Page 1

DISPENSER AND HOSE RETROFIT

INSTALLATION MANUAL

C35593

GASBOY INTERNATIONAL LLC

Page 2

Page 3

FUEL POINT

DISPENSER AND HOSE RETROFIT

INSTALLATION

MANUAL

C35593

REV. 03/28/03

INSTALLERS - IMPORTANT

In addition to installation information, this manual contains warnings, safeguards

and procedures on the use and care o f the Fuel Point System. Please leave this

manual with the system owner after the installation is complete.

Copyright 2003 by Gasboy International LLC All rights reserved.

The information in this document is confidential and proprietary. No further disclosure shall be made without

permission from Gasboy International LLC. Gasboy International LLC believes that the information in this document

is accurate and reliable. However, we assume no responsibility for its use, nor for any infringements of patents or

other rights of third parties resulting from its use. We reserve the right to make changes at any time without notice.

GASBOY INTERNATIONAL LLC LANSDALE, PA

Page 4

IMPORTANT WARNINGS AND SAFEGUARDS

Gasoline and petroleum products are flammable. To avoid injury or death to persons or damage to equipment or

property, follow these listed warnings and other warnings and precautions outlined in this manual when installing, using,

or working around this equipment. Check with GASBOY Technical Services for compatibility of liquids with pump

materials.

TURN OFF AND LOCK OUT ALL POWER TO PUMP BEFORE PERFORMING SERVICE, MAINTENANCE OR IN THE EVENT

All products must be installed by a

qualified installer and used in

conformance with all building, fire, and

environmental codes and other safety

requirements applicable to its

installation and use, including, but not

limited to, NFPA 30, NFPA 30A, NFPA

395 & NFPA 70. A qualified installer is

familiar with fuel systems installations

under the above stated building, fire,

and environmental codes and other

safety requirements for the particular

type of installation.

This product is only part of a fuel

dispensing system and additional

equipment and accessories, such as,

but not limited to, breakaway

connectors, shear valves, pressure

regulators, flow limiters, and other

safety devices may be necessary to

meet the applicable codes.

For maximum safety, we recommend

that all employees be trained as to the

location and procedure for turning off

power to th e enti re system. Instru ctions

regarding proper operation of the

equipment along with the appropriate

safety warnings should be posted in

plain view at the fuel island.

Before performing service or

maintenance (including changing of fuel

filters or strainers) or in the event of a

fuel spill, turn off and lock out all power

to the system. In battery-powered

pumps, disconnect power source. In

submersible pump applications, turn off

and lock out power at the master panel

and close any impact valves to the

submersible pump and any other

dispensers which use that submersible

pump. AC power can feed back into a

shut-off dispenser when dispensers

share a common submersible pump or

starter relay. Also block islands so no

vehicles can pull up to the dispenser

when the dispenser is being worked on.

DO NOT use Teflon tape for any pipe

threads in the product.

DO NOT use consumer pumps for

pumping fuel or additives into aircraft.

DO NOT use commercial pumps for

direct fueling of aircraft without filters

and separators necessary to ensure

product purity.

DO NOT use where sanitary design is

required (for food products for human

consumption) or with water-based

liquids.

DO NOT smoke near the pump or when

using the pump.

DO NOT use near open flame or

electrical equipment which may ignite

fumes.

DO NOT permit the dispensing of

gasoline or other petroleum products

into a vehicle with its motor running.

DO NOT permit the dispensing of

gasoline or other petroleum products

into unapproved containers or into

approved containers in or on vehicles

includin g trucks. All contain ers must be

filled on the ground to prevent static

discharge. Always use Approved and

Listed hoses and nozzles with electric

pumps and dispensers.

DO NOT block open the nozzle in any

manner. Nozzles shall conform to UL

and NFPA code requirements for

attended or unattended service.

DO ensure that the pump is equipped

with proper filters based on the product

being dispensed and its intended use.

DO wear safety goggles and protective

clothes when dispensing any liquid

which may be potentially harmful or

hazardous.

DO keep all parts of body and loose

clothing clear of belts, pulleys, and other

exposed moving parts at all times.

OF A FUEL SPILL.

DO require washing and changing of

clothes if fuel is spilled on a person or

his/her clothing. Keep away from open

flames, sparks, or people smoking.

DO provide a receptacle for catching

product from pump/meter when

servicing.

DO clean up product spills on the

driveway. Turn off and lock out all

power prior to cleanup.

DO insure pump is properly grounded.

DO insure hose is compatible with fluid

being dispensed.

DO inspect hose, nozzle, and pump on

a regular basis for wear, damage, or

other conditions which may create a

safety or environmental hazard.

DO make sure all pipe threads are

properly cut and the inside reamed to

remove burrs. Use UL classified

gasoline-resisting compound on all

joints of gasoline handling piping.

Sealing compound must also be

resistant to Gasohol (Ethanol and

Methanol). Use gasoline-resistant pipe

compound on male threads only; pipe

compound used on female threads can

be squeezed into the supply line where

it can enter the product stream and

become lodged in the pump or meter.

DO ensure that junction box covers are

in place and properly tightened. Mating

surfaces between the box and cover

must be free of dirt, nicks, and

scratches. All unused entries into the

junction box must be properly plugged.

035282 Rev. 1267

GASBOY INTERNATIONAL LLC.

707 North Valley Forge Rd. Lansdale, PA, 19446 ● (215) 855-4631 ● FAX: (215) 855-0341

Page 5

CONTENTS

Section 1: INTRODUCTION

Purpose..................................................................................................... 1-1

System Overview ...................................................................................... 1-1

Fueling Sequence ..................................................................................... 1-2

Important Hose Modification Pointers - Read Before Proceeding............. 1-2

Testing the Fuel Point Installation............................................................. 1-3

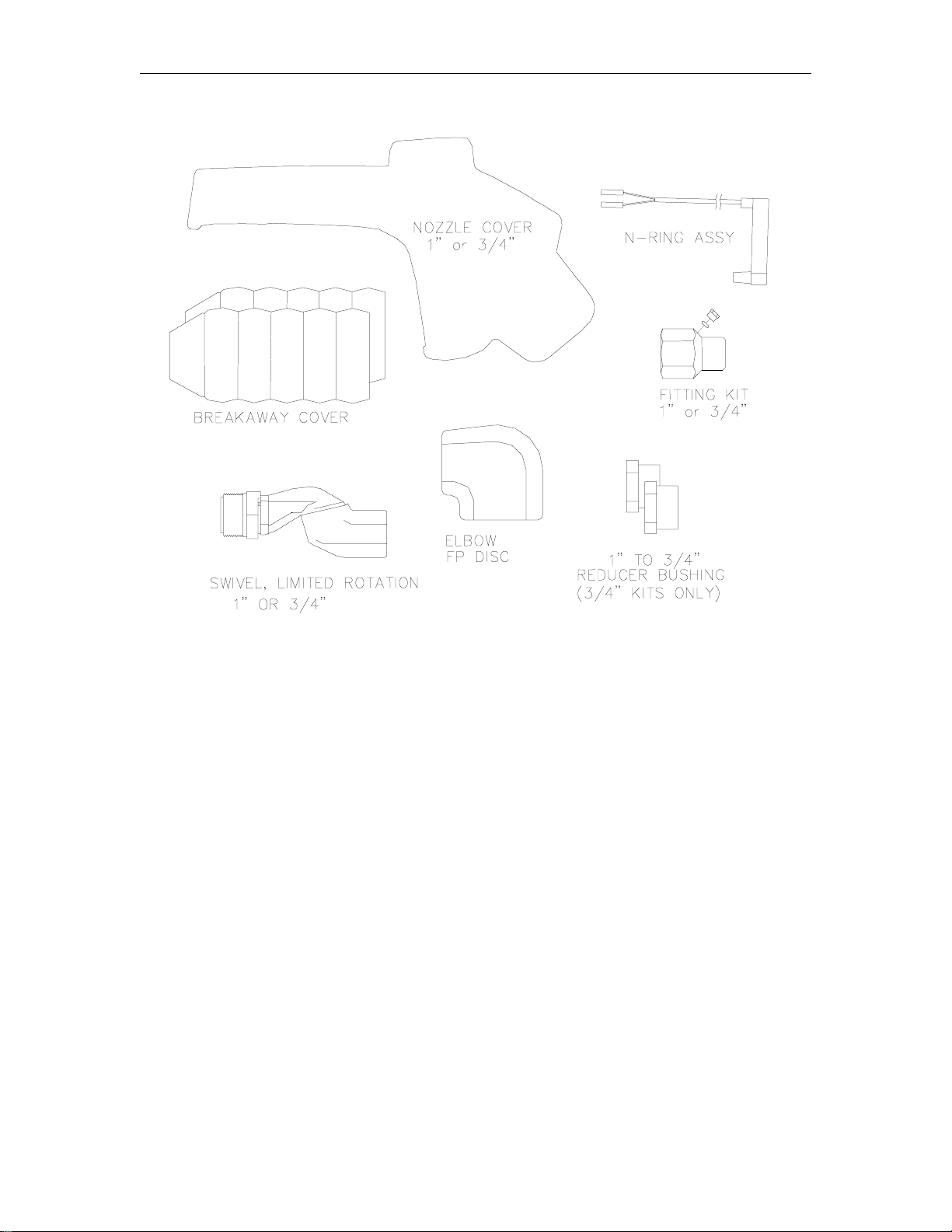

Component Overview................................................................................ 1-4

Section 2: GETTING STARTED

General Information .................................................................................. 2-1

Before You Begin...................................................................................... 2-2

Approved Nozzles For Use With Dispenser Retrofit Kits .......................... 2-2

Dispenser Retrofit Jbox Assemblies.......................................................... 2-3

Unpacking the Dispenser Retrofit Kit ........................................................ 2-3

Fuel Point Hose Retrofit Kits..................................................................... 2-4

Internal Wire Retrofit Components............................................................ 2-7

Using This Manual..................................................................................... 2-8

Section 3: STANDARD INTERNAL WIRE HOSE RETROFIT

Step A: Disassemble Hose....................................................................... 3-1

Step B: Construct Hose Assemblies (Internal Wire)................................. 3-2

Step C: Final Hose and Nozzle Assembly................................................ 3-4

Step D: Reassemble ............................................................................... 3-5

Step E: Complete N-Ring Wiring.............................................................. 3-6

Step F: Apply Power and Check Installation............................................ 3-6

Section 4: VAPOR RECOVERY RETROFIT KITS

Vapor Recover Small Parts Kit, C07389................................................... 4-2

Step A: Construct Vapor Recovery Hose Assemblies............................... 4-3

Step B: Nozzle Assembly.......................................................................... 4-4

Step C: Final Vapor Recovery Hose Assembly......................................... 4-5

Step D: Reassemble Hose to Pump.......................................................... 4-6

Step E: Complete N-Ring Wiring............................................................... 4-7

Step F: Apply Power and Check Installation............................................. 4-7

03/28/03 Contents-1

Page 6

Page 7

Section 1

INTRODUCTION

PURPOSE

The GASBOY Fuel Point Dispenser and Hose Retrofit Installation Manual is provided to assist you

in installing the Listed dispenser retrofit kits for the Fuel Point system on your pumps. This manual

should be supplied to the installer prior to installation to ensure your components are installed

properly. Faulty installations are the major cause of system malfunctions. The system

components must be installed as described in this manual to ensure the reliability and proper

operation of the system. Please read this entire manual before starting installation.

GASBOY provides a toll-free number for customers and installer s having any questions pertaining

to the installation: 1-800-444-5529

SYSTEM OVERVIEW

Fuel Point adapts to Listed GASBOY fuel management systems for hassle-fr ee fueling. System

applications determine actual components required. Your system may consist of several or all of

the following components:

• a GASBOY fuel management system (FMS) (Listed models 1000, 1000P, or 2000S CFN)

• Fuel Point Reader (FPR)

• Pumps/dispensers modified using Listed Dispenser and Hose Retrofit Kits (consisting of I/S

Pre-amp and one or two kits)

• Vehicles equipped with materials from Vehicle Installation Kits (See Manual C35699)

• Vehicle Module(s) (VM’s)

03/28/03 1-1

Page 8

GASBOY Fuel Point System

FUELING SEQUENCE

Fueling a vehicle with a Fuel Point Vehicle Module (VM) is accomplished as follows:

1. Insert nozzle into vehicle tank. Vehicle ID, fuel control and odometer/hour data is

automatically transmitted from the VM via nozzle (N-Ring) and tank (T-Ring) antennas to the

Fuel Point Reader (FPR).

2. FPR communicates with the Fuel Management System (FMS) CFN or 1000 FleetKey unit.

3. FMS authorizes and records vehicle data.

4. When the nozzle is removed, it suspends the transaction, Reinsertion resumes transaction.

5. Transaction terminates when dispenser is turned off, nozzle is inserted into another vehicle, or

suspended transaction is not resumed.

6. Transactions are stored in memory for on-demand retrieval and logger printout.

IMPORTANT HOSE MODIFICATION POINTERS - READ BEFORE

PROCEEDING

Modifying the hose at a work bench is recommended. Use appropriate tools and components. For

reliable and long-lasting installations pay particular attention to the following points as you read the

remainder of the manual:

• Handle the internal hose wire assemblies carefully. Make sure the wire doesn’t become

nicked or cut. A damaged wire within the hose will allow fuel to enter and wick past O-ring

seals inside the jacket, leaking fuel at the connectors and inside the J-box/pre-amp assembly

in the base of the pump.

• If the system does not read the VM after installation of the antenna, first check for continuity

between the N-ring and pre-amp located in the J-box amplifier.

• PVC breakaway and nozzle covers are designed to conceal the breakaway connectors and

wire. The covers must be properly installed.

1-2 03/28/03

Page 9

Introduction

TESTING THE FUEL POINT INSTALLATION

The following test procedures are helpful:

• If the system is set up for use with cards or key activation, first test the pump using the card

or key. Pump a small amount of fuel and check the logger printout to insure the correct

amount is registered. This will test the complete system without the Fuel Point.

• If a master authorizer is available and programmed for the site, it can be used to test the

pump assembly. Hold the authorizer near the N-ring and activate.

• Test the modified pump with a vehicle equipped for use with Fuel Point.

• Verify the hose wiring. At the amplifier/j-box 35 to 40 ohms through the N-ring is required.

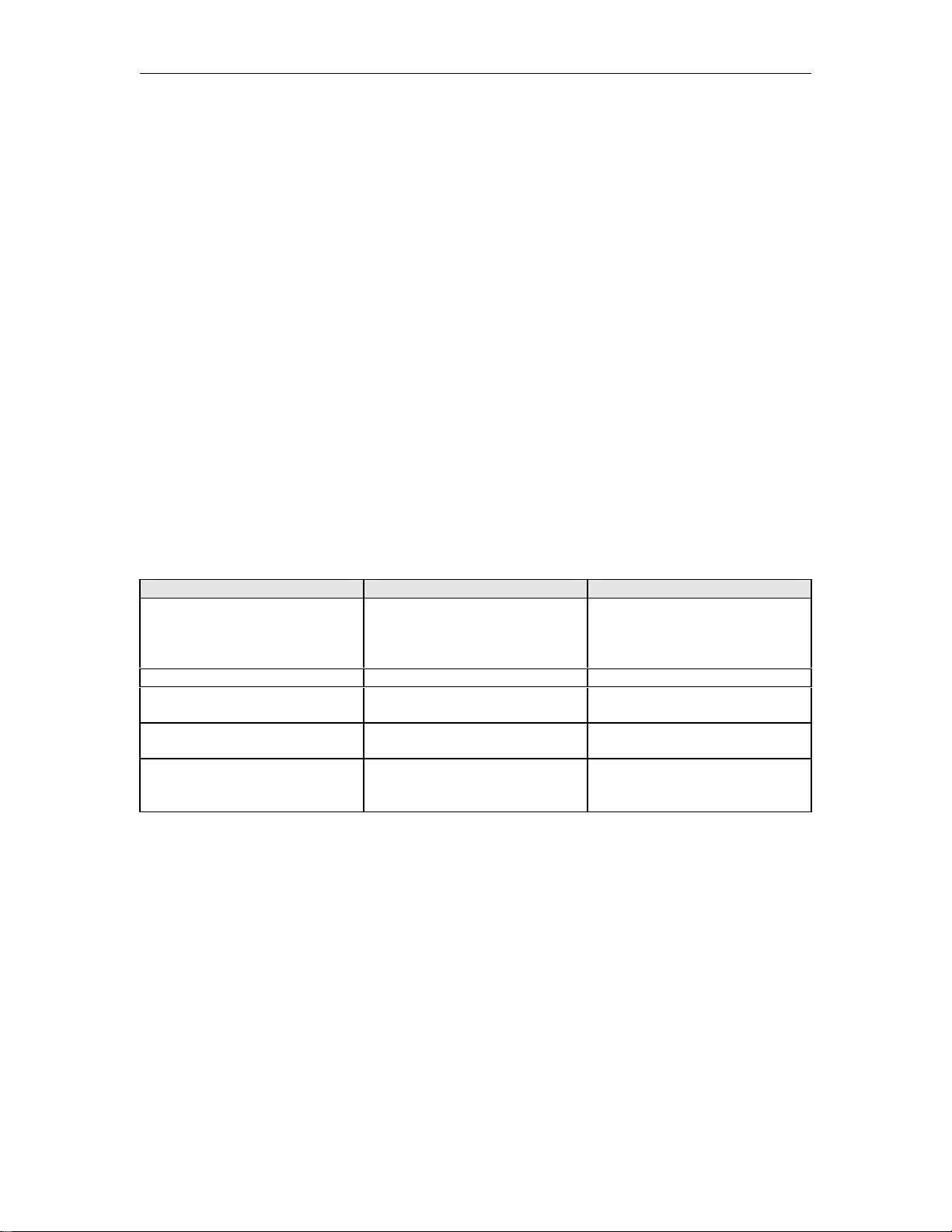

• The following chart provides details for using the Fuel Point Reader LED indicators (on

C08886 PCB) while troubleshooting wiring problems. The chart assumes only one vehicle is

fueling as DL3 and 4 are shared by up to 8 hoses. DL3 and 4 indicate the communications

between the FP Reader and FMS unit. DL1 and 2 indicate communications between the FP

Reader and Vehicle Module.

DL4 DL3 DL2 DL1

* * * *

Red Grn Red Grn

Pump/Nozzle Status Indicator Status Remarks

Not Pump/Nozzle dependent DL4,3 Flashing RS 485 communications.

Should be flashing

continuously. Should mirror the

2 Red LED’s on RS 485 PCB.

Nozzle inserted in vehicle DL1 flashes once Acknowledges Vehicle present.

Nozzle inserted in vehicle DL1,2 flash rapidly Vehicle Module sending data

to FP Reader.

Nozzle starts fueling DL1 flashes on-off Indicates nozzle is stilll present

in vehicle.

Nozzle removed DL1 ceases flashing after short

delay.

NOTE: Turning the pump handle to off or a system time out will cease all activity on DL3

and 4. When testing several vehicles, a small quantity of fuel should be pumped. If

quantity is not pumped, the system will shut off after a programmable number of no

quantity operations. The system must be re-enabled at the terminal. Refer to the

appropriate manual for system in use. When testing several transactions (nozzle

in/outs) you must delay about 5 seconds if communications is lost.

System in suspend mode.

Allows fueler to start fueling

second tank.

1065 1-3

Page 10

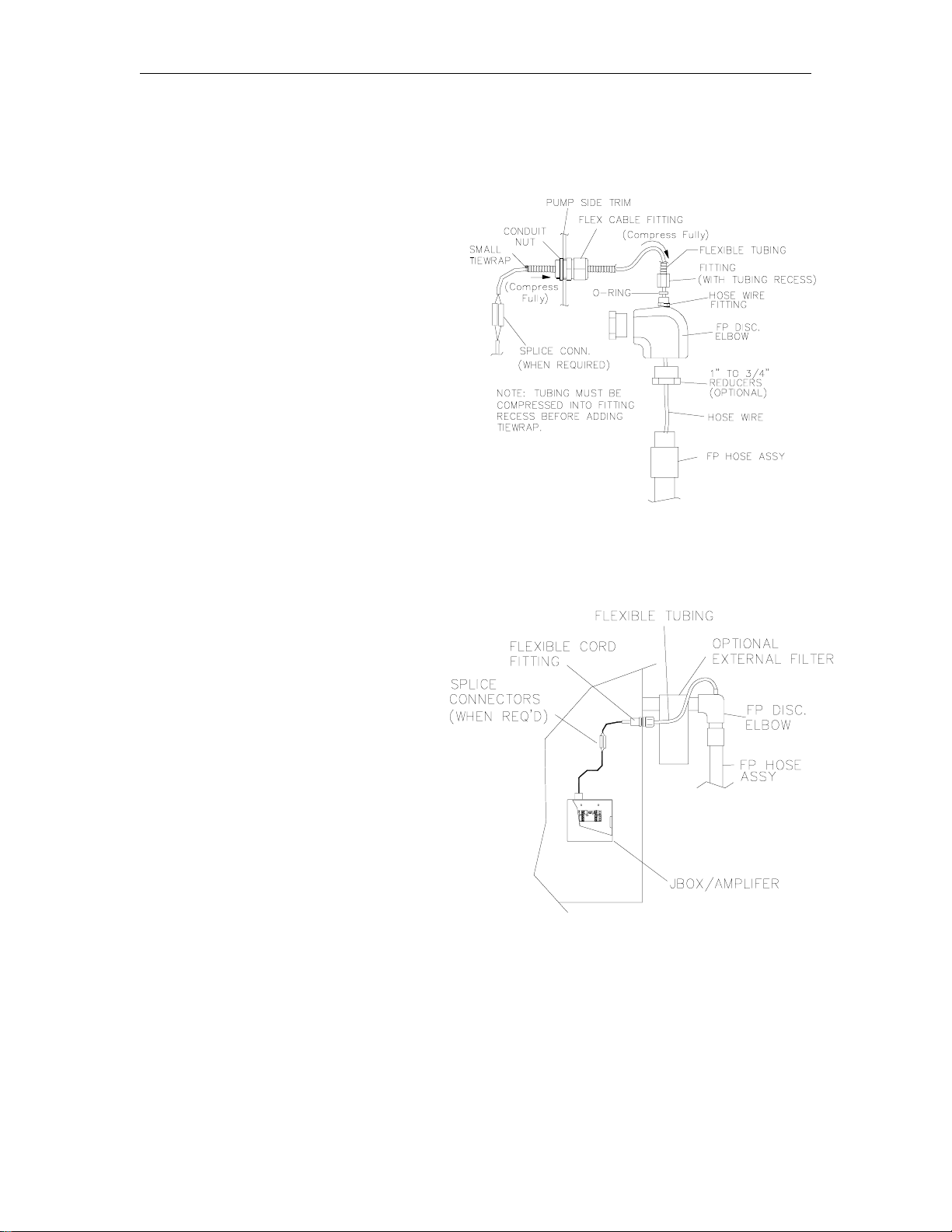

GASBOY Fuel Point System

COMPONENT OVERVIEW

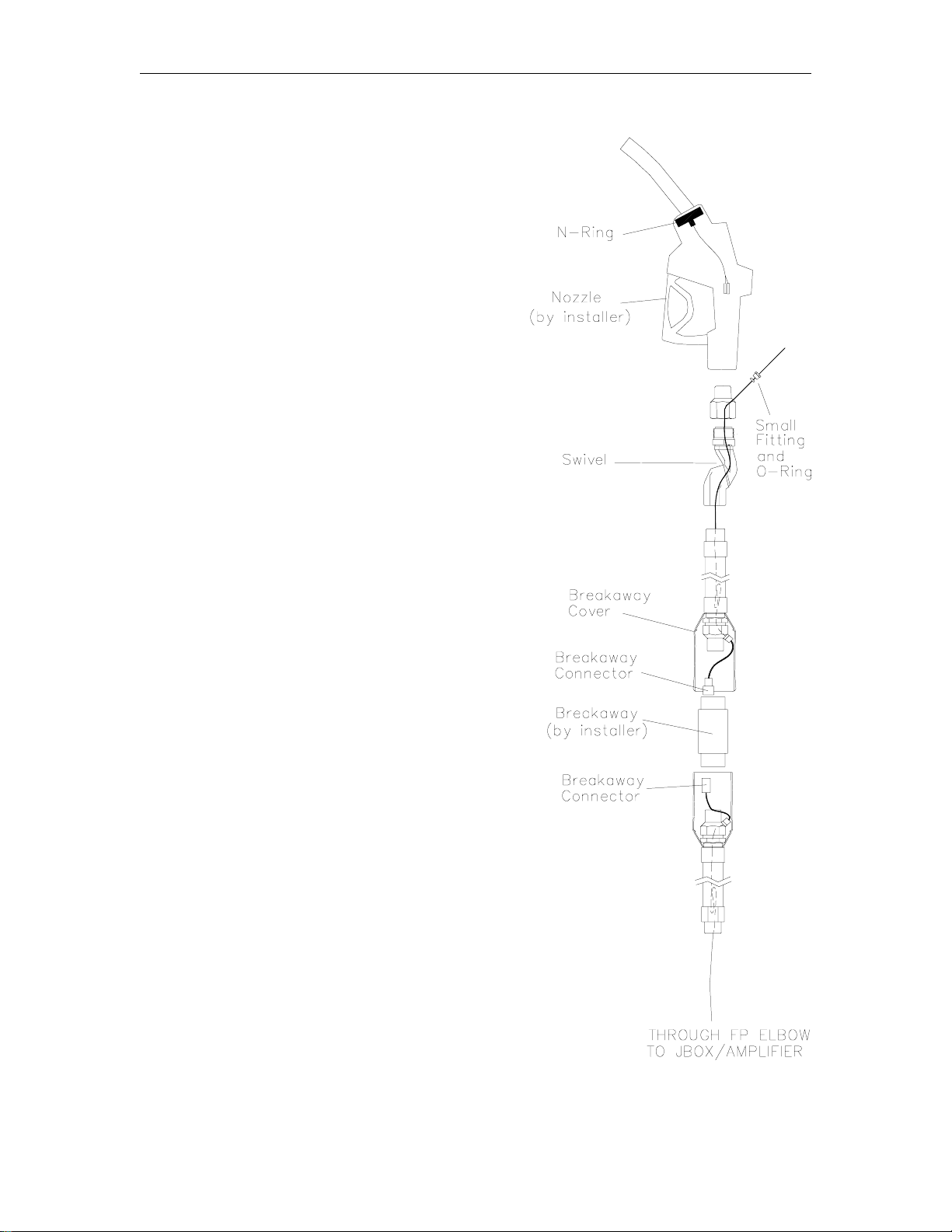

As you read the following descriptions, refer to the

drawing at the right for an overall view of the

assembled hose.

The GASBOY Fuel Point system requires

modification of existing pumps and hoses using

retrofit kits or installing internal-wired, factoryassembled hoses. Each hose outlet requires a

Fuel Point Amplifier available in single, twin or 2-4

hose multiple product assemblies. Hose retrofit

kits provide the parts for field modification of ULapproved fueling dispensers and pumps. To

discourage tampering, hose wiring is internal to the

hose or enclosed in flexible metal tubing.

Connectors are concealed by PVC covers and the

breakaway connector can be reconnected after

drive-offs

Hose assemblies and kits are available in a variety

of configurations for UL-Listed ¾” and 1” standard

and most Vapor Recovery style nozzles. Kits can

be assembled differently based on the breakaway

location. A list of kits and assembly instructions

are discussed later in this manual. Kits include

parts shown in the diagram at right except hoses,

nozzles and fuel breakaway which are to be

supplied by the installer. Wired hoses include

same parts plus the hoses.

The N-Ring assembly (nozzle antenna) mounts at

the base of the fueling spout of the nozzle. The NRing transmits and receives communications to

and from a Fuel Point-equipped vehicle via a TRing (tank ring antenna).

The hose wire provides communications between

the N-ring and Fuel Point J-Box/Amplifier mounted

in the base of the pump. Internal hose wiring

enters and exits the hose through special brass

fittings outfitted with O-ring compression seals.

Hose wires are constructed with a factory-installed

slack loop to compensate for hose stretch that can

occur during a drive-off.

1-4 03/28/03

Page 11

Section 2

GETTING STARTED

GENERAL INFORMATION

The following procedures assume the dispenser to be modified is UL-Listed and has been

installed according to the applicable codes, including a Listed hose assembly, hose nozzle valve,

and breakaway installed according to the manufacturer’s instructions. Apply a UL-classified pipe

lubricant/sealant to all pipe threads. Communications from the vehicle to the Fuel Point reader are

provided by the hose wire. GASBOY recommends that this wire be concealed from the end user

to discourage tampering.

Fuel Point dispensers may be configured in three styles depending on the individual application.

Give careful consideration to the hose style.

Style 1 (Breakaway at Dispenser) and Style 3 (Breakaway at Nozzle) can be constructed from

standard kits. Be sure to specify the kit that meets your particular hose length requirements. Style

3 (Breakaway at the High Hose Clamp) should be specified when a high hose feature is to be

used. Extended hose kits provide for up to a 20-foot main hose length. Style 1 or 2 should be

used where nozzle weight may be a consideration.

03/28/03 2-1

Page 12

GASBOY Fuel Point System

BEFORE YOU BEGIN

CAUTION: Assembly and installation of required components may require drilling and/or

sealing parts. Always assemble hose, nozzles, and any components away from

the fuel site in a safe environment where potentially hazardous fumes are not

present.

Use conduit layout drawings in the Fuel Point Reader Manual, C35628 and check installation for

Fuel Point conduits and J-boxes.

All installations must conform with all building/fire codes, all Federal, State, and Local codes,

National Electrical Code, (NFPA 70), NFPA 30, and Automotive and Marine Service Station Code

(NFPA 30A) codes and regulations. Canadian users must also comply with the Canadian

Electrical Code.

APPROVED NOZZLES FOR USE WITH DISPENSER RETROFIT KITS

Standard interchangeable UL-Listed 3/4 and 1" nozzles may be used with Fuel Point. Nozzle

selection may be affected by vehicle type, vehicle tank configurations, locations and opening

diameter. With the nozzle antenna ring (N-ring) installed, check each vehicle for the following:

• Install a test N-ring on the nozzle. For each vehicle, check the read distance from the N-ring

to vehicle tank (T-ring). Fuel Point will communicate when the rings are no more than 9"

apart provided there is no metal blocking the signal (because N-ring is inside fill collar

opening).

• Check that the nozzle spout is fully inserted into the vehicle’s tank opening and the vehicle

can be safely fueled. If necessary, use a nozzle with a longer spout (OPW 7H with #5 BHB0125 12" spout or Richards Mark 12). Note that longer nozzle may affect pump nozzle

hook/boot configuration.

Vapor Recovery nozzles approved for use with Fuel Point are listed in the table below.

Nozzle MFR. V/R Balanced V/R Balanced V/R Assisted

Short Spout Long Spout

OPW 211V & 211VXS 11VF & 111VXS 11VA & 11VAA

Emco/Wheaton 4015 A4001 & A4005 A4500 & A4505

Husky 5010 5210 V3

Healy ~ ~ 400 & 600

Catlow ~ ~ VM-1

NOTE: The above nozzles are only to be used if the dispenser “replacement label” indicates

acceptability.

For other special applications, call GASBOY Technical Service at 1-800-444-5529.

2-2 03/28/03

Page 13

Getting Started

DISPENSER RETROFIT J-BOX ASSEMBLIES

For Fuel Point, each pump or dispenser will require at least one J-Box/Amplifier Assembly and

one Hose Retrofit Kit for each hose outlet from the list below.

J-Box/Amplifier Assembly

C06832 One Hose

C06833 Two Hose

UNPACKING THE DISPENSER RETROFIT KIT

The contents of the hose modification kit portion of the dispenser retrofit kit is broken down on the

following two pages. You will need the following tools to complete this installation:

• pipe wrenches

• screwdrivers

• meter

• small crescent wrench

• electrical tape

• electrician’s snake or pull wire

• scissors

• ruler

• UL-classified pipe thread sealant

• O-Ring lubricant (Parker O-Lube or

equivalent)

• 6" Heavy-duty tapered Head Cutters

Pliers (Klein, #490PL108)

• Automatic Single Squeeze wire stripper

(Stripmaster, #462ST028)

•

channel lock pliers

• special clamp pincer tool

for VR and VA nozzles

• Crimp tool with crimp

mechanism in head, not in

handle, (T&B #WT-111 or

Klein #490ST016)

03/28/03 2-3

Page 14

GASBOY Fuel Point System

FUEL POINT HOSE RETROFIT KITS

Retrofit Kits include Fuel Point specific parts required to modify existing pumping units. Dual

Plane swivel is included with kit. Hoses, nozzles and breakaways are supplied by the

installer.

¾” P/N 1” P/N V/R Description Max Hose Length

C07100 C07101 C07407 Standard Retrofit Hose Kit 13’ (1+12’)/(12+1’)

C07102 C07103 C07106 High Hose Retriever Retrofit Kit 13’ (6.5+ 6.5’)

C07183 C07104 C07408 Extended Hose Kit Retrofit Kit 21’ (1+20’)

C07440 C07105 ~ Extended High Hose Retrofit Kit 21’ (6+15’)*

C07400 C07401 C07109 Overhead Hose Retrofit Kit 10’ (9’+1)

Internal Wire Factory-Wired Hose Assembly Kit

Factory-wired hose assembly kits include Fuel Point components factor y-wir ed in hoses, complete

with swivel, fittings and hose wires fully assembled. Nozzles and breakaways are to supplied

by the installer

¾ P/N 1” P/N Description Hose Length

C07290 C07295 Wired Hose Assy Kit Standard B/A @ Pump 13’ (12+1)

C07291 C07296 Wired Hose Assy Kit Standard B/A @ Nozzle 13’ (1+12)

C07292 C07297 Wired Hose Assy Kit High Hose B/A Mid. 12’ (6 + 6)

C07293 C07298 Wired Hose Assy Kit Extended B/A @ Nozz 21’ (1 + 20)

C07441 C07402 Wired Hose Assy Kit Extd/High Hose B/A @ Mid. 20’ (6 + 15)*

C07294 C07299 Wired Hose Assy Kit Overhead B/A @ Pump 10’ (9 + 1)

*NOTE: Use this kit for applications where lower nozzle mounting height does not allow for

proper hose hangup, such as Gasboy 1” Front Load 9800A and 215A/216A Series

Pumps.

2-4 03/28/03

Page 15

Getting Started

Kit Contents

1 012116 Nozzle Cover, 3/4”

012113 Nozzle Cover, 1”

2 C07279 N-Ring Assembly

3 012181 Breakaway Cover, Qty. 2

4 C07347 Fitting Kit, 3/4"

C07349 Fitting Kit, 1”

5 003622 Elbow, FP Disc

6 064574 Swivel, Limited Rotation, 3/4”

064575 Swivel, Limited Rotation, 1”

7 C09848 Reducer Bushing, Qty. 2 (3/4” kits only)

(See next page for Hose Wire Parts)

1065 2-5

Page 16

GASBOY Fuel Point System

Kit Contents (Continued)

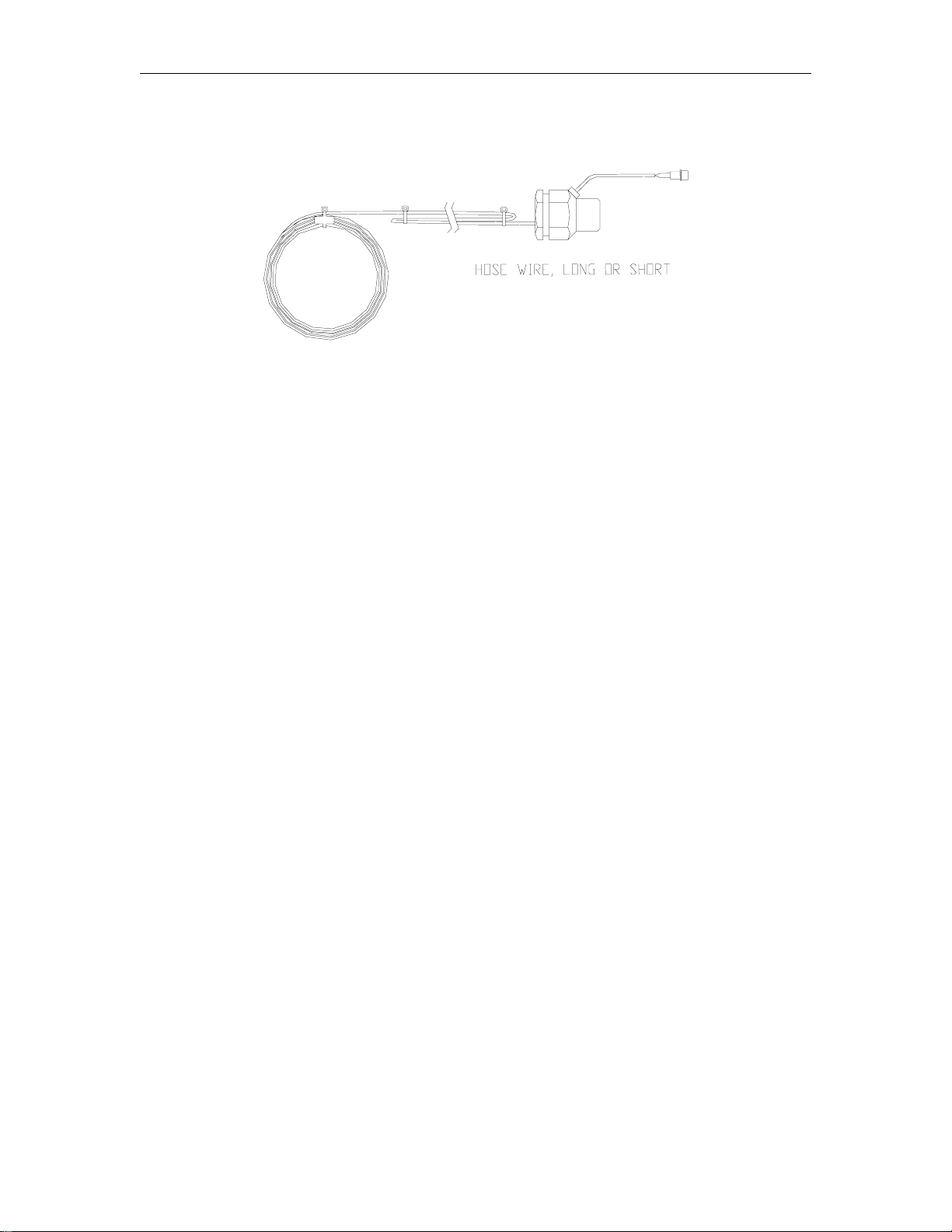

8 Short Hose Wire, Qty. 1

C07341 Wire Assy., 3/4" dia. x 1’ whip hose

C07342 Wire Assy., 3/4" dia. x 8’ hose max.

C07274 Wire Assy., 1" dia. x 1’ whip hose

C07275 Wire Assy., 1" dia. x 8’ hose max.

9 Long Hose Wire, Qty. 1

C07345 Wire Assy., 3/4" dia. x 6-8’ hose max.

C07346 Wire Assy., 3/4" dia. x 12-15’ hose max.

C07344 Wire Assy., 3/4" dia. x 20’ hose max.

C07325 Wire Assy., 1" dia. x 6-8’ hose max.

C07326 Wire Assy., 1" dia. x 12-15’ hose max.

C07327 Wire Assy., 1" dia. x 20’ hose max.

2-6 03/28/03

Page 17

Getting Started

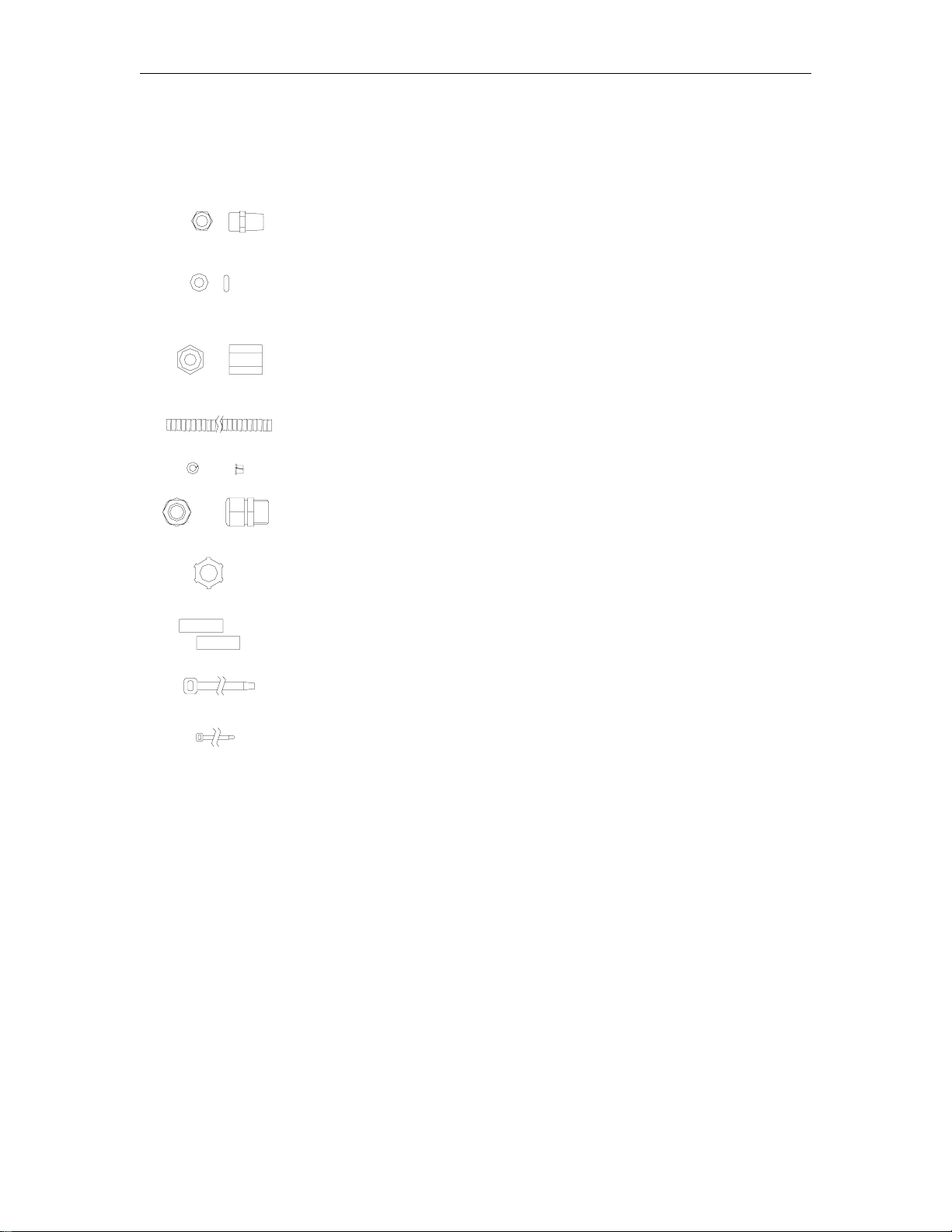

INTERNAL WIRE RETROFIT COMPONENTS

Internal Wire Small Parts Kit, C07348

1 C35972 Fitting, Hose Wire, Qty. 1

2 048865 O-Ring Seal, Qty. 2

3 C35999 Fitting, O-Ring, Tubing, Qty. 1

4 C36004 Tubing, Qty. 1

5 C09756 Plastic Bushing, Qty. 2

6 C09767 Fitting, ½” NPT Sealing, Qty. 1

7 039130 Nut, Conduit, ½” NPT, Qty. 1

8 C08899 Connector, Sealing Butt, Qty. 2

9 C08879 Tiewrap, Large, Qty. 2

10 0M0042 Tiewrap, Small, Qty. 2

1065 2-7

Page 18

GASBOY Fuel Point System

USING THIS MANUAL

The remainder of this manual contains procedures for assembling your antenna and hose. The

steps for hose retrofit are summarized below:

STANDARD HOSE RETROFIT

• STEP A: DISASSEMBLE HOSE

• STEP B: CONSTRUCT HOSE ASSEMBLIES (INTERNAL WIRE)

Hose #1 Assembly, Nozzle End

Hose #2 Assembly, Nearest Pump

• STEP C: FINAL HOSE AND NOZZLE ASSEMBLY

• STEP D: REASSEMBLE

Hose to Pump

• STEP E: COMPLETE N-RING WIRING

• STEP F: APPLY POWER AND CHECK INSTALLATION

VAPOR RECOVERY RETROFIT

• STEP A: CONSTRUCT VAPOR RECOVERY HOSE ASSEMBLIES

Hose 1 Assembly, Pump End

Hose 2 Assembly, Nozzle End

• STEP B: NOZZLE ASSEMBLY

• STEP C: FINAL VAPOR RECOVERY HOSE ASSEMBLY

• STEP D: REASSEMBLE HOSE TO PUMP

• STEP E: COMPLETE N-RING WIRING

• STEP F: APPLY POWER AND CHECK INSTALLATION

2-8 03/28/03

Page 19

Section 3

STANDARD INTERNAL WIRE HOSE RETROFIT

STEP A: DISASSEMBLE HOSE

1. Turn off pump power.

2. Remove hose assembly at the discharge elbow fitting. Be sure to provide a container under

the fitting to avoid any product spillage on the ground.

3. Drain and wipe hose to remove fuel residue and move to a safe location away from the

fueling site.

4. For Hose Retrofit Kits, follow Steps B through F.

5. For installation of a factory-wired hose, refer to assembled hose drawings in Step B and

proceed directly to Step C and follow Steps C through F.

03/28/03 3-1

Page 20

GASBOY Fuel Point System

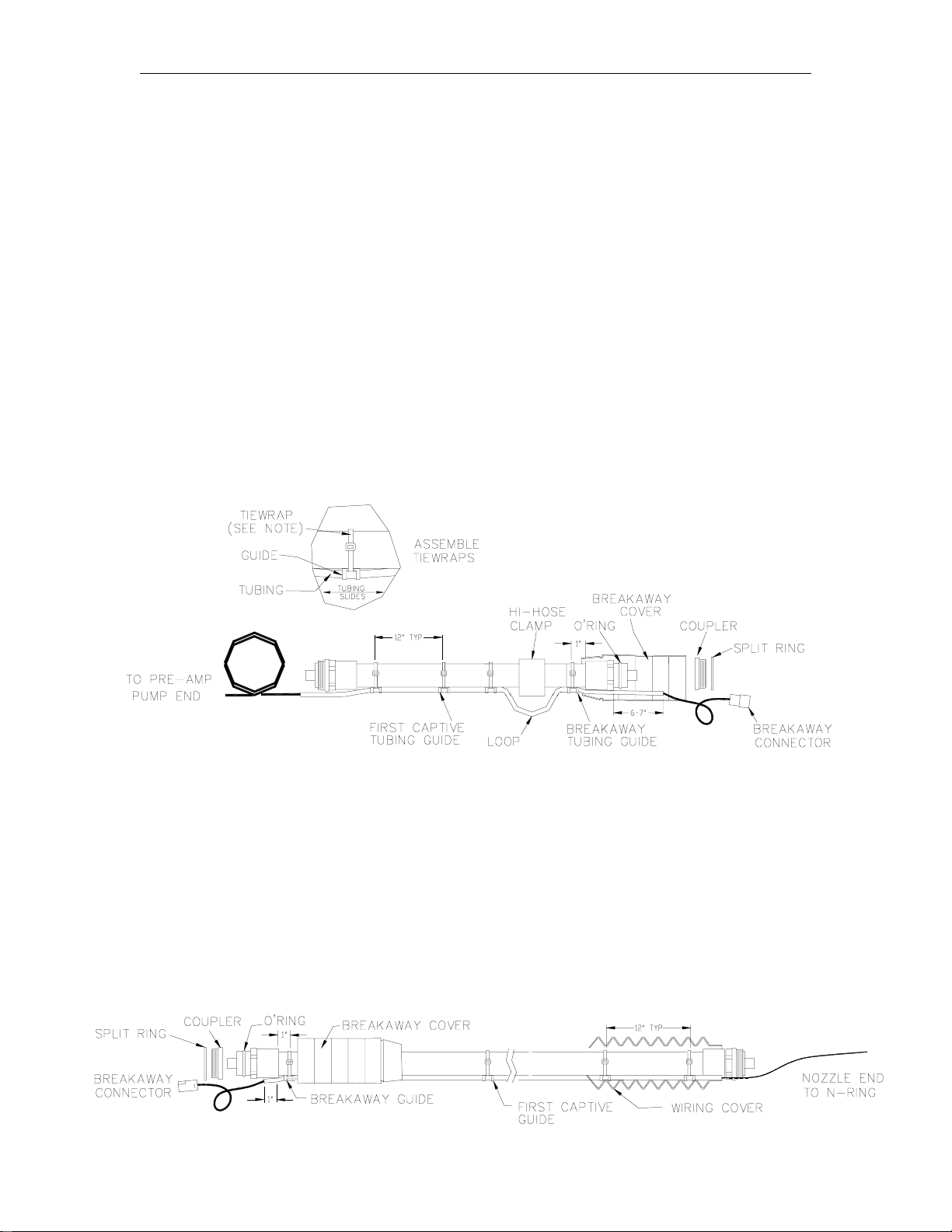

STEP B: CONSTRUCT HOSE ASSEMBLIES (INTERNAL WIRE)

HOSE #1 ASSEMBLY (Nozzle End)

NOTE: All pipe threads must have UL-approved sealant applied and threads tightened fully.

Nozzle and breakaway are supplied by installer.

1. Refer to the pump diagram found earlier in this manual and determine the hose style required

(breakaway at nozzle, pump, or mid-hose at high hose clamp).

2. Starting at the breakaway end, carefully snake loose end of appropriate wire assembly

through the hose, taking care not to disturb the slack loop. Apply thread lubricant, thread

hose to large fitting and tighten fully.

3. Assemble the PVC breakaway cover as shown.

4. Use a pull wire and feed loose hose wire through swivel supplied with the kit. Apply thread

sealant and thread swivel to hose end.

5. Continuing at the swivel, locate the large fitting kit and remove small compression fitting and

O-ring and feed loose hose wire through large brass fitting and out the wire exit hose.

Reassemble the O-ring and compression fitting and tighten fully. Gently tug on the wire to

confirm it is fully sealed.

6. Set hose assembly aside and continue by assembling hose 2.

3-2 03/28/03

Page 21

Standard Hose Retrofit

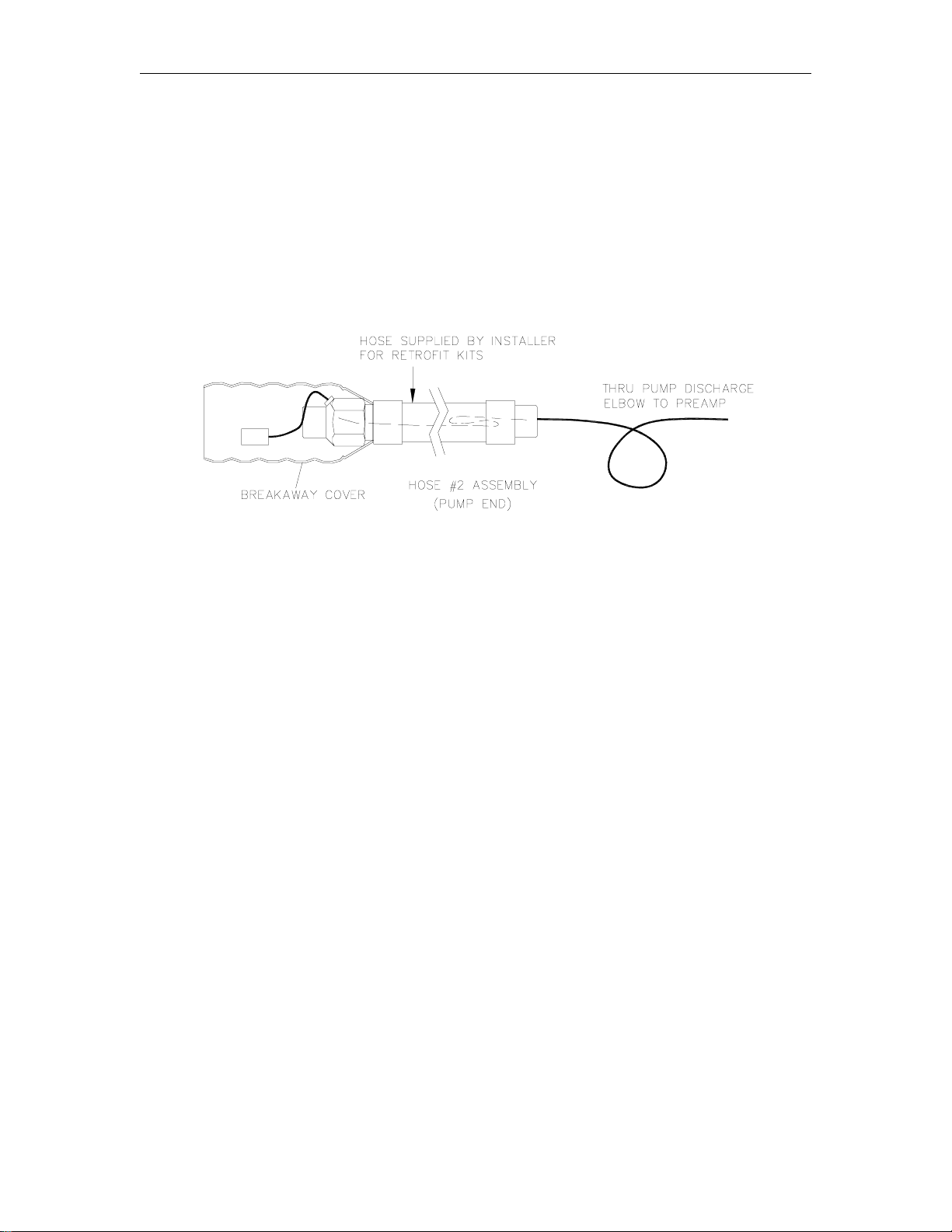

STEP B (CONT’D): CONSTRUCT HOSE ASSEMBLIES

Hose #2 Assembly (Nearest Pump)

7. Continuing at the breakaway, locate the second hose wire assembly from the kit and carefully

snake loose end through the hose (taking care not to disturb the slack loop), apply sealant and

thread large fitting on hose and fully tighten.

8. Assemble PVC cover as shown and proceed to STEP C: FINAL HOSE AND NOZZLE

ASSEMBLY.

9182 3-3

Page 22

GASBOY Fuel Point System

STEP C: FINAL HOSE AND NOZZLE ASSEMBLY

1. Assemble Breakaway and Nozzle: Determine

fuel flow direction and apply thread sealant to all

tapered threads. Assemble breakaway between

Hose #1 and Hose #2 according to

manufacturer’s directions. Install nozzle to Fuel

Point fitting on Hose #1. Tighten all connections

fully.

2. Complete N-Ring Wiring: Assemble N-ring on

nozzle. Strip 1-1/2” from hose wire outer jacket

and ¼” from 2 wires and crimp hose wire to N-ring

butt connectors Pull nozzle cover over the

nozzle, arrange wire to conceal and tiewrap as

needed. Stretch PVC cover to conceal brass wire

exit and tiewrap to close.

Assembly Note: To strip hose wire, first score

outer jacket using 12AWG stripper setting, then

strip using 10AWG setting.

3. Test N-Ring Wiring: Use ohmmeter and test N-

ring circuit for approximately a 35 ohm reading.

4. Test hose mechanically to insure nozzle shutoff

mechanism is operational and all fittings are fully

tightened.

5. Nozzles vary in design. If the handle locking

mechanism does not operate freely, remove the

lock bracket or replace with a nozzle with

mechanism designed within handle area.

3-4 03/28/03

Page 23

Standard Hose Retrofit

STEP D : REASSEMBLE

Hose to Pump

1. Install the J-Box/amplifier: Unless

installed previously, remove the cover

and install the portable cord fitting and

thread it to the J-Box. Thread the

assembly onto the I/S conduit which was

installed previously according to the Fuel

Point Reader Manual, C35628.

Assemble the wired hose to the pump.

2. Locate and install flex cable fitting:

Determine a location to install the flex

cable fitting (furnished with the hose kit).

Mark the location and remove the pump

trim panel to a safe location and machine

a 7/8” hole. Reinstall the trim panel and

install the flex cable fitting with conduit nut

supplied. Fully compress tubing in fitting

recess and secure with tiewrap.

3. Complete hose wire installation:

NOTE: Use UL approved thread sealant on all tapered threads.

a. Remove the existing discharge

elbow and discard. Install Fuel

Point elbow from kit. For ¾” hose

installations install the two reducer

bushings supplied.

b. Assemble supplied hose wire

fitting and tighten fully with

wrench.

c. Use Hose 2 Assembly and feed

hose wire loose end through the

elbow and out the small exit fitting.

d. Cut hose wire lead to

approximately 24” from end of

hose, saving the trimmed wire for

later use.

e. Assemble O-ring (using O-ring

lubricant), tube fitting, tubing and

nylon bushing supplied. Tighten

fitting completely using wrench.

f. Fully compress tubing against fitting in recess and add tiewrap to hold in place.

g. Feed tubing and wire through the flex cable fitting, adjust and tighten.

h. Using trimmed wire, splice to hose wire using butt connectors supplied and route to J-

Box/amplifier.

i. Strip wire and connect to amplifier.

9182 3-5

Page 24

GASBOY Fuel Point System

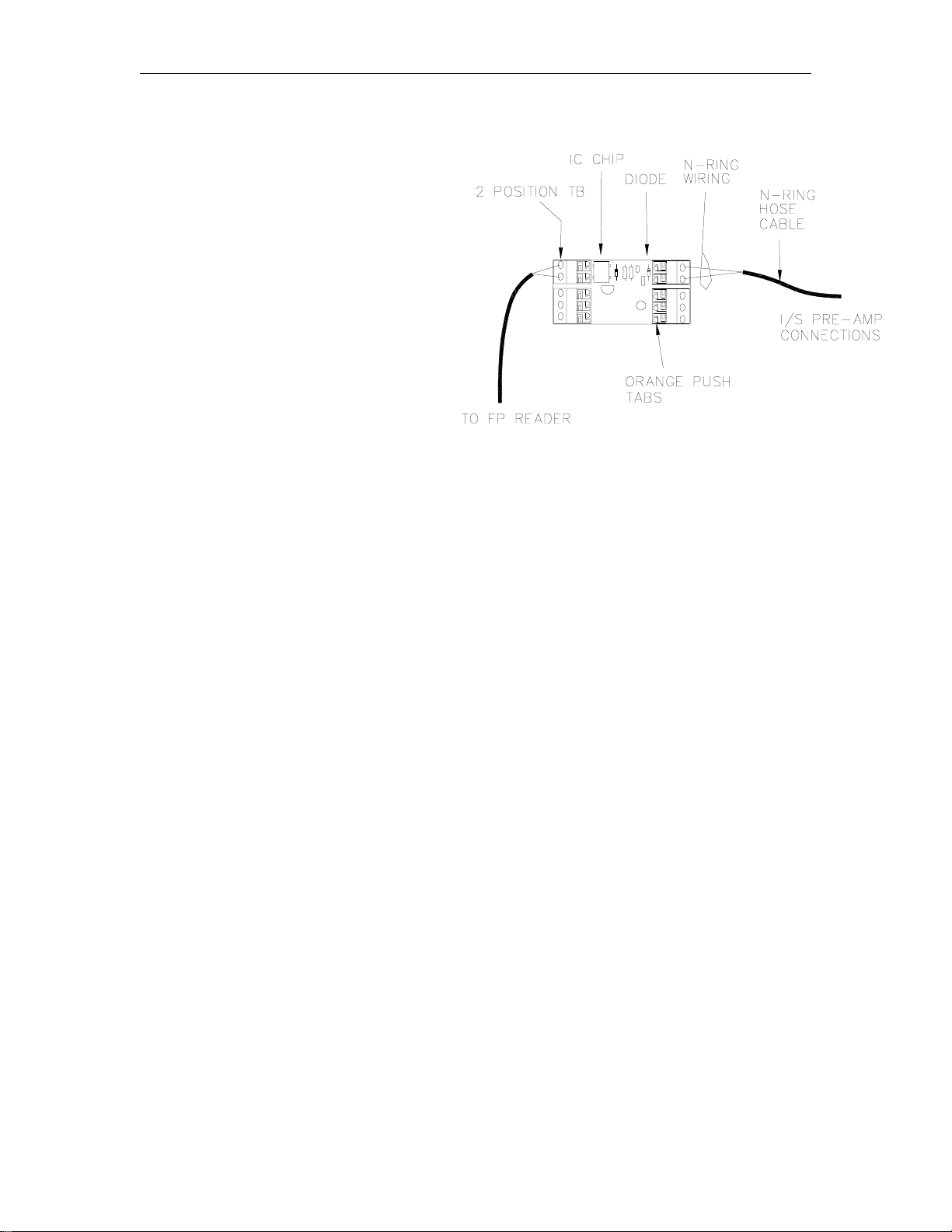

STEP E: COMPLETE N-RING WIRING

1. At the J-Box, cut the pump wire to

about a 15" length and remove 2" of

outer jacket. Strip (2) wires 3/8" from

the N-Ring hose cable. You are now

ready to make the final N-Ring

connections.

2. The N- Ring hose cable connects to the

two (2) section terminals nearest the

diode. To insert, press the orange tabs

and insert wire. Release tab and verify

a tight connection.

CAUTION: Wire polarity is not important, but connection to the wrong side of the pre-amp

assembly will cause damage!!!

STEP F: APPLY POWER AND CHECK INSTALLATION

IMPORTANT: Before applying power and checking installation, all wiring must be

complete from Fuel Point Reader to Junction Box Pre-amp. Refer to the

1. Return power to pumps and fuel management system. Switch system to AUTO operation.

For mechanical pumps, the switches are located on the pump control unit; for GASBOY

electronic pumps, these switches are on the CPU board behind the bezel assembly. For

other manufacturer’s pumps, refer to their installation/operation manuals.

2. Test the installation on a vehicle equiped to operate with Fuel Point. If communications ar e

intermittent, check and insure the N-ring and T-ring are within 9" of each other and the N-ring

communications path to the T-ring is not blocked by the metal fill tube (see TIP 1).

TIP 1: Vehicles with large metal fill pipes can allow the nozzle to be fully inserted in the tank

opening. The metal fill tube can block N-ring communications. If this condition exists, use a

nozzle with a extra long spout and provide a mechanism to hold the spout at a 5" to 9" gap

with the ring communication path unobstructed.

Once the system is communicating, pump a small amount of fuel and check for fuel leaks at

all threaded hose connections. For internally-wired hoses, check all O-ring seals and check

for faulty hose wires (see TIP 2).

TI P 2: If hose assembly leaks at one of the O-ring seals, tighten the pressure fitting only as

needed. Do not overtighten; this can also cause leaks. Finger tight, plus 1/4 to 3/8 turns is

sufficient torque to seal.

Internally wired hoses must be checked for damaged internal hose wiring (see WARNING).

WARNING: A nick or cut in the hose wire located within the hose will allow fuel to enter the

jacket interior and travel past o-ring seals. Fuel will be found in connectors and/or J-box.

When this occurs, immediately remove the pump from service and install new hose wiring.

appropriate installation/operation manuals to verify this.

3-6 03/28/03

Page 25

Section 4

VAPOR RECOVERY RETROFIT KITS

Fuel point Vapor Recovery Kits are available in several styles for most common applications

Two style kits are available depending on the type pumping unit used.

Standard single and twin pumps with a high hose retriever require High Hose retrofit kit. Due to

varying hose lengths used in these applications, the hose wire assemblies are available for 4-1/2’

hose, breakaway at the nozzle and 6-1/2’ hose, breakaway at the pump. The kit includes

additional parts for field-modification of other hose lengths.

Kits are available for GASBOY Astra pumps in standard lengths or extended for hoses up to and

including 20’ lengths. These kits require field modifications due to the unlimited hose lengths

encountered.

03/28/03 4-1

Page 26

GASBOY Fuel Point System

VAPOR RECOVERY SMALL PARTS KIT, C07389

4-2 03/28/03

Page 27

Vapor Recovery Retrofit Kits

STEP A: CONSTRUCT VAPOR RECOVERY HOSE ASSEMBLIES

Hose 1 Assembly (Pump End)

1. Balanced hose assemblies require removal of one threaded coupler before proceeding.

Starting at the breakaway end, remove split ring and carefully remove coupler. Be careful not

to damage the O-ring seals. Set aside coupler and split ring for re-installation during Step C:

Final Vapor Recovery. (For high hose retractor applications, add the high hose clamp

approximately 6” from the hose end.)

2. Add PVC wire covers, trimming as needed with sharp scissors. Do not over-trim openings,

covers should fit tightly around hose.

3. Locate the appropriate wire assembly from the kit and assemble to the hose with 8” tiewraps

approximately at 12” centers (See diagram below). Slide tiewraps between the tubing and

the guide. Tiewraps must be assembled to allow the wire assembly to slide through the

plastic guides. (See diagram below). Do not tighten fully to allow adjustment during Final

Assembly. Inspect and lubricate O-ring and reassemble coupler to hose end. When a

clamp is used, adjust tubing to form a 2-3” loop.

Hose 2 Assembly (Nozzle End)

4. Assemble the nozzle end hose repeating Steps 1-3. Hose wire tubing is furnished to fit

popular hose lengths. The small parts kit contains parts to lengthen the tubing two

additional feet. For additional lengths less than two feet, the tubing can be cut to desired

length using a hacksaw and then deburred using a small file. To assemble the added

tubing, start at the nozzle end (end without connector) and cut the tiewrap. Assemble

bushings and tubing, compress slightly and hold in place using the small tiewrap supplied

with the kit.

03/28/03 4-3

Page 28

GASBOY Fuel Point System

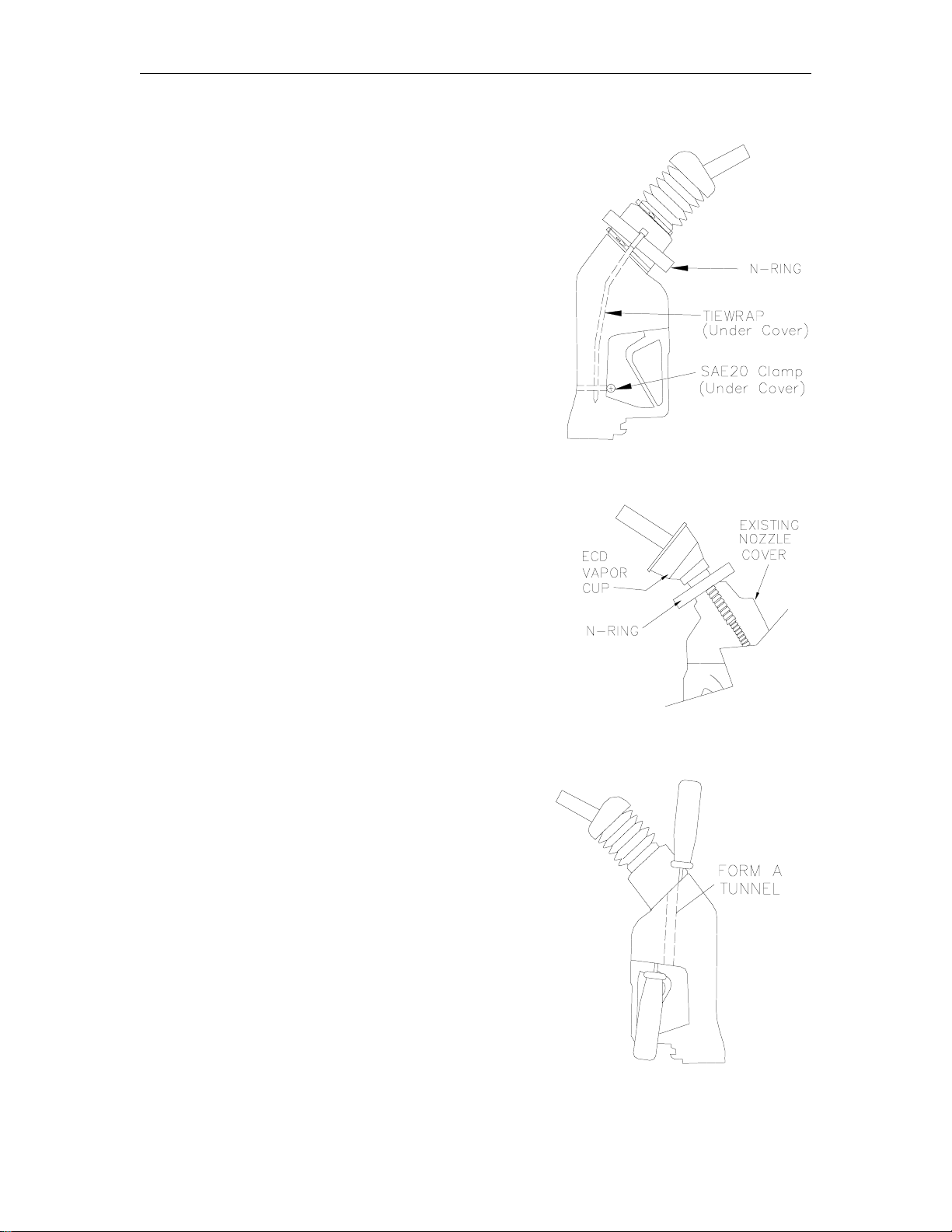

STEP B: NOZZLE ASSEMBLY

1. See Vapor Recovery Nozzle list (Section 2) for

nozzles approved by UL for use with Fuel Point.

Locate the N-Ring assembly and follow Step 2 for

balanced nozzle assemblies or follow Step 3 for Vapor

Assist nozzles.

2. For balanced nozzles with bellows, measure the

diameter of the bellows at the base of the spout just

above the check valve, if present. Trim the N-ring

membrane to a diameter slightly smaller than the

measured diameter. Pull the N-ring assembly over

the bellows end cap and position it at the bellows

base.

3. For assist-style nozzles using an ECD cup:

Increase the size of the opening in the N-ring

membrane enough to slip over the ECD cup.

Position the N-ring at the base of the nozzle spout.

4. Carefully feed the N-Ring cable under the nozzle

cover and along one side of the nozzle (See TIP

below). On the opposite side of the N-Ring, install

an 11” tiewrap and feed the tail under the cover and

down the opposite side of the nozzle.

TIP: Using two large screwdrivers, insert one from

the fuel spout end and the second from the

opposite end forming a tunnel to feed the

cable and the tiewrap under the nozzle cover.

Lift handles to enlarge the tunnel.

5. Assemble an SAE 20 mini- clamp around the nozzle

handle under the PVC cover to hold the cable and

tiewrap in place (see diagram above right). Adjust

the tubing and clamp so the does not interfere with

the nozzle handle operation. Set assembled nozzle

aside for final assembly later.

4-4 03/28/03

Page 29

Vapor Recovery Retrofit Kits

STEP C: FINAL VAPOR RECOVERY HOSE ASSEMBLY

1. Assemble Breakaway and Nozzle: Determine fuel

flow direction and assemble the fuel breakaway

between hose #1 and hose #2 according to

manufacturer’s directions. Tighten all connections

fully.

2. Complete N-Ring Wiring: Strip 1-1/2” from outer

jacket and ¼” from 2 wir es and crimp hose wire to

N-ring butt connectors. Clamp hose and N-ring

tubing using SAE 24 clamp provided. (see diagram

below). Test assembly to insure clamped tubing

restricts the swivel action at the nozzle coupling.

3. Test N-Ring Wiring: Mate the breakaway

connectors and test n-ring circuit for approximately a

35 ohm reading.

4. Test Mechanical Assembly: Insure nozzle shutoff

mechanism operates correctly and all threads are

tightened fully.

03/28/03 4-5

Page 30

GASBOY Fuel Point System

STEP D: REASSEMBLE HOSE TO PUMP

1. Install the J-Box/Amplifier: Unless installed

previously, remove the cover and thread the

portable cord fitting to J-Box. Thread J-Box to

I/S metal conduit installed previously according

to the Fuel Point Reader Manual C35628.

Assemble the wired hose to the pump.

2. Locate and Install Flex Cable Fitting:

Determine a location to install the flex cable

fitting furnished in the small parts kit. Mark the

location and remove the pump trim panel to a

safe location and machine a 7/8” diameter

hose. Reinstall the trim panel and install the

fitting with conduit nut supplied. For

installations using GASBOY-furnished hoses

with swivel lock mechanisms, proceed to Step

E: Complete N-Ring Wiring.

NOTE: Excess hose wire length can be

coiled and stored within the

pumping unit.

3. Install Swivel Limit Mechanisms:- Fuel Pointwired hoses cannot have continuous swivel motion

in the hose assembly. Swivel Limit Kits are

furnished and are to be installed following the

diagram at the right.

4. Clamp the aluminum stop bracket to the

breakaway using clamp furnished. WARNING: Do

not clamp to the hose coupling. Operation of

the swivel and stop bracket can loosen the

threaded coupling.

5. Install the stop clamp as shown and tighten fully.

6. Slide all PVC covers in place and proceed to Step

E: Complete N-Ring Wiring.

4-6 03/28/03

Page 31

Vapor Recovery Retrofit Kits

STEP E: COMPLETE N-RING WIRING

1. At the J-Box, cut the pump wire to

about a 15" length and remove 2" of

outer jacket. Strip (2) wires 3/8" from

the N-Ring hose cable. You are now

ready to make the final N-Ring

connections.

2. The N- Ring hose cable connects to the

two (2) section terminals nearest the

diode. To insert, press the orange tabs

and insert wire. Release tab and verify

a tight connection.

CAUTION: Wire polarity is not important, but connection to the wrong side of the pre-amp

assembly will cause damage!!!

STEP F: APPLY POWER AND CHECK INSTALLATION

IMPORTANT: Before applying power and checking installation, all wiring must be

complete from Fuel Point Reader to Junction Box Pre-amp. Refer to the

1. Return power to pumps and fuel management system. Switch system to AUTO operation.

For mechanical pumps, the switches are located on the pump control unit; for GASBOY

electronic pumps, these switches are on the CPU board behind the bezel assembly. For

other manufacturer’s pumps, refer to their installation/operation manuals.

2. Test the installation on a vehicle equipped to operate with Fuel Point. If communications are

intermittent, check and insure the N-ring and T-ring are within 9" of each other and the N-ring

communications path to the T-ring is not blocked by the metal fill tube (see TIP 1).

TIP 1: Vehicles with large metal fill pipes can allow the nozzle to be fully inserted in the tank

opening. The metal fill tube can block N-ring communications. If this condition exists, use a

nozzle with a extra long spout and provide a mechanism to hold the spout at a 5" to 9" gap

with the ring communication path unobstructed.

Once the system is communicating, pump a small amount of fuel and check for fuel leaks at

all threaded hose connections. For internally-wired hoses, check all O-ring seals and check

for faulty hose wires (see TIP 2).

TI P 2: If hose assembly leaks at one of the O-ring seals, tighten the pressure fitting only as

needed. Do not overtighten; this can also cause leaks. Finger tight, plus 1/4 to 3/8 turns is

sufficient torque to seal.

Internally wired hoses must be checked for damaged internal hose wiring (see WARNING).

WARNING: A nick or cut in the hose wire located within the hose will allow fuel to enter the

jacket interior and travel past o-ring seals. Fuel will be found in connectors and/or J-box.

When this occurs, immediately remove the pump from service and install new hose wiring.

appropriate installation/operation manuals to verify this.

03/28/03 4-7

Page 32

GW01 - 6/04/02 Rev. 1

WARRANTY

General Statements:

Gasboy International LLC. warrants all new equipment manufactured by Gasboy agai nst defective mat eri al and/or workmanship, for the warranty

period specified below, when the equipment i s installed in accordanc e with specifications prepared by Gas boy.

This warranty does not cover damage caused by acci dent, abuse, Acts of God, lack of surveillance of automatic recording systems, negligence,

mis-application, faulty installation, improper or unauthorized maintenanc e, installation or use in vi ol ation of product manuals , i n structions, or warnings.

Under no circumstanc e shall Gasboy be liable for any indirect , special, or consequent i al damages, losses, or expenses to include, but not limited

to, loss of product, los s of profits, litigation fees , or the use, or inability to use, our product for any for any purpose whatsoever.

Parts Only - During the warranty period, Gasboy will, at its option, repair or replace defective parts returned transportat i on prepai d to its factory.

On-Site Labor Included - Gasboy will also provide, within the Continental United States and during the warranty period, the services of an

Authorized Service Representati ve (A S R) for on-site repair or replacement of defective parts.

Replacement Parts - A ny system com ponent s that are not part of the original system order, includi ng Island Card Readers, Pump Cont rol Uni ts, etc.,

are considered replacement part s.

Equipment Term Coverage

Commercial Pumps and Dispensers

Full-Cabinet Consumer Pum ps

Small Transfer Pumps, Meters,

Pressure Regulators

Keytrol One year from date of instal l ation or 18 mos. from date of

Fuel Management Systems :

- CFN/ Profit Point

- Series 1000/Fleetkey

- TopKAT

- Fuel Point Readers

(sold with new systems)

Additional Fuel Point Items:

- Fuel Point Readers sold for

retrofitting existing systems.

- Fuel Point vehicle and dispenser

components.

Encoders, Embos sers, Modems,

CRTs, and Logger Printers

Air Diaphragm Pumps Three years from date of purchas e (for full warranty

Items not m anufactured by Gasboy

(ex. automatic nozzles, hoses, swivels,

etc.)

Replacement Parts One year from date of Gasboy International ' s invoice to the

To the extent permitted by law, this warranty is made in lieu of all other warranties , expressed or implied, includi ng warranties of freedom from patent

infringement, or merchant abilit y, or fitness for a particular purpose, or arising from a course of dealing or us age of trade. No one is authorized to

vary the terms of the warranty nor may anyone make any warranty of representation, or assume any liability other than that herein stated, i n

connection with the sale desc ri bed herei n. The acceptance of any order by Gasboy International is expressly made subject to the purchaser' s

agreement to these condit i ons.

One year from date of install ation or 18 mos. from date of

Gasboy International’s invoi ce to the purchaser, whichever

comes first.

One year from date of install ation or 18 mos. from date of

Gasboy International’s invoi ce to the purchaser, whichever

comes first.- Excepting the Model 2020 Hand Pump, which

has a 90-day warranty from date of GASBOY International’s

invoice.

Gasboy International’s invoi ce to the purchaser, whichever

comes first.

One year from date of start-up or 15 mos. from date of

Gasboy International’s invoi ce to the purchaser, whichever

comes first .- The basic warranty only applies to systems

which have been started up by a Gasboy Authorized Service

Representative (ASR).

One year from date of start-up or 15 mos. from date of

Gasboy International’s invoi ce to the purchaser,

whichever comes first.

Purchased with Fuel Management Syst em (Encoders,

Embossers only):

90 days from the date of s t art-up by a Gasboy ASR, or 180

days from date of Gasboy I nternational's invoice, whichever

occurs first.

Purchased with Fuel Management System

(Modems, CRTs, and Logger Printers only):

Matches system warranty.

Purchased Separately:

90 days from date of Gasboy International's

invoice to the purchaser.

description, see Price List).

Not warranted by Gasboy International (consul t original

manufacturer’s warranty).

purchaser.

Parts and Labor.

Parts Only.

Parts and Labor.

Parts and Labor.

Parts Only.

Purchased with System

(Encoders, Embos sers only):

Parts only.

Purchased with System (Modems,

CRTs, Logger Printers only):

Matches system warranty.

Purchased Separately:

Parts Only.

Parts Only.

Not Applicable.

Parts Only.

GASBOY INTERNATIONAL LLC

P.O. Box 309, Lansdale, PA 19446 ● (800) 444-5579 ● FAX: (800) 444-5569 ● www.gasboy.com

Loading...

Loading...