Garlock Gasketing Products

Performance with proven reliability

Leaders in Sealing Integrity

Garlock Fluid Sealing Products Technical Manual

Garlock Gasketing

Today’s environmental concerns demand positive seals. Garlock® gaskets provide

that assurance, and perform with proven reliability.

CONTENTS

Gasketing Products

Introduction ............................................................................. 3

Gasketing Selection and TAMPS ............................................. 4

Bolting and Flange Information ................................................ 6

Compressed Inorganic Fiber Gasketing ................................... 7

Styles 5500 & 5507 ........................................................ 7

High Temp Compressed Graphite or

Carbon Fiber Gasketing ........................................................... 8

Style 9900, 9800, 9850 ................................................... 9

High Temperature Gaskets

Style 4122 - FC THERMa-PUR

BLUE-GARD

MULTI-SWELL

Vegetable Fiber Gasketing ..................................................... 15

GYLON

STRESS SAVER

GRAPH-LOCK

Premium Grade Rubber Gasketing ........................................ 24

Reinforced Rubber Gasketing & Diaphragm .......................... 26

®

Compressed Gasketing .................................. 12

Styles 3000 to 3700 / 2900, 2950 ................................. 13

Styles 660, 681 ............................................................. 15

Styles 3500, 3504, 3510 ............................................... 16

Style 3535 Joint Sealant ............................................... 16

Thermally Bonded GYLON

Style HP 3560, HP 3561 ............................................... 17

Style 3565 ENVELON

Style 3540 ..................................................................... 18

Style 3545 ..................................................................... 18

Style 3128 HOCHDRUCK

Styles 22, 7797, 7986, 8314, 98206,

9064, 9122, 9518, 9520, 9780 ...................................... 25

™

Style 3760/3760-U ...................................... 14

®

Gasketing ................................................................ 16

®

®

Gasketing ................................................... 20

®

Gasketing ..................................................... 22

™

.................................... 10

®

......................................... 16

................................................. 17

®

........................................... 23

Engineering Data

Chemical Resistance Chart .................................................... 27

Sheet Sizes and Tolerances ................................................... 45

"M" and "Y" Data ..................................................................... 46

Gasket Constants .................................................................. 47

Before Installation .................................................................. 48

Installation ............................................................................. 48

Gasket Assembly Stress Recommendations ........................ 48

Torque and Stress Tables .......................................................49

Gasket Design Tips ................................................................54

Gasketing Terms .................................................................... 55

Test Procedures ..................................................................... 60

Test Equipment ..................................................................... 62

Application Data Form ........................................................... 63

Leaders in Sealing Integrity

Garlock Fluid Sealing Products Technical Manual

Pressure – psig (bar)

Garlock Gasketing Products

The demands of modern applications make the choice of the

right sealing product an important consideration, both in the

design of new equipment and in choosing the new products

which will replace those no longer suitable.

This catalog provides some typical examples of appropriate

applications, but is not intended to be a warranty of performance.

All specific uses of sealing products require independent study

and specific evaluation for suitability.

Garlock will provide the technical assistance of its applications

engineers, who will give you specific recommendations. Please

consult us. We are ready to help you make the right choice.

Choosing the wrong sealing product can result in property

damage and/or serious personal injury. Do not rely on the

general criteria, which may not suit your application as well as

one that Garlock Engineering can help you choose. Reliability

and service to our customers is what the Garlock name means.

Let us help you choose the right product for your application.

®

®

5500, 5507

1

3000

3200,

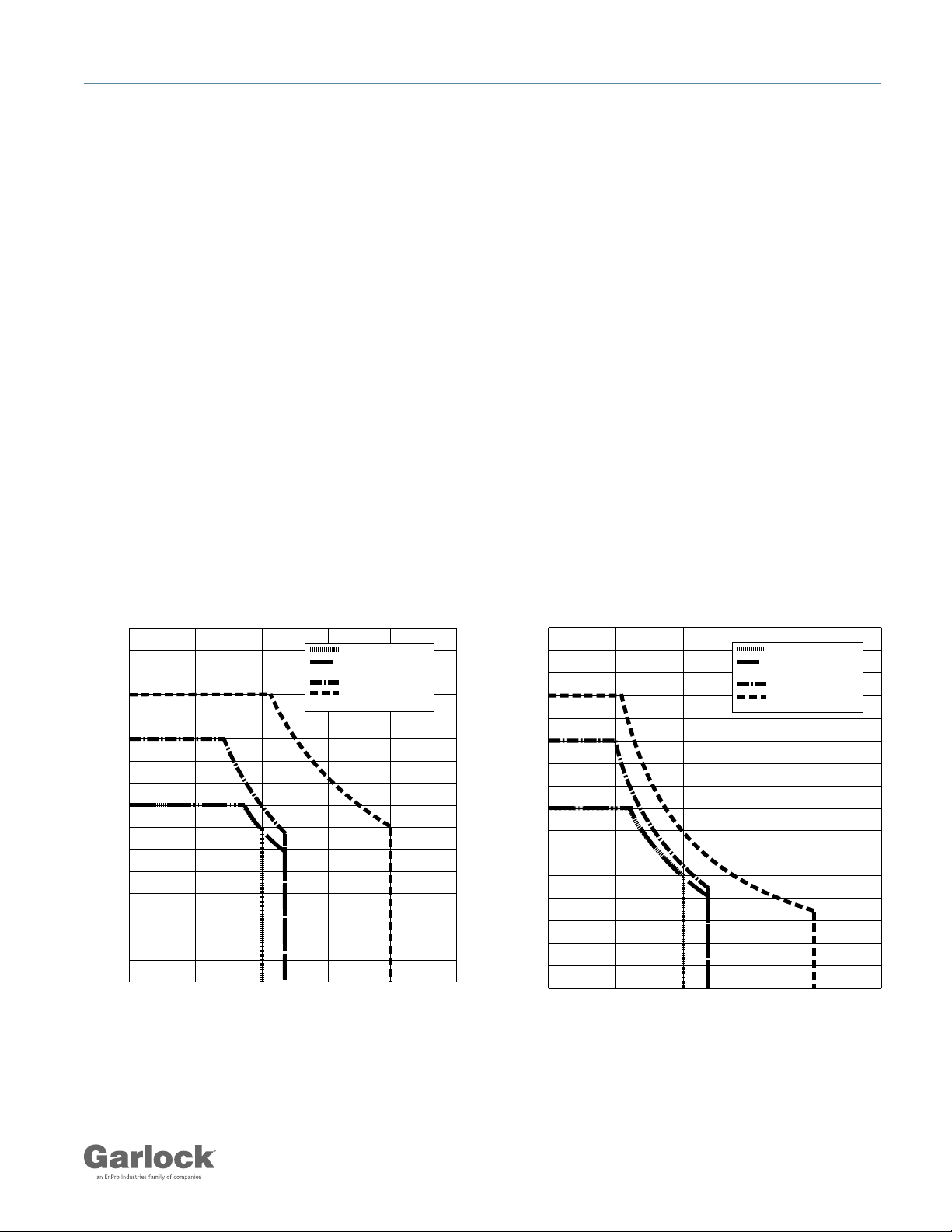

PxT Graph for 1/32" and 1/16" Compressed Gasketing

800

(427)

BLUE-GARD

700

(371)

600

(315)

BLUE-GARD

3300, 3400, 3700

®

IFG

G-9900, 9800, 9850

Garlock gasketing products are manufactured in completely

modernized facilities. Tight quality controls are used to

assure product conformance to specifications and uniformity

that results in unvarying performance on the job. Garlock is

certified to ISO 9001:2000 standards and is audited regularly

(every 30 months) by the Nuclear Procurement and Issues

Committee (NUPIC).

Today’s environmental concerns demand positive seals.

Garlock gaskets provide that assurance and perform

with proven reliability. Whether your industry is chemical

processing, hydrocarbon processing, power generation,

pulp and paper, microelectronics or transportation, Garlock

gasketing products are the logical choice.

Garlock also manufactures a wide range of elastomeric and

metallic gaskets. For products not listed in this catalog, contact

Garlock Gasket Applications Engineering at 1.800.448.6688.

PxT Graph for 1/8" Compressed Gasketing

800

(427)

700

(371)

600

(315)

1

BLUE-GARD® 3000

BLUE-GARD

3300, 3400, 3700

®

IFG

5500, 5507

G-9900, 9800, 9850

®

3200,

500

(260)

400

(201)

300

(150)

Te mperature – °F (°C)

200

(95)

100

(38)

0

0 500 1000 1500 2000 2500

(34.5) (69) (103.5) (138) (172.5)

500

(260)

400

(201)

Temperature – °F (°C)

300

(150)

200

(95)

100

(38)

0

0 500 1000 1500 2000 2500

NOTES:

1. Based on ANSI RF flanges at our preferred torque. When approaching maximum

pressure or continuous operating temperature, or 50% of maximum PxT, consult

Garlock Applications Engineering.

(34.5) (69) (103.5) (138) (172.5)

Pressure – psig (bar)

Leaders in Sealing Integrity

3

Garlock Fluid Sealing Products Technical Manual

Gasketing Selection

FACTORS AFFECTING GASKET PERFORMANCE

A gasket has one basic function: to create a positive seal between

two relatively stationary parts. The gasket must do a number of

different jobs well to function properly: first, create an initial seal;

second, maintain the seal over a desired length of time; third, be easily

removed and replaced. Varying degrees of success are dependent

on how well the gasket does the following:

1. Seals system fluid.

2. Chemically resists the system fluid to prevent serious impairment

of its physical properties.

3. Deforms enough to flow into the imperfections on the gasket

seating surfaces to provide intimate contact between the gasket

and the seating surfaces.

4. Withstands system temperatures without serious impairment of its

5. Is resilient and resists creep enough to maintain an adequate portion

6. Has sufficient strength to resist crushing under the applied load, and

7. Does not contaminate the system fluid.

8. Does not promote corrosion of the gasket seating surfaces.

9. Is easily and cleanly removable at the time of replacement.

During the gasket product selection process that follows, we recommend

that these nine (9) factors be used as a checklist from the viewpoint

of the user’s degree of need for each factor and the manufacturer’s

degree of compliance.

performance properties.

of the applied load.

maintain its integrity when being handled and installed.

Selecting gasketing materials for particular applications

is not an easy task. The variables present in a flanged

connection seem endless and yet all of them must be taken

into consideration to assure a proper seal. In the past, the

acronym "TAMP" (Temperature, Application, Media and

Pressure) seemed to give sufficient information to make a

gasketing recommendation. Today, items such as: the flange

material, the bolt grade, the flange surface finish (and many

other variables) also affect how well a gasket will perform. In

addition, the definition of what a seal is has changed drastically

over the years. Leakage measurements in some applications

have gone from drips a minute to parts per million.

Our catalog is designed to help guide you through the various

gasketing products and narrow your choices. All industry

standard tests are included in order to allow an end user a

means of comparison between different materials. Many

of the test procedures require that the tests be conducted

on 1/32" material. As a rule of thumb, gasket performance

decreases as material thickness increases. In addition,

compressive loads must be increased with thicker materials.

Proper bolting sequences are necessary to ensure those

compressive loads are uniform. The temperature, pressure

and P x T ratings are all based on optimum conditions. When

approaching those extremes, it is suggested that you consult

with the Garlock Applications Engineering Department or

possibly upgrade to a material that has higher ratings.

As industry standards change and new products are introduced,

this catalog will be updated. In the meantime, we urge you to

take advantage of our experienced personnel for assistance.

In-plant training, instructional videos, additional technical

information and gasketing recommendations all are available

to help in your selection process. Please feel free to call, fax,

write, or e-mail us should you have any questions or concerns.

Garlock is here to help.

Selection thought process:

There is a thought process required when selecting a

gasket; it basically involves narrowing the choices as we

learn the requirements and service conditions. While many

people are familiar with the need to know the temperature,

media, and pressure, few realize how important it is to fully

understand the “application”, which can be thought of as the

mechanical situation the gasket will see. First and foremost

is the compressive load applied to the gasket. With standard

flanges, such as 150# raised face (RF), we know the range of

compressive load on the gasket. With non-standard flanges, we

require more information. While not quite as simple as this, a

way to begin this thought process is this: Rubber and some

of the softer materials are preferred in light weight and/or full

face/flat face flanges; fiber and GYLON

flanges; Flexseal spirals or Kammprofile gaskets for high temp/

high pressure/high compressive load situations. We then

consider temperature, pressure and media to select a material.

®

gaskets for 150# RF

Leaders in Sealing Integrity

4

Garlock Fluid Sealing Products Technical Manual

Gasketing Selection & TAMPS

TEMPERATURE

In most selection processes, the temperature of the fluid at the gasketed

joint should be considered first. This will reduce the number of product

candidates quickly, especially as temperatures go from 200°F (95°C)

to 1,000°F (540°C). When system operating temperatures approach a

particular gasket material’s maximum continuous operating temperature

limit, an upgrade to a superior material is suggested. In some situations

cryogenic temperatures must also be considered.

APPLICATION

The most important information under application is the type of flange

and bolts used. The number, size and grade of bolts, along with the flange

thickness and material, determine the load available. The surface area

being compressed is calculated from the gasket contact dimensions.

The load from the bolts and the contact area of the gasket result in the

compressive load available to seal the gasket. We have calculated and

tabulated this information on standard ANSI raised face flanges (see

page 51). The compressive stress available on nonstandard flanges

must be calculated on an individual basis. Without this information, we

cannot choose between various types of materials such as elastomeric

(rubber) gaskets, compressed sheet, GRAPH-LOCK

For example, nonmetallic flanges such as FRP and CPVC are mostly

designed for rubber gaskets. They typically use a full face gasket, and the

allowable torque is limited so that the flanges do not crack when bolted.

Flat faced flanges made from cast iron, aluminum, bronze, or light weight

angle iron or plate will also use a full face gasket to avoid bending forces

in the flanges. We try to use softer gaskets in these as well, although

fiber gaskets and GRAPH-LOCK

Flanges that create very high compressive loads might require a metallic

spiral wound or kammprofile, but many can also be sealed with a fiber

or GYLON

RF flange is best suited for a metal gasket.

MEDIA

There are thousands of different fluids. We cannot, in this manual,

make recommendations for all fluids. Fortunately, however, there are a

relatively limited number of fluids that make up the vast majority of the

media encountered in industry. A general overview of fluid compatibility

is provided for the most popular styles shown in this manual (see

Chemical Resistance chart, pages 27 - 44). System clean out and flushes

should also be considered. Additional information on products versus

fluids is available upon request.

PRESSURE

Next to be considered is the internal pressure of the fluid at the gasketed

joint. We list the maximum pressure limits for each style. If severe and

frequent pressure changes are involved, we should be given the details,

since an alternative product may be needed.

®

gasket. A 150# RF flange is fine with any of these; a 600#

®

will often work.

®

and GYLON® styles.

SPECIAL REQUIREMENTS

In addition to the TAMPS, there are other requirements that are IN

ADDITION to the information listed above. Examples are compliance

with FDA, fire resistance, electrically insulating properties, cleaned

for oxygen service, etc. We have the words IN ADDITION in caps

because it is not uncommon to be asked for a “fire resistant” gasket

or an FDA gasket, without the necessary TAMP information.

PRESSURE (PSIG OR BARG) X TEMPERATURE (°F OR °C)

We strongly recommend that pressure and temperature be considered

simultaneously by using the following procedure:

1. First select the Garlock style(s) being considered for your

2. List the maximum pressure, temperature and P x T value for the

3. Make sure the actual service conditions do not exceed the style

Example: BLUE-GARD

1. Pressure Limit: 1,000 psig (70 bar)

2. Maximum Temperature Limit: 700°F (370°C);

3. P x T Limit: 350,000* (12,000)

At 1,000 psig (70 bar), maximum temperature is 350°F (180°C).

IMPORTANT

Maximum pressure and P x T ratings are based on the use of ANSI

RF flanges at our preferred torque. The ratings were developed

using laboratory tests at ideal gasketing conditions. Field conditions

will undoubtedly affect the gasket performance.

When approaching maximum pressure, continuous operating

temperature, minimum temperature or 50% of maximum PxT,

consult Garlock Applications Engineering.

We hasten to point out that this method for gasket selection is merely

a general guide and should not be the sole means for selecting or

rejecting a product.

* P x T based on 1/16" sheet thickness unless otherwise stated.

application/service,

style(s),

limitations in any of the three criteria. If they don’t, the style(s)

can be used, provided all other requirements are met. If they do

exceed any one limit, another style or styles should be considered.

Rarely can a style be recommended when the service conditions

of pressure and temperature are both at the maximum limits for

that style.

®

Compressed Gasketing Style 3000

Continuous Operating Temp.: 400°F (205°C)

Leaders in Sealing Integrity

5

Garlock Fluid Sealing Products Technical Manual

Bolting and Flange Information

The gasket’s function is to seal two different surfaces held together by

one of several means, the most common being screw-threaded devices

such as bolts. Sometimes the fastener itself must be sealed, as in the

case of a steel drum bung.

The bolt is a spring. It is an elastic member that has been stretched to

develop a load. The more spring provided by the bolt, the better the

retention of stress on the gasket to maintain a leakproof joint. It must

not be over-elongated (over-strained), or the elastic limit of the steel

will be exceeded. The bolt then deforms and, with continued loading

(stressing), may break.

PROPER TIGHTENING

To avoid such problems with bolt tightening, the use of a torque

wrench is recommended. The torque tables on page 50 show the

recommended torque values for Garlock compressed sheet, GYLON

and GRAPH-LOCK

flanges. The equipment designer may specify the recommended torque

to prevent damage to the equipment from over torquing. Garlock’s

recommended assembly stresses, page 49, may help the equipment

designer determine the maximum allowable torque per bolt. The load

will be retained better by using a bolt with a longer grip, thereby ensuring

a leakproof joint.

IMPERFECTIONS

There are limits on the degree of flange surface imperfection that can

be sealed successfully with a gasket. Large nicks, dents, or gouges

must be avoided, since a gasket cannot properly seal against them.

The surface finish of a flange is described as follows:

1. Roughness: Roughness is read in millionths of an inch (or meter) as

the average of the peaks and valleys measured from a midline of the

flange surface. This is expressed either as rms (root mean square) or

AA (arithmetic average). The difference between these two methods of

reading is so small that they may be used interchangeably. Roughness

is also expressed as AARH (arithmetic average roughness height).

2. Lay: Lay is the direction of the predominant surface-roughness

pattern. Example: multidirectional, phonographic spiral serrations, etc.

3. Waviness: Waviness is measured in thousandths or fractions of an

inch. Basically, it is the departure from overall flatness.

®

gasketing materials in 150 lb. and 300 lb. raised face

FLANGE FINISH

Typical roughness readings can be from 125 to 500 micro-inches for

serrated flanges and 125-250 micro-inches for non-serrated flanges.

Fine finishes, such as polished surfaces, should be avoided. Adequate

"bite" in the surface is required to develop enough friction to prevent the

gasket from being blown out or from extruding or creeping excessively.

SERRATIONS OR ROUGHNESS

The lay of the finish should follow the midline of the gasket if possible.

Take, for example, concentric circles on a round flange, or a phonographic

spiral. Every effort should be made to avoid lines across the face, such

as linear surface grinding, which at 180° points will cross the seal area

at right angles to the gasket, allowing a direct leak path.

Waviness is seldom a problem under normal conditions. There are two

®

areas that must be watched, however, since excessive waviness is

very difficult to handle.

The first area is glass-lined equipment where the natural flow of the

fused glass creates extreme waviness. Often the answer here is to use

thick and highly compressible gasketing.

The second area of concern is warped flanges. If warpage is caused by

heat or internal stresses, re-machining is generally sufficient. However,

warpage due to excessive bolt loads or insufficient flange thickness

results in what is generally called bowing.

The solution is to redesign for greater flange rigidity. Sometimes backer

plates can be added to strengthen the design without having to replace

the parts. Another step would be to add more bolts. When this is done,

usually smaller bolt diameters are possible, thus adding more bolt stretch

and better joint performance.

Leaders in Sealing Integrity

6

Garlock Fluid Sealing Products Technical Manual

Styles 5500 and 5507

Compressed Inorganic Fiber Gasket

BENEFITS

Tighter Seal

» Inorganic fiber gasketing offers excellent thermal stability with

minimal weight loss

» Reduced creep relaxation and improved torque retention

provide optimal sealability

Temperature resistant

» Non-oxidizing fibers withstand a continuous operating

temperature of up to 550˚F (290˚C), and maximum spike of

800˚F (425˚C)

» Style 5500 has passed the Garlock Fire Test and is ABS Fire

Safe Type Approved

Media

Style 5500

» Water, aliphatic hydrocarbons, oils, gasoline, saturated steam

inert gases, most refrigerants

Style 5507

» Water, saturated steam

†

TYPICAL PHYSICAL PROPERTIES*

4.5

5500

Color Gray Sand

Binder Nitrile (NBR) EPDM

Temperature

Pressure

P x T, max.

(bar x ˚C)

Sealability (ASTM F37B)

ASTM Fuel A

Nitrogen

Creep Relaxation (ASTM F38) % 25 15

Compressibility Average (ASTM F36) % 10 10

Recovery (ASTM F36) % >50 >50

Tensile Strength across grain

(ASTM F152)

Density lbs/ft

Gas Permeability

(DIN 3535 Part 4)

1

1

, continuous max. psig (bar) 1,200 (83) 1,200 (83)

(psig x ˚F)

2

3

Maximum

Minimum

Continuous Max.

1/32", 1/16"

(0.8mm, 1.6mm)

1/8"

(3.2mm)

ml/hr

ml/hr

psi

2

(N/mm

)

3

(g/cm3) 100 (1.60) 105 (1.68)

800˚F (425˚C)

-100˚F (-75˚C)

550˚F (290˚C)

400,000

(14,000)

275,000

(9,600)

0.3

1.0

1,500

(10)

cc/min. 0.05 0.04

5507

800˚F (425˚C)

-100˚F (-75˚C)

550˚F (290˚C)

400,000

(14,000)

275,000

(9,600)

0.2

1.0

1,500

(10)

, mild chemicals and mild alkalies

NOTES:

4

1

Based on ANSI RF flanges

at our preferred torque.

When approaching maximum

pressure, continuous

operating temperature,

minimum

temperature or 50% of

maximum PxT, consult Garlock

Engineering.

2

ASTM F37B Sealability

ASTM Fuel A (isooctane):

Gasket load = 500 psi (3.5

N/mm2), Int. pressure = 9.8

psig (0.7 bar)

Nitrogen:

Gasket load = 3,000 psi

(20.7 N/mm2), Int. pressure =

30 psig (2 bar)

3

DIN 3535 Part 4 Gas

Permeability, cc/min. (1/16"

thick)

Nitrogen:

Gasket load = 4,640 psi (32

N/mm2), Int. pressure = 580

psig (40 bar)

4

Saturated steam service

guidelines:

› For optimal performance,

use thinner gaskets when

possible.

› Minimum recommended

assembly stress = 4,800 psi.

› Preferred assembly stress =

6,000 psi to 10,000 psi.

› Retorque the bolts/studs

prior to pressurizing the

assembly.

› If the service is superheated

steam, contact Applications

Engineering.

†

,

†

For steam service above 150 psig contact Applications Engineering

* Values do not constitute specification limits

Leaders in Sealing Integrity

7

Garlock Fluid Sealing Products Technical Manual

High Temp Compressed Graphite

or Carbon Fiber Gasketing

TYPICAL PHYSICAL PROPERTIES*

4

9900

Color Mahogany Black Black

Composition Graphite with nitrile Carbon with SBR Carbon with nitrile

Temperature

Pressure

P x T, max.

1

1

(psig x ˚F)

(bar x ˚C)

Sealability (ASTM F37B)

ASTM Fuel A

Nitrogen

2

Maximum

Minimum

Continuous Max.

1,000˚F (540˚C)

-100˚F (-75˚C)

650˚F (340˚C)

psig (bar) 2,000 (138) 2,000 (138) 2,000 (138)

1/32", 1/16"

(0.8mm, 1.6mm)

1/8"

(3.2mm)

ml/hr

ml/hr

700,000

(25,000)

350,000

(12,000)

0.3

0.6

Creep Relaxation (ASTM F38) (1/32") % 9 15 15

Compressibility Average (ASTM F36) % 9 8 8

Recovery (ASTM F36) % >55 >55 >55

Tensile Strength across grain

(ASTM F152)

psi

(N/mm

Density lbs/ft

Gas Permeability

(DIN 3535 Part 4)

3

cc/min. 0.015 0.015 0.015

2

)

3

(g/cm3) 110 (1.76) 105 (1.68) 105 (1.68)

1,800

(12)

4

9800

900˚F (480˚C)

-100˚F (-75˚C)

650˚F (340˚C)

700,000

(25,000)

350,000

(12,000)

0.3

0.6

1,800

(10)

4

9850

900˚F (480˚C)

-100˚F (-75˚C)

650˚F (340˚C)

700,000

(25,000)

350,000

(12,000)

0.3

0.6

1,800

(12)

This is a general guide and should not be the sole means of selecting

or rejecting this material. ASTM test results in accordance with ASTM

F-104; properties based on 1/16" (1.6mm) sheet thickness.

* Values do not constitute specification limits

All styles are furnished with an anti-stick parting agent as standard.

NOTES:

1

Based on ANSI RF flanges at our preferred torque. When approaching maximum

pressure, continuous operating temperature, minimum

temperature or 50% of maximum PxT, consult Garlock Engineering.

2

ASTM F37B Sealability

ASTM Fuel A (isooctane):

Gasket load = 500 psi (3.5 N/mm2), Int. pressure = 9.8 psig (0.7 bar)

Nitrogen:

Gasket load = 3,000 psi (20.7 N/mm2), Int. pressure = 30 psig (2 bar)

3

DIN 3535 Part 4 Gas Permeability, cc/min. (1/16" thick)

Nitrogen:

Gasket load = 4,640 psi (32 N/mm2), Int. pressure = 580 psig (40 bar)

4

Saturated steam service guidelines:

› For optimal performance, use thinner gaskets when possible.

› Minimum recommended assembly stress = 4,800 psi.

› Preferred assembly stress = 6,000 psi to 10,000 psi.

› Retorque the bolts/studs prior to pressurizing the assembly.

› If the service is superheated steam, contact Applications Engineering.

Leaders in Sealing Integrity

8

Garlock Fluid Sealing Products Technical Manual

Style 9900

BENEFITS

Tough & Reliable

» Graphite fiber gasketing withstands extreme temperatures and

pressures, as well as many chemicals

» Passed Garlock fire tests and is ABS Fire Safe Type Approved

» See note below for STR 508

Tighter Seal

» Maintains superior seal during thermal cycling, even in

saturated steam

» Significantly reduces emissions to meet stringent Clean Air Act

requirements

†

and hot oils

NOTE:

1. For nuclear orders, specify Style G-9920.

2. Refer to Mil Spec section under "Gasketing Terms" for order/inquiry

requirements

Easy to Install

» Graphite fiber sheet is easier to handle and cut than exfoliated

graphite sheets or metal-inserted gasket material

Media

» Saturated steam†, water, inert gases, aliphatic hydrocarbons,

oils, gasoline and most refrigerants

Hi-Temp Styles 9800 / 9850

BENEFITS

Heat & Pressure Resistant

» Carbon fiber gasketing excels in harshest conditions - intense

heat, high pressure, saturated steam

» Laboratory tested for fire safety

Tighter Seal

» Maintains effective seal during pressure and temperature

fluctuations

» Superior torque retention lowers leakage rates and reduces

maintenance time

Convenient

» Flexible material is easy to handle and cut

» Sheet sizes to 150" x 150" (3.8m x 3.8m) minimize waste and

inventory costs

†

and hot oils (Style 9850)

Media

Style 9800

» Saturated steam

Style 9850

» Saturated steam

and most refrigerants

NOTES:

†

For steam service above 150 psig, contact Engineering

Refer to “Military Specifications” section under “Gasketing Terms” for order/

inquiry requirements. To ensure receipt of product with the required STR 508

approvals, certification will be required; associated fees based on quantity.

†

, water and inert gases

†

, water, aliphatic hydrocarbons, oils, gasoline

Various gasket materials including 9900, 9800, 9850 and 5500,

have been tested to industry fire test standards.

Leaders in Sealing Integrity

9

Garlock Fluid Sealing Products Technical Manual

THERMa-PUR™ Style 4122/4122-FC

FC, CMG, KAMM, Spiral Wound

THERMa-PUR™ is a proprietary new gasketing material designed for use in high temperature

sealing applications and is produced using an environmentally friendly solvent-free process.

THERMa-PUR

temperature resistance.

VALUE & BENEFITS

Extreme Temperature

» Able to withstand high temperatures, whether continuous

or in thermal cycling conditions

Oxidation Resistance

» Contains proprietary materials that provide improved weight

loss characteristics over other high temperature solutions.

(see graph)

Hydrophobic & Electrically Insulating

» Resists water and provides electrical isolation thus reducing

the possibility of corrosion between flanges made of

dissimilar metals

Easy Release from Flanges

» Does not stick to flanges making removal of gaskets easy

and fast

Safer Handling (4122-FC)

» Patent-pending fiber core makes gaskets safer to handle

when compared to traditional high temperature gaskets

with steel cores

IDEAL FOR

» Marine and Land-based Exhaust Systems

» Biomass Gasification Process

» Oil and Gas Production

» Mineral and Fertilizer Processing

» Incineration Process

» Co-generation Systems

» Turbochargers Equipment

» Process Drying Equipment

CONFIGURATIONS

» Available in;

› Sheet

› Standard Flexseal Spiral Wound Configurations: RW/RWI/

SW/SWI

› Standard Flexseal Spiral Wound Configurations with facing

material on the winding faces

› Kammprofile

› THERMONIC

™

is yet another innovative Garlock sealing solution that provides more than just

TYPICAL PHYSICAL PROPERTIES

Continuous max. +1832°F (1000°C)

1

psig (bar) 4122-FC 500 (34.5)

2

4122-FC

™

Corrugated metal gasket

Temperature

Pressure

P x T, max.

psig x °F (bar x °C)

Typical Physical Properties for 4122FC*:

ASTM Test Method F36

Compressibility, range, %

Recovery %

ASTM F38

Creep Relaxation, %

ASTM F152

Tensile, w/insert, psi (N/mm2)

ASTM F1315

Density, lbs./ft3 (grams/cm3)

ASTM D149

Dielectric Properties, volts/mil.

Gasket Factor ‘M’ 3.0

Gasket Factor ‘Y’ 10,000

NOTES:

1. Based on ANSI RF flanges at our preferred torque. When approaching maximum

pressure, continuous operating temperature, minimum temperature or 50% of

maximum PxT, consult Garlock Engineering.

2. PxT = psig x ºF (bar x ºC)

* This is a general guide and should not be the sole means of selecting or rejecting

this material. ASTM test results in accordance with ASTM F-104; properties based

on 1/16" (1.6mm) gasket thickness unless otherwise mentioned. Values do not

constitute specifiacation limits.

150,000 (5,100)

35-45

18

25

1,200 (8.3)

85 (1.36)

100

10

Leaders in Sealing Integrity

Garlock Fluid Sealing Products Technical Manual

d

original

weight

K

G

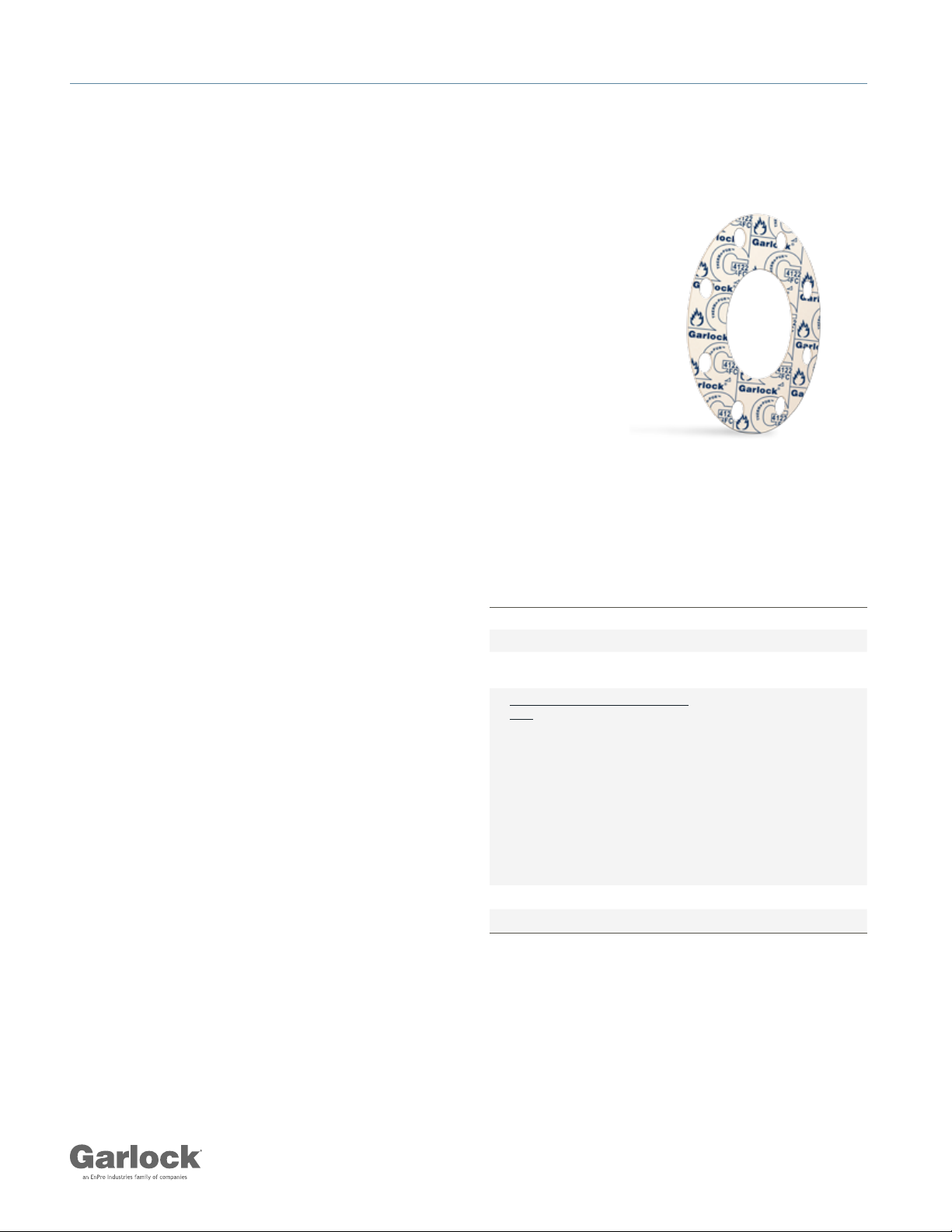

OUT PERFORMS

™

THERMa-PUR

laboratory testing

out performed vermiculite based gaskets in

†

. THERMa-PUR™ showed significantly less

leakage even in extreme thermal cycling condition

†For test details, please contact Garlock Engineering

LeakageTes twithThermalCycling(CutGasket)

800

Temperature:Thermalcyclingbetween

ambientand1000F.

700

Application:2”300#RaisedFaceFlanges

600

Media:Nitrogen

Internalpressure:30psig

500

Torque:60ft‐lbs

Installationgasketload: 8000psi

400

Thickness:1/16”

300

AGERATE(ml/hr)

LEA

200

100

4122‐FC

VermiculiteGasket

0

Ambient

249 85 717 84 790

1stThermal

Cycle@1000°F

25 36 152 45 152

Ambient

(cooldown)

2ndThermal

Cycle@1000°F

.

LeakageTes twithThermalCycling(MetallicGasket)

Ambient

(cooldown)

50

40

30

20

ERATE(ml/hr)

10

LEAKA

4122‐KAMM

4122‐CMG

VermiculiteSWG

KAMM ‐Kammprofile

CMG ‐ CorrugatedMetalGasket

SWG‐ SpiralWoundGasket

0

Ambient

1stThermal

Cylce@1000°F

1.4 2.8 4.8 5.7 5.2

0.10 0.80 0.53 0.10 0.53

1.0 49.5 3.4 53.3 3.8

Ambient

(cooldown)

2ndThermal

Cycle@1000°F

Temperature:Thermalcycling

betweenambientand1000F.

Application:2”300#Raised

FaceFlanges

Media:Nitrogen

Internalpressure:30psig

Torque:60ft‐lbs

Installationgasketload:

8000psi

Ambient

(cooldown)

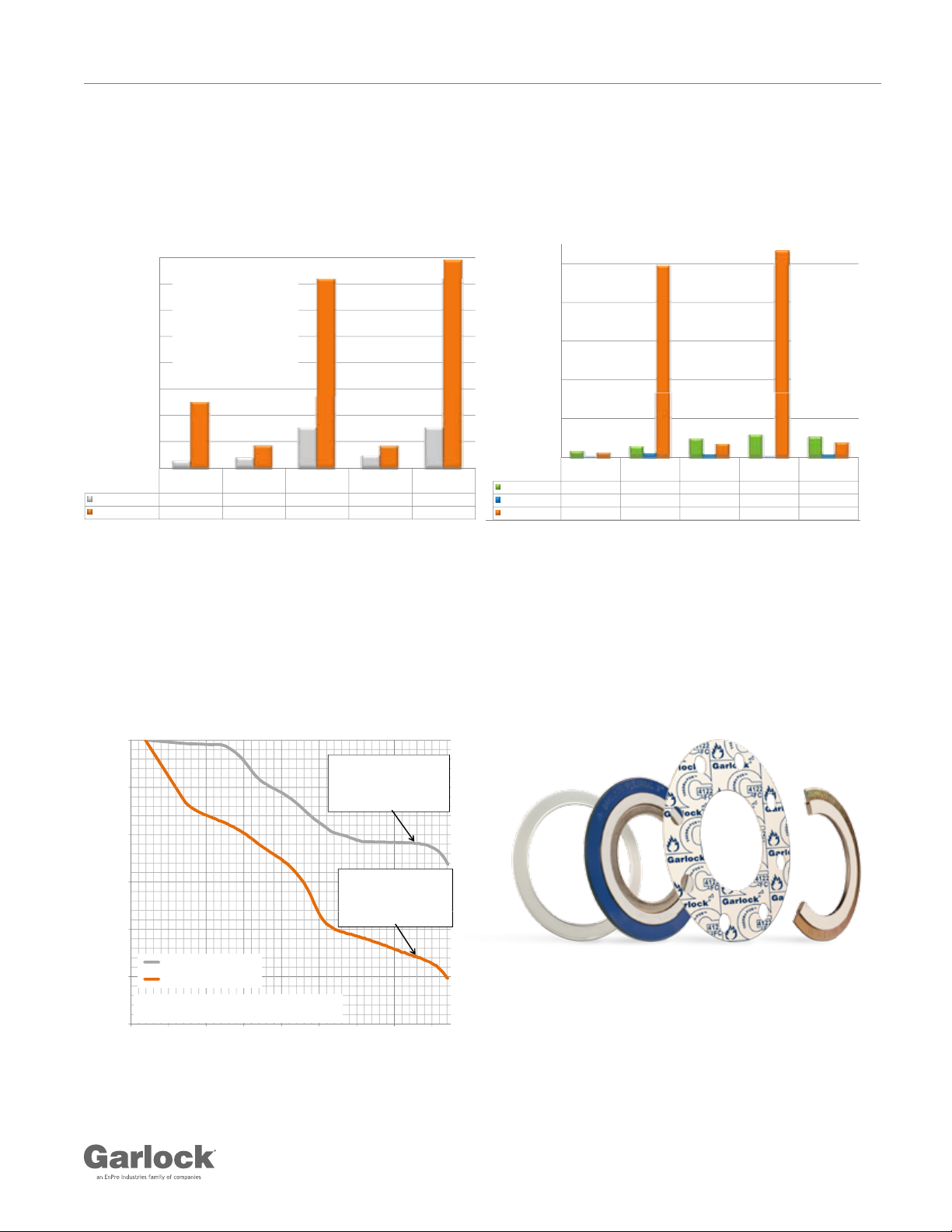

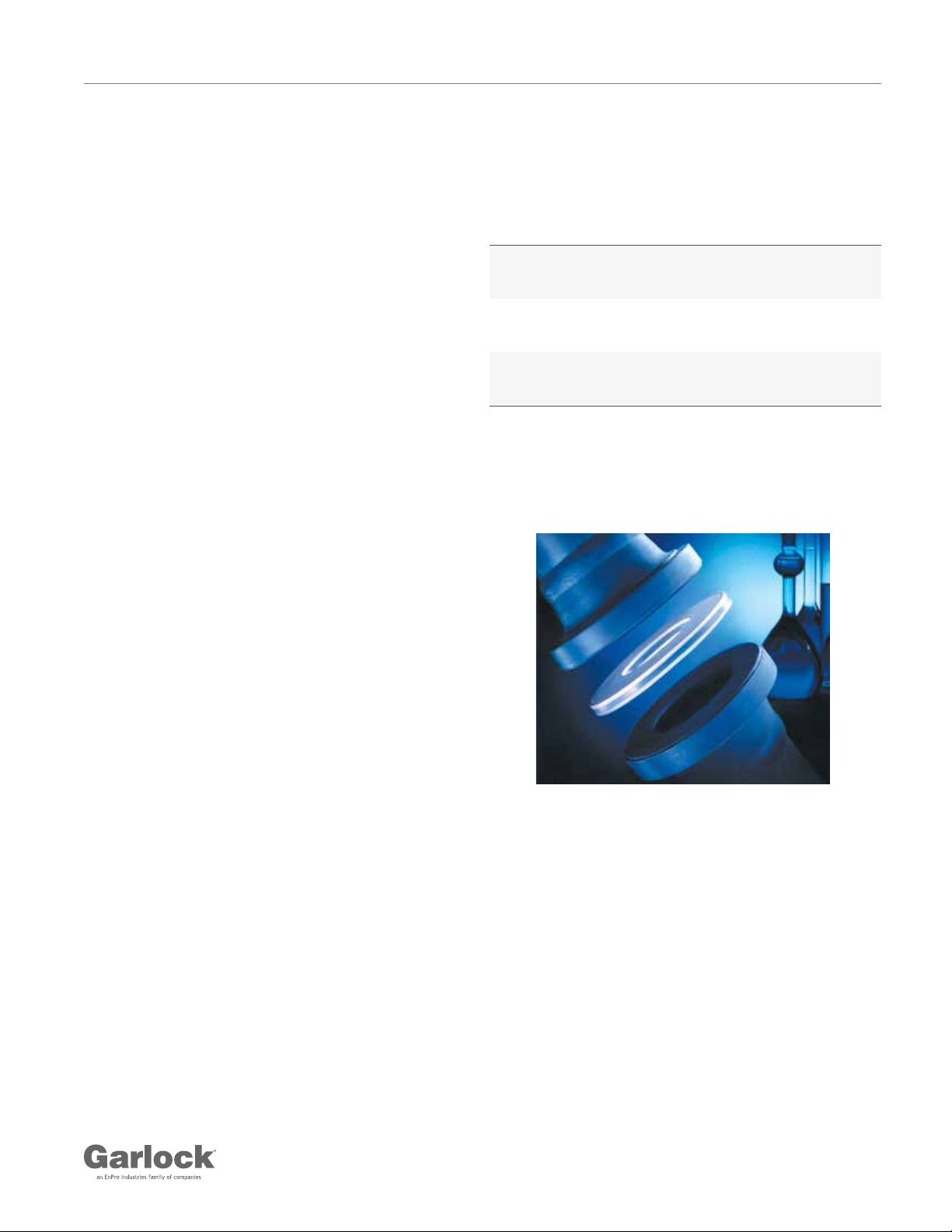

LOW WEIGHT LOSS

THERMa-PUR™ proprietary formulation resists oxidation and has

improved weight loss property by almost 2X when compared

to other high temp organic based gaskets such as graphite and

vermiculite.

Weight Loss Tesng (TGA¹)

100

THERMa-PUR™

THERMa-PUR™

maintained 95% of

98

96

94

ual Mass (%)

92

Resi

THERMa-PUR™

90

Vermiculite Gasket

¹TGA—thermal gravimetric analysis in oxygen atmosphere

@ 80°F to 1650°F with 30min hold at max temperature

88

0 200 400 600 800 1000 1200 1400 1600

Temperature ( F)

maintained 95% of

its original weight

it's original weight

Vermiculite Gasket

Vermiculite Gasket

lost 10% of its

lost 10% of its

original weight

Leaders in Sealing Integrity

11

Garlock Fluid Sealing Products Technical Manual

BLUE-GARD® Compressed Gasketing

TYPICAL PHYSICAL PROPERTIES*

3000 3200/3400

4/5

Color Blue Off-white/

Grey-black

Binder Nitrile (NBR) SBR Neoprene (CR) EPDM Nitrile (NBR)

Temperature

Pressure

P x T, max.

1

1

(psig x ˚F)

(bar x ˚C)

Sealability (ASTM F37B)

ASTM Fuel A

Nitrogen

2

Maximum

Minimum

Continuous Max.

+700°F (+370°C)

-100°F (-75°C)

+400°F (+205°C)

+700°F (+370°C)

-100°F (-75°C)

+400°F (+205°C)

+700°F (+370°C)

-100°F (-75°C)

+400°F (+205°C)

psig (bar) 1,000 (70) 1,200 (83) 1,200 (83) 1,200 (83) 1,000 (70)

1/32", 1/16"

(0.8mm, 1.6mm)

1/8"

(3.2mm)

ml/hr

ml/hr

350,000

(12,000)

250,000

(8,600)

0.2

0.6

350,000

(12,000)

250,000

(8,600)

0.3

0.7

Creep Relaxation (ASTM F38) % 21 18 20 20 25

Compressibility Average (ASTM F36) % 8 10 10 10 8

Recovery (ASTM F36) % 50 50 50 50 50

Tensile Strength across grain

(ASTM F152)

psi

(N/mm

Density lbs/ft

Gas Permeability

(DIN 3535 Part 4)

3

cc/min. 0.05 0.03 0.08 0.04 -

2

)

3

(g/cm3) 100 (1.60) 100 (1.60) 105 (1.68) 100 (1.60) 105 (1.68)

2,150

(15)

2,250

(15)

3300

4

3700

4

2900/2950

Black Light grey Black/Green

350,000

(12,000)

250,000

(8,600)

0.2

1.0

1,800

(12)

+700°F (+370°C)

-100°F (-75°C)

+400°F (+205°C)

350,000

(12,000)

250,000

(8,600)

0.3

0.7

1,800

(12)

+700°F (+370°C)

-100°F (-75°C)

+400°F (+205°C)

350,000

(12,000)

250,000

(8,600)

0.5

1.00

1,500

(10)

NOTES:

1

Based on ANSI RF flanges at our preferred torque. When approaching maximum

pressure, continuous operating temperature, minimum temperature or 50% of

maximum PxT, consult Garlock Engineering.

2

ASTM F37B Sealability

ASTM Fuel A (isooctane):

Gasket load = 500 psi (3.5 N/mm2), Int. pressure = 9.8 psig (0.7 bar)

Nitrogen:

Gasket load = 3,000 psi (20.7 N/mm2), Int. pressure = 30 psig (2 bar)

3

DIN 3535 Part 4 Gas Permeability, cc/min. (1/16" thick)

Nitrogen:

Gasket load = 4,640 psi (32 N/mm2), Int. pressure = 580 psig (40 bar)

4

Saturated steam service guidelines:

› For optimal performance, use thinner gaskets when possible.

› Minimum recommended assembly stress = 4,800 psi.

› Preferred assembly stress = 6,000 psi to 10,000 psi.

› Retorque the bolts/studs prior to pressurizing the assembly.

› If the service is superheated steam, contact Applications Engineering

5

Refer to Mill spec section under "Gasketing Terms" for order/inquiry requirements

This is a general guide and should not be the sole means of selecting

or rejecting this material. ASTM test results in accordance with ASTM

F-104; properties based on 1/32" (0.8mm) sheet thickness.

* Values do not constitute specification limits

All styles are furnished with an anti-stick parting agent as standard.

12

Leaders in Sealing Integrity

Garlock Fluid Sealing Products Technical Manual

BLUE-GARD® Styles 3000 to 3700

BENEFITS

Excellent Sealability

» Unique blend of aramid fibers, fillers and elastomeric binders

provides improved torque retention and drastically lowered

emissions levels

Versatile

» Variety of elastomers excel in a wide range of services

» See note below for DTL 24696

Cost Savings

» Cuts operational costs through reduced:

› Waste

› Maintenance efforts

› Stocked inventory

› Fluid loss

› Energy consumption

Styles 2900, 2950

BENEFITS

Ideal for utility services

» Excellent sealability

» Improved thermal stability

» Good for general service

MEDIA

3000 Water, aliphatic hydrocarbons, oils & gasoline

*

, 3400 Water, saturated steam†, inert gases

3200

3300 Water, saturated steam

3700 Water, saturated steam

2900, 2950 Water, aliphatic hydrocarbons, oils & gasoline

NOTE:

All styles are furnished with an anti-stick parting agent as standard.

†

For steam service above 150psig, contact Engineering.

* Refer to “Military Specifications” section under “Gasketing Terms” for order/inquiry

requirements. To ensure receipt of product with the required DTL 24696 branding,

certification will be required; associated fees based on quantity.

» WRC BS 6920 Approved

» Meets BS7531 Grade Y Specifications

†

, refrigerants, oils and fuels

†

and mild chemicals

WARNING:

The failure to select the proper sealing product for your application can result in property

damage and/or serious personal injury. You should not purchase or use any of the

products identified in this brochure without undertaking a thorough, independent study,

and obtaining an evaluation of your particular application by qualified professionals. The

descriptions of the products contained in this brochure constitute general guidelines as

to product selection and installation and may not be appropriate for your particular project.

The performance data and metrics contained in this brochure are not specification min/

max limits, or guarantees of performance, but instead represent typical values that have

been established based upon field testing, customer field reports, and/or in-house testing.

Actual performance will vary from these values and you should not rely upon these figures

in determining the suitability of the use of the product for any particular application.

While the utmost care has been used in compiling this brochure, we assume no

responsibility for errors. Specifications subject to change without notice. This edition

cancels all previous issues. Subject to change without notice.

GARLOCK is a registered trademark for packings, seals, gaskets, and other products

of Garlock.

Leaders in Sealing Integrity

13

Garlock Fluid Sealing Products Technical Manual

MULTI-SWELL™ Style 3760, 3760-U

BENEFITS

Ultra-tight seal in water and oil applications

» Proprietary formulation creates additional gasket load when the

gasket comes in contact with oil or water

» Twice as compressible as standard fiber gaskets - conforms to

irregular surfaces

Versatile

» Stops leakage in:

› Gear boxes

› Compressors

› Pumps

› Lube oil systems

› Access covers

TYPICAL PHYSICAL PROPERTIES*

3760

Color Blue/off-white

Binder Proprietary

Temperature

Pressure

P x T, max. (psig x ˚F)

(bar x ˚C)

Sealability (ASTM F37B)

ASTM Fuel A

Nitrogen

Gas Permeability

(DIN 3535 Part 4)

Creep Relaxation (ASTM F38)

Compressibility Average

(ASTM F36) %

Recovery (ASTM F36) %

Tensile Strength across grain

(ASTM F152) psi (N/mm2)

Density 1/32" (0.8mm) thk lbs/ft3 (g/cm3)

This is a general guide and should not be the sole means of selecting or

rejecting this material. ASTM test results in accordance with ASTM F-104;

properties based on 1/32" (0.8mm) sheet thickness.

1

2

2

3

Minimum

Continuous Max

Max., psig (bar) 500 (34.5)

1/32", 1/16"

(0.8mm, 1.6mm)

1/8"

(3.2mm)

ml/hr

ml/hr

cc/min. -

% 30

-100 °F ( -75°C)

400°F (205°C)

150,000

(5,100)

100,000

(3,400)

0.20

0.40

15

40

1,000 (6.9)

85 (1.36)

NSF 61 certified MULTI-SWELL™ Style 3760-U

Nuclear Safety Related - 10CFR 50 Appendix B

NOTES:

1

Based on ANSI RF flanges at our preferred torque. When approaching

maximum pressure, continuous operating temperature, minimum

temperature or 50% of maximum PxT, consult Garlock Engineering.

2

ASTM F37B Sealability

ASTM Fuel A (isooctane):

Gasket load = 500 psi (3.5 N/mm2), Int. pressure = 9.8 psig (0.7 bar)

Nitrogen:

Gasket load = 3,000 psi (20.7 N/mm2), Int. pressure = 30 psig (2 bar)

3

DIN 3535 Part 4 Gas Permeability, cc/min. (1/16" thick)

Nitrogen:

Gasket load = 4,640 psi (32 N/mm2), Int. pressure = 580 psig (40 bar)

* Values do not constitute specification limits

14

Leaders in Sealing Integrity

Garlock Fluid Sealing Products Technical Manual

Vegetable Fiber Gasketing

TYPICAL PHYSICAL PROPERTIES*

660 681

Material Vegetable fiber with cork granules

and glue-glycerin binder

Temperature

1

212°F (10 0°C ) 212°F (10 0°C )

Pressure, max psig (bar) 20 0 (15) 20 0 (15)

P x T, max. psig x ˚F (bar x ˚C)

Widths available inches

Thickness available inches

40,000 (1,300) 40,000 (1,300)

36 36

1/64 , 0.021,

1/3 2, 3 /6 4, 1/16,

3/32, 1/8, 3/16, 1/4

Compressibility at 1,000 psi Range %

Recovery %

Tensile Strength, min. psi (N/mm2)

Meets Specifications

ASTM-D-1170-62T, Grade P-3415-A; SAE

40-55 25- 40

>40 >40

1,000 (7) 2,000 (14)

J90, Grade P-3415-A; MIL-G-12803C,

Grade P-3415-A

Vegetable fiber with glue-glycerin binder

0.00 6, 0.010, 1/6 4,

0.021, 1/32, 3/64,

1/16, 3/32, 1/8, 3/16, 1/4

ASTM-D-1170-62T, Grade P-3313-B; SAE J90,

Grade P-3313-B; MIL-G-12803C, Grade P-

3313-B; HH-P-96F Type 1

NOTES:

1

Gasket materials are immersed in fluids for 22 hours at 70°-85°F (21-29°C).

* Values do not constitute specification limits

VEGETABLE FIBER TOLERANCES ON THICKNESS

0.006" ±0.0035" 0.062" ±0.005"

0.010" ±0.0035" 0.094" ±0.008"

0.015" ±0.0035" 0.125 " ±0.016 "

0.021" ±0.005" 0.1 87" ±0.016"

0.0 31" ±0.005" 0.250" ±0.016 "

0.046" ±0.005"

WARNING:

The failure to select the proper sealing product for your application can result in property

damage and/or serious personal injury. You should not purchase or use any of the

products identified in this brochure without undertaking a thorough, independent study,

and obtaining an evaluation of your particular application by qualified professionals. The

descriptions of the products contained in this brochure constitute general guidelines as

to product selection and installation and may not be appropriate for your particular project.

The performance data and metrics contained in this brochure are not specification min/

max limits, or guarantees of performance, but instead represent typical values that have

been established based upon field testing, customer field reports, and/or in-house testing.

Actual performance will vary from these values and you should not rely upon these figures

in determining the suitability of the use of the product for any particular application.

While the utmost care has been used in compiling this brochure, we assume no

responsibility for errors. Specifications subject to change without notice. This edition

cancels all previous issues. Subject to change without notice.

GARLOCK is a registered trademark for packings, seals, gaskets, and other products

of Garlock.

Leaders in Sealing Integrity

15

Garlock Fluid Sealing Products Technical Manual

GYLON® Family

Styles 3500 to 3510

BENEFITS

Tighter seal

» Improved performance over conventional PTFE

» Reduced product loss and emissions

Reduced creep relaxation

» Unique manufacturing process minimizes cold flow problems

typical of skived and expanded PTFE sheets

» Excellent bolt torque retention

Chemical resistance

» Withstands a wide range of chemicals for extended service life

in a wide variety of applications

Cost savings

» Cuts operational costs through reduced:

› Fluid loss

› Energy consumption

› Maintenance costs

Largest sheet sizes*

» Offers some of the largest sheet sizes in the industry

» Improved material utilization reduces waste

Branding and color coding

» Easy identification of superior GYLON® products

» Reduces misapplication and use of unauthorized, inferior

substitutes

MEDIA

GYLON® 3500

GYLON® 3504

GYLON® 3510

NOTES:

1

ASTM F37B Sealability, milliliters/hour (1/4" thick)

ASTM Fuel A (isooctane):

Gasket load: 3,000 psi (20.7 N/mm2), Internal pressure: 30 psig (2 bar)

2

DIN 3535 Part 4 Gas Permeability, cc/min. (1/4" thick)

Nitrogen:

Internal pressure: 580 psig (40 bar), Gasket load: 4,640 psi (32 N/mm2)

* 60" x 60" (1524 mm x 1524 mm), 70" x 70" (1778 mm x 1778 mm),

60" x 90" (1524 mm x 2286 mm)

Strong acids (except hydrofluoric), solvents,

hydrocarbons, water, steam, chlorine, and cryogenics.

Conforms to FDA regulations. (For oxygen service,

specify "Style 3502 for oxygen service.")

Moderate concentrations of acids and some caustics,

hydrocarbons, solvents, water, refrigerants, and

cryogenics. Conforms to FDA regulations. (For oxygen

service, specify "Style 3505 for oxygen service.")

Strong caustics, moderate acids, chlorine, gases, water,

steam, hydrocarbons, and cryogenics. Conforms to FDA

regulations. (For oxygen service, specify "Style 3503 for

oxygen service.")

16

› Inventory costs

› Waste

Thermally Bonded GYLON

®

BENEFITS

Effective seal

» Patented bonding process produces large one piece gaskets

without dovetailed joints for easier installation

» GYLON

®

material provides the excellent chemical resistance of

PTFE without creep relaxation and cold flow problems

Versatile

» Ideal for corrosive applications with extra-large flanges

» Styles 3500, 3502, 3503, 3504, 3505, 3510, 3540, HP 3560, HP

3561 and 3565 can all be welded using this process

Style 3535 Joint Sealant

BENEFITS

Chemical resistance

» Pure PTFE is chemically inert, withstands a wide range of

chemicals

» Conforms to FDA regulations

Easy to install

» Continuous length on spools is easily cut and formed

» Strong adhesive backing aids installation on narrow or hard-

to-reach flanges

» Available in widths from 1/8" to 1"

TYPICAL PHYSICAL PROPERTIES*

Sealability (ASTM F37B)1 ml/hr 0.1

2

Gas Permeability (DIN 3535 Part 4)

Temperature -450°F (-268°C) to 500°F (260°C)

Pressure 800 psig max.

WARNING:

The failure to select the proper sealing product for your application can result in property

damage and/or serious personal injury. You should not purchase or use any of the

products identified in this brochure without undertaking a thorough, independent study,

and obtaining an evaluation of your particular application by qualified professionals. The

descriptions of the products contained in this brochure constitute general guidelines

as to product selection and installation and may not be appropriate for your particular

project.

The performance data and metrics contained in this brochure are not specification

min/max limits, or guarantees of performance, but instead represent typical values

that have been established based upon field testing, customer field reports, and/or

in-house testing. Actual performance will vary from these values and you should not

rely upon these figures in determining the suitability of the use of the product for any

particular application.

While the utmost care has been used in compiling this brochure, we assume no

responsibility for errors. Specifications subject to change without notice. This edition

cancels all previous issues. Subject to change without notice.

GARLOCK is a registered trademark for packings, seals, gaskets, and other products

of Garlock.

cc/min. 0.05

Leaders in Sealing Integrity

GYLON® Styles HP 3560 / HP 3561

BENEFITS

Tighter seal

» Perforated .008" thick stainless steel core increases resistance

to pressure fluctuations and thermal cycling

» GYLON

eliminating the need for frequent retorquing

Chemical resistance

» Seals aggressive chemicals in hostile environments where

safety or blowout resistance is crucial*

®

offers superior cold flow and creep resistance,

Garlock Fluid Sealing Products Technical Manual

MEDIA

HP 3560

HP 3561

Style 3565

ENVELON

Strong acids (except hydrofluoric), solvents, hydrocarbons, water, steam, chlorine, and cryogenics (For

oxygen service, specify "HP 3562 for oxygen service.")

Strong caustics, moderate acids, chlorine, gases, water,

steam, hydro-carbons, cryogenics (For oxygen service,

specify "HP 3563 for oxygen service.")

Moderate concentrations of acids ENVELON® and

®

caustics, hydrocarbons, solvents, cryogenics, and glasslined equipment. Conforms to FDA regulations.

GYLON® Style 3565 ENVELON® Gasketing

BENEFITS

Tighter seal

» Soft, deformable exterior conforms to surface irregularities;

ideal for worn, warped or pitted flanges

» Stable blue core improves cold flow resistance

» Low bolt load requirements ensure a tight seal on glass-lined

or wavy flanges

» Direct sintering of GYLON® layers prevents leak paths and

adhesive contamination

Easy to install

» Unitized construction avoids jacket fold over

» Rigid core facilitates installation of large gaskets

Minimizes inventory

» Custom-cut gaskets from large sheets offer convenience while

reducing costly inventory buildup

» Ideal replacement for slit, milled, formed shield and double

jacketed envelope gaskets

NOTES:

*

Consult Garlock Applications Engineering when using flanges in pressure

classes above 300 lbs.

** Patents #4,961,891; #4,900,629

†

When sealing uneven flanges, gasket must be four times thicker than

maximum gap between flanges.

†

†

WARNING:

The failure to select the proper sealing product for your application can result in property

damage and/or serious personal injury. You should not purchase or use any of the

products identified in this brochure without undertaking a thorough, independent study,

and obtaining an evaluation of your particular application by qualified professionals. The

descriptions of the products contained in this brochure constitute general guidelines as

to product selection and installation and may not be appropriate for your particular project.

The performance data and metrics contained in this brochure are not specification min/

max limits, or guarantees of performance, but instead represent typical values that have

been established based upon field testing, customer field reports, and/or in-house testing.

Actual performance will vary from these values and you should not rely upon these figures

in determining the suitability of the use of the product for any particular application.

While the utmost care has been used in compiling this brochure, we assume no

responsibility for errors. Specifications subject to change without notice. This edition

cancels all previous issues. Subject to change without notice.

GARLOCK is a registered trademark for packings, seals, gaskets, and other products

of Garlock.

**

Leaders in Sealing Integrity

17

Garlock Fluid Sealing Products Technical Manual

GYLON® Style 3545

BENEFITS

Tighter seal

» Higher compressible PTFE outer layers seal under low bolt load -

suitable for many flat face and glass-lined flanges*

» Compressible layers conform to surface irregularities, especially

on warped, pitted or scratched flanges

» Rigid PTFE core reduces cold flow and creep normally associated

with conventional PTFE gaskets

Excellent chemical compatibility

» Pure PTFE withstands a wide range of chemicals

Easy to cut and install

» Soft PTFE can be cut easily from larger sheets, reducing inventory

costs and expensive downtime

» Rigid PTFE core facilitates installation, especially on large diameter

flanges and hard-to-reach areas

GYLON® Style 3540

» Pure microcellular PTFE

» Similar to Style 3545, but without rigid core

» Ideal for wavy, warped, pitted or scratched flanges and for

many types of flat face* flanges

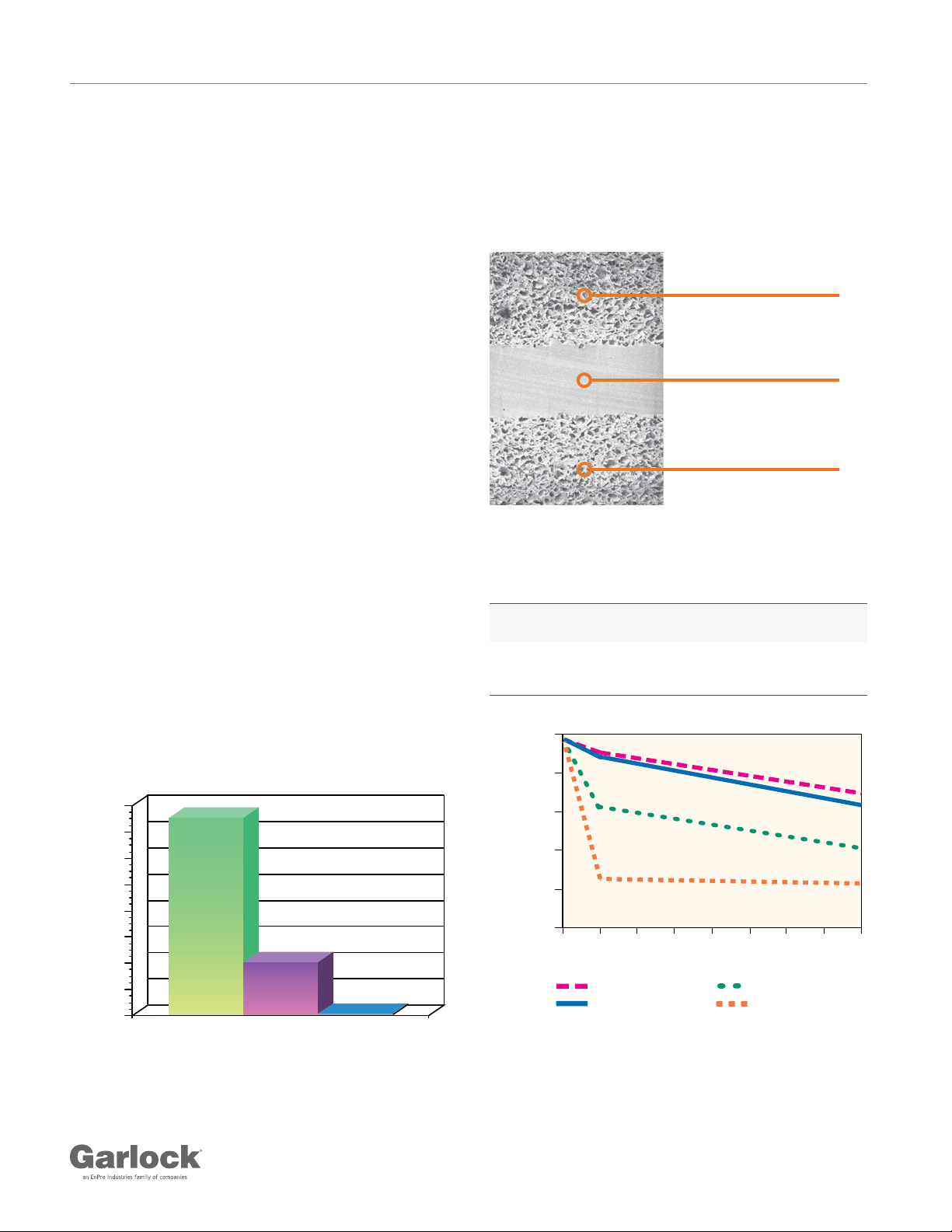

TEST RESULTS

DIN 3535 Gasket Permeation Test

0.16

0.14

0.12

0.10

0.08

0.06

Leak Rate (cc/min.)

0.04

0.02

0

NOTES:

Dramatically reduced leakage of GYLON

Average of three tests, using 580 psig nitrogen with 4,640 psi gasket load according

to DIN 3535 requirements. All samples 1/16" (1.6 mm) thick.

Expanded

PTFE

®

GYLON

3540

®

3540 and 3545.

GYLON

3545

®

CONFIGURATION

Microcellular PTFE

Rigid PTFE

Microcellular PTFE

Cross-sectional view under electron microscope. All layers

manufactured using proprietary GYLON

®

process - thermally fused

layers, without the use of adhesives.

MEDIA

GYLON® 3540

GYLON® 3545

7500

(53.5)

6000

(42)

4500

(31.5)

3000

(21)

1500

(10.5)

Bolt Load Retained – psi (bar)

0

High bolt load retention of GYLON® 3540 and 3545, especially at high

temperatures, indicates gasket is less likely to incur gross leakage

(blowout).

* For flat face flanges, a minimum compressive stress of 1,500 psi (10.3 N/

mm2) is recommended on the contacted gasket area for

150 psig (1.0 N/mm2) liquid service. Consult with the flange manufacturer to

confirm that adequate compressive stress is available.

Strong caustics, strong acids, hydrocarbons and

chlorine, cryogenics. Conforms to FDA regulations.

Strong caustics, strong acids, hydrocarbons, chlorine

and cryogenics and glass-lined equipment. Conforms

to FDA regulations.

DIN 52913 Gasket Bolt Load vs. Time

0 2 4 6 8 10 12 14 16

GYLON® 3540

GYLON

Hours at 500°F (260°C)

®

3545

Expanded PTFE

Skived PTFE

18

Leaders in Sealing Integrity

Loading...

Loading...