Garland UTGG24-G24 Operation Manual

INSTALLATION AND

OPERATION MANUAL

US RANGE UT SERIES

HEAVY DUTY GAS

COUNTER EQUIPMENT

Français . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 17

Españo. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Página 33

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

Users are cautioned that maintenance and repairs must be performed by a Garland/US Range authorized service

agent using genuine Garland/US Range replacement parts. Garland/US Range will have no obligation with

respect to any product that has been improperly installed, adjusted, operated or not maintained in accordance

with national and local codes or installation instructions provided with the product, or any product that has its

serial number defaced, obliterated or removed, or which has been modified or repaired using unauthorized parts

or by unauthorized service agents. For a list of authorized service agents, please refer to the Garland/US Range web

site at http://www.Garland-Group.com. The information contained herein, (including design and parts specifications),

may be superseded and is subject to change without notice.

PLEASE READ ALL SECTIONS OF THIS MANUAL

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

IN THE COMMONWEALTH OF MASSACHUSETTS

THIS PRODUCT MUST BE INSTALLED BY A

LICENSED PLUMBER OR GAS FITTER. APPROVAL

NUMBER: G-1-07-05-28

For Your Safety:

Post in a prominent location, instructions to be

followed in the event the user smells gas. This

information shall be obtained by consulting

your local gas supplier.

Part # 4528530 Rev. 1 (11/03/11)

© 2010 The Garland Group

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the state of California to cause cancer and/or birth defects

or other reproductive harm. Installation and servicing of this product could expose you to airborne

particles of glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/ceramic fibers

is known to the state of California to cause cancer. Operation of this product could expose you to

carbon monoxide if not adjusted properly. Inhalation of carbon monoxide is known to the state of

California to cause birth defects or other reproductive harm.

Keep appliance area free and clear of combustibles.

Page 2

Part # 4528530 Rev. 1 (11/03/11)

TABLE OF CONTENTS

SPECIFICATIONS: HOT PLATES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SPECIFICATIONS: STEP-UP HOT PLATES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

SPECIFICATIONS: CERAMIC-BRIQUETTE CHAR-BROILERS. . . . . . . . . . . . . . . . . . . . 6

SPECIFICATIONS: RADIANT CHAR-BROILERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

SPECIFICATIONS: GRIDDLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

PRE INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Damage Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Rating Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Gas Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Leg Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Air Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

ADJUSTMENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Burner Adjustments – All Models. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

OPERATION: ALL MODELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Lighting Standing Pilots - All Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Shutdown Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

MAINTENANCE & CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Seasoning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Griddle (standard steel plate) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Griddle (optional chrome) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Cast Iron Top Grates (Hot Plates & Char-Broilers) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Griddle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Open Top Burners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Cast Iron Top Grates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Char-Broilers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Stainless Steel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Part # 4528530 Rev. 1 (11/03/11)

Page 3

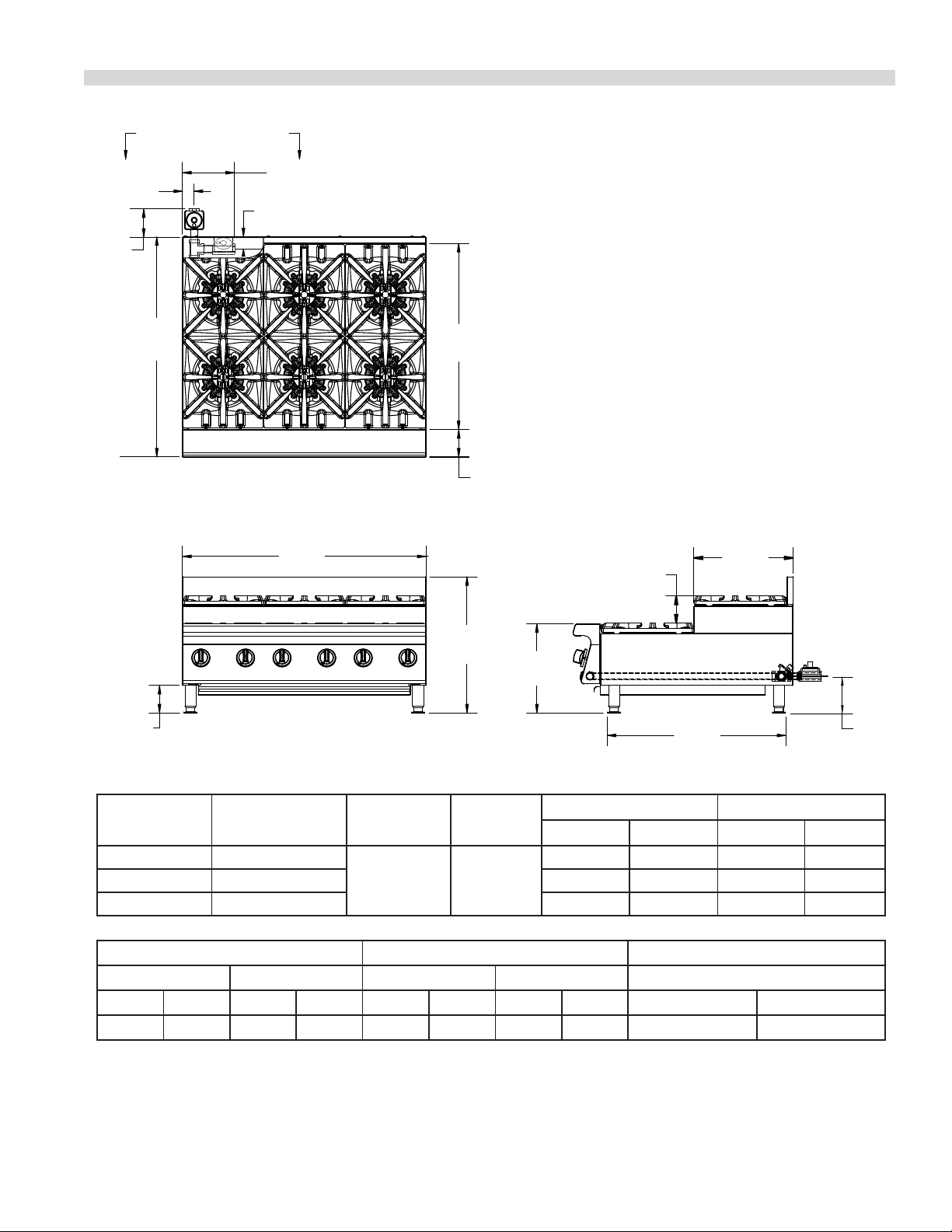

SPECIFICATIONS: HOT PLATES

STRAIGHT (STD) OR FLUSH-REAR

Heavy Duty Gas Hot Plates

GAS INLET w/REGULATOR

1.7”

[43mm]

4.0”

[102mm]

*

32.0”

[814mm]

7.6”

[192mm]

1.7”

[43mm]

27.2”

[691mm]

For use with Natural or Propane gas only.

Gas input ratings shown for installations up to

2000 ft., (610m), above sea level. Please specify

altitudes over 2000 ft. and gas type when ordering.

Garland/U.S. Range products are not approved

or authorized for home or residential use, but are

intended for commercial applications only.

Garland/U.S. Range will not provide service,

warranty, maintenance or support of any kind

other than in commercial applications.

* Please add 5” (127mm) in overall depth

with attachment condiment rail option.

4.0”

[102mm]

Model #

UTOG12-2 11-13/16 (300)

UTOG24-4 23-5/8 (600) 120,000 104,000 135/61 8

UTOG36-6 35-7/16 (900) 180,000 156,000 191/87 25

UTOG48-8 47-1/4 (1200) 240,000 208,000 247/112 33

WIDTH

Width

In (mm)

4.0”

[102mm]

15.8”

[402mm]

Height

(w/std legs)

13 (330) 32 (814)

Depth

In (mm)

13.0”

[330mm]

26.0”

[660mm]

Total Input (BTU) Shipping Information

NAT PRO Lbs/Kg Cu Ft

60,000 52,000 73/33 4

[136mm]

5.3”

SUPPLY OPERATING PRESSURE MANIFOLD OPERATING PRESSURE CLEARANCES

NATURAL GAS PROPANE NATURAL GAS PROPANE INSTALLATION TO COMBUSTIBLE

"WC MBar "WC Mbar "WC MBar "WC Mbar Sides Rear

7 17.5 11 27.5 4.5 11 10 24.5 14" (356mm) 6” (152mm)

Page 4

Part # 4528530 Rev. 1 (11/03/11)

SPECIFICATIONS: STEP-UP HOT PLATES

Heavy Duty Gas Step-Up Hot Plates

STRAIGHT (STD) OR FLUSH-REAR

GAS INLET w/REGULATOR

1.7”

[43mm]

4.0”

[102mm]

*

32.0”

[814mm]

* Please add 5” (127mm) in overall depth

with attachment condiment rail option

7.6”

[192mm]

1.7”

[43mm]

.

27.2”

[691mm]

4.0”

[102mm]

For use with Natural or Propane gas only.

Gas input ratings shown for installations up to

2000 ft., (610m), above sea level. Please specify

altitudes over 2000 ft. and gas type when ordering.

Garland/U.S. Range products are not approved

or authorized for home or residential use, but are

intended for commercial applications only.

Garland/U.S. Range will not provide service,

warranty, maintenance or support of any kind

other than in commercial applications.

4.0”

[102mm]

Model #

UTOG24-4 23-5/8 (600)

UTOG36-6 35-7/16 (900) 180,000 156,000 191/87 25

UTOG48-8 47-1/4 (1200) 240,000 208,000 247/112 33

SUPPLY OPERATING PRESSURE MANIFOLD OPERATING PRESSURE CLEARANCES

NATURAL GAS PROPANE NATURAL GAS PROPANE INSTALLATION TO COMBUSTIBLE

"WC MBar "WC Mbar "WC MBar "WC Mbar Sides Rear

7 17.5 11 27.5 4.5 11 10 24.5 7” (178mm) 6” (152mm)

WIDTH

Width

In (mm)

19.8”

[503mm]

Height

(w/std legs)

19-13/16 (503) 32 (814)

Depth

In (mm)

13.0”

[330mm]

120,000 104,000 135/61 8

26.0”

14.5”

[368mm]

5.3”

[136mm]

4.0”

[102mm]

[660mm]

Total Input (BTU) Shipping Information

NAT PRO Lbs/Kg Cu Ft

Part # 4528530 Rev. 1 (11/03/11)

Page 5

SPECIFICATIONS: CERAMIC-BRIQUETTE CHAR-BROILERS

LOW GRATE POSITION

STRAIGHT (STD) OR FLUSH-REAR

Heavy Duty Gas Ceramic Briquette Char-Broilers

1.7”

[43mm]

4.0”

[102mm]

*

32.1”

[814mm]

GAS INLET w/REGULATOR

7.6”

[192mm]

1.7”

[43mm]

1.4” [35mm] HANDLE DEPTH MAX

3/4” (83mm) DIVIDER ON

UTBG48-AB48 and UTBG60-AB60

adjustable broilers

* Please add 5” (127mm) in overall depth

with attachment condiment rail option.

WIDTH

2.4”

[62mm]

TROUGH

DEPTH

4.0”

[102mm]

15.9”

[404mm]

.

For use with Natural or Propane gas only.

Gas input ratings shown for installations up to

2000 ft., (610m), above sea level. Please specify

altitudes over 2000 ft. and gas type when

ordering.

Garland/U.S. Range products are not approved

or authorized for home or residential use, but

are intended for commercial applications only.

Garland/U.S. Range will not provide service,

warranty, maintenance or support of any kind

other than in commercial applications.

21.2”

[538mm]

GRATE DEPTH

13.0”

[330mm]

5.5°

HIGH GRATE

POSITION

1.4°

4.0”

[102mm]

Model #

UTBG24-AB24 23-5/8 (600)

UTBG36-AB36 35-7/16 (900) 90,000 391/178 26

UTBG48-AB48 47-1/4 (1200) 120,000 514/283 34

UTBG60-AB60 59-1/16 (1500) 150,000 635/288 41

SUPPLY OPERATING PRESSURE MANIFOLD OPERATING PRESSURE INSTALLATION CLEARANCES

NATURAL GAS PROPANE NATURAL GAS PROPANE

"WC MBar "WC Mbar "WC MBar "WC Mbar

7 17.5 11 27.5 4.5 11 10 24.5

Width

In (mm)

Height

(w/std legs)

13 (330) 32 (814)

Depth

In (mm)

26.0”

[660mm]

Total

Input (BTU)

60,000 283/129 19

SURROUNDINGS ONLY

Shipping Information

Lbs/Kg Cu Ft

CLEARANCE: 0”

FOR INSTALLATION IN

NON-COMBUSTIBLE

5.3”

[136mm]

Page 6

Part # 4528530 Rev. 1 (11/03/11)

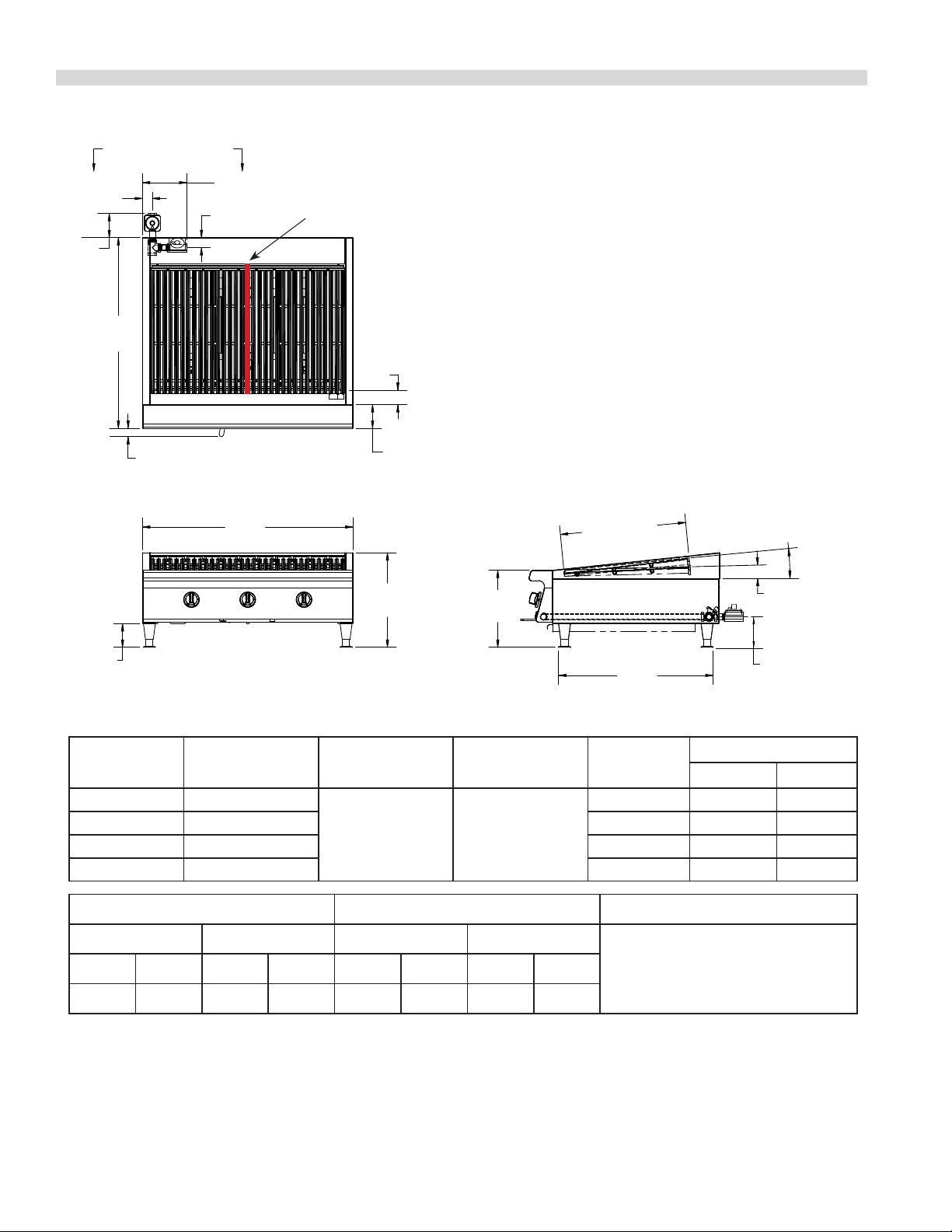

SPECIFICATIONS: RADIANT CHAR-BROILERS

LOW GRATE POSITION

[660mm]

STRAIGHT (STD) OR 3/4" N.P.T.

Heavy Duty Gas Radiant Char-Broilers

GAS CONNECTION OPTIONS FOR MODEL UTBG72-NR72

FLUSH REAR GAS INLET w/REGULATOR

1.7”

[43mm]

4.0”

[102mm]

*

32.1”

[814mm]

7.6”

[192mm]

1.7”

[43mm]

3/4” (83mm) DIVIDER ON

UTBG48-AR48 and UTBG60-AR60

adjustable broilers.

For use with Natural or

Propane gas only. Gas input

ratings shown for

installations up to 2000 ft.

2.4”

[62mm]

TROUGH

DEPTH

(610m), above sea level.

Please specify altitudes over

2000 ft. and gas type when

ordering.

STRAIGHT (STD) OR NEARLY FLUSH 1” N.P.T REAR GAS

INLET w/REGULATOR.

21.2”

[538mm]

GRATE DEPTH

5.5°

GRATE ANGLE

* Please add 5” (127mm) in overall depth

with attachment condiment rail option.

4.0”

[102mm]

Model #

With Adjustable Grates

UTBG24-AR24 23-5/8 (600)

UTBG36-AR36 35-7/16 (900) 108,000 391/178 26

UTBG48-AR48 47-1/4 (1200) 144,000 514/283 34

UTBG60-AR60 59-1/16 (1500) 180,000 635/288 41

With Non-Adjustable Grates

UTBG24-NR24 23-5/8 (600)

UTBG36-NR36 35-7/16 (900) 108,000 391/178

UTBG48-NR48 47-1/4 (1200) 144,000 514/283

UTBG60-NR60 59-1/16 (1500) 180,000 635/288

UTBG72-NR72 70 7/8(1800) 216,000 690/313

1.4” [35mm] HANDLE DEPTH MAX

WIDTH

Width

In (mm)

4.0”

[102mm]

15.9”

[404mm]

Height

(w/std legs)

13.0”

[330mm]

Depth

In (mm)

13 (330) 32 (814)

13 (330) 32 (814)

NON-ADJUSTABLE GRATE

21.2”

[538mm]

GRATE DEPTH

ADJUSTABLE GRATE

26.0”

Total

Input (BTU)

Shipping Information

Lbs/Kg Cu Ft

72,000 283/129 19

72,000 283/129

5.5°

HIGH GRATE

POSITION

1.4°

5.3”

[136mm]

18

25

33

40

47

SUPPLY OPERATING PRESSURE MANIFOLD OPERATING PRESSURE INSTALLATION CLEARANCES

NATURAL GAS PROPANE NATURAL GAS PROPANE CLEARANCE: 0”

"WC MBar "WC Mbar "WC MBar "WC Mbar

7 17.5 11 27.5 4.5 11 10 24.5

FOR INSTALLATION IN

NON-COMBUSTIBLE

SURROUNDINGS ONLY

Part # 4528530 Rev. 1 (11/03/11)

Page 7

SPECIFICATIONS: GRIDDLES

STRAIGHT (STD) OR FLUSH-REAR

Heavy Duty Gas Griddles

1.7”

[43mm]

4.0”

[102mm]

*

[814mm]

[102mm]

16.3”

[415mm]

GAS INLET w/REGULATOR

32.1”

4.0”

7.6”

[192mm]

1.7”

[43mm]

WIDTH

2.0”

[51mm]

CORD

(OPT. ELEC. IGN)

23”

[584mm]

PLATE

DEPTH

3.8”

[98mm]

TROUGH

DEPTH

15.8”

[402mm]

For use with Natural or Propane gas only.

0.8”

[21mm]

CORD

(OPT. ELEC. IGN)

Gas input ratings shown for installations up

to 2000 ft., (610m), above sea level. Please

specify altitudes over 2000 ft. and gas type

required when ordering.

Garland/U.S. Range products are not

approved or authorized for home or

residential use, but are intended for

commercial applications only. Garland / U.S.

Range will not provide service, warranty,

maintenance or support of any kind other

than in commercial applications.

* Please add 5” (127mm) in overall depth

with attachment condiment rail option

13.0”

[330mm]

.

4.0”

[102mm]

Model #

Thermostat Controlled Standard Griddle (1" steel plate)

UTGG24-GT24 23-5/8 (600)

UTGG36-GT36 35-7/16 (900) 96,000 370/168 22

UTGG48-GT48 47-1/4 (1200) 128,000 441/200 33

UTGG60-GT60 59-1/16 (1500) 160,000 578/262 40

UTGG72-GT72 70-7/8 (1800) 192,000 800/363 47

Manually Controlled Standard Griddle (1" steel plate)

UTGG24-G24 23-5/8 (600)

UTGG36-G36 35-7/16 (900) 78,000

UTGG48-G48 47-1/4 (1200) 104,000

UTGG60-G60 59-1/16 (1500) 130,000

UTGG72-G72 70-7/8 (1800) 156,000

SUPPLY OPERATING PRESSURE MANIFOLD OPERATING PRESSURE CLEARANCES

NATURAL GAS PROPANE NATURAL GAS PROPANE INSTALLATION TO COMBUSTIBLE

"WC MBar "WC Mbar "WC MBar "WC Mbar Sides Rear

7 17.5 11 27.5 4.5 11 10 24.5 6" (152mm) 6” (152mm)

Width

In (mm)

Height

(w/std legs)

13 (330) 32 (814)

13 (330) 32 (814)

16.0”

[406mm]

TRAY DEPTH

Depth

In (mm)

25.9”

[657mm]

Total

Input (BTU)

64,000 270/122 18

52,000

Shipping Information

Lbs/Kg Cu Ft

247/112 18

359/159 22

446/202 33

561/254 40

690/309 47

5.3”

[136mm]

GAS INLET

Page 8

Part # 4528530 Rev. 1 (11/03/11)

PRE INSTALLATION

Damage Check

Damage check: Check carton or crate for possible damage

incurred in shipping. After carefully un-crating, check for

“concealed” damage. Report any damage immediately to

your carrier.

Rating Plate

The correct type of gas for which the unit was manufactured

is noted on the rating plate, and this type of gas must be

used.

When corresponding with the factory or your local

authorized factory service center regarding service problems

or replacement parts, be sure to refer to the particular model

by the correct model number (including the prex and

INSTALLATION

General

1. Carefully remove appliance from carton or crate. Burner

tie wires and other packing material should be removed

at this time. The protective material covering the stainless

steel should be removed immediately after the appliance

is installed, before it is red.

2. Remove top grates and place out of the way, to prevent

damage.

3. Should it be necessary to remove the steel griddle

plate from models equipped with griddle thermostats,

the griddle thermostat bulb and capillary must rst be

withdrawn from the bulb shield assembly, located on the

underside of the griddle plate. This can be accomplished

with the griddle front raised and supported by blocks of

wood. Loosen the four pal nuts around each thermostat

control bulb shield assembly to the griddle plate and

withdraw the griddle thermostat bulb.

4. When a griddle plate is being installed on models

equipped with griddle thermostats, the thermostat bulb

must be inserted in the groove between the plate and

the bulb shield assembly. This can be accomplished with

the griddle front raised and supported by blocks of wood.

It is important for accurate temperature control that the

bulb be located inside the groove. Tighten the four pal

nuts securing the bulb shield assembly to the griddle

plate.

5. These appliances must be installed under an adequate

ventilation system. Refer to section titled Ventilation for

further instructions.

sux letters and numbers) and the warranty serial number.

The rating plate axed to the appliance contains this

information.

We suggest installation, maintenance and repairs should be

performed by your local authorized service agency listed in

your information manual pamphlet.

In the event you have any questions concerning the

installation, use, care or service of the product, write or call

our Product Service Department.

This product must be installed by professional personnel as

specied. Garland/U.S. Range products are not approved or

authorized for home or residential use, but are intended for

commercial applications only. Garland / U.S. Range will not

provide service, warranty, maintenance or support of any

kind other than in commercial applications.

Gas Connections

The local gas authority should be consulted at the

installation planning stage in order to establish the

availability of an adequate supply of gas and to ensure

that the meter is adequate for the required ow rate. The

pipe work from the meter to the appliance must be an

appropriate size.

All xed (non-mobile) appliances MUST be tted with an

accessible upstream gas shut o valve as a means of isolating

the appliance for emergency shut o and for servicing. A

union or similar means of disconnection must be provided

between the gas-cock and the appliance.

A manually operable valve must be tted to the gas supply

to the kitchen to enable it to be isolated in an emergency.

Wherever practical, this shall be located either outside the

kitchen or near to an exit in a readily accessible position.

Where it is not practical to do this, an automatic isolation

valve system shall be tted which can be operated from a

readily accessible position near to the exit.

In locations where the manual isolation valve is tted or the

automatic system can be reset this notice MUST be posted:

“ALL DOWNSTREAM BURNER AND PILOT VALVES MUST

BE TURNED OFF PRIOR TO ATTEMPTING TO RESTORE THE

SUPPLY. AFTER EXTENDED SHUT OFF, PURGE BEFORE

RESTORING GAS.”

6. All burner adjustments and setting shall be made by a

qualied gas technician.

Part # 4528530 Rev. 1 (11/03/11)

Page 9

INSTALLATION

1. The installation and connection must be performed by a

licensed gas technician in compliance with local codes,

or in the absence of local codes, with CAN/CGA-B149

Installation Code or with the national Fuel Gas Code, ANSI

Z223.1/NFPA No. 54 – Latest Edition.

2. The correct type of gas for which the unit was

manufactured is noted on the rating plate, and this type

of gas must be used.

3. If it is a new installation have the gas authorities check

meter size and piping to assure that the appliance is

supplied with necessary amount of gas pressure required

to operate properly.

4. The gas pressure must be checked when the appliance

is installed, to ensure that the gas pressure is the same

as specied on the rating plate. If necessary, pressure

adjustments can be made at the pressure regulator,

supplied on each unit.

NOTE: When installing as a ush mount pressure regulator

connection, (to allow for equipment installations against

a non-combustible wall), a certied exible gas hose and

quick disconnect assembly is required to allow the unit to

be moved in the event an adjustment of the gas pressure

regulator is required.

5. Have a qualied gas technician check the gas pressure

to make certain that existing gas facilities (meter, piping,

etc.) will deliver the BTU’s of gas required at the appliance

with no more than ½” water column pressure drop. When

checking pressure, be certain that all the equipment on

same gas line is turned to the “ON” position.

6. The appliance and its individual shut o valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in

excess of 1/2 PSIG. (3.45 KPA).

7. The appliance must be isolated from the gas supply

piping system by closing its individual manual shut o

valve during any pressure testing of the gas supply piping

system at test pressures equal to or less than 1/2 PSIG.

(3.45 KPA).

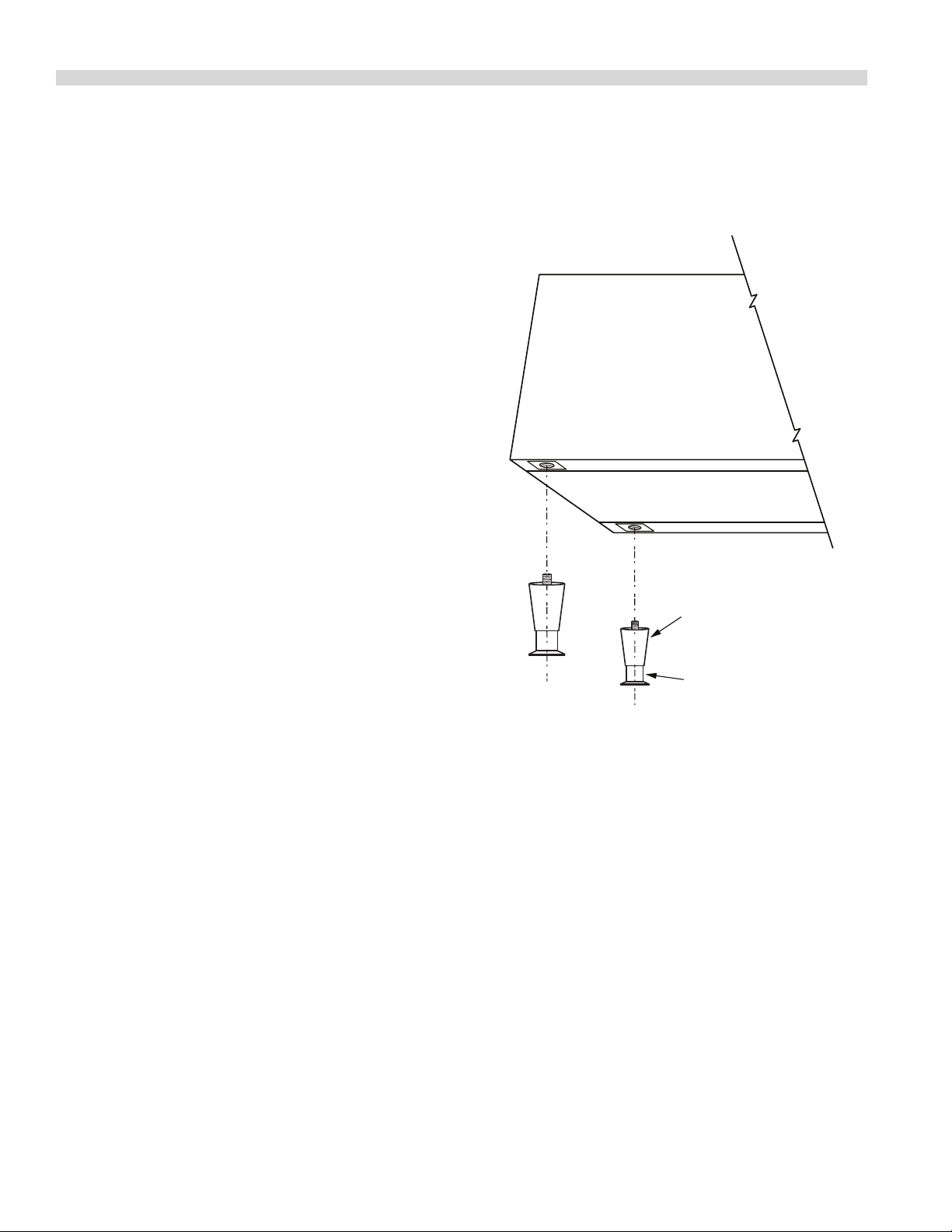

Leg Installation

Your new appliance has been supplied with four 4”(102mm)

adjustable legs. These legs are threaded into holes on the

bottom. Once the legs are installed turn the leveling foot at

the bottom of the leg.

LEG INSTALLATION

UNDERSIDE OF UNIT

4" [102mm]

ADJUSTABLE LEG

(QTY 4)

LEVELING FOOT

Level the appliance by adjustment of leveling bolts or legs.

Use a spirit level and check for level four ways; across front

and back, then down left and right edges. Level any adjacent

units to the rst. A griddle may not rest evenly on the

appliance body if it is not properly leveled.

8. Make certain that the new piping, joints and connections

have been made in a clean manner and have been

purged, so that the piping compound, chips, etc., will not

clog pilots, valves and/or controls. Use pipe joint sealant

that is certied for use with liqueed petroleum gas.

9. WARNING: Check gas connections for leaks, using soap

solution or similar means.

Do Not Check with an Open Flame.

Page 10

Part # 4528530 Rev. 1 (11/03/11)

INSTALLATION

Ventilation

Ventilation requirements may be subject to local

building and re codes. Consult local authorities

having jurisdiction.

Counter equipment must be installed in a location in which

the facilities for ventilation permit satisfactory combustion

of gas and proper venting. Proper ventilation is imperative

for good operation of the appliance. The ideal method

of ventilating counter equipment is the use of a properly

designed ventilating canopy, which should extend at least

6”/152mm beyond all sides of the appliance (except against

the wall if the canopy is a wall installation). This is usually part

of a mechanical exhaust system.

ADJUSTMENTS

Air Supply

1. It is necessary that sucient room air ingress be allowed

to compensate for the amount of air removed by any

ventilating system. Otherwise, a subnormal atmospheric

pressure will occur, aecting the appliance operation

adversely and causing undesirable working conditions.

2. Appliances shall be located so as not to interfere with

proper circulation of air within the conned space. All gas

burners and pilots require sucient air to operate.

3. Large objects should not be placed in front of the

appliance which might obstruct the air ow through

the front. Do not obstruct the ow of combustion and

ventilation air.

4. Do not permit fans to blow directly at the appliance, and

wherever possible, avoid open windows adjacent to the

appliance sides and back; also wall type fans which create

air cross-currents within the room.

Burner Adjustments – All Models

1. Before making any adjustment, turn all gas valves

to “OFF”. Remove the burner tie wires, if not already

removed. Be sure all piping is gas tight and that air is

purged from lines.

2. All units are shipped from factory at burner ratings set

for the gas specied on the rating plate at normal gas

pressure. The only adjustment necessary is for that

governing air.

Air Adjustment: If necessary, the air is adjusted by rotating

the air shutter on burner. The burner must have enough air

that the tips of the ames are not yellow, but not so much air

that the ames will lift o the burner ports. Securely tighten

air shutter screw so air shutter cannot be moved.

NOTE: All adjustments must be performed by a qualied gas

technician.

Part # 4528530 Rev. 1 (11/03/11)

Page 11

OPERATION: ALL MODELS

Lighting Standing Pilots - All Models

After the appliance has been installed by a licensed gas

trades-person all connections, pilot lights and controls have

been inspected for proper operation. All gas appliances

that use standing pilot systems are generally assumed to

be operating with the pilot on continuously. The appliances

should not be restarted except in the event of a gas service

interruption to the facility.

If a pilot ame does go out, here are the basic steps to check

before you re-light the pilot:

1. Check to see that all gas lines are in place and secured

and that there is no accumulation of gas inside the unit.

2. Check to make sure that the main shut o valve is in the

o position.

3. Turn the thermostat to the o position. (If applicable)

4. Turn on or open the main shut o valve to the appliance.

5. Follow pilot lighting procedures applicable to your

model. The pilot should ignite within a few attempts. You

will be able to see the pilot ame on a hotplate under the

protective pilot shield cast into the burner top grate. Pilot

ames on griddles and broilers can be viewed through

observation holes in the stainless steel front panel.

BROILERS:

a. Light the pilots with a long match or taper through

the opening(s) in the valve panel.

b. Turn the burner valve on to the full position. A sharp

ame should be about 1/4” high.

c. To shut down turn all valves to the o position. If the

appliance is to be shut down for an extended period

of time, close the in-line gas valve.

HOTPLATES:

a. Pilots are easily accessible. Make sure the individual

burner valve is in the o position, then use an open

ame device, match, or BBQ lighter to ignite.

VALVECONTROL GRIDDLES:

a. Make sure the individual valve control is in the o

position.

b. Use the piezo spark (or electric spark if your model

has this option) button(s) to ignite the pilot.

c. Once the pilot is lit you may now turn your valve

control to the high or low ame setting.

d. To shut down the main burner turn the valve to o

position.

THERMOSTATCONTROL GRIDDLES:

a. Turn griddle thermostat control

knob to the “ ” position and

then push in to engage the ow

of gas through the safety device

to the pilot.

b. While holding the knob in, light

pilot by pressing the red piezo lighter button or the

black igniter button if your model has the electric

ignition option.

c. Continue to hold the knob in for 15 seconds after

ignition, then release. Pilot should remain lit.

d. If the pilot burner fails to light or does not stay lit,

wait 5 minutes and repeat steps a through c.

e. Turn the griddle thermostat knob to desired cooking

temperature.

f. To shut down the main burner turn the control knob

to the “ ” position.

6. If you do not have a pilot ame established fairly quickly

and begin to smell gas, shut o the main valve and wait

ve minutes to let the gas build-up escape.

7. Only once the pilot ame has been established should

you turn on the burner control. When the burner control

is on it allows gas ow to the burner. If there is no pilot

ame it will allow gas to build up and cause possible

delayed ignition, which could result in an explosion.

Shutdown Procedure

To shutdown, turn all main burner valves to OFF position.

If the appliance is to be shut down for an extended period

of time, close the pilot valves, (gum valves), by turning their

set screws clockwise. (On thermostat-controlled griddles,

turning the thermostat dial to the OFF position is all that’s

required. There are no pilot valves.) Finally, turn the manual

valve on the main gas supply to the OFF position.

Page 12

Part # 4528530 Rev. 1 (11/03/11)

MAINTENANCE & CLEANING

NOTE: Any maintenance or service involving disassembly

of components should be made by a qualied service

technician. Also, ensure gas supply to the appliance is shut

o.

You have purchased the nest commercial cooking

equipment available anywhere. Like any other ne precision

built piece of equipment, it should be given regular care and

maintenance.

Periodic inspections by your dealer or qualied service

agency are recommended to check temperatures,

adjustments and ensure moving parts are operative.

Whenever possible, avoid overheating idle equipment as this

is the primary cause for increased service costs.

When corresponding with the factory or your equipment

dealer regarding service problems or replacement parts, be

sure to refer to the particular model by the correct model

number (including prex and sux letters and numbers)

and the serial or code number. The rating plate axed to the

appliance contains this information.

Seasoning

Griddle (standard steel plate)

1. Remove all factory applied protective material by

washing with hot water, mild detergent or soap solution.

2. Apply a thin coat of cooking oil to the griddle surface,

about one ounce per square foot of griddle surface.

Spread over the entire griddle surface with a cloth to

create a thin lm. Wipe o any excess oil with a cloth.

3. Light all burners, set at the lowest possible setting. Some

discoloration will occur when heat is applied to steel.

4. Heat the griddle slowly for 15 to 20 minutes. Then wipe

away oil. Repeat the procedure 2 to 3 times until the

griddle has a slick, mirror like nish.

Griddle (optional chrome)

1. Remove all factory applied protective material by washing

with hot water, mild detergent or soap solution.

2. A chrome plate griddle does not have a porous surface

such as a steel griddle plate so seasoning is something

you do not need to do but regular cleaning will ensure

longer life for your griddle and better cooking results.

3. Turn griddle plate temperature setting to between 300

to 350 degrees F (149 to 177 deg. C). Pour water on the

griddle ahead of a soft bristle brush. Then scrub the

griddle clean sweeping the water and debris into the

grease trough. This should remove much of the debris on

the griddle.

4. For stubborn burnt on food use a mild nonabrasive

cleaner with the water and a soft metal scraper.

Cast Iron Top Grates (Hot Plates & Char-Broilers)

1. Wash the cast iron top grates thoroughly with a mild soap

and warm water.

2. Dry the grates thoroughly with a clean cloth.

3. Immediately after drying, season the top grates lightly

with a non-toxic oil, (liquid vegetable oil or spray oil).

WARNING: DO NOT SEASON THE GRATES WHILE THEY

ARE INSTALLED ON THE APPLIANCE. Seasoning grates

over an open ame could cause a ash re.

4. After seasoning, reinstall the grates. Turn all the burners

on at their lowest setting. Allow the oil on the grates to

burn o for at least 20 minutes before using.

RE-SEASONING OF THE GRATES WILL BE REQUIRED

WHENEVER THEY HAVE BEEN CLEANED. FAILURE TO

SEASON GRATES WILL RESULT IN RUSTING.

IMPORTANT: Do not set to a high position (on valve control)

or 450° (on thermostat control) during “break-in” period

NOTE: Steel griddle surface will tone (blue discoloration)

from heat. This toning will not diminish function or operation

and it is not a defect.

The griddle will not require reseasoning if it is used properly.

If the griddle is over heated and product begins to stick to

the surface it may be necessary to repeat the seasoning

process again. If the griddle is cleaned with soap and water it

will be necessary to reseason the griddle surface.

Part # 4528530 Rev. 1 (11/03/11)

Page 13

MAINTENANCE & CLEANING

Cleaning

Griddle

To produce evenly cooked, browned griddle products, keep

griddle free from carbonized grease. Carbonized grease on

the surface hinders the transfer of heat from the griddle

surface to food product. This results in uneven browning

and loss of cooking eciency, and worst of all, carbonized

grease tends to cling to grilled foods, giving them a highly

unsatisfactory and unappetizing appearance. To keep the

griddle clean and operating at peak performance, follow

these simple instructions:

a. AFTER EACH USE clean griddle thoroughly with a

grill scraper or spatula. Wipe o any excess debris

left from cooking process.

b. ONCE A DAY clean griddle surface with a grill brick

and grill pad. Remove grease container and clean

thoroughly, in the same manner as any ordinary

cooking utensil.

c. ONCE A WEEK clean griddle surface thoroughly.

If necessary, use a grill stone or grill pad over the

griddle surface. Rub with grain of the metal while

still warm. A detergent may be used on the plate

surface to help clean it, but care must be taken to

be sure it is thoroughly removed. After removal of

detergent, the surface of the plate should be covered

with a thin lm of oil to prevent rusting. To remove

discolorations, use a non-abrasive cleaner. Before reusing, the griddle must be reseasoned. Keep griddle

drain tube to grease container clear at all times.

CAUTION: This griddle plate is steel, but the surface is

relatively soft and can be scored or dented by careless use

of spatula. Be careful not to dent, scratch, or gouge the plate

surface. This will cause food to stick in those areas. Also, note,

since this is a steel griddle if a light coating of oil is not always

present rust will develop on exposed and uncoated areas.

Open Top Burners

Cleaning of the open top burner is a simple procedure,

and, if done at regular intervals, will prolong the life of the

appliance and ensure good ame characteristics.

1. The most common problem with open burners is

spillage. Once the burner ports are partially plugged with

food, the air-to-gas mixture is disturbed and results in an

inecient burner.

2. Wipe any spills as they occur.

3. Top grates and trays should be removed daily, washed,

rinsed and dried thoroughly.

4. Use a wire brush to clean the ports of the burners. Ignite

and check for clogged holes.

5. If any clogged holes are apparent, the burner should be

lifted out and brushed inside and out with a small Venturi

brush. Each port on the burner itself should be cleaned

with a properly sized wire or thumb drill. Wash with soap

and hot water if grease is observed on the burners. Dry

thoroughly.

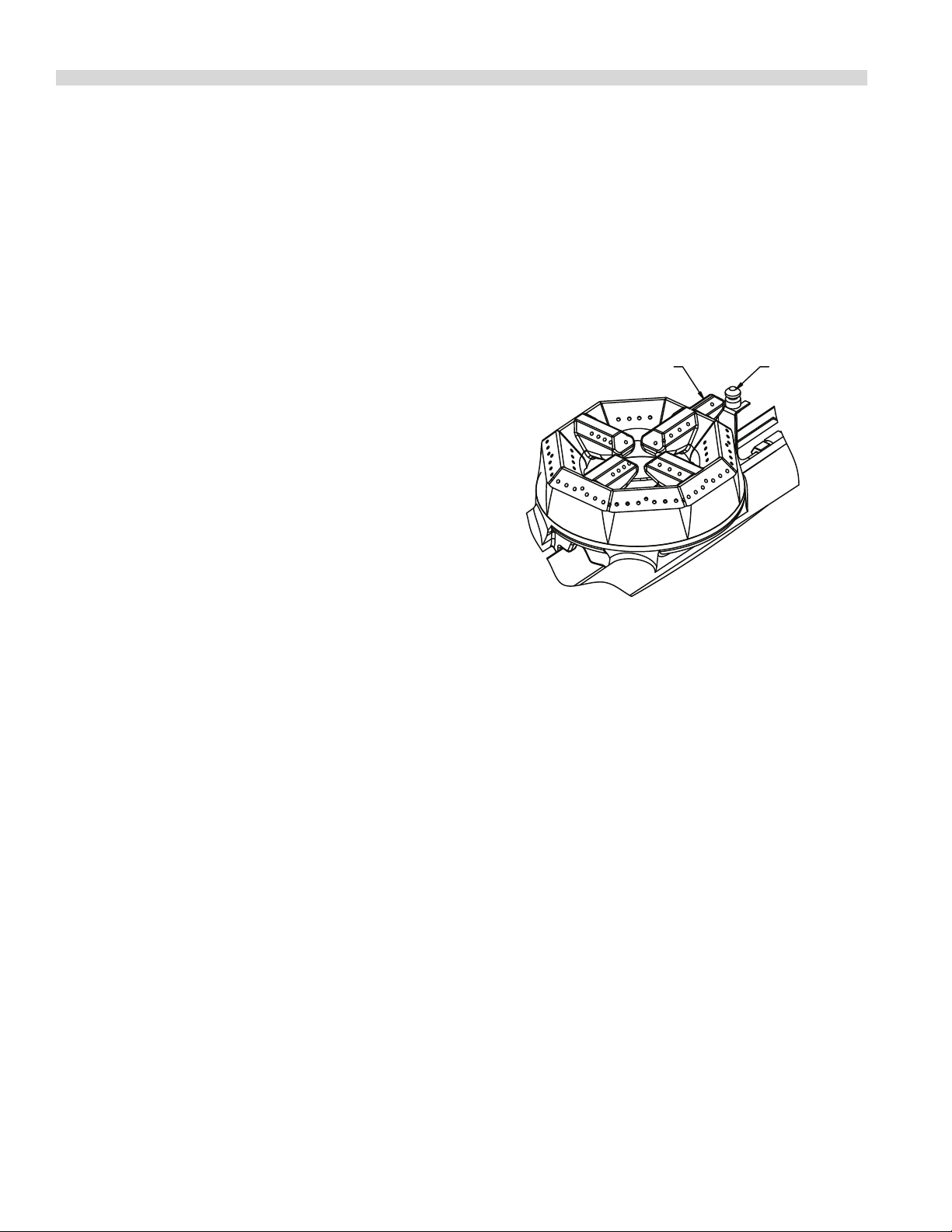

6. When reinstalling the open top burner head be sure the

burner ports are lined up correctly to the pilot. On the

cast burner head there is an extended nger with port

openings, when this is in line with the pilot, the burner is

installed correctly.

EXTENDED FINGER

7. If an abnormal ame appears around the edges, it is

usually a sign of grease or dirt in the throat of the burner.

Remove the burner venturi (main body that the burner

heads sit on) to access the air shutter opening. Remove

grease and dirt from the air shutter area carefully. Do

not adjust the shutter setting. The air shutter allows the

proper amount of air to mix with the ow of gas coming

in from your valve/thermostat orice and should not be

adjusted unless by a licensed gas tter technician.

ABOUT STEPUP HOT PLATE BURNERS: The step up cast

burner housing is assembled at the factory with two locating

pins to ensure that the housing can only be installed in the

correct positions should they be removed for cleaning. One

pin is located on the top of the housing to ensure the burner

head is oriented correctly when installed so that the lighter

nger is correctly pointing at the pilot ame. The second is

located on the housing bottom and must t into the slot on

the burner support, otherwise the burner will not be stable.

PILOT

Cast Iron Top Grates

Cast iron top grate(s) can be cleaned with mild soap and

warm water. For baked on material, a wire brush can be

used. Dry thoroughly. Lightly coat with vegetable oil to help

prevent rust from forming.

Page 14

Part # 4528530 Rev. 1 (11/03/11)

MAINTENANCE & CLEANING

Char-Broilers

Establish a regular cleaning schedule. It is necessary to avoid

obstruction between grates and to allow proper combustion

and performance.

1. Broiling grates should be wiped daily while still warm,

using a heavy cloth or other grease absorbing material to

remove grease and burnt food before they burn into the

grid. Remove burnt materials, such as carbonized grease

or food, with a sti wire brush. Do Not use Any Type Of

Steel wool. Small particles may be left on the grid surface

and get into food products.

A common cleaning practice is to turn grates upside

down to burn o the encrusted material. Do not do this

with the radiant broilers! The ame from the burners is

shielded by a cast iron radiant, which prevents ame from

reaching the grates. It is likely that cooked-on matter will

cook in even deeper rather than burn o.

2. Broiling grates should be washed thoroughly using a wire

brush and a hot, mild detergent or soap solution. Rinse

with clear, warm water.

3. Dry thoroughly.

4. Immediately after drying, season the top grates lightly

with a non-toxic oil, (liquid vegetable oil or spray oil)

RADIANT BROILERS: Remove the radiants and wire brush

them clean; then wash in hot soapy water. A rule of thumb is

that if the grates are becoming encrusted,so are the radiants.

Stainless Steel

For routine cleaning, wash with a hot water and detergent

solution. Wash just a small area at a time or the water will

evaporate leaving the chemicals behind causing streaking.

Rinse the washed area with a clean sponge dipped in a

sanitizing solution and wipe dry with a soft clean cloth

before it can dry.

Use a paste (of water and a mild scouring powder) if you

have to, but never rub against the grain. All stainless steel has

been polished in one direction. Rub with the polish lines to

preserve the original nish. Then thoroughly rinse as before.

To prevent ngerprints there are several stainless steel

polishes on the market that leave an oily or waxy lm. Do not

use on surfaces that will be in contact with food.

Stainless steel may discolor if overheated. These stains can

usually be removed by vigorous rubbing with a scouring

powder paste.

Use only stainless steel, wood or plastic tools if necessary

to scrape o heavy deposits of grease and oil. Do not use

ordinary steel scrapers or knives, as particles of the iron may

become imbedded and rust. NEVER USE STEEL WOOL.

Either a typical bleach solution or hot water can be used to

sanitize stainless steel.

CERAMIC BRIQUETTE BROILERS: With the cooking grates

removed, turn over all the briquettes and debris will burn o.

5. The front grease trough collects grease via downspout

that empties into the drip tray. Additional grease which

drips past the radiants or ceramic briquettes is also

collected in the same drip tray. The tray must be checked

frequently during operation and drained as necessary.

Spills should be wiped as they occur and at end of each

day the drip tray should be emptied, washed in hot soapy

water., and thoroughly dried before reinstalling.

NOTE: Do not waste gas or abuse equipment by leaving

valves at high temperature settings while not in use.

Throughout all idling periods, set valves at low temperature

setting to keep grids warm. Re-set valves as required for

periods of heavy load. Turn valves to OFF at end of daily

operation. When the broiler is running, never use objects

such as sheet pans to cover the grates in order to hold in heat

in an attempt to burn o grease or other debris.

Part # 4528530 Rev. 1 (11/03/11)

Page 15

Loading...

Loading...