MATERIAL PROPERTIES

*

Color: Light grey

Composition: Aramid fibers with a EPDM binder

Fluid Services1:

Water, saturated steam4, and mild chemicals

Temperature2, °F (°C)

Minimum: -100 (-73)

Continuous Max: +400 (+205)

Maximum: +700 (+371)

Pressure2, Maximum, psig (bar):

1200 (83)

P x T (max.)2, psig x °F (bar x °C)

1/32 and 1/16": 350,000 (12,000)

1/8": 250,000 (8,600)

TYPICAL PHYSICAL PROPERTIES

*

ASTM F36

Compressibility, range, %:

7-17

ASTM F36

Recovery, %:

40

ASTM F38

Creep Relaxation, %:

25

ASTM F152

Tensile, Across Grain, psi (N/mm2):

2500 (17)

ASTM F1315

Density, lbs./ft.3 (grams/cm3):

100 (1.60)

ASTM F433

Thermal Conductivity (K), W/m°K (Btu.·in./hr.·ft.

2

·°F):

0.29-0.38 (2.00-2.65)

ASTM D149

Dielectric Properties, range, volts/mil.

Sample conditioning 1/16" 1/8"

3 hours at 250°F: 451

(3)

-620 291

(3)

96 hours at 100% Relative Humidity:

13471ASTM F586 Design Factors 1/16" & Under 1/8"

"m" factor: 3.5 6.7

"y" factor, psi (N/mm2):

2800 (19.3) 4200 (28.9)

ROTT

Gasket Constants, 1/8":

Gb=1,318 a=0.258 Gs=0.60

ASTM F104

Line Call Out:

F712902A9B4E99K5L104M9

(5)

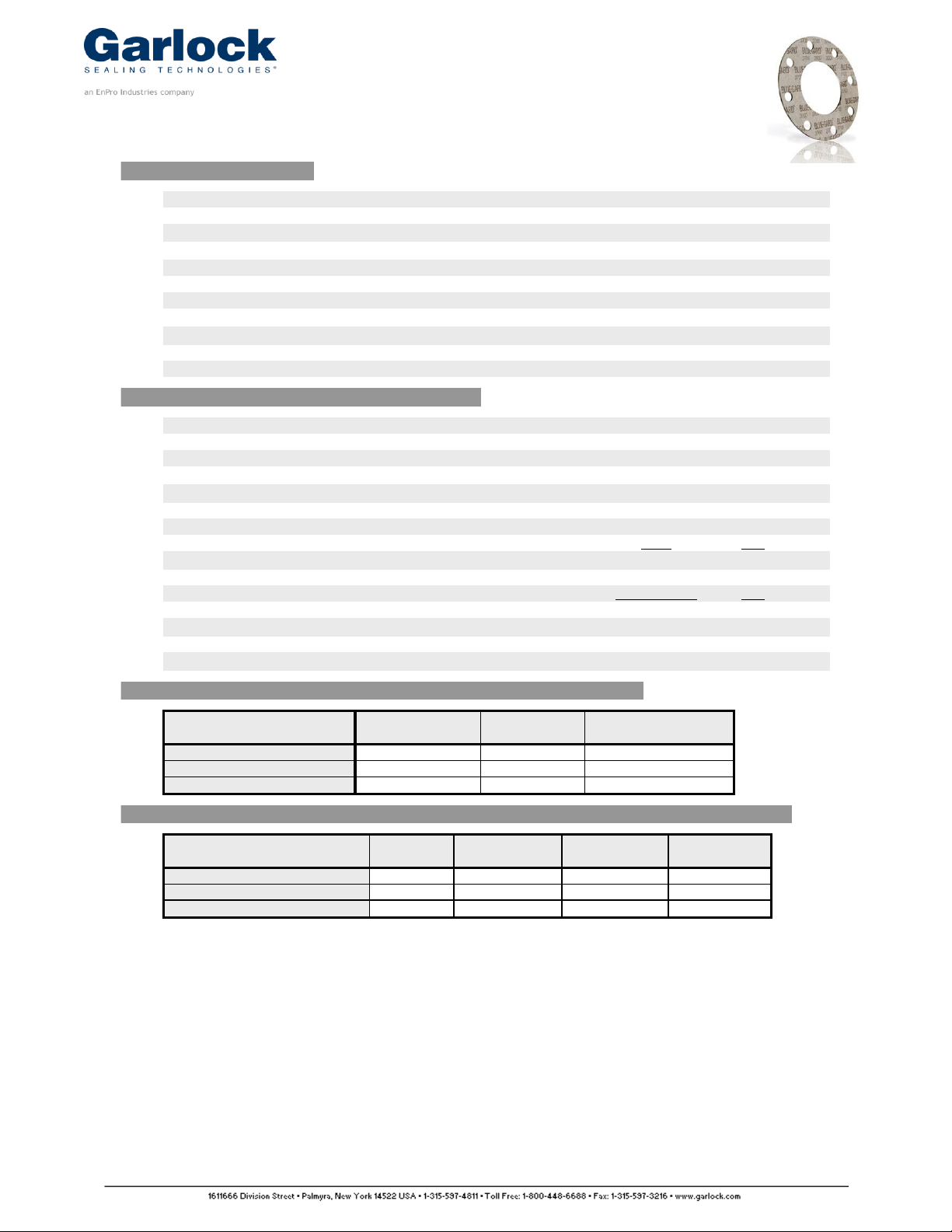

SEALING CHARACTERISTICS

*

Gasket Load, psi (N/mm2):

Internal Pressure, psig (bar):

Leakage

IMMERSION PROPERTIES*- ASTM F146 Fluid Resistance after Five Hours

Notes:

3

Indicates current arced around and not through gasket. Dielectric higher than indicated.

4

These styles are not preferred choices for steam service, but are successful when adequately compressed. Minimum recommended assembly stress

= 4,800psi. Preferred assembly stress = 6,000-10,000psi. Gasket thickness of 1/16" strongly preferred. Retorque the bolts/studs prior to pressurizing

the assembly. For saturated steam above 150psig or superheated steam, consult Garlock Engineering.

5

Fourth numeral 9: % Thickness Increase in IRM Oil #903 = 60-100% max. A9: Leakage in Fuel A (Isooctane), Gasket Load = 500psi (3.5N/mm2),

Pressure = 9.8psig (0.7bar): Typical = 0.1ml/hr, Max = 1.0ml/hr. A9: Leakage in Nitrogen, Gasket Load = 3,000psi (20.7N/mm2), Pressure = 30psig

(2bar): Typical = 0.7ml/hr, Max = 2.0ml/hr. E99: % Increase in ASTM Fuel B: Weight: 100% max., Thickness: 20-50% max. M9: Tensile Strength =

2,250psi min. (15N/mm2 min.).

This is a general guide and should not be the sole means of selecting or rejecting this material. ASTM test results in accordance with ASTM F-104;

properties based on 1/32" (0.8mm) sheet thickness unless otherwise mentioned.

* Values do not constitute specification Limits

1

See Garlock chemical resistance guide.

2

Based on ANSI RF flanges at our preferred torque. When approaching maximum pressure, continuous operating temperature, minimum temperature

or 50% of maximum PxT, consult Garlock Applications Engineering. Minimum temperature rating is conservative.

500 (3.5)

3000 (20.7)

4640 (32)

9.8 (0.7)

30 (2)

580 (40)

ASTM F37B

ASTM F37B

DIN 3535- 4

Fuel A

Nitrogen

Gas Permeability

20-35

Thickness Increase, (%)

-

Tensile Loss, (%)

---

Weight Increase, (%)

-

-

ASTM IRM #903

-

10-40

60-100

70-85°F (20-30°C)

20-50

-

Garlock BLUE-GARD® 3700

ASTM Fuel A

ASTM Fuel B

300°F (150°C)

300°F (150°C)

70-85°F (20-30°C)

0.1 ml/hr.

0.7 ml/hr.

0.04 cc/min

ASTM #1 Oil

Loading...

Loading...