Page 1

Fuel Point® Fuel Management System

Vehicle Module Programming

Manual

MDE-4524A

(formerly C35629)

Page 2

Computer Programs and Documentation

Federal Communications Commission (FCC) Warning

All Gasboy computer programs (including software on diskettes and within memory chips) and documentation are copyrighted by, and shall remain the property of, Gasboy. Such

computer programs and documents may also contain trade secret information. The duplication, disclosure, modification, or unauthorized use of computer programs or

documentation is strictly prohibited, unless otherwise licensed by Gasboy.

This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy, and if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense. Changes or modifications not expressly

approved by the manufacturer could void the user’s authority to operate this equipment.

Approvals

Gasboy, Greensboro, is an ISO 9001:2000 registered facility.

Underwriters Laboratories (UL):

UL File# Products listed with UL

MH4314

MH6418

MH7404

MH10581 Key control unit, Model GKE-B Series

All dispensers and self-contained pumping

units

Power operated Transfer Pump Models 25,

25C, 26, 27, 28, 72, 72S, 72SP, 72X, 73 and

1820

Hand operated Transfer Pump Models 1230

Series, 1243 Series, 1520 and 1720 Series

Card reader terminals, Models 1000, 1000P

Site controller, Model 2000S CFN Series

Data entry terminals, Model TPK-900 Series

Fuel Point Reader System

New York City Fire Department (NYFD):

NYFD C of A # Product

4823 9100A, 9140A, 9152A, 9153A,

4997 9822A, 9823A

5046 9100Q, 9140Q, 9152Q, 9153Q,

9800A, 9840A, 9850A, 9852A,

9853A, 9140

9800Q, 9840Q, 9852Q, 9853Q

National Conference of Weights and Measures (NCWM) - Certificate of Compliance (CoC):

Gasboy pumps and dispensers are evaluated by NCWM under the National Type Evaluation Program (NTEP). NCWM has issued the following CoC:

CoC# Product Model # CoC# Product Model # CoC# Product Model #

95-179A2 Dispenser

95-136A5 Dispenser 9800 Series 91-057A3 Controller

9100 Retail Series, 8700

Series, 9700 Series

91-019A2 Dispenser

9100 Commercial

Series

1000 Series FMS,

2000S-CFN Series

California Air Resources Board (CARB):

Executive Order # Product

G-70-52-AM Balance Vapor Recovery

G-70-150-AE VaporVac

Patents

Gasboy products are manufactured or sold under one or more of the following US patents:

Dispensers

5,257,720

Point of Sale/Back Office Equipment

D335,673

Trademarks

Non-registered trademarks

Atlas™

Consola™

Infinity™

Registered trademarks

ASTRA

Fuel Point

Gasboy

Keytrol

Slimline

Additional US and foreign patents pending.

®

®

®

®

®

Additional US and foreign trademarks pending.

Other brand or product names shown may be

trademarks or registered trademarks of their

respective holders.

This document is subject to change without notice. · For information regarding Gasboy Literature, call (336) 547-5661

E-mail: literature@gasboy.com · Internet: http://www.gasboy.com

© 2006 GASBOY · All Rights Reserved

Page 3

Table of Contents

Table of Contents

1 – Introduction 1-1

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Intended Users. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Related Reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Abbreviations and Acronyms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

2 – Important Safety Information 2-1

In an Emergency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

3 – Component Overview 3-1

Vehicle Module Programmer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Charging the Programmer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Battery Pack Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

4 – Preparation for Programming 4-1

Vehicle Module Field Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

System ID. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Vehicle Module Number (Enter VM Number). . . . . . . . . . . . . . . . . . . . . . . .4-1

ID Fields. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

FleetKey . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

CFN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Reader Entry Fields (RDR FLD 1,2, or 3) . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Expiration Date (Enter EXPIRE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Product Limit (Enter LIMIT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Product Authorization (Enter AUTH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Price Level (Enter PRICE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Odometer Or Hours Selection (SEL ODOMETER - 0, HOURS - 1) . . . . . . . . . . . . . . 4-7

MDE-4524A Vehicle Module Programming Manual· May 2006 Page i

Page 4

Table of Contents

Odometer or Hours Entry (Enter ODOMETER) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Odometer Ratio (Enter ODO RATIO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Hours Ratio (Enter ODO Ratio) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Dual Counters (DUAL COUNTERS, NO - 0, YES - 1) . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Vehicle Module Program Data Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

5 – Operation 5-1

Ground Loop Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

General Programmer Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Turning On Programmer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Turning Off Programmer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Mode Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Accepting Old Data and Clearing the Display for New Data Entry . . . . . . . 5-2

Entering Numeric Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Entering Alphanumeric Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Entering Spaces and Special Characters . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Entering Odometer or Hours Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Editing Within a Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Programmer Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Program Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Testing the Odometer/Hours Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Edit Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Calibrate Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Master Authorizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Limitations of Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Page ii MDE-4524A Vehicle Module Programming Manual· May 2006

Page 5

Purpose Introduction

1 – Introduction

Purpose

This manual describes the Vehicle Module (VM) Programmer and the steps needed to program

®

the vehicle module component of your Fuel Point

module contains all system information including system and vehicle identification,

authorized fuel type and transaction limit information. This manual also describes the Master

Authorizer, a hand-held device that allows the site supervisor to authorize the pump for a

single transaction on an equipment not equipped with a vehicle module.

The Vehicle Module (VM) itself should be installed according to the guidelines and

restrictions outlined in C35699 Fuel Point Vehicle Module Installation Manual.

Gasboy provides a toll-free number for customers and installers having any questions

pertaining to the installation: 1-800-444-5529.

System. When programmed, the vehicle

Intended Users

This manual is written for Authorized Service Contractors (ASCs) and Customer Specified

Contractors (CSCs).

Related Reading

The following documents contain related information and may be helpful when programming

the Vehicle Module:

Document Number Title GOLD Library

C35699 Fuel Point Vehicle Module Installation Manual Gasboy Fuel Management Products

C35923 SCII/SCIII POS & Shift Change Manual Gasboy Fuel Management Products

MDE-4255 Gasboy Warranty Policy Statement Gasboy Commercial and Retail

Pumps

MDE-4524A Vehicle Module Programming Manual· May 2006 Page 1-1

Page 6

Introduction Abbreviations and Acronyms

Abbreviations and Acronyms

The following table contains a list of abbreviations and acronyms used in this guide.

Acronym Definition

ASC Authorized Service Contractor

CSC Customer Specified Contractor

FMS Fuel Management System

ID Identification

MM Month

PCM Powertrain Control Module

VM Vehicle Module

YY Year

Warranty

For information on warranty, refer to MDE-4255 Gasboy’s Warranty Policy Statement. If you

have any warranty-related questions, contact Gasboy’s Warranty Department at its Greensboro

location.

Page 1-2 MDE-4524A Vehicle Module Programming Manual· May 2006

Page 7

2 – Important Safety Information

Important Safety Information

This section introduces the hazards and safety precautions

associated with installing, inspecting, maintaining or servicing

this product. Before performing any task on this product, read

this safety information and the applicable sections in this

manual, where additional hazards and safety precautions for

your task will be found. Fire, explosion, electrical shock or

pressure release could occur and cause death or serious

injury if these safe service procedures are not followed.

Preliminary Precautions

You are working in a potentially dangerous environment of

flammable fuels, vapors, and high voltage or pressures. Only

trained or authorized individuals knowledgeable in the related

procedures should install, inspect, maintain or service this

equipment.

Emergency Total Electrical Shut-Off

The first and most important information you must know is

how to stop all fuel flow to the pump and island. Locate the

switch or circuit breakers that shut-off all power to all fueling

equipment, dispensing devices, and submerged turbine

pumps (STPs).

!

WARNING

!

The EMERGENCY STOP, ALL STOP, and

PUMP STOP buttons at the cashier’s station

WILL NOT shut off electrical power to the

pump/dispenser.

Total Electrical Shut-Off Before Access

Any procedure requiring access to electrical components or

the electronics of the dispenser requires total electrical shutoff of that unit. Know the function and location of this switch

or circuit breaker before inspecting, installing, maintaining, or

servicing Gasboy equipment.

Evacuation, Barricading and Shut-Off

Any procedures requiring accessing the pump/dispenser or

STPs requires the following three actions:

This means that even if you activate these

stops, fuel may continue to flow uncontrolled.

You must use the TOTAL ELECTRICAL SHUTOFF in the case of an emergency and not only

these cashier station “stops.”

Read the Manual

Read, understand and follow this manual and any other

labels or related materials supplied with this equipment. If you

do not understand a procedure, call the Gasboy Customer

Service at 1-800-444-5579, Tech Support 1-800-444-5529. It

is imperative to your safety and the safety of others to

understand the procedures before beginning work.

Follow the Regulations

There is applicable information in NFPA 30A; Automotive and

Marine Service Code, NFPA 70; National Electrical Code (NEC),

OSHA regulations and federal, state, and local codes which

must be followed. Failure to install, inspect, maintain or

service this equipment in accordance with these codes,

regulations and standards may lead to legal citations with

penalties or affect the safe use and operation of the

equipment.

Replacement Parts

Use only genuine Gasboy replacement parts and retrofit kits

on your pump/dispenser. Using parts other than genuine

Gasboy replacement parts could create a safety hazard and

violate local regulations.

Safety Symbols and Warning Words

This section provides important information about warning

symbols and boxes.

Alert Symbol

This safety alert symbol is used in this manual and

on warning labels to alert you to a precaution which must be

followed to prevent potential personal safety hazards. Obey

safety directives that follow this symbol to avoid possible

injury or death.

Signal Words

These signal words used in this manual and on warning

labels tell you the seriousness of particular safety hazards.

The precautions that follow must be followed to prevent

death, injury or damage to the equipment

DANGER - This signal word is used to alert you to a

hazard to unsafe practice which will result in death or

!

serious injury

WARNING - This alerts you to a hazard or unsafe

practice that could result in death or serious injury.

!

CAUTION with Alert symbol - This signal word

designates a hazard or unsafe practice which may

!

result in minor injury.

CAUTION without Alert symbol - When used by itself,

CAUTION designates a hazard or unsafe practice

which may result in property or equipment damage.

- An evacuation of all unauthorized persons and vehicles

using safety tape, cones or barricades to the effected units

- A total electrical shut-off of that unit

MDE-4524A Vehicle Module Programming Manual· May 2006 Page 2-1

Working With Fuels and Electrical Energy

Prevent Explosions and Fires

Fuels and their vapors will become explosive if ignited.

Spilled or leaking fuels cause vapors. Even filling customer

tanks will cause explosive vapors in the vicinity of dispenser

or island.

Page 8

t

S

t

c

f

W

w

a

a

s

c

t

t

d

W

e

e

a

c

t

S

c

e

Important Safety Information

No Open Flames

Open flames from matches, lighters, welding

orches or other sources can ignite fuels and their vapors.

No Sparks - No Smoking

parks from starting vehicles, starting or using power tools,

burning cigarettes, cigars or pipes can also ignite fuels and

heir vapors. Static electricity, including an electrostatic

harge on your body, can cause a spark sufficient to ignite

uels and their vapors. After getting out of a vehicle, touch the

metal of your vehicle to discharge any electrostatic charge

before you approach the dispenser island.

orking Alone

It is highly recommended that someone who is capable of

rendering first aid be present during servicing. Be familiar

ith Cardiopulmonary Resuscitation (CPR) methods if you

re working with or around high voltages. This information is

vailable from the American Red Cross. Always advise the

tation personnel about where you will be working, and

aution them not to activate power while you are working on

he equipment. Use the OSHA tag out and lock out

procedures. If you are not familiar with this requirement, refer

o information in the service manual and OSHA

ocumentation.

orking With Electricity Safely

Be sure to use safe and established practices in working with

lectrical devices. Poorly wired devices may cause a fire,

xplosion or electrical shock. Be sure grounding connections

re properly made. Make sure that sealing devices and

ompounds are in place. Be sure not to pinch wires when

replacing covers Follow OSHA Lock-Out and Tag-Out

requirements. Station employees and service contractors

need to understand and comply with this program completely

o ensure safety while the equipment is down.

Emergency First Aid

Informing Emergency Personnel

Compile the following information for emergency personnel:

• Location of accident (for example, address, front/back of

building, and so on.)

• Nature of accident (for example, possible heart attack, run

over by car, burns, and so on.)

• Age of victim (for example, baby, teenager, middle-age,

elderly)

• Whether or not victim has received first aid (for example,

stopped bleeding by pressure, and so on.)

• Whether or not a victim has vomited (for example, if

swallowed or inhaled something, and so on.)

WARNING

!

Gasoline ingested may cause unconsciousness

and burns to internal organs.

Do not induce vomiting.

Keep airway open.

Oxygen may be needed at scene.

Seek medical advice immediately.

WARNING

!

Gasoline inhaled may cause unconsciousness

and burns to lips, mouth and lungs.

Keep airway open.

Seek medical advice immediately.

WARNING

!

Gasoline spilled in eyes may cause burns to eye

tissue.

Irrigate eyes with water for approximately 15

minutes.

Seek medical advice immediately

Hazardous Materials

ome materials present inside electronic enclosures may

present a health hazard if not handled correctly. Be sure to

lean hands after handling equipment. Do not place any

quipment in mouth.

WARNING

!

Gasoline spilled on skin may cause burns.

Wash area thoroughly with clear/water.

Seek medical advice immediately.

!

WARNING

This area contains a chemical known to the State of

California to cause cancer.

IMPORTANT: Oxygen may be needed at scene if gasoline

has been ingested or inhaled. Seek medical advice

immediately.

Lockout/Tagout

WARNING

!

This area contains a chemical known to the State of

California to cause birth defects or other reproductive

harm.

Lockout/Tagout covers servicing and maintenance of

Machines and equipment in which the unexpected

energization or start up of the machine(s) or equipment or

release of stored energy could cause injury to employees or

personnel. Lockout/Tagout applies to all mechanical,

hydraulic, chemical or other energy, but does not cover

electrical hazards. Reference Subpart S of 29 CFR Part 1910

IMPORTANT: Oxygen may be needed at scene if gasoline

has been ingested or inhaled. Seek medical advice

- Electrical Hazards, 29 CFR Part 1910.333 contains specific

Lockout/Tagout provision for electrical hazards.

immediately.

Page 2-2 MDE-4524A Vehicle Module Programming Manual· May 2006

Page 9

In an Emergency

The following actions are recommended regarding these hazards:

Important Safety Information

WARNING

!

Spilled fuels, accidents involving pumps/dispensers, or uncontrolled fuel flow creates

a serious hazard.

Fire or explosion may result causing serious injury or death.

Follow established emergency procedures.

Collision of Vehicle with Unit Fire at Island Fuel Spill

• Do not go near fuel spill or allow anyone else in the area.

• Use station EMERGENCY CUTOFF immediately. Turn off all system circuit breakers to

the island(s).

• Do not use console E-STOP, ALL STOP keys to shut off power. These keys do not remove

AC power and do not always stop product flow.

• Take precautions to avoid igniting fuel. Do not allow starting of vehicles in the area. No

open flames, smoking or power tools in the area.

• Do not expose yourself to hazardous conditions such as fire, spilled fuel or exposed

wiring.

• Call emergency numbers.

MDE-4524A Vehicle Module Programming Manual· May 2006 Page 2-3

Page 10

Important Safety Information

This page is intentionally left blank.

Page 2-4 MDE-4524A Vehicle Module Programming Manual· May 2006

Page 11

Vehicle Module Programmer Component Overview

3 – Component Overview

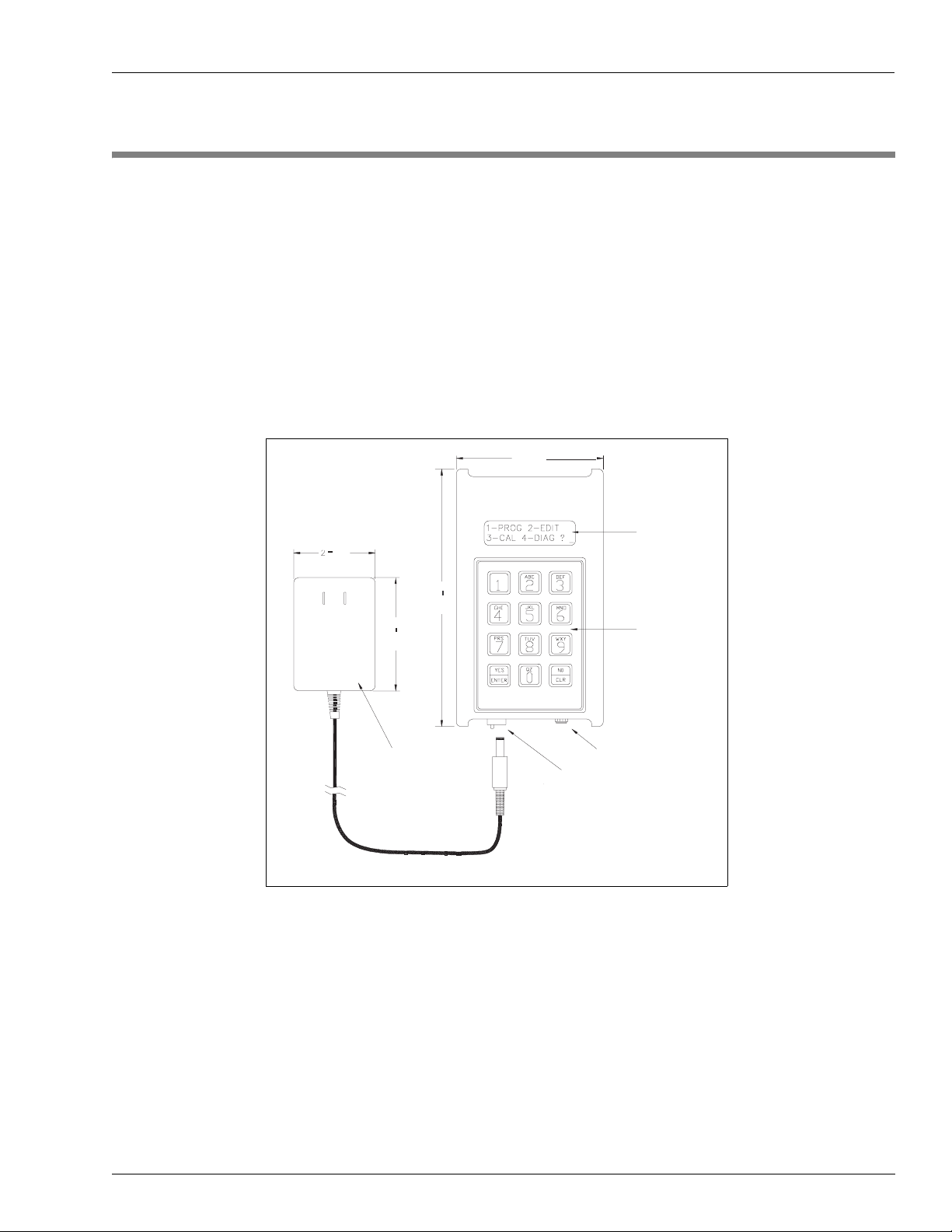

Vehicle Module Programmer

The Vehicle Module (VM) Programmer is a hand-held, cordless device used to interact with

the Fuel Point System components. It contains an antenna for communicating to the VM

through the vehicle T-Ring antenna. The two-line, alphanumeric display prompts the user

through each step, making it easy to use in the shop, in the fleet yard, at the job site, or at the

fueling island.

Figure 3-1

C06736 VM Programmer with Charger

3 9/16

(90.50)

1/4

2

(57.15)

(158.75)

6 1/4

2 3/4

(69.85)

CHARGER

CONNECTOR

CHARGER

32 CHARCTER

ALPHANUMERIC

DISPLAY

ALPHANUMERIC

KEYPAD

FACTORY PROGRAMMING

CONNECTOR

Note: C06736 VM Programmer will be shipped only till end of February 2006. Starting

March 2006, M06728A001 VM Programmer will be shipped.

The Programmer has five operating modes which are explained in detail in “Programmer

Operating Modes” on page 5-7.

• Program. When initially installing the VM, it allows you to load the vehicle's

identification and fuel control data, similar to encoding data for a card- or key-based Fuel

Management System (FMS). The VM can be re-programmed with new data at any time.

• Edit. This mode allows you to read back data to verify that a VM was programmed

correctly. It can also be used to change partial data in a programmed VM without reentering the entire VM data (as in Program mode).

MDE-4524A Vehicle Module Programming Manual· May 2006 Page 3-1

Page 12

Component Overview Vehicle Module Programmer

• Calibrate. The calibration feature is used initially to automatically calculate the odometer

ratio if it is not known. It is also used periodically to adjust for slight variations between

the odometer or hour meter and the VM.

• Diagnostic. Reads the entire VM and displays the results as a string of data.

• Ver si on . Reads and displays a VM's software revision date.

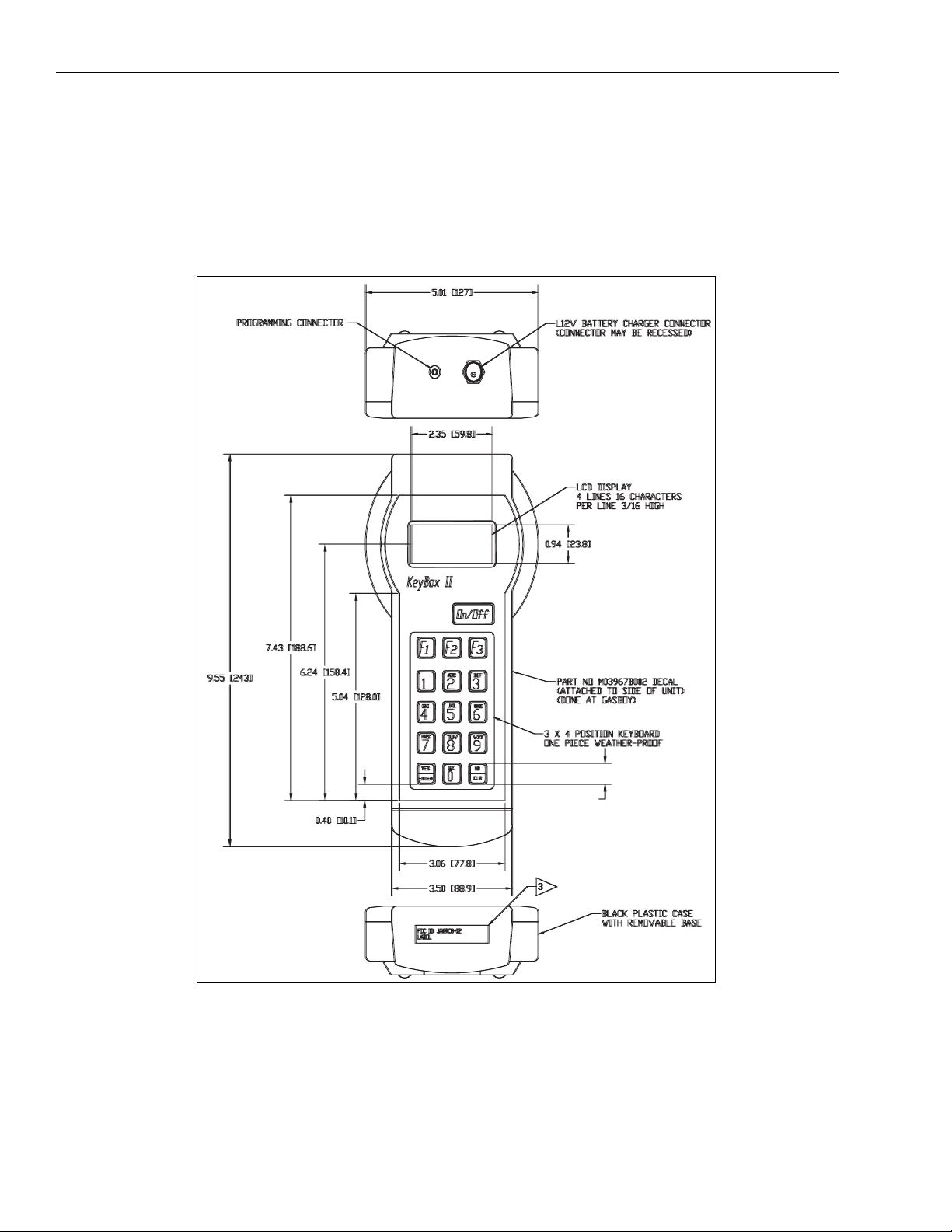

Figure 3-2 M06728A001 VM Programmer with Charger

View from top

Note: New programmer

does not use old

batteries (C09492).

View from below

Page 3-2 MDE-4524A Vehicle Module Programming Manual· May 2006

Page 13

Vehicle Module Programmer Component Overview

Charging the Programmer

Before using your Programmer for the first time, you must charge it overnight. After which the

Programmer and charger should always be plugged into a 115 VAC outlet when not in use to

keep the batteries charged.

Battery Pack Replacement

C06736 Replacement Batteries

In the event that the original batteries fail to hold a charge, Gasboy offers a replacement

battery pack (C09492).

Figure 3-3 C09492 Replacement Battery Pack

M06728A001 Replacement Batteries

The M06728A001 VM Programmer uses 5 commercially available AA Nickel Metal Hydride

(NiMH) batteries. Nickel Cadmium batteries (NiCd) may not be used in this programmer.

Note: The battery pack used in the Fuel Point Programmer may be damaging to the

environment if it is not disposed properly. Gasboy urges you to support your

community's recycling effort.

MDE-4524A Vehicle Module Programming Manual· May 2006 Page 3-3

Page 14

Component Overview Vehicle Module Programmer

This page is intentionally left blank.

Page 3-4 MDE-4524A Vehicle Module Programming Manual· May 2006

Page 15

Vehicle Module Field Descriptions Preparation for Programming

4 – Preparation for Programming

Vehicle Module Field Descriptions

The VM contains various data fields such as vehicle identification, allowable fuel type and

quantity, and miles or hours driven. It is important to understand these fields and their

interaction with the rest of the system. The Programmer is ordered from the factory to match

the base FMS, therefore, some of the fields described below might not be available with every

Programmer. Also, the VM does not use all of the fields that are encoded on a card or key, such

as the restriction digit, which serves no purpose with Fuel Point. Additionally, some of these

fields may be programmed into every VM at a site, but not prompted for during the

programming sequence, either for security reasons, or because the data is always the same.

Default prompts for commonly used fields are shown in parentheses after the field description.

System ID

The System ID is a unique number that identifies your system and safeguards against access

by users of other systems. Your unique System ID is assigned to the Programmer at the

factory; you will not be prompted for it during programming.

Vehicle Module Number (Enter VM Number)

The VM Number is used to identify the VM and is the lockout field used in the fuel

management system. The VM number length is fixed at 5 digits for FleetKey systems and

makes up the entire lockout field. For CFN systems, the VM Number can be up to 8 digits, and

can make up the entire lockout field for bit-mapped lockout, or can be combined with other

fields on the VM for limited lockout.

IMPORTANT INFORMATION

Every VM used at a site must have a unique VM Number because the Fuel Point Reader

uses the VM Number and System ID to monitor on-going transactions to tell if the

nozzle is still inserted into the same vehicle.

MDE-4524A Vehicle Module Programming Manual· May 2006 Page 4-1

Page 16

Preparation for Programming ID Fields

ID Fields

The ID Fields stored in the VM are used to identify the vehicle, driver, department, etc., and

are typically set to match the headings in the transaction printout. There are some differences

between the FleetKey and CFN systems as shown below.

FleetKey

The FleetKey system always has a 5-digit KEY1/VM field which is the main lockout field for

Key and VM transactions, and a 5-digit KEY2 field, which can be used as a secondary lockout

field for keys and not used with the VM. In addition, the FleetKey system can handle up to 8

additional ID Fields up to a maximum of 20 alphanumeric characters.

CFN

The CFN system allows up to 5 unique fields (maximum 19 digits) to make up what is

collectively referred to as the “account number.” When using bit-mapped lockout, the VM

field makes up the entire lockout field. When using limited lockout, the VM field is used for

part of the lockout and the other ID Fields in the account number make up the remainder of

the lockout field.

For CFN only, the VM can contain extra fields that would not be a part of the account field,

and thus not be used for lockout, but still may be stored in the transaction file. These fields can

be stored under the transaction's MANUAL field and, as long as the router fields are not used

for bank networking, they can be stored under the ROUTER field headings. One of the extra

fields can be alphanumeric, and will be stored as a ROUTER STRING in the transaction file.

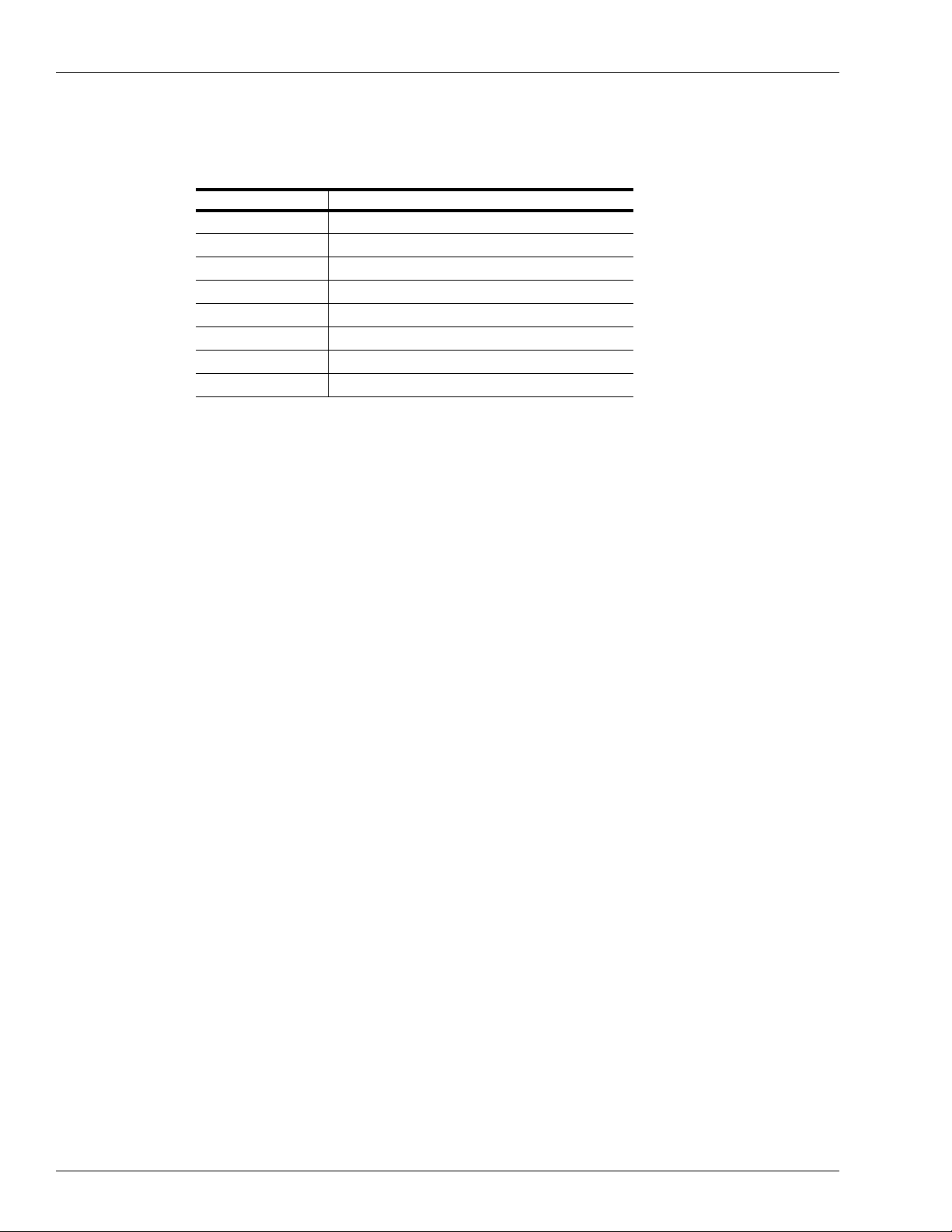

Here is a list of currently available ID Fields and their corresponding three-digit type number.

The type number is used for programming the VM with the Reader Entry fields, as explained

later.

FIELD TYPE FIELD TYPE FIELD TYPE

Account 065 Driver 071 Security 081

Agency 099 Employee 072 Shift 082

Asset 090 Equipment 073 SKU 083

Badge 067 Fleet 074 Social Security 084

Bus 091 Job 066 Stock 085

Card 068 License 075 Tender Type * 095

Charge 079 Manifest 076 Track-II * 222

Clock 069 Manual 077 Trailer 104

Company 107 Participant ID 093 Truck 103

Department 070 Patron 078 Type 100

District 101 PIN 092 Unit 106

Division 089 Reefer 102 Vehicle 086

DIVLOC 088 Route 080 Work Order 087

* These fields require special handling and are explained below.

Page 4-2 MDE-4524A Vehicle Module Programming Manual· May 2006

Page 17

ID Fields Preparation for Programming

Tender Type

For CFN only, the 3-digit Tender Type field is used in conjunction with the Track-II field

explained below. If used, it must come before the Track-II field. If not used, the tender will

default to credit. Refer Point Of Sale and Shift Change Manual C35923.

Track-II

For CFN only, the Track-II field is used to program a VM to match a bank card or some other

non-club card format. When it is used, you typically would not have any of the other ID fields

on the VM. When matching data from an existing card, a field separator character (-) must be

represented as a D on the Programmer.

Reader Entry Fields (RDR FLD 1,2, or 3)

For CFN only, these fields are used to gather identification data from an island or dispenser

card reader, and merge that information with the data stored on the VM. For example, if

multiple drivers share a vehicle, you may want to encode only vehicle data on the VM, and

have employee and department identification entered via keypad or magnetic stripe card. Up

to 3 entries can be required for each VM transaction. These entries can be used as part of the

lockout field.

Each Reader Entry Field is made up of 1 mandatory part, and up to 3 optional parts. When

the Programmer prompts for a Reader Entry Field, you will see 3, 4, 6, or 7 to 26 question

marks, depending on the number of mandatory and optional parts required. Note that for

optional part 2 to be used, optional part 1 must also be present, and for optional part 3 to be

used, optional parts 1 and 2 must be present.

PART LENGTH DESCRIPTION

mandatory 3 ID Field to be

gathered from card

reader; from list

optional 1 1 How data is

gathered; keypad or

magnetic card

optional 2 2 Maximum number

optional 3 1-20 Card reader prompt

of digits to be

gathered; 1 to 19

while gathering data

Mandatory Part

The first 3 question marks prompt for the mandatory part. This is the 3-digit ID Field type for

the data that will be gathered from the card reader.

Optional Part 1

The fourth question mark prompts for the first optional part. If this part is not included (only

three question marks shown), the data field will be entered from the card reader's keypad, the

maximum number of digits gathered from the card reader will be whatever the card reader will

allow (for example, the Gasboy ICR will allow 16 digits), the digits will be shown on the

reader display as entered, and the card reader entry prompt will be the default prompt loaded in

the SCII FUELPT Global Parameters.

MDE-4524A Vehicle Module Programming Manual· May 2006 Page 4-3

Page 18

Preparation for Programming Expiration Date (Enter EXPIRE)

If this part is present, there are 3 possible values:

0 = data will be entered through card reader keypad and the entered data will be shown on the

reader display

1 = data will be entered through the card reader keypad and the data will be shown as asterisks

(*) on the reader display for security purposes

2 = the data will be entered through the card reader via a special Fuel Point card

Optional Part 2

Question marks 5 and 6 prompt for the second optional part. If this part is not included (only 5

question marks shown), the maximum number of digits gathered from the card reader will be

whatever the card reader will allow (for example, the Gasboy ICR will allow 16 digits), and

the card reader entry prompt will be the default prompt loaded in the SCII FUELPT Global

Parameters.

If this part is present, there are 3 possible values:

0 = maximum number of digits gathered will be whatever the card reader will allow

1-16 = maximum number of digits gathered via keypad entry

1-19 = maximum number of digits gathered via a special Reader Entry data card

Optional Part 3

Question marks 7 through 26 prompt for the message to display at the card reader when

prompting for the Reader Entry data. If this part is not present, the prompt at the card reader

will be the default prompt loaded in the SCII FUELPT Global Parameters. If this part is

present, it allows you to enter a card reader prompt unique to each VM. For example, you may

want to have all of the pooled-cars prompt ENTER EMPLOYEE and all of the off-road

vehicles prompt ENTER JOB.

Expiration Date (Enter EXPIRE)

The Expiration Date is assigned to establish a lifetime for the VM. FleetKey uses 4 digits

(YYMM) and CFN systems may use either 4 digits (YYMM) or 2 digits (YY). If programmed

with all zeros in the field, expiration is ignored.

Page 4-4 MDE-4524A Vehicle Module Programming Manual· May 2006

Page 19

Product Limit (Enter LIMIT) Preparation for Programming

Product Limit (Enter LIMIT)

The Product Limit code is used to restrict the maximum quantity of fuel dispensed per

transaction. It is provided as a safeguard to prevent accidental spillage. FleetKey can handle

up to 10 limit codes (0-9), and CFN systems can handle up to 100 (default is 20). The limit

codes do not have to be numbered sequentially. In both systems, not having the limit code on

the VM is the same as if it was on with code 0.

The limit code programmed in the VM is not an actual quantity amount. When your

Authorized Service Representative (ASR) configures your FMS, a table is set up to your

specifications. The table contains limit codes and quantity values assigned to those limit

codes. Limit codes are linked with a type of vehicle and are assigned a quantity just slightly

greater than the vehicle's fuel tank capacity.

Complete Table 4-1, Product Limit Codes, prior to programming the VM. Make sure the

completed table is available at start-up, so it can be loaded into the system at that time.

Photocopy this sheet if you need more space.

Table 4-1: Product Limit Codes

Limit Code Quantity

Product Authorization (Enter AUTH)

This code authorizes the fuel types the vehicle is allowed to access. An authorization code

allows one or more fuel types, also represented as codes. FleetKey can handle up to 9 (1-9)

authorization codes and each code allows up to 5 fuel types. CFN systems can handle up to

100 authorization codes and each code allows up to 100 fuel types (default is 40). In FleetKey,

authorization code 0 always allows all fuel types. In CFN systems, if no fuel types are loaded

for authorization code 0, it will allow all fuel types, otherwise, code 0 will allow the fuel types

loaded. In both systems, not having the authorization code on the VM is the same as if it was

on with code 0.

First, assign a 2-digit fuel code to each of your fuel types, using Table 4-2. Then, assign the

fuel codes to the authorization codes as you require, using Table 4-3. Make sure this

information is available to load into the FMS at start-up. Photocopy these sheets if you need

more space.

MDE-4524A Vehicle Module Programming Manual· May 2006 Page 4-5

Page 20

Preparation for Programming Price Level (Enter PRICE)

Table 4-2: Fuel Code Assignments

Fuel Code Description

Table 4-3: Authorization Assignments

Product Codes

Auth. Code

Allowed

Price Level (Enter PRICE)

Price Level is used only with CFN systems. It enables you to have different prices for each

fuel type. In the system, you have price codes and price levels. One price code is assigned to

each pump hose. Each price code can have multiple price levels. By programming different

price levels into different AM’s, it is possible to charge different prices to different customers

at the same pump. If the VM does not have a price level, the system uses level 2.

For example, suppose pump 1 is assigned price code 1, and price code 1 allows 3 price levels.

The 3 price levels are set as:

level 0 = $1.259

level 1 = $1.219

level 2 = $1.179

One customer may have a VM programmed with price level 1 and another may have price

level 2. The first customer would get charged $1.219, while the second customer gets charged

$1.179 at the same pump.

Page 4-6 MDE-4524A Vehicle Module Programming Manual· May 2006

Page 21

Odometer Or Hours Selection (SEL ODOMETER - 0, HOURS - 1) Preparation for Programming

Make sure the price codes and price levels are loaded during the FMS start-up. Use Table 4-4,

to lay out your price codes and levels. Photocopy this sheet if you need more space.

Table 4-4: Price Code Assignments

Price Level 1 Level 2 Level 3 Level 4 Level 5

Odometer Or Hours Selection (SEL ODOMETER - 0, HOURS - 1)

The odometer or hours data is stored in a counter field. A single VM has 1 counter field, while

a dual VM has 2. The Programmer's Odometer or Hours Selection input prompt determines

whether the counter field following the selection, is used for odometer or for hours. Enter 0 if

the VM is to record odometer or 1 if it is to record engine hours. For a dual VM, the selection

prompt occurs twice, once for each counter.

Each counter field has an associated ratio field, described in detail later in this section, that

contains the number of pulses in a mile (odometer), or the number of time intervals in an hour

(hour meter). The maximum value of the counter field 1 ratio is 640000, and the maximum

counter field 2 ratio is 64000. Since some vehicle's odometer ratios may be higher than 64,000

pulses per mile, counter 1 should be used for odometer and counter 2 used for hours, in a dual

VM. Since a single VM uses only counter field 1, it can be programmed for either odometer or

hours, without worry of ratio limitations.

Odometer or Hours Entry (Enter ODOMETER)

This field allows you to enter decimal number up to 1 decimal place (maximum of 7 digits

before decimal). For odometer, enter the dashboard odometer reading. For hours, enter the

reading from the hour meter.

MDE-4524A Vehicle Module Programming Manual· May 2006 Page 4-7

Page 22

Preparation for Programming Odometer Ratio (Enter ODO RATIO)

Odometer Ratio (Enter ODO RATIO)

The VM receives odometer data as a series of pulses. These pulses may come from sensors

mounted to the transmission, transaxle, or drive shaft, or from circuits in the vehicle's

computer module or cruise control.

IMPORTANT INFORMATION

The vehicle's ABS system must not be used as a source for odometer pulses.

Any Fuel Point Vehicle Modules currently installed must be immediately

disconnected from the ABS system.

With electronic speed transducers, the connection should be made at one of

these locations: at the buffered output side of any vehicle's control modules,

such as the powertrain control module (PCM); or, if buffered output is not

available, at the transmission's speed generator signal wire.

The number of pulses-per-mile is affected by several factors, such as, tire size, axle ratio, and

transmission specifications. Due to all these variances, the VM requires you to program in a

ratio of the number of pulses it is expected to receive per mile. This section helps you to

determine the proper ratio for your particular vehicle. If you do not know the vehicle specs, the

VM Programmer has a calibration feature to help narrow down the correct odometer ratio.

Keep in mind that the ratio for the first counter field has a maximum limit of 640000 and the

maximum ratio for the second counter (for a dual VM) is 64000. For this reason, the first

counter field should be odometer and the second should be hours, when using a dual VM.

Mechanical Odometer Cable

Older vehicles use a mechanical cable to deliver odometer pulses to the dashboard. To allow

the VM to record these pulses, a mechanical transducer should have been purchased and

installed according to the guidelines and restrictions outlined in C35699 Fuel Point Vehicle

Module Installation Manual. The formula for figuring the mechanical odometer ratio is:

Cable revs/mile X sensor pulses/rev

Cable revs per mile is the number of revolutions the mechanical cable turns for each mile.

This number can be found in the transmission specification. Typically it is:

Domestic - 1000 revs/mile

Foreign - 900 revs/mile

Sensor pulses per rev is the number of electronic pulses generated for each revolution of the

sensor input. This is determined by the sensor manufacturer and may be stamped on the

sensor. A common value is 8 pulses/rev.

Page 4-8 MDE-4524A Vehicle Module Programming Manual· May 2006

Page 23

Odometer Ratio (Enter ODO RATIO) Preparation for Programming

Therefore, the typical odometer ratio for a domestic vehicle is 8000 pulses/mile and for a

foreign vehicle it is 7200 pulses/mile. Use these values for the VM odometer ratio if you are

not sure of the exact values.

Electronic Odometer

On new vehicles, the odometer signal to the VM is tapped off an existing sensor or

speedometer signal from an electronic circuit. Several ways to figure the electronic odometer

ratio are shown below:

• Match working vehicle. If a previously equipped vehicle has accurate odometer data in

the VM, use the same ratio for all other vehicles in the fleet with the same specs.

• Use published ratio. If the VM odometer input is a conditioned signal coming from the

vehicle's computer module or cruise control, the manufacturer's wiring diagram may show

the number of pulses per mile it is generating. These values are typically round numbers

such as 10,000, 20,000, or 40,000.

Figure 4-1

Sample Wiring Diagram. Notice Pulses Per Mile.

IGNITION

VEHICLE

SPEED

INPUT

4000 PULSES

PER MILE

INSTRUMENT

CLUSTER

ELECTRONIC CONTROL MODULE

VEHICLE

SPEED

INPUT

(ECM)

2000 PULSES

PER MILE

VEHICLE

SPEED

SENSOR

PERMANENT

MAGNET

GENERATOR

4000 PULSES

PER MILE

VEHICLE

SPEED

INPUT

CRUISE

CONTROL

MODULE

• Use engine computer ratio. Today’s over-the-road trucks have smart engines allowing

you to view and adjust many performance parameters through the diagnostic port. If the

VM odometer signal is tapped off from the same signal source as the dashboard

speedometer, you can use the speedometer ratio stored in the engine computer for the VM

odometer ratio.

• Calculate from vehicle specs. If the VM odometer receives input directly from the

speedometer sensor mounted in the transmission, you may be able to calculate the correct

ratio using specs from the vehicle manufacturer.

MDE-4524A Vehicle Module Programming Manual· May 2006 Page 4-9

Page 24

Preparation for Programming Odometer Ratio (Enter ODO RATIO)

Figure 4-2

SENSOR

OUTPUT

VOLTAGE

Sample Speedometer Circuit

SPEEDOMETER

SENSOR

TRANSMISSION

MAGNETIC

FIELD

SPEEDOMETER

Although there are variations among manufacturers and vehicle types, a typical speedometer

system on a rear-drive-axle vehicle is described here. A gear, usually called the speedometer

signal gear, is mounted to the output shaft of the transmission. The speedometer sensor is

mounted to the transmission so that its tip is in close proximity to the signal gear's teeth. A

permanent magnet located in the speedometer sensor establishes a magnetic field at the tip.

The magnetic field is repeatedly cut by the teeth on the signal gear, creating alternating current

voltage impulses that are transmitted to the speedometer. The frequency and amplitude of the

signal is directly proportional to the speed of the signal gear. The speed of the signal gear is

determined by the rotation of the drive shaft, which is determined by the drive axle ratio and

tire size. Therefore, the number of pulses-per-mile from the speedometer sensor is calculated

from the formula:

# teeth on signal gear X tire revs/mile X drive axle ratio

# of teeth on signal gear is found in the transmission specifications. A typical number of teeth

is 16.

Tire revs per mile can be found in the tire manufacturer's spec sheet. These figures are

standard throughout the tire industry. For example, a new 12.00 R 20 tubeless tire turns 470

revolutions per mile.

Page 4-10 MDE-4524A Vehicle Module Programming Manual· May 2006

Page 25

Odometer Ratio (Enter ODO RATIO) Preparation for Programming

Figure 4-3

Sample Truck Tire Size Chart

TUBE TIRES TUBELESS TIRES

Tire Size Revs

Per Mile

Tire Size

Revs

Per Mile

Drive axle ratio can be found in the manufacturer's line setting ticket, and also on a tag

attached to the differential assembly on rear wheel drive vehicles.

Figure 4-4 Sample Line Setting Ticket

Drive axle

ratio

MDE-4524A Vehicle Module Programming Manual· May 2006 Page 4-11

Page 26

Preparation for Programming Hours Ratio (Enter ODO Ratio)

Figure 4-5 Sample Rear Differential Showing Axle Ratio Marking

SN 622451A

16645837C95 502CA200--4Z

Example:

Signal gear teeth = 16

Tire size = 10.00 R 20 = 502 revs/mile

Axle ratio = 3.41:1

Ratio = 16 x 502 x 3.41

= 27,389 (drop the decimal places)

• Use programmer's calibration feature. If you cannot figure the odometer ratio using any

method listed above, just enter any number and let the VM Programmer's calibration

feature narrow down the correct ratio. This method may require several calibrations to get

a good ratio, and the vehicle may have to travel several hundred miles between the

calibrations. Start with a number between 10,000 and 100,000.

RATIO 4.78

Hours Ratio (Enter ODO Ratio)

The VM counts time in increments of approximately 128ms, therefore the hours ratio is fixed

at 28,000 pulses-per-hour. Regardless of what is entered for this ratio, the VM automatically

changes it to 28,000. You should just press the ENTER key for the ratio prompt of an hours

counter.

Dual Counters (DUAL COUNTERS, NO - 0, YES - 1)

This field determines if the Programmer prompts for a second counter (odometer or hours)

field. Enter 0 for a single VM or 1 for a dual VM.

Page 4-12 MDE-4524A Vehicle Module Programming Manual· May 2006

Page 27

Vehicle Module Program Data Sheet Preparation for Programming

Vehicle Module Program Data Sheet

As you can see, there are many fields that may be programmed into a VM. It is helpful to write

all of the data to be programmed into a chart that you can take out to the vehicle. Here is a

sample of a chart with the data filled in. On the next page is a blank chart, you can tailor to

your system.

VM

NUMBER

1374 288 AJY6755 8 1 ODOM 8000 HRS N/A

1375 1644 TAM 0 6 93 6 2 ODOM 26000 HRS N/A

1376 108 TL1999 3 4 ODOM 40000 HRS N/A

1377 5766 SRL5320 3 4 ODOM 40000 N/A N/A

VEHICLE

NUMBER

LICENSE

PLATE

LIMIT

CODE

AUTH

CODE

COUNTER

1 TYPE

COUNTER

1 RATIO

COUNTER

2 TYPE

COUNTER

2 RATIO

MDE-4524A Vehicle Module Programming Manual· May 2006 Page 4-13

Page 28

Preparation for Programming Vehicle Module Program Data Sheet

VM

NUMBER

VEHICLE

NUMBER

LICENSE

PLATE

LIMIT

CODE

AUTH

CODE

COUNTER

1 TYPE

COUNTER

1 RATIO

COUNTER

2 TYPE

COUNTER

2 RATIO

Page 4-14 MDE-4524A Vehicle Module Programming Manual· May 2006

Page 29

Ground Loop Communications Operation

5 – Operation

Ground Loop Communications

If the vehicle has been wired for ground loop fueling, the T-Ring is connected to the VM's

Gate connectors. The Programmer modes: Program, Edit, Calibrate, and Version will not work

via the VM's Gate connectors. The Programmer can access those modes only through the

VM's T-Ring connectors. There are two ways to accomplish this:

• Use a spare T-Ring with a long cable attached. The cable connects to the T-Ring

connectors on the VM. There is no need to disconnect the VM’s Gate ring. The

Programmer can now use any mode to access the VM via the temporary T-Ring. When

finished, disconnect the T-Ring so that it can be used to check other vehicles.

• At the VM, move the ring wires from the Gate connectors to the T-Ring connectors. Any

Programmer mode can be accessed via the vehicle's gate ring mounted to the underside of

the vehicle. When finished using the Programmer, move the ring wires back to the Gate

ring connectors on the VM.

Note: The Programmer's Diagnostic mode can be accessed from a ring at either the Gate or

T-Ring connectors.

General Programmer Operation

This section describes the standard operating style of the VM Programmer common to all

operating modes. In the text, YES and ENTER refer to the key labeled YES/ENTER; NO

and CLR refer to the key labeled NO/CLR.

Turning On Programmer

Turning Off Programmer

To turn the Programmer on, press and hold the Enter key (in C06736 VM Programmer with

Charger) or On/Off key (in M06728A001 VM Programmer with Charger) until the main

menu appears.

On/Off

Press the CLR and 3 keys simultaneously (in C06736 VM Programmer with Charger) or

On/Off key (in M06728A001 VM Programmer with Charger) to turn the Programmer off. To

conserve battery power, the Programmer also shuts itself off when it has completed

programming or calibrating a VM, or when there is no keypad activity for 100 seconds.

MDE-4524A Vehicle Module Programming Manual· May 2006 Page 5-1

Page 30

Operation General Programmer Operation

Mode Selection

After the Programmer is turned on, the first menu, showing modes 1 through 4 is displayed.

Within 4 seconds, the second menu, showing mode 5, is displayed. The Programmer toggles

between menus every 4 seconds, or you can manually switch menus by pressing ENTER. To

select a mode, press the mode number followed by ENTER. Selection can be made for any

mode even when the display is not currently showing its associated menu

_

_

DIAG ?

?

1

YES

ENTER

_

1 PROG 2 EDIT

_

3 CAL 4

5 -- VERS

ENTER VM NUMBER:

522748_

Accepting Old Data and Clearing the Display for New Data Entry

The Programmer saves previously entered data for the Program and Edit modes. When

stepping through these modes, that data is displayed for each field so that you can just press

ENTER to keep the data as-is and advance to the next field. If you need to change any data

within a field, you must press the CLR key first, to clear the field for new data entry. Then

press the ENTER key to save the change. In order to avoid repetition throughout this manual,

most subsequent example sequences starts with the field already cleared.

Note: If you make any mistake while typing the data, you can press the CLR key to go back to

the beginning of the current field, then type the correct data.

ENTER VM NUMBER:

5001

YES

ENTER

NO

CLR

ENTER DIVISION:

006442

ENTER LICENSE:

TAM0693

ENTER LICENSE:

???????_

Page 5-2 MDE-4524A Vehicle Module Programming Manual· May 2006

Page 31

General Programmer Operation Operation

Entering Numeric Data

On the keypad, press the number that you want to enter into the field. If there are multiple

digits within a field, the cursor automatically advances to the next position. After all digits

have been entered, press ENTER to advance to the next field. If you press ENTER before all

data has been entered, it will fill the un-entered most significant digits with zeros, then

advance to the next field. For example, to enter the number 16 into a 4-digit field, type 1, 6,

ENTER. The data will be stored as 0016.

ENTER VEHICLE:

1

1?

??

MNO

6

YES

ENTER

ENTER VEHICLE:

16?

ENTER LIMIT:

5_

Entering Alphanumeric Data

On the keypad, the keys 2 through 0 have letters above the numbers. While entering data into

an alphanumeric field, the first time you press a number, it shows that number, but the cursor

does not advance to the next position. The second time you press the same number, it shows

the first letter marked above the number. Pressing it again shows the second letter, and

pressing it a fourth time shows the third letter. An alphanumeric field can have any

combination of letters and numbers. In an alphanumeric field, you must press the ENTER key

to advance the cursor. After all characters have been entered, press ENTER to advance to the

next field. If you press ENTER before all data has been entered, it will fill the un-entered most

significant characters with zeros, then advance to the next field. For example, to enter the

string A37R into a six character field, type:

2, 2, ENTER, 3, ENTER, 7, ENTER, 7, 7, 7, ENTER, ENTER.

?

The data is stored as 00A37R.

MDE-4524A Vehicle Module Programming Manual· May 2006 Page 5-3

Page 32

Operation General Programmer Operation

Alphanumeric fields are not standard and must be specified while ordering the Fuel Point and

Fuel Management System from the factory.

ABC

ABC

YES

ENTER

DEF

3

YES

ENTER

PRS

7

YES

ENTER

PRS

7

PRS

7

ENTER VEHICLE:

2

ENTER VEHICLE:

2

ENTER VEHICLE:

ENTER VEHICLE:

ENTER VEHICLE:

ENTER VEHICLE:

ENTER VEHICLE:

ENTER VEHICLE:

ENTER VEHICLE:

2?????

?????

A

A?

????

????

A3

???

A3?

A37

???

A37?

A377

A37P

??

??

??

PRS

7

YES

ENTER

YES

ENTER

ENTER VEHICLE:

??

A37R

ENTER VEHICLE:

A37R?

ENTER LIMIT:

?

5_

Page 5-4 MDE-4524A Vehicle Module Programming Manual· May 2006

Page 33

General Programmer Operation Operation

Entering Spaces and Special Characters

If the VM is set up to store the reader prompt for the Reader Entry Fields, you will probably

need to enter spaces and other characters for the message. On the Programmer, the 1 key

scrolls through a list of available characters. When entering data into an alphanumeric field,

the first time you press the 1 key, it shows as 1. After that, the 1 key shows a different

character each time it is pressed, until it gets back to 1. Press ENTER to select one of the

special characters as it is displayed. The special characters available are:

SPACE

# number sign

?question mark

^ caret

. period/decimal point

- hyphen

,comma

ENTER RDR FLD 1:

066008ENTER?

ENTER RDR FLD 1:

1

066008ENTER1

ENTER RDR FLD 1:

1

066008ENTER

ENTER RDR FLD 1:

1

066008ENTER#

ENTER RDR FLD 1:

1

066008ENTER?

ENTER RDR FLD 1:

1

066008ENTER^

ENTER RDR FLD 1:

1

066008ENTER.

ENTER RDR FLD 1:

1

066008ENTER-????

????

????

????

????

????

????

????

ENTER RDR FLD 1:

1

066008ENTER,

ENTER RDR FLD 1:

1

066008ENTER_????

ENTER RDR FLD 1:

YES

ENTER

066008ENTER ?

MDE-4524A Vehicle Module Programming Manual· May 2006 Page 5-5

????

???

Page 34

Operation General Programmer Operation

Entering Odometer or Hours Data

The odometer and hours fields (generically referred to as the counter fields), allow entry of 7

whole digits plus tenths.

DEF

3

ENTER ODOM [1]

???????.3

PRS

ENTER ODOM [1]

7

MNO

6

ENTER ODOM [1]

TUV

ENTER ODOM [1]

8

GHI

ENTER ODOM [1]

4

MNO

ENTER ODOM [1]

6

YES

ENTER

ENTER ODO RATIO

Editing Within a Field

To edit data within a field, press the CLR key to set the cursor back one space. It has now

erased the data previously entered in that position. Each subsequent press of the CLR key sets

the cursor back another space. Once you get to the position you want, start entering the correct

data.

??????3.7

?????37.6

????376.8

???3768.4

??37684.6

?

?????

ABC

2

MNO

6

TUV

8

NO

CLR

NO

CLR

JKL

5

Page 5-6 MDE-4524A Vehicle Module Programming Manual· May 2006

ENTER ODO RATIO

2?????

ENTER ODO RATIO

26????

ENTER ODO RATIO

26B???

ENTER ODO RATIO

26????

ENTER ODO RATIO

2?????

ENTER ODO RATIO

25????

Page 35

Programmer Operating Modes Operation

Programmer Operating Modes

Program Mode

When the VM is initially installed, the Program Mode allows you to load the vehicle's

identification and fuel control data, similar to encoding data for a card- or key-based FMS.

Since the programmer is set up at the factory, it prompts for the fields, needed for the VM to

work at each specific site. An explanation of the fields that may be used is given in the

previous section. The VM can be re-programmed with new data at any time.

Here is a typical programming session incorporating all of the items previously discussed.

Your Programmer may be set up differently than the examples. Just key in the data for your

particular situation as prompted on the Programmer display. Remember, if at any time you

make a mistake typing the data, you can press the CLR key to go back to the beginning of the

current field, then type the correct data.

1 Take the completed VM Program Data sheet out to the vehicle.

2 Turn on the Programmer. Refer to “Turning On Programmer” on page 5-1.

3 Select Program mode.

1

4 Enter the VM number.

1

5 Enter the Vehicle number.

ABC

2

YES

ENTER

DEF

3

TUV

8

1 - PROG 2 - EDIT

3 - CAL 4 - DIAG ?

PRS

7

TUV

8

GHI

4

YES

ENTER

YES

ENTER

ENTER VEHICLE:

ENTER VM NUMBER:

288???

1374?

MDE-4524A Vehicle Module Programming Manual· May 2006 Page 5-7

Page 36

Operation Programmer Operating Modes

6 Enter the License number.

Note: Since this is an alphanumeric field, you must press ENTER to advance to the next

character position.

7 Enter the Limit code.

TUV

8

8 Enter the Authorization code.

1

9 Odometer is the first field counter that appears.

QZ

0

10 When programming a newly installed VM, it is a good idea to test the installation. Press

YES

ENTER

YES

ENTER

YES

ENTER

ENTER LIMIT:

8

ENTER AUTH.

1

SEL ODOMETER - 0

0_ HOURS - 1

ENTER at the following prompt to set the odometer at 0000000.0. The correct initial reading

of the odometer is loaded after testing the odometer connection.

YES

ENTER

Page 5-8 MDE-4524A Vehicle Module Programming Manual· May 2006

ENTER ODOM [1]

???????.?

Page 37

Programmer Operating Modes Operation

11 Enter 1 as the ratio. This allows a quick way to test if the VM is recording pulses, without

having to drive very far.

1

12 This is a dual VM.

1

13 The second field is hours.

1

14 Since you want to test the installation, enter an engine hours reading that ends in 0.9 (0.9 hours

YES

ENTER

YES

ENTER

YES

ENTER

ENTER ODO RATIO:

1????

DUAL COUNTERS 1

NO - 0 YES - 1

SEL: ODOMETER - 0

SCND 1

HOURS - 1

equals 54 minutes). That way, you only have to wait 6 minutes to verify that the engine hours

connection is functioning. The correct starting hours reading will be loaded after testing.

1

15 Hold the Programmer near the vehicle's T-Ring. If the vehicle is equipped with two T-Rings,

ABC

2

DEF

3

WXY

9

YES

ENTER

PRESET TIME [2]

[H] ????123.9

perform the programming at one ring, then use the second ring while Testing the Programmed

VM steps. This allows testing of both ring circuits.

HOLD PROGRAMMER

NEAR TANK RING

IMPORTANT INFORMATION

IMPORTANT INFORMATION

The Programmer cannot program a VM for engine hours when the vehicle is

running. Ensure the vehicle is shut off during Programming.

MDE-4524A Vehicle Module Programming Manual· May 2006 Page 5-9

Page 38

Operation Programmer Operating Modes

16 When communications is established, a series of beeps will be heard. Continue to hold the

Programmer near the T-Ring. Programming takes about 15 seconds.

TRANSMITTING

PLEASE WAIT

17 When programming is complete, you will hear a long beep.

TRANSMISSION

COMPLETE

18 The Programmer turns off automatically

Testing the Odometer/Hours Operation

1 Since the odometer ratio was programmed as 1, you only need to back the car up about 10 feet,

then forward again, to make the VM think you drove many miles. Since this particular vehicle

is also recording engine hours, you need to let it idle for at least 6 minutes to get the VM to

increment to the next hour.

!

DANGER

To avoid the build-up of deadly carbon-monoxide gas, DO NOT idle the vehicle in an

enclosed area.

2 Turn on the Programmer. Refer to “Turning On Programmer” on page 5-1.

3 Select Calibrate mode. We are only using Calibrate mode here because we know the odometer

data is incorrect. The sequence presented here does not use Calibrate mode features for

determining the correct ratio and resetting the initial counters. These features are explained

later in the Calibrate Mode section.

DEF

3

YES

ENTER

1 - PROG 2 - EDIT

3 - CAL 4 - DIAG ?

Page 5-10 MDE-4524A Vehicle Module Programming Manual· May 2006

Page 39

Programmer Operating Modes Operation

4 Hold the Programmer near the vehicle's T-Ring. If the vehicle is equipped with two T-Rings,

use a different ring than used earlier, in order to check both rings.

HOLD PROGRAMMER

NEAR TANK RING

IMPORTANT INFORMATION

The Programmer cannot calibrate a VM with engine hours when the vehicle is

running. Ensure the vehicle is shut off during Calibrate mode.

5 When communication is established, a series of beeps will be heard. Continue to hold the

Programmer near the T-Ring. It takes about 5 seconds to read the data.

TRANSMITTING

PLEASE WAIT

6 As we want to check both counters, select 2.

ABC

2

7 The display now shows the counter 1 odometer data. The number on the top line represents the

YES

ENTER

SEL CALIB: 1ST - 0

2ND - 1 BOTH - 2 ?

initial programmed whole odometer. The bottom left shows the ratio, and the bottom right

shows the current VM odometer. If the current VM odometer is greater than the initial

odometer, you have verified that the odometer circuit is functioning properly. Now you can

program in the correct starting odometer.

YES

ENTER

LAST[1]? 0000000

000001.0 0000124

Note: If the current VM odometer does not change, check the VM installation.

8 Enter the dashboard odometer reading.

ABC

2

GHI

1

4

MDE-4524A Vehicle Module Programming Manual· May 2006 Page 5-11

MNO

6

PRS

7

TUV

8

YES

ENTER

ENTER ODOM [1]

??26841.7

Page 40

Operation Programmer Operating Modes

9 Press 1, since we want to change the ratio as well as the odometer.

1

10 The calculated ratio shown is incorrect because the initial data loaded was just test data. Press

YES

ENTER

MILEAGE ONLY - 0

COUNT RATIO -1 1

NO, since you do not want to accept the calculated ratio.

NO

CLR

11 Enter the correct odometer ratio, if known. If you do not know the correct ratio, enter a number

RAT 000001.0 OLD

? 000000.2 NEW

between 8000 and 100000.

8

00

0

YES

ENTER

ENTER ODOMETER

RATIO 8000??

Note: Keep in mind that this ratio is an estimate and may be incorrect. When this testing

procedure is complete, take a short (3-4 mile) test drive. This should provide enough

data to provide a closer ratio. Then redo the testing procedure using the new number.

Enter YES to accept the calculation ratio at Step 10.

12 The top line shows the newly entered odometer and ratio. Press ENTER if these are correct.

YES

ENTER

13 The display now shows the counter 2 hours data. Similar to counter 1 above, the top line

ODOMETER 0026841

RATIO 008000 ?

displays the initial hour entry, and the bottom line shows the ratio on the left (always 28000 for

hours), and the current hours on the right. If the current VM hours is greater than the initial

hours, you have verified that the engine hours circuit is functioning properly. Now you can

program in the correct starting engine hours.

YES

ENTER

LAST[2]? 0000000

28000.0 0000124

Note: If the VM hours does not change, check the VM installation.

Page 5-12 MDE-4524A Vehicle Module Programming Manual· May 2006

Page 41

Programmer Operating Modes Operation

14 Enter the hour meter reading, including tenths if present. Remember to enter leading zeros as

necessary. If there is no hour meter, just press 0, then ENTER to start the hours counter at

zero.

GHI

4

0

15 Hold the Programmer near the vehicle's T-Ring.

HOLD PROGRAMMER

NEAR TANK RING

16 When communications is established, a series of beeps will be heard. Continue to hold the

JKL

5

0

MNO

6

YES

ENTER

PRESET TIME [2]

[H] ???4560.0

Programmer near the T-Ring. Programming takes about 5 seconds.

TRANSMITTING

PLEASE WAIT

17 When programming is complete, you will hear a long beep.

Edit Mode

TRANSMISSION

COMPLETE

18 The Programmer turns off automatically.

Before continuing, you can use Edit Mode to verify that the data you entered during Program

Mode is correct. This mode will display all VM data except for the counter data. The counter

data is available via Calibrate Mode, which will be explained later.

1 Turn on the Programmer. Refer to “Turning On Programmer” on page 5-1.

2 Select Edit mode.

ABC

2

YES

ENTER

1 - PROG 2 - EDIT

3 - CAL 4 - DIAG ?

MDE-4524A Vehicle Module Programming Manual· May 2006 Page 5-13

Page 42

Operation Programmer Operating Modes

3 Hold the Programmer near the vehicle's T-Ring. A series of beeps will be heard while the

Programmer gathers the data.

HOLD PROGRAMMER

NEAR TANK RING

4 The Programmer displays the first field. If you do not want to make any changes, press the

ENTER key to advance to the next field.

YES

ENTER

ENTER VM NUMBER:

00288

ENTER VEHICLE:

5931

5 To make changes, press the CLR key to clear the data, then enter the new data. When finished,

press ENTER to advance to the next field.

NO

CLR

JKL

5

DEF

3

9

1

YES

ENTER

6 Make changes to as many fields as necessary. Once all fields have been accepted, hold the

ENTER VEHICLE:

????

ENTER VEHICLE:

5931

Programmer near the T-Ring.

YES

ENTER

YES

ENTER

ENTER LIMIT:

8

ENTER AUTH:

2

HOLD PROGRAMMER

NEAR TANK RING

7 A series of beeps will be heard while the VM is being Programmed.

8 When programming is complete, a long beep will be heard.

9 The Programmer turns off automatically.

Page 5-14 MDE-4524A Vehicle Module Programming Manual· May 2006

Page 43

Programmer Operating Modes Operation

Calibrate Mode

Calibrate mode is used initially to automatically calculate the odometer ratio if it is not known.

It is also used periodically to adjust for slight variations between the odometer and the VM. If

any of the counter fields is used for engine hours, you do not need to perform calibration, as

the VM keeps very accurate time.

Odometer Calibration

1 Turn on the Programmer. Refer to “Turning On Programmer” on page 5-1.

2 Select Calibrate mode.

DEF

3

3 Hold the Programmer near the vehicle's T-Ring.

HOLD PROGRAMMER

NEAR TANK RING

YES

ENTER

1 - PROG 2 - EDIT

3 - CAL 4 - DIAG ?

IMPORTANT INFORMATION

The Programmer cannot calibrate a VM with engine hours when the vehicle is

running. Ensure that the vehicle is shut off during Calibrate mode.

4 When communication is established, a series of beeps will be heard. Continue to hold the

Programmer near the T-Ring. It takes about 5 seconds to read the data.

TRANSMITTING

PLEASE WAIT

5 The Programmer prompts you to select the VM counter which you want to update. Since the

ST

odometer is typically connected to counter 1, select 1

QZ

0

MDE-4524A Vehicle Module Programming Manual· May 2006 Page 5-15

YES

ENTER

SEL CALIB: 1ST - 0

2ND - 1 BOTH - 2 ?

.

Page 44

Operation Programmer Operating Modes

6 The display now shows the counter 1 (odometer in this example) data. The number on the top

line represents the initial programmed whole odometer. The bottom left shows the ratio, and

the bottom right shows the current VM odometer. If the true ratio was not known at the time

the VM was installed, the current VM odometer probably does not match the dashboard

odometer.

LAST[1]? 0023896

008000.0 0026432

The longer a vehicle is driven, the more accurate the calibration calculation becomes. For a

very accurate calibration, run the calibration, then drive the vehicle for the duration of your

normal scheduled vehicle maintenance. Then check calibration for accuracy. Change ratio if

needed according to the criteria in Step 7.

7 At this point you need to determine if you will make any changes to the odometer and/or ratio,

based on the criteria that follows:

• If the current VM odometer matches the dashboard odometer, you do not need to make

any changes. If this is a Single VM (only 1 counter field), you can turn the Programmer off

and end this session. If it is a dual VM and counter 2 is used for odometer, press ENTER

twice to advance to counter field 2. Perform these same three criteria checks on counter

field 2.

LAST[1]? 0023896

008000.0 0026432

26431 8

VM matches dashboard

• If the difference between the current VM odometer and dashboard odometer is within 1

percent the total dashboard miles driven so far, the ratio is already very accurate and you

only need to update the mileage, not the ratio. Proceed to the section

Odometer Only” on page 5-17.

“Updating the

LAST[1]? 0023896

008000.0 0026418

26431

8

VM within 1% of dashboard

• If the difference between the current VM odometer and the dashboard odometer is greater

than 1percent of the total dashboard miles driven so far, you need to update both mileage

and ratio. Proceed to the section

“Updating the Odometer and Ratio” on page 5-17.

LAST[1]? 0023896

008000.0 0026204

26431

8

VM greater than 1% of dashboard

Page 5-16 MDE-4524A Vehicle Module Programming Manual· May 2006

Page 45

Programmer Operating Modes Operation

Updating the Odometer Only

1 Press ENTER to advance to the odometer input field.

YES

ENTER

2 Enter the dashboard odometer, including tenths if present. Remember to enter leading zeros as

ENTER ODOM [1]

???????.?

necessary.

ABC

2

DEF

3

3 Select 0 since you do not want to change the ratio. Proceed to the section “Download New

1

MNO

6

TUV

8

GHI

4

YES

ENTER

ENTER ODOM [1]

??26431.8

Calibration Data to VM” on page 5-18.

QZ

0

YES

ENTER

MILEAGE ONLY - 0

COUNT RATIO -1 0

Updating the Odometer and Ratio

1 Press ENTER to advance to the odometer input field.

YES

ENTER

2 Enter the dashboard odometer, including tenths if present. Remember to enter leading zeros as

necessary.

DEF

3

ENTER ODOM [1]

???????.?

ABC

2

1

MNO

6

TUV

8

GHI

4

YES

ENTER

ENTER ODOM [1]

??26431.8

MDE-4524A Vehicle Module Programming Manual· May 2006 Page 5-17

Page 46

Operation Programmer Operating Modes

3 Select 1 to allow the Programmer to calculate the correct ratio.

YES

1

4 Press YES to accept the calculated ratio. Proceed to Download New Calibration Data to VM.

ENTER

YES

ENTER

RAT 008000.0 OLD

? 007281.0 NEW

MILEAGE ONLY - 0

COUNT RATIO -1 1