Page 1

MDE-486

8F

Fuel Point PLUS

Vehicle Installation and Configuration Manual

This document is based on Orpak’s FuelOmat Gold Vehicle Installation

and Configuration Manual P/N 817407300

Page 2

SAFETY CONSIDERATIONS

Read all warning notes and instructions carefully. They are included to help you installing the Product safely

in the highly flammable environment of the fuel station. Disregarding these warning notes and instructions

could result in serious injury or property damage. It is the installer responsibility to install, operate and

maintain the equipment according to the instructions given in this manual, and to conform to all applicable

codes, regulations and safety measures. Failure to do so could void all warranties associated with this

equipment.

Remember that the fuel station environment is highly flammable and combustible. Therefore, make sure

that actual installati

a flammable environment, according to the local regulations and relevant standards.

on is performed by experienced personnel, licensed to perform work in fuel station and at

WARNING - EXPLOSION HAZARD

Read all warning notes and instructions carefully. They are included to help you installing the Fuel

Ring equipment safely in the highly flammable environment of the vehicle fuel tank. Disregarding

these warning notes and instructions could result in serious injury or property damage. It is the

installer responsibility to install, operate and maintain the equipment according to the instructions

given in this manual, and to conform to all applicable codes, regulations and safety measures.

Failure to do so could void all warranties associated with thi

s equipment.

Remember that the fuel vehicle fuel tank is highly flammable and combustible. Therefore, make

sure that actual installation is performed by experienced personnel, licensed to perform work in

fuel stations, cars and highly flammable environments.

When working on fuel tank inlet, make sure it is completely empty and closed.

The fumes are volatile and hence harmful to your health, if breathed for an extended period.

WARNING – PASSING VEHICLES

When working in any open area of vehicle fuel tank, beware of passing vehicles that could hit you.

Block off the work area to protect yourself and other persons. Use safety cones or other signaling

devices.

WARNING

Components substitutions could impair intrinsic safety.

Attaching unauthorized components or equipment will void your warranties.

CAUTION

Do not attempt to make any repair on the printed circuit boards residing in the Product, as this will

void all warranties related to this equipment.

Page 3

WARNING

When using the glue, carefully use and apply the glue over the surfaces in order to prevent any glue

leakage on the vehicle, to avoid any damage to the vehicle.

PROPRIETY NOTICE

This document contains propriety and confidential information. It is the property of ORPAK

SYSTEMS Ltd. It may not be disclosed or reproduced in whole or in part without written consent

of ORPAK SYSTEMS. The information in this document is current as of the date of its

publication, but is subject to change without notice.

DISCLAIMER

This document is provided for reference only. Although every effort has been made to ensure

correctness, ORPAK SYSTEMS does not guarantee that there are no errors or omissions in this

document.

FCC Compliance Statement

The FCC Wants You to Know:

This equ

device, pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment generates uses

and can radiate radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this equipment does cause

harmful interference

equipment off and on, the user is encouraged to try to correct the interference by one or more of

the following

a) Reorient or relocate the receiving antenna.

b) Increase the separation between the equipment and receiver.

c) Connect the equipment to an outlet on a circuit different from that to which the receiver is

connected.

d) Consult the dealer or an experienced radio/TV technician.

Modifications not expressly approved by the manufacturer could void the user authority to operate

the equipment under FCC Rules.

ipment has been tested and found to comply with the limits for a Class B & C digital

to radi

measures :

o or television reception, which can be determined by turning the

FCC Warning

Page 4

Fuel Ring programming must be done prior to its

installation on the fuel inlet, since the WP (Wireless

Programmer) is not designed for explosive

environments.

WARNING

Wireless Nozzle Reader programming must be done

in a safe area, since the WNRP (Wireless Nozzle

Reader Programmer) is not designed to be use in the

Hazardous Locations.

ATEX Intrinsic Safety Certification

Wireless Nozzle Readers Type (WNR-2 as well) 1, 2 & 3 p/n 800939055, 800939056 & 800939057 have been

issued with an EC-Type Examination Certificate ISSeP09ATEXnnn. This confirms compliance with the

European ATEX Directive 94/9/EC for Group II, Category 1G, II 1 G Ex ia IIB T4 Ga

This image c annot current ly be displayed.

ATEX Intrinsic Safety Certification

Wireless Nozzle Readers Type (WNR-2 as well) 1, 2 & 3 p/n 800939055, 800939056 & 800939057 have been

issued with an EC-Type Examination Certificate ISSeP09ATEXnnn. This confirms compliance with the

European ATEX Directive 94/9/EC for Group II, Category 1G, II 1 G Ex ia IIB T4 Ga

Used Standards:

WARNING

- IEC 60079-0 : General requirements,

- IEC 60079-11 : Equipment protection by intrinsic safety 'i' ,

- IEC 60079-26 : Equipment with equipment protection level (EPL) Ga,

This document is the property of:

ORPAK SYSTEMS Ltd.

ISRAEL

Page 5

Fuel Point PLUS Vehicle Installation and Configuration Manual

V

TABLE OF CONTENTS

Paragraph

SECTION 1

INTRODUCTION

Page

1-1. SCOPE ................................................................................................................................ 13

1-2. FUEL POINT PLUS SYSTEM DESCRIPTION ............................................................... 13

1-3. MANUAL STRUCTURE .................................................................................................. 14

1-4. USING THIS MANUAL.................................................................................................... 14

1-5. REFERENCES ................................................................................................................... 15

SECTION 2 FUEL RING DESCRIPTION &

INSTALLATION

2-1. OVERVIEW ....................................................................................................................... 16

2-1.1. Fuel Ring Main Components ......................................................................................... 16

2-2. TYPICAL INSTALLATION KITS ................................................................................... 17

2-3. FUEL RING COILS ........................................................................................................... 19

2-3.1. Shaped Coil .................................................................................................................... 19

2-3.2. Self Installed Coil .......................................................................................................... 20

2-3.3. Molded Coil ................................................................................................................... 21

2-4. VEHICLE SURVEY .......................................................................................................... 22

2-5. LIGHT VEHICLES INSTALLATION .............................................................................. 23

2-5.1. General ........................................................................................................................... 23

2-5.2. Preliminary Instructions ................................................................................................. 23

2-5.3. Required Tools ............................................................................................................... 24

2-5.4. Installation Procedure .................................................................................................... 24

2-5.4.1. Installing the ID Chip inside the Trunk..................................................................... 28

2-6. HEAVY DUTY VEHICLES INSTALLATION ................................................................ 30

2-6.1. General ........................................................................................................................... 30

2-6.2. Preliminary Instructions ................................................................................................. 30

2-6.3. Required T

ools ............................................................................................................... 31

2-6.4. Coil Installation.............................................................................................................. 31

2-6.4.1. Long Neck Fuel Inlet Installation Procedure ............................................................ 31

2-6.4.2. Short Neck Fuel Inlet Installation ............................................................................. 33

2-6.4.3. Self Installation ......................................................................................................... 35

2-6.5. Chip Installation ............................................................................................................. 35

2-6.5.1. Installing the Chip with a Security Cover ................................................................. 35

2-6.5.2. Installing the Chip without Security Cover ............................................................... 37

SECTION 3 DATAPASS & µDATAPASS DESCRIPTION

&

Page 6

Fuel Point PLUS Vehicle Installation and Configuration Manual

VI

Paragraph Page

TABLE OF

INSTALLATION

CONTENTS

3-1. OVERVIEW ....................................................................................................................... 38

3-1.1. Vehicle Data Provided ................................................................................................... 38

3-1.2. Availability of Vehicle Data according to Vehicle Interface Type................................ 39

3-2. DATAPASS DESCRIPTION ............................................................................................. 40

3-2.1. Technical Specifications ................................................................................................ 42

3-2.2. DataPass Pinout.............................................................................................................. 43

3-3. µDATAPASS DESCRIPTION........................................................................................... 44

3-3.1. Technical Specifications ................................................................................................ 45

3-3.2. µDataPass Pinout ........................................................................................................... 47

3-4. TOOLS REQUIRED FOR INSTALLATION.................................................................... 47

3-5. LIGHT VEHICLES INSTALLATION .............................................................................. 47

3-5.1. Checking Vehicle Protocol............................................................................................. 47

3-5.2. Installing the μDataPass ................................................................................................. 48

3-5.3. Installing the DataPass ................................................................................................... 49

3-5.3.1. Adaptor Plug.............................................................................................................. 52

3-5.3.2. Installing a Pulse Divider Device .............................................................................. 53

3-6. HEAVY VEHICLES INSTALLATION ............................................................................ 56

3-6.1. General ........................................................................................................................... 56

3-6.2. Connecting the DataPass to Odometer Pulses Source ................................................... 56

3-6.3. Connecting the DataPass to the Vehicle Bus ................................................................. 60

SECTION 4 PROGRAMMING VEHICLE

UNITS

4-1. GENERAL .......................................................................................................................... 63

4-2. WIRELESS PROGRAMMER............................................................................................ 63

4-2.1. WP Specifications .......................................................................................................... 64

4-2.2. Battery Saving and Battery Chargers ............................................................................. 66

4-3. WIRELESS PROGRAMMER REGISTRATION AND CONFIGURATION .................. 67

4-3.1. FHO Installation ............................................................................................................. 67

4-3.2. WP Tunnel Installation................................................................................................... 67

4-3.3. Establishing WP - HO Communication ......................................................................... 70

4-3.4. Updating Vehicle List .................................................................................................... 73

4-3.5. Local Download ............................................................................................................. 76

4-3.6. Show Files ...................................................................................................................... 78

4-3.7. Update DP SW ............................................................................................................... 80

4-4. WP FUNCTIONAL PRINCIPLES..................................................................................... 82

4-4.1. Main Function Keys ....................................................................................................... 82

4-4.2. Common Actions............................................................................................................ 83

4-4.3. Common Parameters ...................................................................................................... 83

Page 7

Fuel Point PLUS Vehicle Installation and Configuration Manual

VII

Paragraph Page

TABLE OF

CONTENTS

4-5. FR AND DP PROGRAMMING SEQUENCE FOR HEAVY VEHICLES ...................... 86

4-5.1. Setting DP-Heavy Vehicle Interface Communication Parameters ................................ 98

4-6. FR AND DP PROGRAMMING SEQUENCE FOR LIGHT VEHICLES ........................ 99

4-7. FR AND µDP PROGRAMMING SEQUENCE ................................................................ 105

4-8. PROGRAMMING DP ONLY............................................................................................ 110

4-9. ADDING FP TO DP ONLY............................................................................................... 113

4-10. REPLACING DP ................................................................................................................ 115

4-11. ADD DP TO FP .................................................................................................................. 117

4-12. CLEARING DIAGNOSTIC TROUBLE CODES (DTCS) ............................................... 119

4-12.1. General ........................................................................................................................... 119

4-12.2. Operating Instructions.................................................................................................... 120

SECTION 5

TROUBLESHOOTING

5-1. GENERAL.......................................................................................................................... 122

SECTION 6

APPENDIX A FINDING DP CALIBRATION FACTORS FOR NEW

VEHICLE

GLOSSARY

MODELS

OBD-II

A-1. GENERAL.......................................................................................................................... 126

A-2. DP CALIBRATION PROCEDURE .................................................................................. 126

Page 8

Fuel Point PLUS Vehicle Installation and Configuration Manual

VIII

LIST OF ILLUSTRATIONS

Figure

Page

Figure 1-1. Fuel Point PLUS System Architecture 14

Figure 2-1. Fuel Ring Components 16

Figure 2-2. Light Vehicle Typical Installation Kit Components 18

Figure 2-3. Heavy Vehicle Kit Description 19

Figure 2-4. Fuel Ring Shaped Coil 20

Figure 2-5. Fuel Ring Self Installed Coil 21

Figure 2-6. Fuel Ring Molded Coil 22

Figure 2-7. Typical Installation Approved Location 24

Figure 2-8. ID Chip Preferred Position 25

Figure 2-9. Inserting One-Way Screw 26

Figure 2-10. Applying Adhesive 26

Figure 2-11. Securing the Clamps 27

Figure 2-12. Securing the ID Chip 28

Figure 2-13. Drillin

g the Trunk 28

Figure 2-14. Securing the ID Chip 29

Figure 2-15. CV Joint Banding Tool and Cutter 31

Figure 2-16. Positioning the Clamps 32

Figure 2-17. Tightening the Clamps 33

Figure 2-18. Complete Coil Installation on Long Neck Inlet 33

Figure 2-19. Securing Clamps on Short Neck Inlet 34

Figure 2-20. Complete Coil Installation on Short Neck Inlet 35

Figure 2-21. Complete Coil Self – Installation 35

Figure 2-22. ID Chip Installed in a Security Cover 36

Figure 2-23. Attaching the Security Cover to a Bar 36

Figure 2-24. Tightening Security Cover 37

Figure 3-1. DataPass f

or Light Vehicles (OBD-II) 41

Figure 3-2. DataPass (J1708/FMS) for Heavy Vehicles 41

Figure 3-3. DataPass Harness 42

Figure 3-4. µDataPass for CAN Bus 45

Figure 3-5. µDataPass for K-Line Bus 45

Figure 3-6. VCM Unit 48

Figure 3-7. Diagnostics Connector 48

Figure 3-8. Pluging the μDataPass 49

Figure 3-9. Tightening the μDataPass 49

Figure 3-10.OBDII Connector Wiring to DataPass Harness 50

Figure 3-11. OBDII Connector Pins Layout 50

Page 9

Fuel Point PLUS Vehicle Installation and Configuration Manual

IX

LIST OF

Figure Page

Figure 3-12. Removing the Diagnostics Connector Panel 51

Figure 3-13. Soldering DataPass Harness to Diagnostics Connector Wires 51

Figure 3-14. Wrapping Connections in Insulating Tape 51

Figure 3-15. Covering Unconnected Wires with Insulating Tape 52

Figure 3-16. Fastening the DataPass Unit 52

Figure 3-17. Connecting the Adapter Plug 53

Figure 3-18. Connecting the DataPass to the Adaptor Plug 53

Figure 3-19. Pulse Divider 54

Figure 3-20. Tachograph Extraction Slots 57

Figure 3-21. Removing the Tachograph 57

Figure 3-22. Tachograph Wiring 58

Figure 3-23. Connecting DataPass Harness to Tachograph Wiring 58

Figure 3-24. Wrapping Connections in Insulating Tape 58

Figure 3-25. Covering the Harness with Insulating Tape 59

Figure 3-26. Connecting the DataPass 59

Figure 3-27. Fastening DataPass and Harness 60

Figure 3-28. Typical Bus Connector 60

Figure 3-29. J1708 (J1587) 6P Harness – DataPass Connection 61

Figure 3-30. J1708 (J1587) 9P Harness – DataPass Connection 61

Figure 3-31. J1939 Harness – DataPass Connection 61

Figure 4-1. Home Base Solution Wireless Programmer 64

Figure 4-2. WP Battery Chargers 66

Figure 4-3. Administration Setup Screen – General Tab 67

Figure 4-4. WP Tunnel Setup Wizard Welcome Screen 68

Figure 4-5. WP Tunnel Setup Wizard License Agreement Screen 68

Figure 4-6. WP Tunnel Setup Wizard Choose Install Location Screen 69

Figure 4-7. WP Tunnel Setup Wizard Connection Settings Screen 69

Figure 4-8. WP Tunnel Setup Wizard Installation Complete Screen 70

Figure 4-9. Admin Screen – Registration Tab 71

Figure 4-10. WP Tunnel Main Screen 71

Figure 4-11. Approving WP Registration 73

Figure 4-12. WP Tunnel – Vehicle List Update 74

Figure 4-13. WP Tunnel – Vehicle List Update 76

Figure 4-14. U581 OBD-II Memo Scanner 119

Figure 4-15. Memo Scanner Start Up Screen 120

Figure 4-16. Detecting Vehicle's Protocol 120

ILLUSTRATIONS

Page 10

Fuel Point PLUS Vehicle Installation and Configuration Manual

X

LIST OF

Figure Page

Figure 4-17. Vehicle Diagnosis Menu 121

Figure 4-18. Trouble Codes Screen 121

Figure 4-19. Erasure Confirmation Message 121

ILLUSTRATIONS

Page 11

Fuel Point PLUS Vehicle Installation and Configuration Manual

XI

LIST OF

TABLES

Table

Page

Table 2-1. Light Vehicle - Kit Description 17

Table 2-2. Heavy Vehicle - Kit Description 17

Table 2-3. Shaped Fuel Rings 19

Table 2-4. Self-Installed Fuel Rings 20

Table 2-5. Molded Fuel Ring 21

Table 2-6. Vehicle Survey – Example 22

Table 2-7. Common Bus Connectors 23

Table 3-1. DP Types 38

Table 3-2. DataPass Plus Vehicle Parameters 39

Table 3-3. Availability of Vehicle Data according to DataPass and Interface Type 39

Table 3-4. DataPass Specifications 42

Table 3-5. DataPass Pinout 43

Table 3-6. μDataPass Specifications 45

Table 3-7. µDataPass Pinout 47

Table 3-8. Harness O

BDII Connections 50

Table 3-9. Pulse Divider Connections 54

Table 3-10. Pulse Divider Pinout 55

Table 3-11. Tachograph – DataPass Harness Connections 56

Table 3-12. Pulse Output Pin in Various Types of Tachographs 56

Table 3-13. BUS Connector Typical Pin Out Description 61

Table 4-1. Wireless Programmer Specifications 65

Table 4-2. WP Upgrade Sequence 72

Table 4-3. Vehicle List Update Sequence 75

Table 4-4. Local Download Sequence 77

Table 4-5. Show Files Address Sequence 78

Table 4-6. Update DP Software Sequence 80

Table 4-5. Wireless Programmer Main Function Keys and Shortcuts 82

Table 4-6. Wirel

ess Programmer Common Actions 83

Table 4-7. Common Parameters 83

Table 4-10. FR and DP Heavy Programming Sequence 86

Table 4-11. DP Heavy Programming Sequence – Pulses Interface 95

Table 4-10. DP – Heavy Vehicle Interfaces Communication Parameters Values 98

Table 4-11. FR and DP Light Programming Sequence 99

Table 4-12. DP Light Programming Sequence – Pulses Interface 103

Table 4-13. FR and μDP Programming Sequence 105

Table 4-16. Program DP Only Sequence 110

Page 12

Fuel Point PLUS Vehicle Installation and Configuration Manual

X

LIST OF

Table Page

Table 4-17. Add FP to DP Sequence 113

Table 4-18. Replace DP Sequence 115

Table 4-19. Add DP to FP Sequence 117

Table 4-14. U581 OBD-II Memo Scanner Controls and Main Components 119

Table 5-1. Troubleshooting Guide 122

Table A-1. DP Parameters Viewing and Editing Sequence 128

Table A-2. DP Calibration Sequence 130

TABLES

Page 13

Fuel Point PLUS Vehicle Installation and Configuration Manual

13

SECTION 1

INTRODUCTION

1-1. SCOPE

This manual is provided to assist the user in installing the Fuel Point PLUS vehicle units: Fuel Ring

and DataPass. The vehicle units must be installed as described in this manual to ensure the system

reliability and proper operation. This manual includes a general and functional description of the

vehicle units, their main components and installation requirements. The manual is intended for

qualified authorized installers and technicians of Fuel Point PLUS vehicle units and their

components.

1-2. FUEL POINT PLUS SYSTEM DESCRIPTION

Gasboy's Fuel Point PLUS is an automated system utilized to identify vehicles refueling in gas

stations that utilizes wireless technology for transferring vehicle data. The Wireless Nozzle Reader

(WNR), a self contained unit installed on the fueling nozzle, reads the Fuel Ring using contactless

technology and transmits the encrypted data to the nearest WGT using short range, spread spectrum

wireless communication. The WGT receives both DataPass and Fuel Ring vehicle data, decrypts the

information and transmits it to the station automation system. For further information on the Fuel

Point PLUS station-side equipment, please refer to Station Installation and Setup Manual for New

Deployments, P/N MDE-4851.

Figure 1-1 shows a basic diagram of Gasboy's Fuel Point PLUS architecture.

Page 14

Fuel Point PLUS Vehicle Installation and Configuration Manual

14

Figure 1-1. Fuel Point PLUS System Architecture

1-3. MANUAL STRUCTURE

This manual comprises the following sections:

Section 1: Introduction

This section provides a general description of the Fuel Point PLUS system in general.

Section 2: Fuel Ring Description and Installation

This section provides a detailed of the Fuel Ring units and comprehensive installation instructions

for light/heavy vehicles.

Section 3: DataPass & µDataPass Description and Installation

This section provides a detailed of the DataPass & µDataPass units and comprehensive installation

instructions for light/heavy vehicles.

Section 4: Programming Vehicle Units

This section provides instructions on the programming sequence of the vehicle units installed in

private and heavy duty vehicles using the Wireless Programmer device, as well as instructions for

setting up the WP.

Section 5: Troubleshooting

This section provides a list of common problems related to the vehicle units or to its communication

with the Fuel Point PLUS system, as well as corrective action instructions.

Section 6: Glossary

Includes a glossary of terms used in the manual.

Appendix A: Finding DP Calibration Factors For New OBD-II Vehicle Models

This appendix describes the procedure for finding out calibration factors of DP/μDP units' odometer

reading for new vehicle models equipped with OBD-II systems.

1-4. USING THIS MANUAL

This manual includes comments planted along the text, in order to draw the reader’s attention to

important issues. The comments are accompanied by symbols for ease of reference. The following

comment types are used:

WARNING

An operating procedure, practice or similar, if not

correctly followed, could result in injury or loss of

life.

Page 15

Fuel Point PLUS Vehicle Installation and Configuration Manual

15

An operating procedure, practice, or similar, if not

strictly observed, could result in damage to, or

destruction of equipment

TIP

CAUTION

A useful guidance whose purpose is to use the

system more effectively

NOTE

A relevant comment which is important to

emphasize

INSIGHT

Theoretical or functional information regarding the

system, which has to do with the discussed issue

1-5. REFERENCES

For additional and complementary information regarding Gasboy’s Fuel Point PLUS Installation

and Setup, please refer to the following manuals:

Islander PLUS and ICR PLUS Installation Manual, P/N MDE-4811

Fuel Point PLUS Station Installation and Setup Manual for New Deployments, P/N MDE-4851

Page 16

Fuel Point PLUS Vehicle Installation and Configuration Manual

16

SECTION 2

FUEL RING DESCRIPTION &

INSTALLATION

2-1. OVERVIEW

Fuel Ring is a passive vehicle identification tag for refueling (RFID with no internal power sources)

which provides encrypted information on the vehicle identity, corporation or driver identification

and fuel type.

Fuel Ring includes a coil installed around the vehicle's fuel tank inlet and an ID chip. The coil

receives the transmission from the Wireless Nozzle Reader and transmits the chip information to

the Fuel Point PLUS system.

Fuel Ring features a patented removal protection mechanism to eliminate risk of theft or fraud. The

coil and the chip are connected through a cable, so that the ID chip can be installed either in a

concealed place inside the truck or next to the fuel tank inlet in light vehicles (the distance between

the coil and the ID chip must not exceed 39.37"-1M). Enhanced protection is achieved by

correlating the DataPass and the Fuel Ring of the same vehicle

The following section describes two types of installation procedures:

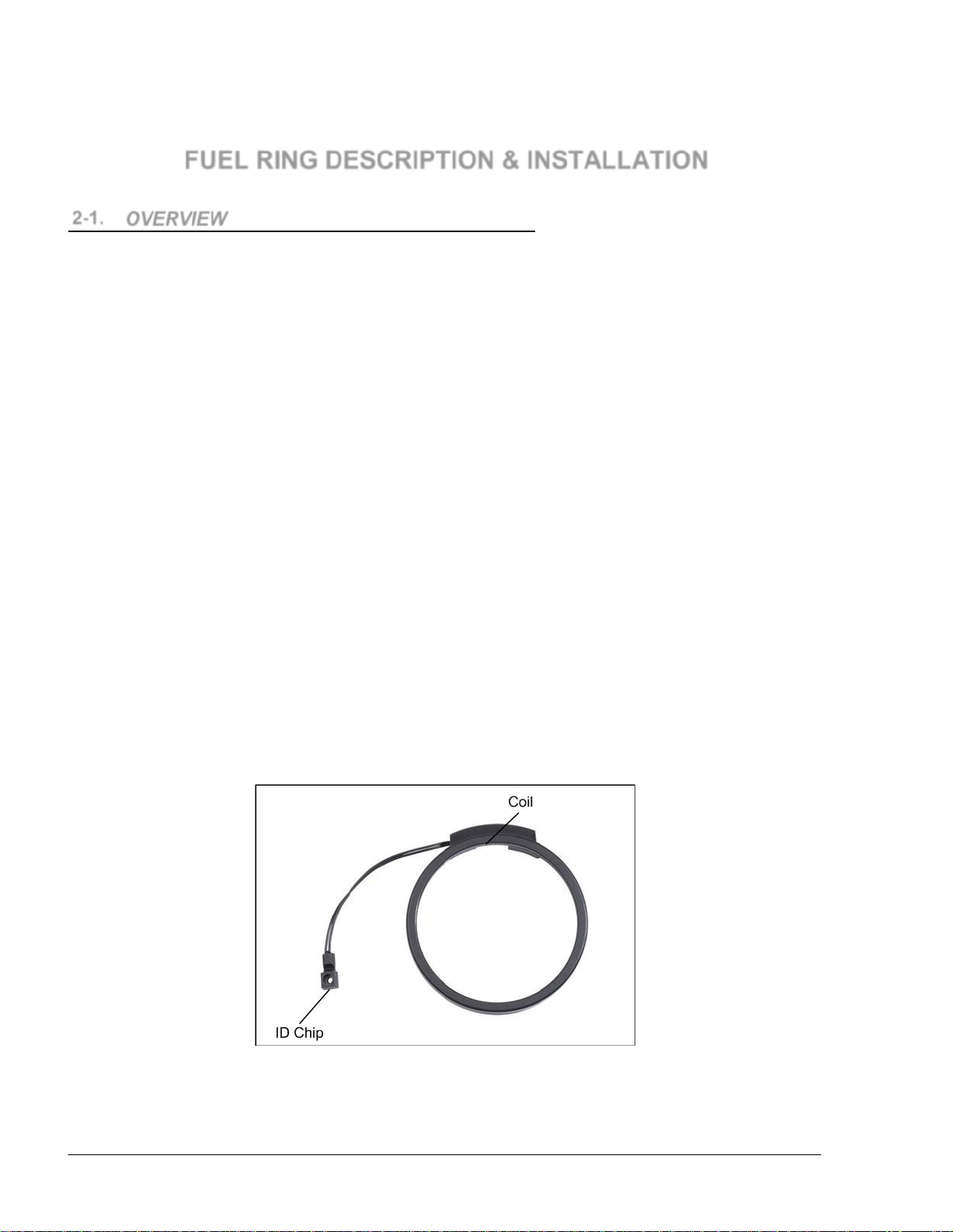

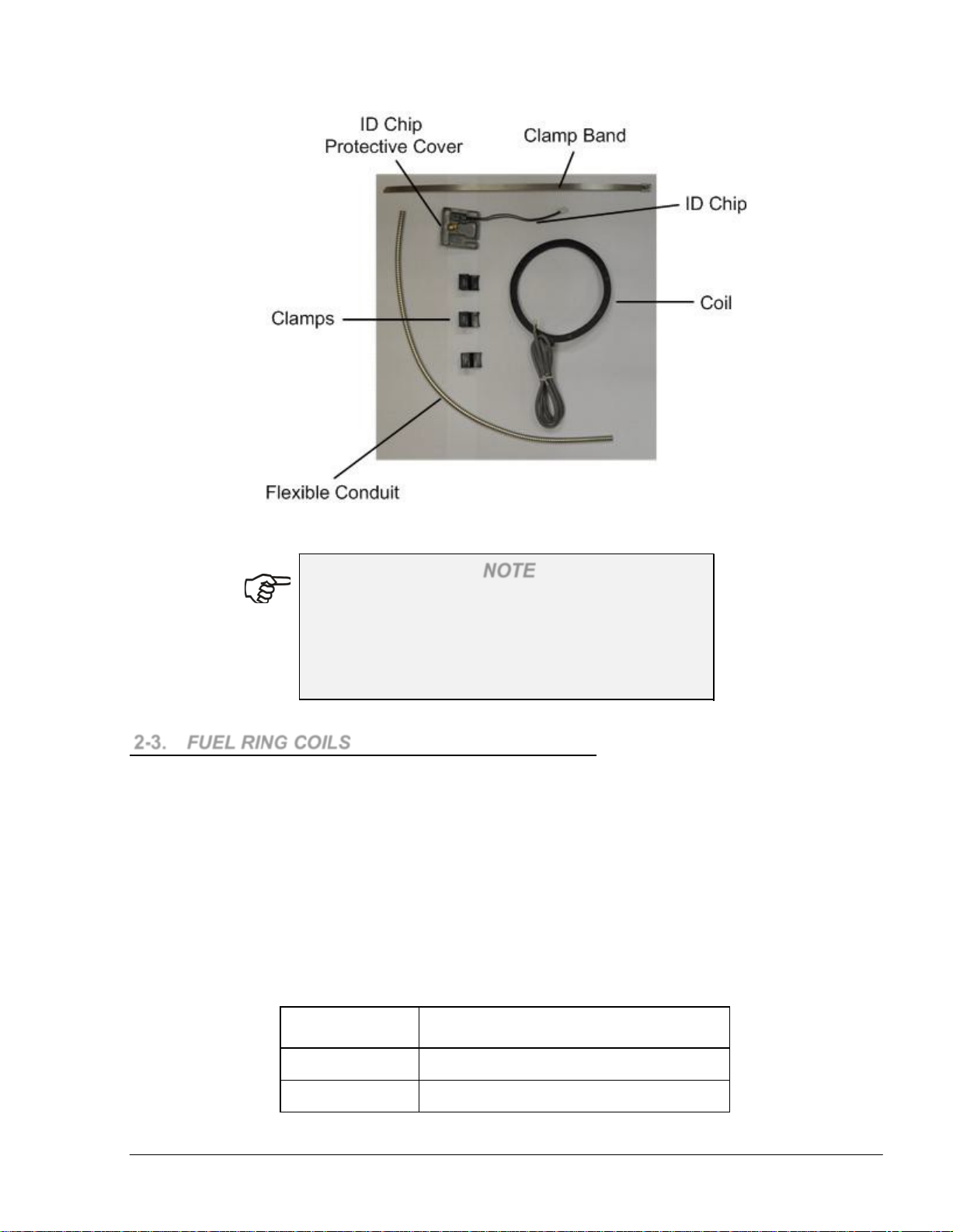

2-1.1. Fuel Ring Main Components

The Fuel Ring comprises two major parts as follows:

A coil (a uniquely designed coil for Fuel Point PLUS vehicle installations)

A one-time programmed ID chip housed in a casting package, protecting the unit from

Installation on private vehicles (see paragraph 2-5)

Installation on heavy vehicles (see paragraph 2-6)

mechanical damage.

Figure 2-1. Fuel Ring Components

Page 17

Fuel Point PLUS Vehicle Installation and Configuration Manual

17

2-2. TYPICAL INSTALLATION KITS

815801001

Table 2-1 and Table 2-2 show a typical kit description (see also Figure 2-2, Figure 2-3). Note that

the ID chip and the Fuel Ring coil are separate components and do not form part of the light or

heavy vehicle kits.

NOTES

1. Each item in the Fuel Ring kit has a minimum

ordering quantity. Please refer to Gasboy's

marketing personnel for ordering information.

2. Certain items (e.g. glue, Glue Accelerator,

Adhesive) are not supplied and must be

purchased by the customer as they are required

for installation

3. Programming/configuring the Fuel Ring with the

WP must be performed prior to installation, due

to safety requirements.

Table 2-1. Light Vehicle - Kit Description

Kit P/N P/N Description Packs

Qty.

M09678B008 100 Fuel Ring Installation Kit for Light Vehicles, without

glue

815202401 Screw, self drilling, 6x1"flat, 100 pcs 2

815206001 Screw, one-way, 100pcs, 2.9x9.5mm 1

("¼) Cable clamp, black,100 pcs 2

Table 2-2. Heavy Vehicle - Kit Description

Kit P/N P/N Description Packs

M09678B009

100 Fuel Ring Installation Kit for Heavy Vehicles, without

glue

814905500 Fuel Ring security cover 100

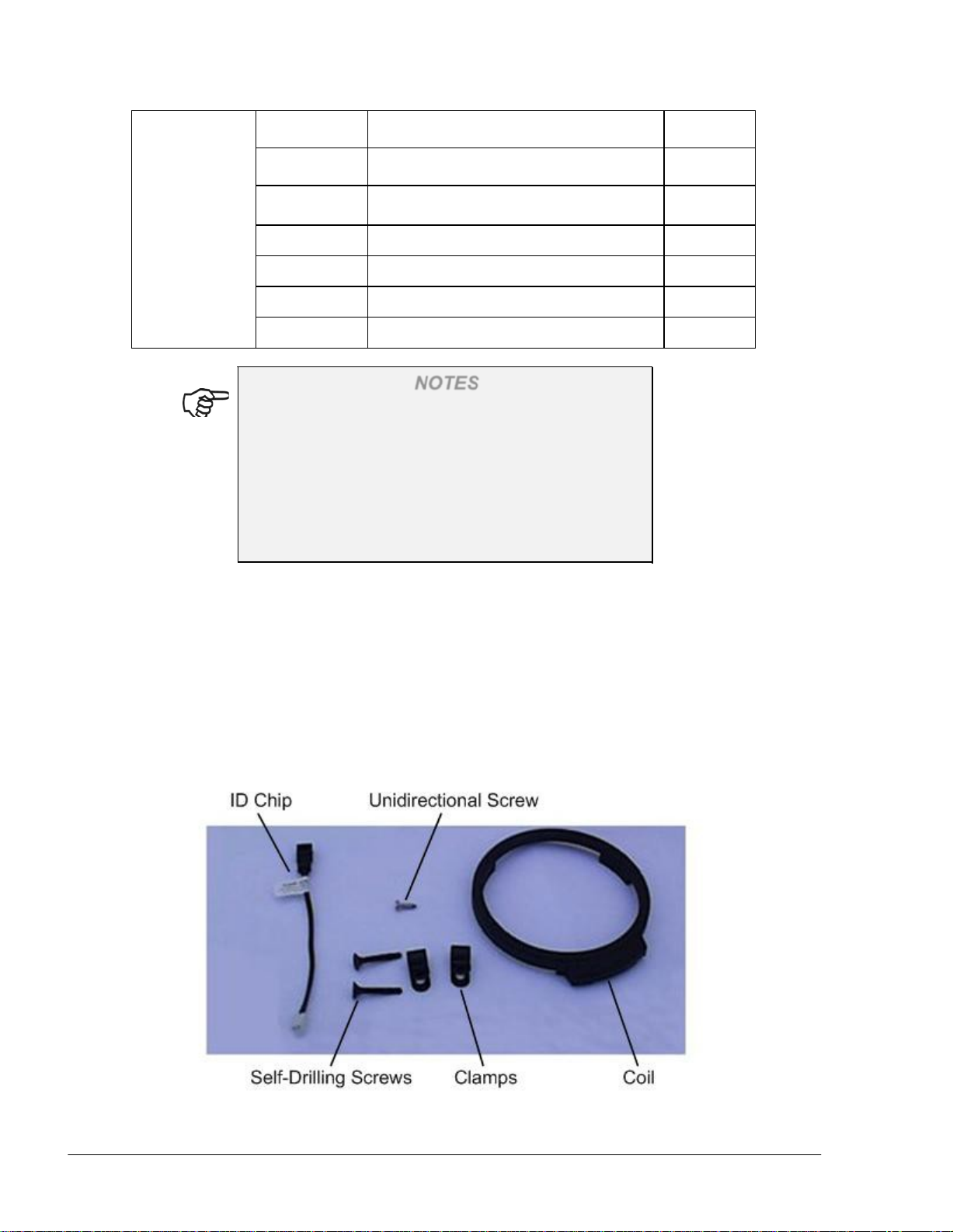

Qty.

Page 18

Fuel Point PLUS Vehicle Installation and Configuration Manual

18

815202401 Screw, self drilling, 6x1"flat, 100 pcs 2

815206900 Screw, security bolt, M8x20 100

815305500

Washer, flat,

M8/EXT=20mm/1 2mm

815801001 ("¼) Cable clamp, black,100 pcs 2

815805802 Nirosta wire, 25pcs 2

815806001 Clamp-coil holder, 100 pcs 3

815806400 Band, Lok-Tie BL213, 7.9x482mm 50

NOTES

1. For cases where fuel inlet neck is short, use the

provided stainless wire; otherwise use the clamp

band

2. If the coil/ID chip cannot be secured using

wires/clamp bands/screws, use Super Glue and a

fast activation accelerator. Cover the device with

a dual component adhesive (such as Epoxy).

The following adhesive substances are recommended for use:

1. SuperGlue, Cyanoacrylate- CA01, HOLDTITE

100

2. Glue, Acrylic, ST3294, high VEL. Black, HOLDTITE

3. Surface cleaning solution

4. Activator, pronto, 60ml (3M)

Figure 2-2. Light Vehicle Typical Installation Kit Components

Page 19

Fuel Point PLUS Vehicle Installation and Configuration Manual

19

M09678B006

Figure 2-3. Heavy Vehicle Kit Description

To extend SuperGlue and accelerator shelf life, store

the products at a temperature of 200 C or less. High

temperature conditions or direct sunlight reduces

shelf life dramatically. For more details refer to

manufacturer's instructions.

2-3. FUEL RING COILS

The following Fuel Ring coils are available to fit a wide range of fuel inlets:

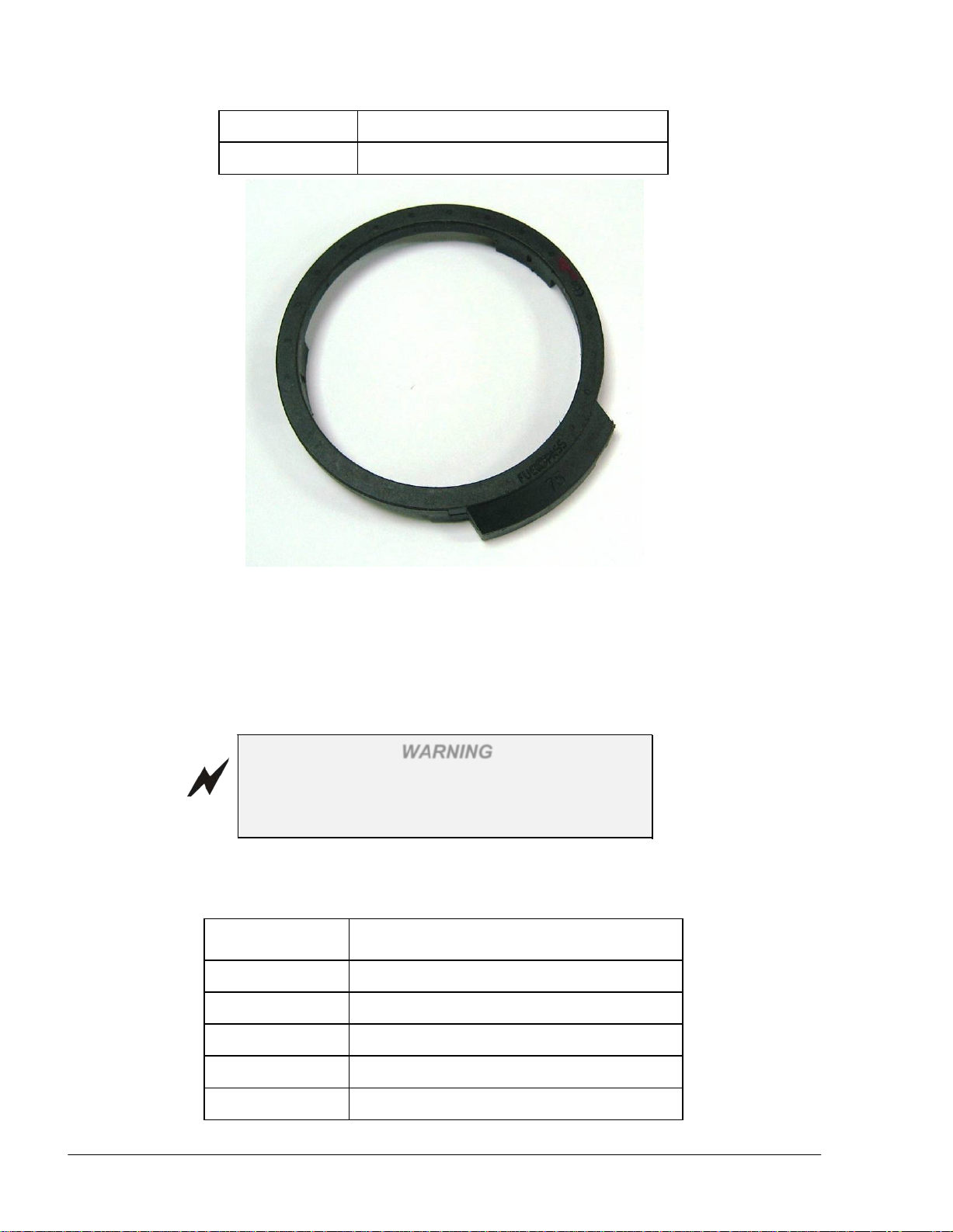

2-3.1. Shaped Coil

Designed to maintain a distance from metal surfaces, the Shaped coil (see Figure 2-4, Table 2-3)

includes an ID chip connector and three support legs which can be easily glued.

Intended for use in cases where an easy connection to the ID chip is required, mainly when the chip

is close to the Wireless Nozzle Reader, e.g. private vehicles.

The Shaped coil is connected to the ID chip by plugging the chip's connector to the coil's connector.

Table 2-3. Shaped Fuel Rings

NOTE

Part Number

M09678B005

Shaped, 2.95"

Shaped,3.34"

Description

Page 20

Fuel Point PLUS Vehicle Installation and Configuration Manual

20

M09678B007

M09680B020

Shaped, 3.74"

ID chip

Figure 2-4. Fuel Ring Shaped Coil

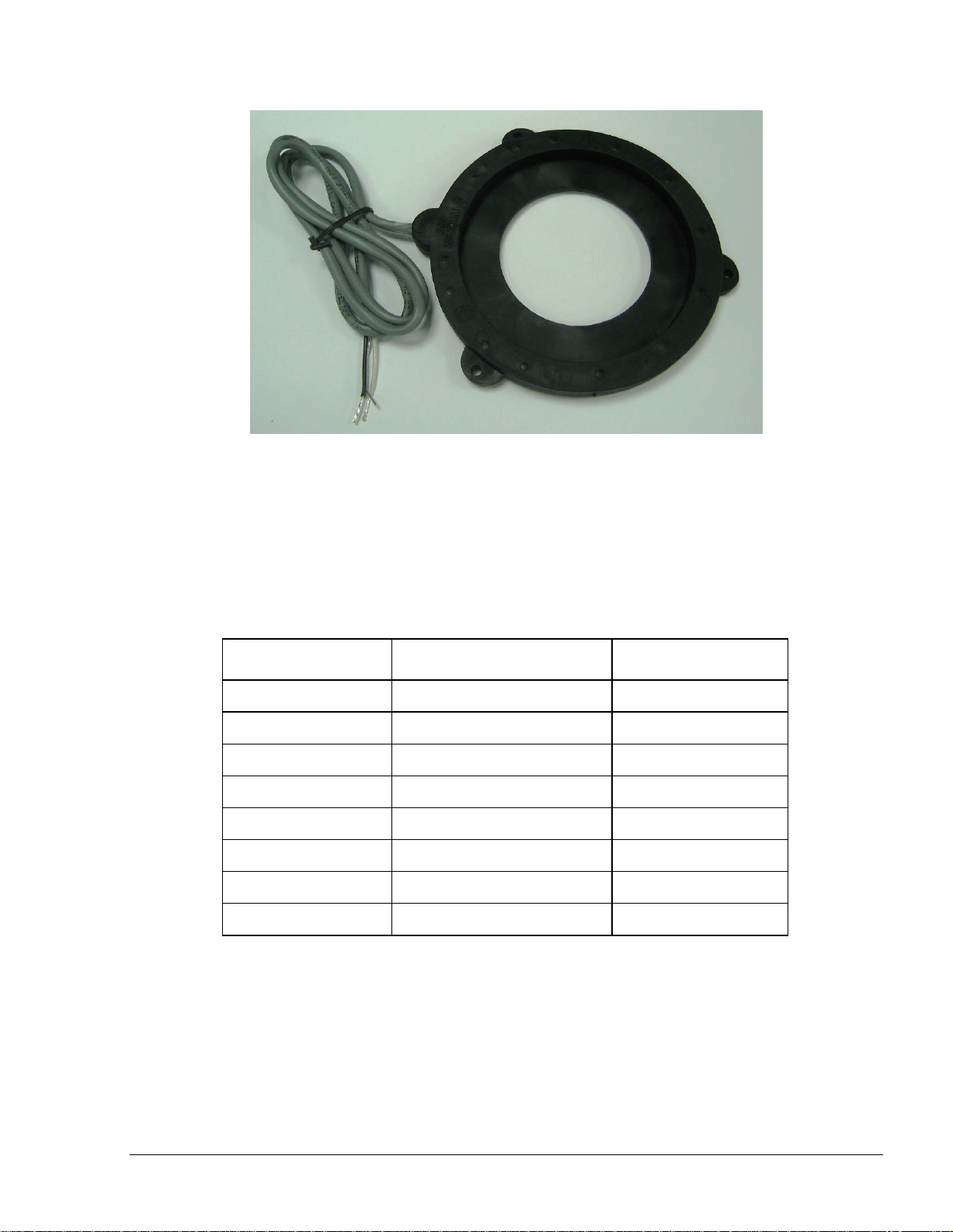

2-3.2. Self Installed Coil

The Self Installed coil (see Figure 2-5, Table 2-4) is rubber coated and includes an internal rubber

ring designed for installation in heavy or light vehicles having short fuel inlet necks.

The Self Install coil should not be used in tanks

made of Aluminum. Use supporting legs to keep it

up off the surface.

The ID chip connector should be cut, in order to be connected to the coil's wires.

Table 2-4. Self-Installed Fuel Rings

Part Number

M09678B001 Self-installed, 2.75"

M09678B002 Self -installed, 4.13"

WARNING

Description

M09678B003 Self-installed, 4.72"

M09678B004 Self-installed, 5.11"

M09680B020 ID chip

Page 21

Fuel Point PLUS Vehicle Installation and Configuration Manual

21

Figure 2-5. Fuel Ring Self Installed Coil

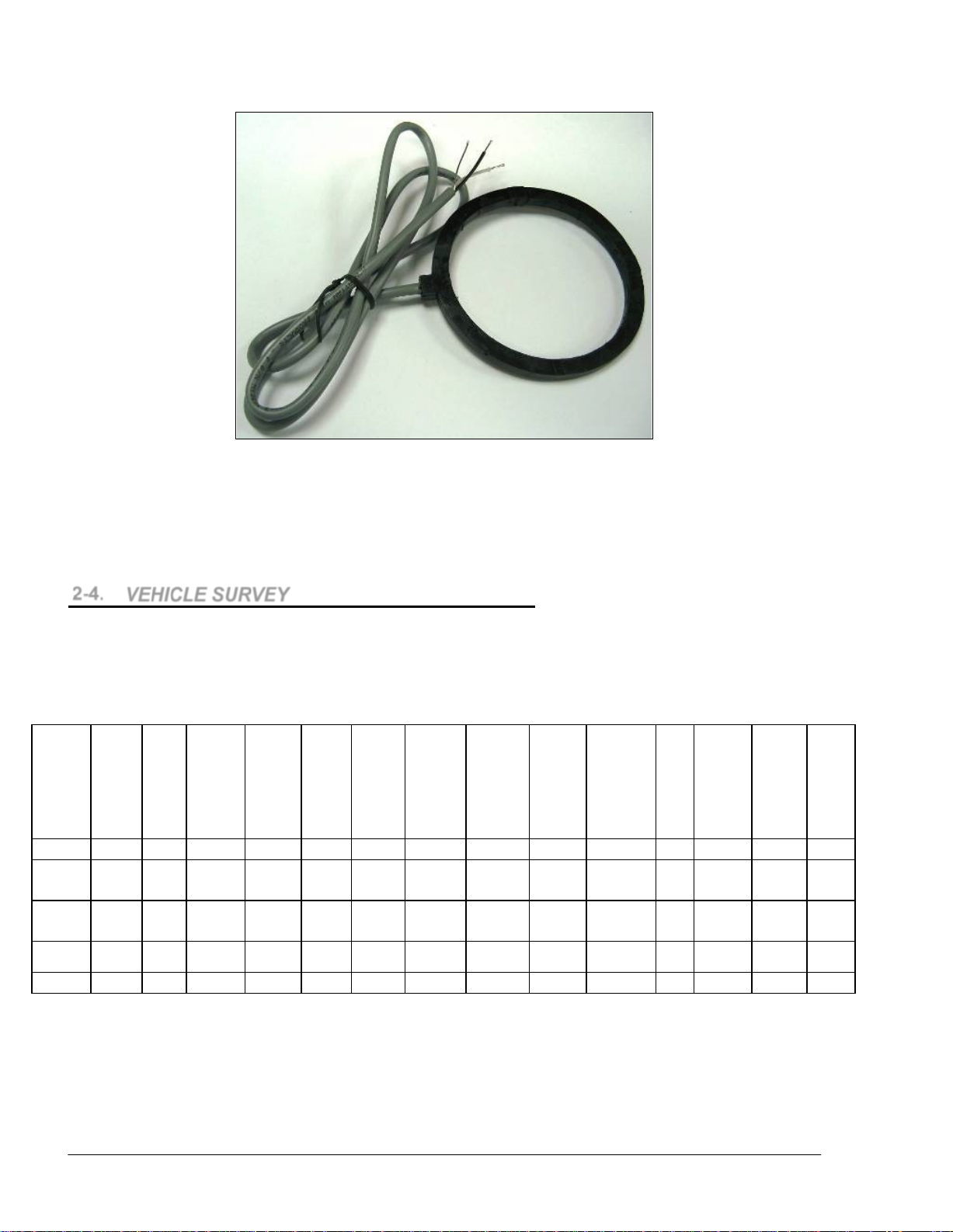

2-3.3. Molded Coil

Widely used, the Molded coil (see Figure 2-6, Table 2-5) is ~7mm thick and can slightly change its

shape.

Table 2-5. Molded Fuel Ring

Part Number

Description

Notes

M09678B010 Molded coil, 2.165" Cable length: 100cm

M09678B011 Molded coil, 3.15"

M09678B012 Molded coil, 3.54"

M09678B013 Molded coil, 3.74"

M09678B014 Molded coil, 4.33"

M09678B015 Molded coil, 4.72" For heavy vehicles

M09678B016 Molded coil, 5.11" For heavy vehicles

M09678B017 Molded coil, 5.71" For heavy vehicles

Page 22

Fuel Point PLUS Vehicle Installation and Configuration Manual

22

N

of

on

er

d

o

C

VOLVO

S50

2005

80

1 CAN

OBD II

Elect.

12

Germany

5

11

6

nd

9

nd

VPW

85

12

Figure 2-6. Fuel Ring Molded Coil

2-4. VEHICLE SURVEY

Before performing the vehicle installation fill in the following table as shown in Table 2-6 so as to

order to order the relevant equipment for the vehicle (DataPass, µDataPass, adapters, etc.).

Table 2-6. Vehicle Survey – Example

Vehicle

manuf.

Liaz

Mercedes

Ford transit 2003 85

Lada private 1996

Model

25625-

305 2004 75

Year

2005 95

external

diameter

(mm)

Fuel

Inlet/neck

high (mm)

200

250

20

umber

tanks

1

2

1

1

BUS type

ISO9141

K-line

J1850

BUS

Connecti

type

pin, rou

connector

pin, rou

connector

OBD II

Fuel

Inlet

Table 2-7 shows of the most commonly used vehicle plugs:

Odometer

manuf.

Kinzle mechanic

Odomet

type

Elect.

Elect.

Elect.

Mechanical

odometer

connection

thread

1.75" 24

2.25" 24 yes

1.5"

size

Power

12

Articulate

us yes / n

omments

bus

bus

Origin

Russia

Germany

UK

Russia

Page 23

Fuel Point PLUS Vehicle Installation and Configuration Manual

23

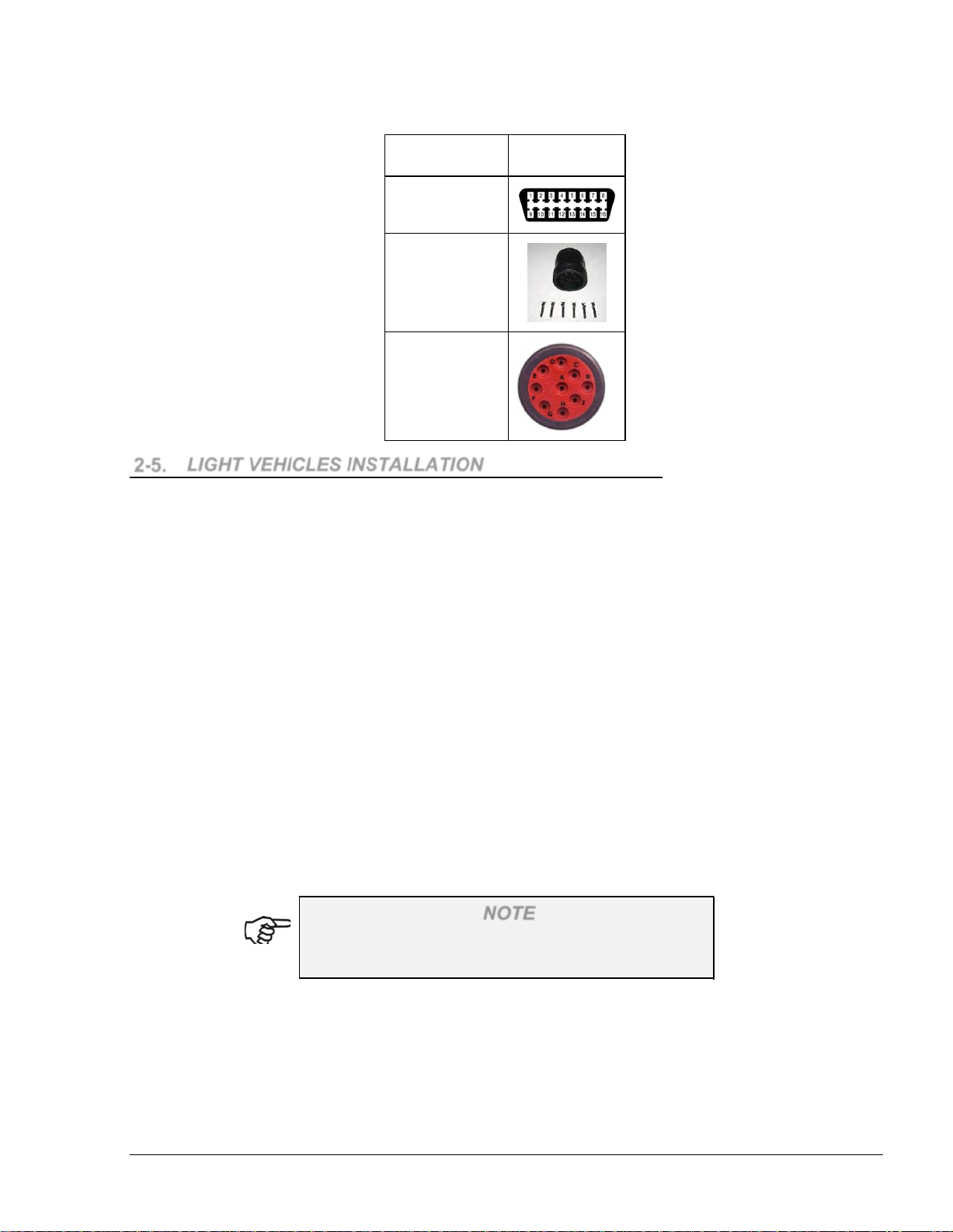

Table 2-7. Common Bus Connectors

Type

Connector

OBD II

6-PIN round

connector

9-PIN round

connector

2-5. LIGHT VEHICLES INSTALLATION

2-5.1. General

Two techniques, or a combination of both, are available for installing the coil unit:

By gluing the coil's bottom surface to the vehicle

By gluing the coil's bottom surface to the vehicle and clamping it

Place the coil unit around the fuel inlet. Pay special attention to the coil's flat part direction –

verify that the bottom legs surface of the plastic molded coil type faces the surface of the

vehicle. In general, it is possible to place the coil in a number of ways; still, it is advisable to

place the coil in the center of the fuel tank inlet to achieve better performance.

The ID chip is installed by gluing it to the vehicle and by securing the unit using a special screw

in order to prevent removal and theft. The chip's installation is performed either in a concealed

place in the luggage compartment, or in a visible place near the fuel tank inlet. When properly

secured against theft, the unit becomes damaged the moment it is pulled away from the vehicle

after installation is completed. It is required to place the ID chip in a less acces

theft and tampering. A distance of up to 100cm between the coil and the ID chip is permitted.

2-5.2. Preliminary Instructions

Warranty does not cover defects or damage caused

by improper installation.

NOTE

In order to prevent possible problems and difficulties during the installation, please verify that:

1. The coil in use is larger than the fuel tank inlet to improve coil assembly

2. The coil is being kept away from metal surfaces, maintaining an air gap of at least 5mm

3. The coil is assembled as close as possible to the Wireless Nozzle Reader coil when the

fueling nozzle is inserted

sible location for

Page 24

Fuel Point PLUS Vehicle Installation and Configuration Manual

24

4. The unit is handled and carefully, avoiding mechanical pressure on the chip. Improper

handling could damage the unit and cause malfunction

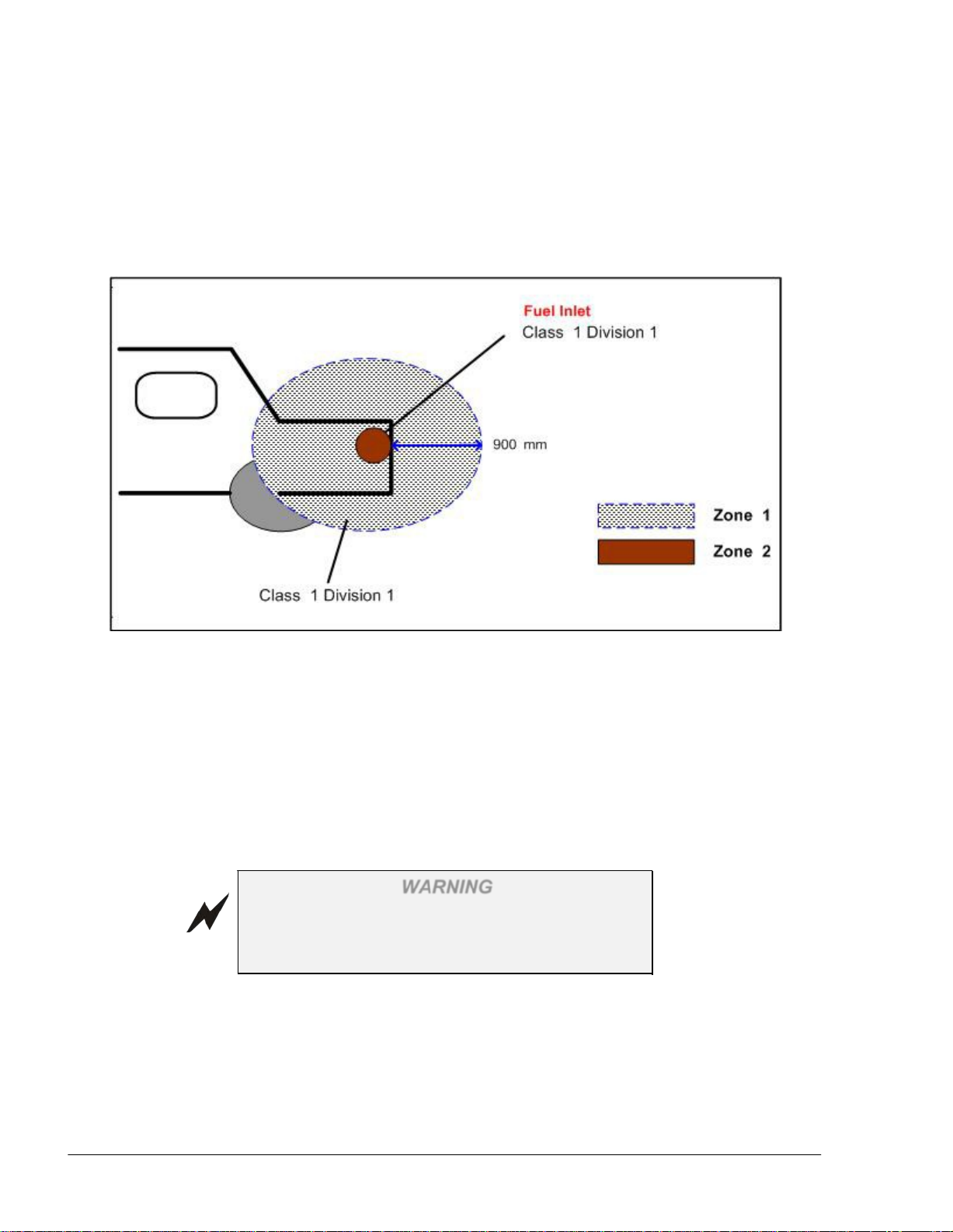

5. The installation area complies with the approved location as shown in Figure 2-7. Please

note that this drawing applies to an open fuel inlet

6. Fuel Ring should only be installed when fuel inlet cover is closed.

Figure 2-7. Typical Installation Approved Location

2-5.3. Required Tools

Cutter

Crimping tool

Pliers

A drilling machine approved for hazardous environment

2-5.4.Installation Procedure

Proceed as follows:

1. Ensure that the fuel tank inlet cover is closed

Before installing or servicing equipment, carefully

observe the warnings and precautions provided at

the beginning of this manual.

2. Use a Fuel Ring of optimal size (refer to Table 2-5) which can be easily placed around

the fuel tank inlet and allows the opening and closing of the fuel tank inlet cover

3. Choose an optimal and secure position for the ID chip. In cases where the installation is

performed near the fuel tank inlet, it is preferable to choose the upper part of the

WARNING

Page 25

Fuel Point PLUS Vehicle Installation and Configuration Manual

25

compartment, at the sides if possible, but not at the bottom, as the fuel nozzle may

damage the ID chip while refueling. The surface must be flat for better gluing and to

ensure that the unit is not damaged by pressure applied during installation

4. Using a soft sandpaper (e.g. #300), slightly sand the area where the ID chip is to be

glued. Pay attention not to damage the car color

5. Clean thoroughly the surface on which the coil and ID chip are to be placed using a

clean cloth and cleaning solution

6. The ID chip is installed with glue with the option of using a special screw, which is also

included in the kit:

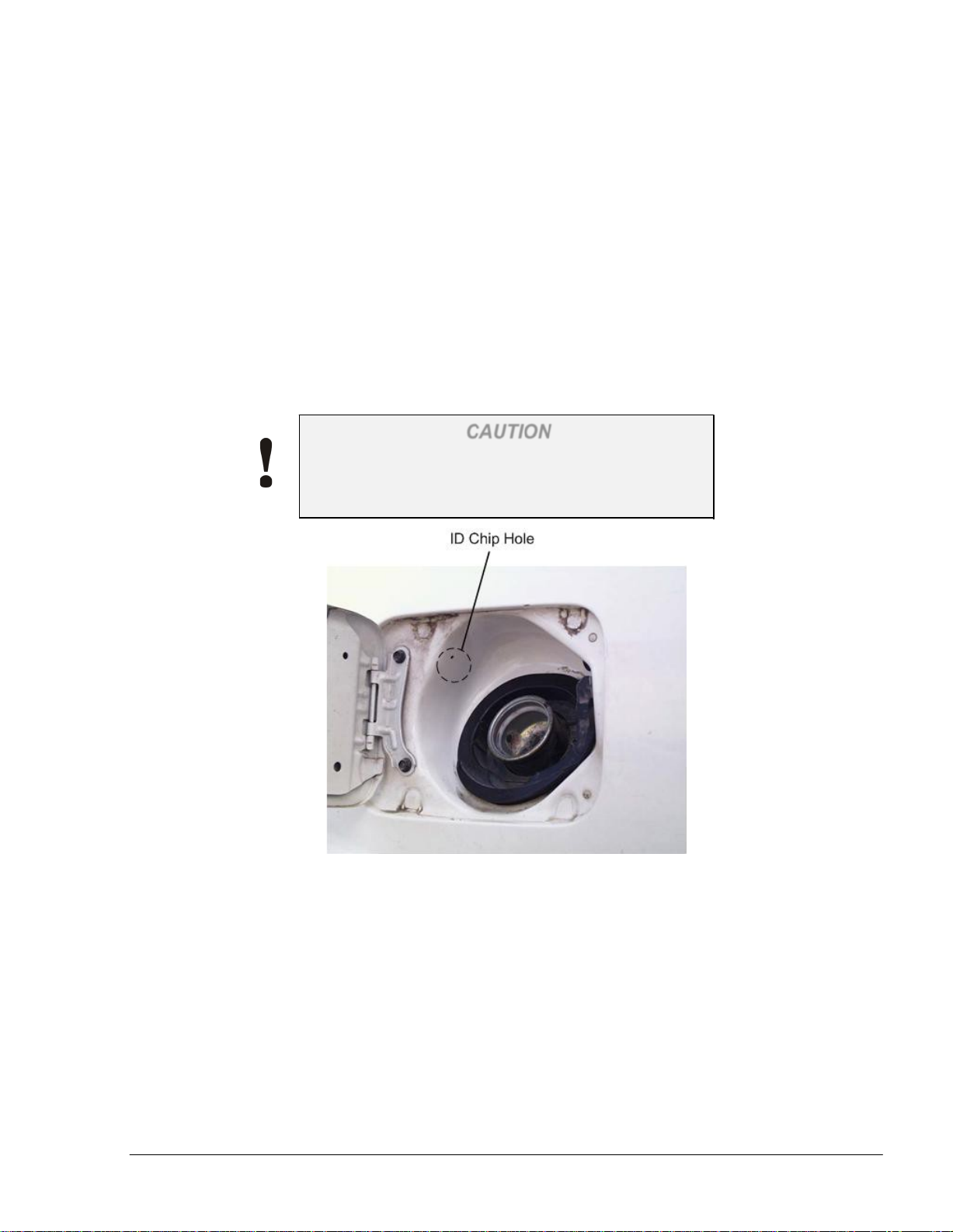

a. In the designated area (see Figure 2-8), drill a 0.094" (2.4 mm) diameter hole. Be

careful not to drill through the fuel tank. Upon drilling completion, make sure to

clean the area before applying the glue

CAUTION

Drilling should be performed by authorized

personnel equipped with a dedicated drilling

machine.

Figure 2-8. ID Chip Preferred Position

b. Insert the one-way special screw into the ID chip (see Figure 2-9)

Page 26

Fuel Point PLUS Vehicle Installation and Configuration Manual

26

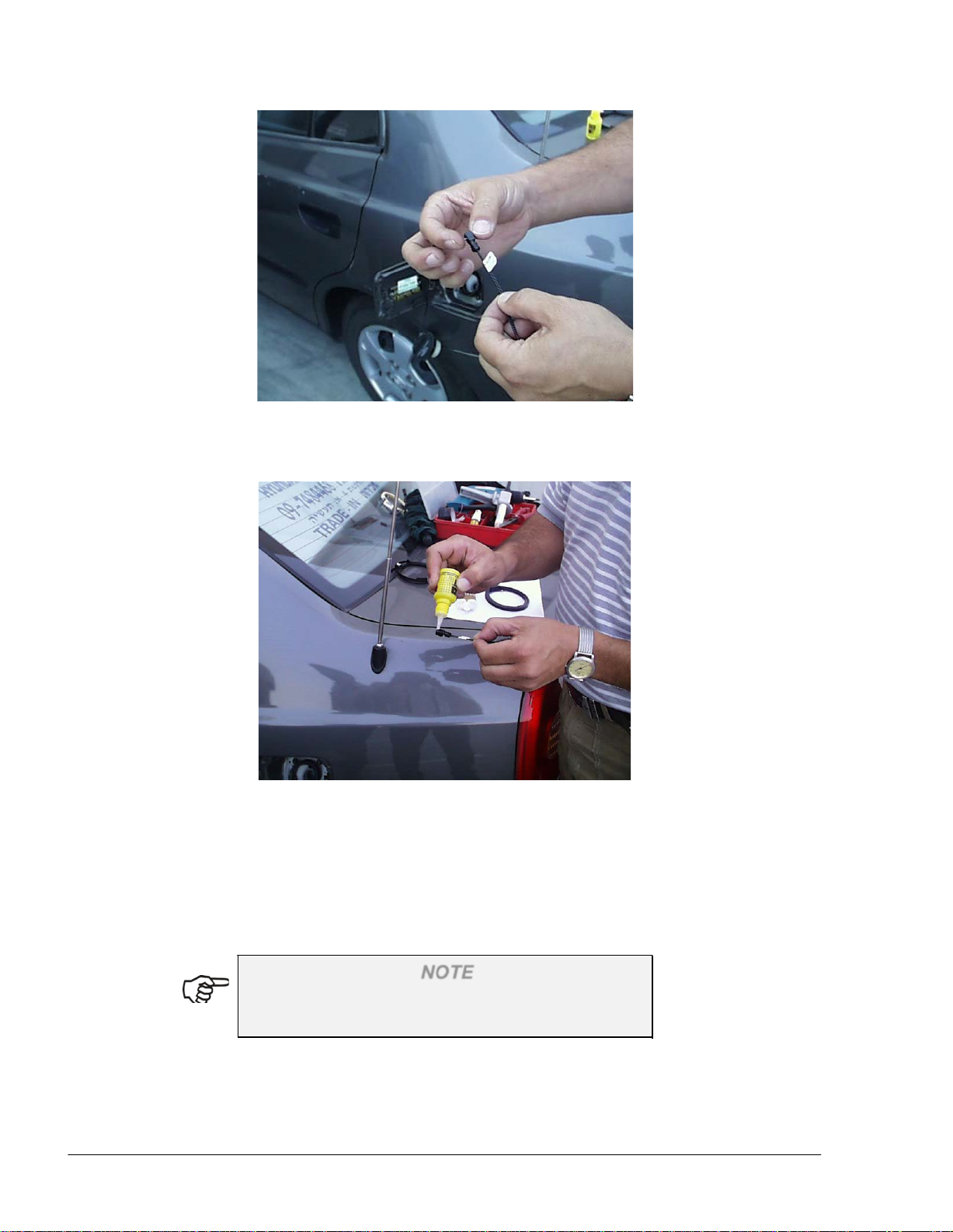

Figure 2-9. Inserting One-Way Screw

c. Apply instant glue to the back part of the ID chip (see Figure 2-10)

Figure 2-10. Applying Adhesive

d. Secure the screw into position in the space prepared, without applying too much

pressure on the screw. Make sure to go through all the instructions in order to

prevent malfunction

e. Spray instant glue accelerator - Activator, pronto, 60ml (3M) around the glued

area

NOTE

When installing the Shaped coil, first connect the ID

chip to the coil.

7. After connecting the coil to the ID chip, to avoid corrosion caused by humidity and

accumulation of fluid at the connection area (shaped coil only), it is recommended to:

seal the connector's area by applying dual component glue DP-805NS (3M), or neutral

silicon on top of the connectors such as Terostat939, or Holdtite HNCS

Page 27

Fuel Point PLUS Vehicle Installation and Configuration Manual

27

8. To secure the coil using clamps:

a. Place two clamps on the coil

b. Place the coil so that the coil support legs face the metal surface and the cable

extending from the coil faces the ID chip

c. Using two self-drilled screws, secure the clamps (see Figure 2-11). Be very

careful not to drill through the fuel tank.

Figure 2-11. Securing the Clamps

To secure the coil using glue:

a. Clean the surface to be glued

b. Apply few drops of Cyanoacrylate adhesive (SuperGlue) to the bottom of the

coil's support legs surface

c. Place the coil so that the coil support legs face the metal surface and the cable

extending from the coil faces the ID chip and hold for several seconds

d. While securing the coil, spray instant glue accelerator around the area.

9. To secure the unit against theft, apply Acrylic, dual-components (epoxy glue) to the

upper and lower part of the chip only as shown in Figure 2-12

Page 28

Fuel Point PLUS Vehicle Installation and Configuration Manual

28

Figure 2-12. Securing the ID Chip

2-5.4.1. Installing the ID Chip inside the Trunk

As aforementioned, to prevent theft and tampering it is highly recommended to install the ID

chip in a concealed place in the luggage compartment. This procedure is also suggested for

vehicles having plastic fuel inlets.

Proceed as follows:

1. Drill a 0.094" (2.5mm) hole inside the trunk near the fuel inlet using a drilling machine

approved for hazardous environment (see Figure 2-13)

Figure 2-13. Drilling the Trunk

2. Clean thoroughly the surface on which the ID chip is to be placed using a clean cloth

and cleaning solution

Page 29

Fuel Point PLUS Vehicle Installation and Configuration Manual

29

3. Apply instant glue to the back part of the ID chip

4. Secure the screw into position in the space prepared, without applying too much

pressure on the screw (see Figure 2-14)

5. Spray instant glue accelerator - Activator, pronto, 60ml (3M) around the glued area

Figure 2-14. Securing the ID Chip

6. Drill a 0.236" (6mm) hole inside the trunk near the fuel inlet and pass the ID chip wires

through the hole

7. Connect the ID chip to the coil's connector and seal the connector's area as described

above

Page 30

Fuel Point PLUS Vehicle Installation and Configuration Manual

30

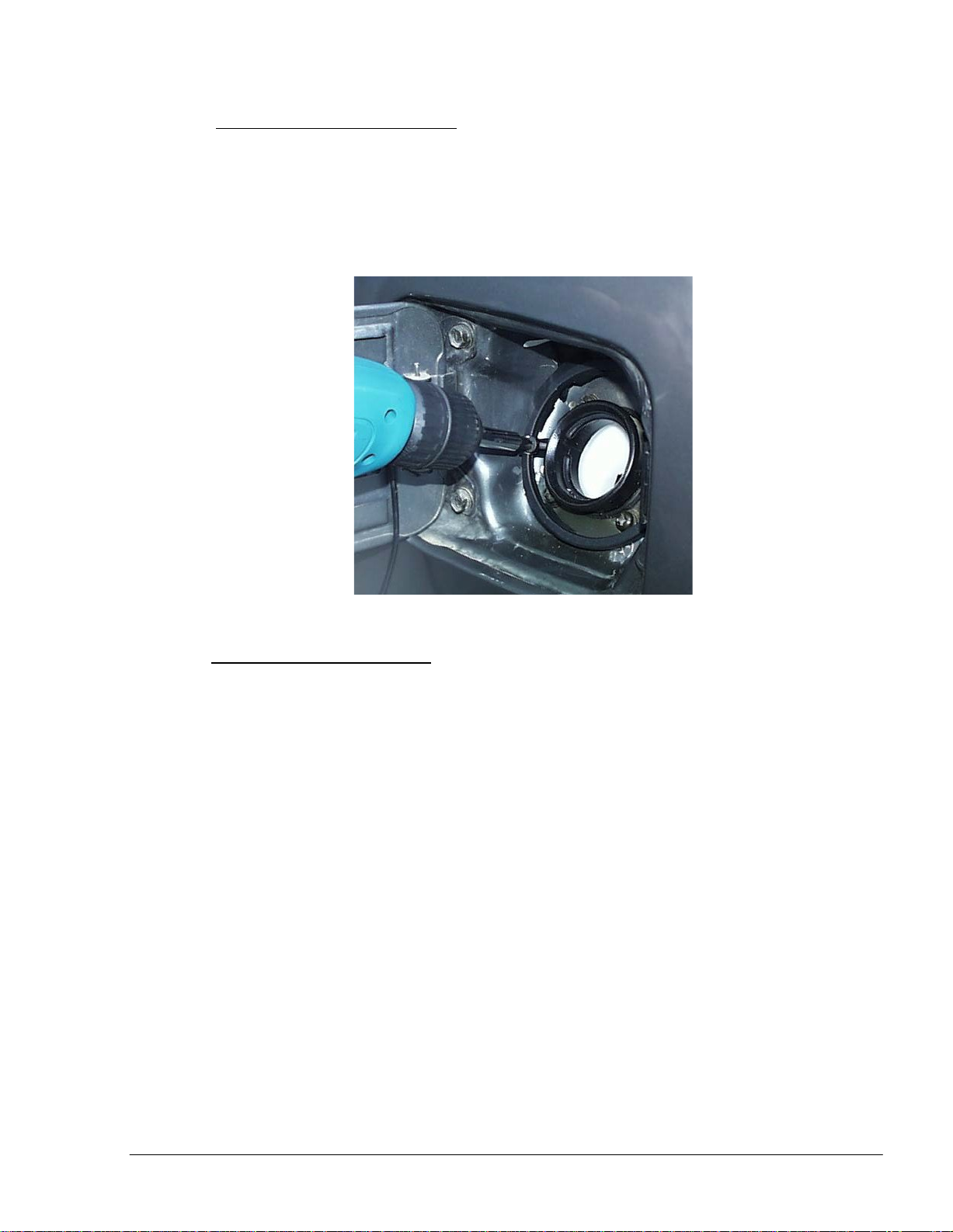

2-6. HEAVY DUTY VEHICLES INSTALLATION

2-6.1. General

In order to provide a solution for various fuel tank inlets in different truck models, the following

installation configurations are available:

Long Neck Fuel Inlet Installation

Short Neck Fuel Inlet Installation

Self installation

The coil unit is placed around the fuel inlet. Positioning the Fuel Ring as far as possible from the

surface of the truck, achieves better performance. The coil should be installed using Gasboy's

molded Fuel Ring clamps. Those clamps are used to achieve sufficient distance from the fuel tank

inlet and from the fuel tank surface for maximum performance. The ID chip is secured against theft

and is damaged when pulled away from the vehicle after installation is completed.

2-6.2. Preliminary Instructions

Before installing or servicing equipment, carefully

observe the warnings and precautions provided at

the beginning of this manual.

WARNING

NOTE

Warranty does not cover defects or damage caused

by improper installation.

In order to prevent possible problems and difficulties during the installation, please verify that:

1. The coil in use is larger than the fuel tank inlet diameter by approximately 0.984" (25mm)

2. The coil is assembled as close as possible to the inlet cap, without interfering with the

opening and closing of the fuel tank inlet cover

3. In cases where the fuel tank is made of aluminum, a gap of at least 76mm" is maintained

between the coil and the tank and also between the coil and the fuel inlet (larger coil is

recommended)

4. In cases where the Security cover is used, it is positioned as close as possible to the fuel inlet

and to a side wall to prevent rotation or any movement which could damage the ID chip or

the wiring

5. The coil cable is protected from harsh environment by a metal conduit

6. The ID chip is placed in a less accessible location for prevention of theft and tampering

7. The ID chip is not secured to the fuel tank. The Fuel Ring cable is long enough to allow

placing the ID chip in a safe and hidden place inside the truck (a distance of up to 100cm

between the coil and the ID chip is permitted)

Page 31

Fuel Point PLUS Vehicle Installation and Configuration Manual

31

8. The unit is handled and carefully, avoiding mechanical pressure on the chip. Improper

handling could damage the unit and cause malfunction

9. In long neck installations, an additional metal band is tied under the installed coil to prevent

the coil from sliding down and guarantee extra safety.

2-6.3. Required Tools

Cutter

Crimping tool

Pliers

Isolation tape

0.5" (13mm) wrench key

Soldering iron

Soldering tin

CV joint banding tool and cuter (see Figure 2-15)

2-6.4.Coil Installation

2-6.4.1. Long Neck Fuel Inlet Installation Procedure

This installation method is implemented in fuel tanks where the fuel tank inlet protrudes sufficiently

from the fuel tank surface. It makes use of vertical positioning of the molded coil clamps.

Proceed as follows:

1. Place an adequate number of clamps evenly around the coil (use three to five clamps per

coil size). Make sure that the clamps are positioned vertically (see Figure 2-16)

Figure 2-15. CV Joint Banding Tool and Cutter

Page 32

Fuel Point PLUS Vehicle Installation and Configuration Manual

32

Figure 2-16. Positioning the Clamps

2. Remove the fuel inlet cover

3. Tighten the clamps to the fuel tank inlet using the stainless steel clamp band: insert the

clamp band into the designated slots of the clamps. Fasten the metal band firmly to

avoid future sliding of the Fuel Ring using the joint banding tool and cuter (see

Figure 2-17)

Before tightening the metal band, raise the coil as

much as possible to bring it close to the fuel inlet

(less than 3cm) and verify that the coil does not

interfere with the opening and closing of the fuel

tank inlet cover.

NOTE

Page 33

Fuel Point PLUS Vehicle Installation and Configuration Manual

33

Figure 2-17. Tightening the Clamps

4. Lock and tighten it and then cut the edges using the CV Joint Banding Tool and cutter

5. Using a drilling machine or pliers, insert the provided conduit termination nipples at

each side of the flexible conduit

6. Thread the coil wire through the flexible conduit

7. Verify that the cover can be properly closed upon completion of the installation.

Then close the fuel inlet cover. (see Figure 2-18)

Figure 2-18. Complete Coil Installation on Long Neck Inlet

2-6.4.2. Short Neck Fuel Inlet Installation

This installation is implemented in fuel tanks where the fuel tank inlet does not protrude sufficiently

from the fuel tank surface. This installation method makes use of horizontal positioning of the

molded coil clamps.

Proceed as follows:

1. Use a Fuel Ring of optimal size which can be easily placed around the fuel tank inlet and

allows the opening and closing of the fuel tank inlet cover (use a coil larger than the fuel

tank inlet diameter by approximately 35 mm)

2. Insert a metal wire into the molded clamps in the designated slots. Use adequate number

of clamps to position the coil firmly around the fuel tank inlet (use three to five clamps

per coil size). Make sure to position the clamps horizontally as shown in Figure 2-19

Page 34

Fuel Point PLUS Vehicle Installation and Configuration Manual

34

Figure 2-19. Securing Clamps on Short Neck Inlet

3. Using the pistol grip (or pliers), pull the metal wire and twist it until the molded coil

clamps are firmly fastened to the truck's fuel tank inlet. Please note that fastening the

metal wire too strongly may tear the molded coil clamps or wire, while fastening it too

weakly may cause the coil to slide

Before tightening the metal band, raise the coil as

much as possible to bring it close to the fuel inlet

(less than 30mm) and verify that the coil does not

interfere with the opening and closing of the fuel

tank inlet cover.

4. After tightening the metal wire, cut the redundant part of the wire using a cutter.

5. Insert the coil into the molded clamps as shown in Figure 2-20

NOTE

Page 35

Fuel Point PLUS Vehicle Installation and Configuration Manual

35

2-6.4.3. Self Installation

Self installation is performed where both long neck and short neck fuel inlet installations cannot be

performed. The coil is equipped with a rubber membrane, which attaches the coil firmly to the fuel

tank inlet using pressure.

Figure 2-20. Complete Coil Installation on Short Neck Inlet

Proceed as follows:

1. Use a Fuel Ring of optimal size which can be easily placed around the fuel tank inlet and

allows the opening and closing of the fuel tank inlet cover (use a coil larger than the fuel

tank inlet diameter by approximately 25 mm)

NOTE

Raise the coil as much as possible to bring it close to

the fuel inlet (less than 30mm), and verify that the

coil does not interfere with the opening and closing

of the fuel tank inlet cover.

2. Install a metal band around the fuel tank inlet and underneath the coil. to prevent the coil

from sliding down

3. Install the coil on the fuel tank inlet applying pressure (see Figure 2-21)

Figure 2-21. Complete Coil Self – Installation

2-6.5.Chip Installation

2-6.5.1. Installing the Chip with a Security Cover

In order to install the ID chip using a Security cover, proceed as follows:

1. Close the fuel inlet cover

2. Choose an optimal and secure position for the Security cover

Page 36

Fuel Point PLUS Vehicle Installation and Configuration Manual

36

3. Connect the ID chip wires to the coil wires after cutting the chip’s connector by

soldering them or using connection terminals (Conn end. Wire ETC EC-2), or any other

suitable connection

4. Verify that the ID chip is programmed with correct data, using the Wireless Programmer

5. Glue the ID chip inside the Security cover (see Figure 2-22)

Figure 2-22. ID Chip Installed in a Security Cover

6. Attach the security cover to a free hole in the vehicle chassis using the ~0.33" (8mm)

dedicated screw

7. If there are not unoccupied holes, create a ~0.33" (8mm) thread hole using a tap in any

available bar and attach the security cover as shown in Figure 2-23

Figure 2-23. Attaching the Security Cover to a Bar

8. Tighten the screw until its head is broken; the Security cover and the ID chip are now

fully secured and cannot be removed from the vehicle.

Page 37

Fuel Point PLUS Vehicle Installation and Configuration Manual

37

Figure 2-24. Tightening Security Cover

2-6.5.2. Installing the Chip without Security Cover

1. Close the fuel inlet cap

2. Choose an optimal, secure and flat position for the ID chip

3. In the designated area, drill a 0.94" (2.4mm) diameter hole. Do not drill through the fuel

tank! Upon drilling completion, clean the area before applying the glue

4. When installing any coil other than the Shaped coil, connect the ID chip wires to the coil

wires after cutting the chip’s connector by soldering them or using connection terminals

(Conn end. Wire ETC EC-2), or any other suitable connection

5. Verify that the ID chip is programmed with correct data, using the Wireless Programmer

Screw the unidirectional screw through the ID chip in the space prepared. Carefully push

the ID chip towards the vehicle's surface. Don’t tighten the screw firmly; verify that the

chip has a certain amount of freedom and can slightly rotate

6. Tighten the coil-ID chip wires to a fixed object, so as not to interfere with the refueling

process.

Page 38

Fuel Point PLUS Vehicle Installation and Configuration Manual

38

SECTION 3

DATAPASS &

µDATAPASS DESCRIPTION &

INSTALLATION

3-1. OVERVIEW

DataPass is a miniature unit that connects to the vehicle bus and captures data from the vehicle

CPU/BUS. The data is transmitted to the nearest Wireless Gateway Terminal (WGT) in the

forecourt.

The following types are available:

µDataPass / µDataPass+: plugs into the vehicle diagnostic connector (OBD), intended for

light and commercial vehicles

DataPass / DataPass+: connected to the vehicle bus and used in light vehicles, heavy

vehicles and trucks

Table 3-1 enumerates the types of DataPass units available for heavy and light vehicles and the

compatible vehicle interfaces. The device type is recognized by the Wireless Programmer, as

well as by the WGT and OrData system.

Table 3-1. DP Types

Name DP Type Vehicle Interfaces

DP for Heavy Vehicles

DP Heavy

J1587, J1939, FMS, Pulses

vehicle

DP+ for Heavy Vehicles

DP Heavy

J1587, J1939, FMS, Pulses

vehicle

DP for Light Vehicles

DP Light

vehicle

µDataPass CAN Bus

µDataPass+ CAN Bus

µDataPass k-line

µDataPass+ k-line

µDP CAN OBD II CAN

µDP CAN OBD II CAN

µDP K-Line OBD II K Line

µDP K-Line OBD II K Line

OBD II CAN, OBD II K

Line, Pulses

3-1.1. Vehicle Data Provided

The basic DataPass and µDataPass units collect Odometer and Engine Hour information from the

vehicle and it is sent through the WGT network to the FHO for the fleet manager to use.

Page 39

Fuel Point PLUS Vehicle Installation and Configuration Manual

39

The DataPass Plus and µDataPass Plus vehicle units collect on top of Odometer and Engine Hour,

is

n

nts

additional information from the vehicle, enabling the Fleet Managers to get an updated picture on

the vehicles' current status. Table 3-2 describes all vehicle parameters which may be collected and

reported by DataPass Plus devices.

Table 3-2. DataPass Plus Vehicle Parameters

Parameter

Description

Odometer The odometer reading from the vehicle

Main Engine Hour Number of engine hours of the vehicle's main engine

Error Codes On-Board Diagnostics error codes

Aux#1 E.H. Engine Hours of the utility engine which may be

connected to vehicle bus or to DataPass physical line

#1

Aux#2 E.H. Engine Hours of the utility engine which may be

connected to vehicle bus or to DataPass physical line

#2

PTO Power take-off operating hours

Idle Time Idle time counter starts whenever the vehicle's engine

running while the speed is zero for a period longer tha

the threshold defined for the vehicle. Number of eve

and accumulated idle time are both provided

Over Speeding Accumulated time that the vehicle was driven over the

speed threshold set for the vehicle

Over RPM Number of events in which the vehicle crossed the set

RPM threshold

Fuel Level Fuel volume reading at the time of data downloading

(when vehicle enters the WGT network)

Fuel Consumed Total amount of fuel the vehicle consumed (from day

one)

3-1.2. Availability of Vehicle Data according to Vehicle Interface Type

Table 3-3 enumerates the list of data parameters that can be supported by each of the vehicle

interface types. The various DataPass types can provide parameters according to their availability in

the various interfaces.

Table 3-3. Availability of Vehicle Data according to DataPass and Interface Type

DP+ Heavy μDP+ μDP+ DP Heavy μDP μDP

Page 40

Fuel Point PLUS Vehicle Installation and Configuration Manual

40

Int. Type/

Data Item

1587 1939 FMS PLS CAN K J1587 J1939 FMS PLS CAN K

Odometer + + + + + + + + + + + +

Error

Codes

Main

E.H.

+ + + - + + - - - - - -

+ + + + + + + + + + + +

Aux1 E.H + + + - - - - - - - - -

Aux2 E.H + + + - - - - - - - - -

PTO

Timer

+ + + - - - - - - - - -

Idle Time + + + - + + - - - - - -

Fuel

Consumed

Fuel

Level

Over

speeding

Over

RPM

+ + + - - - - - - - - -

+ + + - + + - - - - - -

+ + + - + + - - - - - -

+ + + - + - - - - - - -

Availability of parameters may vary from vehicle to

vehicle, since a parameter defined in the interface

protocol may be actually not provided by the

vehicle.

3-2. DATAPASS DESCRIPTION

DataPass and is used in heavy and light vehicles and supports most common bus protocols.

The following units are available:

DataPass for light vehicles P/N M09693B004 (see Figure 3-1)

NOTE

Page 41

Fuel Point PLUS Vehicle Installation and Configuration Manual

41

DataPass + for heavy vehicles, P/N M09693B001

Figure 3-1. DataPass for Light Vehicles (OBD-II)

Figure 3-2. DataPass (J1708/FMS) for Heavy Vehicles

The DataPass is installed using the provided DataPass harness (see Figure 3-3). The harness is

installed inside the driver cabin, behind the dashboard and connects to the vehicle's diagnostics

connector in light vehicles, or to the diagnostics plug rear wiring in heavy vehicles.

Page 42

Fuel Point PLUS Vehicle Installation and Configuration Manual

42

Figure 3-3. DataPass Harness

3-2.1. Technical Specifications

Table 3-4 lists the specifications for the DataPass units.

Table 3-4. DataPass Specifications

Parameter Value

Height 15 mm

Width 70 mm

Physical

Depth 21 mm

Weight 45g

Connectors 562810 Molex

Supply voltage Normal operation: 12VDC

(Nominal)

Minimum: 10 VDC

Maximum: 32 VDC

Current

consumption

Electrical

(typical)

Temperature

Environmental

Conditions

Range

Humidity 95% non-condensing

KLINE Mode:

Sleep mode: 5mA

Active mode: 35mA

CAN Mode:

Sleep mode: 5mA

Active mode: 25mA

J1708 Mode:

Sleep mode: 5mA

Active mode: 25mA

Operating: -40 to +70 ºC

Storage: -40 to +85 ºC

Page 43

Fuel Point PLUS Vehicle Installation and Configuration Manual

43

Parameter Value

Wireless

Interfaces

Single IEEE802.15.4 wireless

channel

Operating Frequency:

ISM 2.405 to 2.480 GHz

(Global license free band)

Implements proprietary mesh

network

IEEE802.15.4

Modem

DSSS/FA – Direct Sequence

Spread Spectrum with

Frequency Agility

Supported network topologies:

Propriety mesh network

Channel capacity:

Communication

Wireless Antenna Built in PCB Antenna

Wired Interfaces OBDII – J2284/ISO15765 (CAN

16 frequency channels /

5MHz channel spacing

Transmit power output:

2mW (3dbm)

Receive sensitivity:

-101dbm

BUS)

Data rate: 250Kbps / 500Kbps

OBDII – ISO14230/ISO9141

(KLINE)

Data rate: 10400bps

J1708/J1587

Data rate: 9600bps

3-2.2. DataPass Pinout

Table 3-5 details the DataPass connector pinout.

Table 3-5. DataPass Pinout

Pin # Pin Name Description

10 VIN- Supplied voltage (–)

9 VIN+ Supplied voltage (+)

Page 44

Fuel Point PLUS Vehicle Installation and Configuration Manual

44

PULSES

interface is selected (via the WP)

8 K LINE Utilized for K- line protocol

7 Rx Used for diagnostics

6 Tx Used for diagnostics

5 ODO

Pulses representing mileage from vehicle; use when PLS

4 VPW For future use

3 BUS L For CanBus protocol, connect to 'CAN L' in the vehicle bus

(OBD-II DataPass type only)

For J1708 protocol, connect to 'Line A' in the vehicle bus

(J1708 DataPass type only). For J1939 protocol, connect to

CAN L to DP pin 3

2 BUS H For CanBus protocol, connect to 'CAN H' in the vehicle bus

(OBD-II DataPass type only)

For J1708 protocol, connect to 'Line B' in the vehicle bus

(J1708 DataPass type only)

For J1939 protocol, connect to CAN H to DP pin 2

J1939 - communication type protocol utilized in trucks (its

implementation varies from truck manufacturer to the other; it

is recommended to test the DataPass with the relevant vehicle

to ensure it is supported

1 ENG

HOUR*

*Connect pin#1 (blue) to ignition switch, to achieve Sleep mode for the

DataPass, or connect pin#1 to pin#9 (no timeout Sleep mode).

Signal representing engine hours from vehicle; use when PLS

interface is selected (via the WP)

3-3. µDATAPASS DESCRIPTION

Intended for light and commercial vehicles, the µDataPass is a connector shaped unit that plugs into

the light vehicle On Board Diagnostics connector (OBD II).

The following units are available:

μDataPass for CAN Bus protocol, P/N M09693B002 (see Figure 3-4)

μDataPass+ for CAN Bus protocol, P/N M09693B005

μDataPass for K-Line Bus protocol, P/N M09693B003 (see Figure 3-5)

μDataPass + for K-Line Bus protocol, P/N M09693B006

Page 45

Fuel Point PLUS Vehicle Installation and Configuration Manual

45

Figure 3-4. µDataPass for CAN Bus

Figure 3-5. µDataPass for K-Line Bus

Please check the manufacturer specifications for the

proper protocol supported by the vehicle.

3-3.1. Technical Specifications

Table 3-6 lists the specifications for the μDataPass units.

Table 3-6. μDataPass Specifications

Parameter Value

Height 22 mm

Width 70 mm

Physical

Electrical

Depth 17 mm

Weight 10g

Connectors OBDII compatible (male)

Supply voltage Normal operation: 12VDC

NOTE

Page 46

Fuel Point PLUS Vehicle Installation and Configuration Manual

46

(Nominal)

(KLINE)

Parameter Value

Minimum: 10 VDC

Maximum: 32 VDC

Current

consumption

(typical)

KLINE Interface:

Sleep mode: 4mA

Active mode: 35mA

CAN Interface:

Sleep mode: 4mA

Active mode: 25mA

Environmental

Conditions

Temperature

Range

Wireless

Interfaces

Operating: -40 to +70 ºC

Storage: -40 to +85 ºC

Single IEEE802.15.4 wireless

channel

Operating Frequency:

ISM 2.405 to 2.480 GHz

Communication

IEEE802.15.4

Modem

(Global license free band)

Implements proprietary Mesh

network

DSSS/FA – Direct Sequence

Spread Spectrum with

Frequency Agility

Supported network topologies:

Propriety Mesh network

Channel capacity:

16 frequency channels /

5MHz channel spacing

Transmit power output:

2mW (3dbm)

Receive sensitivity:

-101dbm

Wireless Antenna Built in PCB Antenna

Wired Interfaces OBDII – J2284/ISO15765 (CAN

BUS)

Data rate: 250Kbps / 500Kbps

OBDII – ISO14230/ISO9141

Page 47

Fuel Point PLUS Vehicle Installation and Configuration Manual

47

Data rate: 10400bps

Parameter Value

3-3.2. µDataPass Pinout

Table 3-7 details the µDataPass connector pinout:

Table 3-7. µDataPass Pinout

Pin # Pin Name Description

16 VIN+ Supplied voltage (+)

4 VIN- Supplied voltage (-)

7 K-line (ISO) Utilized for K- line protocol

6 CAN H For CanBus protocol, connect to 'CAN

H' in the vehicle bus

14 CAN L For CanBus protocol, connect to 'CAN

L' in the vehicle bus

3-4. TOOLS REQUIRED FOR INSTALLATION

The following tools may be needed for installing the DataPass and μDataPass units:

Star head Screwdriver (TORX)

Flat head Screwdriver

Philips head screwdriver

Cutter

Isolating tape

Soldering iron

Soldering tin

3-5. LIGHT VEHICLES INSTALLATION

3-5.1. Checking Vehicle Protocol

In order to install and use the appropriate µDataPass/DataPass unit, it is necessary to check out the

bus protocol: K-Line or Can bus. The Vehicle Call Monitor unit – VCM (see Figure 3-6) enables

users to find out which OBD-II protocol is supported by the vehicle, for cases where the

manufacturer specifications are not available.

Page 48

Fuel Point PLUS Vehicle Installation and Configuration Manual

48

Proceed as follows:

1. Connect the VCN unit to the OBD-II connector using a DataPass harness (P/N

M09680B051)

2. The appropriated indicator LED is lit (K-Line or CAN)

Figure 3-6. VCM Unit

3-5.2. Installing the μDataPass

The µDataPass installation is a very simple process. However, since µDataPass is a very small

device, it is recommended to fasten the unit to the vehicle using a nylon thread or similar fastener to

prevent loss if removed from the OBD II connector during vehicle servicing.

Proceed as follows:

1. Locate the standard On Board Diagnostics (OBD II, see Figure 3-7) connector (usually

hidden behind one of the panels below the steering wheel, or near the pedals)

2. Remove the panel covering the Diagnostics connector

Figure 3-7. Diagnostics Connector

3. Gently plug the µDataPass into the Diagnostics connector being careful not to bend the

µDataPass pins (see Figure 3-8)

Page 49

Fuel Point PLUS Vehicle Installation and Configuration Manual

49

Figure 3-8. Pluging the μDataPass

4. Tighten the µDataPass in place using a finger (see Figure 3-9)

Figure 3-9. Tightening the μDataPass

5. Re-assemble the board covering the Diagnostics connector.

3-5.3. Installing the DataPass

NOTE

µDataPass installation is the preferred solution for

light vehicles, so the following procedure is rare and

conducted in cases where µDataPass cannot be used.

When access to the rear Diagnostics connector is

problematic, the Adaptor Plug is used (see Para. 3-

5.3.1). In cases where the vehicle Bus cannot be

located, find an Odometer pulses source and connect

to the DataPass.

The DataPass is connected to the Diagnostics connector (see Figure 3-10, Figure 3-11 and

Table 3-8) using the DataPass Harness, exposing the Diagnostics connector's wiring and welding

each of its wires to the corresponding wire in the DataPass Harness as specified in Table 3-8.

Page 50

Fuel Point PLUS Vehicle Installation and Configuration Manual

50

White*

To white wire in VIU

Pulse out to VIU

Yellow**

7

K-line

Green***

6

CAN H

Gray***

14

CAN L

Red****

16

VIN+

Black

4

VIN-

Blue****

16

+POLE

Figure 3-10.OBDII Connector Wiring to DataPass Harness

Table 3-8. Harness OBDII Connections

Short

Harness Wire

OBD-2 Pin

* Do not connect if VIU in exists

** If K-line communication is utilized, do not connect Green & Gray wires

*** If CANBUS communication is utilized, do not connect Yellow wire

**** Short is connected between red and blue wires if engine hour output is not used

Figure 3-11. OBDII Connector Pins Layout

Proceed as follows:

1. Locate the standard On Board Diagnostics (OBD II, see Figure 3-7) connector (usually

hidden behind one of the panels below the steering wheel, or near the pedals)

2. Remove the Diagnostics connector panel (see Figure 3-12)

CAUTION

Confirm the bus protocol in use before proceeding

with the installation. Consult vehicle's technical

specifications if needed.

Description

Page 51

Fuel Point PLUS Vehicle Installation and Configuration Manual

51

Figure 3-12. Removing the Diagnostics Connector Panel

3. Solder DataPass Harness wires to Diagnostics connector wires as in Table 3-8 (see

Figure 3-13)

Figure 3-13. Soldering DataPass Harness to Diagnostics Connector Wires

4. Wrap each soldered wire in insulating tape (see Figure 3-14)

Figure 3-14. Wrapping Connections in Insulating Tape

5. Cut unconnected wires, attach them to the harness and cover with insulating tape (see

Figure 3-15)

Page 52

Fuel Point PLUS Vehicle Installation and Configuration Manual

52

Figure 3-15. Covering Unconnected Wires with Insulating Tape

6. Wrap the newly created harness in insulating tape

7. Connect the DataPass to the harness

8. Fasten the DataPass to any of the vehicle panels/rods using a tie wrap; verify that the

unit does not move (see Figure 3-16)

Figure 3-16. Fastening the DataPass Unit

9. Fasten the newly created harness to any of the vehicle panel/rod; verify that the harness

3-5.3.1. Adaptor Plug

As previously mentioned, the Adaptor plug is used only in cases where it is difficult to access the

connector's rear side.

Perform the following steps:

is well secured

10. Re-assemble the Diagnostics connector panel.

3. Connect the red connector of the adaptor plug to the car's Diagnostics connector (see

Figure 3-17)

Page 53

Fuel Point PLUS Vehicle Installation and Configuration Manual

53

Figure 3-17. Connecting the Adapter Plug

4. Connect the white connector of the adaptor plug to the DataPass connector (see

Figure 3-18)

Figure 3-18. Connecting the DataPass to the Adaptor Plug

5. Fasten the DataPass to the vehicle using a tie wrap; verify that the unit does not move.

3-5.3.2. Installing a Pulse Divider Device

The Pulse Divider (see Figure 3-19) is used in cases where the vehicle's pulse output cannot be read

by the DataPass due to weak signal, too high frequency or vehicle differential signal.

The Pulse Divider receives the inappropriate vehicle signal (Pickup signal), shapes it and/or divides

its frequency to match the signal to the DataPass requirements for reading. Two types of devices are

available:

Pulse Divider (full functionality)

Pulse Divider 4 Digital (limited functionality)

Usually installed behind the dashboard, near the wiring hub of the vehicle, the Pulse Divider can be

connected in three ways: refer to Table 3-9 and Table 3-10 for optional connections and pinout.

Page 54

Fuel Point PLUS Vehicle Installation and Configuration Manual

54

Figure 3-19. Pulse Divider

Table 3-9. Pulse Divider Connections

Signal Type Description Connection Diagram

Option A

Option B

Option C

Input pulses are

above/under zero

level and/or weak

Input pulses are

above zero level

(positive)

Input pulses are

differentia

Page 55

Fuel Point PLUS Vehicle Installation and Configuration Manual

55

Table 3-10. Pulse Divider Pinout

Pin# Wire Color Name Description

1 RED DC INPUT Input voltage from vehicle to Pulse Divider

(10-28VDC)

2 BLACK GROUND Vehicle ground

3 BROWN SIGNAL IN 1 Input pulses from vehicle to Pulse Divider

4 GREEN SIGNAL IN 2 Input pulses from vehicle to Pulse Divider

(when input signal is differential).

Threshold voltage applied to Pulse Divider

when Input pulses are other than differential

5 ORANGE DC OUT N/A

6 GRAY REF/V OUT 1.4VDC reference voltage connected to the

green wire only in cases where Option B is

utilized (otherwise unused)

7 VIOLET :2 OUT Output signal divided by 2

8 YELLOW :4 OUT Output signal divided by 4

9 BLUE :8 OUT Output signal divided by 8

10 WHITE :16 OUT Output signal divided by 16

Page 56

Fuel Point PLUS Vehicle Installation and Configuration Manual

56

3-6. HEAVY VEHICLES INSTALLATION

Pulse

output

Notes

PIN #4 is an alternative in cases

where C3 is available

VDO Kienzle Type – 1314

C3

VDO Kienzle Type – 1315

Z4

D3 / B7 are alternatives in cases

where B8 is available

D3 / B7 are alternatives in cases

where B8 is available

VOLVO Motometer

Type EGK100 ,EGK100-01

B8 / B3 are alternatives in cases

where B7 is available

MAZ truck

B7

3-6.1.General

Obtaining Odometer and Engine hours in heavy vehicles can be done in two ways:

Connecting DataPass to odometer pulses output (directly, or via tachograph's pulses output)

Connecting the DataPass to the vehicle bus, which allows retrieving additional information

from the vehicle computer

3-6.2.Connecting the DataPass to Odometer Pulses Source

A simple way to retrieve odometer pulses is from the truck’s tachograph output.

Installation of the DataPass requires disassembling the vehicle's tachograph and accessing its rear

side wiring in order to connect the DataPass harness to the tachograph's wiring.

Table 3-11 depicts

the connections running between the tachograph and the DataPass. There are

common types of tachographs where Pulse output pin number differs from each other; refer to

Table 3-12. to locate the applicable pin number according to tachograph type and model.

Table 3-11. Tachograph – DataPass Harness Connections

DataPass Harness Wire

White

Red

Black

Blue

Table 3-12. Pulse Output Pin in Various Types of Tachographs

Tachograph

Pulse output

VIN+

VIN-

Vehicle switch

Tachograph Types

VDO Kienzle Type – 1310

VDO Kienzle Type – 1318

VDO Kienzle Type – 1319

C3 / #4

B8 / D3 / B7

B8 / D3 / B7

B7 / B8 / B3

Perform the following steps:

Page 57

Fuel Point PLUS Vehicle Installation and Configuration Manual

57

1. Locate the tachograph in the vehicle. Two extraction slots are placed on both sides (see

Figure 3-20)

Figure 3-20. Tachograph Extraction Slots

2. Use the dedicated extraction tool to disassemble the tachograph (see Figure 3-21)

Figure 3-21. Removing the Tachograph

Handle each wire individually until it is fully

connected and isolated to avoid shorts.