This is the brilliant new star among automatic turntables, featuring zero degree tracking error and 12 other major advances.

- Page The Zero 100 true tangent tone arm 2 plus 2 15% vertical tracking adjustment 4 Cartridge overhang adjustments 4 Sliding weight stylus force setting 4 Magnetic anti-skating control 5 Variable speed ±3% 6 Illuminated stroboscope 6 Interchangeable spindles 6

- Patented Synchro-Lab Motor

- Kinetically matched turntable

- Gentle 2-point record support

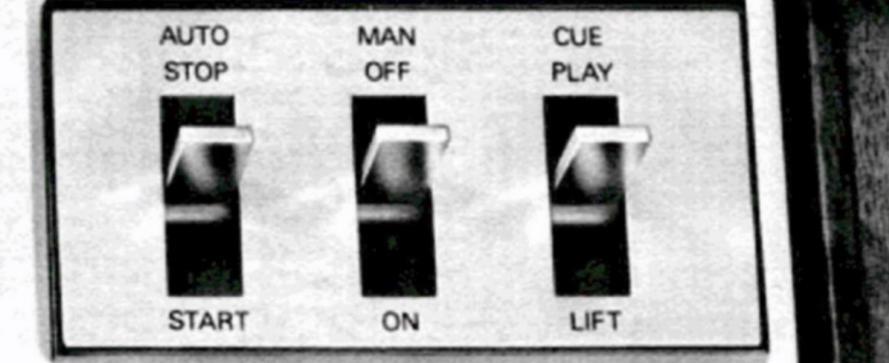

- Separate control tabs for Auto; Manual; Cueing/Pausing

Again, the innovator!

The components that comprise high fidelity systems have become increasingly sophisticated. In turn, the demands placed on the automatic turntable for higher performance standards have also increased. These stringent requirements have led to higher price categories for automatic turntables than ever before.

Nevertheless, the Garrard Laboratories resisted the temptation to build a so-called "super changer", until they were satisfied that sufficiently meaningful improvements were feasible, to justify the establishment of such a new product category.

Over the years, Garrard has invented, pioneered and introduced virtually every significant new feature in automatic record playing units. Many of these have been revolutionary, and together they have upgraded the entire character of the automatic turntable.

But change, merely for the sake of change, has been sternly resisted.

Therefore, such notable innovations as anti-skating controls, built-in stylus pressure gauges, cueing and pause controls, dynamically balanced low mass tone arms and combination synchronous-induction motors (to name a few) were first introduced on Garrard automatic turntables ... but only after the need was established and they were thoroughly researched, tested and perfected. Today, they are standard on most of the higher-priced automatic turntables of all manufacturers.

The Zero 100 is a dramatic new concept, with styling as advanced as its features. It is a new classic, which others will emulate for years to come.

While the appearance of a product does not improve performance, it does connote craftsmanship and quality – and reflects the aesthetics most people appreciate in products which are precision-engineered. In the Zero 100, new materials have been used – such as plexiglas, brass, machined parts, satin finish aluminum – all set off on a sparkling white unit plate. Garrard has made the Zero 100 the very personification of quality.

The revolutionary ne

Only Automatic Turntable with

This is the brilliant new star among automatic turntables, featuring zero degree tracking error and 12 other major advances.

- Page The Zero 100 true tangent tone arm 2 plus 2 15% vertical tracking adjustment 4 Cartridge overhang adjustments 4 Sliding weight stylus force setting 4 Magnetic anti-skating control 5 Variable speed ±3% 6 Illuminated stroboscope 6 Interchangeable spindles 6

- Patented Synchro-Lab Motor

- Kinetically matched turntable

- Gentle 2-point record support

- Separate control tabs for Auto; Manual; Cueing/Pausing

Again, the innovator!

The components that comprise high fidelity systems have become increasingly sophisticated. In turn, the demands placed on the automatic turntable for higher performance standards have also increased. These stringent requirements have led to higher price categories for automatic turntables than ever before.

Nevertheless, the Garrard Laboratories resisted the temptation to build a so-called "super changer", until they were satisfied that sufficiently meaningful improvements were feasible, to justify the establishment of such a new product category.

Over the years, Garrard has invented, pioneered and introduced virtually every significant new feature in automatic record playing units. Many of these have been revolutionary, and together they have upgraded the entire character of the automatic turntable.

But change, merely for the sake of change, has been sternly resisted.

Therefore, such notable innovations as anti-skating controls, built-in stylus pressure gauges, cueing and pause controls, dynamically balanced low mass tone arms and combination synchronous-induction motors (to name a few) were first introduced on Garrard automatic turntables ... but only after the need was established and they were thoroughly researched, tested and perfected. Today, they are standard on most of the higher-priced automatic turntables of all manufacturers.

The Zero 100 is a dramatic new concept, with styling as advanced as its features. It is a new classic, which others will emulate for years to come.

While the appearance of a product does not improve performance, it does connote craftsmanship and quality – and reflects the aesthetics most people appreciate in products which are precision-engineered. In the Zero 100, new materials have been used – such as plexiglas, brass, machined parts, satin finish aluminum – all set off on a sparkling white unit plate. Garrard has made the Zero 100 the very personification of quality.

The revolutionary ne

Only Automatic Turntable with

This is the brilliant new star among automatic turntables, featuring zero degree tracking error and 12 other major advances.

- Page The Zero 100 true tangent tone arm 2 plus 2 15% vertical tracking adjustment 4 Cartridge overhang adjustments 4 Sliding weight stylus force setting 4 Magnetic anti-skating control 5 Variable speed ±3% 6 Illuminated stroboscope 6 Interchangeable spindles 6

- Patented Synchro-Lab Motor

- Kinetically matched turntable

- Gentle 2-point record support

- Separate control tabs for Auto; Manual; Cueing/Pausing

Again, the innovator!

The components that comprise high fidelity systems have become increasingly sophisticated. In turn, the demands placed on the automatic turntable for higher performance standards have also increased. These stringent requirements have led to higher price categories for automatic turntables than ever before.

Nevertheless, the Garrard Laboratories resisted the temptation to build a so-called "super changer", until they were satisfied that sufficiently meaningful improvements were feasible, to justify the establishment of such a new product category.

Over the years, Garrard has invented, pioneered and introduced virtually every significant new feature in automatic record playing units. Many of these have been revolutionary, and together they have upgraded the entire character of the automatic turntable.

But change, merely for the sake of change, has been sternly resisted.

Therefore, such notable innovations as anti-skating controls, built-in stylus pressure gauges, cueing and pause controls, dynamically balanced low mass tone arms and combination synchronous-induction motors (to name a few) were first introduced on Garrard automatic turntables ... but only after the need was established and they were thoroughly researched, tested and perfected. Today, they are standard on most of the higher-priced automatic turntables of all manufacturers.

The Zero 100 is a dramatic new concept, with styling as advanced as its features. It is a new classic, which others will emulate for years to come.

While the appearance of a product does not improve performance, it does connote craftsmanship and quality – and reflects the aesthetics most people appreciate in products which are precision-engineered. In the Zero 100, new materials have been used – such as plexiglas, brass, machined parts, satin finish aluminum – all set off on a sparkling white unit plate. Garrard has made the Zero 100 the very personification of quality.

The revolutionary ne

Only Automatic Turntable with

Heart of the ZERO 100 is a revolutionary new tone arm

"ZERO" stands for Zero Tracking Error

The maintenance of zero degree tracking error over the full surface of the record has long been an experts' dream. From an engineering standpoint, the value of the principle is wellrecognized, not only for obtaining the finest sound reproduction and eliminating distortion, but for preserving the record grooves. The problem has been to obtain these results with minimal friction and realistic cost. Since the feature is so desirable, there have been some separate tone arms and manual combinations attempting to play records back with zero degree tracking error, but these have had unacceptable friction levels, or were unduly expensive. Certainly, they could not be used on automatic players.

Garrard has spent many years on this development, discarding hundreds of ideas which did not meet its criteria. Now, at last, this advancement of the first magnitude is presented for home use on the Zero 100 automatic turntable.

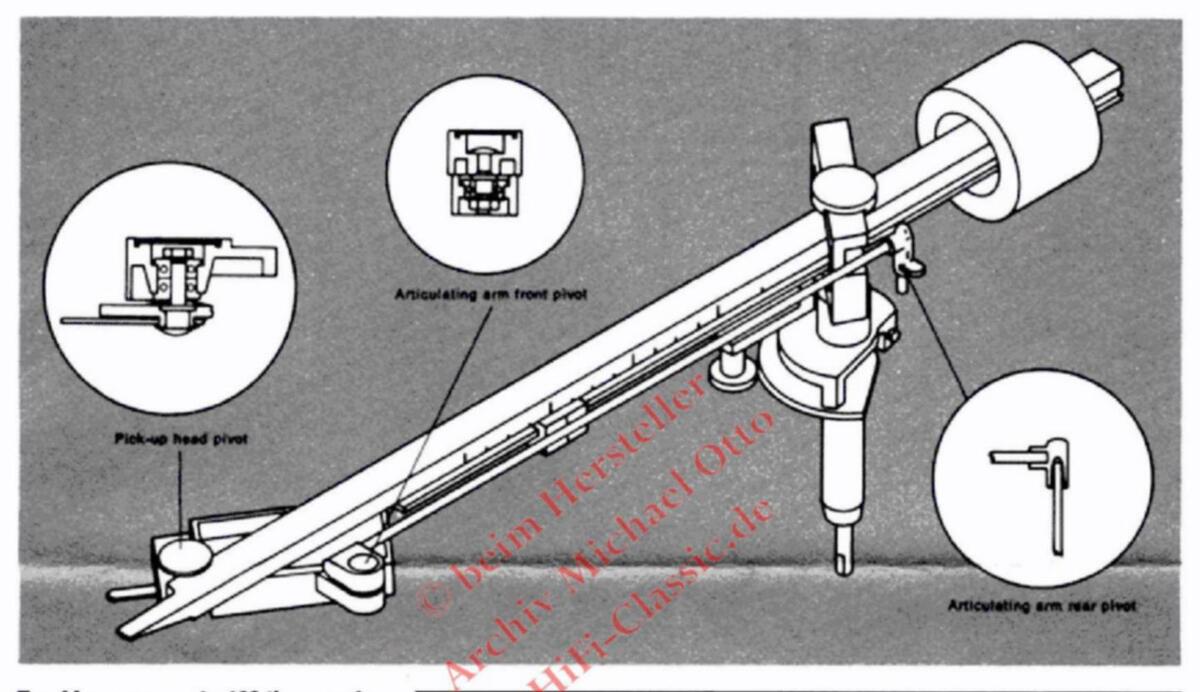

How the arm is built

In common with many examples of engineering ingenuity, the solution to the problem of tracking error looks deceptively simple on the surface.

The new arm is designed so that the cartridge housing is pivoted directly above the stylus tip. The degree of pivot is controlled by an auxiliary articulating arm. The amount of cartridge head pivoting, the length and position of the articulating arm...indeed, all the complex geometrical problems involved... were solved and optimized by computer. Without this procedure, the successful design and execution of this tone arm would have been impossible.

The combination of computerized design and arm articulation through advanced pivotry, results in the tracking geometry shown in the diagram. Note that the stylus is perpendicularly tangent to the groove throughout the record – a dramatic achievement of primary importance in the search for perfect reproduction.

Heart of the ZERO 100 is a revolutionary new tone arm

"ZERO" stands for Zero Tracking Error

The maintenance of zero degree tracking error over the full surface of the record has long been an experts' dream. From an engineering standpoint, the value of the principle is wellrecognized, not only for obtaining the finest sound reproduction and eliminating distortion, but for preserving the record grooves. The problem has been to obtain these results with minimal friction and realistic cost. Since the feature is so desirable, there have been some separate tone arms and manual combinations attempting to play records back with zero degree tracking error, but these have had unacceptable friction levels, or were unduly expensive. Certainly, they could not be used on automatic players.

Garrard has spent many years on this development, discarding hundreds of ideas which did not meet its criteria. Now, at last, this advancement of the first magnitude is presented for home use on the Zero 100 automatic turntable.

How the arm is built

In common with many examples of engineering ingenuity, the solution to the problem of tracking error looks deceptively simple on the surface.

The new arm is designed so that the cartridge housing is pivoted directly above the stylus tip. The degree of pivot is controlled by an auxiliary articulating arm. The amount of cartridge head pivoting, the length and position of the articulating arm...indeed, all the complex geometrical problems involved... were solved and optimized by computer. Without this procedure, the successful design and execution of this tone arm would have been impossible.

The combination of computerized design and arm articulation through advanced pivotry, results in the tracking geometry shown in the diagram. Note that the stylus is perpendicularly tangent to the groove throughout the record – a dramatic achievement of primary importance in the search for perfect reproduction.

Heart of the ZERO 100 is a revolutionary new tone arm

"ZERO" stands for Zero Tracking Error

The maintenance of zero degree tracking error over the full surface of the record has long been an experts' dream. From an engineering standpoint, the value of the principle is wellrecognized, not only for obtaining the finest sound reproduction and eliminating distortion, but for preserving the record grooves. The problem has been to obtain these results with minimal friction and realistic cost. Since the feature is so desirable, there have been some separate tone arms and manual combinations attempting to play records back with zero degree tracking error, but these have had unacceptable friction levels, or were unduly expensive. Certainly, they could not be used on automatic players.

Garrard has spent many years on this development, discarding hundreds of ideas which did not meet its criteria. Now, at last, this advancement of the first magnitude is presented for home use on the Zero 100 automatic turntable.

How the arm is built

In common with many examples of engineering ingenuity, the solution to the problem of tracking error looks deceptively simple on the surface.

The new arm is designed so that the cartridge housing is pivoted directly above the stylus tip. The degree of pivot is controlled by an auxiliary articulating arm. The amount of cartridge head pivoting, the length and position of the articulating arm...indeed, all the complex geometrical problems involved... were solved and optimized by computer. Without this procedure, the successful design and execution of this tone arm would have been impossible.

The combination of computerized design and arm articulation through advanced pivotry, results in the tracking geometry shown in the diagram. Note that the stylus is perpendicularly tangent to the groove throughout the record – a dramatic achievement of primary importance in the search for perfect reproduction.

Advanced pivotry for minimal friction The extremely low — in fact, negligible friction — which is essential to this concept, has been achieved with costly, precision-loaded ball bearings, and a free-floating universal pivot. These are among the very few parts of the Zero 100 which Garrard does not build. Instead, they are purchased from an outstanding manufacturer specializing entirely in the design and construction of

pivots for gyroscopes and other sophisticated space-age equipment. The articulating arm, which depends upon this advanced pivotry, is fashioned of stainless steel tube by Garrard.

Records are made with the cutter perpendicular (tangent at right angle) to each groove. When a conventional tone arm plays this back, the arm describes an arc from its pivot. Because of the fixed head, it produces a varying

amount of tracking error, which can only measure zero at the two points where the cartridge is truly perpendicular to the groove. Tracking error, therefore, is inherent in the performance of all conventional tone arms. It is measured and expressed in degrees per inch. It produces distortion in the second harmonic, and, until now, could not be successfully eliminated by any tone arm on automatic playback units.

Tracking error up to 160 times as low per inch as standard tone arm!

A comparison of the tracking error measurements of any conventionally pivoted tone arm with those of the Zero 100, indicates the magnitude of the breakthrough which Garrard has achieved.

Consider that there are 3,600 seconds of arc in a degree ... and that a conventional tone arm may produce tracking error as high as 4 degrees, or 14,400 seconds at its full playing radius. The tracking error of the Zero 100 tone arm is calculated to measure a remarkable 90 seconds, placing it in the area of 160 times as small per inch as the error of conventional tone arms.

The true tangent tone arm clearly establishes the Zero 100 as a revolutionary development of the first order.

Conversely, above and beyond the tone arm, the features described on the following pages place the Zero 100 in a class by itself, at the very forefront of all automatic turntables available today.

Advanced pivotry for minimal friction The extremely low — in fact, negligible friction — which is essential to this concept, has been achieved with costly, precision-loaded ball bearings, and a free-floating universal pivot. These are among the very few parts of the Zero 100 which Garrard does not build. Instead, they are purchased from an outstanding manufacturer specializing entirely in the design and construction of

pivots for gyroscopes and other sophisticated space-age equipment. The articulating arm, which depends upon this advanced pivotry, is fashioned of stainless steel tube by Garrard.

Records are made with the cutter perpendicular (tangent at right angle) to each groove. When a conventional tone arm plays this back, the arm describes an arc from its pivot. Because of the fixed head, it produces a varying

amount of tracking error, which can only measure zero at the two points where the cartridge is truly perpendicular to the groove. Tracking error, therefore, is inherent in the performance of all conventional tone arms. It is measured and expressed in degrees per inch. It produces distortion in the second harmonic, and, until now, could not be successfully eliminated by any tone arm on automatic playback units.

Tracking error up to 160 times as low per inch as standard tone arm!

A comparison of the tracking error measurements of any conventionally pivoted tone arm with those of the Zero 100, indicates the magnitude of the breakthrough which Garrard has achieved.

Consider that there are 3,600 seconds of arc in a degree ... and that a conventional tone arm may produce tracking error as high as 4 degrees, or 14,400 seconds at its full playing radius. The tracking error of the Zero 100 tone arm is calculated to measure a remarkable 90 seconds, placing it in the area of 160 times as small per inch as the error of conventional tone arms.

The true tangent tone arm clearly establishes the Zero 100 as a revolutionary development of the first order.

Conversely, above and beyond the tone arm, the features described on the following pages place the Zero 100 in a class by itself, at the very forefront of all automatic turntables available today.

Advanced pivotry for minimal friction The extremely low — in fact, negligible friction — which is essential to this concept, has been achieved with costly, precision-loaded ball bearings, and a free-floating universal pivot. These are among the very few parts of the Zero 100 which Garrard does not build. Instead, they are purchased from an outstanding manufacturer specializing entirely in the design and construction of

pivots for gyroscopes and other sophisticated space-age equipment. The articulating arm, which depends upon this advanced pivotry, is fashioned of stainless steel tube by Garrard.

Records are made with the cutter perpendicular (tangent at right angle) to each groove. When a conventional tone arm plays this back, the arm describes an arc from its pivot. Because of the fixed head, it produces a varying

amount of tracking error, which can only measure zero at the two points where the cartridge is truly perpendicular to the groove. Tracking error, therefore, is inherent in the performance of all conventional tone arms. It is measured and expressed in degrees per inch. It produces distortion in the second harmonic, and, until now, could not be successfully eliminated by any tone arm on automatic playback units.

Tracking error up to 160 times as low per inch as standard tone arm!

A comparison of the tracking error measurements of any conventionally pivoted tone arm with those of the Zero 100, indicates the magnitude of the breakthrough which Garrard has achieved.

Consider that there are 3,600 seconds of arc in a degree ... and that a conventional tone arm may produce tracking error as high as 4 degrees, or 14,400 seconds at its full playing radius. The tracking error of the Zero 100 tone arm is calculated to measure a remarkable 90 seconds, placing it in the area of 160 times as small per inch as the error of conventional tone arms.

The true tangent tone arm clearly establishes the Zero 100 as a revolutionary development of the first order.

Conversely, above and beyond the tone arm, the features described on the following pages place the Zero 100 in a class by itself, at the very forefront of all automatic turntables available today.

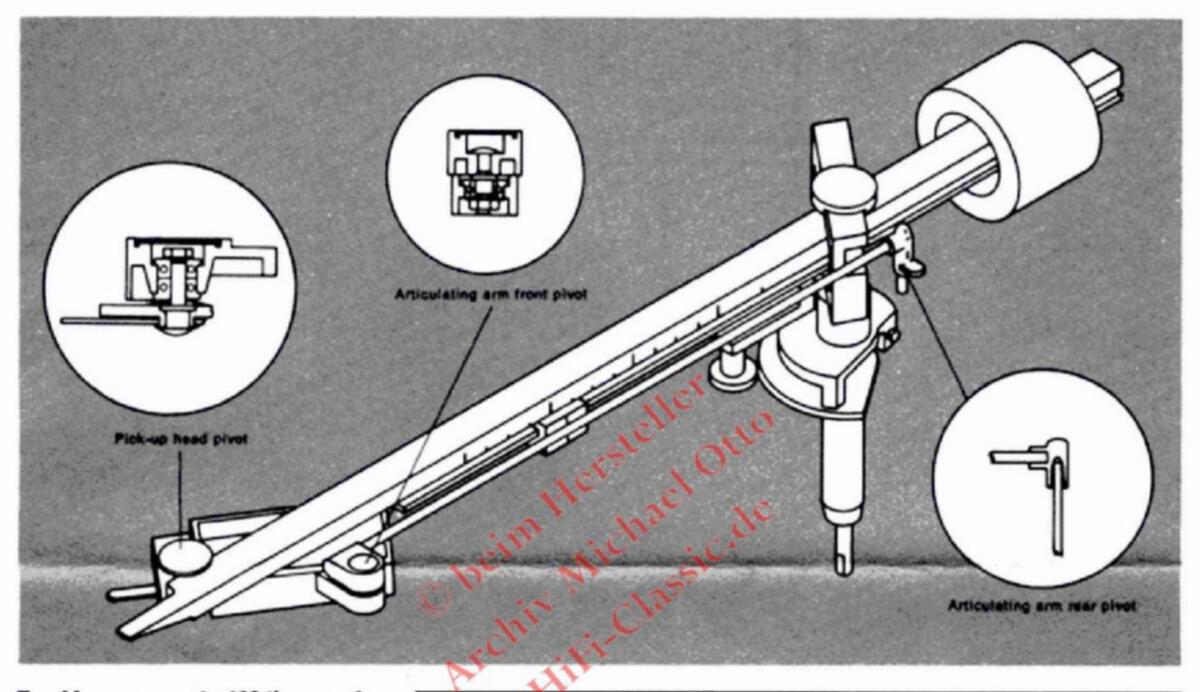

Sliding weight for setting etylus force along an extended scale

In order to impart stability and precision to the increasingly important stylus force setting, the Zero 100 tone arm utilizes a brass weight which slides under the arm.

With the weight set at "Zero", the arm is balanced to a neutral "see-saw" position. The weight is then moved forward under the arm to set in the correct stylus force. It is frictionally engaged to

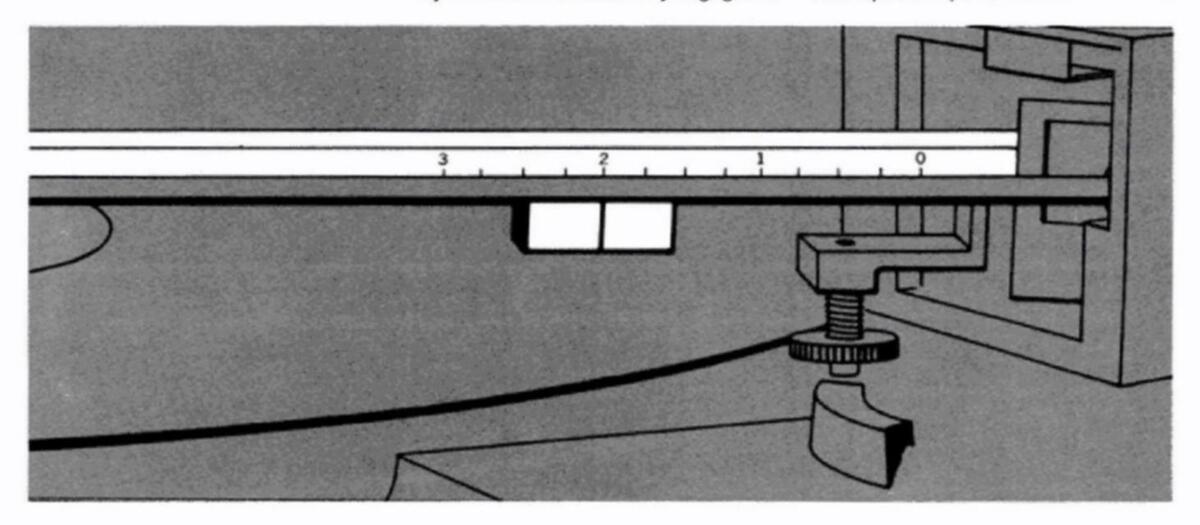

15" Vertical tracking adjustment

Discs are recorded with the cutter set at 15". Therefore, for the finest reproduction, the stylus should approach this angle as closely as possible. The Zero 100 tone arm shell provides an adjustment lever for this purpose. When single records are played, a flick of the lever to "Manual" sets the cartridge and stylus angle at precisely 15". When a stack of records is played, the lever is moved to "Automatic," and the angle of the stylus will be precisely 15* at the third record.

Cartridge overhang adjustment

In order to assure the full benefits of zero degrees tracking error, and the 15° adjustment, the stylus tip must be positioned with absolute accuracy. The slotted cartridge carrier of the Zero 100 is provided with a lucite gauge, used when the cartridge is mounted. The cartridge carrier is inserted into the gauge, and the cartridge is accurately positioned for mounting by simply moving it to the point where the stylus tip lines up with the two cross hairs on the gauge.

the tone arm, to retain its exact position; yet it can be easily moved when desired.

Since it requires a movement of 1%" to change the stylus force by one gram, a fraction of a gram can be set with extreme accuracy. This carries through the concept of the Zero 100 tone arm, which is designed to track the most sensitive cartridges at the precise fractional forces required for their optimum performance.

Sliding weight for setting etylus force along an extended scale

In order to impart stability and precision to the increasingly important stylus force setting, the Zero 100 tone arm utilizes a brass weight which slides under the arm.

With the weight set at "Zero", the arm is balanced to a neutral "see-saw" position. The weight is then moved forward under the arm to set in the correct stylus force. It is frictionally engaged to

15" Vertical tracking adjustment

Discs are recorded with the cutter set at 15". Therefore, for the finest reproduction, the stylus should approach this angle as closely as possible. The Zero 100 tone arm shell provides an adjustment lever for this purpose. When single records are played, a flick of the lever to "Manual" sets the cartridge and stylus angle at precisely 15". When a stack of records is played, the lever is moved to "Automatic," and the angle of the stylus will be precisely 15* at the third record.

Cartridge overhang adjustment

In order to assure the full benefits of zero degrees tracking error, and the 15° adjustment, the stylus tip must be positioned with absolute accuracy. The slotted cartridge carrier of the Zero 100 is provided with a lucite gauge, used when the cartridge is mounted. The cartridge carrier is inserted into the gauge, and the cartridge is accurately positioned for mounting by simply moving it to the point where the stylus tip lines up with the two cross hairs on the gauge.

the tone arm, to retain its exact position; yet it can be easily moved when desired.

Since it requires a movement of 1%" to change the stylus force by one gram, a fraction of a gram can be set with extreme accuracy. This carries through the concept of the Zero 100 tone arm, which is designed to track the most sensitive cartridges at the precise fractional forces required for their optimum performance.

Sliding weight for setting etylus force along an extended scale

In order to impart stability and precision to the increasingly important stylus force setting, the Zero 100 tone arm utilizes a brass weight which slides under the arm.

With the weight set at "Zero", the arm is balanced to a neutral "see-saw" position. The weight is then moved forward under the arm to set in the correct stylus force. It is frictionally engaged to

15" Vertical tracking adjustment

Discs are recorded with the cutter set at 15". Therefore, for the finest reproduction, the stylus should approach this angle as closely as possible. The Zero 100 tone arm shell provides an adjustment lever for this purpose. When single records are played, a flick of the lever to "Manual" sets the cartridge and stylus angle at precisely 15". When a stack of records is played, the lever is moved to "Automatic," and the angle of the stylus will be precisely 15* at the third record.

Cartridge overhang adjustment

In order to assure the full benefits of zero degrees tracking error, and the 15° adjustment, the stylus tip must be positioned with absolute accuracy. The slotted cartridge carrier of the Zero 100 is provided with a lucite gauge, used when the cartridge is mounted. The cartridge carrier is inserted into the gauge, and the cartridge is accurately positioned for mounting by simply moving it to the point where the stylus tip lines up with the two cross hairs on the gauge.

the tone arm, to retain its exact position; yet it can be easily moved when desired.

Since it requires a movement of 1%" to change the stylus force by one gram, a fraction of a gram can be set with extreme accuracy. This carries through the concept of the Zero 100 tone arm, which is designed to track the most sensitive cartridges at the precise fractional forces required for their optimum performance.

Magnetic anti-skating control

Garrard introduced the first anti-skating device in an automatic turntable with its patented sliding weight design, which is still used in the (up-to-now) 3 top Garrard models.

An anti-skating control is necessary to offset the normal tendency of the tone arm to move (skate) across the record toward the center. As the disc revolves, with the arm tracking, an inward skating force is created which must be counteracted and neutralized by an equal force in the opposite direction. This prevents wear on the inner side of the groove, premature damage to the record, and distortion.

Now, a unique and exceptionally precise anti-skating control has been designed for the Zero 100 and built

into the tone arm assembly. A precision sliding scale, calibrated in fractions of a gram and reading conveniently from the top, shows the exact amount of anti-skating force being applied. The scale has two settings: one for elliptical; the other for conical stylii.

The simple but ingenious Zero 100 anti-skating control utilizes the wellknown magnetic principle that like poles repel each other. Built differently than any previous device of its kind, it is frictionless; not mechanically connected to the tone arm; and requires neither springs nor weights.

A ceramic disc magnet is mounted on the pivoting tone arm gimbal; and another affixed above it on the rigid plexiglas tone arm housing. A ferrous metal shield, with the precision reading

scale mounted on it, slides between the two magnets, to set the anti-skating force desired. When the shield is between the total areas of the magnets. they have no effect on each other, since the shield blocks the magnetic flux. However, as the shield is moved outward, it exposes the magnetic field, creating an infinitely variable amount of magnetic repulsion. This, in turn, exerts a controllable and measurable twisting force on the tone arm, as the two magnetic poles push apart, establishing the correct starting amount of anti-skating force desired, as indicated on the reading scale; and varying to the correct force required at every distance from the center of the record as the stylus moves inward along the radius.

Magnetic anti-skating control

Garrard introduced the first anti-skating device in an automatic turntable with its patented sliding weight design, which is still used in the (up-to-now) 3 top Garrard models.

An anti-skating control is necessary to offset the normal tendency of the tone arm to move (skate) across the record toward the center. As the disc revolves, with the arm tracking, an inward skating force is created which must be counteracted and neutralized by an equal force in the opposite direction. This prevents wear on the inner side of the groove, premature damage to the record, and distortion.

Now, a unique and exceptionally precise anti-skating control has been designed for the Zero 100 and built

into the tone arm assembly. A precision sliding scale, calibrated in fractions of a gram and reading conveniently from the top, shows the exact amount of anti-skating force being applied. The scale has two settings: one for elliptical; the other for conical stylii.

The simple but ingenious Zero 100 anti-skating control utilizes the wellknown magnetic principle that like poles repel each other. Built differently than any previous device of its kind, it is frictionless; not mechanically connected to the tone arm; and requires neither springs nor weights.

A ceramic disc magnet is mounted on the pivoting tone arm gimbal; and another affixed above it on the rigid plexiglas tone arm housing. A ferrous metal shield, with the precision reading

scale mounted on it, slides between the two magnets, to set the anti-skating force desired. When the shield is between the total areas of the magnets. they have no effect on each other, since the shield blocks the magnetic flux. However, as the shield is moved outward, it exposes the magnetic field, creating an infinitely variable amount of magnetic repulsion. This, in turn, exerts a controllable and measurable twisting force on the tone arm, as the two magnetic poles push apart, establishing the correct starting amount of anti-skating force desired, as indicated on the reading scale; and varying to the correct force required at every distance from the center of the record as the stylus moves inward along the radius.

Magnetic anti-skating control

Garrard introduced the first anti-skating device in an automatic turntable with its patented sliding weight design, which is still used in the (up-to-now) 3 top Garrard models.

An anti-skating control is necessary to offset the normal tendency of the tone arm to move (skate) across the record toward the center. As the disc revolves, with the arm tracking, an inward skating force is created which must be counteracted and neutralized by an equal force in the opposite direction. This prevents wear on the inner side of the groove, premature damage to the record, and distortion.

Now, a unique and exceptionally precise anti-skating control has been designed for the Zero 100 and built

into the tone arm assembly. A precision sliding scale, calibrated in fractions of a gram and reading conveniently from the top, shows the exact amount of anti-skating force being applied. The scale has two settings: one for elliptical; the other for conical stylii.

The simple but ingenious Zero 100 anti-skating control utilizes the wellknown magnetic principle that like poles repel each other. Built differently than any previous device of its kind, it is frictionless; not mechanically connected to the tone arm; and requires neither springs nor weights.

A ceramic disc magnet is mounted on the pivoting tone arm gimbal; and another affixed above it on the rigid plexiglas tone arm housing. A ferrous metal shield, with the precision reading

scale mounted on it, slides between the two magnets, to set the anti-skating force desired. When the shield is between the total areas of the magnets. they have no effect on each other, since the shield blocks the magnetic flux. However, as the shield is moved outward, it exposes the magnetic field, creating an infinitely variable amount of magnetic repulsion. This, in turn, exerts a controllable and measurable twisting force on the tone arm, as the two magnetic poles push apart, establishing the correct starting amount of anti-skating force desired, as indicated on the reading scale; and varying to the correct force required at every distance from the center of the record as the stylus moves inward along the radius.

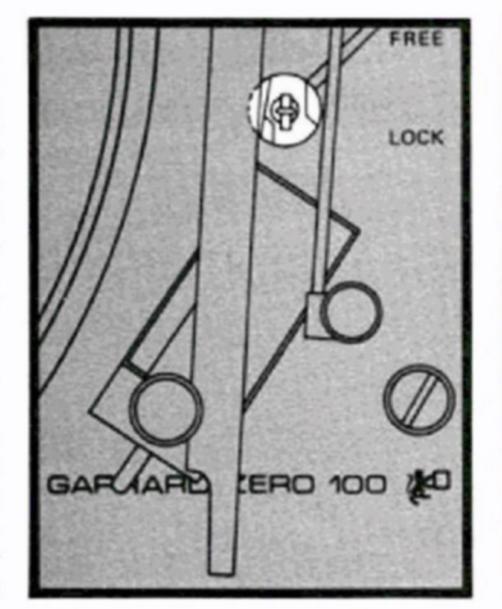

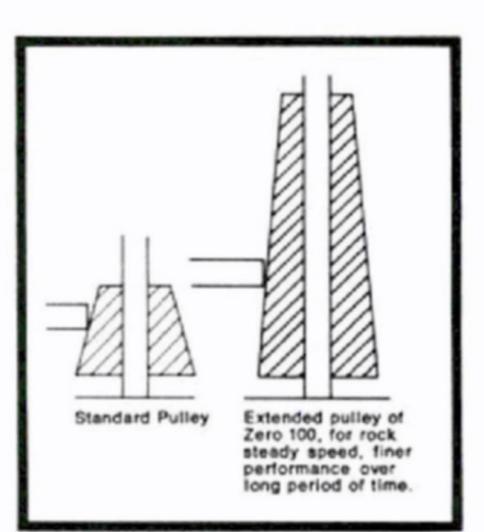

Variable speed control

(±3½% @ 33½ ±2½% @ 45 rpm) Variable speed is actually non-essential for the usual listening purposes when the record playing unit is equipped with a synchronous motor, since the motor insures accurate, stable speed. However, it is a welcome convenience for critical listeners with perfect pitch who prefer to play recordings at the exact speed they select; for others who simply enjoy records best at speeds they determine themselves; and for musicians who wish to "tune" the record player in order to accompany a musical instrument.

Variable speed units are not new. For satisfactory performance, the inherent requirements are to have a completely stable motor, and a minimal taper on the pulley which controls the speed variation, so that it does not introduce wow or flutter. Now, with Garrard's proven synchronous motor, and with the development of a long, very slightly tapered pulley, the speed control in the Zero 100 has achieved the necessary degree of perfection.

Speed variation in the Zero 100 is approximately ±3%. This creates an adjustment in pitch equivalent to one semi-tone.

Illuminated stroboscope

visible, illuminated line.

(Essential with variable speed.) The speed of the turntable is easily and accurately adjusted by moving a ring around the control knob which sets speed and record size. It can be monitored continuously through the stroboscope window, by watching the highly

Tone arm safety restrictor

No effort has been spared by the Garrard Laboratories to insure enjoyment by the owner. One example is the tone arm safety restrictor built into the Zero 100 tone arm to prevent it from being set down on the unit plate outside the edge of the record. A positive stop prevents accidental damage to the stylus.

Interchangeable spindles

There are two instantly removable spindles. The short one, for single play, rotates in the same manner as spindles on manual turntables. The long spindle accommodates a stack of six records for automatic play at 33½ rpm. An optional automatic spindle is available for wide hole, 45 rpm records.

Variable speed control

(±3½% @ 33½ ±2½% @ 45 rpm) Variable speed is actually non-essential for the usual listening purposes when the record playing unit is equipped with a synchronous motor, since the motor insures accurate, stable speed. However, it is a welcome convenience for critical listeners with perfect pitch who prefer to play recordings at the exact speed they select; for others who simply enjoy records best at speeds they determine themselves; and for musicians who wish to "tune" the record player in order to accompany a musical instrument.

Variable speed units are not new. For satisfactory performance, the inherent requirements are to have a completely stable motor, and a minimal taper on the pulley which controls the speed variation, so that it does not introduce wow or flutter. Now, with Garrard's proven synchronous motor, and with the development of a long, very slightly tapered pulley, the speed control in the Zero 100 has achieved the necessary degree of perfection.

Speed variation in the Zero 100 is approximately ±3%. This creates an adjustment in pitch equivalent to one semi-tone.

Illuminated stroboscope

visible, illuminated line.

(Essential with variable speed.) The speed of the turntable is easily and accurately adjusted by moving a ring around the control knob which sets speed and record size. It can be monitored continuously through the stroboscope window, by watching the highly

Tone arm safety restrictor

No effort has been spared by the Garrard Laboratories to insure enjoyment by the owner. One example is the tone arm safety restrictor built into the Zero 100 tone arm to prevent it from being set down on the unit plate outside the edge of the record. A positive stop prevents accidental damage to the stylus.

Interchangeable spindles

There are two instantly removable spindles. The short one, for single play, rotates in the same manner as spindles on manual turntables. The long spindle accommodates a stack of six records for automatic play at 33½ rpm. An optional automatic spindle is available for wide hole, 45 rpm records.

Variable speed control

(±3½% @ 33½ ±2½% @ 45 rpm) Variable speed is actually non-essential for the usual listening purposes when the record playing unit is equipped with a synchronous motor, since the motor insures accurate, stable speed. However, it is a welcome convenience for critical listeners with perfect pitch who prefer to play recordings at the exact speed they select; for others who simply enjoy records best at speeds they determine themselves; and for musicians who wish to "tune" the record player in order to accompany a musical instrument.

Variable speed units are not new. For satisfactory performance, the inherent requirements are to have a completely stable motor, and a minimal taper on the pulley which controls the speed variation, so that it does not introduce wow or flutter. Now, with Garrard's proven synchronous motor, and with the development of a long, very slightly tapered pulley, the speed control in the Zero 100 has achieved the necessary degree of perfection.

Speed variation in the Zero 100 is approximately ±3%. This creates an adjustment in pitch equivalent to one semi-tone.

Illuminated stroboscope

visible, illuminated line.

(Essential with variable speed.) The speed of the turntable is easily and accurately adjusted by moving a ring around the control knob which sets speed and record size. It can be monitored continuously through the stroboscope window, by watching the highly

Tone arm safety restrictor

No effort has been spared by the Garrard Laboratories to insure enjoyment by the owner. One example is the tone arm safety restrictor built into the Zero 100 tone arm to prevent it from being set down on the unit plate outside the edge of the record. A positive stop prevents accidental damage to the stylus.

Interchangeable spindles

There are two instantly removable spindles. The short one, for single play, rotates in the same manner as spindles on manual turntables. The long spindle accommodates a stack of six records for automatic play at 33½ rpm. An optional automatic spindle is available for wide hole, 45 rpm records.

Proven features retained

The innovations described on the previous pages are all introduced for the first time on the Zero 100. In addition, it retains the fully-tested major features of the advanced series of Garrard automatic turntables, which it now heads.

GARRARD ZERO 100

SPECIFICATIONS 2 speed, 33% and 45 rpm, 100-130 volts, 60 cycles AC (50 cycle kit available). MINIMUM CABINET DIMENSIONS Lett to right, 15%," Front to rear, 14%," Above motor board, 4%" Below motor board, 2%," MINIMUM CABINET DIMENSIONS (Turntable on Base with Dust Cover) Lett to right, 16%," Front to rear, 15%," Top to bottom, 8%,"

Retained— The Garrard Synchro-Lab Motor, an ingenious concept based upon split-rotor design. It combines the powerful torque and instant acceleration of the traditional induction motor; with the unwavering, perfect speed of a synchronous motor, locked into the accurately controlled 60-cycle frequency of the electric current. With

the Synchro-Lab Motor, there are no changes in musical pitch caused by drops in voltage due to appliances or other heavy loads on the line at the same time.

Retained-The Garrard full-diameter turntable. One of the advantages of the synchronously griven Zero 100 is

that it does not require a heavy turntable to act as a flywheel, as would an induction motor. Instead, there's a fullsized aluminum turntable, carefully balanced and matched to the kinetic energy of the Synchro-Lab Motor. The turntable mat is heavily ribbed for easy cleaning and safe support of the record through its full diameter.

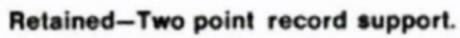

Garrard's exclusive record support system guarantees utmost safety and reliability. Records on the Zero 100 are handled automatically with the care and delicacy they require for long life and fine performance. The record stack is supported at the outer edge by a sturdy platform. The oversized clip at the top of the platform is easily grasped, quickly raised over the stack, where it acts as an effective stabilizer. Records are supported positively, and drop into place on a micro-cushion of air.

Retained – Unitized escutcheon with finger-tab, cue/pause control. Putting the right controls, in the right form, in the right place (a concept known as "human engineering") is an important Garrard feature. The Zero 100 incorporates a handsome control panel with three customized finger-tab controls: one to run the machine on automatic; one for manual operation; and the third for viscous damped cue and pause control.

Proven features retained

The innovations described on the previous pages are all introduced for the first time on the Zero 100. In addition, it retains the fully-tested major features of the advanced series of Garrard automatic turntables, which it now heads.

GARRARD ZERO 100

SPECIFICATIONS 2 speed, 33% and 45 rpm, 100-130 volts, 60 cycles AC (50 cycle kit available). MINIMUM CABINET DIMENSIONS Lett to right, 15%," Front to rear, 14%," Above motor board, 4%" Below motor board, 2%," MINIMUM CABINET DIMENSIONS (Turntable on Base with Dust Cover) Lett to right, 16%," Front to rear, 15%," Top to bottom, 8%,"

Retained— The Garrard Synchro-Lab Motor, an ingenious concept based upon split-rotor design. It combines the powerful torque and instant acceleration of the traditional induction motor; with the unwavering, perfect speed of a synchronous motor, locked into the accurately controlled 60-cycle frequency of the electric current. With

the Synchro-Lab Motor, there are no changes in musical pitch caused by drops in voltage due to appliances or other heavy loads on the line at the same time.

Retained-The Garrard full-diameter turntable. One of the advantages of the synchronously griven Zero 100 is

that it does not require a heavy turntable to act as a flywheel, as would an induction motor. Instead, there's a fullsized aluminum turntable, carefully balanced and matched to the kinetic energy of the Synchro-Lab Motor. The turntable mat is heavily ribbed for easy cleaning and safe support of the record through its full diameter.

Garrard's exclusive record support system guarantees utmost safety and reliability. Records on the Zero 100 are handled automatically with the care and delicacy they require for long life and fine performance. The record stack is supported at the outer edge by a sturdy platform. The oversized clip at the top of the platform is easily grasped, quickly raised over the stack, where it acts as an effective stabilizer. Records are supported positively, and drop into place on a micro-cushion of air.

Retained – Unitized escutcheon with finger-tab, cue/pause control. Putting the right controls, in the right form, in the right place (a concept known as "human engineering") is an important Garrard feature. The Zero 100 incorporates a handsome control panel with three customized finger-tab controls: one to run the machine on automatic; one for manual operation; and the third for viscous damped cue and pause control.

Proven features retained

The innovations described on the previous pages are all introduced for the first time on the Zero 100. In addition, it retains the fully-tested major features of the advanced series of Garrard automatic turntables, which it now heads.

GARRARD ZERO 100

SPECIFICATIONS 2 speed, 33% and 45 rpm, 100-130 volts, 60 cycles AC (50 cycle kit available). MINIMUM CABINET DIMENSIONS Lett to right, 15%," Front to rear, 14%," Above motor board, 4%" Below motor board, 2%," MINIMUM CABINET DIMENSIONS (Turntable on Base with Dust Cover) Lett to right, 16%," Front to rear, 15%," Top to bottom, 8%,"

Retained— The Garrard Synchro-Lab Motor, an ingenious concept based upon split-rotor design. It combines the powerful torque and instant acceleration of the traditional induction motor; with the unwavering, perfect speed of a synchronous motor, locked into the accurately controlled 60-cycle frequency of the electric current. With

the Synchro-Lab Motor, there are no changes in musical pitch caused by drops in voltage due to appliances or other heavy loads on the line at the same time.

Retained-The Garrard full-diameter turntable. One of the advantages of the synchronously griven Zero 100 is

that it does not require a heavy turntable to act as a flywheel, as would an induction motor. Instead, there's a fullsized aluminum turntable, carefully balanced and matched to the kinetic energy of the Synchro-Lab Motor. The turntable mat is heavily ribbed for easy cleaning and safe support of the record through its full diameter.

Garrard's exclusive record support system guarantees utmost safety and reliability. Records on the Zero 100 are handled automatically with the care and delicacy they require for long life and fine performance. The record stack is supported at the outer edge by a sturdy platform. The oversized clip at the top of the platform is easily grasped, quickly raised over the stack, where it acts as an effective stabilizer. Records are supported positively, and drop into place on a micro-cushion of air.

Retained – Unitized escutcheon with finger-tab, cue/pause control. Putting the right controls, in the right form, in the right place (a concept known as "human engineering") is an important Garrard feature. The Zero 100 incorporates a handsome control panel with three customized finger-tab controls: one to run the machine on automatic; one for manual operation; and the third for viscous damped cue and pause control.

Loading...

Loading...