Garlock Blue-Gard 3700 User Manual

GARLOCK

an EnPro Industries family of companies

1666 Division Street

Palmyra, NY 14522

Tel: 1-877-GARLOCK / 315.597.4811

Fax: 800.543.0598 / 315.597.3216

www.garlock.com

BLUE-GARD® Style 3700

MATERIAL PROPERTIES*:

Color:

Light Gray

Composition:

Aramid fibers with a EPDM binder

Fluid Services (see chemical resistance guide):

Water, saturated steam3, and mild chemicals

Temperature1, °F (°C)

Minimum:

-100 (-73)

Continuous Max:

+400 (+205)

Maximum:

+700 (+371)

Pressure1, Maximum, psig (bar):

1200 (83)

P x T (max.)1, psig x °F (bar x °C):

1/32 and 1/16”:

350,000 (12,000)

1/8”

250,000 (8,600)

TYPICAL PHYSICAL PROPERTIES*:

ASTM F36

Compressibility , average, %:

10

ASTM F36

Recovery, %:

40

ASTM F38

Creep Relaxation, %:

25

ASTM F152

Tensile, Across Grain, psi (N/mm2):

2250 (15.5)

ASTM F1315

Density, lbs./ft.3 (grams/cm3):

100 (1.60)

ASTM F433

Thermal Conductivity (K), W/m°K (Btu.·in./hr.·ft.

2

·°F):

0.29-0.38 (2.00-2.65)

ASTM D149

Dielectric Properties, range, volts/mil.

Sample conditioning

1/16”

1/8”

3 hours at 250oF

451

(3)

-620

291

(3)

96 hours at 100% Relative Humidity:

134

71

ASTM F586

Design Factors

1/16” & Under

1/8”

"m" factor:

3.5

6.7

"y" factor, psi (N/mm2):

2800 (19.3)

4200 (28.9)

SEALING CHARACTERISTICS*

ASTM F37B – Fuel A

ASTM F37B - Nitrogen

DIN 3535 – Nitrogen

Gasket Load, psi (N/mm2):

500 (3.5)

3000 (20.7)

4640 (32)

Internal Pressure, psig (bar):

9.8 (0.7)

30 (2)

580 (40)

Leakage

0.3 ml/hr.

0.7 ml/hr.

0.04 cc/min

Notes:

* This is a general guide and should not be the sole means of selecting or rejecting this material. ASTM test results in accordance with ASTM F-104; properties

1

Based on ANSI RF flanges at our preferred torque. When approaching maximum pressure, continuous operating temperature, minimum temperature or 50% of

maximum PxT, consult Garlock Applications Engineering. Minimum temperature rating is conservative.

2

These styles are not preferred choices for steam service, but are successful when adequately compressed Minimum recommended assembly stress = 4,800psi.

Preferred assembly stress = 6,000-10,000psi. Gasket thickness of 1/16" strongly preferred. Retorque the bolts/studs prior to pressurizing the assembly. For

saturated steam above 150psig or superheated steam, consult Garlock Engineering.

3

Indicates electric current arced around and not through the gasket. Dielectric strength is higher than indicated.

REV: 10/11/2016

Ring

Bolt Hole

Bolt Hole

24

24.00

28.25

32.00

29.50201.38

Series A

Bolt Hole

Bolt Hole

60

60.00

67.50

73.00

69.25521.88

Series B

Bolt Hole

Bolt Hole

60

60.00

64.19

67.94

65.44521.38

Full Face

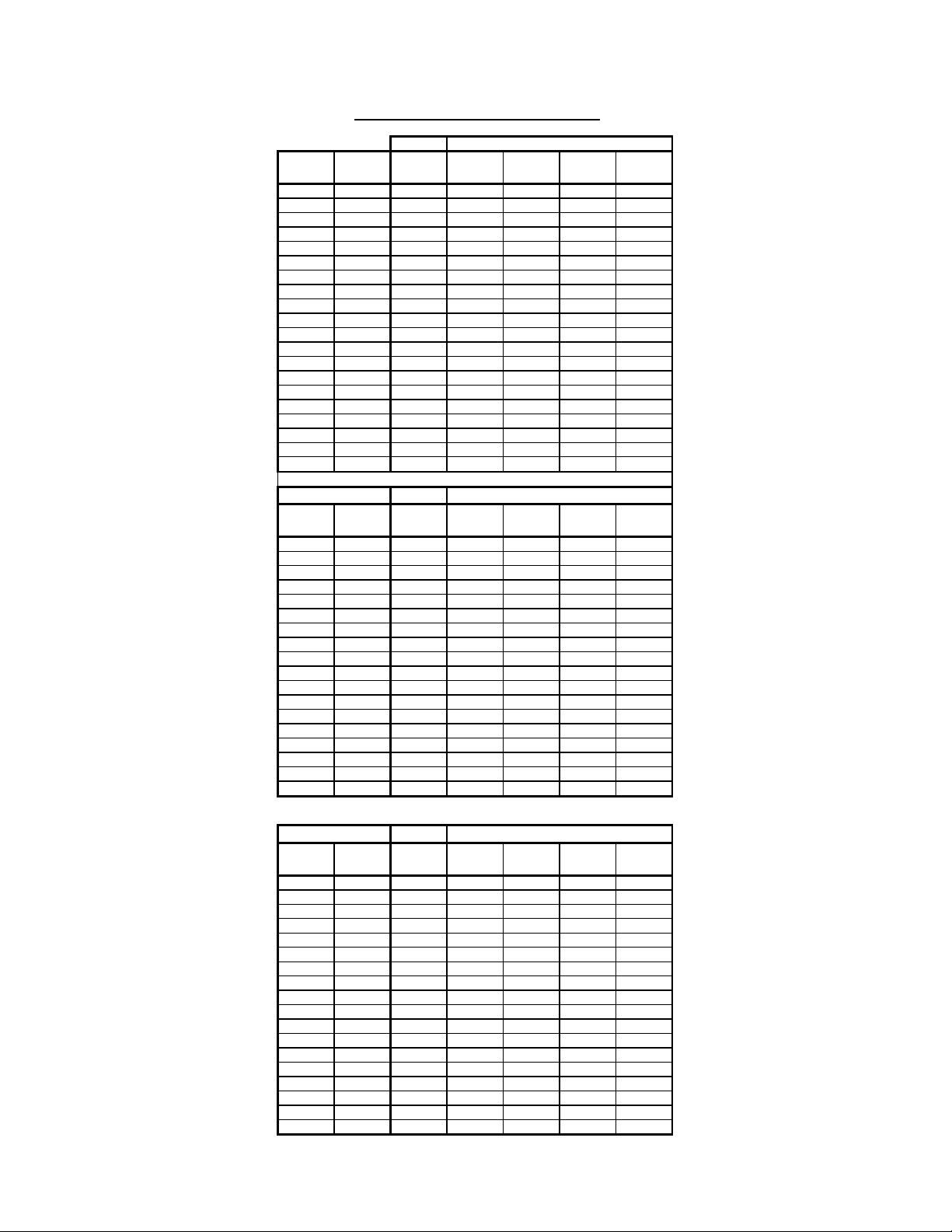

ASME B16.21* Non-metallic Gasket Dimensions for

ASME B16.5 & B16.47 - 150# Flanges

Pipe Size

Gasket

0.5 0.84 1.88 3.50 2.38 4 0.63

0.75 1.06 2.25 3.88 2.75 4 0.63

1 1.31 2.62 4.25 3.13 4 0.63

1.25 1.66 3.00 4.63 3.50 4 0.63

1.5 1.91 3.38 5.00 3.88 4 0.63

2 2.38 4.12 6.00 4.75 4 0.75

2.5 2.88 4.88 7.00 5.50 4 0.75

3 3.50 5.38 7.50 6.00 4 0.75

3.5 4.00 6.38 8.50 7.00 8 0.75

4 4.50 6.88 9.00 7.50 8 0.75

5 5.56 7.75 10.00 8.50 8 0.88

6 6.62 8.75 11.00 9.50 8 0.88

8 8.62 11.00 13.50 11.75 8 0.88

10 10.75 13.38 16.00 14.25 12 1.00

12 12.75 16.13 19.00 17.00 12 1.00

14 14.00 17.75 21.00 18.75 12 1.13

16 16.00 20.25 23.50 21.25 16 1.13

18 18.00 21.62 25.00 22.75 16 1.25

20 20.00 23.88 27.50 25.00 20 1.25

Gasket

Pipe Size

26 26.00 30.50 34.25 31.75 24 1.38

28 28.00 32.75 36.50 34.00 28 1.38

30 30.00 34.75 38.75 36.00 28 1.38

32 32.00 37.00 41.75 38.50 28 1.63

34 34.00 39.00 43.75 40.50 32 1.63

36 36.00 41.25 46.00 42.75 32 1.63

38 38.00 43.75 48.75 45.25 32 1.63

40 40.00 45.75 50.75 47.25 36 1.63

42 42.00 48.00 53.00 49.50 36 1.63

44 44.00 50.25 55.25 51.75 40 1.63

46 46.00 52.25 57.25 53.75 40 1.63

48 48.00 54.50 59.50 56.00 44 1.63

50 50.00 56.50 61.75 58.25 44 1.88

52 52.00 58.75 64.00 60.50 44 1.88

54 54.00 61.00 66.25 62.75 44 1.88

56 56.00 63.25 68.75 65.00 48 1.88

58 58.00 65.50 71.00 67.25 48 1.88

I.D.

I.D.

Gasket

O.D.

Ring

Gasket

O.D.

Gasket

O.D.

Gasket

O.D.

Bolt

Circle

Full Face*

Bolt

Circle

Qty.

Qty.

Dia.

Dia.

* ASME B16.21 doesnot provide full facedimensions for ASME B16.47 - 150# flanges.

Ring

Pipe Size

Gasket

26 26.00 28.56 30.94 29.31 36 0.88

28 28.00 30.56 32.94 31.31 40 0.88

30 30.00 32.56 34.94 33.31 44 0.88

32 32.00 34.69 37.06 35.44 48 0.88

34 34.00 36.81 39.56 37.69 40 1.00

36 36.00 38.88 41.62 39.75 44 1.00

38 38.00 41.12 44.25 42.12 40 1.12

40 40.00 43.12 46.25 44.12 44 1.12

42 42.00 45.12 48.25 46.12 48 1.12

44 44.00 47.12 50.25 48.12 52 1.12

46 46.00 49.44 52.81 50.56 40 1.25

48 48.00 51.44 54.81 52.56 44 1.25

50 50.00 53.44 56.81 54.56 48 1.25

52 52.00 55.44 58.81 56.56 52 1.25

54 54.00 57.62 61 58.75 56 1.25

56 56.00 59.62 63 60.75 60 1.25

58 58.00 62.19 65.94 63.44 48 1.38

* ASME B16.21 does not provide full face dimensions for ASME B16.47 - 150# flanges.

I.D.

Gasket

O.D.

Gasket

O.D.

Full Face*

Bolt

Circle

Qty.

Dia.

Loading...

Loading...