GARLOCK

an EnPro Industries family of companies

1666 Division Street

Palmyra, NY 14522

Tel: 1-877-GARLOCK / 315.597.4811

Fax: 800.543.0598 / 315.597.3216

www.garlock.com

Gasket Factors

Gasket Constants

Stress reqired for tightness

Filler

M

Y (psi)

Gb (psi)

a

Gs (psi)

S 100 (psi)

S 1,000 (psi)

S 10,000 (psi)

Graphite

3.00

10,000

2,300

0.237

13

6,581

11,823

20,405

PTFE

3.00

10,000

4,500

0.140

70

8,575

11,836

16,339

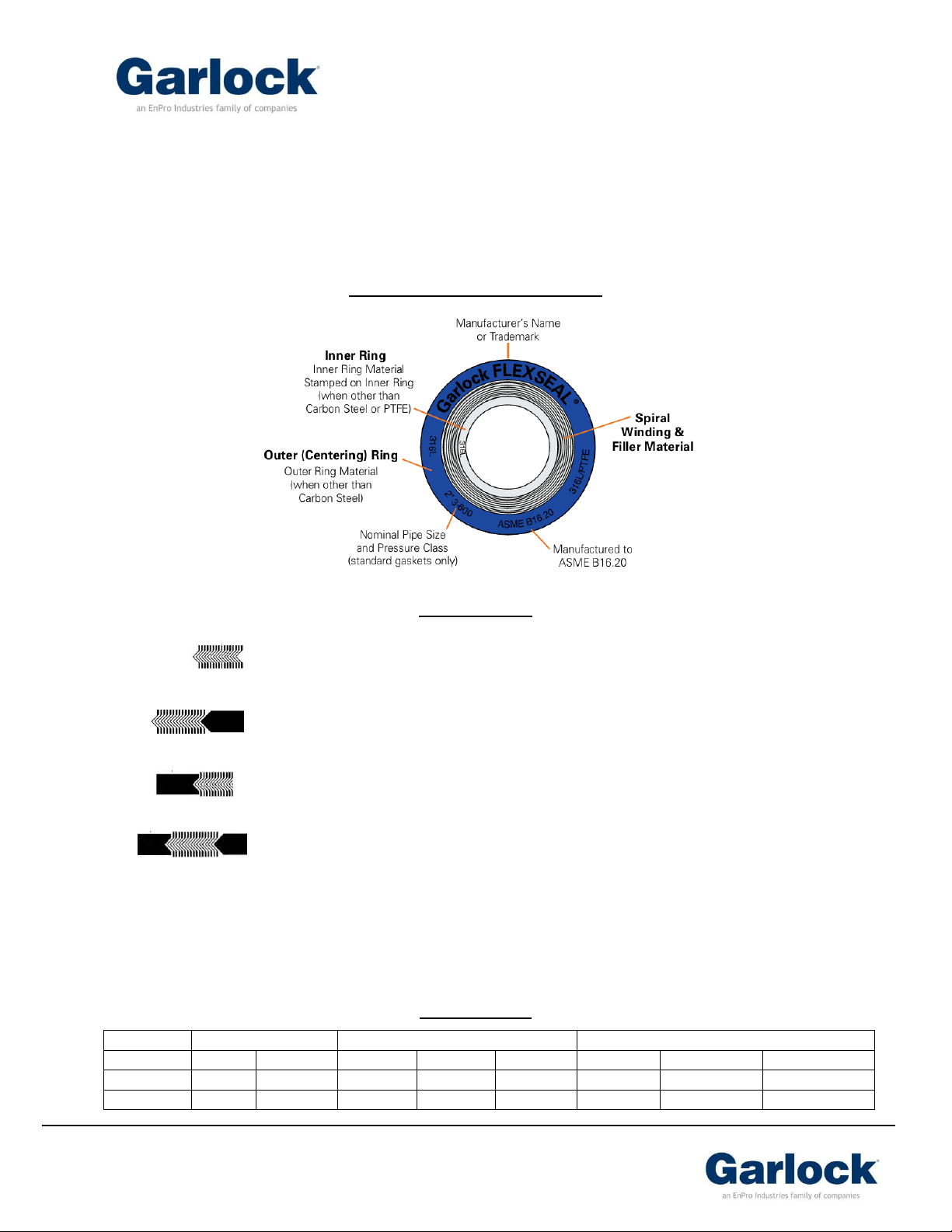

FLEXSEAL® Spiral Wound Gasket

FLEXSEAL® Spiral wound gaskets are made with an alternate combination of preformed metal wire and

soft filler material(s) that forms a highly effective seal when compressed between two flanges. A vshaped crown centered in the metal strip acts as a spring, giving the gasket greater resiliency under

varying conditions.

Identification (per ASME B16.20)

Configurations

SW – Spiral windings only – designed for tongue & groove, male-female, and

groove-to-flat flanges.

SWI - Spiral windings and an inner ring* – designed for tongue & groove, male-

female, groove-to-flat flanges were the ID is open to the process stream.

RW – Spiral windings and an outer centering ring that is used to locate the gasket,

provide additional radial strength and can act as a compression limiter.

RWI** - Spiral windings, an outer centering ring that is used to locate the gasket,

provide additional radial strength and can act as a compression limiter, and an

inner ring* to reduce/prevent radial buckling.

*NOTE – Spiral wound gasket inner ring metallurgy is typically the same as the winding material.

**NOTE - ASME B16.20 mandates inner rings on all PTFE filled spiral wound gaskets, and for 24” NPS and larger

gaskets in Class 900#, 12” NPS and larger in 1500#, and 4” NPS and larger gaskets in Class 2500#. Also, gaskets

ordered in compliance with ASME B16.20 are sold with inner rings (FLEXSEAL RWI) unless otherwise specified by

the customer at the time of order.

Design Factors

GARLOCK

an EnPro Industries family of companies

1666 Division Street

Palmyra, NY 14522

Tel: 1-877-GARLOCK / 315.597.4811

Fax: 800.543.0598 / 315.597.3216

www.garlock.com

Outside Diameter Tolerances

Inside Diameter Tolerances

½” through 8” NPS

+/- .030”

+/- .016”

10” through 24” NPS

+.060” / -.030”

+/- .030”

ID

OD

Gasket Thickness

Width Limits

Compressed

Thickness

Up to 1”

+.016” / -0”

+0” / -.031”

Thickness**

Tolerance

Minimum

Maximum†

1” to 24”

+.031” / -0”

+0” / -.031”

.125”

+/- .005”

3/16”

1”

.090” - .100”

24” to 36”

+.047” / -0”

+0” / .063”

.175”

+/- .005”

¼”

1-1/2”

.125” - .135”

36” to 60”

+.063” / -0”

+0” / .063”

.250”

+/- .005”

5/16”

1-1/2”

.180” - .200”

60” and above

+.094” / -0”

+0” / .094”

.285”

+/- .005”

5/16”

1-1/2”

.200” - .220”

Rev. March 2017

Tolerances (for ASME B16.20 gaskets)

Tolerances (for Non-ASME windings)

**Measured across the metallic portion of the gasket not including the filler, which may protrude slightly. The thickness tolerance exception is

+.010” / -.005” on gaskets with 1) less than a 1” ID and greater than 26” ID, 2) PTFE filled gaskets, and 3) gaskets with flange widths of 1” or

greater.

†

For widths larger than what is shown, please contact Garlock.

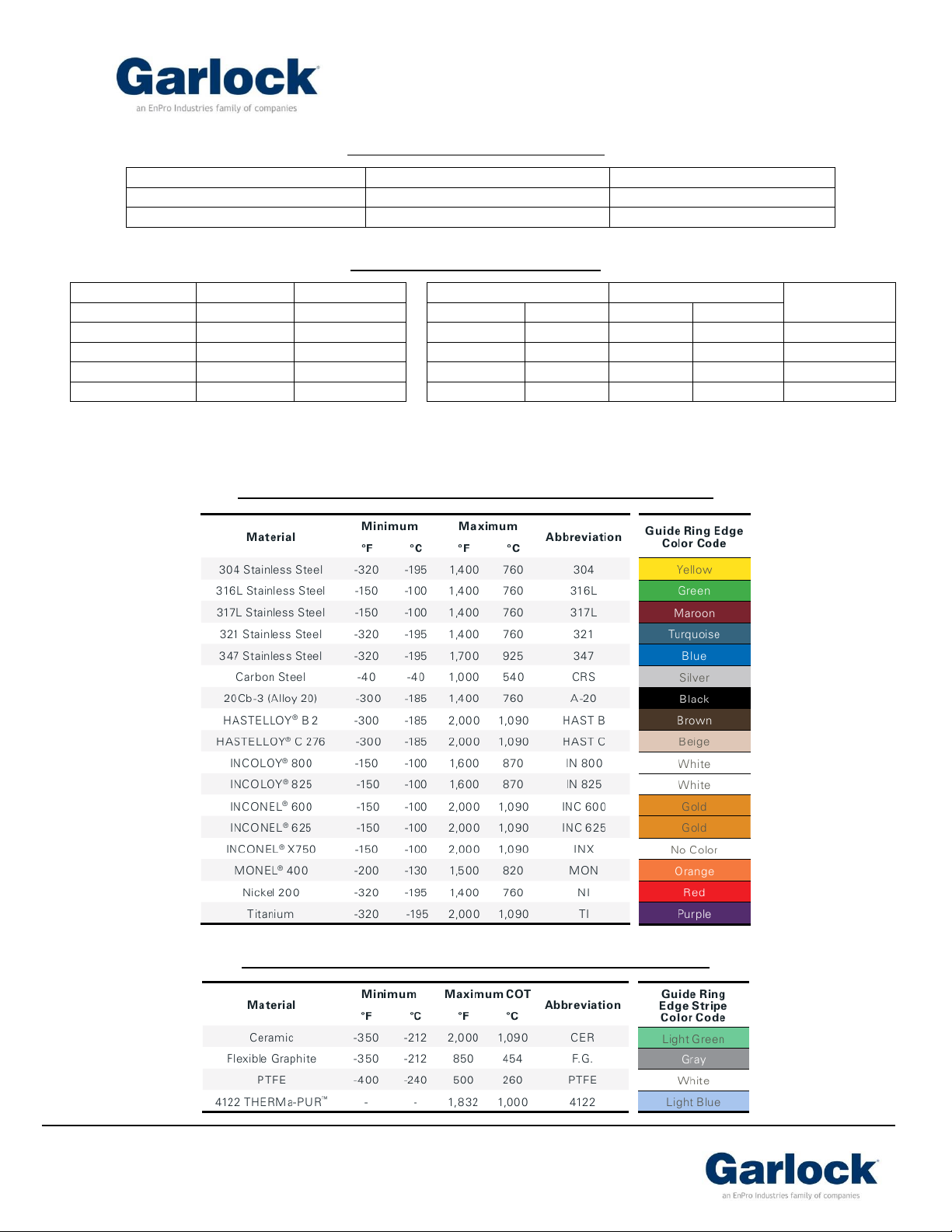

Temperature Limits & Color Coding for Metals (ASME B16.20)

Temperature Limits & Color Coding for Fillers (ASME B16.20)

Loading...

Loading...