Garland XPE12-0L, XPE12-0R, XPG12-0L, XPG12-0R, XPE24-1L Service Manual

...

Electric/Gas Dual Side Xpress Plus Grill

Models:

XP(E/G)12

XP(E/G)24, XP(E/G)24-1(L/R)

XP(E/G)36, XP(E/G)36-1(L/R), XP(E/G)36-2(L/R)

Service Manual

Please read all sections of this manual and retain for future reference.

For your safety:

Post in a prominent location, instructions to be followed

in the event the user smell gas. This information shall be

obtained by consulting your local gas supplier.

DRAFT VERSION

XP(E/G)12 Shown

XP(E/G)24 Shown

Original Instructions

Document: GAR_SM_4601777 (4/16)

XP(E/G)36 Shown

THIS PAGE INTENTIONALLY LEFT BLANK

Safety Notices

DEFINITIONS

DANGER

Indicates a hazardous situation that, if not avoided, will

result in death or serious injury. This applies to the most

extreme situations.

Warning

Indicates a hazardous situation that, if not avoided,

could result in death or serious injury.

Caution

Indicates a hazardous situation that, if not avoided,

could result in minor or moderate injury.

Notice

Indicates information considered important, but not

hazard-related (e.g. messages relating to property

damage).

NOTE: Indicates useful, extra information about the

procedure you are performing.

DISCLAIMERS

DANGER

It is the responsibility of the equipment owner to

perform a Personal Protective Equipment Hazard

Assessment to ensure adequate protection during

maintenance procedures.

DANGER

The on-site supervisor is responsible for ensuring that

operators are made aware of the inherent dangers of

operating this equipment.

NOTE: Proper installation, care and maintenance are

essential for maximum performance and trouble-free

operation of your equipment. Visit our website

www.mtwkitchencare.com for manual updates,

translations, or contact information for service agents in

your area.

Warning

Do Not Store Or Use Gasoline Or Other Flammable

Vapors Or Liquids In The Vicinity Of This Or Any Other

Appliance. Never use flammable oil soaked cloths or

combustible cleaning solutions, for cleaning.

Warning

Do not store combustible materials on the appliance.

Warning

Only trained and authorized service personnel or store

manager should access the service screens. If changes

to these settings are made incorrectly they will cause

the unit to malfunction.

Caution

Maintenance and servicing work other than cleaning as

described in this manual must be done by an authorized

service personnel.

DANGER

Do not install or operate equipment that has been

misused, abused, neglected, damaged, or altered/

modified from that of original manufactured

specifications.

DANGER

All utility connections and fixtures must be maintained

in accordance with local and national codes.

Warning

Warning labels mounted directly on the equipment

must be observed at all times and kept in a fully legible

condition.

Warning

Read this manual thoroughly before operating, installing

or performing maintenance on the equipment. Failure

to follow instructions in this manual can cause property

damage, injury or death.

Warning

This appliance is not intended for use by persons

(including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge,

unless they have been given supervision concerning

use of the appliance by a person responsible for their

safety. Do not allow children to play with this appliance.

Notice

Routine adjustments and maintenance procedures

outlined in this manual are not covered by the warranty.

Warning

This product contains chemicals known to the State

of California to cause cancer and/or birth defects or

other reproductive harm. Operation, installation, and

servicing of this product could expose you to airborne

particles of glass-wool or ceramic fibers, crystalline

silica, and/or carbon monoxide. Inhalation of airborne

particles of glass-wool or ceramic fibers is known to the

State of California to cause cancer. Inhalation of carbon

monoxide is known to the State of California to cause

birth defects or other reproductive harm.

ELECTRICAL

DANGER

Check all wiring connections, including factory

terminals, before operation. Connections can become

loose during shipment and installation.

DANGER

Do not operate any appliance with a damaged/pinched

cord or plug. All repairs must be performed by a qualified

service company.

LOCATION

Warning

Two or more people or a lifting device are required to lift

this appliance.

Warning

To avoid instability the installation area must be capable

of supporting the combined weight of the equipment

and product. Additionally the equipment must be level

side to side and front to back.

Warning

No structural material on the appliance should be

altered or removed to accommodate placement of the

appliance under a hood.

Warning

Be aware of the red mark in the threaded steem caster

to indicated the maximum adjustment. Adjusting above

the red mark could cause the caster to fail & the unit to

tip. For more information see installation section 2.

Warning

The appliance must be isolated from the gas supply

piping system by closing its individual manual

shutoff valve during any pressure testing of the gas

supply piping system at test pressures equal to or

less than ½ psi (3.5 kPa).

Caution

This equipment must only be operated under an

approved hood system in accordance with local regulations

in force. This unit is intended for indoor use only.

DANGER

Failure to disconnect the power at the main power

supply could result in serious injury or death. The power

switch DOES NOT disconnect all incoming power.

DANGER

Copper wire suitable for at least 75°C (167°F) must be

used for power connections.

Warning

This appliance must be grounded and all field wiring

must conform to all applicable local and national

codes. Refer to rating plate for proper voltage. It is the

responsibility of the end user to provide the disconnect

means to satisfy the authority having jurisdiction.

Warning

Do not use electrical appliances or accessories other

than those supplied by the manufacturer.

Warning

This equipment must be positioned so that the plug is

accessible unless other means for disconnection from

the power supply (e.g., circuit breaker or disconnect

switch) is provided.

Warning

Disconnect electric power at the main power disconnect

for all equipment being serviced. Observe correct

polarity of incoming line voltage. Incorrect polarity can

lead to erratic operation.

Warning

Never touch anything that runs on electricity when your

hands are wet.

CODE

CLEARANCE

Warning

Authorized Service Representatives are obligated to

follow industry standard safety procedures, including,

but not limited to, local/national regulations for

disconnection / lock out / tag out procedures for all

utilities including electric, gas, water and steam.

Warning

For an appliance equipped with casters, (1) the installation

shall be made with a connector that complies with the

Standard for Connectors for Movable Gas Appliances ANSI

Z21.69 • CSA 6.16, and a quick-disconnect device that

complies with the Standard for Quick-Disconnect Devices

for Use With Gas Fuel, ANSI Z21.41 • CSA 6.9, (2) adequate

means must be provided to limit the movement of the

appliance without depending on the connector and the

quick-disconnect device or its associated piping to limit

the appliance movement and (3) the location(s) where

the restraining means may be attached to the appliance

shall be specified.

DAMAGE

DANGER

Improper installation, adjustment, alteration, service,

or maintenance of this appliance or installation of

a damaged appliance can result in DEATH, INJURY,

EQUIPMENT DAMAGE, and void the warranty. NEVER

install damaged appliances, equipment, or accessories.

ALWAYS have installation and service performed by

trained and authorized personnel.

Caution

Pouring water or ice on a hot heating elements/heated

surfaces will cause damage..

Warning

Pinch Hazard. Keep hands and tools clear from the area

above the platens when platens are in motion towards

the exhaust hood. Be aware that adjacent platens may

unexpectedly move at any time. “Turn Grill Off” at

main switch when cleaning platens as there can be an

unexpected movement of the platens

Caution

Do not block the supply and return air vents or the air

space around the air vents. Keep plastic wrappings,

paper, labels, etc. from being airborne and lodging in

the vents. Failure to keep the air vents clear will result in

unsatisfactory operation of the system.

Caution

Do not position the air intake vent near steam or heat

exhaust of another appliance.

Warning

Slipping Hazard: Grease from food products will splatter.

The areas surrounding the grill are a slipping hazard due

to the splatter zone. Clean the area surrounding the grill

regularly. The grill may be slippery. Ensure floor area is

clean. Care needs to be taken as equipment may be hot.

Warning

Failure to maintain required clearances and additional

distances as needed can result in INJURY and

EQUIPMENT DAMAGE.

Consult manufacturers’ literature, and sales and service

agencies as needed.

DANGER

To reduce the risk of fire, the equipment is to be

installed in non-combustible surroundings only, with no

combustible material within 18” (457 mm) of the sides,

front or rear of the appliance or within 40 “ (1 m) above

the appliance. The appliance is to be mounted on floors

of noncombustible construction with noncombustible

flooring and surface finish and with no combustible

material against the underside or on noncombustible

slabs or arches and have no combustible material

against the underside. Such construction shall in all

cases extend not less than 12” (305 mm) beyond the

equipment on all sides.

DANGER

Risk of fire/shock. All minimum clearances must be

maintained. Do not obstruct vents or openings.

Warning

Pinch Hazard. Ensure a minimum of 1" clearance

between the hood and the uppermost position of the

platen arm. To reduce the risk of chrushing injuries

between platen & hood.

CLEANING

Caution

Ensure platens are down, in closed position, when

moving grill. Follow the procedure to avoid potential

damage, loss of calibration on the platen, and error

messages.

Caution

Never use an acid based cleaning solution on exterior

panels! Many food products have an acidic content,

which can deteriorate the finish. Be sure to clean the

stainless steel surfaces of ALL food products.

Caution

Do not use caustic cleaners on any part of the equipment

or equipment cavity . Use mild, non abrasive soaps or

detergents, applied with a sponge or soft cloth. Never

use sharp implements or harsh abrasives on any part of

the equipment.

Warning

When cleaning interior and exterior of unit, care should

be taken to avoid front power switch and the power

cord(s). Keep water and/or cleaning solutions away from

these parts.

Warning

Turn grill off and unplug the unit before cleaning the

side/back panels. Do not remove any panel during

cleaning.

Warning

Interior cleaning must be performed by a qualified

service technician only.

Warning

Never use a high-pressure water jet for cleaning or hose

down or flood interior or exterior of units with water. Do

not use power cleaning equipment, steel wool, scrapers

or wire brushes on stainless steel or painted surfaces.

Warning

Be aware that adjacent platens may unexpectedly move

at any time. “Turn Grill Off” at main switch when cleaning

platens as there can be an unexpected movement of the

platens.

PERSONAL PROTECTION

DANGER

All utilities (gas, electric, water and steam) must be OFF

to all equipment and locked out of operation according

to OSHA approved practices during servicing. Always

allow unit to cool.

DANGER

Use appropriate safety equipment during installation

and servicing.

DANGER

Never stand on the unit! They are not designed to

hold the weight of an adult, and may collapse or tip if

misused in this manner.

DANGER

Keep power cord AWAY from HEATED surfaces. DO NOT

immerse power cord or plug in water. DO NOT let power

cord hang over edge of table or counter.

Warning

DO NOT use the unit for storage. DO NOT leave paper

products, cooking utensils, or food in the unit when not

in use.

Warning

Allow heated equipment to cool down before

attempting to clean, service or move. Unit must be cool

to touch and disconnected from power source.

Warning

Always wear some type of protective covering on your

hands and arms when opening the unit.

Caution

Use a commercial-grade cleaner formulated to

effectively clean and sanitize food contact surfaces. Read

the directions for use and precautionary statements

before use. Particular attention must be paid to the

concentration of cleaner and the length of time the

cleaner remains on the food-contact surfaces.

Warning

Steam can cause serious burns. Always wear some type

of protective covering on your hands and arms when

opening the unit. When platen is Lifting, move away

face and body from the escaping steam.

Warning

Remove all removable panels before lifting and

installing.

Warning

Do not contact moving parts.

Warning

When using cleaning fluids or chemicals, rubber gloves

and eye protection (and/or face shield) must be worn.

Warning

Use caution when handling all metal surface edges of

the equipment.

Warning

This equipment is intended for indoor use only. Do not

install or operate this equipment in outdoor areas.

Warning

All covers and access panels must be in place and

properly secured, before operating this equipment.

Warning

Do not spray aerosols in the vicinity of this appliance

while it is in operation.

Warning

Risk of burns from high temperatures. You may get

burnt if you touch any of the parts during cooking.

Surfaces close to the cooking surface including side

panels may get hot enough to burn skin. Use extreme

caution to avoid coming in contact with hot surfaces

or hot grease. Wear personal protective equipment.

Warning

This appliance must be installed with sufficient

ventilation to prevent the occurrence of unacceptable

concentrations of substances harmful to the health of

personnel in the room in which it is installed.

Warning

Hazard. Keep hands and tools clear from the area above

the platens when platens are in motion towards the

exhaust hood. Be aware that adjacent platens may

unexpectedly move at any time. “Turn Grill Off” at

main switch when cleaning platens as there can be an

unexpected movement of the platens.

Warning

Slipping Hazard: Grease cans must be properly installed

before use. Improper installation will result in grease

on the floor which will create a slipping hazard. Ensure

grease cans are emptied and cleaned as needed to

prevent grease from overflowing onto the floor. The grill

may be slippery. Ensure floor area is clean. Care needs to

be taken as equipment may be hot

Warning

Pinch Hazard. Keep hands and tools clear of area between

platen and grill plate when platens are in motion. Be

aware that adjacent platens may unexpectedly move at

any time. “Turn Grill Off” at main switch when cleaning

platens as there can be an unexpected movement of the

platens.

Warning

Post in a prominent location, instructions to be followed

in the event the user smell gas. This information shall be

obtained by consulting your local gas supplier.

Warning

When checking for burner ignition or performance, do

not get too close to the burners. Slow ignition can cause

possible flashback, increasing the potential for facial

and body burns.

Safety Notices

Section 1

General Information

Section 2

Installation

Table of Contents

Definitions.................................................................................................................................................3

Disclaimers ................................................................................................................................................3

Location .....................................................................................................................................................4

Electrical ....................................................................................................................................................4

Damage......................................................................................................................................................5

Clearance ...................................................................................................................................................5

Read This Manual ............................................................................................................. 11

Unit Inspection .................................................................................................................11

Model Numbers ................................................................................................................11

Serial Plate Numbers ........................................................................................................11

Main Features and Components .....................................................................................12

Items included with the purchase of your new grill from manufacturer: ....................13

3 Platen Dimensions Specification .................................................................................14

2 Platen Dimensions Specification .................................................................................15

1 Platen Dimensions Specification .................................................................................16

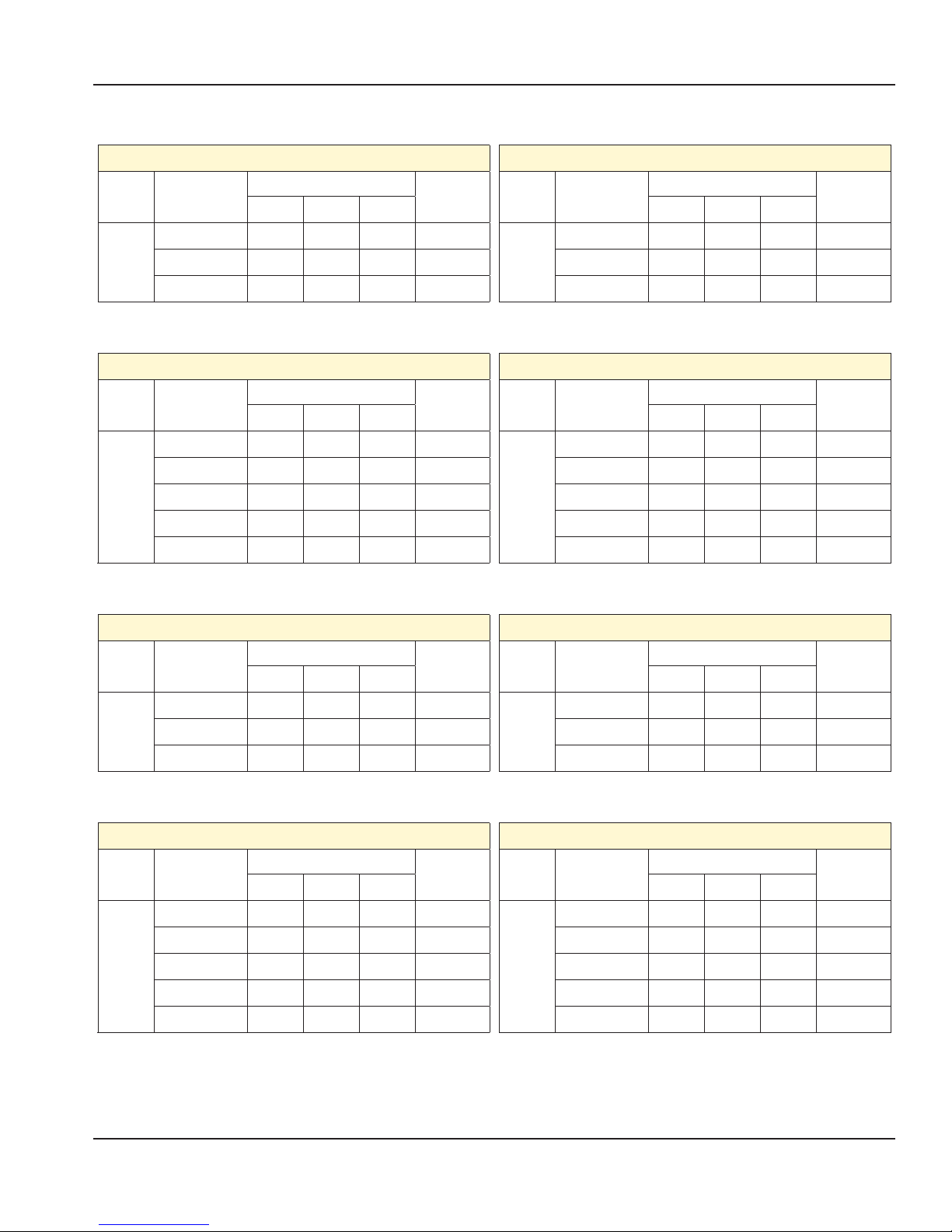

Electrical Input Specification - WYE (electric XPE-12 CE models) ................................. 17

Electrical Input Specification - DELTA (electric XPE-12 models) ...................................17

Electrical Input Specification - WYE (gas XPG-12-CE models) ......................................17

Electrical Input Specification - DELTA (gas XPG-12 models) .........................................17

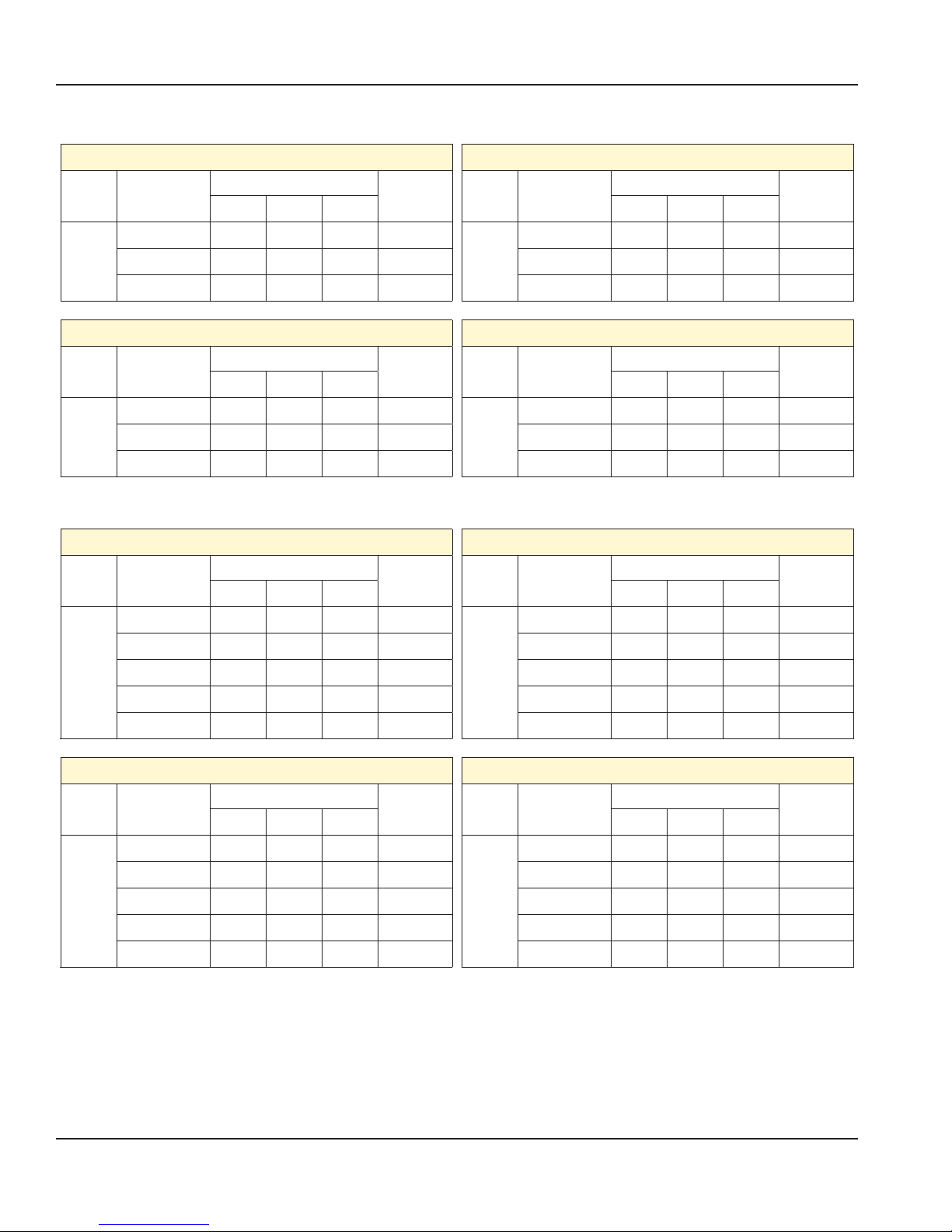

Electrical Input Specification - WYE (electric XPE-24 CE models) ................................. 18

Electrical Input Specification - DELTA (electric XPE-24 models) ...................................18

Electrical Input Specification - WYE (gas XPG-24 CE models) ....................................... 19

Electrical Input Specification - DELTA (gas XPG-24 models) .........................................19

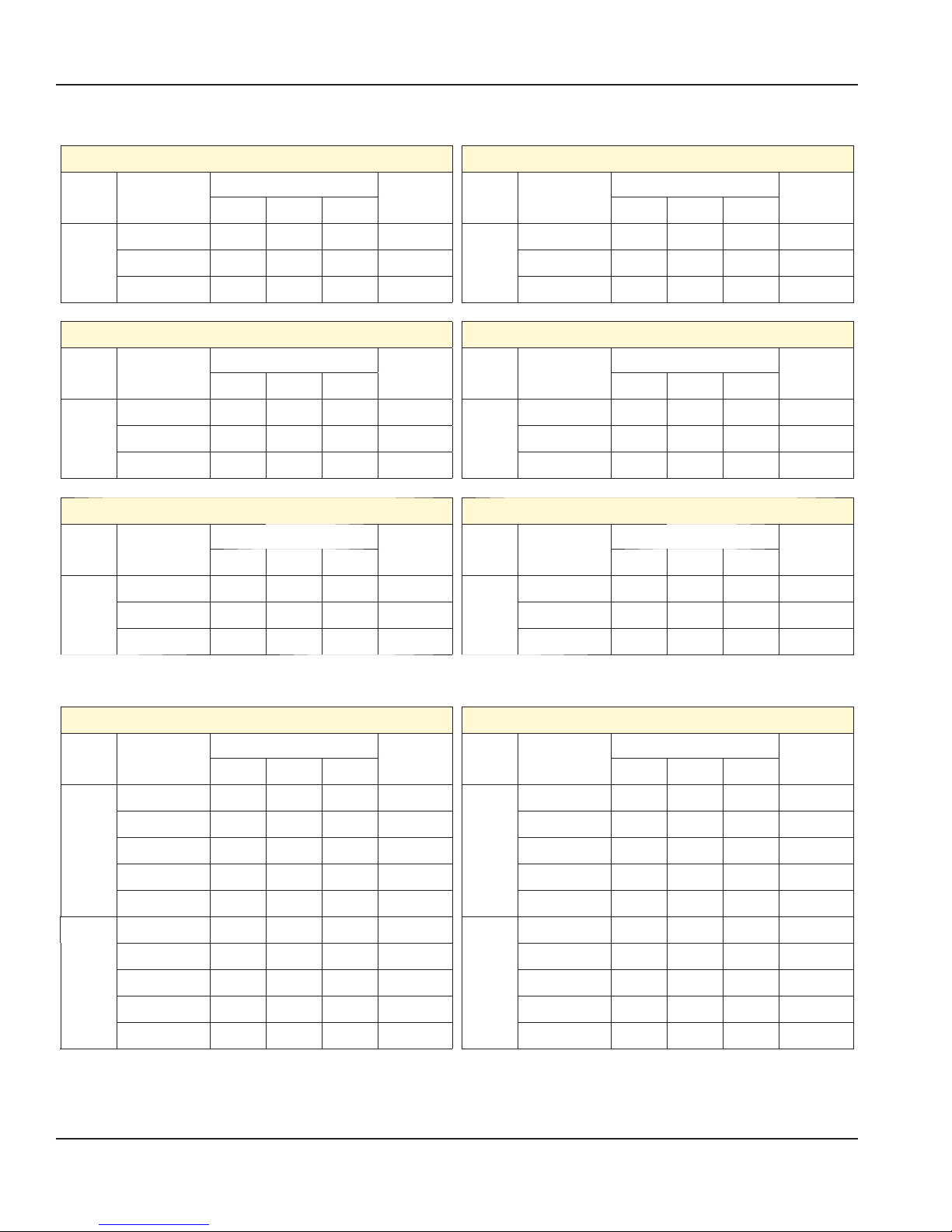

Electrical Input Specification - WYE (electric XPE-36 CE models) ................................. 20

Electrical Input Specification - DELTA (electric XPE-36 models) ...................................20

Electrical Input Specification - DELTA (electric XPE-36models) ....................................21

Electrical Input Specification - WYE (gas XPG-36 CE models) ....................................... 22

Electrical Input Specification - DELTA (gas XPG-36 models) .........................................22

Gas Input Specification .................................................................................................... 24

Removing Grill From Wood Crate ....................................................................................25

Transporting Grill To Location .........................................................................................26

Location ............................................................................................................................26

Clearance Requirements ..................................................................................................26

Leveling .............................................................................................................................26

Exhaust Hood Requirements ...........................................................................................26

Appliances Equipped with Casters .................................................................................27

Casters Adjustment Procedure .......................................................................................27

Temporary Storage ..........................................................................................................28

Gas Connector Requirements: ........................................................................................28

National Codes Requirements: ........................................................................................28

Installation store responsibilities: ..................................................................................29

Restraining device installation Procedure .....................................................................29

“Desi Pak” bags from the grill: ........................................................................................30

Removing “Desi Pak” bags from the grill: ......................................................................30

Gas Connections, and Pipe Sizing: .................................................................................30

Flue Upper Rear Panel Install Instruction.......................................................................32

Startup Procedure ............................................................................................................34

8 Document: GAR_SM_4601777 (4/16)

Section 3

Operation

Section 4

Maintenance

Table of Contents (continued)

Sequence of Operation ....................................................................................................35

easyToUCH™ Controller ...................................................................................................36

Home Screen, Recipe Selector Screen & Icons .........................................................................36

On Screen Warnings and Alerts Messages .................................................................................37

Operations Overview .........................................................................................................................37

easyTOUCH™ Procedures .................................................................................................38

Start Up & Preheat ............................................................................................................................... 38

Cook A Recipe ....................................................................................................................................... 38

Check Temperatures ........................................................................................................................... 39

Canceling a Cook Cycle ..................................................................................................................... 39

Change Cook Time/Gap .................................................................................................................... 39

Create New Recipe .............................................................................................................................. 40

Create a New Menu ............................................................................................................................42

Turn Menus OFF or ON ...................................................................................................................... 42

Activate Sleep Mode Manually ....................................................................................................... 43

Shutdown .............................................................................................................................................. 43

Cleaning Reminders ........................................................................................................................... 43

Special Settings — Time & Gap Adjustment Limits ................................................................ 44

Volume Adjustment ........................................................................................................................... 44

Section 5

Troubleshooting

Section 6

Controls

Cleaning the easyToUCH™ controller..............................................................................47

Cleaning the Stainless Steel Panels ................................................................................47

Cleaning During Operation .............................................................................................47

Daily Cleaning ..................................................................................................................48

Moving the Grill ................................................................................................................51

Cooking Issues .................................................................................................................. 52

Temperature Issues ..........................................................................................................54

UI issues ............................................................................................................................56

Settings Mode: .................................................................................................................65

Factory Settings Mode: ....................................................................................................65

Change Password ................................................................................................................................ 65

Change the Time ................................................................................................................................. 65

Change the Date .................................................................................................................................. 66

Factory Settings ................................................................................................................................... 66

Recipe Reset (from USB) ...................................................................................................................66

Reset To Factory Defaults .................................................................................................................66

Software Update .................................................................................................................................. 66

Calibration Settings Mode: ..............................................................................................66

Gap Calibration .................................................................................................................................... 66

Hood Height .......................................................................................................................................... 67

Thermocouple Calibration ............................................................................................................... 67

Time/Gap Adj. Limits .......................................................................................................................... 67

Document: GAR_SM_4601777 (4/16) 9

Test Setting Mode: ...........................................................................................................67

Collect System Log .............................................................................................................................67

Heater State ........................................................................................................................................... 67

Settings Mode: .................................................................................................................67

Clean Settings ....................................................................................................................................... 67

Heat Errors & Limits ............................................................................................................................68

Language ............................................................................................................................................... 68

Prompts Definitions ............................................................................................................................68

Protein Definitions .............................................................................................................................. 68

Sleep Configutarion ...........................................................................................................................68

Temperature Units .............................................................................................................................. 68

Volume ....................................................................................................................................................68

Instructions for Software Update ...................................................................................69

Section 7

Component Check Procedures

Reading the LEDs - SIB ....................................................................................................71

Reading the LEDs - SIB - Diagnose Platen Errors ...........................................................72

Reading the LEDs - SIB - Platen Homing ........................................................................73

Reading the LEDs - SSRB ..................................................................................................74

Replacement of shaft seal & cap o-ring Procedure ................................................................ 75

Actuator Replacement Procedure .................................................................................................77

Section 9

Diagrams

Table of Contents (continued)

Wiring Diagram ................................................................................................................79

Section 10

Tools & Cleaning Supplies

Recommended Cleaning Supplies ................................................................................106

1 Platen Electric - XPE12 WYE (4532832) ....................................................................................80

2 Platen Electric - XPE24 WYE (4532833) ....................................................................................82

3 Platen Electric - XPE36 WYE (4532834) ....................................................................................84

1 Platen Gas - XPG12 WYE (4532835) ........................................................................................... 86

2 Platen Gas - XPG24 WYE (4532836) ........................................................................................... 88

3 Platen Gas - XPG36 WYE (4532837) ........................................................................................... 90

1 Platen Electric - XPE12 DELTA (4532838) ................................................................................. 94

2 Platen Electric - XPE24 DELTA (4532839) ................................................................................. 96

3 Platen Electric - XPE36 DELTA (4532840) ................................................................................. 98

1 Platen GAS - XPE12 DELTA (4532841) .....................................................................................100

2 Platen GAS - XPE24 DELTA (4532842) .....................................................................................102

3 Platen GAS - XPE36 DELTA (4532843) .....................................................................................104

10 Document: GAR_SM_4601777 (4/16)

Section 1

General Information

Read This Manual

Garland Commercial Equipment developed this manual as

a reference guide for the owner/operator and installer of

this equipment. Please read this manual before installation

or operation of the machine. A qualified service technician

must perform installation and start-up of this equipment,

consult Section 5 within this manual for service assistance.

If you cannot correct the service problem, call your Service

Agent or Distributor. Always have your model and serial

number available when you call.

Your Service Agent ____________________________

Service Agent Telephone Number _________________

Your Local Distributor ___________________________

Distributor Telephone Number ____________________

Model Number _______________________________

Serial Number ________________________________

Installation Date ______________________________

Unit Inspection

Thoroughly inspect the unit upon delivery. Immediately

report any damage that occurred during transportation

to the delivery carrier. Request a written inspection report

from a claims inspector to document any necessary claim

Model Numbers

This manual covers the following models:

XP(E/G)12, XP(E/G)12-0(L/R)

XP(E/G)24, XP(E/G)24-1(L/R), XP(E/G)24-0(L/R)

XP(E/G)36, XP(E/G)36-1(L/R), XP(E/G)36-2(L/R)

XP(E/G)36-0(L/R)

Grill plate width

Type

Model Prex

Upper Platen

* see note

XP G 36 - 1 R

Starting to:

XPress Plus

R: Right

L: Left

G: Gas

E: Electric

0,1, 2

12in, 24in, 36in

* Sux not used if all platens included

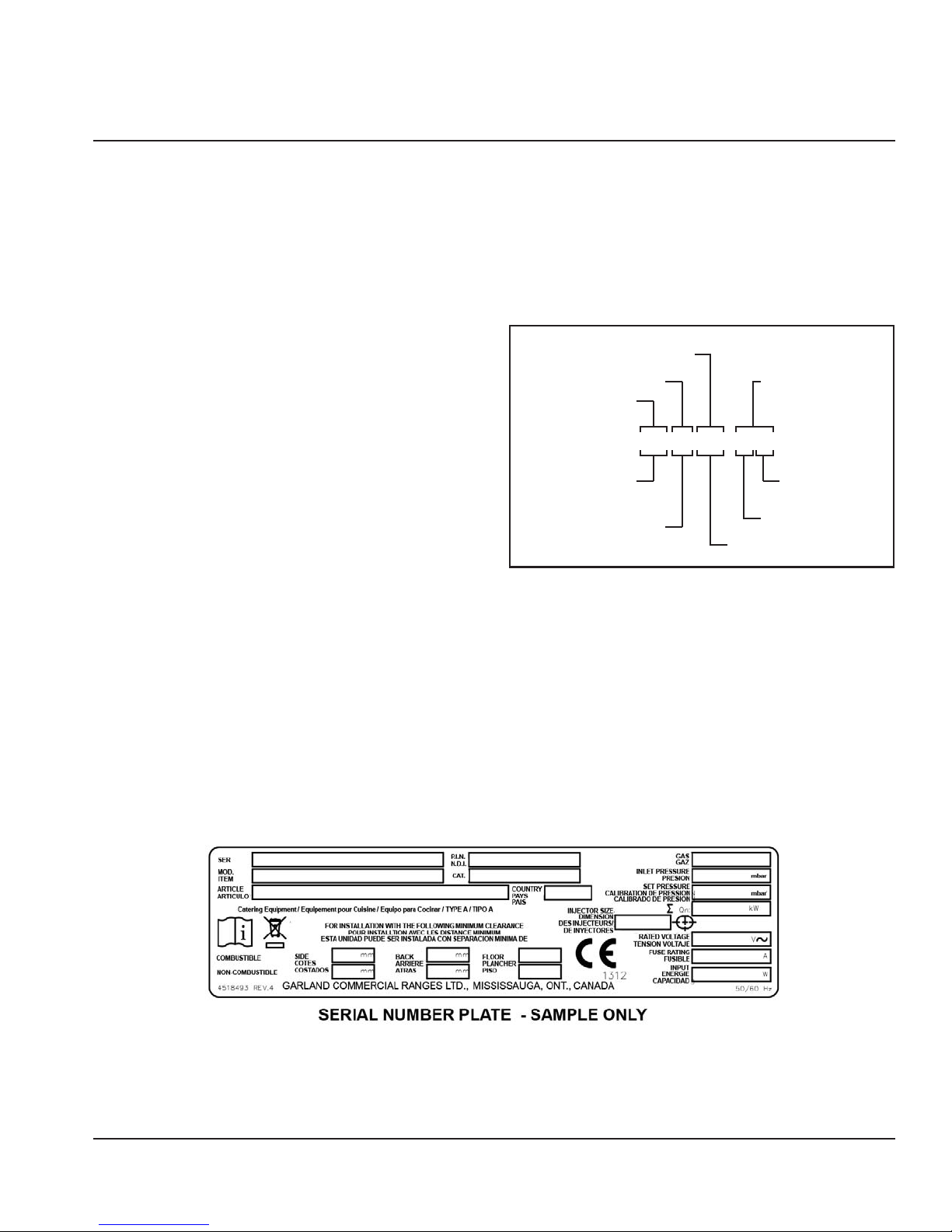

Serial Plate Numbers

The serial plate is affixed to the lower left corner of the

right panel and a serial sticker on front edge of the chassis.

Important information such as the unit’s model number,

serial number, and electrical/gas specifications can be

found on the serial plate. Serial plate is located is manual

covers the following models:

Document: GAR_SM_4601777 (4/16) 11

General Information Section 1

14

11

12913

15

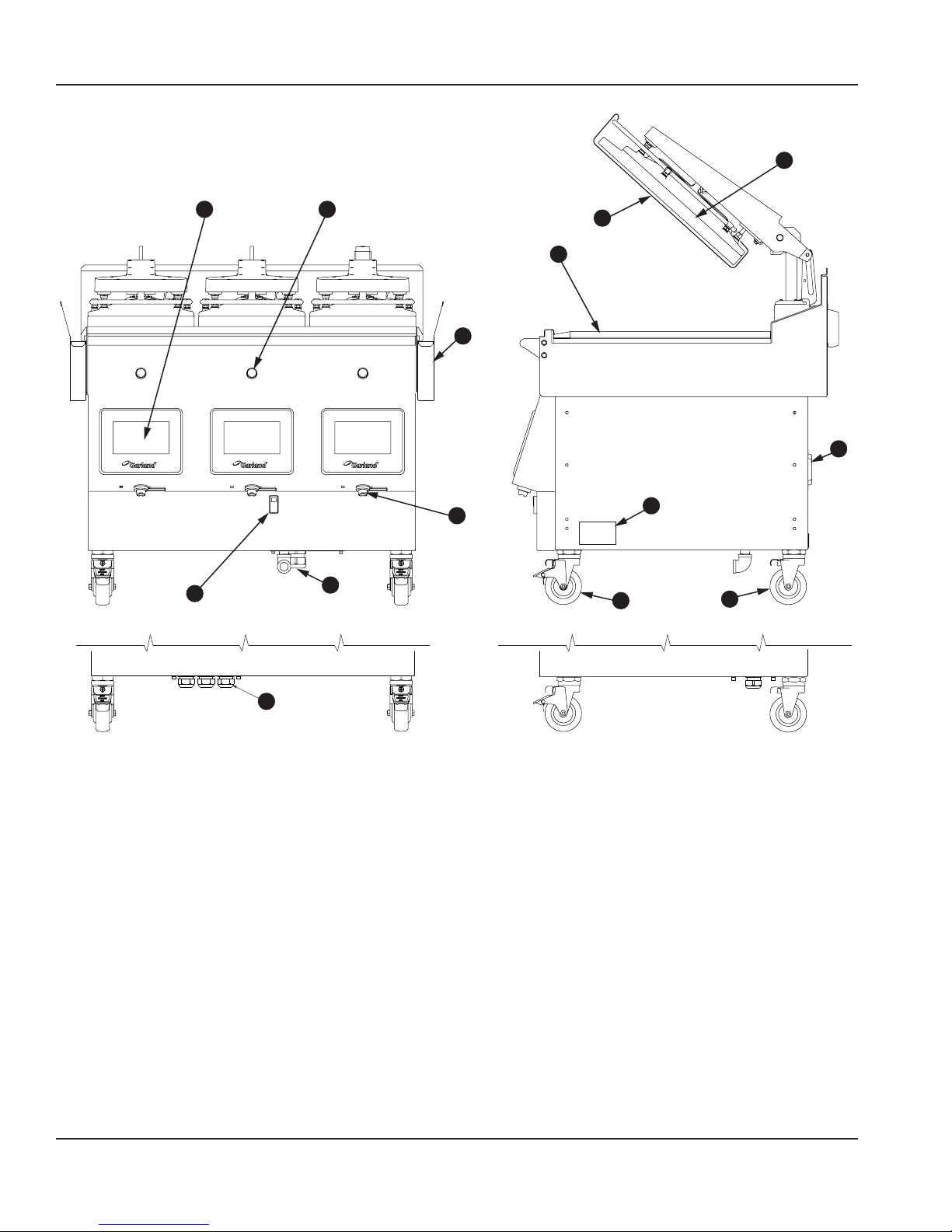

3 PLATEN SHOWN

2 3

1

5

7

6

8

10

Main Features and Components

1. On/Off Power Switch

2. easyToUCH™ Touch sensitive controls for easy operation.

3. Green Push Button

• press to start cook

• press and hold to abort.

5. Platen - providing double-side cooking. Each platen can

be controlled separately.

6. Grill Plate - cooking surface with three (3) cook zones,

each zone can be controlled separately.

7. Release Material Sheet - non-stick surface for easy of

operation and cleaning.

12 Document: GAR_SM_4601777 (4/16)

8. Grease Buckets.

9. Front Casters - height adjustable swivel casters, with

brakes.

10. Rear Casters - height adjustable swivel casters, without

brakes.

11. USB Ports - for easyToUCH

12. Incoming gas manifold (gas models)

13. Circuit Breaker

14. Main Electric Power Cables and Plugs (electric models).

15. Rating Plate location. - important information such as

the unit’s model number, serial number, and electrical

specifications can be found on the serial plate.

Section 1 General Information

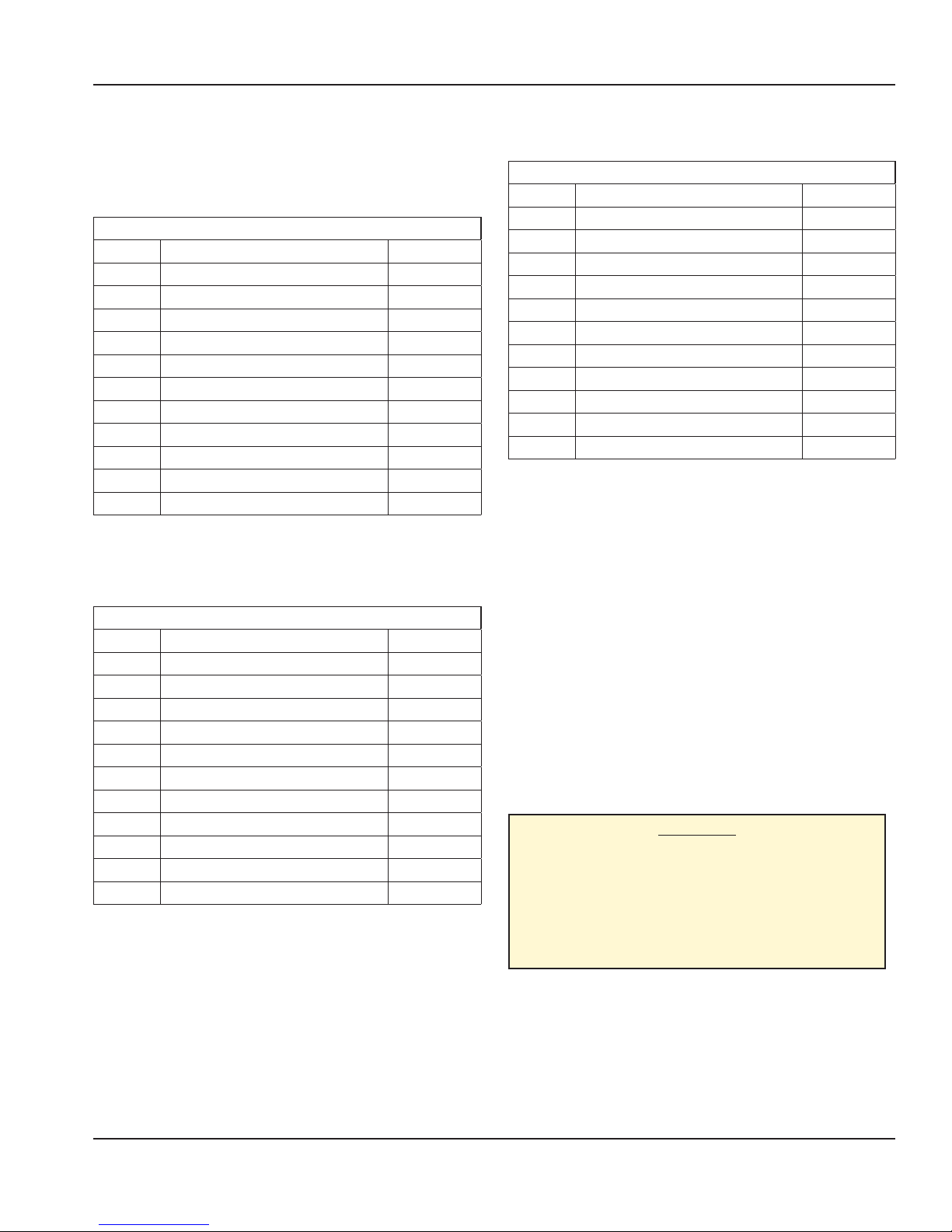

Items included with the purchase of your new

grill from manufacturer:

1. One Grill 1 platen gas & electric includes the

following list;

1 PLATEN

Part # Description Qty

4527294 Release Material Sheet Clips 3

4600722 Release Material Sheet Hanger 1

4600866 Release Material Sheet (box) 1

4600207 Grease Drawer Slide LT - GM 1

4600206 Grease Drawer Slide RT - GM 1

as speci ed

as speci ed

1838701

4532089

4601665

4532522

NOTE: Quantity may vary according to the model.

2. One Grill 2 platen gas & electric includes the

following list;

Part # Description Qty

4527294 Release Material Sheet Clips 6

4600722 Release Material Sheet Hanger 2

4600866 Release Material Sheet (box) 1

4600207 Grease Drawer Slide LT - GM 1

4600206 Grease Drawer Slide RT - GM 1

as speci ed

as speci ed

1838701

4532089

4601665

4532522

NOTE: Quantity may vary according to the model.

Grease Buckets - right side 1

Grease Buckets - left side 1

Platen Levelling Tool 1

Service Wrench 1

Garland Grill Start Up Form 1

Installation Operation Manual 1

2 PLATEN

Grease Buckets - right side 1

Grease Buckets - left side 1

Platen Levelling Tool 1

Service Wrench 1

Garland Grill Start Up Form 1

Installation Operation Manual 1

3. One Grill 3 platen gas & electric included the

following list, except countries mentioned

3 PLATEN

Part # Description Qty

4527294 Release Material Sheet Clips 9

4600722 Release Material Sheet Hanger 3

4600866 Release Material Sheet (box) 1

4600207 Grease Drawer Slide LT - GM 1

4600206 Grease Drawer Slide RT - GM 1

as speci ed

as speci ed

1838701

4532089

4601665

4532522

Grease Buckets - right side 1

Grease Buckets - left side 1

Platen Levelling Tool 1

Service Wrench 1

Garland Grill Start Up Form 1

Installation Operation Manual 1

NOTE: Quantity may vary according to the model.

Items NOT INCLUDED from the manufacturer:

1. Any electrical cords needed for application.

2. Any ue box needed for application.

3. Any extra grease buckets or grease rails needed for

application.

THE FOLLOWING INSTALLATION PROCEDURE

CAN BE PERFORMED BY A:

• Factory authorized service center

• An approved installation person approved by Garland.

• Licensed installer contracted by purchaser of grill.

• Contact local Garland Factory Authorized Service Center

for more details.

CAUTION:

PRIOR TO INSTALLATION, CHECK THE ELECTRICAL

SUPPLY TO ENSURE INPUT VOLTAGE AND PHASE

MATCH THE EQUIPMENT VOLTAGE RATING AND

PHASE. MANY LOCAL CODES EXIST, IT IS THE

RESPONSIBILITY OF THE OWNER/INSTALLER TO

COMPLY WITH THESE CODES.

Document: GAR_SM_4601777 (4/16) 13

General Information Section 1

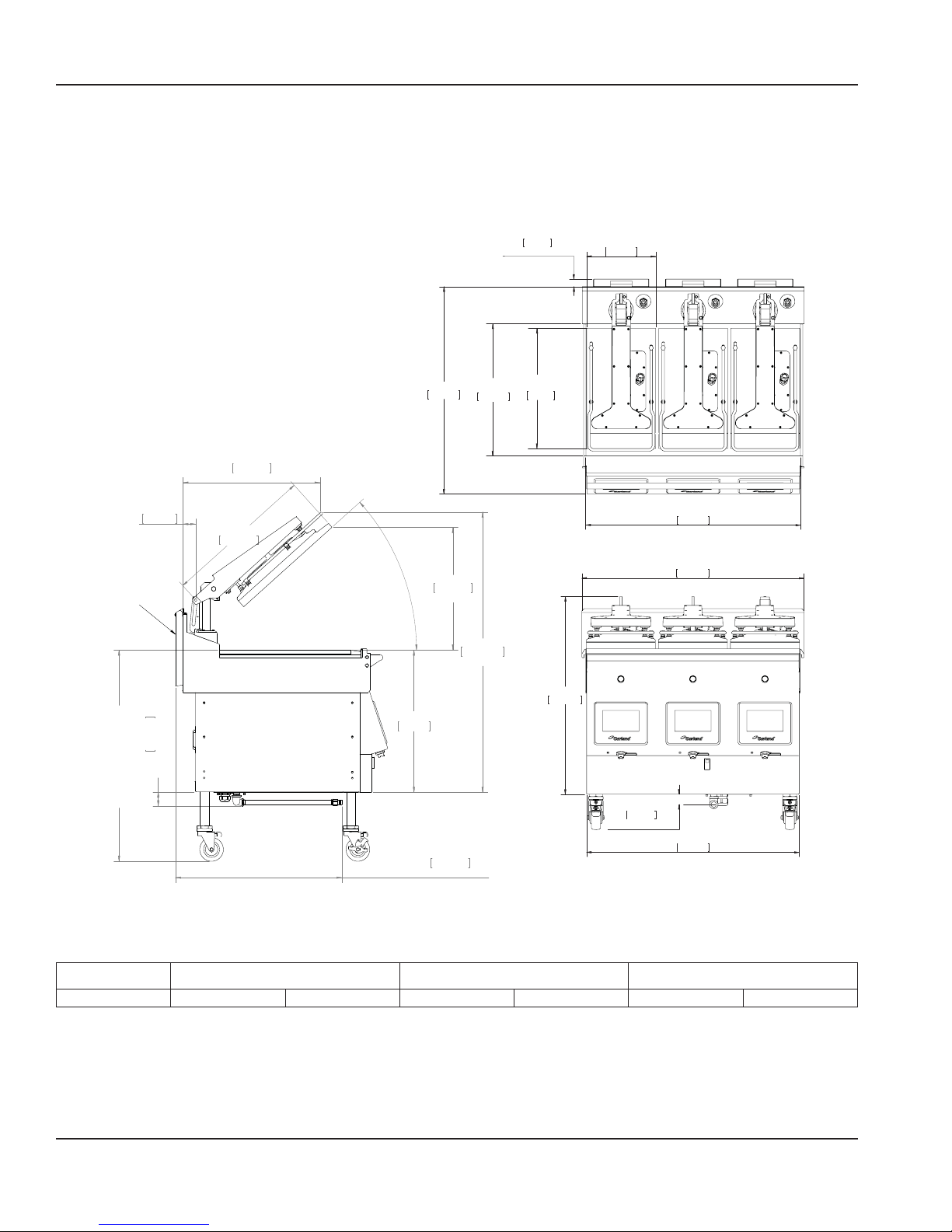

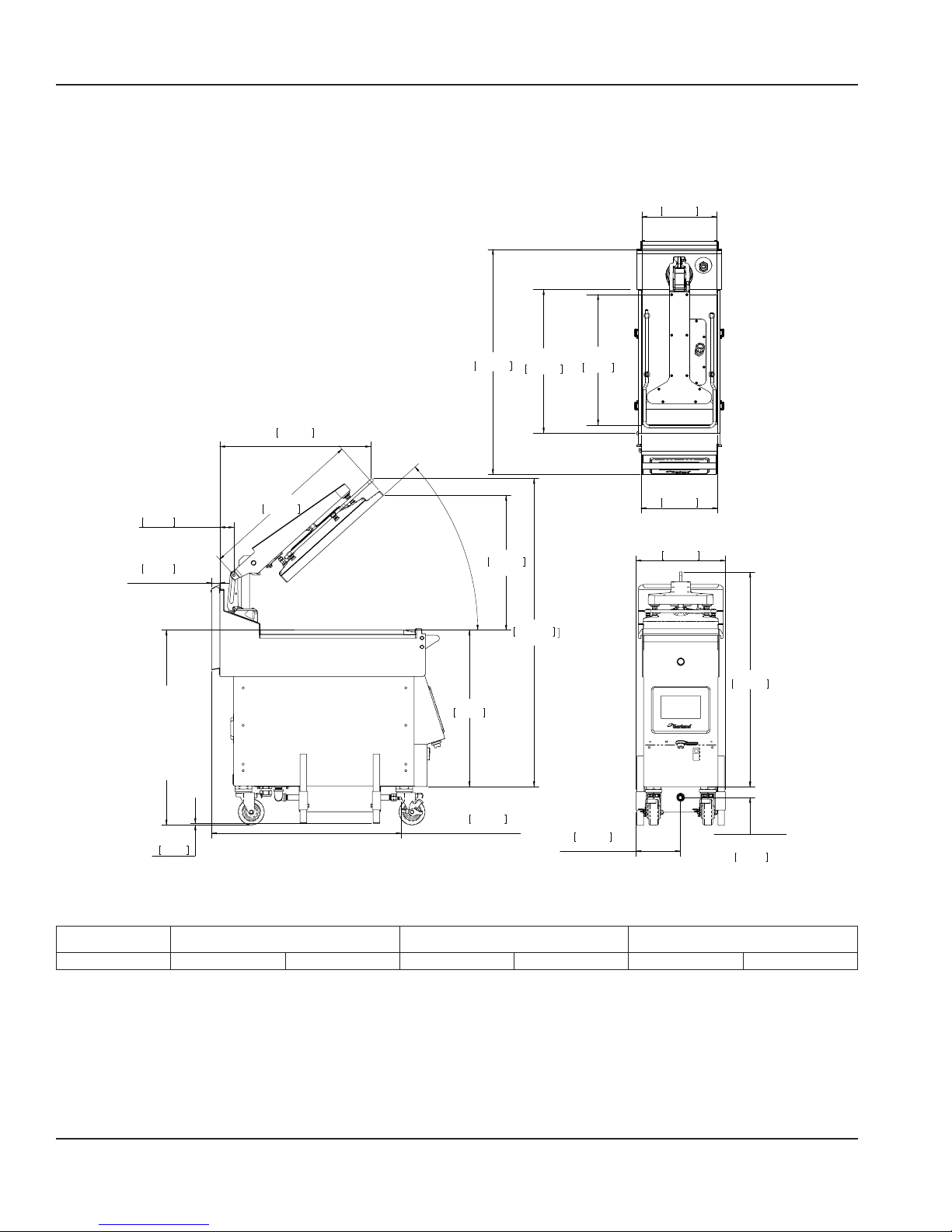

3 Platen Dimensions Specification

Dimensions: model: XP(E/G)36

1.255in

31.9mm

FOR GAS UNITS ONLY

TOP HEATER

11.500in

292.1mm

2.170in

55.1mm

FLUE BOX

FOR GAS

UNITS ONLY

59.9mm

FOR GAS UNITS ONLY

2.359in

[903.6 MAX TO 759.1 MIN]

35.574 MAX TO 29.887 MIN

25.250in

641.4mm

23.124in

587.4mm

MIN

22.000in

558.8mm

TOP HEATER

20.000in

508mm

32.941in

836.7mm

1.726in

43.8mm

FOR GAS UNITS ONLY

FRONT VIEW

GRILL PLATE

35.750in

908.1mm

TOP VIEW

36.979in

939.3mm

35.413in

899.5mm

GRILL PLATE

34.505in

876.4mm

42°

MAX

20.636in

524.1mm

MAX

47.212in

1199.2mm

MAX

23.978in

609mm

GAS CONNECTION

28.068in

712.9mm

FOR GAS UNITS ONLY

Model Height* Width** Depth

XP(E/G)24

* Height not including caster

** Without grease buckets.

32 in 812 mm 24 in 610 mm 34.5 in

14 Document: GAR_SM_4601777 (4/16)

876 mm

Section 1 General Information

2 Platen Dimensions Specification

Dimensions: model: XP(E/G)24

TOP HEATER

1.255in

31.9mm

FOR GAS UNITS ONLY

11.500in

292.1mm

2.170in

55.1mm

FLUE BOX

FOR GAS

UNITS ONLY

59.9mm

FOR GAS UNITS ONLY

2.359in

[903.6 MAX TO 759.1 MIN]

35.574 MAX TO 29.887 MIN

25.250in

641.4mm

23.124in

587.4mm

MIN

22.000in

MAX

FOR GAS UNITS ONLY

TOP HEATER

20.000in

508mm

32.941in

836.7mm

9.219in

234.2mm

GAS CONNECTION

GRILL PLATE

23.750in

603.3mm

TOP VIEW

24.979in

634.5mm

23.413in

594.7mm

FRONT VIEW

1.726in

43.8mm

FOR GAS UNITS ONLY

GRILL PLATE

34.505in

876.4mm

42°

MAX

23.978in

609mm

GAS CONNECTION

FOR GAS UNITS ONLY

20.636in

524.1mm

MAX

28.068in

712.9mm

558.8mm

47.212in

1199.2mm

Model Height* Width** Depth

XP(E/G)24

* Height not including caster

** Without grease buckets.

32 in 812 mm 24 in 610 mm 34.5 in

Document: GAR_SM_4601777 (4/16) 15

876 mm

General Information Section 1

1 Platen Dimensions Specification

Dimensions: model: XP(E/G)12

TOP HEATER

11.5in

292.1mm

2.2in

55.1mm

FLUE BOX

1.3in

31.8mm

(GAS UNITS ONLY)

[903.6 MAX TO 759.1 MIN]

35.574 MAX TO 29.887 MIN

25.3in

641.4mm

23.1in

587.4mm

MIN

22.0in

558.8mm

UPPER HEATER

20.0in

508mm

GRILL PLATE

11.8in

298.5mm

TOP VIEW

TOP VIEW

13.7in

348.1mm

32.9in

836.7mm

GRILL PLATE

34.5in

876.4mm

42°

MAX

20.6in

524.1mm

MAX

47.2in

1199.2mm

MAX

24.0in

609mm

ADJUST TO

0.25in

6.4mm

Model Height* Width** Depth

XP(E/G)12

* Height not including caster

** Without grease buckets.

32 in 812 mm 12 in 305 mm 34.5 in

16 Document: GAR_SM_4601777 (4/16)

GAS CONNECTION

29.1in

738.3mm

(GAS UNITS ONLY)

GAS CONNECTION

6.8in

172.3mm

GAS UNITS ONLY

FRONT VIEW

GAS CONNECTION

1.7in

42.2mm

(GAS UNITS ONLY)

876 mm

Section 1 General Information

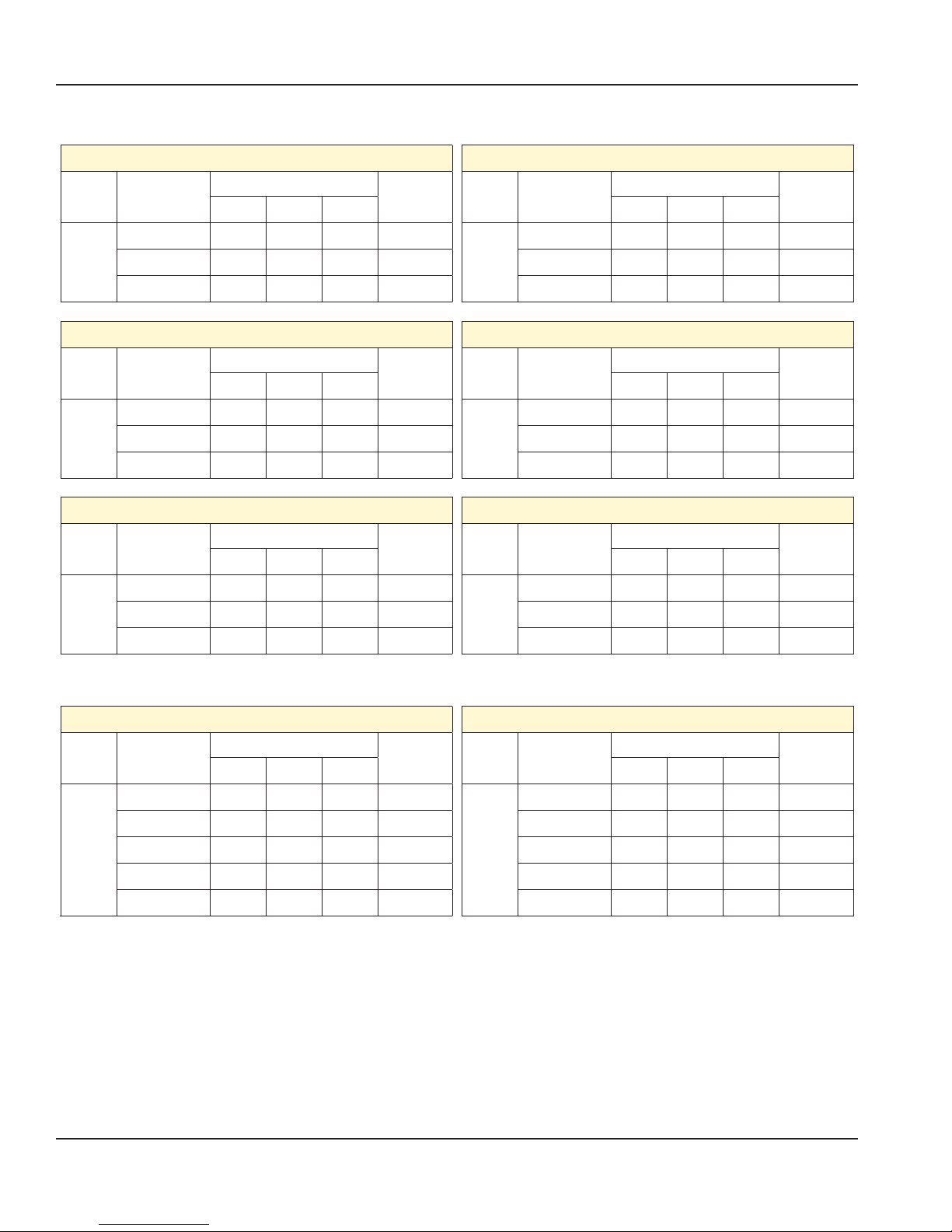

Electrical Input Specification - WYE (electric XPE-12 CE models)

Model

1

Platen

XPE-12 CE Models (electric models)

Volts

3NɎ(WYE)

50/60Hz

Total Current (A)

Power(kW)

L1 L2 L3

220V/380V 12.6 15.2 13.8 7.9

230V/400V 11.8 14.6 13.8 7.9

240V/415V 11.8 14.6 13.8 7.9

XPE-12 (0L,0R) CE Models (electric models)

Volts

Model

3NɎ(WYE)

50/60Hz

220V/380V 0.0 15.2 13.8 5.2

1

Platen

230V/400V 0.0 14.6 13.8 5.3

240V/415V 0.0 14.6 13.8 5.3

Electrical Input Specification - DELTA (electric XPE-12 models)

Model

1

Platen

XPE-12 Models (electric models)

Volts

3Ɏ(WYE)

50/60Hz

Total Current (A)

Power(kW)

L1 L2 L3

200V 23.6 26.5 25.8 8.0

208V 23.3 26.2 25.6 8.1

220V 22.0 23.7 24.1 7.9

230V 21.2 22.6 23.5 7.9

240V 21.0 22.5 23.4 7.9

Model

Platen

XPE-12 (0L,0R) Models (electric models)

Volts

3Ɏ(WYE)

50/60Hz

200V 13.9 16.8 25.8 5.3

208V 14.0 16.5 25.6 5.4

1

220V 13.8 15.2 24.1 5.2

230V 13.8 14.6 23.5 5.3

240V 13.8 14.6 23.4 5.3

Electrical Input Specification - WYE (gas XPG-12-CE models)

Total Current (A)

Power(kW)

L1 L2 L3

Total Current (A)

Power(kW)

L1 L2 L3

Model

XPG-12 CE Models (gas models)

Volts

3NɎ(WYE)

50/60Hz

Total Current (A)

L1 L2 L3

Power(kW)

Model

XPG-12 (0L,0R) CE Models (gas models)

220V/380V 12.6 4.7 0.0 3.4

1

Platen

230V/400V 11.8 4.7 0.0 3.4

1

Platen

240V/415V 11.8 4.7 0.0 3.4

Electrical Input Specification - DELTA (gas XPG-12 models)

XPG-12 Models (gas models)

Model

1

Platen

Volts

3Ɏ(WYE)

50/60Hz

200V 14.4 16.8 4.7 3.5

208V 14.0 16.5 4.8 3.5

220V 12.6 15.0 4.7 3.4

230V 11.8 14.2 4.7 3.4

240V 11.8 14.1 4.7 3.4

Total Current (A)

L1 L2 L3

Power(kW)

Model

1

Platen

Volts

3NɎ(WYE)

50/60Hz

Total Current (A)

Power(kW)

L1 L2 L3

220V/380V 0.0 4.7 0.0 0.8

230V/400V 0.0 4.7 0.0 0.8

240V/415V 0.0 4.7 0.0 0.8

XPG-12 (0L,0R) Models (gas models)

Volts

3Ɏ(WYE)

50/60Hz

Total Current (A)

Power(kW)

L1 L2 L3

200V 0.0 4.7 0.0 0.8

208V 0.0 4.8 0.0 0.8

220V 0.0 4.7 0.0 0.8

230V 0.0 4.7 0.0 0.8

240V 0.0 4.7 0.0 0.8

Document: GAR_SM_4601777 (4/16) 17

General Information Section 1

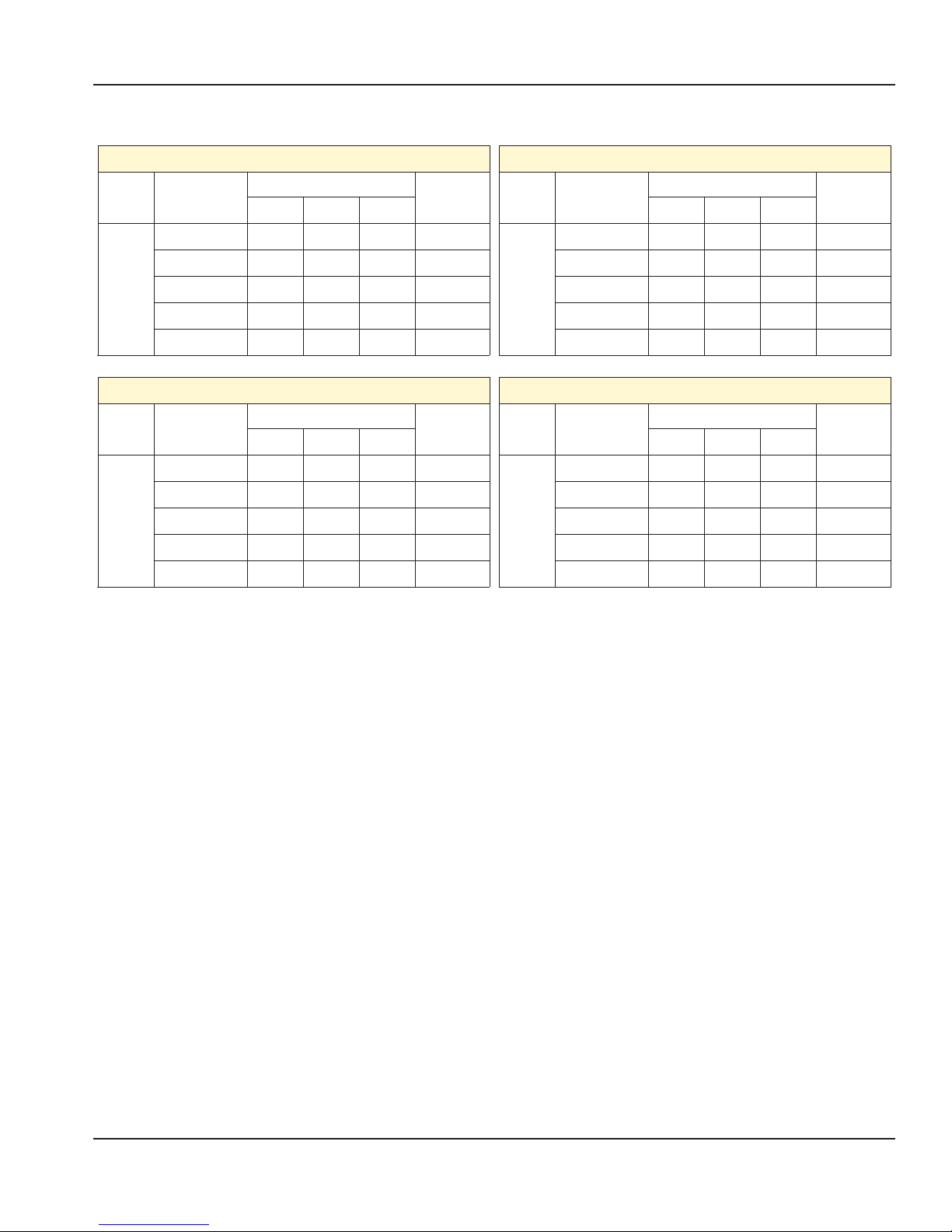

Electrical Input Specification - WYE (electric XPE-24 CE models)

Model

2

Platen

Model

2

Platen

XPE-24 CE Models (electric models)

Volts

3NɎ(WYE)

50/60Hz

Total Current (A)

Power(kW)

L1 L2 L3

220V/380V 27.3 24.9 27.1 15.8

230V/400V 26.4 23.9 25.8 15.9

240V/415V 26.4 23.7 25.8 15.9

XPE-24 1L CE Models (electric models)

Volts

3NɎ(WYE)

50/60Hz

Total Current (A)

Power(kW)

L1 L2 L3

220V/380V 27.3 13.8 2701 13.1

230V/400V 26.4 13.8 25.8 13.2

240V/415V 26.4 13.8 25.8 13.2

XPE-24 (0L,0R) CE Models (electric models)

Volts

Model

3NɎ(WYE)

50/60Hz

220V/380V 27.3 13.8 15.2 10.4

2

Platen

230V/400V 26.4 13.8 14.6 10.5

240V/415V 26.4 13.8 14.6 10.5

XPE-24 1R CE Models (electric models)

Volts

Model

3NɎ(WYE)

50/60Hz

220V/380V 27.3 24.9 15.2 13.1

2

Platen

230V/400V 26.4 23.9 14.6 13.2

240V/415V 26.4 23.7 14.6 13.2

Electrical Input Specification - DELTA (electric XPE-24 models)

Model

2

Platen

XPE-24 Models (electric models)

Volts

3Ɏ(WYE)

50/60Hz

Total Current (A)

Power(kW)

L1 L2 L3

200V 51.6 48.7 49.4 16.0

208V 50.8 48.1 48.4 16.2

220V 46.8 45.1 44.6 15.8

230V 44.9 43.9 42.8 15.9

240V 44.5 43.0 42.3 15.9

Model

Platen

XPE-24 (0L,0R) Models (electric models)

Volts

3Ɏ(WYE)

50/60Hz

200V 40.0 37.8 25.8 10.6

208V 39.6 37.5 25.6 10.8

2

220V 36.8 35.5 24.1 10.4

230V 35.7 35.1 23.5 10.5

240V 35.4 34.8 23.4 10.5

Total Current (A)

Power(kW)

L1 L2 L3

Total Current (A)

Power(kW)

L1 L2 L3

Total Current (A)

Power(kW)

L1 L2 L3

XPE-24 1L Models (electric models)

Model

Volts

3Ɏ(WYE)

50/60Hz

Total Current (A)

L1 L2 L3

200V 51.6 37.8 38.8 13.3

208V 50.8 37.5 38.1 13.5

2

Platen

220V 46.8 35.5 35.1 13.1

230V 44.9 35.1 33.7 13.2

240V 44.5 34.8 33.5 13.2

18 Document: GAR_SM_4601777 (4/16)

Power(kW)

Model

2

Platen

XPE-24 1R Models (electric models)

Volts

3Ɏ(WYE)

50/60Hz

Total Current (A)

Power(kW)

L1 L2 L3

200V 40.0 48.7 37.9 13.3

208V 39.6 48.1 37.1 13.5

220V 36.8 45.1 34.5 13.1

230V 35.7 43.9 33.3 13.2

240V 35.4 43.0 33.0 13.2

Section 1 General Information

Electrical Input Specification - WYE (gas XPG-24 CE models)

Model

XPG-24 CE Models (gas models)

Volts

3NɎ(WYE)

50/60Hz

Total Current (A)

L1 L2 L3

Power(kW)

Model

XPG-24 (0L,0R) CE Models (gas models)

220V/380V 4.7 12.6 16.7 6.8

2

Platen

230V/400V 4.7 11.8 15.5 6.9

2

Platen

240V/415V 4.7 11.8 15.6 6.9

XPG-24 1L CE Models (gas models)

Model

Volts

3NɎ(WYE)

50/60Hz

Total Current (A)

L1 L2 L3

Power(kW)

Model

220V/380V 4.7 0.0 16.7 4.2

2

Platen

230V/400V 4.7 0.0 15.5 4.2

2

Platen

240V/415V 4.7 0.0 15.6 4.2

Electrical Input Specification - DELTA (gas XPG-24 models)

XPG-24 Models (gas models)

Model

2

Platen

Volts

3Ɏ(WYE)

50/60Hz

200V 22.9 16.8 28.3 7.0

208V 20.5 16.5 27.6 7.0

220V 18.8 15.0 25.1 6.8

230V 18.0 14.2 23.7 6.9

240V 17.8 14.1 23.5 6.9

Total Current (A)

L1 L2 L3

Power(kW)

Model

2

Platen

Volts

3NɎ(WYE)

50/60Hz

Total Current (A)

Power(kW)

L1 L2 L3

220V/380V 4.7 0.0 4.7 1.5

230V/400V 4.7 0.0 4.7 1.5

240V/415V 4.7 0.0 4.7 1.5

XPG-24 1R CE Models (gas models)

Volts

3NɎ(WYE)

50/60Hz

Total Current (A)

Power(kW)

L1 L2 L3

220V/380V 4.7 12.6 4.7 4.2

230V/400V 4.7 11.8 4.7 4.2

240V/415V 4.7 11.8 4.7 4.2

XPG-24 (0L,0R) Models (gas models)

Volts

3Ɏ(WYE)

50/60Hz

Total Current (A)

Power(kW)

L1 L2 L3

200V 7.9 4.7 4.7 1.5

208V 8.0 4.8 4.8 1.6

220V 7.7 4.7 4.7 1.5

230V 7.7 4.7 4.7 1.5

240V 7.6 4.7 4.7 1.5

XPG-24 1L Models (gas models)

Model

Volts

3Ɏ(WYE)

50/60Hz

Total Current (A)

L1 L2 L3

200V 20.9 4.7 18.4 4.2

208V 20.5 4.8 18.0 4.3

2

Platen

220V 18.8 4.7 16.4 4.2

230V 18.0 4.7 15.6 4.2

240V 17.8 4.7 15.4 4.2

Document: GAR_SM_4601777 (4/16) 19

Power(kW)

Model

2

Platen

XPG-24 1R Models (gas models)

Volts

3Ɏ(WYE)

50/60Hz

Total Current (A)

Power(kW)

L1 L2 L3

200V 7.9 16.8 16.8 4.2

208V 8.0 16.5 16.5 4.3

220V 7.7 15.0 15.0 4.2

230V 7.7 14.2 14.2 4.2

240V 7.6 14.1 14.1 4.2

General Information Section 1

Electrical Input Specification - WYE (electric XPE-36 CE models)

Model

3

Platen

Model

3

Platen

Model

3

Platen

XPE-36 CE Models (electric models)

Volts

3NɎ(WYE)

50/60Hz

Total Current (A)

Power(kW)

L1 L2 L3

220V/380V 39.3 39.3 39.3 23.6

230V/400V 37.2 37.2 37.2 23.8

240V/415V 37.2 37.2 37.2 23.8

XPE-36 1L CE Models (electric models)

Volts

3NɎ(WYE)

50/60Hz

Total Current (A)

Power(kW)

L1 L2 L3

220V/380V 23.7 23.7 39.3 18.3

230V/400V 26.4 26.4 37.2 18.5

240V/415V 26.4 26.4 37.2 18.4

XPE-36 2L CE Models (electric models)

Volts

3NɎ(WYE)

50/60Hz

Total Current (A)

Power(kW)

L1 L2 L3

220V/380V 39.3 27.3 39.3 21.0

230V/400V 37.2 26.4 37.2 21.2

240V/415V 37.2 26.4 37.2 21.1

XPE-36 (0L,0R) CE Models (electric models)

Model

Volts

3NɎ(WYE)

50/60Hz

Total Current (A)

L1 L2 L3

220V/380V 27.3 27.3 27.3 15.7

3

Platen

230V/400V 26.4 26.4 26.4 15.8

240V/415V 26.4 26.4 26.4 15.8

XPE-36 1R CE Models (electric models)

Model

Volts

3NɎ(WYE)

50/60Hz

Total Current (A)

L1 L2 L3

220V/380V 27.3 39.3 27.3 18.3

3

Platen

230V/400V 26.4 37.2 26.4 18.5

240V/415V 26.4 37.2 26.4 18.4

XPE-36 2R CE Models (electric models)

Model

Volts

3NɎ(WYE)

50/60Hz

Total Current (A)

L1 L2 L3

220V/380V 39.3 39.3 27.3 21.0

3

Platen

230V/400V 37.2 37.2 26.4 24.2

240V/415V 37.2 37.2 26.4 21.1

Power(kW)

Power(kW)

Power(kW)

Electrical Input Specification - DELTA (electric XPE-36 models)

Model

3

Platen

Cord

1

3

Platen

Cord

2

XPE-36 Models (electric models)

Volts

3Ɏ(WYE)

50/60Hz

Total Current (A)

Power(kW)

L1 L2 L3

200V 25.8 23.6 26.5 16.0

208V 25.6 23.3 26.2 16.2

220V 23.7 22.0 24.1 15.8

230V 22.6 21.2 23.5 15.9

240V 22.5 21.0 23.4 15.9

200V 49.4 51.6 48.7 8.0

208V 48.4 50.8 48.1 8.1

220V 44.6 46.8 45.1 7.9

230V 42.8 44.9 43.9 7.9

240V 42.3 44.5 43.0 7.9

Model

Platen

Cord

Platen

Cord

XPE-36 (0L/R) Models (electric models)

Volts

3Ɏ(WYE)

50/60Hz

200V 25.8 13.9 16.8 5.3

3

208V 25.6 14.0 16.5 5.4

220V 24.1 13.8 15.2 5.2

1

230V 23.5 13.8 14.6 5.3

240V 23.4 13.8 14.6 5.3

200V 25.8 40.0 37.8 10.6

3

208V 25.6 39.6 37.5 10.8

220V 24.1 36.8 35.5 10.4

2

230V 23.5 35.7 35.1 10.5

240V 23.4 35.4 34.8 10.5

Total Current (A)

Power(kW)

L1 L2 L3

20 Document: GAR_SM_4601777 (4/16)

Section 1 General Information

Electrical Input Specification - DELTA (electric XPE-36models)

Model

3

Platen

Cord

1

3

Platen

Cord

2

Model

3

Platen

Cord

1

3

Platen

Cord

2

XPE-36 1L Models (electric models)

Volts

3Ɏ(WYE)

50/60Hz

Total Current (A)

Power(kW)

L1 L2 L3

200V 25.8 23.6 26.5 8.0

208V 25.6 23.3 26.2 8.1

220V 24.1 22.0 23.7 7.9

230V 23.5 21.2 22.6 7.9

240V 23.4 21.0 22.5 7.9

200V 25.8 40.0 37.8 10.6

208V 25.6 39.6 37.5 10.8

220V 24.1 36.8 35.5 10.4

230V 23.5 35.7 35.1 10.5

240V 23.4 35.4 34.8 10.5

XPE-36 2L Models (electric models)

Volts

3Ɏ(WYE)

50/60Hz

Total Current (A)

Power(kW)

L1 L2 L3

200V 13.9 16.8 25.8 5.3

208V 14.0 16.5 25.6 5.4

220V 13.8 15.2 24.1 5.2

230V 13.8 14.6 23.5 5.3

240V 13.8 14.6 23.4 5.3

200V 51.6 48.7 49.4 16.0

208V 50.8 48.1 48.4 16.2

220V 46.8 45.1 44.6 15.8

230V 44.9 43.9 42.8 15.9

240V 44.5 43.0 42.3 15.9

Model

3

Platen

Cord

1

3

Platen

Cord

2

Model

3

Platen

Cord

1

3

Platen

Cord

2

XPE-36 1R Models (electric models)

Volts

3Ɏ(WYE)

50/60Hz

Total Current (A)

Power(kW)

L1 L2 L3

200V 23.6 26.5 25.8 8.0

208V 23.3 26.2 25.6 8.1

220V 22.0 23.7 24.1 7.9

230V 21.2 22.6 23.5 7.9

240V 21.0 22.5 23.4 7.9

200V 40.0 37.8 25.8 10.6

208V 39.6 37.5 25.6 10.8

220V 36.8 35.5 24.1 10.4

230V 35.7 35.1 23.5 10.5

240V 35.4 34.8 23.4 10.5

XPE-36 2R Models (electric models)

Volts

3Ɏ(WYE)

50/60Hz

Total Current (A)

Power(kW)

L1 L2 L3

200V 25.8 13.9 16.8 5.3

208V 25.6 14.0 16.5 5.4

220V 24.1 13.8 15.2 5.2

230V 23.5 13.8 14.6 5.3

240V 23.4 13.8 14.6 5.3

200V 49.4 51.6 48.7 16.0

208V 48.4 50.8 48.1 16.2

220V 44.6 46.8 45.1 15.8

230V 42.8 44.9 43.9 15.9

240V 42.3 44.5 43.0 15.9

Document: GAR_SM_4601777 (4/16) 21

General Information Section 1

Electrical Input Specification - WYE (gas XPG-36 CE models)

Model

3

Platen

Model

3

Platen

Model

3

Platen

XPG-36 CE Models (gas models)

Volts

3NɎ(WYE)

50/60Hz

Total Current (A)

Power(kW)

L1 L2 L3

220V/380V 16.7 16.7 16.7 10.2

230V/400V 15.5 15.5 15.5 10.3

240V/415V 15.6 15.6 15.6 10.3

XPG-36 1L CE Models (gas models)

Volts

3NɎ(WYE)

50/60Hz

Total Current (A)

Power(kW)

L1 L2 L3

220V/380V 4.7 4.7 16.7 4.9

230V/400V 4.7 4.7 15.5 5.0

240V/415V 4.7 4.7 15.6 5.0

XPG-36 2L CE Models (gas models)

Volts

3NɎ(WYE)

50/60Hz

Total Current (A)

Power(kW)

L1 L2 L3

220V/380V 16.7 4.7 16.7 7.6

230V/400V 15.5 4.7 15.5 7.7

240V/415V 15.6 4.7 15.6 7.6

Model

3

Platen

Model

3

Platen

Model

3

Platen

XPG-36 (0L/R) CE Models (gas models)

Volts

3NɎ(WYE)

50/60Hz

Total Current (A)

Power(kW)

L1 L2 L3

220V/380V 4.7 4.7 4.7 2.3

230V/400V 4.7 4.7 4.7 2.3

240V/415V 4.7 4.7 4.7 2.3

XPG-36 1R CE Models (gas models)

Volts

3NɎ(WYE)

50/60Hz

Total Current (A)

Power(kW)

L1 L2 L3

220V/380V 4.7 16.7 4.7 4.9

230V/400V 4.7 15.5 4.7 5.0

240V/415V 4.7 15.6 4.7 5.0

XPG-36 2R CE Models (gas models)

Volts

3NɎ(WYE)

50/60Hz

Total Current (A)

Power(kW)

L1 L2 L3

220V/380V 16.7 16.7 4.7 7.6

230V/400V 15.5 15.5 4.7 7.7

240V/415V 15.6 15.6 4.7 7.6

Electrical Input Specification - DELTA (gas XPG-36 models)

XPG-36 Models (gas models)

Model

3

Platen

Volts

3Ɏ(WYE)

50/60Hz

200V 31.7 31.7 31.7 10.4

208V 30.9 30.9 30.9 10.6

220V 28.3 28.3 28.3 10.2

230V 27.3 27.3 27.3 10.3

240V 26.1 26.1 26.1 10.3

Total Current (A)

L1 L2 L3

Power(kW)

Model

3

Platen

XPG-36 (0L/R) Models (gas models)

Volts

3Ɏ(WYE)

50/60Hz

Total Current (A)

Power(kW)

L1 L2 L3

200V 7.0 7.0 7.0 2.3

208V 6.9 6.9 6.9 2.3

220V 6.3 6.3 6.3 2.3

230V 6.1 6.1 6.1 2.3

240V 5.8 5.8 5.8 2.3

22 Document: GAR_SM_4601777 (4/16)

Section 1 General Information

Electrical Input Specification - DELTA (gas XPG-36 models), continuation

Model

3

Platen

Model

3

Platen

XPG-36 1L Models (gas models)

Volts

3Ɏ(WYE)

50/60Hz

Total Current (A)

Power(kW)

L1 L2 L3

200V 20.6 7.0 20.6 5.0

208V 20.1 6.9 20.1 5.1

220V 18.4 6.3 18.4 4.9

230V 17.8 6.1 17.8 5.0

240V 17.0 5.8 17.0 5.0

XPG-36 2L Models (gas models)

Volts

3Ɏ(WYE)

50/60Hz

Total Current (A)

Power(kW)

L1 L2 L3

200V 31.7 20.6 20.6 7.7

208V 30.9 20.1 20.1 7.8

220V 28.3 18.4 18.4 7.6

230V 27.3 17.8 17.8 7.7

240V 26.1 17.0 17.0 7.6

Model

3

Platen

Model

3

Platen

XPG-36 1R Models (gas models)

Volts

3Ɏ(WYE)

50/60Hz

Total Current (A)

Power(kW)

L1 L2 L3

200V 7.0 20.6 20.6 5.0

208V 6.9 20.1 20.1 5.1

220V 6.3 18.4 18.1 4.9

230V 6.1 17.8 17.8 5.0

240V 5.8 17.0 17.0 5.0

XPG-36 2R Models (gas models)

Volts

3Ɏ(WYE)

50/60Hz

Total Current (A)

Power(kW)

L1 L2 L3

200V 20.6 31.7 20.6 7.7

208V 20.1 30.9 20.1 7.8

220V 18.4 28.3 18.4 7.6

230V 17.8 27.3 17.8 7.7

240V 17.0 26.1 17.0 7.6

Document: GAR_SM_4601777 (4/16) 23

General Information Section 1

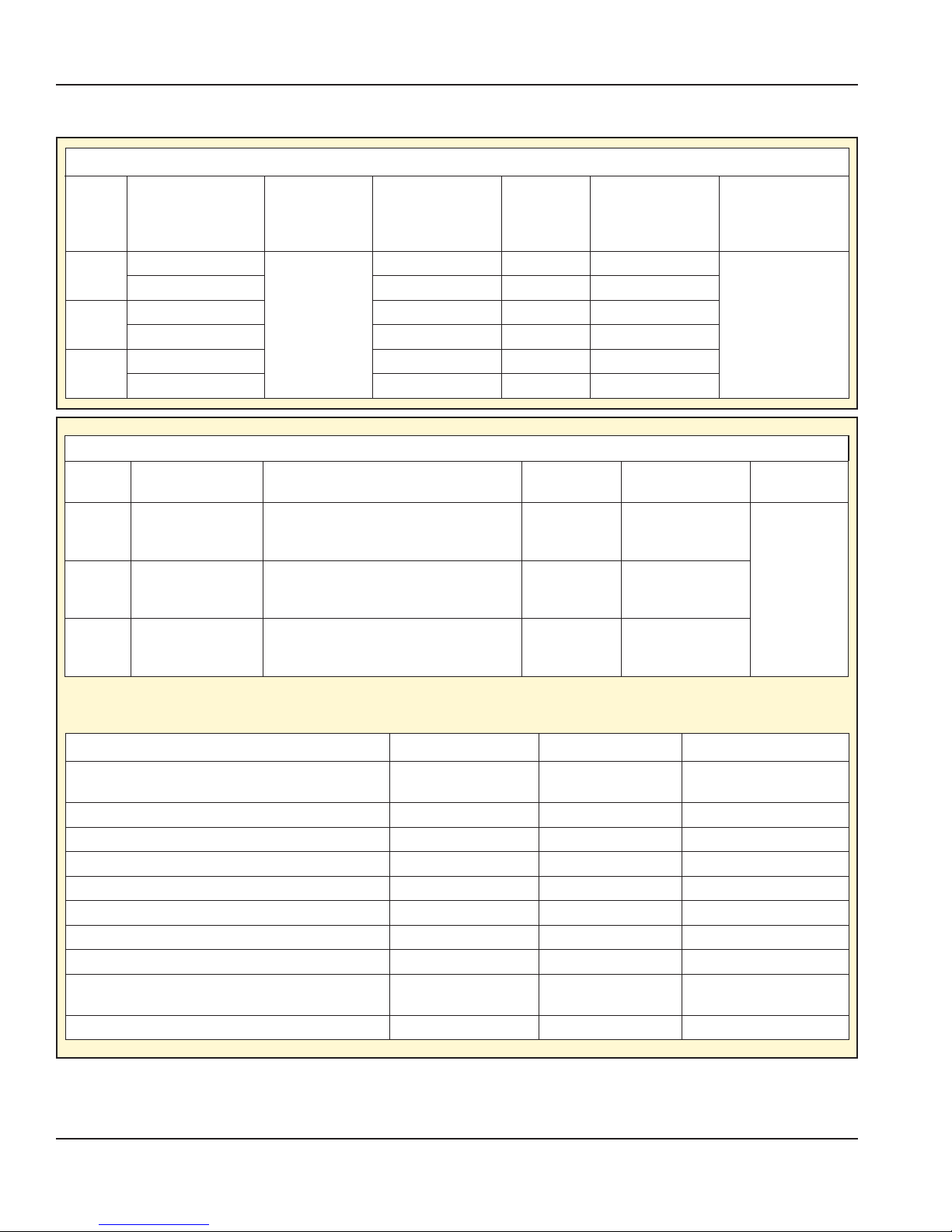

Gas Input Specification

Gas Grills, 1, 2 & 3 Platen North America - all CSA models.

GAS

1

Platen

2

Platen

3

Platen

Input Speci cation - All CE Models.

GAS

GROUP

G20 2.93

G31 2.93

NATURAL GAS

PROPANE 20,000 1.2mm 11.0” WC

NATURAL GAS 40,000 1.5mm 7.0” WC

PROPANE 40,000 1.2mm 11.0” WC

NATURAL GAS 60,000 1.5mm 7.0” WC

PROPANE 60,000 1.2mm 11.0” WC

MAX INPUT NET

PER BURNER kW

MAX INPUT

NET PER

BURNER

BTU/H

10,000

TOTAL INPUT RATING kW

5.86kW - (For XPE12 series)

11.72kW - (For XPE24 series)

17.58kW - (For XPE36 series)

5.86kW - (For XPE12 series)

11.72kW - (For XPE24 series)

17.58kW - (For XPE36 series)

5.86kW - (For XPE12 series)

11.72kW - (For XPE24 series)

17.58kW - (For XPE36 series)

TOTAL INPUT

RATING

BTU/H

20,000 1.5mm 7.0” WC

INJECTOR

SIZE

INJECTOR

SIZE mm

SUPPLY PRESSURE

IN W.C.

PRESSURE mbar

1.5mm

1.5mm

1.2mm

BURNER

10mbar

(4.0” WC)

13.7mbar

(5.5” WC)

10mbar

(4.0” WC)

BURNER MANIFOLD

PRESSURE

IN W.C.

4.0” WC

FAN SPEED

SETTING (RPM)

10,000G25 2.93

For G31 propane gas, the unit has been set at the factory for a 37mbar supply pressure. A factory authorized service

technician must adjust the unit if a 30mbar supply pressure is used.

COUNTRY GAS CATEGORY GAS TYPE SUPPLY PRESSURE (mbar)

AT, CH, CY, CZ, DK, EE, ES, FI, FR, GB, GR, HR, IE, IT, LT, LU,

LV, NL, NO, PT, RO, SE, SI, SK, TR

HU I2H G20 25

DE, LU, PL, RO I2E G20 20

BE I2E(R) G20 20

FR I2E(r) G20/G25 20/25

FR, NL I2L G25 25

RO I2L G25 20

FI, HU,NL, RO I3P G31 30

BE, CH, CZ, ES, FR, GB, GR, HU, IE, IT, LT, NL, PL, PT, SI, SK,

HR

AT, BE, CH, CZ, DE, ES, FR, GB, GR, HU, NL, SK I3P G31 50

I2H G20 20

I3P G31 37

NOTE: For installations up to 2000ft. units being installed at higher elevation must be configured accordingly at the factory

or modified at the installation site by a factory authorized service technician.

24 Document: GAR_SM_4601777 (4/16)

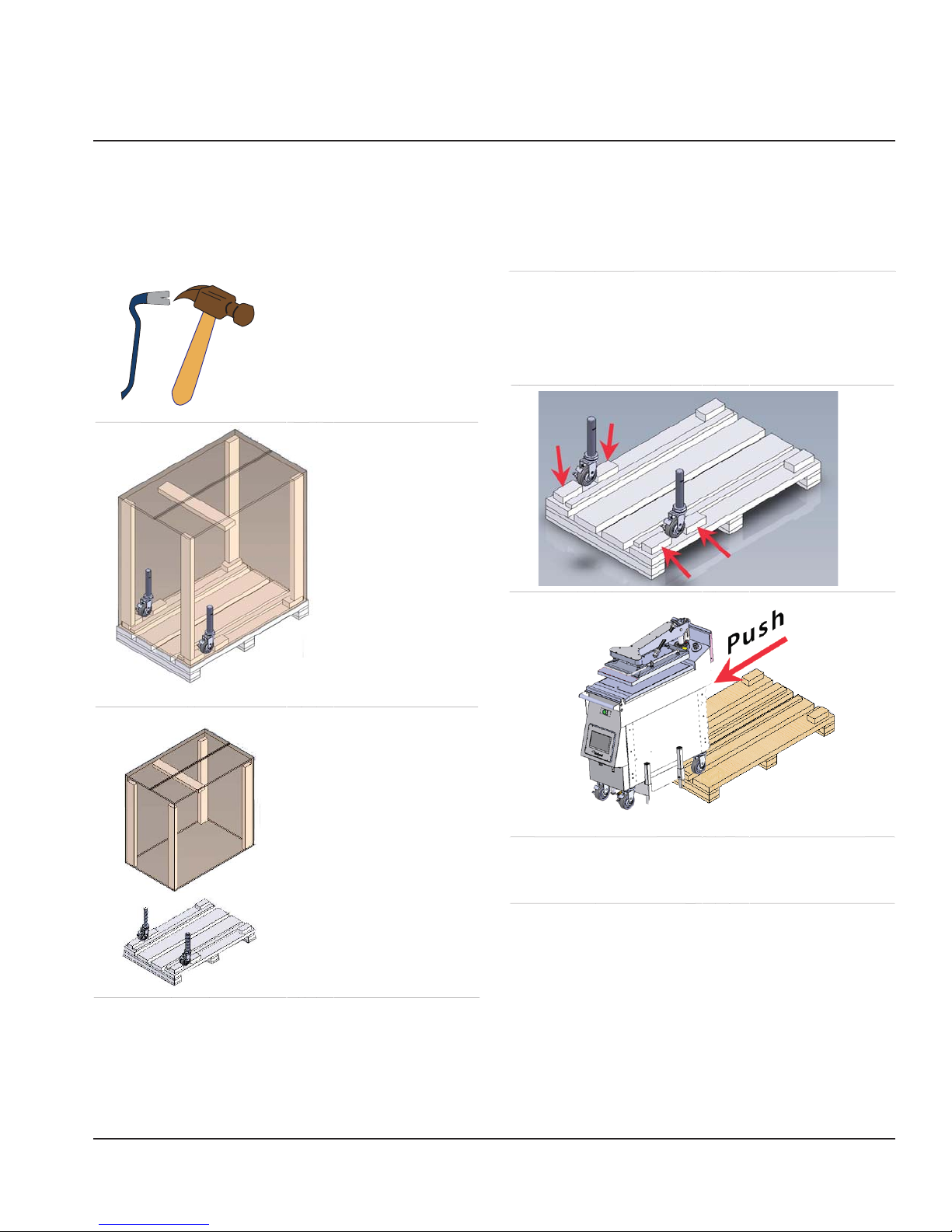

STOP! - Follow the instructions below to safely and easily remove unit from packaging skid.

Unit very heavy Personal Protective Equipment (PPE) required.

Removing Grill From Wood Crate

Tools required.

1. PACKAGING

Section 2

Installation

IS DIVIDED IN

TWO PARTS,

CARDBOARD

BOX AND THE

WOOD SKID.

3. REMOVE AND DISCARD THE TWO (2) WOOD

BLOCKS LOCKING EACH OF THE FRONT CASTER.

NOTE: ENSURE FRONT CASTER BRAKES ARE ON

WHILE BLOCK ARE BEEN REMOVED.

4.

2. REMOVE AND

DISCARD THE

CARDBOARD BOX

COVERING THE UNIT.

Document: GAR_SM_4601777 (4/16)

5. RELEASE THE FRONT CASTER BRAKES AND PUSH

UNIT FORWARD OFF OF THE SKID. ENSURE THAT

THE UNIT ROLLS STRAIGHT AS IT IS BEING MOVED.

Installation Section 2

Transporting Grill To Location

Transporting your new grill to the kitchen requires the

following criteria.

• Plan first before anything else. Lower your risk of

encountering problems during the transport process.

• Understand brake caster mechanism to apply or release

when requires.

• Keep top platen down during transportation.

• Match transportation speed to conditions.

• Turn downhill, not uphill, if stability becomes uncertain

on slope or ramp.

• Push/pull the grill by the towel bar straight even with

the gentle slope.

• Do not push/pull diagonally across it.

• Do not push/pull by conduit or platen arm.

• One (1) platen model is

narrow, take extra care

for slope and ramp. If

slope or ramp is greater

than ±100 there is

potential that the grill

will tip-over, ask for

10

Ý

help and use the proper

techniques transporting

the grill.

Location

The location selected for the equipment must meet the

following criteria. If any of these criteria are not met, select

another location.

• The location MUST be level and capable of supporting

the weight of the equipment:

→ 3platen - 238.1 kg (525 lbs) approximately.

→ 2platen - 165.6 kg (365 lbs) approximately.

→ 1platen - 154.2 kg (340 lbs) approximately.

• The location MUST be free from and clear of

combustible materials.

• Equipment MUST be level both front to back and side to

side.

• Position the equipment so it will not tip or slide.

• The air temperature must be at least 40°F (4.4°C) must

not exceed 110°F (43.3°C).

• Proper air supply for ventilation is REQUIRED AND

CRITICAL for safe and efficient operation. Refer to

Clearance Requirements chart.

• Do not obstruct the flow of ventilation air. Make sure the

air vents of the equipment are not blocked

• The location must not be near heat-generating (broiler,

dishwashers, etc) equipment or in direct sunlight and

must be protected from weather.

• Do not install the equipment directly over a drain.

Steam rising up out of the drain will adversely affect

operation, air circulation, and damage electrical /

electronic components.

• Do not store anything on top of a unit.

Clearance Requirements

Entry Installation

Uncrated Sides Rear

32" x 35.8" x 31.4"*

(812 mm x 909 mm x 798 mm)

* Depth 31.4” (798 mm), with towel bar and front panel removed

2"

(51 mm)4"(102 mm)

Leveling

Position the unit under the hood and in its normal

operational position to prevent warping of the grill plate &

optimize cooking performance.

• Adjust the unit by turning the casters clockwise to raise

the unit and counterclockwise to lower the unit.

• Adjust the casters until the grill plate is level and at the

proper height.

• Grill must be level front to back, side to side and

diagonally. This leveling must be done with the unit

under the hood and it’s normal operation.

• Tighten the lock nut on each caster tightly against the

bottom of the unit.

• When the unit is in place, lock the front casters to

prevent movement.

• Lock the casters from swiveling to facilitate moving the

unit straight in and out for cleaning.

Exhaust Hood Requirements

1. Install the equipment under an Exhaust Hood.

2. The exhaust hood must extend over the exhaust ports

and meet the following requirements:

A. The exhaust hood must be sized for the cumulative

ventilation requirements of all the appliances in

the area under the hood.

B. If an existing hood cannot be used, a new one

must be constructed over the equipment.

C. When determining hood size; include clearances.

NOTE: Always turn ON the exhaust hood when the unit is

running to prevent condensation in the unit.

26 Document: GAR_SM_4601777 (4/16)

Section 2 Installation

Ventilation

Hood

25.4

1.00

Min.

Platen

Clearance between Platen and Hood

Positioning

The unit is very heavy and mechanical assistance may be

required to lift and position the appliance.

The unit is designed to be installed on a smooth and

level floor built to withstand the weight of the fully laden

appliance.

The unit is pre-installed with casters for ease of mobility for

cleaning and servicing. Take proper care to push or pull the

grill and ensure the grill does not tip over.

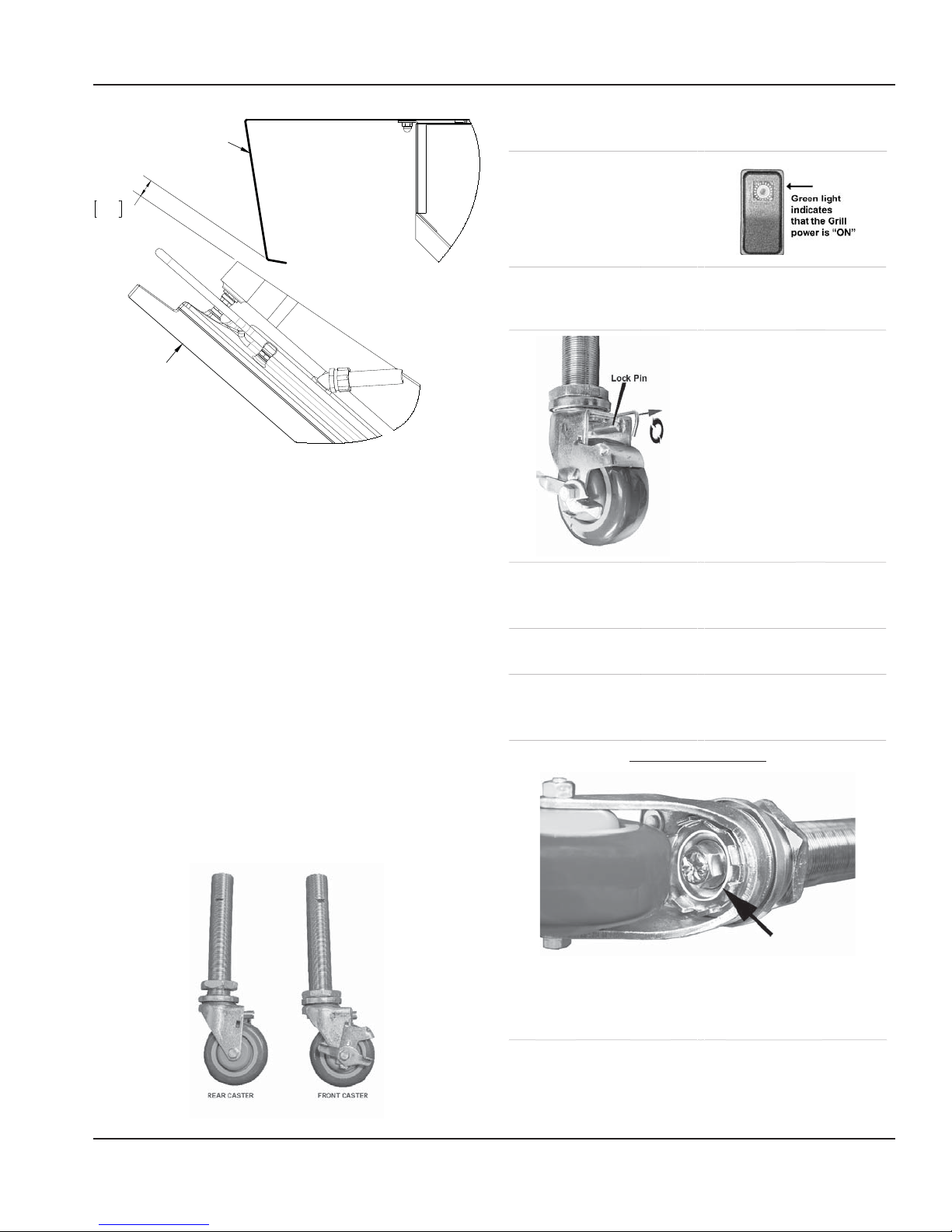

Casters Adjustment Procedure

1. Turn the clamshell grill

Green Power Main Switch

OFF. (green light o )

2. Rear and front Casters have a threaded stem to

adjust the level of the grill independent of the swiveling

action.

3. All casters are

adjustable.

4. Lock the caster swivel

using the locking pin.

Pull the clip and turn 90

degrees, release pin. (Note:

applying the locking pin in

the lock position will lock

the swivel of the caster

assembly).

5. Carefully raise the unit slightly so that the wheel is

o the ground and no longer bearing unit weight.

6. Loosen caster jam nut by turning it counterclockwise

with a wrench.

Appliances Equipped with Casters

The unit is shipped with casters installed in place, some

adjustment may be required to level the unit. The front

and rear casters are adjustable, only the front casters have

brakes.

Garland recommends installing restraining chains/cables

from the floor/wall to the rear of the unit. These restraints

limit the mobility of the appliance.

7. Adjust the caster assembly by turning the caster

(swivel locking pin on) counterclockwise to increase the

height or clockwise to decrease the height.

IMPORTANT NOTE

On the caster assembly shown above there is a nut used

to assemble the swivel system - do not use wrench on

this nut. This nut is intended for the caster swiveling

system only.

Document: GAR_SM_4601777 (4/16) 27

Installation Section 2

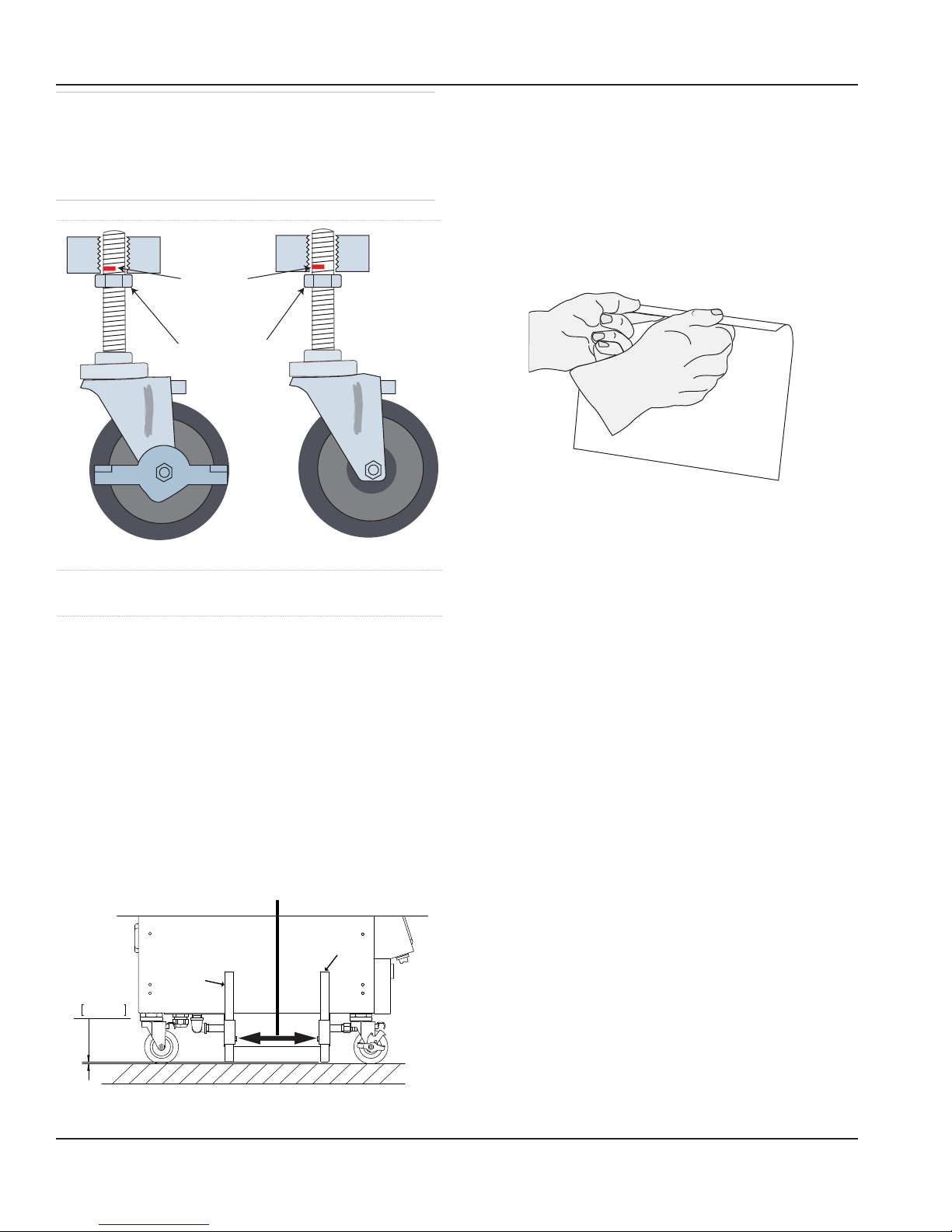

8. Beware of the red mark in the threaded stem to

indicated the maximum adjustment. Red mark in the

threaded stem portion should not be visible.

Warning: Adjusting above the red mark could cause the

caster to fail & the unit to tip.

Red Mark in Shaft

Should

NOT be Visible

Caster Jam Nuts

FRONT CASTER WITH BRAKE REAR CASTER WITHOUT BRAKE

9. After the grill is completely level, tighten caster jam

nut to secure the caster assembly.

Securing Stabilizer Grill System (1 platen models only)

Stabilizer system will help prevent the grill from tippingover within a range of 00 to 100 degrees angle perpendicular

to the front of the unit.

1. Proceed and complete Caster Adjustment Procedure as

mentioned above.

2. Lower the stabilizing arms, (total of four (4) arms

located beside the side panels) until the arms touch the

floor.

3. Raise each arm 0.25” (6.4mm) off the floor and secure

the arm with the bolt on the side of each arm, as shown

below.

Tight bolts to secure arm in place

total of four (4) bolts

Remove Stainless Steel Plastic Film Cover

Removing this film is one of the things that must be done

once the Grill is in place. The film covers both internal and

external components (e.g. side panels, grease shield) and

must be removed before turning the grill on.

1. Using a plastic scraper, wedge the film away from the

stainless steel.

2. Grasp and pull the film very gently away from the

stainless steel.

PEEL OFF PLASTIC FILM

Temporary Storage

Garland provides adequate protection under normal

conditions in transit and storage. The grill may need

additional protection if it is stored near salt water, a tropical

area, or other unfavorable conditions. Please contact

Garland immediately if these conditions occur.

Gas Connector Requirements:

• Installation shall be made with the gas connector

that has been supplied loose with the grill. The quick

disconnect fitting and gas shut off valve must be

installed in the direction indicated on their outer body.

• NOTE: When checking gas pressure, be sure that all

other equipment on the same gas line is on.

• The appliance and its individual shut-off valve must be

disconnected from the gas supply piping system during

any pressure testing of that system pressures in excess

of ½ PSIG (3.45kPa).

• Adequate clearance must be provided for servicing and

proper operation.

Stabilizer Arm

ADJUST TO

0.25in

6.4mm

Stabilizer Arm

NOTE: UNDER NO CIRCUMSTANCES SHOULD YOU

REMOVE THE STABILIZER SYSTEM FROM GRILL.

28 Document: GAR_SM_4601777 (4/16)

National Codes Requirements:

• The type of gas for which the grill is equipped is

stamped on the serial plate mounted on the lower left

corner of the right panel. Connect a grill to the gas type

stamped on the data plate only.

• The installation must conform to the National Fuel Gas

Code ANSI Z223.1-1998 or latest edition, NFPA No. 54 –

latest edition and National Electrical Code ANSI/NFPA

70-1990 or latest edition and/or local code to assure

safe and efficient operation. In Canada, the installation

Section 2 Installation

must comply with CSA B149.1 and local codes where

applicable.

• In Canada, electrical connection must comply with

applicable sections of the Canadian Electrical Code,

C22.1 - 1990, latest edition, “Safety Standard for

Installation, Part 1” and C22.2- No. O-M 1982 latest

edition.

Installation store responsibilities:

• The installation shall be made with a connector that

complies with the Standard for Connectors for Moveable Gas Appliances, ANSI Z21.69/CSA 6.16, and quickdisconnect device that complies with the Standard for

Quick Disconnect Devices for Use with Gas Fuel, ANSI

Z21.41/CSA 6.9.

• The front Casters on the appliance are equipped with

brakes to limit the movement of the appliance without

placing any strain on the connector or quick disconnect

device or its associated piping.

• Please be aware: required restraint is attached to a

bracket, (which is located on the front of the grill,

underneath, closest to the gas connection) and if

disconnection of the restraint is necessary, be sure

to reconnect the device after the appliance has been

returned to its original position.

• Conduct training with your crew personnel to ensure

maximum utilization of the grill. Once the installation

is complete as per the procedures below, a factory

authorized service company MUST startup the grill

according to Garland Commercial Ranges startup

standards.

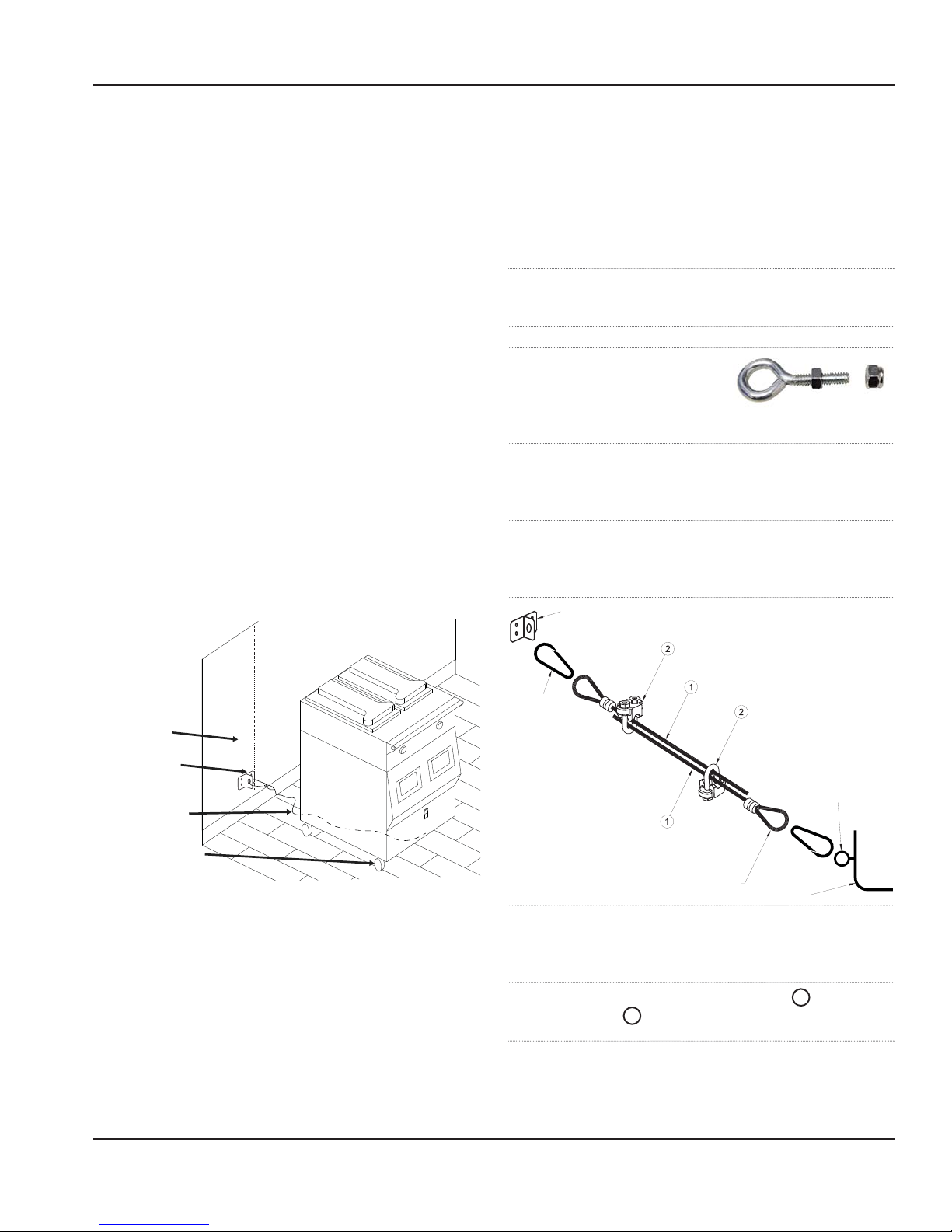

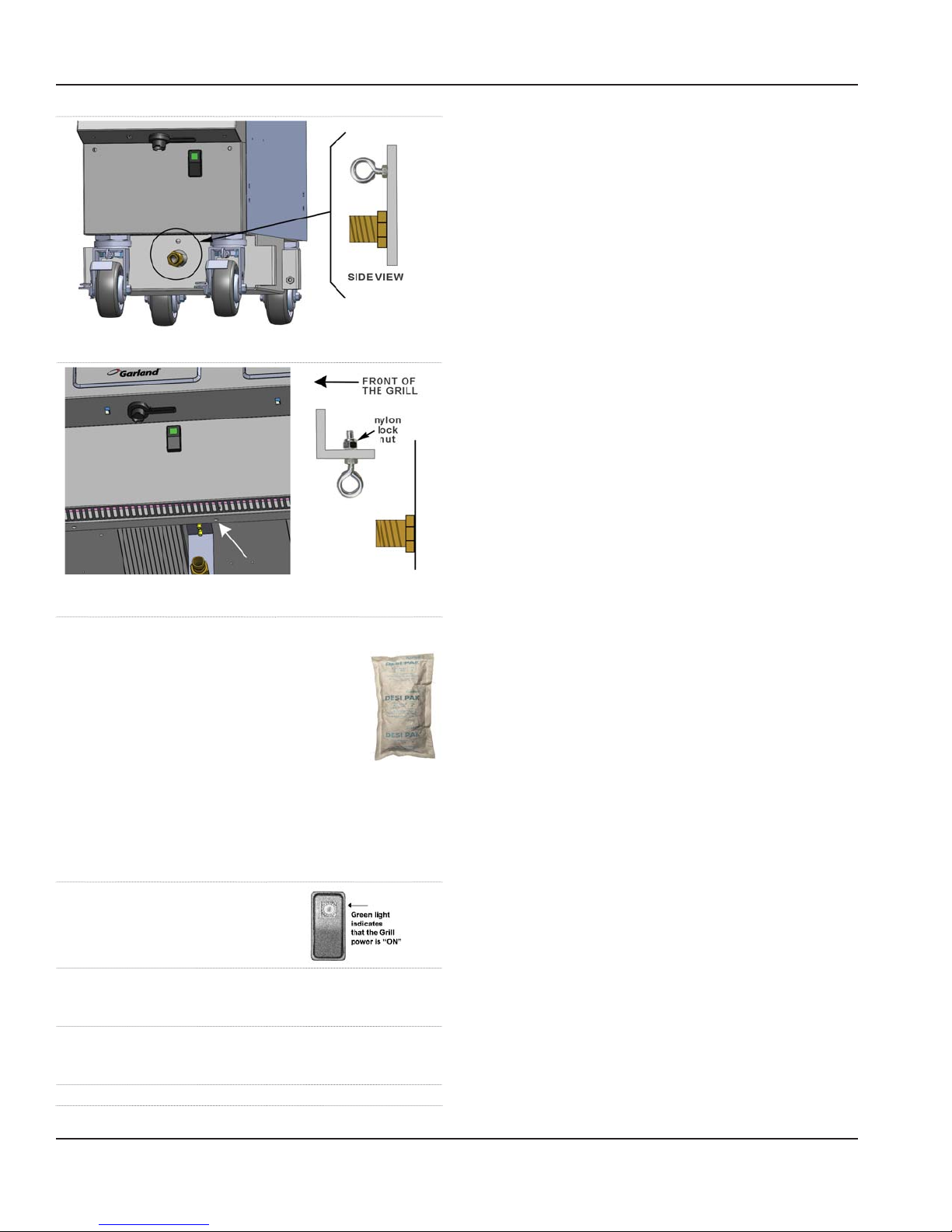

Restraining device installation Procedure

1. Shutoff main gas line valve and disconnect the quickdisconnect gas line device before the following

installation .

2. Attach the bracket to a stud in the wall.

3. Locate the area in the

frame on front of the grill

underneath, to place the

eye-bolt. Closest to the gas

connection

4. For model one (1) platen grill gas. Discard nylon

lock nut of the eye-bolt and screw it underneath

of the front panel above the gas line (Figure

A), tighten eye-bolt jam nut to secure it in place.

5. For model two & three (2&3) platen grill gas. Slide

the eye-bolt through the hole and place the nylon

lock nut on the inside frame and tighten securely

(Figure B).

attached to the wall

spring loaded

hook

STUD

BLOCKING SECURE

TO CONCRETE WALL

OR STUD

RESTRAINING CABLE

FRONT CASTER WITH

BRAKE TO SECURE GRILL

• “Adequate clearance must be provide for air opening

into the combustion chamber, and for proper servicing”

• Not intended to be installed adjacent to combustible

walls or on combustible floors.

• Ensure grill has been installed by a competent trained

installation person.

• Ensure store readiness of utilities, product & personnel.

loop

appliance

6. Attach one of the spring-loaded hook to the bracket

on the wall and the other end to the eye-bolt (grill).

adjust the proper distance of the cable 1 and tight

both clamps 2 to secure the both cables

7. Test straining cable by moving the grill, movement of

the grill must not place any strain on the connector or

quick disconnect device or its associated piping.

eye-bolt

• Contacting your local Garland Factory Authorized

Service Center for a startup date.

• Participate in the startup to ensure a successful startup

and familiarity with the grill.

Document: GAR_SM_4601777 (4/16) 29

Installation Section 2

Gas Connections, and Pipe Sizing:

• The size of the gas line is very important. If the line is too

small, the gas pressure at the burner manifold will be

low. This will cause slow recovery and delayed ignition.

The incoming gas pressure line should be a minimum of

1-1/2”. All grills require a 3/4” connection.