, Control Valve

Cover

15 Gasket, Filter Cover 1 44 Spring, Filter 1

16 Gasket, Inlet

(separator)

17 Gasket, Outlet

(separator)

1 31 Seal, Lip (with plug) 1

1 35 • Ring, Retaining 1

(see Note 1)

1 40 Screw, M6 1x20mm 6

1 43 Spring, Control Valve

(H.D.)

1 45 Stator, H.D. 1

1 46 Check Valve 1

-

1

18 Insert 1 46A O-ring 1

19 Key 1 47 Strainer Assembly-149

micron

20 Nut, Tube (see Note 1) 1 • Strainer, 70 Micron 1

21 Nut 1 • Metal Strainer (not

shown)

22 O-ring 1 48 Tube, Vent Assy- 9024

(see Note 1)

23 Plug, Pipe 1/4 2 Tube, Vent Assy- 9033 &

9036

24 Pulley 1 49 Valve Assembly, Bypass 1

25 Ring, Throw Out (H.D.) 2 50 Valve Assembly, Control 1

26 Ring, Clamping 1 51 Valve, Relief 30-50 PSI 1

1

1

2

3

Page 16 MDE-4447A Global Pumping Unit Operation and Service Manual · May 2008

Parts Lists and Kits Model M04920B015 - Pumping Unit Parts List

Item Part Description Quantity Item Part Description Quantity

27 Ring, Retaining 1 52 Valve Assembly, Float 1

28 Rotor Support

Assembly

29 Cover, Rotor 1 54 Washer (see Note 1) 2

30 Screw, M3.5 Flat Hd 3 55 Washer, Lock 1

Notes:

1. Not part of the pumping unit.

2. Current pumping units use a 10-blade assembly. If you have a 6 or 8-blade rotor assembly, you can replace

blades, but the replacement rotor assembly uses a 10-blade design. When you need to replace the blades, it is

also recommended that you replace 6 or 8-blade rotor assemblies with a 10-blade rotor assembly for quieter

operation and better performance.

1 53 Washer 1

Air Eliminator Parts Breakdown

Refer to the table below Figure 4-7 on page 18 for a parts listing.

Figure 4-5: Air Eliminator Parts Breakdown

60

61

62

Adjustable Bypass Parts Breakdown

Refer to the table below Figure 4-7 on page 18 for a parts listing.

Figure 4-6: Adjustable Bypass Parts Breakdown

72

73

74

63

75

MDE-4447A Global Pumping Unit Operation and Service Manual · May 2008 Page 17

Model M04920B015 - Pumping Unit Parts List Parts Lists and Kits

Air Eliminator Float Assembly Parts Breakdown

Refer to the table below Figure 4-7 for a parts listing.

Figure 4-7: Air Eliminator Float Assembly Parts Breakdown

65

64

Item Part Description

56 Clip (not shown)

57 End Plug (not shown)

58 O-ring (not shown)

59 Separator (not shown)

60 Air Separator Tube Variable Orifice

61 Piston Air Separator Tube Variable Orifice

62 Spring

63 End Cap Separator Tube Variable Orifice

64 3/8-inch Pipe Plug

65 Housing Air Valve Float Assembly

66 Gasket Air Valve Float Assembly

67 Needle Air Valve Float Assembly

68 Gland Nut Air Valve Float Assembly

69 Float - Air Valve Float Assembly

70 Retaining Ring - External 3.5mm

71 Retaining Ring - External 3.5mm

72 Nut

73 Screw - Adjustable

74 Gasket - Screw

75 Cover

69

71

67

68

70

Page 18 MDE-4447A Global Pumping Unit Operation and Service Manual · May 2008

Parts Lists and Kits Kits for M04920B003 and M04920B015

Kits for M04920B003 and M04920B015

The kits listed in the table below are available for Gilbarco Global Pumping Units. Refer to

“Kit Component Parts” on page 20 for additional information.

Kit Number Kit Description

M04920K100 Bypass Valve

M04920K101 Strainer

M04920K102 Master Seal

M04920K104 Control Valve

M04920K105 Lip Seal

M04920K107 Sump Float - OIML (B005)

M04920K109 Inlet Check Valve

M04920K110 Overflow Che ck Valve

M04920K116 Blades

M04920K117 Pumping Element Field Rebuild

M04920K118 Pumping Element Shop Rebuild

M04920K119 Inlet Adapter

Note: Alternate Fuel Pumps M04920B011 and M04920B0 12 require special kits.

Contact Gilbarco's Engineering Department for assistance.

Kit Revision History

Kit Number Kit Description

M04920K103 Blades M04920K113

M04920K106 Pumping Elemen t Field Rebuild M04920K114

M04920K108 Pumping Element Shop Rebuild M04920K115

M04920K111 Sump Float - Non OIML (B001) M04920K107

M04920K112 Blades M04920K113

M04920K113 Blades M04920K116

M04920K114 Pumping Element Field Rebuild M04920K117

M04920K115 Pumping Element Shop Rebuild M04920K118

Replacement Kit

Number

MDE-4447A Global Pumping Unit Operation and Service Manual · May 2008 Page 19

Kit Component Parts Parts Lists and Kits

Kit Component Parts

M04920K100 - Bypass Valve M04920K117 - Pumping Element Field Rebuild

Bypass Valve • 10-blade Rotor and Shaft

M04920K101 - Strainer

70 Micron Strainer • Retaining Ring

M04920K102 - Master Seal

• Clamp Ring Gasket • Shaft Seal w/ Plug

• Bypass Valve Cover Gasket • Square Seal

• Control Valve Cover Gasket

• Filter Cover Gasket • 10-blade Rotor and Shaft

• Atmos. Chamb. Cover Gasket • Blade

• Inlet Gasket • Throw out Ring

M04920K104 -Control Valve

• Control Valve • Rotor Cover

• Heavy Duty Spring • Rotor Cover Gasket

M04920K105 - Lip Seal

• Lip Seal • Shaft Seal w/ Plug

• Square Seal • Square Seal

•Blade

• Woodruff Key

M04920K118 - Pumping Element Shop Rebuild

• Retaining Ring

• Woodruff Key

M04920K107 - Sump Float - OIML (B005) M04920K119 - Inlet Adapter

• Float Valve Assembly (Rogers) • Inlet Adapter

•O-Ring •Gasket

• Non-Reversing Float • Bolt

M04920K109 - Inlet Check Valve

•O-Ring

• Check Valve Assembly

M04920K110 - Overflow Check Valve

• Air Valve Housing

• Air Valve Gasket

• Valve Sub Assm. Air Vent

• Float (Rogers)

• Retaining Ring

M04920K116 - Blades

•Blade

• Shaft Seal w/ Plug

• Square Seal

Page 20 MDE-4447A Global Pumping Unit Operation and Service Manual · May 2008

General Vacuum and Pressure Information Troubleshooting

5 – Troubleshooting

General Vacuum and Pressure Information

The following components are normally associated with pump pressure:

• Control Valve

• Meter

• Computer or Pulser Drive Linkage

•Hose

• Nozzle

The following components are normally associated with pump vacuum:

•Blades

• Rotor/Stator

• Filter

• Bypass Valve and Seat

• Float (opened)

• Installation piping

• Tank Vent Pipe

• Angle Check Valve or Foot Valve

• Tank burial depth

Vacuum readings can vary with each installation. To calculate pump vacuum, proceed as

follows:

1 An inch of mercury is required to lift gasoline 1-1/2 feet. Divide the total lift by 1-1/2 feet to

obtain vacuum.

2 Allow an inch of mercury for each angle check, foot valve, or vertical check valve.

3 Allow an inch of mercury for each 60 feet of piping.

4 Add the readings obtained in steps 1, 2 and 3 to determine the approximate vacuum reading at

fast flow.

Note: Excessive vacuum indicates a restriction. Low vacuum indicates a leak.

MDE-4447A Global Pumping Unit Operation and Service Manual · May 2008 Page 21

Troubleshooting Vacuum Gauge Readings (Inches of Mercu r y)

Vacuum Gauge Readings (Inches of Mercury)

The following table shows normal vacuum gauge readings for a variety of lift vs. run

situations.

Notes:1) The following table shows normal vacuum gauge readings for general lift vs. run

situations. This is intended as a guideline only. Readings will vary depending on

other factors, such as pipeline size, number of bends, elevation, fuel composition and

so on.

2) Readings are listed in inches of mercury (in-hg). Some gauges may read in

centimeters of mercury (cm-hg), Pounds per Square Inch (PSI) or bar. See

Conversion Factors.

Vertical Lift (Feet)345678910

Horizontal Run - 0 feet 3.0 3.6 4.3 4.9 5.5 6.1 6.8 7.4

Horizontal Run - 60 feet 3.9 4.5 5.2 5.8 6.4 7.0 7.7 8.3

Conversion Factors

• 1 in-hg = 2.54 cm-hg

• 1 in-hg = -0.491 PSI

• 1 in-hg = -0.034 bar

• 1 ft = 0.3048 meter

Use Gauge Readings to Troubleshoot Self-Contained Dispensers

There are a variety of conditions that can contribute to no delivery or slow delivery. A

pressure/vacuum gauge is an important tool in determining whether the problem is on the

vacuum side or pressure side of the pump.

The vacuum gauge reading can help you determine if there are restrictions of flow in the

suction piping system. It will also help you determine the ability of the pumping unit to pump.

Note: Vacuum gauge readings in the following sections are shown in inches of mercury.

Testing Pump Vacuum

To test the vacuum of the pump, proceed as follows:

1 Remove the pipe plug in the center of the strainer or filter cover. The cover is marked for easy

identification.

2 Install the vacuum gauge.

3 Start the pump and open the nozzle to full flow for a true reading.

Page 22 MDE-4447A Global Pumping Unit Operation and Service Manual · May 2008

Use Gauge Readings to Troubleshoot Self-Contained Dispensers Troubleshooting

4 With the nozzle open, a normal vacuum reading is 6-8 inches of mercury for normal suction.

See Figure 5-1.

Figure 5-1: Vacuum Reading - Nozzle Open

With the nozzle closed, a normal vacuum reading is 0. See Figure 5-2.

5

Figure 5-2: Vacuum Reading - Nozzle Closed

Testing Pump Pressure

To test the pressure of the pump, proceed as follows:

1 Remove the pipe plug in the center of the control valve cover. Covers are marked for easy

identification.

2 Install the pressure gauge.

3 Start the pump and open the nozzle to full flow for a true reading.

4 With the nozzle open, a normal pressure reading is 16-18 PSI pressure.

5 With the nozzle closed, a normal pressure reading is 25-28 PSI pressure. See Figure 5-3 on

page 24.

MDE-4447A Global Pumping Unit Operation and Service Manual · May 2008 Page 23

Troubleshooting Troubleshooting Using Gauge Readings

Figure 5-3: Pressure Reading - Nozzle Closed

Troubleshooting Using Gauge Readings

The following examples help you determine the possible cause of a problem by observing the

gauge readings on the inlet (vacuum) and outlet (pressure) side of the pumping unit. Actual

readings may vary slightly, depending on installation and environmental conditions.

Figure 5-4: Gauge Troubleshooting 1

Symptoms: No Flow; Nozzle Open

Check Inlet Side

Probable Causes:

• Control Valve Stuck Shut

• Bypass Valve Open

• Atmospheric Float Valve Open

At Control Valve

Cover

• Stuck Rotor Blades

• Broken Suction Line

• Strainer or Filter Completely

Plugged or in Backwards

• Empty Tank

At Strainer

(or Filter)

Cover

Page 24 MDE-4447A Global Pumping Unit Operation and Service Manual · May 2008

Troubleshooting Using Gauge Readings Troubleshooting

Figure 5-5: Gauge Troubleshooting 2

Symptoms: No Flow; Nozzle Open

Probable Causes:

• Seized Meter

• Jammed Computer or Geared

Box

• Completely Restricted Nozzle or

Hose

At Control Valve

Cover

Symptoms: Slow or No Flow; Pump

Laboring; Nozzle Open

Check Inlet Side

At Strainer (or Filter)

Cover

At Control Valve

Cover

At Control Valve

Cover

Probable Causes:

• Supply Line Restriction

• Stuck Foot Valve (in Tank)

• Angle Check Valve or Vertical

Check Valve

• Restricted Tank Vent

Symptoms: Slow or No Flow;

Nozzle Open

Check Outlet Side

Probable Causes:

• Control Valve not Opening Fully

• Pump Vapor Locked

At Strainer (or Filter)

Cover

At Strainer (or Filter)

Cover

MDE-4447A Global Pumping Unit Operation and Service Manual · May 2008 Page 25

Troubleshooting Troubleshooting Using Gauge Readings

Figure 5-6: Gauge Troubleshooting 3

Symptoms: No Flow or Slow

Delivery; Nozzle Open

Probable Causes:

• Worn Bypass Valve or Rotor

Blades

• Worn Rotor or Stator

• Air Leak in Suction Pipe

At Control Valve

Cover

• Dirty Filter

Symptoms: Slow Flow; Nozzle

Open

Check Outlet Side

At Strainer (or Filter)

Cover

At Control Valve

Cover

At Control Valve

Cover

Probable Causes:

• Partially Restricted Nozzle or

Hose

• Bind in Computer, Gear Box,

Meter

• Pulser Drive Linkage

Symptoms: No Flow or Slow

Delivery; Nozzle Open

Probable Cause:

• Tank Burial Too Deep (High Lift)

At Strainer (or Filter)

Cover

At Strainer (or Filter)

Cover

Page 26 MDE-4447A Global Pumping Unit Operation and Service Manual · May 2008

Resolving Problems on Pumping Units Troubleshooting

Figure 5-7: Gauge Troubleshooting 4

Symptoms: Motor Laboring;

Circuit Breaker Trips; Motor

Failing; Nozzle Closed

Probable Cause:

• Bypass Valve Stuck Shut

Reading

At Control Valve

May Vary

Cover

At Strainer (or Fil ter)

Cover

Resolving Problems on Pumping Units

Refer to the following tables for specific troubleshooting information.

Problem

The motor starts but the pump does not deliver fuel.

Cause Action

The fuel supply is below the suction stub in

the storage tank.

The vent pipe is plugged in the storage tank. Clean the vent pipe.

The strainer screen or filter assembly has an

obstruction.

The bypass valve is not seated properly due

to wear or obstruction.

The v-belt is loose or broken. Adjust or replace the v-belt.

There is an obstruction in the atmospheric

float valve.

The pump is out of prime. Check for a faulty foot valve in the storage tank or a faulty check

The suction line is leaking. Start the pump and open the nozzle. If bursts of air are felt while

The intake line, foot valve, angle check

valve, or vertical check valve have an

obstruction.

The suction stub in the storage tank is on the

bottom of the tank.

The control valve has an obstruction. Clean the control valve. It must slide freely in the valve cavity.

The nozzle is not working. Replace the nozzle.

Two pumps are connected to one storage

tank with one suction line. There is a faulty

check valve in one of the supply lines*.

Fill the storage tank.

Remove obstructions from the screen or filter assembly.

Check the valve for an obstruction causing the valve to stay

open, and/or replace the bypass valve.

Clean the float and valve area. Check for swelling and binding

in the linkage.

valve in the suction line.

holding a finger on the vent tube, the suction line is damaged.

Repair or replace.

Connect a vacuum gauge to the 1/4 inch plug on the filter cover.

Turn the pump on and open the nozzle. A reading of 15 or more

inches of mercury with no flow indicates a complete blockage in

the suction line. Clean the line or replace.

Ensure that there is a four-inch clearance.

Disconnect the vent tube on the idle pump. Install a short

copper tube. Place the end of the copper tube in a container of

liquid. If the liquid is drawn out of the container when the

opposite pump is operated with an open nozzle, the line check

valve is faulty. Replace the check valve.

MDE-4447A Global Pumping Unit Operation and Service Manual · May 2008 Page 27

Troubleshooting Resolving Problems on Pump ing Units

Cause Action

*Not recommended.

Problem

The pump runs, but delivery is slow.

Cause Action

The fuel supply level is low. Fill the storage tank.

The vent pipe is partially obstructed. Clean the vent pipe.

The strainer screen or filter assembly has a

partial obstruction.

The bypass valve is not seated properly. Check the valve for any obstructions which may cause the valve to

The v-belt is loose. Adjust the v-belt.

The voltage is too low. Check the power supply voltage. The dispenser uses a 115 VAC,

A blade or blades in the rotary pump will not

move.

An automatic nozzle has been installed. Delivery speed will be reduced by 10-25%. If the maximum speed

The motor is defective. Inspect the motor for loose connections. If no loose connections

There is a slow leak in the suction line or

intake line.

The intake line, foot valve, angle or vertical

check valve is partially obstructed.

The control valve is partially obstructed. Check the valve for an obstruction. Replace if necessary.

The nozzle check valve is sticky. Clean or replace the nozzle check valve.

The hose is defective (flattened). Replace the hose.

Remove obstructions from the screen or filter assembly.

stay open.

60 cycle electrical circuit. Check for many pieces of equipment on

one electrical line.

Check the rotor and blades for damage. Replace the blades and/

or rotor, if necessary.

is desired, replace with a standard nozzle.

are found, the motor is defective. Repair or replace.

Start the pump and open the nozzle. If bursts of air are felt while

holding a finger on the vent tube, the suction line or intake line is

damaged. Repair or replace.

Connect a vacuum gauge to the 1/4 inch plug on the filter cover.

Turn the pump on and open the nozzle. A reading of 11 to 13

inches of mercury with no flow indicates a partial obstruction in the

suction line. Clean or replace the suction line components.

Problem

The motor will not run.

Cause Action

The power is off. Check the circuit breaker in the station.

The motor is defective. Disconnect the power supply. Inspect the motor for loose

connections. If no loose connections are found, the motor is

defective. Repair or replace.

Problem

The dispenser does not deliver an accurate amount of product.

Cause Action

There is an obstruction in the control

valve.

There is an obstruction in the air

eliminator vent tube.

Page 28 MDE-4447A Global Pumping Unit Operation and Service Manual · May 2008

Clean the control valve. It must slide freely in the valve cavity.

Clean the vent tube.

Resolving Problems on Pumping Units Troubleshooting

Cause Action

The meter needs calibration. Check calibration test equipment for accuracy. Calibrate the meter.

Problem

There is fuel running out of the vent tube opening when the pump is in operation.

Cause Action

There is an obstruction in the atmospheric

float valve. The valve is being held closed.

The suction chamber in the pump is

flooded (above ground tank)*.

* Not recommended.

Clean the float and valve area. Ensure that the float opens completely.

Check the storage tank level. If it is higher than the pumping unit

(above ground tank)*, the condition will continue. Install Tokheim 52

valve.

Problem

The computer jumps when the pump is turned on.

Cause Action

The control valve is not seated properly. Check the valve for an obstruction between the O-Ring and the seat.

Inspect the O-Ring for damage. Replace the valve or O-Ring, if

required.

There is an obstruction in the expansion

relief dill valve.

The gaskets are leaking. Replace worn gaskets.

There is a worn nozzle. Replace the nozzle.

There is a leak in the hose. Replace the hose.

Temperature extremes cause the liquid to

expand or contract.

Check the valve by pulling the spring loaded seat. Clean any foreign

matter from the valve. To install the dill valve in the control valve, use

a valve tool.

Problem will be solved when the pump begins to operate.

MDE-4447A Global Pumping Unit Operation and Service Manual · May 2008 Page 29

Troubleshooting Resolving Problems on Pump ing Units

This page is intentionally left blank.

Page 30 MDE-4447A Global Pumping Unit Operation and Service Manual · May 2008

Vapor Lock Causes Reasons for Vapor Lock

6 – Vapor Lock Causes

Vapor Lock is a problem that results from ambient temperatures, vapor pressure of the product

and installation. It is not a characteristic of a pump.

Reasons for Vapor Lock

Atmospheric Pressure

Atmospheric Pressure of 14.7 PSI (sea level) presses on the liquid in the tank. See Figure 6-1.

Figure 6-1: Atmospheric Pressure

Atmospheric

Pressure (14.7 PSI)

60º F

MDE-4447A Global Pumping Unit Operation and Service Manual · May 2008 Page 31

Reasons for Vapor Lock Vapor Lock Causes

Vapor Pressure

Vapor Pressure (the amount of pressure required to keep the product in a liquid form at 60° F)

of today's product is approximately 10 PSI. See Figure 6-2 on page 32.

Figure 6-2: Vapor Pressure

10 PSI required to keep

product in liquid form

60º F

Working Pressure

The difference between Atmospheric Pressure and Vapor Pressure is known as the Working

Pressure. The Working Pressure is all that the pump can c reate without the product turning to

vapor. See Figure 6-3.

14.7 PSI Atmospheric Pressure

- 10.0 PSI Vapor Pressure

4.7 PSI Working Pressure

Figure 6-3: Working Pressure

Atmospheric

Pressure

Less

Vapor Pressure

equals

Working Pressure

60º F

14.7 PSI

10.0 PSI

4.7 PSI

Page 32 MDE-4447A Global Pumping Unit Operation and Service Manual · May 2008

Vapor Lock Causes Reasons for Vapor Lock

Measuring Suction

To measure a pump’s suction, the Working Pressure must be converted to inches of vacuum.

To do this, multiply the Working Pressure by 2. The result is the number of inches of vacuum

that a pump can create before the product changes to a vapor. See Figure 6-4.

Figure 6-4: Converting Working Pressure to Inches of Vacuum

Atmospheric

Pressure (14.7 PSI)

equals 30 inches of

mercury

14.7 PSI of Atmospheric

Pressure pushes down

on the bowl of mercury

and causes it to rise to 30

inches.

4.7 PSI Working Pressure = 9.4 inches of vacuum. See Figure 6-5.

Figure 6-5: PSI and Vacuum Equivalents

4.7 PSI = 9.4 inches of Vacuum

PSI

Vacuum

MDE-4447A Global Pumping Unit Operation and Service Manual · May 2008 Page 33

Reasons for Vapor Lock Vapor Lock Causes

Installation is the Key

The condition of installation dictates how much suction a pump must create to pump the

product.

It takes 1 inch of vacuum to lift gas 1.5 feet vertically.

To determine the inches of vacuum required to lift the gas in a system, proceed as follows:

1 Measure the distance from the top of the product in the tank to the center of the pumping unit.

See Figure 6-6. Divide the distance by 1.5 to obtain the inches of vacuum required by the

pump to lift the product.

For example: 9 feet of lift requires 6 inches of vacuum by the pump. See Figure 6-6.

Figure 6-6: Amount of Vacuum Required for Pump Suction

Amount of

Lift

Vacuum

Required

60º F

It takes 1 inch of vacuum by the pump to overcome the restriction of an angle check valve or

foot valve (not part of the pump, but a necessary part of the installation). See Figure 6-7.

Figure 6-7: Compensating for Angle Check or Foot Valve

1 inch of vacuum to overcome the restriction

of an angle check valve or foot valve

Angle Check Valve

Foot Valve

Page 34 MDE-4447A Global Pumping Unit Operation and Service Manual · May 2008

Vapor Lock Causes Reasons for Vapor Lock

It takes 1 inch of vacuum by the pump to overcome the restriction of 60 feet of horizontal

piping from the tank to the pump. See Figure 6-8.

Figure 6-8: Compensating for Horizontal Piping

60 Feet of Horizontal Piping = 1 inch of Vacuum

60ºF

To obtain the inches of vacuum required to deliver the product, simply add A, B and C.

2

A. 9 feet of lift = 6 inches of suction

B. Angle check or foot valve= 1 inch of suction

C. 60 feet horizontal run= 1 inch of suction

TOTAL 8 inches of suction

With 9.4 inches of suction to work with and only 8 inches of vacuum required, conditions are

normal and the pump delivers the product without vapor locking.

Note: This condition exists when the product is at 60° F.

MDE-4447A Global Pumping Unit Operation and Service Manual · May 2008 Page 35

Vapor Lock Conditions Vapor Lock Causes

Vapor Lock Conditions

Using the same example as above, 8 inches of vacuum is still required to deliver the product.

With higher ambient temperatures, the vapor pressure of the product changes. As mentioned

above, the Vapor Pressure of today's product is 10 PSI at 60° F. At temperatures of 90° F or

higher, it can go as high as 12 PSI.

Figure 6-9: Vapor Pressure at 95º F

95º F

Vapor Pressure of Product

may be as high as 12 PSI

Using the same formulae in “Working Pressure” on page 32, the Working Pressure equals

Atmospheric Pressure less the Vapor Pressure. See Figure 6-10.

14.7 PSI Atmospheric Pressure

- 12.0 PSI Vapor Pressure of the product

2.7 PSI Working Pressure

Figure 6-10: Working Pressure - Vapor Lock Conditions

Atmospheric

Pressure

Less

95º F

14.7 PSI

Vapor Pressure

equals

Working Pressure

Page 36 MDE-4447A Global Pumping Unit Operation and Service Manual · May 2008

12.0 PSI

2.7 PSI

Vapor Lock Causes Vapor Lock Conditions

Multiplying the 2.7 Working Pressure by 2 equals 5.4 inches of vacuum that the pump can

create before the product turns to vapor. See Figure 6-11 on page 37.

Figure 6-11: PSI and Vacuum Equivalents - Vapor Lock Conditions

2.7 PSI = 5.4 inches of Vacuum

PSI

Vacuum

It still takes 8 inches of vacuum to deliver the product, but with higher temperatures, there is

only 5.4 inches of vacuum to lift the product. The result is Vapor Lock.

Figure 6-12: Vapor Lock Conditions

The pump plays a very small part in vapo r lock situations. The main reasons for vapor lock are

as follows:

• Installation

• Amount of product in the storage tank

• Vapor Pressure of the product

Note: Vapor lock does not occur in diesel pumps because the Vapor Pressure of diesel is

approximately 8 PSI.

The only solution for vapor lock in hot climates is to keep the installation and pump cool.

MDE-4447A Global Pumping Unit Operation and Service Manual · May 2008 Page 37

Vapor Lock Conditions Vapor Lock Causes

© 2008 Gilbarco Inc.

7300 West Friendly Avenue · Post Office Box 22087

Greensboro, North Carolina 27420

Phone (336) 547-5000 · http://www.gilbarco.com · Printed in the U.S.A.

MDE-4447A Global Pumping Unit Operation and Service Manual · May 2008

Loading...

Loading...