Manual

SF6-Aciditor

Version 1.2

SF6-Aciditor

2

© G.A.S. Gesellschaft für analytische Sensorsysteme mbH

DortmundBioMedicineCenter

Otto-Hahn-Straße 15

D-44227 Dortmund, Germany

Phone: +49 231 / 97 42 - 65 50

Fax: +49 231 / 97 42 - 65 55

E-Mail: info@gas-dortmund.de

Internet: www.gas-dortmund.de

2.2.2010

SF6-Aciditor

3

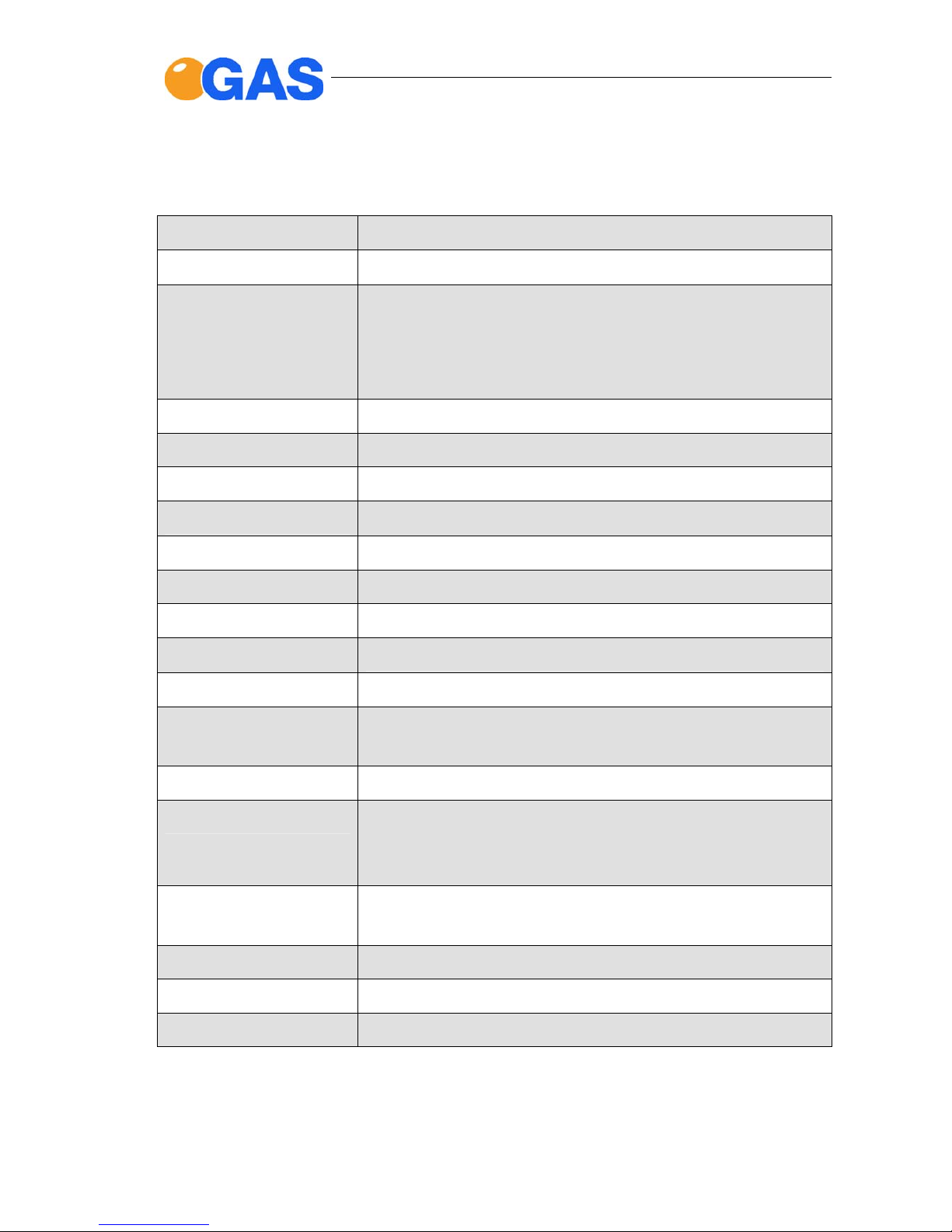

1 General Information 4

1.1 Information about the Manual 4

1.2 Explanation of Symbols 4

1.3 Scope of Supply 5

1.4 Liability and Guarantee 5

1.5 Copyright 6

1.6 Return and Disposal 6

1.7 Customer Service 6

2 Transport, Packing and Storage 7

2.1 Inspection after Transport 7

2.2 Transport 7

2.3 Packing 7

2.4 Storage 7

3 Cleaning and Maintenance 8

3.1 Cleaning 8

3.2 Maintenance 8

3.3 Exchange of the sensor / Calibration 8

4 Security 9

4.1 Intended Use 9

4.2 Responsibility of the Operator 9

4.3 Requirements of the Personnel 10

4.4 Dangers 10

5 Introduction 11

5.1 Working Principle 12

6 System Operation 14

6.1 Loading of Battery 14

6.2 Insertion of the SO

2

-Sensor 15

6.3 Operation of the SF

6

- Aciditor 17

6.4 Purging of the SF

6

-Aciditor 19

6.5 Settings 20

6.5.1 Turn on/off beeper 20

6.5.2 Reset lifetime counter 20

6.6 Exchange of the SO

2

-Sensor 22

7 Technical Data 25

SF6-Aciditor

4

1 General Information

1.1 Information about the Manual

This manual describes a safe and adequate handling of the SF

6

-Aciditor. Following the

instructions of the indicated safety aspects and instructions as well as the national and/or

local rules and general safety regulations concerning the prevention of accidents are

absolutely imperative.

Before starting the work with the device read the manual completely and thoroughly

particularly the chapter security and respective safety references. Assure that you/the

operator comprehend the terms described.

The manual is part of the device. It has to be stored together with and next to the device at

any time.

1.2 Explanation of Symbols

Important and safety-relevant references in this manual are characterized by symbols. These

indications which are in-line with industrial safety must be respected and followed at any

time.

Information!

This symbol calls information, which are to be considered for efficient and

perfect handling of the equipment.

NOTE! Danger for real values!

This symbol indicates references, which can lead to damages,

malfunctioning and/or loss of the device.

WARNING! Danger by electric current!

This symbol marks references, which can lead to health impairments,

injuries, lasting body damages or to death due to electric current.

VERY DANGEROUS! Injury or mortal danger!

This symbol marks references, which can lead to health impairments,

injuries, lasting body damage or to death.

SF6-Aciditor

5

1.3 Scope of Supply

Assure that you have received the full scope of supply. If there is any part missing, please

contact the G.A.S.-hotline immediately.

The scope of supply consists of:

• SF

6

-Aciditor

• SO

2

-Sensor foil sealed

• Transport case

• Battery charger

• Manual SF

6

-Aciditor

• Instrument’s quality test report

• 4 m long PTFE connecting hose with wire coating, self-closing stainless steel

couplings on both ends

1.4 Liability and Guarantee

All data and reference within this manual are compiled under the valid regulations, the stateof-the-art as well as G.A.S. experiences of several years.

The manual has to be stored together with and close to the device at any time and

accessible to all persons, who work with it.

This manual must be read carefully before starting to work with the equipment! G.A.S. does

not overtake any liability for damage and disturbances, resulting from neglect or ignorance of

the manual’s instruction.

The text and graphics do not correspond necessarily to the scope of supply. The figures

and/or diagrams do not correspond to the yardstick 1:1.

The actual scope of supply might deviate from special (customized) equipments, the

recourse of additional order options or due to newest technical changes concerning the data

and references described herein as well as the graphic representations. For questions

please contact the G.A.S.-hotline.

G.A.S. reserves the right to realize technical changes of the product due to improvements

without explicitly mentioning them.

SF6-Aciditor

6

1.5 Copyright

The manual is confidential. It is beyond doubt exclusively made and also meant for the

personnel directly dealing with the equipment. All data, texts, designs, pictures and other

representations within this manual are protected in the sense of the copyright law and are

subject to further commercial patent rights. Each abuse is liable to prosecution.

Passing it on to third persons as well as duplications in any kind and form - also in part - as

well as the use and/or report of contents are not permitted without written agreement of the

manufacturer. Offences lead to payment of damages. We reserve ourselves the right for

further legal actions as well as all further rights according to the practice of commercial

patent rights.

1.6 Return and Disposal

For a professional redemption, the device or/and its components must be returned to the

manufacturer or to a third party authorized by the manufacturer!

1.7 Customer Service

For questions concerning the equipment a customer service is available:

- Phone: ++49 231 / 97 42 - 65 50

- Fax: ++49 231 / 97 42 - 65 55

- E-Mail: info@gas-dortmund.de

The telephone hotline is attainable from Monday to Friday from 8:00 to 17:00 hours. In urgent

cases and if you use fax or e-mail, please indicate your telephone number.

G.A.S.

Gesellschaft für analytische Sensorsysteme mbH

DortmundBioMedicineCenter

Otto-Hahn-Straße 15

44227 Dortmund

http://www.gas-dortmund.de

SF6-Aciditor

7

2 Transport, Packing and Storage

2.1 Inspection after Transport

Check the supply immediately after delivery concerning its completeness and/or transport

damages. If you detect outwardly recognizable transport damage, do not receive the supply,

or only under reservation. State the extent of the damage on the provided delivery note

and/or the transportation documents of the feeder. Generate a complaint. Lodge a complaint

of covered defect immediately after recognizing, as claims due to transport damages can

only be made valid within the complaint periods (usually 7 days).

2.2 Transport

The equipment should be moved only within the provided carrying case. By this means,

transport damages can be avoided.

2.3 Packing

If no redemption agreement concerning the packing was agreed upon, separate the different

materials according to kind and size and supply it to further use or recycling.

Information!

Dispose the packing material always environmentally friendly and according to

the valid local regulations. If necessary, ask a recycling company.

2.4 Storage

Store the device only under the following conditions:

• Until the use of the equipment keep the

provided suit-case locked

• Do not store unsecured

• Do not store outside

• Store only dry and dust free

• Avoid mechanical vibrations

• Do not expose the device to aggressive

media

• Protect the device against sun exposure

• Storage temperature: -10 to 60 °C

• If you do not use the device, check the

storage condition, regularly

• Protect against unauthorized access

SF6-Aciditor

8

3 Cleaning and Maintenance

Natural aging and the wear of certain components of the equipment require a regular

cleaning and maintenance.

3.1 Cleaning

Clean the device only with a dry or easily damp cloth.

NOTE! Danger for real values!

Do not use cleaning agents, which contain solvents, acids or bases.

3.2 Maintenance

Maintenance of the device should only be carried out at G.A.S. or through specially trained

and by G.A.S. authorized personnel.

3.3 Exchange of sensor / Calibration

The sensor of the SF6-Aciditor has a lifetime of two years and has to be exchanged after this

time period. How to exchange the sensor is described in chapter 6.4 of this manual. New

calibrated sensors should only be purchased from G.A.S..

Information!

Using the SO

2

-sensor more than two years is not recommended due to an

signal degradation of < 2 % per month.

SF6-Aciditor

9

4 Security

This section gives an overview of all important safety aspects for an optimal protection of the

personnel as well as for the safe and trouble free use of the device. Additionally, the

individual chapters contain concrete safety references with respect to the prevention of direct

dangers which are indicated by symbols.

4.1 Intended Use

The device may not be operated by introducing highly aggressive gases or liquids! The

working reliability is only ensured when the equipment is applied for its purpose:

To measure SO

2

up to 100 ppmv (standard) in SF6 or in other non aggressive gases !

NOTE! Danger for real values!

Each use of the device, that differs from the intended use is forbidden and will

be regarded as “out of purpose”.

All claims or requirements of any kind against the manufacturer and/or its authorized persons

that arise due to damages from a not intended use of the device will be rejected. All

damages that arise from a not intended use are of the operator’s responsibility.

The intended use of the equipment and its correct handling according are described in the

operating instructions of this manual. Other parts than the parts belonging to the scope of

supply, may only be used after G.A.S.’ approval.

4.2 Responsibility of the Operator

This manual must be kept in direct access and together with the device and accessible to the

operating staff at any time. The hints, information and instructions are to be followed without

any restrictions or reservation!

Besides the indicated safety references and instructions in this manual, the local rules for the

prevention of accidents and the general safety regulations - valid for the area of application

of the device - as well as the valid environmental-protection regulations are to be considered

and respected.

The technical responsible as well as the operator should take care of a trouble free use of

the device as well as of clear definitions of the competences during operation, maintenance

and cleaning.

SF6-Aciditor

10

4.3 Requirements of Personnel

Only authorized and trained technical personnel may work with the instruments. The operator

must have received an instruction over existing and all possible dangers.

Technical personnel in this context are defined as skilled employees who are knowledgeable

due to their educational background. In case the foreseen personnel do not have the

necessary qualifications to operate the instrument, it must be trained.

The competencies for the work on and with the device must be specified and kept

undoubtedly at any time so that with respect to security issues no unclear situation might

come up.

The equipment should only be operated by reliable and responsible personnel. Personnel

that might be under the influence of drugs or alcohol are to be kept off the device at any time.

Further to that non-authorized personnel should not operate the device.

Any changes of the equipment, which impair security of the personnel must immediately be

reported to the operator and every person dealing with it.

4.4 Dangers

The equipment was subject to an endangerment analysis. The construction and execution of

the device corresponds to the today's state-of-the-art. The device is reliable in service when

operated according to its intended use.

VERY DANGEROUS! Injury or mortal danger!

The equipment is not certified for the employment in areas with explosive gas

air mixtures (zone 0).

SF6-Aciditor

11

5 Introduction

The increased application of SF6 in gas-insulated electrical equipment, such as switchgear or

transmission lines, has led to many recent analytical investigations on the stability and

decomposition of SF

6

. Although SF6 shows great chemical inertness it decomposes under

electrical stress, in the presence of arcs, sparks or partial discharges. Among the products

found are species such as SOF

2

, SO2F2, SOF4, S2F10, SO2, HF, SiF4 and others.

The decomposition of SF

6

further

depends on gas pressure,

electrode materials and the inner

surface materials of the

equipment. Despite the proven

reliability of such components in

the electrical power distribution

systems, failures occur due to the

above mentioned SF

6

aging under

electrical stress.

The laboratory analysis of

decomposition products were carried out by gas chromatography, gas chromatography/

mass spectrometry or infrared spectroscopy. The methods described above are complicated,

expensive, require specially trained personnel and can only be used in a laboratory.

Using ion mobility spectrometer (IMS) a good quality assessment of the SF

6

in SF6-filled

compartment can be achieved. The IMS is calibrated to measure all kind of decomposition

products in sum and in combination with a moisture sensor and SF

6

percentage sensor a

comprehensive monitoring of the SF

6

can be achieved. For monitoring the quality of SF6

G.A.S. recommends to use a multi-functional device with a combination of the above

mentioned sensors such as, the SF

6

-Analyser or SF6-Breaker-Analyser, that allows to

implement a Condition Based Maintenance (CBM) and a fault detection at an early stage via

a gas analytical approach (see www.gas-dortmund.de).

SF6-Aciditor

12

5.1 Working Principle

The SF6-Aciditor is a stand-alone device designed to quickly and accurately measure the

amount of sulfur dioxide (SO

2

) in SF6. Because the unit contains an automatic flow and

pressure control module, the user does not need to be concerned with setting the correct

flow rate, or compensating for variations in equipment pressure. All readings are displayed in

real-time on the touchpad display, in parts per million volume (ppm

v

).

The SF

6

-Aciditor has been particularly developed to be used on arced or otherwise stressed

SF

6

. Unlike conventional decomposition testers, which require disposable detector tubes, this

unit uses an electro-chemical sensor (catalytic principle).

The applied electro-chemical sensor incorporates a gold based, three electrodes and acid

electrolyte system.

The introduced SF

6

diffuses into the SO2-sensor. Here it reacts at the sensing electrode

through an oxidative process, according to the following equation:

Equation 1: Sensing process

Sulphur Dioxide (SO

2

): SO2 + 2H2O = H2SO4 + 2H+ + 2e-

The Counter electrode acts to balance the reaction at the sensing electrode, by means of an

oxygen reduction forming water as a consequence.

Equation 2: Counter reaction:

Oxygen Reduction: 1/2O

2

+ 2H+ + 2e- = H2O

The two equations represent the overall cell reaction as follows:

SO

2

+ 1/2O2 + H2O = H2SO4

In case of a SO

2

presence within the SF6 under inspection, equation 1 changes its electrochemical potential and electrons are released consecutively. Thus a change of currency is

detected and converted to ppm

v

-values.

The applied sensor carries a transmitter board that includes a temperature compensation

and a calibration in the specified range.

SF6-Aciditor

13

While the sensor must be replaced (by the user) every 2 years, its accuracy and sensitivity

do not strongly degrade due to use (<2% per month). Calibration is not required. The

universally accepted CIGRE B3.02.01 standard for re-usable SF

6

is currently 12 ppmv for

SO

2

/SOF2 – which falls well within the 0-100ppmv (standard) range of the SF6-Aciditor.

Main features:

• Compact, lightweight

• Low maintenance effort

• Cost effective

• No consumables required

• Highly sensitive

• Touch-screen interface

• Fast results, typically < 15 seconds

• Battery supply (min. 10 hours)

SF6-Aciditor

14

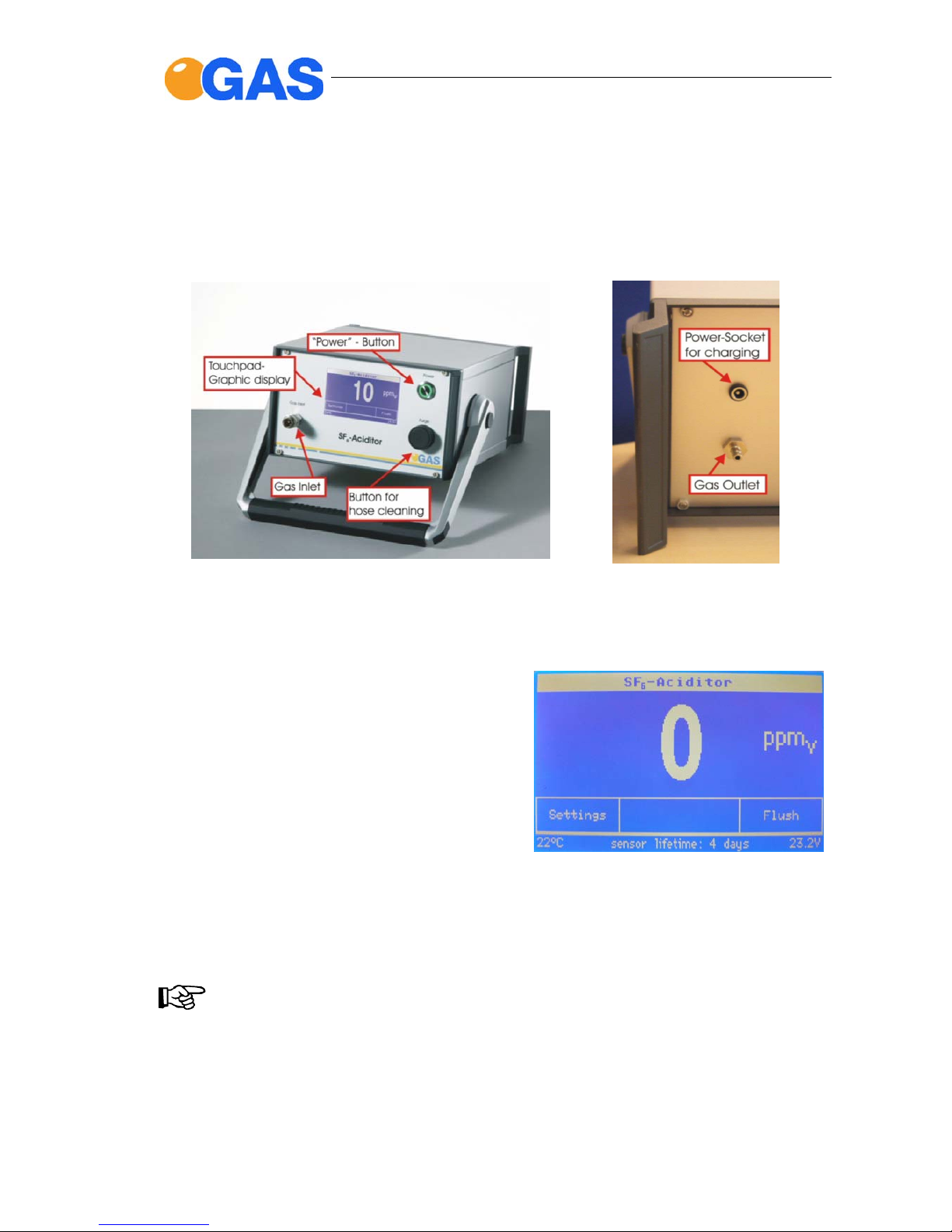

6 System Operation

6.1 Loading of Battery

The SF6-Aciditor is equipped with a 3.2Ah Lithium-Ion battery which allows to operate the

device for more than 10 hours. If the voltage which is always displayed during operation

drops under 21V a warning message “Low battery” appears on the display. An automatic

shutdown of the SF

6

-Aciditor will be executed if the voltage drops under 18V. The voltage is

at maxima at 25.2V.

For recharging the battery:

1. Turn off the SF

6

-Aciditor.

2. Connect the power plug connector of the

delivered battery charger to the power socket.

3. Plug the instrument’s connector into the socket

on the back plane (see picture).

4. Wait until the red charge lamp of the battery

charger is extinguished. The battery is charged

with a charge current of 1.5 A and a voltage of

25.2V. The maximum charge time of an empty

battery is approx. 2,5 hours.

5. Disconnect the plugins.

6. The SF

6

-Aciditor is again ready for measuring.

SF6-Aciditor

15

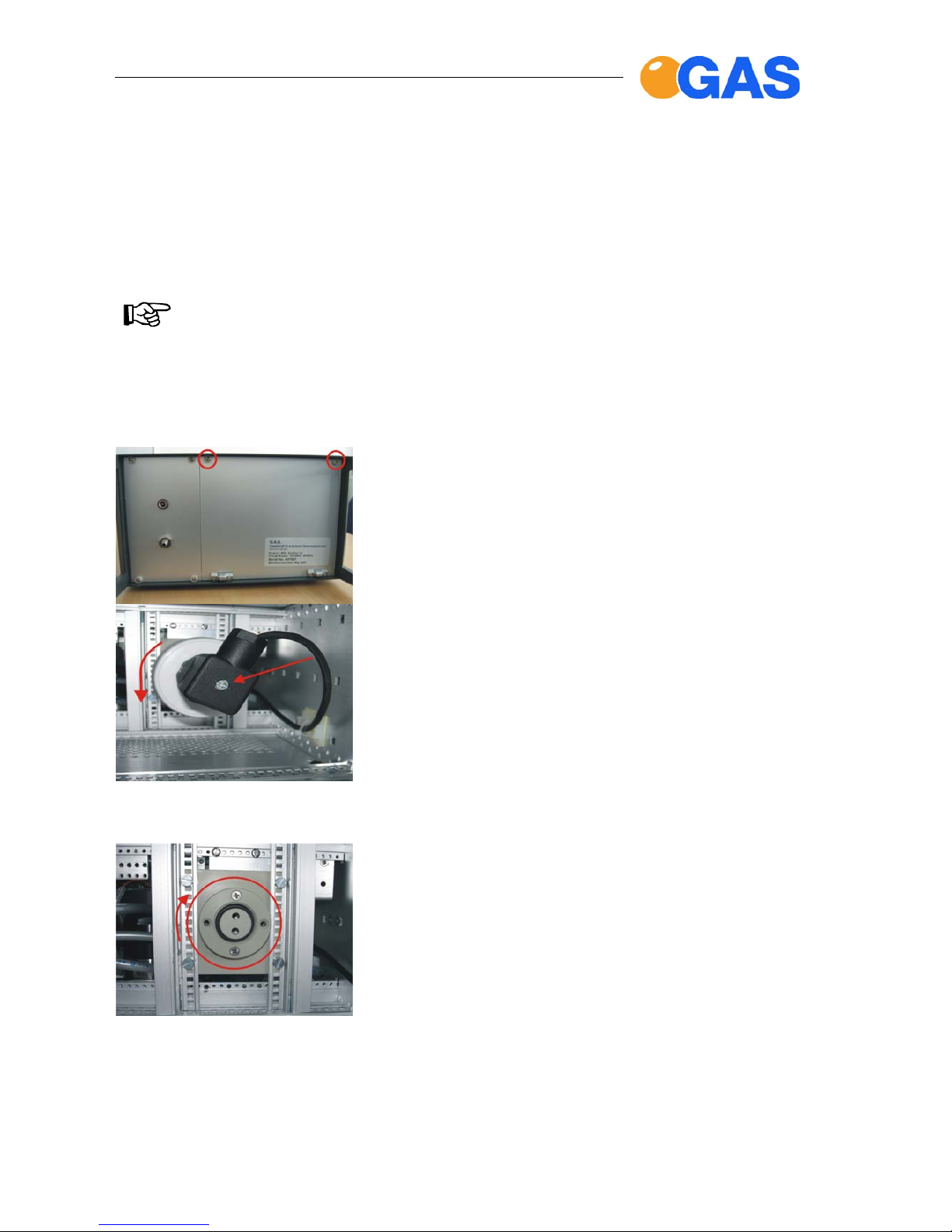

6.2 Insertion of the SO2-Sensor

Before operation of the SF6-Aciditor the SO2-Sensor that comes in a separate plastic foil has

to be insert. How to insert the sensor inside the SF

6

-Aciditor is described step by step as

follows:

1. Assure that the SF

6

-Aciditor has been

turned off.

2. Unscrew the marked screws on the back

panel of the SF

6

-Aciditor and turn down the

partial back panel.

3. Open the foil sealing of the SO

2

-sensor

and take out the sensor.

4. Insert the winding of the SO

2

-sensor into

the indicated thread of the back plane (red

marked in the picture) and turn it right while

pressing it lightly.

5. Turn the sensor until reaching the

bedstop. Mount the adapter as shown on the

picture and fix the screw (red marked).

6. Turn the partial back panel up and fix the

marked screws.

SF6-Aciditor

16

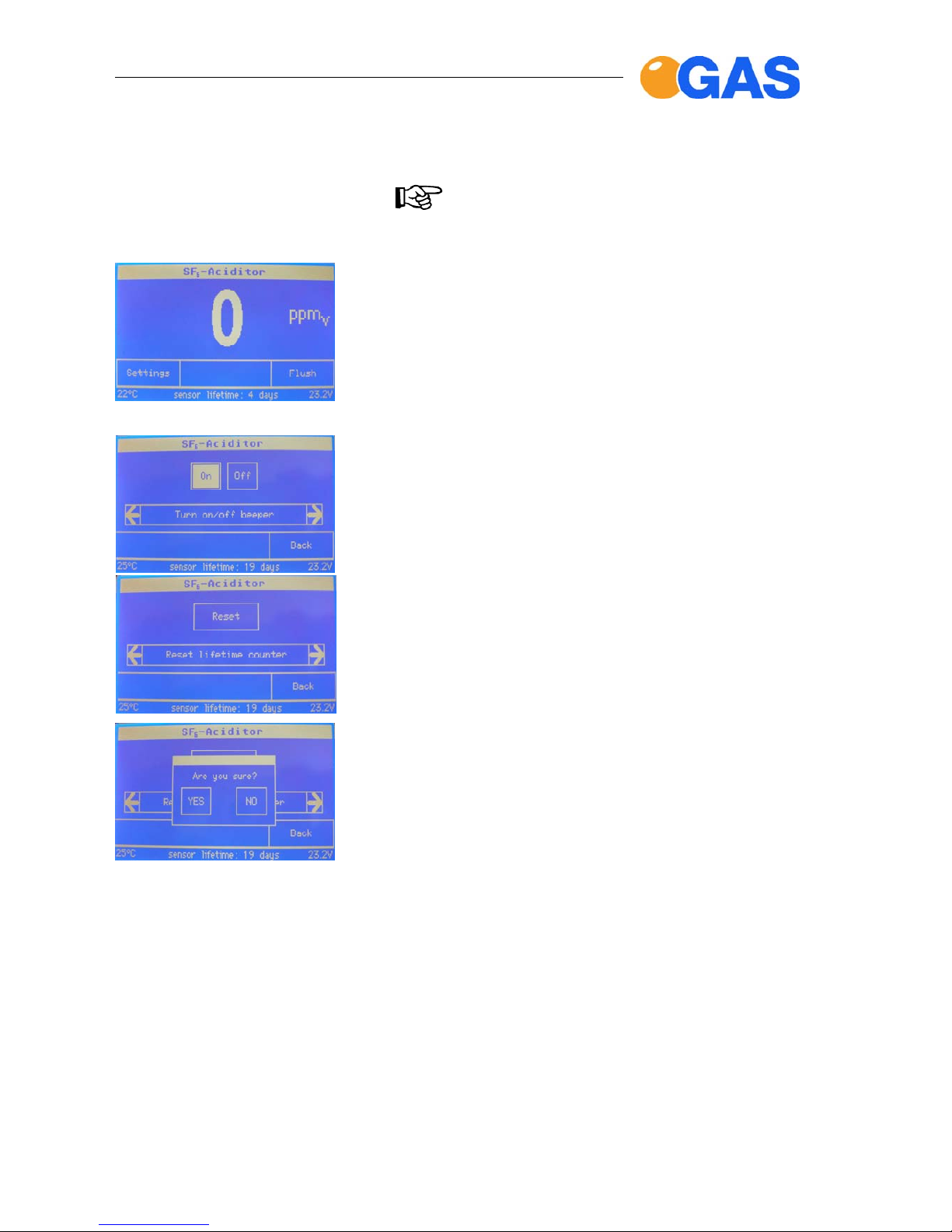

Note:

Carry out the following steps without a gas

connection to the hose!

7. Turn on the SF

6

-Aciditor using the

“Power”-switch on the front panel of the

device and wait until the main screen is

displayed (see picture). Pressing “Settings”

on the touchpad display opens the first menu

point.

8. Pressing the right arrow leads to the

second menu point for resetting the lifetime

counter.

9. For resetting the lifetime counter press

“Reset” on the touchpad display.

10. Confirm the resetting by pressing “YES”.

Executing “Back” on the touchpad display

switches back to the main screen. The SF

6

Aciditor is now ready for operation or can be

turned off using the power button on the

front panel.

SF6-Aciditor

17

6.3 Operation of the SF6-Aciditor

For operating the SF6-Aciditor the following instructions and information are needed.

The following steps explain how to operate the SF

6

-Aciditor in detail.

1. Turn on the SF

6

-Aciditor using the

“Power”-switch on the front panel of the

device and wait until the main screen is

displayed (see picture).

2. Connect a sampling bag or a recycling

system at the “Gas Outlet” on the back of

the SF

6

-Aciditor (optional).

3. Connect the SF

6

-Aciditor (Gas Inlet) with the delivered hose (equipped with self-

sealing quick-connectors) and appropriate adapters to the SF

6

-filled compartment.

4. Open the valve at the SF

6

-filled compartment.

Information!

The SF

6

-Aciditor has no internal valve. If there is an open connection to an

SF

6

-filled compartment, the gas passes through the device with 20 L/h. This,

independently whether the device is turned on or off !!

SF6-Aciditor

18

5. To clean the tube press the “Purge”-button for approx. 4 seconds.

6. After letting off the finger, the measurement immediately starts. The final value of the

measurement is reached when there are no further changes of the displayed value.

The SF

6

-Aciditor needs less than 2 minutes to reach the final value. The SF6-Aciditor

works at ambient pressure and is temperature compensated up to 60 °C.

7. After measuring a SO

2

content over zero the sensor has to be purged. Please look at

chapter 6.4.

8. Disconnect the SF

6

-Aciditor from the SF6-filled compartment.

9. Disconnect the connected sampling bag or recycling system from the “Gas Outlet” on

the back of the SF

6

-Aciditor (optional).

10. Assure that the hose has been

disconnected. Turn off the SF

6

-Aciditor by

pressing the “Power”-switch on the front

panel. For a longer lifetime of the sensor

ambient air will be pumped through the

sensor for 10 seconds. The sensor needs

some residual humidity to extend its

lifetime. Therefore ambient air is

automatically pumped through the sensor

to store it with some humidity.

Information!

The SF

6

-Aciditor has an internal flow rate regulation. Independently from the

compartment pressure the SF

6

-Aciditor measures at ambient pressure with a

flow of 20 L/h. Allowed inlet pressure: 0.5 to 35 bar.

Information!

Using a recycling system or sampling bag closely watch the filling status

of it !! The SF

6

-Aciditor has no automatic turn off or any other safety

system in case of an overpressure inside the device because of a filled

sampling bag or recycling system.

Information!

Before turning of the SF

6

-Aciditor the hose has to be disconnected. Otherwise

SF

6

instead of air will be pumped through the sensor and the lifetime of the

sensor will decrease.

SF6-Aciditor

19

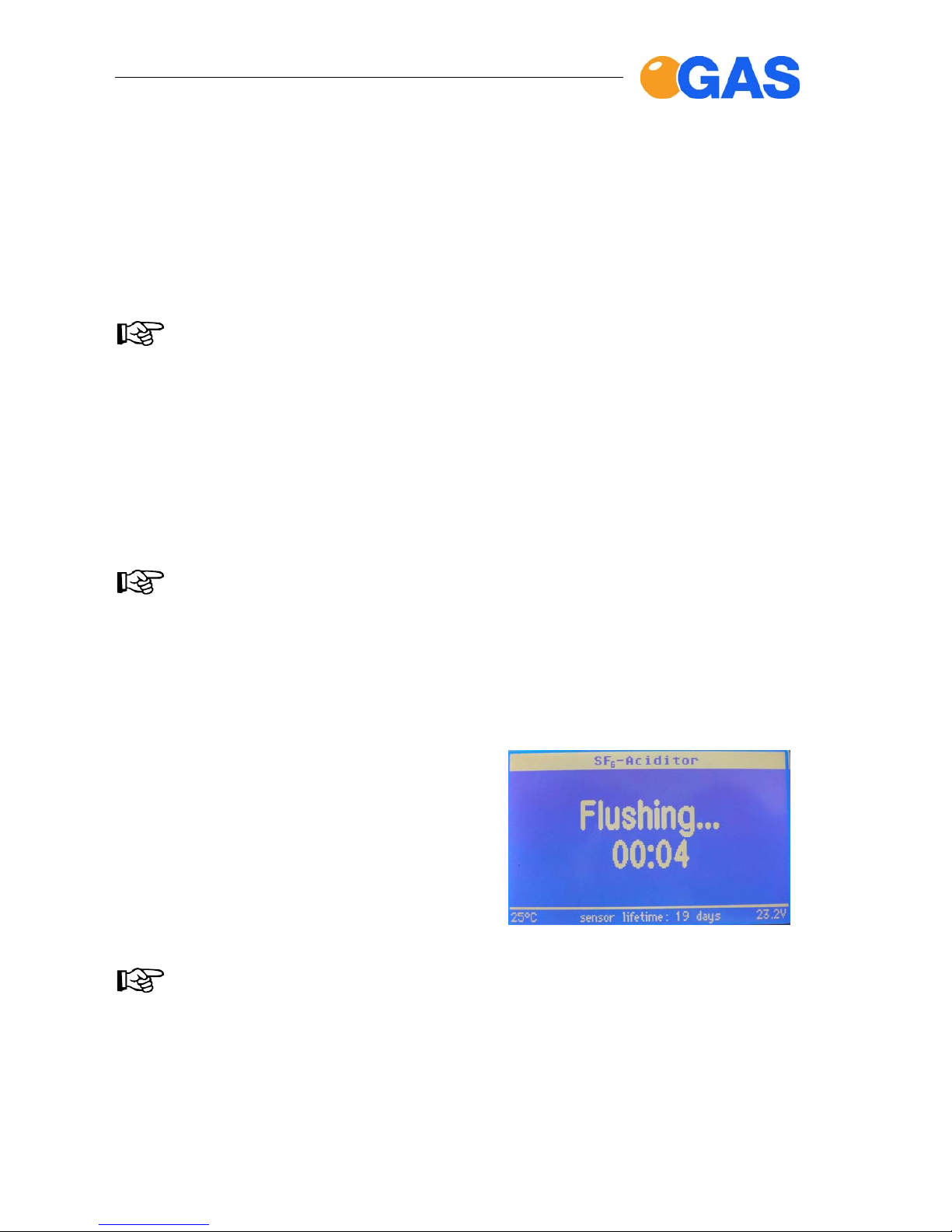

6.4 Purging of the SF6-Aciditor

After measuring a SF6 sample with an SO2 concentration above zero the SO2-sensor has to

be purged with ambient air. Therefore keep SF

6

-Aciditor turned on, disconnect the hose at

the gas inlet and press “Flush” on the touchpad display. The pump starts pumping ambient

air through the sensor (see picture).

Air has to be pumped through the sensor until the SO

2

concentration has again reached 0

ppm

v

. The pumping process can be aborted by pressing “Flush” on the touchpad display.

The SF

6

-Aciditor is again ready for operation.

Information!

For a longer lifetime and a correct reading the SO

2

-sensor has to be purged

after each time measuring a SO

2

-concentration > 0 ppmv.

DO NOT FORGET TO DISCONNECT THE HOSE BEFORE !!

SF6-Aciditor

20

6.5 Settings

For adjusting the settings of the SF6-Aciditor press “Settings” on the touchpad display. The

following screen appears.

6.5.1 Turn on/off beeper

In the first menu point the beeper for all acoustic signals like keypad tones, alarm tones, etc.

can be turned on and off. The white marked button “On” shows the active status of the

device. To switch to the other status, touch the non marked button.

In order reach the next menu point press the right arrow on the touchpad.

6.5.2 Reset lifetime counter

In the second menu point of settings it is possible to reset the lifetime counter of the SO

2

-

sensor. The SO

2

-sensor has a recommended lifetime of two years. The lifetime counter

which is displayed on the bottom of the screen in every menu point counts up every day.

After two years installed in the SF

6

-Aciditor a warning reminds the operator to exchange the

SO

2

-sensor. The lifetime counter has to be reset after every installation.

SF6-Aciditor

21

Pressing the left arrow on the touchpad switches back to the first menu point of “Settings”. To

go back to the main screen press “Back”.

Information!

Using the SO

2

-sensor for more than two years leads to an incorrect reading of

the sensor. (<2% per month of signal degradation)

SF6-Aciditor

22

6.6 Exchange of the sensor

The SO2-sensor installed inside the SF6-Aciditor has a recommended lifetime of two years to

guarantee a correct reading. The lifetime counter on the bottom of the screen reminds the

operator when to replace it. The exchange the SO

2

-sensor is described in detail below.

1. Assure that the SF

6

-Aciditor is turned off.

2. Loosen the marked screws on the back

panel of the SF

6

-Aciditor and turn down the

partial back panel.

3. Loosen the screw of the adapter (red

marked) and remove the adapter from the

sensor. Turn the sensor until the sensor is

out of the thread of the backplane.

4. Open the foil sealing of the new SO

2

-

sensor and take out the sensor.

5. Insert the winding of the SO

2

-sensor into

the indicated thread of the back plane (red

marked in the picture) and turn it right while

pressing it lightly.

Information!

Using the SO

2

-sensor for more than two years is not recommended due to the

excessive signal degradation (<2% per month).

SF6-Aciditor

23

6. Turn right the sensor until reaching the

bedstop. Mount the adapter as shown on the

picture and fix the screw (red marked).

7. Turn up the partial back panel and fix the

marked screws.

Note:

Carry out the following steps without a gas

connection to the hose!

8. Turn on the SF

6

-Aciditor using the

“Power”-switch on the front panel of the

device and wait until the main screen is

displayed (see picture). Pressing “Settings”

on the touchpad display opens the first

Setting menu point.

9. Pressing the right arrow leads to the

second menu point for resetting the lifetime

counter.

10. For resetting the lifetime counter press

“Reset” on touchpad display.

SF6-Aciditor

24

11. Confirm the resetting by pressing “YES”.

Executing “Back” on the touchpad display

switches back to the main screen. The SF

6

Aciditor is now ready for operation again or

can be turned off using the power button on

the front panel.

SF6-Aciditor

25

7 Technical Data

Measurement Principle

Electro-chemical (catalytic principle)

Range

0-100 ppm

v

(standard), alternatively 0-10 ppm

v

or 0-500 ppm

v

Readings

Temperature compensated

Resolution: 1 ppmv for 0 - 100 ppmy sensor

0.1 ppmv for 0 - 10 ppmy sensor

3 ppmv for 0 – 500 ppmv sensor

Response time T 90

<15s

Humidity range

Up to 90 % non-condensating

Lifetime

2 years from installation

Maximum zero shift

0.1 ppm

v

for all sensor types

Long-term stability

< 2 % signal degradation per month (linear)

Flow rate

< 20 L/h

Measuring time

approx. 2 minutes

⊄ Gas consumption

approx. 0.7 L per measurement at ambient pressure

Pressure

0.5-35 bar (gaseous) / automatic flow rate regulation

Operation

Purge function for hose cleaning

Cleaning function with ambient air

Display

Touchpad – Graphic display (240x128 Pixel)

Supply

Lithium-Ion battery with min. 10 h capacity

Rechargeable 100-265 AC V 50/60Hz

Battery voltage displayed

Temperature

Storage: -10 to 60 °C

Operation: 0 to 50 °C

Calibration

None required

Dimension

280 x 140 x 300 mm (WxHxL)

Weight

approx. 6 kg

Loading...

Loading...