Page 1

This document is based on Orpak’s Truck Controller Unit (OrTC)

installation manual P/N 817438028

MDE-4814C

Fuel Truck Controller

INSTALLATION MANUAL

Page 2

Page 3

SAFETY CONSIDERATIONS

Read all warning notes and instructions carefully. They are included to help you installing the Product safely

in the highly flammable environment of the fuel station. Disregarding these warning notes and instructions

could result in serious injury or property damage. It is the installer responsibility to install, operate and

maintain the equipment according to the instructions given in this manual, and to conform to all applicable

codes, regulations and safety measures. Failure to do so could void all warranties associated with this

equipment.

Remember that the fuel station environment is highly flammable and combustible. Therefore, make sure

that actual installation is performed by experienced personnel, licensed to perform work in fuel station and at

a flammable environment, according to the local regulations and relevant standards.

For UL listing; All peripherals equipment connected to the device must be UL listed and suitable for the

applications.

WARNING - EXPLOSION HAZARD

Install the Product only in the non-hazardous area of the fuel station.

Use standard test equipment only in the non- hazardous area of the fuel station, and approved test equipment

for the hazardous areas.

In the installation and maintenance of the Product, comply with all applicable requirements of the National

Fire Protection Association NFPA-30 “Flammable and Combustible Liquids Code”, NFPA-30A “Code for

Motor Fuel Dispensing Facilities and Repair Garages”, NFPA-70 “National Electric Code”, federal, state and

local codes and any other applicable safety codes and regulations.

Do not perform metal work in a hazardous area. Sparks generated by drilling, tapping and other metal work

operations could ignite fuel vapors and flammable liquids, resulting in death, serious personal injury,

property loss and damage to you and other persons.

CAUTION - SHOCK HAZARD

Dangerous AC voltages that could cause death or serious personal injury are used to power the Product.

Always disconnect power before starting any work. The Product has more than one power supply connection

port. Disconnect all power before servicing.

CAUTION – EXTERNAL WIRING

For supply connections, use wires suitable for at least 90°C.

Signal wiring connected in this box must be rated at least 300 V.

Page 4

WARNING – PASSING VEHICLES

When working in any open area of fuel station, beware of passing vehicles that could hit you. Block off the

work area to protect yourself and other persons. Use safety cones or other signaling devices.

WARNING

Components substitutions could impair intrinsic safety.

Attaching unauthorized components or equipment will void your warranties.

CAUTION

Do not attempt to make any repair on the printed circuit boards residing in the Product, as this will void all

warranties related to this equipment.

PROPRIETY NOTICE

This document contains propriety and confidential information. It is the property of ORPAK SYSTEMS

Ltd. It may not be disclosed or reproduced in whole or in part without written consent of ORPAK

SYSTEMS. The information in this document is current as of the date of its publication, but is subject to

change without notice.

DISCLAIMER

This document is provided for reference only. Although every effort has been made to ensure correctness,

ORPAK SYSTEMS does not guarantee that there are no errors or omissions in this document.

FCC Compliance Statement

The FCC Wants You to Know:

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to

Part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause harmful interference to

radio communications. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the interference by

one or more of the following measures :

a) Reorient or relocate the receiving antenna.

b) Increase the separation between the equipment and receiver.

c) Connect the equipment to an outlet on a circuit different from that to which the receiver is connected.

d) Consult the dealer or an experienced radio/TV technician.

Page 5

FCC Warning

Modifications not expressly approved by the manufacturer could void the user authority to operate the

equipment under FCC Rules.

This document is the property of:

ORPAK SYSTEMS Ltd.

ISRAEL

Page 6

Page 7

i

TABLE OF CONTENTS

Paragraph

Page

SECTION 1 GENERAL DESCRIPTION

1-1. SCOPE ................................................................................................................................ 8

1-2. DESCRIPTION .................................................................................................................. 8

1-3. SYSTEM OVERVIEW ...................................................................................................... 9

1-3.1. Fuel Truck Controller System ........................................................................................ 9

1-3.2. Vehicle Identification ..................................................................................................... 9

1-3.3. Remote Web Access ...................................................................................................... 9

1-3.4. Fleet Head Office ........................................................................................................... 9

1-3.5. Restrictions and Limits .................................................................................................. 9

1-3.6. Fuel Truck Controller Capabilities for Mobile Station Management ............................ 10

1-3.7. System Workflow - Example ......................................................................................... 11

1-4. FUEL TRUCK CONTROLLER STRUCTURE ................................................................ 12

1-4.1. Main Components .......................................................................................................... 12

1-4.2. Fuel Truck Controller General Configuration ............................................................... 14

1-4.3. Fuel Truck Controller Main Components Location ....................................................... 15

1-5. AVAILABLE CONFIGURATIONS ................................................................................. 16

1-5.1. General ........................................................................................................................... 16

1-5.2. Vehicle Identification System – FuelPoint PLUS.......................................................... 16

1-5.3. WGT External Box – Optional ...................................................................................... 16

1-5.4. Safety Barriers ............................................................................................................... 17

1-5.5. Modem/Router ............................................................................................................... 18

1-5.6. External TAG Reader (OrTR)........................................................................................ 18

1-5.7. Fuel Truck Controller with OrTR and WGT ................................................................. 19

1-5.8. Fuel Truck Controller - Standard Models ...................................................................... 20

1-6. SECURITY AND PROTECTION ..................................................................................... 21

1-6.1. General ........................................................................................................................... 21

1-6.2. Authorization Security ................................................................................................... 21

1-6.3. Network Security ........................................................................................................... 21

1-6.4. RF Network Security ..................................................................................................... 21

1-6.5. Maintenance Security ..................................................................................................... 21

1-6.6. RTC Backup ................................................................................................................... 21

1-7. HOUSING .......................................................................................................................... 21

1-8. SPECIFICATIONS ............................................................................................................. 23

1-9. STANDARDS .................................................................................................................... 23

Fuel Truck Controller Manual

Page 8

ii

TABLE OF CONTENTS

Paragraph

Page

1-9.1. Communication Standards ............................................................................................. 23

1-9.2. Security Standards .......................................................................................................... 24

1-10. MANUAL STRUCTURE ................................................................................................... 25

1-11. USING THIS MANUAL .................................................................................................... 26

1-12. REFERENCES ................................................................................................................... 27

SECTION 2 PRELIMINARY INSTALLATION INSTRUCTIONS

2-1. GENERAL .......................................................................................................................... 28

2-2. PRELIMINARY INSTALLATION INSTRUCTIONS ..................................................... 28

2-2.1. General ........................................................................................................................... 28

2-2.2. Precautions and Safety Notes ......................................................................................... 29

2-3. CONDUITS INSTALLATION .......................................................................................... 29

2-3.1. General ........................................................................................................................... 29

2-3.2. Conduit Requirements .................................................................................................... 29

2-3.3. Type of Conduits in the Truck ....................................................................................... 30

2-3.4. Wiring Openings in Fuel Truck Controller .................................................................... 31

2-3.5. Conduits Installation Procedures .................................................................................... 31

2-4. CABLES ............................................................................................................................. 31

2-4.1. General ........................................................................................................................... 31

2-4.2. Cable Types .................................................................................................................... 32

2-4.3. Cables Routing ............................................................................................................... 32

2-5. Electrical System ................................................................................................................ 33

2-5.1. External Fuse .................................................................................................................. 33

2-5.2. Fuel Truck Controller Power System ............................................................................. 33

2-6. GROUNDING AND SHIELDING .................................................................................... 34

2-7. CONNECTIONS TO FUEL TRUCK CONTROLLER ..................................................... 35

SECTION 3 INSTALLATION PROCEDURES

3-1. GENERAL .......................................................................................................................... 37

3-2. INSTALLATION SPECIFICATIONS ............................................................................... 37

3-2.1. General ........................................................................................................................... 37

3-2.2. Precautions and Safety Notes ......................................................................................... 37

3-3. FUEL TRUCK - OVERVIEW ........................................................................................... 38

3-3.1. General ........................................................................................................................... 38

3-4. MAPPING THE TRUCK ................................................................................................... 39

Fuel Truck Controller Manual

Page 9

iii

TABLE OF CONTENTS

Paragraph

Page

3-4.1. General ........................................................................................................................... 39

3-4.2. Locating all objects of the fuel truck ............................................................................. 39

3-4.3. Assigning Logical IDs ................................................................................................... 39

3-5. INSTALLING THE FUEL TRUCK CONTROLLER ....................................................... 40

3-5.1. Installation Assembly Parts ............................................................................................ 40

3-5.2. Preliminary Procedures .................................................................................................. 41

3-5.3. Fuel Truck Controller Installation in Driver's Cabin ..................................................... 41

3-5.4. Determining the Spot Installation Fuel Truck Controller with Shock Absorber Assembly41

3-5.5. Shock Absorbers Assembly - Installation Procedures ................................................... 42

3-5.6. Fuel Truck Controller Installation Assembly ................................................................ 43

3-6. INSTALLATION OF FUEL TRUCK CONTROLLER WITH WALL MOUNT KIT ..... 44

3-6.1. Installation Assembly Parts ............................................................................................ 44

3-6.2. Installation Procedures ................................................................................................... 44

3-7. WIRING ............................................................................................................................. 46

3-7.1. General ........................................................................................................................... 46

3-7.2. Wiring Requirement ....................................................................................................... 46

3-7.3. Wiring Procedures ......................................................................................................... 46

3-7.4. General ........................................................................................................................... 46

3-7.5. Mechanical Pump – Terminal Block - Pin-Out Connections ........................................ 47

3-8. PUMP - REQUIRED CONNECTIONS ............................................................................. 51

3-9. WIRING THE PERIPHERALS ......................................................................................... 52

3-9.1. Valve Wiring .................................................................................................................. 52

3-9.2. Pulser Wiring ................................................................................................................. 53

3-9.2.1. Electronic Pulser ....................................................................................................... 54

3-9.2.2. Mechanical Pulser ..................................................................................................... 54

3-9.3. In-Use Switch ................................................................................................................. 55

3-9.4. Nozzle Installation ......................................................................................................... 56

3-10. WIRING TO GENERAL COMPONENTS ....................................................................... 56

3-10.1. Connection to Barrier Set within the Pump (Optional).................................................. 56

3-11. ONGOING TRANSACTION INDICATION .................................................................... 57

3-12. POST-INSTALLATION CHECKLIST ............................................................................. 57

3-13. FUEL TRUCK CONTROLLER SETUP ........................................................................... 57

SECTION 4 PRINTER

4-1. GENERAL .......................................................................................................................... 58

4-2. DESCRIPTION .................................................................................................................. 58

Fuel Truck Controller Manual

Page 10

iv

TABLE OF CONTENTS

Paragraph

Page

4-3. SPECIFICATIONS ............................................................................................................. 59

4-4. PRINTER INSTALLATION .............................................................................................. 59

4-5. PRINTER SETUP ............................................................................................................... 61

4-6. MAINTENANCE ............................................................................................................... 65

4-6.1. Paper Roll Replacement ................................................................................................. 65

4-6.2. Cleaning ......................................................................................................................... 65

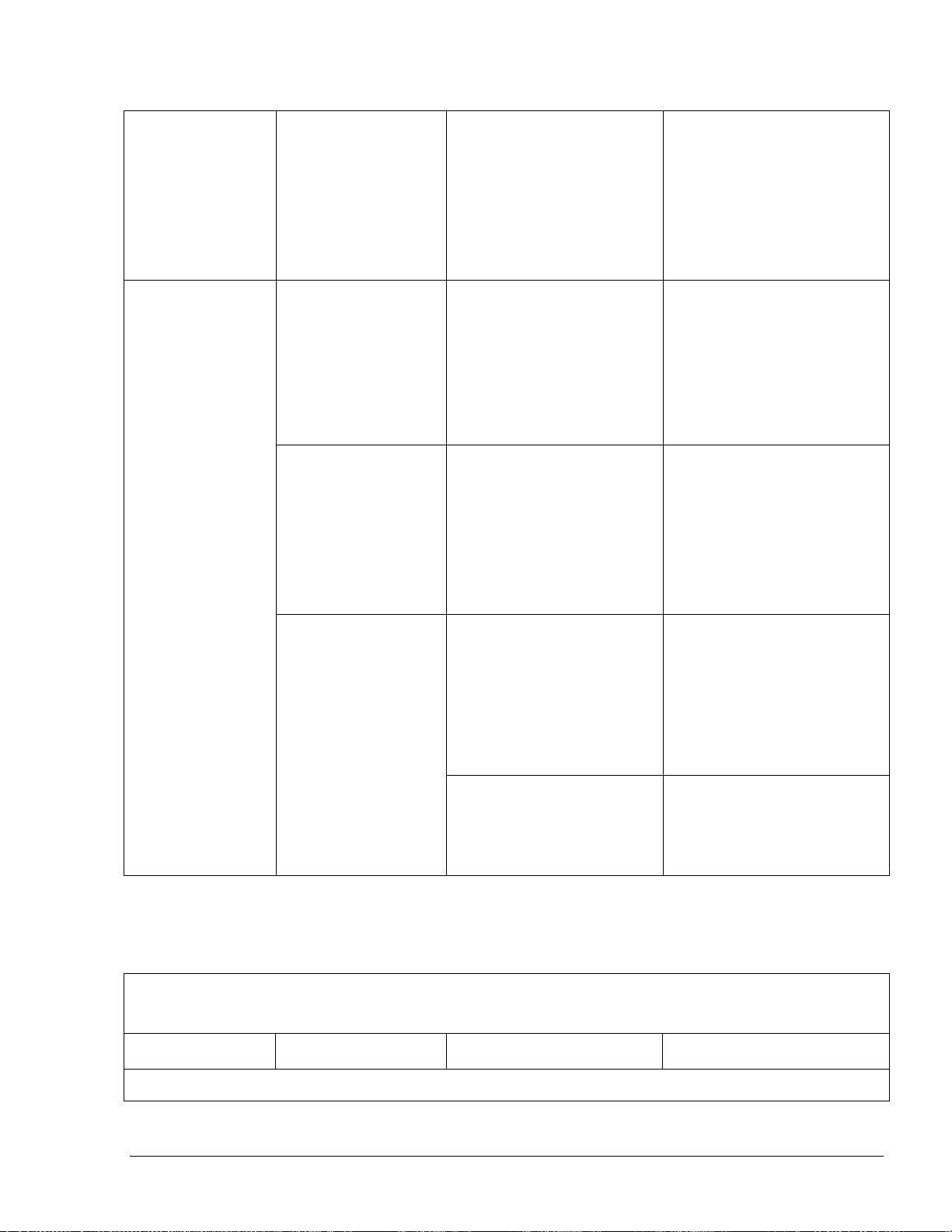

SECTION 5 MAINTENANCE

5-1. GENERAL .......................................................................................................................... 66

5-2. TROUBLESHOOTING ...................................................................................................... 66

5-2.1. Fuel Truck Controller Troubleshooting ......................................................................... 66

5-2.2. Communication Troubleshooting ................................................................................... 72

5-3. CLEANING ........................................................................................................................ 75

SECTION 6 GLOSSARY

6-1. FUELOMAT GLOSSARY ................................................................................................. 76

6-2. COMMUNICATION GLOSSARY .................................................................................... 77

APPENDIX A WIRING DIAGRAM

APPENDIX B SITE SURVEY FORM - EXAMPLE

Fuel Truck Controller Manual

Page 11

v

LIST OF ILLUSTRATIONS

Figure

Page

Figure 1-1. Fuel Truck Controller - General View with Shock Absorber Assembly .......................... 8

Figure 1-2. Fuel Truck Controller on a Fuel Truck - General Configuration Diagram .................... 10

Figure 1-3. Internal Configuration Diagram – Mechanical Pump..................................................... 14

Figure 1-4. Fuel Truck Controller Internal Components Location ................................................... 15

Figure 1-5. Wireless Gateway Terminal (WGT) ............................................................................... 17

Figure 1-6. Tag Reader (OrTR) ......................................................................................................... 18

Figure 1-7. Fuel Truck Controller with OrTR ................................................................................... 19

Figure 1-8. Fuel Truck Controller with OrTR and WGT ................................................................. 19

Figure 1-9. Fuel Truck Controller - General View with Shock Absorber Assembly ........................ 22

Figure 1-10. Shock Absorber - Detail ............................................................................................... 22

Figure 2-1. Fuel Truck Controller Wiring Openings ......................................................................... 30

Figure 2-2 Power Supply – Block Diagram ..................................................................................... 34

Figure 2-3 Cables Shielding ............................................................................................................. 34

Figure 2-4 Fuel Truck Controller Terminal Block, Power and LAN Connections .......................... 35

Figure 3-1. Fuel Truck Controller with Mechanical Pumps – System Diagram .............................. 38

Figure 3-2 Shock Absorber Assembly – Installation Holes ............................................................. 42

Figure 3-3 Fuel Truck Controller with Shock Absorber Assembly – Installation Holes ................. 43

Figure 3-4 Installing Fuel Truck Controller on Shock Absorber Brackets – Installation Holes ...... 43

Figure 3-5 Rear Panel Support Holes ............................................................................................... 45

Figure 3-6 Wall Bracket, Installation Example ................................................................................ 45

Figure 3-7 Wall Bracket, Dimensions (mm) .................................................................................... 45

Figure 3-8 Terminal Lug .................................................................................................................. 46

Figure 3-9 Terminal Block ............................................................................................................... 49

Figure 3-10 Terminal Block – Mechanical Pump - Wiring List Label ............................................ 49

Figure 3-11 Terminal Block – Mechanical Pump - Wiring List Label Installed ............................. 50

Figure 3-12. Fuel Truck Controller Mechanical Pump - Terminal Block Detailed Connections ..... 53

Figure 3-13 Terminal Block and 3-Wire Pulser – Wiring Connections ........................................... 54

Figure 3-14 Terminal Block and 2-Wire Pulser – Wiring Connections ........................................... 55

Fuel Truck Controller Manual

Page 12

vi

LIST OF ILLUSTRATIONS

Figure

Page

Figure 3-15. In-Use Switch ................................................................................................................ 55

Figure 3-16 Terminal Block – Barrier Inside Pump Wiring Link (Axial Barrier) ........................... 56

Figure 4-1. Mobile Printer – Main Components............................................................................... 58

Figure 4-2. Printer Harnesses ........................................................................................................... 60

Figure 4-3. OrCUAdministrator – Serial/Modem Settings Screen ................................................... 61

Figure 4-4. OrCUAdministrator – System Information Screen ........................................................ 62

Figure 4-5. SiteOmat – Buses Dialog Box ....................................................................................... 63

Figure 4-6. SiteOmat – Printers Dialog Box..................................................................................... 64

Figure 4-7. Paper Roll Direction....................................................................................................... 65

Fuel Truck Controller Manual

Page 13

vii

LIST OF TABLES

Table

Page

Table 2-1. Conduits into Fuel Truck Controller ............................................................................... 31

Table 2-2. Fuel Truck Controller, Cables Type................................................................................ 32

Table 2-3. Fuel Truck Controller, Cables Routing ........................................................................... 33

Table 2-4. Nozzles to Fuel Truck Controller, Cables Routing ......................................................... 33

Table 3-1. Fuel Truck Controller, Installation Assembly Parts ........................................................ 40

Table 3-2. Fuel Truck Controller, Assembly Parts ........................................................................... 44

Table 3-3. Fuel Truck Controller Terminal Block - Mechanical Pump – Connections Definition .. 47

Table 4-1. Mobile Printer Specifications .......................................................................................... 59

Table 4-1. Fuel Truck Controller Troubleshooting ........................................................................... 66

Table 4-2. Communication Troubleshooting..................................................................................... 73

Fuel Truck Controller Manual

Page 14

8

0

11--11.. SSCCOOPPEE

11--22.. DDEESSCCRRIIPPTTIIOONN

SECTION 1

GENERAL DESCRIPTION

This manual is provided to assist you in installing – Gasboy’s Fuel Truck Controller. The system

must be installed as described in this manual to ensure the system reliability and proper operation.

This manual includes a general and functional description of the Fuel Truck Controller and its main

components. It also provides the installation procedures for the Fuel Truck Controller.

This manual is intended for qualified authorized installers of the Fuel Truck Controller and its

components.

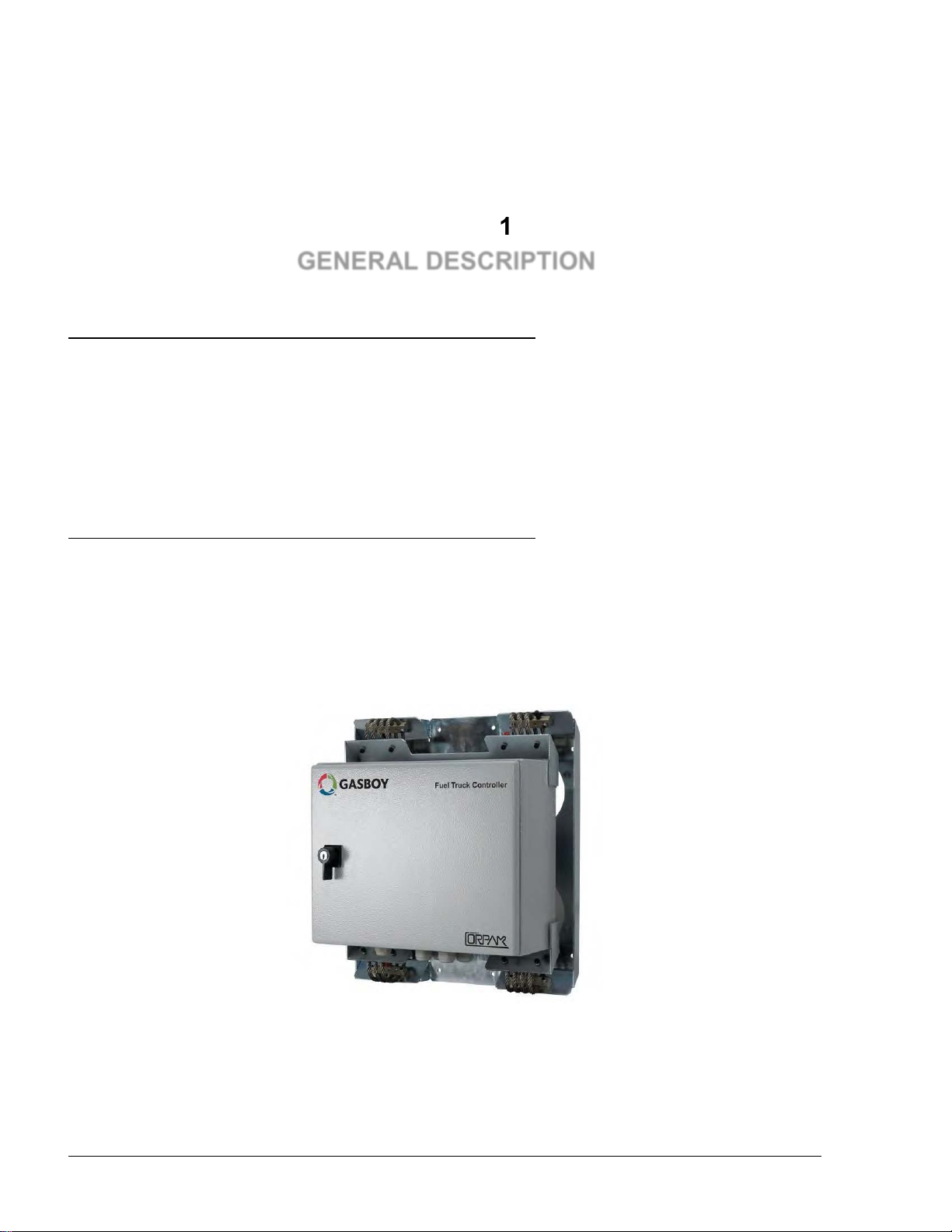

Fuel Truck Controller is a fuel control and data acquisition system. Fuel Truck Controller system is

a self-contained weather-resistant cabinet installed on fuel trucks used as mobile refueling station.

Fuel Truck Controller (see Figure 1-1) is a core component in Gasboy’s solution for mobile

refueling stations. Fuel Truck Controller provides the central function of the mobile site controller.

It also fulfills other essential services on site such as Vehicle/Driver Identification System,

Transaction data storage, devices control and more.

Figure 1-1. Fuel Truck Controller - General View with Shock Absorber Assembly

Fuel Truck Controller Manual

Page 15

9

11--33.. SSYYSSTTEEMM OOVVEERRVVIIEEWW

11--33..11.. FFuueell TTrruucckk CCoonnttrroolllleerr SSyysstteemm

11--33..22.. VVeehhiiccllee IIddeennttiiffiiccaattiioonn

11--33..33.. RReemmoottee WWeebb AAcccceessss

11--33..44.. FFlleeeett HHeeaadd OOffffiiccee

11--33..55.. RReessttrriiccttiioonnss aanndd LLiimmiittss

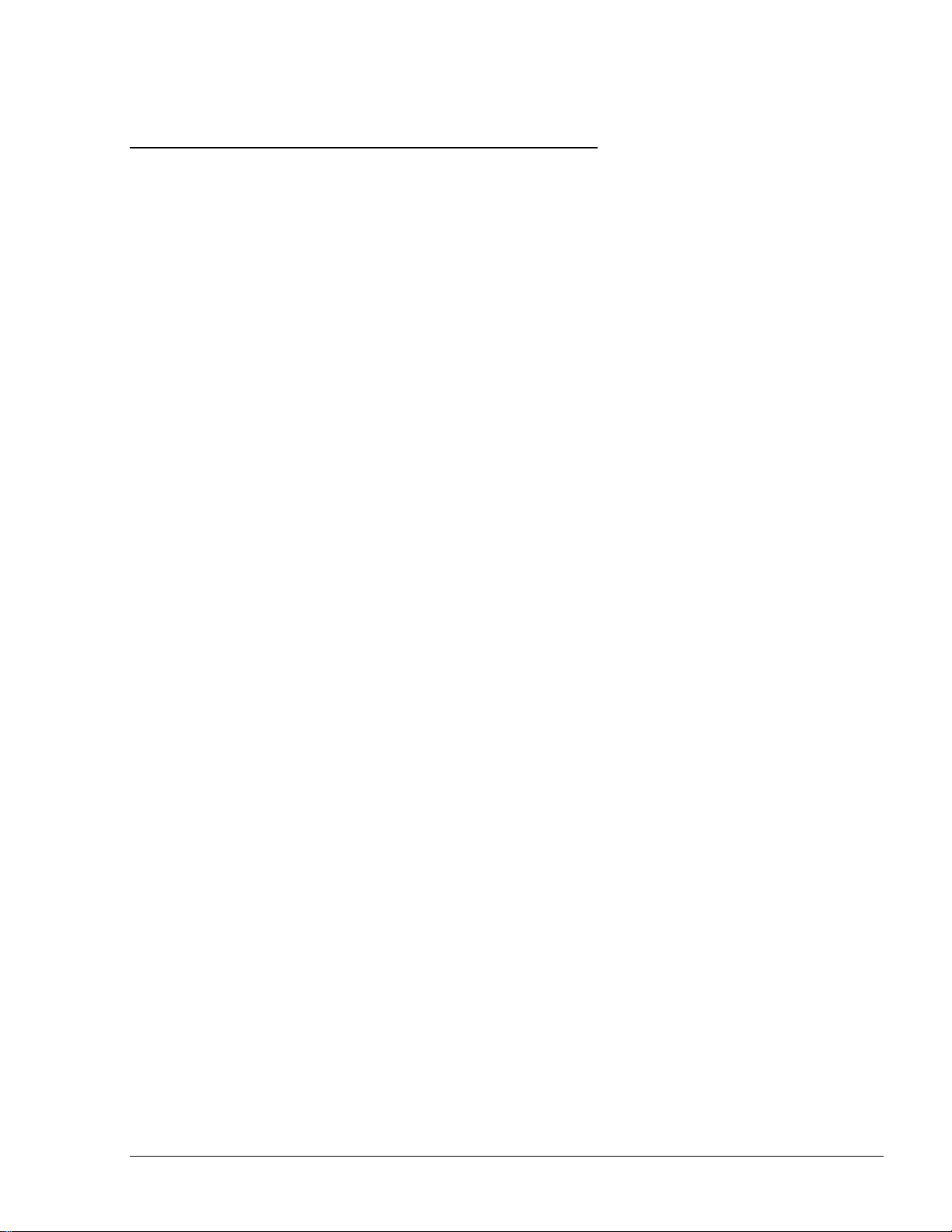

Fuel Truck Controller system is a mobile Fleet Management System. The system controls, monitors

and stores on-the-spot refueling data by tanker truck for customers with large land moving

equipment. The system is suitable for a large range of home base customers.

The system consists of a Controller mounted on the truck and Vehicle Identification Units (VIU)

installed on the fleet vehicles.

Fuel Truck Controller enables refueling of vehicles equipped with VIUs only. The vehicles fuel

inlet must be positioned in the proximity of the fuel pump nozzle, ensuring end-to-end

authentication of the vehicle, meaning that only authorized vehicles get fuel. After providing fuel,

the system registers the transaction data (see Figure 1-2).

The heart of the mobile solution is the Orpak Controller Unit (OrCU) operating with the SiteOmat

automation software. SiteOmat runs on an embedded operating system. OrCU is a hardware

platform designed to survive the harsh gas station environment. It uses a solid state FLASH disk

and RTC (Real Time Clock) with back-up, along with surge suppressors for transients and noise

immunity. The system also includes power fail recovery mechanisms.

Vehicle Identification is an essential feature for maximal control and savings on fuel expenditure.

The dispenser is authorized to refuel after a positive identification of the vehicle and only while the

nozzle is inside the fuel inlet of the identified vehicle. All transaction information is automatically

recorded. A combined vehicle and driver identification is also possible for tight tracking.

Remote Web-based capabilities for monitoring, management and maintenance are available. A

standard PC with Internet Browser (Explorer) is used for remote management of Fuel Truck

Controller. There is no need for special purpose management software thanks to the built-in Web

server technology integrated into Fuel Truck Controller.

Centralized management is provided by the optional Fleet Head Office server. The Fleet Head

Office consolidates the data from multiple sites and generates reports, including exception reports.

It also enables control of the limits and restrictions placed on the various fleet vehicles.

Furthermore, authorized fleet personnel are able to log-in remotely and are always in control.

Control of a fleet’s fuel consumption can be maximized by defining limits. Optional limits include:

volume per day/week/month, fuel type. In case of communication failure, the specific site will be

able to refuel for a predefined grace period (parameter) using the most recent limits stored in its

database.

Fuel Truck Controller Manual

Page 16

10

11--33..66.. FFuueell TTrruucckk CCoonnttrroolllleerr CCaappaabbiilliittiieess ffoorr MMoobbiillee SSttaattiioonn MMaannaaggeemmeenntt

The Fuel Truck Controller provides features for a comprehensive mobile refueling station

management by enabling a large variety of communication links: Cellular, dial-in modem, WiFi,

radio modem and satellite.

Figure 1-2. Fuel Truck Controller on a Fuel Truck - General Configuration Diagram

Fuel Truck Controller Manual

Page 17

11

11--33..77.. SSyysstteemm WWoorrkkffllooww -- EExxaammppllee

An example of an operational workflow for self-service at the Fuel Truck Controller site is provided

below:

The Fuel Truck Controller equipped fuel truck arrives at the construction site to refuel its fleet

vehicles. All fleet vehicles equipped with FuelPoint PLUS devices. The operator inserts the nozzle

into a vehicle fuel inlet and waits for authorization. Truck data is automatically read and stored in

the Controller for authentication and authorization. Upon approval, the fueling transaction starts, at

the end of which the transaction data is kept internally until transferred to the Head Office (HO) for

future billing.

Fuel Truck Controller Manual

Page 18

12

11--44.. FFUUEELL TTRRUUCCKK CCOONNTTRROOLLLLEERR SSTTRRUUCCTTUURREE

11--44..11.. MMaaiinn CCoommppoonneennttss

Following is a short description of the Fuel Truck Controller main sub units:

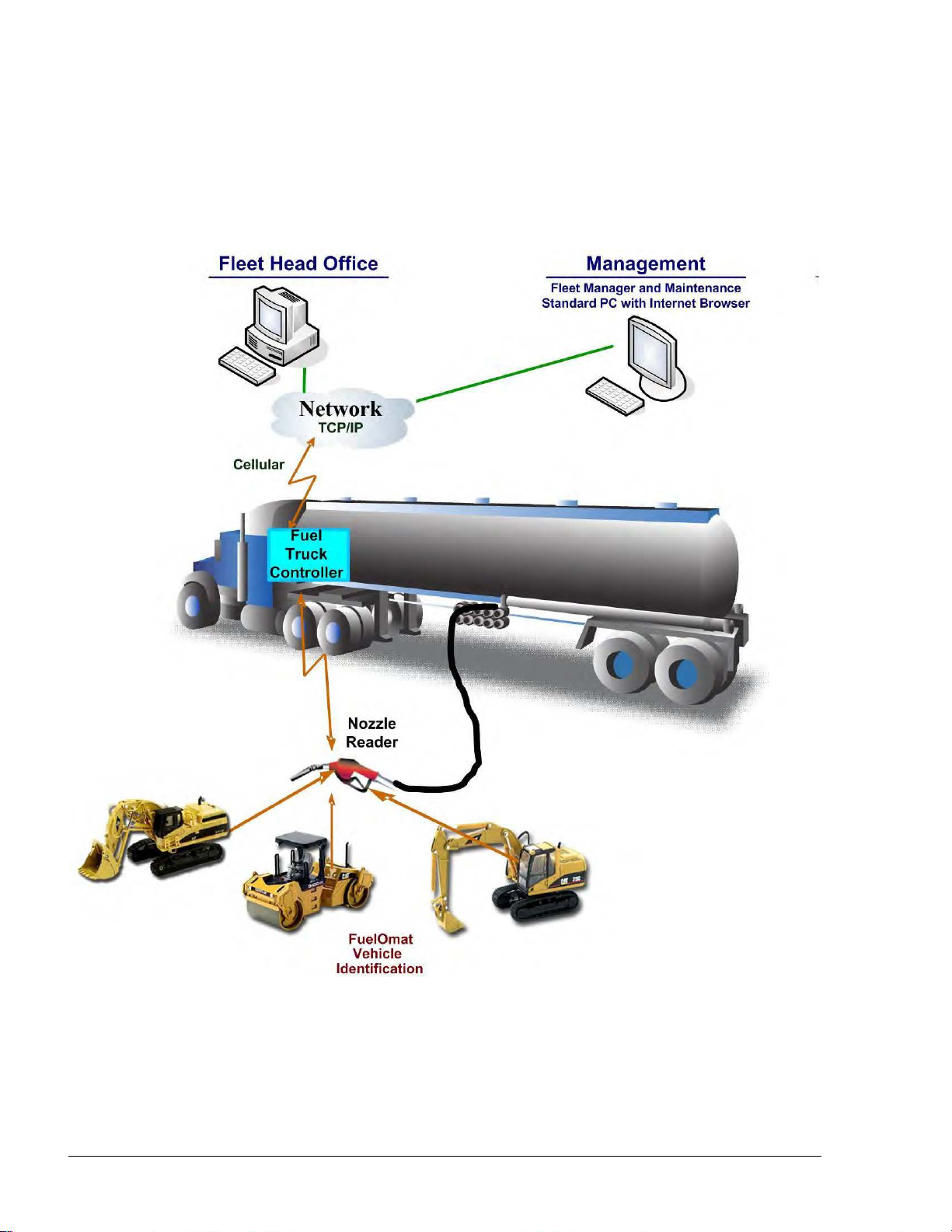

Orpak Controller Unit (OrCU)

Orpak Controller Unit (OrCU) is a complete controller with its

own embedded operating system. The unit consists of an

embedded hardware platform with a solid state Flash hard disk,

Real Time Clock (RTC) with backup, along with surge

suppressors for transient and noise immunity

It features two separate and isolated networks (TCP/IP over

Ethernet). One network links the Fuel Truck Controller system

components. The second network is intended for external

remote communication (Head Office, 3rd party systems). This

network is protected by SSL security.

OrCU includes a built-in server for Web access trough an internet browser (Explorer).

8-Port CommVerter

The 8-Port CommVerter is the communication interface

to the peripheral pumps. It consists of communication

modules for the mechanical pump elements. The

CommVerter includes one MPI-C card and sub card for

interface to two mechanical pumps, an Ethernet Switch.

The CommVerter communicates with the Site Controller

(OrCU) via a LAN (Ethernet) link.

Micro Vehicle Identification Transceiver (uVIT) (Optional):

The uVIT reads Orpak’s vehicle identification

components through the VIRO Receivers (Receiver

coil) installed on the hose nozzle equipment. The uVIT

supports up to eight VIRO Receivers. The connection

to the VIRO receiver must be done through an

intrinsically safety barrier. The uVIT performs the first

level of authentication by decrypting the string

transmitted from the vehicle. As an option for several

applications, the uVIT includes some capabilities for

peripheral equipment interface.

The uVIT is connected to the system via a LAN (Ethernet) link.

Optional Mobile Printer

Fuel Truck Controller Manual

Page 19

13

Fuel Truck Controller includes an optional Mobile Printer. Installed in

the driver's cabin and directly connected to the Controller Unit viva

RS-232 link, this compact device prints out all fueling transactions.

The Mobile Printer includes two LED indicators on the front panel:

Green: Power On

Red: Out of paper

Fuel Truck Controller Manual

Page 20

14

11--44..22.. FFuueell TTrruucckk CCoonnttrroolllleerr GGeenneerraall CCoonnffiigguurraattiioonn

Figure 1-3 shows a general configuration diagram of Fuel Truck Controller.

Figure 1-3. Internal Configuration Diagram – Mechanical Pump

Fuel Truck Controller Manual

Page 21

15

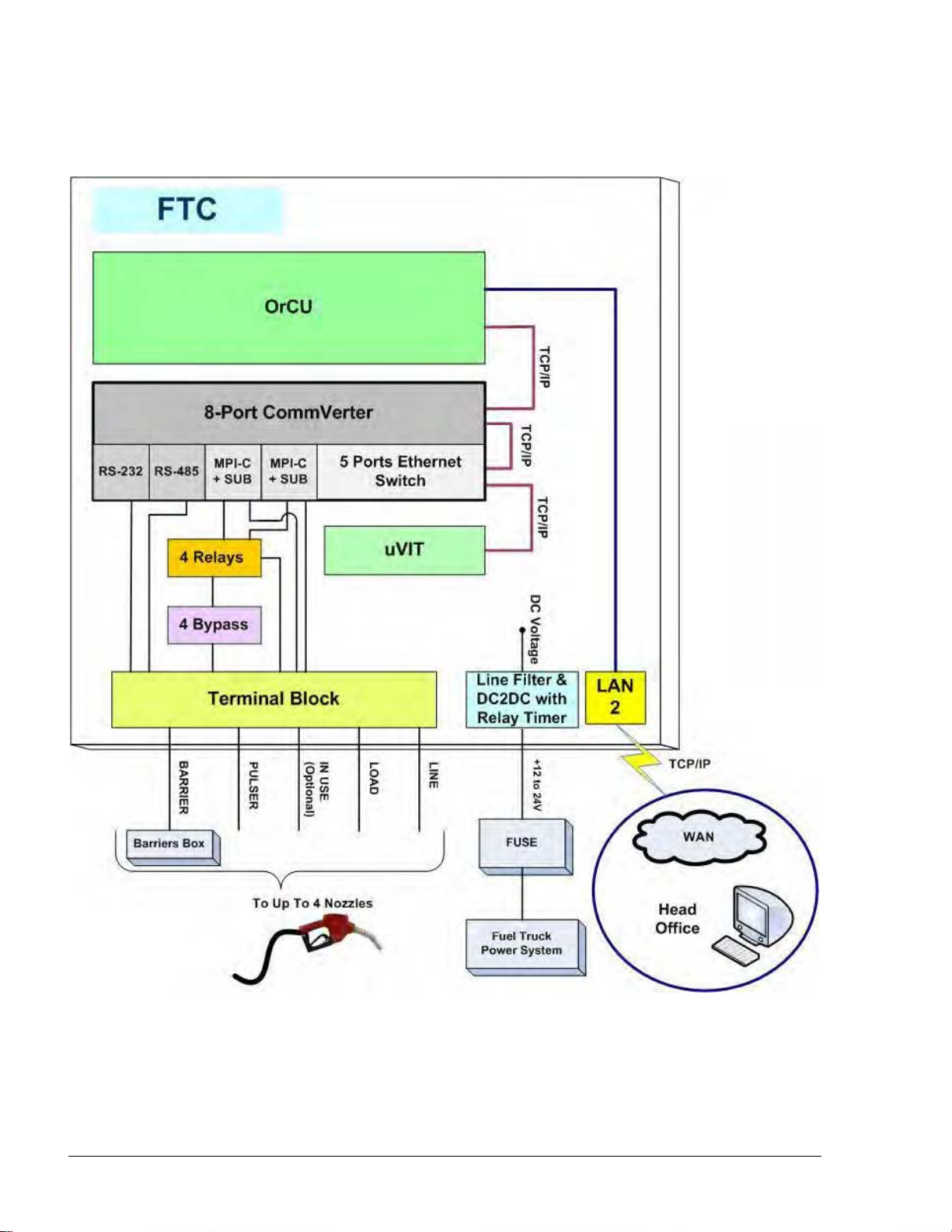

11--44..33.. FFuueell TTrruucckk CCoonnttrroolllleerr MMaaiinn CCoommppoonneennttss LLooccaattiioonn

Figure 1-4 shows the location of the main components of Fuel Truck Controller.

Figure 1-4. Fuel Truck Controller Internal Components Location

Fuel Truck Controller Manual

Page 22

16

11--55.. AAVVAAIILLAABBLLEE CCOONNFFIIGGUURRAATTIIOONNSS

11--55..11.. GGeenneerraall

11--55..22.. VVeehhiiccllee IIddeennttiiffiiccaattiioonn SSyysstteemm –– FFuueellPPooiinntt PPLLUUSS

11--55..33.. WWGGTT EExxtteerrnnaall BBooxx –– OOppttiioonnaall

The Fuel Truck Controller is available in several configurations, in accordance with its intended use

and with the components installed. All configurations are manufactured in accordance with specific

customer request.

The following paragraphs describe the several configurations, and their devices composition.

The following options are available for vehicle identification:

Wireless Gateway Terminal (WGT) – with this terminal, the vehicle identification process

is performed in a wireless mode.

Micro Vehicle Identification Transceiver (uVIT) – Orpak’s wired vehicle authorization

system.

No vehicle identification unit: The vehicle identification process will be done manually by

the truck driver with any accepted authorization devices such as cards, or tags. This option

will require external tag reader connected to Fuel Truck Controller (refer to paragraph1-5.6).

The Wireless Gateway Terminal (WGT) receives DataPass, FuelOpass and VIU signals, decrypts

their information and transmits it to the Station automation system (OrCU) in a secure manner over

an RF signal. This setup enables the RF signal to travel through various routes and bypass possible

interferences (such as a big truck/bus). The transmission signal range is 10 meters.

The WGT is designed to be installed in a designated external box on the truck on the side facing the

fueling elements. The WGT will be connected to the Fuel Truck Controller box using CAT5E

cable. More than one WGT external boxes can be mounted on one truck for better RF area

coverage. In this case one WGT box will be Master and the other(s) will be routers. For further

details, see WGT External Installation Guide, document no. MDE-4815

Fuel Truck Controller Manual

Page 23

17

11--55..44.. SSaaffeettyy BBaarrrriieerrss

Figure 1-5. Wireless Gateway Terminal (WGT)

The units that provide data to the WGT are:

DataPass - DataPass is a miniature unit that connects to the vehicle bus and captures data

from the vehicle CPU/BUS. It then transmits this data to the nearest Wireless Gateway

Terminal (WGT) in the forecourt.

FuelOpass - FuelOpass is a passive vehicle identification tag for refueling. Its encrypted

data includes the account to be charged and is read by the Nozzle Reader device using RFID

contactless technology.

VIU - VIU is an active Vehicle Identification Unit for refueling. The data includes odometer

and engine hour meter.

Nozzle Reader (NR) - Nozzle Reader is a self contained unit installed on the nozzle which

reads the FuelOpass data using contactless technology.

To obtain maximal grid availability, several WGT units can be installed to create a robust 'mesh'

network.

Safety Barriers are required in the truck whenever the Fuel Truck Controller includes an uVIT.

uVIT is electrically connected to the transceiver coil of the nozzle. This coil is intended for use in

potentially explosive atmosphere. Therefore the connection between these devices must be done

via an intrinsically safe barrier. Consequently, the truck must be equipped with an external Barriers

Box. The barriers in use depend on the geographical location of the installation:

Barriers and nozzle rings must be installed on dispensers as UL Listed by Report Retrofit

kits prior to the installation of the Fuel Truck Controller.

P/N 808012500 Barrier4 (Atex – For all regions except North America)

Fuel Truck Controller Manual

Page 24

18

11--55..55.. MMooddeemm//RRoouutteerr

11--55..66.. EExxtteerrnnaall TTAAGG RReeaaddeerr ((OOrrTTRR))

Please consult your local cellular service provider for the type of router supported in your area. The

router will be provided from your service provider with proper installation instructions. The router

will be connected to the LAN input in OrCU box.

OrTR (P/N 800910910) - OrTR (Orpak Tag Reader) receives Orpak tag signals for refuel

authorization purpose. OrTR transmits the information to the Station automation system (OrCU)

over a CAT5E or RS-485 cable. OrTR contain LCD with 2 lines display. OrTR is designed to be

installed in a non hazardous, convenient and secured area in accordance with local state regulations.

In the vehicle two installation alternatives are available:

External box in any non hazardous area. This installation mode requires a dedicated

mounting bracket. Such an installation shall be performed within safety distances required

for any installation adjacent to dispensers.

Installed beneath Fuel Truck Controller box with mounting bracket (P/N 814930300)

For further details, see OrTR Installation Guide, document no. MDE - 4816.

Figure 1-6. Tag Reader (OrTR)

Fuel Truck Controller Manual

Page 25

19

Figure 1-7. Fuel Truck Controller with OrTR

11--55..77.. FFuueell TTrruucckk CCoonnttrroolllleerr wwiitthh OOrrTTRR aanndd WWGGTT

In this configuration (see Figure 1-8), the Fuel Truck Controller encompasses most types of

authorization devices. The Wireless Gateway Terminal (WGT) provides vehicle identification

process in wireless mode while Orpak Tag Reader (OrTR) reads Orpak tag signals to complete any

transaction.

WGT communicates with Fuel Truck Controller over the LAN (CAT5E cable) and is powered

directly by Fuel Truck Controller. RF transmission of data from WGT enables sending data of all

transactions to the Station controller.

Figure 1-8. Fuel Truck Controller with OrTR and WGT

Fuel Truck Controller Manual

Page 26

20

11--55..88.. FFuueell TTrruucckk CCoonnttrroolllleerr -- SSttaannddaarrdd MMooddeellss

Table 1-1. Fuel Truck Controller - Standard Models

Name

Gilbarco P/N

Orpak P/N

Fuel Truck Control Unit for 2 hose

PA039600200

800938901

Fuel Truck Control Unit for 4 hose

PA039600400

800938902

Table 1-1 define all the available product numbers for the different configurations of Fuel Truck

Controller:

Fuel Truck Controller Manual

Page 27

21

11--66.. SSEECCUURRIITTYY AANNDD PPRROOTTEECCTTIIOONN

11--66..11.. GGeenneerraall

11--66..22.. AAuutthhoorriizzaattiioonn SSeeccuurriittyy

11--66..33.. NNeettwwoorrkk SSeeccuurriittyy

11--66..44.. RRFF NNeettwwoorrkk SSeeccuurriittyy

11--66..55.. MMaaiinntteennaannccee SSeeccuurriittyy

11--66..66.. RRTTCC BBaacckkuupp

11--77.. HHOOUUSSIINNGG

The transaction activities of the Fuel Truck Controller are secured and protected for transmission

and authorization activities.

The contact-less tags include Triple DES encrypted data for user identification and billing.

Consequently, the Fuel Truck Controller includes a special Security Application Module (SAM) for

decryption and matching identification. Upon tag reading, the Fuel Truck Controller attempts to

decrypt the string from the tag. The Fuel Truck Controller disregards Tags whose security scheme

does not match the Fuel Truck Controller internal SAM.

The Ethernet LAN is isolated from the external WAN by the Site Controller (OrCU). In case of

remote maintenance, a firewall should be applied either at the router level or preferably at the Home

Base Station level.

The Fuel Truck Controller EIA 802.15.4 RF network is encrypted, using the AES 128 security

standard.

The Fuel Truck Controller maintenance and setup procedures require inserting a user name and

password for access. For further information, please refer to the SiteOmat station controller Setup

Manual, P/N MDE-4817

Fuel Truck Controller is locked by key to prevent unauthorized access to the bypass switches and

controller electronics.

The Real Time Clock backup is based on a maintenance free 1 Farad supercapacitor. Backup time is

3 to 6 days before time and date loss.

Fuel Truck Controller enclosure is a weather-proof metal cabinet, able to sustain the harsh

environment of the Island. The Fuel Truck Controller is installed with a rear shock absorber

assembly that dampens vibrations from truck and road (see Figure 1-9).

The overall structure is installed vertically on any flat surface and secured with eight screws. See

anti-vibration shock absorbers in Figure 1-10.

Fuel Truck Controller is locked by key for safety and security. The key should be kept in a wellkept, secure and safe place.

Fuel Truck Controller Manual

Page 28

22

We recommend installing the Fuel Truck Controller box in the truck cabin or any other protected

compartment on the truck. Any installation should provide convenient access for service and

maintenance.

Figure 1-9. Fuel Truck Controller - General View with Shock Absorber Assembly

Figure 1-10. Shock Absorber - Detail

Fuel Truck Controller Manual

Page 29

23

11--88.. SSPPEECCIIFFIICCAATTIIOONNSS

Supply Voltage:

12 – 24 VDC

Power Consumption:

2.6A max.

Operating Temperature:

-22 F to +104 F (-30 C to +40 C)

Storage Temperature:

-22 F to +104 F (-30 C to +40 C)

Humidity:

80% Non-condensing

Dimensions:

- Box without Shock Absorber

Assembly:

Box with Shock Absorber

Assembly:

W x H x D: 15 x 11.80 x 6.10 "

(380 x 300 x 155 mm)

W x H x D: 16.50 x 18.10 x 7.90 "

(420 x 460 x 200 mm)

Communication Interface:

RS-485 – 9600 bps, Half-Duplex

RS-232

Ethernet RJ-45 - 10 Mbps

Valve Control Maximum Current

(4 Solid State Relay Channels):

12 V / 2A , 24V / 1A

Pulser power supply voltage

12 VDC / 30 mA max

Pulser Input High level voltage

Pulser Input High level sink

current (@15V)

9 to 15 VDC

3 mA

In use "On" level (Input)

Dry contact only (5V/1mA maximum)

11--99.. SSTTAANNDDAARRDDSS

11--99..11.. CCoommmmuunniiccaattiioonn SSttaannddaarrddss

The following physical, electrical and environmental specifications are applicable to the Fuel Truck

Controller:

The Fuel Truck Controller communicates, in its different models, over the following standards:

RS-485 link

TCP/IP over Ethernet

EIA 802.15.4

Fuel Truck Controller Manual

Page 30

24

11--99..22.. SSeeccuurriittyy SSttaannddaarrddss

Triple DES encryption for Payment Devices (Contact-less tags, magnetic stripe cards, etc.)

Fuel Truck Controller Manual

Page 31

25

11--1100.. MMAANNUUAALL SSTTRRUUCCTTUURREE

This manual comprises of the following sections:

Section 1: General Description

This section provides a general description of the Fuel Truck Controller system.

Section 2: Preliminary Installation Procedures

This section provides the preliminary installation requirements and procedures to be performed

before installing Fuel Truck Controller.

Section 3: Installation Procedures

This section provides a detailed description of Fuel Truck Controller installation requirements and

procedures.

Section 4: Maintenance

This section provides basic maintenance instructions for the Fuel Truck Controller.

Section 5: Glossary

This section includes a glossary of terms used for the Fuel Truck Controller description.

Appendix A: Wiring Diagram

This appendix includes the Wiring Diagram of the Fuel Truck Controller.

Appendix B - Site Survey Form – Example

This appendix includes an example of a form to be filled during a Site Survey. You may add or

remove parts of the questionnaire in order to fit it to your customer working environment.

Fuel Truck Controller Manual

Page 32

26

11--1111.. UUSSIINNGG TTHHIISS MMAANNUUAALL

This manual includes alerting comments inserted along the document, in order to draw the reader’s

attention to important issues. The comments are accompanied by symbols for ease of reference.

The following comment types are used:

WARNING

An operating procedure, practice, etc., if not

correctly followed, could result in injury or loss of

life.

CAUTION

An operating procedure, practice, etc, if not strictly

observed, could result in damage to, or destruction

of equipment.

TIP

This note is aimed for using the system in better

efficiently way.

NOTE

This comment is of importance for emphasizing.

INSIGHT

More detailed technical/ functional information in

regard relevant issue.

Fuel Truck Controller Manual

Page 33

27

11--1122.. RREEFFEERREENNCCEESS

For additional and complementary information regarding the Fuel Truck Controller system, please

refer to the following manuals:

uVIT Installation and Operation Manual, Document No. 817412300

8-Port CommVerter User’s Manual, Document No. MDE-4812

WGT outdoor unit Installation Guide, document no. MDE-4815.

OrTR Installations guide, document no. MDE-4816.

SiteOmat Station Controller User’s Manual, Document No. MDE-4817

SiteOmat Station Controller Setup Manual, Document No. MDE-4818

Fuel Truck Controller Manual

Page 34

28

0

22--11.. GGEENNEERRAALL

22--22.. PPRREELLIIMMIINNAARRYY IINNSSTTAALLLLAATTIIOONN IINNSSTTRRUUCCTTIIOONNSS

22--22..11.. GGeenneerraall

SECTION 2

PRELIMINARY INSTALLATION INSTRUCTIONS

This section provides the preliminary installation procedures for Fuel Truck Controller. These

instructions shall be performed in order to ready the fuelling truck to the installation of Fuel Truck

Controller.

These procedures include:

Preliminary installation instructions

Wiring and Wire Conduits requirements

Installation procedures and requirements depend, to some extent, on the specific fuel dispenser

models and the fuel truck layout. Therefore, use the information in this section to develop

installation plans for each specific installation. Since installation requirements vary widely from

case to case, no installation hardware is supplied by the equipment manufacturer, and installation

planners must develop their own requirements.

NOTE

Perform a truck survey prior to installation.

Refer to Appendix B "Site Survey Form".

The customer should provide an installation plan, designed by an authorized engineer, and

applicable to all authorities. This plan design should reflect the existing electric infrastructure of

the site.

Fuel Truck Controller Manual

Page 35

29

22--22..22.. PPrreeccaauuttiioonnss aanndd SSaaffeettyy NNootteess

22--33.. CCOONNDDUUIITTSS IINNSSTTAALLLLAATTIIOONN

22--33..11.. GGeenneerraall

22--33..22.. CCoonndduuiitt RReeqquuiirreemmeennttss

Prior to actual installation activities, carefully observe the precautions and safety notes below.

WARNING

Before installing or servicing equipment, carefully

observe the warnings and precautions provided at

the beginning of this manual.

Remember that the fuel truck environment is highly flammable and combustible.

Therefore, make sure that actual installation is performed by experienced personnel,

licensed to perform work in fuel trucks and capable of implementing all applicable

requirements of the National Fire Protection Association NFPA-30 “Flammable and

Combustible Liquids Code”, NFPA-30A “Code for Motor Fuel Dispensing Facilities and

Repair Garages”, NFPA-70A “National Electric Code”, federal, state and local codes and

any other applicable safety codes and regulations.

System power may come from more than one source. Disconnect all power sources before

attempting to work on the system.

Install the Fuel Truck Controller only in non-hazardous locations, in an area in accordance

with the safety restrictions.

Fuel Truck Controller site preparation is in the customer’s responsibility.

Do not connect power to the Fuel Truck Controller until complete installation is inspected

and certified.

Do not perform any metal work in the hazardous area. Sparks generated by drilling,

tapping and metal work operations could ignite fuel vapors and flammable liquids, resulting

in death, serious personal injury, property loss and damage to you and other persons.

The installation of the Fuel Truck Controller requires setting several conduits in the fuel truck. The

conduits are required for the routing and protection of the different types of cables.

The installation of the Fuel Truck Controller requires preparing beforehand the conduits and cables

layout in the fuel truck. This procedure consists of

Installing conduits within the truck,

Inserting the proper cables

Connecting to power.

Conduits must comply with the following requirements:

Conduits should be installed in accordance with local regulations.

Fuel Truck Controller Manual

Page 36

30

It is recommended to use metal conduits (preferably Vx metal) to provide the necessary

22--33..33.. TTyyppee ooff CCoonndduuiittss iinn tthhee TTrruucckk

shielding and protection.

Conduits should be inserted in the Fuel Truck Controller through openings provided in the

bottom plate (see Figure 2-1). Connect the wiring through optional glands or appropriate metal

tubing. For UL/cUL listing, this product has only been evaluated for use without the optional

glands.

(*) All glands in picture are optional

Figure 2-1. Fuel Truck Controller Wiring Openings

The types of conduits in the truck are a function of the different equipment and their location in the

truck. The following conduits are required in the Fuel truck:

Voltage conduits

o DC power for Fuel Truck Controller

o Pump control from pumps to Fuel Truck Controller

o Pump In-use signal from pumps to Fuel Truck Controller

Communication conduits

o Pulser from pumps to Fuel Truck Controller

o Barriers/Coils from pumps to Fuel Truck Controller – Non-Intrinsically safe

wiring (NIS). Barriers may be enclosed in a special, separate Barriers Box.

Power conduit

o Fuel Truck Controller is fed from the truck power system, after the ignition

switch. Conduits of power cable should be done in accordance with local practice.

NOTE

Barriers Box is not provided with Fuel Truck

Controller.

Fuel Truck Controller Manual

Page 37

31

22--33..44.. WWiirriinngg OOppeenniinnggss iinn FFuueell TTrruucckk CCoonnttrroolllleerr

Table 2-1. Conduits into Fuel Truck Controller

No.

Conduit Type

Type

1

Low voltage

Pulser, Barrier

2

Voltage

DC power

3

Voltage

Control, In-use

22--33..55.. CCoonndduuiittss IInnssttaallllaattiioonn PPrroocceedduurreess

22--44.. CCAABBLLEESS

22--44..11.. GGeenneerraall

Fuel Truck Controller includes several wiring openings to carry specific wires, as listed in

Table 2-1 and shown in Figure 2-1.

Proceed as follows:

1. Determine the location of the Fuel Truck Controller in the fuel truck.

2. Install a junction box close to the valve for valve control.

3. Install a junction box for the pulser and nozzle antenna.

4. Deploy two conduits from the junction boxes to the Fuel Truck Controller (pulser, valve and

nozzle antenna).

5. Deploy a conduit from truck power system to Fuel Truck Controller. Fuel Truck Controller

is fed from the truck power system, after the ignition switch.

This paragraph describes the requirements and procedures for the insertion of cables in the conduits.

Fuel Truck Controller Manual

Page 38

32

NOTE

22--44..22.. CCaabbllee TTyyppeess

Table 2-2. Fuel Truck Controller, Cables Type

No.

Function

Type

1

Power supply and valve control

As used in vehicles 1.5 – 2.5 mm²

(15 to 13 AWG)

2

Coil (Barrier)

Data communication cable, 300 V RMS,

90ºC, shielded twisted pair, oil

resistant, 24 AWG, low capacitance

below 60 PF/meter similar to Belden

9729 cable

3

Pulser and In-use signal

4

LAN

CAT5E, Shielded , 300 V RMS, 90ºC

similar to Belden 121700A

5

GND

Ground cable 0.4" (10.8 mm2)

22--44..33.. CCaabblleess RRoouuttiinngg

The type of required cable varies in accordance with

the device it connects. The wire used must be

stranded and not a solid core. Select a cable

specification in accordance with local environment

conditions.

CAUTION

For supply connections, use wires suitable for at

least 90°C.

Signal wiring connected in this box must be rated at

least 300 V

Table 2-2 lists the types of cables used for the wiring of the Fuel Truck Controller system.

Connections should be done through a junction box (4x4x4" (10x10x10 cm)) located near

peripherals.

Route the cables from peripherals to Fuel Truck Controller as listed in Table 2-3 and Table 2-4.

Proceed as follows:

Fuel Truck Controller Manual

Page 39

33

Table 2-3. Fuel Truck Controller, Cables Routing

No.

Functional

Description

From

To

Cable Type

(*)

1

DC Power

DC to DC voltage

converter

Fuel Truck Controller box

terminal block

1

2

LAN

Low voltage junction box

4

3

Pulser

Fuel Truck

Controller box

Meter register, Pulser

3 4 Valve control

Valve

Fuel Truck Controller box

terminal block

1

Route cables from the nozzles to Fuel Truck Controller through a Barriers box. Proceed as follows:

Table 2-4. Nozzles to Fuel Truck Controller, Cables Routing

No.

Functional

Description

From

To

Cable Type

(*)

1

Nozzle antenna

Junction box

Barriers box

2

2

Barriers

Barriers box

Fuel Truck Controller

terminal block

2

22--55.. EElleeccttrriiccaall SSyysstteemm

22--55..11.. EExxtteerrnnaall FFuussee

22--55..22.. FFuueell TTrruucckk CCoonnttrroolllleerr PPoowweerr SSyysstteemm

(*) Refer To Table 2-2.

The Fuel Truck Controller requires an external fuse. Additional vehicle type 6 Amp fuse should be

installed between the truck's power supply system and the Fuel Truck Controller.

SAFETY CAUTION

The fuse should link the wire very close to the

battery, and at the distribution point (via a

distribution block).

The truck's power supply system is connected to the terminal block in the Fuel Truck Controller.

The system uses a Line Filter between the terminal block and the main switch in order to attenuate

conducted interference. The Line Filter is coupled with Timer relay, this timer provides 30 seconds

delay between power-feed and power output. This delay protects against short bursts of power

when the driver starts the truck. The delay is reset at each starting attempt. Consequently, Fuel

Fuel Truck Controller Manual

Page 40

34

Truck Controller is turned on 30 seconds after the truck is powered, when the motor should be

22--66.. GGRROOUUNNDDIINNGG AANNDD SSHHIIEELLDDIINNGG

operating steadily.

Fuel Truck Controller does not include a power switch.

Figure 2-2 Power Supply – Block Diagram

Proper system grounding is an extremely important part of the system installation. As with the DC

power, the grounds for all system components should return to the same circuit breaker panel. This

helps you assure a common ground throughout the system, necessary for protection of the RS-485

data loop circuitry.

The Fuel Truck Controller box is shielded through its installation screws to the vehicle chassis.

Fuel Truck Controller includes several grounding studs in order to comply with requirements. The

DC power ground wire should be attached to the stud close to the Line Filter.

Each shielded cable connected to the Fuel Truck Controller is stripped of its shielding at the box

entry. Its shield wires are bundled together at the entrance of the box and attached to a shielding

stud within the Fuel Truck Controller box. Figure 2-3 shows a functional diagram of the shielding.

Figure 2-3 Cables Shielding

Fuel Truck Controller Manual

Page 41

35

22--77.. CCOONNNNEECCTTIIOONNSS TTOO FFUUEELL TTRRUUCCKK

CCOONNTTRROOLLLLEERR

Most connections to the Fuel Truck Controller are performed to the Terminal Block located at the

bottom of the box (see Figure 2-4). The required connections are:

1. Pump wiring connections:

Pulser

Valve

In use (Optional, not existing in most cases)

2. Communications:

RS-485 for peripheral device

3. Power

DC Power to Line Filter

4. Other connections, not to the Terminal Block:

LAN connection

(*) All glands in picture are optional

Figure 2-4 Fuel Truck Controller Terminal Block, Power and LAN Connections

Fuel Truck Controller Manual

Page 42

36

Fuel Truck Controller Manual

Page 43

37

0

33--11.. GGEENNEERRAALL

33--22.. IINNSSTTAALLLLAATTIIOONN SSPPEECCIIFFIICCAATTIIOONNSS

33--22..11.. GGeenneerraall

33--22..22.. PPrreeccaauuttiioonnss aanndd SSaaffeettyy NNootteess

SECTION 3

INSTALLATION PROCEDURES

This section provides the installation procedures for the Fuel Truck Controller.

These procedures include:

Fuel Truck Controller installation

Wiring

Post installation check.

Installation procedures and requirements depend, to some extent, on the specific fuel truck and its

mechanical and electrical layout. Therefore, use the information in this section to develop an

installation plan for each specific installation. Since installation requirements vary widely from

case to case, no installation hardware is supplied by the equipment manufacturer, and installation

planners must develop their own requirements.

NOTE

Perform a site survey of the fuel truck prior to

installation

The customer should provide an installation plan, designed by an authorized engineer. This plan

design should reflect the existing electric infrastructure of the fuel truck.

Prior to actual installation activities, carefully observe the precautions and safety notes detailed in

paragraph 2-2.2 and at the opening pages.

Fuel Truck Controller Manual

Page 44

38

33--33.. FFUUEELL TTRRUUCCKK -- OOVVEERRVVIIEEWW

33--33..11.. GGeenneerraall

Prior to installation, you are required to obtain an overview of the fuel truck functional architecture.

This overview is required in order to draw an architecture diagram with all components and their

communication links.

Figure 3-1 shows a functional diagram of the links within the fuel truck with mechanical pump.

Figure 3-1. Fuel Truck Controller with Mechanical Pumps – System Diagram

Fuel Truck Controller Manual

Page 45

39

33--44.. MMAAPPPPIINNGG TTHHEE TTRRUUCCKK

33--44..11.. GGeenneerraall

33--44..22.. LLooccaattiinngg aallll oobbjjeeccttss ooff tthhee ffuueell ttrruucckk

33--44..33.. AAssssiiggnniinngg LLooggiiccaall IIDDss

The mapping of the fuel truck is required prior to installation. This procedure consists of the

following steps.

Locate installation of related objects in the fuel truck

Locate the intended position of the Fuel Truck Controller

Draw a basic map of the site with all the objects

Logical IDs should be assigned to the Pump and Nozzle:

Assign an id. to the pump (P)

Assign an id. to its nozzle (N)

Fuel Truck Controller Manual

Page 46

40

33--55.. IINNSSTTAALLLLIINNGG TTHHEE FFUUEELL TTRRUUCCKK CCOONNTTRROOLLLLEERR

33--55..11.. IInnssttaallllaattiioonn AAsssseemmbbllyy PPaarrttss

Table 3-1. Fuel Truck Controller, Installation Assembly Parts

Item No.

Part Number

Description

Qty

1

800938901

(PA039699200)

Fuel Truck Controller

1

2

819040120

(M09680B039)

Shock Absorber Assembly

1

3

815216200

Pan head screw, M6 x16

8

4.

815322200

Flat Washer, M6

8

5

815303100

Spring Washer, M6

8

6

815222000

M8 x 20 mm Hex bolt (*)

4

7

815305500

Washer, Flat, M8

4

8

815122000

Nut, M8

4

9

814605600

(M09680B035)

Shock absorber

4

10

814979800

Plate, shock absorbers

4

The Fuel Truck Controller can be installed in two configurations:

a. Installation of Fuel Truck Controller only

This type of configuration is designed for installing the Fuel Truck Controller in locations

such as inside truck cabins, that are not exposed to the harsh environment and thus do not

require shock absorbers.

b. Installation of Fuel Truck Controller with Shock Absorber Assembly

This type of configuration is designed for installation of the Fuel Truck Controller in

vehicles (not in driver's cabins) in areas of the vehicle that are exposed to the harsh

environment which need shock absorbers.

For installation of the Fuel Truck Controller with Shock Absorber Assembly, the client must

order the Shock Absorber Assembly (P/N 819040120) in addition to ordering the Fuel Truck

Controller (P/N 800938901).

Table 3-1 lists the assembly parts for the installation of the Fuel Truck Controller.

(*) Optional, for installing the Fuel Truck Controller to the Shock Absorber assembly.

Fuel Truck Controller Manual

Page 47

41

33--55..22.. PPrreelliimmiinnaarryy PPrroocceedduurreess

33--55..33.. FFuueell TTrruucckk CCoonnttrroolllleerr IInnssttaallllaattiioonn iinn DDrriivveerr''ss CCaabbiinn

33--55..44.. DDeetteerrmmiinniinngg tthhee SSppoott IInnssttaallllaattiioonn FFuueell TTrruucckk CCoonnttrroolllleerr wwiitthh SShhoocckk AAbbssoorrbbeerr

AAsssseemmbbllyy

For installation of Fuel Truck Controller only, the following procedures should be performed in

this order:

Installing the Fuel Truck Controller on the support rails in driver's cabin

Running cables through the conduits to Fuel Truck Controller

Wiring Fuel Truck Controller.

For installation of Fuel Truck Controller with the Shock Absorber Assembly, the following

procedures should be performed in this order:

Installing Shock Absorbers Assembly on support flanges in the selected area on the

truck

Installing the Fuel Truck Controller on Shock Absorbers Assembly.

Running cables through the conduits to Fuel Truck Controller

Wiring Fuel Truck Controller.

To install the Fuel Truck Controller in the driver's cabin, perform the following steps:

a. Look for the support rail at the back of the driver's cabin in the fuel truck. There are usually

two perpendicular rails.

b. Select the rail where installation is easier (less cluttered area)

c. Prepare beforehand two support flanges with two setting holes in each

d. Connect the Fuel Truck Controller through the internal four holes or through the wall mount

bracket to the support flanges.

e. Use dedicated drill screws for the installation to the support rails.

After the Fuel Truck Controller installation is completed, proceed with unit wiring according to

the instructions provided in paragraph 3-7.

Proceed as follows:

1. Look for a support rail at the selected installation location in the fuel truck.

2. Select the rail where installation is easier (less cluttered area)

3. Prepare beforehand two support flanges with two setting holes in each

4. Drill eight M6 Hex threads in the support flanges of the Shock Absorbers plate. See

location and dimensions in Figure 3-2 and Figure 3-3 (10 in Table 3-1)

5. Drill four Hex threads in the rails for the support flanges

6. Install the support flanges and secure with bolts, spring washers and flat washers

Fuel Truck Controller Manual

Page 48

42

33--55..55.. SShhoocckk AAbbssoorrbbeerrss AAsssseemmbbllyy -- IInnssttaallllaattiioonn PPrroocceedduurreess

The Shock Absorbers Assembly should be mounted on any flat surface on the truck. The rear

wall of the shock absorber assembly includes eight holding holes for support screws.

Proceed as follows:

1. Locate the eight installation holes on the mounting flanges (see Figure 3-2 and Figure 3-3)

2. Check that eight M6 Hex threads in the installation flange have been drilled

3. Set Shock Absorbers assembly (2 in Table 3-1)on the spot (see Figure 3-2) so that its

installation holes fit with the threads

4. Secure Shock Absorbers assembly with eight M6 Pan head bolts, M6 flat washers and M6

spring washers (3, 4, 5 in Table 3-1)

Figure 3-2 Shock Absorber Assembly – Installation Holes

Fuel Truck Controller Manual

Page 49

43

33--55..66.. FFuueell TTrruucckk CCoonnttrroolllleerr IInnssttaallllaattiioonn AAsssseemmbbllyy

Figure 3-3 Fuel Truck Controller with Shock Absorber Assembly – Installation Holes

Fuel Truck Controller box is secured to Shock Absorber Assembly from within Fuel Truck

Controller (see Figure 3-4).

Figure 3-4 Installing Fuel Truck Controller on Shock Absorber Brackets – Installation Holes

Proceed as follows:

Fuel Truck Controller Manual

Page 50

44

1. Install Fuel Truck Controller box on assembly on Shock Absorbers Assembly so that the

33--66.. IINNSSTTAALLLLAATTIIOONN OOFF FFUUEELL TTRRUUCCKK CCOONNTTRROOLLLLEERR WWIITTHH WWAALLLL MMOOUUNNTT KKIITT

33--66..11.. IInnssttaallllaattiioonn AAsssseemmbbllyy PPaarrttss

Table 3-2. Fuel Truck Controller, Assembly Parts

Item No.

Part Number

Description

Qty

1

800938901 to 800938932

Fuel Truck Controller

1 2 819022200

Wall Mount Kit

1

2a

814423100

Wall Bracket

4

2b

815122000

Nut M8

4

2c

815222000

Screw, M8x20, Hexagon Head

4

2d

815322000

Washer, Flat, M8

4

2e

815322100

Washer Spring M8

4

2f

815322400

Washer, Insulator, M8

4

33--66..22.. IInnssttaallllaattiioonn PPrroocceedduurreess

shock absorbers fit into place

2. Open Fuel Truck Controller box

3. Secure Fuel Truck Controller box to Shock Absorbers Assembly with four M8 Hex bolts,

four M8 flat washers, and four Nuts (6, 7, 8 in Table 3-1)

4. Perform Fuel Truck Controller wiring (refer to paragraph 3-7)

5. Lock Fuel Truck Controller box door with key.

Table 3-2 lists the assembly parts for the installation of the Fuel Truck Controller.

Proceed as follows:

Note: If the wall mount is already installed, go to step 4.

1. Open Fuel Truck Controller enclosure

2. Turn Fuel Truck Controller enclosure (1 in Table 3-2) so you face its rear panel (see

Figure 3-5)

3. Attach to each support hole in the rear panel a wall bracket (2a in Table 3-2), with nut,

M8x20 screw and flat washer (2b to 2f in Table 3-2). Set the bracket so that they fit to the

proper installation, as shown in Figure 3-6. The wall bracket dimensions are provided in

Figure 3-7.

Fuel Truck Controller Manual

Page 51

45

4. Set the Fuel Truck Controller enclosure (with wall brackets) in the spot and mark the four

holes location from brackets for drilling. Make sure you select place that will allow you to

open completely the Turn Fuel Truck Controller door.

Figure 3-5 Rear Panel Support Holes

Figure 3-6 Wall Bracket, Installation Example

Figure 3-7 Wall Bracket, Dimensions (mm)

Fuel Truck Controller Manual

Page 52

46

33--77.. WWIIRRIINNGG

33--77..11.. GGeenneerraall

33--77..22.. WWiirriinngg RReeqquuiirreemmeenntt

33--77..33.. WWiirriinngg PPrroocceedduurreess

33--77..44.. GGeenneerraall

After completing the installation procedure, perform the wiring procedures. The wiring is

performed in the Fuel Truck Controller Terminal Block only.

The wires should be pulled from the conduits, or in the opposite direction, from the Terminal Block

to the devices in the fuel truck. Proceed as follows:

1. In accordance with the mapping, run cable conduits in accordance with the type of cables to

the spot:

One conduit from the pump valve

One conduit from the pulser

One conduit from the nozzle

One conduit from power

2. Run the cables along the conduits to the openings in the box. Connect the wiring through

optional glands or appropriate metal tubing. For UL/cUL listing, this product has only been

evaluated for use without the optional glands

3. Insert all power and communication cables pass through the openings in the bottom panel.

For any type of pump and wire, prior to inserting a wire, proceed as follows:

1. Insert all wires with a terminal lug only.

2. Use the proper Terminal Crimper to attach the lug to the wire.

3. For UL Listing, The Terminal Lug must be a UL recognized components.

Figure 3-8 Terminal Lug

TIP

Mark each cable at its both ends with a number or

sign that will identify its functionality in the future.

The wiring for Fuel Truck Controller is provided in two modes:

Fuel Truck Controller Manual

Page 53

47

Table 3-3 lists the wiring in the sequential order of the terminals. This table provides the

33--77..55.. MMeecchhaanniiccaall PPuummpp –– TTeerrmmiinnaall BBlloocckk -- PPiinn--OOuutt

CCoonnnneeccttiioonnss

Table 3-3. Fuel Truck Controller Terminal Block - Mechanical Pump – Connections Definition

Terminal No.

Signal Name

Functional Description

1

BARRIER 1 (-)

Connection to Safety Barrier for Nozzle 1 (1st wire)

2

BARRIER 2 (-)

Connection to Safety Barrier for Nozzle 2 (1st wire)

3

BARRIER 3 (-)

Connection to Safety Barrier for Nozzle 3 (1st wire)

4

BARRIER 4 (-)

Connection to Safety Barrier for Nozzle 4 (1st wire)

5

BARRIER 1 (+)

Connection to Safety Barrier for Nozzle 1 (2nd wire)

6

BARRIER 2 (+)

Connection to Safety Barrier for Nozzle 2 (2nd wire)

7

BARRIER 3 (+)

Connection to Safety Barrier for Nozzle 3 (2nd wire)

8

BARRIER 4 (+)

Connection to Safety Barrier for Nozzle 4 (2nd wire)

9

TX-RS232

Transmit (optional RS232 connection)

10

GND-RS232

RS232 Ground (optional RS232 connection)

11

RX-RS232

Receive (optional RS232 connection)

12

RS-485 (+)

(+)RS 485 (optional equipment interface)

13

RS-485 (-)

(-)RS 485 (optional equipment interface)

14

RS-485 GND

(Gnd) Rs485 (optional equipment interface)

15

PULSER 1 P

Pulser Input – Nozzle 1

16

PULSER 2 P

Pulser Input – Nozzle 2

17

PULSER 3 P

Pulser Input – Nozzle 3

signal name and a functional description of the signal.

Figure 3-10 shows the wiring list for connection to the Terminal, as published in the Wiring

Label added to the inner door (see Figure 3-11). The Wiring Label follows the physical

location of the wires in the Terminal Block (see Figure 3-9).

The Fuel Truck Controller Terminal Block connections for a Mechanical Pump are listed in the

following table.

Fuel Truck Controller Manual

Page 54

48

Table 3-3. Fuel Truck Controller Terminal Block - Mechanical Pump – Connections Definition

Terminal No.

Signal Name

Functional Description

18

PULSER 4P

Pulser Input – Nozzle 4

19

GND PULSER 1

Nozzle Grounding – Nozzle 1

20

GND PULSER 2

Nozzle Grounding – Nozzle 2

21

GND PULSER 3

Nozzle Grounding – Nozzle 3

22

GND PULSER 4

Nozzle Grounding – Nozzle 4

23

+12V 1 P

+12 VDC Output to Pulser – Nozzle 1

24

+12V 2 P

+12 VDC Output to Pulser – Nozzle 2

25

+12V 3 P

+12 VDC Output to Pulser – Nozzle 3

26

+12V 4 P

+12 VDC Output to Pulser – Nozzle 4

27

IN USE 1 A

Handle Up - In Use signal input - Nozzle 1

28

IN USE 2 A

Handle Up - In Use signal input - Nozzle 2

29

IN USE 3 A

Handle Up - In Use signal input - Nozzle 3

30

IN USE 4 A

Handle Up - In Use signal input - Nozzle 4

31

IN USE 1 B(-)

Handle Up - In Use (dry contact) signal return - Nozzle 1

32

IN USE 2 B(-)

Handle Up - In Use (dry contact) signal return - Nozzle 2

33

IN USE 3 B(-)

Handle Up - In Use (dry contact) signal return - Nozzle 3

34

IN USE 4 B(-)

Handle Up - In Use (dry contact) signal return - Nozzle 4

35

LOAD 1

Pump control output - Nozzle 1

36

LOAD 2

Pump control output - Nozzle 2

37

LOAD 3

Pump control output - Nozzle 3

38

LOAD 4

Pump control output - Nozzle 4

39

LINE 1

Pump control 12/24 VDC Input - Nozzle 1

40

LINE 2

Pump control 12/24 VDC Input - Nozzle 2

41

LINE 3

Pump control 12/24 VDC Input - Nozzle 3

42

LINE 4

Pump control 12/24 VDC Input - Nozzle 4

43

+12 VDC up to +24 VDC