Page 1

MDE-4820H

88PPOORRTTCCOOMMMMVVEERRTTEER

R

OPERATION AND INSTALLATION MANUAL

This document P/N 817423401 is based on Orpak’s 8 port CommVerter

operation and installation manual P/N 817423400

Page 2

SAFETY CONSIDERATIONS

Read all warning notes and instructions carefully. They are included to help you installing the Product safely

in the highly flammable environment of the fuel station. Disregarding these warning notes and instructions

could result in serious injury or property damage. It is the installer responsibility to install, operate and

maintain the equipment according to the instructions given in this manual, and to conform to all applicable

codes, regulations and safety measures. Failure to do so could void all warranties associated with this

equipment.

Remember that the fuel station environment is highly flammable and combustible. Therefore, make sure

that actual installation is performed by experienced personnel, licensed to perform work in fuel station and at

a flammable environment, according to the local regulations and relevant standards.

WARNING - EXPLOSION HAZARD

Use separate conduit for the intrinsically safe. Do not run any other wires or cables through this conduit,

because this could create an explosion hazard.

Use standard test equipment only in the non- hazardous area of the fuel station, and approved test equipment

for the hazardo us areas.

In the installation and maintenance of the Product, comply with all applicable requirements of the National

Fire Protection Association NFPA-30 “Flammable and Combustible Liquids Code”, NFPA-30A “Code for

Motor Fuel Dispensing Facilities and Repair Garages”, NFPA-70 “National Electric Code”, federal, state and

local codes and any other applicable safety codes and regulations.

Do not perform metal work in a hazardous area. Sparks generated by drilling, tapping and other metal work

operations could ignite fuel vapors and flammable liquids, resulting in death, serious personal injury,

property loss and damage to you and other persons.

CAUTION - SHOCK HAZARD

Dangerous AC voltages that could cause death or serious personal injury are used to power the Product.

Always disconnect power before starting any work. The Product has more than one power supply connection

points. Disconnect all power before servicing.

WARNING – PASSING VEHICLES

When working in any open area of fuel station, beware of passing vehicles that could hit you. Block off the

work area to protect yourself and other persons. Use safety cones or other signaling devices.

Page 3

WARNING

Components substitutions could impair intrinsic safety.

Attaching unauthorized components or equipment will void your warranties.

CAUTION

Do not attempt to make any repair on the printed circuit boards residing in the Product, as this will void all

warranties related to this equipment.

PROPRIETY NOTICE

This document contains propriety and confidential information. It is the property of ORPAK SYSTEMS

Ltd. It may not be disclosed or reproduced in whole or in part without written consent of ORPAK

SYSTEMS. The information in this document is current as of the date of its publication, but is subject to

change without notice.

DISCLAIMER

This document is provided for reference only. Although every effort has been made to ensure correctness,

ORPAK SYSTEMS does not guarantee that there are no errors or omissions in this document.

This document is the property of:

ORPAK SYSTEMS Ltd.

ISRAEL

Page 4

Page 5

TABLE OF CONTENTS

Paragraph Page

GENERAL DESCRIPTION

1

1.1. SCOPE................................................................................................................................ 10

1.2. MANUAL ORGANIZATION............................................................................................ 10

1.3. GENERAL DESCRIPTION............................................................................................... 11

1.4. MODULES......................................................................................................................... 14

1.4.1. Modules .............................................................................................................................. 14

1.5. SPECIFICATIONS............................................................................................................. 15

1.5.1. Communication Rates......................................................................................................... 15

1.5.2. Electrical............................................................................................................................. 15

1.5.3. Mechanical Pump Rates ..................................................................................................... 15

1.5.4. Mechanical.......................................................................................................................... 16

1.5.5. Environmental..................................................................................................................... 16

1.6. PROTECTION ................................................................................................................... 16

2 APPLICA TIONS

2.1. SCOPE................................................................................................................................ 17

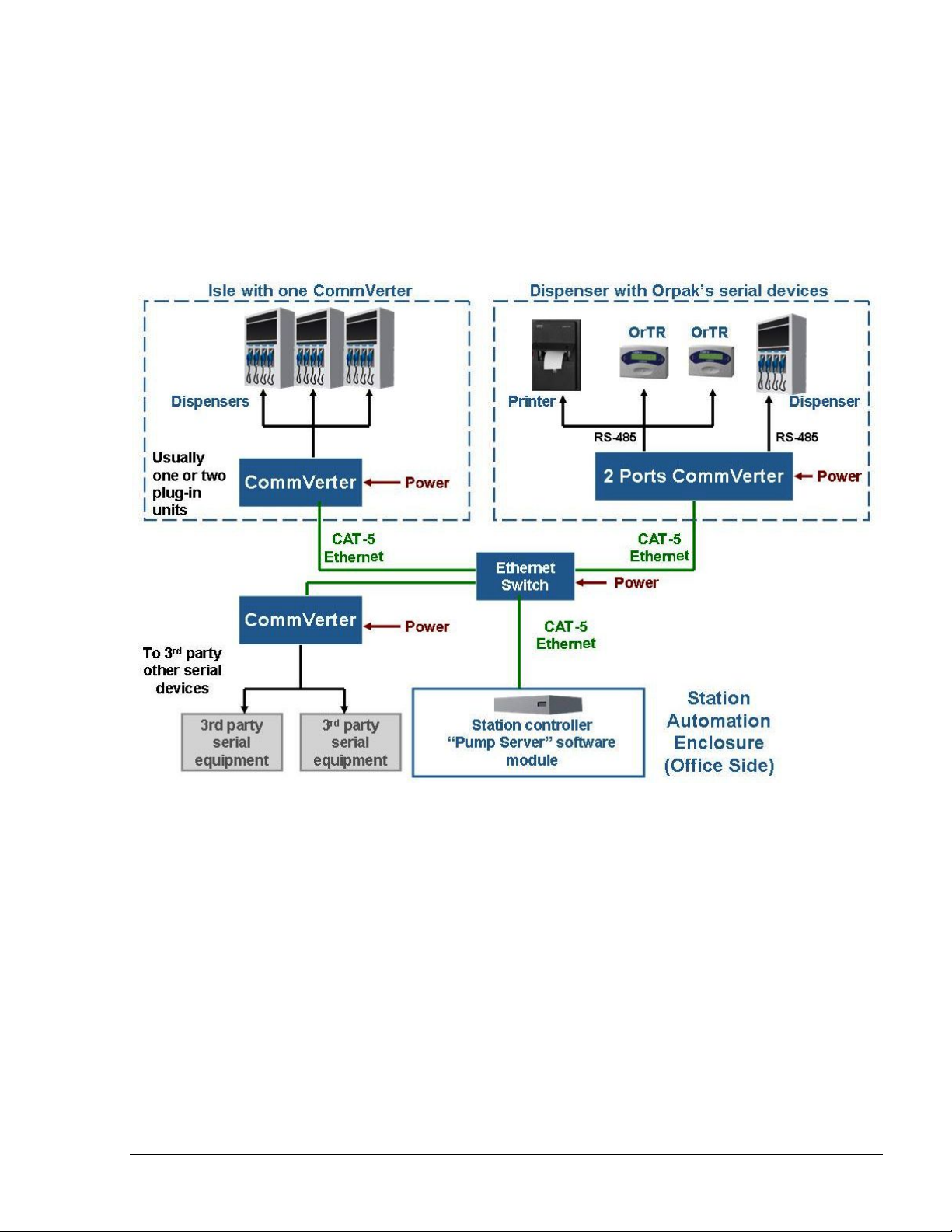

2.2. COMMVERTER SYSTEM ARCHITECTURE ................................................................ 17

2.2.1. General................................................................................................................................ 17

2.2.2. System Architecture 1: Centralized at the Station Office................................................... 18

2.2.3. System Architecture 2: Moved to the Isle Side .................................................................. 19

2.2.4. System Architecture 1: Using an OrPT and/or µVIT on the Isles...................................... 20

2.3. TYPES OF FUEL PUMP AND THEIR COMMUNICATION METHOD........................ 21

2.4. CONNECTORS.................................................................................................................. 24

2.4.1. General................................................................................................................................ 24

2.4.2. Mating a Connector ............................................................................................................ 25

2.5. LAN to RS-485 APPLICATION........................................................................................ 26

2.5.1. RS-485 Connector Pinout................................................................................................... 28

2.5.2. RS-485 Module Jumpers .................................................................................................... 28

2.6. LAN to RS-232 APPLICATION........................................................................................ 32

2.6.1. RS-232 Connector Pinout................................................................................................... 33

2.7. LAN to CURRENT LOOP................................................................................................. 34

8 Port CommVerter Operation and Installation

Manual

i

Page 6

TABLE OF CONTENTS

Paragraph Page

2.7.1. LAN to Current Loop Application...................................................................................... 34

2.7.2. Current Loop Connector Pinout.......................................................................................... 35

2.7.3. Current Loop Module Jumpers........................................................................................... 35

2.7.4. Current Loop Electronic Devices (Pump or any Current Loop Devices)........................... 36

2.7.5. Wayne Pump Configuration Example................................................................................. 39

2.7.6. Gilbarco Legacy & Gasboy 8800 Current Loop Electronic Pumps Configuration............40

2.7.6.1. SiteOmat Configuration for Gilbarco Legacy & Gasboy 8800 Current Loop Electronic

Pumps…………. ............................................................................................................................ 43

2.8. LAN to TOKHEIM APPLICATION ..................................................................................48

2.8.1. Tokheim Connector Pinout ................................................................................................. 49

2.8.2. Tokheim Module Jumpers................................................................................................... 49

2.8.3. Tokheim Electronic Devices (Pump or any Tokheim Devices)..........................................49

2.8.4. Addressing Dual-Sided Tokheim Pumps ............................................................................ 51

2.9. 4xCONTACTOR APPLICATION...................................................................................... 52

2.9.1. 4x Contactor Connector Pinout........................................................................................... 52

2.9.2. 4xContactor Module Jumpers.............................................................................................53

2.9.3. Station Setup ....................................................................................................................... 54

2.9.4. Pump Server Setup.............................................................................................................. 55

2.9.5. 8 Port CommVerter Setup................................................................................................... 56

2.10. LAN to RS422 APPLICATION.......................................................................................... 57

2.10.1. RS422 Module Application................................................................................................. 57

2.10.2. RS-422 Connector Pinout...................................................................................................58

2.10.3. Sub-RS422 Module Application......................................................................................... 58

2.11. LAN TO NUOVO PIGNONE APPLICATION.................................................................. 60

2.11.1. Nuovo Pignone Connector Pinout ......................................................................................61

2.11.2. COPTRON Communication to Nuovo Pignone Card........................................................ 61

2.12. LAN TO RS232/485 APPLICATION................................................................................. 61

2.12.1. RS-232/485 Connector Pinout............................................................................................ 62

.13 MECHANICAL PUMP INTERFACE (MPI-C)

2.13.. MECHANICAL PUMP INTERFACE (MPI-C)

2.13.1. MPI-C Connector Pinout and Signals................................................................................. 63

2.13.2. Mechanical Pump - Pulser Connections.............................................................................64

2.13.2.1. Pulse Rate....................................................................................................................... 64

2.13.2.2. Interface Connections..................................................................................................... 64

2.13.3. Pulse Divider....................................................................................................................... 66

2.13.4. Description for LED's on the MPI-C board........................................................................ 69

.................................................................62 2

ii

8 Port CommVerter Operation and I

nstallation Manual

Page 7

TABLE OF CONTENTS

Paragraph Page

2.14. 5-PORT LAN SWITCH...................................................................................................... 70

2.15. CETIL ER3 MODULE....................................................................................................... 72

2.15.1. Sub module (Suspend Resume Relay Card)....................................................................... 73

2.15.2. Sub Module Pumalan.......................................................................................................... 74

2.16. DOOR OPEN DETECTION.............................................................................................. 75

2.16.1. Door Open Detector Installation......................................................................................... 75

3 COMMVERTER DESCRIPTION

3.1. SCOPE................................................................................................................................ 77

3.2. PHYSICAL......................................................................................................................... 77

3.2.1. Housing............................................................................................................................... 77

3.2.2. Front and Rear Panel .......................................................................................................... 78

3.3. LED INDICATORS............................................................................................................ 79

3.3.1. General................................................................................................................................ 79

3.3.2. Configuration...................................................................................................................... 79

3.4. MAIN BOARD CONNECTORS....................................................................................... 81

3.5. MAIN BOARD JUMPERS................................................................................................ 82

3.6. CHANGING THE IP ADDRESS....................................................................................... 83

4 INSTALLATION AND GROUNDING

4.1. GENERAL.......................................................................................................................... 89

4.2. PRELIMINARY PROCEDURES ...................................................................................... 89

4.2.1. Unpacking and Inspection .................................................................................................. 89

4.2.2. Installation Equipment........................................................................................................ 89

4.2.3. Protective Procedures ......................................................................................................... 90

4.3. INSTALLING THE COMMVERTER............................................................................... 90

4.3.1. General................................................................................................................................ 90

4.3.2. Desktop Installation............................................................................................................ 90

4.3.3. Cables’ Connections ........................................................................................................... 91

4.4. GROUNDING THE COMMVERTER .............................................................................. 92

4.4.1. General................................................................................................................................ 92

4.4.2. Grounding – General Concept............................................................................................ 92

4.4.3. Grounding the 8-port Commverter (without RS485 card) ................................................. 92

4.4.4. Grounding the 8-port Commverter (without RS485 card) ................................................. 93

4.4.5. Verifying the Grounding..................................................................................................... 94

8 Port CommVerter Operation and Installation

Manual

iii

Page 8

TABLE OF CONTENTS

Paragraph Page

4.5. SUB-MODULE INSTALLATION AND GROUNDING ..................................................94

4.5.1. Installation of Protective Isolator Sheet.............................................................................. 94

4.5.2. Connector Mechanical Outline – Check Procedure............................................................94

4.5.3. Sub-Module - Grounding.................................................................................................... 94

4.5.4. Sub-Module Installation – Wiring Label Placing ...............................................................94

4.6. SUB-MODULE REPLACEMENT - REMOVAL INSTRUCTIONS................................95

4.6.1. General................................................................................................................................ 95

4.6.2. Removal Tool – Spring ARC.............................................................................................. 96

4.6.3. Removal Tool – Procedures ................................................................................................97

5 SETUP AND CONFIGURATION

5.1. GENERAL.......................................................................................................................... 98

5.2. DISPLAYING THE MAIN PAGE ..................................................................................... 99

5.3. ETHERNET SETUP PROCEDURES................................................................................ 101

5.4. TCP PORTS SETUP PROCEDURES................................................................................ 102

5.5. SERIAL PORTS SETUP PROCEDURES ......................................................................... 103

5.6. PIPES SETUP PROCEDURES (NOT TO BE USED) ......................................................104

5.7. DIGITAL I/O PORTS SETUP PROCEDURES (NOT TO BE USED).............................. 105

5.7.1. Door Open Detection Digital I/O Port Setup...................................................................... 105

5.8. ADMINISTRATION TASKS PROCEDURES..................................................................107

5.8.1. EEPROM Save Procedures................................................................................................. 107

5.8.2. Service W eb Ports – TCP/IP Timeout Definition Procedures............................................. 109

5.8.3. Login Information Definition Procedures (Not to be used)................................................110

5.9. SYSTEM MONITOR INFORMATION SCREENS.......................................................... 111

5.9.1. General................................................................................................................................ 111

5.9.2. Counters Description .......................................................................................................... 113

5.10. TERMINAL SCREEN (Not to be used)............................................................................. 114

6 CHECKS AND TROUBLESHOOTING

6.1. GENERAL.......................................................................................................................... 115

6.2. POST-INSTALLATION CHECKS..................................................................................... 115

APPENDIX A UPGRADING THE COMMVERT ER TO A NEW VERSION

GENERAL......................................................................................................................................116

iv

8 Port CommVerter Operation and I

nstallation Manual

Page 9

TABLE OF CONTENTS

Paragraph Page

APPLICABILITY .......................................................................................................................... 116

UPGRADING PROCEDURES...................................................................................................... 116

PRELIMINARY SETUP PROCEDURES ..................................................................................... 116

SETTING THE APPLICATION PARAMETERS IN THE DHCP SER VER................................ 118

SETTING THE APPLICATION PARAMETERS ......................................................................... 119

FINAL PROCEDURES.................................................................................................................. 120

MPI-C - DYNAMIC PULSER SAMPLING PERIOD.................................................................. 121

1. GENERAL.......................................................................................................................... 121

2. CALCULATION ................................................................................................................ 121

3. SETTING THE MPI-C....................................................................................................... 122

APPENDIX B PLANNING AND CONNECTION OF PI’S

GENERAL ..................................................................................................................................... 123

CONNECTORS.............................................................................................................................. 123

WORKING WITH COMMVERTER ............................................................................................ 123

8 Port CommVerter Operation and Installation

Manual

v

Page 10

0

LIST OF ILLUSTRATIONS

Figure Page

FIGURE 1-1. COMMVERTER – GENERAL VIEW...................................................................11

FIGURE 1-2. COMMVERTER PCB - GENERAL VIEW........................................................... 12

FIGURE 2-1. COMMVERTER SYSTEM ARCHITECTURE – CENTRALIZED..................... 18

FIGURE 2-2. COMMVERTER SYSTEM ARCHITECTURE – MOVED TO ISLE SIDE ........19

FIGURE 2-3. COMMVERTER SYSTEM ARCHITECTURE – USING AN ORPT AND/OR µVIT2

FIGURE 2-4. COMMVERTER – CONNECTORS......................................................................24

FIGURE 2-5. COMMVERTER PCB - CONNECTORS.............................................................. 24

FIGURE 2-6. COMMVERTER – CONNECTOR........................................................................ 25

FIGURE 2-7. COMMVERTER – LAN TO RS-485 APPLICATION ..........................................26

FIGURE 2-8. RS-485 TWO PORT MODULE ............................................................................. 27

FIGURE 2-9. RS-485 MODULE JUMPERS................................................................................29

FIGURE 2-10 RS-485 ELECTRONIC PUMP - WIRING DIAGRAM ....................................... 30

FIGURE 2-11 RS-485 ELECTRONIC PUMP - WIRING DIAGRAM........................................31

FIGURE 2-12. LAN TO RS-232 CONFIGURATION..................................................................32

FIGURE 2-13. RS-232 TWO-PORT MODULE........................................................................... 32

FIGURE 2-14. CURRENT LOOP TWO-PORT MODULE......................................................... 34

FIGURE 2-15. CURRENT LOOP MODULE JUMPERS............................................................ 36

FIGURE 2-16. CURRENT LOOP WIRING DIAGRAM – SINGLE CLUSTER........................37

FIGURE 2-17. CURRENT LOOP WIRING DIAGRAM – MULTI CLUSTER.......................... 37

FIGURE 2-18. CURRENT LOOP ELECTRONIC PUMP-WIRING DIAGRAM....................... 38

FIGURE 2-19. COMMVERTER UNIT SETUP SITE – MAIN SCREEN..................................40

FIGURE 2-20. COMMVERTER UNIT SETUP SITE – ADMIN SCREEN................................41

FIGURE 2-21. COMMVERTER UNIT SETUP SITE – SERIAL PORTS SCREEN .................. 42

FIGURE 2-22. BUSES DIALOG BOX ........................................................................................ 43

FIGURE 2-23. SETUP PUMP SERVER DIALOG BOX............................................................. 44

FIGURE 2-24. PUMP SERVER SETTINGS DIALOG BOX...................................................... 45

FIGURE 2-25. SETUP PUMP SETTINGS DIALOG BOX .........................................................46

FIGURE 2-26. SETUP PUMP SETTINGS (MORE) DIALOG BOX.......................................... 47

FIGURE 2-27. LAN TO TOKHEIM CONFIGURATION ........................................................... 48

FIGURE 2-28. LAN TO TOKHEIM MODULE, TWO PUMPS CONFIGURATION................ 48

FIGURE 2-29 TOKHEIM ELECTRONIC PUMP - WIRING DIAGRAM .................................50

FIGURE 2-30 TOKHEIM ELECTRONIC PUMP - WIRING DIAGRAM .................................50

FIGURE 2-31 ADDRESSING TOKHEIM DUAL-SIDED PUMPS............................................51

FIGURE 2-31. 4XCONTACTOR MODULE................................................................................ 52

vi

8 Port CommVerter Operation and I

nstallation Manual

Page 11

LIST OF ILLUSTRATIONS

Figure Page

FIGURE 2-32. 4XCONTACTOR MODULE JUMPERS............................................................. 53

FIGURE 2-33. STATION SETUP.................................................................................................. 54

FIGURE 2-35. LAN TO RS422 CONFIGURATION................................................................... 57

FIGURE 2-36. RS422 MODULE ................................................................................................. 57

FIGURE 2-37. RS422 MODULE JUMPER J6 ............................................................................ 57

FIGURE 2-38. SUB-RS422 MODULE ........................................................................................ 59

FIGURE 2-39. NUOVO PIGNONE MODULE CONFIGURATION.......................................... 60

FIGURE 2-40. NUOVO PIGNONE MODULE ........................................................................... 60

FIGURE 2-41. MPI-C MODULE................................................................................................. 62

FIGURE 2-42. MPI-C WITH SUB-MODULE............................................................................. 62

FIGURE 2-43. MPI-C J2 AND J3 JUMPERS.............................................................................. 64

FIGURE 2-44 TERMINAL BLOCK WIRING CONNECTIONS ............................................... 65

FIGURE 2-45: LOW VOLTAGE ELECTRONIC PULSER ......................................................... 65

FIGURE 2-46 TERMINAL BLOCK AND 3-WIRE PULSER – WIRING CONNECTIONS .... 66

FIGURE 2-47. PULSE DIVIDER.................................................................................................. 66

FIGURE 2-48 LEDS ON THE MPI-C.......................................................................................... 69

FIGURE 2-49 5-PORT LAN SWITCH......................................................................................... 70

FIGURE 2-50 5-PORT LAN SWITCH ON 8-PORT PCB........................................................... 71

FIGURE 2-51. CETIL ER3 MODULE + SUB............................................................................ 72

FIGURE 2-52. COMVERTER EXTERNAL CONNECTOR...................................................... 72

FIGURE 2-53. CETIL SUB RELAY MODULE – CONNECTIONS........................................... 73

FIGURE 2-54. SUB MODULE PUMALAN – CONNECTIONS ............................................... 74

FIGURE 2-55. PUMALAN PORT MODULE – GENERAL VIEW CAT. NO. 819223445......... 74

FIGURE 2-56. DOOR OPEN DETECTOR CONNECTION........................................................ 76

FIGURE 3-1. COMMVERTER – FRONT PANEL...................................................................... 77

FIGURE 3-2. COMMVERTER – REAR PANEL (CURRENT LOOP / TOKHEIM

CONFIGURATION) ...................................................................................................................... 78

FIGURE 3-3. FRONT PANEL LEDS CONFIGURATION.......................................................... 79

FIGURE 3-4. COMMVERTER LEDS CONFIGURATION ON PCB........................................ 80

FIGURE 3-5. MAIN BOARD JUMPERS AND CONNECTORS............................................... 83

FIGURE 3-6. COMMVERTER UNIT SETUP SITE – MAIN SCREEN ................................... 84

FIGURE 3-7. COMMVERTER UNIT SETUP SITE – ADMIN SCREEN.................................. 85

FIGURE 3-8. COMMVERTER UNIT SETUP SITE – ETHERNET SCREEN .......................... 86

FIGURE 3-9. COMMVERTER UNIT SETUP SITE – TERMINAL SCREEN........................... 86

FIGURE 4-1. COMMVERTER UNIT – GROUNDING CABLE IN RS-485 CONNECTOR.... 92

FIGURE 4-2. COMMVERTER UNIT – GROUNDING THE UNIT (WITHOUT RS-485 CARD)93

8 Port CommVerter Operation and Installation

Manual

vii

Page 12

LIST OF ILLUSTRATIONS

Figure Page

FIGURE 4-3. COMMVERTER UNIT – DAMAGED SUB-MODULE.......................................95

FIGURE 4-4. SPRING ARC TOOL..............................................................................................96

FIGURE 4-5. SPRING ARC TOOL – DIMENSIONS ................................................................. 96

FIGURE 5-1. COMMVERTER UNIT – SETUP MAIN SCREEN.............................................. 99

FIGURE 5-2. SETUP MAIN SCREEN – FIELDS....................................................................... 100

FIGURE 5-3. ETHERNET SETUP SCREEN............................................................................... 101

FIGURE 5-4. TCP PORTS SETUP SCREEN...............................................................................102

FIGURE 5-5. SERIAL PORTS SETUP SCREEN........................................................................ 103

FIGURE 5-6. PIPES SETUP SCREEN......................................................................................... 104

FIGURE 5-7. DIGITAL I/O PORTS SETUP SCREEN................................................................105

FIGURE 5-8. DIGITAL I/O PORTS SETUP SCREEN – DOOR OPEN DETECTION

ACTIVATION................................................................................................................................. 106

FIGURE 5-9. ADMINISTRATION TASKS SCREEN................................................................. 107

FIGURE 5-10. SERVICE WEB PORTS – TCP/IP TIMEOUT SCREEN ....................................109

FIGURE 5-11. SERVICE WEB PORTS – TCP/IP TIMEOUT SCREEN ....................................110

FIGURE 5-12. SYSTEM MONITOR SCREEN – THREADS RUNNING.................................111

FIGURE 5-13. SYSTEM MONITOR SCREEN – SOCKETS, MEMORY, FILE STATUS........112

FIGURE 5-14. SYSTEM MONITOR SCREEN – RESET COUNTERS, CONFIGURATION

STATUS ..........................................................................................................................................112

FIGURE 5-15. TERMINAL SCREEN.......................................................................................... 114

FIGURE A-1. DHCP SERVER – COMMUNICATION PARAMETERS.................................... 118

FIGURE A-2 APPLICATION SETTING PARAMETERS............................................................ 119

FIGURE A-3 APPLICATION SETTING PARAMETERS............................................................ 120

viii

8 Port CommVerter Operation and I

nstallation Manual

Page 13

LIST OF TABLES

TABLE PAGE

TABLE 1-1. COMMVERTER MODULES................................................................................... 14

TABLE 2-1. RS-485 MODULE JUMPERS STATUS (ACCORDING TO PUMPS) ................... 28

TABLE 2-7. PULSE DIVIDER PINOUT...................................................................................... 68

TABLE 3-1. COMMVERTER LED INDICATION ...................................................................... 81

TABLE 3-2. MAIN BOARD CONNECTOR FUNCTIONALITY............................................... 81

TABLE 3-3. MAIN BOARD JUMPERS FUNCTIONALITY...................................................... 82

TABLE 4-1. COMMVERTER UNIT KIT.................................................................................... 89

8 Port CommVerter Operation and Installation Manual

ix

Page 14

0

SECTION

1

GENERAL DESCRIPTION

1.1. SCOPE

The 8 port CommVerter unit, referred to as "CommVerter" throughout this document, is a

component within the FuelOmat system. It serves as a universal and modular hardware interface

between the Ethernet communication from the Station Controller (FCC) and the other devices

communication interfaces such as RS485/422, Current Loop, etc.

As a communication interface unit, the CommVerter converts the Ethernet communication protocol

of any station devices into RS-485/422, Current Loop or Tokheim communication interfaces and

vice versa.

The CommVerter includes several modules designed to support each communication interface.

Some of these modules can be configured for different protocols by means of built-in Web pages.

The CommVerter unit is designed to survive the harsh forecourt environment. The RS-485 module

uses Spark Gaps protection for the links, and 1.5 KV isolation between the office controller and the

forecourt devices.

1.2. MANUAL ORGANIZATION

This manual provides information on the technical characteristics, installation and operation of the

CommVerter unit. This document deals with the physical level of the communication that is,

connecting the CommVerter unit to a network. It does not cover any software required to configure

the system. The manual is organized as follows:

Section 1. General Description: Includes general information regarding the CommVerter unit, its

components and functionality.

Section 2. Applications: Describes the types of communication where the CommVerter unit

provides interface applications.

Section 3. Description: Includes detailed information regarding the CommVerter unit and its

specifications.

Section 4. Installation and Removal: Provides instructions regarding the installation (and

removal) of the CommVerter unit at the station office.

Section 5. Setup and Configuration: Provides instructions concerning the instructions for the

setup and configuration of the CommVerter unit.

Section 6. Checks and Troubleshooting: Provides several recommended steps for checking the

system operability and for basic troubleshooting.

10

8 Port CommVerter operation and installation manual

Page 15

1.3. GENERAL DESCRIPTION

The CommVerter is a Communication Converter, interfacing serial Forecourt devices such as

pumps and tank level gauges to the station automation system through a standard TCP/IP Ethernet

port.

Unlike off-the-shelf Ethernet to Serial interfaces, the CommVerter is designed to function in the

harsh environment of the petrol stations; eliminating ground loops, power surges and other

RFI/EMI noise to maximize the performance and reliability of the station automation solution. Each

link is ‘floating’ and is DC isolated from all other links and has surge protection and enhanced

filtering.

There are two CommVerters configurations: one which is supplied as an enclosed unit which

includes an internal power supply (as shown in Figure 1-1) and the other as a PCB, which is

installed in Gilbarco's products (see Figure 1-2).

Figure 1-1. CommVerter – General View

8 Port CommVerter operation and installation

manual

11

Page 16

Figure 1-2. CommVerter PCB - General View

The unit supports a combination of up to 8 serial links of various standards as required at the

forecourt, including: RS-232, RS-485 and current loop.

All links are carried to the station automation controller over one Ethernet port.

The specific protocol for each of these forecourt devices is part of the station automation while the

CommVerter unit is the physical serial interface for the specific devices.

One of the prime tasks of the CommVerter at the forecourt is to interface to the dispensers. The

specific protocol for every dispenser type resides in the “pump server” software module of the

station automation and is standard for all Gilbarco’s home base controllers.

The CommVerter unit is part of Gilbarco’s complete station automation solution and is not an

off-the-shelf standard product, but has a modular structure to enable flexibility for various petrol

stations’ configurations and size.

The CommVerter is a platform with plug-in units to address each specific installation.

12

8 Port CommVerter operation and in

stallation manual

Page 17

Petrol stations around the globe are dramatically different in many aspects and the CommVerter

addresses all:

Total number of dispensers –several CommVerter units can be installed at the same

site.

Number of different dispensers at a specific site – various plug-ins are used,

according to the specific links that are required (RS-485, CL, Tokheim, etc.)

Number of contactless tag readers (OrTR, UPI, MiTag) and outdoor printers that

are needed at the petrol station (no more then 6 modules over one RS-485 link).

Number of tank level gauges and other 3rd party serial devices such as payment

terminals.

8 Port CommVerter operation and installation

manual

13

Page 18

1.4. MODULES

1.4.1. Modules

Several types of modules are available to support each communication type. The configuration of

the CommVerter for each application is determined by the type of the installed modules within.

Select the CommVerter module suitable to the conversion method required at your station network.

Table 1-1 lists the available CommVerter modules.

CommVerter Modules P/N

4xCONTACTOR 819223481

Current Loop 819223431

MPI-C+SUB 819223490

Nuevo Pignone (485) 819223485

RS232 819223451

RS232/485 819223441

RS422 819223471

RS422 + SUB 819223472

RS485 819223460

5V P.S. for 8-LAN switch 819523442

Table 1-1. CommVerter Modules

Cetil 819223425

Tokheim 819223420

Pumalan 819223445

14

8 Port CommVerter operation and in

stallation manual

Page 19

1.5. SPECIFICATIONS

Important Notice

At a rate above 9600 bps, the communication protocol with the 8Port Commverter shall handle 250 bytes

packets. The 8Port Commverter does not support a bytes stream flow at a rate higher than 9600 bps.

1.5.1. Communication Rates

The communication rates depend on the type of module.

No. Module Value

1 RS-232 Module 57600 bps max.

2 RS-485 Module 57600 bps max.

3 TCP/IP Module 100 Mbps (optional)

4 Current Loop 24V 45mA 9600 bps max.

5 Tokheim 9600 bps max.

1.5.2. Electrical

No. Parameter Value

1 Supply Voltage:

- Enclosed Commverter

unit

- PCB unit

110 – 230 VAC, 50-60Hz

15 to 24 VDC

2 Power Consumption Typical 5W

Maximum 25W

3 Protection 1.5A Fuse, internal on board.

1.5.3. Mechanical Pump Rates

No. Parameter Value

1 Power supply output voltage

12 VDC +/-20%

to Pulsar Unit

2 Power supply maximum

80 mA max

output current

3 Pulsar Input High level

10 to 16 VDC (standard)

voltage

8 Port CommVerter operation and installation manual

15

Page 20

4 to 10 VDC (require wiring changes)

4 Pulsar Input High level sink

3mA

current (@15V)

5 Maximum pulse rate of

Up to 5 KHz

MPI-C at 50% duty cycle

6 In use "On" level (Input) 4 to 7 VDC

7 In use "Off" level (Input) -1 to 1 VDC

8 In use Input impedance 10 KOhm

9 In use-max Input current

106 uA

using external dry contact

(5VDC)

10 In use-max Input current at 7

50 uA

VDC

11 12 VDC Output 25 mA max

1.5.4. Mechanical

No. Parameter Value

1 Dimensions (HxWxD) 140 x 180 x 50 (mm)

1.5.5. Environmental

No. Parameter Value

1 Operating Temperature

2 Operating Temperature (with power

-30C to +55C

-20C to +50C

supply)

3 Storage Temperature

-30C to +70C

1.6. PROTECTION

The CommVerter in its 485 communication port (refer to Table 1-1) is protected electrically against

lightening and surges using transorbers and gas discharge (Arrosto) devices.

Additionally, grounding is required. Proper grounding is essential for protection to take place.

Refer to paragraph 4.4 - Grounding the Commverter.

16

8 Port CommVerter operation and in

stallation manual

Page 21

0

SECTION

2

APPLICATIONS

2.1. SCOPE

This section provides the interfaces available between the CommVerter and several types of fuel

pumps. This section also includes several applications for the CommVerter in different se ttings

within the station. The CommVerter ensures proper communication between the FCC and the

station devices in accordance with their communication protocols.

2.2. COMMVERTER SYSTEM ARCHITECTURE

2.2.1. General

The CommVerter system architecture consideration depends on the topology of the specific petrol

station.

There are three main architectures:

Centralized at the station office

Moved to the isle side

When using an OrPT and/or µVIT on the isles

8 Port CommVerter Operation and Installation

Manual

17

Page 22

2.2.2. System Architecture 1: Centralized at the Station Office

The CommVerter is usually installed centralized at the station office together with the station

controller. This topology requires serial links all the way from the office to each dispenser or other

forecourt serial devices.

Figure 2-1. CommVerter System Architecture – Centralized

18

8 Port CommVerter Operation and I

nstallation Manual

Page 23

2.2.3. System Architecture 2: Moved to the Isle Side

In some applications, it is recommended to move the CommVerter to the isle side, carrying one

Ethernet link and power cable to the isle and then split to the serial links required at each isle.

Such an architecture usually requires only one or 2 plug-in units for each CommVerter on an isle.

Figure 2-2. CommVerter System Architecture – Moved to Isle Side

8 Port CommVerter Operation and Installation

Manual

19

Page 24

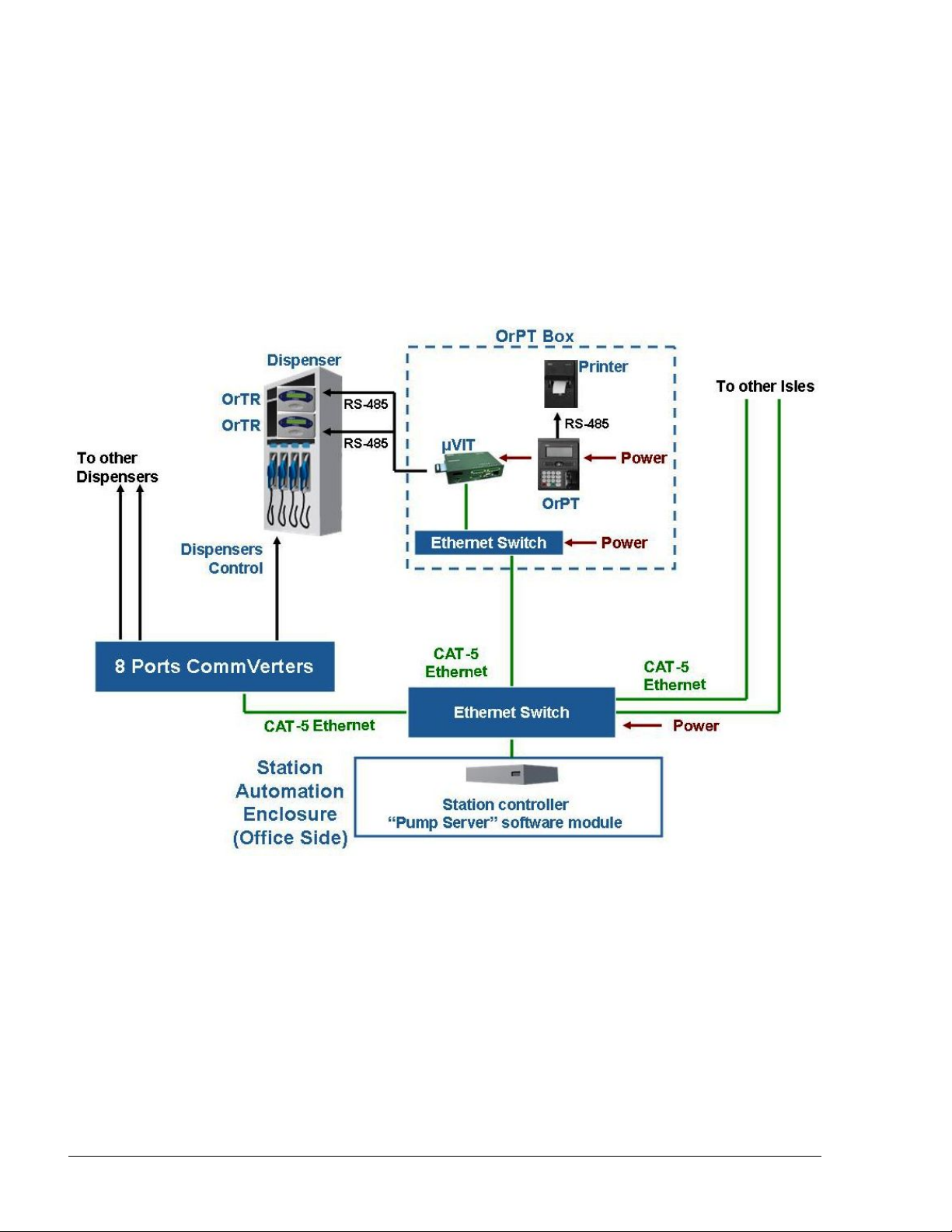

2.2.4. System Architecture 1: Using an OrPT and/or µVIT on the Isles

Other system configuration could be implemented when using an OrPT and/or µVIT on the isles.

In this configuration, both the OrPT and µVIT use a built-in Ethernet to RS-485 CommVerter,

supporting serial forecourt devices on the isle such as printers and contactless tag readers.

These links provided by the µVIT /OrPT could be off-loaded from the centralized CommVerter unit

to minimize cabling and installation cost.

Figure 2-3. CommVerter System Architecture – Using an OrPT and/or µVIT

20

8 Port CommVerter Operation and I

nstallation Manual

Page 25

2.3. TYPES OF FUEL PUMP AND THEIR COMMUNICATIO N METHOD

The CommVerter is used as an interface for several types of fuel pumps, as listed below:

Pump/Dispenser

Manufacturer

Model

(Protocol)

Aplab RS485 819223460 2 8 On 9600 8 None 1

Aplab

Swadesh II

Avery RS485 819223460 2 4 On 9600 8 Odd 1

Baransay

(Gilbarco)

Bennet

Mexico

Bennet

USA

Cetill

EAS1

Cetill

ER3

Dong HWA

(prime)

Communication

Type

RS485 819223460 5787 8 Even 1

RS232 819223451 2 1 N/A 4800 7 Odd 1

Current Loop 819223431 2 4 N/A 4800 8 Even 1

RS485 819223460 2 8 ? 2400 -

Cetil 819523425 1 1 ? 9600 8 None 1

RS485 819223460 2 remove

Board P/N No. of

channels

/ board

(include

sub

board)

Max

Number

of pump

heads

per

channel

Baud

Rate

Jumper

J1

Baud

Rate

Data

Bits

Parity Stop

7 Even 1

9600

9600 8 Even 1

Bits

ENE (=Prime

protocol)

EPCO (=Prime

protocol)

FuelStar RS485 819223460 2 8 Remove 4800 8 Even 1

Gilbarco

USA

Gasboy

USA

Gasboy

USA

Hong Yang RS232 2 4 N/A 4800 8 Even 1

Current Loop 819223431 2 8 Remove 5787 8 Even 1

RS422 819523471/2 2 8

RS485 819223460 2 8 Remove 9600 8 None 1

8 Port CommVerter Operation and Installation

Manual

21

Page 26

No. of

Pump/Dispenser

Manufacturer

Model

(Protocol)

IFSF

L&T

MPD/QPD

L&T

Sprint RS485 819223460 2 8 On 9600 8 None 1

L&T

Z-Line,

Pacemaker

L&T

Tulip ( Mono &

Dual) RS485 819223460 2 8 On 9600 8 None 1

L&T

VMP ( Mono &

Dual)

Communication

Type

USB - >LON or

PCI->LON

RS485 819223460 2 8 On 9600 8 None 1

RS485 819223460 2 8 On 9600 8 None 1

RS485 819223460 2 8 On 9600 8 None 1

Board P/N

1

channels

/ board

(include

sub

board)

Max

Number

of

pump

heads

per

channel

Max

Allowed

In LON

Baud

Rate

Jumper

Baud

Rate

Data

Bits

Parity

Stop

Bits

Maser RS485 819223460 2 8 9600 8 None 1

MPD/QPD RS485 819223460 2 8 Remove 19200 8 None 1

Midco

Single RS485 819223460 2 8 Remove 19200 8 None 1

Midco

MMS

Midco

Surefil RS485 819223460 2 8 Remove 19200 8 None 1

MPI-C

Rev D

MPI

Orpak RS485 819223460 2 8 On 9600 8 None 1

Mepsan RS-485 819223460 2 8 On 9600 8 Odd 1

LPG 2A

Dart/Mepsan RS-485 819223460 2 8 ? ? ? ?

Novotec RS485 819223460 2 8 9600 7 None 1

Nuovo Pignone

Blend

Nuovo Pignone N/P 819223485 2 1 2400 8 Odd 1

RS485 819223460 2 8 Remove 19200 8 None 1

81922349 0 2 1 On 9600 8 None 1

RS485 819223460 2 8 Remove 2400 8 Odd 1

22

8 Port CommVerter Operation and I

nstallation Manual

Page 27

No. of

Pump/Dispenser

Manufacturer

Model

(Protocol)

Petrotec

CEM

Prime RS485 819223460 2 8 Remove 9600 8 Even 1

Pumalan

HT-Retrofit Pumalan 819223445 2 8 N/A 4800 7 Odd 1

Pumptronics

Gilbarco

Real Tech China RS485 2 4 N/A 4800 8 Even 1

S&B T10 RS485 819223460 2 1 Remove 2400 7 Even 1

Schlumberger RS-422 819523471/2 2 1 N/A 1200 7 Even 1

Tatsuno

MPD/QPD RS485 819223460 2 8 Remove 19200 8 Even 1

Tatsuno

Pooly (Nonspace)

Communication

Type

RS422 819523471/2 2 1 N/A 1200 7 Even 2

Current Loop 819223431 2 4800

RS485 819223460 Remove 19200 8 Even 1

Board P/N

channels

/ board

(include

sub

board)

Max

Number

of

pump

heads

per

channel

Baud

Rate

Jumper

Baud

Rate

Data

Bits

Parity

Stop

Bits

Tatsuno Benc RS485 819223460 2 8 On 9600 7 EVEN 2

Tokheim Tokheim 819223420 2 1 N/A 9600 8 None 1

Tokheim Kaisen

L1+ RS485 819223460 2 1 On 9600 8 None 1

Tokheim 8800

(American

Dispenser)

Wayne

Dart RS485 819223460 2 8 On 9600 8 Odd 1

Wayne

Vista

Tokheim 819223420 2 1 N/A 9600 8 None 1

Current Loop 819223431 2 4 N/A 9600 8 Odd 1

8 Port CommVerter Operation and Installation

Manual

23

Page 28

2.4. CONNECTORS

2.4.1. General

The CommVerter in its basic version includes four separate connectors. Each connector supports up

to two distinctive channels for every module. However, in RS-422 and Sub RS-422 modules,

MPI-C and MPI-C + Sub, only one channel is supported.

A rear panel view of the CommVerter unit connectors is shown in Figure 2-4.

Figure 2-4. CommVerter – Connectors

A general view of the CommVerter connectors in PCB configuration (without the casing) is shown

in Figure 2-5.

Figure 2-5. CommVerter PCB - Connectors

24

8 Port CommVerter Operation and I

nstallation Manual

Page 29

2.4.2. Mating a Connector

The CommVerter kit includes one size mating connectors to be wired in accordance with the

selected fuel station configuration and consequently, the required conversion method.

To wire a mating connector (see Figure 2-6), proceed as follows:

1. For all modules, use standard 8-pin Phoenix-type male connector (P/N 813325001),

to be connected to the CommVerter.

2. For LAN connection, use RJ45 cat5 LAN cable (not included in the kit).

3. Wire the connector in accordance with its pinout definition as described in the

following paragraphs. The wiring shall be performed in accordance with the

CommVerter configuration.

NOTE

The connector pinout definition (pin number on top, signal

in second row) is provided when facing the connector,

from right to left.

4. The following paragraphs provide the wiring definition of the ports. These wiring

definitions are also shown on the connectors' labels (see Figure 2-4 and Figure 2-6).

Verify compatibility before connection!!!

Figure 2-6. CommVerter – Connector

8 Port CommVerter Operation and Installation

Manual

25

Page 30

2.5. LAN to RS-485 APPL ICATION

The LAN to RS-485 application is required when connecting fuel pumps and other serial devices to

home base controller that uses TCP/IP communication. In this configuration, the RS-485 Two-Port

module (P/N 819223460) is installed within the CommVerter.

If several CommVerter units are to be connected to the FCC, a Hub must be added to the network in

order to support several connections.

Figure 2-7. CommVerter – LAN to RS-485 Application

The CommVerter diverts the LAN communication to the relevant RS-485/422 device. The relevant

module is addressed with its IP address, and a unique port is configured during the device setup.

Interfaces using this mode of communication and conversion include Wayne Dart, Midco, L&T,

Tatsuno, Aplab, and more.

The following table provides the configuration of the RS-485 piggy-back board (Commverter

module) per type of pump.

Commverter Module Configuration

Aplab (485) 9600,8,N,1

Avery (485) 5700,8,E,1

Gilbarco (485) 9600,8,N,1

L & T (485) 9600,8,N,1

Midco (485) 19200,8,N,1

Nuovo Pignone (485) 2400,8,O,1

Tatsuno (485) 19200,8.E,1

Wayne Dart (485) 9600,8,O,1

26

8 Port CommVerter Operation and I

nstallation Manual

Page 31

Figure 2-8. RS-485 Two Port Module

LEDs Indication

NOTE

This module does not require opening the Commverter to

view the LEDs status and indications. The LEDs are

displayed through the holes of the Commverter cover.

The LEDs indication can be seen in the appropriate

column above the module installation position. The

column holes should be seen at the right-hand side from

the vents of the Power Supply, from top down.

Connector Side

Channel 1 Rx D4

Channel 2 Tx D6

Channel 1 Tx D1

Channel 2 Rx D11

Blank

Blank

LED Blinking – Communication on

LED Off – No communication

8 Port CommVerter Operation and Installation

Manual

27

Page 32

2.5.1. RS-485 Connector Pinout

The following pinout is required for the LAN to RS-485 application, for all devices that supports

RS-485 and RS-485 board.

[ Revision D and above ]

8 7 6 5 4 3 2 1

E G - + E G - +

Channel 2 Channel 1

2.5.2. RS-485 Module Jumpers

The jumpers in the RS-485 m

odule can be set in two different configurations, as shown in

Figure 3-7. The configuration is determined by four consecutive jumpers on the board: J1, J2, J5

and J6.

Every pair of jumpers is allocated to a different channel:

J1 and J2 for Channel 1 / J5 and J6 for Channel 2.

The jumpers determine the transmission rate. Two transmission rates can be selected:

9600 bps

4800 bps

To determine the transmission rate, set the jumpers accordingly. Proceed as follows:

1. Set the baud rate jumpers in the RS-485 cards in accordance with the pumps that

shall be connected to each channel (refer to Table 2-1).

The jumpers are: J1 for Channel 1 and J5 for Channel 2 (see Figure 2-9).

Table 2-1. RS-485 Module Jumpers Status (according to pumps)

8 port

Commverter

Baud rate

Jumper

Aplab Avery Gasboy MIDCO L&T NP NP Blend Tatsuno Wayne

Do not

remove

Do not

remove

Remove Remove

Do not

remove

Remove Remove Remove

Dart

Do not

remove

The Echo jumpers are J9 and J10.

If no jumpers exist echo is enabled.

If jumpers exist echo is disabled (factory default)

28

8 Port CommVerter Operation and I

nstallation Manual

Page 33

LED

Echo

jumper

Baud rate

jumper

* Jumper state 1 is the factory default setting

Figure 2-9. RS-485 Module Jumpers

8 Port CommVerter Operation and Installation

Manual

29

Page 34

RS-485 Electronic Device Pump (For any RS-485 Devices)

The wiring for the RS-485 electronic pump is provided as follows:

Figure 2-10 shows the specific wiring connections between the 8 Port RS-485 card

and the RS-485 pump nozzle, and the terminals that differ from the Mechanical

Pump. The figure shows the parallel connection between two RS-485 devices and

the Terminal Block.

Figure 2-10 RS-485 Electronic Pump - Wiring Diagram

30

8 Port CommVerter Operation and I

nstallation Manual

Page 35

Figure 2-11 RS-485 Electronic Pump - Wiring Diagram

8 Port CommVerter Operation and Installation

Manual

31

Page 36

2.6. LAN to RS-232 APPL ICATION

The LAN to RS-232 application is required when the connection to specific devices, such as TLGs,

is via RS-232. In this application, RS-232 Two-Port module (P/N 819223451) is installed within

the CommVerter.

Figure 2-12 shows a typical station configuration in which the CommVerter is used as an interface

between the Station Controller and several station devices - TLG.

Figure 2-12. LAN to RS-232 Configuration

Figure 2-13. RS-232 Two-Port Module

32

8 Port CommVerter Operation and I

nstallation Manual

Page 37

LEDs Indication

NOTE

This module does not require opening the Commverter to

view the LEDs status and indications. The LEDs are

displayed through the holes of the Commverter cover.

The LEDs indication can be seen in the appropriate

column above the module installation position. The

column holes should be seen at the right-hand side from

the vents of the Power Supply, from top down.

Connector Side

Channel 2 Rx D8

Channel 2 Tx D7

Channel 1 Rx D3

Channel 1 Tx D2

Blank

Blank

LED Blinking – Communication on

LED Off – No communication

2.6.1. RS-232 Connector Pinout

The following pinout is required for the LAN to RS-232 application.

8 7 6 5 4 3 2 1

G D I/O Rx Tx G D I/O Rx Tx

Channel 2 Channel 1

8 Port CommVerter Operation and Installation

Manual

33

Page 38

2.7. LAN to CURRENT LOOP

2.7.1. LAN to Current Loop Application

The LAN to Current Loop configuration is applicable whenever the CommVerter includes a

Current Loop Interface module (P/N 819223431). This communication conversion is used in

stations with pumps such as Wayne, Benett or Gilbarco that use current loop communication.

Figure 2-14. Current Loop Two-Port Module

34

8 Port CommVerter Operation and I

nstallation Manual

Page 39

LEDs Indication

NOTE

This module does not require opening the Commverter to

view the LEDs status and indications. The LEDs are

displayed through the holes of the Commverter cover.

The LEDs indication can be seen in the appropriate

column above the module installation position. The

column holes should be seen at the right-hand side from

the vents of the Power Supply, from top down.

Connector Side

Blank

Blank

Channel 1 Loop D1

Channel 2 Loop D7

Blank

Blank

LED On – Loop between the module and the pump

functional

LED Blinking – Communication on

LED Off – No communication

2.7.2. Current Loop Connector Pinout

The following pinout is required for the LAN to Current Loop application, for all Wayne and

Gilbarco pumps.

8 7 6 5 4 3 2 1

E G - + E G - +

Channel 2 Channel 1

2.7.3. Current Loop Module Jumpers

The jumpers in the Current Loop module can be set in two different configurations, as shown in

Figure 2-15. The configuration is determined by the two jumpers at opposite sides of the board.

Each configuration provides different power supply voltage:

12 Vdc

o

o 24 Vdc (default)

In addition, there are fur jumpers that determine the current level, as follows:

8 Port CommVerter Operation and Installation

Manual

35

Page 40

Jumpers J1, J4 installed; (for old PCBs J3, J6 also installed)

for 45 mA (default) consumption

Jumpers J1, J4 not installed; (for old PCBs J3, J6 also not

installed) for 20 mA consumption

Figure 2-15. Current Loop Module Jumpers

2.7.4. Current Loop Electronic Devices (Pump or any Current Loop Devices)

The wiring for the Current Loop electronic pump is provided as follows:

Figure 2-18 shows the specific wiring connections

and Current Loop pumps. Figure

2-16 and Figure 2-17 show the connection between two

between the 8 Port Current Loop card

Current Loop twin-pumps and the Terminal Block: In cases where connecting twin pumps

on a single cluster (module channel), set each pump with a different head number. If

connecting each twin pump on dedicated cluster, there is no need to reprogram the pump.

Pumps with identical Head number cannot be connected to the same Cluster.

36

8 Port CommVerter Operation and I

nstallation Manual

Page 41

Figure 2-16. Current Loop Wiring Diagram – Single Cluster

Figure 2-17. Current Loop Wiring Diagram – Multi Cluster

8 Port CommVerter Operation and Installation

Manual

37

Page 42

Figure 2-18. Current Loop Electronic Pump-Wiring Diagram

38

8 Port CommVerter Operation and I

nstallation Manual

Page 43

2.7.5. Wayne Pump Configuration Example

The following paragraph provides the pump configuration required for models

3/G7237D/GHJKM/ - P/N 887695-0154/053. Unit version: 54 IGEM

Verify programming codes on the pump as follows:

1. Set F01.00 to “1” for Serial Communications

2. Set F05.00 for the A side address (1-98)

3. Set F06.00 for the B side address (1-98)

4. Set F20.00 to “4” for US Current Loop

5. Set F20.01 to “02” for 9600 baud rate

6. Set F27.00 to “8” for Serial Comm

7. Set F27.01 to “0” for Serial Comm

8. Set F28.00 to “8” for Serial Comm

9. Set F28.01 to “0” for Serial Comm

NNOOTTEE

The F27 and F28 settings are dependant on whether

the unit was shipped with a Pulse Output board. If the

dispenser does not have pulse output, the above

settings should work. If it does have a pulse output

option and a pulse output template loaded, they may

need to be changed. For serial communication, they

should be set as noted above.

Make sure that the Current Jumper on Current Loop module (P/N MO9680B029) is set to 45 mA and

Voltage Jumper is set to 24 VDC.

Verify that the serial communication param

paragraphs 2.3 TYPES OF FUEL PUMP AND THEIR COMMUNICATION METHOD and 5.5

eters are set to: Baud 9600, Parity Odd, 1 stop bit (refer to

SERIAL PORTS SETUP PROCEDURES).

The Current

Loop connec

t

or on the Wayne Pump – US/UK J25 is found on the top right hand side.

8 Port CommVerter Operation and Installation

Manual

39

Page 44

2.7.6. Gilbarco Legacy & Gasboy 8800 Current Loop Electronic Pumps Configuration

To set up the Gasboy 8800 current loop electronic pumps install the current loop board in the

correct slot of the 8 port CommVerter board.

In the following example Slot 3 of the 8 port CommVerter board is used. The port assigned to

Channel 1 of this Slot is 3005.

NNOOTTEE

The Current Loop Interface module can be installed

in any slot of the 8 port CommVerter board. The slot

used may vary depending on system configuration.

Adjust the instructions according the Slot used for

the Current Loop Interface module board. The Slot

used is mapped to the assigned Port number.

In order for the Current loop board to communicate with the Gasboy 8800 pumps the ports setting

must be changed. Proceed as follows:

1. Connect the CommVerter to a PC (LAN Connection)

2. Open the Web browser, and enter the IP address of the Commverter. The Setup Main Screen

is displayed (see Figure 2-19)

Figure 2-19. CommVerter Unit Setup Site – Main Screen

40

8 Port CommVerter Operation and I

nstallation Manual

Page 45

3. Click on Admin Tasks. The Admin screen is displayed. Scroll down the page to reach the

TCP/IP timeouts section (see Figure 2-20)

Figure 2-20. CommVerter Unit Setup Site – Admin Screen

4. Select the Temporary disable (up to 5 minutes) checkbox

5. Click on the Send button in this section of the page

6. Select the Write to eeprom radio button in the Set/Get eeprom section

7. Click on the Send button in this section of the page

8. Select the Reset radio button in the Set/Get eeprom section

9. Click on the Send button in this section of the page

NNOOTTEE

These steps need to be completed in a timely manner

or the EEPROM will reset all changes made prior to

the reset.

8 Port CommVerter Operation and Installation

Manual

41

Page 46

10. Click on Serial Ports. The Serial Ports screen is displayed. Scroll down the page to reach

the Port that needs to be changed (see Figure 2-21)

11. This example refers to Port 205. Actual Port number2xx is determined by the Port assigned

to the Slot of the Current Loop Interface module board

12. Change the port setting as needed. See paragraph 2.3

13. Click on the Send button for the appropriate port

Figure 2-21. CommVerter Unit Setup Site – Serial Ports Screen

14. After changing and sending the Port settings, the eeprom must be updated and reset:

a. Click on Admin Tasks. The Admin screen is displayed

b. Select the Write to eeprom radio button in the Set/Get eeprom section

c. Click on the Send button in this section of the page

d. Select the Reset radio button in the Set/Get eeprom section

e. Click on the Send button in this section of the page

15. Give the system a few minutes to reboot and then verify that the settings have been saved.

42

8 Port CommVerter Operation and I

nstallation Manual

Page 47

2.7.6.1. SiteOmat Configuration for Gilbarco Legacy & Gasboy 8800 Current Loop Electronic Pumps

NNOOTTEE

For further information, please refer to SiteOmat

Installation and Maintenance Manual, P/N MDE-

4817.

In order to configure Gilbarco Legacy & Gasboy 8800 Current Loop Electronic Pumps, proceed as

follows:

1. Go to the SiteOmat Setup screen and click on the Advanced Mode button

2. Select the Buses tab. The Buses dialog box appears (see Figure 2-22)

Figure 2-22. Buses Dialog Box

8 Port CommVerter Operation and Installation

Manual

43

Page 48

3. Set up a bus for use by Gilbarco Legacy & Gasboy 8800 pumps. Note: port number may

differ.

4. Save the newly added Bus by clicking on the New button

5. Select the P. Servers tab. The Setup Pump Server dialog box appears (see Figure 2-23)

6. Set up a Pump Server for use by Gilbarco Legacy & Gasboy 8800 pumps. Note: port

number may differ

7. Save the newly added Pump Server by clicking on the New button

Figure 2-23. Setup Pump Server Dialog Box

8. After adding the Pump server, highlight the Pump Server and Click on the Addtl. Features

button. The Pump Server Settings dialog box appears (see Figure 2-24)

44

8 Port CommVerter Operation and I

nstallation Manual

Page 49

Figure 2-24. Pump Server Settings Dialog Box

9. Add a cluster for use by Gilbarco Legacy & Gasboy 8800 pumps. Be sure to select the

Enable Echo checkbox when adding the cluster

10. Save any changes that were made

11. On the Setup screen, click Save and then Reload. After the reload has been successfully

completed, the Gilbarco Legacy & Gasboy 8800 pumps may be added

12. Click on the Add Pump button on the Setup screen. The Setup Pump Settings dialog box

appears (see Figure 2-25)

8 Port CommVerter Operation and Installation

Manual

45

Page 50

Figure 2-25. Setup Pump Settings Dialog Box

13. Fill in the Pump number, Pump Head, and Number of hoses. The Pump Head number

must match the Pump ID set in Gilbarco Legacy & Gasboy 8800 pump

14. Select the correct Pump server and Cluster from the drop-down lists

15. Set the Message Factors as shown in the screen above. These settings work in most cases

but may need to be adjusted to make the pump and transaction data match

16. Set the Specific section as shown in the screen above. These settings work in most cases but

may need to be adjusted to match the specific pump used

17. Save any changes that were made

18. Select the newly added Pump

19. Select the More Options button. The following screen appears (see Figure 2-26)

20. Set the additional pa

rameters as shown in the screen below. These settings work in most

cases but may need to be adjusted to match the specific pump used

21. Save any changes that were made

22. On the Setup screen, click Save and then Reload

23. After the reload has completed successfully, verify that all added pumps have been saved.

46

8 Port CommVerter Operation and I

nstallation Manual

Page 51

Figure 2-26. Setup Pump Settings (More) Dialog Box

8 Port CommVerter Operation and Installation

Manual

47

Page 52

2.8. LAN to TOKHEIM APPLICATION

The LAN to Tokheim module is installed in the CommVerter whenever the pumps in the station are

of Tokheim brand. The CommVerter converts the LAN into Tokheim (and vice versa). Figure 2-27

shows a block diagram of a LAN to Tokheim communication application

Figure 2-27. LAN to Tokheim Configuration

o This module (two separate ports) interfaces with up to two pumps. In this configuration'

each pump is interfaced in a separate port.

o This module can be set to 5V or12V according to the Pump Interface requirement (Jumper

setting).

Figure 2-28. LAN to Tokheim Module, Two Pumps Configuration

48

8 Port CommVerter Operation and I

nstallation Manual

Page 53

LEDs Indication

NOTE

There is no external indication of the LEDs status.

Remove the Commverter cover to reveal the module

LEDs.

Connector Side

Channel 1 Rx D1

Channel 1 Tx D2

Channel 2 Rx D3

Channel 2 Tx D4

LED Blinking – Communication on

LED Off – No communication

2.8.1. Tokheim Connector Pinout

The following pinout is required for the LAN to Tokheim application, for all Tokheim brand

pump

s.

8 7 6 5 4 3 2 1

G COM TTC TTD G COM TTC TTD

Channel 2 Channel 1

2.8.2. Tokheim Module Jumpers

This module can be set to 5V or 12V according to the Pump Interface requirement. There are two

jumpers that determine the voltage level, as follows:

o Jumpers J1, J2 installed: 5V

o Jumpers J1, J2 removed: 12V

2.8.3. Tokheim Electronic Devices (Pump or any Tokheim Devices)

The wiring for the Tokheim electronic pump is provided as follows:

Figure 2-29 shows the specific wiring connections between the 8 Port Tokheim card

and the Tokheim pump nozzle, and the terminals that differ from the Mechanical

Pump.

8 Port CommVerter Operation and Installation

Manual

49

Page 54

8 PORT

MODULE

P/N:

819223420

DISPENSER

TTD

TTC

DCC-GND

Figure 2-29 Tokheim Electronic Pump - Wiring Diagram

Figure 2-30 Tokheim Electronic Pump - Wiring Diagram

50

8 Port CommVerter Operation and I

nstallation Manual

Page 55

2.8.4. Addressing Dual-Sided Tokheim Pumps

Figure 2-31 shows an example of the pump settings that should be defined in SiteOmat FCC to

address dual-sided Tokheim pumps.

Figure 2-31 Addressing Tokheim Dual-Sided Pumps

8 Port CommVerter Operation and Installation

Manual

51

Page 56

2.9. 4xCONTACTOR APPLICATION

The 4xContactor module includes four relays that toggle status from NC (normally close) to NO

(normally open), and vice versa in accordance with the jumper position (refer to paragraph 2.9.2).

This board is a relays module for four channels.

The relays contact rating is:

1A 24 VDC

0.5A 120 VAC

Figure 2-32. 4xCONTACTOR Module

2.9.1. 4x Contactor Connector Pinout

The following pinout is required for the 4x Contactor application.

8 7 6 5 4 3

2 1

K4 K3 K2 K1

Switch 4 Switch 3 Switch 2 Switch 1

52

8 Port CommVerter Operation and I

nstallation Manual

Page 57

2.9.2. 4xContactor Module Jumpers

The jumpers in the 4xContactor module can be set in two different configurations. The module

includes four consecutive jumpers, J1 to J4.

The jumper configuration determines the status of its related relay.

Figure 2-33. 4xCONTACTOR Module Jumpers

8 Port CommVerter Operation and Installation

Manual

53

Page 58

2.9.3. Station Setup

The relays control the pump's valve according to pump server's pump state which does not support

the suspend resume commands by protocol. Each valve of such pump should be connected to the

relay or through another power relay (according to the voltage or current needs of the valve). 2

pumps example connection is shown on Figure 2-34.

Figure 2-34. Station Setup

54

8 Port CommVerter Operation and I

nstallation Manual

Page 59

2.9.4. Pump Server Setup

The ini file contains definitions used to communicate with the relays.

Example for one pump is given below:

[cluster_01]

commtype=tcp

ip=192.168.1.108

port=3001

enable_echo=N

log_cluster_port=10001

[pump_01]

clusterid=1

addr=1

num_of_nozzles=1

specific=specific_01

[specific_01]

taiwan_soft_ver=N

use_relay=Y

relay_port=6500

relay_ip=192.168.1.108

relay_con_timeout=200

channel=1

New definitions are

relay_port – this is the Digital I/O port for relay's comm

relay_ip - The comverter IP where the relays are placed.

channel - The relay channel which will be activated ( it could be from 1 to 8 ) .

8 Port CommVerter Operation and Installation

Manual

55

Page 60

2.9.5. 8 Port CommVerter Setup

The 8 port CommVerter should be activated via its digital control (see Figure 2-35) listening port.

After setting the port number (should be the same as in the ini file of pump server) and enabling the

checkbox save and reset the CommVerter.

Figure 2-35. Digital Control

56

8 Port CommVerter Operation and Installation Manual

Page 61

2.10. LAN to RS422 APPLICATION

2.10.1. RS422 Module Application

The RS422 module (and the RS422 sub-module) transforms incoming data transmission into

RS-422 standard point to point. The RS422 module is installed on the main board and controls

Channel 1. In this module, pins 1 to 5 (GND) only are active, to provide RS422 transmission.

Figure 2-36. LAN to RS422 Configuration

Figure 2-37. RS422 Module

In order to disable echo, short Jumper J6 as shown in

Figure 2-38.

Figure 2-38. RS422 Module Jumper J6

8 Port CommVerter Operation and Installation

NNOOTTEE

Manual

57

Page 62

NOTE

There is no external indication of the LEDs status.

Remove the Commverter cover to reveal the module

LEDs.

LEDs Indication

Connector Side

Channel 1 Rx D4

Channel 1 Tx D1

LED Blinking – Communication on

LED Off – No communication

2.10.2. RS-422 Connector Pinout

The following pinout is required for the LAN to RS-422 application.

8 7 6 5 4 3 2 1

G T- T+ R- R+

2.10.3. Sub-RS422 Module Application

The RS422 Module has an additional sub-RS422 module on top of it (connector CN4). This

sub-module provide data transmission conversion into RS422 for Channel 2.

The pinout of the connection is the same as for the RS422 module. Pins 1 to 5 (GND) only are

active, to provide RS422 transmission).

58

8 Port CommVerter Operation and I

nstallation Manual

Page 63

Figure 2-39. Sub-RS422 Module

LEDs Indication

NOTE

There is no external indication of the LEDs status.

Remove the Commverter cover to reveal the module

LEDs.

Connector Side

Channel 2 Rx D4

Channel 2 Tx D1

LED Blinking – Communication on

LED Off – No communication

8 Port CommVerter Operation and Installation

Manual

59

Page 64

2.11. LAN TO NUOVO PIGNONE APPLICATION

The LAN to Nuovo Pignone module transforms data transmission into Nuovo Pignone Pump

Interface.

Figure 2-40. Nuovo Pignone Module Configuration

LEDs Indication

Figure 2-41. Nuovo Pignone Module

NOTE

There is no external indication of the LEDs status.

Remove the Commverter cover to reveal the module

LEDs.

Connector Side

Channel 1 Rx D15

Channel 1 Tx D16

Channel 2 Rx D17

Channel 2 Tx D18

LED Blinking – Communication on

LED Off – No communication

60

8 Port CommVerter Operation and I

nstallation Manual

Page 65

2.11.1. Nuovo Pignone Connector Pinout

The following pinout is required for the LAN to RS-232 application.

8 7 6 5 4 3 2 1

TX2- TX2+ RX2- RX2+ TX1- TX1+ RX1- RX1+

Channel 2 Channel 1

2.11.2. COPTRON Communication to Nuovo Pignone Card

Connector TB4A in Coptron pump (Pump Head 1)

Table 2-2 . Pump Communication Connector for 8 Port NP Module

Coptron

Pin Out

pin1_TXB pin3_Tx1+

Nuovo Pignone Card Pin Out

pin2_ TXA pin4_Tx1pin3_ RXB pin1_Rx1+

pin4_ RXA pin2_Rx1-

When Coptron dispenser detects serial-communication, it starts working in automatic mode.

2.12. LAN TO RS232/485 APPLICATION

This module is dual-purpose and supports two different communication protocols: RS232 and

RS485.

The LAN to RS-232 application is required when the connection to specific devices, such as TLGs,

is via RS-232. The RS232 circuit is dedicated for Channel 1

The LAN to RS-485 application is required when connecting fuel pumps and other serial devices to

home base controller that uses TCP/IP communication. The RS485 circuit is dedicated for

Channel 2.

NOTE

There is no external indication of the LEDs status.

Remove the Commverter cover to reveal the module

LEDs.

8 Port CommVerter Operation and Installation

Manual

61

Page 66

LEDs Indication

Connector Side

Channel 1 (RS232) Rx D3

Channel 1 (RS232) Tx D2