Garlock Expansion Joints Installation Manual

Advancing the Science of Sealing

Expansion Joints

Installation and Maintenance Manual

™

Garlock Sealing Technologies

Contents

Elastomeric Expansion Joints

Definition and Function . . . . . . . . . . . . . . . . . . . . . . . . 1

Construction Details. . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Design Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Control Units

Definition and Purpose . . . . . . . . . . . . . . . . . . . . . . . . 6

Standard Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Special Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Measuring and Evaluating Misalignment

Flange-to-Flange Dimensions . . . . . . . . . . . . . . . . . . . 8

Angular Misalignment . . . . . . . . . . . . . . . . . . . . . . . . . 8

Lateral Misalignment . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Torsional Misalignment . . . . . . . . . . . . . . . . . . . . . . . 10

Concurrent Misalignment . . . . . . . . . . . . . . . . . . . . . . 10

Installation Procedures

Removal of Old Expansion Joints . . . . . . . . . . . . . . . 11

Joint Handling and Transporting . . . . . . . . . . . . . . . . 11

Preparation for Installation . . . . . . . . . . . . . . . . . . . . . 11

Joint Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Control Unit Installation . . . . . . . . . . . . . . . . . . . . . . . 12

Maintenance Procedures

Visual and Physical Inspection . . . . . . . . . . . . . . . . . 14

Troubleshooting Control Units . . . . . . . . . . . . . . . . . . 14

Life Expectancy of Elastomeric Joints

Storage Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Shelf Life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Replacement Schedule . . . . . . . . . . . . . . . . . . . . . . . 15

Appendix

Tables I-V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Elastomeric Expansion Joints

Definition and Function

1. Flexible Connector - An elastomeric expansion joint

is a specially designed section of pipe inserted within

a rigid piping system to provide flexibility.

2. Stress Relief - Pipe stress caused by thermal

expansion/contraction or foundation settlement can

be handled by expansion joints.

3. Minor Misalignment - Standard expansion joints

can withstand a minimal amount of existing lateral,

torsional, angular or concurrent misalignment.

Contact the manufacturer for specifics.

4. Isolate/Reduce Vibration - Oscillating movement

around the axis of the expansion joint can be

effectively dampened, eliminating the transmission of

this vibration - preventing equipment damage/failure.

5. Dampen Sound Transmission - Using rubber

flanges, expansion joints can lower the transmission

of undesirable noises.

6. Multiple Arch Type - Expansion joints with up to

four arches may be manufactured to handle greater

movements than a single arch. The movement capa-

bility of a multiple arch expansion joint is typically

that of a single arch type multiplied by the number of

arches. (See Figures 1, 2 & Table I)

7. Natural/Synthetic Elastomer - A wide variety of

elastomers are available to meet specific demands

of industrial applications.

8. Fabric/Metal Reinforced - The strength in an

elastomeric expansion joint is derived from design

features, combined with rubber impregnated layers

of fabric and internal metal reinforcement. (See

Figures 1 & 2)

9. Fabric Reinforcement - In these styles, wide

flowing arch (Figure 3) and U-type (Figure 4), fabric

is used to effectively handle design

parameters outlined.

10. Resistance To Corrosive Media - Special elas-

tomeric liners and covers may be utilized to pro long life of the expansion joint when corrosives are

present.

11. Resistance To Abrasive Media - Abrasive media

may be handled more effectively if a special tube/

liner is used; ie: gum rubber, increasing thick ness

of layers (rubber), steel flow liner, etc.

12. Temperature Capability - Depending on the elas tomer selected, elastomeric expansion joints can

handle a range of -40°F (-40°C) to 400°F (205°C).

Construction Details

Elastomeric expansion joints are constructed of three

basic elements: the tube, the body or carcass, and the

cover. The construction details are shown in Figures 1-4

and each element is defined as follows:

1. Tube - Consists of a protective, leakproof lining

which may be made of synthetic or natural rubber,

depending on operating conditions. The tube is

seamless and it extends through the bore of the joint

to the outside edges of the flanges. Its purpose is to

eliminate the possibility of the materials being

handled from penetrating the carcass and weaken ing the fabric. Tubes can be designed to handle a

wide range of service conditions for chemical, petro leum, sewage, gaseous, and abrasive materials.

When evaluating a specific application, the media

will dictate the type of elastomer needed; ie:

fluoroelastomer (VITON

nitrile, EPDM, HYPALON

rubber, or neoprene elastomers are frequently

specified. FDA- approved materials such as white

neoprene or white EPDM elastomers are also

available.

2. Body or Carcass - Consists of fabric/metal rein forcement. Expansion joints with a combination of

fabric and metal reinforcement are shown in Figures

1 & 2. The expansion joints in Figures 3 & 4 have

fabric reinforcement only.

a. Fabric Reinforcement - The flexible and support-

ing member between the tube and cover. Standard

constructions normally utilize high qual-

VITON and HYPALON are registered trademarks of DuPont Dow

Elastomers.

®

), FEP fluorocarbon,

®

, chlorobutyl, gum

1

Construction Details (cont’d)

Design Types

ity synthetic fabric such as polyester, nylon

®

tire cord or fiberglass/KEVLAR

. Natural fabrics

are also used depending on temperature and pres sure requirements. All fabric plies are impregnated

with a compatible elastomer in order to maintain a

superior bond as well as flexibility.

b. Metal Reinforcement - Consists of solid steel rings

imbedded in the carcass of the expansion joint. The

steel rings reinforce the expansion joint and provide

the dimensional stability needed for pressure or

vacuum service. They are formed from AISI 1018 or

other high strength materials and are either round

or rectangular (see Figures 1 & 2).

3. Cover - A homogeneous layer of rubber com pound bonded to the exterior of the expansion joint.

The prime function of the cover is to protect the

carcass from outside damage. Special elastomers

can be supplied to resist chemicals oils, sunlight,

acid, fumes, and ozone. Environmental conditions

will dictate the exterior of the expansion joint for

additional protection.

The design types of elastomeric expansion joints are

shown in Figures 1 thru 4. The benefits of each type are

described:

Open Arch Expansion Joint

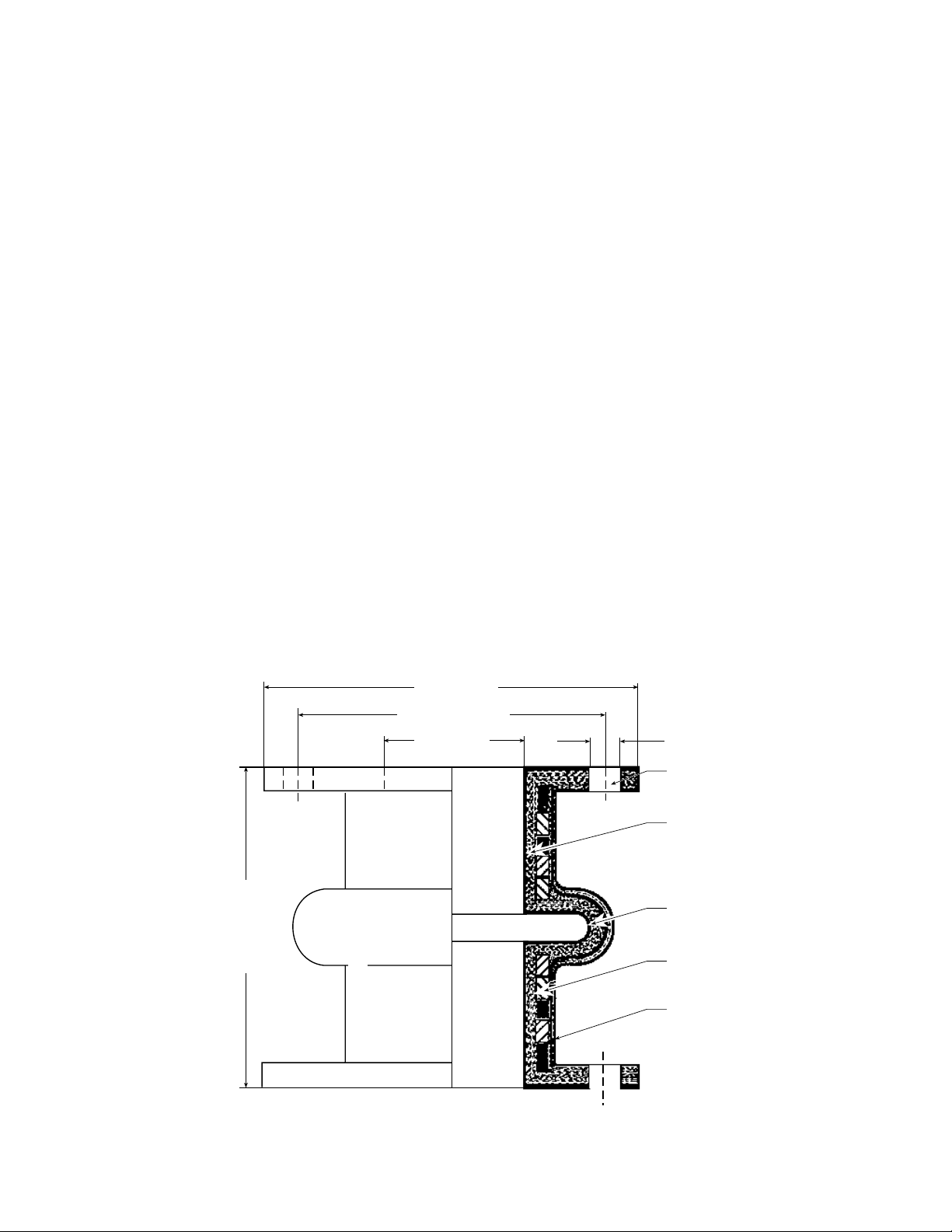

Figure 1 shows a standard spool type expansion joint.

The joint has one open abrupt arch, which is utilized

absorb movements in piping systems. The flanges of

the expansion joint are integral with the body and are

drilled to conform to the bolting pattern of the metal

flanges of the pipe line. This type of rubber faced flange

is of sufficient thickness to form a leakproof seal against

the metal flanges without the use of gaskets.

Expansion joints with two or more arches may be manufactured to accommodate greater movement. Multiple

arch expansion joints are capable of handling the movements of a single arch expansion joint multiplied by the

number of arches.

Therefore, movement dictates the number of arches

required, subsequently the number of arches dictates

face-to-face allowance. See Appendix, Table I for added

information on face-to-face dimensions and typical

movement capabilities of open arch expansion joints.

to

KEVLAR is a registered trademark of DuPont.

2

Flange O.D.

Bolt Circle Diameter

Joint I.D.

Face-to-Face (FF)

Figure 1

Cross sectional view of single open arch expansion joint.

Bolt Hole

Diameter

Bolt Hole

Tube

Carcass Fabric

Reinforcement

Carcass Metal

Reinforcement

Cover

Design Types (cont’d)

The expansion joint is reinforced with fabric plies and

round or rectangular body rings. The number of fabric

plies and metal rings is directly proportional to the pressure rating of the expansion joint. Utilization of metal

body rings provides the dimensional stability needed

for vacuum and pressure service. Typical pressure and

vacuum ratings of expansion joints in Figure 1 are listed in

Appendix, Table V. Service temperature of the expansion

joint depends on the materials of construction.

Expansion joints constructed of polyester fabric and chlorobutyl are rated for temperatures up to 250°F (121°C).

®

EPDM and fiberglass/KEVLAR

fabric allows for up to

300°F (149°C) service. When constructed of fiberglass/

®

KEVLAR

fabric and fluoroelastomer they can withstand

temperatures up to 400°F (204°C).

Always contact the manufacturer before specifying and

purchasing expansion joints for your specific application.

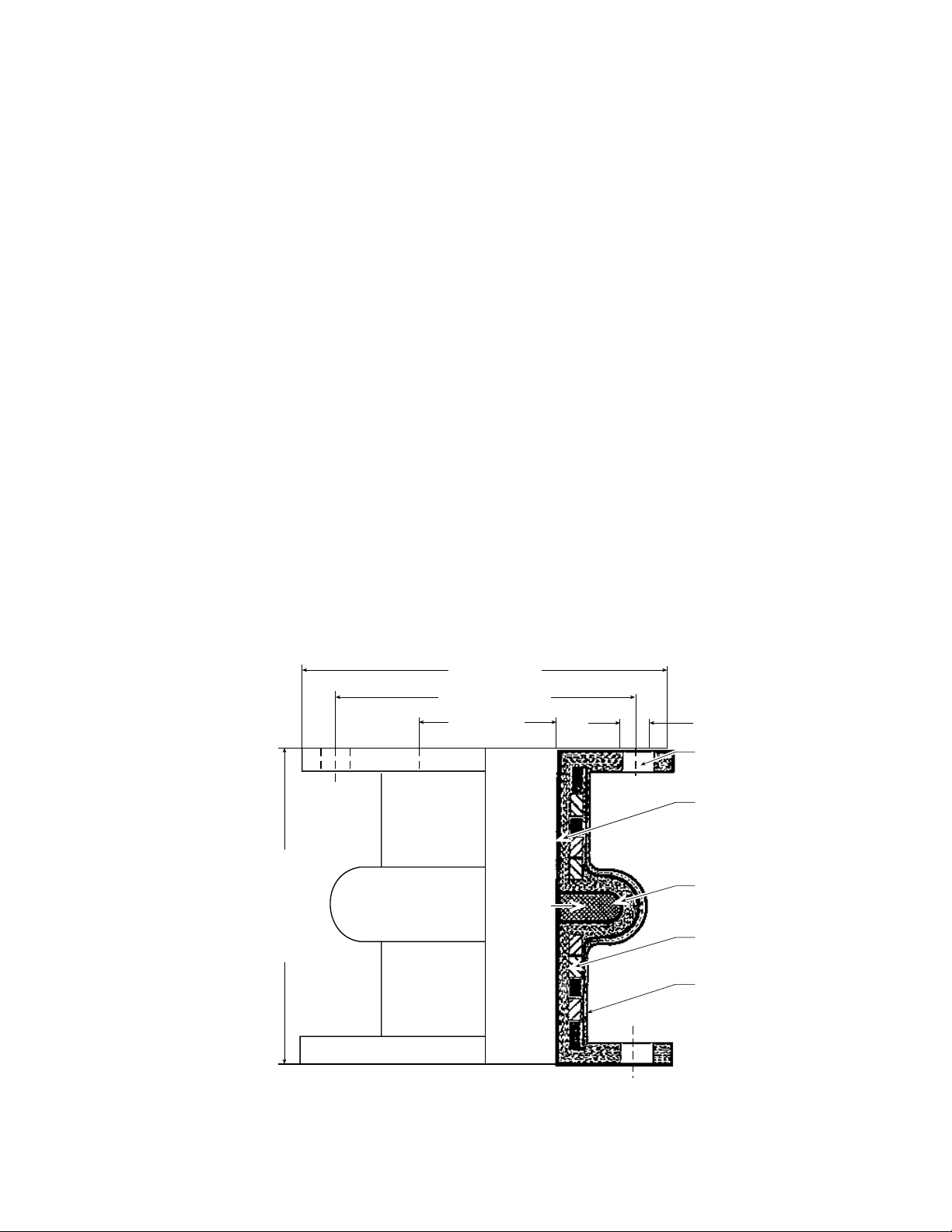

Filled Arch Expansion Joint

The open arch design of Figure 1 may be modified to

reduce turbulence and to prevent the entrapment of

solids. Shown in Figure 2 is a standard arch type elastomeric expansion joint manufactured with a bonded, lower

durometer rubber arch filler to provide a smooth interior

bore. Filled arches built as an integral part of the carcass

decrease the flexibility of the joint and should be used

only when necessary. Using a filled arch expansion joint

reduces movement capabilities by 50%.

Filled arch expansion joints can be constructed to handle

the same temperature, pressure and vacuum requirements as open arch expansion joints. For typical pressure and vacuum capabilities, refer to Appendix, Table V.

Face-to-Face (FF)

Flange O.D.

Bolt Circle Diameter

Joint I.D.

Soft

Arch

Filler

Figure 2

Cross sectional view of filled arch expansion joint.

Bolt Hole

Diameter

Bolt Hole

Tube

Carcass Fabric

Reinforcement

Carcass Metal

Reinforcement

Cover

KEVLAR is a registered trademark of DuPont.

3

Design Types (cont’d)

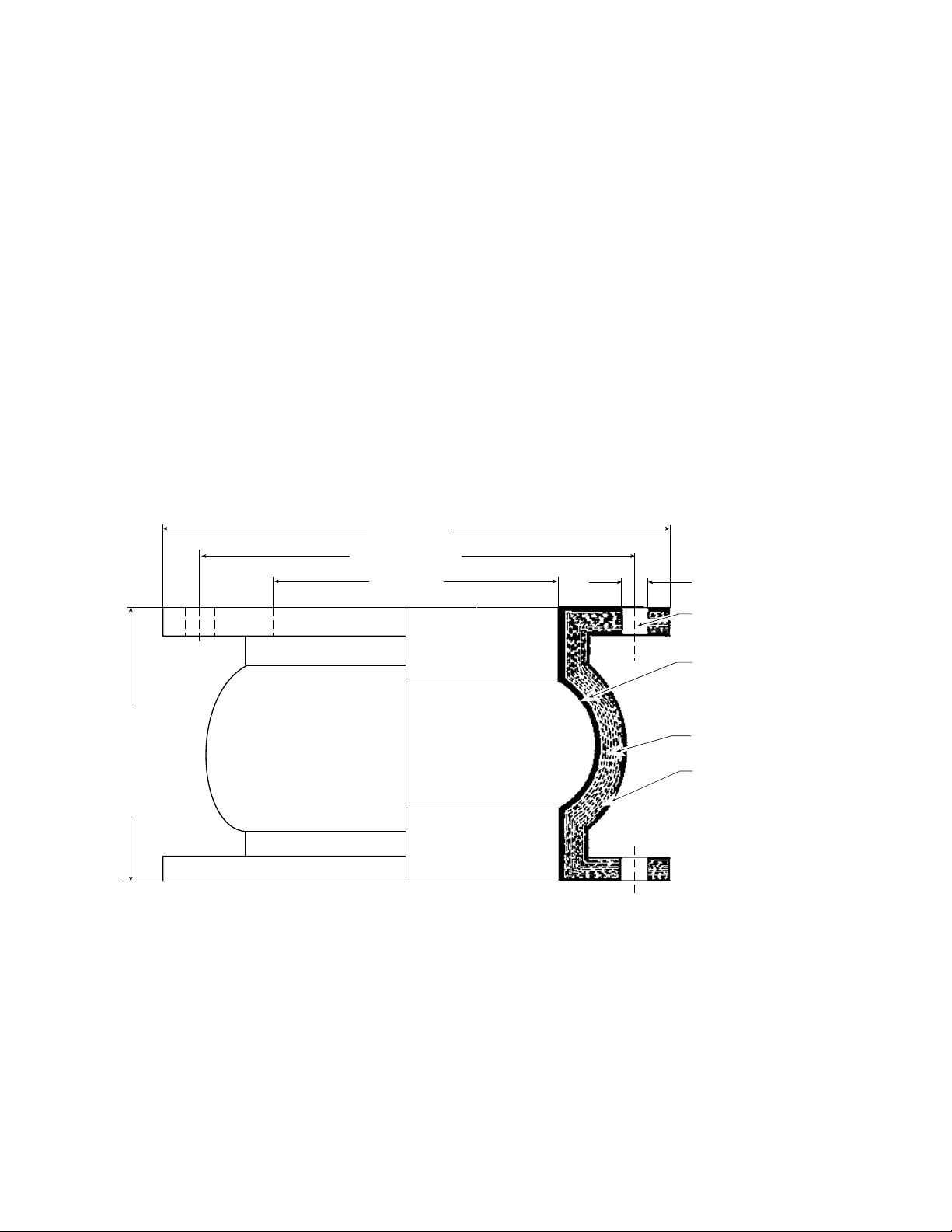

Flowing Arch Expansion Joint

Figure 3 shows a self-flushing or flowing arch expansion

joint. The streamlined flowing arch reduces turbulence and

allows smooth, quiet flow. There is no possibility of sediment build-up and no need to fill the arch, so movement

is not restricted.

The expansion joint is constructed of high strength nylon

tire cord without any metal reinforcement. As a result, the

expansion joint is very flexible, with up to 30% greater

ability to absorb compression movement over the open

arch expansion joint. For added information on movement

capabilities of the flowing arch expansion joints, refer to

Appendix, Table I.

Flange O.D.

Bolt Circle Diameter

Joint I.D.

The nylon tire cord fabric provides an exceptionally high

temperature range of -40°F (-40°C) to 250°F (121°C). The

high-strength fabric also produces an expansion joint with

an exceptional burst pressure rating; however, without

metal reinforcement, its vacuum rating is reduced. See

Appendix, Table V for typical pressure and vacuum ratings

of flowing arch expansion joints.

Bolt Hole

Diameter

Bolt Hole

Face-to-Face (FF)

Tube

Carcass Fabric

Reinforcement

Cover

Figure 3

Cross sectional view of flowing arch expansion joint.

4

Loading...

Loading...