Garlock LS-200, LS-315 User Manual

Drawings for Reference Only

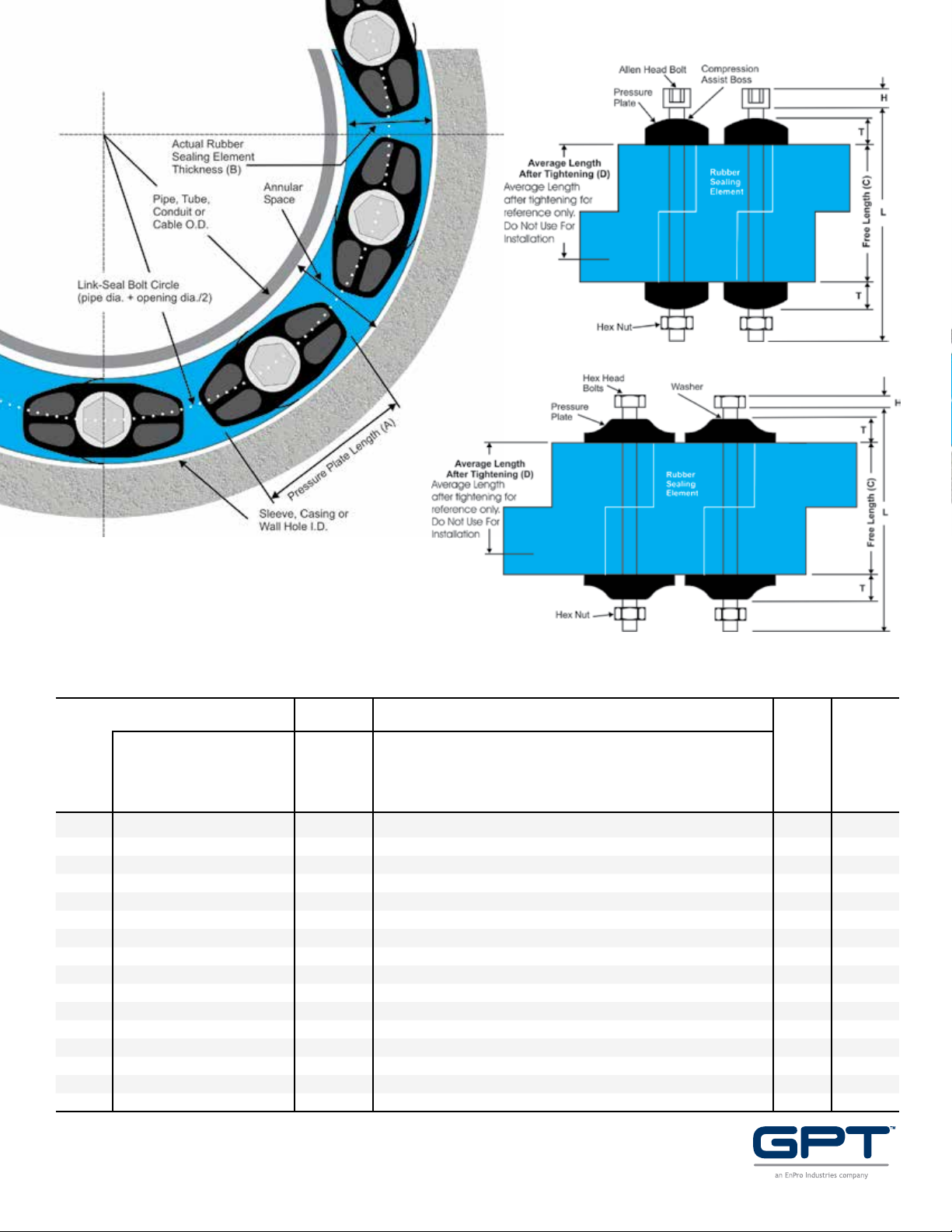

FOR LS200 THROUGH LS315

FOR LS325 THROUGH LS650

Technical Data Submittal Sheet

Supplement 11/06/2018

* DIMENSIONAL DATA FOR MODELS C, L, O, S316, S61, LS316 & OS316

Rubber Sealing Elements

LINK

SEAL®

Model

No.

LS-200-* 0.48” 1.75” 1.38” 1.06” 0.31” 4mm Allen (0.157”) 4.95mm (0.195”) M5-0.8 65mm (2.559”) 0.70 2.25”

LS-275-* 0.61” 1.75” 1.38” 0.97” 0.31” 4mm Allen (0.157”) 4.95mm (0.195”) M5-0.8 65mm (2.559”) 0.75 2.25”

LS-300-* 0.69” 2.37” 1.87” 1.56” 0.44” 6mm Allen (0.236”) 7.87mm (0.310”) M8-1.25 90mm (3.543”) 2.15 3.00”

LS-315-* 0.81” 2.37” 1.87” 1.44” 0.44” 6mm Allen (0.236”) 7.87mm (0.310”) M8-1.25 90mm (3.543”) 2.30 3.00”

LS-325-* 0.88” 2.63” 2.00” 3.13” 1.00” 13mm (0.511”) 5.30mm (0.215”) M8-1.25 110mm (4.33”) 5.50 4.00”

LS-340-* 1.00” 2.70” 2.25” 1.48” 0.66” 13mm (0.511”) 5.30mm (0.215”) M8-1.25 110mm (4.33”) 3.30 4.00”

LS-360-* 1.24” 2.70” 2.25” 2.05” 0.77” 13mm (0.511”) 5.30mm (0.215”) M8-1.25 110mm (4.33”) 5.10 4.00”

LS-400-* 1.38” 3.50” 2.75” 3.50” 1.06” 17mm (0.669”) 6.40mm (0.250”) M10-1.5 130mm (5.118”) 12.00 5.00”

LS-410-* 1.43” 3.37” 2.87” 2.52” 0.88” 17mm (0.669”) 6.40mm (0.250”) M10-1.5 130mm (5.118”) 8.20 5.00”

LS-425-* 1.06” 3.00” 2.25” 3.50” 1.19” 17mm (0.669”) 6.40mm (0.250”) M10-1.5 130mm (5.118”) 10.00 5.00”

LS-475-* 1.56” 3.38” 2.63” 2.63” 0.88” 17mm (0.669”) 6.40mm (0.250”) M10-1.5 130mm (5.118”) 10.00 5.00”

LS-500-* 2.25” 3.75” 2.75” 3.63” 1.06” 19mm (0.748”) 7.50mm (0.300”) M12-1.75 140mm (5.511”) 22.50 5.00”

LS-525-* 2.06” 3.75” 2.87” 3.63” 1.06” 19mm (0.748”) 7.50mm (0.300”) M12-1.75 140mm (5.511”) 21.00 5.00”

LS-575-* 1.81” 3.75” 3.00” 3.00” 1.00” 19mm (0.748”) 7.50mm (0.300”) M12-1.75 140mm (5.511”) 15.50 5.00”

LS-615-* 3.09” 4.00” 3.00” 6.00” 1.90” 24mm (0.944”) 10.57mm (0.416”) 5/8-11 185mm (7.280”) 60.60 6.00”

LS-650-* 2.71” 3.98” 3.00” 3.96” 1.19” 19mm (0.748”) 7.50mm (0.300”) M12-1.75 140mm (5.511”) 26.10 6.00”

Actual

Thinckness

(B)

Free

Length

(C)

Avg.

Length

After

Tighening

(D)

Pressure

Plates

(A) (T)

Allen Head Hex

Across Flats

Bolts

(H) Thread Size (L)

Weight

for

10 Link

Sections

(lbs)

Min.

Required

Seating

Width

Visit www.gptindustries.com for literature and installation instructions

LINK-SEAL® Modular Seal Model Properties

4990 Iris S treet

Wheat Ridge, CO 80033

Tel: (3 03) 988 -1242

Fax: (303) 988-1922

645 5 Clara Road, Su ite 300

Housto n, TX 77041

Tel: (713) 747-6948

Fax: (7 13) 747-6029

www.gptindustries.com

WITH EPDM SEAL ELEMENTS

EPDM (Black & Blue)

*Sustained operation near temperature

limits may affect life expectancy.

WITH NITRILE SEAL ELEMENTS

Nitrile (Green)

*Sustained operation near temperature

limits may affect life expectancy.

WITH SILICONE SEAL ELEMENTS

Silicone (Grey)

Sustained operation near temperature

limits may affect life expectancy.

Model “C” LINKSEAL® Modular Seal

Suitable for direct ground burial, normal

atmospheric conditions, and conditions with

occasional or periodic water contact. Provides

electrical isolation where cathodic protection is

required.

Type: Standard

Seal Element: EPDM (Black) or EPDM (Blue)

Pressure Plates: Reinforced Nylon Polymer

Bolts & Nuts: Steel with 2-part Zinc Dichromate

& proprietary corrosion inhibiting coating.

Temp. Range: -40˚ to 250˚F (-40˚ to 121˚C)*

Model “O” LINKSEAL® Modular Seal

Nitrile rubber is resistant to oils, fuel and many

solvents (gasoline, motor oil, kerosene, methane,

jet fuel, hydraulic fluid, water, etc.)

Type: Oil Resistant

Seal Element: Nitrile (Green)

NOTE: Not U.V. Resistant

Pressure Plates: Reinforced Nylon Polymer

Bolts & Nuts: Steel with 2-part Zinc Dichromate

& proprietary corrosion inhibiting coating

Temp. Range: -40˚ to 210˚F (-40˚ to 99˚C)*

Model “T” LINKSEAL® Modular Seal

Silicone rubber is ideal for temperature extremes.

The “T” model is one-hour Factory Mutual

approved.

Type: High/Low Temperature

Seal Element: Silicone (Grey)

Pressure Plates: Steel Zinc Dichromate

Bolts: Steel with 2-part Zinc Dichromate &

proprietary corrosion inhibiting coating.

Temp. Range: -67˚ to 400˚F (-55˚ to 204˚C)*

Model “S-316” LINKSEAL® Modular Seal

For chemical processing & waste water

treatment. High level of water-resistance,

resistant to most inorganic acids and alkalis,

and most organic chemicals (acetone, alcohol,

ketones).

Type: Stainless

Seal Element: EPDM (Black) or EPDM (Blue)

Pressure Plates: Reinforced Nylon Polymer

Bolts & Nuts: 316 Stainless Steel

Temp. Range: -40˚ to 250˚F (-40˚ to 121˚C)*

Model “OS-316” LINKSEAL® Modular Seal

Combination of oil resistant rubber and

stainless steel hardware

Type: Oil Resistant

Seal Element: Nitrile (Green)

NOTE: Not U.V. Resistant

Pressure Plates: Reinforced Nylon Polymer

Bolts & Nuts: 316 Stainless Steel

Temp. Range: -40˚ to 210˚F (-40˚ to 99˚C)*

Models “FD/FS” LINKSEAL® Modular Seal

Double seal for added protection

Type: Fire Seals

Seal Element: Silicone (Grey)

Pressure Plates: Steel zinc dichromate

Bolts: Steel with 2-part Zinc Dichromate &

proprietary corrosion inhibiting coating.

Temp. Range: -67˚ to 400˚F (-55˚ to 204˚C)*

NOTE: Sustains a constant temp. of 325°F (163°C)

MATERIAL PROPERTIES OF LINKSEAL® MODULAR SEAL ELEMENTS

Property ASTM Method EPDM (EPDM L) Nitrile Silicone

Hardness (shore A) D-2240 50 ±5 (40 ±5) 50 ±5 50 ±5

Tensile D-412 1450 psi 1300 psi 860 psi

Elongation D-412 400% 300% 250%

Compression Set S-395

Specific Gravity D-297 1.10 1.15 1.40

Carbon Steel

Carbon steel, zinc dichromated per ASTM B633, with an additional

corrosion inhibiting proprietary organic coating. (passes 1470 hour

salt spray test)

Tensile Strength = 60,000 psi, minimum.

Stainless Steel

ANSI Type = 316, Per ASTM F593-95

Tensile Strength = 85,000 psi, average

22 hrs. @ 158° F (70° C)

15%

22 hrs. @ 212° F (100° C)

45%

22 hrs. @ 350° F (177° C)

40%

MATERIAL PROPERTIES OF COMPOSITE PRESSURE PLATESBOLT & NUT SPECIFICATION

Property ASTM Method Value

Izod Impact - Notched D-256 1.11 ft-lb/in

Tensile Strength @ Yield D-638 20,000 psi

Tensile Strength - Break D-638 20,250 psi

Flexural Strength @ Yield D-790 30,750 psi

Flexural Modulus D-790 1,124,000 psi

Elongation, Break D-638 11.07%

Specific Gravity D-792 1.38

Moisture Content -- 0.18%

Loading...

Loading...