Page 1

Preliminary

GTX 327 INSTALLATION MANUAL

GARMIN Corporation

1200 E. 151st Street

Olathe, KS 66062

Dwg. Number 190-00187-02 Rev. 1

Approvals Date

Drawn MD 10/07/99

Chkd.

Proj. Mgr.

This document and the specifications contained herein

are the property of GARMIN Corporation and may not

be reproduced or used in whole or in part as the basis

for manufacturing or sale of products without written

permission of GARMIN Corporation.

Confidential

Released

Archive Filename: 190-00187-02-01.zip

Document Source: MS Word

Rev. Date Description of Change ECO #

1

10/07/99 Engineering Release ---

Page 2

Preliminary

*7;

,167$//$7,21

0$18$/

GARMIN International, Inc.

1200 E. 151

Olathe, KS 66062 USA

190-00187-02 Revision 1

October 1999

st

Street

Page 3

Preliminary

© Copyright 1999

GARMIN Corporation

All Rights Reserved

Except as expressly provided below, no pa rt of this manual may be reproduced, copied, transmitted,

disseminated, downloaded or stored in any storage medium, for any purpose without the express prior

written consent of GARMIN Corporation. GARMIN Corporation hereb y grants permission to download a

single copy of this manual and of any revision to this manual onto a hard drive or other electronic storage

medium to be viewed and to print one copy of this manual or of any revision hereto, provided that such

electronic or printed copy of this manual or revision must contain the complete text of this copyright notice

and provided further that any unauthorized commercial distribution o f this manual o r any revision hereto is

strictly prohibited.

GARMIN International, Inc.

1200 E. 151

Olathe, KS 66062 USA

Telephone: 913-397-8200

Dealer Line: 1-800-800-1420

Web Site Address: www.garmin.com

st

Street

RECORD OF REVISIONS

Revision Revision

Date

1 10/07/99 Engineering Rel ease ----

Description ECO #

GTX 327 Installation Manual Page A

190-00187-02 Rev 1

Page 4

Preliminary

TABLE OF CONTENTS

1. GENERAL DESCRIPTION................................................................................................................. 1

1.1 INTRODUCTION................................................................................................................................ 1

1.2 EQUIPMENT DESCRIPTION............................................................................................................1

1.3 INTERFACE SUMMARY...................................................................................................................1

1.4 GTX 327 TRANSPONDER SPECIFICATIONS ................................................................................ 2

1.5 EQUIPMENT AVAILABLE ...............................................................................................................2

1.6 INSTALLATION ACCESSORIES...................................................................................................... 3

1.7 ADDITIONAL EQUIPMENT REQUIRED........................................................................................ 3

1.8 INSTALLATION APPROVAL........................................................................................................... 3

1.9 LIMITED WARRANTY...................................................................................................................... 4

2. INSTALLATION.................................................................................................................................5

2.1 INTRODUCTION................................................................................................................................ 5

2.2 UNPACKING AND INSPECTING EQUIPMENT............................................................................. 5

2.3 ANTENNA INSTALLATION............................................................................................................. 5

2.3.1 Location Considerations ........................................................................................................... 5

2.3.2 Antenna Installation .................................................................................................................. 5

2.3.3 Antenna Cable Installation........................................................................................................ 6

2.3.4 Antenna Cable Connectors........................................................................................................ 6

2.4 GTX 327 INSTALLATION................................................................................................................. 8

2.5 COOLING AIR..................................................................................................................................... 8

2.6 ELECTRICAL CONNECTIONS......................................................................................................... 8

3 POST INSTALLATION CONFIGURATION & CHECKOUT PROCEDURE ............................... 10

3.1 AIRCRAFT STATION LICENSING REQUIREMENTS................................................................. 10

3.2 OPERATION...................................................................................................................................... 10

3.2.1 Function Selection Switch ...................................................................................................... 11

3.2.2 Code Selection ........................................................................................................................ 12

3.2.3 Configuration Pages................................................................................................................13

APPENDIX A. CERTIFICATION DOCUMENTS................................................................................... 14

A.1 CONTINUED AIRWORTHINESS....................................................................................................14

A.2 ENVIRONMENTAL QUALIFICATION FORM..............................................................................15

GTX 327 Installation Manual Page i

190-00187-02 Rev 1

Page 5

Preliminary

APPENDIX B. ASSEMBLY AND INSTALLATION DRAWINGS........................................................ 17

B-1 GTX 327 OUTLINE DRAWING ......................................................................................................18

B-2 GTX 327 CONNECTOR/RACK KIT ASSEMBLY DRAWING.....................................................19

B-3 GTX 327 INTERCONNECT WIRING DIAGRAM.......................................................................... 20

B-4 DUAL TXP INTERCONNECT WIRING DIAGRAM,

ENCODING ALTITUDE CONNECTIONS...................................................................................... 21

APPENDIX C. STC PERMISSION........................................................................................................... 22

GTX 327 Installation Manual Page ii

190-00187-02 Rev 1

Page 6

Preliminary

1. GENERAL DESCRIPTION

1.1 INTRODUCTION

This manual provides the installation and operating instructions for the GARMIN GTX 327 Digital Display

Transponder system. Information pertaining to the maintenance, alignment, and procurement of replacement

parts is found in the GTX 327 Maintenance Manual, P/N 190-00187-05.

1.2 EQUIPMENT DESCRIPTION

The GARMIN GTX 327 is a panel-mounted transponder with the addition of timing functions. The

transponder is a radio transmitter and receiver that operates on radar frequencies, receiving ground radar

interrogations at 1030 MHz and transmitting a coded response of pulses to ground-based radar on a

frequency of 1090 MHz.

As with other Mode A/Mode C transponders, the GTX 327 replies with any one of 4,096 codes, which differ

in the position and number of pulses transmitted. By replying to ground transmissions, the GTX 327 enables

ATC to display aircraft identification, altitude and groundspeed on ATC radar screens. The GTX 327 is

equipped with IDENT capability that activates the Special Position Identification (SPI) pulse for 18 seconds.

The GTX 327 is configured with all key controls. The layout of the front panel keys and displays segregates

the transponder’s primary functions from the secondary timing functions. The unit can be configured so the

aircraft avionics master bus can turn the unit on.

1.3 INTERFACE SUMMARY

The GTX 327 provides the following interface connections via the rear connector:

• Ten (10) encoding altimeter inputs.

• External IDENT input.

• External STBY input.

• External suppression pulse input.

• Switched power output of up to 1.5 amps (for digital altitude encoder power).

• Aircraft power input (11 to 33 volts).

• Aircraft dimming buss input voltage.

• Aircraft master switch turn-on option.

• Serial

• Serial

altitude input.

altitude output.

GTX 327 Installation Manual Page 1

190-00187-02 Rev 1

Page 7

Preliminary

1.4 GTX 327 TRANSPONDER SPECIFICATIONS

SPECIFICATION CHARACTERISTIC

TSO, JTSO C74c Class 1A

TSO ENV CAT Refer to appendix A

Applicable Documents FAA TSO C74c; RTCA DO-160C

Temperature Range

GTX 327 Unit Weight 1.60 lbs.

GTX 327 Rack Weight 0.64 lbs.

Power Requirements 11.0 to 33.0 Vdc; Max Power Input: 12 Wat t s

Humidity

Altitude 50,000 Feet

Transmitter Frequency 1090 MHz

Transmitter Power 125 Watts minimum, 150 Watts nominal at the unit antenna

Receiver Frequency 1030 MHz

Receiver Sensitivity - 72dBm Nominal for 90% replies

Mode A Capability 4096 Identification Codes

Mode C Capability 100 Foot Increments from -1000 t o 63,000 feet

External Suppression Input

-20°C to +55°C (Continuous Operation)

95% @ +55°C for 16 Hours; 85% @ +38°C for 32 Hours

port

Low ≤ 0.5V; High ≥ 8V

1.5 EQUIPMENT AVAILABLE

ITEM GARMIN P/N

GARMIN GTX 327 Transponder 010-00188-00

GARMIN GTX 327 Transponder, includes GARMI N i nst allation kit,

P/N 010-10216-00

GARMIN GTX 327 Install at i on kit 010-10216-00

GARMIN GTX 327 Antenna kit 010-10160-00

GTX 327 Installation Manual Page 2

190-00187-02 Rev 1

010-00188-01

Page 8

Preliminary

1.6 INSTALLATION ACCESSORIES

The following installation accessories are available:

• GARMIN GTX 327 Installation Kit, P/N 010-10216-00 containing Connector/Rack Kit,

P/N 011-00338-00 (see figure B-2 for connector/rack kit assembly drawing).

• GARMIN GTX 327 Antenna Kit, P/N 010-10160-00. Note: A transponder antenna approved to TSO

C66( ) or C74( ) that has been installed to meet the requirements of this manual may be approved for

use with the GTX 327.

1.7 ADDITIONAL EQUIPMENT REQUIRED

• Antenna Sealant - Use antenna manufacturer’s instructions, install according to FAA AC 43.13-2A.

• Cables - The installer will supply all system cables. Cable requirements and fabrication is detailed in

Section 2 of this manual.

• Hardware - #6 Flat Head Screw (6 ea.) and #6-32 Self-Locking Nut (6 ea.). Hardware required to

mount installation rack is not provided.

• Encoding Altitude Digitizer - Use encoding altimeter manufacturer’s instructions, install according to

FAA AC 43.13-2A.

1.8 INSTALLATION APPROVAL

The conditions and tests required for TSO approval of the GTX 327 Transponder and antenna are minimum

performance standards. It is the responsibility of those desiring to install this transponder and antenna either

on or within a specific type or class of aircraft to determine that the aircraft installation standards are within

the TSO standards. The GTX 327 and antenna may be installed only if further evaluation by the applicant

documents an acceptable installation and is approved by the administrator. For GTX 327 TSO compliance,

see Appendix A. For antenna TSO compliance, refer to antenna manufacturer’s literature.

GTX 327 Installation Manual Page 3

190-00187-02 Rev 1

Page 9

Preliminary

1.9 LIMITED WARRANTY

GARMIN Corporation warrants this product to be free from defects in materials and manufacture for

one year from the date of purchase. GARMIN will, at its sole option, repair or replace any

components that fail in normal use. Such repairs or replacement will be made at no charge to the

customer for parts or labor. The customer is, however, responsible for any transportation costs. This

warranty does not cover failures due to abuse, misuse, accident or unauthorized alteration or repairs.

THE WARRANTIES AND REMEDIES CONTAINED HEREIN ARE EXCLUSIVE AND IN

LIEU OF ALL OTHER WARRANTIES EXPRESS OR IMPLIED OR STATUTORY,

INCLUDING ANY LIABILITY ARISING UNDER ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, STATUTORY OR

OTHERWISE. THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, WHICH MAY

VARY FROM STATE TO STATE.

IN NO EVENT SHALL GARMIN BE LIABLE FOR ANY INCIDENTAL, SPECIAL, INDIRECT

OR CONSEQUENTIAL DAMAGES, WHETHER RESULTING FROM THE USE, MISUSE, OR

INABILITY TO USE THIS PRODUCT OR FROM DEFECTS IN THE PRODUCT. SOME

STATES DO NOT ALLOW THE EXCLUSION OF INCIDENTAL OR CONSEQUENTIAL

DAMAGES, SO THE ABOVE LIMITATIONS MAY NOT APPLY TO YOU.

To obtain warranty service, call the GARMIN Customer Service department (913-397-8200) for a

returned merchandise tracking number. The unit should be securely packaged with the tracking

number clearly marked on the outside of the package and sent freight prepaid and insured to a

GARMIN warranty service station. A copy of the original sales receipt is required as the proof of

purchase for warranty repairs. GARMIN retains the exclusive right to repair or replace the unit or

software or offer a full refund of the purchase price at its sole discretion. SUCH REMEDY SHALL

BE YOUR SOLE AND EXCLUSIVE REMEDY FOR ANY BREACH OF WARRANTY.

GTX 327 Installation Manual Page 4

190-00187-02 Rev 1

Page 10

Preliminary

2. INSTALLATION

2.1 INTRODUCTION

This section provides the necessary information for the installing the GTX 327 Transponder, and where

required, optional accessories. Installation of the GTX 327 will differ according to equipment location and

other factors. Cabling will be fabricated by the installing agency to fit these various requirements. This

section contains interconnect diagrams, mounting dimensions, and information pertaining to installation.

Any deviations from the installation instructions prescribed in this document shall be accomplished in

accordance with the requirements set forth in FAA AC 43.13-2A.

2.2 UNPACKING AND INSPECTING EQUIPMENT

Carefully unpack the equipment and make a visual inspection of the unit for evidence of damage incurred

during shipment. If the unit is damaged, notify the carrier and file a claim. To justify a claim, save the

original shipping container and all packing materials. Do not return the unit to GARMIN until the carrier has

authorized the claim.

Retain the original shipping containers for storage. If the original containers are not available, a separate

cardboard container should be prepared that is large enough to accommodate sufficient packing material to

prevent movement.

2.3 ANTENNA INSTALLATION

2.3.1 Location Considerations

A. The antenna (GARMIN P/N 010-10160-00) should be well removed from any major

protrusions, such as engine(s), propeller(s), and antenna masts. It should also be as far as

practical from landing gear doors, access doors, or other openings that could effect its

radiation pattern.

B. The antenna should be mounted on the underside of the aircraft and in a vertical position

when the aircraft is in level flight.

C. Avoid mounting the antenna within three feet of the ADF sense antenna or any other

communication antenna and six feet from the DME antenna.

D. To prevent RF interference, the antenna must be physically mounted a minimum distance of

three feet from the GTX 327.

If the antenna is being installed on a composite aircraft, ground planes must sometimes be

added. Conductive wire mesh, radials, or thin aluminum sheets embedded in the composite

material provide the proper ground plane allowing the antenna pattern (gain) to be maximized

for optimum transponder performance.

NOTE

2.3.2 Antenna Installation

A. Install the antenna according to the antenna manufacturer’s instructions and FAA AC 43.132A.

GTX 327 Installation Manual Page 5

190-00187-02 Rev 1

Page 11

Preliminary

2.3.3 Antenna Cable Installation

When routing antenna cables, observe the following precautions:

• All cable routing should be kept as short as possible and as direct as possible.

• Avoid sharp bends.

• Avoid routing cables near power sources (e.g., 400 Hz generators, trim motors, etc.) or near power

for fluorescent lighting.

• Avoid routing cable near ADF antenna cable (allow at least a 12-inch separation).

The table below lists examples of the recommended antenna cable vendors and the type of cable to be used

for specific lengths of cable. Any cable meeting specifications is acceptable for the installation.

Cable Length (in feet) Use Times Microwave

Systems Part Number

5.5 to 10 M17/111-RG303

10 to 17.5 SF-304 or M17/127

17.5 to 27 SF-5394 or M17/79

Cable Length (in feet) Use Electronic Cable

Specialists Part Number

5.5 to 10 ECS 3C142B

10 to 17.5 ECS 311601

17.5 to 27 ECS 311201

27 to 41 ECS 310801

Times Microwave Systems,

P.O. Box 5039

Wallington, CT 06492-5039

Tel: 203-949-8400

Fax: 203-949-8423

Electronic Cable Specialists,

5300 W. Franklin Drive

Franklin, WI 53132

Tel: 800-327-9473

414-421-5300

Fax: 414-421-5301

2.3.4 Antenna Cable Connectors

The antenna cable requires a BNC connector at the antenna and a male BNC “Blindmate” connector

(P/N 330-00198-00, supplied with GTX 327 installation kit 010-10216-00) at the transponder. Instructions

for installing the Blindmate BNC are shown in steps A-G. Follow BNC connector manufacturer instructions

for assembly of the BNC connector.

GTX 327 Installation Manual Page 6

190-00187-02 Rev 1

Page 12

Preliminary

A. Trim coax outer insulation back 0.50”.

B. Trim braid (not center conductor or insulation) back 0.25”.

C. Strip Insulation back 0.120”.

NOTE

Place the ferrule over the coax braid, flush against the coax outer insulation before performing

the next step if the outside diameter of the coax braid is smaller than the inside diameter of the

center connector sidewall opening.

D. Insert cable (center conductor, dielectric and shield braid) through the sidewall of the connector

and solder the center conductor to the center pin of the connector.

NOTE

When using low loss cable it may be necessary to flatten the solid wire center conductor slightly

so it can fit the slot on the RF connector center pin. When soldering, avoid applying excess heat

to the connector body, and center conductor insulator.

E. Heat the outside of the connector sleeve and at the same time apply solder between the braid

and the sleeve. Continue to apply heat until the solder flows evenly.

F. Install 50 V Matching Bushing.

G. Insert connector cap and tack solder in two places.

GTX 327 Installation Manual Page 7

190-00187-02 Rev 1

Page 13

Preliminary

2.4 GTX 327 INSTALLATION

Avoid installing the unit near heat sources. If this is not possible, ensure that additional cooling

is provided. Allow adequate space for installation of cables and connectors. The installer will

supply and fabricate all of the cables. All wiring must be in accordance with FAA

AC 43.13-2A.

A. Assemble the connector/rack kit according to figure B-2. Install the rack assembly according

to the dimensions given in figure B-1. Mounting brackets are not supplied due to the wide

range of mounting configurations available. Suitable mounting brackets may be fabricated

from sheet metal or angle stock. To insure a sturdy mount, rear support for the unit should

be provided.

B. Looking at the bottom of the transponder, make sure the front lobe of the hold down device

is in a vertical position. This can be accomplished by using a 3/32” Allen wrench through

the face plate.

NOTES

C. Slide the unit into the rack until the front lobe of the unit touches the rack. Guide pins on the

back plate will help in the proper alignment of the unit in the rack.

D. Turn the Allen wrench clockwise until unit is secured in the rack. Continue turning until

tight. Do not overtighten the screw.

E. To remove the unit from the rack, turn the 3/32” Allen wrench counterclockwise until it

disengages from the rack.

2.5 COOLING AIR

The GTX 327 meets all TSO requirements without forced air-cooling. However Garmin recommends forced

air-cooling for all products to increase the long-term reliability. The GTX 327 was designed to handle a

constant 450 PRF, with short periods of 1200 PRF. Rate limit is set at 1200PRF. A typical radar site would

interrogate the transponder once every 5 to 10 seconds for approximately 100 msec at a 400 PRF rate. In

very high traffic areas with multiple ground stations and TCAS traffic it is possible to have long term PRF

rates above 450 PRF. The GTX 327 measures the unit temperature and without force air-cooling the reply

rate will be reduced to protect the transmitter from overheating.

2.6 ELECTRICAL CONNECTIONS

All electrical connections, except for the antenna, are made through a single, 25 pin D connector. Figure 2-1

defines the electrical characteristics of all input and output signals and identifies the cable requirements for

each signal. Required connector and associated hardware are supplied in the installation kit

(P/N 010-10216-00). See figures B-3 and B-4 for interconnect wiring diagrams.

GTX 327 Installation Manual Page 8

190-00187-02 Rev 1

Page 14

Preliminary

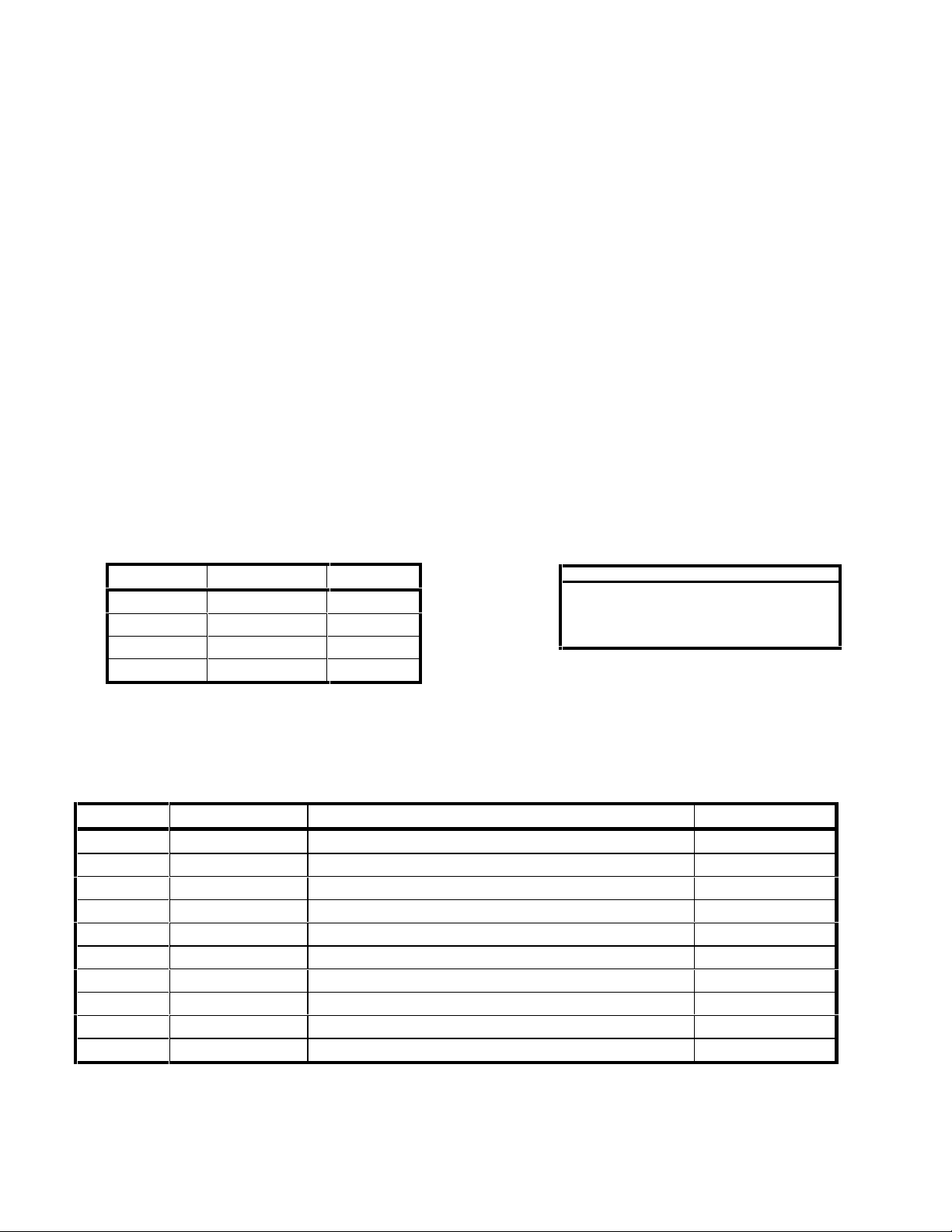

PIN DESCRIPTION I/O

1 AVIONICS MASTER ON In

2 DO NOT CONNECT -3 ALTITUDE A1 In

4 ALTITUDE C2 In

5 ALTITUDE A2 In

6 ALTITUDE A4 In

7 ALTITUDE C4 In

8 EXTERNAL IDENT INPUT In

9 ALTITUDE B1 In

10 ALTITUDE C1 In

11 ALTITUDE B2 In

12 ALTITUDE B4 In

13 POWER GROUND In

14 SWITCHED POWER OUTPUT Out

15 POWER INPUT (+11 TO +33 VDC) In

16 EXTERNAL STANDBY In

17 EXTERNAL SUPPRESSION In

18 ALTITUDE D4 In

19 RS232 In

20 RS232 Out

21 RESERVED -22 SQUAT SWITCH In

23 28 VDC PANEL LIGHTING INPUT In

24 14 VDC/5 VDC PANEL LIGHTING INPUT In

25 POWER GROUND In

Figure 2-1. DB-25 Pin-Out Definitions

GTX 327 Installation Manual Page 9

190-00187-02 Rev 1

Page 15

Preliminary

3. POST INSTALLATION CONFIGURATION & CHECKOUT PROCEDURE

3.1 AIRCRAFT STATION LICENSING REQUIREMENTS

The Telecommunications Act of 1996, effective February 8, 1996, provides the FCC discretion to eliminate

radio station license requirements for aircraft and ships. The GTX 327 installation must comply with current

transmitter licensing requirements. To find out the specific details on whether a particular installation is

exempt from licensing, please see FCC Fact Sheet PR 5000 or contact the FCC at (800)-322-1117.

If an aircraft license is required, make application for a license on FCC form 404, Application for Aircraft

Radio Station License. The FCC also has a fax-on-demand service to provide forms by fax at

(202)-418-0177.

The GTX 327 owner accepts all responsibility for obtaining the proper licensing before using the

transponder.

3.2 OPERATION

NOTE

The coverage you can expect from the GTX 327 is limited to line of sight. Low altitude or

aircraft antenna shielding by the aircraft itself may result in reduced range. Range can be

improved by climbing to a higher altitude. It may be possible to minimize antenna shielding by

locating the antenna where dead spots are only noticed during abnormal flight attitudes.

Figure 3-1. GTX 327 Front Panel

NOTE

The GTX 327 should be turned off before starting aircraft engine(s).

GTX 327 Installation Manual Page 10

190-00187-02 Rev 1

Page 16

Preliminary

3.2.1 Function Selection Switches

The function selection switches are:

• OFF Turns the GTX 327 off.

• STBY Turns the transponder ON in STBY mode or selects STBY mode. When in STBY the

transponder will not reply to any interrogations from the ground radar system. At power

on the last active identification code will be selected.

• ON Turns the transponder ON in Mode A, the identification mode or selects Mode A. At

power on the last active identification code will be selected. In addition to the aircraft’s

identification code, the transponder will also reply to altitude interrogations (mode C) with

signals that do not contain altitude information. The Reply Symbol

displayed when the transponder replies to ground interrogation.

• ALT Turns the transponder on in Mode A and Mode C, or, if already on, selects Mode A and

Mode C. This is the identification and altitude-reporting modes to respond to ATC aircraft

identification interrogations and altitude interrogations with standard pressure altitude

(29.92 inches Hg.) received from an external altitude digital encoder. The ALT position

may be used in aircraft that are not equipped with the optional altitude encoder, however,

the only response will be discreet signals that do not contain altitude information. The

Reply Symbol

interrogation.

" ))) " will be displayed when the transponder replies to ground

" ))) " will be

NOTE

Any time the ON or ALT function is selected the transponder becomes an active part of the beacon

system. Select ON or ALT as late as practical prior to takeoff and to OFF or STBY as soon as

practical after landing unless previously changed to STBY at the request of ATC. An optional Squat

Switch can automate transponder control during take off and landing. If installed and configured the

Squat Switch will automatically transition the transponder to the ALT mode at take off. Upon

landing the Squat Switch will automatically transition the transponder to STBY mode after a preset

time delay. This time delay can be selected via a configuration page.

• IDENT On occasion, the controller will request to SQUAWK IDENT. Respond by

momentarily pressing and releasing the IDENT button. Pressing the IDENT button

activates the Special Position Identification (SPI) Pulse for 18 seconds identifying your

transponder return from other aircraft on the controller’s scope. The word IDENT will be

displayed in the upper left corner of the display while the IDENT feature is active.

• VFR Programs transponder code to the default VFR code. Default code is programmed on a

configuration page. Pressing the VFR button again will restore the last identification code.

GTX 327 Installation Manual Page 11

190-00187-02 Rev 1

Page 17

Preliminary

• FUNC Changes modes displayed on the right side of the display. Displayed data includes

Flight Level: Displays the altitude data supplied to the GTX 327 in feet, flight level format or

Flight Time: Displays the flight time controlled by the Start/Stop button if no Squat Switch is

Count Up Timer: Controlled by START/STOP and CLR button.

Count Down Timer: Controlled by START/STOP, CLR, and CRSR buttons. Count down timer

Contrast: Controlled by 8 and 9 buttons.

Display Brightness: Controlled by 8 and 9 buttons

• START/ STOP Starts and stops the Count Up and Count Down timers.

• CRSR Activates the change fields for the Count Down timer when selected by the FUNC key.

• CLR Resets the Count Up and Count Down timers.

Flight Level, Flight Time, Count Up timer, Count Down timer, screen Contrast, and

Display brightness (if configured for manual contrast and brightness.)

meters depending on configuration setup.

configured or timer starts when the altitude begins to increase. Under Squat Switch

control the timer begins when lift off is sensed.

entered with 0 – 9 buttons.

• 8 Reduces screen Contrast and display Brightness. Enters the number eight into the Count

Down timer.

• 9 Increases screen Contrast and display Brightness. Enters the number nine into the Count

Down timer.

3.2.2 Code Selection

The code selector consists of eight push button (0 – 7) switches that provide 4,096 active identification

codes. Pushing one of these buttons begins the code selection sequence. The new code will not be activated

and stored in EEPROM until the forth button is pressed. Pressing the CLR button will cancel the previous

button press and restore the code prior to the last button press. Pressing the CRSR button when data entry

has begun will remove the cursor and cancel data entry. If an identification code entry is not completed or

there is no other key press for four seconds the last active code will be restored.

NOTE

Attention should be paid to the selected identification code. The selected code should be the one

assigned by air traffic control for IFR flight or rules applicable to transponder use for VFR flight.

Care should be taken not to select code 7500 and all codes in the 7600 and 7700 series (i.e., 7600-7677,

7700-7777) which trigger special indicators in automated facilities. Only nondiscrete code 7500 will be

decoded as the hijack code. An aircraft’s transponder code (when available) is utilized to enhance the

tracking capabilities of the ATC facility, therefore care should be taken when making routine code changes.

GTX 327 Installation Manual Page 12

190-00187-02 Rev 1

Page 18

Preliminary

3.2.3 Configuration Pages

Holding down the CRSR button and pressing the ON button provides access to the configuration pages. The

FUNC button will sequence through the configuration pages. The CRSR button will highlight selectable

fields on each page. When a field is highlighted, numeric data entry will be performed with the 0-9 buttons,

and list selections will be performed with the 8 or 9 buttons. Changes made through the configuration pages

are stored in EEPROM memory.

• Display Backlight Page

Current display backlight intensity: displayed value

Select manual or automatic backlight source

Automatic backlight source: Select automatic backlight source (Photocell, 28Vdc, 5Vdc)

Display backlight filter response time: Select display backlight response time (3-7) (default to 4)

Display backlight filter slope: Select display backlight filter slope value (0-99) (default to 50)

Display backlight filter minimum value: Select display minimum filter slope value (0-99) (default to 50)

Display backlight filter offset: Select display backlight filter offset value (0-99) (default to 50)

• Key Backlight Page

Current key backlight intensity: Displayed value

Automatic key backlight source: Select automatic key backlight source (Photocell, 28Vdc, 5Vdc)

Key backlight filter response time: Select key backlight response time (3-7) (default to 4)

Key backlight filter slope: Select key backlight filter slope value (0-99) (default to 50)

Key backlight filter minimum value: Select key minimum filter slope value (0-99) (default to 50)

Key backlight filter offset: Select key backlight filter offset value (0-99) (default to 50)

• Contrast Configuration Page

Select contrast mode (Auto, Manual) (default, to Auto)

Select contrast offset (0 to99) (default, to 50)

• Operation Configuration Page #1

VFR identification code: Enter the VFR identification code (default 1200)

Altitude Input source: Select the altitude input source [Gray code(default), Icarus, Shadin]

Altitude display format: Select altitude display format [Flight level (default), Feet, Meters]

Aircraft climb rate: Enter aircraft climb rate [100 to 2000 fpm (500 fpm default)]

• Operation Configuration Page #2

SQUAT SWITCH sense

Automatic STBY operation enabled

Automatic STBY delay duration

• Gray Code Input Configuration Page

Gray Code discretes

Gray Code altitude

• Discrete Input Configuration Page

EXTERNAL IDENT input:

EXTERNAL STANDBY input:

SQUAT SWITCH input: On ground equals High or Low

GTX 327 Installation Manual Page 13

190-00187-02 Rev 1

Page 19

Preliminary

APPENDIX A CERTIFICATION DOCUMENTS

A.1 CONTINUED AIRWORTHINESS

Other than for regulatory periodic functional checks, maintenance of the GTX 327 is “on condition” only.

Refer to the GTX 327 Maintenance Manual, (Garmin P/N 190-00187-05). Periodic maintenance of the

GTX 327 is not required.

GTX 327 Installation Manual Page 14

190-00187-02 Rev 1

Page 20

Preliminary

A.2 ENVIRONMENTAL QUALIFICATION FORM

NOMENCLATURE: GTX 327 Airborne ATC Transponder Equipment

TYPE/MODEL/PART NO.: 010-00188-( )

TSO/JTSO COMPLIANCE: TSO - C74c Class 1A

JTSO

MANUFACTURER’S SPECIFICATION AND/OR OTHER

APPLICABLE SPECIFICATION: 004-00070-00 minimum Performance Specification

MANUFACTURER: GARMIN INTERNATIONAL

ADDRESS: 1200 E 151st St, Olathe, Kansas 66062

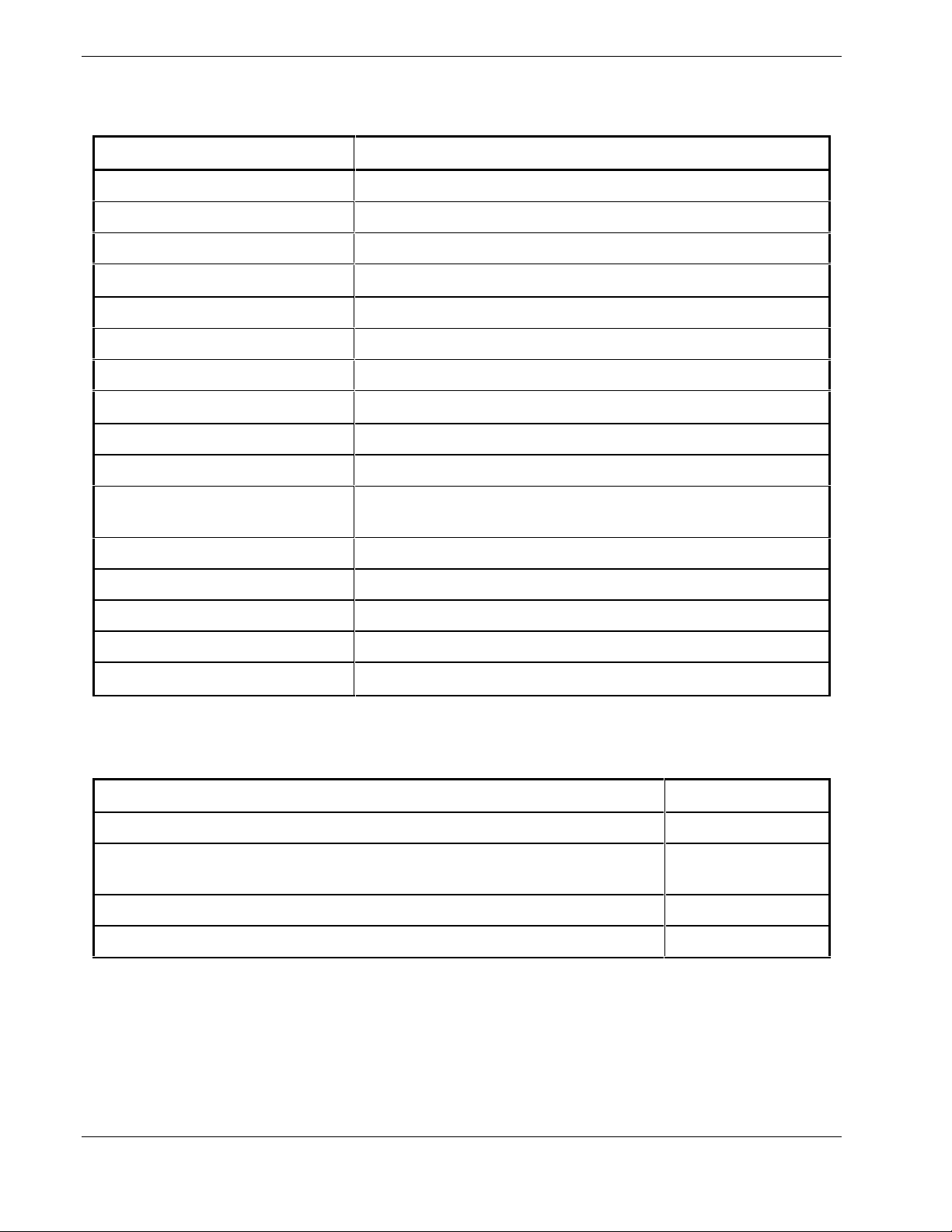

Conditions Section Description of Conducted Tests

Temperature and Altitude 4.0 Equipment tested to Categories A1 & D1 except as noted

Low Temperature 4.5.1 -208 C

High Temperature 4.5.2. & 4.5.3 +558 C

In-Flight Loss of Cooling 4.5.4 Cooling air not required

Altitude 4.6.1 50,000 Feet

Decompression 4.6.2 8,000 to 50,000 Feet

Overpressure 4.6.3 -15,000 Feet

Temperature Variation 5.0 Equipment tested to Category C

Humidity 6.0 Equipment tested to Category A

Shock 7.0 Equipment tested according to DO-160C, Par. 7.2.1

Operational 7.2 6 g’s

Crash Safety 7.3 15 g’s

Vibration 8.0 Equipment tested without shock mounts to Categories B,

M and N (Table 8-1)

Explosion 9.0 Equipment identified as Category X, no test required

Waterproofness 10.0 Equipment identified as Category X, no test required

Fluids Susceptibility 11.0 Equipment identified as Category X, no test required

GTX 327 Installation Manual Page 15

190-00187-02 Rev 1

Page 21

Preliminary

Conditions Section Description of Conducted Tests

Sand and Dust 12.0 Equipment identified as Category X, no test required

Fungus 13.0 Equipment identified as Category X, no test required

Salt Spray 14.0 Equipment identified as Category X, no test required

Magnetic Effect 15.0 Equipment tested to Class Z

Power Input 16.0 Equipment tested to Category B

Voltage Spike 17.0 Equipment tested to Category A

Audio Frequency

18.0 Equipment tested to Category B

Susceptibility

Induced Signal Susceptibility 19.0 Equipment tested to Category A

Radio Frequency

20.0 Equipment tested to Category T

Susceptibility

Radio Frequency Emission 21.0 Equipment tested to Category Z

Lightning Induce Transient

Susceptibility

22.0 Equipment identified as Category XXXX, no test

required

Lightning Direct Effects 23.0 Equipment identified as Category X, no test required

Icing 24.0 Equipment identified as Category X, no test required

GTX 327 Installation Manual Page 16

190-00187-02 Rev 1

Page 22

Preliminary

APPENDIX B

ASSEMBLY AND INSTALLATION DRAWINGS

GTX 327 Installation Manual Page 17

190-00187-02 Rev 1

Page 23

Preliminary

Figure B1 GTX 327 OUTLINE DRAWING

GTX 327 Installation Manual Page 18

190-00187-02 Rev 1

Page 24

Preliminary

NOTE 1

011-003 3 8-0 0 CONNECTOR/ RACK K IT

Item Part Number Description Qty

1 211-62204-16 SCRE W, 4-40 X .75, FLHP , S S/ P 2

2 212-2S 00 1-0 0 WSHR, F LAT, NO N-STD, SS 1

3 232-000 13-01 S NA P RING, E XT, 7/16 1

4 330-00113-25 BACKSHELL, MTLZ PLSTC, 25 CONT. 1

5 33 0-0 018 4- 25 CONN. , D-SUB , M IL CRP, SCKT, 25 1

6 33 0-0 019 8- 00 CONN. BNC, MA LE BLINDM ATE 1

NOT SHOWN 336-00022-00 CONT. SCKT, MIL CRP, SIZE 20 25

NOT SHOWN 336-00023-00 CONT. SCKT, MIL CRP, SIZE 20-18 5

NOT SHOWN 312-0 00 05 -05 TUBING, HT SHRINK 2.3IN

7 11 5-0 028 5- 00 INSTALL RA CK 1

NOT SHOWN 161-00215-00 LABEL, S/N, INSTL RACK 1

8 125-00032-02 BACK PLATE 1

9 211-602 34-06 SCRE W, 4-40X.187, P HP, SS /P 4

10 210-100 00-04 NUT, HE X NY LCKNG, 4-40 2

11 234-100 02 -00 SPRING WASHE R 1

NOTES:

1. THIS PART IS SUPPLIED WITH ITEM 4.

Figure B2 GTX 327 CONNECTOR/RACK KIT ASSEMBLY DRAWING

GTX 327 Installation Manual Page 19

190-00187-02 Rev 1

Page 25

Preliminary

Figure B3 GTX 327 INTERCONNECT WIRING DIAGRAM

GTX 327 Installation Manual Page 20

190-00187-02 Rev 1

Page 26

Preliminary

Figure B4 DUAL TXP INTERCONNECT WIRING DIAGRAM, ENCODING ALTITUDE CONNECTIONS

GTX 327 Installation Manual Page 21

190-00187-02 Rev 1

Page 27

Preliminary

APPENDIX C

STC PERMISSION

Consistent with N8110.69 or Order 8110.4, Aviation Authority approved installations are hereby granted

permission to use ST2484WI-A data to modify aircraft.

GTX 327 Installation Manual Page 22

190-00187-02 Rev 1

Loading...

Loading...