Page 1

Introduction

M

A

Purpose

This document provides instructions for the installation of a wireless solution in TopKAT™

Online, TopKAT, Series 1000, and Islander II Gasboy

modem helps to avoid trenching and installation of metal conduits for communication wires

between the Gasboy system and the PC system. This document also contains information on

using a Serial-to-LAN converter to communicate with one of the Gasboy systems listed above.

See

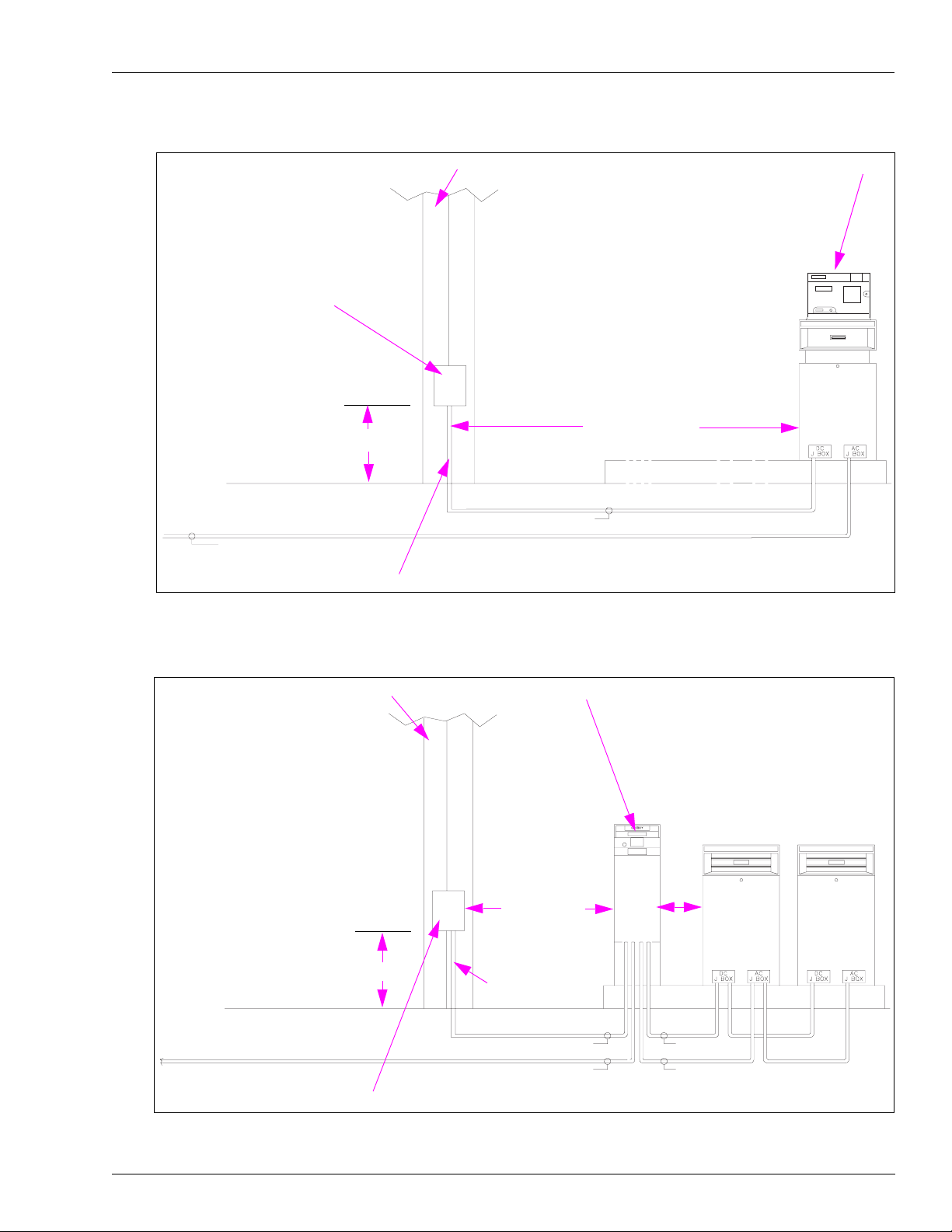

shown in Figure 1.

Figure 1: Gasboy Wireless System - Omnidirectional and Directional Antennas

MDE-4520C

Enhanced Communications Installation Manual

February 2008

®

systems. The installation of a wireless

Serial-to-LAN Connection Installation on page 28. A typical Gasboy Wireless system is

DIRECTIONAL

NTENNA

PRE-MADE 25’

COAX CABLE

MODEM

ENCLOSURE ASSY.

EARTH GROUND

ROD

GASBOY SYSTEM

LIGHTNING

SURGE PROTECTOR

GROUNDING WIRE

VERTICAL

ANTENNA

COAX

EARTH

GROUND

ROD

BUILDING

COAX

GROUNDING

WIRE

RADIO MODE

ENCLOSURE

FEED-THRU

N-CONNECTOR

Notes:1) The distance between the PC system and Gasboy system can be up to 3 miles (4.8

kilometers).

2) If the communication is disrupted between the PC and the Gasboy systems for any

reason, it could take up to 5 minutes to re-initialize.

MDE-4520C Enhanced Communications Installation Manual · February 2008 Page 1

Page 2

Introduction

• The Wireless solution cannot extend communications between Gasboy devices [such as Island

Card Readers (ICR), 9800 series pumps, Gasboy Pump Control Units (PCU)], and other

manufacturer electronic pumps. Also, it is not intended to be used for credit card network

communications.

• The Wireless solution is only intended for point-to-point communication between one PC and

one Gasboy Fuel Management System (FMS) at a time. Multiple Gasboy FMS systems will

require one Base Station kit and one Fueling Position kit for each point-to-point wireless

communication link. An RS-232 A/B has to be locally supplied to switch between the multiple

base stations and Gasboy FMS systems.

Table of Contents

Topic Page

Introduction 1

Important Safety Information 7

Parts Information 9

Site Installation Review and Considerations 13

Site Preparation, Setup Programming, and Testing 20

HyperTerminal Test 25

Serial-to-LAN Connection Installation 28

Appendix: Cable Information 51

IMPORTANT INFORMATION

Required Tools

The following tools are required for the installation of the kit:

Parts List

Fueling Position Wireless Communication Kit (M06544K001)

Description Part Number Quantity

Assembly, Radio Housing M06545A001 1

Bracket, Pedestal to Pole M05844B001 2

Base, Modified TopKAT M05845B001 1

Conduit Fitting M01756A001 1

Tube Flex Conduit Non M01575B003 1

Cable, RS-232/Power To M06543A001 1

Antenna, 8.5 DBD 6 Element M06554A001 1

Cable, Antenna 25 FT Coax M06549A001 1

Sware, Coyote Datacom KS319-001PC 1

• Phillips® Screwdriver

• Soldering Iron and Solder

•Wire Strippers

• Needle Nose Pliers

• Diagonal Cutters

• 3/8 inch Socket Wrench Kit

Page 2 MDE-4520C Enhanced Communications Installation Manual · February 2008

Page 3

Base Station Wireless Communication Kit (M06544K002)

Description Part Number Quantity

Assembly, Radio Housing M06545A002 1

Antenna, 5 DBI Monopole M06553A001 1

Kit, Omni Antenna Mount M06568A001 1

Power Supply M01878B001 1

Lightning Protector M06555B001 1

Genmen Com 1 for Ser Ptr Q13180-20B 1

Cable, Work Area 15 Ft Q13850-15 1

Genmen Coyote Modem Q13180-61 1

Assembly, Mounting Bracket M05971A001 1

Sware, Coyote Datacom KS319-001PC 1

Fueling Position Radio Housing Assembly (M06545A001)

Description Part Number Quantity

NEMA Enclosure, Bud M06546B002 1

Data Radio Module M06551A001 1

Board, Interface RS-232 M06550A002 1

Cable, DB9 To Terminal M06541A001 1

Cable, Radio Power To M06542A001 1

Cable, 13” Coax Reverse M06548A001 1

Lightning Protector M06555B001 1

Assembly, Mounting Bracket M05971A001 1

Bracket, Radio/Modem M05842B001 1

Termn Barrier Strip Q10130-20 1

Bracket, Radio Housing To M05843B001 2

Conduit Fitting M01757A001 1

Cable Assembly, ISL/TOK 12 V Po C07263 1

Introduction

Base Station Radio Housing Assembly (M06545A002)

Description Part Number Quantity

NEMA Enclosure, Bud M06546B002 1

Data Radio Module M06551A001 1

Board, Interface RS-232 M06550A002 1

N-Connector Bulkhead M06572B001 1

Bracket, Radio/Modem M05842B001 1

Suprt Circuit Board Q10651-38 4

Cable, 13” Coax Reverse M06548A001 1

MDE-4520C Enhanced Communications Installation Manual · February 2008 Page 3

Page 4

Introduction

Direct TCP/IP to Serial Interface Kit (M06643K001)

Description Part Number Quantity

25 Pin RS-232 To 10 Base-T M06643B001 1

Label, Ethernet Converter M06727B001 1

Power Supply, Lantronix M06643B002 1

Cable Assembly, RS-232 Modem M/ C04532 1

Serial Tunneling (Direct Connect or Modem Emulation) Interface Kit

(M06643K002)

Description Part Number Quantity

25 Pin RS-232 To 10 Base-T M06643B001 2

Label, Ethernet Converter M06727B001 2

Power Supply, Lantronix M06643B002 2

Cable Assembly, RS-232 Modem M/ C04532 1

DB25M/DB9F Modem Cable Q13240-09 1

Related Documents

Document Number Title GOLD Library

C35963 CFN Series Islander II Installation Manual CFN Series Controllers and POS

MDE-4319 TopKAT Fuel Management System

Installation Manual

MDE-4344 Series 1000 Fuel Management System

Installation Manual

Abbreviations and Acronyms

The following table contains a list of acronyms used in this document.

Term Expansion

AC Alternating Current

ASC Authorized Service Contractor

CFN Cash Flow Network

CD Compact Disk

CDR Call Data Record

COM Communications Port

CSC Customer Specified Contractor

DC Direct Current

DHCP Dynamic Host Configuration Protocol

FCC Federal Communications Commission (http://www.fcc.gov)

ICR Island Card Reader

LAN Local Area Network

NEMA National Electrical Manufacturers Association (http://www.nema.org/)

PC Personal Computer

PCU Pump Control Unit

RF Radio Frequency

RS Request to Send

Series 1000/Fleetkey and TopKAT

Series 1000/Fleetkey and TopKAT

Page 4 MDE-4520C Enhanced Communications Installation Manual · February 2008

Page 5

Intended Users

The intended users of this document are Authorized Service Contractors (ASCs) and

Customer Specified Contractors (CSCs).

Installation Requisites

At each end of the communication loop (namely the fueling position and the PC system), you

require the following:

• One antenna (see note)

• One wireless modem (see note)

• One tower or mast

The basic theory of installation and the guidelines for mounting and placing the antenna,

coaxial cable runs and the parts required, are identical for all systems. The differences between

the two positions is in the programming of the wireless modems at each end of the

communication loop and the RS-232 cables, that are required. For cable details, refer to

Gasboy System End on page 14 and Appendix: Cable Information on page 51.

Notes:1) Currently, you must have one modem at the polling PC for each modem attached to a

Gasboy system (except TopKAT Online). For example, if you have two Series 1000

systems that can be polled from the same PC, you will need two wireless modems at

the polling PC and two antennas.

Introduction

At the

2) The Wireless solution is only intended for point-to-point communication between one

PC and one Gasboy Fuel Management System (FMS) at a time. Multiple Gasboy

FMS systems will require one Base station kit and one Fueling position kit for each

point-to-point wireless communication link. An RS-232 A/B has to be locally supplied

to switch between the multiple base stations and Gasboy FMS systems.

Federal Communications Commission (FCC) Requirements

FCC RF Exposure Statement

This device complies with FCC radiation exposure limits as set forth for an uncontrolled

environment. This device should be installed and operated with a minimum separation

distance of 20 cm (7.87 inches) between the radiator and your body.

FCC Compliance Warning

Changes or modifications to the CDR-915 not expressly approved by Coyote DataCom, Inc.

could void the user’s authority to operate this product.

Note: This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation.

MDE-4520C Enhanced Communications Installation Manual · February 2008 Page 5

Page 6

Introduction

Warranty

This equipment generates and can radiate radio frequency energy and, if not installed and used

in accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, then the user is encouraged to try to correct

the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit that is dif f erent from t he circuit to which

the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

For information on warranty, refer to MDE-4255 Gasboy’s Warranty Policy Statement. If you

have any warranty-related questions, contact Gasboy’s Warranty Department at its Greensboro

location.

Page 6 MDE-4520C Enhanced Communications Installation Manual · February 2008

Page 7

Important Safety Information

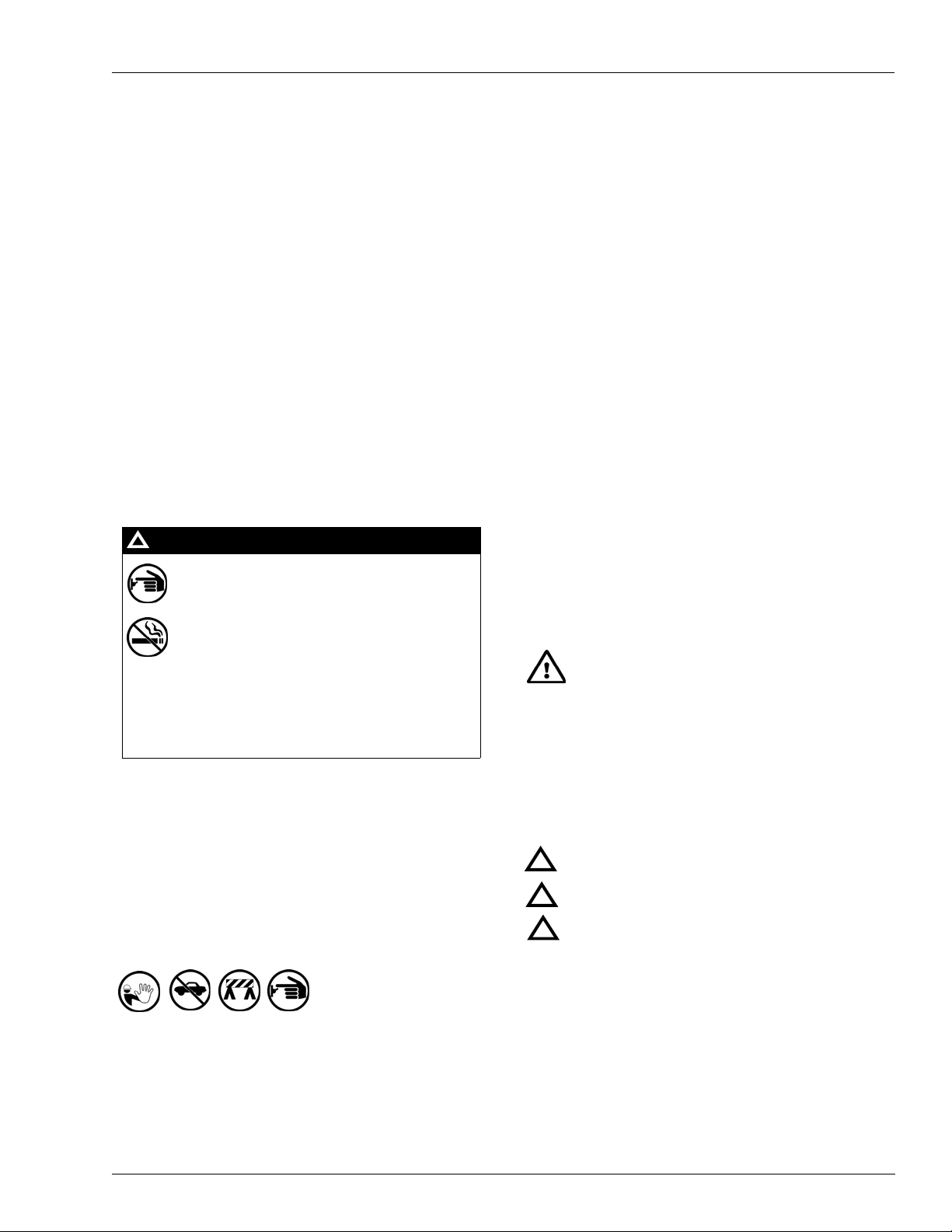

This section introduces the hazards and safety precautions

associated with installing, inspecting, maintaining or servicing

this product. Before performing any task on this product, read

this safety information and the applicable se cti on s in th is

manual, where additional hazards and safety precautions for

your task will be found. Fire, explosion, electrical shock or

pressure release could occur and cause death or serious

injury, if these safe service procedures are not followed.

Preliminary Precautions

You are working in a potentially dangerous environment of

flammable fuels, vapors, and high voltage or pressures. Only

trained or authorized individuals knowledgeable in the related

procedures should install, inspect, maintain or service this

equipment.

Emergency Total Electrical Shut-Off

The first and most important information you must know is

how to stop all fuel flow to the pump/dispenser and island.

Locate the switch or circuit breakers that shut off all power to

all fueling equipment, dispensing devices, and Submerged

Turbine Pumps (STPs).

!

WARNING

!

The EMERGENCY STOP, ALL STOP, and

PUMP STOP buttons at the cashier’s station

WILL NOT shut off electrical po wer to th e pump/

dispenser. This means that even if you activate

these stops, fuel may continue to flow

uncontrolled.

Important Safety Information

Read the Manual

Read, understand and follow this manual and any other

labels or related materials supplied with this equipment. If you

do not understand a procedure, call a Gasboy Authorized

Service Contractor or call the Gasboy Service Center at 1800-444-5529. It is imperative to your safety and the safety of

others to understand the procedures before beginning work.

Follow the Regulations

Applicable information is available in National Fire Protection

Association (NFPA) 30A; Code for Motor Fuel Dispensing

Facilities and Repair Garages, NFPA 70; National Electrical

Code (NEC), Occupational Safety and Hazard Association

(OSHA) regulations and federal, state, and local codes. All

these regulations must be followed. Failure to install, inspect,

maintain or service this equipment in accordance with these

codes, regulations and standards may lead to legal citations

with penalties or affect the safe use and operation of the

equipment.

Replacement Parts

Use only genuine Gasboy replacement parts and retrofit kits

on your pump/dispenser. Using parts other than genuine

Gasboy replacement parts could create a safety hazard and

violate local regulations.

Safety Symbols and Warning Words

This section provides important information about warning

symbols and boxes.

Alert Symbol

You must use the TOTAL ELECTRICAL SHUTOFF in the case of an emergency and not the

console’s ALL STOP and PUMP STOP or

similar keys.

Total Electrical Shut-Off Before Access

Any procedure that requires access to electrical components

or the electronics of the dispenser requires total electrical

shut off of that unit. Understand the function and location of

this switch or circuit breaker before inspecting, installing,

maintaining, or servicing Gasboy equipment.

Evacuating, Barricading and Shutting Off

Any procedure that requires access to the pump/dispenser or

STPs requires the following actions:

• An evacuation of all unauthorized persons and vehicles

from the work area

• Use of safety tape, cones or barricades at the affected

unit (s)

• A total electrical shut-off of the affected unit (s)

This safety alert symbol is used in this manual and

on warning labels to alert you to a precaution which must be

followed to prevent potential personal safety hazards. Obey

safety directives that follow this symbol to avoid possible

injury or death.

Signal Words

These signal words used in this manual and on warning

labels tell you the seriousness of particular safety hazards.

The precautions below must be followed to prevent death,

injury or damage to the equipment:

DANGER: Alerts you to a hazard or unsafe practice

!

which will result in death or serious injury.

WARNING: Alerts you to a hazard or unsafe practice

!

that could result in death or serious injury.

CAUTION with Alert symbol: Designates a hazard or

!

unsafe practice which may result in minor injury.

CAUTION without Alert symbol: Designates a hazard

or unsafe practice which may result in property or

equipment damage.

Working With Fuels and Electrical Energy

Prevent Explosions and Fires

Fuels and their vapors will explode or burn, if ignited. Spilled

or leaking fuels cause vapors. Even filling customer tanks will

cause potentially dangerous vapors in the vicinity of the

dispenser or island.

MDE-4520C Enhanced Communications Installation Manual · February 2008 Page 7

Page 8

Important Safety Information

No Open Fire

Open flames from matches, lighters, welding

torches or other sources can ignite fuels and their vapors.

No Sparks - No Smoking

Sparks from starting vehicles, starting or using power tools,

burning cigarettes, cigars or pipes can also ignite fuels and

their vapors. Static electricity, including an electrostatic

charge on your body, can cause a spark sufficient to ignite

fuel vapors. Every time you get out of a vehicle, touch the

metal of your vehicle, to discharge any electrostatic charge

before you approach the dispenser island.

Working Alone

It is highly recommended that someone who is capable of

rendering first aid be present during servicing. Familiarize

yourself with Cardiopulmonary Resuscitation (CPR) methods,

if you work with or around high voltages. This information is

available from the American Red Cross. Always advise the

station personnel about where you will be working, and

caution them not to activate power while you are working on

the equipment. Use the OSHA Lockout/ Tagout procedures. If

you are not familiar with this requirement, refer to this

information in the service manual and OSHA documentation.

Working With Electricity Safely

Ensure that you use safe and established practices in

working with electrical devices. Poorly wired devices may

cause a fire, explosion or electrical shock. Ensure that

grounding connections are properly made. Take care that

sealing devices and compounds are in place. Ensure that you

do not pinch wires when replacing covers. Follow OSHA

Lockout/T agout requirements. Station employees and service

contractors need to understand and comply with this program

completely to ensure safety while the equipment is down.

Hazardous Materials

Some materials present inside electronic enclosures may

present a health hazard if not handled correctly. Ensure that

you clean hands after handling equipment. Do not place any

equipment in the mouth.

!

WARNING

The pump/dispenser contains a chemical known to the

State of California to cause cancer.

In an Emergency

Inform Emergency Personnel

Compile the following information and inform emergency

personnel:

• Location of accident (for example, address, front/back of

building, and so on)

• Nature of accident (for example, possible heart attack, run

over by car, burns, and so on)

• Age of victim (for example, baby, teenager, middle-age,

elderly)

• Whether or not victim has received first aid (for example,

stopped bleeding by pressure, and so on)

• Whether or not a victim has vomited (for example, if

swallowed or inhaled something, and so on)

WARNING

!

Gasoline ingested may cause unconsciousness

and burns to internal organs.

Do not induce vomiting.

Keep airway open.

Oxygen may be needed at scene.

Seek medical advice immediately.

WARNING

!

Gasoline inhaled may cause unconsciousness

and burns to lips, mouth and lungs.

Keep airway open.

Seek medical advice immediately.

WARNING

!

Gasoline spilled in eyes may cause burns to eye

tissue.

Irrigate eyes with water for approximately 15

minutes.

Seek medical advice immediately.

WARNING

!

Gasoline spilled on skin may cause burns.

Wash area thoroughly with clear water.

Seek medical advice immediately.

IMPORTANT: Oxygen may be needed at scene if gasoline

has been ingested or inhaled. Seek medical advice

immediately.

WARNING

!

Lockout/Tagout

Lockout/Tagout covers servicing and maintenance of

The pump/dispenser contains a chemical known to the

State of California to cause birth defects or other

reproductive harm.

machines and equipment in which the unexpected

energization or start-up of the machine(s) or equipment or

release of stored energy could cause injury to employees or

personnel. Lockout/Tagout applies to all mechanical,

hydraulic, chemical or other energy, but does not cover

electrical hazards. Subpart S of 29 CFR Part 1910 - Electrical

Hazards, 29 CFR Part 1910.333 contains specific Lockout/

Tagout provision for electrical hazards.

Page 8 MDE-4520C Enhanced Communications Installation Manual · February 2008

Page 9

Parts Information

Parts Supplied by Gasboy

The following table lists the parts supplied by Gasboy and the corresponding explanation.

Parts Explanation

Two Wireless Modem Enclosure Assemblies:

• For Fueling Position (M06545A001).

See Figure 2 on page 10.

• For Base Station (M06545A002).

See Figure 3 on page 11.

Antennas:

• At fueling positions: 6 dB Gain

Directional Yagi Antenna (M06554A001)

• At base stations: 5 dB Gain

Omnidirectional (M06553A001)

Parts Information

• One wireless modem enclosure is used at each end of the

communications loop (see note on

• You must have a copy of the Call Data Record (CDR) Setup

Tools version 2.2 or above (KS319 001PC) to program the

modems. This is provided with the M06544K002 kit. This

software is also available as a free download at

http://www.coyotedatacom.com/support.htm

• Y ou will need a PC capable of running the software, a serial port,

and a DB9 male to female cable to connect the PC to the

wireless modem. The same cable can also be used for a laptop.

Note: This cable is assembled in the field from the following

loose parts shipped in the M06544K002 kit:

- Q13850-15 (cable, work area, 15 feet)

- Q13180-20B (gender mender, 9-pin D-sub to jack)

- Q13180-61 (gender mender, Coyote modem, for

M06551A002)

• The power connection for the wireless modem at the Gasboy

system end is provided by the Gasboy system power supply. For

the wireless modem at the PC end, the power is provided from a

M01878B001 110-volt AC to 12-volt DC transformer block. This

transformer MUST be plugged into the same circuit that provides

power to the PC.

• Gasboy supplies 4 Amphenol (82-202) or its equivalent as the N

style male connector (M06547B001) for use with the Base

station kit coaxial cable runs. Two connectors are needed for

each coaxial cable run. These connectors are sized for the RG8/

U cable diameter. If you use a different cable, you will have to

locally purchase connectors that are sized for the cable installed.

Two of these connector kits are used for the coaxial cable run

from the antenna to the lightning suppressor and two are used

for the coaxial cable run for the lightning arrestor to the Base

station kit. See

page 20 for details.

• Once the system communication is fully tested, these

connections MUST be protected by an appropriate sealing tape

(M06571B001) designed for an all weather environment.

• One antenna will be used at each end of the communications

loop (see note on

• A mounting kit to attach the omni antenna to the antenna mast is

supplied as part of the antenna kit (M06568A001).

• In general, a directional antenna is used at the Gasboy system

end of the communications loop and an omnidirectional antenna

at the PC end of the loop.

• On sites with a single Gasboy system, and where the distance

between antennas is more than 2500 feet (762 meters), the use

of two directional antennas is recommended.

• On sites with a single Gasboy system and line of sight partially

blocked by high voltage transformers, microwave towers or in

the neighborhood of airports, the use of two directional antennas

is recommended if the distance between towers exceeds 1500

feet (457.2 meters).

Assembling the Connector (M06547B001) on

page 5).

page 5).

MDE-4520C Enhanced Communications Installation Manual · February 2008 Page 9

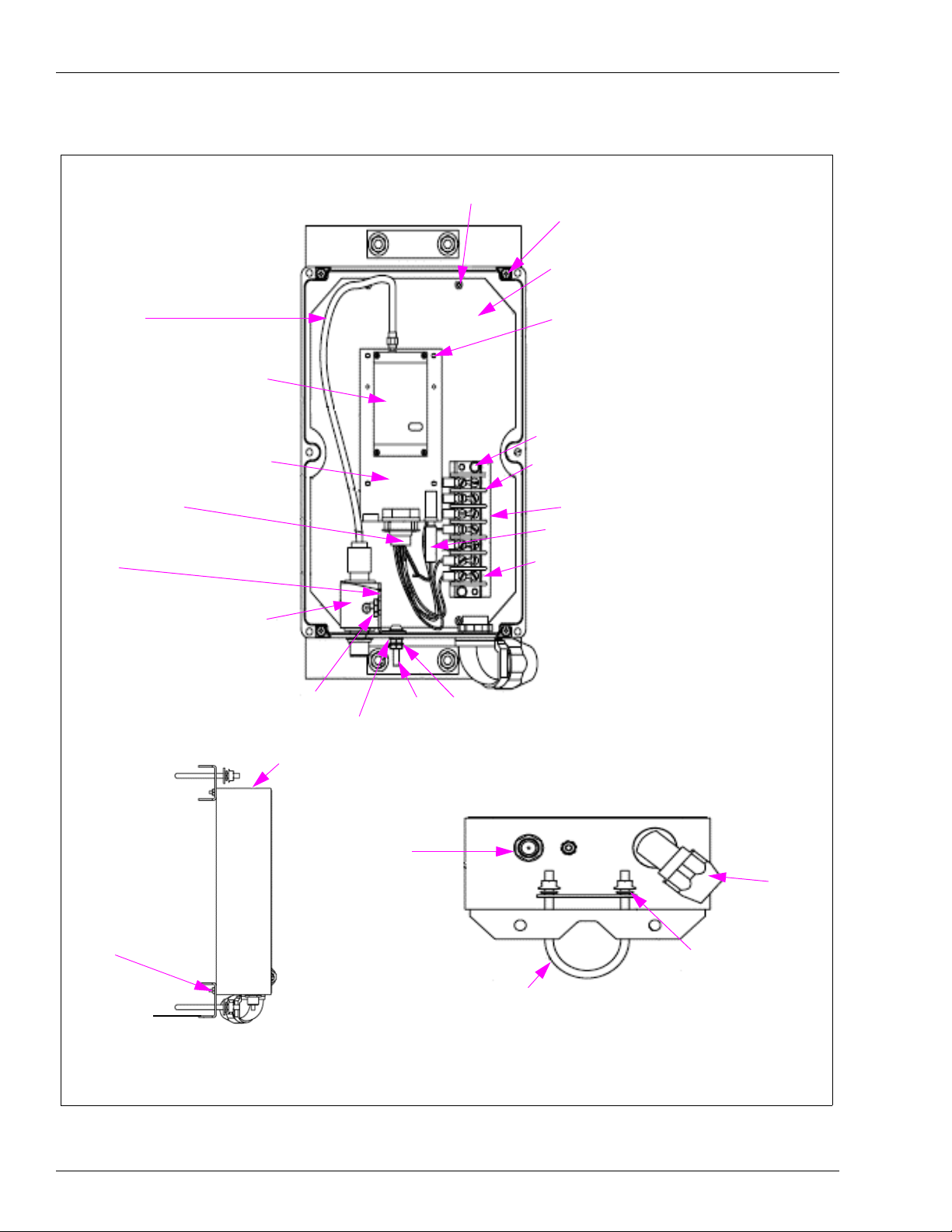

Page 10

Parts Information

Coax Reverse SMA to N Male

Cable

Data Radio Module

Figure 2: Modem Enclosure - Fueling Position

Screw Metric Pan

Head

Screw SEMS

Mounting Plate Bracket

Circuit Board Support

Hex Screw

Interface Board

DB9 to Terminal Block

Cable

Mounting Bracket - Lightning

Arrestor

Lightning Protector

Side View

Hex Nut

Washer

NEMA Enclosure

Coax N

Connection

Screw

Terminal Strip Barrier

Terminal Block Marker Strip

Radio Power to Terminal Block Cable

Terminal Block - Position 1

Hex Nut

View from below the Enclosure

Conduit

Fitting

Hex Nut w/ Lock

washer

Radio Housing

to Pole Mounting

Bracket

U-bolt and Mounting

Hardware

Washer

Spring Lock

Page 10 MDE-4520C Enhanced Communications Installation Manual · February 2008

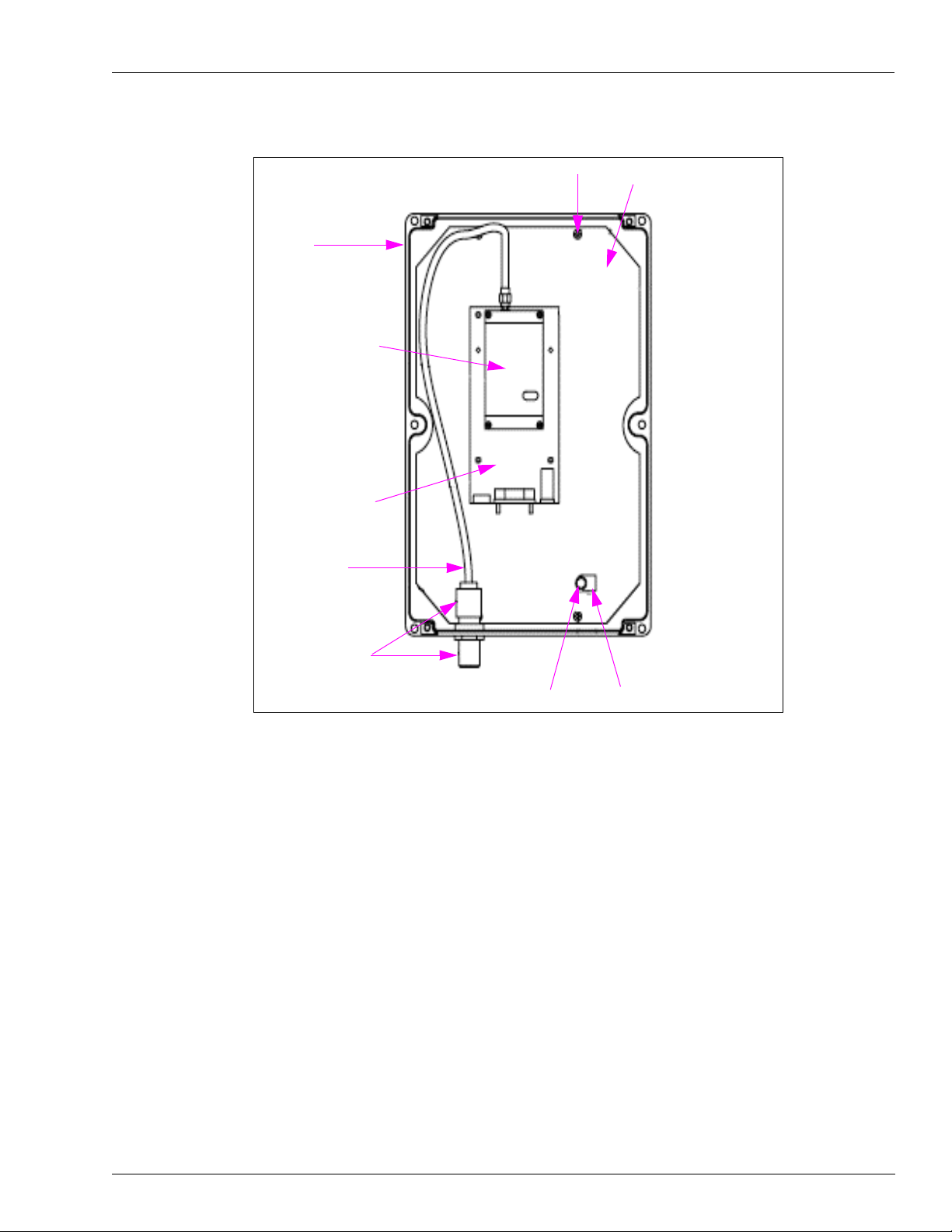

Page 11

Figure 3: Modem Enclosure - Base Station

Parts Information

NEMA

Enclosure

Data Radio Module

Interface Board

Coax Reverse

SMA to N Male

Cable

Screw Head

Radio/Modem Mounting

Plate Bracket

N-Connector Bulk

Head Adaptor

Hex Screw

Cable Clamp

MDE-4520C Enhanced Communications Installation Manual · February 2008 Page 11

Page 12

Parts Information

Additional Parts Supplied at the Gasboy System End

Parts Explanation

Gasboy TopKAT Riser Collar

(M05845B001)

Under the Gasboy TopKAT on a pedestal, a field-installed

Riser Collar is placed. This collar has one flexible conduit

outlet that is attached directly to the wireless modem

enclosure. In addition, it has the clamp assemblies that

attach the Gasboy TopKAT to one leg of the antenna tower

or mast, and facilitates mounting of the wireless modem

enclosure. This conduit will allow DC power and RS-232

communications between the Gasboy TopKAT and the

wireless modem.

• The RS-232 wiring for the individual Gasboy systems is

Appendix: Cable Information on page 51.

listed in

• The DC power wire provided will work with any system.

It may be cut to length, if needed.

IMPORTANT INFORMATION

Do not use this riser collar for any other Gasboy system. It is only to be used on

pedestal mounted TopKATs. For all other Gasboy systems including TopKATs mounted

on a dispenser, refer to page 14.

CAUTION

The Gasboy pedestal mount TopKAT should be completely removed to install the

collar. Ensure that you fully understand how to replace all disconnected cables, so

that they can be properly reinstalled once the collar is installed, and properly

attached. Failure to do so can cause damage to the system, and is not covered by

the warranty.

Additional Parts Supplied at the PC End

Parts Explanation

RS-232 Communication cable (Q13850-15) See Appendix: Cable Information on page 51 for proper

Parts Not Supplied by Gasboy

Parts Explanation

Towers, Masts, and Mast

Mounting Brackets

Towers or masts at the

Gasboy system end

cable connection.

This is a 15-foot CAT-5 Cable with gender menders at each

end to interface the PC to the Modem Interface Board.

• The distributor is responsible for supplying, and properly installing the towers,

masts, or mast mounting brackets.

• The manufacturer's installation manual MUST be followed.

• Up to a 28-foot tower can be installed at the Gasboy system end without the use of

guy wires. This can consist of a 10-foot tower and a 10-foot mast for a total of 18

feet, or a 20-foot tower and a 10-foot mast for a total of 28 feet.

• The height of the tower is to be determined by the line of sight requirements of the

antenna located on the top of this tower or mast, to the PC wireless modem and its

antenna at the top of its mast or tower.

• An appropriate base plate/mounting bracket to support the tower may be sourced

from one of the following:

– Tally Communication (http://www.talleycom.com/)

– Radian (http://www.radiancorp.com/)

Page 12 MDE-4520C Enhanced Communications Installation Manual · February 2008

Page 13

Site Installation Review and Considerations

Parts Explanation

Mast or tower at the PC end • Usually, a building mast bracket will be used at the PC end for the wireless modem

antenna. This bracket must be mounted such that the antenna is above the roof

line of the building it is attached to.

• Usually, you can install a 10-foot mast which gives an 8-foot height increase from

the point of mounting. Masts taller than 10 feet generally require the use of guy

wires for support.

• If an appropriate mounting to the side or top of the building cannot be located, a

tower may be used.

Coaxial cable and

connectors used between

wireless modem enclosure

and antenna

Conduit If the Gasboy system is not a pedestal mounted TopKAT, conduit from the system

Ground Rods and Ground

Wires

• Gasboy requires the use of RG8 or RG8U coaxial cable. Belden 7810 or its

equivalent meets the Gasboy cable loss requirement. If you are using Belden

7810 or its equivalent, it is recommended that cable lengths do not exceed 150

feet (45.72 meters).

Note: Ensure that the drip loops are provided on all the coaxial cable runs. These

should be provided in such a manner that all connectors, antennas, wireless

modem enclosures and the accesses to the building have a drip loop

installed.

to the wireless modem must be supplied.

• Each tower requires a dedicated ground rod located as close as possible to the

tower or mast.

• The tower and the wireless modem enclosures ground lug for that particular end of

the wireless communication loop MUST be connected to that particular ground rod

only.

• The installed ground rod is connected to the tower or mast and to the wireless

modem enclosure ground lug with a ground wire not less than AWG #4.

Site Installation Review and Considerations

At the PC End or the Building End of the Wireless Communications Loop

Ensure the following for wireless modem placement and coaxial cable runs:

• PC power and wireless modem power MUST come from the same AC circuit. The

wireless modem operates in the 900 MHz range, which is in the same range as some

cordless phones and cell phones. It is recommended not to have a 900 MHz spread

spectrum phone base in the vicinity of the wireless modem enclosure.

• Gasboy provides a 15-foot RS-232 communications cable from the PC to the Wireless

modem. This RS-232 cable can be extended to 50 feet only (15.24 meters) and ONLY in

the metal conduit. Cable shield integrity must be maintained if the cable is extended.

• From the wireless modem enclosure to the antenna, you can run RG8/U coaxial cable to

the antenna. During the length of this cable run, it MUST not be run along with or bundled

to AC conduits, CAT-5, or phone line wires. It may cross over these wires at 90 degrees.

• The antenna must be above the roof line and cl ear of obstructions. This antenna must have

a line of sight view of the antenna mounted at the Gasboy system end of the wireless

communication loop.

• A standard building wall mount mast bracket will only give an 8-foot rise without the use

of guy wires. Gasboy recommends the use of the wall mount at the building so as to not

penetrate the building roof. In Northern climates, ensure that the antenna is placed well

above the roof line so that it does not get buried by snow accumulation.

• Currently, you must have one modem at the polling PC for each modem attached to a

Gasboy system (except TopKAT Online). For example, if you have two Series 1000

systems that can be polled from the same PC, you will need two wireless modems at the

polling PC and two antennas.

MDE-4520C Enhanced Communications Installation Manual · February 2008 Page 13

Page 14

Site Installation Review and Considerations

At the Gasboy System End

Note: The fueling position assembly must be mounted no lower than 18 inches above the

ground and no closer than 18 inches to any fuel dispenser.

Antenna Mast or Tower

• The height of the mast or tower will be determined by the line of sight requirement

between this antenna and the PC wireless antenna.

• You are allowed to use a 10-foot mast, or a 10-foot tower and 10-foot mast (11 feet to 18

feet total height), or a 20-foot 1 or 2 section tower and 10-foot mast (21 feet to 28 feet total

height) without the use of guy wires.

• If a tower base section is used, the manufacturers’ requirements for the installation of that

tower must be followed for the height of the tower installed.

Note: A tower and mast section is preferred as it encloses the wireless modem insi de the

tower and protects it from being damaged.

Figure 4: Modem Inside the Tower

Gasboy System

(TopKAT)

Modem Inside

the Tower

Distance to the Modem Enclosure

For Gasboy systems other than a pedestal mount To pKAT unit, the modem enclosure must not

be more than 20 feet (6.1 meters) away. All other wire and conduit requirements specified in

the system installation manual must be followed.

Note: Do not use collar and conduit supplied with the kit.

Page 14 MDE-4520C Enhanced Communications Installation Manual · February 2008

Page 15

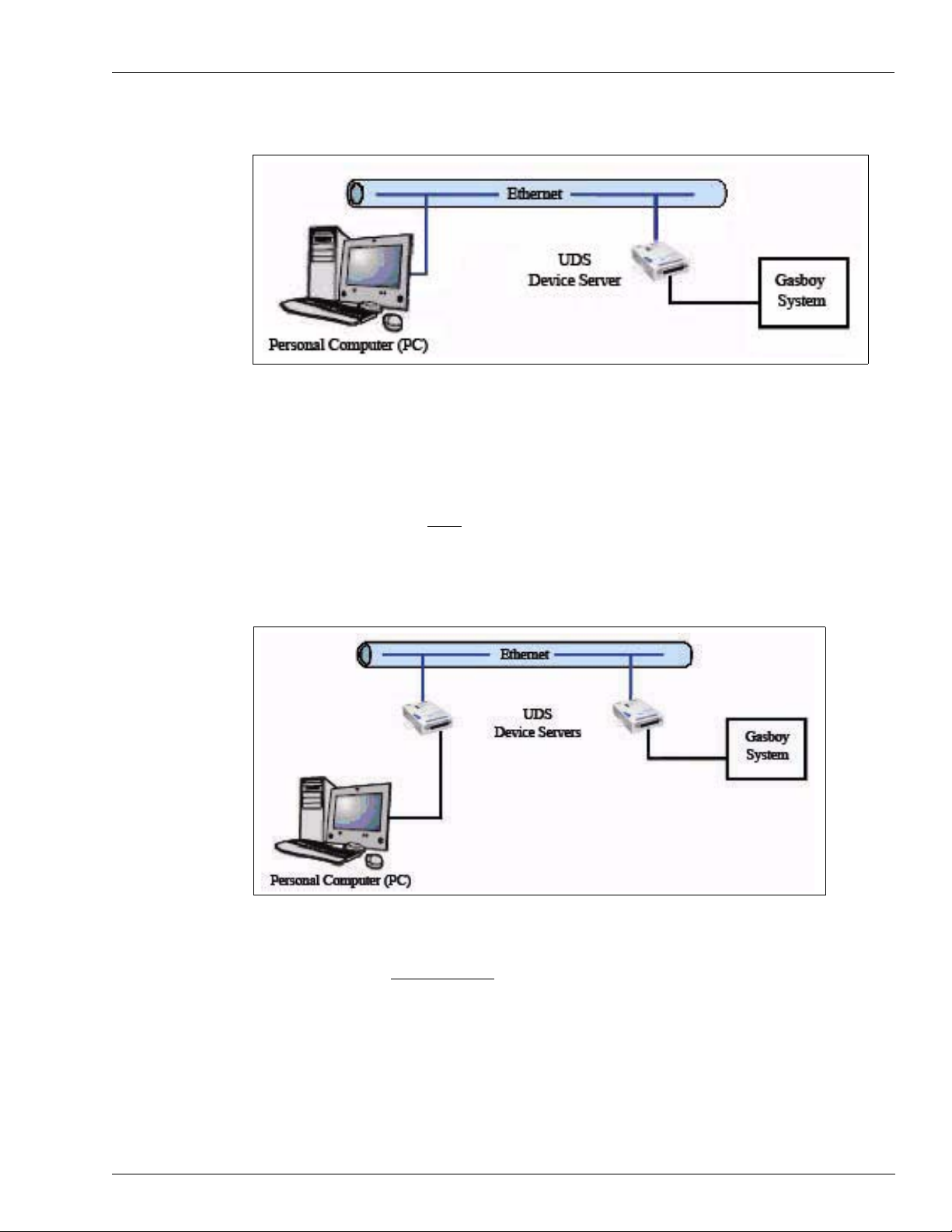

Figure 5: TopKAT Dispenser Mount

Site Installation Review and Considerations

Modem Enclosure Assembly

18” Minimum

AC POWER - SYSTEMS AND PUMPS/DISPENSERS

Conduit (supplied by installer)

Antenna Mast

DC COMMUNICATION CONDUIT

TopKAT

20 Feet Maximum

Figure 6: Gasboy System (Series 1000, Islander)

Antenna Mast

18” Minimum

Conduit (supplied

by installer)

DC COMMUNICATION CONDUIT

AC POWER - SYSTEMS AND PUMPS/DISPENSERS

Gasboy System

20 Feet Max

18” Min

DC RS-485/Pulser

PUMP/DISPENSER AC POWER

Modem Enclosure Assembly

MDE-4520C Enhanced Communications Installation Manual · February 2008 Page 15

Page 16

Site Installation Review and Considerations

Figure 7: TopKAT Mounted on an ASTRA

Antenna Mast

Modem Enclosure

Assembly

18” Minimum

DC COMMUNICATION CONDUIT

Conduit (supplied by installer)

20 Feet Maximum

Connections between the Wireless Modem and a TopKAT Unit

For an installation with a TopKAT unit mounted on a dispenser, connect five of the wires from

the dispenser DC conduit directly to the port (green connector) and connect two others to the

red and black wires on the M06543A001 cable (

M06543A001 cable should be cut short enough so that excess cable is not left in the TopKAT

unit.

If the T opKAT unit is mounted on a 9850 dispenser (that has only six wires in the DC conduit),

connect the black wire from the power supply connector together with the wire connected to

pin 5 of the port connector (green connector). At the modem end, connect that wire to position

5 of the modem terminal block and jumper positions 5 and 7 together.

Figure 8 on page 17). In this case, the

Page 16 MDE-4520C Enhanced Communications Installation Manual · February 2008

Page 17

Site Installation Review and Considerations

Figure 8: Wireless Modem to TopKAT Connections – M06543A001 Cable

TopKAT Power Supply Connection

Wireless Modem

Terminal Block

3

2

7

6

Port Connector

(green connector)

5

4

3

2

1

Wire Colors at Wireless Modem:

7 - black

6 - red

5 - blue

4 - white

3 - brown

2 - green

1 - orange

1

M06543A001 Cable

23

5

4

MDE-4520C Enhanced Communications Installation Manual · February 2008 Page 17

Page 18

Site Installation Review and Considerations

Connections between the Wireless Modem and an Islander

To use the wireless modem with the Islander, you must configure the remote port to be either

port 1 or port 3 (

jumpers (K1 or K2) on the Site Communications I/O board must be configured as shown in

Figure 10.

On the Site Communications I/O PCA, K3 (for port 1) or K4 (for port 3) should not be

jumpered. A C07263 cable (included with the M06544K001 kit) must be installed on the Site

Communications I/O PCA that controls ports 1 and 3. This cable will connect to P10 and pins

6 through 10 of P3 (port 1) or P4 (port 3).

Figure 9: Wireless Modem to Islander Connections

Port 1 (TB5)

Port 3 (TB6)

Figure 9). The Islander CPU K1 (port 1) or K2 (port 3) jumper patch and the

or

1234

5

Figure 10: Jumper Configurations

Site CPU PCA K1 or K2

123

0

1

2

3

4

5

6

7

8

9

A

Wireless Modem

Terminal Block

Site Communication I/O PCA K1 or K2

8

6

4

7

5

3

12

7

6

5

4

3

2

1

Page 18 MDE-4520C Enhanced Communications Installation Manual · February 2008

Page 19

Site Installation Review and Considerations

Connections between the Wireless Modem and a Series 1000 Unit

Figure 11 shows the wiring connections between the wireless modem and a Series 1000

System.

Figure 11: Wireless Modem to Series 1000 Connections

Series 1000

Serial Ports/Pulser Power

Terminal Block

Wireless Modem

Terminal Block

1

P

O

2

R

3

T

4

2

5

1 - 2

3 - 4

5 - 6

7 - 8

PWR

GND

PWR

GND

PWR

GND

PWR

GND

P

U

L

S

E

R

P

O

W

E

R

TXD

DTR

RXD

CD

GND

1

2

3

4

5

6

7

MDE-4520C Enhanced Communications Installation Manual · February 2008 Page 19

Page 20

Site Preparation, Setup Programming, and Testing

Site Preparation, Setup Programming, and Testing

Assembling the Connector (M06547B001)

Parts Required

The following parts are required to assemble a N-plug connector:

•Nut

•Washer

•Gasket

•Clamp

• Male contact

• Plug body

Note: You will need a soldering iron to assemble the connectors.

Figure 12: N-plug Connector Parts

To assemble the N-plug connector, proceed as follows:

1 Place the nut, washer and gasket (with the “V” groove towards the open end of the cable) over

the cable, and cut off the jacket to dimension a.

a = 0.359” (9.1 mm)

c = 0.234” (5.9 mm)

2 Comb out the braid and fold out. Bare the center conductor to dime ns io n c as shown.

Page 20 MDE-4520C Enhanced Communications Installation Manual · February 2008

Page 21

Site Preparation, Setup Programming, and Testing

3 Pull the braid wires forward and taper them towards the center conductor . Place the clamp over

the braid and push it back against the cable jacket.

4 Fold back the braid wires as shown, trim the braid to proper length and form over the clamp as

shown. Tin center conductor and solder on contact.

5 Insert the cable and parts into the connector body. Ensure that the sharp edge of the clamp

seats properly in the gasket. Tighten the nut.

Installing the CDR Tools Software for the Wireless Modem Setup

The CDR Tools Software from Coyote must be used to program the Coyote wireless modem.

This KS319 001PC software is provided with the Base Station kit.

You should load this software on your computer and the Site PC that will be connected to the

wireless modem. When the installation is complete, the Radio Programmer icon appears on

your desktop.

To install the CDR Tools Software, proceed as follows:

1 Insert the diskette into the appropriate drive.

2 Click Start > Run. The Run dialog box appears.

3 Type A:\Setup.

Note: On most computers, the floppy drive is referred to as “A”. If your floppy drive is not

referred to as “A”, type the appropriate letter. The installation process begins.

4 At the License Agreement screen, click Yes.

5 At the Setup Type screen, select Typical and click Next. The copying of files begins.

6 Insert Disk 2 when instructed to do so, and click OK.

7 Click Yes to restart your computer.

MDE-4520C Enhanced Communications Installation Manual · February 2008 Page 21

Page 22

Site Preparation, Setup Programming, and Testing

8 After the PC reboots, connect the appropriate RS-232 cable between the computer COM port

and the wireless modem. See

Appendix: Cable Information on page 51 for cable details.

9 Connect DC power to the modem.

Programming the Wireless Modems

To program the wireless modems, proceed as follows:

1 Click the Radio Programmer icon on your desktop. The Coyote DataCom Radio

Programmer window appears.

Figure 13: Default Coyote DataCom Radio Programmer Window

Destination Group

Source Group

Source Address

Destination

Address

No AckBack

Wait for AckBack

Write

Read

Tx Holdoff Time

Packet Size

Preamble Bytes

CTS De-Assert

CTS Assert

Baud Rate

Note: If you get an error message regarding the COM port, click Utilities > Port Setting and

select the correct port through which you are communicating. The Default setting is

COM 1.

2 Click Read to get Config information from the Modem.

3 Locate the Source Group and Destination Group on the Screen, and set the values to one (1)

for all modems.

Page 22 MDE-4520C Enhanced Communications Installation Manual · February 2008

Page 23

Site Preparation, Setup Programming, and Testing

4 Locate the Source Address and Destination Address, and set the values from the table below.

Note: The values in the table are for PC TopKAT Online Software ONLY using SPECIAL

software in the TopKAT system.

Wireless Modem Source Address Destination Address

PC Modem 100 0

TopKAT Modem Match TopKAT Poll Address 100

Note: The values in the table are for Standar d TopKAT, Series 1000, FleetKey and Islander II

Wireless Modem Source Address Destination Address

PC Modem 100 1

Gasboy System Modem 1 100

Note: Ensure that the auto poll interval (time between successive auto polls) is set to ten (10)

minutes.

5 Locate the box labeled Tx (upper right corner of screen), and set the values from the table

below.

Tx Holdoff Time Packet Size Preamble Bytes

PC TopKAT Online 5 ms (default) 177 (default) 400 or 266 (default)

For all other Gasboy

Systems

200 ms (default) 150 (default) 266 (default)

(default for 2400 baud)

6 Locate Acknowledgement Packet Box.

• “No AckBack” should be selected for sites with multiple PC T opKAT Online systems and

all other Gasboy systems.

• “Wait for AckBack” may be selected for sites with only one PC TopKAT Online system.

Note: Both modems MUST be set to the same option for the modems to function properly.

7 Locate Communications Port Box, and set the values from the table given below.

.

CTS De-Assert CTS Assert Baud Rate

PC TopKAT Online 178 (default) 89 (default) 9600

For all other Gasboy

systems

178 (default) 89 (default) 2400

CAUTION

4800 baud and 9600 baud must not be used for other Gasboy systems. Use of baud rates

higher than 2400 baud will cause modem buffer overflow and the Gasboy system will sign off

prematurely.

Note: Both modems MUST be set to the same value. Baud rate MUST match the Gasboy PC

software baud rate setting.

8 Click Write to save the values entered.

9 Click Read to verify the values entered have been saved correctly.

MDE-4520C Enhanced Communications Installation Manual · February 2008 Page 23

Page 24

Site Preparation, Setup Programming, and Testing

Additional notes for PC TopKAT Online software:

Notes:1) During background polling, the destination address of the modem connected to the

PC will be set by the PC TopKAT Online software to zero (0). This setting will allow

the modem to issue a broadcast command that can be heard by all modems at the

TopKAT systems. Only the TopKAT with the correct poll address will respond to the

command.

2) When the user selects the “Contact a TopKAT” option, the PC TopKAT Online

software will set the destination address of the modem connected to the PC to the

value of the poll address for the selected TopKAT site, and turn on the “AckBack”

option. This will ensure that only the requested TopKAT systems respond to the

entered commands.

3) The PC TopKAT Online software package is specifically designed to allow up to 32

TopKAT systems running specific TopKAT software and controlled by one PC via a

wireless modem.

Radio Programmer Utilities – Spectrum Analyzer

The Radio Programmer software includes the Spectrum Analyzer, which helps you look at the

signals and strengths in the vicinity of your modem.

To access the Spectrum Analyzer, proceed as follows:

1 Ensure that the Gasboy PC software has been closed or shut down; also ensure that the

HyperT erminal session is not running.

2 From Coyote DataCom Radio Programmer window, click Utilities.

3 Click Path Management.

4 Select Spectrum Analyzer.

5 Click START. The signals around your site, which fall into the same spectrum as that of your

wireless modem are read.

Setting Up a Microsoft HyperTerminal for Testing and Troubleshooting

To set up a Microsoft HyperTerminal for testing and troubleshooting, proceed as follows:

1 Open the HyperTerminal (included with most versions of Microsoft Windows software).

2 Create a new connection and use the same port and baud rate as you did for the Gasboy PC

software package.

3 Other Communications setting should be set for 8 data, none/no for parity and 1 stop bit. Flow

control should be “none” for TopKAT and Series 1000 and Xon/Xoff for Gasboy CFN

systems.

4 Terminal emulation should be set to Auto detect.

5 It is recommended that you name and save this as “Gasboy Hyper Connect.”

6 Create a shortcut and place it on the Windows desktop next to the Gasboy PC Software icon

and Radio Programmer icon.

Page 24 MDE-4520C Enhanced Communications Installation Manual · February 2008

Page 25

HyperTerminal Test

Testing the Gasboy System Remote Port

It is recommended that the Gasboy remote port be tested, if possible, with a laptop PC or

terminal before connecting the wireless modem system. Use the same HyperTerminal setup as

listed above. Ensure that the remote port baud rate is properly set up as per the appropriate

Gasboy system Operator or Start up manual. Ensure that the Gasboy port is set up for RS-232

communication and NOT RS-485 communications.

Refer to Appendix: Cable Information on page 51 for Laptop to Gasboy System RS-232

cables.

HyperTerminal Test

Connecting and Testing PC to Gasboy System Communications with the Wireless Modems Connected

At this point, you should have programmed the wireless modem and tested the Gasboy system

remote port, if possible. CDR Tools should be loaded on both the PC end of the

communications loop and a laptop PC. You should have HyperTerminal set up (with the

proper configuration explained above) on both the PC and a laptop PC, if possible. These are

necessary if problems arise during communication testing.

To test PC to Gasboy system communications with the wireless modems, proceed as follows:

1 Connect the wireless modems at both the PC and Gasboy system using the supplied cables.

Ensure the cable used to connect the PC to the wireless modem matches the cable listed in

Appendix: Cable Information on page 51. Ensure that the Gasboy system cabling matches the

system cabling as shown in Figure 8 on page 17, Figure 9 on page 18 , and Figure 11 on page

19.

2 Install and connect the power pack at the PC end, and connect the DC cable at the Gasboy

system end, if you have not done so already.

3 Connect the coaxial cable from the wireless modems to the antennas installed at either the

mast or tower. Check to ensure that the mast, towers, and modems are properly grounded.

4 Open up the previously set up HyperTerminal, and test the communication between the PC

and the Gasboy system. After confirming this communication link, close the HyperTerminal

session. You are ready to test the Gasboy software package.

MDE-4520C Enhanced Communications Installation Manual · February 2008 Page 25

Page 26

HyperTerminal Test

Diagnosing Wireless Modem Installation and Setup Issues

If there is no communication with the Hyper Terminal or the Gasboy PC Package, proceed as

follows:

1 Verify both modems have been properly configured and the proper cables are installed and the

connections are tested. Set the modems to the default parameters before programming.

2 Verify the coaxial connectors have been properly installed and do not short out the entire

cable.

3 For ALL STANDARD Gasboy Fuel Management systems (Standard TopKAT, 1000 series,

FleetKey and Islander II) the baud rate for all devices MUST BE 2400 BAUD. Verify the FMS

system remote port is set for 2400 baud, both modems are set for 2400 baud and the Gasboy

PC Software Package is set for 2400 baud.

Note: For the Gasboy PC TopKAT On Line softwar e ONL Y verify the TopKAT communication

port is set for 9600 baud, both modems are set for 9600 baud and the PC To pKAT On

Line software is set for 9600 baud (the TopKAT system will also have special software

for use with this software package).

4 Verify the wireless modem settings for the system and software on the site are as per the charts

provided in this manual (refer to

5 If the wireless communications is intermittent, for example, if you receive a few characters or

Programming the Wireless Modems on page 22).

one or 2 lines, once again check the modem programming. Ensure that other than the source

and destination address the setup is identical. Ensure that “No Ack Back” is selected and

“Preamble Bytes” is set to 266.

6 “In Manager Mode” may appear on the Gasboy PC Software package screen when subsequent

attempts to “Contact the Site” or “Polling Session” are initiated. The time period this can occur

in is approximately 5 minutes. This has been so far only noted with the standard Gasboy PC

T o pKAT software. It is caused by the way the wireless modems ends the “Contact the Site” or

a “Polling Session”. To avoid this, ensure that the auto poll interval is set to 10 minutes. To

clear this state, contact the site with Hyper Terminal and then end the session with the “EX”

command.

7 If the wireless modems work properly with Hyper Terminal but report an error with the

Gasboy Software package, for example, a “No DCD signal” use the signal tests below.

Page 26 MDE-4520C Enhanced Communications Installation Manual · February 2008

Page 27

Coyote Modem and Communication Port Signal Testing

Note: The CDR 915 is compatible with the CDR 9150 modem. With the differences noted

below.

• When the modem is plugged into power, it should show a YELLOW light on the front

near the connector. It should also flash the GREEN light approximately once per second

even if no second modem is in the area.

• If the green transmit light is not flashing, plug and unplug the power connector to the

modem. This can happen if the communication cable is inadvertently disconnected and

reconnected. If this continually happens, use an ohm meter to verify point-to-point

connection, if necessary.

• The pin outs are referenced to a 9 pin connector for voltage measurements. Refer to the

Figure 14 on page 28 if conversion to 25 pin outs need to be made.

• The CDR 9150 does not provide Pin 1 DCD. It provides the Pin 6 (DSR) and Pin 8 (CTS)

signals. Sites that are replacing a CDR 915 with a CDR 9150 must ensure they order the

new cable listed in Appendix A,

Q13180-20B and Q13180-61) on page 51or modify the existing cable to provide the Pin 1

to Pin 6 jumper as shown in the table on page 51.

• The signals between Gasboy system and modem or between PC and modem may be

verified by the use of an RS-232 Breakout box. An LED will verify the presence of the

individual signals. They may also be measured using a Digital Volt/Ohm Meter. Ensure

that you do not short the pins. Those voltages are provided below. The wireless modem

need not be connected to a PC or Fleet system for the tests below. If the wireless modem

does not provide the proper communications signals, it indicates a bad modem and a new

one should be ordered.

• Use Pin 5 for signal ground.

• If measured at the modem (no cable attached):

- Pin 1 (DCD) is measured to be 6.8 VDC nominal (CDR 915 ONLY).

- Pin 6 (DSR) is measured to be 6.8 VDC nominal.

- Pin 8 (CTS) is measured to be 6.35 VDC nominal dropping to below 6 VDC when the

GREEN transmit light flashes on the CDR 915.

• When you are using the cable mentioned in Appendix: Cable Information on page 51 with

Pins 1 and 6 jumpered internally, the voltage will be 6.35 VDC nominal if measured at the

9 pin connector that will plug into the PC.

• These voltages may vary slightly due to the meter used.

• The PC needs to provide two communication signals. To test these signals a

communications program such as Hyper Terminal must access the communication port to

be tested.

Note: The Coyote Radio Programmer software only provides the DTR signal.

• Pin 4 (DTR) Hyper Terminal and Coyote Radio Programmer software .

• Pin 7 (RTS) Hyper Terminal software only.

• Both of these signal should measure 5.5 VDC nominal.

• If these two signals are not properly provided by the PC's communication port, a problem

with the PC communications port is indicated. Use a second port on the PC if available.

Have the PC repaired as necessary.

• With the Wireless modem connected to the PC, all five signals (DCD, DSR, CTS, DTR

and RTS) must be present for the Gasboy software to properly work with the wireless

modem. All five signals are not easily verified with the cables connected without the use

of a RS-232 breakout box.

PC to Wireless Modem (Cable made up of Q13850-15,

HyperTerminal Test

MDE-4520C Enhanced Communications Installation Manual · February 2008 Page 27

Page 28

Serial-to-LAN Connection Installation

Figure 14: Serial (RS-232) Port Interface Pinout and Signals Chart

Serial (RS-232) port interface pinout and signals

9

pin #

3 2 TxD Transmit Data —» Transmits bytes out of PC

2 3 RxD Receive Data «— Receives bytes into PC

7 4 RTS Request To Send —» RTS/CTS flow control

8 5 CTS Clear To Send «— RTS/CTS flow control

6 6 DSR Data Set Ready «— Modem ready to communicate

4 20 DTR* Data Terminal Ready —» Terminal ready to communicate

1 8 DCD Data Carrier Detect «— Modem connected to another

9 22 RI Ring Indicator «— Telephone line ringing

5 7 SG Signal Ground

*Not provided on CDR9150

25

Acronym Full name Direction Mean

pin#

Serial-to-LAN Connection Installation

Serial-to-LAN Configuration Options

There are two options when connecting Gasboy systems to the Serial-to-LAN adapter.

Note: In most cases, a C04532 cable (included with the kit) will be needed to connect the

Serial-to-LAN adapter to the Gasboy Sho rt Haul Modem (C05618) or Gasboy

Termination Box (C05769).

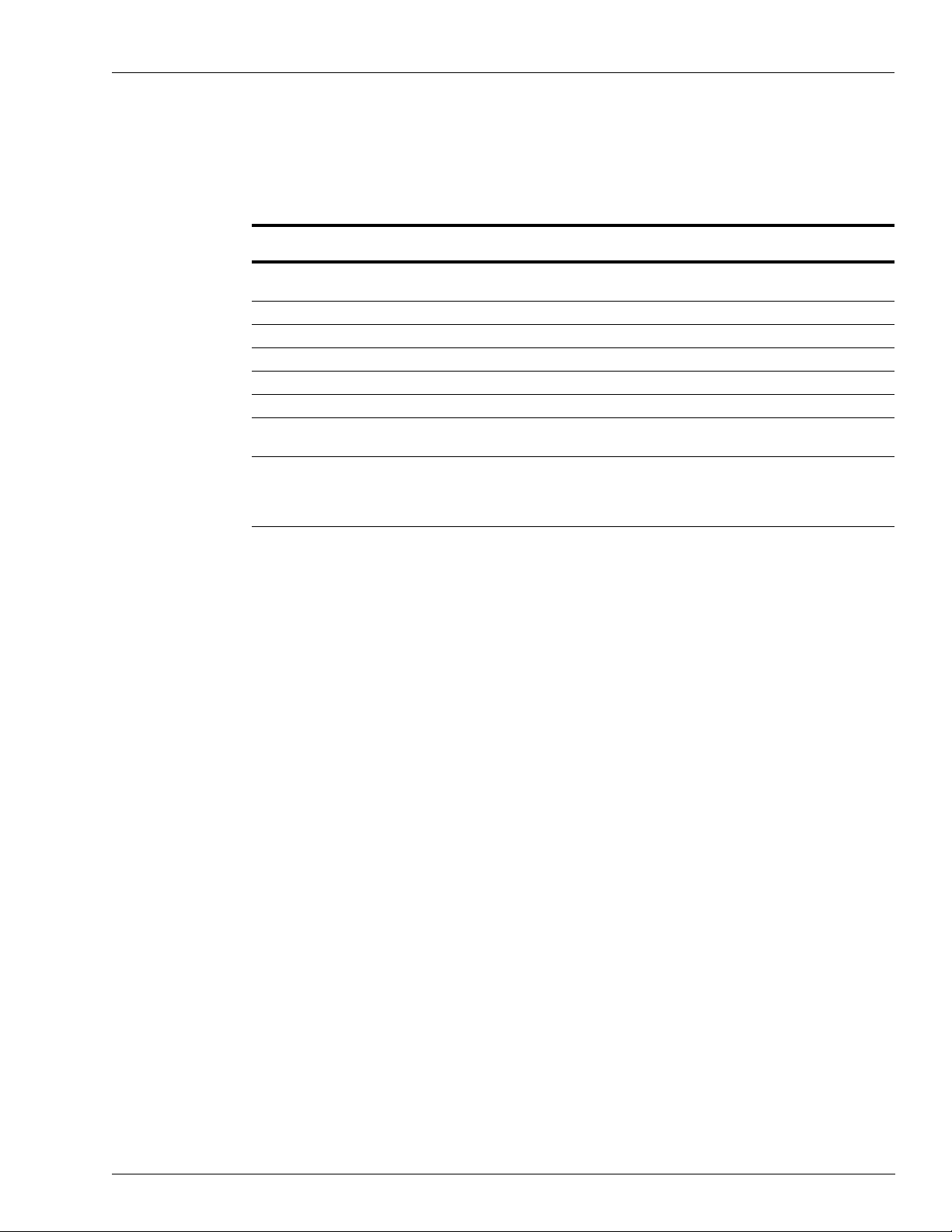

TCP/IP Configuration (use M06643K001)

The first option is to use only one adapter in a Transmission Control Protocol/ Internet Protocol

(TCP/IP) configuration (

one of the Gasboy system’s ser ial ports. The user then uses a PC utility such as Telnet to open

a TCP/IP communication session to the Gasboy system. In this configuration, no serial port is

needed at the PC. With each adapter assigned its own IP address, one PC can be used to

communicate to multiple Gasboy systems (one at a time).

Note: This configuration does not work with the Gasboy PC packages.

Figure 15 on page 29). With this option, the adapter is connected to

Page 28 MDE-4520C Enhanced Communications Installation Manual · February 2008

Page 29

Serial-to-LAN Connection Installation

Figure 15: TCP/IP Configuration

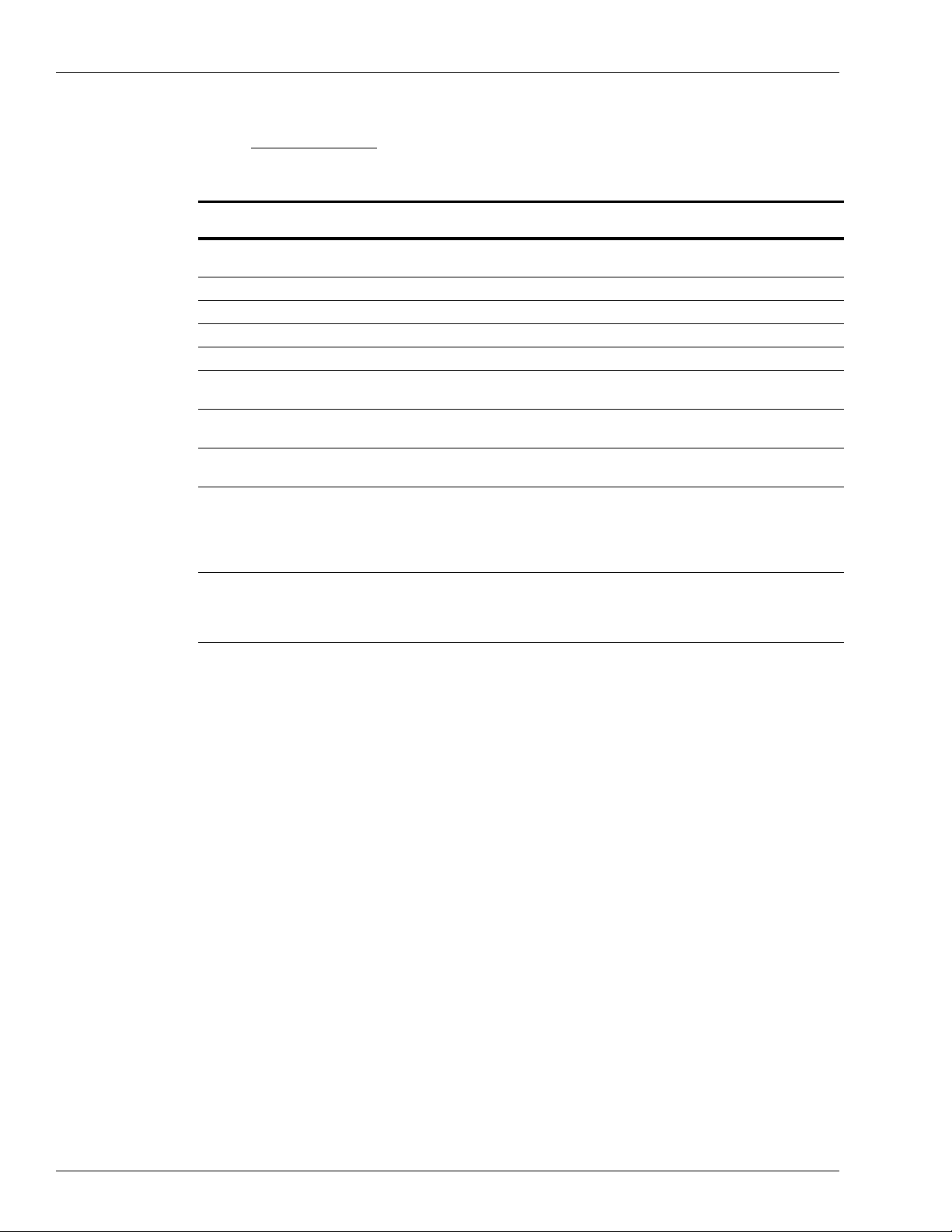

Serial Tunneling Configuration (use M06643K002)

The second option is known as the Serial Tunneling configuration (Figure 16). In this

configuration, one adapter is connected to one of the Gasboy system’s serial ports and a

second adapter is connected to a serial port on the PC.

Note: This configuration works with Gasboy PC packages (such as PC/TopKAT, PC/1000,

PC/CFN).

Figure 16: Serial Tunneling Configuration

The Serial Tunneling configuration has two modes: Direct Connect and Modem Emulation.

• When using the Direct Connect mode, the adapters create a direct connection between the

PC and the Gasboy system that works as if the two (PC and system) had been hard-wired

together. When the adapters are powered up, they establish a TCP/IP link between them.

From that point on, anything transmitted from the PC serial port is sent directly to the

Gasboy system serial port and vice versa. Using this mode, communication can only be

established with one Gasboy system.

MDE-4520C Enhanced Communications Installation Manual · February 2008 Page 29

Page 30

Serial-to-LAN Connection Installation

• When using the Modem Emulation mode, the adapter connected to the PC emulates a

modem. The PC sends AT commands and the adapter responds as if it were a modem.

However, instead of a phone number, the user must use the Gasboy system adapter IP

address and port number (refer to

number to dial. When the IP address and port number are dialed, the adapters establish a

TCP/IP link between them. At this point, they work the same as in Direct Connect mode,

sending and receiving data to and from the serial ports. When the “call” is over, the

adapters drop the TCP/IP connection. Using this mode allows one PC to communicate to

multiple Gasboy systems (one at a time).

Adapter Connections

The Serial-to-LAN adapter (Figure 17) has a standard RJ45 Ethernet port (10Base-T), and

serial port and power connection. The Ethernet port is connected to a standard Ethernet hub or

LAN distribution point, usually with a CAT-5 cable.

For power, connect the AC power supply to the power plug and plug in the AC supply into an

outlet.

Accessing Adapter Parameters on page 32) as the

Figure 17: Serial-to-LAN Adapter

Note: The Reset Switch does not exist on

newer black adapter boxes.

For RS-232 wiring from the Gasboy system (Series 1000, TopKAT, or Islander) to the serial

port, see

Figure 18 on page 31, Figure 19 on page 31 and Figure 20 on page 31.

Note: The terminal blocks on different Gasboy systems may appear different from the ones

shown here, but the point-to-point connections and cables are the same. All

requir ements for RS-232 and RS-422 defined in the Gasboy system installation manuals

apply to the wiring between the system and Serial-to-LAN adapter as well.

Page 30 MDE-4520C Enhanced Communications Installation Manual · February 2008

Page 31

Serial-to-LAN Connection Installation

Figure 18: RS-232 D-Type Connector

100 FEET MAX.

1

2

3

4

5

TXD

DTR

RXD

CD

GND

Figure 19: RS-232 Gasboy Termination Box

100 FEET MAX.

1

2

3

4

5

TXD

DTR

RXD

CD

GND

1

GASBOY

RS232

2

3

4

5

C05769

MODEM CABLE

P/N C04532

P/N C05758

2

20

3

8

7

MALE CONNECTOR

(WIRE END VIEW)

Serial-to-LAN Adapter

14

1

13

25

(see Figure 17 on page 30)

Figure 20: RS-422 Gasboy Short Haul Modem

1500 FEET MAX.

P/N C05618

1

2

3

4

5

System

Ground

TX+

TXRX+

RX-

1

GASBOY

2

3

4

AC

POWER

SHM

MODEM CABLE

P/N C04532

Serial-to-LAN Adapter

(see Figure 17 on page 30)

CFN 3 Connection

To connect to a CFN 3, use a C05995 modem cable from Port 4, 5, or 6 of the CFN 3 to the

serial-to-LAN adapter.

RS-232 PC Connection

To connect the adapter to a serial port of a PC, use a standard PC-to-modem cable

(Q13240-09). Connect it from the PC serial port to the serial port on the adapter.

MDE-4520C Enhanced Communications Installation Manual · February 2008 Page 31

Page 32

Serial-to-LAN Connection Installation

Accessing Adapter Parameters

The IP Address

Certain parameters must be configured before the adapter can function. The first parameter

that must be defined is the Internet Protocol (IP) address. Every device connected to a TCP/IP

network must have a unique IP address. The IP address must be configured before a network

connection is available.

• If your network is not and will not be connected to the Internet, you may use any IP

address.

• If your network is connected or will be connected to the Internet, or if you intend to

operate the Serial-to-LAN adapter on an intranet, you should consult your Network

Administrator with questions about IP address assignments. The adapter ships with a

default IP address of 0.0.0.0, which automatically enables Dynamic Host Configuration

Protocol (DHCP).

- If your network has a DHCP server, it will supply the adapter with an IP address,

gateway address, and subnet mask when the adapter powers up

· For Model UDS10, refer to Configuring the Adapter from the Web Browser Login –

Model UDS10 on page 32.

· For Model UDS1100, refer to Confi guring the Adapt er from the Web Browser Login

– Model UDS1100 on page 33.

- If the IP address is not set automatically via DHCP, it can be set using a serial port login

and setup menu (refer to

UDS1100 on page 35).

Configuring the Adapter from the Serial Port Login – UDS10 or

Configuring the Adapter from the Web Browser Login – Model UDS10

If your network has a DHCP server that has assigned an IP address to the adapter, or if an IP

address has been previously assigned, you can log into it using a standard Web browser with

®

Java

enabled. Consult with your Network Administrator for the device IP address or

identification assigned by the DHCP server to the adapter for this connection.

To configure the Adapter from the web browser login, proceed as follows:

1 Type the adapter IP address into the Web browser URL (Address/Location) field (Figure 21).

Figure 21: Web Browser Address Field

2 Click Connect to log in and gain access to the configuration menu.

Page 32 MDE-4520C Enhanced Communications Installation Manual · February 2008

Page 33

Serial-to-LAN Connection Installation

3 Use the menu buttons to navigate to sub-pages where you can configure adapter settings

Figure 22) and configure the settings.

(

Figure 22: Lantronix Server and Port Configuration Screen – Model UDS10

Configuring the Adapter from the Web Browser Login – Model UDS1100

If your network has a DHCP server that has assigned an IP address to the adapter, or if an IP

address has been previously assigned, you can log in using a standard Web browser with Java

enabled. Consult with your Network Administrator for the device IP address or identification

assigned by the DHCP server to the adapter for this connection.

To configure the Adapter from the web browser login, proceed as follows:

1 Type the adapter IP address into the Web browser URL (Address/Location) field (Figure 23).

Figure 23: Web Browser Address Field

2 Click Connect to log in and gain access to the configuration menu.

MDE-4520C Enhanced Communications Installation Manual · February 2008 Page 33

Page 34

Serial-to-LAN Connection Installation

3 Use the menu buttons to navigate to Channel 1 sub-pages where you can configure adapter

settings (

Figure 24: Lantronix Channel 1 Serial Settings Screen – Model UDS1100

Figure 24 and Figure 25 on page 35) and configure the Channel 1 settings.

Page 34 MDE-4520C Enhanced Communications Installation Manual · February 2008

Page 35

Serial-to-LAN Connection Installation

Figure 25: Lantronix Channel 1 Connection Settings Screen – Model UDS1100

Configuring the Adapter from the Serial Port Login – UDS10 or UDS1100

To configure the Adapter from the serial port login, proceed as follows:

1 Connect a terminal or PC running a Terminal Emulation program to the serial port of the

adapter. The default serial port settings are 9600 baud, 8 bits, no parity, 1 stop bit.

2 To enter Setup (Configuration) mode, cycle power (power off and back on) on the adapter.

After power-up, the self-test begins and the red diagnostic LED starts blinking. You will have

one second to enter three lowercase “x” characters.

Note: The easiest way to enter the Setup mode is to hold down the “x” key at the terminal (or

Emulation Program) while powering up the adapter.

3 When “Press Enter for Setup Mode” appears, press ENTER.

The display in the Setup menu is as shown in the following figures.

• Figure 26 on page 37 for Model UDS10

• Figure 27 on page 38 for Model UDS1100

MDE-4520C Enhanced Communications Installation Manual · February 2008 Page 35

Page 36

Serial-to-LAN Connection Installation

4 To make changes, enter the number assigned to the parameters to be changed and follow the

prompts until all information has been entered. All parameters not listed in the table on

39, page 41, and page 41 should be left at their default values.

• When a parameter prompt is displayed, the current value is shown in parentheses at the

end of the prompt. To change the value, type the new value and press ENTER.

• If you do not want to change the existing value of a parameter, just press ENTER without

entering any data.

5 Once you have set the parameters you wish to change, enter “9” and press ENTER to save the

changes.

Note: Changes are not saved until you save them (that is, entering 9 and then pressing

ENTER).

If your network has a DHCP server that has assigned an IP address to the adapter, or if an IP

address has been previously assigned, you can access the setup menu (

Figure 27 on page 38) by using Telnet.

To access via Telnet, open a Telnet connection to port 9999.

Consult with your Network Administrator for the device IP address or identification assigned

to the adapter for the Telnet connection.

page

Figure 26 on page 37 or

Page 36 MDE-4520C Enhanced Communications Installation Manual · February 2008

Page 37

Serial-to-LAN Connection Installation

Figure 26: Serial-to-LAN Server Setup Menu (Sample) – Model UDS10

*** Lantronix Universal Device Server ***

Serial Number 5433451 MAC address 00204A5482AB

Software version V5.8.0.1 (041112) LTX

Press Enter for Setup Mode

*** basic parameters

Hardware: Ethernet TPI

IP addr 0.0.0.0, no gateway set

*** Security

SNMP is enabled

SNMP Community Name: public

Telnet Setup is enabled

TFTP Download is enabled

Port 77FEh is enabled

Web Server is enabled

ECHO is enabled

Enhanced Password is disabled

*** Channel 1

Baudrate 9600, I/F Mode 4C, Flow 00

Port 10001

Connect Mode: C0

Auto increment source port disabled

Remote IP Adr:--- none ---, Port 00000

Disconn Mode: 00

Flush Mode: 00

*** Expert

TCP Keepalive : 45s

ARP cache timeout: 600s

Monitor Mode @ bootup: enabled

HTTP Port Number: 80

Change Setup:

0 Server configuration

1 Channel 1 configuration

5 Expert settings

6 Security

7 Factory defaults

8 Exit without save

9 Save and exit Your choice ?

Note: If “Change Setup: 9 Save and exit” is selected, the settings are saved and the system reboots.

Step 3

Step 4

Step 4 and

Step 5

MDE-4520C Enhanced Communications Installation Manual · February 2008 Page 37

Page 38

Serial-to-LAN Connection Installation

Figure 27: Serial-to-LAN Server Setup Menu (Sample) – Model UDS1100

*** Lantronix Universal Device Server ***

MAC address 00204A9B0178

Software version V6.1.0.1 (060120) UDS1100

Press Enter for Setup Mode

*** basic parameters

Hardware: Ethernet TPI

IP addr 0.0.0.0/DHCP/BOOTP/AutoIP, no gateway set

DHCP device name: not set

*** Security

SNMP is enabled

SNMP Community Name: public

Telnet Setup is enabled

TFTP Download is enabled

Port 77FEh is enabled

Web Server is enabled

Web Setup is enabled

ECHO is disabled

Enhanced Password is disabled

*** Channel 1

Baudrate 9600, I/F Mode 4C, Flow 00

Port 10001

Connect Mode: C0

Send ‘+++’ in Modem Mode enabled

Auto increment source port disabled

Remote IP Adr:--- none ---, Port 00000

Disconn Mode: 00

Flush Mode: 00

Terminal name:

*** Expert

TCP Keepalive : 45s

ARP cache timeout: 600s

Monitor Mode @ bootup: enabled

HTTP Port Number: 80

MTU Size: 1400

Alternate MAC: disabled

Ethernet connection type: auto-negotiate

Change Setup:

0 Server

1 Channel 1

5 Expert

6 Security

7 Defaults

8 Exit without save

9 Save and exit Your choice ?

Step 3

Step 4

Step 4 and

Step 5

Note: If “Change Setup: 9 Save and exit” is selected, the settings are saved and the system reboots.

Page 38 MDE-4520C Enhanced Communications Installation Manual · February 2008

Page 39

Serial-to-LAN Connection Installation

Settings for the Adapter Connected to the Gasboy System

Once you have access to the setup menu (Figure 26 on page 37 or Figure 27 on page 38), the

following parameters must be set to the value listed for the adapter connected to the Gasboy

system. All other values should be left at their default values. To view/edit the parameters

below, enter “1” at the “Your choice?” prompt and press ENTER.

Parameter

(Figure 26 on page 37) Value Definition

Baud rate Set to match baud rate of the port to which the

adapter is connected

I/F Mode 4C RS-232C, 8 bits, no parity, 1 stop bit

Flow 05 XON/OFF pass characters to host

Port (see note below) Range: 1 - 65535

Connect Mode C0 Accept unconditional, no active startup

Disconn Mode C0 Disconnect with DTR drop, Telnet mode

Flush Mode 44 Input buffer - clear at disconnect

Note: Every TCP connection is defined by a destination IP address and port number. For example, a Telnet

application commonly uses port number 23. A port number is similar to an extension on a private branch

exchange (PBX) telephone system. A range of port numbers are available: 1 - 65535. Port numbers 0, 7, and

9999 are reserved and must not be assigned to the adapter.

9600 is the default value

Output buffer - clear at disconnect

After the parameters have been changed, you can press ENTER at the “Your choice?” prompt

to display the current values. Remember to save the settings once they are set correctly (see

below).

Consult with your Network Administrator for changes to the IP address, gateway address,

subnet mask, or security changes. To change IP address, gateway address, subnet mask

parameters, enter “0” at the “Your choice?” prompt and then press ENTER. To change

security parameters, enter “6” at the “Your choice?” prompt and then press ENTER.

Remember to save the settings once they are set correctly.

Once the parameters are set correctly, save the settings and exit setup by entering “9” at the

prompt and then press ENTER.

Settings for the Adapter Connected to a PC

If you are using the Serial Tunneling option, you will also have a Serial-to-LAN adapter

connected to a serial port on a PC. As described in

page 28, there are two modes:

• Direct connection - virtual hard-wired serial connection

• Modem emulation - allows PC to “dial” the Gasboy system via a LAN connection

Serial-to-LAN Configuration Options on

MDE-4520C Enhanced Communications Installation Manual · February 2008 Page 39

Page 40

Serial-to-LAN Connection Installation

Direct Connect Mode

For the Direct Connection mode, the following parameters must be set to the value listed for

the adapter connected to the PC. To view/edit the parameters below, enter “1” at the “Your

choice?” prompt and press ENTER.

Parameter

(Figure 26 on page 37) Value Definition

Baud rate Set to match the baud rate of the Gasboy system

I/F Mode 4C RS-232C, 8 bits, no parity, 1 stop bit

Flow 05 XON/OFF pass characters to host

Port (see note below) Range: 1 - 65535

Connect Mode C5 Accept unconditional, auto start

Remote IP Adr Set to IP address assigned to Gasboy system

(Remote) Port Set to port assigned to Gasboy system adapter Port to connect to when link is

Disconn Mode C0 Disconnect with DTR drop, Telnet

port to which the adapter is connected

9600 is the default value

IP address to link to at startup

adapter

established

mode

Flush Mode 44 Input buffer - clear at disconnect

Output buffer - clear at disconnect

Note: Every TCP connection is defined by a destination IP address and port number. For example, a Telnet

application commonly uses port number 23. A port number is similar to an extension on a PBX telephone

system. Range of port numbers available: 1 - 65535. Port numbers 0, 7, and 9999 are reserved and must not

be assigned to the adapter.

After the parameters have been changed, you can press ENTER at the “Your choice?” prompt

to display the current values. Remember to save the settings once they are set correctly (see

below).

Consult with your Network Administrator for changes to the IP address, gateway address,

subnet mask, or security changes. To change IP address, gateway address, subnet mask

parameters, enter “0” at the “Your choice?” prompt and then press ENTER. To change

security parameters, enter “6” at the “Your choice?” prompt and then press ENTER.

Once the parameters are set correctly, save the settings and exit setup by entering “9” at the

prompt and then press ENTER.

Page 40 MDE-4520C Enhanced Communications Installation Manual · February 2008

Page 41

Serial-to-LAN Connection Installation

Modem Emulation Mode

For the Modem Emulation mode, the following parameters must be set to the value listed for

the adapter connected to the PC. To view/edit the parameters below, enter “1” at the “Your

choice?” prompt and press ENTER.

Parameter

(Figure 26 on page 37) Value Definition

Baud rate Set to match the baud rate of the Gasboy

system port to which the adapter is

connected

I/F Mode 4C RS-232C, 8 bits, no parity, 1 stop bit

Flow 05 XON/OFF pass characters to host

Port (see note below) Range: 1 - 65535

Connect Mode 16 Modem mode with echo (06 for no

Disconn Mode C0 Disconnect with DTR drop, Telnet

Flush Mode 44 Input buffer - clear at disconnect

Note: Every TCP connection is defined by a destination IP address and port number. For example, a Telnet

application commonly uses port number 23 (a port number is similar to an extension on a PBX-style telephone

system). Range of port numbers available: 1 - 65535. Port numbers 0, 7, and 9999 are reserved and must not

be assigned to the adapter.

9600 is the default value

echo)

mode

Output buffer - clear at disconnect

After the parameters have been changed, you can press ENTER at the “Your choice?” prompt