Page 1

INSTALLATION AND

OPERATION MANUAL

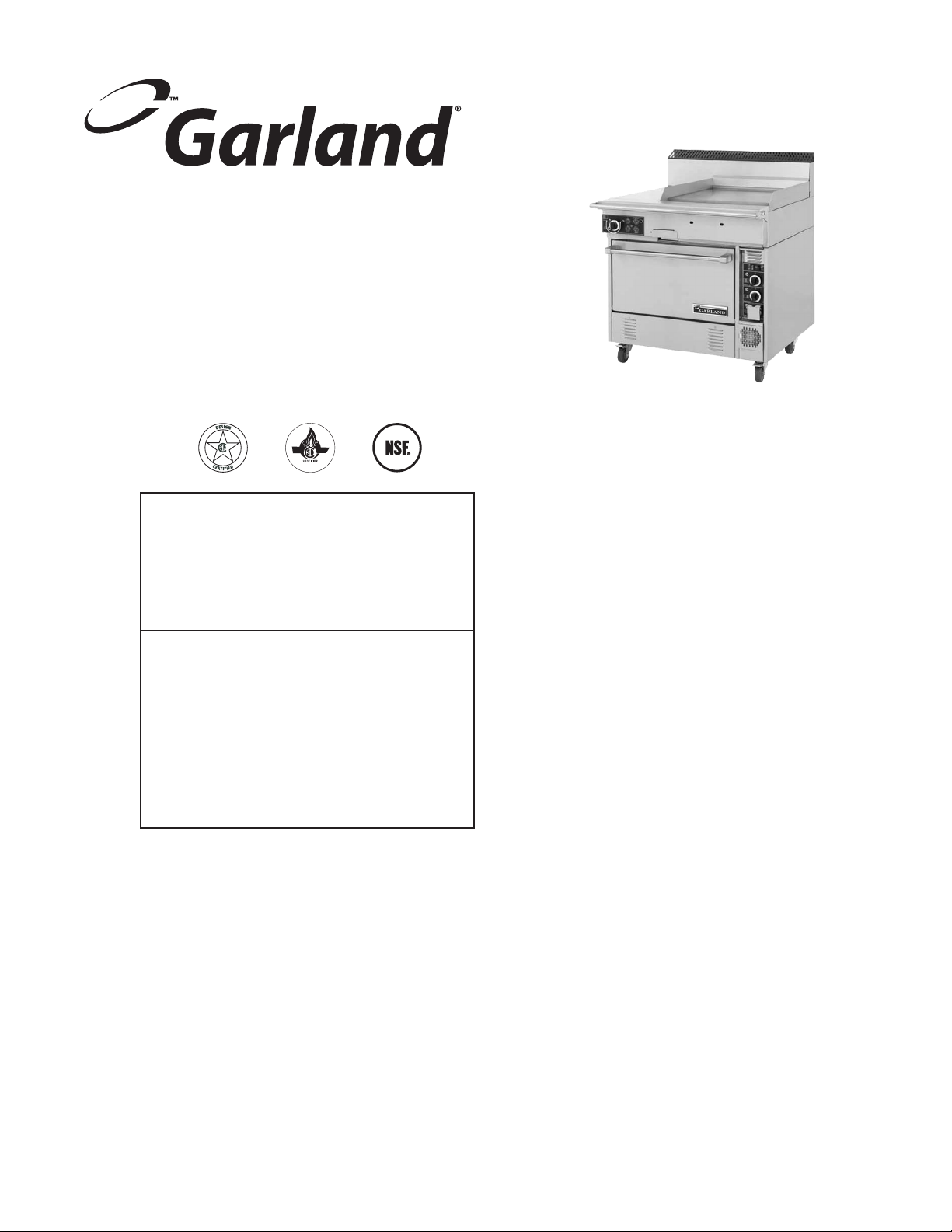

GARLAND® STARFIRE

SENTRY COMBINATION

RANGE, MODEL STW286A

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

PLEASE READ ALL SECTIONS OF THIS MANUAL

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

IN THE COMMONWEALTH OF MASSACHUSETTS

THIS PRODUCT MUST BE INSTALLED BY A

LICENSED PLUMBER OR GAS FITTER. APPROVAL

NUMBER: G-1-07-05-28

For Your Safety:

Post in a prominent location, instructions to be

followed in the event the user smells gas. This

information shall be obtained by consulting

your local gas supplier.

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Part # 4517957 Rev 13 (02/10/11) © 2010 The Garland Group.

Part # 4517957 Rev.13 (02/10/11) Page 1

Page 2

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the state of California to cause cancer and/or birth defects

or other reproductive harm. Installation and servicing of this product could expose you to airborne

particles of glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/ceramic fibers

is known to the state of California to cause cancer. Operation of this product could expose you to

carbon monoxide if not adjusted properly. Inhalation of carbon monoxide is known to the state of

California to cause birth defects or other reproductive harm.

Keep appliance area free and clear of combustibles.

Part # 4517957 Rev. 13 (02/10/11)Page 2

Page 3

TABLE OF CONTENTS

IMPORTANT INFORMATION. . . . . . . . . . . . 2

DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . 4

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . 5

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . 5

Unpacking: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . 6

General Information . . . . . . . . . . . . . . . . . . . . . . . . 6

Rating Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Product Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Appliances Equipped with Casters . . . . . . . . . . . 7

Ventilation & Air Supply . . . . . . . . . . . . . . . . . . . . . 7

Gas Connection: . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Commissioning: . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Burner Adjustments: . . . . . . . . . . . . . . . . . . . . . . . . 9

Griddle /Solid Hot Top Burner . . . . . . . . . . . . 9

Hot Top Minimum Flame Setting . . . . . . . . 9

Oven Burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . 10

Safety concerns . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Operation Controls . . . . . . . . . . . . . . . . . . . . . . . . 10

Griddles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Preparing A New Griddle . . . . . . . . . . . . . . . 10

Lighting The Griddle . . . . . . . . . . . . . . . . . . . 10

Seasoning The Griddle . . . . . . . . . . . . . . . . . 11

Shut Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Solid Hot Tops (STW286A) . . . . . . . . . . . . . . . . . . 11

Lighting The Solid Hot Top . . . . . . . . . . . . . 11

Oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Convection Oven . . . . . . . . . . . . . . . . . . . . . . 11

Lighting the Oven . . . . . . . . . . . . . . . . . . . . . . 11

Shut Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Operating Suggestions . . . . . . . . . . . . . . . . . . . . 12

MAINTENANCE & CLEANING . . . . . . . . . . 12

Stainless steel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Exhaust Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Enameled/Painted Surfaces . . . . . . . . . . . . . . . . 12

Griddle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Cleaning instructions (After each use) . . . 13

Cleaning Instructions

(For Heavy Build Up) . . . . . . . . . . . . . . . . . . . 13

Griddle Do’s & Don’ts . . . . . . . . . . . . . . . . . . . 13

Cleaning Burners . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Griddle / Solid Hot Plate . . . . . . . . . . . . . . . . 13

Convection Oven . . . . . . . . . . . . . . . . . . . . . . 14

Pilot Burner Cleaning . . . . . . . . . . . . . . . . . . . 14

Gas Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Thermostat Calibration . . . . . . . . . . . . . . . . . . . . 14

Oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Griddle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

CONVERSION INSTRUCTIONS . . . . . . . . . 16

FAULT FINDING . . . . . . . . . . . . . . . . . . . . . . 17

REPLACEMENT OF PARTS . . . . . . . . . . . . . 18

Gas Taps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Door Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Control Panel Rocker Switches . . . . . . . . . . . . . 18

Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Heat-On Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Gas Control Valve . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Front Cooling Fan . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Ignition Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Hot Top Ignition Momentary Switch . . . . . . . . 19

Hot Top Spark Generator . . . . . . . . . . . . . . . . . . . 19

WIRING DIAGRAMS . . . . . . . . . . . . . . . . . . 20

For Models Manufactured Up To

Oct /04/2005, Serial # 0509100130513 &

Models Manufactured From Mar/24/2009

S/N 0903100100823 M/D STW280A-0009

(Robertshaw Ignition Control Module) . . . . . . 20

For Models Manufactured From

Oct /05/2005, Serial # 0510100130790 To

Mar/23/2009 S/N 0903100100822

(With Johnson Control Module) . . . . . . . . . . . . 22

For All Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Part # 4517957 Rev.13 (02/10/11) Page 3

Page 4

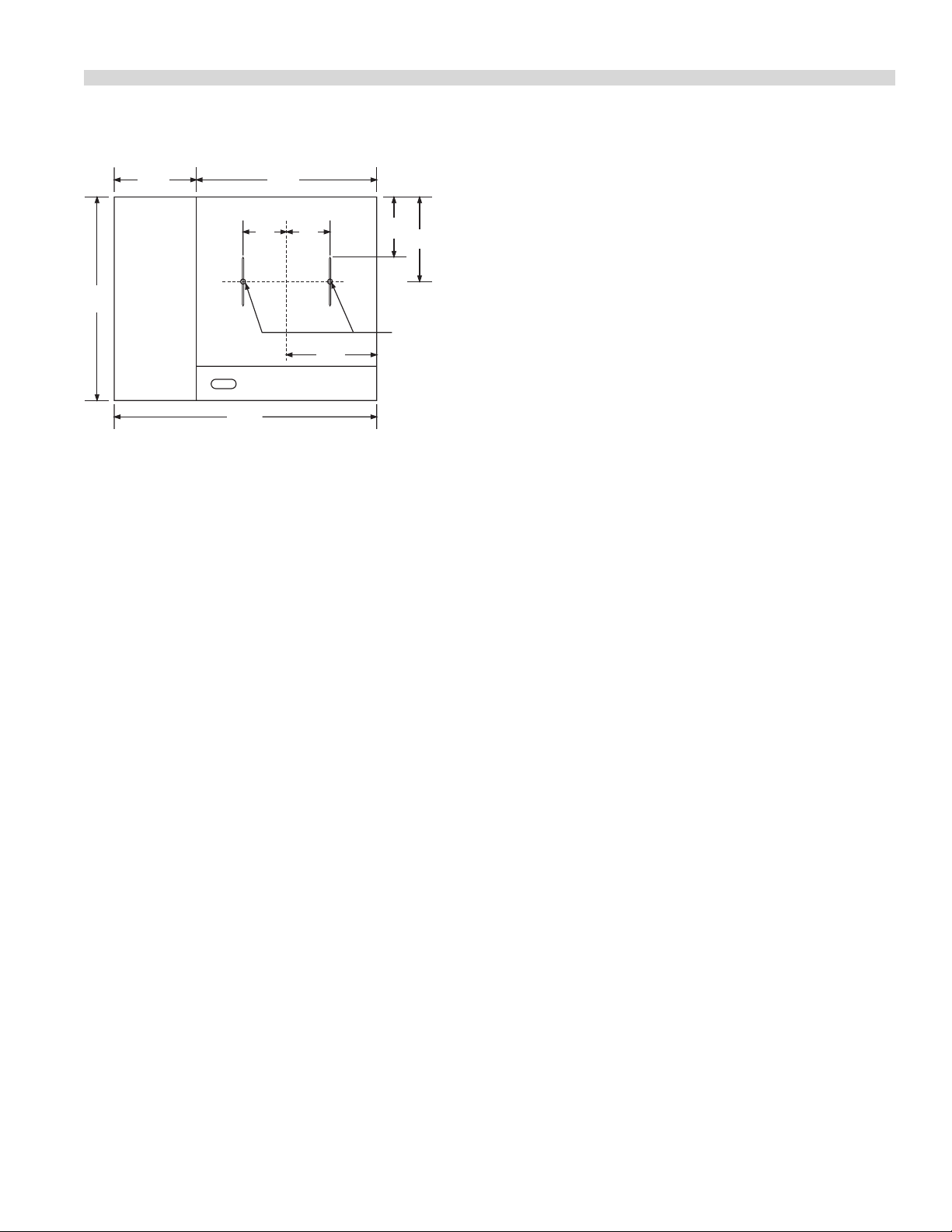

DIMENSIONS

1 1/2"

[38mm]

39 1/2"

[1003mm]

3/4" NPT REAR

FAN

GUARD

12"

[305mm]

GAS INLET

10 1/2"

[267mm]

[83mm]

[610mm]

36"

[915mm]

10' POWER CORD

AT REAR [120V]

3 3/4" [95mm]

3 1/2"

28"

[711mm]

5"

[127mm]

24"

45 1/2"

[1156mm]

[806mm]

[127mm]

31 3/4"

5"

3/4" NPT REAR

GAS INLET

[521mm]

10' POWER CORD

AT REAR

20 1/2"

32 1/2"

[825mm]

34"

[864mm]

Part # 4517957 Rev. 13 (02/10/11)Page 4

Page 5

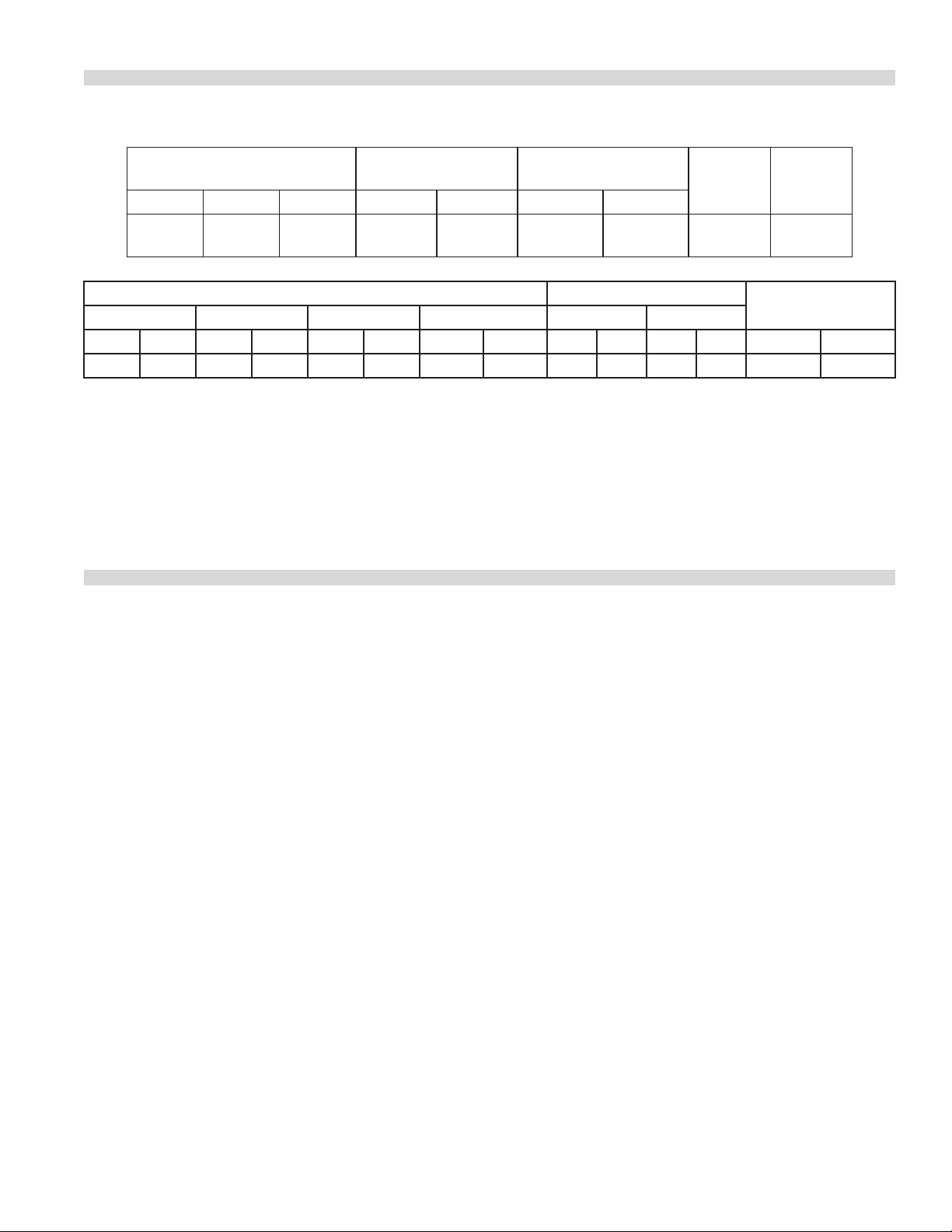

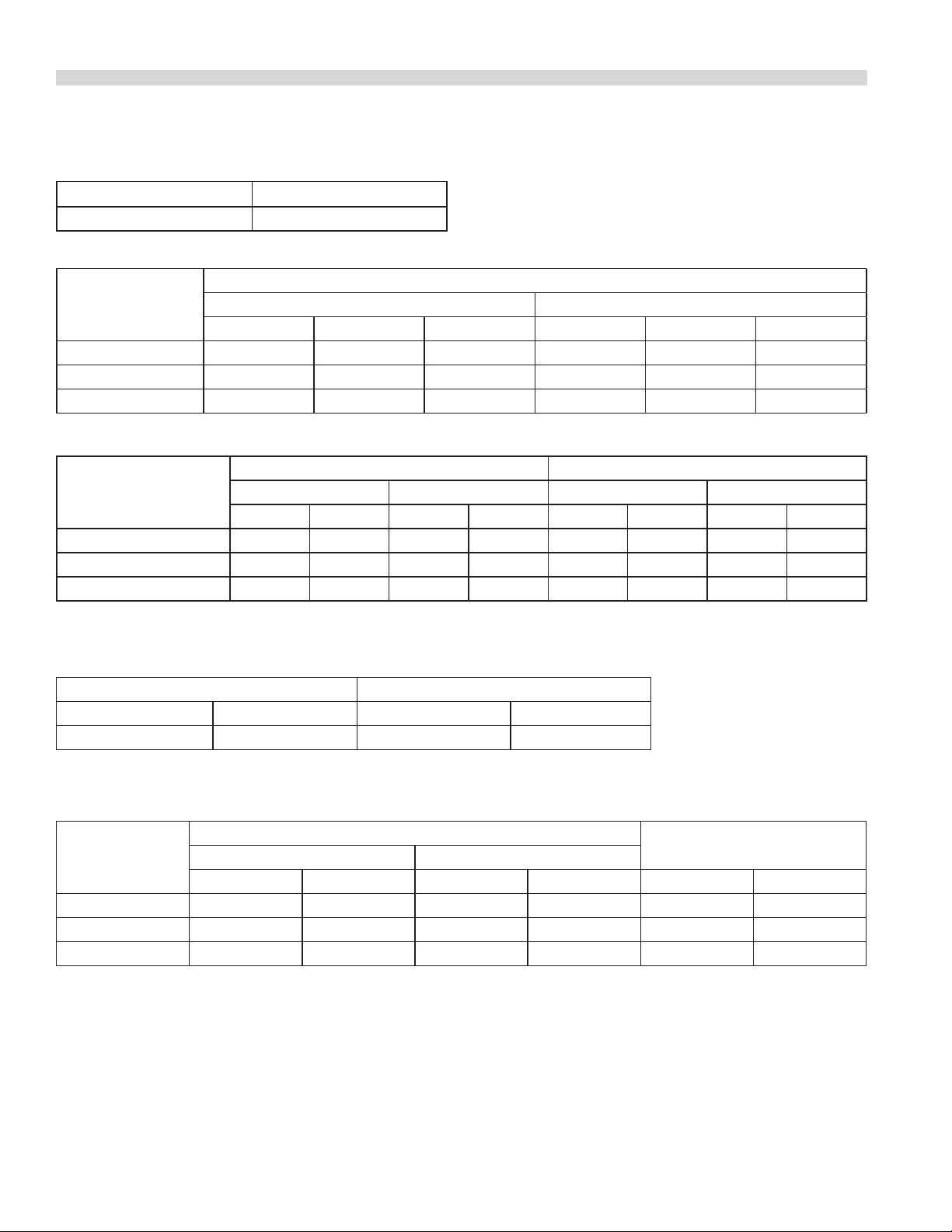

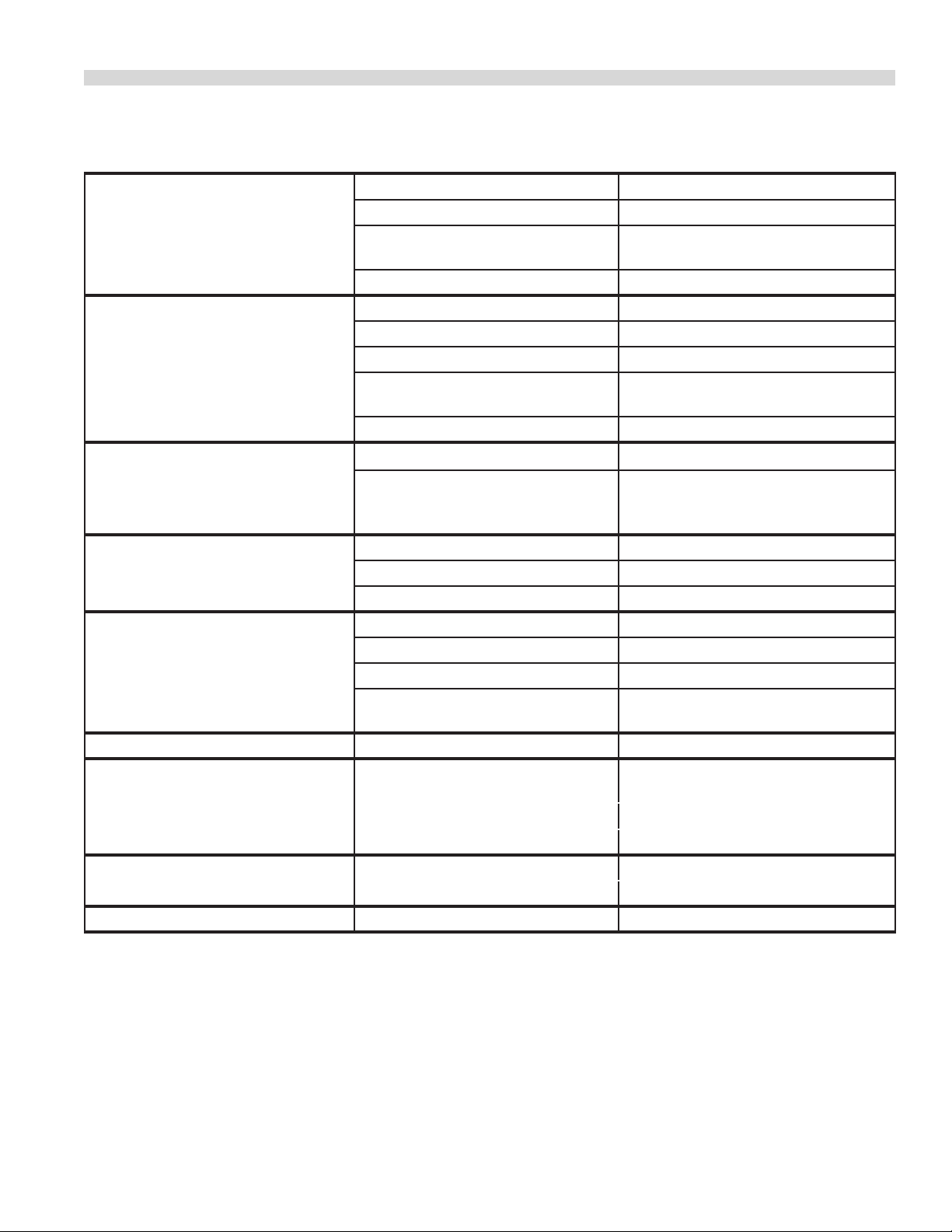

SPECIFICATIONS

Oven Interior Dimensions Entry Clearance

Height Width Depth Crated Uncrated Sides Rear

13-12

(343mm)

Hot Top Griddle Oven Total Natural Propane

BTU kW BTU kW BTU kW BTU KW "WC mbar "WC mbar 120V 230V

25,000 7.32 50,000 14.65 38,000 11.14 113,000 33.11 4.5 11 10 25 4.5 Amps 2.3 Amps

NOTE: Installation clearance reductions are applicable only where local codes permit.

Garland/U.S. Range products are not approved or authorized for home or residential use, but are intended for commercial

applications only. Garland / U.S. Range will not provide service, warranty, maintenance or support of any kind other than in

commercial applications..

Commercial cooking equipment requires an adequate ventilation system. For additional information, refer to the National Fire

Protection Association's standard NFPA96..

26-1/4"

(667mm)

22"

(559mm)

Input Ratings Operating Pressure

43"

(1105mm)

* Distance from combustible construction

37-7/8"

(648mm)

Installation

Clearances*

7"

(178mm)

6"

(152mm)

Shipping

Weight

584lbs

(265kg)

Manifold

Inlet Size

3/4" NPT

Female

Total Maximum

Electrical Load

INTRODUCTION

This equipment must be installed and adjusted by a

competent person in accordance with the law. Failure to

install appliances correctly could lead to prosecution. It is

in your own interests and that of safety to ensure that the

law is complied with. Your Garland Dealer is well qualied to

provide this service.

This appliance should be given regular care and

maintenance. Periodic inspections by the dealer or a

qualied service company are recommended to check

temperature, burner adjustments and to ensure moving

parts are operative. Wherever possible avoid overheating idle

equipment as this is the primary cause of increased service

cost.

“Regular maintenance ensures peak performance.”

Unpacking:

1. Check crate for possible damage sustained during transit.

Carefully remove unit from crate and again check for

damage. Any damage to the appliance must be reported

to the carrier immediately.

2. The wires for retaining the burners and other packing

material must be removed from units. Any protective

material covering stainless steel parts must also be

removed.

3. All ranges are shipped from the factory with casters tted.

4. The type of gas and the supply pressure that the

equipment was set up for at the factory is noted on the

data plate and on the packaging. This type of gas supply

must be used.

5. Do not remove permanently axed labels, warnings or

data plates from the appliance, for this may invalidate the

manufacturer’s warranty.

NOTE: Many parts of the equipment are raw steel i.e griddle

top and solid hot top and can react with moisture forming

rust. This is normal and not considered a defect. Clean with a

stainless steel ber pad. A light coating of salt free oil may be

applied to prevent further rusting.

Part # 4517957 Rev.13 (02/10/11) Page 5

Page 6

INTRODUCTION continued

Rating Plate

All burner input ratings are shown on the name/rating plate

of each range which can be located behind the lower front

kick panel, (located below oven door). To access, remove two

(2) fasteners securing the panel shut.

For proper operation, the fuel information on the data plate

of your new equipment must match your fuel supply.

When corresponding with the factory or equipment dealer

regarding service problems or replacement parts, be sure

to refer to the particular unit by the correct model number,

including prex and sux letters and numbers and serial

number. The rating plate axed to the unit contains this

information.

Safety

It is essential that the instructions in this booklet are strictly

followed for the safe and economical operation of the

equipment. If it is known or suspected that a fault exists

on the appliance then it must not be used until the fault is

rectied by a competent person.

Power Failure Note: In the event of a power failure, no

attempt should be made to operate the oven. The oven is

gas operated but has electrical features, motor and door

switches.

Product Usage

The top of the range is designed for exibility and the

preparation of numerous types of products.

Preparation of soups, stocks and sauces are done on a hot

top where slow even cooking is desirable. Heating larger

quantities of food can be done more eciently than heating

small quantities. Pots and pans should be covered whenever

possible to reduce energy consumption.

High acid sauces, such as tomato should be cooked in

stainless steel vessels rather than aluminum since stainless

will not react chemically. Light coloured sauces may be

dicoloured by the aluminum especially if stirred with a

metal spoon. Salty water may pit aluminum vessels if used

frequently.

INSTALLATION

General Information

Before assembly and connection, check gas supply.

• The type of gas for which the unit is equipped is stamped

on the name/rating plate. Connect a unit stamped “NAT”

only to natural gas, and a unit stamped “PRO” only to

propane.

• In a new installation, have the gas authorities check

meter size and piping to ensure that the gas supply will

deliver sucient pressure to operate the unit properly.

• When adding or replacing equipment, have gas

authorities check gas pressure to ensure that the existing

meter and piping will supply fuel to the appliance with

no more than 0.5 inch water column pressure drop

during operation.

• Before turning on the main gas supply, check the unit to

be certain that all the controls are in the “OFF” position.

• When checking gas pressure, be sure that all other

equipment on the same gas line is turned “ON.” A preset

gas pressure regulator is supplied with GARLAND

Restaurant Series Equipment. It may be necessary to

adjust the regulator to deliver fuel at the pressure shown

on the rating plate.

• In Canada, the installation must comply with local codes,

or in the absence of local codes, with the Installation

Codes for Gas Burning Appliances and Equipment CAN/

CGA-B149.1 and CAN/CGA B149.2, (latest edition), and

with the Canadian Electrical Code C22.1 (latest edition).

Part # 4517957 Rev. 13 (02/10/11)Page 6

Page 7

INSTALLATION continued

In the United States the installation must comply with

the National Fuel Gas Code ANSI Z223.1, (latest edition),

NFPA No. 54, (latest edition), and the National Electrical

Code ANSI/NFPA 70, (latest edition), and/or local codes to

ensure a safe and ecient operation.

• This equipment must be electrically grounded in

accordance with local codes, or in the absence of local

codes, with National Electrical Code, ANSI/NFPA 70, or the

Canadian Electrical Code, CSA C22.2, as applicable.

• The appliance and its individual shut-o (supplied by

others) must be disconnected from the gas supply piping

system during any pressure testing of the system at

pressures in excess of 1/2 PSIG (3.45 KPA). The appliance

must be isolated from the gas supply piping by closing its

individual manual shut-o (supplied by others) during any

pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 PSIG (3.45 KPA).

• Adequate clearance must be provided for servicing and

proper operation.

Clearances

Minimum installation clearance to adjacent combustible

walls and type of oor or base:

MINIMUM CLEARANCES STW286A

LOCATION CLEARANCE

Left Hand Side 7" (178mm)

Right Hand Side 7" (178mm)

Rear 6" (152mm)

TYPE OF FLOOR OR BASE

Combustible

Location

The range should be installed on a rm, smooth and level

oor designed to withstand the weight of the fully laden

appliance. Any openings in the wall beside the appliance

should be sealed.

Appliances Equipped with Casters

• The installation shall be made with a connector that

complies with the Standard for Connectors for Moveable

Gas Appliances, ANSI Z21.69/CSA 6.16, Addenda Z21.69B2006/CSA 6.16B-2006 (or latest edition), and a quickdisconnect device that complies with the Standard for

Quick Disconnects for Use with Gas Fuel, ANSI Z21.41/

CSA 6.9, Addenda Z21.41A-2005/CSA 6.16A-2005 (or

latest edition).

• The front casters on the appliance are equipped with

brakes to limit the movement of the appliance without

placing any strain on the connector or quick disconnect

device or its associated piping.

• Be aware; required restraint is attached to a bracket,

which is located on the rear caster closest to the gas

connection. If disconnection of the restraint is necessary,

be sure to reconnect the device after the appliance is

returned to its original position.

Ventilation & Air Supply

The area in which the appliance is installed must be

adequately ventilated to provide air for combustion, removal

of products of combustion and removal of steam, etc. Proper

ventilation is essential for optimum performance.

The ideal method of ventilating equipment is the use of a

properly designed canopy which should extend six inches,

(152mm), beyond all sides of the appliance(s) and six feet, six

inches, (1981mm), above the oor.

A strong exhaust will create a vacuum in the room. For an

exhaust vent to work properly, replacement air must enter

the room. The amount of air that enters must equal the

amount exhausted. All gas burners and pilots need sucient

air to operate. Large objects should not be placed in front of

the appliance(s) which would obstruct the ow of air into the

front.

Gas Connection:

The gas pipe connection is made at the rear right hand side

of the equipment. The size of the pipe work supplying the

appliance must not be less than the inlet connection which

is 3/4” NPT. An isolating valve is recommended to be close to

the appliance to allow shut down during an emergency or

routine servicing. After installation, the complete pipe work

must be checked for soundness.

Part # 4517957 Rev.13 (02/10/11) Page 7

Page 8

INSTALLATION continued

TABLE A. Gas Flow Rate (total)

NATURAL GAS ( ft3/h ) PROPANE GAS (ft3/h )

113 42

TABLE B. Heat Input Per Burner

NOMINAL HEAT INPUT

BURNER

kW BTU/HR MJ/HR kW BTU/HR MJ/HR

GRIDDLE 7.32 25,000 26.37 7.32 25,000 26.37

HOT TOP 7.32 25,000 26.37 7.32 25,000 26.37

OVEN 11.14 38,000 40.08 8.79 30,000 31.65

TABLE C. Manifold Pressure / Injector Size

BURNER

GRIDDLE 11.2 4.5 42 2.4 25 10 53 1.51

HOT TOP 11.2 4.5 41 2.45 25 10 — 1.5

OVEN 11.2 4.5 31 3.05 25 10 51 1.7

NOTE: The pressure must be measured at the pressure test nipple located on the main manifold, located at the left hand front

of the range where the hot top valve is situated, with all burners lit.

Manifold Pressure Injector Size Manifold Pressure Injector Size

mbar "W.C. DMS mm mbar "W.C. DMS mm

NATURAL GAS PROPANE

NATURAL GAS PROPANE

TABLE D. Adjustment Pressure for “MIN” Valve Position (Hot Top section)

NATURAL GAS PROPANE

mbar "w.c. mbar "w.c.

2.0 0.8 4.5 1.8

NOTE: The pressure must be measured at the test nipple located downstream of the gas valve.

TABLE E. Aeration Shutter Setting / Pilot Flame Length

SHUTTER OPENING

BURNER

OVEN 19 0.750 19 0.750 25.4 1

GRIDDLE 41.3 1.625 41.3 1.625 25.4 1

HOT TOP 41.3 1.625 41.3 1.625 12.5 0.5

NATURAL GAS PROPANE

mm Ins. mm Ins. mm Ins.

PILOT FLAME LENGTH

Part # 4517957 Rev. 13 (02/10/11)Page 8

Page 9

INSTALLATION continued

Commissioning:

The whole of the gas installation, including the meter, should

be inspected, purged and tested for leakage in accordance

with local codes.

1. Ensure that all controls are in the o position and turn on

the main gas supply and electrical mains.

2. Remove the screws securing the front fascia and connect

a U-gauge manometer to the pressure test point on the

main manifold. Operate the main burners in accordance

with the instructions given in the User’s manual.

3. Check that the setting pressure is correct per TABLE C

on the previous page. If necessary, adjust the pressure

governor located at the rear of the range, downstream of

the shut-o valve, to give the required setting.

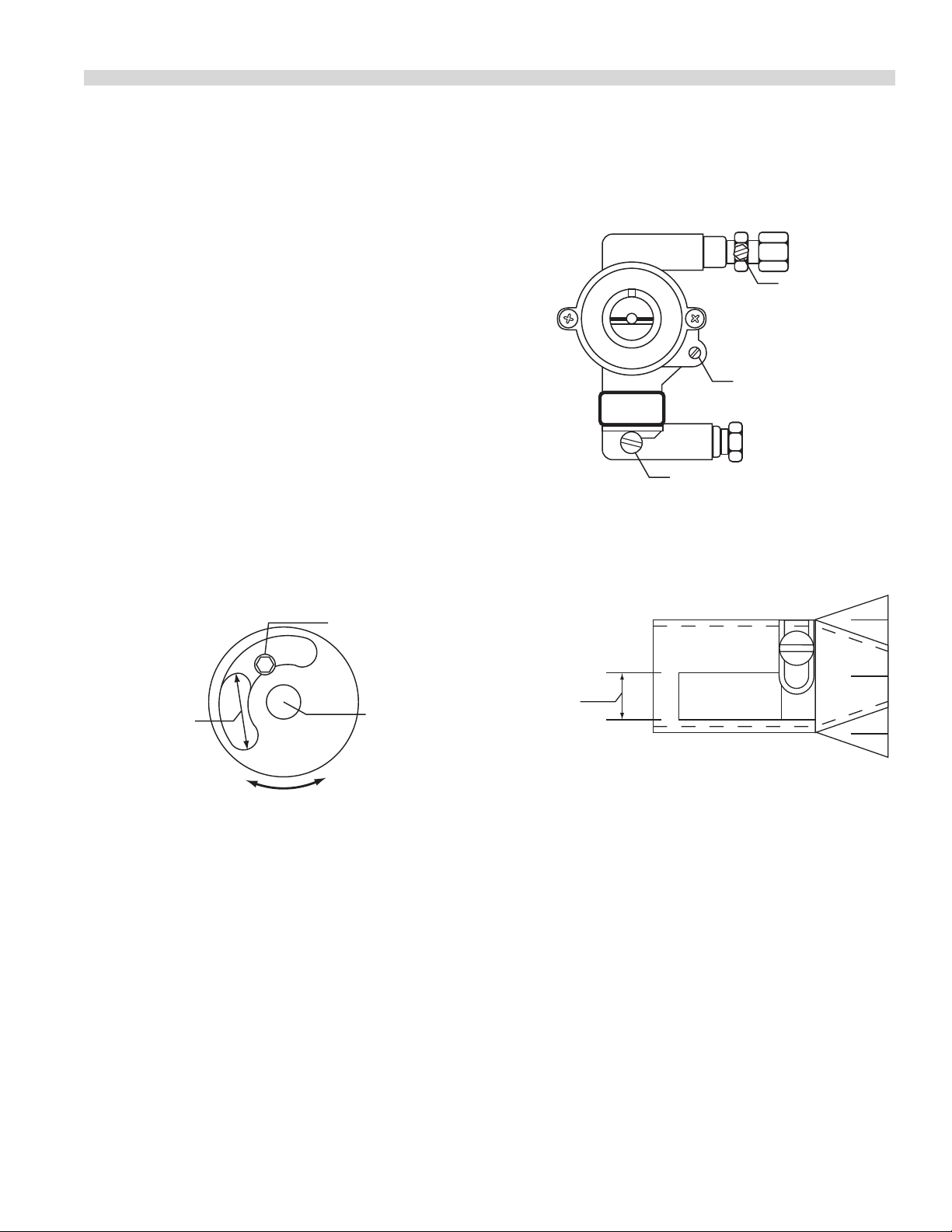

Burner Adjustments:

Griddle /Solid Hot Top Burner

Check that the aeration shutter is set to provide the

required opening per table E on the previous page. Adjust if

necessary.

3. With a at screwdriver, turn the adjuster on the body of

the tap clockwise to reduce the pressure or anti-clockwise

to increase pressure. Set the pressure to correspond with

table D.

PILOT

ADJUSTER

LOW FLAME

ADJUSTER

TEST POINT

Oven Burner

1. Check that the aeration shutter is set to the required

opening per table E. Adjust if necessary.

FIXING SCREW

SHUTTER

OPENING

MEASUREMENT

INJECTOR

LOCATION

Hot Top Minimum Flame Setting

1. Set the gas tap to the MIN position.

2. Connect a U-gauge manometer to the pressure test

nipple located downstream of the gas tap.

SHUTTER

OPENING

MEASUREMENT

When all the settings have been checked, remove the Ugauge manometer, replace the pressure test point screw and

the lower front panel.

Instruct the user or purchaser in the ecient and safe

operation of the appliance.

Tell the user of the location of the gas isolation cock for use

in an emergency. Leave this User Installation and Servicing

Instruction Manual with the user or purchaser.

Part # 4517957 Rev.13 (02/10/11) Page 9

Page 10

OPERATION

Safety concerns

It is the responsibility of the supervisor or equivalent

person to ensure that users of this equipment wear suitable

protective clothing and draw attention to the fact that some

parts will by necessity become very hot and will cause burns

if touched accidentally.

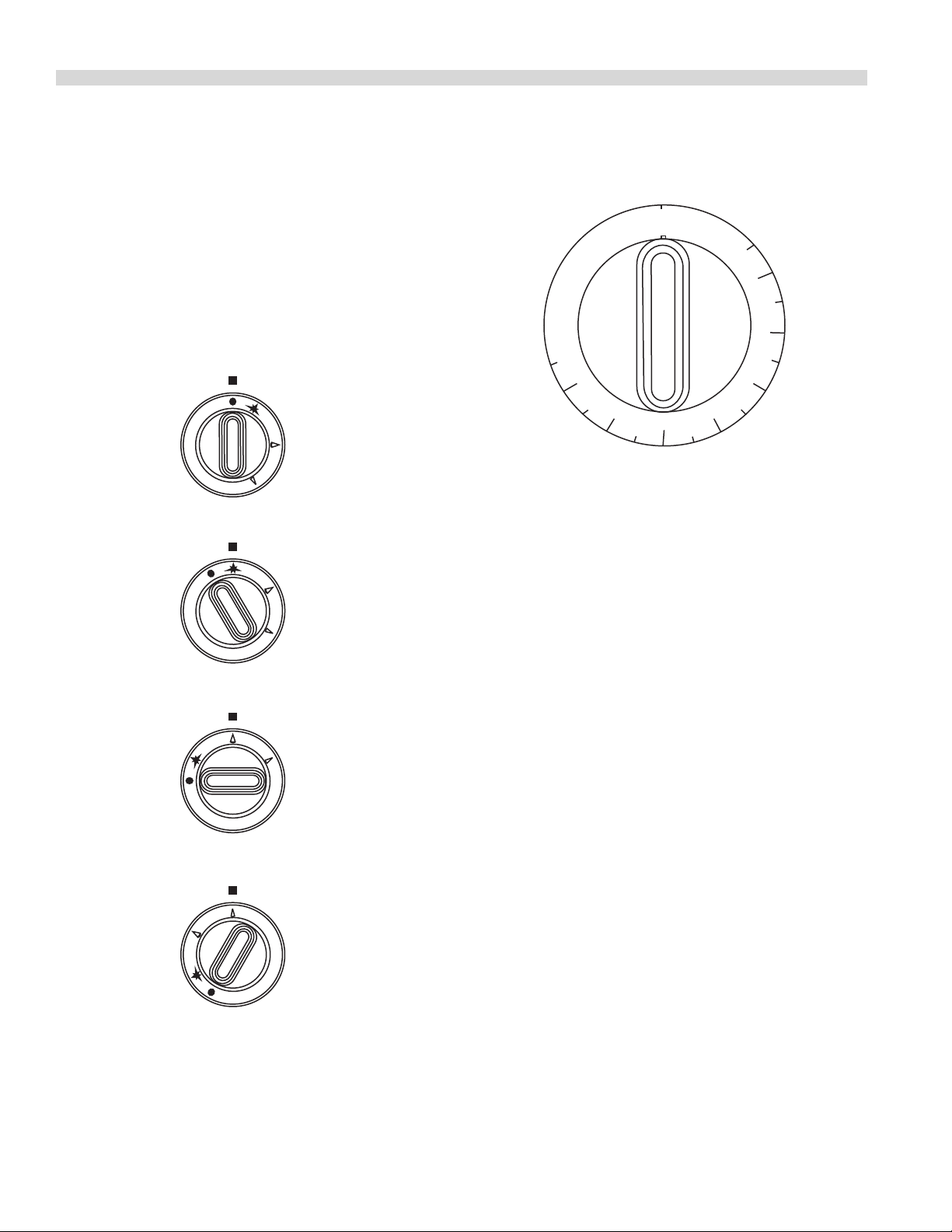

Operation Controls

SOLID TOP (STW286A)

OFF

OVEN/GRIDDLE TOP

F

F

O

0

F

4

°

4

1

2

6

2

0

5

1

0

0

2

0

5

2

0

Griddles

Griddle tops are designed to have food cooked directly on

the surface. Do not put pots or pans on the griddle surface as

this will scratch or nick the surface and will result in improper

cooking or sticking of the product. Never salt food over the

griddle since this will build up a gummy residue making it

dicult to clean.

5

0

0

4

5

0

4

0

0

3

5

0

3

0

IGNITION

FULL FLAME

LOW FLAME

Avoid hitting the surface of the griddle with the edge of a

spatula since this will cause nicks. The most frequently used

temperatures are 300° F (149°C) to 350°(177°C). After one

ring, the griddle plate will discolour, this is normal and will

not aect cooking performance.

Check the grease container and drain frequently during

heavy use to prevent overow.

Preparing A New Griddle

1. Remove the protective coating on the surface using a

mild detergent.

2. Thoroughly rinse the griddle with vinegar and a water

solution (3/4 cup vinegar per quart of water) and dry.

Lighting The Griddle

NOTE: Ensure that the gas and electrical supply to the

appliance are turned “ON”. During the initial ignition cycle, air

must be purged from the gas line and thus it may take two or

three tries for ignition to occur.

Part # 4517957 Rev. 13 (02/10/11)Page 10

Page 11

OPERATION continued

1. Turn the power switch to the “ON” position.

2. Set the thermostat to the desired temperature.

3. If ignition fails and /or the ignition system goes into

lockout, set the power switch to the “O” position.

4. Wait ve minutes and repeat steps 1 and 2. If the problem

persists have the unit checked by a competent service

technician.

Seasoning The Griddle

1. Use a clean cloth, rub a thin and even layer of oil into the

griddle surface. Oil should be an unsalted shortening or

high temperature cooking oil.

2. Set the griddle thermostat to 131°F (55°C) and heat

the griddle surface until the oil begins to caramelize

(turn a golden brow colour). Once this occurs, turn the

thermostat to “O”.

3. Scrape o the caramelized oil with a standard spatula.

4. Repeat step 1 and set the griddle thermostat to 275°F

(135°C).

3. When the pilot is lit, continue to hold the tap for 20

seconds, then release it. If the pilot extinguishes or fails to

hold, wait ve (5) minutes and then repeat step 1.

4. When the pilot is established, push the tap in again and

turn it anti-clockwise to the full ame position “ ” thus

lighting the main burner.

5. For low ame or simmer, push the tap in again and turn it

anti-clockwise to the low ame “ ” position.

6. To shut the burner o, turn the dial to the “ ” position

and the safety device will disengage within 60 seconds.

Oven

The temperature is automatically controlled by the

thermostat so that satisfactory cooking can be repeated. For

the best performance the following instructions should be

followed.

GRID SHELVES – There are three shelf positions. The shelf

position is governed by the size of the product to be cooked.

Always push the shelf back into the oven until it stops by

making contact with the rear of the oven.

5. Repeat steps 2 & 3. The griddle is now seasoned and

ready for use.

Shut Down

1. Set the thermostat to the lowest setting and turn the

power switch to the “O” position.

Solid Hot Tops (STW286A)

Recommended where long term stock pot cooking is

required for soups, sauces or stocks. Pots can be placed

anywhere on the hot top. The maximum recommended

stockpot size is 12” (305mm) in diameter.

The recommended pre-heat time is 30 minutes. This will

thoroughly saturate the plate. Pots must have at bottoms

for maximum contact with the hot surface. Roasting pans

with straps should never be used on a top since only the

straps touch the surface and heat transfer will be minimal.

Lighting The Solid Hot Top

1. Push in the tap and turn it anti-clockwise to the ignition

position “ ”.

2. Holding the tap fully in, depress the ignitor switch button

and observe that the pilot lights. If it does not, depress

the ignitor switch button until it does.

TRAY SIZE – A cake tray may be used on each shelf. Single

trays or dishes must not be allowed to overhang the shelf

in any direction, since this will adversely aect the heat

circulation.

PREHEAT TIME – Allow at least 45 minutes after turning

the oven on from cold, with the thermostat at the desired

temperature before loading the oven with food to be

cooked. Put the food in quickly and close the oven door.

Convection Oven

The forced air range oven consists of a food preparation

chamber completely sealed from the combustion area. This

permits an ecient method of circulating the heated air

within the cooking chamber.

Lighting the Oven

NOTE: Ensure that the gas and electrical supply to the

appliance are turned “ON”. During the initial ignition cycle, air

must be purged from the gas line and thus it may take two to

three tries for ignition to occur.

1 Turn the power switch to the “ON” position and the Cook/

cool switch to the “COOK” position.

2 Set the thermostat to the desired position.

Part # 4517957 Rev.13 (02/10/11) Page 11

Page 12

OPERATION continued

3. If ignition fails and or the ignition system goes into

lockout, set the power switch to the “O” position.

4. Wait ve minutes and repeat steps 1 and 2. If a problem

persists have the unit checked by a competent

technician.

Shut Down

1. Set the thermostat to the lowest setting and turn the

power switch to the “O” position.

MAINTENANCE & CLEANING

Operating Suggestions

1. Turn the power switch to the “O” position when the range

is not in use.

2. Clean the range as soon as possible after cooking tomato

or vinegar based products that have a high acid content.

These foods can cause pitting of the surface.

3. Allow the oven to preheat before adding product.

4. During an electrical power interruption, turn the power

switch to the “O” position. The oven cannot be made to

operate without electrical power

Regular servicing by a competent person is recommended

to ensure the continued safe and ecient performance of

the appliance. The frequency will vary, depending on the

installation conditions and usage. Usually once per year is

adequate.

WARNING: Turn o the gas supply to the appliance at the

service cock and the electrical mains before commencing

any servicing work.

IMPORTANT: Test for gas leakage on completion of any

servicing work.

A regular cleaning schedule should be established to ensure

ecient operation.

WARNING: This appliance is not protected against water

jets. Do not clean with water jets.

Stainless steel

Stainless Steel should be cleaned using a mild detergent,

a soft cloth and hot water. If it is necessary to use a nonmetallic scouring pad, always rub in the direction of the grain

in the metal to prevent scratching. Wash a small area at a

time and rinse the washed area with a clean sponge dipped

into a disinfectant and wipe dry with a soft clean cloth before

it can dry.

Use only stainless steel, wood or plastic tools to scrape o

heavy deposits of grease or oil. Do not use ordinary steel

scrapers or knives as particles of iron my become embedded

and rust. NEVER USE STEEL WOOL.

Exhaust Filter

Inspect the front exhaust lter weekly, if on inspection the

lter appears dirty it can be cleaned by hand with hot water

and dish detergent. The lter is easily removed by sliding out

of the lower front panel of the unit.

Enameled/Painted Surfaces

Establish a regular cleaning schedule. Any spills should be

wiped o immediately. The unit should be allowed to cool

down before cleaning any exterior surfaces. Wipe exposed

cleanable surfaces when cool with mild detergent and

hot water. Stubborn residue spots may be removed with a

scouring pad. Dry thoroughly with a clean cloth.

Part # 4517957 Rev. 13 (02/10/11)Page 12

Page 13

MAINTENANCE & CLEANING continued

Griddle

Cleaning instructions (After each use)

1. Use a traditional 2.5”-3” (64mm-76mm) scraper or spatula

to scrape the griddle surface (to remove food particles

and oil residues) towards the grease trough using even

back to front strokes.

2. Pour shortening or oil onto the griddle surface using a

straight front to back motion. Clean the griddle using a

griddle stone or grill screen. Always wipe with the grain

of the steel, never sideways.

3. Using a clean cloth, rub a thin and even layer of oil into

the griddle surface.

4. Remove the grease drawer, empty and wash thoroughly

with soap and water. Replace.

Cleaning Instructions (For Heavy Build Up)

NOTE: After using cleaners & grease cutter, re-season the

griddle.

NOTE: Apply to a warm griddle for best results.

1. Using a traditional 2.5”-3” (64mm-76mm) scraper or

spatula scrape the griddle surface (to remove food

particles and oil residues) towards the grease trough

using even back to front strokes.

Griddle Do’s & Don’ts

Do’s

1. Season the griddle, This will prevent foods from sticking

and make it easier to keep the surface clean.

2. Keep the surface clean. Scraping the surface throughout

production to clear foods and oils prevents build up and

will make it easier to keep the surface clean.

3. Turn the temperature down during slow periods.

Reducing the temperature or turning sections o during

slow periods will conserve energy and prevent the plate

from over heating.

Don’ts

1. Do not use salt to clean the griddle surface. Salt is

corrosive and can cause pitting of the griddle.

2. Do not allow metal utensils (Spatula, scraper, etc.) to

nick and/or dent the surface of the griddle, The edges of

these utensils are sharp and will create divots that oil can

collect in and caramelize which will cause sticking.

3. Do not use the griddle as a hot top. A large pan or pot will

trap heat and cause the griddle plate to warp.

4. Do not overheat the griddle to preheat faster. Preheating

takes 15-20 minutes.

2. Apply griddle cleaner evenly over the griddle surface and

let it sit as directed. Follow the procedures on the label of

the specic cleaning product.

3. Using a traditional scraper or spatula, slosh around the

griddle cleaner to remove the build up.

4. Scrape the griddle surface towards the grease-trough

using even back to front strokes. Repeat step 2 if

necessary.

5. Using a mild detergent, clean the surface and rinse

thoroughly with water and vinegar solution, Dry the

griddle.

6. Using a clean cloth rub a thin and even layer of oil into

the griddle surface.

7. Re-season the griddle as detailed in griddle operation.

The griddle is now ready for use.

Cleaning Burners

Griddle / Solid Hot Plate

1. Lift o the griddle plate or solid hot top. Use caution: This

will require assistance due to the weight of the griddle /

solid hot top.

2. Lift the rear of the burner and slide backwards o the

injector tting.

3. Clean the burners in hot soapy water with a sti

scrubbing brush.

4. Rinse and shake well to remove any debris.

5. Reassemble in the reverse order.

Part # 4517957 Rev.13 (02/10/11) Page 13

Page 14

MAINTENANCE & CLEANING continued

Convection Oven

1. Open the lower kick panel.

2. Remove the left & right hand oven door springs. USE

CAUTION: the oven door will need additional support to

remain closed.

3. Remove the left and right hand radiation shields.

4. Remove the two (2) screws that secure the pilot bracket

and disconnect the pilot tubing at the union connection.

5. Remove the injector support and slide the burner and

burner pan forwards out of the combustion chamber.

6. Clean the burner with a sti scrubbing brush and shake

the burner well to ensure that ports are clear of any

debris.

7. Reassemble in the reverse order.

Pilot Burner Cleaning

1. Remove the main burners (refer to the section on main

burner cleaning).

2. Disconnect the pilot gas supply pipe from the pilot jet.

3. Remove the pilot jet.

1. Place the thermocouple of the test instrument in the

center of the oven.

2. Turn the oven temperature control dial to 400°F. In order

to allow the oven temperature to stabilize, the oven

control must be allowed to cycle twice before taking a

test reading.

3. Check the temperature reading just when the control

cycles “OFF” as indicated by cycling pilot lamp. If the

temperature does not read within 15°F of the dial setting,

recalibrate as follows:

4. Carefully remove the thermostat dial, not disturbing the

dial setting.

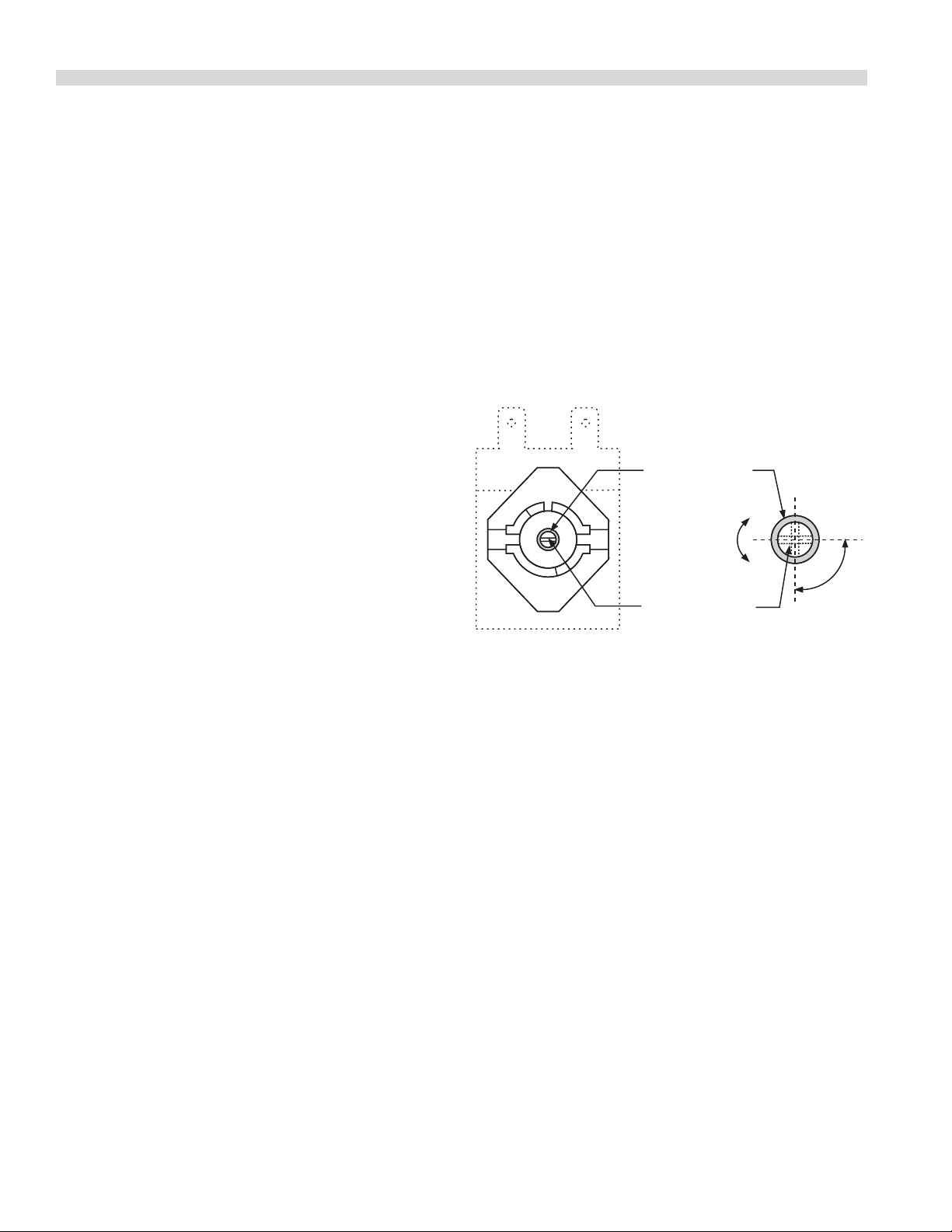

"B" Dial Shaft

Decrease

Increase

1/4

Turn

"A" Calibration

Screw Head

4. Clean by blowing through or washing. Do not use wire to

clear the pilot jet.

5. Reassemble in the reverse order.

Gas Valve

Re-greasing of the gas taps is not recommended. If the

tap spindle becomes seized or dicult to turn, refer to

Replacement of Parts section in this manual.

Thermostat Calibration

Oven

It is normal for a hydraulic thermostat cycling with a

temperature dierential of 45° to 50°F. If the thermostat

is cycling beyond the 15° tolerance above or below the

set point and the appliance is under warranty, recalibrate

the thermostat or if not under warranty, consult owner for

proper action. If the thermostat is out of calibration more

than 50°, it will not likely hold an attempt of recalibration. We

suggest that the thermostat be replaced.

5. Hold the thermostat shaft steady and with a small at

blade screw driver, turn the calibration screw located

inside the shaft clockwise to decrease the temperature

and anti-clockwise to increase the temperature. Note:

Each 1/4 turn of the screw will create a change of

approximately 25°F.

6. Replace the thermostat dial and repeat steps 1 through 3

to verify that correct adjustment has been made.

Griddle

1. Use a test instrument with a special disc type

thermocouple or a reliable surface type pyrometer. Note:

a drop of oil on the face of the disc will provide better

contact with the plate.

2. Set all griddle thermostats to 300°F. In order to allow the

griddle temperature to stabilize, the thermostats must be

allowed to cycle twice before taking a test reading.

Part # 4517957 Rev. 13 (02/10/11)Page 14

Page 15

MAINTENANCE & CLEANING continued

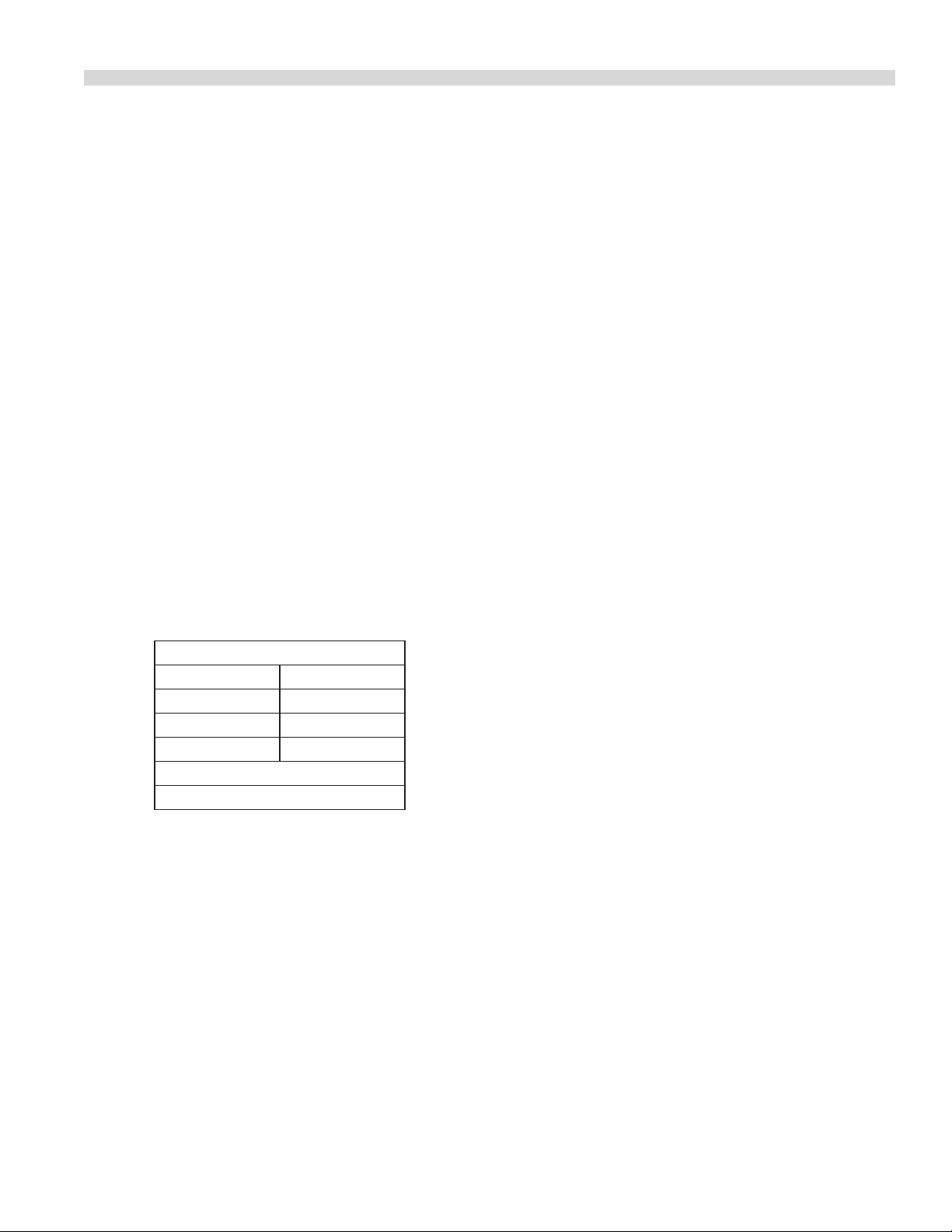

TOP VIEW

5. Hold the thermostat shaft steady and with a small at

blade screw driver, turn the calibration screw located

inside the shaft clockwise to decrease the temperature

and anti-clockwise to increase the temperature. Note:

Each 1/4 turn of the screw will create a change of

approximately 25°F.

6. Replace the thermostat dial and repeat steps 1 through 3

to verify that correct adjustment has been made.

Miscellaneous

1. Grease the door hinges and check for loose fasteners.

Tighten as necessary.

28.0

24.012.0

6.0 6.0

GRIDDLEHOT TOP

12.0

7.3

ref.

11.5

Place

Thermocouple

Here

36. 0

FRONT

To nd the location of the sensing bulbs, locate the exact

center of the griddle. Measure 6" to the left and 6" to the

right. Place the temperature sensor there.

3. Check the griddle temperature when the thermostat just

cycles “OFF” by placing the thermocouple rmly on the

griddle surface directly above the sensing bulb of the

thermostat. (see the following diagram for how to nd

the location directly above the thermostat sensing bulb)

The reading should be between 285°F and 315°F. If the

reading is outside of these limits, calibrate as follows:

4. Carefully remove the thermostat dial, not disturbing the

dial setting.

2. Wire brush the surface of the griddle to remove baked

on material, wash with hot water, dry thoroughly. Lightly

coat the surface with vegetable oil to prevent rusting.

3. Wipe exposed cleanable surfaces with a mild detergent

and hot water. Stubborn residue may be removed with

a lightweight non-metallic scouring pad. Stainless steel

areas should be washed with a mild detergent, hot

water and a soft cloth. If necessary to use a non-metallic

scouring pad always rub in the direction of the grain in

the metal to prevent scratching. NEVER USE STEEL WOOL.

4. Check the operation of the ame safety device by closing

the gas supply during burner operation. Listen for the

ame failure valve on the combination gas control

“clicking” closed. This action must occur within 1 second

of extinguishing the main burner ame.

5. Clean the oven racks, shelves and guides with hot soapy

water and dry thoroughly. Clean the oven interior with

a propriety oven cleaner following the manufacturers

instructions.

Part # 4517957 Rev.13 (02/10/11) Page 15

Page 16

CONVERSION INSTRUCTIONS

Servicing must be carried out by a competent person in

accordance with the law.

WARNING: Turn o the gas supply to the appliance at the

service cock and the electrical mains before commencing

any servicing work.

IMPORTANT: Test for gas leakage on completion of any

servicing work.

The following instructions are intended to describe the

operations necessary to convert equipment from operation

on one gas to another.

1. Ensure that all of the parts necessary to make the

conversion have been supplied as follows:

a. Injector ttings ( One required for each main burner

& one required for each pilot).

b. Regulator, (one per unit ).

If any of the required parts are missing, contact your

Garland dealer before attempting to carry out the

conversion.

2. Remove the burners following the instructions given in

this manual.

3. Replace each injector tting with the new tting that is

supplied.

NOTE: Before doing so, refer to Table C in this manual to

ensure that the correct injector has been supplied for the

gas supply being converted to.

4. Replace the spring in the governor with the new spring

supplied.

Upon completion of all the above operations, follow the

section in the manual on “Commissioning” and ensure

that the setting pressure and all burner ame settings are

adjusted accordingly.

Part # 4517957 Rev. 13 (02/10/11)Page 16

Page 17

FAULT FINDING

PROBLEM POSSIBLE CAUSES SOLUTION

No power to oven. Check power supply.

Cook/Cool Down switch set to “Cook”

position. Light o. Motor not working.

Cook/Cool Down switch set to “Cook”

position. Light on motor not working.

Cook/Cool Down switch set to”Cook.”

Motor working thermostat set to

temperature, lamp “on,” oven not

heating.

Noisy convection oven.

Cook/Cool Down switch set to “Cool

Down”, motor not working.

Oven too hot or not hot enough Thermostat out of calibration. Check calibration/replace thermostat.

No spark to igniter

Spark to igniter,thermostat set to

temperature. Burner does not go on.

Oven doors will not stay closed. Broken or damaged door spring Replace door spring

Defective Cook/Cool Down switch Replace switch.

Faulty wiring.

Defective door switch. Replace switch

Oven door partially open. Close door.

Door switch out of alignment. Align switch.

Defective motor. Replace motor.

Faulty wiring.

Faulty motor relay Replace relay

Combination gas valve not opening. Defective thermostat replace.

Defective valve/thermostat Replace valve/thermostat.

Blower wheel rubbing on oven bae Adjust blower wheel.

Blower wheel loose on motor shaft. Retighten blower wheel.

Defective motor Replace motor.

Defective Cook/Cool down switch. Replace switch.

Defective door switch. Replace switch.

Door switch out of alignment. Align switch.

Faulty wiring.

Disconnected or loose hi voltage

wires.

Defective DSI control module. Replace DSI module

No power to oven Check power supply.

Defective combination gas valve. Replace valve.

Defective thermostat controller. Replace controller

Check condition of all wires &

connections

Check condition of all wires &

connections

Check condition of all wires &

connections

Reconnect hi voltage wires.

Wiring Diagrams can be found at the end of this manual. A relevant schematic can be found on the inside of the control panel

when it is slid out for service.

Part # 4517957 Rev.13 (02/10/11) Page 17

Page 18

REPLACEMENT OF PARTS

WARNING: Turn o the gas supply to the appliance at the

service cock and the electrical mains before commencing

any servicing work.

IMPORTANT: Test for gas leakage on completion of any

servicing work.

Gas Taps

1. Pull the knob o of each gas tap and thermostat on the

unit.

2. Remove the screws securing the fascia panel and remove

panel and grease drawer.

3. Remove the appropriate burner (if necessary) following

the procedure given in the section on Main Burner

Cleaning.

4. Disconnect the thermocouple connection at the gas tap.

5. Disconnect the pilot and main burner tubing connections

at the gas tap.

6. Disconnect the tubing connection at the inlet of the gas

tap and remove the tap.

7. Replace with the new tap.

8. Reassemble in the reverse order.

Door Switch

3. Disconnect the wires from the taps on the switch. Be sure

to note which wire connects to which terminal on the

switch.

4. Depress the tabs of the switch body and push the switch

through the opening in the control panel.

5. Replace the switch and reassemble in the reverse order.

Thermostat

1. Remove the fastener securing the control compartment

access panel.

2. Slide out the control drawer to access the thermostat.

3. Remove the dial from the thermostat and the screws

securing the thermostat body to the control panel.

4. Remove the wires from the thermostat terminals. Be sure

to note which wire connects to which terminal on the

thermostat.

5. Remove the thermostat sense bulb.

6. Replace the faulty thermostat and reassemble in the

reverse order.

Heat-On Lamp

1. Remove the fastener securing the control compartment

access panel.

1. Remove the lower kick panel.

2. Disconnect the wires from the terminals on the body of

the switch.

3. Remove the screws securing the door switch to the

mounting bracket and remove the door switch.

4. Replace the faulty door switch.

5. Make certain that the newly installed door switch is

properly adjusted so as to interrupt the power supply

to the gas control system and fan motor when the oven

doors are opened.

Control Panel Rocker Switches

1. Remove the fastener securing the control compartment

access panel.

2. Slide out the control drawer to access the switch.

2. Slide out the control drawer to access the lamp.

3. Disconnect the supply wires to the lamp body and

remove the faulty lamp.

4. Reassemble in the reverse order.

Gas Control Valve

1. Remove the fastener securing the control compartment

access panel.

2. Slide out the control drawer.

3. Remove the main body side panel to access the gas train.

4. Break the pipe union connection at the inlet of the gas

control and the 7/16” union connection located at the

outlet of the control.

5. Remove the wires from the connections to the gas valve.

Be sure to note which wires connect to which terminal

before doing so.

Part # 4517957 Rev. 13 (02/10/11)Page 18

Page 19

REPLACEMENT OF PARTS continued

6. Replace the control and reassemble in the reverse order.

Front Cooling Fan

1. Remove fastener securing the control compartment

access panel.

2. Slide out the control drawer.

3. Disconnect the fan supply harness form the unit wiring

harness.

4. Remove fasteners retaining the fan and set aside.

5. Replace the faulty motor.

6. Reassemble in the reverse order.

Motor

1. Open the oven doors.

2. Remove the oven racks and guides.

3. Remove the two (2) wing screws securing the fan guard

and remove the guard.

Ignition Control

1. Remove the fastener securing the control compartment

access panel.

2. Slide out the control drawer to access the lamp.

3. Disconnect the supply wires to faulty ignition control

(noting the wire connections)

4. Replace the faulty control.

6. Reassemble in the reverse order.

Hot Top Ignition Momentary Switch

1. Remove the griddle grease drawer.

2. Remove the fasteners securing the front panel.

3. Remove the nuts securing the switch box to the front

panel.

4. Disconnect the 2 wires to the switch.

5. Unscrew the switch from the front panel.

4. Using an allen head wrench loosen the screw securing

the blower wheel to the motor shaft and remove the

wheel.

5. Remove the four (4) screws securing the motor mount

plate to the oven casing back and pull the plate forward

into the oven compartment.

6. Disconnect the motor wire connections (note which wire

connects to which) and replace faulty motor.

8. Reassemble in the reverse order.

6. Replace the switch and reassemble in reverse order.

Hot Top Spark Generator

1. Remove the fastener securing the control compartment

access panel.

2. Slide out the control drawer to access the generator

module.

3. Disconnect the wires to the generator.

4. Remove fastener retaining the generator.

5. Replace the faulty module and reassemble in reverse

order.

Part # 4517957 Rev.13 (02/10/11) Page 19

Page 20

WIRING DIAGRAMS

REV.#

DATE

DR.DESCRIPTION

49

REVISIONS

55

55

55

E4

MOTOR: 1/3hp, 115V, 50/60Hz, 3.6 AMP,

230V, 50/60Hz, 1.8 AMP

PAPST COOLING FAN:

115V MODEL 4606N 50/60 HZ, 18W

230V MODEL 4656N 50/60 HZ, 18W

SOLENOID VALVES (EACH):

24V, 50/60Hz, 0.4A MAX.

SP845 IGNITION MODULE:

24V, 50/60Hz, 0.25A

FLAME SENSE CURRENT 0.7 MICROAMPS MINIMUM REQUIRED

HOT TOP IGNITION MODULE

100-120V 0.6VA

220-240V 0.8VA TOTAL MAXIMUM LOAD:

120V 50/60Hz, 4.5 AMPS

230V 50/60Hz, 2.3 AMPS

HOT TOP

HOT TOP SPARK ELECTRODE

I

POWER SWITCH

48

ON

6

0

OFF

7

5

COOK/COOL SWITCH

SW1

21

27

28

30

OFF

SW2

COOL

COOK

26

I

II

0

SPARK ELECTRODE

29

19

30

7

6 8

5

BASE

OMRON

ALTERNATE

4

RELAY CONNECTION

1 3

2

FLAME SENSOR

E1

18

11

12

PL1

38

26

GRIDDLE LEFT

THERMOSTAT

F1

SPARK

SP 845

49

31

5

1431531

1431526

J1

BLACK

6

7

49

48

50

51

52

2

1

4

WHITE

3

GREEN

30

19

9

12

29

14

11

53

RELAY RL1

31

8 4

5 1 13

11

10

9

8

J2

1434533

1431528

13

15

53

52

M~

COOLING FAN

24

18

12

RED 208V

WHITE 120V

ORANGE 240V

T1

BLACK

10

16

COM

SELECT

9

14

M~

OVEN MOTOR

(With Robertshaw Ignition Control Module)

For Models Manufactured Up To Oct /04/2005, Serial # 0509100130513 &

Models Manufactured From Mar/24/2009 S/N 0903100100823 M/D STW280A-0009

3

2

1

IGNITION MODULE

48

22

25

32

21

NSEES

NDG

R

T

GND

/

VMV

P

H

T

24V

E

D

L

P

V

V

M

CTL1

17

MV1

PV1

GRIDDLE LEFT VALVE

LN

E

47

SWITCH BOX

48 47

54

27

28

23

PL2

42

24

25

33

TH1

GRIDDLE RIGHT

THERMOSTAT

TH2

42

M

V

41

20

35

32

36

38

37

35

P

V

E

D

L

24V

33

H

T

/

VMV

39

19

GND

F2

ELECTRODE

SPARK

P

R

T

NDG

NSEES

FLAME SENSOR

40

MV2

37

36

1431526

PV2

GRIDDLE RIGHT VALVE

SP 845

SPARK

E2

SPARK ELECTRODE

39

41

1431526

CTL2

17

F3

E3

FLAME SENSOR

40

PL3

OVEN THERMOSTAT

18

E

S

N

E

S

D

N

G

SPARK

46

31

TH3

43

V

GND

M

/

R

V

T

P

ALL DIMENSIONS ARE IN INCHES

TOLERANCE ±0.015" UNLESS OTHERWISE SPECIFIED

REV

SW3

N

N

CO

29

34

46

44

34

V

D

24V

E

MVP

H

L

T

SP 845

MV3

OVEN VALVE

PV3

STW286A

:

DATE

:

SCALE

:

CHK. BY

NOV 29/97NAV.C.

21

SHT OF

4517604

WIRING DIAGRAM STW286A

:

TITLE:

DR.

45

CTL3

45

43

44

1431526

Part # 4517957 Rev. 13 (02/10/11)Page 20

Page 21

WIRING DIAGRAMS continued

REV.#

DATE

DR.DESCRIPTION

49

REVISIONS

55

55

55

E4

MOTOR: 1/3hp, 115V, 50/60Hz, 3.6 AMP,

230V, 50/60Hz, 1.8 AMP

PAPST COOLING FAN:

115V MODEL 4606N 50/60 HZ, 18W

230V MODEL 4656N 50/60 HZ, 18W

SOLENOID VALVES (EACH):

24V, 50/60Hz, 0.4A MAX.

SP845 IGNITION MODULE:

24V, 50/60Hz, 0.25A

FLAME SENSE CURRENT 0.7 MICROAMPS MINIMUM REQUIRED

HOT TOP IGNITION MODULE

100-120V 0.6VA

220-240V 0.8VA TOTAL MAXIMUM LOAD:

120V 50/60Hz, 4.5 AMPS

230V 50/60Hz, 2.3 AMPS

HOT TOP

HOT TOP SPARK ELECTRODE

I

ON

POWER SWITCH

6

0

OFF

7

5

COOK/COOL SWITCH

SW1

21

27

28

30

OFF

SW2

COOL

COOK

26

I

II

0

PL1

26

FLAME SENSOR

GRIDDLE LEFT

THERMOSTAT

38

49

48

SPARK ELECTRODE

F1

E1

29

19

30

ALTERNATE

RELAY CONNECTION

5

OMRON

1 3

7

BASE

2

18

SPARK

6 8

11

4

SP 845

12

31

6

7

49

(With Robertshaw Ignition Control Module)

48

50

5

51

52

For Models Manufactured Up To Oct /04/2005, Serial # 0509100130513

2

1

Models Manufactured From Mar/24/2009 S/N 0903100100823 M/D STW286a-0009

1431526

1431531

4

J1

WHITE

3

x2

x3

x1

E

N

L1

30

19

9

12

29

14

11

53

RELAY RL1

31

8 4

5 1 13

11

10

9

8

J2

1434533

1431528

13

15

53

52

M~

COOLING FAN

24

18

12

RED 208V

WHITE 120V

ORANGE 240V

T1

BLACK

10

16

COM

SELECT

9

14

M~

OVEN MOTOR

3

2

1

IGNITION MODULE

48

22

25

32

21

NSEES

NDG

R

T

GND

/

VMV

P

H

T

24V

E

D

L

P

V

V

M

CTL1

17

MV1

PV1

GRIDDLE LEFT VALVE

LN

E

47

SWITCH BOX

47 47

54

27

28

23

PL2

42

24

25

33

TH1

GRIDDLE RIGHT

THERMOSTAT

TH2

42

M

V

41

20

35

32

36

38

37

35

P

V

E

D

L

24V

33

H

T

/

VMV

39

19

GND

NDG

NSEES

F2

SPARK

ELECTRODE

P

R

T

SPARK

FLAME SENSOR

40

MV2

37

36

1431526

PV2

GRIDDLE RIGHT VALVE

CTL2

SP 845

E2

E3

SPARK ELECTRODE

39

41

1431526

PL3

OVEN THERMOSTAT

17

E

S

N

E

S

F3

FLAME SENSOR

40

46

31

TH3

43

18

V

D

GND

M

N

/

R

V

G

T

P

SPARK

ALL DIMENSIONS ARE IN INCHES

TOLERANCE ±0.015" UNLESS OTHERWISE SPECIFIED

REV

SW3

N

N

CO

29

34

46

44

34

V

D

24V

E

MVP

H

L

T

SP 845

MV3

OVEN VALVE

PV3

STW286A

:

DATE

:

SCALE

:

CHK. BY

DEC 10/2003NAN.B.

21

SHT OF

4517606

WIRING DIAGRAM STW286A

:

TITLE:

DR.

45

CTL3

45

43

44

1431526

Part # 4517957 Rev.13 (02/10/11) Page 21

Page 22

WIRING DIAGRAMS continued

REV.#

DATE

DR.DESCRIPTION

49

REVISIONS

HOT TOP

IGNITION MODULE

3 AMPS

MOTOR: 1/3hp, 115V, 50/60Hz, 3.6 AMP,

230V, 50/60Hz, 1.8 AMP

PAPST COOLING FAN:

115V MODEL 4606N 50/60 HZ, 18W

230V MODEL 4656N 50/60 HZ, 18W

SOLENOID VALVES (EACH):

24V, 50/60Hz, 0.4A MAX.

G770 IGNITION MODULE:

24V, 50/60Hz, 0.2A

FLAME SENSE CURRENT 0.15 MICROAMPS MINIMUM REQUIRED

HOT TOP IGNITION MODULE

100-120V 0.6VA

220-240V 0.8VA TOTAL MAXIMUM LOAD:

120V 50/60Hz, 4.5 AMPS

230V 50/60Hz, 2.

I

49

0

ON

OFF

POWER SWITCH

SW1

7

6

5

27

28

30

OFF

SW2

COOL

COOK

26

I

II

0

COOK/COOL SWITCH

48

SPARK ELECTRODE

29

19

30

7

6 8

5

BASE

OMRON

(With Johnson Control Module)

48

6

7

49

5

1431526

J1

1431531

BLACK

For Models Manufactured From Oct /05/2005, Serial # 0510100130790 To Mar/23/2009 S/N 0903100100822

53

50

51

52

2

1

4

WHITE

3

GREEN

ALTERNATE

4

RELAY CONNECTION

1 3

2

31

30

19

9

12

29

14

18

11

RELAY RL1

31

8 4

5 1 13

11

9

8

12

10

J2

1434533

1431528

13

14

15

52

53

M~

M~

COOLING FAN

55

55

55

E4

HOT TOP SPARK ELECTRODE

21

FLAME SENSOR

GRIDDLE LEFT

E1

F1

18

32

11

12

24

16

LN

3

2

1

E

47

SWITCH BOX

48 47

48

22

PL1

PL2

38

25

26

32

TH1

THERMOSTAT

36

38

37

G 770

SENSE 4

M.V. 3

P.V. 1

THS 2

LED

5

GROUND

35

17

20

T1

54

27

28

23

42

24

25

33

GRIDDLE RIGHT

THERMOSTAT

TH2

42

41

33

40

36

5

21

39

18

17

PL3

46

31

OVEN THERMOSTAT

G 770

SENSE 4

M.V. 3

P.V. 1

THS 2

LED

GROUND

24

F2

E2

SPARK

ELECTRODE

FLAME SENSOR

CTL2

43

5

GROUND

CTL3

RED 208V

WHITE 120V

COM

BLACK

ORANGE 240V

10

SELECT

9

MV1

35

39

MV2

37

E3

FLAME SENSOR

SPARK ELECTRODE

41

40

ALL DIMENSIONS ARE IN INCHES

TOLERANCE ±0.015" UNLESS OTHERWISE SPECIFIED

REV

SW3

NO

NC

29

34

TH3

46

44

34

M.V. 3

P.V. 1

THS 2

LED

F3

MV3

36

PV1

OVEN MOTOR

1431526

GRIDDLE

LEFT VALVE

PV2

1431526

IGHT VALVE

GRIDDLE

R

PV3

OVEN VALVE

STW286A

:

DATE

JULY 10/2003NAN.B.

:

SCALE

:

CHK. BY

11

SHT OF

4520660

WIRING DIAGRAM STW286A

:

TITLE:

DR.

COM

45

SENSE 4

G 770

45

43

44

1431526

Part # 4517957 Rev. 13 (02/10/11)Page 22

Page 23

WIRING DIAGRAMS continued

REV.#

DATE

DR.DESCRIPTION

49

REVISIONS

HOT TOP

IGNITION MODULE

230V, 50/60Hz, 1.8 AMP

PAPST COOLING FAN:

115V MODEL 4606N 50/60 HZ, 18W

230V MODEL 4656N 50/60 HZ, 18W

SOLENOID VALVES (EACH):

24V, 50/60Hz, 0.4A MAX.

G770 IGNITION MODULE:

24V, 50/60Hz, 0.2A

FLAME SENSE CURRENT 0.15 MICROAMPS MINIMUM REQUIRED

HOT TOP IGNITION MODULE

100-120V 0.6VA

220-240V 0.8VA TOTAL MAXIMUM LOAD:

120V 50/60Hz, 4.5 AMPS

30

COOK

28

OFF

230V 50/60Hz, 2.3 AMPS

27

SW2

COOL

MOTOR: 1/3hp, 115V, 50/60Hz, 3.6 AMP,

49

POWER SWITCH

6

I

0

ON

OFF

SW1

7

5

26

I

II

0

COOK/COOL SWITCH

48

SPARK ELECTRODE

29

19

30

7

6 8

5

BASE

OMRON

(With Johnson Control Module)

48

6

7

49

5

1431526

For Models From Oct /05/2005, Serial # 0510100130790 To Mar/23/2009 S/N 0903100100822

J1

1431531

53

50

51

52

2

1

4

3

x2

x3

x1

E

N

L1

ALTERNATE

RELAY CONNECTION

1 3

2

4

31

30

19

9

12

29

14

18

11

RELAY RL1

31

8 4

5 1 13

10

1431528

1434533

12

J2

11

9

8

13

14

15

52

53

M~

M~

COOLING FAN

HOT TOP SPARK ELECTRODE

FLAME SENSOR

E1

F1

18

11

12

24

RED 208V

ORANGE 240V

SELECT

9

OVEN MOTOR

55

55

E4

21

GRIDDLE LEFT

32

16

T1

WHITE 120V

BLACK

10

55

LN

3

2

1

E

47

SWITCH BOX

48 47

48

22

PL1

PL2

38

25

26

32

54

27

28

23

42

24

25

33

PL3

46

31

REV

SW3

29

ALL DIMENSIONS ARE IN INCHES

TOLERANCE ±0.015" UNLESS OTHERWISE SPECIFIED

NO

NC

34

TH1

THERMOSTAT

36

38

37

SENSE 4

M.V. 3

P.V. 1

THS 2

LED

5

GROUND

17

COM

MV1

GRIDDLE RIGHT

THERMOSTAT

TH2

42

G 770

41

40

36

35

21

20

SENSE 4

M.V. 3

P.V.

1

THS 2

33

LED

5

GROUND

39

24

18

17

39

35

MV2

37

OVEN THERMOSTAT

TH3

G 770

F2

E2

SPARK

ELECTRODE

FLAME SENSOR

CTL2

5

GROUND

CTL3

46

43

44

34

M.V. 3

P.V. 1

THS 2

LED

F3

E3

FLAME SENSOR

SPARK ELECTRODE

41

MV3

40

36

PV1

GRIDDLE

LEFT VALVE

1431526

PV2

RIGHT VALVE

GRIDDLE

1431526

PV3

OVEN VALVE

STW286A

4520661

11

SHT OF

:

DATE

JULY 10/2005NAN.B.

:

SCALE

:

CHK. BY

WIRING DIAGRAM STW286A

:

TITLE:

DR.

COM

45

SENSE 4

G 770

45

43

44

1431526

Part # 4517957 Rev.13 (02/10/11) Page 23

Page 24

WIRING DIAGRAMS continued

MOTOR: 1/3hp, 115V, 50/60Hz, 3.6 AMP,

230V, 50/60Hz, 1.8 AMP

PAPST COOLING FAN:

115V MODEL 4606N 50/60 HZ, 18W

230V MODEL 4656N 50/60 HZ, 18W

SOLENOID VALVES (EACH):

24V, 50/60Hz, 0.4A MAX.

SP845 IGNITION MODULE:

24V, 50/60Hz, 0.25A

FLAME SENSE CURRENT 0.7 MICROAMPS

MINIMUM REQUIRED

HOT TOP IGNITION MODULE

100-120V 0.6VA

220-240V 0.8VA

TOTAL MAXIMUM LOAD:

120V 50/60Hz, 4.5 AMPS

230V 50/60Hz, 2.3 AMPS

REV.#

DATE

DR.DESCRIPTION

REVISIONS

ALL DIMENSIONS ARE IN INCHES

TOLERANCE ±0.015" UNLESS OTHERWISE SPECIFIED

REV

STW286A

:

DATE

DEC 10/2003NAN.B.

:

SCALE

:

CHK. BY

SCHEMATIC DIAGRAM, 120V

:

TITLE:

DR.

N

SHT OF

4517605

For All Models

FLAME SENSOR

SPARK ELECTRODE

GND

SENSE

IGN

IGNITION CONTROL

GRIDDLE LEFT

PV1

MV1

PL1

SPARK ELECTRODE

TH

PV

MV

IGN

IGNITION CONTROL

CTL1

TH1

FLAME SENSOR

TH

GND

SENSE

GRIDDLE RIGHT

PV2

TH2

PV

MV2

MV

CTL2

PL2

SPARK ELECTRODE

IGN

IGNITION CONTROL

FLAME SENSOR

GND

SENSE

OVEN

13(7) 5(3)

PV3

MV3

PL3

TH

PV

MV

CTL3

TH3

RL1a

RL1

13(7) 14(8)

SW3

COM

NO

NC

DOOR SWITCH

COOL

COOK

OFF

SW2

COOK-COOL SWITCH

M~

IGNITION MODULE HOT TOP

RL1b

T1

24V ~

4A

12(6) 8(4)

120V ~

M~

COOLING FAN

SPARK ELECTRODE HOT TOP

PB

SW1

POWER

L1

Part # 4517957 Rev. 13 (02/10/11)Page 24

Page 25

WIRING DIAGRAMS continued

MOTOR: 1/3hp, 115V, 50/60Hz, 3.6 AMP

230V, 50/60Hz, 1.8 AMP

SOLENOID VALVES (EACH)

24V, 50/60Hz, 0.4A MAX.

SP845 IGNITION MODULE:

24V, 50/60Hz, 0.25A

FLAME SENSE CURRENT 0.7 MICROAMPS MINIMUM REQUIRED

TOTAL MAXIMUM LOAD:

120V 50/60Hz, 4.5 AMPS

230V 50/60Hz, 2.3 AMPS

REV.#

DATE

DR.DESCRIPTION

REVISIONS

ALL DIMENSIONS ARE IN INCHES

TOLERANCE ±0.015" UNLESS OTHERWISE SPECIFIED

REV

STW286A

:

DEC 8/97NAVC

DATE

:

SCALE

:

CHK. BY

SCHEMATIC DIAGRAM, 230V

:

TITLE:

DR.

N

SHT OF

4517607

For All Models

FLAME SENSOR

SPARK ELECTRODE

GND

SENSE

IGN

IGNITION CONTROL

GRIDDLE LEFT

PV1

MV1

PL1

SPARK ELECTRODE

TH

PV

MV

IGN

IGNITION CONTROL

CTL1

TH1

FLAME SENSOR

GND

SENSE

GRIDDLE RIGHT

PV2

MV2

PL2

SPARK ELECTRODE

TH

PV

MV

IGN

IGNITION CONTROL

CTL2

TH2

FLAME SENSOR

GND

SENSE

OVEN

13(7) 5(3)

PV3

MV3

PL3

RL1

13(7) 14(8)

warning light

TH

PV

MV

CTL3

TH3

RL1a

thermodisc

SW3

COM

NO

NC

DOOR SWITCH

COOL

COOK

OFF

SW2

COOK-COOL SWITCH

T1

24V ~

4A

M~

IGNITION MODULE HOT TOP

RL1b

12(6) 8(4)

230V ~

M~

COOLING FAN

SPARK ELECTRODE HOT TOP

PB

SW1

POWER

L1

Part # 4517957 Rev.13 (02/10/11) Page 25

Page 26

Revision History

Rev Page Description Date

12

Part list removed - was on page 20 to 27.

Removed Garland Commercial Industries, front Cover

Oct 27/10

Part # 4517957 Rev. 13 (02/10/11)Page 26

Page 27

Part # 4517957 Rev.13 (02/10/11) Page 27

Page 28

Page 29

Page 30

Pièce nº 4517957 Rev. 13 (02/10/11) Page 27

Page 31

Pièce nº 4517957 Rev. 13 (02/10/11)Page 26

0 INSTRUCTIONS D’INSTALLATION ET D’UTILISATION SORTI (Book released) Oct 27/10

Rev Page Description Date

HISTORIQUE DE LA RÉVISION

Page 32

L1

POWER

SW1

PB

SPARK ELECTRODE HOT TOP

IGNITION MODULE HOT TOP

RL1b

COOLING FAN

M~

12(6) 8(4)

230V ~

Pièce nº 4517957 Rev. 13 (02/10/11) Page 25

COOK-COOL SWITCH

SW2

OFF

COOK

COOL

13(7) 5(3)

RL1a

NC

COM

SW3

thermodisc

DOOR SWITCH

NO

CTL3

MV

TH3

PV

TH

OVEN

SENSE

GND

FLAME SENSOR

IGNITION CONTROL

IGN

SPARK ELECTRODE

4A

24V ~

T1

warning light

CTL2

MV

TH2

GRIDDLE RIGHT

IGN

SENSE

GND

PV

TH

FLAME SENSOR

SPARK ELECTRODE

TH1

CTL1

IGNITION CONTROL

MV

PV

TH

GRIDDLE LEFT

SENSE

GND

FLAME SENSOR

IGNITION CONTROL

IGN

Pour tous les modèles

SPARK ELECTRODE

N

SCHEMATIC DIAGRAM, 230V

4517607

SHT OF

STW286A

M~

REV

DR.

TITLE:

:

TOLERANCE ±0.015" UNLESS OTHERWISE SPECIFIED

CHK. BY

ALL DIMENSIONS ARE IN INCHES

:

REVISIONS

SCALE

:

DR.DESCRIPTION

DATE

DATE

DEC 8/97NAVC

:

REV.#

13(7) 14(8)

RL1

PL3

PV3

MV3

PL2

PV2

MV2

TOTAL MAXIMUM LOAD:

120V 50/60Hz, 4.5 AMPS

230V 50/60Hz, 2.3 AMPS

PL1

PV1

MV1

MOTOR: 1/3hp, 115V, 50/60Hz, 3.6 AMP

230V, 50/60Hz, 1.8 AMP

SOLENOID VALVES (EACH)

24V, 50/60Hz, 0.4A MAX.

SP845 IGNITION MODULE:

24V, 50/60Hz, 0.25A

FLAME SENSE CURRENT 0.7 MICROAMPS MINIMUM REQUIRED

SCHÉMAS DE CÂBLAGE suite

Page 33

L1

POWER

SW1

PB

SPARK ELECTRODE HOT TOP

IGNITION MODULE HOT TOP

RL1b

COOLING FAN

M~

12(6) 8(4)

Pièce nº 4517957 Rev. 13 (02/10/11)Page 24

COOK-COOL SWITCH

SW2

OFF

COOK

COOL

TH1

CTL1

IGNITION CONTROL

MV

PV

TH

GRIDDLE LEFT

SENSE

GND

FLAME SENSOR

IGNITION CONTROL

IGN

Pour tous les modèles

SPARK ELECTRODE

120V ~

13(7) 5(3)

RL1a

NC

SW3

COM

NO

DOOR SWITCH

CTL3

MV

TH3

PV

TH

OVEN

SENSE

GND

FLAME SENSOR

IGNITION CONTROL

IGN

SPARK ELECTRODE

4A

24V ~

T1

CTL2

MV

TH2

GRIDDLE RIGHT

IGN

SENSE

GND

PV

TH

FLAME SENSOR

SPARK ELECTRODE

N

SCHEMATIC DIAGRAM, 120V

4517605

SHT OF

STW286A

M~

REV

DR.

TITLE:

:

TOLERANCE ±0.015" UNLESS OTHERWISE SPECIFIED

CHK. BY

ALL DIMENSIONS ARE IN INCHES

:

REVISIONS

SCALE

:

DR.DESCRIPTION

DATE

DATE

DEC 10/2003NAN.B.

:

REV.#

13(7) 14(8)

RL1

PL3

PV3

MV3

120V 50/60Hz, 4.5 AMPS

230V 50/60Hz, 2.3 AMPS

TOTAL MAXIMUM LOAD:

PL2

PV2

MV2

24V, 50/60Hz, 0.25A

FLAME SENSE CURRENT 0.7 MICROAMPS

MINIMUM REQUIRED

HOT TOP IGNITION MODULE

100-120V 0.6VA

220-240V 0.8VA

SP845 IGNITION MODULE:

PL1

PV1

MV1

MOTOR: 1/3hp, 115V, 50/60Hz, 3.6 AMP,

230V, 50/60Hz, 1.8 AMP

PAPST COOLING FAN:

115V MODEL 4606N 50/60 HZ, 18W

230V MODEL 4656N 50/60 HZ, 18W

SOLENOID VALVES (EACH):

24V, 50/60Hz, 0.4A MAX.

SCHÉMAS DE CÂBLAGE suite

Page 34

Pièce nº 4517957 Rev. 13 (02/10/11) Page 23

GRIDDLE

OVEN VALVE

1431526

PV3

44

MV3

SPARK ELECTRODE

FLAME SENSOR

43

45

E3

F3

G 770

LED

M.V. 3

SENSE 4

P.V. 1

THS 2

5

RIGHT VALVE

1431526

PV2

40

41

MV2

35

39

CTL3

GROUND

17

18

24

39

45

34

44

43

46

TH3

34

46

FLAME SENSOR

ELECTRODE

F2

OVEN THERMOSTAT

31

SPARK

E2

CTL2

G 770

GROUND

LED

THS 2

P.V. 1

M.V. 3

SENSE 4

21

5

40

33

TH2

33

25

24

42

PL3

23

29

28

COM

27

NO

NC

SW3

54

1431526

36

37

36

41

42

GRIDDLE RIGHT

THERMOSTAT

PL2

20

35

LEFT VALVE

G 770

GRIDDLE

GROUND

36

TH1

32

22

LED

THS 2

P.V. 1

M.V. 3

SENSE 4

PV1

MV1

OVEN MOTOR

14

9

SELECT

10

ORANGE 240V

BLACK

COM

WHITE 120V

RED 208V

12

T1

16

17

5

37

38

24

12

4

11

32

68

18

19

F1

E1

SPARK ELECTRODE

M~

29

18

2

BASE

7

13

J2

11

19

13

OMRON

5

COOLING FAN

15

1431528

1434533

8

10

84

14

12

30

31

RELAY CONNECTION

ALTERNATE

30

51 13

9

L1

N

E

M~

x1

x3

52

53

x2

3

1431531

Pour les modèles fabriqués entre le05 oct 2005, nº de série 0510100130790 et le23 mars 2009 S/N 0903100100822

J1

1431526

4

1

2

9

11

52

51

50

RELAY RL1

31

53

5

29

49

7

6

48

(avec module de commandeJohnson

48

GRIDDLE LEFT

THERMOSTAT

FLAME SENSOR

COOK/COOL SWITCH

0

II

I

26

25

38

PL1

21

48