Page 1

FleetKey Fuel Management System

KE200 Key Encoder/Maintenance

Terminal Operation Manual

MDE-4465A

Page 2

Computer Programs and Documentation

Federal Communications Commission (FCC) Warning

All Gasboy computer programs (including software on diskettes and within memory chips) and documentation are copyrighted by, and shall remain the property of, Gasboy. Such

computer programs and documents may also contain trade secret information. The duplication, disclosure, modification, or unauthorized use of computer programs or

documentation is strictly prohibited, unless otherwise licensed by Gasboy.

This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy, and if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense. Changes or modifications not expressly

approved by the manufacturer could void the user’s authority to operate this equipment.

Approvals

Gasboy, Greensboro, is an ISO 9001:2000 registered facility.

Underwriters Laboratories (UL):

UL File# Products listed with UL

MH4314

MH6418

MH7404

MH10581 Key con t r o l u n i t , M o d e l G K E - B S e r i e s

All dispensers and self-contained pumping

units

Power operated Transfer Pump Models 25,

25C, 26, 27, 28, 72, 72S, 72SP , 72X, 73 and

1820

Hand operated Transfer Pump Models 1230

Series, 1243 Series, 1520 and 1720 Series

Card reader terminals, Models 1000, 1000P

Site controller, Model 2000S CFN Series

Data entry terminals, Model TPK-900 Series

Fuel Point Reader System

New York City Fire Department (NYFD):

NYFD C of A # Product

4823 9100A, 9140A, 9152A, 9153A,

4997 9822A, 9823A

5046 9100Q, 9140Q, 9152Q, 9153Q,

5087 8753K, 8853K, 9153K, 9853K

9800A, 9840A, 9850A, 9852A,

9853A, 9140

9800Q, 9840Q, 9852Q, 9853Q

(restricted to diesel and nonretail gasoline sales)

National Conference of Weights and Measures (NCWM) - Certificate of Compliance (CoC):

Gasboy pumps and dispensers are evaluated by NCWM under the National Type Evaluation Program (NTEP). NCWM has issued the following CoC:

CoC# Product Model # CoC# Product Model #

95-179A2 Dispenser

95-136A5 Dispenser 9800 Series 91-057A3 Controller

9100 Retail Series, 8700

Series, 9700 Series

91-019A2 Dispenser

9100 Commercial

Series

1000 Series FMS,

2000S-CFN Series

California Air Resources Board (CARB):

Executive Order # Product

G-70-52-AM Balance Vapor Recovery

G-70-150-AE VaporVac

Patents

Gasboy products are manufactured or sold under one or more of the following US patents:

Dispensers

5,257,720

Point of Sale/Back Office Equipment

D335,673

Trademarks

Non-registered trademarks

Atlas™

Consola™

Infinity™

Registered trademarks

ASTRA

Fuel Point

Gasboy

Keytrol

Slimline

Additional US and foreign patents pending.

®

®

®

®

®

Additional US and foreign trademarks pending.

Other brand or product names shown may be

trademarks or registered trademarks of their

respective holders.

This document is subject to change without notice. · For information regarding Gasboy Literature, call (336) 547-5661

E-mail: literature@gasboy.com · Internet: http://www.gasboy.com

© 2007 GASBOY · All Rights Reserved

Page 3

Table of Contents

1 – System Overview 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Hardware Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

KE200 PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Communications Ports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Communication Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

KE200 Switch Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Communications Terminations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Internal Modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Communication Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Using the KE200 Keypad and Key Receptacle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Using the KE200 Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Using Your Logger Printout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

System Access and Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Before Proceeding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2 – KE200 Setup - Standalone 15

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Accessing KE200 Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Maintenance Mode (1000 FleetKey only) . . . . . . . . . . . . . . . . . . . . . . . .15

Encode Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Setup Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

System Flow Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Setting Up the KE200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Load Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Load Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Load Station ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Load System ID. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Load Working Key. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Configure ID Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Number of ID Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Edit or View Field Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Configure Maintenance Transactions (1000 FleetKey only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Reset Transaction Pointer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Reset Transaction File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Load Transaction Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Configure Maintenance Table (1000 FleetKey only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Build a Maintenance Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Clear the Maintenance Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Load Country Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

3 – KE200 Setup - Terminal 35

Using the Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Entering Commands and Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Signing On to the Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007 Page i

Page 4

Signing Off of the Terminal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Lost or Forgotten Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Setting Up the KE200. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Clear Maintenance (CL MA) (1000 FleetKey only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Encode Key (EN KE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Exit (EX) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Help (HE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Load Country (LO CO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Load Date (LO DA). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Load Format (LO FO). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Load IDFIELDS (LO ID) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Load Maintenance (LO MA) (1000 FleetKey only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Load PIN (LO PI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Load Signon (LO SI). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Load Station (LO ST) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Load System (LO SY). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Load Transactions (LO TR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Print Country (PR CO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Print Date (PR DA). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Print Format (PR FO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Print IDfields (PR ID) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Print Maintenance (PR MA) (1000 FleetKey only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Print PIN (PR PI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Print Records (PR RE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Print Station (PR ST) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Print System (PR SY). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Print Transactions (PR TR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Read Key (REA KE). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Reset Pointer (RES PO) (1000 FleetKey only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Reset Records (RES RE). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Reset Transactions (RES TR) (1000 FleetKey only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Version (V) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4 – Encoding Keys 63

Methods of Encoding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Key Fields. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Field Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Key Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Field Separators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

System ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Key Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

ID Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Supervisor Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Expiration Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Product Limit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Product Authorization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Price Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Check Digit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Previous Odometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Last Odometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Reasonableness Check Digit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Odometer Retries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Page ii MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007

Page 5

Minimum Miles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Maximum Miles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Vehicle Class (1000 FleetKey only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Maintenance X Odometer (1000 FleetKey Systems only). . . . . . . . . . . .69

Maintenance X Date (1000 FleetKey Systems only) . . . . . . . . . . . . . . . .69

PIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

CRC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Preparing for Encoding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Filling Out the Key Encoding Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Series 1000/CFN Key Encoding Form. . . . . . . . . . . . . . . . . . . . . . . . . . .71

Encoding from the Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Reading Key from the Keypad. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

View Encode Records - Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Reset Encode Records - Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Encoding from the Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

5 – Performing Maintenance 77

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Perform Maintenance (1000 FleetKey only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

View Maintenance (1000 FleetKey only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Appendix A – Error Messages A-1

Appendix B – Parts List and Preventive Maintenance B-1

KE200 - Exterior View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

FleetKeys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

KE200 - Inside Top Cover View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Modem Option (Not Illustrated) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

KE200 - MPU View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Index Index-1

MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007 Page iii

Page 6

This page is intentionally left blank.

Page iv MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007

Page 7

Introduction System Overview

1 – System Overview

Introduction

The Gasboy® KE200 Key Encoder/Maintenance T e rminal allows you to encode Fleetkeys that

are used in the 1000 FleetKey system and the CFN system with the key option. It also allows

you to update the data key with maintenance information for the FleetKey system.

Figure 1-1: FleetKey

A Fleetkey is a small, plastic-encased integrated circuit which is capable of storing and

retaining data. The Fleetkey is inserted, for encoding and maintenance purposes, into the

receptacle labeled “FLEETKEY” that is located on the face of the KE200. Encoding involves

electronically writing user-identification information for system access onto a Fleetkey.

The encoder itself can function as a standalone unit, or it can be attached to a data terminal or

host computer that allows easier setup and encoding. For the standalone unit, the keypad

allows you direct access to all setup, encoding, and maintenance procedures using a series of

menus. When a data terminal is attached, you can perform all setup and all encoding (with the

exception of inserting the key , which must be done at the KE200) using simple commands and

stored encoding formats. Maintenance tables and transactions can be set up and updated from

the data terminal. However, key updating must be performed at the KE200. When attached to

a host computer, communication is via command and response packets. All data exchanged

between the KE200 and the host computer is packaged as a data packet. C35365 KE200 Host

Communications Command and Response Format manual contain s info rma tion on

communications and commands.

MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007 Page 1

Page 8

System Overview Hardware Description

Hardware Description

The KE200 Key Encoder/Maintenance Terminal is a microprocessor controlled unit that

encodes and updates Fleetkeys. It also serves as a maintenance terminal where technicians can

update keys as part of the Fleetkey Maintenance Option.

It can be used in any of the following ways:

• Standalone

• With an ASCII terminal or a Cathode Ray Tube (CRT) monitor

• With a PC using appropriate interface software

The unit is compact and durable, and is equipped with a 20-position tactile feel membrane

keypad and a key receptacle for insertion of Fleetkeys. A Manager's keyswitch is provided

with two key types (Manager and Maintenance) to safeguard the system from unauthorized

access. The system has 32K of battery-backed RAM, which safeguards system data in the

event of a power failure. Two communication ports are provided: an RS-232 logger port,

which is usually used for a printer, and an RS-232/RS-422 port used for communication with

external devices (PC, CRT, and so on). A third port is also available for use with an optional

1200/2400 baud built-in modem.

Power 120 VAC, 60 Hz., 22W. Plugs into any standard 115 VAC

Operating Environment 0 to 40° C, 32 to 104° F, with a relative humidity of 20 - 80%,

Location The KE200 should be located in an office or garage type

wall outlet. The power line should be free from any surges or

other electrical interference.

non-condensing.

environment in an area protected from direct contact with the

weather. It should not be installed over a hazardous location.

Page 2 MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007

Page 9

Hardware Description System Overview

Figure 1-2: KE200 Hardware

8.5”

8.875”

5.1”

MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007 Page 3

Page 10

System Overview KE200 PCB

KE200 PCB

The KE200 PCB is the controller for the key encoder. Jumper settings on the PCB for each of

the following must be made to ensure correct operation.

• Port 1 configuration for RS-232 or RS-422

• Baud Rates for Ports 1, 2, and 3

• Program address (map type)

Figure 1-3 illustrates the jumper position for each and shows where the jumper patch appears

on the PCB.

Figure 1-3: KE200 PCB

K2 Baud Rate

Port 1

K3 Baud Rate

Port 2

K4 Baud Rate

Port 3 Modem

K5 Beeper Enable

Page 4 MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007

Page 11

Communications System Overview

Communications

Communications Ports

The KE200 has two asynchronous ports to connect a logger printer and/or a data terminal. The

connection can be made by a direct cable or via a telephone modem. Ports 1 and 2 can be set to

a variety of baud rates (300, 600, 1200, 2400, 4800, and 9600) depending on the equipment

being connected.

• Port 1 is an RS-232/RS-422 port used to connect to external devices such as a PC, CRT or

external modem.

• Port 2 is an RS-232 port used to directly connect a printer (logger) to the KE200.

• A third port is also available for use with a built-in 1200/2400 baud modem (optional).

The cable length from the RS-232 port to the device is limited to 100 feet. If the distance

exceeds 100 feet, a Gasboy Short Haul Modem (P/N C05618) is required.

Communication Protocol

Devices that communicate with the KE200 must be able to transmit and receive full duplex,

ASCII, asynchronous data via an EIA RS-232 connection.

The KE200 uses a simple terminal protocol. No special characters are transmitted to designate

the beginning or end of the data blocks. Data is transmitted in serial bit format per character , as

follows:

One start bit, eight data bits, one stop bit.

Each character is echoed back to the transmitting device. This checks the integrity and enables

CRT operators to display transmitted data.

When used with the computer (or host) mode interface, the host computer initiates all

communications between itself and the KE200, with command packets. The KE200 responds

to the host command packets with response packets. All data exchanged between the KE200

and the host computer is packaged as a data packet.

KE200 Switch Settings

An 8-position switch bank, located on the KE200 CPU board is used to set the poll address and

the communications mode for the KE200. On switch bank SW1, for SW1-1 through SW1-4,

set the poll address when the Computer Mode interface is active. SW1-5 indicates the

communications mode for the KE200's Port 1. The last three switch positions (SW1-6 through

SW1-8) are currently unused. All switch settings are read during program initialization, at

power-up. If changes are made, the KE200 must be turned off then on, to recognize them.

MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007 Page 5

Page 12

System Overview Communications

The following table contains Poll Address Switch Settings for SW1-1 through SW1-4.

Address SW1-1 SW1-2 SW1-3 SW1-4

01 CLOSED CLOSED CLOSED CLOSED

02 OPEN CLOSED CLOSED CLOSED

03 CLOSED OPEN CLOSED CLOSED

04 OPEN OPEN CLOSED CLOSED

05 CLOSED CLOSED OPEN CLOSED

06 OPEN CLOSED OPEN CLOSED

07 CLOSED OPEN OPEN CLOSED

08 OPEN OPEN OPEN CLOSED

09 CLOSED CLOSED CLOSED OPEN

10 OPEN CLOSED CLOSED OPEN

11 CLOSED OPEN CLOSED OPEN

12 OPEN OPEN CLOSED OPEN

13 CLOSED CLOSED OPEN OPEN

14 OPEN CLOSED OPEN OPEN

15 CLOSED OPEN OPEN OPEN

16 OPEN OPEN OPEN OPEN

Note: The poll address is the same for both Port 1 and Port 3 (internal modem port).

Position 5 on switch bank SW1 is used to select the communications mode for Port 1. When

position 5 is closed, the port operates in the Standard Terminal mode providing operator

prompts and messages. Activity through Port 1 is also sent to the logger port while Port 1 is in

the Terminal mode.

When position 5 is open, the Computer Mode interface is selected for Port 1. While in the

Computer mode, the port only responds to Computer mode command packets. Gasboy PC

software uses Computer mode to communicate with the KE200. Activity through Port 1 is not

sent to the logger port while it is set for Computer mode.

SW1-5 Definition

CLOSED Terminal mode selected for Port 1

OPEN Computer mode selected for Port 1

Page 6 MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007

Page 13

Communications System Overview

Communications Terminations

The wiring terminations for various communication options are provided below:

RS-232 - Data Terminal Communications for Ports 1 and 2

Pin Function Input/Output

2 TxD - Transmit data Input

3 RxD - Receive data Output

7 Signal ground Ground

8 DCD - Data Carrier Detect Output

20 DTR - Data Terminal Ready Input

RS-422 - Device Communications for Port 1

Pin Function Input/Output

1 Tx+ - Transmit data Output

2 Tx- - Transmit data Output

3 Rx+ - Receive data Input

4 Rx- - Receive data Input

5 Signal ground Ground

Internal Modem

The optional built-in modem on the KE200 is a Bell 103J/212A compatible answer modem.

The KE200 supports a 2400 baud internal modem, which is part of the modem kit (P/N

C06319).

The modem is designed for 0-300, 1200, or 2400 baud, full duplex, asynchronous

communication. The modem is mounted inside the KE200 system at the factory . Power for the

modem is supplied by the KE200 system.

The modem is designed to meet or exceed the direct connection registration requirements of

the FCC rules. This means the modem will connect directly with a jack supplied by the phone

company. The customer has to order this jack and have it installed. To order this equipment

from the phone company, specify the following:

• Any one of the following jacks: RJ11C or RJ41S, or RJ45S.

• The registration number of 6BHUSA-24793-DT-E.

• The data transmission rate of 0-300 baud, 1200 baud, or 2400 baud.

• The Bell equivalent of 103J/212A.

MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007 Page 7

Page 14

System Overview Communication Wiring

Communication Wiring

The figures below show the various wiring schemes that are available for the installation of the

KE200.

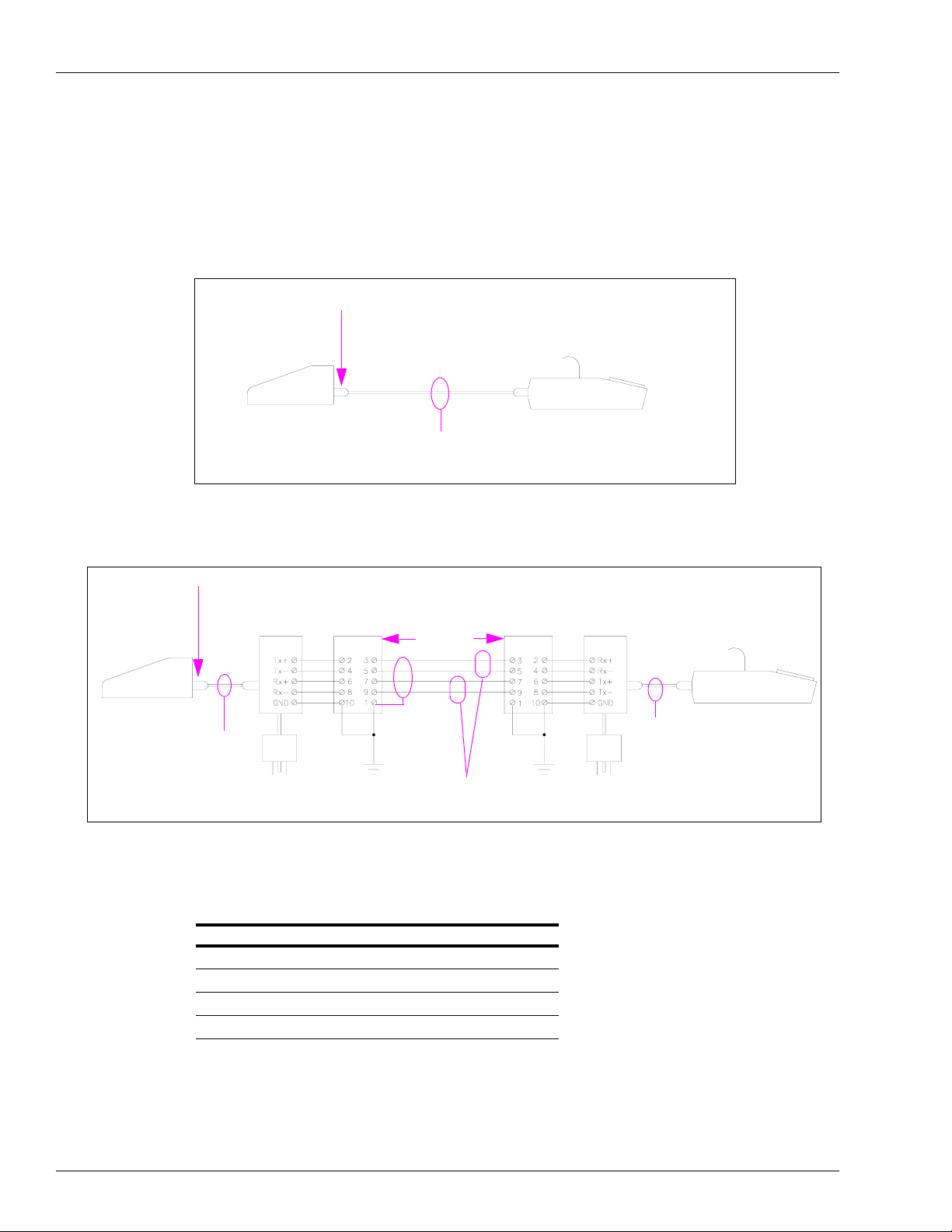

Figure 1-4: RS-232 Connection

KE200 Port 1 or 2

Peripheral Device

(Terminal or Modem)

EIA 1:1 Cable

P/N C04549

Figure 1-5: Short Haul Modem - ME800

KE200 Port 1 or 2

EIA 1:1 Cable

(P/N C04549)

SHM -ME800

(P/N C02479)

AC Power AC Ground

Protector

(P/N C08159)

Maximum

Distance

(see Note)

Shield

GND

(if used)

2 Twisted Pairs

(see Note)

Protector

(P/N C08159)

AC Ground

SHM -ME800

(P/N C02479)

Peripheral Device

EIA 1:1 Cable

(P/N C04549)

AC Power

Note: Maximum distances specified by the manufacturer are listed here. These distances are

valid when you use 22 AWG or 24 AWG two twisted-pair unshielded cable (a shielded

cable will reduce the distance to one-third of the values shown).

Baud Rate Distance

300 and 1200 baud 10 miles

2400 baud 5 miles

4800 baud 4 miles

9600 baud 2 miles

Page 8 MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007

Page 15

Cables System Overview

Figure 1-6: RS-422 Gasboy Short Haul Modem

KE200

Port 1

P2

Cables

Field Wiring 1500 Feet Max.

Shield Ground

Port 1

AC Ground

Gasboy SHM

(P/N C05618)

AC Power

Peripheral Device

EIA 1:1 Cable

(P/N C04549)

The drawing below shows the pin-to-pin layout of the EIA 1:1 cable (Gasboy P/N C04549).

Figure 1-7: Pin-to-Pin Layout of EIA 1:1 Cable

Male Connector

100 Feet Max.

P/N C05758

Male Connector Male Connector

(Wire End View)

MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007 Page 9

Page 16

System Overview Using the KE200 Keypad and Key Receptacle

Using the KE200 Keypad and Key Receptacle

The keypad for the encoder is simple, consisting of numeric keys 0-9, and the following keys:

Figure 1-8: KE200 Keypad and Receptacle

• ENTER transmits entered information to the encoder and allows you to move through the

prompts. It is also used to acknowledge and clear error or status messages.

• CLEAR clears the entry. It is used as a “NO” response to a verification prompt. When

pressed twice in encoding mode, it enters special field separators and supervisor entry

characters.

•F1 in Setup and Maintenance modes allows you to move to the next prompt. It is disabled

for Encoding mode.

• F2 in Setup and Maintenance modes allows you to move to the previous prompt. It is

disabled for Encoding mode.

• RESET in Encoding or Setup modes returns you to the first prompt in the group. It is

disabled in Edit mode.

• PREV in Encode mode returns you to the previously displayed prompt. If you are at the

first prompt in a group, you will exit to the Encode menu. In Setup or Maintenance modes,

it backs you out by group. Use the flow diagram in Section 2 to visualize the following:

If you are at FIELD SIZE, under the group SELECT ID FIELD and you press PREV

once, you return to SELECT ID FIELD. If you press PREV again, CONFIG ID MENU

displays. If you press PREV again, SETUP MENU displays.

• ENCODE in Encode mode skips any intermediate prompts, validates remaining

unentered data, and takes you immediately to the ENCODE KEY verification menu from

whatever prompt you were at. If errors exist in the unentered data, the system returns to

the prompt in error and displays RANGE ERROR.

•“A”, “B”, “C” selects maintenance category in Setup and Maintenance modes.

• A key receptacle on the right-hand side of the encoder face allows you to insert Fleetkeys

for encoding or maintenance updating.

Page 10 MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007

Page 17

Using the KE200 Display System Overview

Using the KE200 Display

The display has some distinguishing characteristics that will help you determine what entry is

required. A flashing cursor at the end of a prompt indicates that the KE200 is waiting for input

from the keypad (0-9) or “A”, “B”, “C” keys. If there is no flashing cursor on an input prompt,

use the “F1” or “F2” keys to toggle between possible choices for that prompt. When you

encounter an error or status message, press ENTER to clear the message. In an error

condition, the KE200 displays the field in error for correction. In Encoding mode, you may see

the following special characters on the display: “~” for field separator and “*” for supervisor

entry . These are discussed later in Field Descriptions, ID Fields (see

page 23).

“Configure ID Fields” on

Using Your Logger Printout

When you have a logger (printer) attached to Port 2 of your KE200 system, all significant

events are recorded on this printout. The following events are logged: power-ups, sign-ons,

sign-offs, mode changes, setup and load commands, encode key commands, reset commands,

encode records (if you answered yes to LOG KEY DATA?) and maintenance transactions.

Each logger printout entry is set up the same. It contains where the command originated

(system, keypad, Port 1 or Port 3), the command or event, and a date/time stamp. A sample

logger printout is shown below.

Figure 1-9: Logger Printout

MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007 Page 11

Page 18

System Overview System Access and Operating Modes

System Access and Operating Modes

To guard against unauthorized use, the KE200 system has two types of access keys:

• A manager key, which allows access to both the Encoding and Maintenance modes

• A maintenance key, which allows access to Maintenance modes only.

The key is inserted into the front of the encoder cabinet. It has three possible positions which

correspond to the system modes:

•Idle

• Maintenance

• Encode/Setup

The key position for each mode is shown in Figure 1-10. You can access the modes only when

the proper key is inserted and in the correct position.

Figure 1-10: Key Positions for Each Mode

When a data terminal is in use, the KE200 must be in Idle mode to enable operation of all the

commands. When the KE200 is a standalone, Idle mode has no function other than to display

the current date and time.

Maintenance mode allows you to view and update maintenance information on a key. All

maintenance is performed from the KE200; you cannot perform maintenance from the data

terminal.

Encode/Setup mode allows access to all system setup parameters and encoding fields . The key

must be in this position for you to set up your system from the KE200 or to encode keys from

the KE200.

Page 12 MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007

Page 19

Before Proceeding System Overview

Before Proceeding

You can begin to set up the KE200 for operation, if you have a general understanding of how

the system works.

When you first use the system, you will have to perform setup functions to define your system

attributes, configure the maintenance table, set your units and date format, and run any

diagnostics that are required. The procedure for setting up the KE200 differs depending on

whether you are using the keypad or a data terminal.

With the keypad, you must progress through a series of displayed menus and fill in the data for

each. With the terminal, you can run a “SETUP” routine that automatically prompts you for

the data necessary to run your system, or you can execute commands individually.

The section “KE200 Setup - Standalone” on page 15 describes setting up the system using the

Standalone KE200. The section “KE200 Setup - Terminal” on page 35 describes setting up the

system using the data terminal.

Once your system is set up, you must encode your keys, based on your system layout and use

some of the values you entered in Setup mode. Once your keys are initially encoded, you will

have to access Encode mode infrequently, when you need to add additional keys, or change

data on a key. The section

encoding and encoding procedures for both the standalone KE200 and the data terminal.

“Encoding Keys” on page 63 contains general information on key

Finally, you will have to record Performed Maintenance as scheduled. The section

“Performing Maintenance” on page 77 describes viewing maintenance information on the key

and performing maintenance.

MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007 Page 13

Page 20

System Overview Before Proceeding

This page is intentionally left blank.

Page 14 MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007

Page 21

Overview KE200 Setup - Standalone

2 – KE200 Setup - Standalone

Overview

The standalone KE200 allows you direct access to all setup, encoding (numeric fields only),

and maintenance procedures. You must enter commands via the keypad and a series of menus

are displayed, which guide you through setup, encoding, and maintenance.

Accessing KE200 Modes

The different modes of the KE200 are determined by the position of the Manager’s key. When

the KE200 is standalone, Idle mode has no function, other than to display the current date and

time. Maintenance mode allows you to view and update maintenance information on a key.

Encode/Setup mode allows access to all system setup parameters and encoding fields. The key

must be in this position for you to set up your system from the KE200 or to encode keys from

the KE200.

Maintenance Mode (1000 FleetKey only)

Note: You can use either the Manager key or the Maintenance key to access Maintenance

mode.

To access Maintenance mode, proceed as follows:

1 Turn th e Manager key to MAINT. The system displays the following:

MAINTENANCE MODE:

PERFORM MAINTENANCE

2 Press ENTER to display the first Perform Maintenance prompt.

PERFORM MAINTENANCE:

INSERT KEY

MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007 Page 15

Page 22

KE200 Setup - Standalone System Flow Diagram

Encode Mode

To access Encode mode, proceed as follows:

1 Turn th e Manager key to ENCODE. The system displays the following:

SELECT OPTION:

ENCODE

2 If you wish to encode keys, press ENTER. The system displays the following:

ENCODE MENU:

ENCODE KEY

Setup Mode

To access Setup mode, proceed as follows:

1 Turn th e Manager key to ENCODE. The system displays the following:

SELECT OPTION:

ENCODE

2 If you wish to enter Setup mode, press F1. The system displays the following:

SELECT OPTION:

SETUP

3 Press ENTER to display the first Setup prompt.

SETUP MENU:

LOAD DATE

System Flow Diagram

The KE200 Key Encoder/Maintenance Terminal software is designed to facilitate easy

navigation.

Page 16 MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007

Figure 2-1 on page 17 shows the system layout by manager key position.

Page 23

System Flow Diagram KE200 Setup - Standalone

Figure 2-1: System Flow Diagram

MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007 Page 17

Page 24

KE200 Setup - Standalone Setting Up the KE200

Setting Up the KE200

The first time you use your Key Encoder/Maintenance Terminal, perform the following steps

in order to load your system with the necessary data for processing.

1 With the Manager key inserted and in the idle position, turn the power switch, located on the

left side of the face to “ON”. The KE200 displays the current date and time (these were set at

the factory to Eastern time).

2 Perform the Reset Records command. See “Encoding Keys” on page 63 and “Reset Encode

Records - Keypad” on page 75.

3 Enter Setup mode and perform the following:

• Load Date (if not correct)

• Load Time (if not correct)

• Load Station ID for your key encoder/maintenance terminal.

• Load System ID: This must match the system ID of your FleetKey system. Refer to the

key layout provided with your FleetKey system.

• Load Working Key: This must match the working key of your FleetKey system. Refer to

the key layout provided with your FleetKey system.

• Load Country options.

• Configure ID fields: The fields you configure must match the fields as you ordered them.

Only numeric fields can be encoded using the KE200 keypad. If your ID fields are

alphanumeric (FleetKey only), you must use a data terminal for encoding input. Refer to

your key layout.

• Configure Maintenance Transactions (FleetKey only): This includes resetting the

transaction pointer, resetting the transaction file and loading the transaction number.

• Configure Maintenance table (FleetKey only): This includes clearing the Maintenance

Table to eliminate any data that may have been present from testing and loading a

Maintenance Table that matches the one defined in your FleetKey system.

• Run diagnostics, if necessary.

Once the above steps are performed, your system is ready to encode keys and record

Performed Maintenance.

The commands listed above are discussed on the pages that follow, in the order in which they

appear on the Setup menu.

Page 18 MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007

Page 25

Load Date KE200 Setup - Standalone

Load Date

Use “LOAD DATE” to load the current date. The KE200 should be factory set with the correct

date, but occasionally you may need to change it.

To load date, proceed as follows:

1 Enter the Setup mode as described previously. The system displays the following:

SETUP MENU:

LOAD DATE

2 Press ENTER. The system displays the following:

3 Type the correct date and press ENTER. The display returns to the following:

Load Time

SETUP MENU:

The currently loaded date appears on the second line of the display.

MMDDYY

1 2 1 6 9 1

SETUP MENU:

LOAD DATE

To display another primary prompt, press F1 or F2 until the desired prompt appears.

To exit back to “SELECT OPTION: SETUP”, press PREV.

Use “LOAD TIME” to load the current time in 24-hour format (00:00 to 23:59). The KE200 is

factory set to Eastern time with the correct time, but occasionally you may need to change it.

To load time, proceed as follows:

1 Enter Setup Mode as described previously. The system displays the following:

SETUP MENU:

LOAD DATE

MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007 Page 19

Page 26

KE200 Setup - Standalone Load Station ID

2 Press F1 or F2 until the following is displayed:

SETUP MENU:

LOAD TIME

3 Press ENTER. The prompt now reads:

LOAD TIME: HHMMSS

095521

The currently loaded time appears on the second line of the display.

4 Type the correct time and press ENTER. The display returns to the following:

SETUP MENU:

LOAD TIME

5 To display another primary prompt, press F1 or F2 until the desired prompt appears.

6 To exit back to “SELECT OPTION”, press SETUP > PREV.

Load Station ID

Use “LOAD STATION ID” to load a number of up to three digits to identify the key encoder/

maintenance terminal. This identifier is similar to the site ID used in the FleetKey system. It is

used mainly to identify the station for communication with PCs or other communications

equipment.

To load station ID, proceed as follows:

1 Enter Setup Mode as described previously. The system displays the following:

SETUP MENU:

LOAD DATE

2 Press F1 or F2 until the following appears:

SETUP MENU:

LOAD STATION ID

Page 20 MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007

Page 27

Load System ID KE200 Setup - Standalone

3 Press ENTER. The currently loaded value appears on the second line of the display.

LOAD STATION ID:

000

4 Type a one to three digit identifier and press ENTER. The display returns to the following:

SETUP MENU:

LOAD STATION ID

5 To display another primary prompt, press F1 or F2 until the desired prompt appears.

6 To exit back to “SELECT OPTION”, press SETUP > PREV.

Load System ID

Use “LOAD SYSTEM ID” to load the 4-digit system ID of your FleetKey system. This

number is verified with the key when you perform maintenance.

To load system ID, proceed as follows:

1 Enter Setup Mode as described previously. The system displays the following:

SETUP MENU:

LOAD DATE

2 Press F1 or F2 until the following appears:

SETUP MENU:

LOAD SYSTEM ID

3 Press ENTER. The currently loaded value appears on the second line of the display.

SYSTEM ID:

5630

4 Type the system ID of your FleetKey system. This number appears on your key layout.

5 Press ENTER. The display returns to the following:

SETUP MENU:

LOAD SYSTEM ID

MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007 Page 21

Page 28

KE200 Setup - Standalone Load Working Key

6 To display another primary prompt, press F1 or F2 until the desired prompt appears.

7 To exit back to “SELECT OPTION”, press SETUP > PREV.

Load Working Key

Use “LOAD WORKING KEY” to load the 4-digit working key used with your FleetKey

system. This number is used to encrypt and decrypt Personal Identification Numbers (PINs)

when you encode your keys.

To load working key, proceed as follows:

1 Enter Setup Mode as described previously. The system displays:

SETUP MENU:

LOAD DATE

2 Press F1 or F2 until the following appears:

SETUP MENU:

LOAD WORKING KEY

3 Press ENTER. The currently loaded value appears on the second line of the display.

LOAD WORKING KEY:

1234

4 Type the working key for your FleetKey system. This number appears on your key layout.

5 Press ENTER. The display returns to the following:

SETUP MENU:

LOAD WORKING KEY

6 To display another primary prompt, press F1 or F2 until the desired prompt appears.

7 To exit back to “SELECT OPTION”, press SETUP > PREV.

Page 22 MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007

Page 29

Configure ID Fields KE200 Setup - Standalone

Configure ID Fields

Use “CONFIG ID FIELDS” to identify the number of ID fields and the name, size, and format

of each. The system has a set number of predefined field names (VEHICLE, EMPLOYEE,

TRAILER, EQUIPMENT, PATRON, S.S. NO., MISC, DRIVER, ACCOUNT, or

DEPARTMENT). You must choose one of these names. If you have a field that does not

exactly match one of these names, select one that is close or select “MISC”. ID fields used on

CFN systems with the key option must be numeric.

To configure ID fields , proceed as follows:

Number of ID Fields

1 Enter Setup Mode as described previously. The system displays:

SETUP MENU:

LOAD DATE

2 Press F1 or F2 until the following appears:

SETUP MENU:

CONFIG ID FIELDS

3 Press ENTER. The display prompts:

CONFIG ID MENU:

NO. OF ID FIELDS

4 To identify the number of ID fields, proceed to step 5. To edit/view ID fields, proceed to step

7.

5 Press ENTER. The currently loaded value appears on the second line of the display.

NO. OF ID FIELDS

2

6 Type the number of ID fields configured in your FleetKey system and press ENTER. The

display returns to the following:

CONFIG ID MENU:

NO. OF ID FIELDS

MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007 Page 23

Page 30

KE200 Setup - Standalone Configure ID Fields

Edit or View Field Data

7 Press F1. The system displays the following:

CONFIG ID MENU:

EDIT/VIEW ID FIELD

8 Press ENTER. The system displays the following:

SELECT ID FIELD:

#1 EMPLOYEE,04,N

The second line of the display shows the current attributes of field 1 (number, name, size, and

format). If no data has been loaded for the field, the system displays “no data loaded...”.

9 To select data for a different ID field, press F1 or F2 until the desired field data is displayed.

10 To change one or more of the displayed field's attributes, press ENTER. The system prompts:

ID FIELD #1:

FIELD NAME

11 To change the field name, press ENTER. The currently loaded value appears on the second

line of the display.

FIELD NAME:

EMPLOYEE

12 Press F1 or F2 to scroll through the list of available field names. When the desired name is

displayed, press ENTER. The display returns to the following:

ID FIELD #1:

FIELD NAME

13 To change another field attribute, press F1. The system displays the following:

ID FIELD #1:

FIELD SIZE

Page 24 MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007

Page 31

Configure ID Fields KE200 Setup - Standalone

14 To change the size (length) of the field, press ENTER. The currently loaded value appears on

the second line of the display.

FIELD SIZE:

40

15 Type the new field size and press ENTER. The display returns to the following.

ID FIELD #1:

FIELD SIZE

16 To change another field attribute, press F1 to display the following.

ID FIELD #1:

FIELD FORMAT

17 To change the format of the field (numeric or alpha), press ENTER.

Note: Fields used on CFN systems with the key option must be numeric.

The currently loaded value appears on the second line of the display.

FIELD FORMAT:

NUMERIC

18 Press F1 or F2 to toggle between choices. When the desired choice is displayed, press

ENTER. The system returns to “FIELD FORMAT”.

Note: Numeric ID fields can be set up as incrementing or decrementing fields to speed data

entry. However, these fields can only be encoded this way using the “LOAD FORMA T”

terminal command. See

19 To change the attributes for another field name, press PREV. The display returns to the

“Load Format (LO FO)” on page 42.

following:

SELECT ID FIELD:

#1 EMPLOYEE,04,N

Repeat the procedure from step 9 onwards.

20 To exit to the “EDIT/VIEW ID FIELD” prompt, press PREV twice.

21 To exit to the “SETUP MENU” prompt, press PREV thrice. Then press F1 to select another

primary prompt.

MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007 Page 25

Page 32

KE200 Setup - Standalone Configure Maintenance Transactions (1000 FleetKey only)

Configure Maintenance Transactions (1000 FleetKey only)

“CONFIGURE MAINTENANCE TRANSACTIONS” is a menu item that provides access to

three submenus that allow you to reset the maintenance transaction pointer, reset the

transaction file, and load the starting transaction number for maintenance transactions.

Maintenance transactions are stored in the KE200 in circular memory storage. The system

keeps track of these transactions by a beginning (FIRST) and ending (LAST) pointer system.

The FIRST pointer is set with the “Reset Transaction Number” procedure. The LAST pointer

advances as transactions are stored. The KE200 stores 980 maintenance transactions. You can

print these transactions via the RS-232 port, or you can print only specific ones by moving the

FIRST pointer using the “Reset Transaction Pointer” procedure. Ensure that you replace the

pointer to its original location after printing the desired transactions. If you leave the pointer

ahead of transactions not yet printed, transactions may be overwritten and lost.

When the entire maintenance transaction file has been filled, a “MEMORY FULL” condition

exists. The KE200 will not accept new maintenance transactions until space has been freed up.

To free transaction space, first, print or poll the existing maintenance transactions. Then,

advance the FIRST transaction pointer using the reset transaction pointer procedure. This will

free space below the first pointer allowing new transactions to overwrite the old ones.

To configure Ma intenance Transactions, proceed as follows:

1 Enter Setup Mode as described previously. The system displays the following:

SETUP MENU:

LOAD DATE

2 Press F1 or F2 until the following appears:

SETUP MENU:

CONFIG MAINT TRANS

Reset Transaction Pointer

Use “RESET TRANS POINTER” to reset the starting point for printing maintenance

transactions via an RS-232 port. For example, if you have 50 transactions in the maintenance

transaction file (your ending pointer is at 50) and you want to print only the last 10

transactions, you will have to move your FIRST pointer to 40.

Note: Ensure that you return your pointer to its starting location to avoid losing transactions.

Page 26 MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007

Page 33

Configure Maintenance Transactions (1000 FleetKey only) KE200 Setup - Standalone

To reset Transaction Pointer, proceed as follows:

1 From the “CONFIG MAINT TRANS” display, press ENTER. The system displays the

following:

MAINT TRANS MENU:

RESET TRANS POINTER

2 Press ENTER. The system displays the following:

RESET TRANS POINTER:

?

3 Type the number at which you want transactions to start and press ENTER.

Reset Transaction File

Use “RESET TRANS FILE” to reset the maintenance transaction file.

To reset Transaction file, proceed as follows:

1 From the “CONFIG MAINT TRANS” display, press ENTER. The system displays the

following:

MAINT TRANS MENU:

RESET TRANS POINTER

2 Press F1 until the system displays the following:

MAINT TRANS MENU:

RESET TRANS FILE

3 Press ENTER. The system displays the following:

ARE YOU SURE?

<ENT>=YES <CLR>=NO

4 Press ENTER to reset the file. The system displays the message “COMMAND

COMPLETED”.

MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007 Page 27

Page 34

KE200 Setup - Standalone Configure Maintenance Table (1000 FleetKey only)

Load Transaction Number

Use “LOAD TRANS NUMBER” to load a starting number for your maintenance transactions.

To start your transactions at the number you desire, this command value must be set to the

number before the one you wish to start at (for example, if your first transaction is to be

number 1, set this command to zero).

To load Transaction number, proceed as follows:

1 From the “CONFIG MAINT TRANS” display, press ENTER. The system displays the

following:

MAINT TRANS MENU:

RESET TRANS POINTER

2 Press F1 until the system displays the following:

MAINT TRANS MENU:

LOAD TRANS NUMBER

3 Press ENTER. The currently loaded value appears on the second line of the display.

LOAD TRANS NUMBER:

0035

4 Type a 4-digit transaction number and press ENTER. The system returns to the following:

MAINT TRANS MENU:

LOAD TRANS NUMBER

5 To exit to the “SETUP MENU” prompt, press PREV, then press F1 to select another primary

prompt.

Configure Maintenance Table (1000 FleetKey only)

“CONFIG MAINTENANCE TABLE” is a menu item that provides ac cess to two submenus

which allow you to load the maintenance table or clear the maintenance table. As discussed in

detail in the FleetKey Operation Manual, the Maintenance table consists of up to 20 classes of

vehicle, with the three maintenance types (A, B, and C) and a “MILES” and “DAYS” between

maintenance entry defined for each. The maintenance table you enter at the KE200 Encoder

must be identical to the one entered at the FleetKey system.

Use “CLEAR MAINT TABLE” when you start up your system or before the initial loading of

the maintenance table to clear out any leftover information that may be present from factory

testing. Use the “CLEAR” option with care as it deletes the entire maintenance table and loads

it with zeros.

Page 28 MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007

Page 35

Configure Maintenance Table (1000 FleetKey only) KE200 Setup - Standalone

To configure Maintenance Table, proceed as follows:

Build a Maintenance Table

1 Enter Setup Mode as described previously. The system displays the following:

SETUP MENU:

LOAD DATE

2 Press F1 or F2 until the following appears:

SETUP MENU:

CONFIG MAINT TABLE

3 Press ENTER. The system prompts:

MAINT TABLE MENU:

LOAD MAINT TABLE

If you wish to load a maintenance table, press ENTER. The system prompts:

VEH. CLASS (1-20):

10

4 Enter the class you wish to define and press ENTER (to define data for class “1”, just press

ENTER). The system displays:

VEHICLE CLASS #01:

A: M=010000 D=000

Line 2 contains the current data for maintenance type A (miles and days).

5 If you wish to display data for another maintenance type (B or C), press F1 or F2. When the

desired maintenance type data is displayed, press ENTER. The system displays:

MAINTENANCE x:

MILES

MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007 Page 29

Page 36

KE200 Setup - Standalone Configure Maintenance Table (1000 FleetKey only)

6 To enter miles, press ENTER. The currently loaded value appears on the second line of the

display:

MILES:

010000

7 Enter up to six digits to represent the number of miles between maintenance (for example, if

maintenance “A” is to be performed every 10,000 miles, enter 10000) and press ENTER. The

display returns to:

MAINTENANCE x:

MILES

8 To enter days, press F1 and ENTER. The system displays the following:

DAYS:

000

The currently loaded value appears on the second line of the display.

9 Enter up to three digits to represent the number of days between maintenance (for example, if

maintenance “A” is to be performed every 60 days, enter 60) and press ENTER. The display

returns to:

MAINTENANCE A:

DAYS

10 To define data for another maintenance type, press PREV and repeat this procedure from step

5 onwards.

11 To define maintenance types for another class, press PREV twice and repeat this procedure

from step

12 To return to the “SETUP MENU” display, press PREV four times.

4 onwards.

Clear the Maintenance Table

To clear the maintenance table, proceed as follows:

1 Enter Setup Mode as described previously. The system displays the following:

SETUP MENU:

LOAD DATE

Page 30 MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007

Page 37

Load Country Options KE200 Setup - Standalone

2 Press F1 or F2 until the following appears:

SETUP MENU:

CONFIG MAINT TABLE

3 Press ENTER. The system prompts:

MAINT TABLE MENU:

LOAD MAINT TABLE

4 Press F1 or F2 until the system prompts:

MAINT TABLE MENU:

CLEAR MAINT TABLE

5 To clear the maintenance table, press ENTER. The system prompts you with the following

query:

ARE YOU SURE?

<ENT>=YES <CLR>=NO

6 To clear the maintenance table, press ENTER. To leave the maintenance table unchanged,

press CLEAR. The display returns to the following:

MAINT TABLE MENU:

CLEAR MAINT TABLE

7 To return to the “SETUP MENU”, press PREV.

Load Country Options

Use “LOAD COUNTRY OPTIONS” to enter the units of measure (miles or kilometers) and

the date format to be used (MM/DD/YY, YY/MM/DD, or DD/MM/YY). The date format you

select will show up in Idle mode, in encoding records, in maintenance transactions, or when

you are viewing maintenance.

MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007 Page 31

Page 38

KE200 Setup - Standalone Load Country Options

To load Country options, proceed as follows:

1 Enter Setup mode as described previously. The system displays the following:

SETUP MENU:

LOAD DATE

2 Press F1 or F2 until the following appears:

SETUP MENU:

LOAD COUNTRY OPTIONS

3 Press ENTER. The system displays the following:

COUNTRY OPTIONS:

UNITS

4 To enter units, press ENTER. The system displays the following:

UNITS:

MILES

5 Press F1 to toggle between miles and kilometers. When the desired choice displays, press

ENTER. The display returns to the following:

COUNTRY OPTIONS:

UNITS

6 To enter the date format, press F1. The system displays the following:

COUNTRY OPTIONS:

DATE FORMAT

7 Press ENTER. The system displays the following:

DATE FORMAT:

MM/DD/YY

8 Press F1 to toggle between “MM/DD/YY”, “YY/MM/DD”, or “DD/MM/YY”. When the

desired choice appears, press ENTER. The display returns to “COUNTRY OPTIONS: DATE

FORMAT”.

9 To return to the “SETUP MENU”, press PREV.

Page 32 MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007

Page 39

Diagnostics KE200 Setup - Standalone

Diagnostics

The KE200 Key Encoder/Maintenance Terminal contains six diagnostics:

• RAM Test - tests RAM

• ROM Test - tests ROM

• Keypad Test - tests keypad

• Display Test - tests display

• Key Read Totalizers - displays number of keys read or written to

• Program Version - provides program version information and program date

To access any of the diagnostics, proceed as follows:

1 Enter Setup mode as described previously. The system displays the following:

SETUP MENU:

LOAD DATE

2 Press F1 or F2 until the system displays the following:

SETUP MENU:

DIAGNOSTICS

3 Press ENTER. The system displays the first diagnostic test.

DIAGNOSTICS MENU:

RAM TEST

To perform a RAM test, skip to step 4. To perform another test, skip to step 5.

4 Press ENTER. The message “RAM PASSED” or “RAM FAILED” appears.

5 To select another diagnostic, press F1 or F2 to display the available choices. When the desired

diagnostic appears, press ENTER.

Note: If you select “KEYPAD TEST”, press the keys on the face of the unit and verify that they

match the displayed key name. To exit from the keypad test, press ENTER twice.

MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007 Page 33

Page 40

KE200 Setup - Standalone Diagnostics

This page is intentionally left blank.

Page 34 MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007

Page 41

Using the Terminal KE200 Setup - Terminal

3 – KE200 Setup - Terminal

Using the Terminal

Using the data terminal to set up the KE200 and Encode keys is different and easier compared

to setting up and encoding from the keypad. Ensure that the manager's key on the KE200 is in

the Idle position. You do not have to switch between modes when using the terminal.

Commands at the data terminal are keyed in directly, eliminating the need for menus. Once

you begin running the system, you will quickly memorize the necessary commands. If needed,

a special HELP command is available which lists the commands and their abbreviations.

When setting up the system, the terminal command set includes a “SETUP” command, which

automatically prompts you for the setup data. Alternatively, you can execute commands

individually.

When encoding, using the terminal speeds up the input by allowing you to load and use stored

encoding formats. These formats allow you to enter field type specifiers and values that will

automatically increment, decrement, or keep a field constant as you proceed through your

encoding operation. See the

Entering Commands and Input

At the data terminal, you must key in commands at the asterisk prompt. In the procedures for

Terminal mode, the short form of the command is shown in uppercase letters. However, you

can type whole or partial words to run the commands and you can use either uppercase or

lowercase letters.

Load commands have various possible values contained in “< >” brackets after the command.

The system also displays the current value of the command. You can press ENTER to accept

the displayed value or type a different one.

You can abort the running of any command by pressing the CTRL and C keys. The KE200

supports “X-ON/X-OFF” protocol for halting data transmission. To halt or suspend data from

being transmitted, issue an “X-OFF” command by pressing the CTRL and S keys. To resume

data transmission, issue the “X-ON” command by pressing the CTRL and Q keys. The KE200

also supports the more command pipe (for example, “PR FO | more”). To resume data display

after a “more” command, press any key.

“Load Format (LO FO)” on page 42 for details.

MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007 Page 35

Page 42

KE200 Setup - Terminal Signing On to the Terminal

You may make a mistake when you enter commands and data. If you need to delete text, you

can use backspace to move the cursor to the error and type over to correct it, or you can press

the delete key repeatedly to back the cursor up to the error location. When you use the delete

method, the system inserts a slash and prints the characters in reverse order from the way they

were entered. When you reach the error location, press the correct character. The system

inserts another slash and you can continue typing the correct string. For example, if you typed

“PRUNT DATE”, pressing delete repeatedly back to the error and then typing the correct

string will display text similar to the following:

Signing On to the Terminal

Once your data terminal is connected to the KE200, or your phone modems are in place, you

can communicate with your system. T o guard against unauthorized access, the system requires

a sign-on password before you can enter commands on the system.

To sign on to the terminal, proceed as follows:

1 Turn on the power to your data terminal.

2 If you are using phone modems, dial and establish a connection with the site modem. If you

are using a computer, follow the instructions of your interface program.

3 The system should display “SIGN ON:”. If it does not, press RETURN. “SIGN ON:” will

then appear.

4 Type a 1 to 16-character alphanumeric password and press RETURN. The password is not

displayed as you type it. When the correct password is entered, an asterisk prompt (*) appears

and you can enter commands.

If you are signing on for the first time, the password is “GASBOY”, which needs to be typed

in uppercase.

To change the password, use the “LOad SIgn-on” command.

If you enter the password incorrectly, the system returns to the “SIGN ON:” prompt. Repeat

4.

step

Page 36 MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007

Page 43

Signing Off of the Terminal KE200 Setup - Terminal

Signing Off of the Terminal

To sign off from the terminal, type EXIT and press ENTER.

The data terminal for KE200 communication is set to a 5 minute time-out. This means that if

the terminal does not register any input for 5 minutes, it automatically signs off.

Lost or Forgotten Password

If you forget your sign-on password , the KE200 system provides a way for you to gain system

access.

1 Place the manager’s key in the “ENCODE” position.

2 At the “SIGN ON:” prompt, type “GASBOY” and press ENTER. The asterisk prompt

appears.

3 Re-load your sign-on password using the “LOAD SIGNON” command.

Setting Up the KE200

The first time you use your Key Encoder/Maintenance Terminal, you must perform the

following steps in order to load your system with the necessary data to perform your

processing:

1 With the Manager key inserted and in the idle position, turn the power switch located on the

left side of the face to “ON”. The KE200 displays the current date and time (these were set at

the factory to Eastern time).

2 Sign on to the terminal as described in “Signing On to the Terminal” on page 36.

3 At the asterisk command prompt, use the “LO SI” command to load your sign-on code

(password) if you have not already done so.

4 Type “SETUP” and pre ss ENTER. “SETUP” is a batch program containing all commands

needed to load the KE200 for operation. Some commands are not included; see the

page 58 for details. If desired, you can also run all the load commands manually. The

commands to be run are:

- “LO DA”, loads date and time

- “LO SY”, loads the system ID. This must match the system ID of your FleetKey system.

- “LO ST”, loads the station ID.

- “LO PI”, loads the working key (for pin calculation). This must match the working key

of your FleetKey system.

- “LO CO”, loads country options for units and date format.

“Setup” on

MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007 Page 37

Page 44

KE200 Setup - Terminal Clear Maintenance (CL MA) (1000 FleetKey only)

- “LO ID”, loads ID fields. The fields you configure must match the fields as you ordered

them. Consult your key layout.

- “LO FO”, loads formats for key encoding.

- “RES RE”, resets encoding records file.

- “RES TR”, resets maintenance transaction file.

- “LO TR”, loads the starting transaction number.

- “CL MA”, clears the maintenance table (1000 FleetKey only).

- “LO MA”, loads the maintenance table. This table must match the one defined in your

FleetKey system. (1000 FleetKey only).

Once the above steps are performed, your system is ready to encode keys and record

performed maintenance.

The following pages contain all terminal commands, in alphabetical order.

The symbol “↵” is shown in examples to denote that the “ENTER” key is pressed.

Clear Maintenance (CL MA) (1000 FleetKey only)

Use “CLEAR MAINTENANCE” when you start up your system or before the initial loading

of the maintenance table to clear out any residual information that may be present from factory

testing. Use the “CL MA” option with care as it deletes the entire maintenance table and loads

it with zeros.

To clear the maintenance table, proceed as follows:

1 At the asterisk prompt, type “CL MA” and press ENTER. The system responds with the

message, “CLEAR MAINTENANCE TABLE? <Y OR N>:”.

2 Type “Y” to clear or “N” not to clear and press ENTER. The system displays the message,

“COMMAND COMPLETED”.

Encode Key (EN KE)

Encoding your keys involves taking all the information you want on the key (from the

encoding form) and electronically writing it onto each key.

There are two methods for encoding: Formatted Encode and Unformatted Encode. A

Formatted Encode uses the field values loaded with the “LOAD FORMAT” command. An

Unformatted Encode prompts for every field and you must enter a value for each.

Page 38 MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007

Page 45

Encode Key (EN KE) KE200 Setup - Terminal

Sometimes you will have to enter special characters into a field: field separators, and

supervisor entry fields. Field separators are represented by a tilde “~” character and are used

mainly during dual key encoding. Supervisor entry fields are represented by an asterisk “*”

and are used when encoding supervisor key fields.

To encode the key, proceed as follows:

1 Type “EN KE” and press ENTER. The system responds with the message, “FORMATTED

ENCODE? <Y OR N>:”

2 Type “Y” if you want to encode using the formats loaded with the “LOad FOrmat” command,

or “N” to override the formats and enter data for each field. Press ENTER. The system

prompts: “DISPLAY KEY DATA? <Y OR N>:”.

3 Type “Y” to display data on the terminal for the key upon completion of encoding or “N” not

to display the data. The system prompts: “LOG KEY DATA? <Y OR N>:”.

4 Type “Y” to print (on the logger) key field headings and key data for all keys encoded during

this session or “N” not to log the data. The system prompts “KEY TYPE?”.

5 Type the key type you wish to encode and press ENTER. The system responds with the first

prompt for that key type (this prompt will vary depending on whether you are doing a

Formatted or Unformatted Encode).

The system displays prompts until all key fields contain data, then displays the message,

“ENCODE KEY? <Y OR N>”.

6 To encode the key, type “Y” and press ENTER. The system displays the message, “INSERT

KEY”.

7 Insert the key into the KE200 receptacle and turn to the right. The system displays the

following message:

“ENCODING KEY #xxxxx...COMPLETED

REMOVE KEY”.

8 Remove the key. If you replied “Y” to “DISPLAY KEY DATA”, the data is displayed on your

terminal.

Note: The data you may have entered for the Previous Odometer and Last Odometer fields

will appear next to PREVIOUS ODOM (2) and LAST ODOM (2) in the display.

If you replied “Y” to “LOG KEY DATA”, a logger entry is made. The “KEY TYPE” prompt

reappears.

A sample logger entry is shown below:

9 Repeat this process from step 5 onwards to encode additional keys.

10 Press ENTER to exit to the asterisk prompt.

MDE-4465A KE200 Key Encoder/Maintenance Terminal Operation Manual · October 2007 Page 39

Page 46