INSTALLATION, OPERATION,

AND SERVICE MANUAL

MASTER SERIES GAS XPRESS GRILL,

MODELS XG24CE, XG36CE

BE/FR

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

PLEASE READ ALL SECTIONS OF THIS MANUAL

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

For Your Safety:

Post in a prominent location, instructions to be

followed in the event the user smells gas. This

information shall be obtained by consulting

your local gas supplier.

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

GARLAND COMMERCIAL INDUSTRIES

185 East South Street

Freeland, Pennsylvania 18224

Phone: (570) 636-1000

Fax: (570) 636-3903

Part # 4517129 Rev.1 (03/10/10)

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Enodis UK LTD.

Swalloweld Way, Hayes, Middlesex UB3 1DQ ENGLAND

Telephone: 081-561-0433

Fax: 081-848-0041

© 2005 Garland Commercial Industries, Inc.

INTRODUCTION

The Garland Xpress Grill provides a method for ecient two-sided cooking, while accommodating a variety of products. The

unit will also serve as a at grill, and meets all standards for safety, eciency, and cleanliness.

The Garland Xpress Grill complies with the essential requirements of the Directives 89/109/EEC, 73/23/EEC, 89/336/EEC, and

the standards, EN60335, IEC801.2, IEC801.3, IEC801.4, IEC801.5, IEC801.6, IEC801.11.

Standard Features:

• Stainless steel front, top & sides

• 33,000 BTU/Hr input for each twelve-inch section of

griddle

• Built in pressure regulator, (one per twelve inch section of

griddle), and gas shut-o valve

• ¾" thick, Carbon steel griddle plate, machine ground,

highly polished

• Swivel casters complete with front brakes (4)

• Die cast aluminum electric top heating elements rated

380V/400V/415V

• Automatic lifting and lowering top heaters

• Towel bar with bun pan lip

• Stainless steel dual side grease collectors

• Separate programmable controller for each

twelve-inch section

• Multi-colored LED indicator lights to identify operational

mode

• One year limited parts and labor warranty

(USA & Canada)

Part # 4517129 Rev.1 (03/10/10)Page 2

TABLE OF CONTENTS

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Standard Features: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

DIMENSIONS AND SPECIFICATIONS, MODEL XG24CE. . 4

DIMENSIONS AND SPECIFICATIONS, MODEL XG36CE. . 5

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

National Codes Requirements: . . . . . . . . . . . . . . . . . . . . . . . . . 7

Connections, and Pipe Sizing: . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Appliances Equipped with Castors: . . . . . . . . . . . . . . . . . . . . . 8

Electrical Connections: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Burner Manifold Pressure Test/Adjustment: . . . . . . . . . . . . . 8

Burner Air Adjustment:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Ventilation and Clearance:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Master Power Switch: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

LED Indicators:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Display: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Product Buttons (0-9):. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Power Button: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Program Button: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Temperature Button: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Up/Down Arrow Buttons; 2 Functions: . . . . . . . . . . . . . . . .10

Enter Button: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Cancel/Raise Platen Button, (Green): . . . . . . . . . . . . . . . . . .10

Black Button: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

GRILL CONTROLS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Installing Release Material: . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

NORMAL OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installing Release Material: . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Lighting Instructions: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Shut Down Instructions:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Simplied Cook Cycle Instructions: . . . . . . . . . . . . . . . . . . . .12

To Cook in Two-Sided Mode: . . . . . . . . . . . . . . . . . . . . . . . . . .13

To Cook in Flat Grill Mode:. . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Enter Standby Mode:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Exit Standby Mode: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

To Display the Current Temperatures: . . . . . . . . . . . . . . . . . .14

To View Settings for a Menu Item:. . . . . . . . . . . . . . . . . . . . . .14

To Clean the Grill: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

PLATEN SET: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

EXTENDED TIME: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

INSTANT ON TIME: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

START DELAY: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

CLEANING AND MAINTENANCE . . . . . . . . . . . . . . . . . . . . 14

Cleaning During Operation: . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Daily Cleaning:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

PROGRAMMING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Programming Modes/Menu Sequence: . . . . . . . . . . . . . . . .16

Menu Items...

To Change the Cook Time of a Product: . . . . . . . . . . . . . . . .18

To Turn Platen, (2-Sided), Cooking On/O: . . . . . . . . . . . . .18

To Change Upper Platen Set Temperature: . . . . . . . . . . . . .18

To Change Grill Set Temperature: . . . . . . . . . . . . . . . . . . . . . .18

To Change Product Gap Setting:. . . . . . . . . . . . . . . . . . . . . . .18

To Change Product Button, “Key” Assignment . . . . . . . . . .19

To Change a Product Name: . . . . . . . . . . . . . . . . . . . . . . . . . . .19

System Info...

To View Recovery Time - Upper Platen:. . . . . . . . . . . . . . . . .19

To View Recovery Time - Grill:. . . . . . . . . . . . . . . . . . . . . . . . . .19

To View the Garland Part Number: . . . . . . . . . . . . . . . . . . . . .19

To View the Flash Number: . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

To View the Software Number:. . . . . . . . . . . . . . . . . . . . . . . . .20

To View the Download Number: . . . . . . . . . . . . . . . . . . . . . . .20

System Setup

To Change temperature Units, (°F or °C): . . . . . . . . . . . . . . .20

To Change Gap Setting Display Units:. . . . . . . . . . . . . . . . . .20

To Change the Alarm Volume: . . . . . . . . . . . . . . . . . . . . . . . . . 21

To Change the Key Chirp:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

To Change Probe Calibration - Upper:. . . . . . . . . . . . . . . . . .21

To Change Probe Calibration - Grill: . . . . . . . . . . . . . . . . . . . .21

To Change Platen Set: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

To Change Instant-On Time:. . . . . . . . . . . . . . . . . . . . . . . . . . . 22

To Change Control Type: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

To Turn Extended Time On/O: . . . . . . . . . . . . . . . . . . . . . . . .22

To Change the Grill Function:. . . . . . . . . . . . . . . . . . . . . . . . . .23

To Change the Start Delay: . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

To Change the Alarm Mode: . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

To Turn Clean Mode On/O: . . . . . . . . . . . . . . . . . . . . . . . . . . .23

To Add a Product Name in Library:. . . . . . . . . . . . . . . . . . . . .23

To Modify a Product Name in Library: . . . . . . . . . . . . . . . . . . 24

Service Mode

To Change SCK Address:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

To Perform Limit Switch Test: . . . . . . . . . . . . . . . . . . . . . . . . . . 24

CALIBRATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Bi-Weekly Calibration:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

ERROR MESSAGES:

PROBE ERROR: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

PLATEN DOWN ERROR:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

PLATEN UP ERROR:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

HEATING ERROR:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

COMM ERROR: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

MOTOR OVER CURRENT:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

MOTOR ERROR: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

IGNITION ERROR:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

FLASHING LED(S):. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

WIRING DIAGRAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Part # 4517129 Rev.1 (03/10/10) Page 3

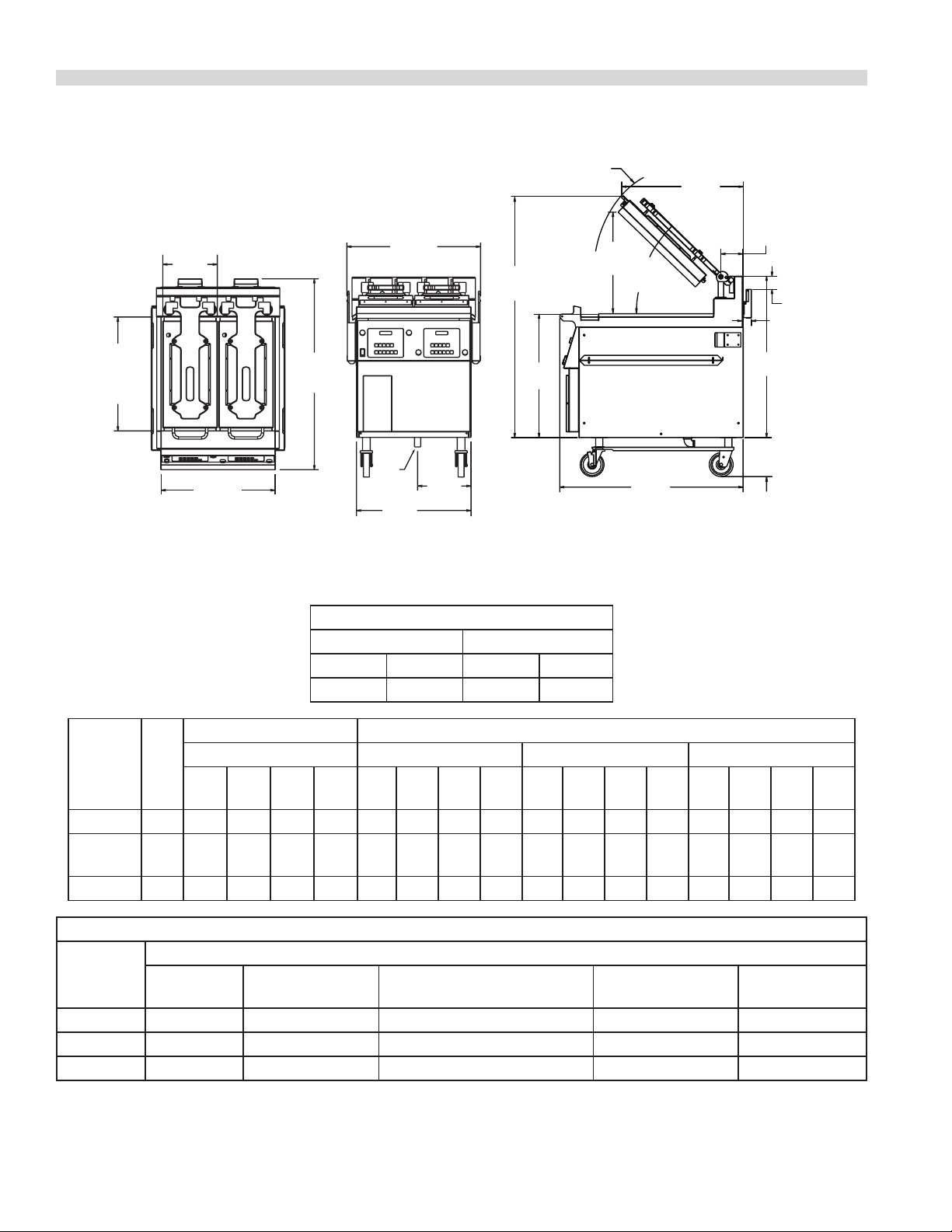

DIMENSIONS AND SPECIFICATIONS, MODEL XG24CE

26-23/32"

[678mm]

24"

[610mm]

GRILL

PLATE

DEPTH

11-1/2"

[292mm]

TOP

HEATER

(2 PLACES)

TOP VIEW

40-1/4"

[1022mm]

28-3/16"

[716mm]

FRONT VIEW

50-1/2"

[1282mm]

AVERAGE

25-7/8"

[656mm]

FROM PLATEN

ARM PIVOT

[584mm]

23"

44.03°

MAX

AVERAGE

[48° MAX]

RIGHT SIDE VIEW

25-1/2"

[646mm]

AVERAGE

4-41/64"

[118mm]

1-23/32"

[44mm]

33-25/32"

[858mm]

2-3/4"

[70mm]

7" [178mm] MIN

11" [279mm] MAX

24"

[610mm]

GRILL PLATE WIDTH

3/4"

NPT

GAS

INLET

24-1/8"

[614mm]

11-1/4"

[286mm]

38-25/64"

[975mm]

Clearances

Entry Installation

Crated Uncrated Sides Rear

1207mm 813mm 152mm 76mm

Loading kW Per Phase Nominal Amps Per Line

Model

Total

kW

Load

380/400/415V 380V 400V 415V

L1/N

L1/L2L1/L3L2/

L3

L1/N L1 L2 L3 L1/N L1 L2 L3 L1/N L1 L2 L3

XG24CE 8.74 0.74 2.66 2.66 2.66 3.36 15.90 12.46 12.46 3.22 13.40 11.55 11.55 3.08 12.10 11.11 11.11

XG24CE-1

L/R

4.56 0.56 1.33 1.33 1.33 2.54 7.33 6.02 6.02 4.30 19.80 17.32 17.32 4.12 18.75 16.70 16.70

XG24CE-F 0.38 0.38 0.00 0.00 0.00 1.72 1.00 0.00 0.00 1.58 0.95 0.00 0.00 0.91 12.10 11.11 11.11

Gas Pressure

Manifold

Supply

Gas Group

Input/Burner

(Net Maximum)

Injector Size

Air Shutter Setting

(each burner)

Burner Pressure

20 mbar G20 7.9kW 2.79mm x2 (marked 0.110) 2.79 10.8mm (2 o) 7.5 mbar

25 mbar G25 7.9kW 2.79mm x2 (marked 0.110) 2.79 10.8mm (2 o) 7.5 mbar

37 mbar G31 8.1kW/ 579.2g/h 2.26mm x2 (marked 0.089) 2.79 9.0mm (2 o) 6.8 mbar

Part # 4517129 Rev.1 (03/10/10)Page 4

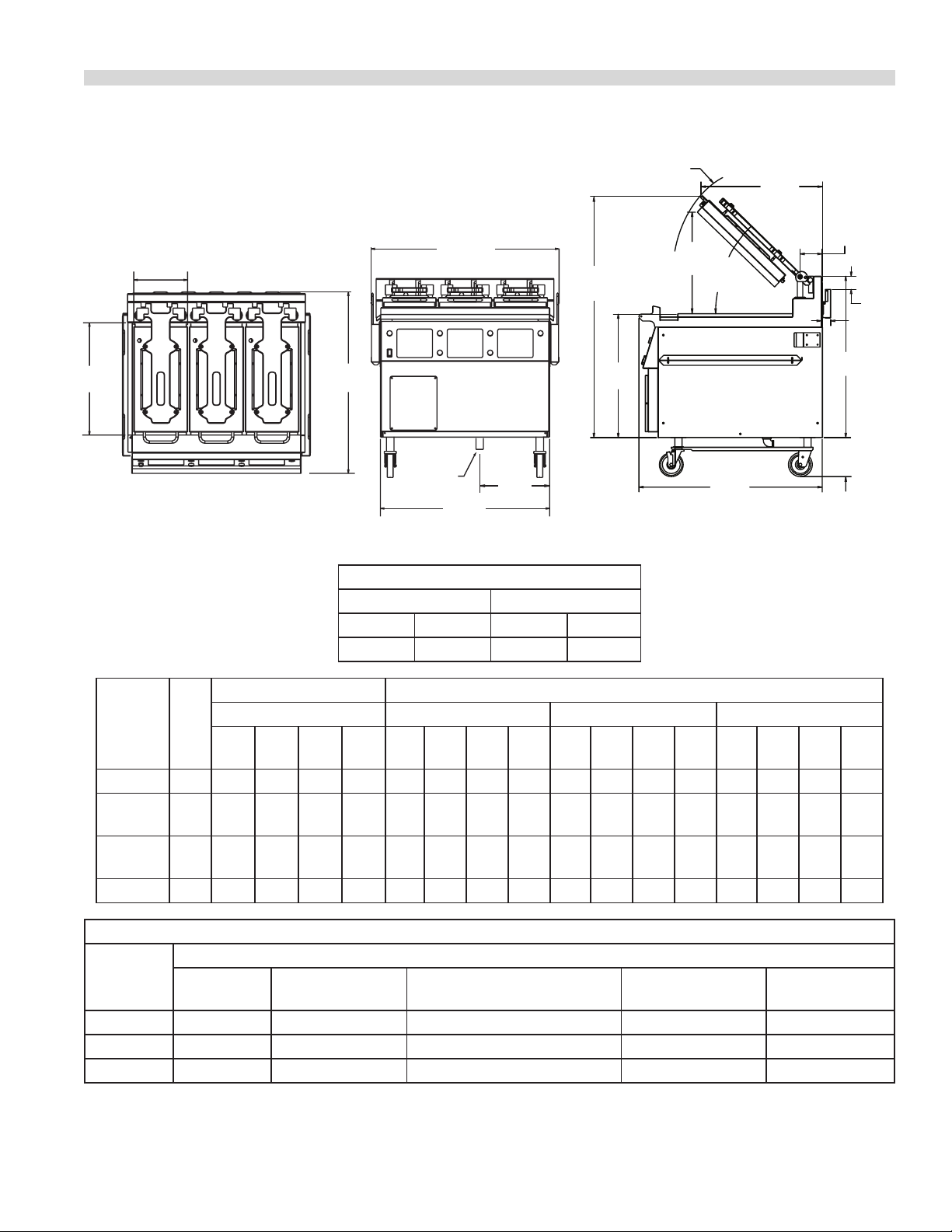

DIMENSIONS AND SPECIFICATIONS, MODEL XG36CE

26-23/32"

[678mm]

FROM PLATEN

ARM PIVOT

25-1/2"

[646mm]

AVERAGE

24"

[610mm]

11-1/2"

[292mm]

TOP HEATER

(3 PLACES)

GRILL PLATE 24"x 36"

[610mm x 914mm]

TOP VIEW

40-3/16"

[1021mm]

38-3/4"

[985mm]

FRONT VIEW

3/4"

GAS

INLET

36-1/8"

[918mm]

12-5/8"

[321mm]

Clearances

Entry Installation

Crated Uncrated Sides Rear

1207mm 1035 mm 152mm 76mm

50-1/2"

[1282mm]

AVERAGE

25-7/8"

[656mm]

23"

[584mm]

MAX

44.03°

AVERAGE

[48° MAX]

RIGHT SIDE VIEW

38-25/64"

[975mm]

4-41/64"

[118mm]

2-3/4"

[70mm]

1-23/32"

[44mm]

33-25/32"

[858mm]

7" [178mm] MIN

11" [279mm] MAX

Loading kW Per Phase Nominal Amps Per Line

Model

Total

kW

Load

380/400/415V 380V 400V 415V

L1/N

L1/L2L1/L3L2/

L3

L1/N L1 L2 L3 L1/N L1 L2 L3 L1/N L1 L2 L3

XG36CE 12.99 0.99 4.00 4.00 4.00 4.50 20.48 18.23 18.23 4.30 19.80 17.32 17.32 4.12 18.75 16.70 16.70

XG36CE-2

L/R

XG36CE-1

L/C/R

8.81 0.81 2.67 2.67 2.67 4.00 14.01 12.16 12.16 3.52 13.57 11.55 11.55 3.37 12.83 11.14 11.14

4.63 0.63 1.33 1.33 1.33 2.8 7.42 6.06 6.06 2.70 7.12 5.75 5.75 4.12 18.75 16.70 16.70

XG36CE-F 0.45 0.45 0.00 0.00 0.00 2.04 1.18 0.00 0.00 1.95 1.13 0.00 0.00 1.87 1.08 0.00 0.00

Gas Pressure

Manifold

Supply

Gas Group

Input/Burner

(Net Maximum)

Injector Size

Air Shutter Setting

(each burner)

Burner Pressure

20 mbar G20 7.9kW 2.79mm x2 (marked 0.110) 2.79 10.8mm (2 o) 7.5 mbar

25 mbar G25 7.9kW 2.79mm x2 (marked 0.110) 2.79 10.8mm (2 o) 7.5 mbar

37 mbar G31 8.1kW/ 579.2g/h 2.26mm x2 (marked 0.089) 2.79 9.0mm (2 o) 6.8 mbar

Part # 4517129 Rev.1 (03/10/10) Page 5

SAFETY PRECAUTIONS

Always follow these safety precautions when operating the

Xpress Grill.

• THIS GRILL MUST be operated by persons who have

been given adequate training.

• THIS EQUIPMENT MUST ONLY BE OPERATED UNDER AN

APPROVED HOOD SYSTEM.

• DO NOT operate the grill without reading this operation

manual.

• DO NOT operate the Xpress grill unless all service and

access panels are in place and fastened properly.

The Garland Xpress Grill is a semi-automatic cooking

appliance. The upper platen is lowered automatically,

following the manual, two-handed initiation of the cooking

cycle, and the upper platen is raised automatically upon

completion of the cooking cycle.

When two sided cooking, the area between the upper platen

and the griddle plate should be regarded as a “danger zone.”

During two sided cooking the operator must not be within

this danger zone. When used as a at grill, then this area is no

longer a danger zone, the platens do not move.

For whatever reason, be it cleaning, maintenance, or normal

operation, any exposed person must use extreme caution if

within this danger zone.

In two side cooking the upper platen remains in the lowered

position by nature of its own weight. It is not locked down. It

can be raised by lifting up on the handle on the front of the

platen.

The Xpress Grill may during its operation emit airborne noise

equivalent to a continuous A weighted sound pressure level

of 73dB(A).

WARNING: To avoid serious personal injury:

• DO NOT attempt to repair or replace any part of the

Xpress Grill unless all main power supplies to the grill

have been disconnected.

• USE EXTREME CAUTION in setting up, operating and

cleaning the Xpress Grill to avoid coming in contact

with hot grill surfaces or hot grease. Suitable protective

clothing should be worn to prevent the risk of burns.

• DO NOT clean this appliance with a water jet.

• DO NOT apply ICE or COLD WATER to a HOT grill surface.

• NOTE all warning labels and markings axed to the grill.

WARNING: After turning the master power switch to the

START position, the grill will go through initialization. If

the upper platens are in the lowered position they will

return to their raised upper position. This movement takes

approximately 8 seconds.

INSTALLATION

IMPORTANT: Rating plates for this appliance are located in

two places: 1) inside back panel on left side, 2) under front

control panel on center.

This equipment must be installed by a competent factory

trained, certied, licensed and / or authorized service or

installation person.

WARNING: This appliance must be properly earthed.

Prior to installation, the four casters, supplied loose with the

grill, must be securely located on the underside of the base.

The casters tted with a brake must be located at the front of

the grill.

This appliance should be connected to a potential

equalization system. A labeled equipotential bonding point

is tted to the rear of the grill.

It is recommended that this grill be connected to a residual

current,, (earth leakage),, device with a tripping current not

exceeding 30mA. The leakage current of this grill will not

exceed 5mA.

Part # 4517129 Rev.1 (03/10/10)Page 6

INSTALLATION continued

CAUTION: Prior to installation, check the electrical supply

to ensure input voltage and phase match the equipment

voltage rating and phase. See data plate located rear left side

of grill and lower front panel.

Grill is to be located directly under ventilation system.

Once installed in the grill station underneath the ventilation

system, the platens, in their highest position, must not

interfere with the lower lip of the ventilation system hood.

The raised position of each platen is adjusted by raising

or lowering the upper of the two microswitches, (limit

switches), in the rear of the grill. The lower microswitch

position must not be adjusted.

Grill plate must be level front to back, side to side and

diagonally. This leveling must be done with the unit under

the hood and in it’s normal operational position to prevent

warping of the grill plate.

NOTE: Fuses are installed to prevent damage in the event of

failure of the upper microswitch.

Installation shall be made with the gas connector that has

been supplied loose with the grill. The quick disconnect

tting and gas shut o valve must be installed in the

direction indicated on their outer body.

NOTE: When checking gas pressure, be sure that all other

equipment on the same gas line is on.

The appliance and its individual shut-o valve must be

disconnected from the gas supply piping system during any

pressure testing of that system pressures in excess of 1/2

PSIG (3.45kPa).

Adequate clearance must be provided for servicing and

proper operation.

Connections, and Pipe Sizing:

The size of the gas line is very important. Ensure that the

pipe size is adequate for the demand, including other gas

appliances on the same supply. If the line is too small, the

gas pressure at the burner manifold will be low. This will

cause slow recovery and delayed ignition. The incoming gas

pressure line should be a minimum of 1-1/2”. All gas Xpress

Grills are supplied with a 3/4” NPT threaded male tting,

which must be adapted in the eld to a suitable connection

that applies to ISO 7-1 or ISO 228-1.

Before connecting new pipe the pipe must be blown out to

dispose of any foreign particles. These particles will cause

improper operation.

When using thread compound, use small amounts on male

threads only. Use a compound that is not eected by the

chemical action of LP gases. Avoid applying compound

to the rst two threads to prevent clogging of the burner

orices and control valve.

Have the installer check all gas plumbing with a soap

solution for leaks. DO NOT USE matches, candles or other

ignition sources in checking for leaks.

The grill must be disconnected from the gas supply system

when pressure testing of that system at pressures in excess of

150mbar.

Check the data plate to determine the proper type of gas

before connecting the quick disconnect or piping from the

building gas supply.

An incoming gas pressure test nipple is provided on the

incoming gas manifold for pressure checks.

National Codes Requirements:

The type of gas for which the grill is equipped is stamped on

the data plate on the inside rear of the unit and on the lower

front panel. Connect a grill stamped for Natural Gas (High

(H) or Low (L) Caloric Value) only to Natural Gas; connect

those stamped for Propane Gas only to Propane Gas. When

installing gas grills, the installation must comply with the

latest edition of the codes and installation regulations in

force.

Part # 4517129 Rev.1 (03/10/10) Page 7

INSTALLATION continued

Appliances Equipped with Castors:

Prior to installation, the four castors, supplied loose with the

grill, must be securely located on the underside of the base.

The castors tted with a brake must be located at the front of

the grill.

• Once castors are installed, adjust the unit by turning

them clockwise to raise the unit and counterclockwise to

lower the unit.

• Adjust the castors until the grill plate is level and at the

proper height.

• Screw the lock nut on each castor tight against the

bottom of the unit.

• When the unit is in place, lock the front castors to prevent

movement.

Grill plate must be level front to back, side to side and

diagonally. This leveling must be done with the unit under

the hood and in it’s normal operational position to prevent

warping of the grill plate.

Electrical Connections:

Burner Manifold Pressure Test/Adjustment:

Burner operating gas pressure can be checked at the outlet

side of the gas valve at the pressure test point.

To adjust the burner pressure:

1. The pressure test nipple is located in the gas valve on the

side opposite the burner.

2. Remove the sealing screw from the pressure test nipple

and connect a manometer.

3. Remove the sealing cap on the gas valve regulator, turn

on the grill, and adjust the screw in the regulator to give

the correct pressure.

4. Turn o the grill, ret the regulator sealing cap, remove

the manometer, replace the seal screw in the test nipple

and test for gas leaks.

Gas pressures should be checked by the local Gas Company

or an authorized service agency only.

Test all piping and connections for gas leaks. A rich soap

solution should be used for this purpose. Never use a ame.

Electrical connections must be in accordance with the

current IEE Wiring Regulations. The supply should have a

contact separation of at least 3mm on all poles. Adequate

means of disconnection of the supply must be provided.

It is recommended that this grill be connected to a residual

current (earth leakage) device with a tripping current not

exceeding 30mA. The leakage current of this grill will not

exceed 5mA.

CAUTION: Prior to installation, check the electrical supply

to ensure input voltage and phase match the equipment

voltage rating and phase. See data plate located rear left side

of grill and lower front panel.

The entry point for the electrical connection is located on

the base of the appliance. Remove the punch-out plate, and

punch out the required size to the supply cable. Secure the

cable in place with a gland tting and suitable means of

strain relief.

All electrically operated appliances must be electrically

earthed in accordance with local codes; or in the absence

of local codes, with the latest edition of National Wiring

Regulations. A wiring diagram is located on the rear panel of

the grill. See rating plate in rear of grill, or lower front panel

for proper voltages.

Burner Ignition Verication by the Installer:

Once the grill is properly installed, turn the grill power switch

on. Press the ON/OFF switch on the grill control to heat the

grill in Standby Mode. The will attempt to ignite the burners.

Verify Burner Ignition as Follows:

1. The controls will attempt to ignite the burners when the

grill calls for heat to the griddle plate.

2. If ignition does not occur on the rst attempt, the lower

LED (for the grill plate) will begin to ash to alert the

installer that the rst attempt at burner ignition has

failed.

3. The control will then attempt to ignite the burners up to

four (4) more times.

4. If, after four (4) attempts, the burners have not ignited,

the control will shut down and display “IGNITION ERROR.”

5. Inspect the gas and ignition systems for possible

problems.

Part # 4517129 Rev.1 (03/10/10)Page 8

INSTALLATION continued

Additional Burner Ignition Verication:

1. Drop the front control panel so that the heat shield is

visible.

2. Turn the grill ON and press the ON/OFF switch on the

control to heat the grill in Standby Mode.

3. Rotate the round shutter to expose the burner sight glass.

4. When the grill attempts to ignite the burners, look

through the sight glass to verify ignition.

The burner should ignite and the ame should appear blue

with no orange tipping. If the burner ame cannot be seen,

inspect ignition and gas system for possible problems.

Burner Air Adjustment:

Once burner ignition is veried by looking through the sight

glass, burner air adjustment may be required. Adjust the

burner air as follows:

1. Loosen the lock nut on the blower motor shutter.

2. The blower shutter can be rotated to allow more or less

air into the burners.

3. Adjust the shutter until the burner ame is blue with no

orange tipping.

4. Tighten the lock nut.

NOTE: Burner air shutters should only be adjusted by factory

authorised service personnel.

Ventilation and Clearance:

One of the most important considerations of ecient grill

operation is proper ventilation and air supply. Insure the

grill is installed so the products of combustion are removed

eciently and the ventilation system does not produce

drafts that interfere with proper burner operation.

Proper operation of exhaust fans (speed, rotation and

adjustment) is essential. In addition to the exhaust system

the make-up air system, (HVAC), for the kitchen is the

air supply for the combustion air for the burners. Proper

incoming air is essential for all gas operated equipment. Poor

incoming make-up will cause inecient burner operation,

delayed ignition and possible burner failure.

Any ventilation system will break down if improperly

maintained. The duct system, hood, and the lters must be

cleaned on a regular basis and kept grease free.

The room containing the grill is required to have a

permanent air vent. The minimum eective area of the vent

shall be 4.5 cm² per kW. Air vents shall be of such a size to

compensate for the eects of any extract fan in the premises.

NOTE: Parts which have been protected by the

manufacturer and agent, are not to be adjusted by the

installer or the user.

Part # 4517129 Rev.1 (03/10/10) Page 9

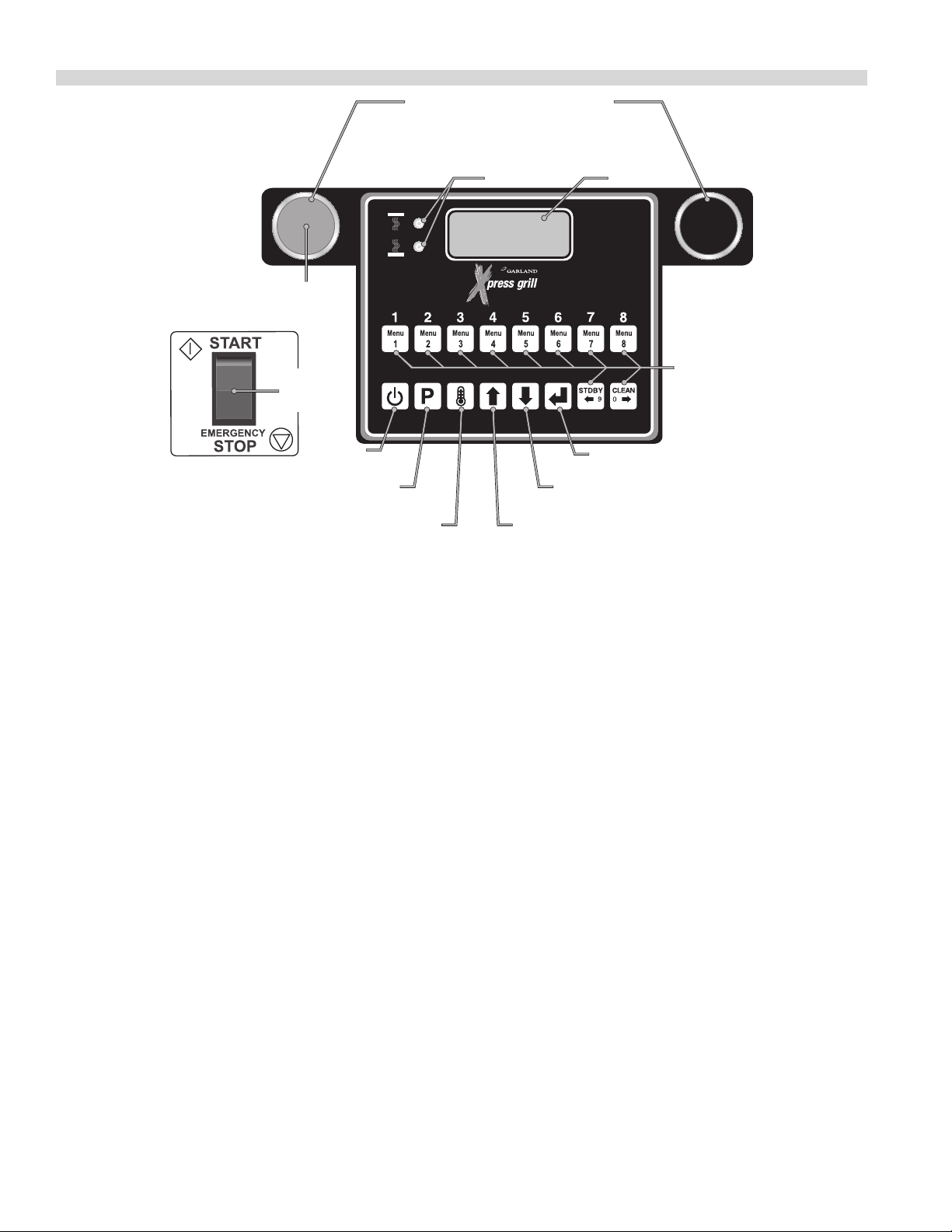

GRILL CONTROLS

BUTTON

BUTTON

CANCEL/

RAISE PLATEN

BUTTON

MASTER

POWER

SWITCH

POWER

BUTTON

PROGRAM

"START COOK TIME COUNTDOWN" (flat grill cooking)

BUTTON

TEMPERATURE

WHEN PUSHED SIMULTANEOUSLY:

OR "LOWER PLATEN" (two-sided cooking)

LED

INDICATORS

DOWN ARROW

BUTTON

UP ARROW

DISPLAY

ENTER

BUTTON

PRODUCT

BUTTONS

Master Power Switch:

Controls power to the grill and must be turned “ON” to start

operation. The controller display will be active when the

switch is “ON”.

LED Indicators:

There are two, (2), indicator lights, indicating the

temperature status of each control’s heat zones; one, (1), on

the upper platen, (top light), and one, (1), on the grill surface.

Each light can display three, (3), dierent colors, indicating

temperature status for the corresponding zone.

Red: The zone is too hot, (more than 79°F/45°C over the set

temperature), or heat zone failure.

Amber: The zone is calling for heat.

Green: The zone is at or above the set temperature.

Display:

The controller display will contain information relevant to

each operation in both cook and program modes.

Product Buttons (0-9):

Buttons 0-9 can be assigned to product items. Buttons 9 and

0 are used to move the cursor left or right when creating

or modifying product names in “PROD NAME LIB” program

mode.

Power Button:

After the main power switch is turned on, this button will put

the control into cook mode. If pressed again, the control will

go back to displaying “OFF.”

Program Button:

The primary function is to access Programming and

Calibration of the grill. Push and hold for ve (5) seconds.

Display will ask for the code. After entering code, ve

programming features will be accessible “MENU ITEMS,”

“SYSTEM INFO,” “SYSTEM SETUP,” “SERVICE MODE,” and

“PRODUCT NAME LIB.”

Temperature Button:

In the Cook mode, each time the button is pressed the

current temperature for one zone is displayed. The grill

temperature is displayed rst followed by the platen

temperature. After ve (5) seconds, the display will return to

the menu item selected.

Up/Down Arrow Buttons; 2 Functions:

1. In the cook mode, the Up/Down Arrow Buttons will cycle

through the dierent menu items.

2. In the program mode, the Up/Down Arrow Buttons will

change the value of the current setting.

Enter Button:

Function is to accept programming steps.

Cancel/Raise Platen Button, (Green):

During the cooking cycle, pressing this button will cancel the

cooking timer and return the grill to the “IDLE” mode. This

button will also bring the grill out of STANDBY.

Black Button:

When both Black and Green “CANCEL/RAISE” buttons are

pressed simultaneously, the upper platen will lower to the

griddle surface.

Part # 4517129 Rev.1 (03/10/10)Page 10

Loading...

Loading...